Page 1

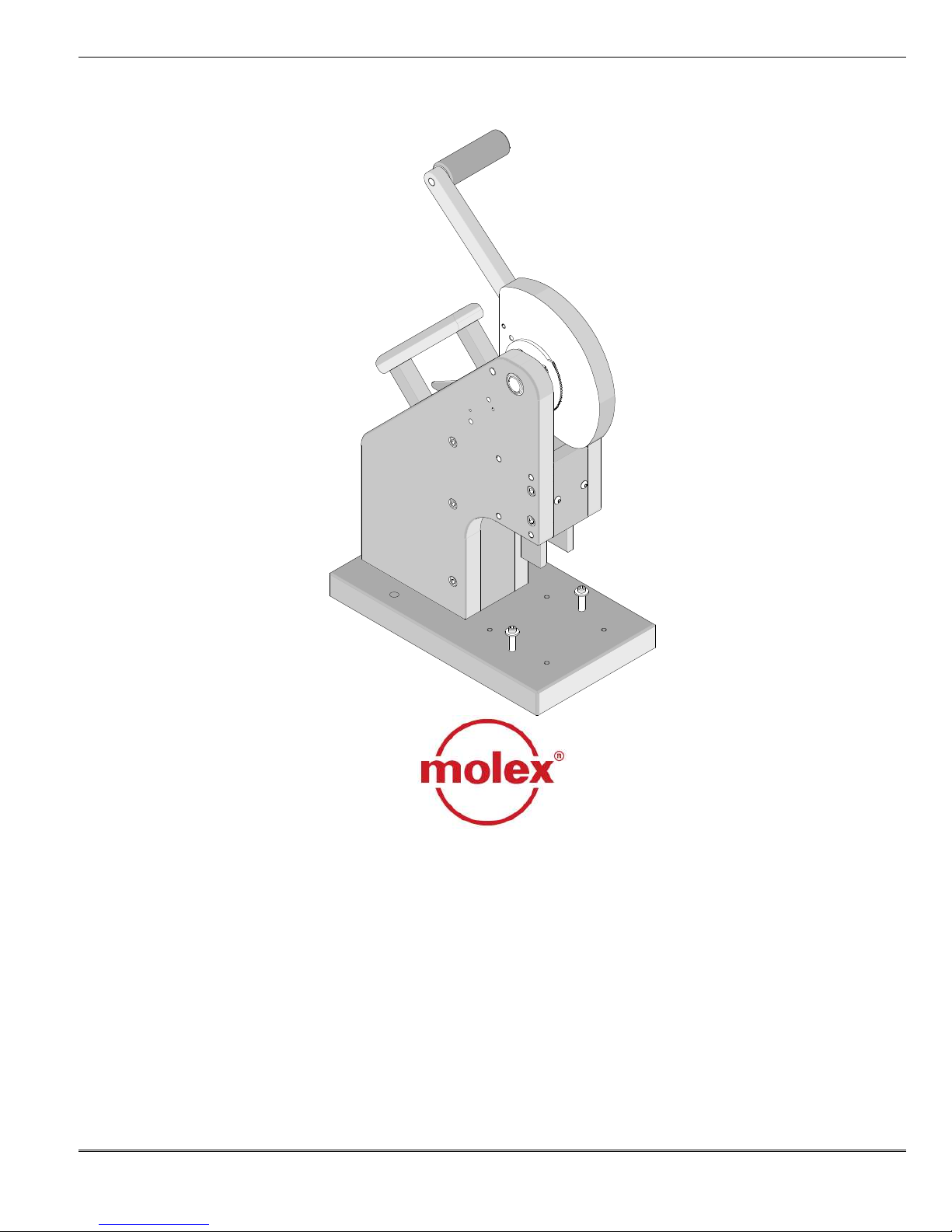

Molex Standard Manual Assembly Press

Molex Standard Manual Assembly Press

Description

Operation

Maintenance

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 1 of 16

Revision: D Revision Date: 10-08-09

Instruction Manual

Order No. 11-31-6356

Engineering No. AM-60026-50

Page 2

Molex Standard Manual Assembly Press

WARNING

NEVER OPERATE, SERVICE, OR ADJUST THIS PRESS OR INSTALL CRIMP DIES WITHOUT PROPER

INSTRUCTION AND WITHOUT FIRST READING AND UNDERSTANDING THE INSTRUCTIONS IN

THIS MANUAL.

