FLIPR® Tetra

High Throughput Cellular Screening System

User Guide

0112-0109 H

December 2011

This document is provided to customers who have purchased Molecular Devices, LLC

(“Molecular Devices”) equipment, software, reagents, and consumables to use in the

operation of such Molecular Devices equipment, software, reagents, and

consumables. This document is copyright protected and any reproduction of this

document, in whole or any part, is strictly prohibited, except as Molecular Devices

may authorize in writing.

Software that may be described in this document is furnished under a license

agreement. It is against the law to copy, modify, or distribute the software on any

medium, except as specifically allowed in the license agreement. Furthermore, the

license agreement may prohibit the software from being disassembled, reverse

engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only

to designate those manufacturers’ products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers’ and/or their product names as

trademarks.

Molecular Devices makes no warranties or representations as to the fitness of this

equipment for any particular purpose and assumes no responsibility or contingent

liability, including indirect or consequential damages, for any use to which the

purchaser may put the equipment described herein, or for any adverse circumstances

arising therefrom.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their

respective owners. These trademarks may not be used in any type of promotion or

advertising without the prior written permission of Molecular Devices, Inc.

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

© 2011 Molecular Devices, LLC.

All rights reserved.

Contents

Chapter 1: System Overview . . . . . . . . . . . . . . . . . . . . . 13

Fluorescence Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Luminescence Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Minimum Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2: System Hardware Features . . . . . . . . . . . . . 17

Overview of FLIPR Tetra System Hardware Features . . . . 17

System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Plate-Handling System . . . . . . . . . . . . . . . . . . . . . . . . . 18

Five-Position Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Instrument Status Panel . . . . . . . . . . . . . . . . . . . . . . . 21

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Robotic Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Observation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Liquid-Handling System . . . . . . . . . . . . . . . . . . . . . . . . 25

Standard Pipettor Head. . . . . . . . . . . . . . . . . . . . . . . . 25

Cell Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pin Tool Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Compatible Plate Configurations. . . . . . . . . . . . . . . . . . 30

Tip and Pin Tool Loading . . . . . . . . . . . . . . . . . . . . . . . 31

Tip and Pin Tool Washing . . . . . . . . . . . . . . . . . . . . . . 31

Optical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CCD Camera Options . . . . . . . . . . . . . . . . . . . . . . . . . 33

LED Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Emission Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Computer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Host Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Embedded Computer . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 3: Startup and Shutdown . . . . . . . . . . . . . . . . . 41

0112-0109 H 3

Contents

Starting Up the System . . . . . . . . . . . . . . . . . . . . . . . . . 41

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 4: Software Installation . . . . . . . . . . . . . . . . . . 43

Installing ScreenWorks Software . . . . . . . . . . . . . . . . . . 43

Activating the ScreenWorks Peak Pro License. . . . . . . . . . 44

Online vs. Offline Installation . . . . . . . . . . . . . . . . . . . . . 45

Online (Instrument) Mode . . . . . . . . . . . . . . . . . . . . . . 45

Offline (Desktop) Mode . . . . . . . . . . . . . . . . . . . . . . . . 46

Uninstalling ScreenWorks Software. . . . . . . . . . . . . . . . . 46

Chapter 5: ScreenWorks Software Overview . . . . . . . . . 47

ScreenWorks Software Main Screen . . . . . . . . . . . . . . . . 47

Title Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

File Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Instrument Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Window Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Instrument Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Instrument Status Tab . . . . . . . . . . . . . . . . . . . . . . . . 66

Instrument Configuration Tab . . . . . . . . . . . . . . . . . . . 68

Process Explorer Tab. . . . . . . . . . . . . . . . . . . . . . . . . . 69

Experiment Window . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Constructing Protocols Using FLIPR Tetra Processes . . . . 70

Settings Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Setup Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Assign Plate to Position . . . . . . . . . . . . . . . . . . . . . . . . 74

Data File Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Temperature Control. . . . . . . . . . . . . . . . . . . . . . . . . . 77

Auto Print Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Analysis Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Analyzing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Exporting Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Batch Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Image Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Transfer Fluid Process . . . . . . . . . . . . . . . . . . . . . . . . 108

Aspirate Table (Standard Pipettor) . . . . . . . . . . . . . . . 109

Dispense Table (Standard Pipettor) . . . . . . . . . . . . . . 112

Aspirate Configuration (Pin Tool) . . . . . . . . . . . . . . . . 115

Dispense Configuration (Pin Tool) . . . . . . . . . . . . . . . 116

Mix Fluid Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Mix Fluid (Standard Pipettor) . . . . . . . . . . . . . . . . . . . 117

Mix Fluid (Pin Tool). . . . . . . . . . . . . . . . . . . . . . . . . . 119

Mix with TF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Read Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Read with TF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Wash Tips or Pins Process . . . . . . . . . . . . . . . . . . . . . . 123

Wash Tips (Standard Pipettor) . . . . . . . . . . . . . . . . . . 124

Wash Pins (Pin Tool). . . . . . . . . . . . . . . . . . . . . . . . . 125

Blot Pins Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Pause Pipettor Process . . . . . . . . . . . . . . . . . . . . . . . . 126

Wash Cell Reservoir Process . . . . . . . . . . . . . . . . . . . . 127

Finish With Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Chapter 6: Exchanging Hardware . . . . . . . . . . . . . . . . 129

Exchanging Pipettor and Pin Tool Heads . . . . . . . . . . . . 129

Uninstalling a Pipettor or Pin Tool Head . . . . . . . . . . . 129

Installing the Pipettor Head . . . . . . . . . . . . . . . . . . . . 131

Uninstalling Wash Reservoir Top . . . . . . . . . . . . . . . . 133

Installing Wash Reservoir Top . . . . . . . . . . . . . . . . . . 134

Resetting FLIPR Tetra System after Changing Pipettor Heads

134

Exchanging the 1536 Tip Gasket . . . . . . . . . . . . . . . . . 135

Installing the Gasket . . . . . . . . . . . . . . . . . . . . . . . . 135

Removing the Tip Block and Gasket . . . . . . . . . . . . . . 136

Exchanging Pin Tools . . . . . . . . . . . . . . . . . . . . . . . . . 137

Loading and Unloading the Pin Tool . . . . . . . . . . . . . . 137

Exchanging LED Modules . . . . . . . . . . . . . . . . . . . . . . 138

0112-0109 H 5

Contents

Uninstalling LED Modules. . . . . . . . . . . . . . . . . . . . . . 138

Installing LED Modules . . . . . . . . . . . . . . . . . . . . . . . 139

Changing Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Uninstalling a Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Installing an Emission Filter . . . . . . . . . . . . . . . . . . . . 143

Installation of Plate Hold-Down Devices . . . . . . . . . . . . 144

Selection of Appropriate Plate Hold-Down . . . . . . . . . . 144

Cell Reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Installing Cell Reservoir. . . . . . . . . . . . . . . . . . . . . . . 146

Uninstalling Cell Reservoir. . . . . . . . . . . . . . . . . . . . . 147

Chapter 7: Calibration and Signal Test. . . . . . . . . . . . . 149

Optical Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Adding a Read Plate to Plate Library . . . . . . . . . . . . . . 149

Recalibrating the Optics. . . . . . . . . . . . . . . . . . . . . . . 150

Running a Signal Test . . . . . . . . . . . . . . . . . . . . . . . . . 153

System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Running a Plate Prior to an Experiment . . . . . . . . . . . . 154

Chapter 8: Running an Experiment . . . . . . . . . . . . . . . 157

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Preparing Cells for Adherent Assays . . . . . . . . . . . . . . . 157

Location of Cells in the Plate . . . . . . . . . . . . . . . . . . . 157

Cell Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Cell Seeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Preparing Cells for Suspension Assays. . . . . . . . . . . . . . 159

Location of Cells in the Plate . . . . . . . . . . . . . . . . . . . 159

Cell Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Cell Seeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Powering-Up the System . . . . . . . . . . . . . . . . . . . . . . . 159

Checking the System . . . . . . . . . . . . . . . . . . . . . . . . . 160

Running the Yellow Plate Signal Test. . . . . . . . . . . . . . 160

Dye-Loading the Cells for Fluorescence Assays. . . . . . . . 161

Loading Duration and Temperature. . . . . . . . . . . . . . . 161

Preparing a Source/Compound Plate . . . . . . . . . . . . . . . 162

Preparation Time for the Source Plate . . . . . . . . . . . . . 162

Recommended Source Plates . . . . . . . . . . . . . . . . . . . 162

Concentration of Compounds in the Source Plate . . . . . 162

Addition and Mixing of Compounds to the Cell Plate . . . 162

6 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Compound Plates for Suspension Assays. . . . . . . . . . . 163

Setting Up an Assay Protocol. . . . . . . . . . . . . . . . . . . . 164

Creating a Protocol File . . . . . . . . . . . . . . . . . . . . . . . 164

Optimizing the Optics and Fluid Dispensing . . . . . . . . . . 165

Optimizing the Hardware Settings . . . . . . . . . . . . . . . 165

Optimizing Optics Hardware . . . . . . . . . . . . . . . . . . . 165

Adjusting the Pipettor Height. . . . . . . . . . . . . . . . . . . 167

Adjusting the Fluid Dispensing Speed . . . . . . . . . . . . . 168

Optimizing Fluid Volume . . . . . . . . . . . . . . . . . . . . . . 168

Optimizing Pin Tool Delivery . . . . . . . . . . . . . . . . . . . 169

Optimizing Cell Delivery . . . . . . . . . . . . . . . . . . . . . . 169

Start the Assay Run . . . . . . . . . . . . . . . . . . . . . . . . . 169

FLIPR Calcium Assay Kit Protocol . . . . . . . . . . . . . . . . . 170

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Calcium Assay Kit Experimental Protocol. . . . . . . . . . . 172

Running the FLIPR Calcium Assay Kit . . . . . . . . . . . . . 174

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . 176

FLIPR Membrane Potential Assay Kit Protocol . . . . . . . . 177

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Cell Preparation for the FLIPR Membrane Potential Assay179

Dye Loading Using the FLIPR Membrane Potential Assay Kit

180

Running the FLIPR Membrane Potential Assay . . . . . . . 181

Troubleshooting the FLIPR Membrane Potential Assay Kit . .

