Page 1

ImageXpress® Micro

High Content Imaging System

Options

User Guide

5014166 D

September 2015

Page 2

This document is provided to customers who have purchased Molecular Devices

equipment, software, reagents, and consumables to use in the operation of such

Molecular Devices equipment, software, reagents, and consumables. This document

is copyright protected and any reproduction of this document, in whole or any part,

is strictly prohibited, except as Molecular Devices may authorize in writing.

Software that may be described in this document is furnished under a nontransferrable license. It is against the law to copy, modify, or distribute the software

on any medium, except as specifically allowed in the license agreement.

Furthermore, the license agreement may prohibit the software from being

disassembled, reverse engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only to

designate those manufacturers’ products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers’ and/or their product names as

trademarks.

Each product is shipped with documentation stating specifications and other

technical information. Molecular Devices products are warranted to meet the stated

specifications. Molecular Devices makes no other warranties or representations

express or implied, including but not limited to, the fitness of this product for any

particular purpose and assumes no responsibility or contingent liability, including

indirect or consequential damages, for any use to which the purchaser may put the

equipment described herein, or for any adverse circumstances arising therefrom. The

sole obligation of Molecular Devices and the customer's sole remedy are limited to

repair or replacement of the product in the event that the product fails to perform as

warranted.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These

trademarks may not be used in any type of promotion or advertising without the prior written permission of

Molecular Devices, LLC.

Patents:

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

© 2015 Molecular Devices, LLC.

All rights reserved.

http://www.moleculardevices.com/productpatents

Page 3

Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Who this User Guide is For. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Obtaining Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 1: Environment Control Option

Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environment Control Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Items Included in the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Items to Be Provided by the Customer. . . . . . . . . . . . . . . . . . . . . . 11

Setting Up Environmental Control. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting Up the Water Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting Up the Carbon Dioxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Loading the Sample Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environment Control Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Environmental Parameters in Image Information . . . . . . . . . . . . . 19

Performing Timelapse Experiments. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reviewing Timelapse Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 2: Fluidics Option Operations . . . . . . . . . . . . . . . . . . . . 27

Fluidics Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Items to Be Provided by the Customer. . . . . . . . . . . . . . . . . . . . . . 29

Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting Up Fluidics Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring Fluidics Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Manual Fluidics Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Performing Fluidics Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Preventing Evaporation from Compound Plates . . . . . . . . . . . . . . . 43

Evaluated Seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5014166 D 3

Page 4

ImageXpress Micro High Content Imaging System Options User Guide

Chapter 3: Environment Control and Fluidics

Options Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Carbon Dioxide Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Cleaning the Water Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Waste Disposal Box and Plate Sealing Ring . . . . . . . . . . . . . . . . . . . . 47

Chapter 4: Transmitted Light Option Operations . . . . . . . . . . . 49

Transmitted Light Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Transmitted Light Software Configuration . . . . . . . . . . . . . . . . . . . . 54

Transmitted Light Phase Ring Alignment . . . . . . . . . . . . . . . . . . . . . . 56

Transmitted Light Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4 5014166 D

Page 5

Preface

Who this User Guide is For

This user guide is written for those who want to use an ImageXpress®

Micro High Content Imaging System with any of the following optional

components:

• ImageXpress Environment Control option

• ImageXpress Fluidics option

• ImageXpress Transmitted Light option

The ImageXpress Environment Control option, ImageXpress Fluidics

option, and ImageXpress Transmitted Light option described in this guide

are available for only the ImageXpress Micro High Content Imaging

System.

Conventions

In this user guide, the following typographical conventions are used.

WARNING! A warning indicates an operation that can cause personal

injury if precautions are not followed.

CAUTION! Indicates an operation that can cause damage to the

instrument, device, or data, if the precautions are not followed.

Note: Provides essential information for the completion of a

procedure.

Tip: Provides useful information that helps apply the techniques and

procedures in the text to your specific needs, and can also provide

shortcuts. The information in a tip is not essential to the completion of a

procedure.

.

5014166 D 5

Page 6

ImageXpress Micro High Content Imaging System Options User Guide

MetaXpress Software

Use the MetaXpress® Software with the ImageXpress Micro System to

select a standard image analysis routine or to develop a custom protocol

to fit your specific acquisition and analysis needs. The MetaXpress

Software workflow is divided into two major parts: acquisition and

analysis.

• The acquisition workflow involves configuring settings, acquiring

images, and storing plate data in a database.

• The analysis workflow consists of processing, enhancing, and

analyzing acquired plate data. See the MetaXpress High Content

Image Acquisition & Analysis Software Analysis Guide included

on the MetaXpress Software installation USB flash drive.

Simplified Menu Structure

An optional simplified menu structure can be installed to reduce the

number of top-level menus in the MetaXpress Software. All the features

of the software are available in this reorganized menu structure.

The procedures in this guide describe both the default menu structure

and the simplified menu structure.

You can use the Menu Map in the Help menu to help you find the

locations of features in the simplified menu structure. The Menu Map is

available only after the simplified menu installation.

1. Click Help > Menu Map.

2. In the Menu Map dialog, select to view the Default to

customized menu map.

3. Click the menu path where the software feature you want is

found in the default menu structure.

The simplified menu path appears to the right of the desired

feature in the menu.

4. Click the menu path in the software window to access the

desired feature.

For example, if you want to make a duplicate of an image, then use the

following procedure:

1. Click Help > Menu Map.

2. In the Menu Map dialog, select to view the Default to

customized menu map.

3. Click Edit > Duplicate.

The simplified menu path -> Edit: Image: Duplicate Image/Plane

appears to the right of the Image option in the submenu.

6 5014166 D

Page 7

Obtaining Support

Molecular Devices is a leading worldwide manufacturer and distributor

of analytical instrumentation, software, and reagents. We are committed

to the quality of our products and to fully supporting our customers with

the highest possible level of technical service.

Our support web site,

link to the Knowledge Base with technical notes, software upgrades,

safety data sheets, and other resources. If you do not find the answers

you are seeking, follow the links to the Technical Support Service Request

Form to send an email message to a pool of technical support

representatives.

You can contact your local representative or contact Molecular Devices

Technical Support by telephone at 800-635-5577 (U.S. only) or

+1 408-747-1700. In Europe call +44 (0) 118 944 8000.

Part of effective communication with Molecular Devices is determining

the channels of support for the ImageXpress Micro System, including the

MetaXpress Software. Molecular Devices provides a wide range of

support:

Preface

4. In the software window, click Edit > Image > Duplicate

Image/Plane.

http://www.moleculardevices.com/support, has a

• Documentation: Check the guides that are included on the

installation media and the help that is available within the

MetaXpress Software. Help for an active dialog can be accessed

by pressing F1 on your keyboard.

• Online knowledge base: The knowledge base has links to

technical notes, software upgrades, newsletters, user guides,

and other resources. Visit the Molecular Devices Support web

page at http://www.moleculardevices.com/support and follow

the links to the knowledge base.

• MetaMorph Software forum: This forum has information on

journal scripts and custom modules, and has links to videos and

webinars that can help you troubleshoot problems and be more

productive using the software. Visit the forum at

metamorph.moleculardevices.com/forum.

5014166 D 7

Page 8

ImageXpress Micro High Content Imaging System Options User Guide

• Technical Support:

Phone: Contact Technical Support at (800)-635-5577 (U.S. only)

or +1 408-747-1700. In Europe call +44 (0) 118 944 8000.

Online: Visit

http://www.moleculardevices.com/support and

follow the links in the knowledge base to the Technical Support

Request Form to send an email to a group of experienced

Technical Support representatives.

Please have the system ID number, system serial number,

software version number, and the name of the system owner

available when you call.

To find your system ID number, in the MetaXpress Software,

click Help > About MetaXpress. The About dialog displays

your system ID number.

The system serial number is located on your instrument.

• Additional support resources include:

Nikon web-based microscopy course:

http://www.microscopyu.com

The Molecular Probes Handbook:

http://www.lifetechnologies.com/us/en/home/references/

molecular-probes-the-handbook.html

This resource offers advice on fluorescent probes and can

help you determine if there are better stains available for

your analysis.

The following sites offer filter information:

- http://www.chroma.com

- http://www.semrock.com

- http://www.omegafilters.com

8 5014166 D

Page 9

Environment Control Option Operations

The ImageXpress® Environment Control option is designed to maintain an

environment for living cells to enable multi-day live-cell timelapse

imaging. Temperature, carbon dioxide, and humidity can all be

maintained within the sample plate so that cells can be kept alive for

many days, growing at a rate comparable to that expected in a standard

cell culture incubator. In addition to offering kinetic and timelapse

imaging capabilities, the environmental enclosure can accommodate a

single-channel fluidics robot for delivering compounds during

experimentation.

The ImageXpress Environment Control option can be installed together

with either the Fluidics option or the Transmitted Light option.

See also:

• Fluidics Option Operations on page 31

• Transmitted Light Option Operations on page 55

This chapter contains the following sections:

• Environment Control Hardware on page 10

• Setting Up Environmental Control on page 14

• Environment Control Software on page 21

• Doing Timelapse Experiments on page 23

1

5014166 D 9

Page 10

ImageXpress Micro High Content Imaging System Options User Guide

Environment Control Hardware

The ImageXpress Environment Control option consists of a sealing ring

on top of the sample plate and a top door above the plate that together

forms a small, sealed volume. Humidified carbon dioxide is sourced into

this small volume to form the required environment above the plate.

Temperature is controlled within the upper half of the instrument.

The ImageXpress Environment Control option consists of the following

hardware subsystems:

• Temperature control within the upper half of the base

instrument. Warm air is provided from the Environmental

Control Option Controller or the Systems Power & Options

Controller through an air hose. Feedback from temperature

sensors installed near the plate maintains the temperature. The

temperature can be controlled within a range of 30°C to 40°C,

when the ambient room temperature is 22°C or lower.

• Carbon dioxide is provided from a customer-supplied tank of

pre-mixed 5% CO2 and 95% air. The tank regulator must be set

between 15 PSI and 20 PSI. The Environmental Control Option

Controller or the Systems Power & Options Controller controls

the flow to the space above the plate, maintained by the live-cell

sealing ring. If a plate is ejected and loaded, the system conducts

a purge cycle automatically.

• Humidity is passively provided by bubbling the carbon dioxide

through a water reservoir, minimizing evaporation from the

sample plate over the duration of a timelapse experiment.

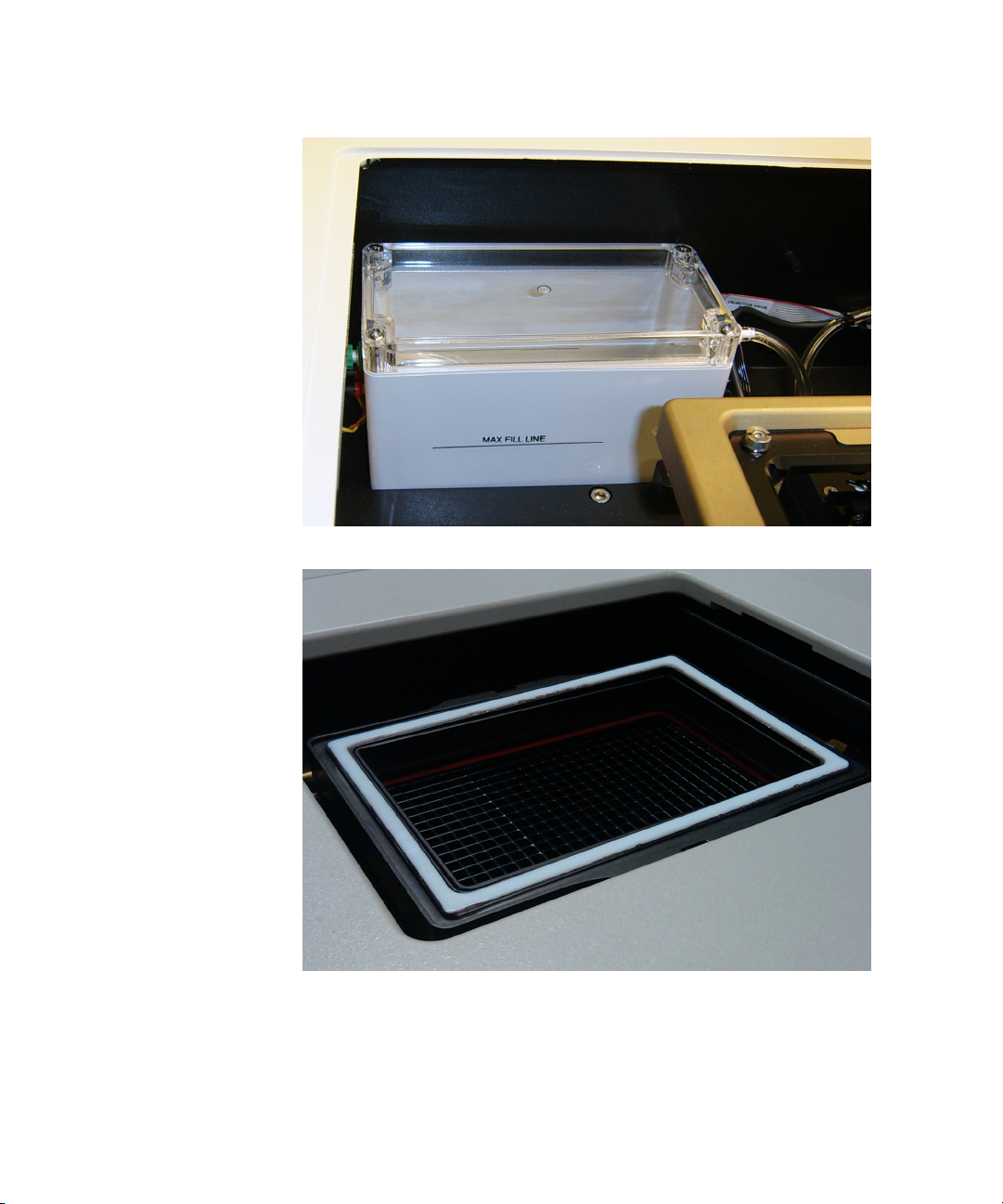

Items Included in the Installation

The following hardware components are included in an ImageXpress

Environment Control option installation:

• ImageXpress Micro Environmental Control Option Controller or

the ImageXpress Micro Systems Power & Options Controller.

See Figure 1-1 on page 11 and Figure 1-2 on page 11.

• Warm air hose and carbon dioxide tubing. See Figure 1-3 on

page 12 and Figure 1-4 on page 12.

• Temperature sensors. To ensure accurate readings, the sensors

are located near the sample plate.

• Water reservoir. See Figure 1-5 on page 13.

• Live-cell sealing ring. Compatible with 96-well and 384-well

standard height plates. The standard height for these plates is

14.35 mm ± 0.25 mm (0.5650 inches ± 0.0098 inches). See

Figure 1-6 on page 13.

10 5014166 D

Page 11

Environment Control Option Operations

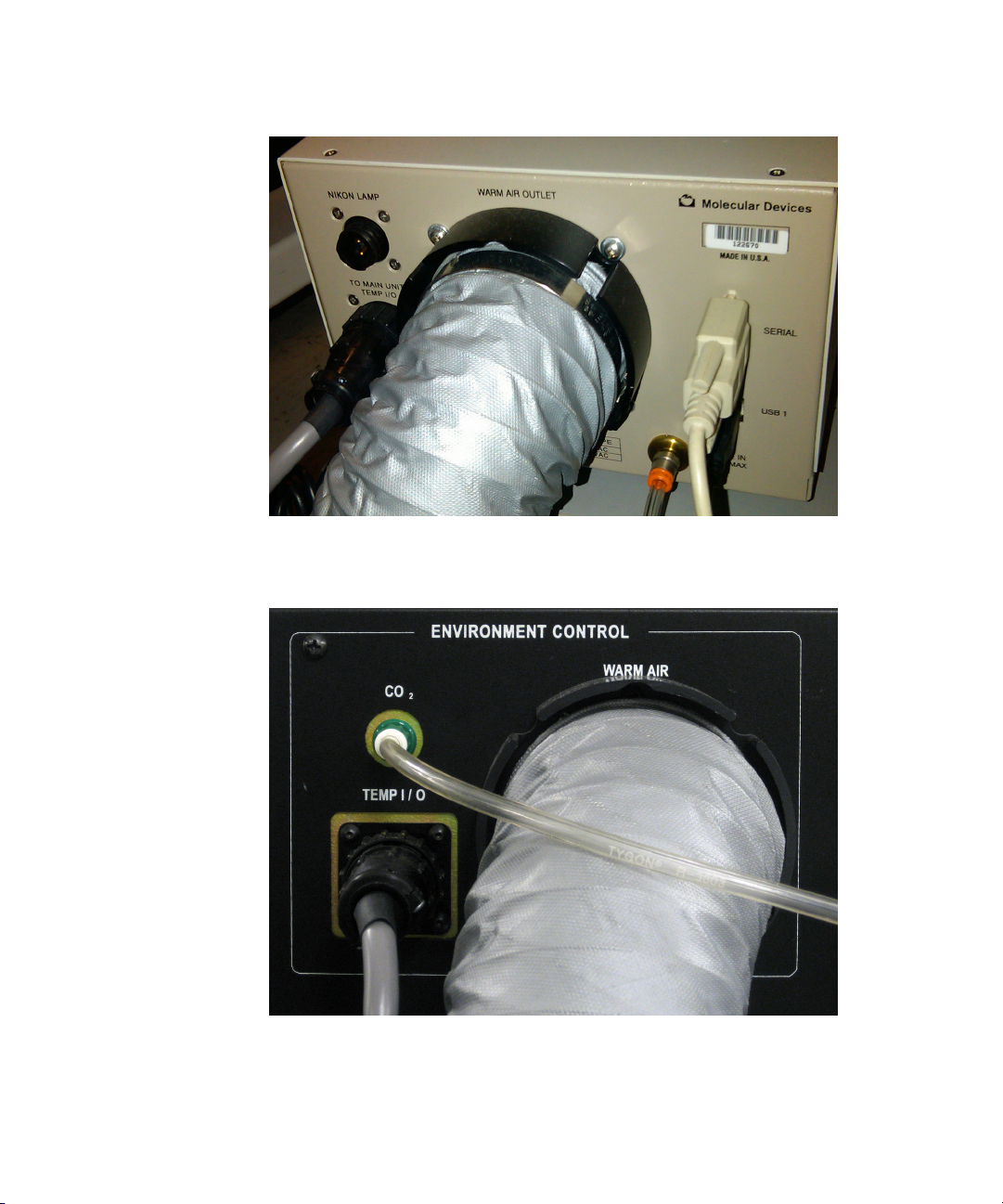

Figure 1-1: Environmental Control Option Controller used for the

ImageXpress Micro Standard and XLS Systems

Figure 1-2: Systems Power & Options Controller used for the

ImageXpress Micro Confocal System

Note: The Compound Plate Temperature setting is available only when

the Fluidics option is also installed.

