Page 1

SpectraMax®Paradigm®

Multi-Mode Detection Platform

User Guide

5014038 E

May 2015

Page 2

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

This document is provided to customers who have purchased Molecular Devices equipment, software,

reagents, and consumables to use in the operation of such Molecular Devices equipment, software,

reagents, and consumables. This document is copyright protected and any reproduction of this

document, in whole or any part, is strictly prohibited, except as Molecular Devices may authorize in

writing.

Software that may be described in this document is furnished under a non-transferrable license. It is

against the law to copy, modify, or distribute the software on any medium, except as specifically

allowed in the license agreement. Furthermore, the license agreement may prohibit the software

from being disassembled, reverse engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their products, which

may contain parts whose names are registered as trademarks and/or function as trademarks of their

respective owners. Any such usage is intended only to designate those manufacturers’ products as

supplied by Molecular Devices for incorporation into its equipment and does not imply any right and/or

license to use or permit others to use such manufacturers’ and/or their product names as trademarks.

Each product is shipped with documentation stating specifications and other technical information.

Molecular Devices products are warranted to meet the stated specifications. Molecular Devices makes

no other warranties or representations express or implied, including but not limited to, the fitness of

this product for any particular purpose and assumes no responsibility or contingent liability, including

indirect or consequential damages, for any use to which the purchaser may put the equipment

described herein, or for any adverse circumstances arising therefrom. The sole obligation of Molecular

Devices and the customer's sole remedy are limited to repair or replacement of the product in the

event that the product fails to do as warranted.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These trademarks may not

be used in any type of promotion or advertising without the prior written permission of Molecular Devices, LLC.

Patents: http://www.moleculardevices.com/productpatents

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

©2015 Molecular Devices, LLC.

All rights reserved.

2 5014038 E

Page 3

Contents

Safety Information 7

Warnings, Cautions, Notes, and Tips 7

Symbols on Instrument Labels 8

Before Operating the Instrument 9

Electrical Safety 9

Laser Safety 10

Chemical and Biological Safety 11

Moving Parts Safety 12

Cleaning and Maintenance Safety 13

Chapter 1: Introduction 15

Applications 16

Dual Photomultiplier Tubes 16

Microplate Controls 16

Environmental Controls 18

Chapter 2: Read Modes and Read Types 19

Supported Read Types 19

Absorbance Read Mode 23

Fluorescence Intensity Read Mode 28

Luminescence Read Mode 33

Time-Resolved Fluorescence Read Mode 38

FRET Read Mode 44

HTRF Read Mode 45

Fluorescence Polarization Read Mode 49

AlphaScreen Read Mode 53

Western Blot TRF Read Mode 57

Chapter 3: Unpacking and Setting Up the Instrument 61

Contents of the Package 62

Unpacking the Instrument 63

Removing the Transport Locks 67

Connecting the Instrument Cables 72

Unlocking the SpectraMaxParadigm Instrument 75

5014038 E 3

Page 4

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Connecting and Disconnecting a Gas Supply 76

Chapter 4: Using the Instrument 79

Front Panel Controls and Indicators 80

Turning the Instrument On and Off 82

Using Detection Cartridges 84

Loading and Unloading Microplates 90

Chapter 5: Available Detection Cartridges 93

Absorbance Detection Cartridge 94

Tunable Wavelength (TUNE) Detection Cartridge 97

Multi-Mode (MULTI) Detection Cartridge 102

AlphaScreen Detection Cartridges 107

Cisbio HTRF Detection Cartridge 110

Time Resolved Fluorescence (TRF) Detection Cartridge 113

Fluorescence Intensity (FI) Detection Cartridges 116

Fluorescence Intensity (FI) GeneBLAzer Detection Cartridge 119

Fluorescence Intensity Dual Label (FI-DL) (MultiTox-Fluor) Detection Cartridge 122

Fluorescence Polarization (FP) Detection Cartridges 125

Glow Luminescence (LUM) Detection Cartridges 128

Dual Color Luminescence (LUM) (BRET2) Detection Cartridge 131

Dual Color Luminescence (LUM) (Chroma-Glo) Detection Cartridge 136

ScanLater Western Blot (WB) Detection Cartridge 142

Chapter 6: Maintenance and Troubleshooting 147

Doing Preventive Maintenance 148

Cleaning the Instrument 149

Replacing Fuses 149

Moving the Instrument 152

Packing the Instrument for Storage or Service 153

Troubleshooting 164

Obtaining Support 165

Appendix A: Instrument Specifications 167

Computer System Specifications 167

Physical Specifications 168

4 5014038 E

Page 5

Appendix B: System Diagrams and Dimensions 171

Appendix C: Electromagnetic Compatibility 173

Glossary 175

Index 183

5014038 E 5

Page 6

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

6 5014038 E

Page 7

Safety Information

The safety information section provides information on the safe use of the instrument,

including the use of user-attention statements in this guide, a key to understanding the

safety labels on the instrument, precautions to follow before operating the instrument, and

precautions to follow while operating the instrument.

Please read and observe all warnings, cautions, and instructions. Remember, the most

important key to safety is to operate the instrument with care.

WARNING! If the instrument is used in a manner not specified by Molecular

Devices, the protection provided by the equipment might be impaired.

Warnings, Cautions, Notes, and Tips

All warning symbols in the user guide are framed within a yellow triangle. An exclamation

mark is used for most warnings. Other symbols can warn of other types of hazards such as

biohazard, electrical, or laser safety warnings as are described in the text of the warning.

When warnings and cautions are displayed in this guide, be careful to follow the specific

safety information related to them.

The following user-attention statements can be displayed in the text of Molecular Devices

user documentation. Each statement implies a particular level of observation or

recommended procedure as described:

WARNING! A warning indicates a situation or operation that could cause

personal injury if precautions are not followed.

CAUTION! A caution indicates a situation or operation that could cause damage to

the instrument or loss of data if correct procedures are not followed.

Note: A note calls attention to significant information.

Tip: A tip provides useful information or a shortcut, but is not essential to the

completion of a procedure.

5014038 E 7

Page 8

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

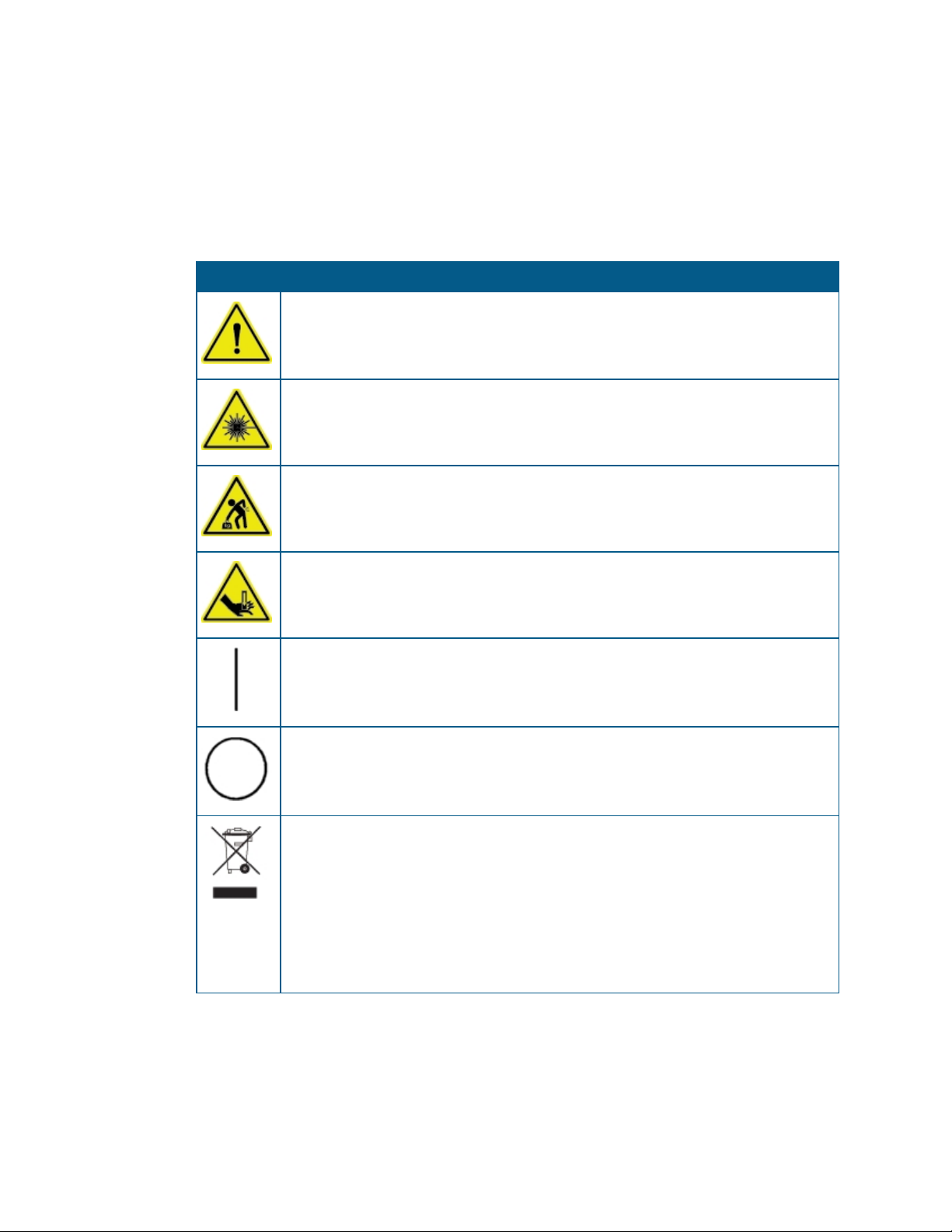

Symbols on Instrument Labels

Each safety label located on the instrument contains an alert symbol that indicates the type

of potential safety hazard related to the label. The following table lists the alert symbols that

can be found on Molecular Devices instruments.

