Page 1

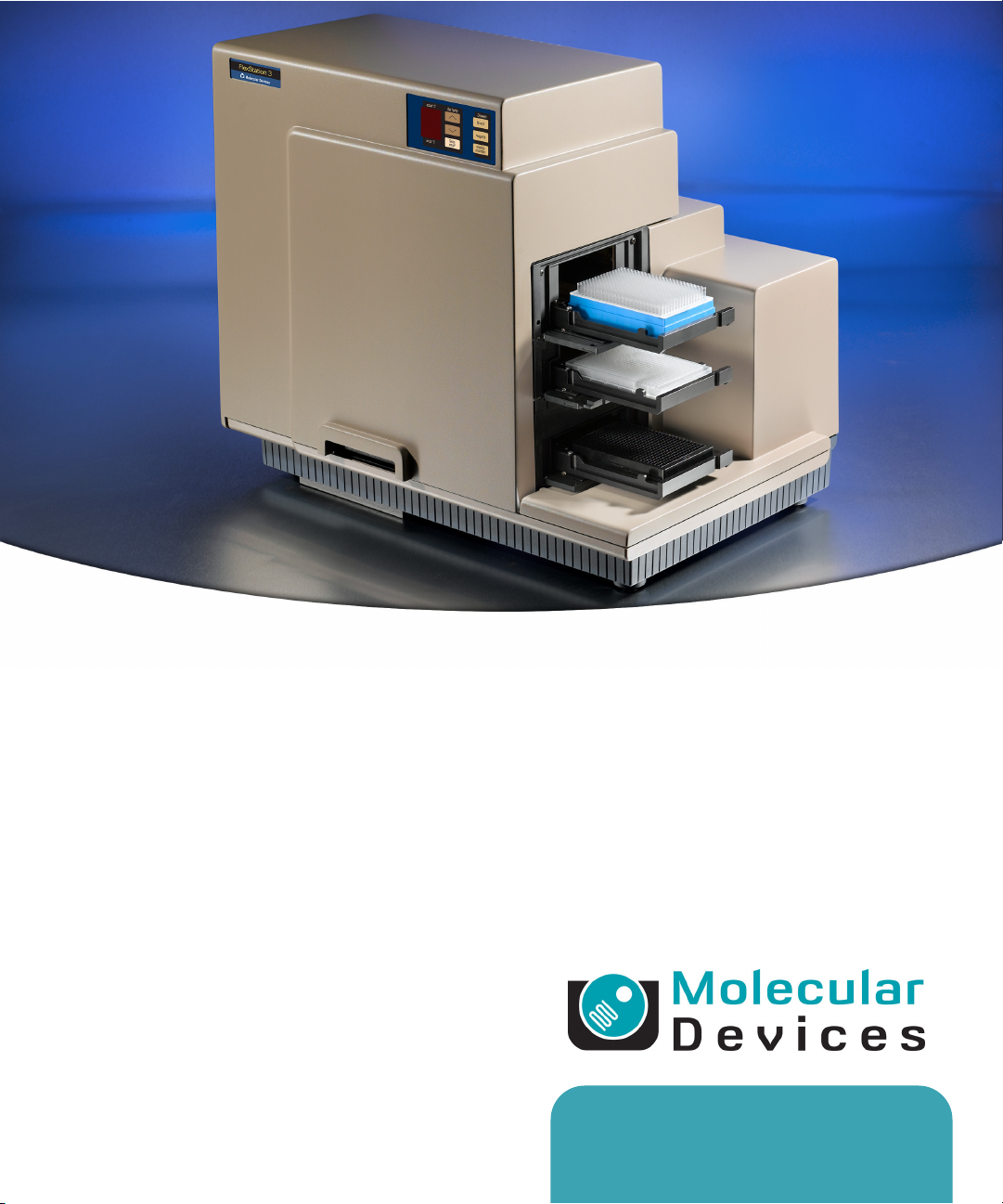

FlexStation® 3 Benchtop Multi-Mode

Microplate Reader

User Guide

0112-0127 B

June 2013

www.moleculardevices.com

Page 2

This document is provided to customers who have purchased Molecular Devices

equipment, software, reagents, and consumables to use in the operation of such

Molecular Devices equipment, software, reagents, and consumables. This document

is copyright protected and any reproduction of this document, in whole or any part,

is strictly prohibited, except as Molecular Devices may authorize in writing.

Software that may be described in this document is furnished under a nontransferrable license. It is against the law to copy, modify, or distribute the software

on any medium, except as specifically allowed in the license agreement.

Furthermore, the license agreement may prohibit the software from being

disassembled, reverse engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only to

designate those manufacturers’ products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers’ and/or their product names as

trademarks.

Each product is shipped with documentation stating specifications and other

technical information. Molecular Devices products are warranted to meet the stated

specifications. Molecular Devices makes no other warranties or representations

express or implied, including but not limited to, the fitness of this product for any

particular purpose and assumes no responsibility or contingent liability, including

indirect or consequential damages, for any use to which the purchaser may put the

equipment described herein, or for any adverse circumstances arising therefrom. The

sole obligation of Molecular Devices and the customer's sole remedy are limited to

repair or replacement of the product in the event that the product fails to perform as

warranted.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These

trademarks may not be used in any type of promotion or advertising without the prior written permission of

Molecular Devices, LLC.

Patents:

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

© 2013 Molecular Devices, LLC.

All rights reserved.

http://www.moleculardevices.com/productpatents

Page 3

Contents

Chapter 1: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How To Use This User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

User Guide Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions Used for Precautionary Information. . . . . . . . . . . . . 10

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service-Trained Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Avoiding Mechanical Problems During Fluid Transfer . . . . . . . . . 11

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Covers and Instrument Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluidics Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Detection Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Overview of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Choosing an Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Preparing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Preparing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Running the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Analyzing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Instrument Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Assay Read Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SoftMax Pro Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Set Up the Reader and Software Parameters . . . . . . . . . . . . . . . . 42

Acquire Data from the Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Perform Complex Data Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

0112-0127 B 3

Page 4

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Chapter 2: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

General Precautionary Information . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Unpacking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Unpacking the Fluidics Module and Accessories . . . . . . . . . . . . . . 51

Unpacking the Detection Module . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Removing the Shipping Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installing the Fluidics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Installing the Pipettor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting Up the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connecting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Installing the Drawer Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Microplate Adapter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Compound Baseplate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing SoftMax Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 3: Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Starting Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Setting the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Displaying the Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting the Temperature with the Control Panel . . . . . . . . . . . . . .73

Setting the Temperature with SoftMax Pro Software . . . . . . . . . . 74

Setting Up the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

SoftMax Pro Software Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Read Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Read Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Wavelengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Assay Plate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Wells to Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Automix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

AutoCalibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Settling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

AutoRead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SoftMax Pro Software Parameters for Fluid Transfer. . . . . . . . . . . . 86

Compound Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 0112-0127 B

Page 5

Contents

Compound Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Triturate Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Pipette Tips Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Compound and Tip Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Pipette Tip Air Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Settings Displayed in Plate Sections . . . . . . . . . . . . . . . . . . . . . . . . . 98

Other Software Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Reading a Microplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Loading Tips and Microplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Starting the Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Selecting a Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Replacing Data in a Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Viewing Experiment Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Optimizing Fluorescence Assays . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Using Spectral Scanning to Optimize Excitation and Emission

Wavelengths for Fluorescence Assays . . . . . . . . . . . . . . . . . . . . . 105

Optimizing Time-Resolved Fluorescence Assays . . . . . . . . . . . . . . 110

Optimizing Fluorescence Polarization Assays . . . . . . . . . . . . . . . . . 111

Optimizing Luminescence Assays . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Chapter 4: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Obtaining Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Moving the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Cleaning the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cleaning Up Spills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Cleaning the Fan Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Cleaning the Barrels on the Pipettor Head. . . . . . . . . . . . . . . . . . 117

Using the Microplate Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Microplate Adapter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Removing the Microplate Adapter . . . . . . . . . . . . . . . . . . . . . . . . 120

Using the Compound Baseplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Replacing the Flash Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Long-Term Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Chapter 5: Troubleshooting Procedures. . . . . . . . . . . . . . . . . . 129

Problems During Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

0112-0127 B 5

Page 6

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Opening a Drawer Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Understanding Potential Mechanical Problems . . . . . . . . . . . . . . . 133

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Before Using the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Avoiding Mechanical Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

In Case of Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Recovering from Mechanical Problems in Flex Mode when Using

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Assessing a Mechanical Problem . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Opening the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Evaluating the Tip Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Inspecting Inside the Fluidics Module . . . . . . . . . . . . . . . . . . . . . .139

Removing the Pipettor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Expelling Undispensed Fluid from Tips . . . . . . . . . . . . . . . . . . . . . 145

Recovery Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

General Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Other Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Tilting or Removing the Fluidics Module . . . . . . . . . . . . . . . . . . . . . 149

Tilting the Fluidics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Removing the Fluidics Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Appendix A: Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . 153

Ordering Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Appendix B: Performance Specifications . . . . . . . . . . . . . . . . . 155

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

6 0112-0127 B

Page 7

Description

Introduction

1

This chapter provides background information on the system, including

descriptions of the principal components and overviews of how the

system functions. It is divided into the following sections:

• Introduction, see page 7

• How To Use This User Guide, see page 9

• Safety Information, see page 9

• System Overview, see page 13

• System Components, see page 15

• Overview of Operation, see page 32

• Theory of Operation, see page 33

• SoftMax Pro Software, see page 41

The FlexStation® 3 Benchtop Multi-Mode Microplate Reader combines

the performance of the Molecular Devices SpectraMax® M5e MultiMode Microplate Reader with an integrated 8-channel or 16-channel

pipettor into one compact benchtop reader. This integrated system

provides users with a multi-detection platform capable of increasing the

liquid handling throughput and flexibility for biochemical-based and cellbased assays. Using an integrated 8-channel or 16-channel pipettor

increases assay flexibility by transferring reagents from 96 or 384 distinct

wells in a source plate to the read plate. This method enables users to

define individual reagents or compound concentrations to be delivered

to each well during the assay. The direct transfer from a source

microplate reduces consumption and allows more assay conditions to be

explored in a single microplate, making the system equally amenable to

agonist and antagonist assay formats. These additions can either occur

concurrently with kinetic analysis of reactions or before an assay to

automate reagent additions. Combined fluid transfer with multidetection optics provides a single reader capable of performing a broad

span of applications that pass through drug discovery and research

environments.

0112-0127 B 7

Page 8

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Based on the SpectraMax M5e instrument platform, the FlexStation 3

instrument can address detection modalities including absorbance,

fluorescence intensity, fluorescence polarization, time-resolved

fluorescence, and luminescence. Dual monochromators allow users to

target the optimal assay excitation and emission wavelengths, while

eliminating the need to change expensive band pass filters between

experiments. Dual PMTs are integrated into the system to provide

flexibility to detect multiple detection modes, while a separate PMT

provides additional sensitivity for luminescence applications. Reference

diodes automatically adjust to slight fluctuations in excitation intensity to

reduce measurement noise. Absorbance applications are enhanced using

top-quality UV-grade fibers to provide high light transmission in the

lowest wavelengths. These optical characteristics enable the system

performance to be comparable to a top-of-the-line dedicated

spectrophotometer or spectrofluorometer with no trade-off between

instrument performance and the number of read modes.

