Molecular Devices SpectraMax M3, SpectraMax M4, SpectraMax M5e, SpectraMax M5 User Manual

SpectraMax® M3, M4, M5, and M5e

Multi-Mode Microplate Readers

User Guide

0112-0115 F

July 2010

This document is provided to customers who have purchased Molecular Devices, Inc.

(“Molecular Devices”) equipment, software, reagents, and consumables to use in the

operation of such Molecular Devices equipment, software, reagents, and

consumables. This document is copyright protected and any reproduction of this

document, in whole or any part, is strictly prohibited, except as Molecular Devices

may authorize in writing.

Software that may be described in this document is furnished under a license

agreement. It is against the law to copy, modify, or distribute the software on any

medium, except as specifically allowed in the license agreement. Furthermore, the

license agreement may prohibit the software from being disassembled, reverse

engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only

to designate those manufacturers' products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers' and/or their product names as

trademarks.

Molecular Devices makes no warranties or representations as to the fitness of this

equipment for any particular purpose and assumes no responsibility or contingent

liability, including indirect or consequential damages, for any use to which the

purchaser may put the equipment described herein, or for any adverse circumstances

arising therefrom.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, Inc. or their

respective owners. These trademarks may not be used in any type of promotion or

advertising without the prior written permission of Molecular Devices, Inc.

Product manufactured by Molecular Devices, Inc.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, Inc. is ISO 9001 registered.

© 2010 Molecular Devices, Inc.

All rights reserved.

Printed in the USA.

Contents

Chapter 1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Certified SpectraMax® M5e-HTRF Readers . . . . . . . . . . . . 8

Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dynamic Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PathCheck® Pathlength Measurement Technology . . . . . . 9

Automix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supported Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Computer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Instrument Control. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Data Collection and Display . . . . . . . . . . . . . . . . . . . . . 10

Data Reduction and Plotting . . . . . . . . . . . . . . . . . . . . 10

Immediate Results Reporting and Analysis . . . . . . . . . . 10

Reader Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Temp On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Temp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wavelengths (

Ref . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Read Cuvette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The Microplate Drawer . . . . . . . . . . . . . . . . . . . . . . . . 15

Microplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Cuvette Chamber. . . . . . . . . . . . . . . . . . . . . . . . . 17

Cuvettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

The Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

0112-0115 F 3

Contents

Chapter 2 Principles of Operation . . . . . . . . . . . . . . . . . 19

Absorbance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optical Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transmittance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PathCheck® Pathlength Measurement Technology . . . . . . 19

Water Constant or Cuvette Reference? . . . . . . . . . . . . . 22

Background Considerations . . . . . . . . . . . . . . . . . . . . . 22

PathCheck Pathlength Measurement Technology

and Interfering Substances . . . . . . . . . . . . . . . . . . . . . 23

Normalizing Absorbance Measurements. . . . . . . . . . . . . 24

Fluorescence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Time-resolved Fluorescence (M4, M5, and M5e only) . . . . 27

Fluorescence Polarization (M5 and M5e only) . . . . . . . . . . 28

Luminescence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . 29

Temperature Regulation . . . . . . . . . . . . . . . . . . . . . . . 29

Read Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Endpoint Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Kinetic Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Spectrum Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Well Scan Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Automix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Computer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting up the Instrument . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the Drawer Adapter . . . . . . . . . . . . . . . . . . . . 36

Removing the Drawer Adapter . . . . . . . . . . . . . . . . . . . . 37

4 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

Chapter 4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cuvette Read—Quick Overview . . . . . . . . . . . . . . . . . . . 39

Microplate Read—Quick Overview . . . . . . . . . . . . . . . . . 40

Preparing for a Cuvette or Microplate Reading . . . . . . . . . 40

Turn the Instrument and Computer On . . . . . . . . . . . . . 40

Set the Temperature (Optional) . . . . . . . . . . . . . . . . . . 41

Select the Wavelength . . . . . . . . . . . . . . . . . . . . . . . . 42

Read the Cuvette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Read the Microplate . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Optimizing Fluorescence Assays. . . . . . . . . . . . . . . . . . . 44

Optimizing Absorbance Assays . . . . . . . . . . . . . . . . . . . 44

Excitation and Emission Wavelengths . . . . . . . . . . . . . 44

Emission Cutoff Filter . . . . . . . . . . . . . . . . . . . . . . . . 45

Readings Per Well . . . . . . . . . . . . . . . . . . . . . . . . . . 45

PMT Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . 45

Using Spectral Scanning to Optimize Excitation

and Emission Wavelengths for Fluorescence Assays . . . . 46

Optimizing Time-resolved Fluorescence Assays . . . . . . . . 50

Optimizing Fluorescence Polarization Assays . . . . . . . . . . 51

Optimizing Luminescence Assays . . . . . . . . . . . . . . . . . . 52

Chapter 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 53

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Moving a SpectraMax Multi-Mode Microplate Reader. . . . . 55

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the Fan Filter . . . . . . . . . . . . . . . . . . . . . . . . . 57

Changing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 61

Opening the Drawer Manually . . . . . . . . . . . . . . . . . . . . 61

Error Codes and Probable Causes. . . . . . . . . . . . . . . . . . 62

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

0112-0115 F 5

Contents

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . 67

SpectraMax® Multi-Mode Microplate Reader

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . 67

System Diagrams and Dimensions . . . . . . . . . . . . . . . . . 73

Common Fluorescence and Luminescence Wavelengths . . 74

Fluorescence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Time-resolved Fluorescence . . . . . . . . . . . . . . . . . . . . . 75

Luminescence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendix B Cables and Accessories . . . . . . . . . . . . . . . . 77

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Serial Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . 77

USB Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Cuvettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Standard and Semi-micro Cuvettes. . . . . . . . . . . . . . . . 79

Ultra-micro Cuvettes (Hellma) . . . . . . . . . . . . . . . . . . . 79

Standard, Semi-micro, and Microcuvettes (Hellma) . . . . 80

Ultra-micro Cuvettes (Hellma) . . . . . . . . . . . . . . . . . . . 81

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6 0112-0115 F

Description

Introduction

The SpectraMax® M3, M4, M5, and M5e Microplate Readers are a series

of dual-monochromator, multidetection, multi-mode instruments with a

triple-mode cuvette port and 6-well to 384-well microplate reading

capability. Detection modalities are shown in Table 1-1.

