Page 1

Battery Powered Crimping Tool

BATTERY POWERED CRIMPING TOOL

Operation Manual

Order No. 63816-0200 (110 V)

Order No. 63816-0250 (220 V)

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 1 of 33

Revision: E Revision Date: 06-07-12

Page 2

Battery Powered Crimping Tool

Table of Contents

BATTERY POWERED CRIMPING TOOL ........................................................................................................................ 1

Safety Warnings and Information ..................................................................................................................................... 3

SECTION 1 ...................................................................................................................................................................... 7

Description ................................................................................................................................................................................... 7

1.1. Features ....................................................................................................................................................................... 7

1.2. Technical Specifications .............................................................................................................................................. 8

1.3 Delivery Check ............................................................................................................................................................. 8

SECTION 2 ...................................................................................................................................................................... 9

Power Crimp Heads and Adapters............................................................................................................................................... 9

2.1 Comparison Chart - Hand and Power Crimp Tools.................................................................................................... 10

2.2 63816-0600 Power Crimp Adapter for Type 4A Hand Crimp Tools ........................................................................... 11

2.3 63816-0300 Power Crimp Head for Type 2C and 4C Hand Crimp Tools .................................................................. 13

2.4 63816-0800 Power Crimp Head for Type 4D Hand Crimp Tools ............................................................................... 15

2.5 63816-0900 Power Adapter for Type AT Air Crimp Heads ........................................................................................ 18

SECTION 3 .................................................................................................................................................................... 20

Set-Up and Adjustments ............................................................................................................................................................ 20

3.1 Set-Up ........................................................................................................................................................................ 21

3.2 Operation ................................................................................................................................................................... 22

3.3 Preventive Instructions .............................................................................................................................................. 23

SECTION 4 .................................................................................................................................................................... 24

General Terminal Specifications and Crimping Operation ......................................................................................................... 24

4.1 Scope ......................................................................................................................................................................... 25

4.2 Crimping Terminals .................................................................................................................................................... 25

SECTION 5 .................................................................................................................................................................... 26

Preventive Maintenance ............................................................................................................................................................ 26

5.1 Periodic Cleaning ....................................................................................................................................................... 27

5.2 Battery and Charging Unit.......................................................................................................................................... 28

5.3 Disposal ..................................................................................................................................................................... 29

5.4 Warranty .................................................................................................................................................................... 29

SECTION 6 .................................................................................................................................................................... 30

Parts List, Assembly Drawings, and Troubleshooting ................................................................................................................ 30

6.1 Parts List and Assembly Drawings ............................................................................................................................ 31

6.2 Troubleshooting ........................................................................................................................................................ 33

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 2 of 33

Revision: E Revision Date: 06-07-12

Page 3

Battery Powered Crimping Tool

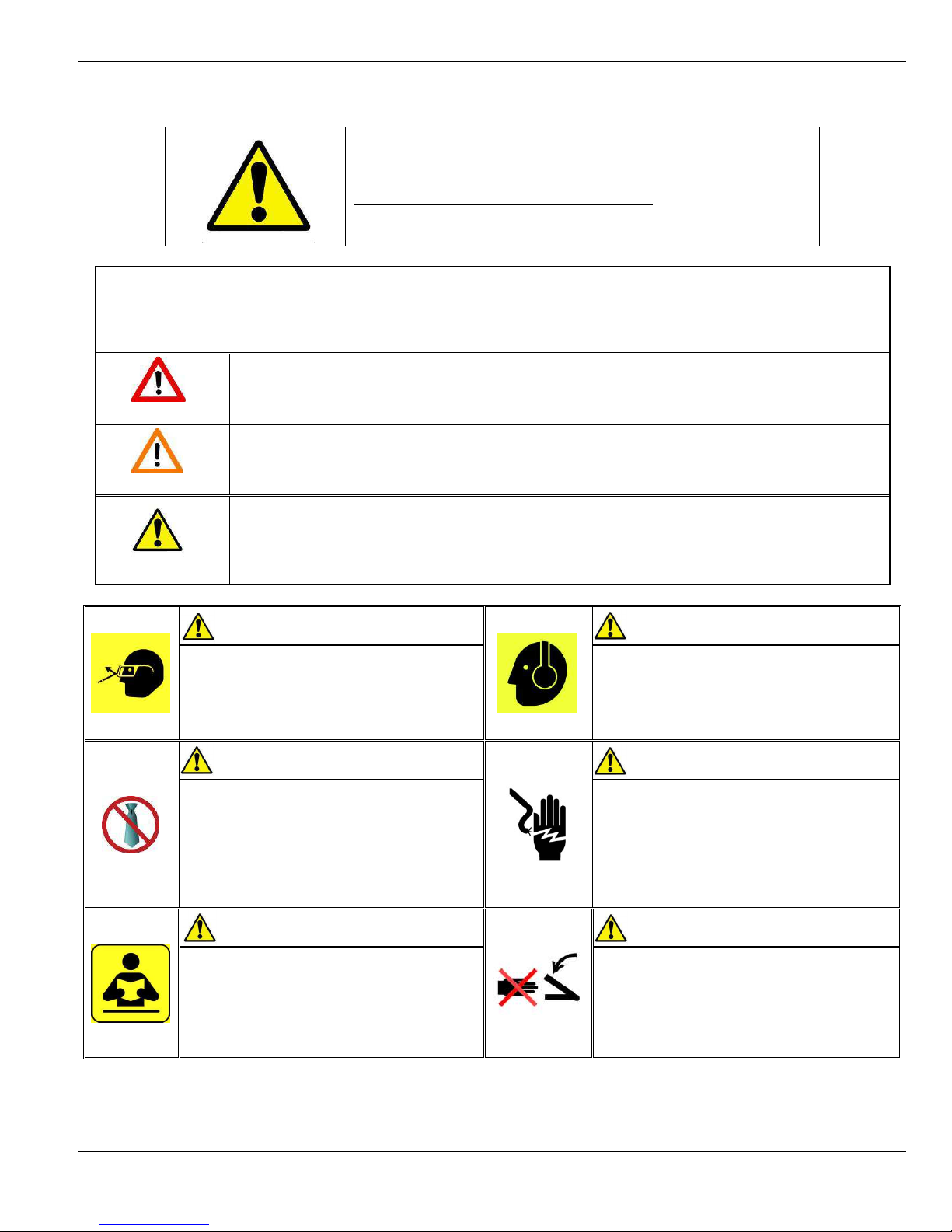

Read

and

understand

all of the instructions and safety information in this

SAFETY ALERT SYMBOL

CAUTION:

WARNING

WARNING

Always

wear proper eye protection when

WARNING

WARNING

Electric shock hazard:

WARNING

WARNING

Pinch points:

Safety Warnings and Information

manual before operating or servicing this tool.

Keep this manual available when using this tool.

Replacement manuals are available for download at no charge at

www.molex.com.

This symbol is used to call your attention to hazards or unsafe practices which could result in an injury

or property damage. The signal word, defined below, indicates the severity of the hazard. The message

after the signal word provides information for preventing or avoiding the hazard.

DANGER:

DANGER

WARNING

Indicates an imminently hazardous situation which, if not avoided, could result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION may also be used to alert against unsafe practices associated with events that could lead

to personal injury.

Operating or servicing this tool.

Failure to wear eye protection could result in

serious eye injury from flying debris or hydraulic oil.