5014166 D 11

Page 12

ImageXpress Micro High Content Imaging System Options User Guide

Figure 1-3: Environment Control option warm air hose and carbon

dioxide tubing on the back of the Environmental Control Option

Controller

Figure 1-4: Environment Control option warm air hose and carbon

dioxide tubing on the back of the ImageXpress Micro Standard System

12 5014166 D

Page 13

Environment Control Option Operations

Figure 1-5: Environment Control option water reservoir

Figure 1-6: Environment Control option live-cell sealing ring

5014166 D 13

Page 14

ImageXpress Micro High Content Imaging System Options User Guide

Items to Be Provided by the Customer

The customer must provide the following items for the Environment

Control option installation:

• A tank of pre-mixed 5% CO2 and 95% air.

• The regulator, fittings, and tubing required to deliver 15 to 20 PSI

carbon dioxide from the tank to the Environmental Control

Option Controller or the Systems Power & Options Controller.

• Microwell plates with standard ANSI height. Most 96-well and

384-well plates are standard height. The standard height for

these plates is: 14.35 mm ± 0.25 mm (0.5650 inches ± 0.0098

inches).

• Deionized water to maintain humidity.

Setting Up Environmental Control

An FSE (Field Service Engineer) installs the ImageXpress Environment

Control option. After installation, environmental control can be set up for

experiments.

Setting the Temperature

The temperature controller is calibrated before the instrument ships

from the factory. Use the external temperature controller to set the

temperature that you want the environmental enclosure to maintain.

14 5014166 D

Page 15

Environment Control Option Operations

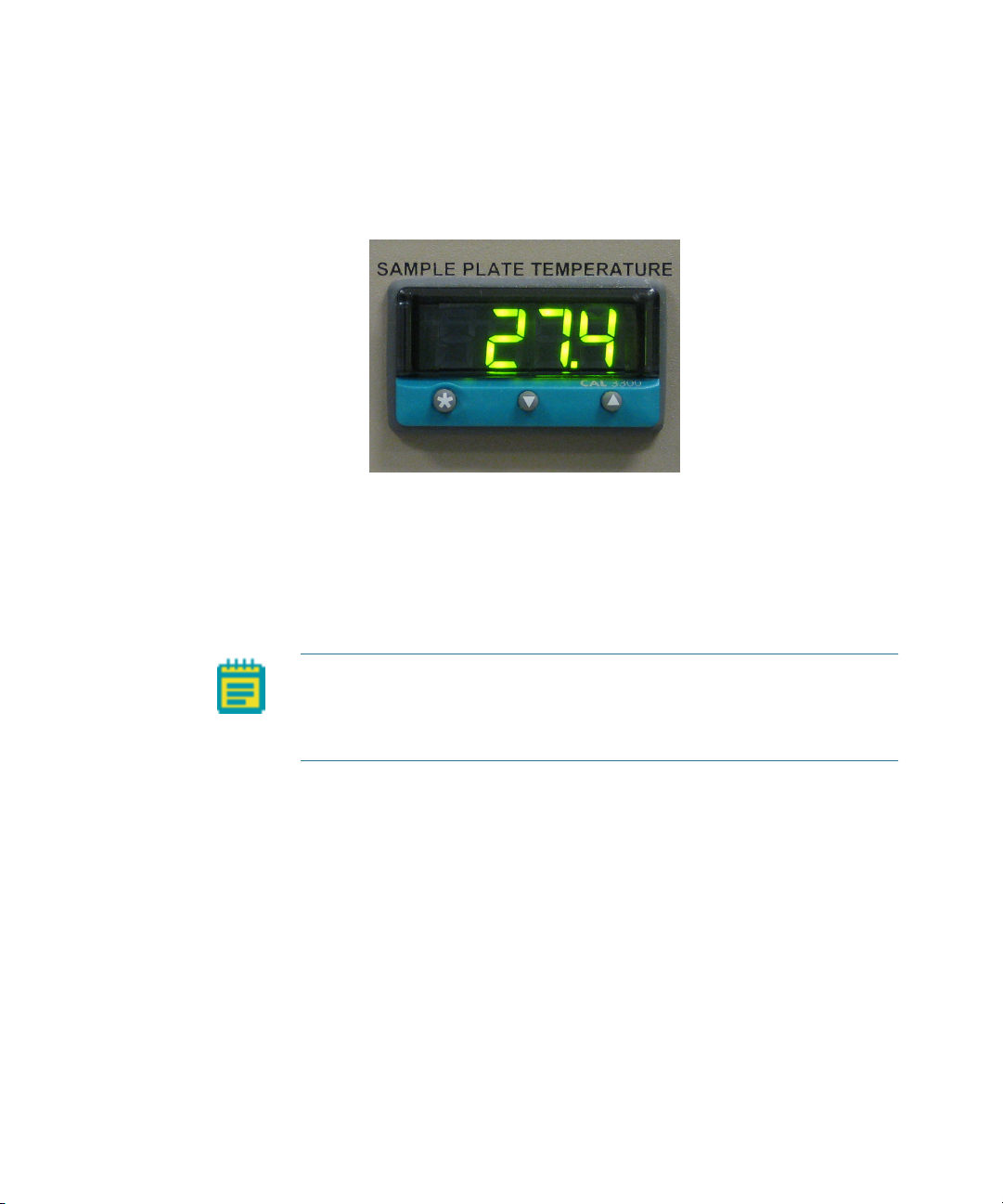

To set the temperature

1. On the front of the Environmental Control Option Controller or

the Systems Power & Options Controller, view the current

sample plate temperature.

Figure 1-7: Sample Plate Temperature control interface

2. To view the temperature set point, press .

3. To increase the temperature set point, press and .

4. To decrease the temperature set point, press and .

After you release , the current temperature in the chamber is

displayed.

Note: For the ImageXpress Micro Confocal System, you can set the

temperature with the Instrument power switch in the On position. To

regulate the temperature in the chamber, the Sample Heater power

switch must be also in the On position.

Setting Up the Water Reservoir

Air supplied to the environmental enclosure flows through the water

reservoir to make sure the air has a high degree of humidity.

Tools required for setup:

Syringe

Deionized Water (preferably sterilized)

5014166 D 15

Page 16

ImageXpress Micro High Content Imaging System Options User Guide

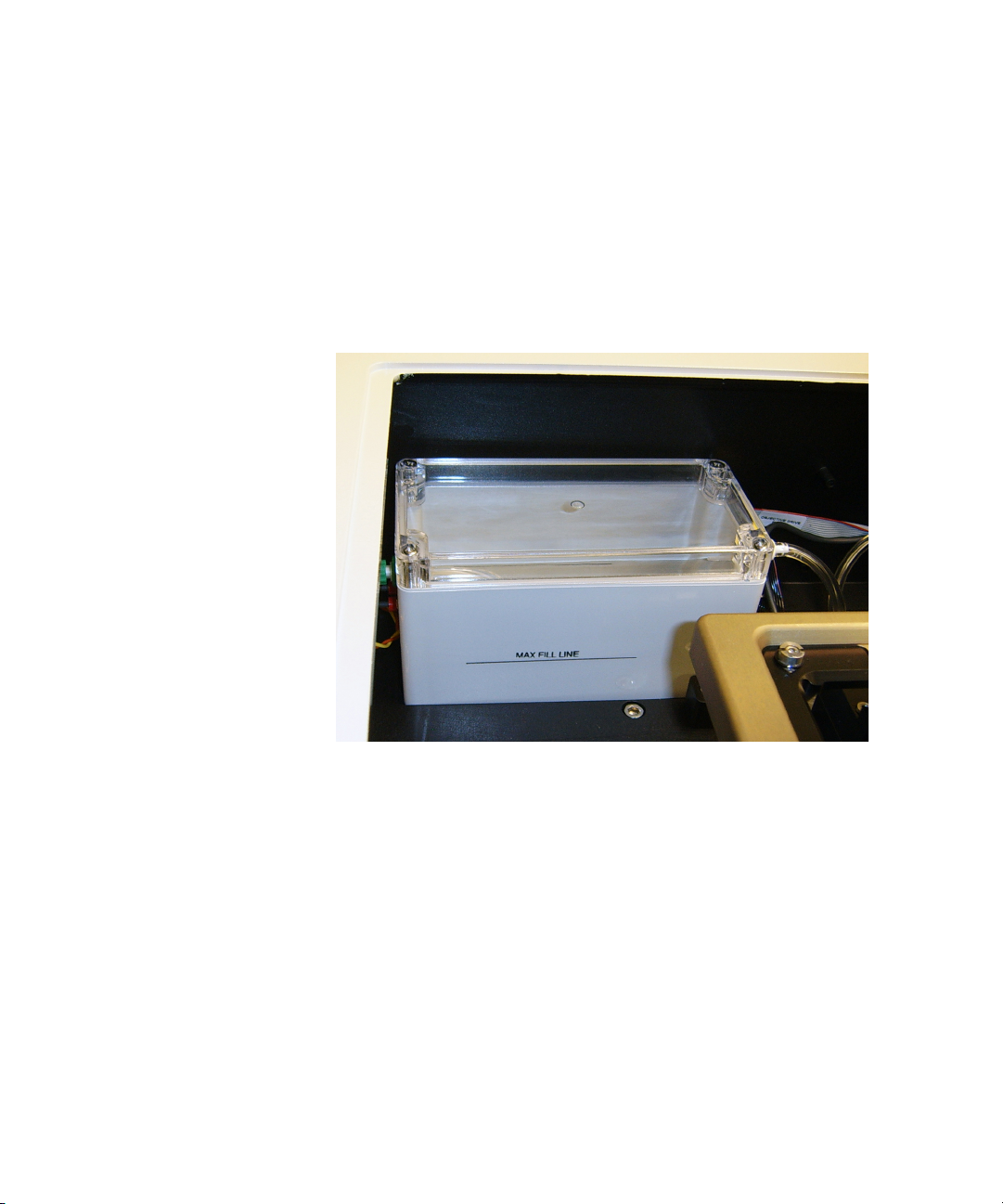

To set up the water reservoir

1. In the MetaXpress software, click Screening > Plate acquisition

and Control > Eject Plate to open the top door of the instrument.

2. Remove the insert that surrounds the top door.

3. Disconnect the CO

the instrument.

4. Insert a syringe filled with deionized water into the luer lock.

5. View the water reservoir through the open top panel.

/air tubing from the luer lock on the rear of

2

Figure 1-8: Environment Control option water reservoir

6. Dispense the deionized water from the syringe into the water

reservoir until the water reaches the fill line.

7. Remove the syringe from the luer lock.

8. Reconnect the CO

/air tubing to the luer lock.

2

9. Replace the insert that surrounds the top door.

10. In the MetaXpress software, click Screening > Plate acquisition

and Control > Load Plate to close the top door of the instrument.

16 5014166 D

Page 17

Environment Control Option Operations

Setting Up the Carbon Dioxide

A pre-mixed CO2 tank with a regulator must be set up and connected to

the carbon dioxide controller. The carbon dioxide controller then controls

the flow rate of carbon dioxide delivered to the water reservoir within

the environmental enclosure.

Before you begin, make sure the water reservoir is set up. See

the Water Reservoir on page 15.

To set up the carbon dioxide

1. Connect the tubing from the pre-mixed CO2 tank to the

Environmental Control Option Controller or the Systems Power &

Options Controller.

2. Verify that the tubing from the Environmental Control Option

Controller or the Systems Power & Options Controller to the

instrument is connected.

3. Connect the regulator to the CO

4. Turn on the CO

regulator to approximately 15 PSI to 20 PSI.

2

5. From the top of the ImageXpress Micro System, lift the insert

surrounding the top door and remove it. Keep the top door of

the instrument closed.

6. Verify that there is a steady flow of bubbles in the water

reservoir.

7. Replace the insert surrounding the top door.

8. Check the environmental control settings to verify that the CO

pressure is OK. See Environment Control Software on page 21.

tank.

2

Setting Up

2

After setting up the carbon dioxide

Load an unlidded plate with the live-cell sealing ring on top. If there are

concerns about contamination, a breathable seal can be used over the

top of the plate. See Loading the Sample Plate on page 18.

Note: Before you do imaging experiments, wait for the system and

plate to reach equilibrium. Allow at least two hours for the system and

30 minutes for the plate. Because focus settings and offsets change with

temperature, you might need to optimize them after the system and

plate have reached equilibrium.

5014166 D 17

Page 18

ImageXpress Micro High Content Imaging System Options User Guide

Loading the Sample Plate

You must use the live-cell sealing ring to maintain the CO2 flow to the

sample plate. The sealing ring helps to contain the inputted air directly

over the cells and maintains the proper CO2 and temperature levels.

WARNING! BIOHAZARD! Wear gloves when handling sample plates.

Note: To ensure that it is at the proper temperature, before you load

the sample plate, make sure that the live cell sealing ring is in the system

or in the incubator.

To load the sample plate

1. In the MetaXpress software, click Screening > Plate acquisition

and Control > Eject Plate to open the top door of the instrument.

2. Insert the sample plate into the stage and then remove the lid

from the plate. If there are concerns about contamination, a

breathable seal can be used over the top of the plate.

18 5014166 D

Page 19

Environment Control Option Operations

3. Place the live-cell sealing ring directly on top of the plate, making

sure that it fits securely onto the plate.

Figure 1-9: Environment Control option live-cell sealing ring

4. In the MetaXpress software, click Screening > Plate acquisition

and Control > Load Plate to close the top door of the instrument.

Note: Temperature fluctuations in the plate and its

surroundings cause the plate and its cells to shift in X,Y, and Z

direction. To minimize these temperature fluctuations, take the

following precautions.

5014166 D 19

Page 20

ImageXpress Micro High Content Imaging System Options User Guide

Before you run an experiment:

• Allow the instrument to warm up for at least two hours.

• Make sure the plate sealing ring is at 37°C before use, either by

keeping it inside the instrument or inside an incubator. Incorrect

sealing-ring temperature can cause temperature fluctuation.

• Wait 30 minutes to 1 hour for the plate to reach equilibrium. You

can use a journal to set this waiting period.

The current temperature in the chamber is displayed on the

front of the controller.

• If there is interstitial space between wells, pipette deionized

water or media into these areas. This helps to increase the

thermal mass of the plate and reduces overall evaporation.

1.

Note: Due to the changes in Z height over time, you might need

to adjust the plate focus parameters in the MetaXpress software

occasionally. To do so, open the MetaXpress software, and then

click Screening > Plate Acquisition Setup > Plate tab > Edit Plate

Bottom Settings. Increase the adjacent well max variation to

accommodate the added Z-height variation introduced by the

fluctuation of temperature.

When setting laser autofocus options, make sure that the

instrument and plate temperatures are at equilibrium. Roomtemperature laser autofocus settings are not ideal when the

system is used at higher temperatures.

20 5014166 D

Page 21

Environment Control Software

The MetaXpress software controls the ImageXpress Micro System

screening and monitors the system’s environmental parameters. You can

check Environment Control settings and connections in the MetaXpress

software.

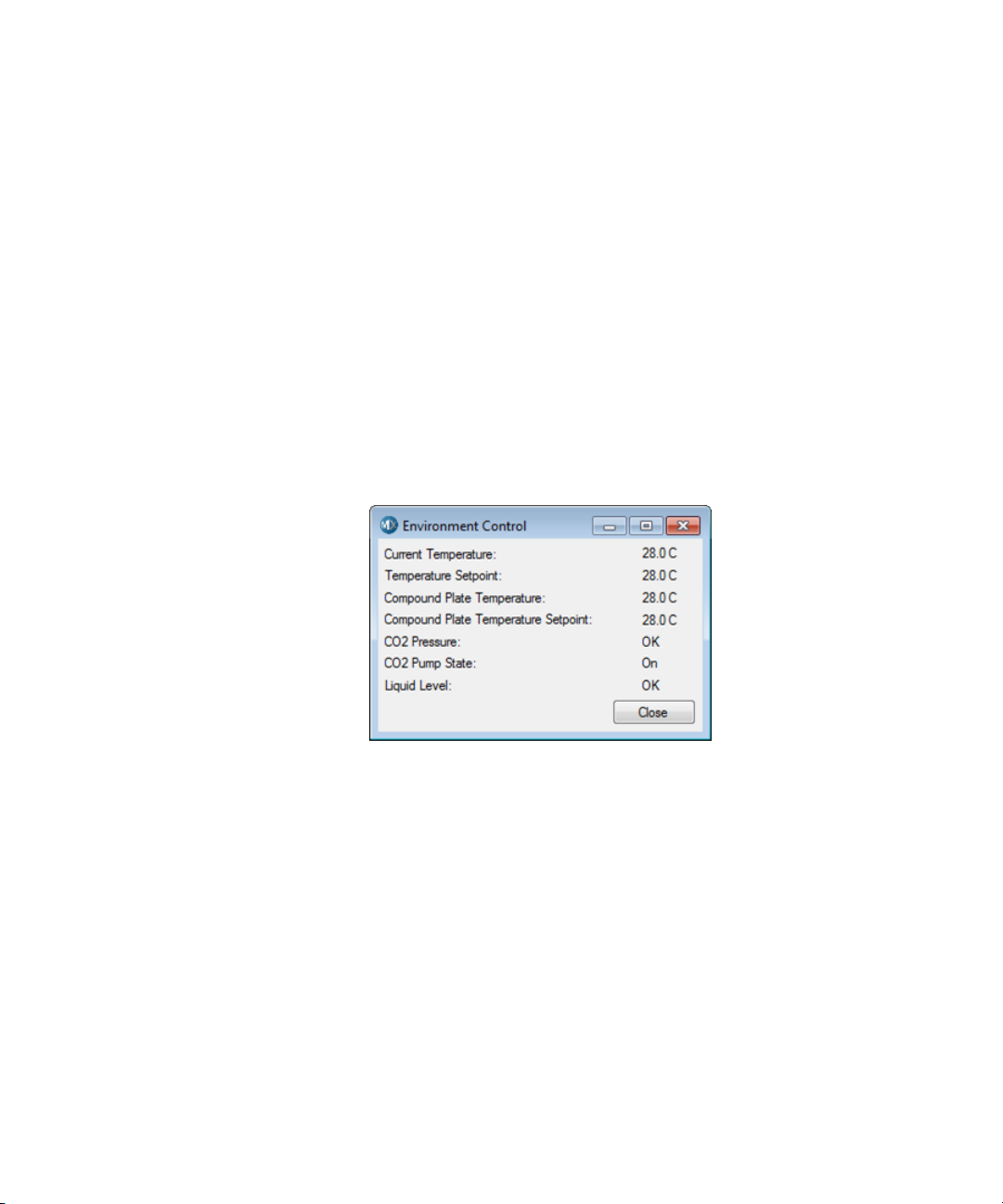

To check the Environment Control settings

1. In the MetaXpress software, click Devices > Environment

Control.