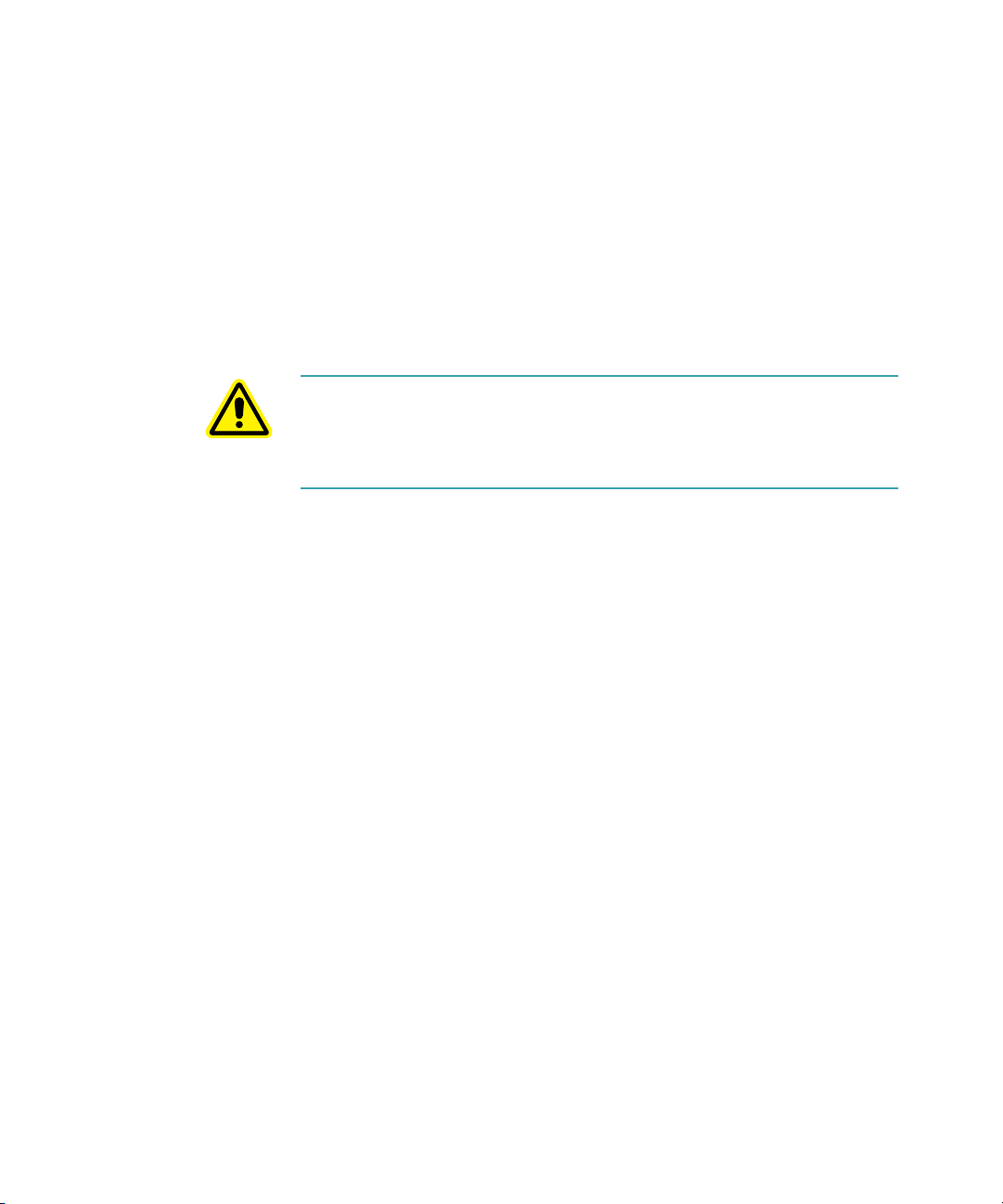

Figure 1-1: FlexStation 3 Instrument

8 0112-0127 B

Page 9

How To Use This User Guide

This user guide was written to ensure safe and proper use of the system.

Before use, read this user guide carefully to realize the full capabilities of

the system. Also, if something is unclear during daily use or if a problem

occurs, please refer to this user guide.

User Guide Organization

This user guide is organized as follows:

• Description on page 7 provides background information on the

system, including component descriptions, functional overviews,

and safety information.

• Installation on page 49 provides instructions for setting up the

reader.

• Operating Procedures on page 65 provides instructions for

starting up the reader, setting parameters for the various read

modes, and reading a microplate.

• Maintenance on page 113 provides instructions for cleaning the

fan filter, changing the fuses, and moving the system to a new

location.

• Troubleshooting Procedures on page 129 provides instructions

for diagnosing and solving common problems, as well as a list of

error conditions.

• Parts and Accessories on page 153 provides a list of spare parts.

• Performance Specifications on page 155 provides the technical

specifications for the instrument.

• Glossary on page 163 provides a list of terms and definitions.

Description

Safety Information

When operated properly in a safe environment and according to the

instructions in this user guide, there are no known hazards associated

with the FlexStation 3 instrument. However, proper use requires an

understanding of situations that are potentially dangerous and can result

in serious injury. All users must be familiar with the guidelines in this

section before working with the system.

0112-0127 B 9

Page 10

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

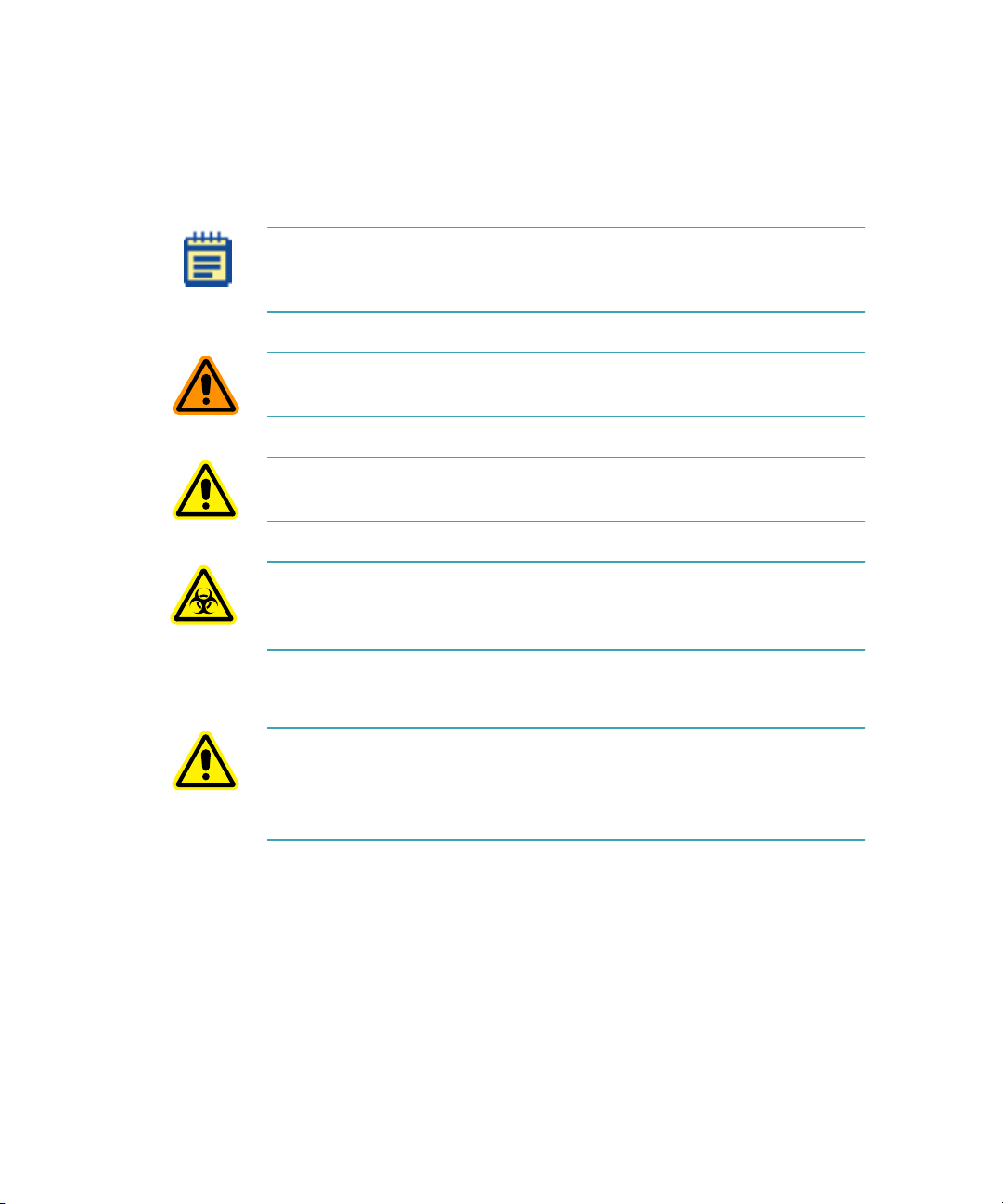

Conventions Used for Precautionary Information

This user guide uses the following conventions to provide technical and

safety information of special interest.

Note: A note gives background information that is provided to clarify a

particular step or procedure. A not can also provided an instruction to

ensure correct results and optimal performance.

CAUTION! A caution is an instruction that, if not followed, can result in

damage to the system or in loss of data.

WARNING! A warning is an instruction that, if not followed, can result

in potential injury to a person working with the system.

WARNING! BIOHAZARD. A biohazard warning indicates a condition

involving potentially infectious biological agents requiring that proper

handling precautions be taken.

Electrical Safety

WARNING! Follow all instructions in this user guide and on system

labels. If you use the system in a manner not specified by Molecular

Devices, then any protections provided by the system might be

impaired.

10 0112-0127 B

Page 11

Description

Service-Trained Users

There are two types of users described in this user guide. Most

procedures required for operating and troubleshooting can be

performed by any user who has read the instructions in this user guide

and is familiar with the system. However, all installation procedures, and

some more complex service and troubleshooting procedures, require the

expertise of a service-trained user. Whenever the following warning

message appears, a service-trained user must perform the procedure to

ensure user safety and to prevent instrument damage.

Example:

WARNING! The following procedures must be completed by a

service-trained user. Do not attempt the following procedures if you

have not been trained properly by appropriate Molecular Devices

personnel.

Avoiding Mechanical Problems During Fluid Transfer

Because of the complex mechanical nature of the FlexStation 3

instrument, including both fluidics and optical reading, smooth and

reliable operation of the system depends on both good design and

operator knowledge.

To prevent problems of a mechanical nature, be sure to read all sections

of this user guide before attempting a reading with fluidics. See

Understanding Potential Mechanical Problems on page 133.

Safety Messages

Observe the following warnings and precautions:

High internal voltages. Always turn off the power switch and unplug the

system power cord before removing labeled covers or panels.

Xenon-arc flash lamp. Do not look directly at the flash lamp while it is

illuminated. The lamp emits ultraviolet radiation at levels that can injure

the eye if viewed directly.

Electrical grounding. Never use a two-prong plug or extension cord to

connect primary power to the system. Use of a two-prong adapter

disconnects the utility ground, creating a severe shock hazard. Always

connect the system power cord directly to a three-prong receptacle with

a functional ground.

0112-0127 B 11

Page 12

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Spilled liquids. Avoid spilling liquids on the system. Fluid spilled into

internal components creates a potential shock hazard. Wipe up all spills

immediately. Do not operate the system if internal components have

been exposed to spilled fluid. Unplug instrument if there is a fluid spill in

the instrument and contact Technical Support.

Replacement fuses. Use replacement fuses with the required current

rating and specification. Improper fuses or short-circuiting the fuse

holders can cause fire or damage the instrument.

Power rating. Ensure the system is connected to a power receptacle that

provides voltage and current within the specified rating for the system.

Use of an incompatible power receptacle can create electrical shock and

fire hazards.

Remove watches and jewelry before removing any panels from the

instrument.

Warning labels. There are several labels affixed to the instrument covers

and inside panels. The purpose of these labels is to alert the user to use

caution when servicing a component or the instrument. The user should

be aware that ignoring the instructions on any instrument label can

result in a hazardous condition that can cause injury.

Identification labels: The following label, among others, appears on the

instrument.

\

Figure 1-2: FlexStation 3 Instrument Label

12 0112-0127 B

Page 13

System Overview

The FlexStation 3 Benchtop Multi-Mode Microplate Reader is a

monochromator-based microplate reader that has 6-well, 12-well, 24well, 48-well, 96-well, and 384-well microplate reading capability for

absorbance, fluorescence intensity, fluorescence polarization, timeresolved fluorescence, and luminescence. When using the integrated

pipettor, the instrument offers 96-well and 384-well microplate-tomicroplate fluid transfer, 8 or 16 wells at a time.

The top portion of the instrument, the fluidics module, uses an 8-channel

or 16-channel pipettor, to expand assay flexibility by transferring

reagents from a 96-well or 384-well source plate to the assay plate.

When transferring reagents from distinct wells of a microplate, users can

define individual reagents or concentrations to be delivered in each well

during their assay. This direct transfer allows more assay conditions to be

explored in a single microplate, reducing reagent consumption as well as

making the system more amenable to both agonist and antagonist assay

formats. In addition, kinetic cell-based assay throughput (for example,

calcium mobilization) is increased when 8 or 16 wells of a microplate are

analyzed in conjunction rather than individually.

Integrated pipetting provides flexibility, and also offers users parameters

to optimize assay robustness. Trituration, mixing via aspiration and

dispense of the pipettor, encourages mixing to either resuspend source

plate compounds or spontaneously mix reagents to promote a rapid

response with minimal assay variability. Dispense parameters can also be

optimized for each experiment to accommodate cells with different

adherence characteristics to prevent cell dislodging. Furthermore, the

integrated fluidics platform uses disposable pipette tips to minimize

reagent cross contamination between wells or experiments.

The fluidics module interfaces with the lower reading chamber which

encloses a high-powered Xenon flash lamp as the light source. Sensitivity

or read-speed can be optimized by varying the number of lamp flashes

per read.