Table S-1: Instrument Label Alert Symbols

Symbol Indication

This symbol indicates that the product documentation needs to be consulted.

This symbol indicates a potential laser hazard. The instrument is rated a Class 1 Laser

Product because it can house one or more laser modules, and the laser light cannot be

accessed. See Laser Safety on page 10.

This symbol indicates a potential lifting hazard. To prevent injury, use a minimum of

two people to lift the instrument. For information about the weight of the instrument,

see Physical Specifications on page 168.

This symbol indicates a potential pinch hazard.

This symbol on the power switch indicates power on. See Turning the Instrument On

and Off on page 82.

This symbol on the power switch indicates power off. See Turning the Instrument On

and Off on page 82.

This symbol on the product is required in accordance with the Waste Electrical and

Electronic Equipment (WEEE) Directive of the European Union. It indicates that you

must not discard this electrical or electronic product or its components in domestic

household waste or in the municipal waste collection system.

For products under the requirement of the WEEE directive, please contact your

dealer or local Molecular Devices office for the procedures to facilitate the proper

collection, treatment, recovery, recycling, and safe disposal of the device.

8 5014038 E

Page 9

Before Operating the Instrument

Make sure that everyone involved with the operation of the instrument has:

Received instruction in general safety practices for laboratories.

Received instruction in specific safety practices for the instrument.

Read and understood all Safety Data Sheets (SDS) for all materials being used.

Electrical Safety

To prevent electrically related injuries and property damage, properly inspect all electrical

equipment before use and immediately report all electrical deficiencies. Contact Molecular

Devices technical support for servicing of equipment that requires the removal of covers or

panels.

WARNING! HIGH VOLTAGE. Within the instrument is the potential of an

electrical shock hazard existing from a high voltage source. All safety instructions

should be read and understood before proceeding with the installation,

maintenance, and servicing of all modules.

Safety Information

Do not remove the instrument covers. To prevent electrical shock, use the supplied power

cords only and connect to a properly grounded wall outlet. Use only multi-plug power strips

that are provided by the manufacturer.

To protect against fire hazard, replace the fuses only with the same type and rating as the

original factory-installed fuses. See Replacing Fuses on page 149.

To ensure sufficient ventilation and provide access for disconnecting power from the

instrument, maintain a 20cm to 30cm (7.9in. to 11.8in.) gap between the rear of the

instrument and the wall.

Molecular Devices recommends turning the power off when the instrument is not in use.

5014038 E 9

Page 10

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

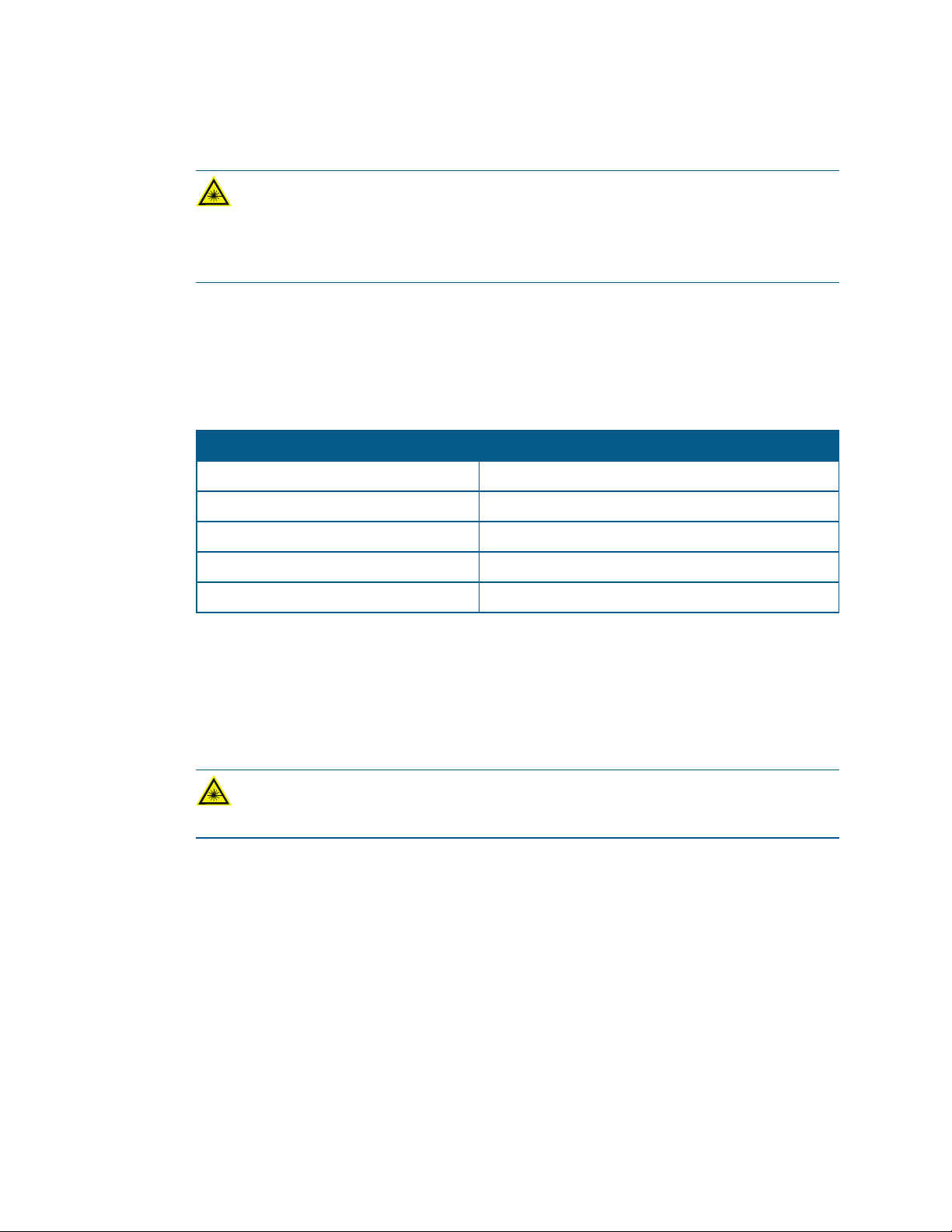

Laser Safety

WARNING! LASER LIGHT. This symbol indicates that a potential hazard to

personal safety exists from a laser source. When this symbol is displayed in this

guide, be careful to follow to the specific safety information related to the

symbol.

The SpectraMaxParadigm Multi-Mode Detection Platform is rated a Class 1 Laser Product

because it houses one or more laser modules, and the laser light cannot be accessed.

The embedded laser module inside the SpectraMaxParadigm Multi-Mode Detection

Platform basic instrument is used for the plate height detection and has the following

specifications.

Table S-2: Embedded Laser Module Specifications

Item Description

Lasertype Diode laser

Wavelength 650nm

Maximumoutputpower 0.9mW, cw

Laser class Class2 (IEC60825-1, ed. 2.0:2007)

Fan angle 58°

The SpectraMaxParadigm Multi-Mode Detection Platform is equipped with a redundant

laser safety system. A hardware interlock prevents the laser module from turning on, unless

the microplate chamber flap is closed and the front cover of the detection cartridge drawers

are in place. The user or the service engineer is not exposed to radiation from the laser

module during operation, maintenance, or service. The closed microplate chamber provides

the protective housing.

WARNING! LASER LIGHT. The instrument must be operated only when all the

doors and panels of the instrument are in place and closed.

Laser or Laser Diodes in Detection Cartridges

Some detection cartridges can have a laser or laser diode up to Laser Class 4 inside the

detection cartridge. The lasers are non-operational until after the detection cartridges are

properly installed in the SpectraMaxParadigm Multi-Mode Detection Platform.

10 5014038 E

Page 11

Chemical and Biological Safety

Normal operation of the instrument can involve the use of materials that are toxic,

flammable, or otherwise biologically harmful. When using such materials, observe the

following precautions:

Handle infectious samples based on good laboratory procedures and methods to

prevent the spread of disease.

Observe all cautionary information printed on the original containers of solutions before

their use.

Dispose of all waste solutions based on the waste disposal procedures of your facility.

Operate the instrument in accordance with the instructions outlined in this guide, and

take all the necessary precautions when using pathological, toxic, or radioactive

materials.

Splashing of liquids can occur. Therefore, take applicable safety precautions, such as

using safety glasses and wearing protective clothing, when working with potentially

hazardous liquids.

Use a correctly contained environment when using hazardous materials.

Use a compressed gas supply in a well-ventilated area. The instrument is not air-tight,

and so gas can escape into the atmosphere surrounding the instrument. When using

potentially toxic gas, always observe the applicable cautionary procedures as defined by

your safety officer to maintain a safe working environment.

Observe the applicable cautionary procedures as defined by your safety officer when

using flammable solvents in or near a powered-up instrument.

Observe the applicable cautionary procedures as defined by your safety officer when

using toxic, pathological, or radioactive materials.

Safety Information

WARNING! Never use the instrument in an environment where potentially

damaging liquids or gases are present.

CAUTION! Use of organic solvents (such as dichloromethane) can cause harm to the

optics in the instrument. Extreme caution is recommended when using organic

solvents. Always use a plate lid and do not place a plate containing these materials in

the microplate chamber for prolonged periods of time. Damage caused by the use of

incompatible or aggressive solvents is NOT covered by the instrument warranty.

5014038 E 11

Page 12

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Moving Parts Safety

To prevent injury due to moving parts, observe the following:

Never try to exchange labware, reagents, or tools while the instrument is operating.

Never try to physically restrict the moving components of the instrument.

Keep the instrument work area clear to prevent obstruction of the movement. Provide

clearance in the front of the instrument of 18cm (7.1in.) for the microplate drawer and

15cm (5.9in.) for the detection cartridge drawer.