In the simplified menu, click Control > ImageXpress >

Environment Control.

In the Environment Control dialog, the Current Temperature

and the Temperature Setpoint values are displayed.

Temperature is recorded in degrees Centigrade.

Carbon dioxide pressure is recorded as Low or OK.

Environment Control Option Operations

Figure 1-10: Environment Control dialog

When the top door of the ImageXpress instrument is opened, the

MetaXpress Software triggers the environment control to increase the

flow rate of the carbon dioxide in order to flood the chamber with

humidified and carbon dioxide-controlled air. When a plate is loaded, the

system transiently purges the carbon dioxide at a higher flow rate.

However, the MetaXpress Software does not control the parameters,

such as the level of CO

or temperature. These parameters are controlled

2

directly through their hardware devices, such as the temperature

controller on the Environmental Control Option Controller or the

Systems Power & Options Controller (Figure 1-1 on page 11 and

Figure 1-2 on page 11) and the regulator on the carbon dioxide tank.

5014166 D 21

Page 22

ImageXpress Micro High Content Imaging System Options User Guide

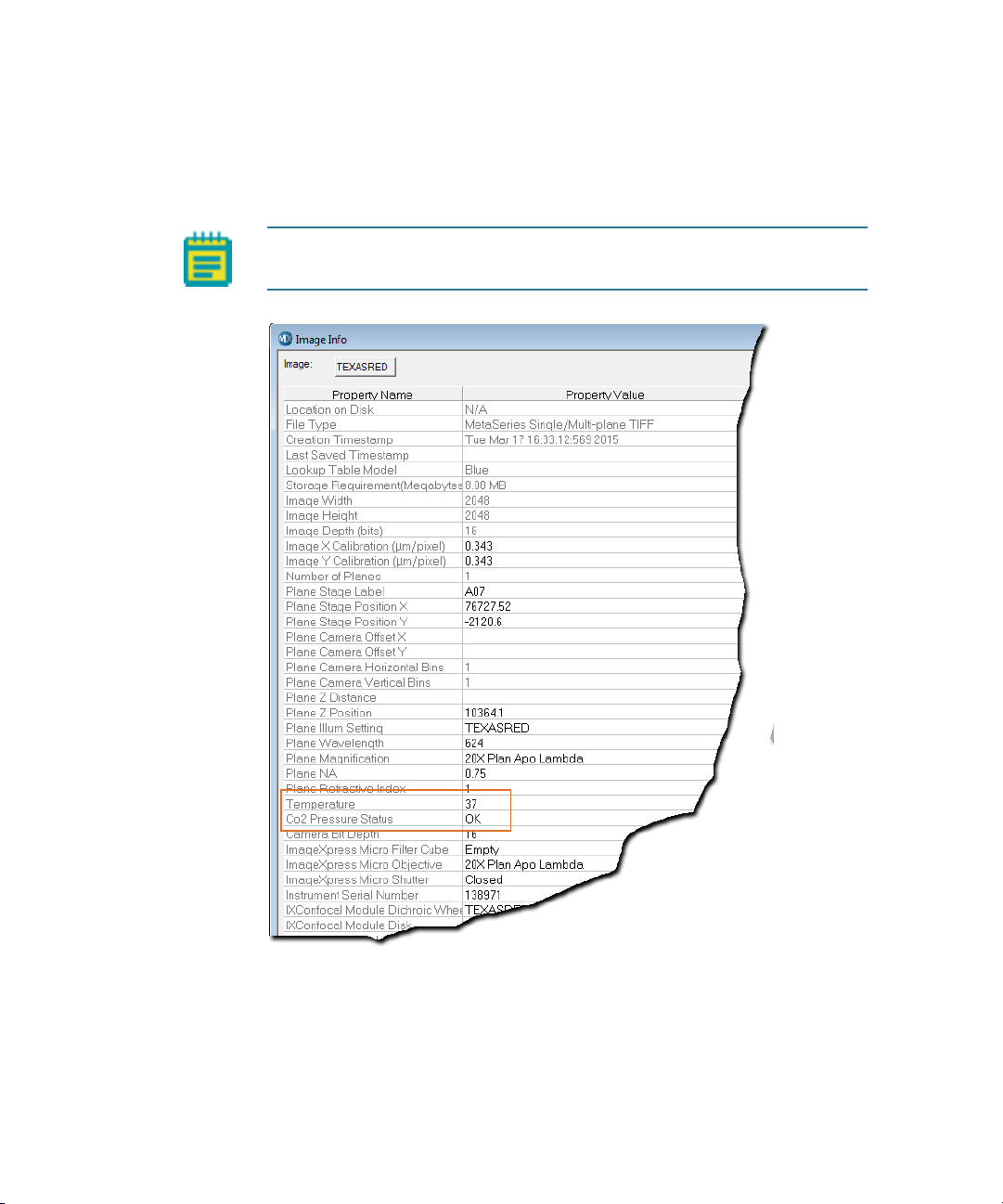

Environmental Parameters in Image Information

The MetaXpress Software records environmental information when

images are captured as shown in Figure 1-11 on page 22.

Note: There are wire sensors in the system to detect water, but the

software does not record this as an image annotation.

Figure 1-11: Image information annotation with environmental

parameters

22 5014166 D

Page 23

Doing Timelapse Experiments

The ImageXpress Environment Control option incubates live cells,

enabling imaging experiments to be performed over hours or days. Wells

can be imaged repeatedly at fixed time intervals, and movies can be

constructed from a series of images.

Note: In a timelapse experiment, the time starts when the first well is

acquired. If the acquisition time exceeds the time specified for the

timelapse experiment, the system proceeds as fast as possible. As a

result, the time between time points might not match the time

specified, but timestamps on images are accurate.

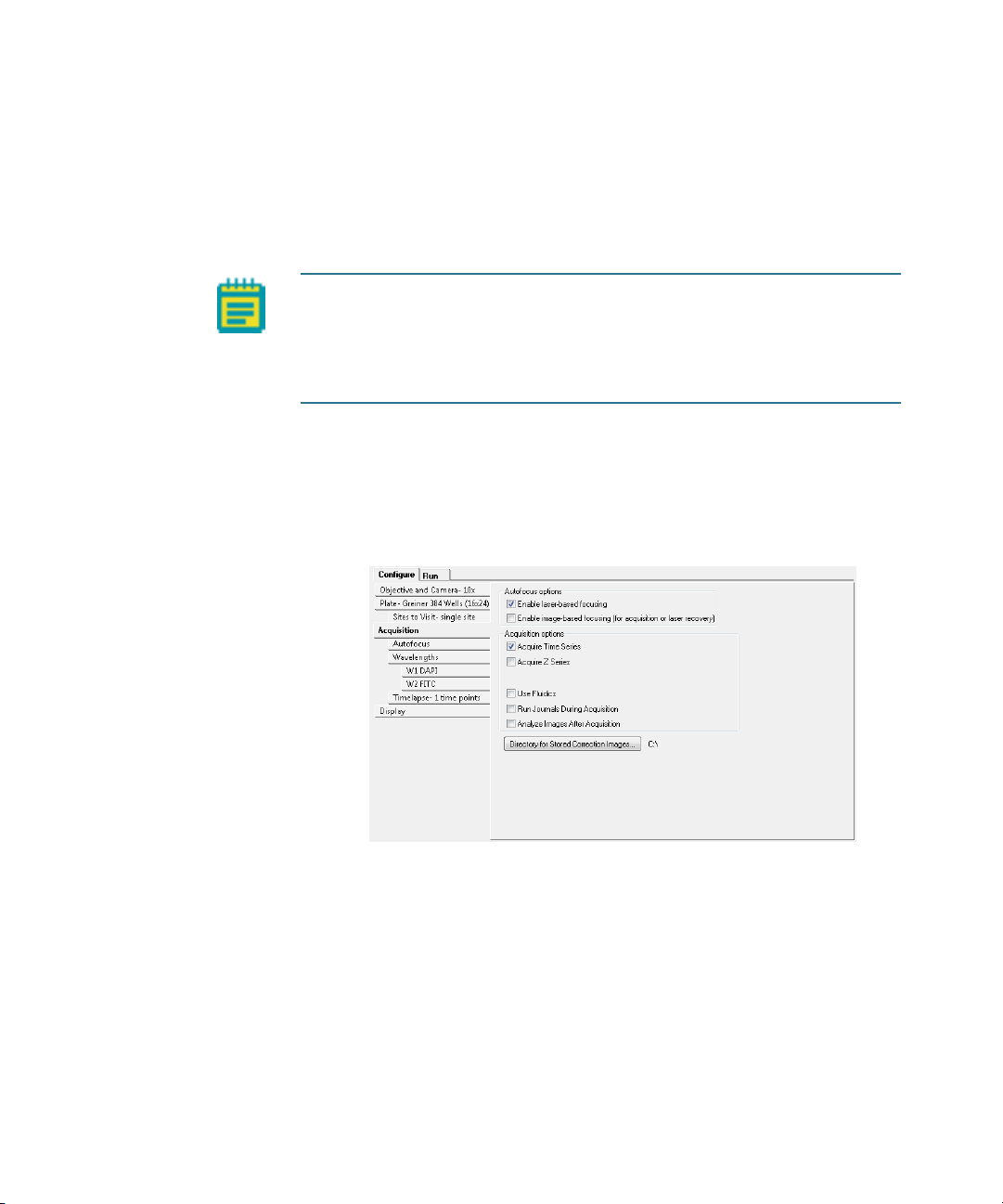

To Set Up a Timelapse Experiment

1. In the MetaXpress software, click Screening > Plate Acquisition

Setup.

2. In the Plate Acquisition Setup dialog, in the Configure tab, open

the Acquisition tab. See

Environment Control Option Operations

Figure 1-12.

p

Figure 1-12: Acquire Time Series

3. Select Acquire Time Series.

5014166 D 23

Page 24

ImageXpress Micro High Content Imaging System Options User Guide

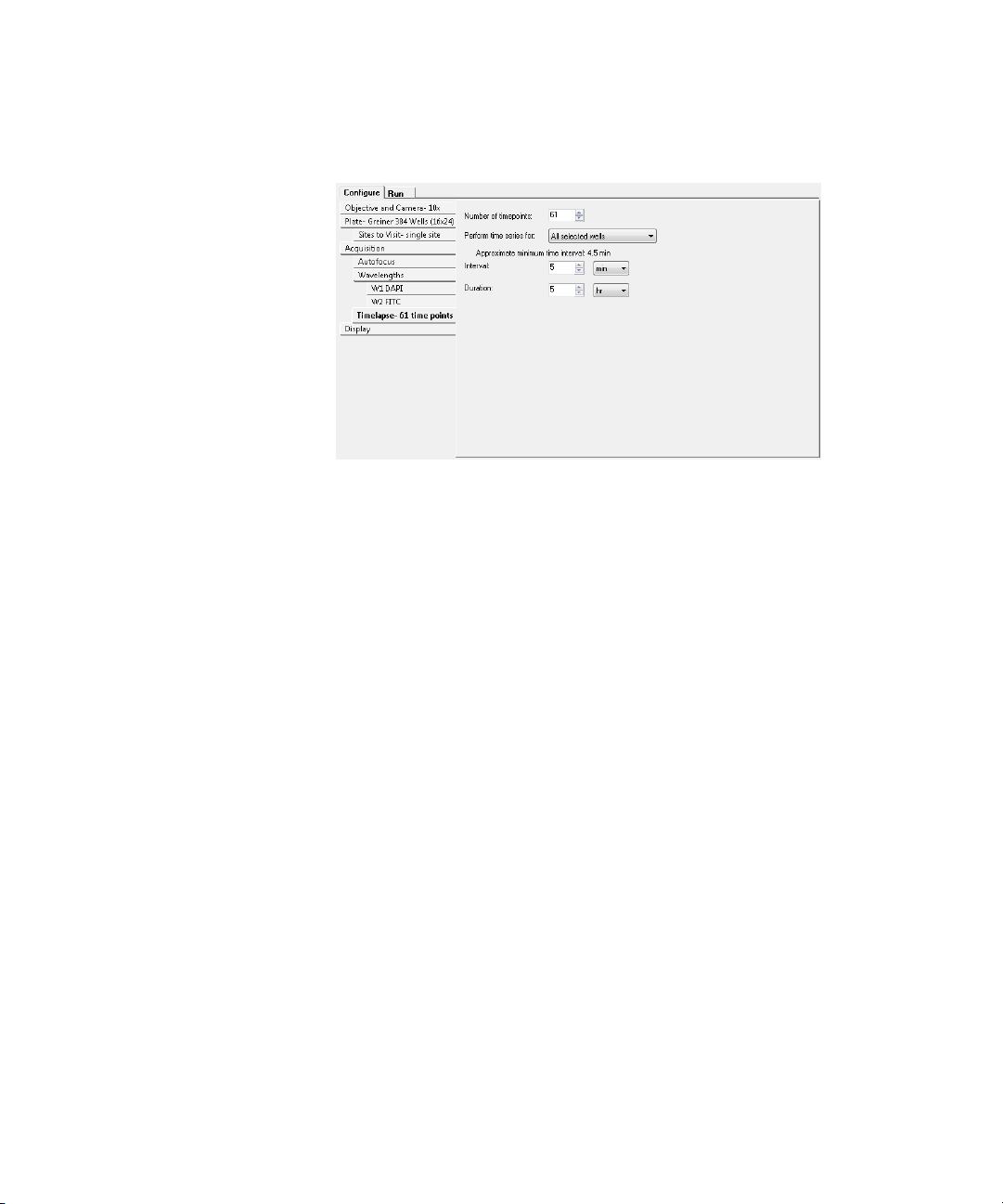

4. Under Configure, click Timelapse to configure timelapse

acquisition options. See Figure 1-13 on page 24.

Figure 1-13: Timelapse tab

5. In the Number of time points field, specify the number of time

points to use. Fluidic events can be associated with these time

points. See

Doing Fluidics Experiments on page 43.

6. Click Perform time series for and select one of the following

methods for acquiring a series of timelapse images,

corresponding to different types of experiments:

All selected wells is used for long timelapse experiments.

The system images all wells at the first time-point, then all

wells at the second time point, and so on.

One well then the next is used for a fast kinetic experiment.

The system images all time points on well 1, then moves to

well 2 and images all time points, and so on.

One row then the next or one column then the next is

suitable for an experiment using manual pipetting.

24 5014166 D

Page 25

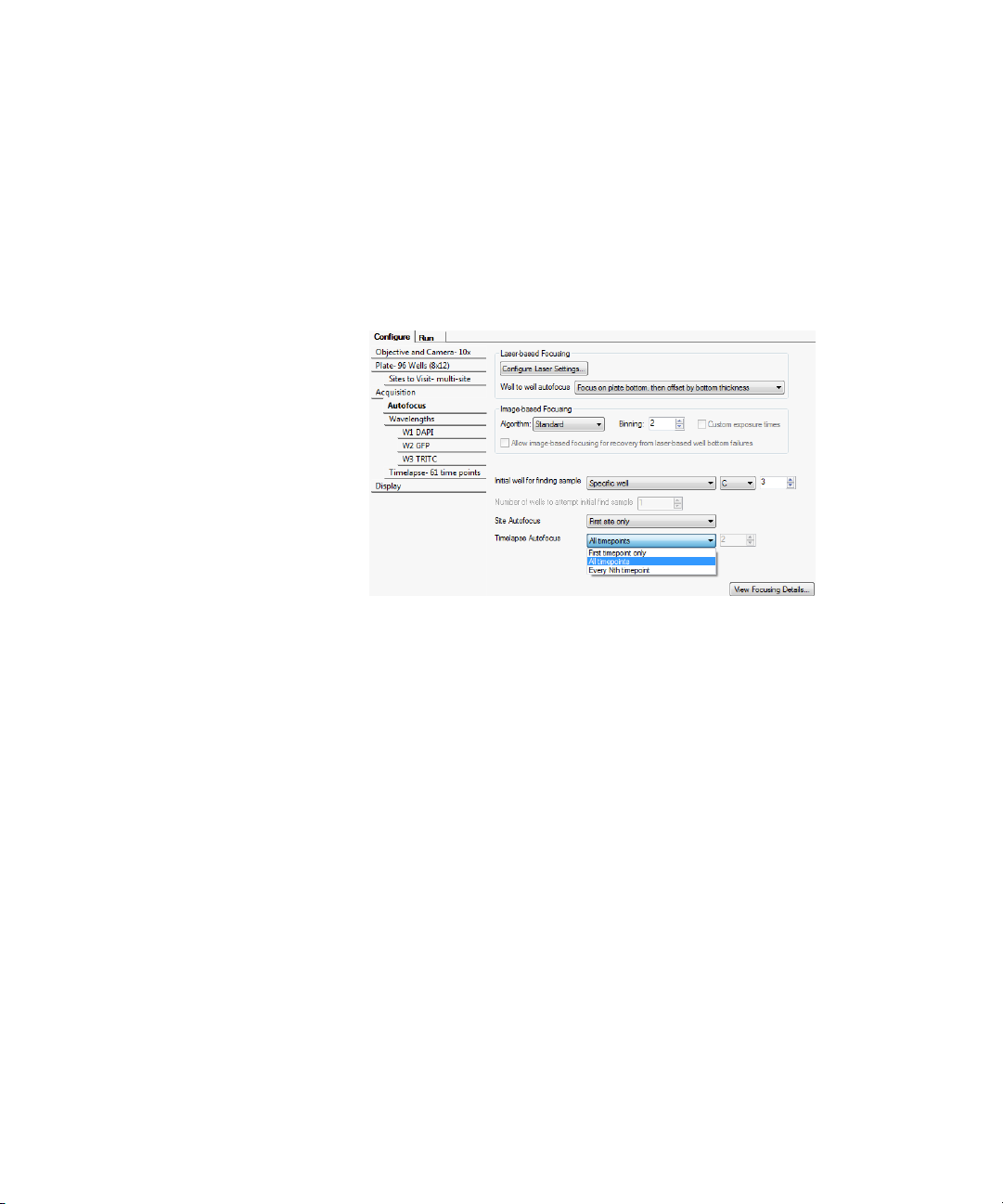

Environment Control Option Operations

7. If applicable, select additional options on the Autofocus tab. See

Figure 1-14 on page 25. These options include:

First timepoint only: Recommended for fast kinetic

experiments.