183

Voltage Sensor Probes Assay Protocol . . . . . . . . . . . . . 184

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Cell Preparation for the voltage Sensor Probe Assay. . . 185

Running the Voltage Sensor Probe Assay . . . . . . . . . . 187

Luminescence Assay Protocol . . . . . . . . . . . . . . . . . . . 188

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Coelenterazine Loading For Adherent Assays . . . . . . . . 189

Coelenterazine Loading for Suspension Cell Assays . . . 190

Preparation of Cell Reservoir and Running the Assay . . 191

Optimizing an Assay . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 9: Troubleshooting . . . . . . . . . . . . . . . . . . . . . 197

Instrument Status Colors . . . . . . . . . . . . . . . . . . . . . . 197

Troubleshooting Start-Up . . . . . . . . . . . . . . . . . . . . . . 198

0112-0109 H 7

Contents

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 200

Troubleshooting the Pipettor . . . . . . . . . . . . . . . . . . . . 205

Troubleshooting the Optics . . . . . . . . . . . . . . . . . . . . . 210

Troubleshooting the Yellow Plate . . . . . . . . . . . . . . . . . 215

Troubleshooting the Tip Washer . . . . . . . . . . . . . . . . . . 216

Troubleshooting the Cell Reservoir . . . . . . . . . . . . . . . . 218

Troubleshooting Data . . . . . . . . . . . . . . . . . . . . . . . . . 218

Troubleshooting Robotic Integration . . . . . . . . . . . . . . . 219

Appendix A: Robotic Integration . . . . . . . . . . . . . . . . . 221

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . 221

Interface Versioning . . . . . . . . . . . . . . . . . . . . . . . . . 221

Instrument Overview . . . . . . . . . . . . . . . . . . . . . . . . . 222

Instrument Basic Function . . . . . . . . . . . . . . . . . . . . . 222

Instrument Hardware Introduction . . . . . . . . . . . . . . . 222

Instrument Layout . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Plate Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Plate-Handling System . . . . . . . . . . . . . . . . . . . . . . . 225

Instrument Layout Terminology (i.e., Where’s the front?) . .

226

Robotic Plate Loading . . . . . . . . . . . . . . . . . . . . . . . . 226

Optics Access Door . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Washer placement . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Cell Suspension Placement. . . . . . . . . . . . . . . . . . . . . 228

Other Instrument Access Areas . . . . . . . . . . . . . . . . . 228

Monitor and Keyboard Placement . . . . . . . . . . . . . . . . 230

Required access areas. . . . . . . . . . . . . . . . . . . . . . . . 230

FLIPR Tetra System Control Architecture . . . . . . . . . . . . 233

General Description . . . . . . . . . . . . . . . . . . . . . . . . . 233

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Remote Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Communication Protocol and Address . . . . . . . . . . . . . 236

General Remote Mode Use . . . . . . . . . . . . . . . . . . . . . 236

Setting Up Protocols for Remote Control Use . . . . . . . . . 240

General Directions . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Settings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Analysis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

8 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Transfer Fluid Processes . . . . . . . . . . . . . . . . . . . . . . 243

Wash Tips Processes . . . . . . . . . . . . . . . . . . . . . . . . 244

Mix Fluid Processes . . . . . . . . . . . . . . . . . . . . . . . . . 244

Read Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Finish with Source Processes . . . . . . . . . . . . . . . . . . . 244

Wash Cell Reservoir Processes. . . . . . . . . . . . . . . . . . 244

Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Command Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Version<CR>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Status<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Loadplate<TAB>Location, Last Plate[, BAR CODE] <CR> . .

248

Removeplate<TAB>location <CR>. . . . . . . . . . . . . . . 250

Openprotocol<TAB>File Name<CR> . . . . . . . . . . . . . 251

Findprotocols<TAB>Folder<CR> . . . . . . . . . . . . . . . . 251

Runexperiment<TAB>[Data File Name]<CR> . . . . . . . 252

Stopexperiment<CR>. . . . . . . . . . . . . . . . . . . . . . . . 253

Clearerror<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Loadtips<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Unloadtips<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Cyclecameratemp<CR> . . . . . . . . . . . . . . . . . . . . . . 257

Tempcontrolonoff<TAB>Temp<CR> . . . . . . . . . . . . . 257

Washtips<TAB>Fluid Type, Wash Cycles, Volume/Stroke,

Aspirate Speed, Pump Speed, Strokes, Hold Time, Dispense

Speed<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Configuration <CR> . . . . . . . . . . . . . . . . . . . . . . . . . 260

Statusex<CR>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Cellflaskcontrol<TAB>Rate<CR> . . . . . . . . . . . . . . . . 264

Washcellreservoir<TAB>Fluid Type, Fill Speed, Drain

Destination, Drain Speed, Wash Cycles, Hold Time, Volume

Level<CR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Error Handling and Reporting . . . . . . . . . . . . . . . . . . . 267

Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Appendix A—Remote Interface Revision History. . . . . . . 270

V1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

V1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

V1.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

V1.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

0112-0109 H 9

Contents

Appendix B—Bar Code Specifications . . . . . . . . . . . . . . 271

About Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Bar Code Recommendations . . . . . . . . . . . . . . . . . . . 271

Bar Code Specifications . . . . . . . . . . . . . . . . . . . . . . . 272

Appendix B: Data Processing Algorithms . . . . . . . . . . . 273

Hypothetical Experiment . . . . . . . . . . . . . . . . . . . . . . . 273

Crosstalk Correction . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Determining Crosstalk Correction . . . . . . . . . . . . . . . . 274

Spatial Uniformity Correction . . . . . . . . . . . . . . . . . . . . 275

Determining Spatial Uniformity Correction . . . . . . . . . . 275

Negative Control Correction . . . . . . . . . . . . . . . . . . . . . 276

Determining Negative Control Correction. . . . . . . . . . . 277

Positive Control Scaling . . . . . . . . . . . . . . . . . . . . . . . . 278

Determining the Positive Control Scaling . . . . . . . . . . . 278

Subtract Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Determining Subtract Bias . . . . . . . . . . . . . . . . . . . . . 279

Response Over Baseline . . . . . . . . . . . . . . . . . . . . . . . 280

Determining Response Over Baseline Correction. . . . . . 280

Appendix C: Consumables and Accessories . . . . . . . . . 283

FLIPR Tetra System Accessories . . . . . . . . . . . . . . . . . . 283

Field Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Pipettor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Optics Consumables . . . . . . . . . . . . . . . . . . . . . . . . . 284

Pipetting Consumables . . . . . . . . . . . . . . . . . . . . . . . 285

Cell Reservoir Consumables . . . . . . . . . . . . . . . . . . . . 286

Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

96-Well Read Plates . . . . . . . . . . . . . . . . . . . . . . . . . 287

96-Well Read Plate Masks . . . . . . . . . . . . . . . . . . . . . 287

96-Well Source Plates . . . . . . . . . . . . . . . . . . . . . . . . 288

384-Well Read Plates . . . . . . . . . . . . . . . . . . . . . . . . 289

384-Well Source Plates . . . . . . . . . . . . . . . . . . . . . . . 290

1536-Well Read Plates . . . . . . . . . . . . . . . . . . . . . . . 290

1536-Well Source Plates . . . . . . . . . . . . . . . . . . . . . . 291

Source Reservoirs. . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Assays Performed on the FLIPR Tetra System . . . . . . . . 291

Calcium Flux Consumables. . . . . . . . . . . . . . . . . . . . . 291

FLIPR Membrane Potential Assay Kit Consumables . . . . 293

10 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Equipment and Supplies Suggested to Perform

Assays with Your FLIPR Tetra System. . . . . . . . . . . . . . 293

Appendix D: Using AquaMax Sterilant . . . . . . . . . . . . . 295

Principle of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Materials Required but Not Provided. . . . . . . . . . . . . . . 295

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Reagent Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . 296

Reagent Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Warnings, Precautions and Limitations . . . . . . . . . . . . . 296

Appendix E: Decontamination Certificate . . . . . . . . . . 299

Procedure for Completing the Certificate. . . . . . . . . . . . 299

Appendix F: Electromagnetic Compatibility (EMC) . . . 301

REGULATORY INFORMATION FOR CANADA

(ICES/NMB-001:2006) . . . . . . . . . . . . . . . . . . . . . . . . 301

ISM EQUIPMENT CLASSIFICATION (Group 1, Class A) . . 301

INFORMATION FOR THE USER (FCC NOTICE) . . . . . . . . 301

0112-0109 H 11

Contents

12 0112-0109 H

System Overview

This chapter provides an overview of the FLIPR® Tetra High Throughput

Cellular Screening System requirements.

FLIPR® Tetra Systems are fluorescence- and luminescence-based

microplate readers with an integrated 1536-, 384- or 96-pipettor. They

perform rapid throughput cell-based assays while providing accurate

and precise kinetic data. Primary applications include intracellular

calcium mobilization and membrane potential. In addition, an expanded

choice of wavelengths enables you to utilize a broad range of

fluorescent dyes.

The FLIPR® Tetra System includes:

• Simultaneous 96-, 384- or 1536-well liquid or cell transfer

• Expanded wavelength support

• User-configurable pipettors and optics

• Agile internal plate handling

• Standard, (EMCCD) camera for fluorescence applications or

Aequorin, (ICCD) camera for fluorescence and luminescence

• Cell suspension option

• Slim platform with minimal facilities requirements.

An overhead pipettor delivers compound to all wells of the read plate

simultaneously. A protocol file configured in ScreenWorks Software—

the system-control and analysis program for FLIPR® Tetra System—

coordinates timing of compound delivery with multiple time-point

exposures so that the resulting sequence of data points spans

compound addition.

ScreenWorks Software displays relative light units versus time for all

1536-, 384- or 96-wells on the system’s monitor. Updates occur in

real-time as allowed by processing speed. Data can be exported as

relative light units over time (time sequence), or as a single value per

well (statistic). Export data files are in ASCII text file format for input

into spreadsheet or database programs.

1

Fluorescence Mode

In fluorescence mode the system’s LEDs illuminate the bottom of a

1536-, 384- or 96-well ‘read’ plate containing cells loaded with

fluorescent dye, and measure the fluorescence in each well. By taking a

sequence of measurements in conjunction with compound application,

changes in fluorescence emission characteristics due to the binding of

particular ions (for example, Ca2+, H+ or Na+) can be tracked.

0112-0109 H 13

System Overview

Light-emitting diodes (LEDs) in the FLIPR® Tetra System produce light

at distinct wavelength ranges to excite the fluorescent dye that has

been added to the cells in the read plate wells. The entire well plate

bottom is illuminated. Fluorescent light emitted by the dye—again, for

the entire plate—passes through an emission filter before being

captured in a CCD camera, standard EMCCD or Aequorin ICCD.

Fluorescence is measured from each well independently, and converted

into a numerical value. The FLIPR® Tetra System can be configured with

two LED banks and three emission filters, allowing the software

configuration of up to four excitation/emission wavelength

combinations (‘read modes’). Thus, up to four different fluorescence

effects can be measured within a single experiment.