The instrument has adjustable optics to define the read height, or z-height. In a top

read, the read height is the gap between the lens and the top of the microplate, or the

top of the lid if the microplate is lidded.

CAUTION!To prevent damage to the instrument, the height of the microplate must

not exceed 25mm, including the lid if the microplate is lidded.

Transport locks are placed on the detection cartridge drawers and the microplate drawer to

protect the instrument from damage during shipping. The transport locks must be removed

before powering on the instrument.

To move the microplate drawer or the detection cartridge drawers into or out of the

instrument, always use the buttons on the keypad or the controls in the software. See Using

Detection Cartridges on page 84 or Loading and Unloading Microplates on page 90.

CAUTION! To prevent damage to the installed detection cartridges and the

instrument, do not manually slide the detection cartridge drawer in or out when the

instrument is powered on or when one or more detection cartridges are installed in

the drawer.

Note: Observe all warnings and cautions listed for all external devices attached to or in

use during the operation of the instrument. See the applicable user guide for the

operating and safety procedures of that device.

12 5014038 E

Page 13

Cleaning and Maintenance Safety

Observe the cleaning procedures outlined in this guide for the instrument.

Do the following before cleaning equipment that has been exposed to hazardous material:

Contact the applicable Chemical and Biological Safety personnel.

Review the Chemical and Biological Safety information contained in this guide.

Do only the maintenance described in this guide. Maintenance procedures other than those

specified in this guide can be done only by Molecular Devices qualified personnel. See

Obtaining Support on page 165.

WARNING! BIOHAZARD. It is your responsibility to decontaminate

components of the instrument before requesting service by a service engineer or

returning parts to Molecular Devices for repair. Molecular Devices will not accept

items that have not been decontaminated where it is applicable to do so. If parts

are returned, they must be enclosed in a sealed plastic bag stating that the

contents are safe to handle and are not contaminated.

Safety Information

For approved cleaning and maintenance procedures, see Maintenance and Troubleshooting

on page 147.

5014038 E 13

Page 14

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

14 5014038 E

Page 15

Chapter 1: Introduction

The SpectraMax®Paradigm® Multi-Mode Detection Platform from Molecular Devices® is a

user-upgradeable, multi-mode microplate reader capable of performing absorbance,

fluorescence, time-resolved fluorescence (including HTRF), fluorescence polarization,

AlphaScreen®, AlphaLISA®, and luminescence measurements. An external computer running

the SoftMax® Pro provides integrated instrument control, data display, and statistical data

analysis.

Detection cartridge modularity lets you configure the system to meet your current needs,

while providing flexibility to address future applications. Up to six detection cartridges can be

installed in each of the two detection cartridge drawers. The software detects the installed

cartridge configuration and does all measurement types supported by the detection

cartridges. For information about detection cartridges, see Available Detection Cartridges on

page 93.

Depending on the application, the instrument can read 6, 12, 24, 48, 96, and 384-well

microplates. For micro-volume measurements, the instrument supports SpectraDrop 24-well

Micro-Volume Microplates and SpectraDrop 64-well Micro-Volume Microplates. The

instrument is capable of reading 1536-well microplates when used with specific detection

cartridges. See Selecting Suitable Microplate Types on page 91.

1

CAUTION! To prevent damage to the instrument, the height of the microplate must

not exceed 25mm, including the lid if the microplate is lidded.

The SoftMax Pro Software can collect data from one or more microplates and store it in a

single data file, using the same or different instrument settings for different microplates.

Assays requiring a read in two or more read modes or read types can be combined in a single

experiment and run with a single command in the software, by defining separate microplate

reads and enabling Auto Read. For information on the acquisition and analysis capabilities of

the software, see the SoftMax Pro Software application help or user guide.

The SpectraMaxParadigm Instrument can be integrated with an automated laboratory

system. When integrated, the detection protocols are accessed by the robotic controller

software.

5014038 E 15

Page 16

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Applications

The high sensitivity and flexibility of the SpectraMaxParadigm Instrument make it useful for

applications in the fields of biochemistry, cell biology, immunology, molecular biology, and

microbiology.

Typical applications include ELISA, nucleic acid, protein, enzymatic type homogeneous and

heterogeneous assays, microbial growth, endotoxin testing, and pipettor calibration.

Application notes with specific application protocol suggestions can be found in the

Information Center and the Knowledge Base on the Molecular Devices web site at

www.moleculardevices.com.

Dual Photomultiplier Tubes

The SpectraMaxParadigm Instrument is equipped with two photo multiplier tubes (PMTs).

The dual PMTs let the instrument measure two separate emissions successively or

simultaneously, resulting in faster read times and increased throughput.

Microplate Controls

Microplate controls include Shake and On-the-Fly Detection. The instrument can also detect

the height and position of a microplate in the microplate drawer.

Shake

The Shake feature of the instrument permits the contents of the wells in a microplate to be

mixed automatically inside the microplate chamber before each read cycle, making it

possible to do kinetic analysis of solid-phase, enzyme-mediated reactions.

Shake must be selected before you start a read. The process related to the Shake setting

depends on the selected read mode:

In endpoint reads, Shake shakes the plate for a definable number of seconds and then

reads at all selected wavelengths.

In kinetic reads, Shake can shake the plate for a definable number of seconds before the

initial reading, and for a definable number of seconds before each subsequent reading.

The following Shake settings are available for the SpectraMaxi3x Instrument:

Intensity: Low, Medium, or High. The actual shake speed is based on the microplate

format.

Direction: Linear or Orbital patterns.

Duration: Length of time in seconds (1 to 60).

Molecular Devices strongly recommends the use of Shake for ELISAs and other solid-phase,

enzyme-mediated reactions to enhance accuracy.

16 5014038 E

Page 17

Chapter 1: Introduction

On-the-Fly Detection

With some detection cartridges, the instrument can read microplates as the microplate

drawer is moving within the chamber instead of pausing the microplate drawer to read each

well. This results in shorter read times.

There are two On-the-Fly Detection modes:

Selecting Performance results in a faster read time than not using On-the-Fly Detection,

but not as fast as the Speed mode. Performance provides considerably better results

than Speed for demanding assays.

Selecting Speed results in the fastest possible read time per microplate. However, there

is a trade-off between the data quality and read speed because each well is sampled for

shorter integration times.

The following table compares the read time for different plate types in each of the on-the-fly

detection modes. These read times do not include the time needed for the microplate

drawer to move the plate into the instrument and start the read, and then move the plate

out of the instrument, which can add approximately 25 seconds to the overall read time.

Table 1-1: Plate Read Times for On-the-Fly Detection (±5seconds)

Mode 96-well 384-well 1536-well

Optimized for speed 12seconds 25seconds 50seconds

Optimized for performance 20seconds 40seconds 80seconds

Microplate Height Sensing

Microplates up to a height of 25mm can be placed in the microplate drawer of the

instrument. A sensor detects the height of a microplate positioned in the microplate drawer

and confirms that the height is consistent with the selected microplate type and that it is

positioned properly on the microplate drawer.

CAUTION! To prevent damage to the instrument, the height of the microplate must

not exceed 25mm, including the lid if the microplate is lidded.

5014038 E 17

Page 18

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Environmental Controls

The environmental controls of the instrument include temperature regulation and a gas

inlet.

Temperature Regulation

The temperature inside the microplate chamber can be maintained at ambient plus 4°C ± 1°C

up to 45°C. When using a detection cartridge that has a flash lamp, temperature can be

maintained at ambient plus 5°C ± 1°C up to 45°C. You can set and control the temperature by

using the software. See the SoftMax Pro Software application help or user guide.

Note:The temperature sensors detect the temperature of the air inside the chamber,

not the temperature of the samples in the microplate. If you use the instrument to

warm the samples, Molecular Devices recommends that you use a seal or lid on the

microplate to prevent evaporation of the sample. Using a seal or lid also helps to

maintain uniform temperature. Letting the prepared sample equilibrate inside the

microplate chamber can take an hour or more. You can speed up equilibration by prewarming the sample and the assay reagents to the desired temperature before

placing the microplate in the chamber. Validate the data quality to determine whether

the seal or lid can stay on the microplate for the read.

Gas Inlet

The gas inlet permits the partial pressure of CO2, nitrogen, or other gas inside the microplate

chamber to be applied. This is useful when reading a cell-based assay in which the CO

environment needs to be controlled to keep cell cultures alive. The gas supply is not

controlled or monitored by the instrument or software. See Connecting and Disconnecting a

Gas Supply on page 76.

Note: The combination of temperature and CO2environment controls does not create

a true CO2incubator environment in the instrument.

Use a compressed gas supply in a well-ventilated area. The instrument is not air-tight, and so

gas can escape into the atmosphere surrounding the instrument. When using potentially

toxic gas, always observe the applicable cautionary procedures as defined by your safety

officer to maintain a safe working environment.

2

18 5014038 E

Page 19

Chapter 2: Read Modes and Read Types

The detection capabilities of the SpectraMaxParadigm Multi-Mode Detection Platform are

determined by the installed detection cartridges. Up to six detection cartridges can be

installed in each of the two detection cartridge drawers. For information about detection

cartridges, see Available Detection Cartridges on page 93.

The software detects the installed cartridge configuration and does all measurement types

supported by the detection cartridges. Use the SoftMax Pro Software to define the

parameters for the read mode and read type of your assay. See the SoftMax Pro Software

application help or user guide.

Application notes with specific application protocol suggestions can be found in the

Information Center and the Knowledge Base on the Molecular Devices web site at

www.moleculardevices.com.