Never wear clothing or jewelery that is loose or

That could potentially get caught in this tool.

Failure to observe this warning could result in

Severe Injury or death.

Never operate, service, install, or adjust this

tool without proper instruction and without

first reading and understanding the instructions

in this manual and all applicable manuals.

Always wear proper ear protection when

Operating or servicing this tool.

This tool is not insulated. When using this unit near

energized electrical lines, use proper personal

protective equipment.

Failure to observe this warning could result in

severe injury or death

Keep hands away from the crimping head when

crimping.

Failure to observe this warning could result In

severe injury or death.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 3 of 33

Revision: E Revision Date: 06-07-12

Page 4

Battery Powered Crimping Tool

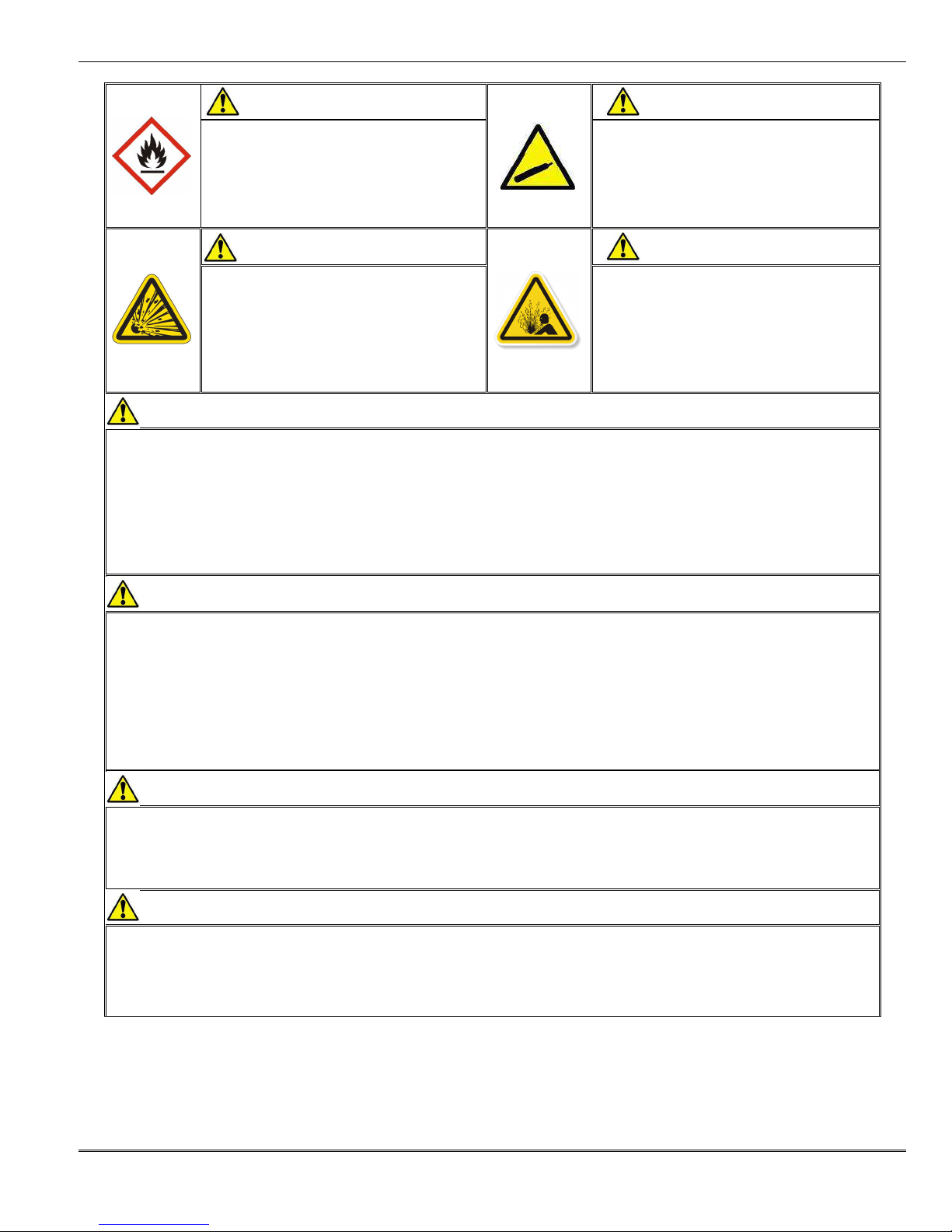

WARNING

WARNING

Do not use

compressed air to clean this tool.

WARNING

WARNING

Inspect tool and dies before use. Replace any

CAUTION

Do not operate the tool without the dies. Damage to the ram or crimping head can result.

CAUTION

CA

UTION

CAUTION

Never

perform any service or maintenance other than as described in this manual.

Do not use solvents or flammable liquids

to clean the crimping tool.

Solvents or flammable liquids could ignite and

cause serious injury or property damage.

Do not dispose of the battery in a fire. It will

vent fumes and may explode.

Failure to observe this warning could result in

severe injury from harmful fumes or burns from

flying debris

Do not operate with the crimping head open. Damage to the ram or seals can result.

This tool is not designed for continuous use. After 100 crimping cycles, allow the crimping tool to cool down for 15 minutes.

Do not place the tool in a vise. The crimping tool is designed for hand-held operation only.

This tool may be used in damp or wet environments; however, we recommend air-drying the tool before use if it becomes soaked.

Use this tool for the manufacturer’s intended purpose only.

The forces created by compressed air can

force debris into the tool.

Failure to observe these precautions may

result in injury or property damage.

worn or damaged parts. A damaged or

improperly assembled tool can break and strike

someone nearby.

Failure to observe this warning could result in

severe injury or death.

Failure to observe these precautions may result in injury or property damage

Do not allow anything to contact the battery’s terminals.

Do not immerse the battery in liquid. Liquid may create a short circuit and damage the battery.

If the battery is immersed, contact your service center for proper handling.

Do not place the battery into a pocket, tool pouch, or tool box with conductive objects.

Conductive objects may create a short circuit and damage the battery.

Do not place a battery on moist ground or grass. Moisture may create a short circuit and damage the battery.

Failure to observe these precautions may result in injury or property damage.

Do not store the battery at more than 60 °C (140 °F). Damage to the battery can result.

Do not use another manufacturer’s charger. Other manufacturers’ chargers may overcharge and damage the battery.

Do not attempt to open the battery. It contains no user-serviceable parts.

Failure to observe these precautions may result in injury or property damage.

Never modify, alter or misuse the equipment

Molex crimp specifications are valid only when used with Molex terminals, applicators and tooling.

Failure to observe this precaution may result in injury and property damage.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 4 of 33

Revision: E Revision Date: 06-07-12

Page 5

Battery Powered Crimping Tool

Tooling Technical Assistance

Molex offers tooling technical assistance for customers who may need some guidance for tooling adjustments. This support

can be obtained by calling either of the two numbers listed below and asking for the Molex Tooling Group.

Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global).

This assistance is limited to the operation and set-up of a customer’s Molex tool. Questions with regard to Molex connector

products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex personnel

or Customer Service Representative.