All timepoints: Recommended for long timelapse

experiments.

Every Nth timepoint: Offers the flexibility to autofocus

regularly during a timelapse experiment.

Figure 1-14: Timelapse Autofocus options

5014166 D 25

Page 26

ImageXpress Micro High Content Imaging System Options User Guide

8. If applicable, select additional options on the Wavelength tabs.

Wavelength tabs provide options for acquiring individual

wavelength images during a timelapse experiment. See

Figure 1-15 on page 26.

These options include:

At all time points: The default for timelapse experiments. All

time points are acquired for this wavelength.

At start of experiment: Only the first time-point is acquired

for this wavelength.

At start/end of experiment: Only the first and last time

points are acquired for this wavelength.

Every nth time point: Acquires timelapse images only for

every nth time-point for this wavelength.

If you do not image a wavelength at every time point, the most

recent image acquired for that wavelength is saved in the

database for that time-point.

Figure 1-15: The Timelapse Acquisition field on the Wavelength

1 tab

26 5014166 D

Page 27

Environment Control Option Operations

Reviewing Timelapse Data

As with other ImageXpress System data, timelapse data is displayed in

the MetaXpress software Review Plate Data dialog.

To review the timelapse data

1. In the MetaXpress software, click Screening > Review Plate Data.

Figure 1-16: Review Plate Data dialog

2. Click Select Plate.

3. In the Select Plate for Review dialog, select a plate, and then

click Select.

4. In the Data view list, click Time vs Well. The montage displays

thumbnails of each time point.

5. To create a stack for viewing as a movie, right-click on one well to

select it.

The well changes color to indicate that the well is selected.

5014166 D 27

Page 28

ImageXpress Micro High Content Imaging System Options User Guide

Note: To clear the selection, click Clear Selection at the bottom

of the dialog.

6. Click Load Selected Images.

In the image window, you can view each time point as a plane in

the stack using the navigation buttons above the image pane.

Figure 1-17: Stack of images with navigation buttons above the

image pane

Note: In a timelapse experiment, the time starts when the first

well is acquired. If the acquisition time exceeds the time

specified for the timelapse experiment, the system proceeds as

fast as possible. As a result, the time between time points might

not match the time specified, but the timestamps on images are

accurate.

28 5014166 D

Page 29

Environment Control Option Operations

To make a movie

1. Before you begin, load timelapse images and create a stack. See

Reviewing Timelapse Data on page 27.

2. Select the image window of the stack on the MetaXpress

Software desktop.

3. In the MetaXpress software, click Stack > Make Movie.

In the Simplified Menu Structure, click Edit > Stack > Make

Movie.

Figure 1-18: Make Movie dialog

4. In the Make Movie dialog, select the desired options.

For information about the available options, view the application

help by pressing F1 while viewing the dialog.

5. Click Save.

5014166 D 29

Page 30

ImageXpress Micro High Content Imaging System Options User Guide

30 5014166 D

Page 31

Fluidics Option Operations

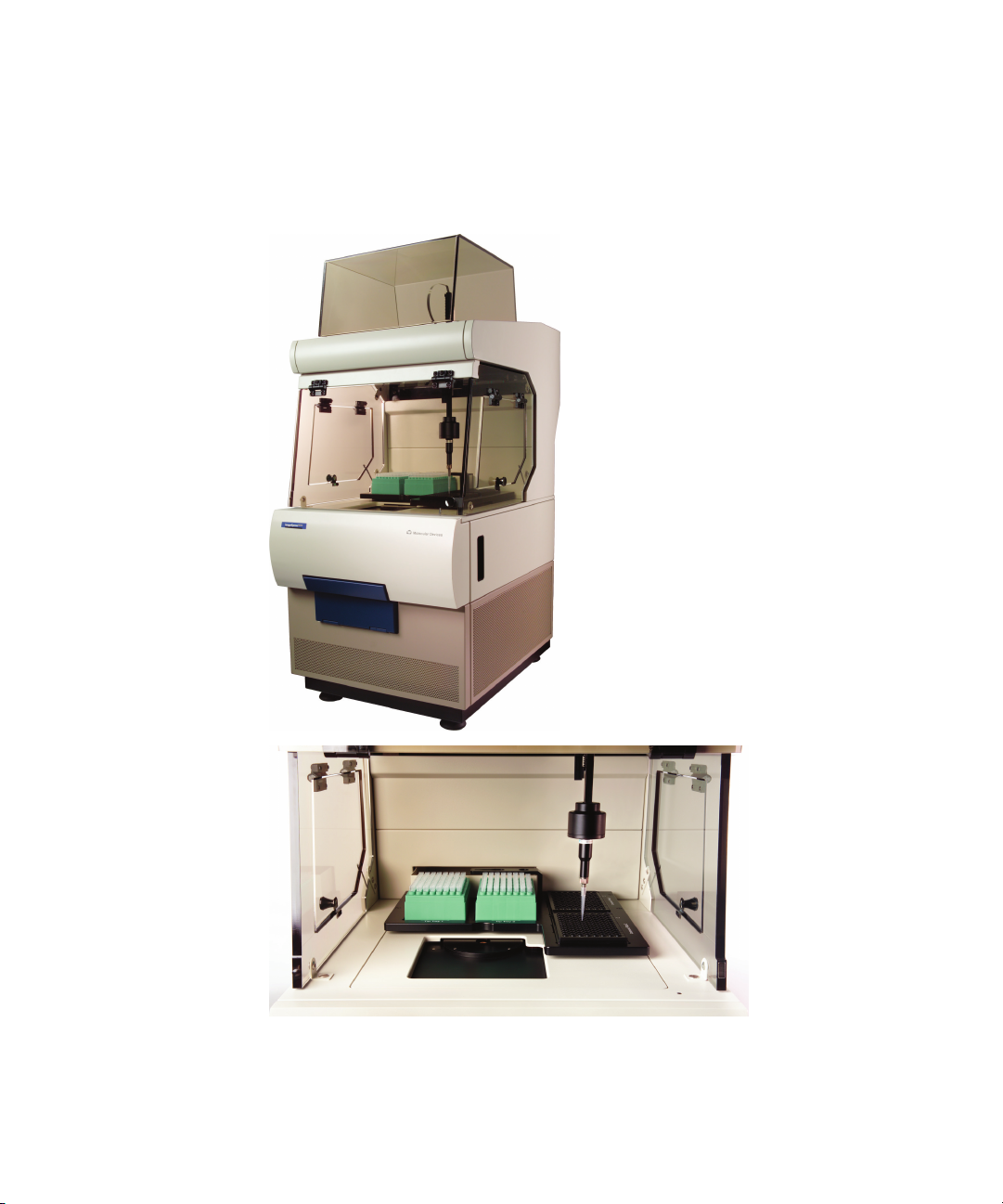

The ImageXpress® Fluidics option consists of a single-channel, fluidics

robot. This robot picks up tips from a tip box and draws fluid from and

delivers fluid to a given well on the compound and sample plates. For the

sample plate, the solenoid-operated plate shutter opens briefly, allowing

the robot access to a given well without compromising the

environmental control.

The robot is capable of dispensing volumes between 3 μL and 200 μL

with an accuracy of ±5% or ±1 μL.

The ImageXpress Fluidics option must be installed with the Environment

Control option. It is not compatible with the Transmitted Light option.

See Also:

• Environment Control Option Operations on page 9.

This chapter contains the following sections:

• Fluidics Hardware on page 31

• Setting Up Fluidics Hardware on page 33

• Configuring Fluidics Software (Stations and Properties) on

page 35

• Doing Fluidics Experiments on page 43

• Preventing Evaporation from Compound Plates on page 49

2

Fluidics Hardware

The ImageXpress Fluidics option consists of the following hardware

components. See Figure 2-1.

• Single-channel pipettor. Used to transfer fluid between two

compound/media plates and the sample plate.

• Shutter. Allows the system to maintain the environment when

not actively pipetting.

• Plate heaters. Used to heat the compound plates. These heat a

little higher than the displayed temperature, which represents

the temperature of the liquid in the well.

• Tip adapters and tip rack positions. Compatible with FLIPR® Tetra

96 tips (Part 9000-0761, 50 racks/case) or 384 tips (Part 90000763, 50 racks/case).

5014166 D 31

Page 32

ImageXpress Micro High Content Imaging System Options User Guide

• Tip stripper. Used for ejecting tips.

• Waste bin. Used to contain ejected tips and discarded liquid.

• Doors with safety interlocks. Prevents doors from being opened

during operation.

Figure 2-1: Fluidics hardware

32 5014166 D

Page 33

Fluidics Option Operations

Items to Be Provided by the Customer

The customer must provide the following items (in addition to the

Environment Control option items):

• ANSI standard compound plates.

• FLIPR Tetra 96 tips (Part 9000-0761, 50 racks/case) or 384 tips

(Part 9000-0763, 50 racks/case). Tips can be ordered from

Molecular Devices.

• Absorbent pad for liquid waste disposal.

Tips

The ImageXpress Fluidics option is compatible with FLIPR Tetra 96 or 384

tips.

After compounds are dispensed, tips are disposed into the waste

disposal tray located at the back of the environmental enclosure.

Plates

The tip and compound plate region inside the environmental enclosure

can accommodate up to two compound plates. Molecular Devices

recommends using standard 96-well or 384-well plates. U-bottom and Vbottom plates are beneficial when withdrawing and dispensing very

small volumes of compound.

Setting Up Fluidics Hardware

The FSE (Field Service Engineer) installs the ImageXpress Fluidics option.

After installation, fluidics can be set up for experiments.

To set up the fluidics hardware

1. Load the tip racks. For proper fit and alignment, insert the right

side first, and then press the left side down into place.

2. Change the tip adapter as appropriate. The tip adapter should be

screwed on firmly but not over-tightened. If the tip adapter is not

properly attached, it might not match the fluidics robot

calibration.

3. Load the compound plates. For proper fit and alignment, insert

the right side first, and then press the left side down into place.

4. Set up environmental control as needed, and allow the

compound-plate temperature to reach equilibrium. See

Up Environmental Control on page 14.

5014166 D 33

Setting

Page 34

ImageXpress Micro High Content Imaging System Options User Guide

5. If required, empty the waste bin.

6. Load an unlidded plate with the live-cell sealing ring on the top.

See

Loading the Sample Plate on page 18.

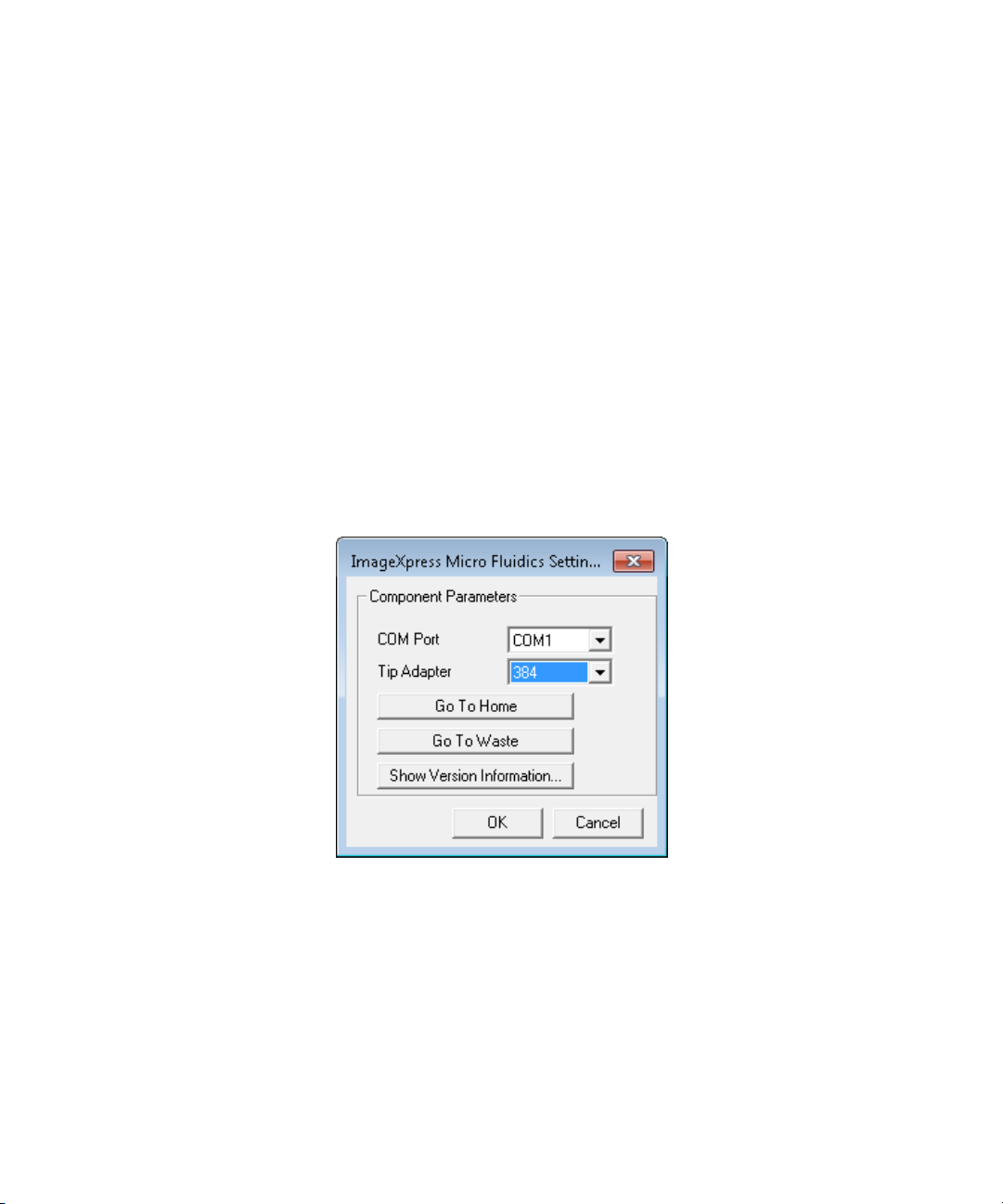

To Configure Fluidics in Meta Imaging Series Administrator

If you change tips, from a 96-well to a 384-well tip, or from a 384-well to

a 96-well tip, you need to configure the fluidics as described in the

following procedure.

1. Click Start > Programs > MetaXpress and then right-click Meta

Imaging Series Administrator and select Run as administrator to

start the MetaXpress Meta Imaging Series Administrator

software.

2. Click Configure Hardware.

3. In the Configure Hardware dialog, select the correct hardware

configuration, and then click Configure Devices.

4. In the right pane of the User Settings for hardware configuration

dialog, click ImageXpress Micro Fluidics, and then click Settings.

Figure 2-2: ImageXpress Micro Fluidics Settings dialog

5. In the ImageXpress Micro Fluidics Settings dialog, If applicable,

change the tip adapter or the COM port.

34 5014166 D

Page 35

Fluidics Option Operations

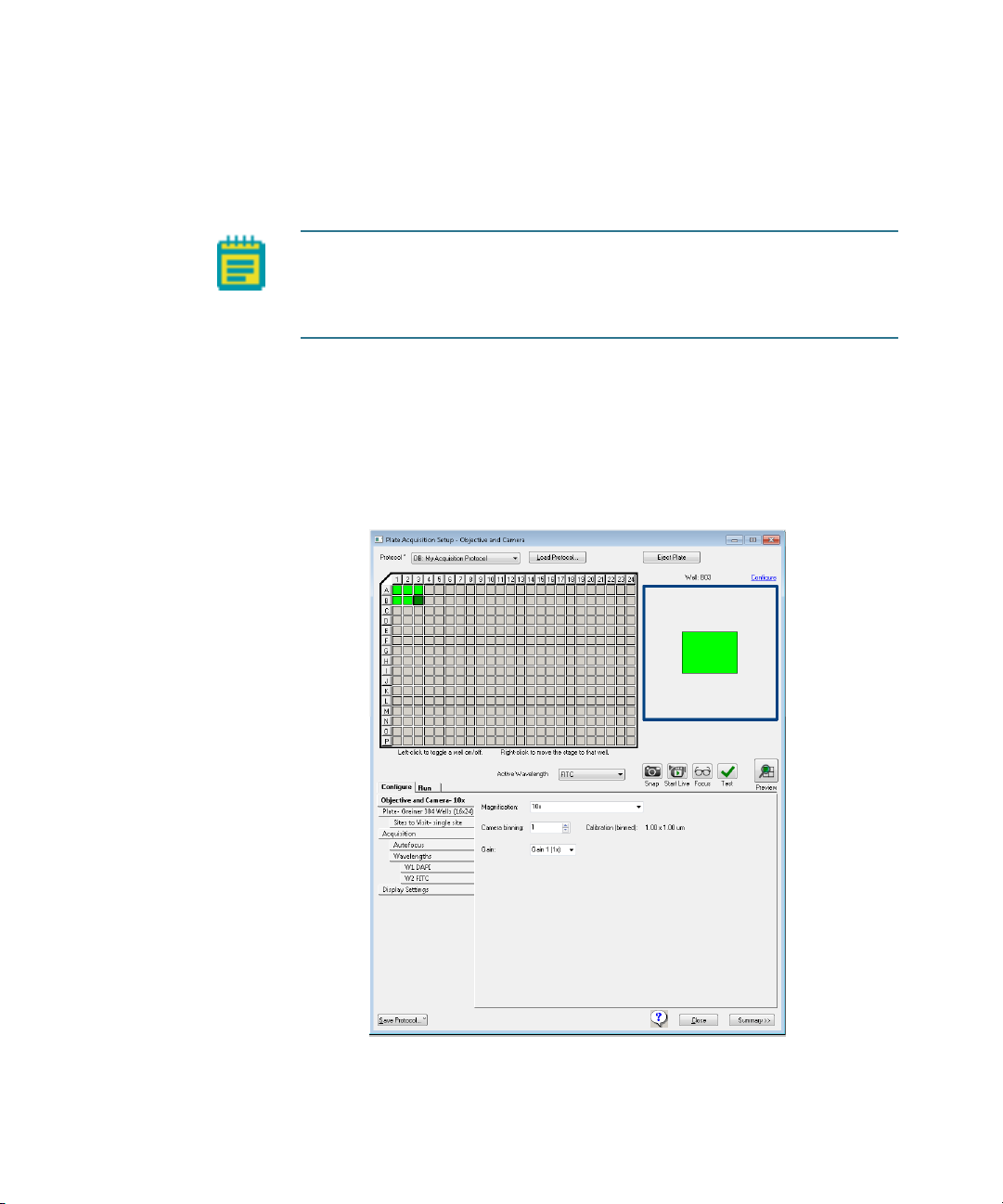

Configuring Fluidics Software (Stations and Properties)

To use the ImageXpress® Fluidics option, you must configure fluidics

stations and properties.