The two holographic diffraction grating monochromators allow selection

of any wavelength between 200 nm and 1000 nm in absorbance; 250 nm

and 850 nm in fluorescence intensity, time-resolved fluorescence (TRF),

or luminescence; and 400 nm and 750 nm for readings in fluorescence

polarization. Excitation and emission wavelengths are optimized using

the mirrored optics to focus light into the sample volume, and cutoff

filters to reduce stray light and minimize background interference.

Description

0112-0127 B 13

Page 14

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

The system has five assay types available which include Flex, Endpoint,

Kinetic, Spectrum, and multi-point Well Scan. Flex mode assay enables

users to transfer fluid from the source read plate while immediately

reading a fast kinetic assay that uses absorbance, fluorescence, or

luminescence detection technologies. Alternatively, the pipettor head

can be used to transfer fluid before an endpoint or kinetic assay to

automate fluid transfer and minimize user interaction.

In addition to fluid transfer, well contents can be mixed automatically by

shaking before each read cycle, making it possible to perform kinetic

analysis of solid-phase, enzyme-mediated reactions.

Top detection in microplates is available for all fluorescence and

luminescence readings. Bottom detection is available for all assay types

except fluorescence polarization. When reading absorbance at

wavelengths below 340 nm, special UV-transparent, disposable or quartz

microplates that allow transmission of the far ultraviolet spectra must be

used.

A plate drawer adapter is provided with the reader. The adapter is

required for optimum performance when reading from the top or

bottom of standard 96-well and 384-well microplates in all read types,

including absorbance.

Variations in measured fluorescence values are virtually eliminated by

internal compensation for detector sensitivity, photomultiplier tube

voltage, and excitation source intensity.

Using the FlexStation 3 instrument with the PathCheck® Pathlength

Measurement Technology allows normalization of variable well volumes

to absorbance readings. In addition PathCheck technology allows for

pipettor validation, including the online 8-channel and 16-channel

pipettors, and to compare experiments from different days.

Temperature in the microplate chamber is isothermal, both at ambient

and when the incubator is turned on. When the incubator is on, the

reading chamber temperature can be controlled from 2°C above ambient

room temperature to 45°C. Please note that the temperature of the

fluidics module is not regulated and that it is recommend that any

microplates or tips should be at the desired temperature before placing

them inside the instrument.

14 0112-0127 B

Page 15

The FlexStation 3 instrument is controlled by an external computer

running the SoftMax® Pro Microplate Data Acquisition and Analysis

Software, which provides integrated instrument control, data display,

and statistical data analysis. The on-board microprocessor calculates and

reports the absorbance, percent transmittance, fluorescence, or

luminescence for each well of a microplate. Data from multiple

wavelengths can be acquired and ratio analysis can be performed during

a single reading, if desired. In addition, different calculations can be

made based on this data using the SoftMax Pro software, including the

subtraction of blanks, quantitation from standard curves, calculation of

IC50 values, and more.

The extreme flexibility and high sensitivity of the FlexStation 3 reader

makes it appropriate for applications within the fields of biochemistry,

cell biology, immunology, toxicology, molecular biology, and

microbiology. Online fluidic integration expands the capabilities of the

instrument to include fast fluorescence (calcium mobilization),

luminescence, and absorbance assays in addition to typical applications

which include ELISA, nucleic acid and protein quantitation,

homogeneous and heterogeneous enzyme-activity assays, and microbial

growth, endotoxin testing, and reporter-gene assays.

System Components

Description

This section describes the major system components listed below.

• Covers and Instrument Panels, see page 17

• Drawers, see page 21

• Fluidics Module, see page 24

• Detection Module, see page 26

• Computer, see page 28

• Accessories, see page 28

• Consumables, see page 30

0112-0127 B 15

Page 16

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

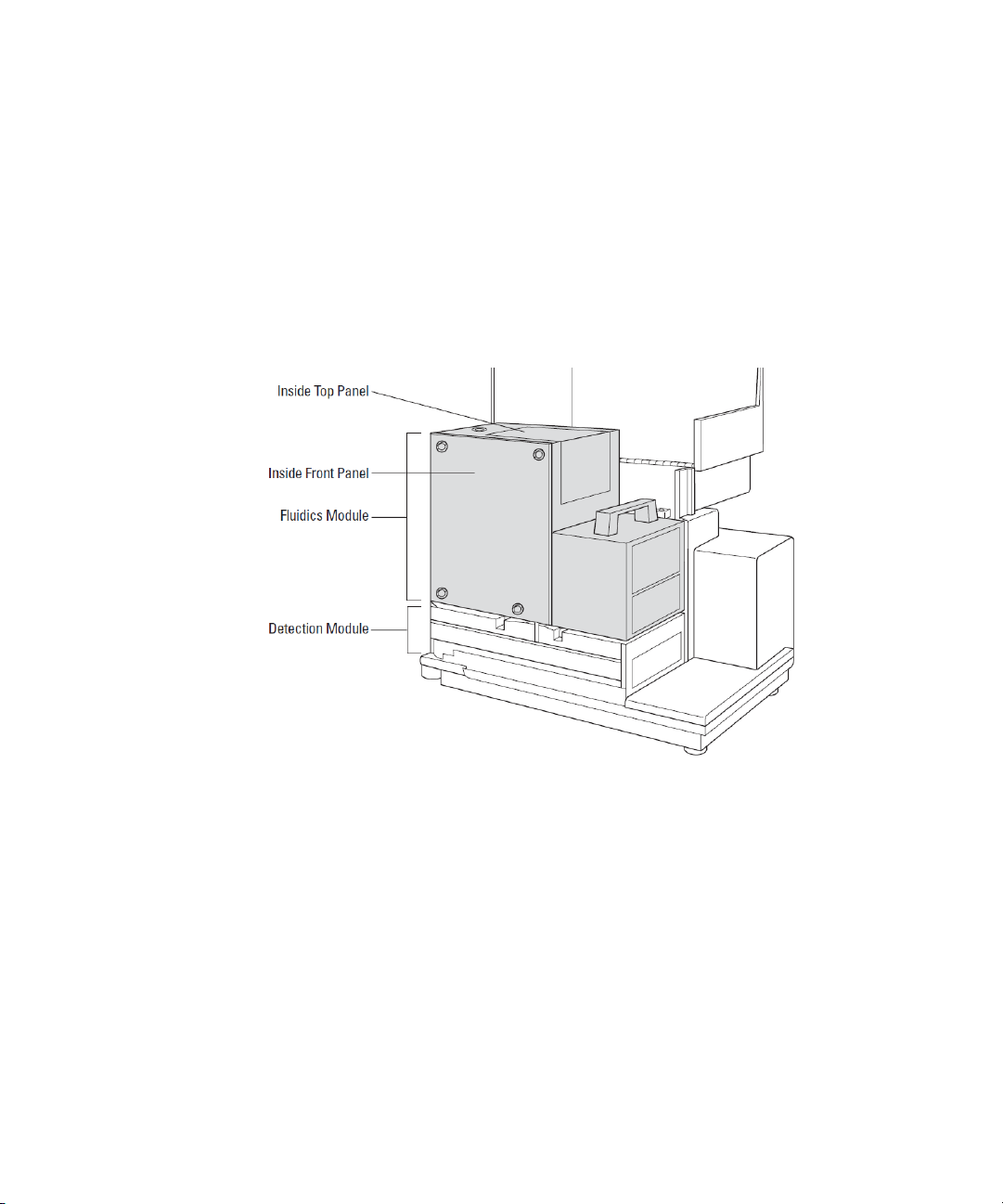

Figure 1-3: Instrument, Front View

Figure 1-4: Instrument, Rear View

16 0112-0127 B

Page 17

Description

Covers and Instrument Panels

Top Cover

The instrument is protected by a molded plastic housing. The large top

cover protects the fluidics module and the exposed portions of the

detection module.

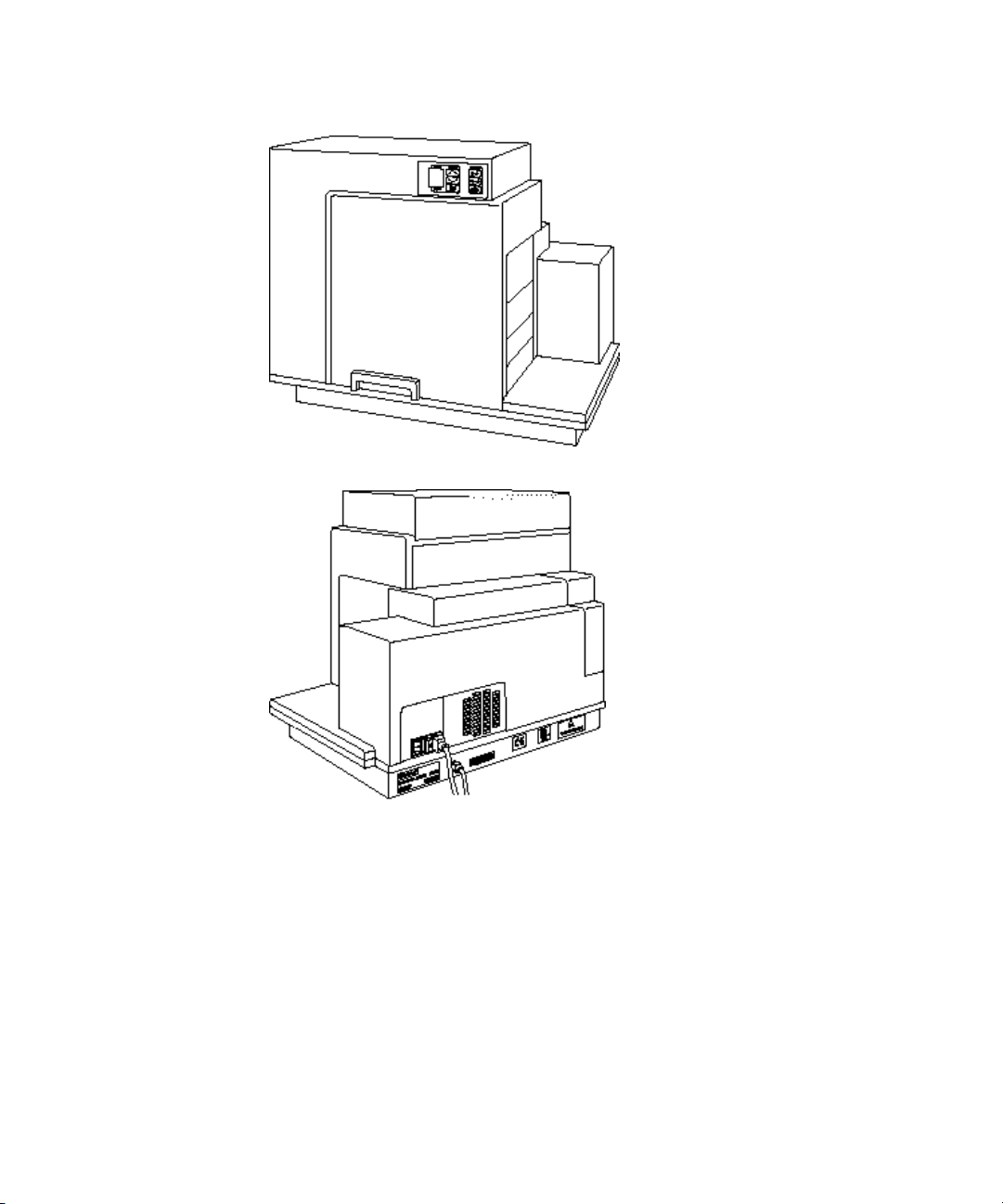

Note: The top cover can be lifted back, as shown in the figure below,

for certain limited troubleshooting procedures. See

Instrument on page 137.

Opening the

Figure 1-5: Lifting Off the Top Cover

Note: To achieve optimal performance during readings, you must

operate the system with the top cover in place.