Luminescence Mode

The FLIPR® Tetra System also provides luminescence mode with the

Aequorin, ICCD camera option. The instrument has a light-tight

enclosure so that it can operate in luminescence mode and a

specialized high-sensitivity ICCD camera can be installed in place of the

standard EMCCD camera. The ICCD camera is mounted directly

beneath the read plate, so images are taken of the entire bottom of the

plate. For cell suspension experiments, an integrated Cell Reservoir

allows uniform cell suspension to be pipetted directly into the read

plate. From the 3 filter positions available on FLIPR® Tetra System, it is

recommended to have one open position, so no filter will be used

during luminescence assay.

As with fluorescence, luminescence is measured from each well

independently, and converted into a numerical value.

System Requirements

This section provides a brief overview of electrical, physical and

environmental requirements of the FLIPR® Tetra System. Please refer

to the FLIPR® Tetra System Pre-Installation Guide for full details.

Electrical

FLIPR® Tetra System consumes 5 A continuous and 9 A peak of 110 V

power and requires 90–240 VAC power source at 50–60 Hz which

equates to 2.5 A continuous and up to 4.5 A peak at 240 VAC/50 Hz.

The system is supplied with a power cord appropriate for the country it

was shipped to. Additional shared outlets are required for computer and

monitor. A power strip is acceptable for providing the additional outlets

for the computer and monitor.

14 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Minimum Space

System dimensions are as follows:

• Without Cell Suspension Module or TETRAcycler™:

approximately 39 inches wide 27 inches deep 70 inches high

(991 mm wide 686 mm deep 1780 mm high).

• With Cell Suspension Module and TETRAcycler: approximately

53 inches wide 27 inches deep 70 inches high (1346 mm

wide 686 mm deep 1780 mm high).

FLIPR® Tetra System is designed with rolling castors so it can be readily

moved to make necessary adjustments and perform maintenance.

Leveling feet are also installed on the lower instrument chassis. These

feet are typically used for stabilizing the instrument when integrated

with a robot, but can also be used to establish a uniform instrument

deck level in situations where the lab floor is not flat. When running an

experiment, please make sure the instrument’s feet are lowered and

leveled.

The computer and monitor are mounted to the right front side of the

instrument with the included clamp, requiring a minimum lab space of

73 inches (1.85 m) wide 82 inches (2.08 m) deep for maneuverability.

A chiller with dimensions 11 inches wide by 13 inches deep 13 inches

high (279 mm 330 mm 330 mm) is connected via a 3-foot (914

mm) long tube to the right side of the instrument. It can be placed

anywhere within that 3 foot radius as long as the user has access to the

on/off button on the chiller.

A minimum 25 inch (635 mm) square footprint for tip wash bottles is

required to the right side of the instrument.

The cabinet should have a user access space of 48 inches (1.22 m) in

front 24 inches

(610 mm) behind 10 inches (254 mm) to the left for servicing the

instrument.

WARNING! FLIPR® Tetra System can weigh as much as 860 lbs

(390 kg). Ensure adequate personnel are present when

installing or moving the system. Follow all necessary safety

precautions and use proper moving techniques.

0112-0109 H 15

System Overview

16 0112-0109 H

System Hardware Features

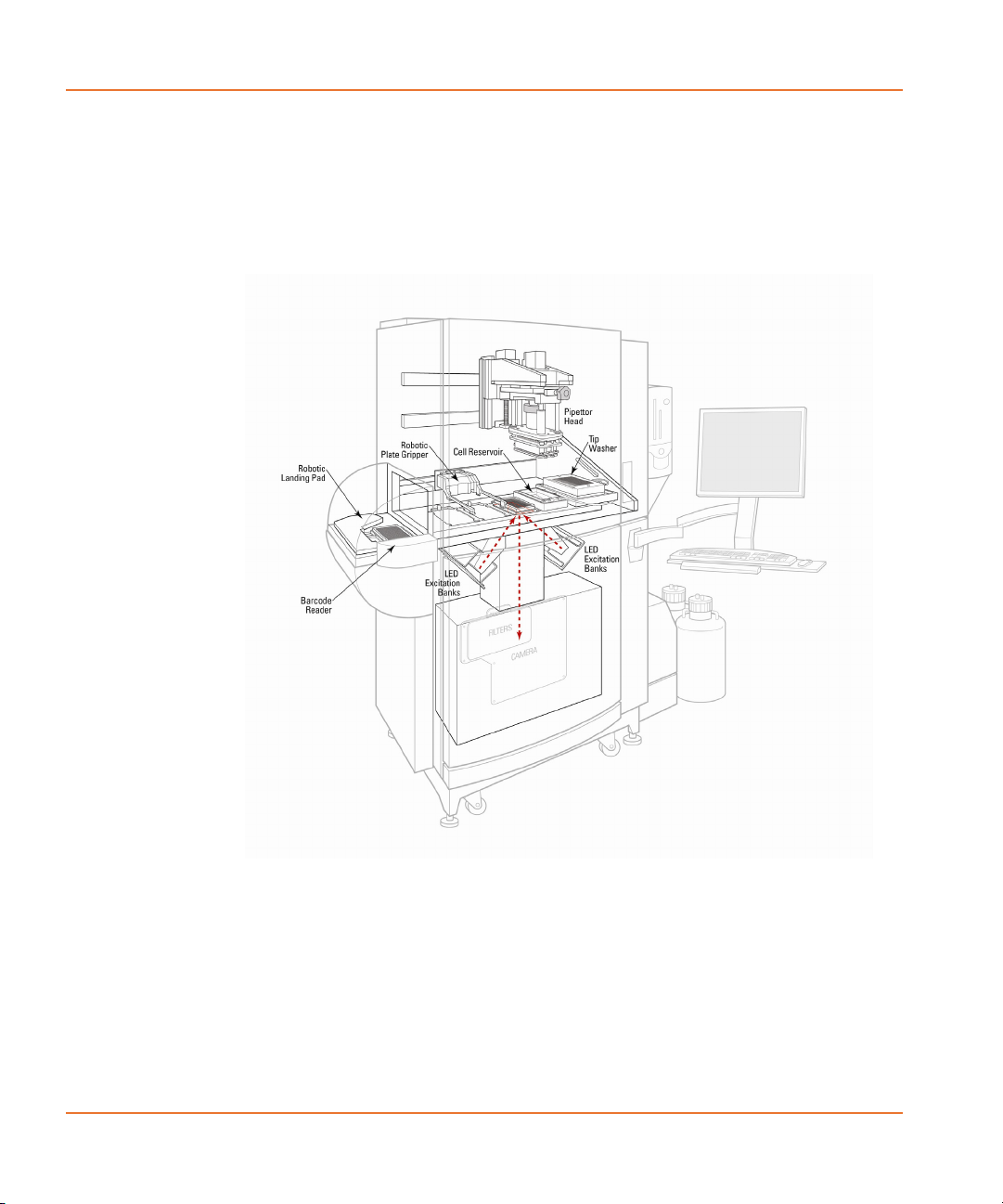

Overview of FLIPR Tetra System Hardware Features

The FLIPR® Tetra System consists of a cabinet 39” (965 mm) wide 27”

(686 mm) deep 70” (1780 mm) high, with a number of components,

including wash bottles, Cell Suspension module, chiller, host computer

and monitor, outside the cabinet.

The cabinet has two compartments, top and bottom, accessed by

manual doors on the front of the cabinet.

A ‘five-position stage’ located in the top compartment is where read

and source plates are positioned during an experiment. There are also

positions for tips and tip washing, as well as the Cell Suspension

reservoir.

The TETRAcycler™ plate shuttle on the back wall of the top

compartment can be used for robotically controlled carriage of

compound or read plates and tips in and out of the cabinet during

experiments. Plates are delivered to and from a landing pad outside the

cabinet on the left hand side.

Mounted on the back wall of the top compartment, above the

TETRAcycler, is the pipettor. The pipettor transfers compounds from

source plates to the read plate, and accesses the tip loading and tip

washing positions. When the Cell Suspension option is installed, the

pipettor also transfers cells in suspension from the Cell Reservoir to the

read plate.

The bottom, ‘dry’, compartment, houses the FLIPR® Tetra System

optics and an embedded computer for control of basic system

functions. Two LED excitation modules, to the left and right, direct light

up onto the base of the read plate, in the five-position stage above.

Light emitted from the read plate passes down through emission filters

directly below the plate to the camera (either the Standard EMCCD

camera or the Aequorin ICCD camera).

The system computer—running ScreenWorks® Software, through which

all user interaction with the system occurs—is attached to the outside

right-hand side of the cabinet. Monitor and keyboard are on an

adjustable arm attached on the right-hand side of the cabinet front.

The Cell Suspension module, if installed, is also mounted on the lower

right side of the instrument. This external module keeps the cells in

suspension and is connected via internal tubing to a Cell Reservoir that

is installed in Position 4 (Source Plate 3). The cells are kept in

suspension via stirring and are pumped into the reservoir for transfer to

the read plate. Up to 4 additional fluid bottles can also be connected to

the reservoir for cleaning purposes.

2

0112-0109 H 17

System Hardware Features

Containers for tip washer fill fluid and waste are placed outside the

cabinet beneath the computer.

Further information on these subsystems is presented in the following

sections.

System Diagram

Figure 2-1 Diagram of the complete FLIPR® Tetra System.

Plate-Handling System

Five-Position Stage

For an experiment, read and source plates are placed in the

five-position stage in the upper compartment of the FLIPR® Tetra

System, where the pipettor is able to transfer compound between

18 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

them. Plates can be loaded manually through the upper compartment

door, prior to an experiment, or robotically, as the experiment proceeds

, using the TETRAcycler.