Note: The Configure Fluidic Stations functions are available at Devices

> Configure Fluidic Stations, in the simplified menu, Control >

ImageXpress > Configure Fluidics Stations, and from the Configure

Stations option from Plate Acquisition Setup > Configure > Fluidics.

This section details the Plate Acquisition Setup > Fluidics > Configure

location, but the procedures are the same if you access the functions

from the menu.

To configure fluidics software

1. In the MetaXpress Software, click Screening > Plate Acquisition

Setup.

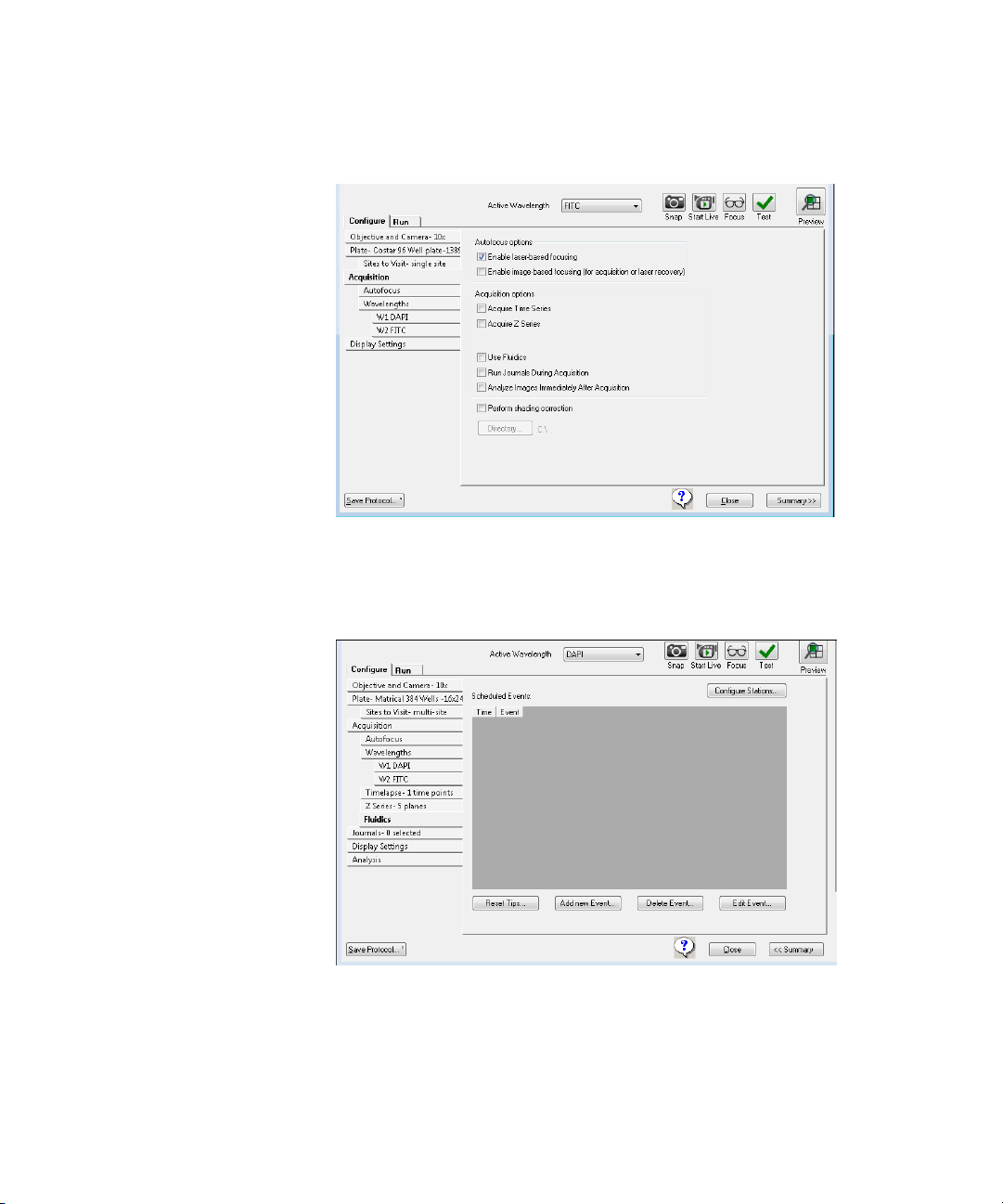

Figure 2-3: Plate Acquisition Setup dialog

5014166 D 35

Page 36

ImageXpress Micro High Content Imaging System Options User Guide

2. On the Plate Acquisition Setup dialog, on the Configure tab,

open the Acquisition tab.

Figure 2-4: Plate Acquisition Setup dialog: Configure tab,

Acquisition tab

3. Under Acquisition, select Use Fluidics.

4. Open the Fluidics tab.

Figure 2-5: Plate Acquisition Setup dialog, Configure tab:

Fluidics tab

36 5014166 D

Page 37

5. Click Configure Stations.

Fluidics Option Operations

Figure 2-6: Configure Fluidics Stations dialog

6. On the Configure Fluidics Stations dialog, for each Tip Tray,

select a Tip Type.

Note: The system comes pre-configured with settings for FLIPR

Tetra 96 and 384 tips.

7. For each Compound Plate, select a Plate Type.

Note: You can use only standard 96-well or 384-well plates for

fluidics.

5014166 D 37

Page 38

ImageXpress Micro High Content Imaging System Options User Guide

8. If applicable, for the Sample Plate, type a value for X, Y, and Z

offsets from the well center (in μm) for the sample plate.

Type a positive Z offset to have the pipettor sample higher than

normal. Type a negative Z offset to have the pipettor sample

lower than normal.

CAUTION! An incorrect X, Y, or Z offset can cause the pipette tip

to crash into the sample plate.

9. If applicable, select Track Volume, and then type a value for the

Initial Volume for Tracking (μl) for each plate.

10. Do one of the following:

If you selected Track Volume, then select Track Liquid

Surface, and then go to Step 11.

Optionally, select Track Volume, select Track Liquid Surface,

clear Track Volume, and then go to Step 11.

Otherwise, go to Step 13.

Note: The Track Liquid Surface feature is used in conjunction

with the Wet Dispense feature. If Track Liquid Surface is

selected, then wet dispensing is done near the liquid surface.

11. Click System Properties.

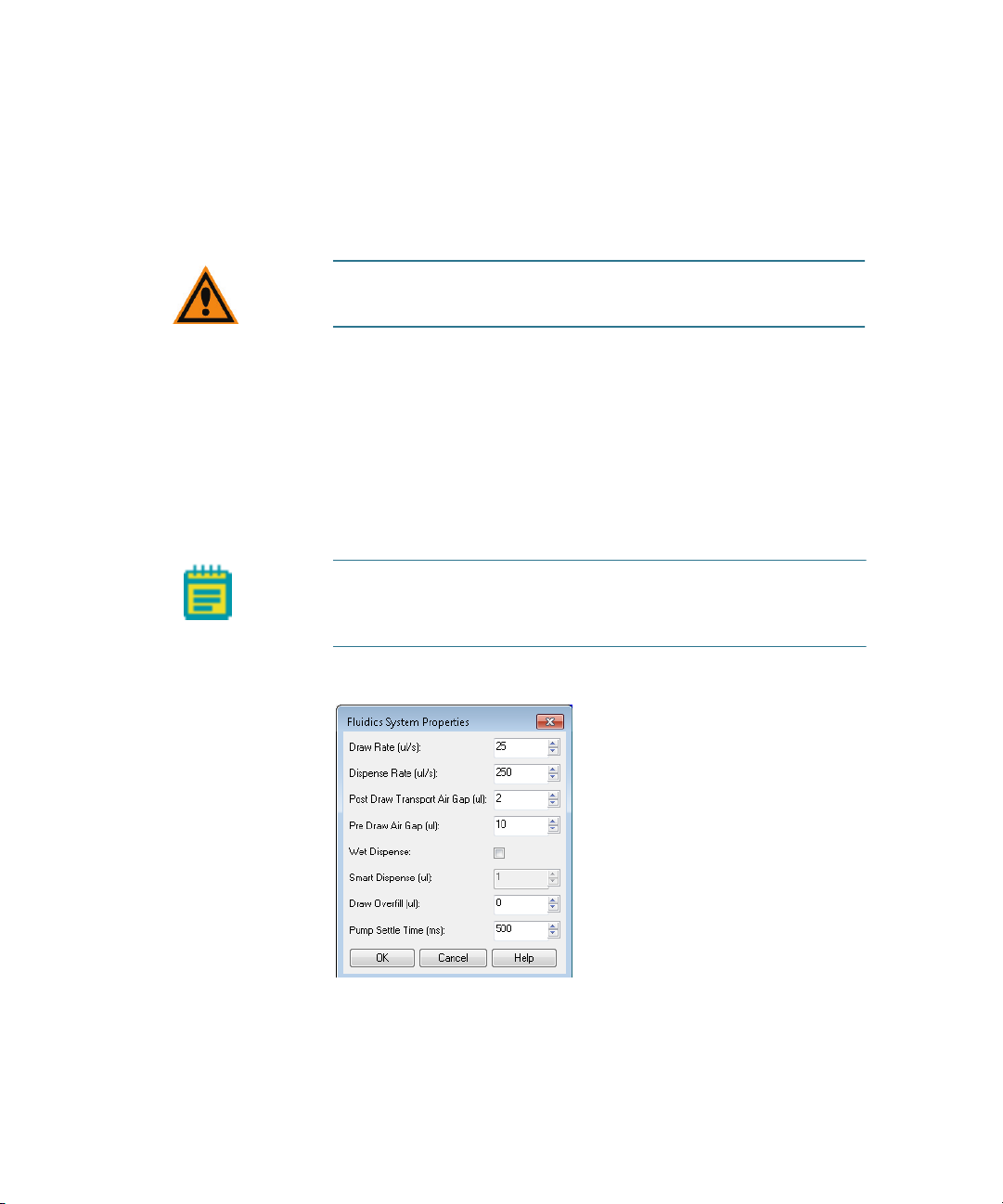

Figure 2-7: Fluidics System Properties dialog

38 5014166 D

Page 39

Fluidics Option Operations

12. On the Fluidics System Properties dialog, leave the default

values for the fluidic system properties set as-is, or modify any

values as needed.

Table 2-1: Fluidic Systems Property values

Option Description

Draw Rate (μl/s) The rate at which the pump draws fluid.

Dispense Rate (μl/s) The rate at which the pump dispenses fluid.

Post Draw Transport

Air Gap (μl)

Pre Draw Air Gap (μl) The volume of air that the pump draws

Wet Dispense Specifies whether the tip should be

Smart Dispense (μl) Enabled only if Wet Dispense is selected. The

Draw Overfill (μl) The volume of fluid that the pump draws in

Pump Settle Time (ms) The time delay that is used to pause

The volume of air that the pump draws after

it draws fluid but before the pump arm

moves. This air prevents fluid from dripping

during pump arm movement. Select this

option for fluids such as DMSO.

before drawing fluid. This is used to push

remaining drops of fluid out of the tip when

dispensing.

immersed in the fluid during dispense

operations at the imaging location. When

enabled, if Track Liquid Surface is also

selected. then dispensing occurs near the

liquid surface; otherwise, the dispensing

occurs near the bottom of the well.

volume that the pump dispenses beyond the

requested fluid dispense volume. The

additional volume is subtracted from the Pre

Draw Air Gap volume. The Smart Dispense

volume must be less than or equal to the Pre

Draw Air Gap volume.

addition to the requested volume of fluid.

You can use Draw Overfill to increase

dispense accuracy when drawing from

compound plates.

Note: Draw Overfill is not applicable for any

other plate type.

movement of the pump arm after a pump

draw or dispense operation to overcome

hysteresis. For most operations, 100 ms is

the recommended value.

5014166 D 39

Page 40

ImageXpress Micro High Content Imaging System Options User Guide

13. Click OK to close the Fluidics System Properties dialog and

return to the Configure Fluidics Stations dialog.

14. If applicable, click Define Tips and in the Define Tips dialog,

define additional tip types, and then click Save.

CAUTION! Improper tip definitions can cause the pipette tip to

crash into the sample plate. Molecular Devices recommends

that you do not make changes to the standard tip definitions.

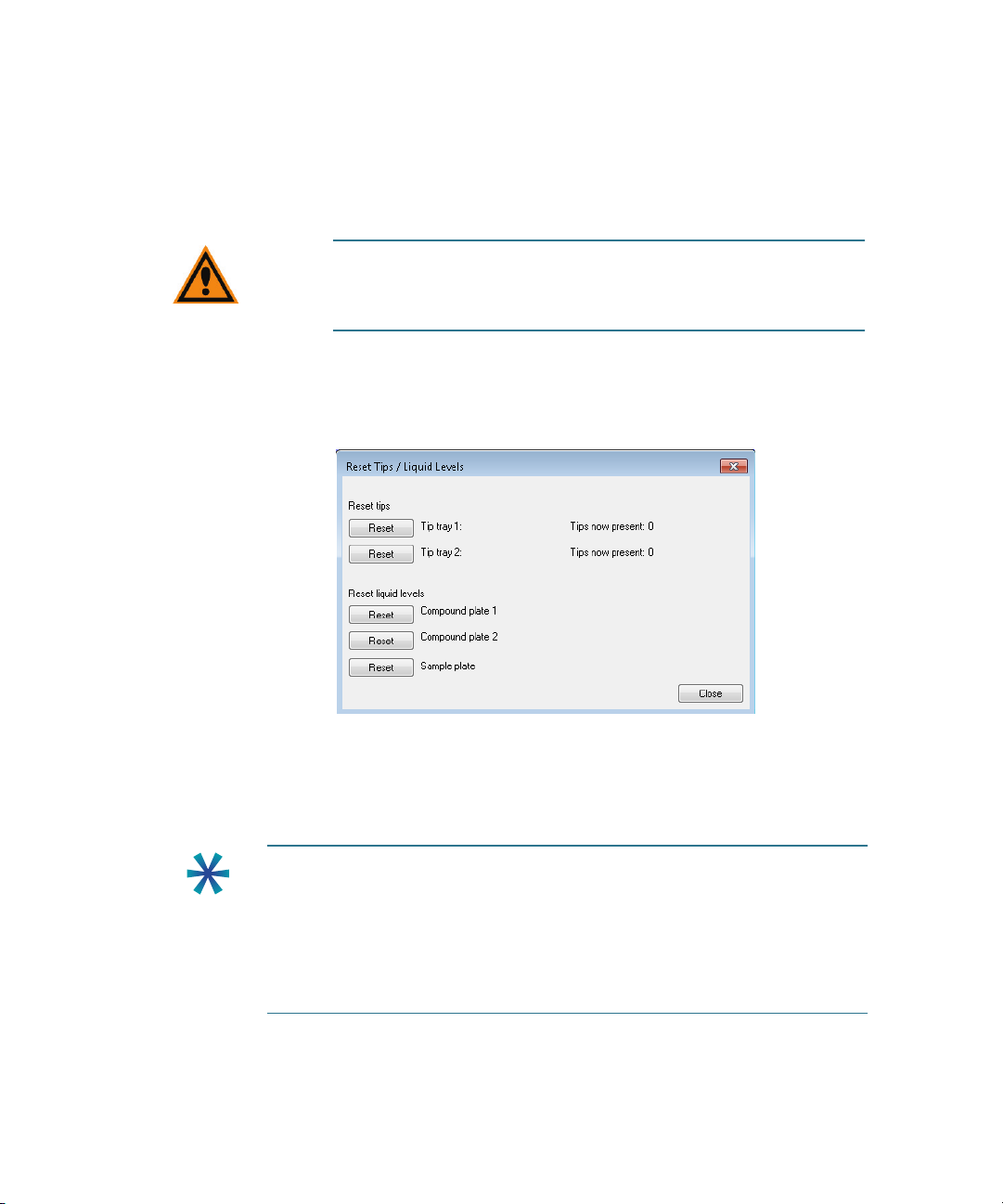

15. After you have completed a dispensing cycle, to indicate that you

have reloaded tip racks and plates, click Reset Tips, and on the

Reset Tips/Liquid Levels dialog, click Reset for the appropriate

tip trays and plates, and then click Close.

Figure 2-8: Reset Tips/Liquid Levels dialog

Manual Fluidics Control

Do the following procedure to control the fluidics station manually.

Tip: The fluidics interface enables you to transfer fluid from one well of

the compound plate to a corresponding well in the sample plate. If you

need to transfer fluid between non-corresponding wells, or if different

actions need to be performed for different wells, record these actions in

a journal (custom routine) to accomplish this. See

a journal on page 42

experiment. See To configure a fluidics experiment on page 43.

40 5014166 D

. You can add journals as events when you run an

To record the steps in

Page 41

Fluidics Option Operations

To control fluidics manually

1. In the MetaXpress software, click Devices > Fluidic Control.

In the simplified menu, click Control > ImageXpress > Fluidic

Control.

2. In the Fluidic Control dialog, specify the action you would like to

do. You can manually pick up and eject tips, draw and dispense

fluid, and mix.