0112-0127 B 17

Page 18

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

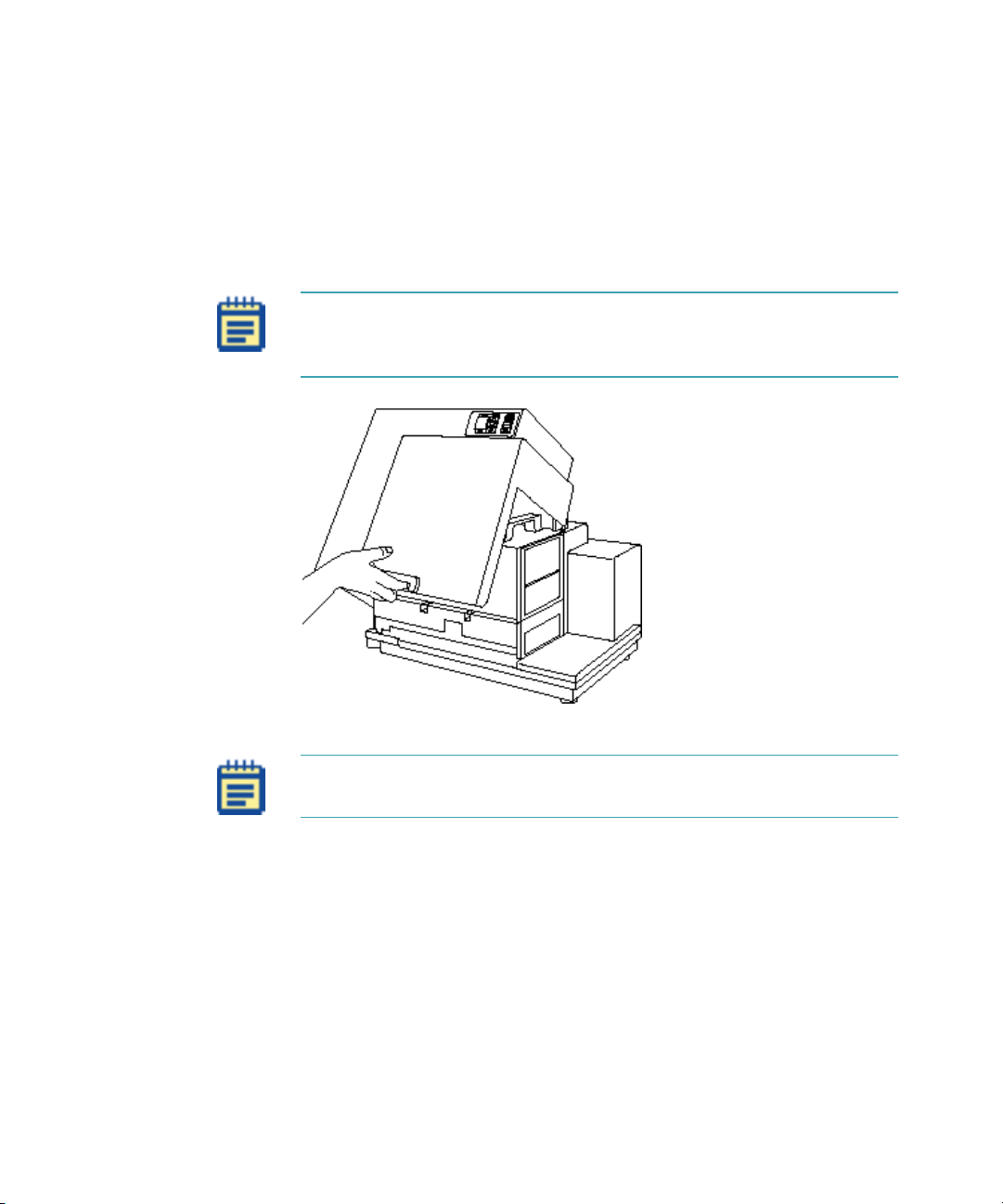

Control Panel

The control panel consists of an LCD and six pressure-sensitive

membrane keys which can be used to initiate and regulate the

temperature and to open and close the drawers.

A 2×3-character liquid crystal display (LCD) shows the current instrument

temperature at all times, and the set point temperature when the

incubator is on.

Figure 1-6: Control Panel

Starting Up the System on page 67 and Setting the Temperature on

See

page 72.

18 0112-0127 B

Page 19

Description

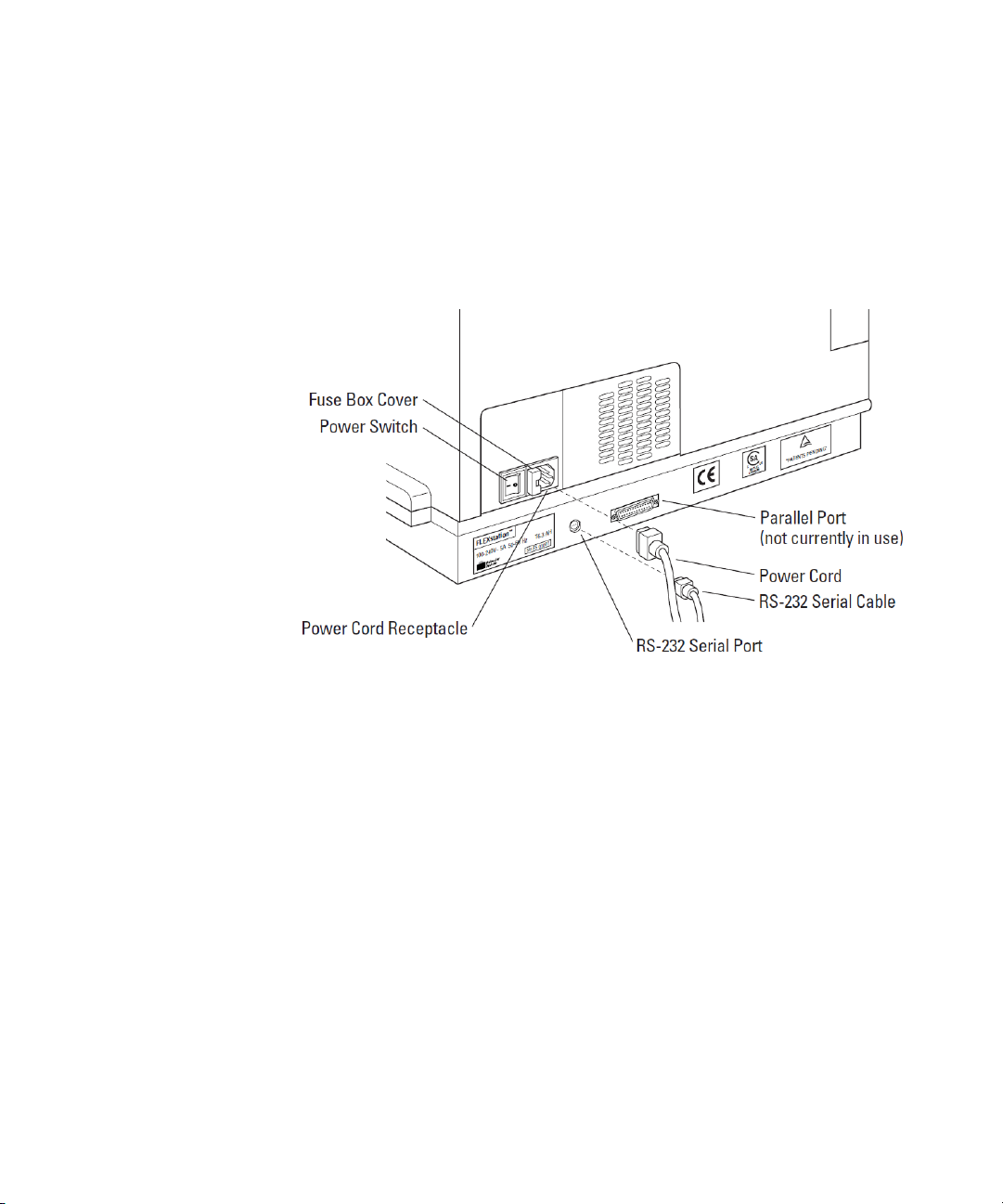

Input/Output Panels

There are two input/output panels on the rear of the instrument.

• The upper input/output panel, on the back cover, consists of a

power switch, fuse box cover, and power cord receptacle.

• The lower panel consists of an RS-232 serial port and parallel

port (not currently active). There are also a number of

identification labels.

Figure 1-7: Input/Output Panels.

For information about attaching the computer cable and power cords to

the instrument, see

0112-0127 B 19

Connecting the Cables on page 61.

Page 20

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

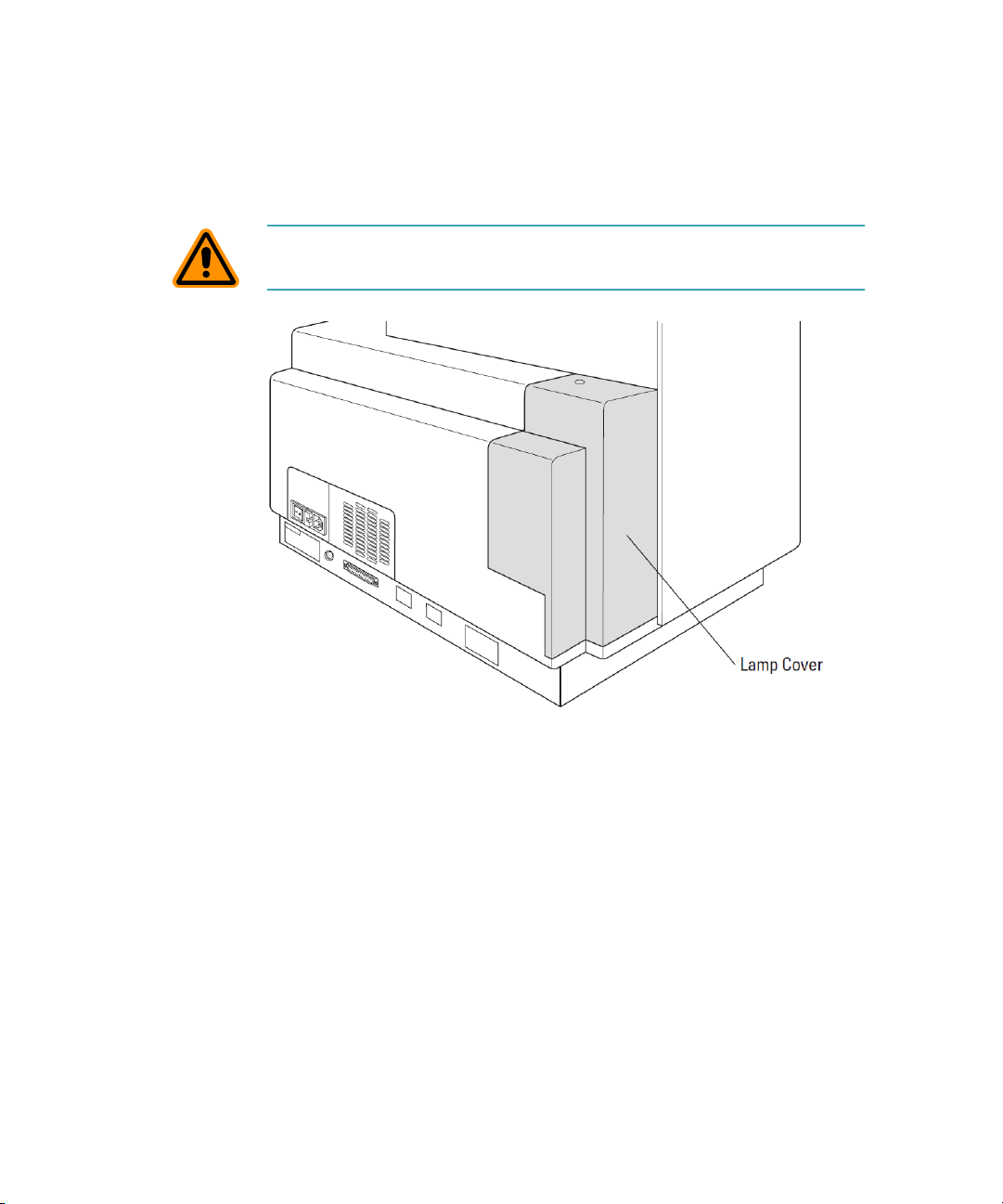

Lamp Cover

The plastic lamp cover provides access to the flash lamp on the right side

of the instrument (as viewed from the rear).

CAUTION! Flash lamp access and maintenance are restricted to servicetrained users.

Figure 1-8: Rear View

Replacing the Flash Lamp on page 123.