For more information on the supported read modes, see the following topics:

Absorbance Read Mode on page 23

Fluorescence Intensity Read Mode on page 28

Luminescence Read Mode on page 33

Time-Resolved Fluorescence Read Mode on page 38

HTRF Read Mode on page 45

FRET Read Mode on page 44

Fluorescence Polarization Read Mode on page 49

AlphaScreen Read Mode on page 53

Western Blot TRF Read Mode on page 57

2

Supported Read Types

For most read modes, endpoint, kinetic, multi-point well-scan, and spectrum microplate

applications can be set up and run with the SoftMax Pro Software.

For more information on the supported read types, see the following topics:

Endpoint Read Type on page 20

Kinetic Read Type on page 20

Well Scan Read Type on page 21

Spectrum Read Type on page 21

Membrane Read Type on page 22

5014038 E 19

Page 20

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Endpoint Read Type

In an Endpoint read, a reading of each microplate well is taken in the center of each well, at a

single wavelength or at multiple wavelengths. Depending on the read mode, raw data values

are reported as optical density (OD), %Transmittance (%T), relative fluorescence units (RFU),

or relative luminescence units (RLU).

Kinetic Read Type

In a Kinetic read, the instrument collects data over time with multiple readings taken in the

center of each well at regular intervals.

The values calculated based on raw kinetic data include VMax, VMax per Sec, Time to VMax,

and Onset Time. Kinetic readings can be single-wavelength or multiple-wavelength readings.

Kinetic analysis can be done for up to 99 hours. The kinetic read interval depends on the

instrument setup parameters selected in the SoftMax Pro Software.

Kinetic analysis has many advantages when determining the relative activity of an enzyme in

different types of microplate assays, including ELISAs and the purification and

characterization of enzymes and enzyme conjugates. Kinetic analysis is capable of providing

improved dynamic range, precision, and sensitivity relative to endpoint analysis.

Peak Pro™ Analysis functions provide advanced peak detection and characterization for

applicable kinetic reads. See the SoftMax Pro Software Formula Reference Guide.

20 5014038 E

Page 21

Chapter 2: Read Modes and Read Types

Well Scan Read Type

A Well Scan read can take readings at more than one location within a well. A Well Scan read

takes one or more readings of a single well of a microplate on an evenly spaced grid inside of

each well at single or multiple wavelengths.

Some applications involve the detection of whole cells in large-area tissue culture plates. Well

Scan reads can be used with such microplates to permit maximum surface area detection in

whole-cell protocols. Since many cell lines tend to grow as clumps or in the corners of

microplate wells, you can choose from several patterns and define the number of points to

be scanned to work best with your particular application.

The following scanning patterns are available:

A horizontal line

A vertical line

A cross pattern

A fill pattern

The fill pattern can be either round or square to match the shape of the well. The image in

the Well Scan settings shows the shape of the well as defined for the selected microplate.

You can set the density of the well scan to determine the number of points to read in a line

pattern or the maximum number of horizontal and vertical points included in a cross or fill

pattern.

Depending on the read mode selected, the values are reported as optical density (OD),

%Transmittance (%T), relative fluorescence units (RFU), or relative luminescence units (RLU).

Spectrum Read Type

Depending on the read mode selected, a Spectrum read measures optical density (OD),

%Transmittance (%T), relative fluorescence units (RFU), or relative luminescence units (RLU)

across a spectrum of wavelengths.

Spectrum reads are available only for specific detection cartridges. See Available Detection

Cartridges on page 93.

5014038 E 21

Page 22

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Membrane Read Type

The Membrane read type is used for a time-resolved fluorescence reading of a Western Blot

membrane. The selected area is read, and a TIFF image is generated with the results of the

read.

The Molecular Devices ScanLater™Western Blot Assay Kit is a novel system for protein

analysis that is incorporated into a SpectraMaxParadigm Multi-Mode Detection Platform.

Membranes are incubated with Eu-chelate labeled secondary antibodies or streptavidin that

bind specifically to the target protein-specific primary antibody. For more information,

contact your Molecular Devices representative or search the knowledge base for ScanLater

or Western Blot at www.moleculardevices.com/support.

For information about the detection cartridge for Western Blot membrane reads, see

ScanLater Western Blot (WB) Detection Cartridge on page 142.

22 5014038 E

Page 23

Absorbance Read Mode

In the Absorbance (ABS) read mode, the instrument measures the Optical Density (OD) of

the sample solutions.

Absorbance is the quantity of light absorbed by a solution. To measure absorbance

accurately, it is necessary to eliminate light scatter. If there is no turbidity, then

absorbance=optical density.

A=log10(I0/I)=–log10(I/I0)

where I0is incident light before it enters the sample, I is the intensity of light after it passes

through the sample, and A is the measured absorbance.

For Absorbance reads, you can choose whether to display absorbance data as Optical

Density (OD) or %Transmittance (%T) in the Reduction dialog.

Optical Density

Optical density (OD)is the quantity of light passing through a sample to a detector relative to

the total quantity of light available. Optical Density includes absorbance of the sample plus

light scatter from turbidity and background. You can compensate for background using

blanks.

Chapter 2: Read Modes and Read Types

A blank well contains everything used with the sample wells except the chromophore and

sample-specific compounds. Do not use an empty well for a blank.

Some applications are designed for turbid samples, such as algae or other micro-organisms

in suspension. The reported OD values for turbid samples are likely to be different when read

by different instruments.

For optimum results, Molecular Devices recommends that you run replicates for all blanks,

controls, and samples. In this case, the blank value that can be subtracted is the average

value of all blanks.

% Transmittance

%Transmittance is the ratio of transmitted light to the incident light for absorbance reads.

T=I/I

0

%T=100T

where I is the intensity of light after it passes through the sample and I0is incident light

before it enters the sample.

Optical Density and %Transmittance are related by the following formulas:

%T=10

2–OD

OD=2–log10(%T)

The factor of two comes from the fact that %T is expressed as a percent of the transmitted

light and log10(100)=2.

When in %Transmittance analysis mode, the SoftMax Pro Software converts the raw OD

values reported by the instrument to %Transmittance using the above formula. All

subsequent calculations are done on the converted numbers.

5014038 E 23

Page 24

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Applications of Absorbance

Absorbance-based detection has been commonly used to evaluate changes in color or

turbidity, permitting widespread use including ELISAs, protein quantitation, endotoxin

assays, and cytotoxicity assays. With absorbance readers that are capable of measuring in

the ultraviolet (UV) range, the concentration of nucleic acids (DNA and RNA) can be found

using their molar extinction coefficients.

For micro-volume measurements, you can use SpectraDrop 24-well Micro-Volume

Microplates and SpectraDrop 64-well Micro-Volume Microplates.

To do absorbance reads, the SpectraMaxParadigm Multi-Mode Detection Platform requires

the Absorbance Detection Cartridge, see page 94.

You can use the Protocol Manager in the SoftMax Pro Software to quickly find and open a

predefined protocol.

More protocols and updated protocols can be downloaded from the Knowledge Base on the

Molecular Devices support web site (www.moleculardevices.com/support) or from the

protocol sharing web site (www.softmaxpro.org).

PathCheck Pathlength Measurement Technology

The temperature-independent PathCheck® Pathlength Measurement Technology

normalizes your absorbance values to a 1cm path length based on the near-infrared

absorbance of water.

The Beer–Lambert law states that absorbance is proportional to the distance that light

travels through the sample:

A = εbc

where A is the absorbance, εis the molar absorptivity of the sample, b is the pathlength, and

c is the concentration of the sample. The longer the pathlength, the higher the absorbance.

Microplate readers use a vertical light path so the distance of the light through the sample

depends on the volume. This variable pathlength makes it difficult to do extinction-based

assays and also makes it confusing to compare results between microplate readers and

spectrophotometers.

The standard pathlength of a 1cm cuvette is the conventional basis for quantifying the

unique absorptivity properties of compounds in solution. Quantitative analysis can be done

on the basis of extinction coefficients, without standard curves (for example, NADH-based

enzyme assays). When using a cuvette, the pathlength is known and is independent of

sample volume, so absorbance is directly proportional to concentration when there is no

background interference.