When calling for service on this tool, a copy of the Tooling Manual and Specific Application Tooling Specification (ATS) Sheet

should be present and a person that is familiar with this tool should be present. Be sure the following information is supplied:

1. Customer name

2. Customer address

3. Person to contact such as (name, title, e-mail, and telephone number

4. Power tool order number (Lease number also if applicable)

5. Serial number (Lease number also if applicable)

6. Molex Connector product order number

7. Urgency of request

8. Nature of problem

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532, USA

Tel: +1 (630) 969-4550

Fax:+1 (630) 505-0049

Visit our Web site at http://www.molex.com

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 5 of 33

Revision: E Revision Date: 06-07-12

Page 6

Battery Powered Crimping Tool

Table of Contents

SECTIONS

1. General Description

2. Power Crimp Heads and Adapters

3. Set-up and Adjustments

4. Terminal Specifications and Crimping Operation

5. Preventive Maintenance

6. Parts List, Assembly Drawing, and Troubleshooting

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 6 of 33

Revision: E Revision Date: 06-07-12

Page 7

Battery Powered Crimping Tool

LOCKING

TRIGGER

CRIMPING

RECHARGEABLE

UNLOCKING

RETRACTOR

SECTION 1

Principal Mechanical Parts of the 63816-0200 (110 V) and the 63816-0250 (220 V) Battery Powered Tool. Battery charger

not shown.

PINS (2)

HEAD

ADAPTER

SLIDE

SWITCH

(NiCad 9.6V) BATTERY

Figure 1-1

Description

The Molex Battery Powered Tool is designed to crimp terminals with the use of interchangeable modular crimp heads or

power crimp heads, and tool kits. This tool has an automatic retractable system which returns the crimping adapter along

with the crimping dies to the starting position when the maximum force is reached. It is equipped with a special brake that

will stop the forward motion of the crimping dies when the trigger is released. The crimping head can be rotated 360° for

better access in difficult working situations.

1.1. Features

Crimps a wide range of products with interchangeable modular crimp heads or power crimp heads, and tool kits, which

reduce the overall cost and provide production flexibility.

Modular crimp heads or power crimp head and dies are easily and quickly interchanged to reduce production down time.

Complete portable system that allows tool to be moved and stored easily.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 7 of 33

Revision: E Revision Date: 06-07-12

Page 8

Battery Powered Crimping Tool

1.2. Technical Specifications

Dimensions (with battery)

Length 292.1mm (11.50”)

Width 76.2mm (3.00“)

Depth 50.8mm (2.00“)

Unpacked Weight 1.50kg (3.31lbs)

Production Rate

250 cycles per hour maximum, depending on operator skill and tool kit installed.

Battery

Voltage 9.6V

Capacity 1.3 Ah

Charging Time Approximately 40 minutes, about 15 minutes with fast-charger

Crimps/battery-charge 150 at 10mm

2

Operating Parameters

Maximum Force 15kN (1.7 tonne-force)

Cycle Time 2.0 seconds

Stroke Length 9.00mm (.354”)

Ambient Temperature -20oC to +40oC

Sound Level 75dB (A) in a distance of 1.0m

Vibrations <2.5m/s

2

1.3 Delivery Check

Carefully remove the Battery Powered Tool from its shipping container and determine that the following items are included in

the package.

For the 63816-0200 (110 V):

63816-0200 Battery Crimping Tool

63816-0202 Battery Unit (2)

63816-0210 Battery Charger

Carrying Case

TM-638160200 Operation Manual

For the 63816-0250 (220 V):

63816-0250 Battery Crimping Tool

63816-0202 Battery Unit (2)

63816-0260 Battery Charger

Carrying Case

TM-638160200 Operation Manual

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 8 of 33

Revision: E Revision Date: 06-07-12

Page 9

Battery Powered Crimping Tool

SECTION 2

Power Crimp Heads and Adapters

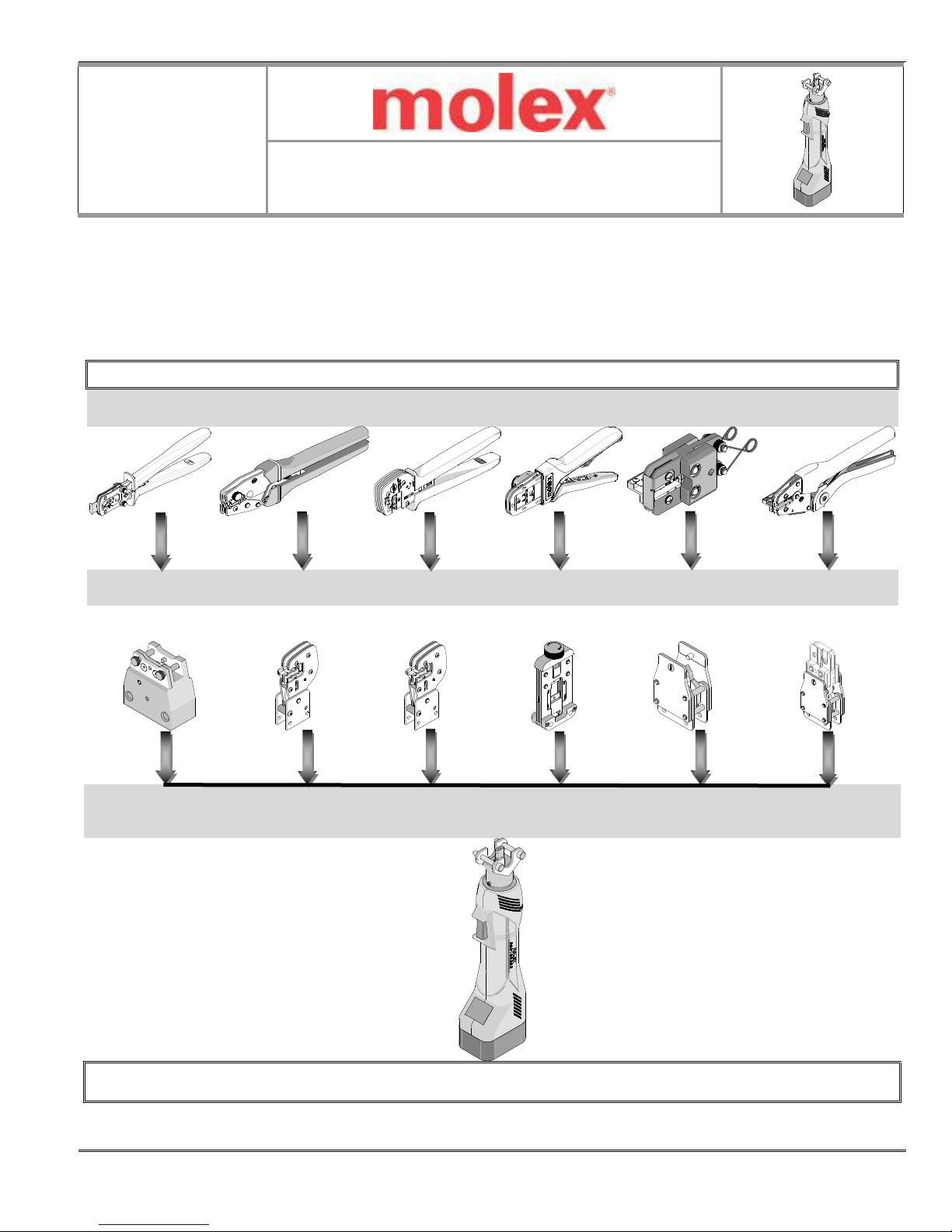

2.1 Comparison Chart - Hand and Power Tools

2.2 63816-0600 Power Crimp Adapter for Type 4A Hand Crimp Tools

2.3 63816-0300 Power Crimp Head for Type 2C and 4C Hand Crimp Tools

2.4 63816-0800 Power Crimp Head for Type 4D Hand Crimp Tools

2.5 63816-0900 Adapter for Type AT Air Crimp Tools (with 64005-0000 Head for Type RHT

Hand Crimp Tools)

NOTE: Hand Crimp tool “Type” with a pictorial illustration, is displayed on the upper right corner of the Hand Crimp

Tool Specification Sheet (ATS) and in the following pages of this manual.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 9 of 33

Revision: E Revision Date: 06-07-12

Page 10

Battery Powered Crimping Tool

Type RHT

64005xx00

AT Head

•

Battery

Power and

Comparison

Chart

Crimp Hand Tools

2.1 Comparison Chart - Hand and Power Crimp Tools

SCOPE

Modular crimp heads, power crimp head, adapters, and dies are easily and quickly interchanged between the hand crimp

tools and the battery powered tools. See chart below.