See

20 0112-0127 B

Page 21

Description

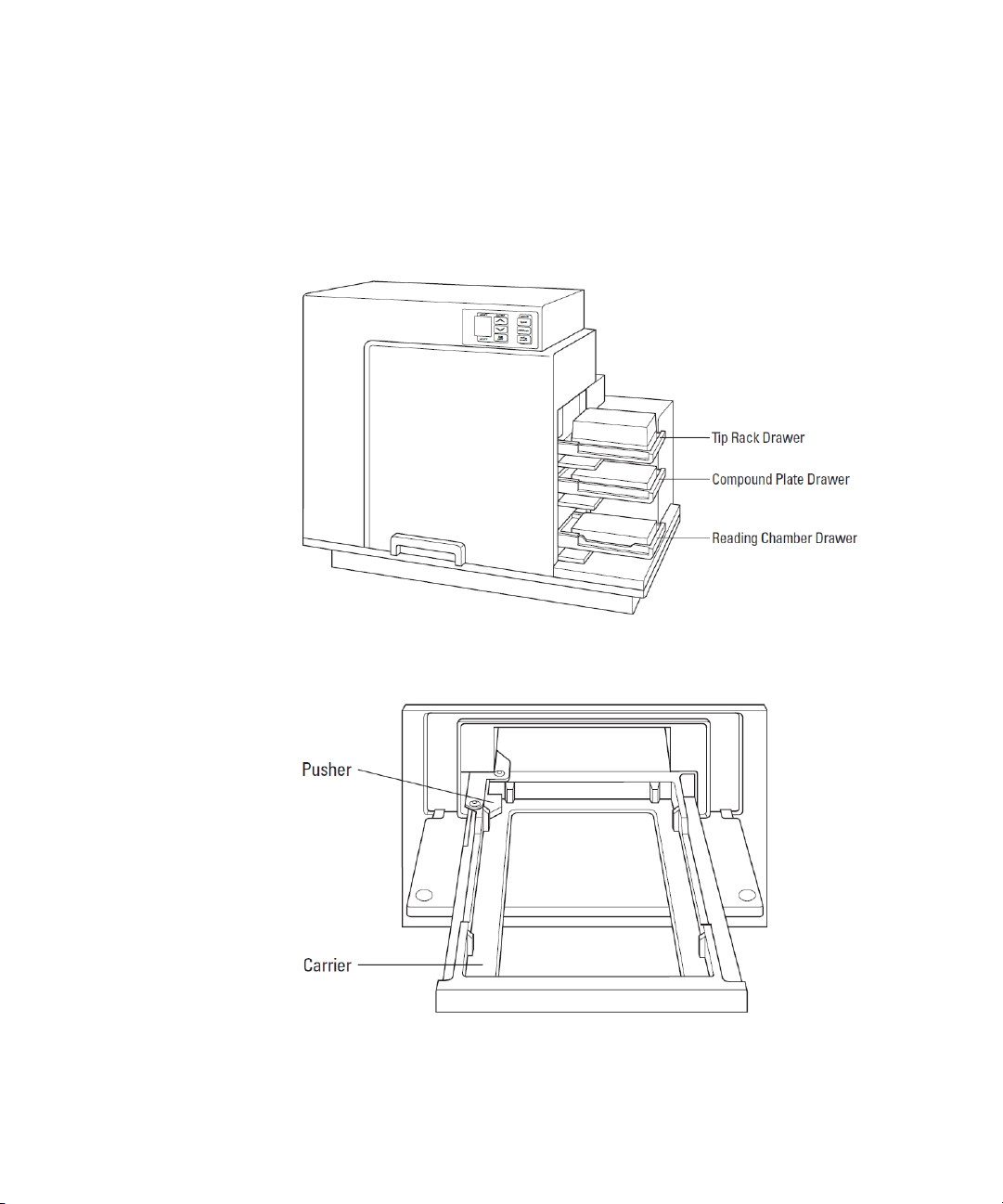

Drawers

The instrument has three drawers that open on the right side. The two

drawers in the fluidics module open and close to move the pipette tip

rack and compound plates (or reservoirs) into and out of the instrument.

The reading chamber drawer in the detection module transports the

assay microplate into the reading chamber.

Figure 1-9: Instrument with Drawers Open and Carriages Accessible

Small plastic pushers, in the front left corner of each drawer, hold the

plates, racks, or reservoirs securely in place when the drawers are closed.

Figure 1-10: Drawer Detail

0112-0127 B 21

Page 22

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

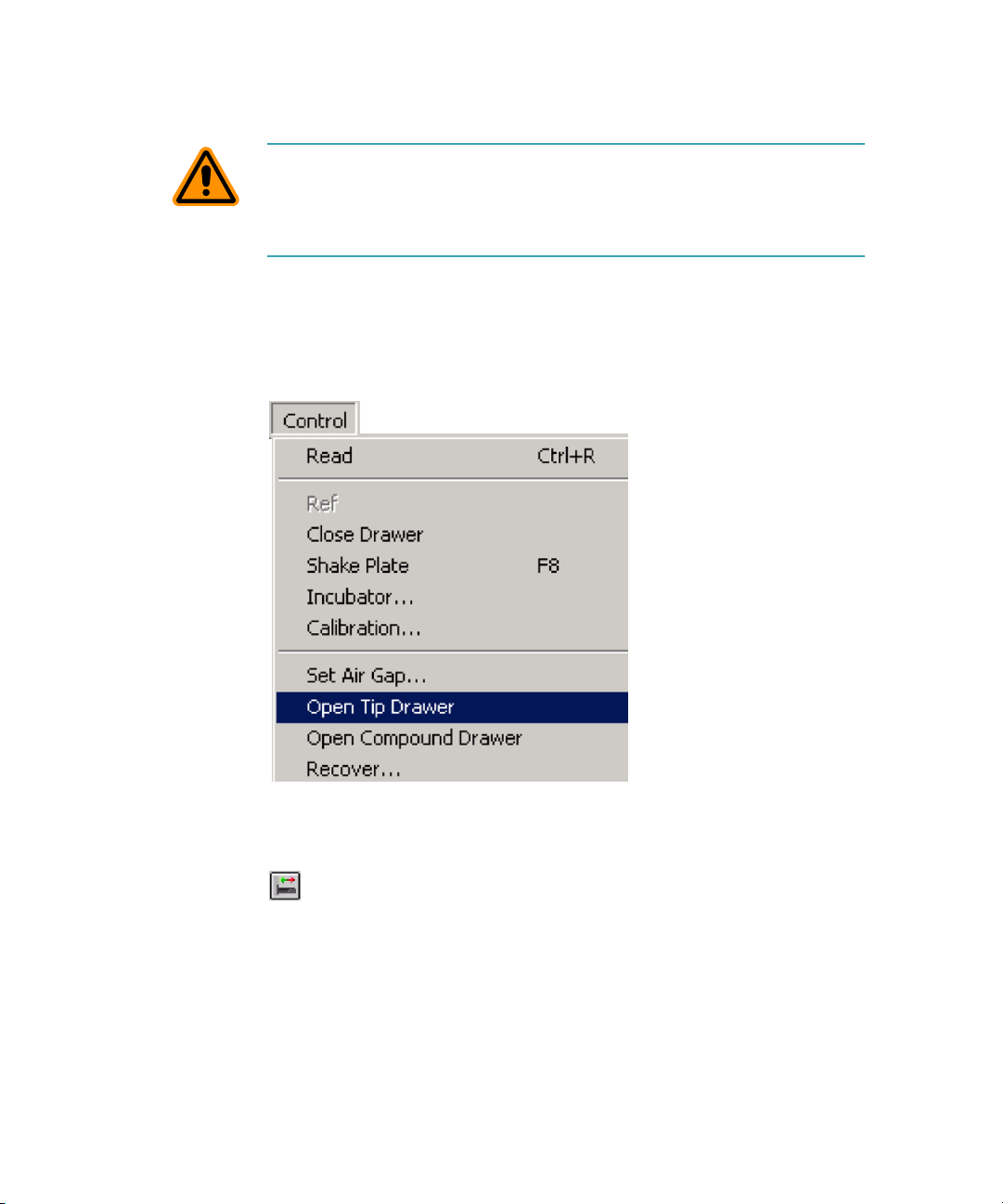

CAUTION! Do not obstruct the movement of any of the drawers. If you

must retrieve a plate after an error condition or power outage, and if the

drawer will not open, it is possible to open the drawer manually. See

Opening a Drawer Manually on page 132.

You can open and close the drawers using either the SoftMax Pro

Software or by pressing the drawer keys on the instrument control panel.

Using the SoftMax Pro Software, open the Control menu and click Tip

Drawer for the tip rack drawer, Compound Drawer for the compound

plate drawer, or Open Drawer for the reading chamber drawer.

Figure 1-11: SoftMax Pro Software Control Menu

You can also open or close the reading chamber drawer with the Drawer

button on the Status Bar.

Figure 1-12: SoftMax Pro Software Drawer Button

22 0112-0127 B

Page 23

Description

Tip Rack Drawer

The top drawer holds the pipette tip rack.

Only tips specified by Molecular Devices for use with the FlexStation 3

instrument can be safely used. See

CAUTION! Do not use parts and accessories that are not authorized by,

specified by or provided by Molecular Devices. Using unauthorized parts

can damage the instrument.

Parts and Accessories on page 153.

Compound Plate Drawer

The compound plate drawer holds a 96-well or 384-well microplate. The

instrument can simultaneously transfer a column of fluids from the

compound plate:

• Eight fluids from a 96-well compound plate to a 96-well assay

plate

• Sixteen fluids from a 384-well compound plate to a 384-well

assay plate

Note: Be sure to install the compound baseplate before placing a

compound plate in the drawer.

Reading Chamber Drawer

The reading chamber drawer opens to accept a 96-well and 384-well

microplate for analysis in the reading chamber. It is the lowest of the

three drawers.

The reading chamber drawer operation varies, depending on the

incubator status. When the incubator is off, the reading chamber drawer

is open at power up and after a read. When the incubator is on, the

drawer closes automatically to maintain the temperature of the reading

chamber.

Note: Be sure to install the black microplate adapter before placing an

assay plate in the drawer for standard 96-well and 384-well microplates.

See Installing the Drawer Adapters on page 62.

0112-0127 B 23

Page 24

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Fluidics Module

The fluidics module houses the pipettor head, several motors, and all the

fluidics components. There are two horizontally-moving carriers, one for

the pipette tip rack and the other for the compound plate. The pipettor

head moves vertically between the drawers.

The fluidics module can be opened, by service-trained users, from the

inside front panel, if necessary for maintenance, or from the inside top

panel to install or remove the pipettor head. The entire fluidics module

can be removed for maintenance or to transport the system to another

location.

Figure 1-13: Fluidics Module

Installing the Fluidics Module on page 53 or See Troubleshooting

See

Procedures on page 129.

24 0112-0127 B

Page 25

Description

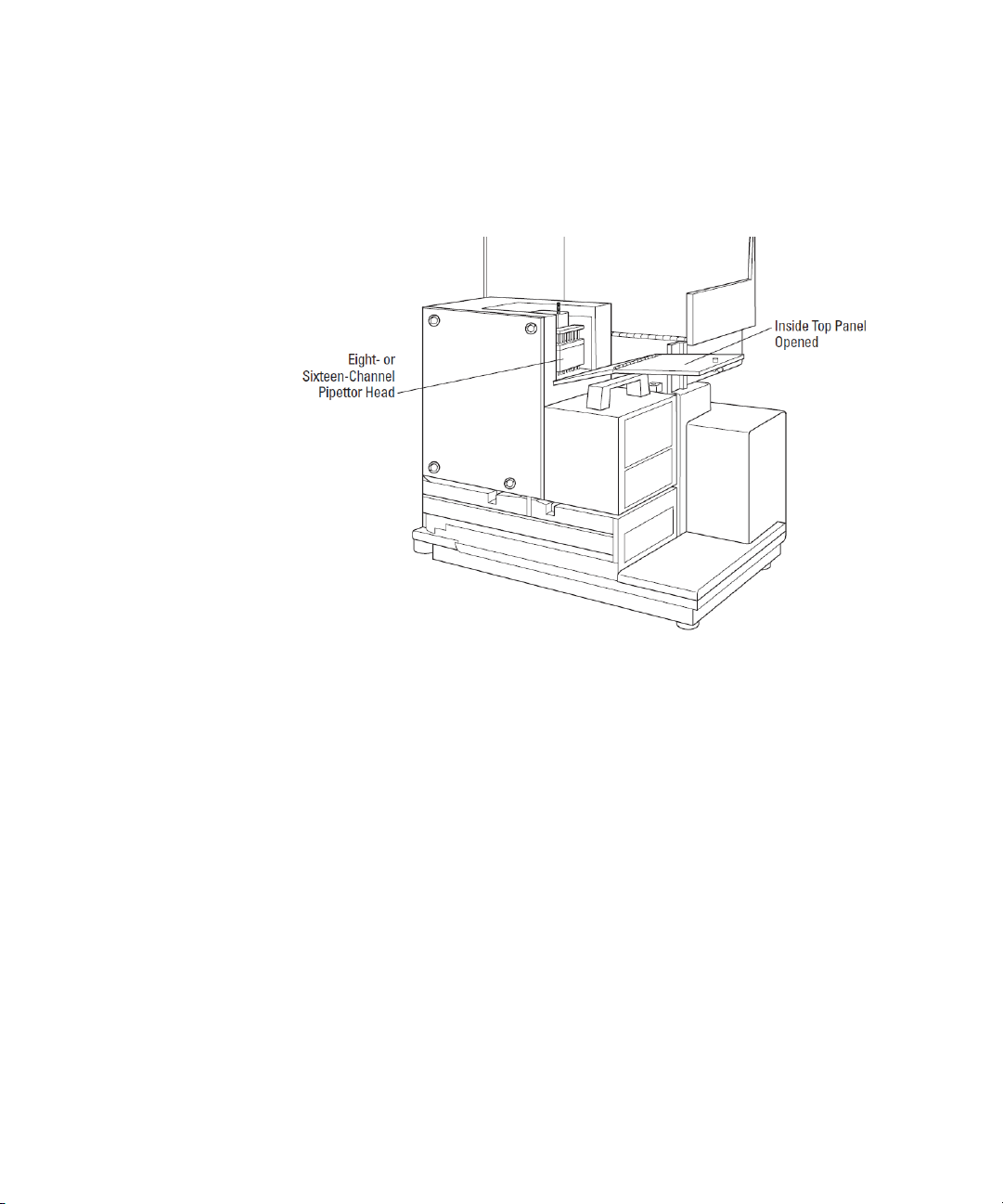

Pipettor Head

The instrument is configured with an 8-channel pipettor head for use

with 96-well microplates or a 16-channel pipettor head for use with 384well microplates.