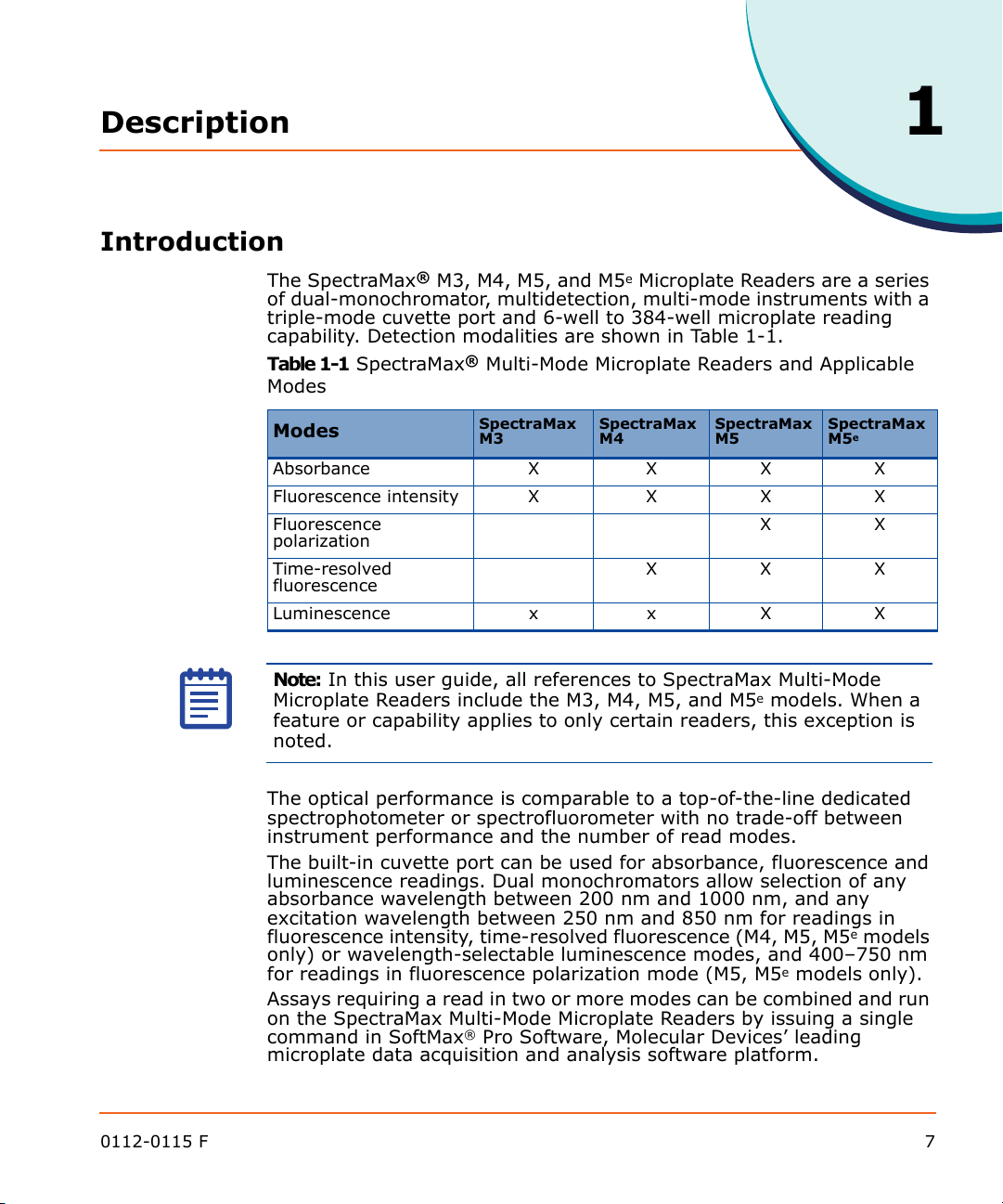

Table 1-1 SpectraMax® Multi-Mode Microplate Readers and Applicable

Modes

1

Modes

Absorbance X X X X

Fluorescence intensity X X X X

Fluorescence

polarization

Time-resolved

fluorescence

Luminescence x x X X

Note: In this user guide, all references to SpectraMax Multi-Mode

Microplate Readers include the M3, M4, M5, and M5e models. When a

feature or capability applies to only certain readers, this exception is

noted.

The optical performance is comparable to a top-of-the-line dedicated

spectrophotometer or spectrofluorometer with no trade-off between

instrument performance and the number of read modes.

The built-in cuvette port can be used for absorbance, fluorescence and

luminescence readings. Dual monochromators allow selection of any

absorbance wavelength between 200 nm and 1000 nm, and any

excitation wavelength between 250 nm and 850 nm for readings in

fluorescence intensity, time-resolved fluorescence (M4, M5, M5e models

only) or wavelength-selectable luminescence modes, and 400–750 nm

for readings in fluorescence polarization mode (M5, M5e models only).

Assays requiring a read in two or more modes can be combined and run

on the SpectraMax Multi-Mode Microplate Readers by issuing a single

command in SoftMax® Pro Software, Molecular Devices’ leading

microplate data acquisition and analysis software platform.

SpectraMax M3SpectraMax M4SpectraMax M5SpectraMax

XX

XXX

M5

e

0112-0115 F 7

Description

Applications

Endpoint, kinetic, spectrum, and multi-point well-scanning applications

combining absorbance and fluorescence in 6-well to 384-well

microplates, as well as endpoint, kinetic, and spectrum applications in

absorbance and fluorescence using cuvettes, can be run with little to no

optimization.

The extreme flexibility and high sensitivity of the SpectraMax Multi-

Mode Microplate Readers make them appropriate for applications within

the fields of biochemistry, cell biology, immunology, molecular biology,

and microbiology.

Typical applications include ELISA, nucleic acid, protein, enzymatic type

homogeneous and heterogeneous assays, microbial growth, endotoxin

testing, and pipettor calibration.

Certified SpectraMax® M5e-HTRF Readers

The SpectraMax M5e reader has the same performance specifications as

the M5 but is certified for use with Cisbio Bioassays’ HTRF

(Homogeneous Time-Resolved Fluorescence) technology. HTRF is a

proprietary time-resolved fluorescence technology that overcomes

many of the drawbacks of standard Fluorescence Resonance Energy

Transfer (FRET) techniques, such as the requirements to correct for

autofluorescence and the fluorescent contributions of unbound

fluorophores.

Optics

The use of two holographic diffraction grating monochromators allows

for individual optimization of wavelengths for both excitation and

emission in fluorescence readings. Mirrored optics focus the light into

the sample volume, and cutoff filters are used to reduce stray light and

minimize background interference. The light source is a high-powered

Xenon flash lamp. Sensitivity or read-speed can be optimized by

varying the number of lamp flashes per read.

Dynamic Range

The dynamic range of detection is from 10-6 to 10

Variations in measured fluorescence values are virtually eliminated by

internal compensation for detector sensitivity, photomultiplier tube

voltage and sensitivity, as well as excitation intensity. The photometric

range is 0–4 ODs with a resolution of 0.001 OD.

8 0112-0115 F

-12

molar fluorescein.

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

PathCheck® Pathlength Measurement Technology

A SpectraMax Multi-Mode Microplate Reader with PathCheck Pathlength

Measurement Technology allows normalization of variable well volumes

to 1-cm cuvette readings. PathCheck Pathlength Measurement

Technology allows for multichannel pipettor validation and for

experiment comparison from different days.

Automix

Using the Automix feature of the SoftMax Pro Software, the contents of

the wells in a microplate can be mixed automatically by linear shaking

before each read cycle, making it possible to perform kinetic analysis of

solid-phase, enzyme-mediated reactions (mixing is not critical for

liquid-phase reactions).

Temperature Control

Temperature in the microplate chamber is isothermal, both at ambient

and when the incubator is turned on. When the incubator is on, the

temperature may be controlled from 2°C above ambient to 60°C.

Supported Plates

Microplates having 6, 12, 24, 48, 96, and 384 wells can be used in the

SpectraMax Multi-Mode Microplate Readers. Top and bottom reads are

available for fluorescence, time-resolved fluorescence and

luminescence detection. When reading optical density at wavelengths

below 340 nm, special UV-transparent, disposable or quartz

microplates and cuvettes that allow transmission of the far UV spectra

must be used.

One plate carrier adapter is provided with the instrument. The adapter

is required for optimum performance with standard 96-well and 384-

well format microplates for all top-read applications.

0112-0115 F 9

Description

Computer Control

An external computer running SoftMax Pro Software, which provides

integrated instrument control, data display, and statistical data

analysis, controls the SpectraMax Multi-Mode Microplate Readers.

Cuvette port functionality can also be controlled using SoftMax Pro

Software.