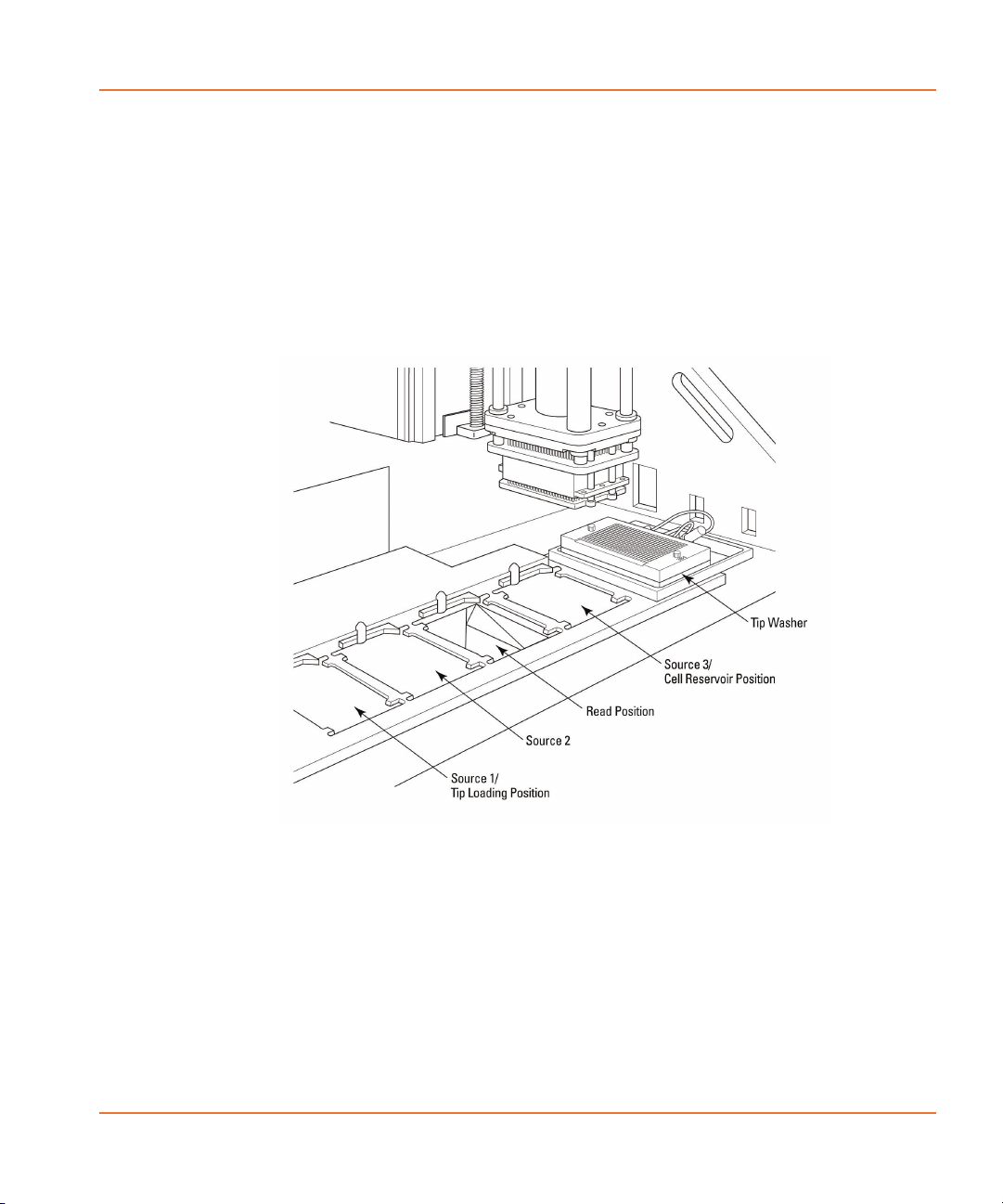

The five positions of the stage are, from left to right:

• Position 1: Tips and/or Source Plate 1

• Position 2: Source Plate 2

• Position 3: Read Plate

• Position 4: Cell Reservoir and/or Source Plate 3

• Position 5: Tip Washer

Figure 2-2 The five-position stage.

Positions 1, 2 and 4 take standard, low volume, deep well and reservoir

source addition plates.

Tip loading and unloading occurs in Position 1, but this position can

double as a source plate position once tips are removed.

Position 3 opens to the optics chamber below for excitation of

fluorophores in read plate wells and emission reading.

Position 4 can be used for the Cell Reservoir included with the Cell

Suspension option. A single Cell Reservoir is compatible with all of the

0112-0109 H 19

System Hardware Features

FLIPR® Tetra System pipettor heads. When the Cell Reservoir is not

present, this position can be used as a source plate position.

Positions 1–4 have a mechanical plate sensor to identify the presence

of plates, tips or reservoirs.

Robotic integration enables the TETRAcycler to exchange up to 12

source plates and tip racks, and one read plate, in an experiment.

A dedicated tip wash reservoir is located in Position 5 and should be

configured to match respective pipettor heads (96, 384 or 1536).

Appropriate tip wash reservoirs are included in the purchase of a

pipettor head. Specific hardware components associated with tip

washing are described in Tip Washing, page 31.

Plates and tip racks are registered with well A1 in the lower left-hand

corner using a plate indexer found in Positions 1–4. The indexers also

serve as mechanical sensors to detect plate or tip presence. If plates or

tips are not present in a Manual Mode experiment, but requested by

software, the instrument will stop and end the experiment. During

Remote Mode, the system notifies the SynchroMax™ ET or third-party

plate-handler that no plate or tip container is present and will stop the

instrument until plates or tips are detected. It is then the responsibility

of the SynchroMax ET or third-party plate-handler to deliver plates or

tips to the system.

Note: Sensors can only detect plate or tip container presence. They

cannot identify the type of plate or tips. It is the user’s responsibility to

ensure that the correct plates and tips are loaded into position.

Temperature Regulation

Positions 1, 2 and 4, for source plates, have optional temperature

control. Temperature settings range from ambient +5 °C to 40 °C.

Equilibrium temperature may take approximately 15 minutes to reach

the set temperature.

Configure temperature regulation with the Temperature Control

ON/OFF toggle command in the Instrument > Manual Operation

menu or corresponding button.

Note: FLIPR® Tetra System does not have humidified air flow.

Temperature regulation is easier to maintain during robotic integration

as temperature loss is minimized when plates are passed through the

20 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Plates

FLIPR® Tetra System accepts 96-, 384- and 1536-well plates that

conform to the proposed ANSI standards submitted by the Society for

Biomolecular Sciences. A sample of suitable source and read plates is

provided in Appendix C: Consumables and Accessories on page 283.

Black walled, clear-bottomed read plates provide an optimal imaging

environment for fluorescence assays. These plates prevent signal

diffraction while allowing excitation and signal access. Black walled,

clear-bottomed plates or white walled plates can be used for

luminescence assays.

For 96-well read plates, an optional slit-shaped mask can be used to

minimize saturation and edge effects associated with these plates.

Simply place the mask over the read position. See Appendix C for types

of masks available.

No mask is required for 1536- and 384-well plates.

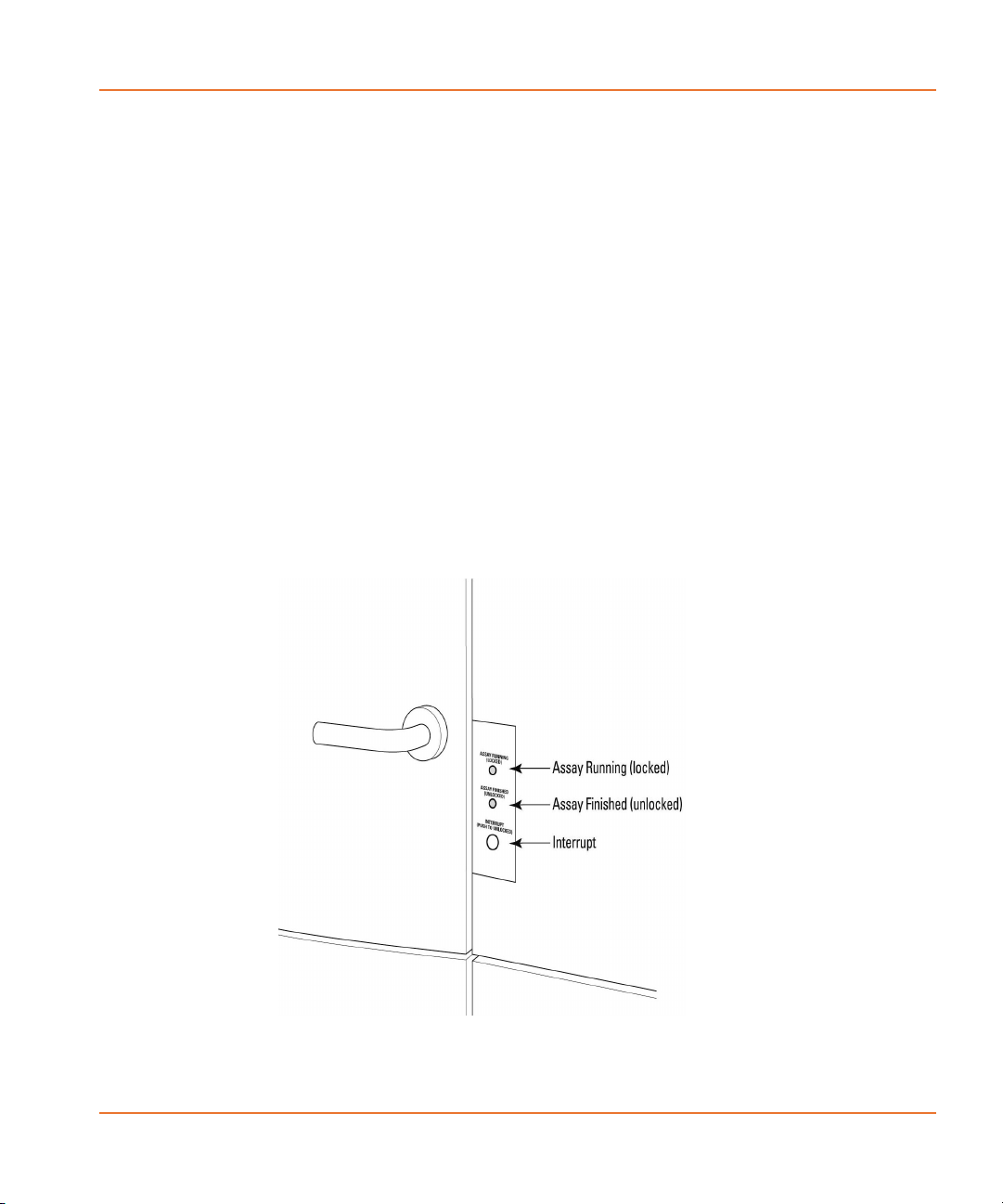

Instrument Status Panel

The Instrument Status panel, located next to the upper door handle,

indicates whether or not the instrument is running and safe to open. It

includes an emergency Interrupt button to stop any processes.

Figure 2-3 The Instrument Status panel.

0112-0109 H 21

System Hardware Features

The panel has two lights as well as the Interrupt button. From the top

of the panel these are:

• Assay Running (Locked)—Yellow light

• Assay Finished (Unlocked)—Green light

• The Interrupt button is an override button to halt all tasks, so

CAUTION! The Interrupt button immediately ends the experiment and

should only be used in emergencies. The system may need to be

reinitialized by selecting Reset from the Instrument menu prior to

resuming normal instrument function.

Manual Mode

In manual operation all assay components must be positioned in the

five-position stage by hand, through the upper manual door, prior to

running an experiment. Once the experiment starts no further plate or

tip changes can be made. If you need to exchange plates or tips during

an experiment then you must run the FLIPR® Tetra System in Remote

Mode, using the TETRAcycler to replace used tips or plates.

The FLIPR® Tetra System always starts in Manual Mode. Toggle

between manual and remote modes with the Set Manual Mode and

Set Remote Mode commands in the Instrument menu, or use the

software buttons available.