Figure 1-14: Pipettor Head

Installing the Pipettor Head on page 56.

See

The barrels on the pipettor head require periodic cleaning to remove

silicone lubricant, dust, and other miscellaneous contamination. See

Cleaning the Barrels on the Pipettor Head on page 117.

0112-0127 B 25

Page 26

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

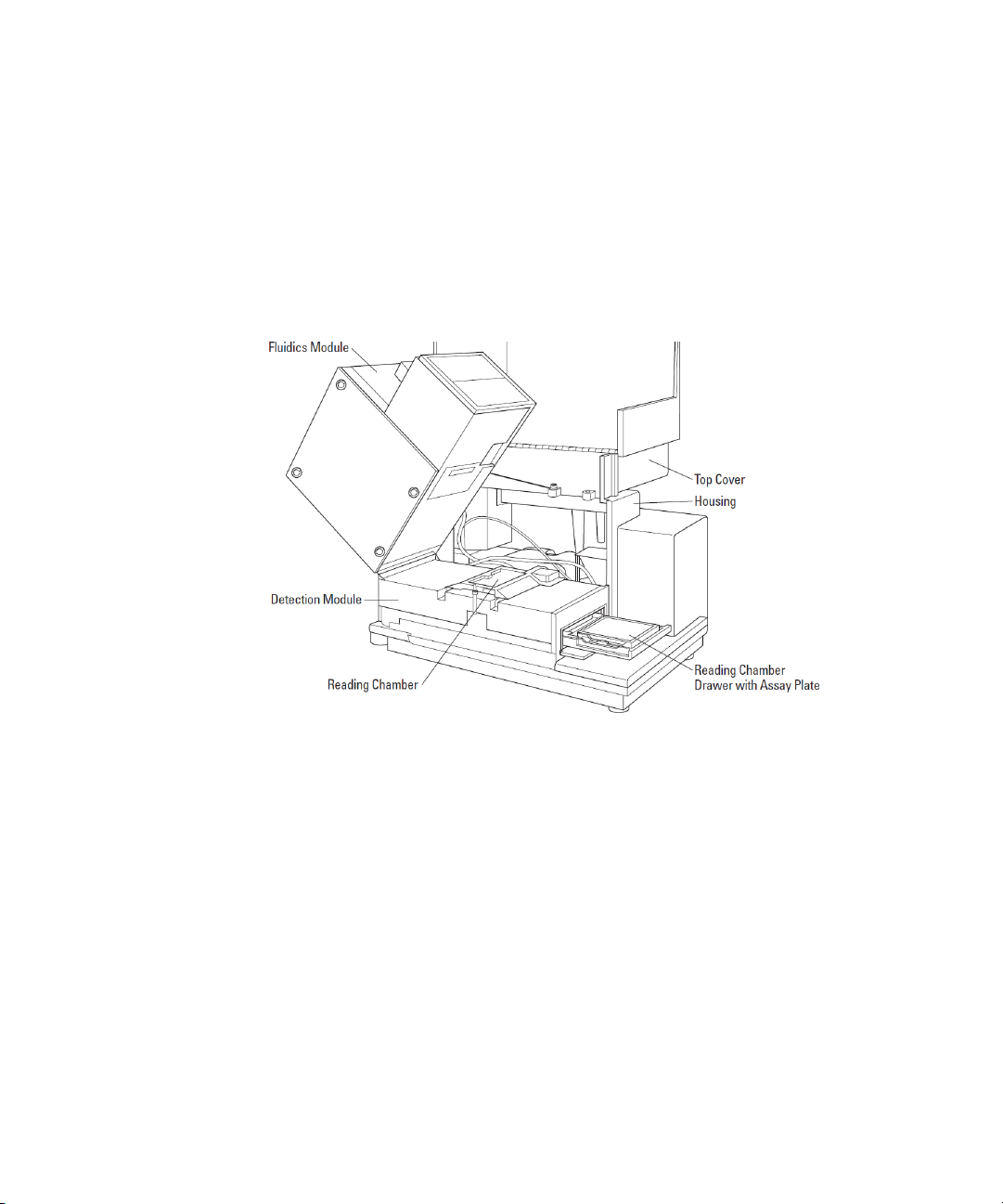

Detection Module

The detection module is the lower portion of the instrument. This

module houses the reading chamber, the optics bench, several cables

and optic fibers, the power supply, the flash lamp, and other hardware.

The fluidics module attaches to the detection module and can be tilted

off to the side, to provide access to the optical system for

troubleshooting or maintenance. The detection module is contained in a

molded plastic housing, to which the top cover is attached at the back of

the instrument.

Figure 1-15: Detection Module Detail

Reading Chamber

The reading chamber includes the assay plate carriage that holds the

assay microplate in the reading chamber during read cycles. The reading

chamber can be maintained at an elevated temperature. It contains both

top and bottom read heads that can be selected in the software.

The instrument uses a plate sensor to assure that an assay plate is

present in the reading chamber before a reading begins.

26 0112-0127 B

Page 27

Description

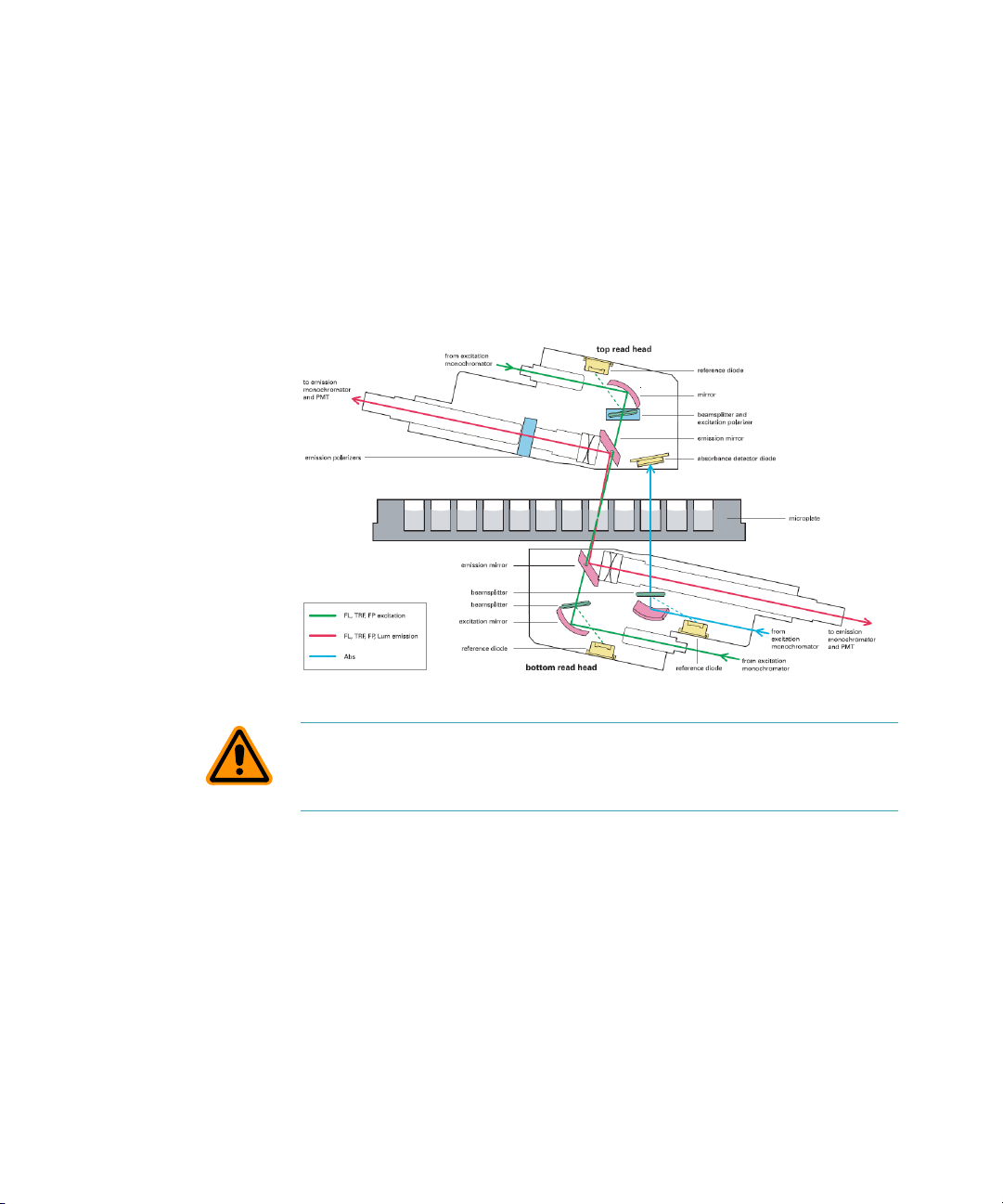

Optical System

The optical system includes a xenon flash lamp, monochromators,

excitation bandpass filters, emission cut-off filters, PMTs, and

photodiodes.

There are a number of cables and fibers that exit the optics bench and

enter the reading chamber. They are the excitation fibers (thin and black

or red, has a collar and pins), emission fibers (black and fatter, with

attached electrical cord), electrical connector to the read head (green

with brass fitting).

Figure 1-16: Optical System

CAUTION! Optical fibers are very fragile, especially the excitation fiber.

Handle cables with extreme care. Do not flex, twist, bend, or stretch the

optical cables.

0112-0127 B 27

Page 28

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Computer

The FlexStation 3 instrument works as a system with the SoftMax Pro

Software. The SoftMax Pro Software must be installed on a dedicated

computer to communicate with and control instrument functions.

The instrument is equipped with an 8-pin DIN RS-232 serial port for

connecting to a computer.

SoftMax Pro Software, version 5.1 or later, is required to control the

FlexStation 3 instrument. TheFlexStation 3 instrument is not currently

supported in SoftMax Pro Software, version 6.x.

The minimum computer configuration includes a Pentium processor with

2.8 GHz, 1 GB hard drive.

See

Installing SoftMax Pro on page 63 and Setting Up the Software on

page 75.

Accessories

The following accessories are included with the system:

• Black microplate adapter (for use in reading chamber drawer)

• Compound baseplate (for use in the compound plate drawer)

• Computer cable

• Power cord, USA/Canada

• Power cord, ECI

• Fuses (2 each)

• User Guide

• Pipettor head, 8-channel and/or 16-channel

• Pipette

• Yellow plate for the respective pipettor head

• Hex key

All necessary accessories are shipped with the system.

Accessories on page 153.

Fuses are rated slow-blow (United States/Canada/Metric: 6.3 amp time

delay). See

Replacing Fuses on page 121.

Parts and

28 0112-0127 B

Page 29

Description

Cables

Molecular Devices recommends that you use high-quality, doubleshielded cables to connect the instrument to the computer. Choose

cables that meet the following requirements:

Serial Interface Cable: The serial interface cable used to connect the

instrument to the computer is a custom cable designed and built by

Molecular Devices. Use the cable supplied by Molecular Devices, or

contact Molecular Devices for specific pin-out requirements: Male DB8

to Female DB9 (custom cable made by Molecular Devices,

P/N 9000-0149).

USB Adapter Cable: Many newer computers do not have a serial port.

You can connect a serial cable between these computers and the

instrument using a USB-to-serial adapter. Molecular Devices has tested

many third-party USB-to-serial adapter cables and has found Keyspan

USA-19HS (Molecular Devices, P/N 9000-0938) to be the most reliable. It

is the only one we recommend.

Note: For specific pin-out requirements, contact Molecular Devices

Technical Support.

Microplate Adapters

The black microplate adapter fits in the assay plate carriage, in the

reading chamber drawer, to elevate standard microplates for both top

reads and bottom reads. Remove the adapter when using high-profile,

6-well, 12-well, 24-well, or 48-well microplates.