24 5014038 E

Page 25

Chapter 2: Read Modes and Read Types

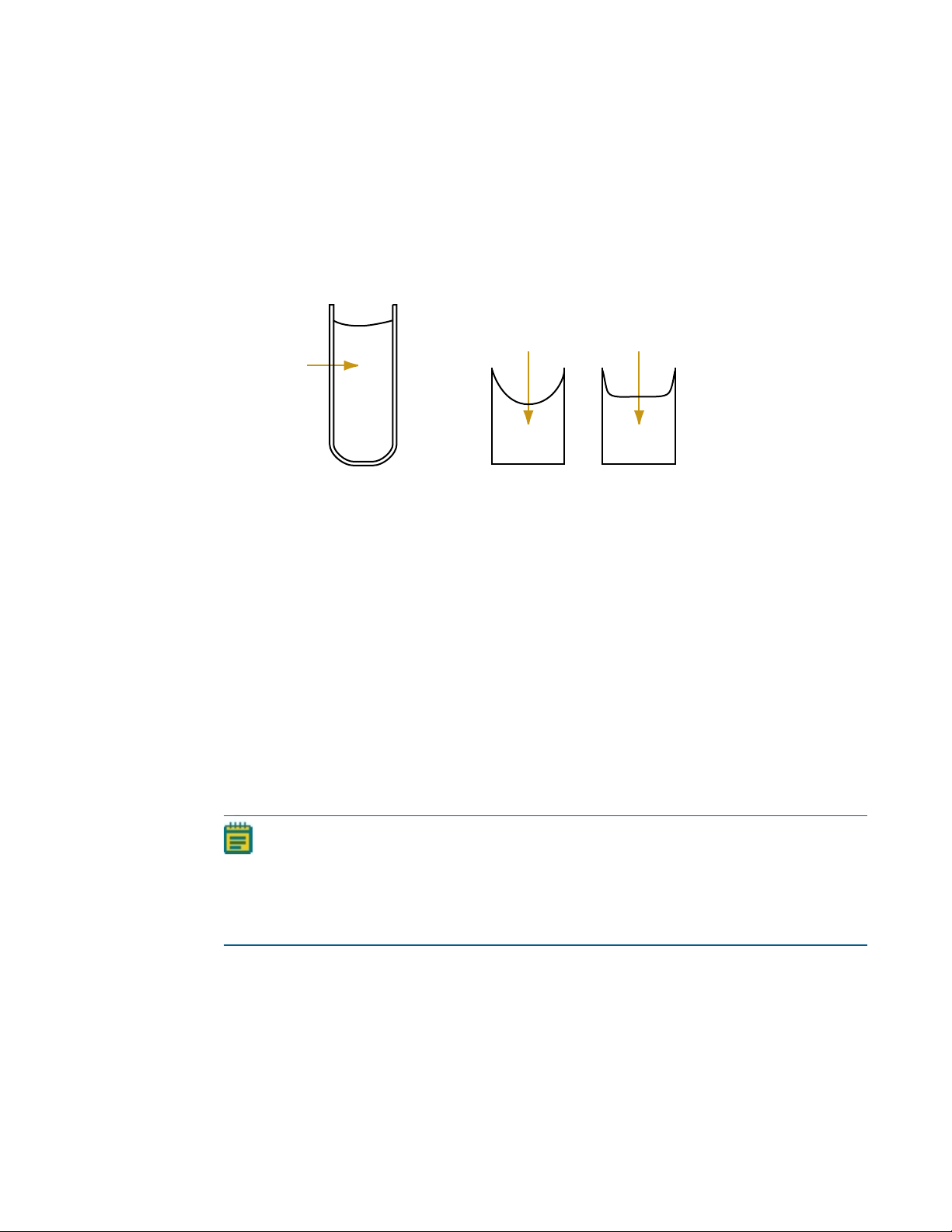

Horizontal

light path

Vertical light path

Cuvette Microplate wells

In a microplate, pathlength is dependent on the liquid volume, so absorbance is

proportional to both the concentration and the pathlength of the sample. Standard curves

are often used to determine analyte concentrations in vertical-beam photometry of

unknowns, yet errors can still occur from pipetting the samples and standards. The

PathCheck technology automatically determines the pathlength of aqueous samples in the

microplate and normalizes the absorbance in each well to a pathlength of 1cm. This way of

correcting the microwell absorbance values is accurate to within ±4% of the values obtained

directly in a 1cm cuvette.

Figure 2-1: Cuvette and Microplate Well Light Paths

The 1cm values can be obtained by using the factory installed Water Constant. PathCheck

technology is used to normalize the data acquired from absorbance endpoint microplate

readings to a 1cm pathlength, correcting the OD for each well to the value expected if the

sample were read in a 1cm cuvette.

Water Constant

The Water Constant correction method is supported for absorbance endpoint reads.

The PathCheck technology is based on the absorbance of water in the near infrared spectral

region (between 900 nm to 1000 nm). If the sample is completely aqueous, has no turbidity

and has a low salt concentration (less than 0.5 M), the Water Constant is sufficient. The

Water Constant is determined for each instrument during manufacture and is stored in the

instrument.

Note: After you have read a plate with PathCheck technology turned on, PathCheck

information is stored permanently in the data file. You have the option of applying, or

not applying, PathCheck technology to the absorbance values. If you do not have

PathCheck technology turned on during the plate read, you cannot apply the

PathCheck Pathlength Measurement Technology feature after the read.

5014038 E 25

Page 26

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Eliminating the Pathlength-Independent Component

Raw OD measurements of microplate samples include both pathlength-dependent

components (sample and solvent) and a pathlength-independent component (OD of

microplate material). The pathlength-independent component must be eliminated from the

calculation to get valid results that have been normalized by the PathCheck technology. You

can do this using a plate blank or using a plate background constant.

Using a Plate Blank

This method can be used if all samples in the microplate are the same volume and you are

not depending on the PathCheck technology to correct for variability in volumes.

To use this method:

1. Designate a minimum of one well (preferably several) as Plate Blank.

2. Pipette buffer (for example, your sample matrix) into those wells and read along with

your samples. Do not use an empty well for a blank.

The SoftMax Pro Software automatically subtracts the average of the blank wells from

each of the samples. The OD of the microplate material is subtracted as part of the blank.

3. Make sure that Use Plate Blank is checked under Other Options in the Data Reduction

dialog.

Using a Plate Background Constant

If your sample volumes are not identical or if you choose not to use a Plate Blank, then you

must use a Plate Background Constant. Omitting a Plate Background Constant results in

artificially high values after being normalized by the PathCheck technology.

To determine the Plate Background Constant:

1. Fill a clean microplate with water.

2. Read at the wavelengths that you will be reading your samples.

The average OD value is the Plate Background Constant. If you intend to read your samples

at more than one wavelength, there should be a corresponding number of Plate Background

Constant values for each wavelength.

Note: It is important that you put water in the wells and not read a dry microplate for

the Plate Background Constant. A dry microplate has a slightly higher OD value than a

water-filled microplate because of differences in refractive indices. Using a dry

microplate results in PathCheck technology normalized values that are lower than

1cm cuvette values.

26 5014038 E

Page 27

Chapter 2: Read Modes and Read Types

Interfering Substances

Material that absorbs in the 900nm to 1000nm spectral region could interfere with

PathCheck technology measurements. Fortunately, there are few materials that do interfere

at the concentrations generally used.

Turbidity is the most common interference. If you can detect turbidity in your sample, you

should not use the PathCheck technology. Turbidity elevates the 900nm measurement

more than the 1000nm measurement and causes an erroneously low estimate of

pathlength. Using Cuvette Reference does not reliably correct for turbidity.

Samples that are highly colored in the upper-visible spectrum might have absorbance

extending into the near-infrared (NIR) spectrum and can interfere with the PathCheck

technology. Examples include Lowry assays, molybdate-based assays, and samples

containing hemoglobins or porphyrins. In general, if the sample is distinctly red or purple,

you should check for interference before using the PathCheck technology.

To determine possible color interference, do the following:

Measure the OD at 900nm and 1000nm (both measured with air reference).

Subtract the 900nm value from the 1000nm value.

Do the same for pure water.

If the delta OD for the sample differs significantly from the delta OD for water, then it is

recommended to not use the PathCheck technology.

Organic solvents could interfere with the PathCheck technology if they have absorbance in

the region of the NIR water peak. Solvents such as ethanol and methanol do not absorb in

the NIR region, so they do not interfere, except for causing a decrease in the water

absorbance to the extent of their presence in the solution. If, however, the solvent absorbs

between 900nm and 1000nm, the interference would be similar to the interference of highly

colored samples as previously described. If you are considering adding an organic solvent

other than ethanol or methanol, you should run a Spectrum scan between 900nm and

1000nm to determine if the solvent would interfere with the PathCheck technology.

5014038 E 27

Page 28

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

500 550 600 650

0

0.5

1.0

Excitation maximum

Emission maximum

Relative Fluorescence

Wavelength (nm)

Absorption

Stokes

Shift

Fluorescence Intensity Read Mode

Fluorescence occurs when absorbed light is re-radiated at a longer wavelength. In the

Fluorescence Intensity (FL) read mode, the instrument measures the intensity of the reradiated light and expresses the result in Relative Fluorescence Units (RFU).

The governing equation for fluorescence is:

Fluorescence = extinctioncoefficient × concentration × quantumyield ×

excitationintensity × pathlength × emissioncollectionefficiency

Fluorescent materials absorb light energy of a characteristic wavelength (excitation), undergo

an electronic state change, and instantaneously emit light of a longer wavelength (emission).

Most common fluorescent materials have well-characterized excitation and emission