Battery Power Crimp Tool and Adapters for Hand Crimp Tools

Type 4A Type 2C Type 4C Type 4D Type AT

638160600 638160300 638160300 638160800 638160900

Adapter Head Head Head Adapter

63816-0200

Battery Powered Crimp Tool

• See Note

+ 638160900

+ Adapter

NOTE: Un-tooled AT heads are not available separately. Customers can install RHT Tooling into one of their existing AT heads.

Caution must be taken as the markings on the AT head will not match the tooling from an RHT tool for a different terminal.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 10 of 33

Revision: E Revision Date: 06-07-12

Page 11

Battery Powered Crimping Tool

63816

-

0001

TYPE 4A

63816

-

0600

For

Type 4A Hand Crimp Tools

63816-0600

Power Crimp

Adapter

Application Tooling

TYPE 4A

2.2 63816-0600 Power Crimp Adapter for Type 4A Hand Crimp Tools

Scope

The 63816-0600 Power Crimp Adapter was created for use with the Type 4A Modular Crimp Heads when used with the

Battery Powered Tool (Order No. 63816-0200).

Installation of Type 4A Modular Crimp Heads onto Power Crimp Adapter

To mount the Type 4A Modular Crimp Heads to the 63816-0600 Modular Crimp Adapter, slide the locking pins outward until

they stop. Then place the crimp head in the upper slot and align the holes with the pins. Then, push in the pins until they lock.

See Figure 2-1.

LOCKING PINS (2)

Figure 2-1

Installation of Type 4A Power Crimp Adapter to Battery Powered Crimping Tool

To install the 63816-0600 Power Crimp Adapter onto the 63816-0200 Battery Powered Tool, refer to Section 3, “Set-Up and

Adjustments”.

Operation

1. Load the terminal as described in the Operation section of the specification sheet for the tool.

2. Cycle the Battery Powered Tool to crimp the terminal to the wire. Hold the trigger until the tool completes the cycle.

3. Remove the crimped terminal from the terminal locator by pressing down on the wire stop and gently pulling on the wire.

The terminal locator can be in either position.

4. Visually inspect the crimped terminal for proper crimp location.

WARNING: Never place fingers into the tooling nest.

MODULAR CRIMP

HEAD WITH TOOLING

ADAPTER

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 11 of 33

Revision: E Revision Date: 06-07-12

Page 12

Battery Powered Crimping Tool

Figure 2

-3

LUBRICATION

Figure 2

-2

Item Order No.

Description

Quantity

1 63816-0600

Power Crimp Adapter

1

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following maintenance steps:

1. This tool was engineered for durability, but like any fine piece of equipment, it needs cleaning and lubrication for a

maximum service life of trouble-free crimping

2. Remove dust, moisture and other contaminants with a clean brush, or soft,

lint-free cloth.

3. Do not use any abrasive materials that could damage the tool.

4. Make certain all pins, pivot points and bearing surfaces in the tool head are

protected with a thin coat of high quality machine oil. Do not oil excessively.

Use light oil, such as SAE 30 weight automotive oil, every 5,000 crimps or

monthly, will significantly enhance the tool life and ensure a stable

calibration. See Figure 2-2 for lubrication points.

5. Store the tool in a clean and dry area when not in use.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of

the best quality materials. All vital components are long life-tested. All tools are

POINTS

(BOTH SIDES)

LIGHT OIL

(EVERY MONTH

OR

5,000 CRIMPS)

warranted free of manufacturing defects for a period of 30 days. Should such a

defect occur, we will repair or exchange the tool if it cannot be repaired, free of

charge. This repair or exchange will not be applicable to altered, misused, or damaged tools.

Parts List

1

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 12 of 33

Revision: E Revision Date: 06-07-12

Page 13

Battery Powered Crimping Tool

ANVILS

POWER

Figure

2-4

M4 X 10 LONG

BHCS

M4 X 18 LONG

BHCS

63816-0300

Power Crimp

Head

Application Tooling

Type 2C Type 4C

Hand Crimp Tools

2.3 63816-0300 Power Crimp Head for Type 2C and 4C Hand Crimp Tools

SCOPE

The 63816-0300 Power Crimp Head was created for use with the Type 2C and 4C Crimp Dies and Locator Kits when used

with the Battery Powered Tool (Order No. 63816-0200).

Installation of Type 2C or 4C Crimp Tool Kit Installation into Power Crimp Head

1. Remove the Crimp Tool Kit from the Type 2C or 4C Hand Crimp Tool. To do this, see the instruction sheet included with the

hand crimp tool.

2. To install the Crimp Tool Kit into the Power Crimp Head, follow the steps below:

PUNCHES

1. Insert the Anvils into the bottom slots of the nest. The wire size markings face toward the front of the head, opposite

from the locator pivot shaft. Install the M4 x 10 long BHCS and tighten in place.

2. Insert the Punches into the top slots of the nest with wire size markings to the front. Install the M4 x 18 long BHCS and

tighten in place. See Figure 2-4.

3. Position the locator with the hole over the brass pivot shaft and snap it into place. See Figure 2-5.

WARNING: Never place fingers into the tooling nest.

Power Crimp Head Installation onto Battery Powered Crimping Tool

To install the 63816-0300 Power Crimp Head onto the 63816-0200 Battery Powered Crimping Tool, refer to Section 3, “SetUp and Adjustments”.

CRIMP HEAD

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 13 of 33

Revision: E Revision Date: 06-07-12

Page 14

Battery Powered Crimping Tool

Figure 2

-7

1

M4 X 8 LONG

Item Order No

Description

Quantity

1 63816

-

0300 Power Crimp Head

1

2 63811

-

4773 Universal Locator Mount

1

LUBRICATION

Operation

1. Load the terminal as described in the Operation section of the specification sheet for the tool.

2. Cycle the Battery Powered Tool to crimp the terminal to the wire. Hold the trigger until the tool completes the cycle.

3. Remove the crimped terminal from the terminal locator by pressing down on the wire stop and gently pulling on the wire.

The terminal locator can be in either position.

4. Visually inspect the crimped terminal for proper crimp location.

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for,

the following maintenance steps:

1. Remove dust, moisture and other contaminants with a clean brush, or soft, lint-free

cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins, pivot points and bearing surfaces in the tool head are

protected with a thin coat of high quality machine oil. Do not oil excessively. This

POINTS

(BOTH SIDES)

LIGHT OIL

(EVERY MONTH

tool was engineered for durability, but like any fine piece of equipment, it needs

cleaning and lubrication for a maximum service life of trouble-free crimping. Use

5,000 CRIMPS)

light oil, such as SAE 30 weight automotive oil, every 5,000 crimps or monthly, will

significantly enhance the tool life and ensure a stable calibration. See Figure 2-6 for

lubrication points.