For example, to remove 20 μl from well A01 in the compound

plate and add it to the sample plate, specify the following:

Action: Draw

Station: Compound Plate 1

Row: A

Column: 1

Volume (μl): 20

3. Click Go.

The fluid is drawn from the plate.

4. In the Action list, click Dispense, and then click Go to add the

fluid to the plate.

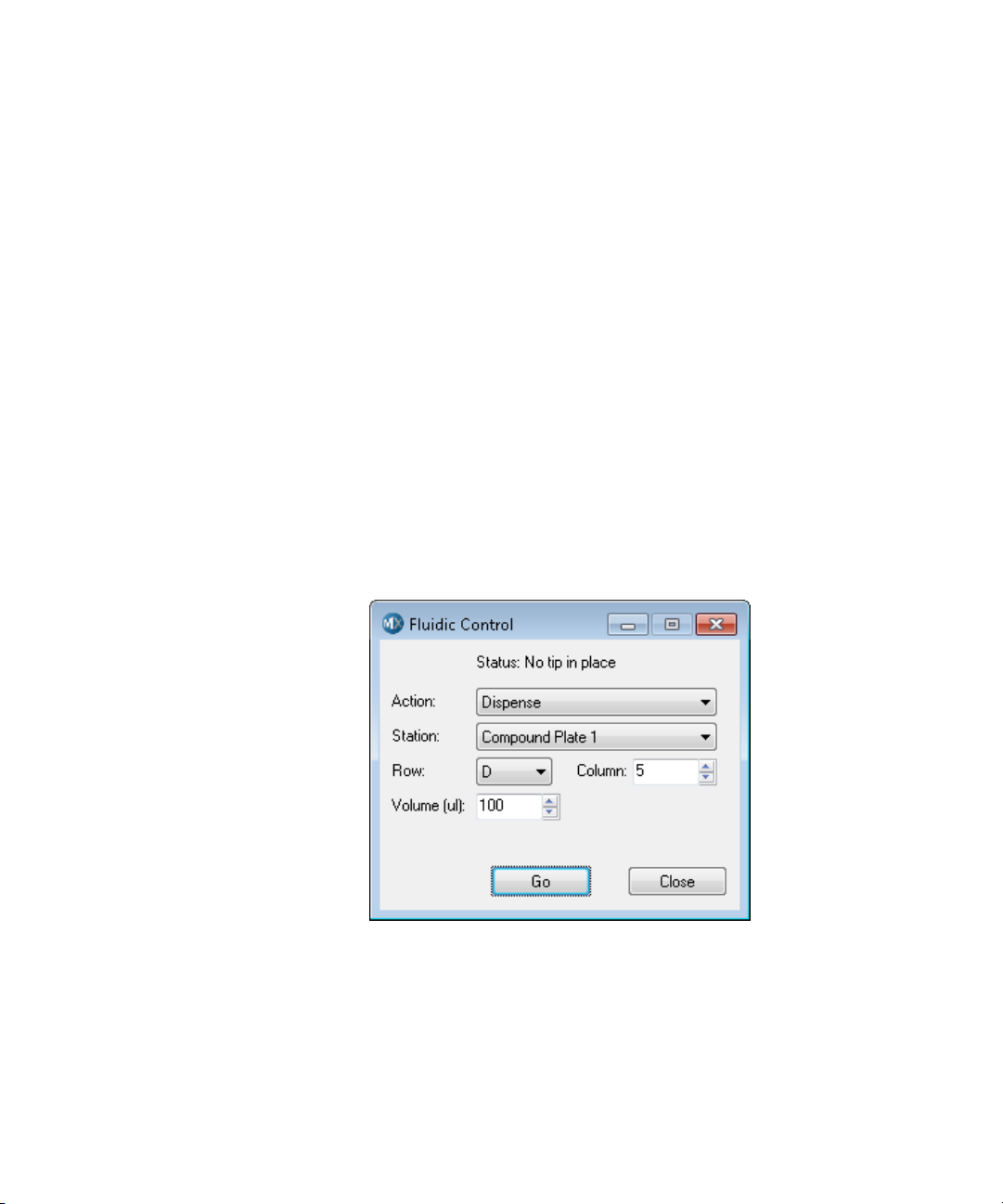

Figure 2-9: Fluidic Control dialog

5014166 D 41

Page 42

ImageXpress Micro High Content Imaging System Options User Guide

To record the steps in a journal

1. In the MetaXpress software, on the Journal menu, click Start

recording.

2. Do the steps that you want to record. See

manually on page 41.

3. Click Journal > Stop recording, and then save the journal file.

4. To modify the journal, click Journal > Edit Journal, and then

select the journal to be edited. See

To control fluidics

Figure 2-10 on page 42.

Figure 2-10: Example Journal using manual fluidics control

42 5014166 D

Page 43

Doing Fluidics Experiments

Fluidics experiments are defined by adding events to the Scheduled

Events list. You can add three types of events: Compound Addition,

Washout, and Journal. Fluidics events can be performed on all wells

being imaged, or on a subset of wells. For example, you can add different

amounts of compound to different wells, or treat wells for different

amounts of time.

Do the following procedure to configure a fluidics experiment.

To configure a fluidics experiment

1. In the MetaXpress software, click Screening > Plate Acquisition

Setup.

2. On the Plate Acquisition Setup dialog, on the Configure tab,

open the Acquisition tab.

Fluidics Option Operations

Figure 2-11: Plate Acquisition Setup dialog: Configure tab,

Acquisition tab

3. Under Configure, click Fluidics to schedule fluidics events. See

Figure 2-12.

5014166 D 43

Page 44

ImageXpress Micro High Content Imaging System Options User Guide

Figure 2-12: Adding events to a fluidics experiment

4. Click Add new Event to add an event to the Scheduled Events

field.

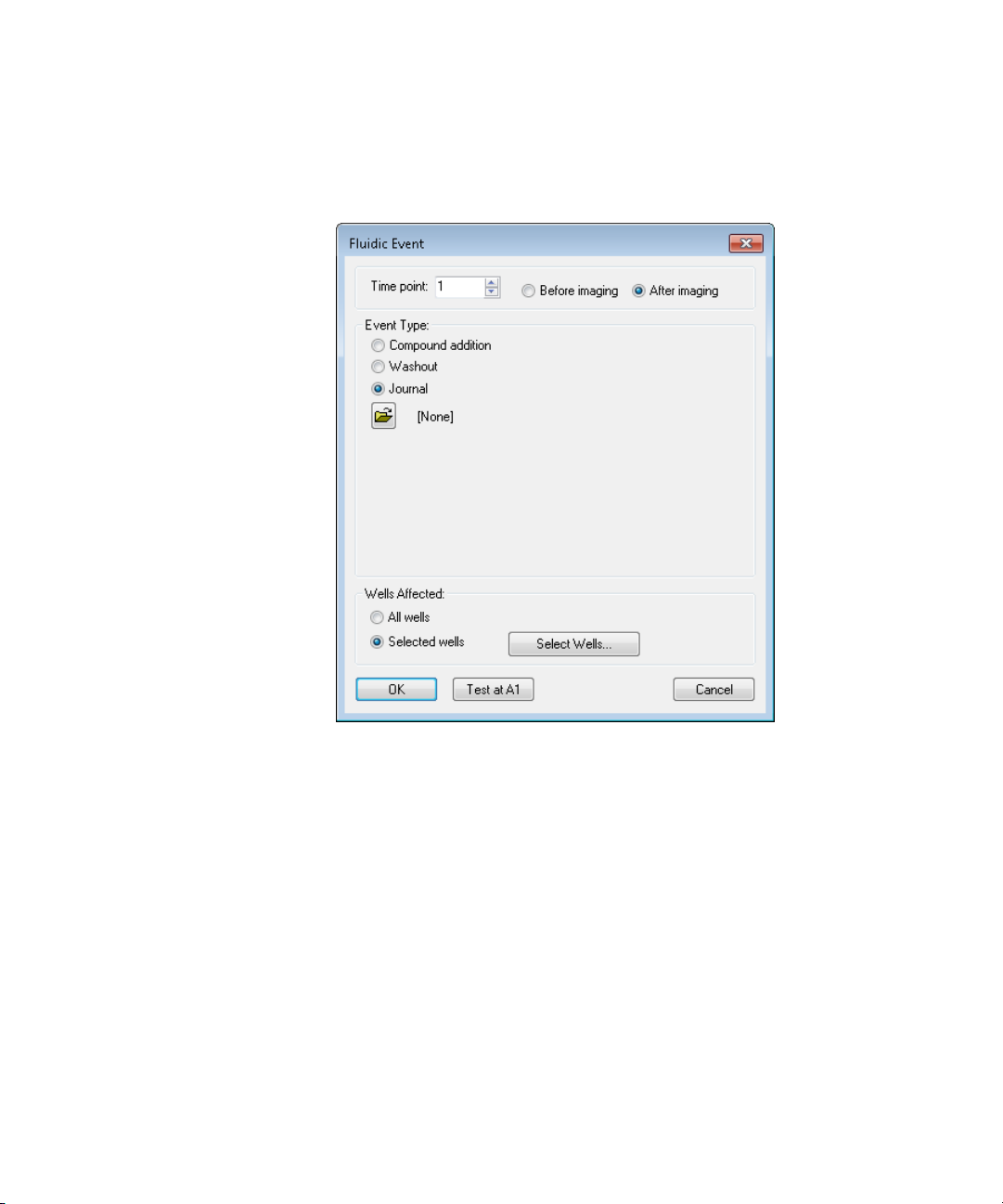

5. In the Fluidic Event dialog, specify the time point at which you

want the event to occur, and then specify whether the event

should occur before or after the time point. See Figure 2-13.

44 5014166 D

Page 45

Fluidics Option Operations

Figure 2-13: Time point setting in Fluidic Event dialog

For example, if you select time point 5 and select Before

imaging, then the fluidic event occurs before the time point. If

you select After imaging, then the fluidic event occurs after the

time point. See

Time point 12345N

Figure 2-14 on page 45.

Event occurs before time point

Before imaging

Event occurs after time point

After imaging

Figure 2-14: Setting events to occur before and after a time

point

Note: The number of time points is set on the Timelapse tab.

See Doing Timelapse Experiments on page 23.

5014166 D 45

Page 46

ImageXpress Micro High Content Imaging System Options User Guide

6. In the Fluidic Event dialog, select the event type and its

properties. Event types include:

Compound addition: A Compound addition event, shown in

Figure 2-15 on page 46, draws liquid from the compound

plate and adds it to the sample plate. There is a one-to-one

mapping between the wells on the compound plate and the

sample plate. That is, compound is removed from a well on

the compound plate and applied to the well in the same

position on the sample plate (for example, A1 to A1, A2 to

A2). When you are running mixes that consist of more than a

single cycle, Mix Dead Volume specifies an amount of fluid

that is to remain in the tip and not to be returned to the well

during intermediate repeated cycles of draws and dispense.

For more information about compound addition settings,

see the MetaXpress Software application help (press F1

while viewing the dialog).

Figure 2-15: Fluidic Event dialog Compound addition event

46 5014166 D

Page 47

Fluidics Option Operations

Washout: A Washout event removes liquid from the sample

plate and replaces it with liquid from the compound plate.

There is a one-to-one mapping between the wells as shown

in Figure 2-16.

An exchange consists of a washout event in which fluid is

removed from the sample plate and discarded, and fresh

media or fluid is placed in the well. If you want the system to

discard the old tip after removing and discarding the fluid

from the sample plate, select New tip each exchange. For

more information, see the software Help (press F1 while

viewing the dialog).

Figure 2-16: Fluidic Event dialog Washout Event

5014166 D 47

Page 48

ImageXpress Micro High Content Imaging System Options User Guide

Journal: A Journal event is used for any special cases or

custom protocols (for example, experiments not using a oneto-one mapping of wells, or drawing once and dispensing

multiple times) as shown in Figure 2-17.

Figure 2-17: Fluidic Event dialog Journal event

7. Click OK.

48 5014166 D

Page 49

Preventing Evaporation from Compound Plates

Incubation at elevated temperatures, such as 37°C, causes rapid

evaporation of water from aqueous compound preparations in storage

plates. DMSO-based preparations are hygroscopic and absorb water from

the surrounding air. To minimize these problems, seal the compound

storage plates with aluminum foil seals before placing them in the

environmental chamber. Foil seals can be pierced during the experiment

by the pipette tips on the fluidics robot, only exposing individual wells

after use.

Seals generally adhere better to plates with raised rings around the wells

than to plates with a smooth surface. Evaporation is greater from the

outer wells of a microplate, both from micro-environmental variations,

and because of poorer adhesion at the outer edges of the seal. It might

be preferable to omit these wells from experiments with long incubation

periods. It is also useful to set up the fluidics plate configuration on an

equivalent, unsealed plate before trying to pipette from a sealed plate.

Evaluated Seals

Molecular Devices has evaluated both heat-applied and pressure-applied

seals with a variety of polypropylene and polystyrene plates. Two

examples are listed here. Other manufacturers might provide similar

performance.

Fluidics Option Operations

Heat-applied seals

Tomtec heat-applied aluminum foil seals

• Part numbers: Tomtec AutoSeal instrument (710-100) and foil

seal material (AS-3)

• For specifications, ordering information, pricing, and sealing

instructions, contact Tomtec (www.tomtec.com)

• Features

Automated robotic plate sealing

Suitable for polypropylene plates

Easily punctured by the fluidics robot using FLIPR Tetra

pipette tips

Compatible with DMSO

Easily peeled from the plate

5014166 D 49

Page 50

ImageXpress Micro High Content Imaging System Options User Guide

Pressure-applied seals

G&L Precision Die Cutting pressure-applied aluminum foil seals

• Part number: G&L Aluminum Microplate Liddings (GL-255)

• For specifications, ordering information, pricing, and sealing

instructions, contact G&L Precision (www.glprecision.com)

• Features

Manual plate sealing

Suitable for polypropylene and polystyrene plates

Easily punctured by the fluidics robot using FLIPR Tetra

pipette tips

Compatible with DMSO

50 5014166 D

Page 51

Environment Control and Fluidics Options Maintenance

It is important to regularly clean the environmental enclosure, including

specific fluidics and environmental components. Components can come

in contact with biological, chemical, and toxic agents. Therefore, all

cleaning procedures should be handled with care. Molecular Devices

recommends that you wear powder-free gloves at all times when you

access the internal components of the enclosure. For additional

information about cleaning the system, see the ImageXpress Micro

Widefield High Content Imaging System User Guide or the ImageXpress

Micro Confocal High Content Imaging System User Guide.

The following sections provide information on how to clean fluidics

components. If you have any further questions about specific cleaning

procedures, contact Technical Support. See

This chapter contains the following sections:

• Carbon Dioxide Tubing on page 52

• Cleaning the Water Reservoir on page 53

• Waste Disposal Box and Plate Sealing Ring on page 54

3

Obtaining Support on page 7.

CAUTION! Never use an autoclave to clean any instrument

components.

5014166 D 51

Page 52

ImageXpress Micro High Content Imaging System Options User Guide

Carbon Dioxide Tubing

The tubing within the environmental enclosure should be cleaned only if

moisture has collected in the tubing or visual inspection of the tubing

suggests contamination. There are two tubing sections associated with

carbon dioxide delivery. One runs from the carbon dioxide controller

located outside the enclosure to the water reservoir within the

enclosure, and the other one exits the water reservoir and delivers the

carbon dioxide to the stage (plate) area.

Do not let the second stretch of tubing leaving the water reservoir to the

stage area come into contact with the water in the reservoir. When

replacing or cleaning tubing, make sure that the exit tubing from the

reservoir is well above the water’s surface. If at any time, you can see

moisture within the tubing, disconnect both ends and use compressed

air to dry the inside of the tubing. Make sure that you reconnect all

tubing.

The tubing that runs from the carbon dioxide controller to the enclosure

has an in-line filter installed near the end closest to the controller. When

reconnecting this tubing make sure that the in-line filter is in the correct

position.

To clean any portion of the tubing

1. Note how the tubing is connected, and then disconnect the

portion of the tubing that is contaminated and remove it from

the environmental enclosure.

2. Use 70% isopropanol to flush the interior of the tubing.

3. Use compressed air to dry the interior of the tubing.

4. Reconnect the tubing within the environmental enclosure,

making sure all connections are tight.

5. Confirm that carbon dioxide is being delivered to the water

reservoir by visually confirming that bubbles move through the

reservoir. See

Setting Up the Carbon Dioxide on page 17.

52 5014166 D

Page 53

Cleaning the Water Reservoir

Air supplied to the environmental enclosure flows through the water

reservoir, ensuring the air has a high degree of humidity.

To clean the water reservoir

Required tool: Phillips screwdriver

1. In the MetaXpress software, click Screening > Plate acquisition

and Control > Eject Plate to open the top door of the instrument.

2. Exit the MetaXpress Software and turn off the ImageXpress

Micro instrument at the main power switch, which is located on

the instrument's external power supply.

3. Remove the insert surrounding the top door, and open or

remove the side panel.

4. Disconnect the air tubing and the sensors from the water

reservoir.

5. Remove the reservoir from the instrument.

6. Using a Phillips screwdriver, remove the screws securing the

reservoir lid to the instrument.

7. Dispose of the water, and then rinse the reservoir with 70%

ethanol.

8. Replace the lid, tighten the screws, and then place the reservoir

back in the instrument.

9. Fill the reservoir with deionized water to the fill line. See

Up the Water Reservoir on page 15.

10. Reconnect the air tubing and sensors to the water reservoir.

11. Replace the insert surrounding the top door, close or replace the

side panel, and close the top door of the instrument.

Environment Control and Fluidics Options Maintenance

Setting

5014166 D 53

Page 54

ImageXpress Micro High Content Imaging System Options User Guide

Waste Disposal Box and Plate Sealing Ring

Proper cleaning of the waste disposal box and the plate sealing ring is

highly dependent on the type of waste being disposed of and whether

the box is being used with a protective liner. These components can

come into direct contact with unlidded sample plates, compounds, and

media. Therefore, Molecular Devices strongly recommends that you

regularly clean between experiments. Clean both components by first

removing them from the environmental enclosure, and then using one of

the following cleaning techniques depending on the severity of

contamination of the box:

• Damp wipe followed by a disinfectant wipe (70% ethanol)

• Exposure to UV by placement within a tissue culture hood

54 5014166 D

Page 55

Transmitted Light Option Operations

The ImageXpress® Transmitted Light option is designed for phasecontrast transmitted-light imaging. In general terms, transmitted light is

used to describe microscopy in which light is transmitted from a source

on one side of the specimen, with the objective on the other side.