WORK SAFELY AT ALL TIMES

For Service, Contact Your

Local Molex Sales Office

Molex Application Tooling Group

2200 Wellington Court

Lisle, Illinois 60532

Tel: 630-969-4550

Fax: 630-505-0049

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 2 of 16

Revision: D Revision Date: 10-08-09

Page 3

Molex Standard Manual Assembly Press

1 General Description

2 Installation, Setup, and Operation

3 Maintenance and Troubleshooting

4 Parts List and Assembly Drawings

Table of Contents

SECTION

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 3 of 16

Revision: D Revision Date: 10-08-09

Page 4

Molex Standard Manual Assembly Press

1.1. Description

1.2. Features

1.3. Technical Specifications

1.4. Delivery Check

1.5. Tools

Section 1

General Description

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 4 of 16

Revision: D Revision Date: 10-08-09

Page 5

Molex Standard Manual Assembly Press

General Description

1.1 Description

The Molex Standard Manual Assembly Press (1131-6356) is versatile, reliable, and inexpensive to

operate. It is designed to provide an effective

method of apply force to a wide variety of

terminating and crimping dies. The Press is easily

converted from right to left hand operation. When

the combinations of crimping dies have been

installed the operator pulls the handle down and

then returns it to the original position. A ratchet

mechanism insures that the press goes through a

full cycle for a complete termination. The press is

suited for low to mid-volume production

requirements.

1.2 Features

Press and tooling is easily portable.

Accepts a wide variety of terminating and

crimping tools kits.

Full cycle ratchet assures complete termination

Easily setup for left or right hand operation.

Tooling changeover is simple and quick.

Termination height is easily adjusted in the

upper tooling holder.

Manually operated, no shop air or electricity

required.

Low handle force to reduce operator fatigue.

1.3 Technical Specifications

Dimensions Press with tooling

Height 533mm (21.00”)

Width 152mm (6.00“)

Depth 267mm (10.50“)

Unpacked weight 23.2kg (50.5 lbs)

Production Rate

300 cycles per hour maximum, depending on

operator skill and tool kit installed.

Operating Parameters

Maximum Force 13.3kN (3,000lbs)

Shut Height 42.0mm (1.65”)

Stroke Length 43.0mm (1.69”)

Adjustment 5.26mm (.207”)

1.4 Delivery Check

The following items are included in this package :

Decription: Quantity

Molex Standard Assembly Press

11-31-6356 (AM-60026-50) 1

Instruction Manual TM-011316356 1

1.5 Tools

The following tools are recommended for setup and

adjustments to the this tool.

Adjustable wrench

Needle nose pliers

English hex wrench set for some non-metric tools.

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 5 of 16

Revision: D Revision Date: 10-08-09

Page 6

Molex Standard Manual Assembly Press

2.1. Instaltion

2.2. Set-Up

2.3. Operation

Section 2

Installation

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 6 of 16

Revision: D Revision Date: 10-08-09

Page 7

Molex Standard Manual Assembly Press

Figure 2

-1

RAM

BASE PLATE

FRAME

RATCHET

RATCHET

FRAME

REMOVE THE

Figure 2

-2

RAM HANDLE

RAM CAM

RAM CAM

RAM HANDLE

REPLACE THE

RIGHT HAND

ROTATE HANDLE

LEFT HAND

RAM HANDLE

HANDLE

RAM CAM

RELEASE

LEVER

2.1 Installation

The Molex Standard Assembly Press 11-31-6356

(AM-60026-50) will need to be secured to a work

surface.

To secure the press, use a bench capable of

supporting at least 150 pounds, with adequate

lighting for easy operation. There are two (2) holes

for 5/16” screws provided in the press base for

fastening the press to the workbench.