Figure 2-6

4. Store the tool in a clean and dry area when not in use.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components

are long life-tested. All tools are warranted free of manufacturing defects for a period of 30 days. Should such a defect

occur, we will repair or exchange the tool if it cannot be repaired, free of charge. This repair or exchange will not be

applicable to altered, misused, or damaged tools.

Parts List

OR

BHCS (REF)

2

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 14 of 33

Revision: E Revision Date: 06-07-12

Page 15

Battery Powered Crimping Tool

Type 4

D Hand Crimp Tools

TOP SLOT

TOP HOOKS

TOP SLOT

OF

LOWER TABS

SQUEEZE

SQUEEZE

LOCATOR

Figure

2-8

MAKE SUR

E

Figure 2

-9

63816-0800

Power Crimp

Head

Application Tooling

2.4 63816-0800 Power Crimp Head for Type 4D Hand Crimp Tools

SCOPE

The 63816-0800 Power Crimp Head was created for use with Type 4D Crimp Dies and Locator when used with the Battery

Powered Tool (Order No. 63816-0200).

Installation for Type 4D Crimp Tooling Installation into Power Crimp Head

First, remove the crimp tooling from the Type 4D Hand Crimp Tool. To do this, see the instruction sheet included with the

hand crimp tool.

To remove the locator from the Power Crimp Head

1. Open the Power Crimp Head to remove the locator.

2. Squeeze gently on the lower area of the locator assembly, shown in Figure 2-8 with your thumb and index finger. The

lower tabs of the locator should disengage from the Power Crimp Head.

3. Lift and pull away from the Power Crimp Head. The top locator hooks should slip out of the top slots easily. See Figure

2-8.

HERE

OF THE

HANDTOOL

HERE

To install the locator in the Power Crimp Head

1. Install the locator assembly.

2. Press the red insert down as far as it will go. See Figure 2-9.

3. The locator goes on the opposite side from the dies with the wire gauge markings.

4. While holding onto the lower part of the locator with your thumb and index finger, insert the

locator top hooks (2) into the Power Crimp Head top slots.

5. Rotate the locator down and press the lower tabs into the two bottom slots of the head. To

secure the locator into place, the lower tabs must snap into place on the head frame.

Removing the Crimp Dies from the Power Crimp Head

1. Open the Power crimp Head.

2. Remove the two M3 BHCS.

3. Remove the crimp dies as shown in Figure 2-10.

4. Make sure all of components removed from the Power Crimp Head are reinstalled into the Power Crimp Head in the same

manner.

THE HANDTOOL

TYPE 4D

CENTER OF LOCATOR

IS IN THE

DOWN POSITION

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 15 of 33

Revision: E Revision Date: 06-07-12

Page 16

Battery Powered Crimping Tool

M3 BHCS

E1

E2

I2

I1

POWER CRIMP HEAD

M3 BHCS

MATCH UP

WIRE GAUGE

LOCKING

Figure 2

-12

KN

URLED

KNOB

Installing the Crimp Dies in the Power Crimp Head

1. Select the desired Type 4D crimping dies.

2. Insert the Anvils or dies (E1 and I1) into the bottom slots of the nest. Install the M3 x 14 long BHCS and lightly tighten in

place.

Note: The tool part number markings on the dies go inward so they will not be visible when installed.

MARKINGS

X 8 LONG

Figure 2-10

X 14 LONG

IDENTIFICATIONS

SHOWING

Figure 2-11

3. Insert the Punches or dies (E2 and I2) into the top slots of the nest. Install the M3 x 8 long BHCS and lightly tighten in

place. See Figure 2-10

4. Make sure the small markings on the individual dies match up and wire gauge identification (AWG) marks should be facing

out and aligned as shown in Figure 2-11.

5.

Note: Make sure the longer screw only goes into the lower dies.

6. Completely close the crimp dies until they are touching, and then securely tighten the M3 BHCS.

Power Crimp Head Installation onto Battery Powered Crimping Tool

To install the 63813-0800 Power Crimp Head onto the 63816-0200 Battery Powered

Tool, refer to Section 3, “Set-Up and Adjustments”.

Adjustments

The crimp height on the 63816-0800 Power Crimp Head can be adjusted, if

necessary. To do this, first measure the conductor crimp height of a crimped

terminal and compare to the crimp specification listed in the product specification for

that terminal. If an adjustment is required, follow the procedure, below:

1. Loosen the locking set screw located just below the knurled knob at the top of

the Power Crimp Head. See Figure 2-12.

2. If the crimp height is too loose, rotate the knob, a small amount, in the counter-

clockwise direction. Crimp another terminal and re-check the crimp height.

3. If the crimp height is too tight, turn the knob clockwise and follow the same procedure.

4. Do this until the proper crimp height is achieved.

5. When the proper crimp height is achieved, lock the set screw.

SET SCREW

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 16 of 33

Revision: E Revision Date: 06-07-12

Page 17

Battery Powered Crimping Tool

2

Figure 2

-11

Item Order No

Description

Quantity

1 63816

-

0800 Power Crimp Head (for style 4D crimp tools)

1

2 63816

-

0801 Return Spring

2

LUBRICATION

Operation

1. To load a terminal and position the wire in the terminal in the Power Crimp

Head, follow the loading procedure as explained in the Hand Crimp Tool

Specification sheet.

2. Crimp the terminal by squeezing the trigger on the side of the battery actuator

until the tool cycles and returns and the jaws open.

3. Remove the terminal from the locator and inspect the crimp for proper quality.

WARNING: Never place fingers into the tooling nest.

Maintenance

It is recommended that each operator of the tool be made aware of, and

responsible for, the following maintenance steps:

This tool was engineered for durability, but like any fine piece of equipment, it

(BOTH SIDES)

(EVERY MONTH

needs cleaning and lubrication for a maximum service life of trouble-free crimping

Remove dust, moisture and other contaminants with a clean brush, or soft, lint-

5,000 CRIMPS)

free cloth.

Do not use any abrasive materials that could damage the tool.

Use light oil, such as SAE 30 weight automotive oil, every 5,000 crimps, or

Figure 2-13

monthly, will significantly enhance the tool life and ensure a stable calibration.

Make certain all sliding surfaces in the tool head are protected with a thin coat of high quality machine oil. See Figure 2-13

for lubrication points. Do not oil excessively and wipe excess oil from the tool frame when complete.

Store the tool in a clean and dry area when not in use.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components

are long life-tested. All tools are warranted free of manufacturing defects for a period of 30 days. Should such a defect

occur, we will repair or exchange the tool if it cannot be repaired, free of charge. This repair or exchange will not be

applicable to altered, misused, or damaged tools.

Parts List

POINTS

LIGHT OIL

OR

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 17 of 33

Revision: E Revision Date: 06-07-12

2

1

Page 18

Battery Powered Crimping Tool

Type RHT

Type AT

AT CRIMP

HEAD

SLOTTED SCREW (2)

Figure 2

-14

AT HEAD

RHT CRIMP

TOOLING KIT

63816-0900

Power Adapter

Application Tooling

Hand Crimp Tools and Air Crimp Heads

2.5 63816-0900 Power Adapter for Type AT Air Crimp Heads

(With 64005-0000 Head for Type RHT Hand Crimp Tools)

SCOPE

The 63816-0900 Power Adapter was created to adapt the 64005 and 64007 series Type AT Crimp Heads for use in the

63816-0200 Battery Powered Tool.