In Manual Mode, the TETRAcycler gripper parks itself on the platelanding pad.

®

The FLIPR

Tetra System is performing a task. The upper and

lower doors are locked and cannot be opened until the task

finishes or is halted using the Interrupt button.

No tasks are being run and it is safe to open the upper and

lower instrument doors.

you can access the instrument. If pressed the yellow light

flashes until the system has reached a safe state to open the

doors, when the green light comes on.

Note: The top compartment door should remain closed during normal

system operation. Do not operate the instrument if the door is open.

All system functions halt when the door is open.

22 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Robotic Integration

To increase the number of plates you can use in an experiment (and

minimize personnel requirements), use the TETRAcycler internal plate

handler coupled with the SynchroMax ET or a third-party plate handler

(for example, stacker system or robotic arm). One read and up to 12

source plates and tip racks can be shuttled in and out of the FLIPR®

Tetra System in one experiment with this method.

When using automated delivery the SynchroMax ET or third-party plate

handler delivers plates to, and picks them up from, the landing pad on

the outside left of the instrument, from where the TETRAcycler shuttles

them in and out of the read compartment. The shuttle door over the

landing pad opens and closes to maintain a light-tight environment

within the compartment.

During automated operation the SynchroMax ET or third-party plate

handler controls the FLIPR® Tetra System by sending instructions to

load protocols, run experiments, and retrieve plates from the landing

pad. These commands are executed immediately upon receipt by the

instrument. Persisting instrument settings cannot be made from the

remote controlling program—these must be configured in ScreenWorks

Software before control is passed to the plate-delivery system.

To pass control to the plate-delivery software select Set Remote Mode

in the Instrument menu in ScreenWorks Software. The FLIPR® Tetra

System remains in remote control until Set Manual Mode is pressed.

The third-party plate handler software communicates with the FLIPR®

Tetra System computer via the serial communication port using TCP/IP.

SynchroMax ET software is installed with ScreenWorks Software on the

FLIPR® Tetra System computer so it is able to communicate directly

with the instrument. See Appendix A: Robotic Integration on page 221

for remote control syntax.

TETRAcycler™

The TETRAcycler is a plate gripper that runs along the back wall of the

upper read compartment, giving it access to Positions 1–4 in the

five-position stage and the landing pad on the outer left-hand side of

the cabinet. It shifts source plates and tip containers between these

locations when under the control of the SynchroMax ET or a third-party

plate handler (see above).

The TETRAcycler carries standard, low volume and deep well 96-, 384and 1536-well plates that conform to propose ANSI standards

submitted by the Society for Biomolecular Sciences. In addition, the

TETRAcycler handles Molecular Devices qualified tips. Reservoirs can be

used during robotic integration, however the TETRAcycler is not able to

move these. All reservoirs must be loaded manually prior to running an

experiment, including the Cell Reservoir.

0112-0109 H 23

System Hardware Features

Note: While the system is compatible with plates that conform to

proposed ANSI standards submitted by the Society for Biomolecular

Sciences, some plates may not be handled as reliably by the

TETRAcycler due to their low plate weight. During robotic integration,

it is recommended that handling of the plates and tips by the

TETRAcycler be evaluated for plate handling robustness prior to

starting a screen.

The FLIPR® Tetra System’s upper and lower door must remain closed

for the duration of experiment. Plates are transported in and out of the

instrument only by the TETRAcycler system’s robotic landing pad door.

WARNING! Do not place your fingers in the TETRAcycler

shuttle door as this may cause injury.

SynchroMax ET™

The SynchroMax ET is a six-stack plate handler available as an optional

purchase with the FLIPR® Tetra System. It delivers plates to and from

the landing pad, integrating with the TETRAcycler, which ferries the

plates to and from their appropriate locations in the five-position stage.

The configuration interface of the SynchroMax ET software is opened

directly from within ScreenWorks Software, making experiment

configuration straightforward.

Observation Panel

In order to view hardware movements in the upper top compartment

while troubleshooting the FLIPR® Tetra System, use the observation

panel. Under normal operating conditions the upper door must be

closed in order to run an experiment, ensuring no light enters the

chamber. When the observation panel is mounted to the chamber,

however, the door can be left open, allowing you to view movements of

the pipettor and TETRAcycler. Normal instrument control is performed

via ScreenWorks Software, SynchroMax ET, or third-party plate

handling software. For the Aequorin ICCD camera test images are

displayed.

The observation panel is stored attached to the inside of the upper

door. To mount the panel, remove it from the door and attach it with

the four captive thumbscrews to the top compartment frame.

24 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

To acquire quality data, reaffix the observation panel to the inner door

prior to running an experiment.

WARNING! If pretending to run in luminescence mode with the

Aequorin ICCD camera, DO NOT touch the white door switches.

Room light will damage the Intensifier. The door switches

detect the open door to protect the camera.

Note: The observation panel should only be used to view internal

pipettor movement; it should not be used during experiments when

data is being accumulated. Test data (in the case of the Aequorin ICCD

camera) or compromised data (with the Standard camera) will be

shown if not collected under dark conditions with closed doors.

Liquid-Handling System

Compounds are transferred from source plates or reservoir to read

plates by the pipettor mounted on the rear wall of the top

compartment, above the TETRAcycler. The pipettor assembly can be

fitted with a standard pipettor head, to use disposable tips, or a pin tool

head, which uses solid or slotted pins to carry compound.

All 1536, 384, or 96 tips or pins operate at the same time,

simultaneously picking up compound from all the wells in a source plate

(or a quarter of the wells; see Compatible Plate Configurations on

page 30 below) or Cell Reservoir, and similarly dispensing these

simultaneously to the read plate. Fluid mixing steps can be configured

for source plates before compound is picked up, and for read plates

once it has been dispensed.

Pipettor heads are user-installable and can be interchanged in

approximately less than 5 minutes; see Exchanging Pipettor and Pin

Tool Heads on page 129.

Standard Pipettor Head

Standard pipettor heads are available in 1536-, 384- and 96-tip

formats.

The 384- and 96-pipettor heads both use disposable plastic tips. In

contrast, the 1536-pipettor head uses a stainless steel tip block with a

disposable 1536-tip gasket.

Plastic tips can be washed or replaced between each compound

addition or at the end of an experiment. The 1536-tip block is washed

at specified times.

0112-0109 H 25

System Hardware Features

Pipettor operations are controlled from within ScreenWorks Software

protocols, or some operations, for example, loading tips, can be

performed individually, directly through commands in the Instrument

menu. Connectors on the back of the pipettor head identify the head

format as 1536, 384, or 96 tips, so ScreenWorks Software only offers

valid plate formats and pipetting parameters for protocol setup.

The standard pipettor head uses air displacement to control aspiration

and dispense speed and volume. The volume of compound to be

transferred is configured in the software, and it is possible to draw

compound from multiple source plates to dispense into one destination

plate, or to aspirate from one plate and dispense to multiple well plates

or quadrants.

The 96- and 384-pipettor heads displace air in the disposable pipette

tips. In the 1536-pipettor head a plunger for each of the 1536 tips

presses against an elastic gasket seated on the tip block. When the

plungers move down they create an initial seal between the gasket and

tip block. Once the seal is created, further plunger movement causes

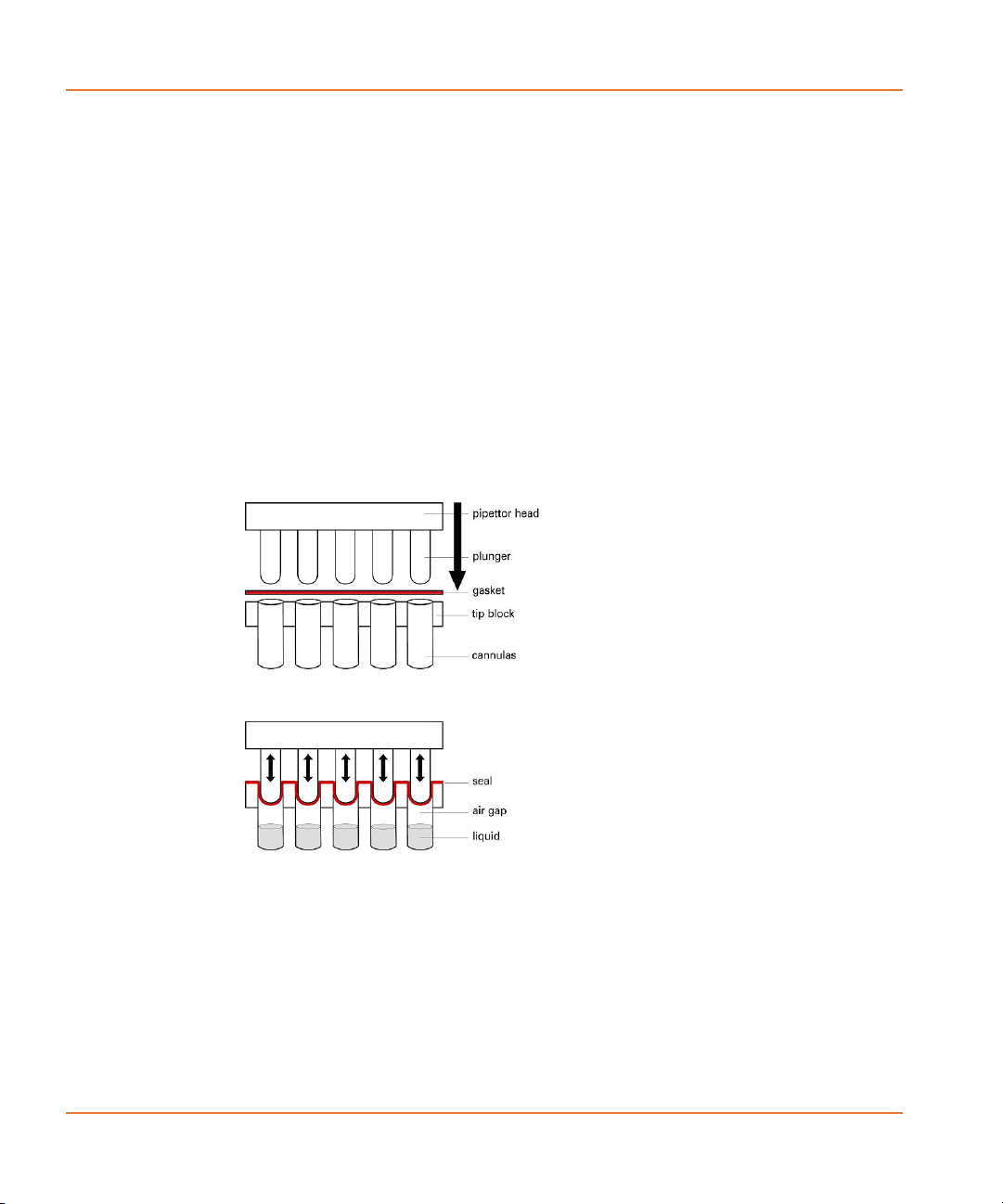

air displacement in the tip block (see Figure 2-4).