Typically the light is first passed through a condenser so high illumination

is focused on the specimen. For more information on phase contrast

microscopy, visit the Nikon website:

www.microscopyu.com/articles/phasecontrast/phasemicroscopy.html

The ImageXpress Transmitted Light option can be installed with or

without the Environment Control option. It is not compatible with the

Fluidics option.

See Also:

• Environment Control Option Operations on page 9

This chapter contains the following sections:

• Transmitted Light Hardware on page 56

• Transmitted Light Software Configuration on page 59

• Transmitted Light Phase Ring Alignment on page 61

4

5014166 D 55

Page 56

ImageXpress Micro High Content Imaging System Options User Guide

Transmitted Light Hardware

The ImageXpress Transmitted Light option consists of the following

hardware components.

• Nikon phase optics. Allows either phase contrast or brightfield

imaging. See Figure 4-1 on page 57 and Figure 4-2 on page 57.

• Phase contrast objectives. Must be selected for phase contrast

imaging.

• White light lamp (halogen). The software controls the lamp

power.

The halogen lamp has a limited life and can be replaced. For

instructions see the following knowledge base article:

http://mdc.custhelp.com/app/answers/detail/a_id/19101/

• Transmitted Light shutter. Controlled by the software. The

shutter protects the sample from the transmitted light when not

imaging. The shutter window maintains the environment of the

sample. See Figure 4-3 on page 58.

• Flip-in Lens. Enables phase ring alignment for the ImageXpress

Micro Standard, XL, and XLS Systems. See Transmitted Light

Phase Ring Alignment on page 61.

On the ImageXpress Micro Confocal System, the phase ring

alignment lens is in the emission filter wheel and is placed in

position using the software.

• Hinge. Allows robotic access to the plate if necessary. See

Figure 4-4 on page 58.

• ImageXpress Micro Transmitted Light Option Controller or the

ImageXpress Micro Systems Power & Options Controller. Used

to turn the option on and off. It is shared with the Environment

Control option when both options are installed. See Figure 1-1

on page 11 and Figure 1-2 on page 11.

56 5014166 D

Page 57

Transmitted Light Option Operations

Figure 4-1: ImageXpress Micro Standard System with the Transmitted

Light option

Figure 4-2: ImageXpress Micro Standard System with Transmitted Light

option (detailed view)

5014166 D 57

Page 58

ImageXpress Micro High Content Imaging System Options User Guide

Figure 4-3: Transmitted Light shutter

1

2

4

3

Figure 4-4: Hinge-release knob and hinge

Item Description

1 Hinge-release knob

2 Hinge

3 Hinge-release knob

4 Assembly tipped back with hinge-release knob unscrewed

58 5014166 D

Page 59

Transmitted Light Software Configuration

You can create illumination settings to turn the lamp on and off. Do the

following procedure to create illumination settings named Transmitted

Lamp Off and Transmitted Light, and to set a level for the lamp

illumination.

Tip: Do not turn the transmitted light on and off or adjust the lamp

power during acquisition. Doing so takes a considerable amount of time

and can possibly damage the lamp.

To configure transmitted light settings in the MetaXpress software

1. In the MetaXpress software, click Devices > Configure

Illumination.

In the simplified menu structure, click Control > Devices >

Configure Illumination.

Transmitted Light Option Operations

Figure 4-5: Configure Illumination dialog: Lamp On

5014166 D 59

Page 60

ImageXpress Micro High Content Imaging System Options User Guide

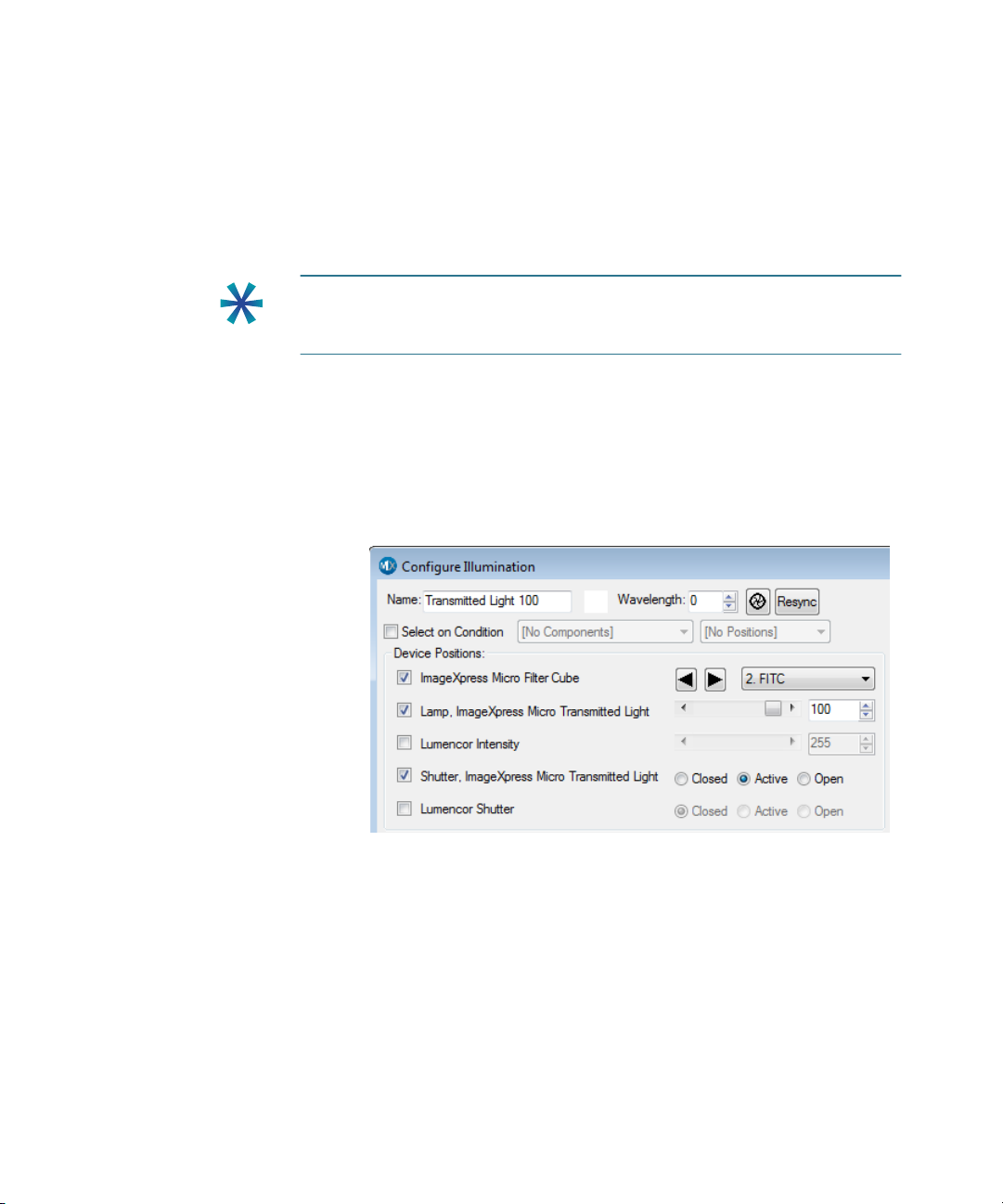

2. In the Configure Illumination dialog, create an illumination

setting named Transmitted Lamp Off, select Lamp, ImageXpress

Micro Transmitted Light, and set the lamp illumination to zero,

as shown in Figure 4-6.

Figure 4-6: Configure Illumination dialog: Transmitted Lamp Off

3. Create an illumination setting named Transmitted Light, select

Lamp, ImageXpress Micro Transmitted Light, and set lamp

illumination as a percentage of full power, as shown in

Figure 4-7.

The example sets the lamp power to 20% of maximum. You can

adjust this setting to meet the requirements of your experiment.

Figure 4-7: Configure Illumination dialog: Transmitted Light

After the settings have been configured, Transmitted Light can be

selected as a wavelength in the Plate Acquisition Setup dialog.

60 5014166 D

Page 61

Transmitted Light Phase Ring Alignment

The FSE (Field Service Engineer) performs phase ring alignment when

installing the ImageXpress Transmitted Light option. After the phase ring

is aligned, the microscope generally holds its position for some objective

changes. However, the alignment should be checked periodically, or

when you see degradation of phase contrast image quality.

Phase ring alignment requires a special lens to be placed in position

before starting the phase ring adjustment procedure.

• On the ImageXpress Micro Standard and XL Systems, the optics

cover is removed and the flip-in lens is manually placed in

position for the phase ring adjustment. See To use the flip-in lens

on the ImageXpress Micro Standard and XL Systems on page 61.

• On the ImageXpress Micro XLS System, the flip-in lens is

manually placed in position for the phase ring adjustment

without removing the optics cover. See To use the flip-in lens on

the ImageXpress Micro XLS System on page 63.

• On the ImageXpress Micro Confocal System, the phase ring

adjustment lens is placed in position for the phase ring

adjustment using the Meta Imaging Series Administrator

Software. See To use the phase ring adjustment lens on the

ImageXpress Micro Confocal System on page 65.

Transmitted Light Option Operations

To use the flip-in lens on the ImageXpress Micro Standard and XL Systems

CAUTION! Wear gloves, and do not touch, move, or otherwise damage

the mirror to the right of the flip-in lens.

1. Power off the instrument.

2. Use a Phillips screwdriver to remove both of the left side panels

of the instrument.

3. Use a 1/16 inch hex key to remove the black optics cover over the

lens.

5014166 D 61

Page 62

ImageXpress Micro High Content Imaging System Options User Guide

4. Move the flip-in lens into place for the alignment procedure.

The flip-in lens must be out of the way for any actual imaging.

Figure 4-8: Flip-in lens on the ImageXpress Micro Standard and

XLS Systems

5. Power on the instrument.

6. Adjust the phase ring. See

To align the phase ring on page 67.

7. After the phase ring has been adjusted, power off the

instrument.

8. Move the flip-in lens out of the optical path.

9. Use a 1/16 inch hex key to install the black optics cover over the

lens.

10. Use a Phillips screwdriver to install both of the left side panels on

the instrument.

62 5014166 D

Page 63

Transmitted Light Option Operations

To use the flip-in lens on the ImageXpress Micro XLS System

1. Power off the instrument.

2. Use a Phillips screwdriver to remove both of the left side panels

of the instrument to access the flip-in lens mounted on the

outside of the optics cover.

Figure 4-9: Flip-in lens on the ImageXpress Micro XLS System

3. Remove the two thumbscrews and their washers from the flip-in

lens mounting plate.

There is a flat washer and a split-ring washer on each

thumbscrew on the flip-in lens assembly.

Figure 4-10: Thumbscrew and washers

4. Remove the flip-in lens assembly from the instrument.

5. Remove the protective cloth bag from the flip-in lens.

6. Move the flip-in lens into it fully extended position.

5014166 D 63

Page 64

ImageXpress Micro High Content Imaging System Options User Guide

Figure 4-11: Flip-in lens extended for phase ring alignment

7. Slide the flip-in lens assembly onto the optics cover with the

flip-in lens on the inside for the phase ring alignment.

8. Install the washers and tighten the thumbscrews to hold the

flip-in lens assembly in position for phase ring alignment.

9. Adjust the phase ring. See

To align the phase ring on page 67.

10. After the phase ring has been adjusted, power off the

instrument.

11. Remove the two thumbscrews and their washers from the flip-in

lens mounting plate.

12. Remove the flip-in lens assembly from the instrument.

13. Move the flip-in lens into it fully closed position.

14. Cover the flip-in lens with the protective cloth bag.

15. Mount the flip-in lens assembly on the optics cover with the

closed and covered flip-in lens on the outside.

16. Install the washers and tighten the thumbscrews.

17. Use a Phillips screwdriver to install both of the left side panels on

the instrument.

64 5014166 D

Page 65

Transmitted Light Option Operations

To use the phase ring adjustment lens on the ImageXpress Micro Confocal System

1. Exit the MetaXpress Software if it is running.

2. Click Start > Programs > MetaXpress and then right-click Meta

Imaging Series Administrator and select Run as administrator to

start the MetaXpress Meta Imaging Series Administrator

software.

3. Click Configure Hardware.

4. In the Configure Hardware dialog, select the correct hardware

configuration, and then click Configure Devices.

5. In the right pane of the User Settings for hardware configuration

dialog, click IXConfocal Module Emission Wheel, and then click

Settings.

Figure 4-12: User Setting Selection of IXConfocal Module

Emission Wheel Settings

5014166 D 65

Page 66

ImageXpress Micro High Content Imaging System Options User Guide

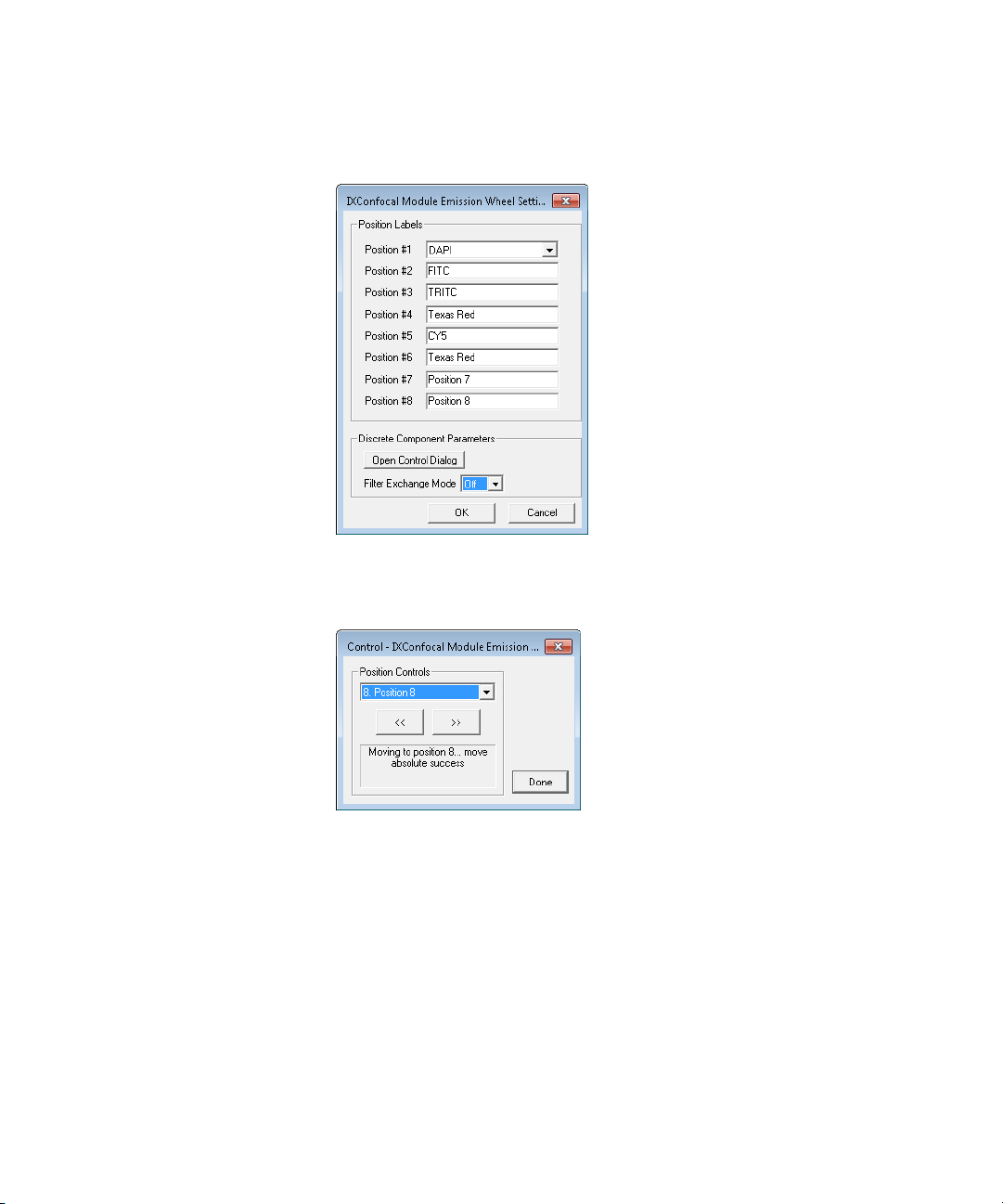

6. In the IXConfocal Module Emission Wheel Settings dialog, set

the Filter Exchange Mode to Off.

Figure 4-13: The IXConfocal Module Emission Wheel Settings

dialog

7. Click Open Control Dialog.

Figure 4-14: IXConfocal Module Emission Wheel Control dialog

8. From the Position Controls, select the numbered position for the

phase ring adjustment lens.

By default, the phase ring adjustment lens is installed in

position 8.

9. After the wheel moves to the selected position, click Done.

10. Close all open dialogs and exit the MetaXpress Meta Imaging

Series Administrator software.

66 5014166 D

Page 67

Transmitted Light Option Operations

To align the phase ring

Note: For the ImageXpress Micro Confocal System, make sure that the

instrument is in widefield mode before aligning the phase ring.

1. Make sure that the phase ring adjustment lens is in place.

On the ImageXpress Micro Standard and XL Systems, the

optics cover is removed and the flip-in lens is manually

placed in position for the phase ring adjustment. See

the flip-in lens on the ImageXpress Micro Standard and XL

Systems on page 61.

On the ImageXpress Micro XLS System, the flip-in lens is

manually placed in position for the phase ring adjustment

without removing the optics cover. See To use the flip-in lens

on the ImageXpress Micro XLS System on page 63.

On the ImageXpress Micro Confocal System, the phase ring

adjustment lens is placed in position for the phase ring

adjustment using the Meta Imaging Series Administrator

Software. See To use the phase ring adjustment lens on the

ImageXpress Micro Confocal System on page 65.