The addition, customers who have Type RHT hand crimp tools along with a Type AT Crimp Head, can load the RHT dies

and locator into the AT crimp head and then in the Battery Powered Tool

Installation

Type AT Air Crimp Head Installation into AT Power Adapter

Install the AT Air Crimp Head onto the AT Power Adapter as shown in Figure 2-15.

Type RHT Crimp Tool Kit into AT Head and AT Power Adapter (One AT Crimp Head required)

Remove the Crimp Tooling Kit from the Type RHT Hand Crimp Tool. To do this, see the instruction sheet included with the

hand crimp tool.

1. Install the RHT tooling kit with locator, into the AT Power Crimp Head. See Figures 2-14.

2. Then install the crimp head onto the AT Power Adapter. This is a typical Type RHT Crimp Tooling Kit arrangement in AT

Head. See Figure 2-15.

For specific tooling, see the specification sheet that is included with the RHT tool.

WARNING: Never place fingers into the tooling nest.

AT CRIMP HEAD

ADAPTER

Figure 2-15

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 18 of 33

Revision: E Revision Date: 06-07-12

Page 19

Battery Powered Crimping Tool

Figure 2

-17

1

Item Order No.

Description

Quantity

1 63816

-

0900 Power Crimp Adapter

1

2 19279

-

0161 Slotted Screw

2

LUBRICATION

Figure 2

-16

Installation of Power Crimp Head with Power Adapter to the Battery Powered Crimping Tool

To install the 63816-0900 Power Adapter onto the 63816-0200 Battery Powered Tool, refer to Section 4, “Set-Up and

Adjustments”.

Operation

1. To load a terminal and position the wire in the terminal in the Power Crimp Head,

follow the loading procedure as explained in the AT Crimp Head (or RHT Hand Crimp

Tool) instruction sheet.

2. Crimp the terminal by squeezing the trigger on the side of the battery actuator until

(BOTH SIDES)

(EVERY MONTH

the tool cycles and returns and the jaws open.

3. Remove the terminal from the locator and inspect the crimp for proper quality.

5,000 CRIMPS)

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for,

the following maintenance steps:

6. This tool was engineered for durability, but like any fine piece of equipment, it needs

cleaning and lubrication for a maximum service life of trouble-free crimping

7. Remove dust, moisture and other contaminants with a clean brush, or soft, lint-free

cloth.

8. Do not use any abrasive materials that could damage the tool.

9. Make certain all pins, pivot points and bearing surfaces in the tool head are protected with a thin coat of high quality

machine oil. Do not oil excessively. Use light oil, such as SAE 30 weight automotive oil, every 5,000 crimps or

monthly, will significantly enhance the tool life and ensure a stable calibration. See Figure 2-16 for lubrication points.

10. Store the tool in a clean and dry area when not in use.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components

are long life-tested. All tools are warranted free of manufacturing defects for a period of 30 days. Should such a defect

occur, we will repair or exchange the tool if it cannot be repaired, free of charge. This repair or exchange will not be

applicable to altered, misused, or damaged tools.

Parts List

POINTS

LIGHT OIL

OR

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 19 of 33

Revision: E Revision Date: 06-07-12

2

Page 20

Battery Powered Crimping Tool

SECTION 3

Set-Up and Adjustments

3.1. Set-up

3.2. Operation

3.3. Preventive Instructions

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 20 of 33

Revision: E Revision Date: 06-07-12

Page 21

Battery Powered Crimping Tool

Figure

3-1 Replacing Power or Modular Crimp Heads

63806

-

0900 (Type

AT)

63816

-

0600 (Type 4A)

63816

-

0300 (Type 2C OR 4C)

63816

-

0800 (Type 4D)

TYPE

2C OR 4C

LOCKING

TYPE

2C OR

4C

BATTERY

CRIMP HEAD

LOCKING

RETRACT

TYPE AT

SLOTTED

BATTERY

63816

-

0900

LOCKING

RETRACT

YOKE

TYPE AT

TYPE 4A

RETRACT

LOCKING

BATTERY

TYPE 4A

63816

-

0600

LOCKING

TYPE

4D

BATTERY

TYPE 4

D

CRIMP HEAD

LOCKING

RETRACT

YOKE

3.1 Set-Up

MODULAR CRIMP

HEAD

MODULAR CRIMP

HEAD

WITH TOOLING

PINS (2)

SCREWS (2)

LATCH

PINS (2)

ADAPTER

POWERED TOOL

SLIDE

POWER CRIMP HEAD

NO TOOLING SHOWN

PINS (2)

POWER CRIMP HEAD

NO TOOLING SHOWN

ADAPTER

YOKE

POWERED

TOOL

SLIDE

YOKE

PINS (2)

ADAPTER

POWERED TOOL

Before starting any work on electrical applications, make sure there are no live cables or parts in the immediate area of the user.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 21 of 33

Revision: E Revision Date: 06-07-12

SLIDE

ADAPTER

POWERED TOOL

SLIDE

PINS (2)

Page 22

Battery Powered Crimping Tool

TYPE 4A

WITH LOCATOR

HOLD TRIGGER

TYPE 4A

WITH LOCATOR

TERMINAL

HOLD TRIGGER

TERMINAL

TYPE 2C AND 4C

WITH LOCATOR

Warning: Remove the battery from the crimping tool before installing and removing dies in the crimp head.

1. Select the appropriate modular crimp head or power crimp head with the proper tooling kit inserted for the application

needed. The Modular Crimp Head with the Battery Powered Crimp Adapter or the Power Crimp Head are sold separately.

2. Remove the locking pins (2) from the battery powered crimp yoke.

3. Place the modular crimp head into the yoke and push down until it engages into the slot of the adapter. The Power Crimp

Heads do not require a separate Power Crimp Adapter.

4. Replace the locking pins (2) making sure the modular crimp head or the Power Crimp Head are secure. The locking pins can

be inserted from either side of the yoke. See Figure 3-1.

WARNING: Electric shock hazard:

This tool is not insulated. When using this unit near energized electrical lines, use proper personal protective

equipment.

Failure to observe this warning could result in severe injury or death

WARNING: Wear eye protection when operating or servicing this tool.

Failure to wear eye protection could result in serious eye injury from flying debris or hydraulic oil.

3.2 Operation

MODULAR CRIMP HEAD

AND WIRE

IN PLACE

POWER CRIMP

ADAPTER

AND WIRE

IN PLACE

DOWN

Figure 3-2

DOWN

1. Insert the proper terminal or connector into the tooling nest and push on the trigger in the handle just enough so the dies

contact the terminal or connector securely. Release the trigger. This allows the operator to make adjustments to the

connector before the final termination. See Figure 3-2.

2. Insert the wire or cable into the terminal. Push on the wire or cable to assure it is fully seated in the terminal.

3. Hold the trigger down again until the crimping tool achieves pressure relief, which is accompanied by an audible “pop”.

The crimping operation can be interrupted at any time during the cycle by releasing the trigger.

4. The crimping cycle is complete when the dies are completely closed and the maximum crimping force is reached. The

dies will automatically release and will go back to their original position.