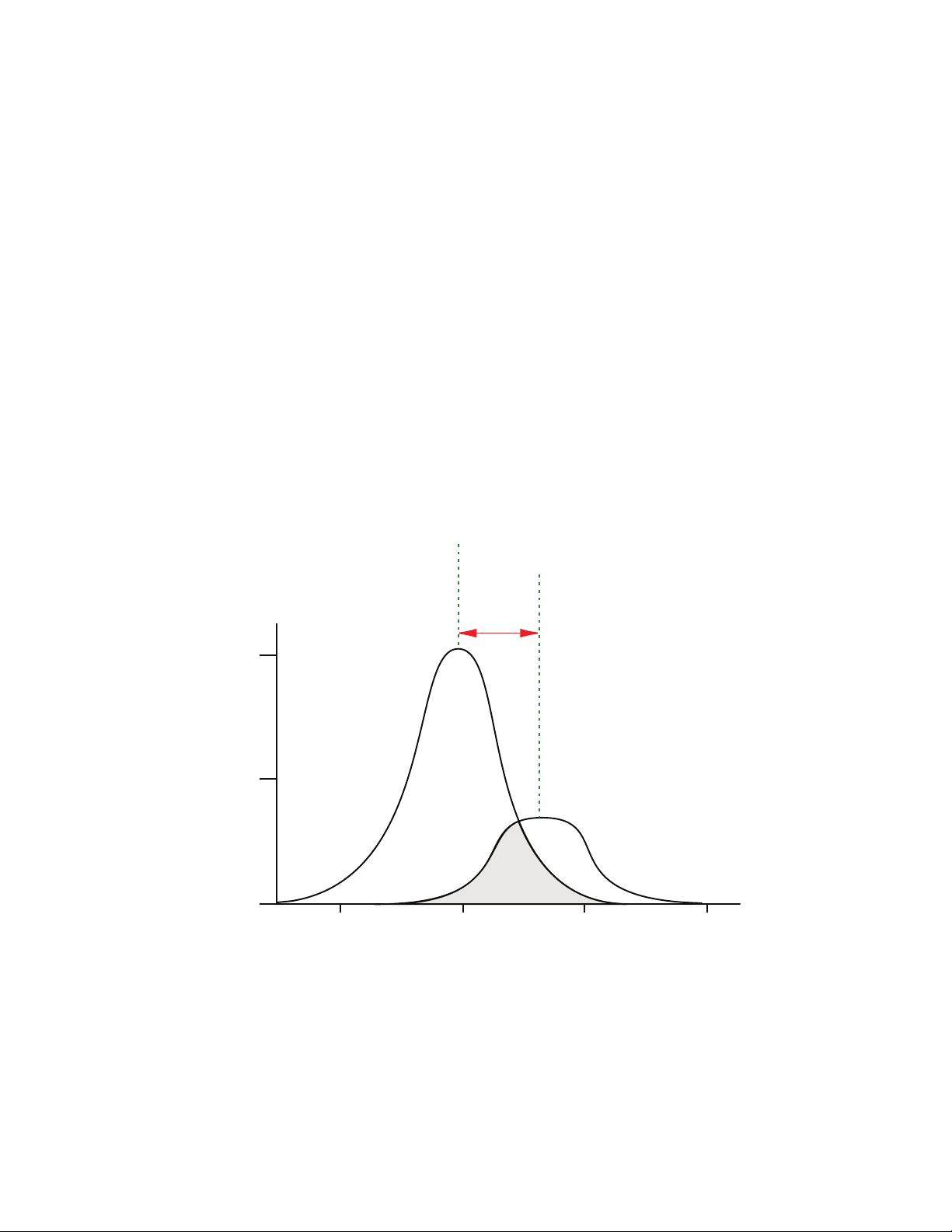

spectra. The following figure shows an example of excitation and emission spectra for a

fluorophore. The excitation and emission bands are each fairly broad, with half-bandwidths

of approximately 40nm, and the difference between the wavelengths of the excitation and

emission maxima (the Stokes shift) is generally fairly small, about 30nm. There is

considerable overlap between the excitation and emission spectra (gray area) when a small

Stokes shift is present.

Figure 2-2: Excitation and Emission Spectra

Because the intensity of the excitation light is usually many tens of thousands of times

greater than that of the emitted light, you must have sufficient spectral separation to reduce

the interference of the excitation light with detection of the emitted light.

28 5014038 E

Page 29

Chapter 2: Read Modes and Read Types

500 550 600 650

0

0.5

1.0

Excitation maximum

of fluorophore

Emission maximum

of fluorophore

Relative Fluorescence

Wavelength (nm)

Excitation

reading wavelength

Emission

reading wavelength

Tip: If the Stokes shift is small, you should choose an excitation wavelength that is as

far away from the emission maximum as possible while still being capable of

stimulating the fluorophore so that less of the excited light overlaps the emission

spectrum, permitting better selection and quantitation of the emitted light.

The Spectral Optimization Wizard in the SoftMax Pro Software provides the best settings

for maximizing the signal to background window, (S-B)/B, while minimizing the optimization

time. You can use this wizard with a Tunable Wavelength (TUNE) Detection Cartridge installed

in the SpectraMaxParadigm Multi-Mode Detection Platform. See the SoftMax Pro Software

application help or user guide.

5014038 E 29

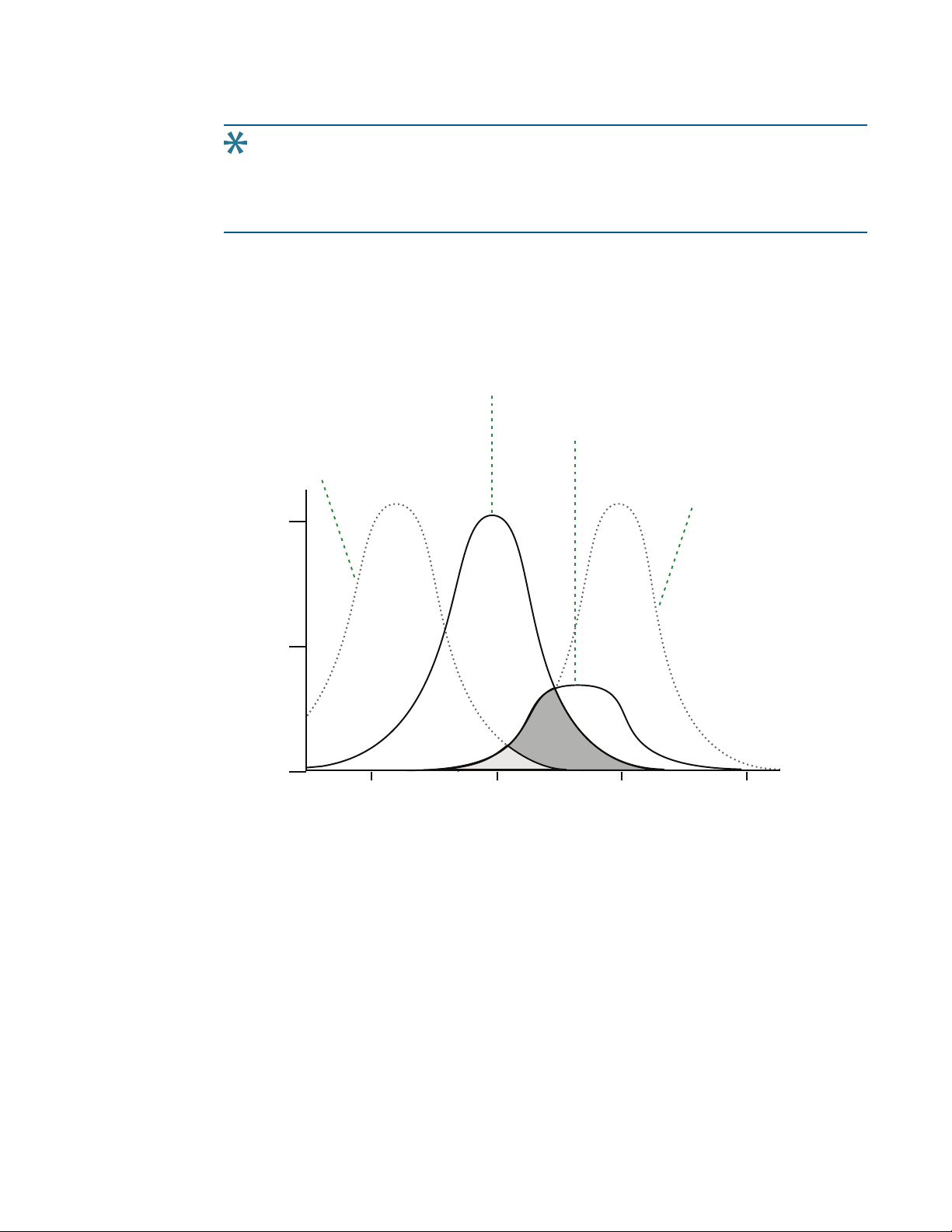

Figure 2-3: Optimized Excitation and Emission Reading Wavelengths

The previous figure shows that the best results are often obtained when the excitation and

emission wavelengths used for reading are not the same as the peak wavelengths of the

excitation and emission spectra of the fluorophore. When the reading wavelengths for

excitation and emission are separated, a smaller quantity of excitation light passes through

to the emission monochromator (gray area) and on to the PMT, resulting in a purer emission

signal and more accurate data.

Page 30

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

The instrument permits scanning of both excitation and emission wavelengths, using

separate tunable dual monochromators. One benefit of scanning emission spectra is that

you can determine more accurately whether the emission is, in fact, the expected

fluorophore, or multiple fluorophores, and not one generated by a variety of background

sources or by contaminants. One more benefit is that you can find excitation and emission

wavelengths that prevent interference when interfering fluorescent species are present.

For this reason, it is desirable to scan emission for both an intermediate concentration of

labeled sample, as well as the background of unlabeled sample. The optimum setting is

where the ratio of the sample emission to background emission is at the maximum.

Fluorescence intensity data is dependent on a number of variables. See Analyzing

Fluorescence Intensity Data on page 31.

Applications of Fluorescence Intensity

Fluorescence intensity is used widely in applications such as fluorescent ELISAs, protein

assays, nucleic acid quantitation, reporter gene assays, cell viability, cell proliferation, and

cytotoxicity. One more major application of this mode is to study the kinetics of ion release.

Some assays use a fluorescent label to selectively attach to certain compounds. The quantity

or concentration of the compound can then be quantified by measuring the fluorescence

intensity of the label, which is attached to the compound. Such methods are often used to

quantify low concentrations of DNA or RNA, for example.

You can use the Protocol Manager in the SoftMax Pro Software to quickly find and open a

predefined protocol.

More protocols and updated protocols can be downloaded from the Knowledge Base on the

Molecular Devices support web site (www.moleculardevices.com/support) or from the

protocol sharing web site (www.softmaxpro.org).

The following detection cartridges have fluorescence intensity read mode capability:

Tunable Wavelength (TUNE) Detection Cartridge, see page 97

Multi-Mode (MULTI) Detection Cartridge, see page 102

Fluorescence Intensity (FI) Detection Cartridges, see page 116

Fluorescence Intensity (FI) GeneBLAzer Detection Cartridge, see page 119

Fluorescence Intensity Dual Label (FI-DL) (MultiTox-Fluor) Detection Cartridge, see page

122

30 5014038 E

Page 31

Chapter 2: Read Modes and Read Types

conc

label

=

(sample – blank)

std – blank

conc

std

Analyzing Fluorescence Intensity Data

Fluorescence intensity data is dependent on a number of variables. Raw data is compared to

a standard curve with known concentrations of a reference label.

A standard curve consists of, at a minimum, a blank sample and a reference standard sample

of known concentration. The raw data can then be expressed in equivalent concentration of

a reference label.