Figure 2-4 Seal creation in the 1536-pipettor head.

Minimum pipettor precision is as follows:

• 3% for 75 μL additions (96-well).

• 4% for 25 μL additions (384-well)

• 6% for 3 μL additions (1536-well)

Performance is dependent on tip/gasket seating and can be

compromised if the seal is broken. Use only Molecular Devices

recommended tips and gaskets to ensure the highest accuracy and to

reduce the possibility of damaging the pipettor. See Appendix C:

26 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Consumables and Accessories on page 283 for recommended tips.

Cell Suspension

The Cell Suspension option consists of two components:

• The Cell Reservoir installable in Position 4 (Source 3) in the 5

position stage.

• The Cell Suspension module located externally on the right side

of the instrument.

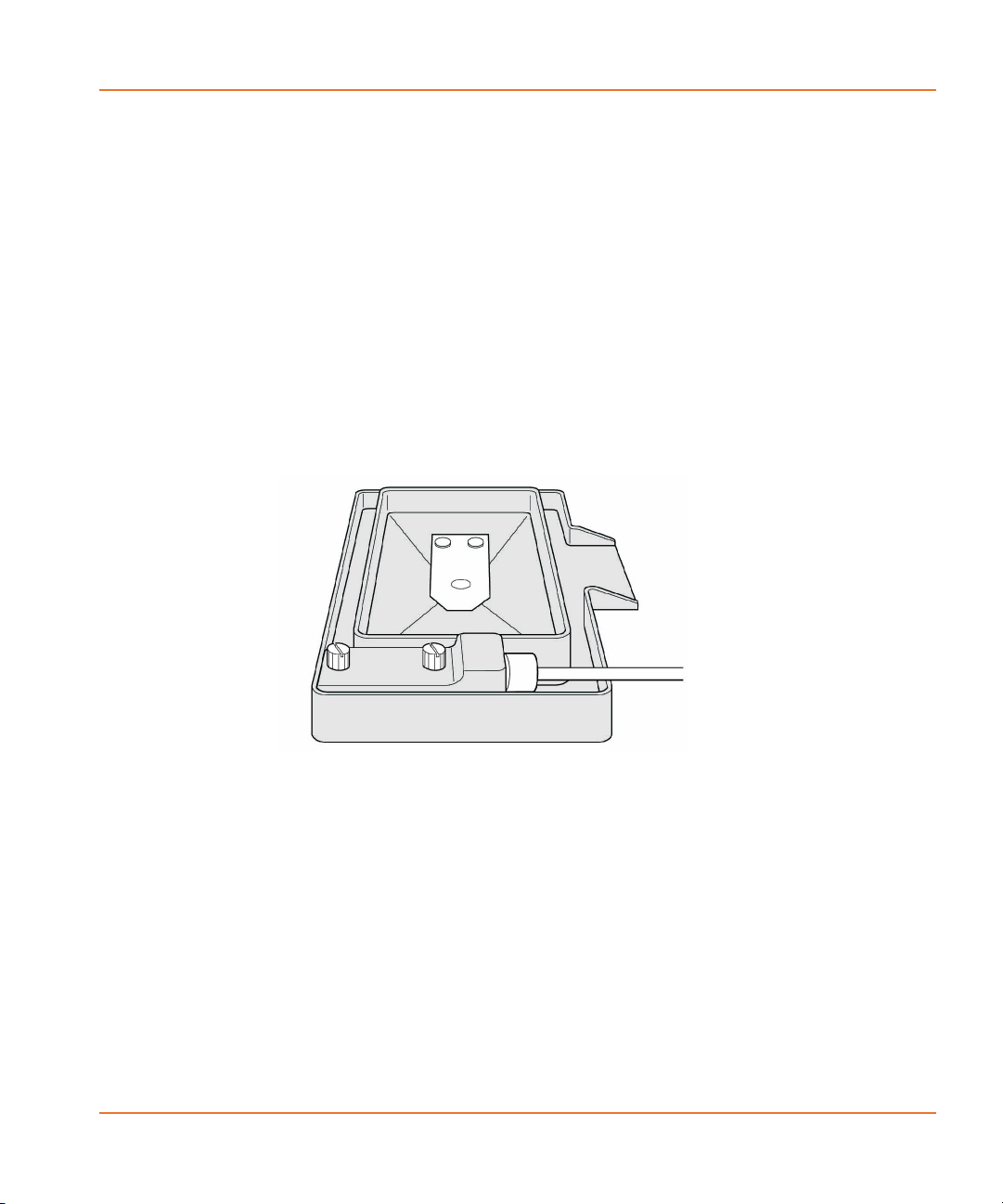

The Cell Reservoir (see Figure 2-5) is user installable. The Cell

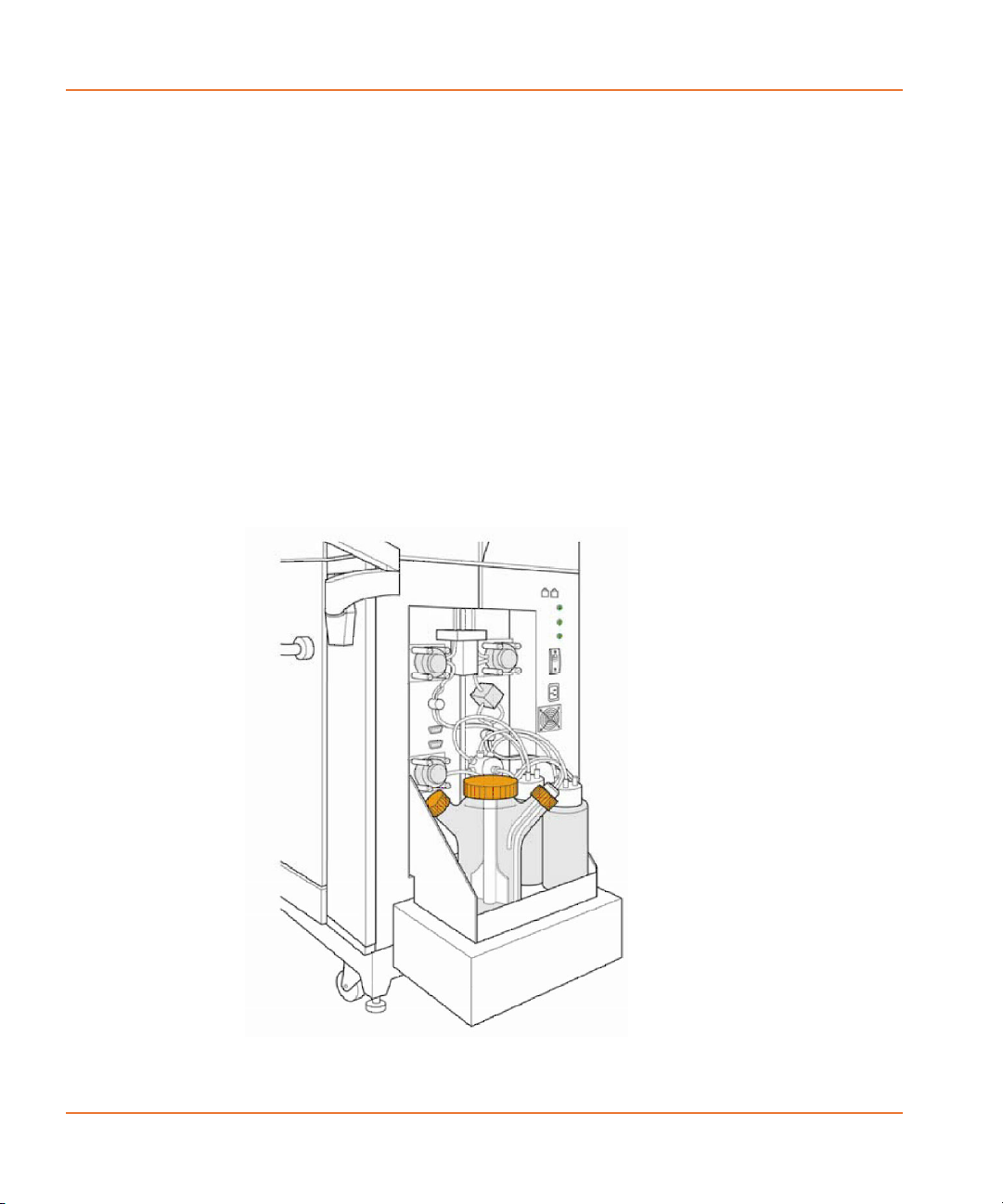

Suspension module (see Figure 2-6) consists of a shelf with a magnetic

motor mounted underneath it, a cell flask with a magnetic stirrer, up to

four fluid bottles for automated cleaning, and a removable cover for

keeping cells in a dark environment.