SoftMax Pro Software provides the following functionality:

Instrument Control

SoftMax Pro Software allows you to set up and run a complete protocol

for the SpectraMax Multi-Mode Microplate Reader, as well as all other

Molecular Devices' microplate readers. Instrument settings can be

saved as a protocol file and used repeatedly for reading different

microplates or cuvettes. All stand-alone instrument functions can be

controlled using the software. In addition, SoftMax Pro Software

provides capabilities that are not available when using an instrument in

stand-alone mode such as user-defined kinetic run times, read

intervals, Automix parameters, etc.

Data Collection and Display

SoftMax Pro Software collects and stores all raw data received from the

instrument. Data is displayed in a grid format that corresponds to the

wells in a microplate or individual cuvettes.

SoftMax Pro Software can collect data from one or more microplates or

cuvettes and store it in a single data file, using the same or different

instrument settings for different microplates or cuvettes. For example,

microplates containing different samples can be read using the same or

different modes, all within the same experiment.

Data Reduction and Plotting

You can manipulate or “reduce” the raw data using dozens of built-in

formulas or define your own analysis structure to quickly and easily

summarize the raw data. More than one reduction can be shown, and

results from different microplates or cuvettes can be compared within

the same experiment.

Immediate Results Reporting and Analysis

Once you have defined instrument settings, and have customized a

SoftMax Pro Software data file with assay information, reduction

settings, custom columns in Group sections, and summary objects, you

can save this information to create an assay protocol. Protocols can be

used throughout a department or company for highly repeatable data

collection and analysis that is completed the second the plate read has

completed.

10 0112-0115 F

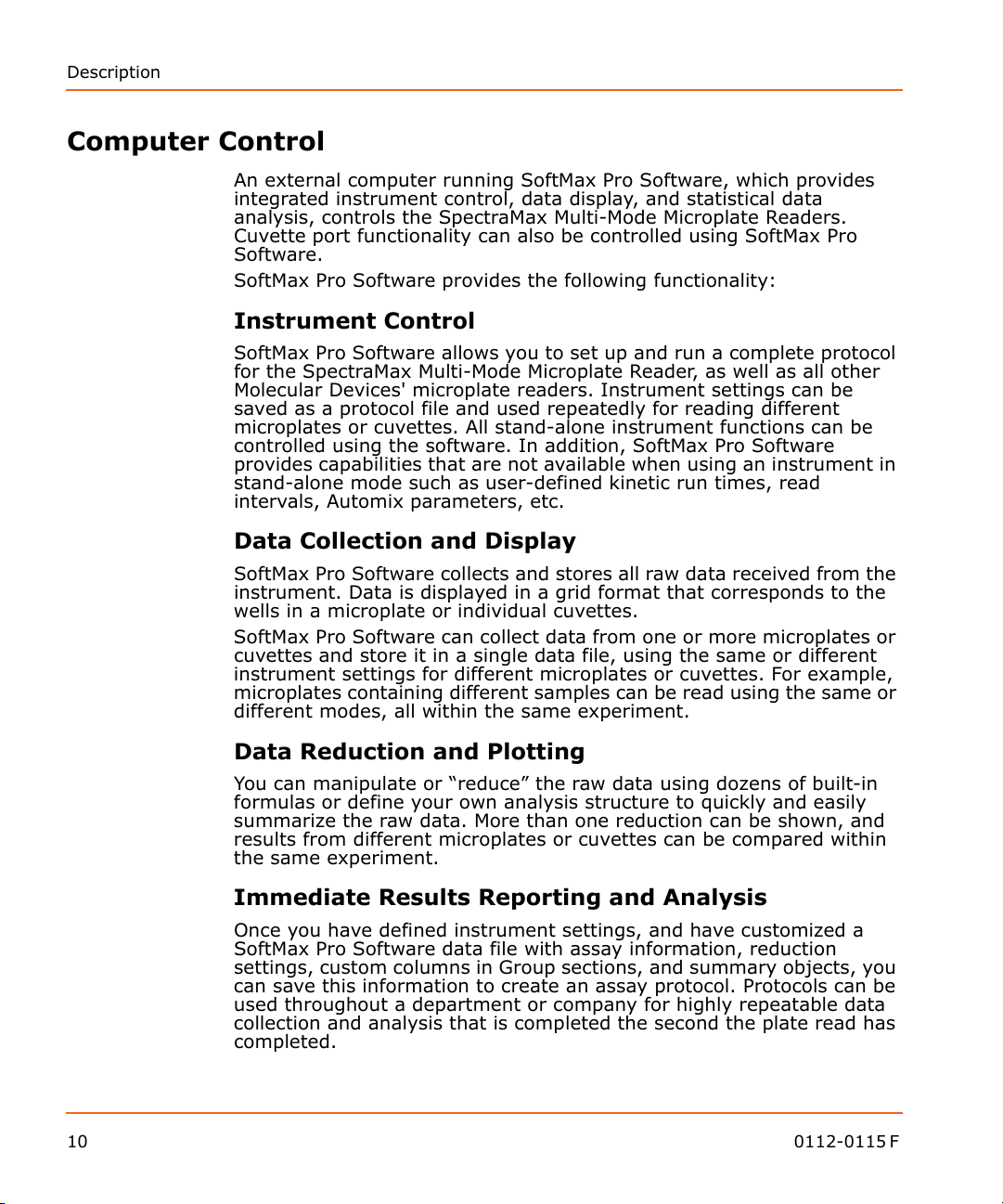

Reader Components

Control Panel Back PanelCuvette Chamber

Microplate Drawer

The main components of the SpectraMax Multi-Mode Microplate

Readers are:

• Control panel: for cuvette chamber control.

• Microplate drawer: used for all five read modes and four read

types.

• Cuvette chamber: used for absorbance, fluorescence intensity,

and luminescence read modes for endpoint, kinetic, and

spectrum scanning.

• Back panel: connections and power switch.

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

Figure 1-1 SpectraMax® components.

0112-0115 F 11

Description

MODE

The Control Panel

Figure 1-2 The control panel.

The control panel consists of a 2-x-20-character LCD and eleven

pressure-sensitive membrane keys that can be used to control some

functions of the instrument. When you press a control panel key, the

instrument performs the associated action.

Note: Settings made in SoftMax Pro Software override control panel

settings.

The left side of the display shows the temperature inside the cuvette

chamber, both actual and set point, and whether or not the

temperature is at the set point (the enunciator blinks if it is not at set

point). The temperature of the microplate chamber lags slightly behind

the temperature in the cuvette chamber. The temperature in the

microplate chamber is reported in the SoftMax Pro Software interface

display.

The middle of the display shows the wavelengths for

absorbance/excitation and emission.

The right side of the display shows the data received from the reading

as absorbance, percent transmission, fluorescence emission or

excitation, or luminescence, and indicates whether or not a reference

measurement was made (enunciator blinks if no reference reading was

taken).

To change the contrast of the display, press

and the temperature

up () or down () setting keys.

12 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

TEMP on/off

TEMP

Temp On/Off

The key enables and disables the incubator that controls the

temperature within both the microplate chamber and the cuvette port.

• When the incubator is on, the set temperature and actual

temperature (cuvette chamber only) are shown on the front

panel LCD display.

• When the instrument is performing a kinetic or spectral scan,

the temperature keys on the front panel are disabled.

Temp

The keys allow you to enter a set point at which to regulate the

cuvette and microplate chamber temperature. However, remember that

the cuvette temperature only is reported on the LCD display, while the

microplate chamber temperature is reported in the SoftMax Pro

Software interface display.