Analyzing and validating fluorescence intensity data generally consists of the following:

Background Correction and Quantification on page 31

Detection Limit on page 32

Linearity and the Linear Dynamic Range on page 32

Background Correction and Quantification

A blank well contains everything used with the sample wells except the label and samplespecific compounds. Do not use an empty well for a blank.

The blank sample reveals the offset underlying each data sample. This offset does not carry

information on the label, and is generally subtracted before data reduction is done.

The blank-subtracted raw data are proportional to the quantity of label in a sample such that

the label concentration is quantified by the following equation.

where conc

is the concentration of the standard, and sample, blank, and standard are

std

average values of replicates for the sample, blank, and standard wells. In the general case

where the standard curve covers a concentration range of more than a few linear logs,

(standard–blank)/conc

is equivalent to the slope of the standard curve, and so the

std

concentration of the label is determined by (sample–blank)/(slopeofstandardcurve).

For optimum results, Molecular Devices recommends that you run replicates for all blanks,

controls, and samples. In this case, the blank value that can be subtracted is the average

value of all blanks.

5014038 E 31

Page 32

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Det Limit =

3 Stdev

blank

std – blank

conc

std

LDR = log10

max conc lin

detec!on limit

( )

Detection Limit

The detection limit is the smallest sample concentration that can be measured reliably above

the blank. Determining the detection limit requires taking a number of blank measurements

and calculating an average value and standard deviation for the blanks. The detection

threshold is defined as the average blank plus three standard deviations. If the average

sample value measures above the threshold, the sample can be detected at a statistically

significant level.

The detection limit can be described by the following equation:

where conc

is the concentration of the standard, StDev

std

is the standard deviation of the

Blan k

blank replicates, and blank and Std are average values of the replicates for the blank and

standard wells.

Determining the detection limit for an assay requires multiple blanks to calculate their

standard deviation.

Linearity and the Linear Dynamic Range

Within a wide range at moderately high concentrations, blanked raw data is proportional to

the quantity of label in a sample.

The linear dynamic range (LDR) is defined by:

where LDRis expressed as a log, and max conc lin is the highest concentration in the linear

range that can be quantified.

When the standard curve after blank reduction is not linear in concentration at the lower

end, there might be an incorrect or contaminated blank.

32 5014038 E

Page 33

Luminescence Read Mode

In luminescence read mode, no excitation is necessary as the species being measured emit

light naturally. For this reason, the lamp does not flash, so no background excitation

interference occurs.

In the Luminescence (LUM) read mode, the instrument provides measurements in Relative

Luminescence Units (RLUs).

Luminescence is the emission of light by processes that derive energy from essentially nonthermal changes, the motion of subatomic particles, or the excitation of an atomic system by

radiation. Luminescence detection relies on the production of light from a chemical reaction

in a sample.

To help eliminate background luminescence from a microplate that has been exposed to

light, Molecular Devices recommends dark adaptation of the microplate by placing the

sample-loaded microplate in the instrument for several minutes before starting the read.

If wavelength selection is desired, you can choose the wavelength where peak emission is

expected to occur. Also, multiple wavelength choices let species with multiple components

be differentiated and measured easily.

Chapter 2: Read Modes and Read Types

When maximum sensitivity is required, Molecular Devices recommends the use of dual-color

luminescence detection cartridges. See Dual Color Luminescence (LUM) (BRET2) Detection

Cartridge on page 131 and Dual Color Luminescence (LUM) (Chroma-Glo) Detection Cartridge

on page 136.

Luminescence can be read from the top or the bottom of a microplate. Solid white

microplates or white microplates with clear bottoms are recommended for luminescence

reads.

Concentrations or qualitative results are derived from raw data with a standard curve or by

comparison with reference controls. See Analyzing Luminescence Data on page 35.

5014038 E 33

Page 34

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Applications of Luminescence

Chemiluminescent or bioluminescent reactions can be induced to measure the quantity of a

particular compound in a sample. Examples of luminescent assays include the following:

Reporter gene assays (the measurement of luciferase gene expression)

Quantitation of adenosine triphosphate (ATP) as an indication of cell counts with cellproliferation, cytotoxicity, and biomass assays

Enzyme measurements with luminescent substrates, such as immunoassays

You can use the Protocol Manager in the SoftMax Pro Software to quickly find and open a

predefined protocol.

More protocols and updated protocols can be downloaded from the Knowledge Base on the

Molecular Devices support web site (www.moleculardevices.com/support) or from the

protocol sharing web site (www.softmaxpro.org).

The following detection cartridges have luminescence read mode capability:

Tunable Wavelength (TUNE) Detection Cartridge, see page 97

Multi-Mode (MULTI) Detection Cartridge, see page 102

Glow Luminescence (LUM) Detection Cartridges, see page 128

Dual Color Luminescence (LUM) (BRET2) Detection Cartridge, see page 131

Dual Color Luminescence (LUM) (Chroma-Glo) Detection Cartridge, see page 136

34 5014038 E

Page 35

Chapter 2: Read Modes and Read Types

Analyzing Luminescence Data

The conversion rate of photons to counts is individual for each reader. Therefore, raw data

from the same plate can seem significantly different from one instrument to the next. Also,

the data format used by other manufacturers might not be counts per second and can be

different by several orders of magnitude. It is important to know that the number of counts

and the size of figures is in no way an indication of sensitivity. See Detection Limit on page 36.

Concentrations or qualitative results are derived from raw data with a standard curve or by

comparison with reference controls. A standard curve consists of, at a minimum, a blank

sample and a reference standard sample of known concentration. The raw data can then be

expressed in equivalent concentration of a reference label. The raw data is normalized to

counts per second by dividing the number of counts by the read time per well.

Analyzing and validating luminescence data generally consists of the following:

Background Correction on page 35

Detection Limit on page 36

Sample Volumes and Concentration of Reactants on page 36

Data Optimization on page 37

Background Correction

The light detected in a luminescent measurement generally has two components: specific

light from the luminescent reaction and an approximately constant level of background light

caused by various factors, including the plate material and impurities in the reagents. The

background can be effectively measured using blank replicates. Blanks should include the

luminescent substrate (chemical energy source) but not the luminescence agent (generally

an enzymatic group which makes the substrate glow).

A blank well contains everything used with the sample wells except the label and samplespecific compounds. Do not use an empty well for a blank.

The blank sample reveals the offset underlying each data sample. This offset does not carry

information on the label, and is generally subtracted before data reduction is done.

For optimum results, Molecular Devices recommends that you run replicates for all blanks,

controls, and samples. In this case, the blank value that can be subtracted is the average

value of all blanks.

To help eliminate background luminescence from a microplate that has been exposed to

light, Molecular Devices recommends dark adaptation of the microplate by placing the

sample-loaded microplate in the instrument for several minutes before starting the read.

5014038 E 35

Page 36

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Det Limit =

3 Stdev

blank

std – blank

conc

std

Detection Limit

The detection limit is the smallest sample concentration that can be measured reliably above

the blank. Determining the detection limit requires taking a number of blank measurements

and calculating an average value and standard deviation for the blanks. The detection

threshold is defined as the average blank plus three standard deviations. If the average

sample value measures above the threshold, the sample can be detected at a statistically

significant level.

The detection limit can be described by the following equation:

where conc

is the concentration of the standard, StDev

std

is the standard deviation of the

Blan k

blank replicates, and blank and Std are average values of the replicates for the blank and

standard wells.

Determining the detection limit for an assay requires multiple blanks to calculate their

standard deviation.

Sample Volumes and Concentration of Reactants

The concentration of the luminescent agent impacts the quantity of light output in a

luminescent reaction. Light is emitted as a result of a reaction between two or more

compounds. Therefore, the quantity of light output is proportional to the quantity of the

limiting reagent in the sample.

For example, in an ATP/luciferin-luciferase system, when total volume is held constant and

ATP is the limiting reagent, the blanked light output is proportional to the concentration of

ATP in the sample, at very high concentrations of ATP. Substrate can be used up and become

rate-limiting, providing it is the rate-limiting component. In this case, the non-linearity is an

effect of the assay and not caused by the microplate reader.

Note: Very bright samples can exceed the linear dynamic range of the instrument. If

such is the case, reading can be done using an attenuation filter.

36 5014038 E

Page 37

Chapter 2: Read Modes and Read Types

Z´ = 1 –

| Mean

c+

– Meanc– |

3(SD

c+

) + 3(SDc– )

Data Optimization

The measurement noise is dependent on the read time per sample (time per plate or time

per well). In particular, the detection limit improves when the read time is increased.

Therefore, it is important to specify the read time when comparing measurements.

All low-light-level detection devices have some measurement noise in common. To average

out the measurement noise, optimization of the time per well involves accumulating as

many counts as possible. Within some range, you can reduce noise (CVs, detection limit) by

increasing the read time per well, as far as is acceptable from throughput and sample

stability considerations.

Z´ is the standard statistical parameter in the high-throughput screening community for

measuring the quality of a screening assay independent of test compounds. It is used as a

measure of the signal separation between the positive controls and the negative controls in

an assay.

The value of Z´ can be determined using the following formula:

where SD is the standard deviation, c+ is the positive control, and c– is the negative control.

A Z´ value greater than or equal to 0.4 is the generally acceptable minimum for an assay.

Higher values might be desired when results are more critical.

Z´ is not linear and can be made unrealistically small by outliers that skew the standard

deviations in either population. To improve the Z´ value, you can increase the quantity of

label in the sample, if acceptable for the assay, or increase the read time per well.