Note: In case of an error or emergency, the ram can be retracted before the crimping cycle is complete. To do this push

the retractor slide towards the battery. See Figure 3-1.

POWER CRIMP HEAD

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 22 of 33

Revision: E Revision Date: 06-07-12

Page 23

Battery Powered Crimping Tool

Warning: An incomplete crimp can cause a fire.

Use proper die, connector, and cable combinations. Improper combinations can result in an incomplete crimp.

The relief valve will sound to indicate a completed crimp. If you do not hear the sound of the relief valve, the crimp is

not complete. Failure to observe these warnings could result in severe injury or death.

3.3 Preventive Instructions

WARNING: Do not dispose of the battery in a fire. It will vent fumes and may explode.

Failure to observe this warning could result in severe injury from harmful fumes or burns from flying debris

WARNING: Inspect tool and dies before use. Replace any worn or damaged parts. A damaged or improperly

assembled tool can break and strike someone nearby. Failure to observe this warning could result in severe injury or

death.

CAUTION:

Do not operate the tool without the dies. Damage to the ram or crimping head can result.

Do not operate with the crimping head open. Damage to the ram or seals can result.

This tool is not designed for continuous use. After 100 crimping cycles, allow the crimping tool to cool down for 15 minutes.

Do not place the tool in a vise. The crimping tool is designed for hand-held operation only.

This tool may be used in damp or wet environments; however, we recommend air-drying the tool before use if it becomes

soaked.

Use this tool for the manufacturer’s intended purpose only.

Failure to observe these precautions may result in injury or property damage.

CAUTION:

Do not allow anything to contact the battery’s terminals.

Do not immerse the battery in liquid. Liquid may create a short circuit and damage the battery.

If the battery is immersed, contact your service center for proper handling.

Do not place the battery into a pocket, tool pouch, or tool box with conductive objects.

Conductive objects may create a short circuit and damage the battery.

Do not place a battery on moist ground or grass. Moisture may create a short circuit and damage the battery.

Failure to observe these precautions may result in injury or property damage.

Avoid dropping this tool. Extreme shock may damage the internal mechanism and result in malfunction of the tool.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 23 of 33

Revision: E Revision Date: 06-07-12

Page 24

Battery Powered Crimping Tool

SECTION 4

General Terminal Specifications and Crimping Operation

4.1. Scope

4.2. Crimping terminals

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 24 of 33

Revision: E Revision Date: 06-07-12

Page 25

Battery Powered Crimping Tool

Wire Size (AWG)

Tooling Color Code

*UL –

486A **UL –

486C ***MIL

-T-

7928

22 8 8

20 13 10

18 20 10

16 30 15

14 50 25

12 70 35

10 80 40

8 Red 90 45 225

6 Blue 100 50 300

4 Yellow

140 - 400

2 Red 180 - 550

1 Blue 200 - 650

1/0 Blue 250 - 700

2/0 Yellow

300 - 750

3/0 Red 350 - 825

4/0 Blue 450 - 875

4.1 Scope

This tool is designed to crimp various Molex terminals and splices using our offering of crimping heads.

Testing

Mechanical

The tensile test, or pull test, is a means of evaluating the mechanical properties of the crimped connections. The following

charts show the UL specifications for various wire sizes. The tensile strength is shown in pound-force, which indicates the

minimum acceptable force to break or separate the terminal from the conductor.

*UL – 486A – Terminals (Copper Conductors Only)

**UL – 486C – Butt Slices and Parallel Slices (Over 6 AWG use 486A values)

***MIL-T-7928 - Military Approved Terminals only as listed

4.2 Crimping Terminals

Specifications and Instructions for crimping are included with the individual Hand Tool / Modular Crimp Heads.

These documents are called the Application Tooling Specification (ATS) Sheets.

These come with complete Hand Tools / Module Crimp Heads. If another copy is needed search on the www.Molex.com for

the hand tool order number desired. In the section Specification & Other Documents click on the Application Tooling

Specification (PDF) (ATS-EN).

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 25 of 33

Revision: E Revision Date: 06-07-12

Page 26

Battery Powered Crimping Tool

SECTION 5

Preventive Maintenance

5.1. Periodic Cleaning

5.2. Storage

5.3. Battery and Charging Unit

5.4. Disposal

5.5. Warranty

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 26 of 33

Revision: E Revision Date: 06-07-12

Page 27

Battery Powered Crimping Tool

Days of the Week

MON

TUE WED

THU

FRI SAT SUN

1

2

3

4

Cleaning

Daily

After use

Lubrication

(2) bolts in crimping head

Use SAE 10W

Hydraulic oil

5.1 Periodic Cleaning

Always clean tool after use and keep moving parts clear of dirt and debris.

This tool is basically maintenance free, only the bolt joints at the crimping head have to be oiled regularly.

Before use:

Inspect dies for wear or damage such as cracks, gouges, or chips.

Inspect the tool for damage or leaks. If damage is detected, return the tool to a Molex representative for inspection.

After use:

Wipe all tool surfaces clean with a damp cloth and mild detergent. Excessive dirt and grit can contribute to the premature

wear of the tool’s internal mechanical parts. If this tool becomes dirty with excessive debris it may jam and become damaged

during operation.

Fully retract the ram. Place the tool in the carrying case. Store in a cool, dry place.

Charge the battery.

WARNING: Do not use compressed air to clean this tool. The forces created by compressed air can force debris

into the tool. Failure to observe these precautions may result in injury or property damage.

WARNING: Do not use solvents or flammable liquids to clean the crimping tool. Solvents or flammable liquids

could ignite and cause serious injury or property damage.

Monthly:

Thoroughly clean all surfaces.

A routine should be established to keep the tool as free from dirt as possible.

An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of this crimping tool or

use this as a template to create your own schedule or use your company’s standard chart, if applicable.

Preventive Maintenance Chart

CHECK SHEET MONTH YEAR _________

Week

Daily

Use

Solution

Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive maintenance be

kept with the tool.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 27 of 33

Revision: E Revision Date: 06-07-12

Page 28

Battery Powered Crimping Tool

Red Charging Unit is ready to operate.

Battery defect

Charging Battery is out of order.

Green

--- Charging cycle stared.

Battery fully charged. Charging unit switches automatically

Yellow

--- Battery is at least 90% charged. Charging can be terminated.

If the Right LED does not light up, the circuit of the battery

5.2 Battery and Charging Unit

WARNING: Do not dispose of the battery in a fire. It will vent fumes and may explode.

Failure to observe this warning could result in severe injury from harmful fumes or burns from flying debris

CAUTION:

Do not store the battery at more than 60 °C (140 °F). Damage to the battery can result.

Do not use another manufacturer’s charger. Other manufacturers’ chargers may overcharge and damage the battery.

Do not attempt to open the battery. It contains no user-serviceable parts.

Failure to observe these precautions may result in injury or property damage.

CAUTION:

Do not allow anything to contact the battery’s terminals.

Do not immerse the battery in liquid. Liquid may create a short circuit and damage the battery.

If the battery is immersed, contact your service center for proper handling.

Do not place the battery into a pocket, tool pouch, or tool box with conductive objects.

Conductive objects may create a short circuit and damage the battery.

Do not place a battery on moist ground or grass. Moisture may create a short circuit and damage the battery.

Failure to observe these precautions may result in injury or property damage.