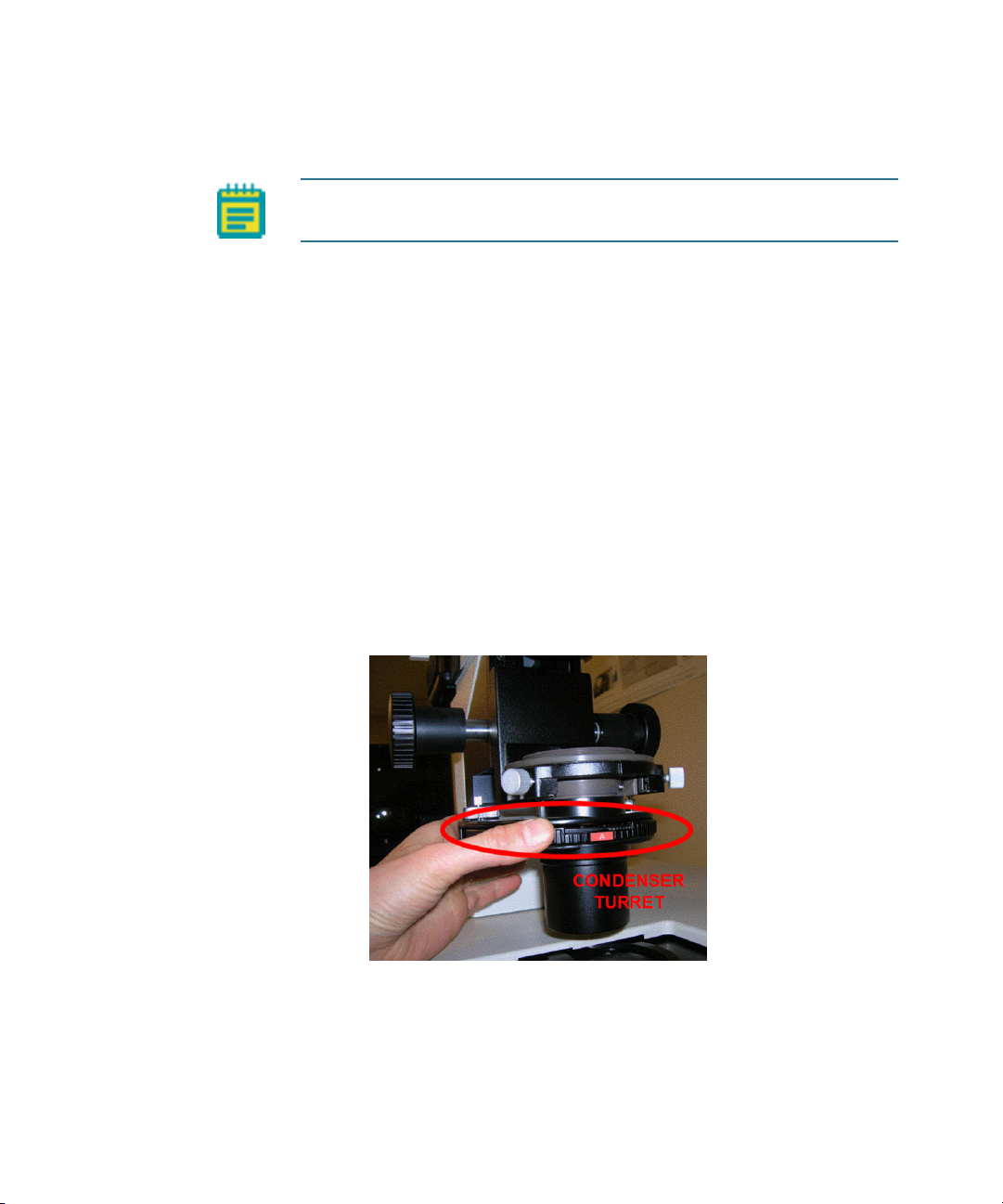

2. Rotate the condenser turret so that the A position is selected (at

the front).

To use

Figure 4-15: Condenser turret with position A at the front

5014166 D 67

Page 68

ImageXpress Micro High Content Imaging System Options User Guide

3. Turn the adjustment ring, which is located below the arm of the

Transmitted Light tower, to the middle of the aperture range.

1

2

Figure 4-16: Aperture stop position for phase ring alignment

Item Description

1 Label indicating aperture range

2 Adjustment ring

68 5014166 D

Page 69

Transmitted Light Option Operations

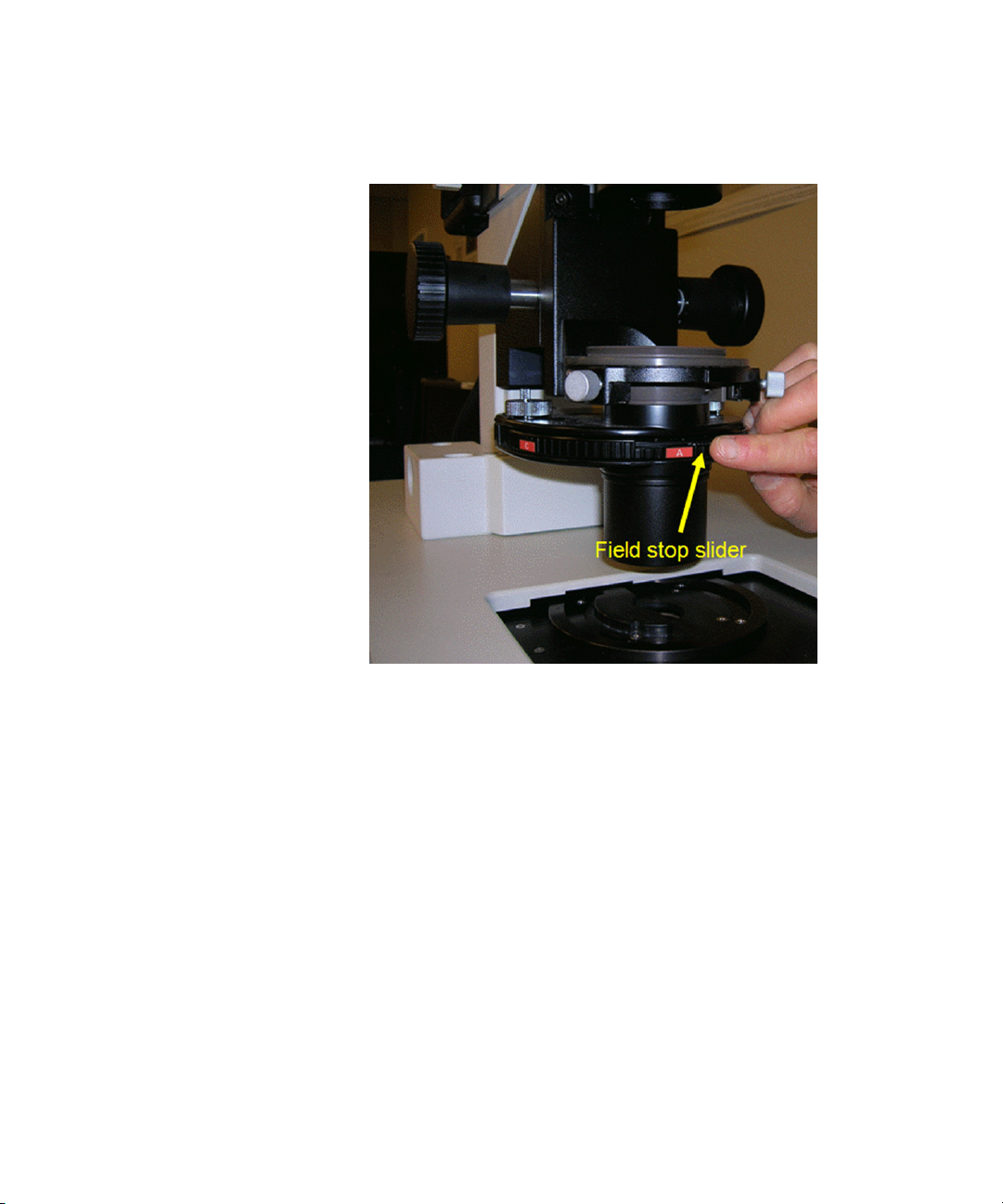

4. Move the field-stop slider, located just above the A label on the

condenser turret, all the way to the right.

Figure 4-17: Field stop slider

5. Select the diffusion filter, or place some lens paper or lint-free

wipes on top of the condenser lens to serve as a diffuser. If

necessary, weigh them down slightly to keep them from blowing

away.

6. In the MetaXpress software, select the desired phase contrast

objective.

7. Set the focus (Z position) to approximately 8000 μm.

If necessary, you can adjust this later.

8. Select the Transmitted Light illumination setting.

9. With no sample present, snap an image.

10. If necessary, adjust the illuminator level and the exposure time

to obtain a visible but not saturated image. The image of the

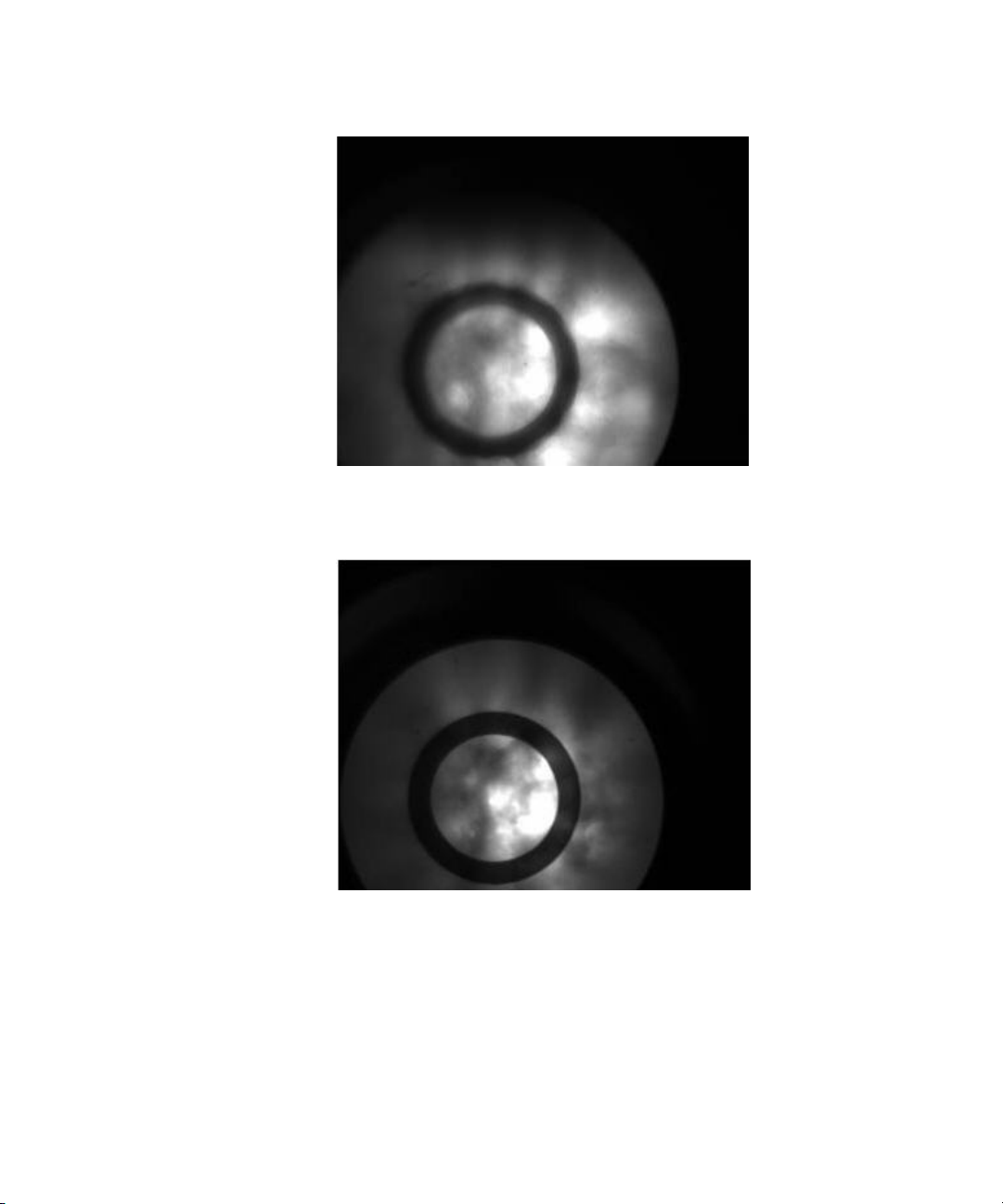

phase ring might be off-center. See

Figure 4-18. This is

acceptable as long as most of the image is visible.

5014166 D 69

Page 70

ImageXpress Micro High Content Imaging System Options User Guide

Figure 4-18: Out-of-focus image of phase contrast ring

11. Adjust the position of the Z-stage to obtain a reasonably sharp

image of the objective phase ring.

Figure 4-19: In-focus image of phase contrast ring

70 5014166 D

Page 71

Transmitted Light Option Operations

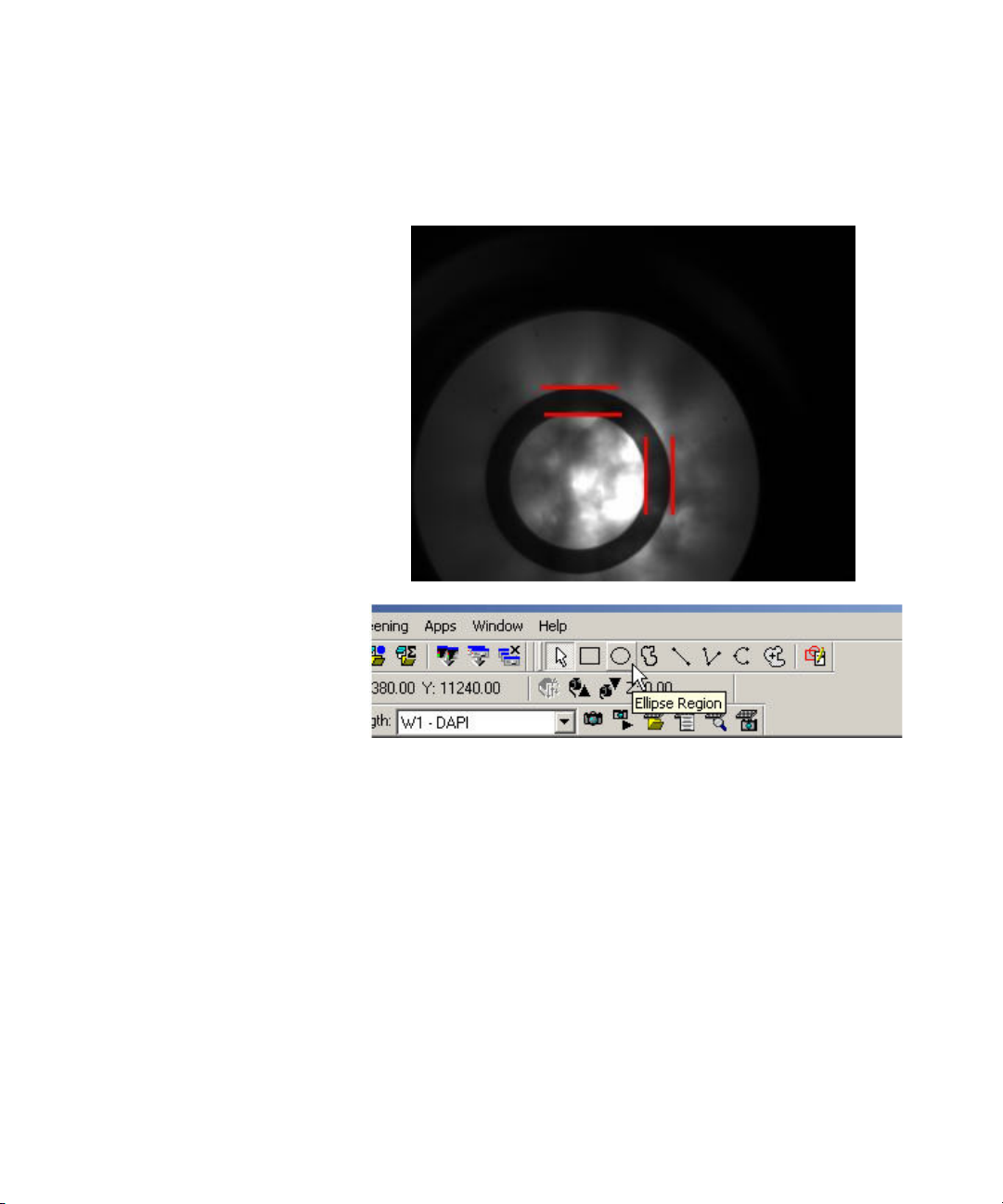

12. Use the region tools in the MetaXpress software to mark the

position of the phase ring. Make sure that you capture both

horizontal and vertical axes. Use either the ellipse region tool or

multiple line tools. See Figure 4-20.

Figure 4-20: Marking the position of the phase ring

13. In the MetaXpress software, click Regions > Save Regions to save

the marked positions.

14. Manually rotate the condenser turret to the appropriate annulus

for the objective (PhL for 4x, Ph1 for 10x and 20x, Ph2 for 40x).

The selected annulus is at the front of the condenser turret.

Phase contrast objectives typically have their specifications

indicated in green letters on the outer barrel. These

specifications also include the matching annulus designation (for

example, PhL, Ph1, Ph2).

5014166 D 71

Page 72

ImageXpress Micro High Content Imaging System Options User Guide

15. Snap an image.

The condenser annulus ring shows. See

need to adjust the exposure time.

Figure 4-21: Image of condenser annulus ring

Figure 4-21. You might

16. In the MetaXpress software, click Live Mode in either the

Acquire or Plate Acquisition and Control dialog.

17. Click Regions > Load Regions to load in the saved regions.

18. Using the condenser annulus centering knobs located on the

right top and left top surface of the condenser turret, center the

condenser annulus ring with the objective phase ring. See

Figure 4-22.

72 5014166 D

Page 73

Transmitted Light Option Operations

19. Lock down the annulus centering knobs.

Figure 4-22: Centering the condenser annulus ring with the

objective phase ring

20. Adjust the height of the Transmitted Light condenser with the

condenser height adjustment knob until a sharp image is

obtained. If required, adjust the lamp power or exposure level.

21. In the MetaXpress software, click Stop Live.

22. For the ImageXpress Micro Standard, XL, or XLS Systems, move

the flip-in lens out of the optical path.

For the ImageXpress Micro Standard and XL Systems, see To

use the flip-in lens on the ImageXpress Micro Standard and

XL Systems on page 61.

For the ImageXpress Micro XLS System, see To use the flip-in

lens on the ImageXpress Micro XLS System on page 63.

For the ImageXpress Micro XLS System, the lens used for phase

ring adjustment automatically moves out of the optical path