Pressing this key scrolls the temperature up or down, starting at the

previous temperature setting (or the default of 37.0°C, if no setting had

been made):

• Pressing the up () or down () arrow once increments or

decrements the displayed temperature by 0.1°C.

• Pressing and holding either arrow increments or decrements the

displayed temperature by 1°C until it is released.

You cannot set a temperature beyond the upper (60°C) or lower (15°C)

instrument limits.

Wavelengths ()

Selects the wavelength to be used for reading the cuvette manually.

Two s et s o f up or down arrow keys are available for setting

absorbance/excitation (fluorescence) wavelengths and emission

(fluorescence) wavelengths.

The control panel does not display the wavelength selected through the

SoftMax Pro application.

Pressing the up or down arrow key scrolls up or down through the

available wavelengths, starting at the previous setting:

• Pressing the up () or down () arrow once increments or

decrements the displayed wavelength by 1 nm.

• Pressing and holding either arrow increments or decrements the

displayed wavelength by 10 nm until it is released.

0112-0115 F 13

Description

DRAWER

Ref

A reading of buffer, water, or air taken in the cuvette that is used as I0

to calculate Absorbance or % Transmittance. If no reference reading is

taken, the instrument uses the I0 values stored in the NVRAM (non-

volatile memory) of the instrument.

This key is disabled during a computer-controlled run.

Read Cuvette

Initiates the sample reading of the cuvette.

This key is disabled during a computer-controlled run.

Mode

A toggle switch used to display cuvette data as percent transmittance

(%T), absorbance (A), relative fluorescence units (RFU), or relative

luminescence units (RLU).

Drawer

The key opens and closes (toggles) the microplate drawer.

14 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

The Microplate Drawer

The microplate drawer is located on the right side of the instrument and

slides in and out of the reading chamber. An internal latch positions the

microplate in the drawer as it closes (allowing for better robot

integration-no springs or clips are used).

The drawer remains in the reading chamber during read cycles.

Figure 1-3 The microplate drawer.

Microplate drawer operation varies, depending on the incubator setting:

• If the incubator is off, the drawer remains open.

• If the incubator is on, the drawer closes after approximately 10

seconds to assist in maintaining temperature control within the

microplate chamber.

Do not obstruct the movement of the drawer. If you must retrieve a

plate after an error condition or power outage and the drawer does not

open, it is possible to open it manually (see

page 61

0112-0115 F 15

).

Troubleshooting on

Description

Microplates

The SpectraMax Multi-Mode Microplate Reader can accommodate SBS-

standard 6-well to 384-well microplates and strip wells. When reading

optical density at wavelengths below 340 nm, special UV-transparent,

disposable or quartz microplates allowing transmission of the deep UV

spectra must be used.

Not all manufacturers' microplates are the same with regard to design,

materials, or configuration. Temperature uniformity within the

microplate may vary depending on the type of microplate used.

Microplates currently supported by the SoftMax Pro Software for use in

this instrument are:

• 96-well Standard, 96 Costar, 96 Greiner Black, 96 Bottom

Offset, 96 Falcon, 96 BD Optilux/Biocoat, 96 BD Fluoroblok MW

Insert, 96 Corning Half Area, 96 MDC HE PS

• 384-well Standard, 384 Costar, 384 Greiner, 384 Falcon, 384

Corning, 384 MDC HE PS

• 48 Costar

• 24 Costar

• 12 Costar, 12 Falcon

• 6 Costar, 6 Falcon.

The SoftMax Pro Software plate list also includes half area and low-

volume plates. SoftMax Pro can always be used to define a new plate

type using the manufacturer's specifications for well size, spacing and

distance from the plate edge.

16 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

The Cuvette Chamber

Figure 1-4 The cuvette chamber.

Located at the right front of the SpectraMax instrument, the cuvette

chamber has a lid that lifts up, allowing you to insert or remove a

cuvette. The chamber contains springs that automatically position the

cuvette in the proper alignment for a reading. The cuvette door must

be closed before initiating a reading.

Cuvettes

The SpectraMax Multi-Mode Microplate Reader can accommodate

standard-height (45 mm), 1 cm cuvettes and 12 x 75 mm test tubes

when used with the test tube cover.

Not all manufacturers' cuvettes are the same with regard to design,

materials, or configuration. Temperature uniformity within the cuvette

may vary depending on the type of cuvette used.

Cuvettes used for absorbance readings are frosted on two sides. Be

sure to handle cuvettes on the frosted sides only. Place the cuvette into

the chamber so that the “reading” (clear) sides face left and right.

Fluorescence cuvettes are clear on all four sides and should be handled

carefully. Place a frosted cuvette into the chamber so that the “reading”

(clear) sides face left and right. Semi-Micro and Ultra-Micro cuvettes

can also be used with an adapter. See

information about supported cuvettes.

0112-0115 F 17

Cuvettes on page 78 for more

Description

Power Switch

Power Cord

Receptacle

Label

Fuse Box

Cover

Computer

Port

Printer

Port

Figure 1-5 The test tube cover.