The charging unit is run with a nominal voltage of 110V or 220V (for Europe) and a frequency of 50-60Hz . New batteries

must be charged before use. To remove the battery from the crimping tool push down on the battery lock and pull out. See

Figure 5-1. To charge the battery plug in the charging unit into a power source and slide the battery upside down into the

charging unit. The normal charging time is about 40 minutes. The charging level of the battery cartridge can be checked by

the right LED (multicolor) of the charging unit.

Color Left LED (red) Right LED (multicolor)

Red

Flashing

Green

Flashing

--- Unit not powered

New or unused battery’s

voltage capacity is insufficient.

--Battery can stay in charge for an indefinite time without being damaged.

Battery too hot or too cold. Remove the battery.

Safety components possibly defected.

into a maintaining level.

is disconnected or the battery is incorrectly polarized.

Notes:

If the standard capacity of the battery is not achieved, it does not mean that the battery is faulty. The full capacity of the

battery can be achieved after 3 charging/discharging cycles.

1. If there is a noticeable decrease in speed of the crimping tool the battery should be recharged. Charge the battery at room

temperature between 10°C-40°C (50°F-104°F).

2. The battery should be charged before storing.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 28 of 33

Revision: E Revision Date: 06-07-12

Page 29

Battery Powered Crimping Tool

PUSH DOWN

LOCK

Figure 5

-1

BATTERY

Cautions:

1. Charging a battery which has been used recently or in the sun or a long period of time the right LED might flash red

(battery temperature) greater than 65°C (149°F). In this case let the battery cool down and try again.

2. Charging the battery at low temperatures under 5°C (41°F) is not possible. The battery temperature must be warmed up

before starting the battery cycle again.

3. Do not expose the charging unit to rain or snow.

4. Do not charge the battery in or around explosive materials or gases.

5. Do not use any other (dry or car) battery with the charging unit or the

crimping tool.

6. Do not use the cord as a handle to carry the battery unit.

7. Do not pull the cord out of a wall socket with force.

8. Do not pull the plug of the charging unit until after the battery has been

charged.

9. Do not insert foreign objects into the ducts of the charging unit.

10. Do not disassemble the charging unit.

11. Do not place the battery in your pocket or a tool box, if there are conductive

materials such as coins, keys, tools or other metallic parts, they may cause

injury or property damage.

5.3 Disposal

ON BATTERY

When this tool is no longer operating properly the different components of this tool

will need to be disposed of separately.

UNIT

1. The battery must be disposed of according to the Rechargeable Battery

Recycling Corporation (RBRC) in the USA, or other applicable guidelines in

other countries.

2. The remaining parts of this tool must be disposed of according to the

domestic environmental standards or the Environmental Protection Agency

(EPA) in the USA, or other applicable guidelines in other countries.

3. Because of possible environmental damage, we recommend disposal of the tool by a professional company.

Do not dispose of this tool in your residential or commercial waste, as it would be hazardous to the environment.

5.4 Warranty

All tools are warranted to be free of manufacturing defects for a period of 30 days. Should such a defect occur, we will repair

or exchange the tool free of charge. This repair or exchange will not be applicable to altered, misused, or damaged tools.

This tool is designed for hand use only. Any clamping, fixturing, or use of handle extensions voids this warranty. After one

year Molex recommends the crimping tool be returned to a Molex representative for inspection. Only the heads of the

crimping tool are permitted to be changed by the operator.

Do not damage the seals of this tool.

If seals are damaged the warranty is void.

CAUTION: Molex crimp specifications are valid only when used with Molex terminals and tooling.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 29 of 33

Revision: E Revision Date: 06-07-12

Page 30

Battery Powered Crimping Tool

SECTION 6

Parts List, Assembly Drawings, and Troubleshooting

6.1. Parts List and Assembly Drawing

6.2. Troubleshooting

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 30 of 33

Revision: E Revision Date: 06-07-12

Page 31

Battery Powered Crimping Tool

3

Figure 6

-1

1

Item Order No

Description

Quantity

1 63816

-

0200 or

63816

-

0250 Battery Powered Tool (110 V) or

Battery Powered Tool (220 V)

1

2 63816

-

0001 Modular Crimp Head Locking Pins

2

3 63816

-

0202 Batt

ery Unit

2

4 63816

-

0210 or

63816

-

0260 Battery Charger

(110 V) or

(220 V)

Not Shown

1

Applications for the Battery Powered Tool

Crimp Head Order No.

Adapter Order No.

Adapter Description

638xx

-

xx70

6400x

-

xx00

63816

-

0300

63816

-

0800

6.1 Parts List and Assembly Drawings

Item No. 4 Not Shown

Note:

The following Modular Crimp Heads and Battery Powered Crimp Adapters are sold separately and are not included with the

63816-0200 (110 V) or the 63816-0250 (220 V) Battery Powered Tool.

The chart below shows all applications for the Battery Powered Tool. See Figure 6-2 and 6-3.

2

(Sold separately)

Figure 6-2 Modular

Figure 6-3 Power

(Type 4A)

(AT)

(Type 2C or 4C)

(Type 4D)

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 31 of 33

Revision: E Revision Date: 06-07-12

Tool Order no. Tool Description

63816-0200 (110 V)

or

63816-0250 (220 V)

63816-0200 (110 V)

or

63816-0250 (220 V)

Battery Power Tool

Battery Power Tool

(Sold separately)

63816-0600

63816-0900

N/A N/A

(Sold separately)

Battery Power

Crimp Adapter

Page 32

Battery Powered Crimping Tool

Figure 6

-

2 Modular Crimp Head

Figure 6

-

3 Power Crimp

Head

TYPE 4A

LOCKI

NG

BATTERY

TYPE 4A

63816

-

0600

LOCKING

PINS (2)

TYPE

4D

BATTERY

TYPE 4D

LOCKING

TYPE

2C or 4

C

BATTERY

TYPE 2C OR 4C

LOCKING

TYPE

AT

SLOTTED

BATTERY

TYPE AT

63816

-

0900

LOCKING

MODULAR

CRIMP HEAD

WITH TOOLING

SCREWS (2)

ADAPTER

PINS (2)

POWERED TOOL

PINS (2)

MODULAR

CRIMP HEAD

WITH TOOLING

ADAPTER

POWERED TOOL

POWER CRIMP HEAD

(NO TOOLING

SHOWN)

POWER CRIMP HEAD

(NO TOOLING

SHOWN)

PINS (2)

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 32 of 33

Revision: E Revision Date: 06-07-12

PINS (2)

POWERED

TOOL

POWERED

TOOL

Page 33

Battery Powered Crimping Tool

Symptom

Cause

Solution

Dirt, contaminants, etc.,

Battery unit contacts corroded.

Clean contacts with pencil eraser or

contact cleaner

Battery unit contacts damaged.

Reform the contacts.

Tool parts worn or damaged.

Contact a Molex representative.

LED glows for

6.2 Troubleshooting

Make sure the battery is charged before toubleshooting this tool.

Tool is inoperative.

Dies stop

during operation.

20 seconds.

in ram area of tool.

Battery charge is low.

Battery charge is low. Charge or replace battery unit.

Visit our Web site at http://www.molex.com

Clean the tool.

Charge or replace battery unit.

Order No: TM-638160200 Release Date: 12.06-07 UNCONTROLLED COPY Page 33 of 33

Revision: E Revision Date: 06-07-12

Loading...

Loading...