Compound Baseplate

Molecular Devices provides a metal baseplate that must be placed in the

compound plate drawer under the compounds plate to reduce stray

light.

0112-0127 B 29

Page 30

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Consumables

The system consumables include:

• Microplates

• Pipette tips

One box (10 racks) of pipette tips is shipped with the system pipettor

head. See

CAUTION! Do not use parts and accessories that are not authorized by,

specified by, or provided by Molecular Devices. Using unauthorized parts

can damage the instrument.

Microplates

The FlexStation 3 instrument can accommodate standard 6-well to

384-well microplates and strip wells. When reading absorbance at

wavelengths below 340 nm, special UV-transparent, disposable or quartz

microplates allowing transmission of the deep UV spectra must be used.

Not all manufacturers’ microplates are the same with regard to design,

materials, or configuration. Temperature uniformity within the

microplate can vary depending on the type of microplate used.

Microplates supported for use in this reader are:

Read plate formats not already loaded as defaults in the SoftMax Pro

Software can be added by manually entering the dimensions using the

Plate Editor in the software.

The instrument can accommodate standard 6-well, 12-well, 24-well,

48-well, 96-well, and 384-well microplates. In Flex or other assay types

which you intend on using fluidic integration you can only use 96-well or

384-well formatted assay plates.

Parts and Accessories on page 153.

• 6-well, 12-well, 24-well, 48-well, 96-well, and 384-well standard

formats

• 96-well half area

• 96-well and 384-well low volume

30 0112-0127 B

Page 31

Description

Figure 1-17: Top View of a 96-Well Microplate

For fluorescence, Molecular Devices generally recommends black-walled,

clear-bottom microplates for bottom reading, and all-black microplates

for top reading, because they have lower backgrounds than clear plates.

For luminescence, white microplates can optimize light collection.

Note: Not all microplates are made with the same materials. Some

plastics, most notably polystyrene, have significant native fluorescence

and can cause moderate to severe background fluorescence, especially

in the UV range. If your fluorescence experiments require high

sensitivity, it might be appropriate to use microplates designed and

designated by the manufacturer to reduce background fluorescence.

0112-0127 B 31

Page 32

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Pipette Tips

• For 96-well assays, Molecular Devices specifies using 96-well,

FlexStation Pipette Tips. These 200 μL tips are available in black

(P/N 9000-0911) and clear (P/N 9000-0912) versions and can be

purchased in 10 racks per box quantities.

• For 384-well assays, Molecular Devices specifies using 384-well,

FLIPR and FlexStation Pipette Tips. These 30 μL tips are available

in black (P/N 9000-0764) and clear (P/N 9000-0763) versions and

can be purchased in 50 racks per case quantities. Please ask your

local sales representative for details regarding purchasing partial

cases.

Tips are available in both black and clear options. Black tips are generally

used during fluorescence assays when auto-fluorescent properties of

clear tips can interfere with your response. Molecular Devices

recommends that you evaluate both black and clear tips during assay

development to determine which tip version is most appropriate to your

assay.

Overview of Operation

Using the FlexStation 3 instrument is a process in five stages:

• Choosing an Experiment

• Preparing the Instrument

• Preparing the Software

• Running the Experiment

• Analyzing the Data

Choosing an Experiment

• New or repeated experiment?

• Does the protocol exist?

Preparing the Instrument

• Turning on the power

• Setting temperature, if needed

• Preparing and loading tips, plates, and compounds

32 0112-0127 B

Page 33

Preparing the Software

• Entering software preferences

• Selecting instrument settings

• Defining templates, reduction parameters, and display

• Confirming hardware and software setup

Running the Experiment

• Initiating the operation (detection or fluidics plus detection)

• Saving the data file

Analyzing the Data

• Modifying the template or parameters as desired

• Saving the data file

• Analyzing the data

• Exporting data to another software application as desired

Theory of Operation

Description

parameters

This section includes the following topics:

• Instrument Design, see page 33

• Assay Read Types, see page 38

Instrument Design

Fluidics

The instrument is designed with a fluidics module that transfers liquids to

the assay plate during a fast kinetic read or before an experiment.

The fluidics module incorporates an 8-channel or 16-channel pipettor

that automatically changes tips and transfers reagents to the plate that is

read in the system. Pipette height and dispensing rate are adjustable. The

instrument can add reagents within milliseconds of a column being read,

enabling fast kinetic assays of transient responses.

As many as three compounds can be transferred from columns in a

compound plate to a single column in an assay plate, at different points

during or before the total read time.

0112-0127 B 33

Page 34

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Mixing

Mixing can be accomplished in one of two ways, using either the

Trituration or Automix functions. Use of these functions are dependant

on the assay performed and the read mode used.

• Trituration is mixing of the well contents in either the compound

or assay plates. This is accomplished by fluid being alternately

aspirated from and dispensed back into a well using the pipettor.

Trituration is available only during assays that include fluid

transfer, including Flex, Endpoint, or Kinetic modes, and can be

performed in either the compound or assay plate. Within the

compound plate, trituration can be used to resuspend

compounds that might have crashed out of solution.

Alternatively, it can be used to promote prompt mixing in the

assay plate when delivering small reagent volumes for fast

kinetic cell-based assays, such as calcium mobilization.

Note: Trituration in the assay plate well may agitate cells,

causing responses not associated with the compound addition.

Assay development should be performed to determine if

trituration is necessary for the assay.

• The Automix function permits automatic shaking of the

microplate at preset intervals, thereby mixing the contents

within each well. Automix must be selected before beginning a

reading. Automix settings vary with assay type.

For Endpoint assays, enabling Automix shakes the plate for a

definable number of seconds and then reads at all selected

wavelengths.

For Kinetic assays, two types of Automix can be enabled. You

can set Automix to shake the plate for a definable number of

seconds before the initial reading or for a definable number

of seconds before each subsequent reading.

Use of Automix is strongly recommended for ELlSA and other

solid-phase, enzyme-mediated reactions to enhance accuracy.

34 0112-0127 B

Page 35

Description

Temperature Regulation

The instrument regulates the temperature of the microplate reading

chamber from 2°C above ambient to 45°C. On power up, when the

incubator is off, the temperature in the reading chamber is ambient and

isothermal. Turning on the incubator by pressing the Temp on/off key

causes the instrument to begin warming the reading chamber and the

fluidics module.

Note: The reading chamber is warmed to the set temperature.

However, the fluidics module might be lower than the set point.

The temperature set point defaults to 37°C at startup. With the incubator

on, the temperature of the reading chamber can be set and regulated

from 2°C above ambient to 45°C. Accuracy of the temperature set point

is only guaranteed if the set point is at least 2°C above ambient. If the

temperature set point is lower than the ambient temperature, the

chamber temperature remains at ambient. Temperature regulation is

controlled by heaters only and, therefore, cannot cool the temperature

to a setting lower than ambient.

Temperature regulation and control of the reading chamber is achieved

through electric heaters, a fan, efficient insulation, and temperature

sensors. The heaters are located within the instrument, which is

insulated to maintain the temperature set point. The seven sensors are

mounted inside the reading chamber and measure the air temperature

and chamber temperature. The temperature feedback closed-loop

control algorithms measure the chamber air temperature, compare it to

the temperature set point, and use the difference to calculate the

regulation of the heating cycles. This technique results in accurate,

precise control of the reading chamber temperature with a temperature

variation of the air across the entire assay plate of less than 1°C.

Temperature uniformity within the assay plate itself depends on its

design, materials, and configuration.

Note: Temperature of samples in all assay plates are affected by

evaporation.

0112-0127 B 35

Page 36

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Time-Tagged Data

The FlexStation 3 instrument is a single-channel reading system.

Although the scan time is very fast (8 wells in about 1.0 seconds; 1 well in

about 50 ms), the difference in the exact time each well is read is

dependent on the number of rows selected in a column. This difference

is an important factor in fast kinetic assays.

For this reason, all readings are tagged with an exact read time, and

when multiple-well fast kinetic responses are plotted, the curves overlie

each other as plotted by the SoftMax Pro Software. If kinetic data are to

be exported, you can choose either time-interpolated data or raw timetagged data. Molecular Devices recommends that you select timeinterpolated data. This option is explained in more detail in the SoftMax

Pro user guide.

Figure 1-18: Time-Tagged Data Example

36 0112-0127 B

Page 37

Description

Optical System

The instrument uses excitation and emission filter wheels to decrease

interference by stray light, thus augmenting the wavelength selection

that is provided by the monochromators. Two independent, singlechannel reading heads can service top and bottom reading requirements.

Both the top reading head and bottom reading head support coaxial

excitation and emission beams.

The instrument’s electrical, firmware, and optical designs incorporate

many features that work together to virtually eliminate instrumentbased day-to-day and instrument-to-instrument variations in measured

fluorescence values.

For more detail of the optical design and an illustration of the optical

system, see

Detection Module on page 26.

Bottom and Top Reading

Switching to bottom or top reading capability is activated through

software. No manual positional switching of the read-head is required.

Bottom reading allows for well scanning ability maximizing the sampling

area for 6-well, 12-well, 24-well, 48-well, 96-well, and 384-well

microplates. In addition, bottom reading enables concurrent reagent

addition to monitor fast kinetic reactions such as calcium mobilization.

Availability of top or bottom reading functions varies depending on the

detection mode.

Note: Clear-bottom plates must be used for bottom reading. Bottom

reading is intended for cell-based assays.

0112-0127 B 37

Page 38

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Assay Read Types

The instrument operates in three integrated fluidics/read (Flex, Endpoint,

and Kinetic) read and two read types. The Table 1-1 on page 39 compares

the types of operation and features that are available for the different

read types.

Note: This user guide describes instrument behavior for Flex read type

primarily. For instructions on other read types, see the SoftMax Pro

user guide.

Flex Reads

The fluidics module is designed to aspirate fluids from a compound

source plate and dispense them into an assay plate. Fluid transfer is

made possible with an 8-channel or 16-channel pipettor that is fully

automated, including changing the tips from a tip rack.

In Flex reads, one to eight or one to sixteen wells in one column of the

assay plate are read repeatedly for a selected total experimental time. At

a preselected point or points during that time sequence, the pipettor can

transfer up to three reagents from the compound plate to the assay

plate. The instrument continues to read at the preselected time intervals

before and after each fluid transfer. After completion of reading the

column (or partial column) for a preselected time, the instrument can

repeat this cycle with other columns. All the data is collected in one data

file represented as a 96-well or 384-well microplate.

For example, an experiment with a two-minute run time accommodates

a 96-well microplate in about 24 minutes.

Run time × Number of columns = Plate time

2 minutes × 12 columns = 24 minutes

38 0112-0127 B

Page 39

Table 1-1: Operation Modes and Features

Description

Operation

Modes

Operation

Type

Read Modes Absorbance,

System

Settings

Top read Yes or No Yes or No Yes or No Yes or No No

Bottom read Yes or No Yes or No Yes or No Yes or No Yes

Wavelength Yes Yes Yes Yes Yes

Automix

before

Automix

between

Timing No Yes No No Yes

Wells to read Yes Yes Yes Yes Yes

AutoCalibrate Yes Yes Yes Yes Yes

Compound

source

Compound

transfer

Triturate Yes Yes No No Yes

Compound

and tips

columns

AutoRead Yes Yes Yes Yes Yes

Well Scan

Editor

PMT sensitivity Yes Yes Yes Yes Yes

Endpoint Kinetic Spectrum Well Scan Flex

Fluidics +

Detection

Fluorescence,

Fluorescence

Polarization,

Luminescence,

and TimeResolved

Fluorescence

Yes Yes Yes Yes No

No Yes No No No

Yes Yes No No Yes

Yes Yes No No Yes

Yes Yes No No Yes

No No No Yes No

Fluidics +

Detection

Absorbance,

Fluorescence,

Fluorescence

Polarization,

Luminescence,

and TimeResolved

Fluorescence

Detection Detection Fluidics +

Detection

Absorbance,

Fluorescence,

Fluorescence

Polarization,

Luminescence,

and TimeResolved

Fluorescence

Absorbance,

Fluorescence,

Luminescence,

and TimeResolved

Fluorescence

Absorbance,

Fluorescence,

and

Luminescence

0112-0127 B 39

Page 40

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Table 1-1: Operation Modes and Features (cont’d)

Operation

Modes

Assay plate

type

Compound

plate type

Endpoint Kinetic Spectrum Well Scan Flex

Yes Ye s Yes Ye s Yes

Yes Yes No No Yes

Endpoint Reads

In Endpoint reads, as well as in Kinetic and Flex reads, you can select

from one to four excitation/emission pairs to obtain readings for each

well of a microplate.