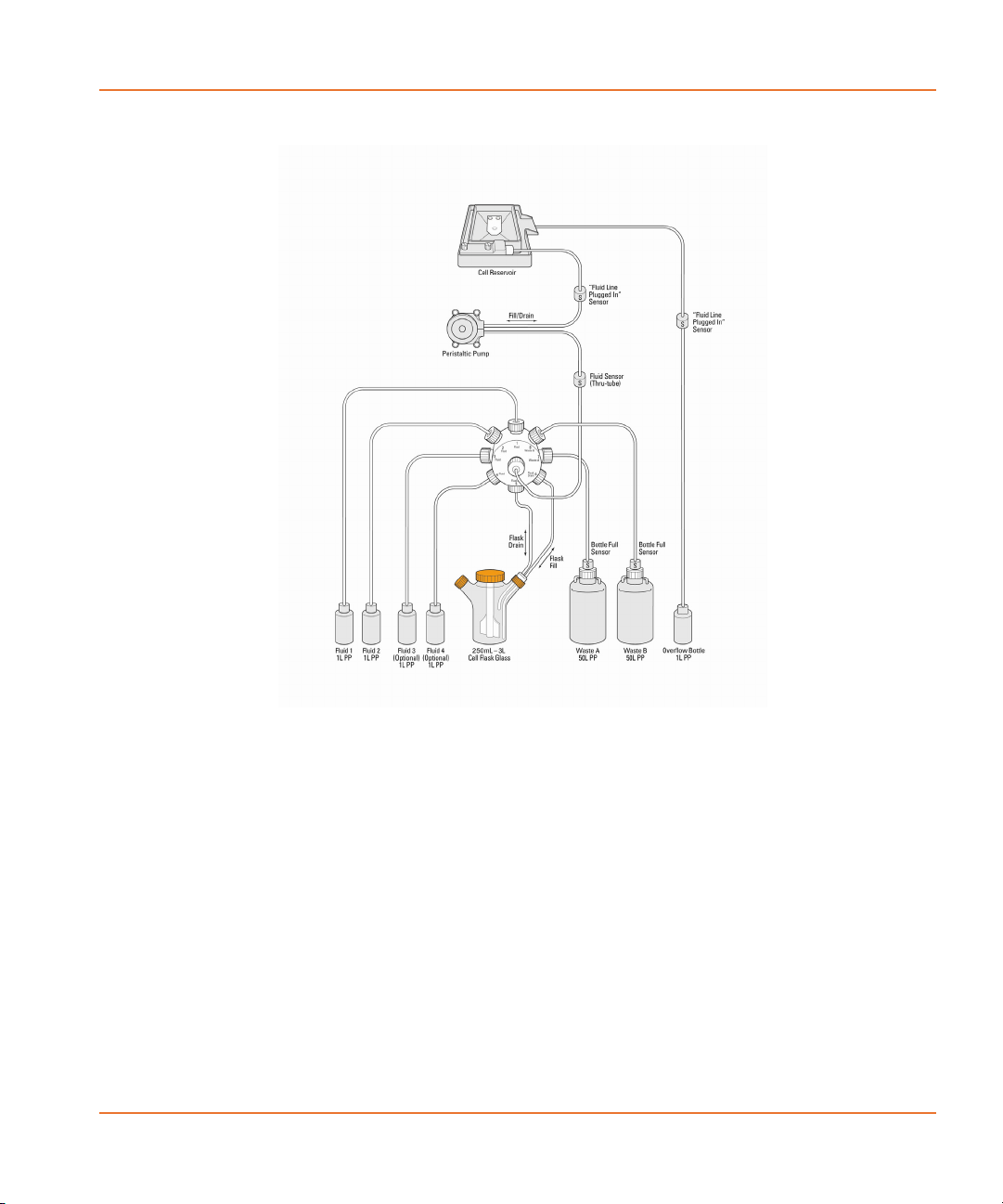

Figure 2-7 demonstrates how the system is connected and shows all

the possible combinations for protocol development.

Figure 2-5 Cell Reservoir.

The Cell Reservoir, which the user places in a source plate location, is

filled from any of the bottles in the external Cell Suspension module by

a pump with adjustable speed and direction.

The Cell Reservoir is a special plate type that has one fluid line used for

both input and output, and an electronic plate ID that is part of the

electrical/fluidic connector which identifies the reservoir to the system.

In the case of an overflow, an overflow trough catches excess fluid and

pipes it to the tip washer overflow trough, which directs it to the

overflow bottle. The reservoir is also autoclavable for cleaning

purposes.

The spinner flask contains a stirrer, which is driven by a magnetically

coupled motor mounted in the lower part of the Cell Suspension

module. The Cell Suspension stir speed can be set in a protocol or with

manual instrument controls. Stir speed of 5 equals approximately 1

0112-0109 H 27

System Hardware Features

revolution per second. From the uniform suspension in the spinner flask

cells are pumped into the Cell Reservoir, where the pipettor head in 96,

384, or 1536 format removes the appropriate amount and cells are

automatically pumped to a specified destination. A protocol in

ScreenWorks Software controls the stir speed and source/destination of

cell suspension activity.

The cell valve selects the source for filling, or the destination for

draining. There are 8 valve positions: flask fill (for filling the reservoir),

flask drain (for draining the reservoir without causing air bubbles),

Waste Bottle A, Waste Bottle B, and Fluid 1–4.

Fluid 1–4 are user specifiable, and can be cleaning solutions, water or

buffer. The user can choose to pump cells back into the cell flask or to

any other fluid bottles. Bottles for Fluid 1 and 2 are automatically

included with the Cell Suspension option.

Cell Reservoir can be washed by either adding the Wash Reservoir

process to the protocol (see Constructing Protocols Using FLIPR Tetra

Processes on page 70), selecting Wash Reservoir in the Instrument

> Manual Operation menu, or manually removing the reservoir and

autoclaving it.

Figure 2-6 Cell Suspension Module.

28 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Figure 2-7 Cell Suspension Module connections.

Pin Tool Head

Pin tools are blocks of solid or slotted pins, where the pins replace the

hollow tips used with a standard pipettor. The pins use capillary action

to pick up and transfer liquid from one plate to another. Their ability to

accurately and reliably transfer compounds in nanoliter volumes allows

users to supply test compounds in 100% DMSO solution, removing the

need to prepare intermediate dilution plates.

The volume that each pin picks up is determined by the size of the pin

(and, if slotted, the size of the slot) and the withdrawal speed of the pin

from the liquid—a faster removal speed leaves more liquid on the pin.

Pins for the 384 pin tool are supplied in four sizes, giving a total range

(across all these sizes) from 84 nL to 656 nL. The 1536 pin tool has

seven different pin sizes, giving a total range from 19 nL to 117 nL.

0112-0109 H 29

System Hardware Features

Each pin size has a specified volume range that it carries:

• The lowest reported volume is for a tip removal speed of 7.8

• The highest reported volume is for a tip removal speed of 57.0

The precise volumes that will be picked up at given tip removal speeds

should be determined by users in assay development.

The FLIPR® Tetra System can be fitted with 384- or 1536-pin tool

heads. Pin tools themselves, in the appropriate 384 or 1536 format,

can be easily and rapidly replaced to change the pin size.

All the pin tools used with the FLIPR® Tetra System are available with a

hydrophobic and lipophobic coating to prevent or reduce the

nonspecific binding of proteins and lipids to the pins.

In order to ensure uniform compound pick-up across the entire pin tool,

pins can be configured to ‘float’ in source plate wells. Individual pins

are not rigidly attached to the pin block, having a small amount of

vertical movement up into the block. When set to float, the pin head

moves down very low so that all pins sit on the bottom of the well and

push up a little into the block. This ensures that all pins are equally

immersed in their wells, i.e., sitting on the bottom. This outcome could

not be guaranteed if the pins were rigidly fixed to the block, given that

plate bottoms are often not completely flat.

mm/s.

mm/s.

Compatible Plate Configurations

The 96- and 384-pipettor heads can be used with source or read plates

with equal or one order higher well number. This is because the FLIPR®

Tetra System can aspirate or dispense into quadrants of a plate. The

following combinations are possible:

• The 96-pipettor head can be used with 96- and 384-well plates.

• The 384-pipettor and pin tool head can be used with 384- and

1536-well plates.

• The 1536-pipettor head can be used only with 1536-well plates.

Deep-well plates or reservoirs can be substituted for standard well

plates.

When compound is aspirated or delivered to a plate with a greater

number of wells than the pipettor head, the quadrant number (1 to 4)

must be entered in the protocol configuration in ScreenWorks Software

for each dispense.

30 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Tip and Pin Tool Loading

For all pipettor and pin tool heads, a sensor informs the software

whether or not tips or a pin tool are loaded. If desired, at the start of an

experiment, tips or a pin tool can be automatically loaded onto the

pipettor head by selecting Load Tips Position in the Settings

process. Otherwise, tip and pin tool loading or unloading must be

requested as independent operations from the Instrument > Manual

Operation menu. Directions for installation of the 1536 tip gasket are

given in Exchanging the 1536 Tip Gasket on page 135.

Tip and pin tool loading steps can be programmed to occur between

fluid transfers within experiment protocols.

Tip and Pin Tool Washing

Tip or pin tool washing is controlled with the Wash Tips or Wash Pins

process in ScreenWorks Software protocols and can be performed

between fluid transfers within an experiment, or after the last fluid

transfer, to prepare tips for the next experiment. Disposable tips, as

well as the 1536-tip head, and 384- and 1536-pin tools, can be

washed.

The washer consists of a reservoir top of the selected pipettor format,

mounted over a wash basin. Detailed instructions for exchanging the

reservoir top are located in Uninstalling Wash Reservoir Top on

page 133. The wash basin is connected to two solvent-supply carboys

and two waste carboys located on the floor beneath the computer

monitor. A basin beneath the tip washer base drains to a waste carboy,

to safely remove any solvent that overflows from the reservoir.

Wash solution fills the reservoir for a calibrated amount of time. Solvent

is then drained from the reservoir after each wash cycle. Up to five

wash cycles can be configured within a single wash process. For tips, a

user-set volume of solvent is drawn up, optionally held for a time, and

then expelled, up to 20 times. For pins, vertical motion of the tip block

is used to agitate the wash solvent around the pins. The option is

available to wash tips or pins in up to two solutions before reusing the

tip washer. When additional wash solutions are required, tips or pins

can be washed in a boat or reservoir, located in one of the source plate

positions, using the Mix Fluid process.

WARNING! High volumes of volatile, flammable solvents in the

reading chamber may cause explosive conditions. Use of 100%

isopropanol, etc., in the tip washer is particularly discouraged

without additional ventilation. Consult your facilities expert to

determine the appropriate ventilation to avoid explosive

conditions.

0112-0109 H 31

System Hardware Features

Pin tools are supplied with blotting stations that can be loaded into one

of the plate positions. Blot pin steps can be configured in the protocol to

remove fluid from the pins, for example, following pin washing.

Note: A waste bottle sensor override (P/N 0700-0827) is available in

the FLIPR® Tetra System accessory kit to bypass the waste sensor and

dispose waste in containers other than the dedicated waste carboys.

Optical System

The FLIPR® Tetra System optics are housed in the bottom compartment

of the main cabinet. In fluorescence assays, where excitation is

required, light from light-emitting diodes (LEDs) is directed at the base

of the read plate exposed in position 3 in the 5-position stage above.

Light emitted from the plate travels down through emission filters

before being captured in the CCD camera. Details on the main

components of the optical system, CCD camera options, the LEDs, and

emission filters, are presented below.

Figure 2-8 FLIPR® Tetra System optics.

32 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

CCD Camera Options

Two camera options are available for purchase with the FLIPR® Tetra

System. A standard, EMCCD (Electron Multiplying CCD) camera is

recommended for fluorescence only experiments, while the more

sensitive Aequorin ICCD (Intensified CCD) camera is designed for both

fluorescence as well as luminescence assays.

Standard EMCCD Camera

The CCD camera is located directly beneath the read plate on the fiveposition stage. The camera is thermoelectrically cooled and requires

about five minutes to reach its operating temperature of -60 ± 2 °C.

WARNING! Do not use the camera before it has reached its

operating temperature—this will result in noisy data. Check the

camera temperature on the Instrument Status panel before

starting an experiment.

The camera uses frame-transfer technology that shifts pixel values

from the exposed portion of the chip to the data processing portion.

This method allows a high acquisition rate and eliminates the possibility

of camera shutter failure.