2.2 Set Up

Left of Right Handed Operation

The Molex Standard Manual Press can be set

up for either left or right handed operators by

simply reversing the handle on the press lever

by following these steps:

1. Remove the #1/4-20 X 1.0” Long SHCS at the

base of the Ram Handle.

2. Remove the Ram Handle Assembly and rotate it

1800.

3. Replace the Ram Handle Assembly to the Ram

Cam.

4. Replace the #1/4-20 X 1.0” Long SHCS and

tighten securely.

ASSEMBLY

#1/4-20 X1.0LG

SHCS

OPERATION

ASSEMBLY 180O

ASSEMBLY

#1/4-20 X1.0LG

SHCS

OPERATION

Ram Stroke Adjustment

The Ram Stroke Adjustment is made only when

there is a tool kit installed.

1. Place the proper tooling into the press.

2. Loosen the #8-32 set screw in the Ram which

locks the Ram Adjusting Screw into place. See

Figure 2-3.

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 7 of 16

Revision: D Revision Date: 10-08-09

Page 8

Molex Standard Manual Assembly Press

RAM

Figure 2

-5

RATCHET

#8-32 SET

Figure 2

-3

RAM

UP

.207” (

5.26mm)

RAM

RAISE FOR UP

Figure 2

-4

RAM

LOWER FOR

RAM ADJUSTING

ADJUSTING

SCREW

SCREW

POSITION

MINIMUM

DEPTH

MAXIMUM

DEPTH

IN THE DOWN

POSITION

3. There is an indicator engraved on the ram just

above the Ram Adjusting Screw. Turn the Ram

Adjusting Screw clockwise (CW) toward the “+”

sign to increase the ram stroke. To decrease

the stroke, turn the Ram Adjusting Screw

counterclockwise (CCW) toward the “-” sign.

Stroke adjustment controls the shut height of the

connector assembly. See Figure 2-4.

DOWN

POSITION

4. Once the correct stroke is set, tighten the

locking #8-32 set screw.

All tool kits are different and may need additional

adjustments. Refer to the individual Instruction

Manuals for the proper tool kit.

POSITION

2.3 Operation

Ram

To cycle the press, pull the press ram handle

down and then return it to its original position.

Warning: Once the press ram handle has started to

descend, it cannot be returned to the up position

until the full stroke of the press has been

completed. In case of a jam or some other

problem, should the press ram ever need to be

returned to the up position before completing the

full stroke, pull up on the ratchet release lever, and

raise the press ram handle. The ratchet release

lever is located on the upper left side of the press

frame. See Figure 2-5.

HANDLE

RELEASE

LEVER

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 8 of 16

Revision: D Revision Date: 10-08-09

Page 9

Molex Standard Manual Assembly Press

3.1. Cleaning

3.2. Lubrication

3.3. Perishable Parts

3.4. Spare Parts

3.5. Troubleshooting

Section 3

Maintenance

Order No TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 9 of 16

Revision: D Revision Date: 10-08-09

Page 10

Molex Standard Manual Assembly Press

GREASE

OIL

Figure 3

-1

OIL

OIL ROLLERS and

OIL

ROLLERS and

3.1 Cleaning

For efficient operation, the tooling should be cleaned daily. Use a soft bristle brush to remove debris from critical

areas. For best results, remove the tooling dies from the press. Brush and then use a clean cloth to wipe off the

upper and lower tooling mounting areas. Before reinstalling tooling, wipe all sides of the forms with a clean cloth.

See Chart 3.1 for recommended Preventive Maintenance Schedule.

NOTE: Using compressed air to clean tooling is not recommended. Chips can wedge in the tooling and/or fly at an

operator.

3.2. Lubrication

1. Grease the ram including the up and down stroke feed arm.

2. Oil all moving parts of the press.

3. Lubricate with multipurpose synthetic lubricant with Teflon or an equivalent. Molex ships its presses pre-greased

with Permatex multi-purpose synthetic grease with Teflon No. 82329. A SAE 10 non-detergent oil or light spindle

oil or 3-in-1 oil should be used on pivot points.