The Back Panel

18 0112-0115 F

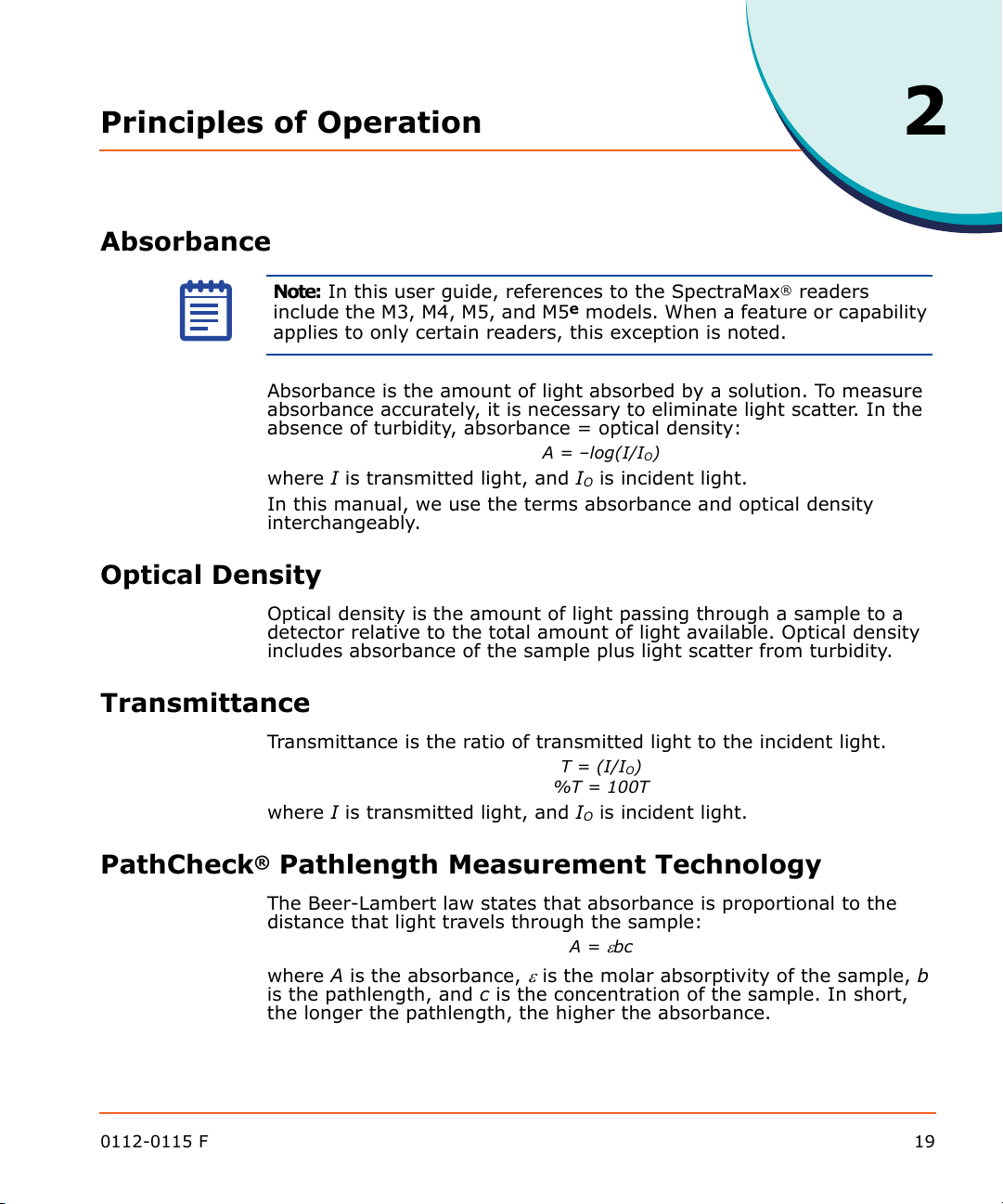

Figure 1-6 Schematic of the back panel of a reader.

The following components are located on the back panel of the

SpectraMax instrument:

• Power switch: a rocker switch, labeled I/O (for on and off,

respectively).

• Power cord receptacle: plug the power cord in here.

• Fuse box cover: cannot be opened while the power cord is

plugged in. When opened, it provides access to the fuse box

containing two fuses that are required for operation.

• Computer port (double-shielded 8-pin RS-232 serial, for use with an

external computer): plug one end of an 8-pin DIN serial cable into

this port; the other end attaches to the serial (modem) port of

the computer.

• Printer port: not used for the SpectraMax instrument

• Label: provides information about the reader, such as line

voltage rating, cautionary information, serial number, etc.

Record the serial number shown on this label for use when

contacting Molecular Devices Technical Support.

Principles of Operation

Absorbance

Note: In this user guide, references to the SpectraMax® readers

include the M3, M4, M5, and M5e models. When a feature or capability

applies to only certain readers, this exception is noted.

Absorbance is the amount of light absorbed by a solution. To measure

absorbance accurately, it is necessary to eliminate light scatter. In the

absence of turbidity, absorbance = optical density:

where I is transmitted light, and IO is incident light.

In this manual, we use the terms absorbance and optical density

interchangeably.

Optical Density

Optical density is the amount of light passing through a sample to a

detector relative to the total amount of light available. Optical density

includes absorbance of the sample plus light scatter from turbidity.

2

A = –log(I/IO)

Transmittance

Transmittance is the ratio of transmitted light to the incident light.

T = (I/IO)

%T = 100T

where I is transmitted light, and IO is incident light.

PathCheck® Pathlength Measurement Technology

The Beer-Lambert law states that absorbance is proportional to the

distance that light travels through the sample:

A =

bc

where A is the absorbance,

is the pathlength, and c is the concentration of the sample. In short,

the longer the pathlength, the higher the absorbance.

0112-0115 F 19

is the molar absorptivity of the sample, b

Principles of Operation

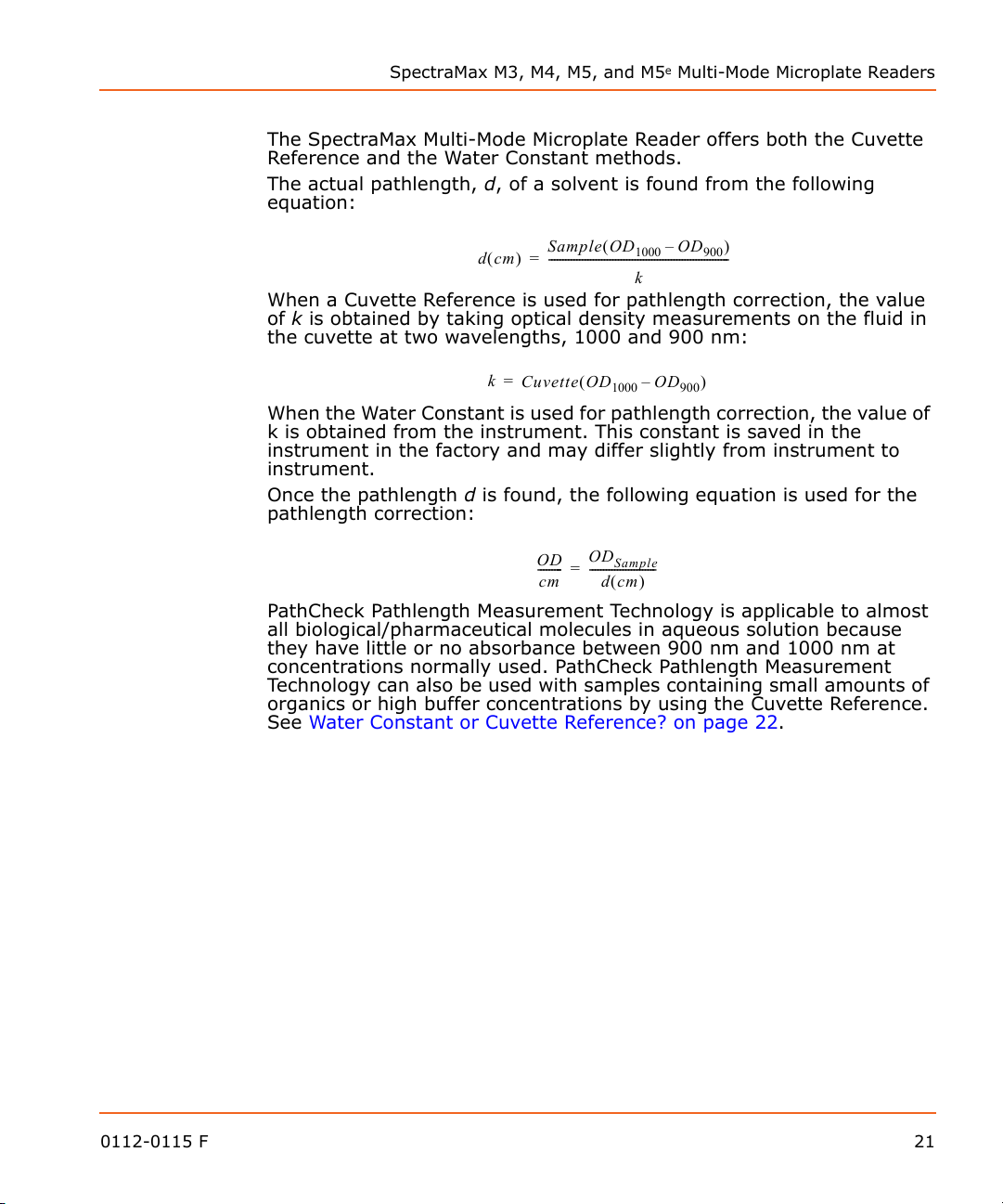

Horizontal

light path

Vertical light path

Cuvette Microplate wells

Microplate readers use a vertical light path so the distance of the light

through the sample depends on the volume. This variable pathlength

makes it difficult to perform extinction-based assays and also makes it

confusing to compare results between microplate readers and

spectrophotometers.

The standard pathlength of a cuvette is the conventional basis for

quantifying the unique absorbtivity properties of compounds in

solution. Quantitative analyses can be performed on the basis of

extinction coefficients, without standard curves (for example, NADH-

based enzyme assays). When using a cuvette, the pathlength is known

and is independent of sample volume, so absorbance is proportional to

concentration.

