Page 1

IDT Manual Hand Tool

IDT

Manual

Hand Tool

Application Tooling

Specification Sheet

Order No. 63600-0478

Change Head List

Order No.

Engineering No.

Connector Series No.

Connector Description

11-21-5196

AM60116

7674

7475

KK® IDT Double Cantilever Contact 3.96mm (.156") Pitch, 2 to 16 Circuits.

40791

40915

IDT 3.96mm (.156") Pitch, 2 to 24 Circuits

11-21-5197

AM60115

7720

7720S

KK ® IDT Double Cantilever Contact, 2.54mm (.100") Pitch,

2 to 28 Circuits.

40555

11-21-8365

AM60519

7720

KK ® IDT Double Cantilever Contact, 2.54mm (.100") Pitch,

2 to 28 Circuits.

40555

11-21-9756

AM60512A

70156

5.08mm ( .200") Pitch , Female Type IDT Connector

11-31-3337

AM60571

87259

87568

Mill-Grid™ IDT 2.00mm (.079") Pitch Cable-to-Board, 10 to 50 Circuits.

70625

71247

MX-50™ 1.27mm (.050") Pitch Slimline Ribbon Cable,

6 to 64 Circuits.

70121

71898

11-31-3339

AM60539

70121

MX-50™ 1.27mm (.050") Pitch Slimline Ribbon Cable, 6 to 64 Circuits.

11-31-3340

AM60575

Cable Shear

11-31-4652

AM60577

5320

40312

QF-50™ 2.54mm (.100") Pitch Receptacle 10 to 64 Circuits.

70625

71247

MX-50™ 1.27mm (.050") Pitch Slimline Ribbon Cable,

6 to 64 Circuits.

71898

11-31-8939

AM60087

42219

42254

SPOX™ IDT 2.50 mm (.098 inch) Pitch, 2 to 15 Circuits

11-32-5759

AM63186

87259

Mill-Grid™ IDT 2.00mm (.079") Pitch, 10 to 50 Circuits.

11-32-6027

AM63175

71156

5.08mm (.200") Disk Drive Power Connector

11-39-0273

AM63538

30452

IDT 2.00mm (.079") Pitch, 2 to 21 Circuits

11-39-0303

AM63534

71690

71694

Mini-Fit IDT™ 4.20mm (.165") Receptacle and Plug, 2 to 12 Circuits.

62100-0300

62100-0300

70107

71178

SL™2.54mm (.100") Pitch Wire-to-Wire Crimp Connector 2 to 25 Circuits.

62100-0400

62100-0400

7674

7675

KK® IDT Double Cantilever Contact. 3.96mm (.156") Pitch, 2 to 16 Circuits.

62100-0700

62100-0700

70400

70475

SL™2.54mm (.100") Pitch Insulation Displacement, 2 to 25 Circuits.

90187

C-Grid III™ 2.54mm (.100") Pitch

62100-2000

62100-2000

87568

Mill-Grid™ IDT 2.00mm (.079") Pitch Cable-to-Board, 10 to 50 Circuits.

69008-0225

69008-0225

7720

7720S

KK® IDT 2.54mm (.100") Double Cantilever Contact, 2 to 28 Circuits

7795

40555

69008-0240

69008-0240

7674

7475

KK® IDT Double Cantilever Contact 3.96mm (.156") Pitch, 2 to 16 Circuits

69008-0250

69008-0250

5320

5320

QF 50™2.54mm (.100") Pitch, 10-64 Circuits.

40312

90635

FEATURES

A full cycle ratcheting hand tool ensures complete crimps

Use with interchangeable Change Head modules that are easy to install

This tool is designed for prototype, low volume, and field repair applications

SCOPE

This Hand Tool is intended to be used with the Change Head Modules listed below:

Doc No: ATS-636000478 Release Date: 12-22-05 UNCONTROLLED COPY Page 1 of 4

Revision: C Revision Date: 07-27-15

Page 2

IDT Manual Hand Tool

Change Head List

Order No.

Engineering No.

Connector Series No.