5014038 E 37

Page 38

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Time-Resolved Fluorescence Read Mode

Time-resolved fluorescence (TRF) is a measurement technique that depends on three

characteristics that lead to better discrimination between the specific signal, proportional to

the quantity of label, and the unspecific fluorescence resulting from background and

compound interference:

Pulsed excitation light sources

Time-gated electronics faster than the fluorescence lifetime

Labels with prolonged fluorescence lifetime

The time-gating electronics introduce a delay between the cut off of each light pulse and the

start of signal collection. During the delay, the unspecific fluorescence (caused by test

compounds, assay reagents, and the microplate) vanishes while only a small portion of the

specific fluorescence from the label is sacrificed. Enough of the specific signal remains during

the decay period with the added benefit of reduced background.

In Time-Resolved Fluorescence read mode, the instrument detects the extremely long

emission half-lives of rare earth elements called lanthanides such as europium (lifetime of

about 700 µs), samarium (lifetime of about 70 µs), or terbium (lifetime of about 1000 µs).

Applications of Time-Resolved Fluorescence

Time-resolved fluorescence (TRF) is widely used in high throughput screening applications

such as kinase assays, and is useful in some fluorescence immunoassays, such as DELFIA

(dissociation-enhanced enzyme linked fluorescence immunoassay). TRF is also useful in

some assay variants of TR-FRET (time-resolved fluorescence resonance energy transfer) in

which the FRET acceptor label acts as a quencher only and does not emit fluorescence. The

proximity between donor label and acceptor (quencher) is then quantified by the intensity

decrease of the donor label.

DELFIA requires washing steps as in an ELISA, but the TR-FRET assay involving quenching is a

homogeneous microplate assay technique and requires only mixing and measuring—no

wash steps are required. It can also be miniaturized, which makes it useful for highthroughput screening applications.

The Cisbio Bioassays HTRF (Homogeneous Time-Resolved Fluorescence) technology is a

proprietary time-resolved fluorescence technology that overcomes many of the drawbacks

of standard Fluorescence Resonance Energy Transfer (FRET) techniques, such as the

requirements to correct for autofluorescence and the fluorescent contributions of unbound

fluorophores. See HTRF Read Mode on page 45.

38 5014038 E

Page 39

Chapter 2: Read Modes and Read Types

You can use the Protocol Manager in the SoftMax Pro Software to quickly find and open a

predefined protocol.

More protocols and updated protocols can be downloaded from the Knowledge Base on the

Molecular Devices support web site (www.moleculardevices.com/support) or from the

protocol sharing web site (www.softmaxpro.org).

The following detection cartridges have time-resolved fluorescence read mode capability:

Tunable Wavelength (TUNE) Detection Cartridge, see page 97

Multi-Mode (MULTI) Detection Cartridge, see page 102

Cisbio HTRF Detection Cartridge on page 110

Time Resolved Fluorescence (TRF) Detection Cartridge, see page 113

Analyzing Time-Resolved Fluorescence Data

A time-resolved fluorescence (TRF) measurement includes a number of pulses. Each pulse

consists of turning the light source on and off (Excitation Time), pausing for a specified length

of time (Measurement Delay), and measuring the fluorescence intensity of the sample for a

specified length of time (Integration Time). These pulses are repeated several times, as

specified in the protocol parameters.

Analyzing and interpreting TRF data generally consists of the following:

Blank Correction on page 39

Data Normalization on page 40

Data Optimization on page 40

Blank Correction

Although background is significantly lower than with fluorescence intensity measurements,

Molecular Devices recommends that you use blanks or assay controls.

A blank well contains everything used with the sample wells except the label and samplespecific compounds. Do not use an empty well for a blank.

The blank sample reveals the offset underlying each data sample. This offset does not carry

information on the label, and is generally subtracted before data reduction is done.

For optimum results, Molecular Devices recommends that you run replicates for all blanks,

controls, and samples. In this case, the blank value that can be subtracted is the average

value of all blanks.

5014038 E 39

Page 40

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

Data Normalization

TRF raw data changes in magnitude when the timing parameters are changed. However, TRF

data are normalized for a number of 1000 pulses. This means that the sample raw data does

not change when only the number of pulses is changed.

When selecting a fast read mode, the raw data becomes slightly lower because during the

continuous plate movement, some signal is collected under non-optimum focusing

conditions.

Data Optimization

There are two timing parameters which can be optimized to adjust the performance of the

measurement as desired: time per well and integration time per cycle.

The measurement noise is dependent on the read time per sample (time per plate or time

per well). In particular, the detection limit improves when the read time is increased.

Therefore, it is important to specify the read time when comparing measurements. For TRF,

the read time per well increases with the selected number of pulses. The time between

pulses and the intensity of each pulse, however, can be different on various systems.

All low-light-level detection devices have some measurement noise in common. To average

out the measurement noise, optimization of the time per well involves accumulating as

many counts as possible. Within some range, you can reduce noise (CVs, detection limit) by

increasing the read time per well, as far as is acceptable from throughput and sample

stability considerations.

To further optimize measurement results, optimize the timing parameters. The following

table and figure can be used as guidelines for the selection of timing parameters.

40 5014038 E

Page 41

Chapter 2: Read Modes and Read Types

t

1

t

4

t

3

t

2

Table 2-1: Time-resolved fluorescence timing parameters example

Parameter Value Comment

Pulse length 0.100ms The period for excitation of the sample, shown as t1in the

following figure.

This is the suggested value for the TUNE, MULTI, and TRF

detection cartridges.

Measurement delay 0.010 ms The delay to ensure the excitation pulse is no longer

detectable, shown as t2in the following figure.

This is the suggested value for the TUNE, MULTI and TRF

detection cartridges.

Integration time per

cycle (pulse)

Integration time per

cycle (pulse)

0.890ms The period for accumulating the signal, shown as t3in the

following figure.

This is the suggested value for the TUNEand MULTI detection

cartridges.

1.890ms The period for accumulating the signal, shown as t3in the

following figure.

This is the suggested value for the TRF detection cartridge.

Figure 2-4: Timing parameters for time-resolved fluorescence

5014038 E 41

Page 42

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

When neglecting the time delay t2compared to the integration time window t3, the

accumulated signal A can be approximated with the following equation:

A / A

= (1 – exp(–M)) x 100%

max

In the previous equation, M is the size of the time window (or integration time) divided by

the exponential decay time constant (or the fluorescence lifetime of the label).

M = (integration time) / (fluorescence lifetime)

For example, using Europium, which has a fluorescence lifetime of 700µs, and the suggested

integration time per cycle of 1.890ms (or 1890µs), M=1890/700=2.7. Inserting this value

of M into the first equation yields A/A

=93%.

max

To optimize the integration time per cycle (pulse), the integration time should be set such

that the value of M produces the desired signal. For example, to get more than 86% signal,

select an integration time such that M is greater than 2.0. Using the previous Europium

example and solving for the integration time, the integration time can be set to M (2.0) times

the fluorescence lifetime (700µs), or 1400µs (1.4ms).

Table 2-2: Achievable accumulated signal percentage compared to M

M 0.25 0.50 0.75 1.00 1.25 1.50 2.00 3.00

A/A

[%] 22 39 53 63 71 78 86 95

max

M can be technically limited by the time between pulses. Further gain in signal above some

value of M can be negligible to improve results.

When performing a dual-label Europium-Samarium measurement, there are more timing

parameters. There is some residual cross-talk of the Samarium signal captured in the

Europium emission channel. Samarium has a much shorter fluorescence lifetime, so to

reduce the cross-talk of Samarium in the Europium channel, Europium is measured in a time

window shifted away from the time window for Samarium. This lets the Europium be

quantified without cross contamination from the Samarium. The known Europium

concentration can then be used to remove the Europium cross-contamination in the

Samarium channel.

42 5014038 E

Page 43

Chapter 2: Read Modes and Read Types

Suggested timing parameters for a dual-label Europium-Samarium measurement are listed in

the following table.

Table 2-3: Time-resolved fluorescence timing parameters for dual-label EuropiumSamarium

Parameter Value Comment

Pulse length 0.100ms The time interval for flash monitoring

This is the suggested value for the TRF detection

cartridge.

Measurement delay (first

window)

Integration time (first window) 0.100ms The period for accumulating the Samarium signal

Measurement delay (second

window)

Integration time (second

window)

0.010ms The delay to ensure the excitation pulse is no longer

detectable

This is the suggested value for the TRF detection

cartridge.

This is the suggested value for the TRF detection

cartridge.

0.140ms The read out of the Samarium signal

This is the suggested value for the TRF detection

cartridge.

0.750ms The period for accumulating the Europium signal

This is the suggested value for the TRF detection

cartridge.

5014038 E 43

Page 44

SpectraMax Paradigm Multi-Mode Detection Platform User Guide

FRET Read Mode

Fluorescence resonance energy transfer (FRET) is a distance-dependent interaction between

the electronic excited states of two dye molecules in which excitation is transferred from a

donor molecule to an acceptor molecule without emission of a photon.

FRET relies on the distance-dependent transfer of energy from a donor molecule to an

acceptor molecule. Due to its sensitivity to distance, FRET has been used to investigate

molecular interactions. FRET is the radiationless transmission of energy from a donor

molecule to an acceptor molecule. The donor molecule is the dye or chromophore that

initially absorbs the energy and the acceptor is the chromophore to which the energy is

subsequently transferred. This resonance interaction occurs over greater than interatomic

distances, without conversion to thermal energy, and without a molecular collision. The

transfer of energy leads to a reduction in the fluorescence intensity and excited state lifetime

of the donor, and an increase in the emission intensity of the acceptor. A pair of molecules

that interact in such a manner that FRET occurs is often referred to as a donor/acceptor pair.

While there are many factors that influence FRET, the primary conditions that need to be

met for FRET to occur are relatively few:

The donor and acceptor molecules must be in close proximity to each other.

The absorption or excitation spectrum of the acceptor must overlap the fluorescence

emission spectrum of the donor.

The degree to which they overlap is referred to as the spectral overlap integral (J).