In a microplate, pathlength is dependent on the liquid volume, so

absorbance is proportional to both the concentration and the

pathlength of the sample. Standard curves are often used to determine

analyte concentrations in vertical-beam photometry of unknowns, yet

errors can still arise from pipetting the samples and standards. The

PathCheck

determines the pathlength of aqueous samples in the microplate and

normalizes the absorbance in each well to a pathlength of 1 cm. This

novel approach to correcting the microwell absorbance values is

accurate to within 2.5% of the values obtained directly in a 1 cm

cuvette.

®

Pathlength Measurement Technology feature automatically

Figure 2-1 Cuvette and microwell light paths.

Reference measurements made by reading the cuvette (Cuvette

Reference) or using factory-stored values derived from deionized water

(Water Constant) can be used to normalize the optical density data for

microplate wells.

Pathlength correction is accomplished only when using the PathCheck

Pathlength Measurement Technology with SoftMax

®

Pro Software.

PathCheck Pathlength Measurement Technology is patented by

Molecular Devices and can be performed only on an Molecular Devices

plate reader.

20 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

dcm

Sample OD

1000

OD

900

–

k

-----------------------------------------------------------------=

k

Cuvette OD

1000

OD

900

–

=

OD

cm

---------

OD

Sample

dcm

------------------------=

The SpectraMax Multi-Mode Microplate Reader offers both the Cuvette

Reference and the Water Constant methods.

The actual pathlength, d, of a solvent is found from the following

equation:

When a Cuvette Reference is used for pathlength correction, the value

of k is obtained by taking optical density measurements on the fluid in

the cuvette at two wavelengths, 1000 and 900 nm:

When the Water Constant is used for pathlength correction, the value of

k is obtained from the instrument. This constant is saved in the

instrument in the factory and may differ slightly from instrument to

instrument.

Once the pathlength d is found, the following equation is used for the

pathlength correction:

PathCheck Pathlength Measurement Technology is applicable to almost

all biological/pharmaceutical molecules in aqueous solution because

they have little or no absorbance between 900 nm and 1000 nm at

concentrations normally used. PathCheck Pathlength Measurement

Technology can also be used with samples containing small amounts of

organics or high buffer concentrations by using the Cuvette Reference.

See

Water Constant or Cuvette Reference? on page 22.

0112-0115 F 21

Principles of Operation

Water Constant or Cuvette Reference?

The PathCheck Pathlength Measurement is based on the absorbance of

water in the near infrared region (between 900 nm and 1000 nm). If

the sample is completely aqueous, has no turbidity and has a low salt

concentration (less than 0.5 M), the Water Constant is adequate. The

Water Constant is determined during manufacture and is stored in the

instrument.

If the sample contains an organic solvent such as ethanol or methanol,

we recommend using the cuvette reference. It is important that the

solvent does not absorb in the 900 nm to 1000 nm range (to determine

whether or not a given solvent would interfere, see the discussion of

interfering substances below). When a non-interference solvent is

added to the aqueous sample, the water absorbance decreases

proportionally to the percentage of organic solvent present. For

example, 5% ethanol decreases the water absorbance by 5% and

results in a 5% underestimation of the pathlength. You can avoid the

error by putting the same water/solvent mixture in a cuvette and using

the Cuvette Reference.

To use the Cuvette Reference, place into the cuvette port a standard

1 cm cuvette containing the aqueous/solvent mixture that is used for

the samples in the microplate. The cuvette must be in place when you

read the microplate. When you click the Read button in the SoftMax Pro

program, the instrument first makes the 900 nm and 1000 nm

measurements in the cuvette, and then makes the designated

measurements in the microplate. The cuvette values are stored

temporarily and used in the PathCheck Pathlength Measurement

Technology calculations for the microplate samples.

Use of Cuvette Reference with PathCheck Pathlength Measurement

Technology is different from a reference reading of a cuvette in a

CuvetteSet section (by clicking the Ref button in the CuvetteSet section

tool bar in the SoftMax Pro program). The cuvette reference used for

PathCheck Pathlength Measurement Technology calculations

(measurements at 900 nm and 1000 nm) does not produce data that

can be viewed in a CuvetteSet section and is used only with data in

microplates, not cuvettes.

Background Considerations

Raw optical density measurements of microplate samples include both

pathlength-dependent components (sample and solvent) and a

pathlength-independent component (OD of microplate material). The

latter must be eliminated from the PathCheck Pathlength Measurement

Technology calculation in order to obtain PathCheck Technology-

normalized results. There are 3 ways to accomplish this: plate blanks,

plate background constants, and plate pre-reads, all of which are

described in the PathCheck Pathlength Measurement Technology

section of the SoftMax Pro User Guide.

22 0112-0115 F

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

PathCheck Pathlength Measurement Technology and Interfering Substances

Any material that absorbs in the 900 nm to 1000 nm spectral region

could interfere with PathCheck Pathlength Measurement Technology

measurements. Fortunately, there are few materials that do interfere at

the concentrations typically used.

Turbidity is the most common interference: if you can detect any

turbidity in your sample, you should not use the PathCheck Technology

feature. Turbidity elevates the 900 nm measurement more than the

1000 nm measurement and causes an erroneously low estimate of

pathlength. Using Cuvette Reference does not reliably correct for

turbidity.

Samples that are highly colored in the upper visible spectrum may have

absorbance extending into the near infrared (NIR) and can interfere

with the PathCheck Pathlength Measurement Technology. Examples

include Lowry assays, molybdate-based assays and samples containing

hemoglobins or porphyrins. In general, if the sample is distinctly red or

purple, you should check for interference before using the PathCheck

Pathlength Measurement Technology.

To determine possible color interference, do the following:

• Measure the optical density at 900 nm and 1000 nm (both

measured with air reference).

• Subtract the 900 nm value from the 1000 nm value.

• Do the same for pure water.

If the delta OD for the sample differs significantly from the delta OD for

water, then it is advisable not to use the PathCheck Technology feature.

Use of Cuvette Reference does not correct for the interference with the

current calculation scheme in the SoftMax Pro program. Currently,

Cuvette Reference involves a single (automated) read at 900 nm and

1000 nm and the automated calculations in the SoftMax Pro program

do not compensate for color or solvent interference. However, you

could correct for such interference by taking two cuvette

measurements and using a different set of calculations. For further

information, contact Molecular Devices Technical Support.

Organic solvents could interfere with the PathCheck Technology feature

if they have absorbance in the region of the NIR water peak. Solvents

such as ethanol and methanol do not absorb in the NIR region, so they

do not interfere, except for causing a decrease in the water absorbance

to the extent of their presence in the solution. Their passive

interference can be avoided by using the Cuvette Reference. If,

however, the solvent absorbs between 900 and 1000 nm, the

interference would be similar to the interference of highly colored

samples described above. If you are considering adding an organic

solvent other than ethanol or methanol, you are advised to run a

spectral scan between 900 nm and 1000 nm to determine if the solvent

would interfere with the PathCheck Technology feature.