Connector Description

69008-0270

69008-0270

6952

7933

KK ® IDT 5.08mm (.200") Pitch, 2 to 16 Circuits

69008-0290

69008-0290

42219

SPOX™ IDT 2.50 mm (.098 inch) Pitch, 2 to 15 Circuits

90650

90652

User Friendly IDT 2.50 mm (.098 inch) Pitch Wire-to-Board, 2 to 20 Circuits

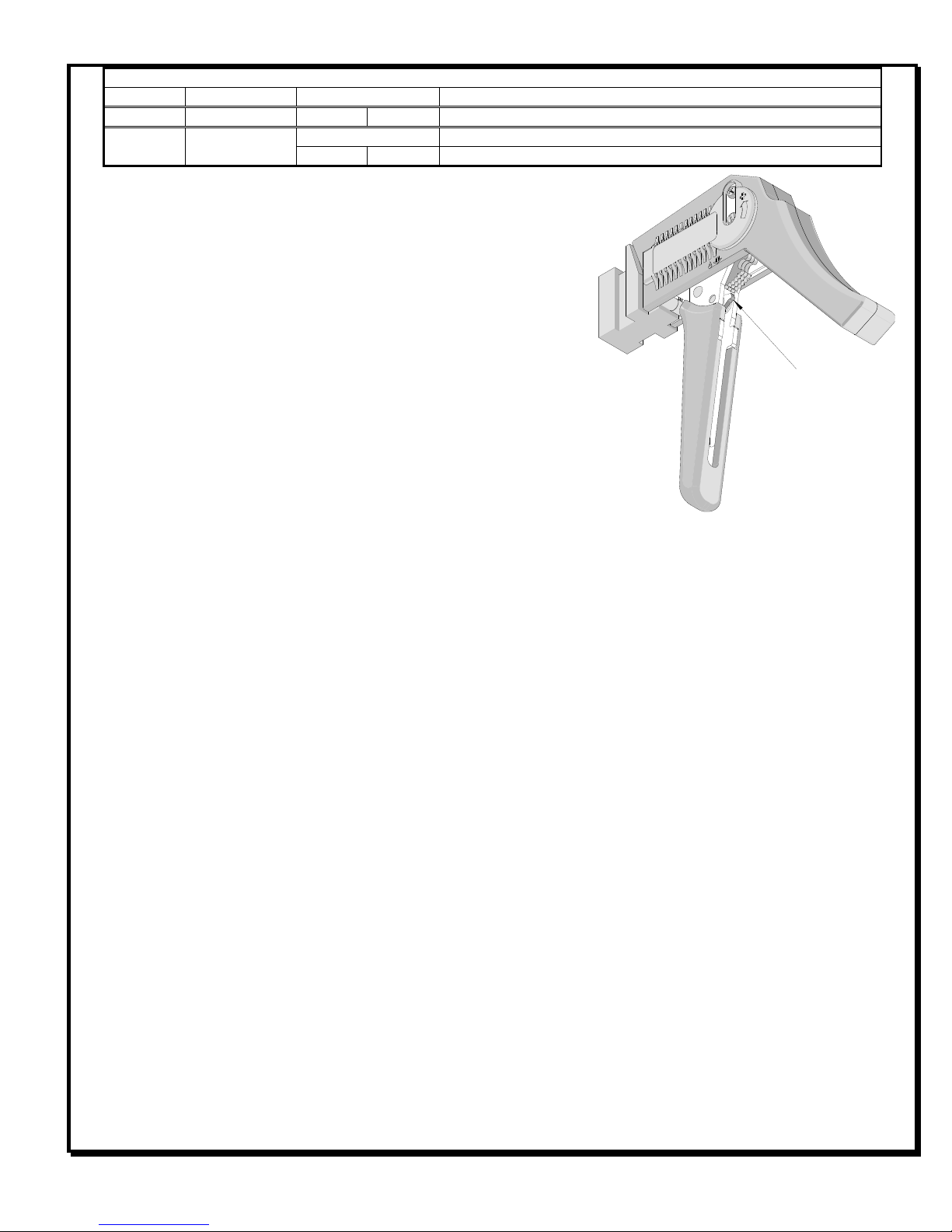

RATCHET

RELEASE LEVER

Figure 1

OPERATION

Select the appropriate Change Head and snap it on the front of the

hand tool until it engages, refer to the chart.