In Endpoint reads, one to eight or one to sixteen wells in one column of

the assay plate are delivered before starting the read. At a preselected

point or points before the read, the pipettor can transfer up to three

reagents from the compound plate to the assay plate. After reagents are

transferred, the read initiates for the entire read area. Unlike Flex, the

read area is not limited to one column at a time in an Endpoint read. All

the data are collected in one data file represented as a 96-well or

384-well microplate.

For more information on this read type, please review the appropriate

section in the SoftMax Pro user guide.

Kinetic Reads

Kinetic analysis can be performed for a total run time of up to 99 hours.

The kinetic read interval depends upon the instrument setup parameters

selected in the SoftMax Pro Software, but is limited to 2 hours and 45

minutes (165 minutes). At the end of a reading, rates are reported as

each well. Kinetic analysis has many advantages when determining the

relative activity of an enzyme in different types of assays, including the

purification and characterization of enzymes and enzyme conjugates.

In Kinetic reads, one to eight or one to sixteen wells in one column of the

assay plate can be delivered before starting the read. At a preselected

point or points before the read, the pipettor can transfer up to three

reagents from the compound plate to the assay plate. After reagents are

transferred, the read initiates for the entire read area. Unlike Flex, the

read area is not limited to one column at a time in Kinetic reads. All the

data are collected in one data file represented as a 96-well or 384-well

microplate.

For more information on this read type, please review the appropriate

section in the SoftMax Pro user guide.

40 0112-0127 B

Page 41

Description

Spectrum Reads

Spectral analysis measures across a spectrum of wavelengths (excitation

250 nm to 850 nm, emission 360 nm to 850 nm). When reading using a

specific detection mode, such as fluorescence, you can set a fixed

wavelength for excitation and scan the emission wavelengths, or set a

fixed wavelength for emission and scan the excitation wavelengths. All

spectrum readings are made using scanning monochromators.

In Spectrum reads, the fluidics module is not enabled.

For more information on this read type, please review the appropriate

section in the SoftMax Pro user guide.

Well Scan Reads

Some applications that involve the detection of whole cells in large area

tissue culture plates can require the use of Well Scan reads. As many cell

lines tend to grow in aggregates or in the edges of microplate wells, this

non-confluent growth pattern can require multiple reads at different

locations in a well.

When used with 6-well, 12-well, 24-well, 48-well, or 96-well plates, well

scanning allows maximum surface area detection for whole cell assays.

No plate adapter is used for tissue culture plates of 24 wells or less.

In Well Scan reads, the fluidics module is not enabled.

For more information on this read type, please review the appropriate

section in the SoftMax Pro user guide.

SoftMax Pro Software

The Molecular Devices SoftMax Pro Software is a highly integrated

program that can be used to:

• Control the reader

• Collect data

• Analyze data

SoftMax Pro software is easy to use, yet is powerful and flexible, and is

necessary to access the full capabilities of the FlexStation 3 instrument.

SoftMax Pro Software allows you to:

• Set Up the Reader and Software Parameters, see page 42

• Acquire Data from the Reader, see page 43

• Perform Complex Data Analysis, see page 44

0112-0127 B 41

Page 42

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Set Up the Reader and Software Parameters

• Read microplates in using Flex, Endpoint, Kinetic, Spectrum, or

Well Scan read types.

Use up to four wavelengths for Flex, Endpoint, Kinetic, and

Well Scan reads.

Perform absorbance and percent transmittance readings in

the 200 nm to 1000 nm range.

Perform fluorescence readings in the 250 nm to 850 nm

range.

Perform luminescence readings in two ways: wavelength

nonspecific (all wavelengths between 360 nm and 630 nm)

or wavelength selectable (250 nm to 850 nm).

Read the whole plate or a subset of microplate wells.

Specify kinetic run times up to 99 hours.

Select your own read intervals for kinetic runs.

Specify the duration for Automix before or between reads.

Automix shakes the microplate at preset intervals, thereby

mixing the contents of each well (highly recommended for

ELISAs and other solid-phase, enzyme-mediated reactions).

Note: Automix is not intended to be used continuously for

several hours.

• Use PathCheck technology to normalize the absorbance readings

in each microplate well to a 1 cm pathlength.

• Design microplate templates to simplify data reduction.

Identify groups of wells with labels of your choice.

Identify individual wells with unique names.

Blank the entire plate, groups, or individual wells.

• Save reader settings, template formats, and data analysis

parameters as assay protocol files and recall them for later use.

Rapid reader and analysis setup for repeated assays.

Uniform analysis for equivalent microplates.

• Turn the incubator on or off to control the temperature in the

read plate drawer.

42 0112-0127 B

Page 43

• Integrate fluid transfer with Endpoint, Kinetic, and Flex reads.

Transfer fluid during the experiment for fast kinetic

fluorescence, luminescence, and absorbance assays.

Transfer fluid before the beginning of an experiment for

endpoint and kinetic applications.

Define the reagent source and tip columns to be used for

each fluid transfer.

Optimize dispense parameters by specifying the volume,

height, and speed of addition.

Specify the number of strokes used during Trituration to mix

the contents of the source and read plates. Trituration uses

the pipettor to mix the contents of a well by aspirating and

dispensing, for both the source and read plates.

Acquire Data from the Reader

• Pre-read microplates.

• Analyze kinetic and spectrum data as it is collected.

• Save data files for in-depth analysis at a later time.

• Save multiple microplates with individual template and data

analysis parameters in one or more experiments in a single data

file.

• Display data on screen.

Raw values, reduced number, or raw values with reduced

number.

Raw microplate data in a microplate format.

Ranged data as integers from 0 to 9 in a microplate format.

Threshold data as being above, below, or between set limits

in a microplate format.

Grayscale data in eight shades of gray corresponding to high

and low limits in a microplate format.

Kinetic or spectrum plots of all microplate wells.

Enlarge the display of individual well plots and overlay

multiple well plots.

Description

0112-0127 B 43

Page 44

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

Perform Complex Data Analysis

• Calculate maximum kinetic rates on non-linear data.

• Assign plate, group, or sample blanks.

• Customize data analysis for each group in the template.

• Create graphs with multiple plots.

• Pick from nine curve-fitting routines.

• Analyze unknown samples against a standard curve.

• Analyze and compare data within a plate, between plates, and

between experiments.

• Customize your print formats.

Print all or individual sections of the data file.

Define and print a report containing only selected sections.

Customize the order of data file sections.

• Export data in tab-delimited ASCII format.

For complete information on the current SoftMax Pro Software, see the

SoftMax Pro User Guide and Formula Reference Guide included with

your FlexStation 3 instrument.

44 0112-0127 B

Page 45

Description

User Interface

This section briefly presents the basic features of the SoftMax Pro

Software user interface. More instructions regarding how to use the

interface appear throughout these instructions during relevant steps.

You can control the instrument by using either buttons and icons in the

windows and along the tool bars, or by using the menus. You can use

either your mouse or keystrokes to make selections.

Note: For complete details about the SoftMax Pro Software and user

interface, refer to your SoftMax Pro User Guide.

Figure 1-19: Plate Section, Flex Mode

0112-0127 B 45

Page 46

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

The Status bar allows you to monitor instrument status and access

several functions with the click of a button. You can verify

communication with SoftMax Pro, and monitor the reading chamber

temperature. The Status bar also provides buttons used to begin a

reading, open the Incubator dialog box, shake the microplate (Automix),

and open or close the instrument drawers. The Status bar can be hidden

by selecting Hide Status from the View menu.

Figure 1-20: SoftMax Pro Software Status Bar

The following icons are present in the Status bar and are used to set up

the instrument or interact with it during operation.

Note: Different Molecular Devices systems have different icons.

Table 1-2: SoftMax Pro Software Status Bar Icons

Icon Description

The Instrument Status icon provides visual confirmation that

SoftMax Pro is communicating with the instrument. Doubleclick this icon to display the Preferences dialog.

The temperature icon displays the current temperature

inside the instrument. Click this icon to display the

Preferences dialog.

Click to begin reading. It changes to Stop during a reading.

Clicking this button also closes any open drawers.

Click the Incubator button to open the Incubator dialog to

change temperature settings.

Click the Automix button to manually shake the assay plate.

Note: The manual shaking that occurs when you click this

button differs from the Automix that can be selected as an

instrument setting within the protocol settings.

Click the Drawer button to open or close the reading

chamber drawer.

46 0112-0127 B

Page 47

Description

One SoftMax Pro Software file contains at least one experiment, and can

contain a section for Notes and one or more Plates. You can enter Notes

and edit Plates using the tool bars shown below.

Figure 1-21: SoftMax Pro Software Plate Section Toolbar

The following icons appear on the Plate Section tool bar.

Table 1-3:

Icon Description

Double-click the Plate icon to open the Plate section in a new

window.

Double-click the Name of Plate icon to open the Section

dialog.

Click the Settings button to open the Instrument Settings

dialog for this plate.

Click the Template icon to open the Template dialog, where

you can create or edit the template. This is used to setup

groups for defining areas of the assay plate.

Click the Reduction icon to configure settings for data

analysis and graph reduction.

Click the Display icon to open the Display dialog and change

your display properties.

Click the Graph icon to enlarge sections of the display into

graphic form.

Click the Mask icon to mask selected wells.

Click the Printer icon to include or exclude a section from a

printed report.

The SoftMax Pro Software provides other icons and tool bars. For

example, you can keep Notes on the experiment in the Notes section.

Groups are also contained in experiments when you define a template.

You can create Graph sections as desired. For details, see your SoftMax

Pro Software User Guide.

0112-0127 B 47

Page 48

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

48 0112-0127 B

Page 49

Installation

2

This chapter provides information about how to install the FlexStation 3

instrument in your laboratory. Installation must be done by qualified

Molecular Devices personnel or a service-trained user.

CAUTION! The following procedures must be completed by a servicetrained user. Do not attempt the installation procedures if you have not

been trained properly by appropriate Molecular Devices personnel.

The following sections describe the installation procedure:

• General Precautionary Information, see page 49

• Unpacking the System, see page 50

• Installing the Fluidics Module, see page 53

• Installing the Pipettor Head, see page 56

• Setting Up the Computer, see page 61

• Connecting the Cables, see page 61

• Installing the Drawer Adapters, see page 62

• Installing SoftMax Pro, see page 63

General Precautionary Information

WARNING! Always make sure the power switch on the instrument is

in the OFF position and remove the power cord from the back of the

instrument before any installation or relocation of the system.

WARNING! Do not install or operate the system in an environment

where potentially damaging liquids or gases are present.

0112-0127 B 49

Page 50

FlexStation 3 Benchtop Multi-Mode Microplate Reader User Guide

CAUTION! Do not touch or loosen any screws or parts other than those

specifically designated in the instructions. Doing so might cause

misalignment and will void the system warranty.

CAUTION! Do not attempt to assemble or disassemble the instrument

with the pipette tips or compound and read plates in place. Spillage or

damage to the pipette tips, plates, or the instrument can occur.

Unpacking the System

This section provides instructions on how to unpack the system safely.

WARNING! The instrument weighs approximately 50 pounds and

should be lifted with care. To prevent injury, use at least two people to

lift the instrument.

Each FlexStation 3 instrument comes with the following components.

• Fluidics module and accessories

• Detection module (main instrument body) in housing

• Computer (can be user-supplied)

• Computer monitor (can be user-supplied)

• SoftMax Pro Software package

Please retain the cartons, all boxes, and any significant packing materials.

If the system needs to be moved to a different location, use the original

packing materials and cartons whenever possible. If the cartons have

been damaged in transit, it is particularly important that you retain them

for inspection by the carrier in case there has also been damage to the

instrument.

As you unpack the system components, examine the packing list that

accompanies the system to be sure all items are present.

50 0112-0127 B

Page 51

Installation

Unpacking the Fluidics Module and Accessories

1. Remove the fluidics module from the cardboard box inside the

wooden crate and take it out of the protective bag. Set it in a safe

place.

2. Remove the box (containing the pipettor head) and the bags of

accessories.

3. Open the accessories bags and remove cables and the hex key.

You will need them later in the assembly procedure.

4. Set packaging aside.

Unpacking the Detection Module

Note: Keep the system in a location that is dedicated to its use, on a

level surface, away from direct sunlight, dust, drafts, vibration, and

moisture.

Tools Needed

• Hex key, 3/32 inch ball drive, L (provided)

• Phillips screwdriver (not provided)

To unpack the detection module:

1. Use two people to unlatch the midsection of the crate (on top

and bottom) and then move that midsection aside. Due to the

size of the crate, this step requires two people.

2. Slide the plastic bag enclosing the instrument out of the way,

around the base of the detection module.

3. Use two people to reach inside the bag and under the

instrument and then lift the instrument out of its shipping tray

and place it on the bench.