0112-0115 F 23

Principles of Operation

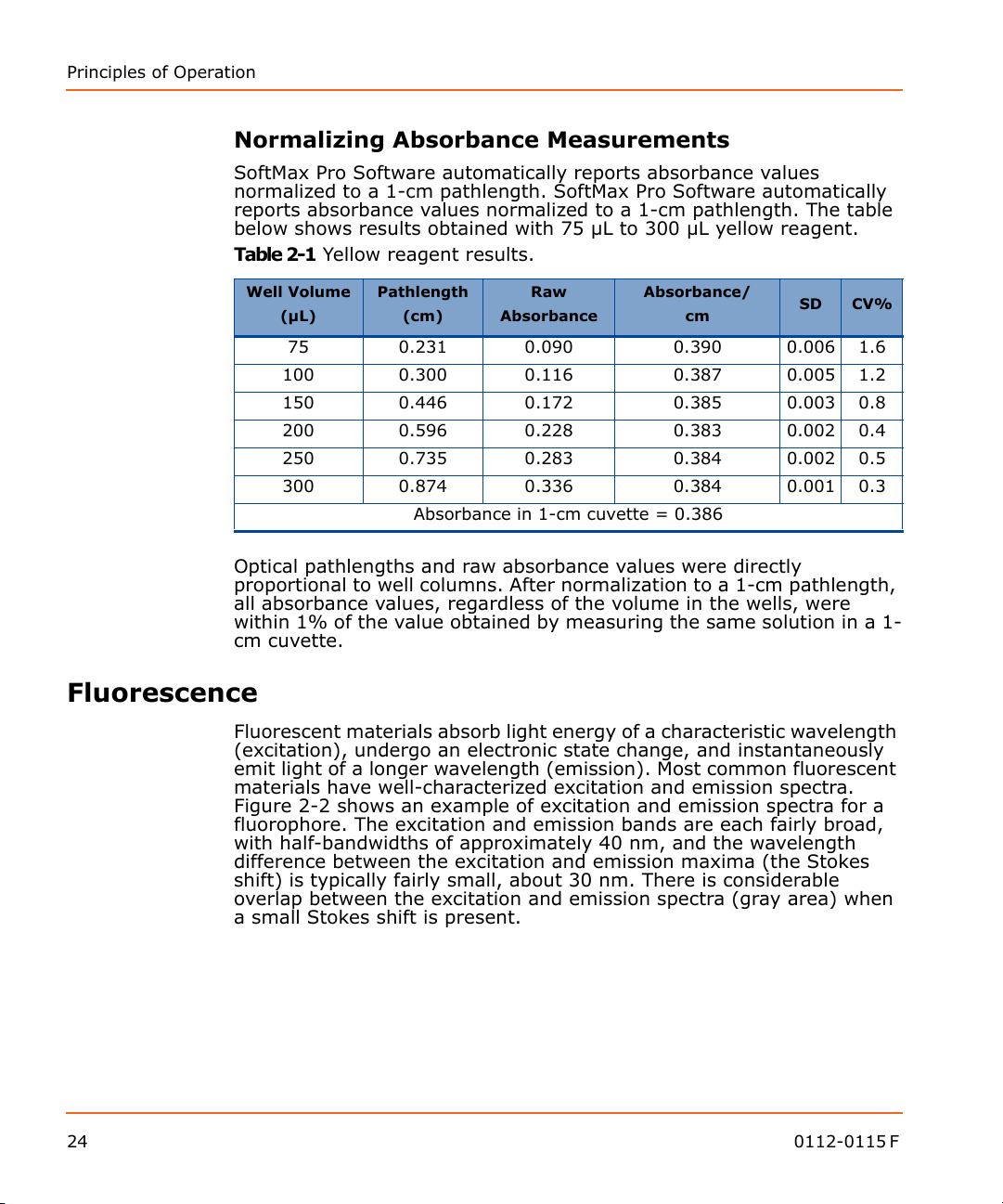

Normalizing Absorbance Measurements

SoftMax Pro Software automatically reports absorbance values

normalized to a 1-cm pathlength. SoftMax Pro Software automatically

reports absorbance values normalized to a 1-cm pathlength. The table

below shows results obtained with 75 µL to 300 µL yellow reagent.

Table 2-1 Yellow reagent results.

Well Volume

Optical pathlengths and raw absorbance values were directly

proportional to well columns. After normalization to a 1-cm pathlength,

all absorbance values, regardless of the volume in the wells, were

within 1% of the value obtained by measuring the same solution in a 1-

cm cuvette.

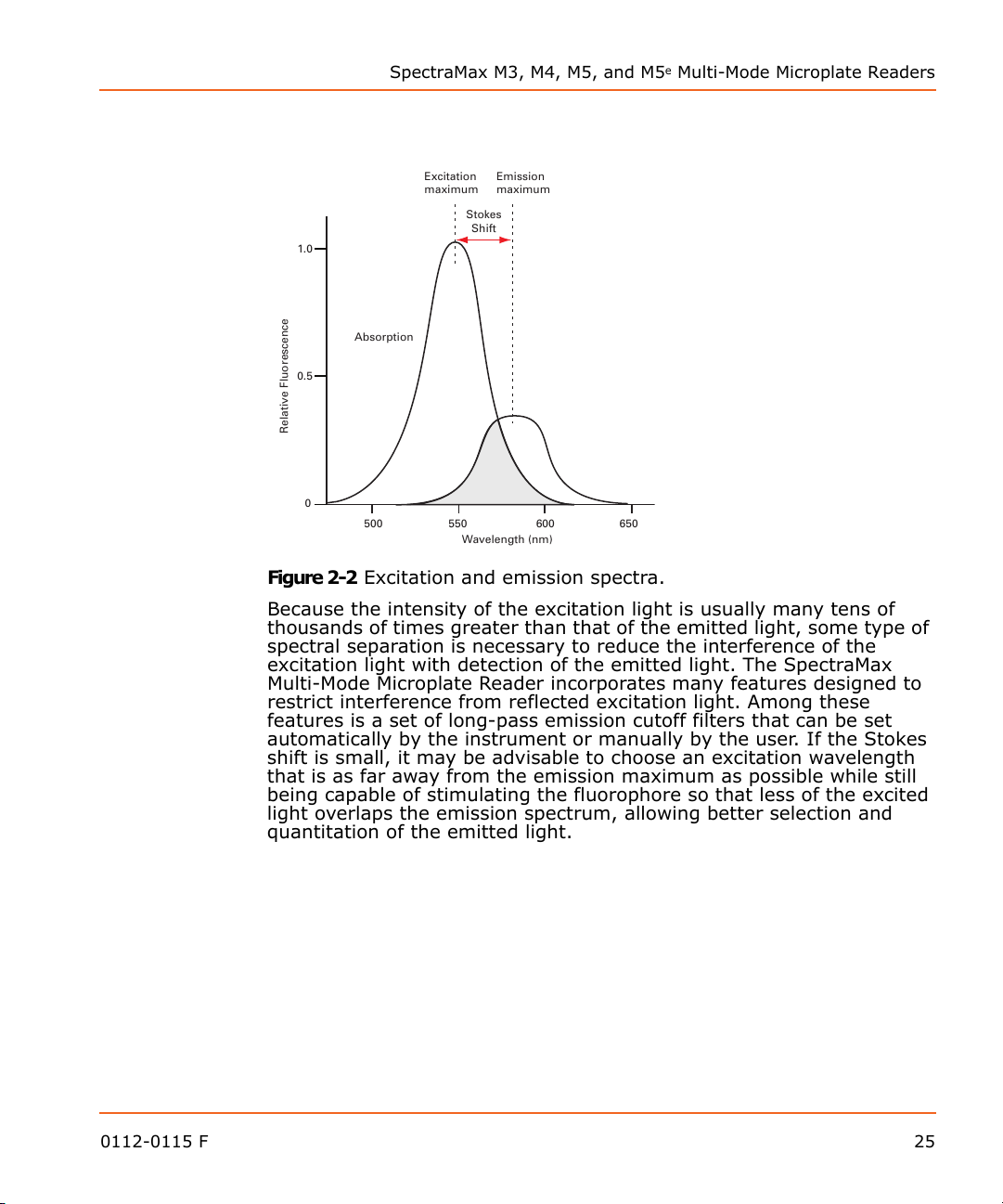

Fluorescence

Fluorescent materials absorb light energy of a characteristic wavelength

(excitation), undergo an electronic state change, and instantaneously

emit light of a longer wavelength (emission). Most common fluorescent

materials have well-characterized excitation and emission spectra.