Refer to the specific Change Head module’s Specification Sheet for

operating instructions.

Maintenance

It is recommended that each operator of the tool be made aware of,

and responsible for, the following maintenance steps:

1. Remove the plastic handles from the metal tool frame by removing

the screws and remove dust, moisture, and other contaminants

with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality machine

oil. Do not oil excessively. The tool was engineered for durability but like any equipment it needs cleaning and

lubrication for a maximum service life of trouble free crimping. Light oil used at the pivot points every 5,000

crimps or 3 months, will significantly enhance the tool life.

4. Wipe excess oil from hand tool, particularly from crimping area.

Miscrimps or Jams

Should this tool ever become stuck or jammed in a partially closed position, Do Not force the handles open or

closed. The tool will open easily by pressing the ratchet release lever up. See Figure 1.

How to Adjust Tool Preload

It may be necessary over the life of the tool to adjust tool handle preload force. Listed below are the steps

required to adjust the crimping force of the hand tool to obtain proper crimp conditions:

1. Remove the 2mm locking screw from the numbered adjusting wheel using a screw driver. See Figure 2.

2. Using the same screw driver turn the adjustment wheel to the next highest number.

Note: The odd numbers are in clockwise (CW) direction and the even numbers are counter clockwise (CCW).

3. Example: If the preload is set at number 5, then to increase the preload, turn the adjustment wheel until the 6

position is located over the 2mm locking screw tapped hole. If it is necessary to move to the 7th position, then

the adjustment wheel should be turned clockwise (CW) until the 7th position is over the 2mm locking screw

tapped hole.

4. Replace the 2mm locking screw, aligning the nearest notch in the setting wheel to locking screw.

5. Check the crimp specifications after the tool handle preload force is adjusted. Repeat these steps until the

desired result is obtained.

th

Doc No: ATS-636000478 Release Date: 12-22-05 UNCONTROLLED COPY Page 2 of 4

Revision: C Revision Date: 07-27-15

Page 3

IDT Manual Hand Tool

NUMBERED ADJUSTMENT

WHEEL

Figure 2

TURN CLOCKWISE (CW) OR

COUNTER CLOCKWISE (CCW)

TO ADJUST THE PRE-LOAD

TURN WITH A SMALL

SCREW DRIVER

REMOVE THE 2MM LOCKING SCREW

Warranty

This tool is for electrical

crimping purposes only. This

tool is made of the best quality

materials. All vital

components are long life

tested. All tools are warranted

to be free of manufacturing

defects for a period of 30

days. Should such a defect

occur, we will repair or

exchange the tool free of

charge. This repair or

exchange will not be

applicable to altered, misused,

or damaged tools. This tool is

designed for hand use only.

Any clamping, fixturing, or use

of handle extensions voids this warranty.

CAUTION: Molex crimp specifications are valid only when used with Molex connectors and tooling.

CAUTIONS:

1. Manually powered hand tools are intended for low volume, prototyping, or field repair. This tool is NOT

intended for production use. Repetitive use of this tool should be avoided.

2. Insulated rubber handles are not protection against electrical shock.

3. Wear eye protection at all times.

4. Use only the Molex connectors specified for crimping with this tool.

Doc No: ATS-636000478 Release Date: 12-22-05 UNCONTROLLED COPY Page 3 of 4

Revision: C Revision Date: 07-27-15

Page 4

IDT Manual Hand Tool

1

Figure 3

2

3

Item Number

Order Number

Description

Quantity

63600-0478

Hand Crimp Tool

Figure 3

1

11-11-0320

Spring (Ratchet)

1 2 63600-0479

Spring (Main)

1 3 69008-0972

Adjuster Wheel

1

PARTS LIST

Visit our Web site at http://www.molex.com

Doc No: ATS-636000478 Release Date: 12-22-05 UNCONTROLLED COPY Page 4 of 4

Revision: C Revision Date: 07-27-15

Loading...

Loading...