The camera is an integrating-type detector using temporal integration

to build up the signal-to-noise ratio. Depending on the intensity of the

emitted light (reliant on dye efficiency and LED power), it may be

necessary to use longer camera exposures. This prevents the measured

fluorescence signal from being dominated by detector noise.

Images are taken of the bottom of the entire plate for a time specified

in the ScreenWorks Software protocol; exposure time can be set from

0.05 to 30 seconds. In ratiometric experiments for example, where two

or more wavelengths are measured, the number of images captured

increases so that an image is taken for each wavelength at the specified

rate. From each image a relative light value is calculated for each well.

The FLIPR® Tetra System reports relative light units (RLUs) in a range

from zero to approximately 12,000.

Note: Relative light units in the FLIPR® Tetra System do not have the

same value as those of previous FLIPR® Tetra Systems.

The light intensity detected by each pixel on the CCD chip can be

amplified using the Gain setting in ScreenWorks Software (Settings

Process). This parameter has a range from zero to 240. Amplification

is exponential, with increments increasing as you go higher up the

range. Fluorescence assays typically use a gain of 130 whereas

0112-0109 H 33

System Hardware Features

luminescence assays should use 200 as a starting point. Gain

optimization should be done during assay development to determine

optimal conditions for your screen.

When a luminescence experiment follows a fluorescence experiment we

recommend that you cycle the camera temperature to eliminate ghost

images that may have been created during the fluorescence assay.

Select Cycle Camera Temperature from the Instrument > Manual

Operation menu to choose this option. The camera warms up to room

temperature to release ghost images, prior to cooling back down to

approximately -60 °C.

Note: Luminescence readings continue to be available with the

Standard, EMCCD camera option, however camera sensitivity is not

optimal for this type of experiment.

Aequorin ICCD Camera

When this option is selected instead of the Standard camera, the ICCD

camera is mounted directly beneath the read plate on the five-position

stage, although at a slightly different height then the Standard EMCCD

camera. This camera operates at -20 °C and requires about 5 minutes

to reach that temperature.

Note: The instrument will detect an error if the user tries to operate

the instrument with the camera out of its recommended temperature

range of -20 °C ± 5 °C.

Similar to the Standard camera, the Aequorin camera also uses frametransfer technology that shifts pixel values from the exposed portion of

the chip to the data processing portion. In this camera, however, the

signal is enhanced prior to reaching the CCD chip: it is amplified in the

intensifier. Using this method there is less noise and therefore the

camera is significantly more sensitive then the Standard EMCCD

camera.

When using the Aequorin ICCD camera images are taken of the bottom

of the plate, amplified in the intensifier and transferred via a fiber optic

taper to the CCD chip. The gain control of the intensifier allows for

bright signal from fluorescence as well as dim signal from luminescence

to be enhanced accordingly, so as to provide the best signal and not

saturate the CCD chip below. In Fluorescence mode the Gain is preset

to 2000, whereas in Luminescence mode the Gain defaults to 280,000,

but can be lowered in the event that the luminescence assay is very

bright.

This camera has a Gate Open % feature, adjustable in Fluorescence

mode only. This feature controls how long the intensifier is on for each

34 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

of the frames collected during the exposure time. This controls the

signal intensity of the assay.

The recommended value range for the ICCD camera is 40,000 to

50,000 (at maximum signal). This camera does not require

temperature cycling when changing between Fluorescence and

Luminescence modes.

Both Cameras

Once calculated, RLUs are displayed in real time in the ScreenWorks

Software Analysis process window (within the limits of computer

processing speed). Data for one wavelength (for example, Read

mode), for all 1536, 384 or 96 wells of the read plate, are displayed in

the Multi-Well Graph on the right side of this view. The Detail Graph

can be populated by selecting wells in the Multi-well graph. When an

experiment is completed, post-assay analysis can be done via

ScreenWorks Software, or data can be exported.

In normal operation images are discarded once RLU values have been

measured. However, for quality control purposes, users can define the

number of images per Read with Transfer Fluid step. Up to 100

images per experiment can be retained. These images can be useful for

troubleshooting problems, such as cells lifting from well bottoms during

compound addition. Images are saved as *.tif files with the same name

and to the same directory as the data file. They can be viewed by

clicking the Image button in the Analysis process page when the

resulting data file is open in ScreenWorks Software.

Please note that the robustness of an assay is not dependent on the

size of the signal; it is better determined by the signal-to-noise ratio. A

commonly used calculation for determining assay robustness is the Z’

factor equation1.

LED Modules

The FLIPR® Tetra System has a total of four LED banks providing

illumination for plate reading. The LED banks pulse on, two at a time,

only when an image is to be captured, protecting cells from possible

dye photo-bleaching.

The LED banks are divided between two modules, one on either side of

the read plate position above. LED banks in corresponding positions in

either module are paired. The paired LED banks pulse simultaneously

during an experiment, so that light strikes the read plate base from two

directions, helping to ensure that the entire plate is maximally

illuminated.

1. Zhang J, Chung TDY and Oldenburg KR. A Simple Statistical Parameter for Use

in Evaluation and Validation of High Throughput Screening Assays. J. Biomol.

Screen. 1999; 4:67-73.

0112-0109 H 35

System Hardware Features

Typically, the two LED bank pairs are set up with LEDs of different

wavelengths, for example., one pair might have LEDs of range 470 nm

to 495 nm, while the other pair might be 510 nm to 545 nm.

Ratiometric experiments can be set up to use both of these

wavelengths, in which case the paired banks fire alternately.

Note: Despite the two excitation wavelengths firing alternately,

output data files show time points for each as occurring

simultaneously.

Deflectors around the LED banks direct all light from the LEDs through

excitation bandpass filters that further refine the wavelength. The light

is then funneled into light pipes that focus it onto the base of the read

plate.

The FLIPR® Tetra System will not operate without the full complement

of LED banks installed, however blank LED banks can be used for one

pair if only one excitation wavelength is available. Unless additional LED

banks are ordered with a purchase, FLIPR® Tetra Systems are shipped

with a set of default calcium LED banks (470–495 nm) and a set of

blank LED banks.

Configuration of LEDs for an experiment is mostly carried out in

ScreenWorks Software in the Settings window; see Setup Read Mode

on page 72 for details. LED banks can be changed by the user in

approximately 10 minutes; refer to Exchanging LED Modules on

page 138 for instructions.

LEDs do not need time to warm up prior to running an experiment.

Startup time is only dependent on the time it takes for the camera to

cool down and for the stage to heat up, if this option is used.

The LEDs are air-cooled by fans, however the light output varies

slightly as they heat up. To help with the heat transfer, a piece of foam

in inserted in the back of the LED bank on each side. Also to counteract

the temperature change, a temporal correction is automatically applied

to the LED feedback circuit to normalize the system.

Flat field calibration is automatically applied to the read plate to adjust

for non-uniformity of illumination across the plate. Refer to Optical

Calibration on page 149 for instructions on how to manually calibrate

the system.

WARNING! Do not look into LED banks when turned on,

especially at intensities over 30% or in the UV spectrum,

unless you are viewing them through the observation panel. If

light is seen escaping the instrument when the LED modules

are turned on, shut down immediately and call Molecular

Devices Technical Support.

36 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Figure 2-9 LED configuration.

Emission Filters

A three-position filter slider holding up to three 60 mm diameter

interference filters is located in front of the CCD camera. The slider can

be alternated in front of the camera to separate out the emission band

of the dye being used. These filters can be used with a single excitation

wavelength or can be paired up with additional emission filters and

LEDs in a ratiometric experiment, for example, as excitation LEDs

alternate between two different wavelengths, filters change at the

same time so that each image taken by the camera matches the right

emission filter with the excitation LED bank. The most common FLIPR®

Tetra System configuration is a LED excitation wavelength of 470–495

nm with a 515–575 nm bandpass emission filter. For luminescence

experiments it is also possible to run without the filter.

Emission filters are user-changeable in approximately 5 minutes; see

Changing Filters on page 141 for instructions. Once installed, filters are

mechanically sensed and the filter configuration can be viewed in the

Instrument Configuration panel in ScreenWorks Software. The

instrument will prompt you to calibrate a new emission filter with

respect to an LED module if they are intended to be used in an

experiment.

0112-0109 H 37

System Hardware Features

Note: If a desired filter is not available, three custom filter cassettes

(P/N 0200-6221) are available for purchase to place filters created by

an outside vendor. Once installed, these filters are displayed as

Custom 1, Custom 2 and Custom 3 in ScreenWorks Software.

Chiller

Because the FLIPR® Tetra System is a light-tight instrument there is

very limited airflow inside the instrument enclosure. To provide a

suitable operating environment for both the Standard EMCCD and

Aequorin ICCD cameras, an external chiller is required. The chiller uses

a special cooling liquid supplied with the instrument and is controlled

via the embedded computer and instrument firmware. The chiller sits

outside of the instrument and is connected via cable and tubing to the

FLIPR® Tetra System.

Computer System

Host Computer

Apart from exchanging hardware and manual loading of plates, all

normal user interaction with the FLIPR® Tetra System is mediated

through the ScreenWorks Software run on an external host Intel

processor-based computer, supplied with the system. The minimum

configuration required is:

• Intel Pentium D processor (3.4 GHz or above)

• Windows XP Professional or Windows 7

• 2 GB of SDRAM (or above)

• Hard Disk Drive (160 GB or above)

• Ethernet adapter

• DVD-CDRW drive

• 1 PCI expansion slot (or above)

Please contact Molecular Devices for any specific questions regarding

the system’s host computer.

38 0112-0109 H

FLIPR® Tetra High Throughput Cellular Screening System User Guide

Embedded Computer

An embedded computer located in the lower chamber controls basic

®

FLIPR

the ScreenWorks Software control software installed on the host

computer and sent to the embedded computer to execute the function.

This setup allows data processing and instrument control to be

performed separately to ensure the greatest productivity during an

experiment.

Tetra System functions. These functions are initiated through

0112-0109 H 39

System Hardware Features

40 0112-0109 H

Startup and Shutdown

This chapter provides procedures for starting up and shutting down the

FLIPR® Tetra High Throughput Cellular Screening System. These

procedures should be followed closely in order to ensure proper

communication between ScreenWorks® Software and the hardware.

Starting Up the System

To start the FLIPR® Tetra System:

1. Turn on the computer and monitor.

2. Simultaneously press the Ctrl+Alt+Delete keys to launch the

Windows operating system.

3. At the prompt enter your password.

Note: After installation, the default password is flipr.

Wait for the operating system to finish starting-up before

proceeding.

4. Turn on the external chiller with the switch located on the left

side of the chiller.

5. Turn on the FLIPR® Tetra System’s power switch located on the

right side of the instrument. The system goes through an

initialization cycle to register all instrument components. This