Figure 2-2 shows an example of excitation and emission spectra for a

fluorophore. The excitation and emission bands are each fairly broad,

with half-bandwidths of approximately 40 nm, and the wavelength

difference between the excitation and emission maxima (the Stokes

shift) is typically fairly small, about 30 nm. There is considerable

overlap between the excitation and emission spectra (gray area) when

a small Stokes shift is present.

Pathlength

(µL)

75 0.231 0.090 0.390 0.006 1.6

100 0.300 0.116 0.387 0.005 1.2

150 0.446 0.172 0.385 0.003 0.8

200 0.596 0.228 0.383 0.002 0.4

250 0.735 0.283 0.384 0.002 0.5

300 0.874 0.336 0.384 0.001 0.3

(cm)

Absorbance in 1-cm cuvette = 0.386

Raw

Absorbance

Absorbance/

cm

SD CV%

24 0112-0115 F

Wavelength (nm)

Relative Fluorescence

Absorption

Excitation

maximum

Emission

maximum

Stokes

Shift

500 550 600 650

0

0.5

1.0

SpectraMax M3, M4, M5, and M5e Multi-Mode Microplate Readers

Figure 2-2 Excitation and emission spectra.

Because the intensity of the excitation light is usually many tens of

thousands of times greater than that of the emitted light, some type of

spectral separation is necessary to reduce the interference of the

excitation light with detection of the emitted light. The SpectraMax

Multi-Mode Microplate Reader incorporates many features designed to

restrict interference from reflected excitation light. Among these

features is a set of long-pass emission cutoff filters that can be set

automatically by the instrument or manually by the user. If the Stokes

shift is small, it may be advisable to choose an excitation wavelength

that is as far away from the emission maximum as possible while still

being capable of stimulating the fluorophore so that less of the excited

light overlaps the emission spectrum, allowing better selection and

quantitation of the emitted light.

0112-0115 F 25

Principles of Operation

Wavelength (nm)

Relative Fluorescence

Excitation

reading

wavelength

Emission

reading

wavelength

Fluorophore’s

excitation

maximim

Fluorophore’s

emission

maximim

500 550 600 650

0

0.5

1.0

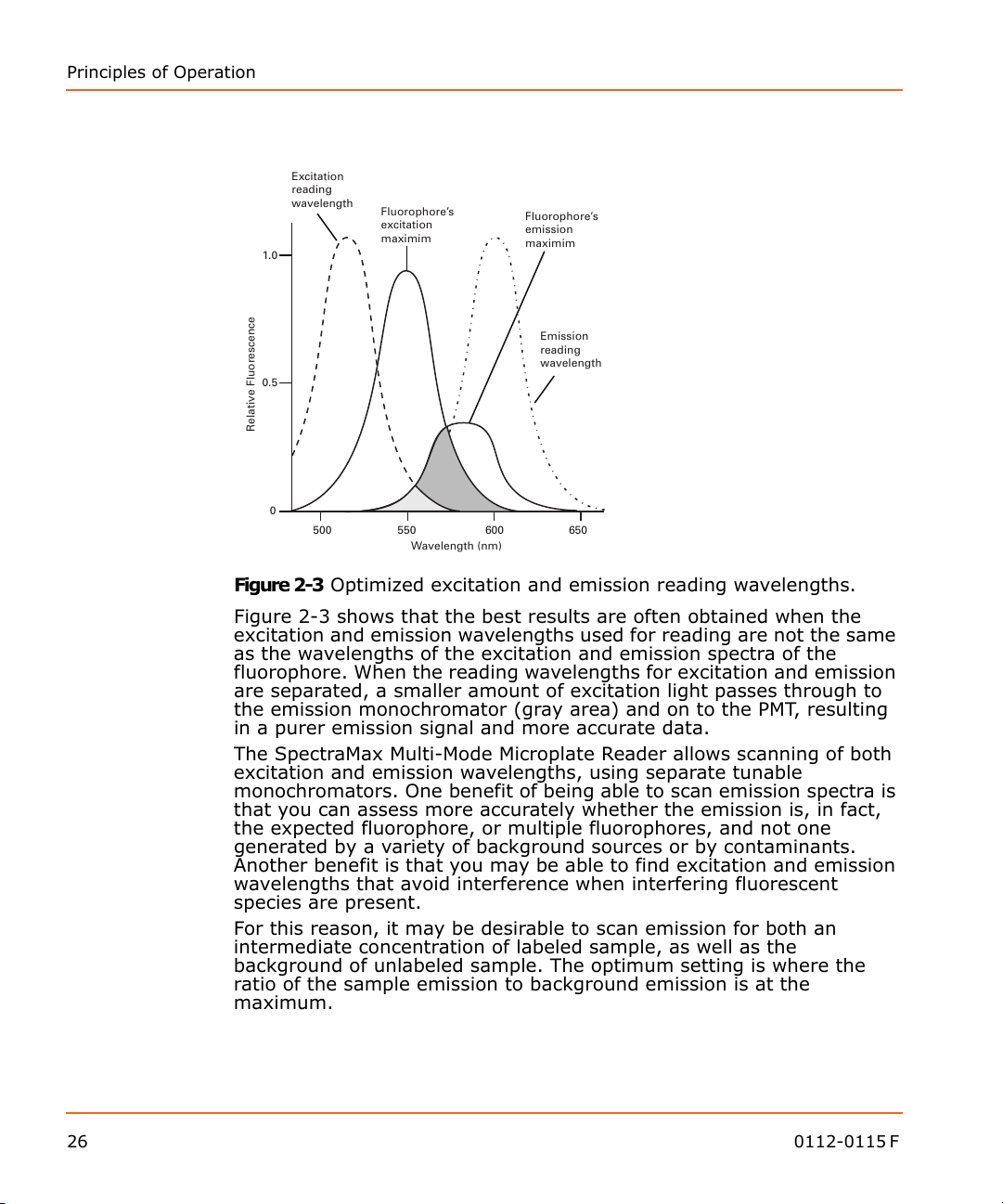

Figure 2-3 Optimized excitation and emission reading wavelengths.

Figure 2-3 shows that the best results are often obtained when the

excitation and emission wavelengths used for reading are not the same

as the wavelengths of the excitation and emission spectra of the

fluorophore. When the reading wavelengths for excitation and emission

are separated, a smaller amount of excitation light passes through to

the emission monochromator (gray area) and on to the PMT, resulting

in a purer emission signal and more accurate data.

The SpectraMax Multi-Mode Microplate Reader allows scanning of both

excitation and emission wavelengths, using separate tunable

monochromators. One benefit of being able to scan emission spectra is

that you can assess more accurately whether the emission is, in fact,

the expected fluorophore, or multiple fluorophores, and not one

generated by a variety of background sources or by contaminants.

Another benefit is that you may be able to find excitation and emission

wavelengths that avoid interference when interfering fluorescent

species are present.

For this reason, it may be desirable to scan emission for both an

intermediate concentration of labeled sample, as well as the

background of unlabeled sample. The optimum setting is where the

ratio of the sample emission to background emission is at the

maximum.

26 0112-0115 F

Loading...

Loading...