WARNING: Never use penetrants such as WD40 for any lubrication on the press.

4. Lubricate all points shown in Figures 3-1 with the specified oil and grease (or equivalent).

GREASE

BEARINGS (2)

BEARINGS (2)

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 10 of 16

Revision: D Revision Date: 10-08-09

Page 11

Molex Standard Manual Assembly Press

An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of your

Press or use this as a template to create your own schedule or use your company’s standard chart, if applicable.

Preventive Maintenance Chart

Daily: Clean. See Section 3.1.

As Required: Lubricate. See Section 3.2.

CHECK SHEET MONTH _________YEAR _________

Week Daily Clean

1

2

3

4

Cleaning

Lubricate

Inspect all tooling

for wear

MON TUE WED THU FRI SAT SUN

Yes Soft Brush Industrial

Yes Replace if signs of wear.

Days of the Week

Solution

Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive

maintenance be kept with the press.

3.3. Perishable Parts

Perishable parts are those parts that come in contact with the product and will wear out over time. Customers are

responsible for maintaining these parts.

There are no perishable parts for Molex Standard Manual Assembly Press. The various tooling kits will have

perishable parts. Molex recommends that all customers keep at least one set of the perishable tool kit in stock at

all times. This will reduce the amount of production down time. For the proper perishable tool kit information,

refer to the Individual Instruction Manual supplied with the Tooling Kits.

3.4. Spare Parts

Customers are responsible for maintaining the Molex Standard Manual Assembly Press. Spare parts are moving

and functioning parts that can be damaged or wear out over time and will require replacement. Molex

recommends that the customer keep some or all of them in stock to reduce production down time. These parts

are identified in the parts list in Section 4.

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 11 of 16

Revision: D Revision Date: 10-08-09

Page 12

Molex Standard Manual Assembly Press

3.5. Troubleshooting

Symptom Cause Solution

Wire does not terminate

properly in terminal

Ram goes down but

will not go up.

Full stroke ratchet

mechanism

not engaging

Improper gauge wire See product for wire gauge

Termination punch set to high or to deep

Sticking ratchet pawl or debris

in mechanism

Adjust the ram stroke. See Ram Stroke

Adjustment See Set-Up. Section 2.2

Clean and lubricate pivot points.

See Section 3 Maintenance.

Release the ram with the ratchet release

Ram set too low

lever and re-adjust the ram stroke.

See Ram Stroke Adjustment See Set-Up.

Section 2.2

Sticking ratchet pawl or debris

in mechanism

Clean and lubricate pivot points.

See Section 3 Maintenance

Broken or damaged ratchet pawl or spring Repair and replace.

Worn Anti-Backup Sprocket Replace.

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 12 of 16

Revision: D Revision Date: 10-08-09

Page 13

Molex Standard Manual Assembly Press

4.1 Parts List

4.2 Assembly Drawings

Section 4

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 13 of 16

Revision: D Revision Date: 10-08-09

Page 14

Molex Standard Manual Assembly Press

4.1 Parts List

Molex Standard Manual Assembly Press 11-31-6356 (AM-60026-50)

Item No. Order No. Engineering No. Description Quantity

1 11-31-7100 AM-60026-1 Base 1

2 11-31-7101 AM-60026-2 Frame Right Hand 1

3 11-31-7102 AM-60026-3 Frame Left Hand 1

4 11-31-7103 AM-60026-4 Tension Column 1

5 11-31-7104 AM-60026-5 Frame Spacer 1

6 11-31-7105 AM-60026-6 Ram 1

7 11-31-7106 AM-60026-7 Ram Adjustment Screw 1

8 11-31-7107 AM-60026-8 Ram Guide Plate 2

9 11-31-7110 AM-60026-11 Ram Cam 1

10 11-31-7111 AM-60026-12 Ram Cam Shaft 1

11 11-31-7113 AM-60026-14 Cam Follower Nut 1

12 11-31-7114 AM-60026-15 Anti-Backup Sprocket 1

13 11-31-7115 AM-60026-16 Anti Backup Pawl 1

14 11-31-7117 AM-60026-18 Anti-Backup Release 1

15 11-31-7118 AM-60026-19 Anti-Backup Release Pivot 1

16 11-31-7119 AM-60026-20 Frame Handle 1

17 11-31-7120 AM-60026-21 Handle Support 2

18 11-31-7121 AM-60026-22 Ram Arm 1

19 11-31-7122 AM-60026-23 Ram Arm Handle 1

20 11-31-7123 AM-60026-24 Handle Shaft 1

21 11-31-7124 AM-60026-25 Front Cover 1

22 11-31-7125 AM-60026-26 Compression Spring .240” OD 2

23 11-31-7126 AM-60026-27 Washer 7/32” ID 2

24 11-31-7128 AM-60026-29 Spacer 2

25 11-31-7132 AM-60026-33 Flat Washer .260” ID 8

26 11-31-7133 AM-60026-34 Flat Washer .340” ID 2

27 11-31-7134 AM-60026-35 Ram Cam Hub 1

28 11-31-7135 AM-60026-36 Spring Anchor 2

29 11-31-7313 AM-60026-37 Hub Spacer 1

30 11-32-4494 AM-60026-98 #8-32 Socket Head Set Screw 1

31 11-32-5278 AM-60026-38 E-Ring .168 ID 1

32 11-32-5279 AM-60026-39 E-Ring .281 ID 1

33 11-32-5280 AM-60026-40 E- Ring .238 ID 8

34 11-31-7108 AM-60026-9 Roller 8

35 11-31-7109 AM-60026-10 Bearing 1/4” ID 8

36 11-31-7112 AM-60026-13 Cam Follower 1

37 11-31-7116 AM-60026-17 Extension Spring .187” OD 1

38 11-31-7127 AM-60026-28 Bearing 5/8” ID 2

39 11-31-7131 AM-60026-32 Detent 1

40 N/A N/A #8-32 by 3/8” Long FHCS 4**

41 N/A N/A #8-32 by 1/4” Long BHCS 2**

42 N/A N/A #8-32 by 3/4” Long SHCS 2**

43 N/A N/A #10-32 by 1/4” Long SSS 1**

44 N/A N/A #1/4-20 by 1.0” Long SHCS 16**

45 N/A N/A #1/4-28 by 3/8” Long SSS Half Dog 2**

46 N/A N/A #5/16-18 by 1-1/2” Long SHCS 6**

47 N/A N/A 1/8 by 5/8” Long Dowel Pin 1**

48 N/A N/A 3/16 by 3/4” Long Dowel Pin 3**

Spare Parts

Hardware

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 14 of 16

Revision: D Revision Date: 10-08-09

Page 15

Molex Standard Manual Assembly Press

Molex Standard Manual Assembly Press 11-31-6356 (AM-60026-50)

Item No. Order No. Engineering No. Description Quantity

49 N/A N/A 5/16 by 1.0” Long Dowel Pin 2**

50 N/A N/A 1/4 by 1-1/2” Long Dowel Pin 8**

** Available from an industrial supply company such as MSC (1-800-645-7270).

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 15 of 16

Revision: D Revision Date: 10-08-09

Page 16

Molex Standard Manual Assembly Press

14

47

24 31

13

37

28

15

48

39

44

16

17

44

25

8

4

33

35

34

50

3

42

23

22

43

44

49

40

1

46

38

10

12

27

9

36

11

30

5

7

29

2

45

32

26

19

20

18

48

44

6

21

41

(4)

(6)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(8)

(8)

(8)

(8)

(2)

(2)

(8)

(10

(2)

(2)

4.2 Assembly

Americas Headquarters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

Far East North Headquarters

Yamato, Kanagawa, Japan

81-462-65-2324

feninfo@molex.com

Figure 4-1

Far East South Headquarters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

Visit our Web site at http://www.molex.com

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headquarters

2222 Wellington Ct.

Lisle, IL 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Order No: TM-011316356 Release Date: 02-05-99 UNCONTROLLED COPY Page 16 of 16

Revision: D Revision Date: 10-08-09

Loading...

Loading...