Molecular Devices AquaMax 2000, AquaMax 4000 User Manual

AquaMax® 2000/4000

Microplate Washer

User Guide

0112-0151 K

June 2014

www.moleculardevices.com

This document is provided to customers who have purchased Molecular Devices, LLC

(“Molecular Devices”) equipment, software, reagents, and consumables to use in the

operation of such Molecular Devices equipment, software, reagents, and

consumables. This document is copyright protected and any reproduction of this

document, in whole or any part, is strictly prohibited, except as Molecular Devices

may authorize in writing.

Software that may be described in this document is furnished under a license

agreement. It is against the law to copy, modify, or distribute the software on any

medium, except as specifically allowed in the license agreement. Furthermore, the

license agreement may prohibit the software from being disassembled, reverse

engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only to

designate those manufacturers’ products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers’ and/or their product names as

trademarks.

Molecular Devices makes no warranties or representations as to the fitness of this

equipment for any particular purpose and assumes no responsibility or contingent

liability, including indirect or consequential damages, for any use to which the

purchaser may put the equipment described herein, or for any adverse circumstances

arising therefrom.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These

trademarks may not be used in any type of promotion or advertising without the prior written permission of

Molecular Devices, LLC.

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

© 2014 Molecular Devices, LLC.

All rights reserved.

Contents

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who This User Guide Is For . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instrument Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Robot and Stacker Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Microplate Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reagent and Waste Bottle Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Setting Up the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting to a StakMax

®

Plate Stacker . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Starting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Main Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Running Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stopping Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Shutting Down the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4: Operation: The Touch Screen Interface . . . . . . . . . . 37

Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Program Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Program Tab: Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . 39

Program Settings Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

0112-0151 K 3

AquaMax® 2000/4000 Microplate Washer User Guide

Program Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Program Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Program Stacker Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjust Dispense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Program Tab: Program Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

New Step Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dispense Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Aspirate Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wash Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

FastWash Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Shake Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Soak Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Repeat Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Purge Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Rinse Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Standby Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Prime Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Managing the Program Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Plates Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Plates Tab: Administrative Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Plate Definition Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Managing the Plate Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Options Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Advanced Options Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Options Tab: Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . . 76

Shutdown Options Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Managing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Automatic Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Restricting Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Chapter 5: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Purging the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Decontaminating the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Cleaning the Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Removing and Storing Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . 88

Cleaning Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4 0112-0151 K

Contents

Moving an AquaMax® Microplate Washer . . . . . . . . . . . . . . . . . . . . 92

Preparing for Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 6: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

General Instrument Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

System Fluidics Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

System Pressure Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

External Communication Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Dispense Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Aspiration Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Wash Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Cell Wash Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Instrument Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 7: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

AquaMax® Microplate Washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix A: Microplate Library . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix B: Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix C: AquaMax Sterilant . . . . . . . . . . . . . . . . . . . . . . . . 115

Principle of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Materials Required but Not Provided. . . . . . . . . . . . . . . . . . . . . . 116

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Preparing the Reagent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Preparing the Complete Sterilant . . . . . . . . . . . . . . . . . . . . . . . . . 117

Using Reagent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Warnings, Precautions, and Limitations . . . . . . . . . . . . . . . . . . . . . 118

Sterilant Solution A Concentrate (4X). . . . . . . . . . . . . . . . . . . . . . 118

Sterilant Solution B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix D: Tips and Applications . . . . . . . . . . . . . . . . . . . . . . 119

Using the Washer for ELISA Based Applications . . . . . . . . . . . . . 119

Using the Washer for Cell Based Applications . . . . . . . . . . . . . . . 119

0112-0151 K 5

AquaMax® 2000/4000 Microplate Washer User Guide

Appendix E: Robot Command Interface . . . . . . . . . . . . . . . . . . 121

Instrument Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Hardware Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Host Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

No Error (OK) Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Error Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

General Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

User Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Program Management Commands . . . . . . . . . . . . . . . . . . . . . . . . . 132

Factory-defined Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Protocol (Program) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Edit/view Opened Protocol Steps . . . . . . . . . . . . . . . . . . . . . . . . . 136

Function-specific Step Arguments and Return Data . . . . . . . . . . . . 138

Plate Library Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

StakMax

Stacker Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Error Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Instrument Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

®

Robot Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

6 0112-0151 K

Who This User Guide Is For

This guide is intended for users of the AquaMax® 2000 and AquaMax

4000 Microplate Washers. The user guide contains setup, operation, and

general maintenance information.

Conventions

Within the scope of this user guide, the following typographical

conventions are used:

WARNING! A warning indicates an operation that can cause personal

injury if precautions are not followed.

CAUTION! Indicates an operation that might cause damage to the

instrument, device, or data, if the precautions are not followed.

Foreword

Note: Emphasizes significant information in a procedure or description.

Tip: Provides useful information or shortcuts, but is not essential to the

completion of a procedure.

0112-0151 K 7

AquaMax® 2000/4000 Microplate Washer User Guide

8 0112-0151 K

Introduction

The AquaMax® Microplate Washers from Molecular Devices can be easily

configured to meet your current application requirements. The modular

design provides affordable upgrade options when your lab requirements

change.

Instrument Features

AquaMax 2000 and AquaMax 4000 Microplate Washers can be

configured to process 96-well and 384-well microplates used in both

biochemical and cell-based assays.

• Wash heads are available in 96-well and 384-well configurations

• All wash heads are interchangeable. The software automatically

• The AquaMax Microplate Washer primes, cleans, and rinses the

• The AquaMax Microplate Washer processes all plate wells

• Whole-well dispensing and aspiration in 384-well plates result in

• The AquaMax Microplate Washer supports most microplate

• The AquaMax Microplate Washer is equipped with two

• All washer operations are controlled through an on-board

• The program library can store up to 3 factory-defined and 100

1

for both plate wash and cell wash.

detects which wash head is installed.

wash heads with the touch of a single button.

simultaneously during dispense, aspirate, and wash operations.

2 to 4 times faster plate processing than other commercially

available plate washers.

formats through its user-definable plate library. Up to 32 plate

types can be stored in the plate library.

(AquaMax 2000 washer) or four (AquaMax 4000 washer) reagent

ports to connect 2 or 4 different dispense bottles. Waste can be

drained into any waste bottle. Non-toxic waste can be drained

directly into a sink. The AquaMax Microplate Washer supports

4 L or 10 L bottles only.

touch-screen user interface.

user-defined programs. Each program can contain up to 50 steps.

0112-0151 K 9

AquaMax® 2000/4000 Microplate Washer User Guide

Robot and Stacker Compatibility

AquaMax Microplate Washers are compatible with Molecular Devices

StakMax® Microplate Handling System. Third party robots can be set up

to control the AquaMax Microplate Washers through a USB command

interface. The USB command interface is detailed in Robot Command

Interface on page 121.

Components

6

1

2

3

4

5

Table 1-1: AquaMax® 4000 Components

Item Description

1 4L reagent reservoirs

2 Back panel with USB and StakMax connectors

3 384-well wash head installed

4 96-well wash head

5 Microplate carriage with microplate

6 Touch screen

10 0112-0151 K

Introduction

Touch Screen

Figure 1-1: AquaMax® touch screen

Instrument operation is controlled through a touch-screen user interface.

The touch screen displays instrument status, provides access to

instrument settings and programs, and controls the optional StakMax

Plate Stacker.

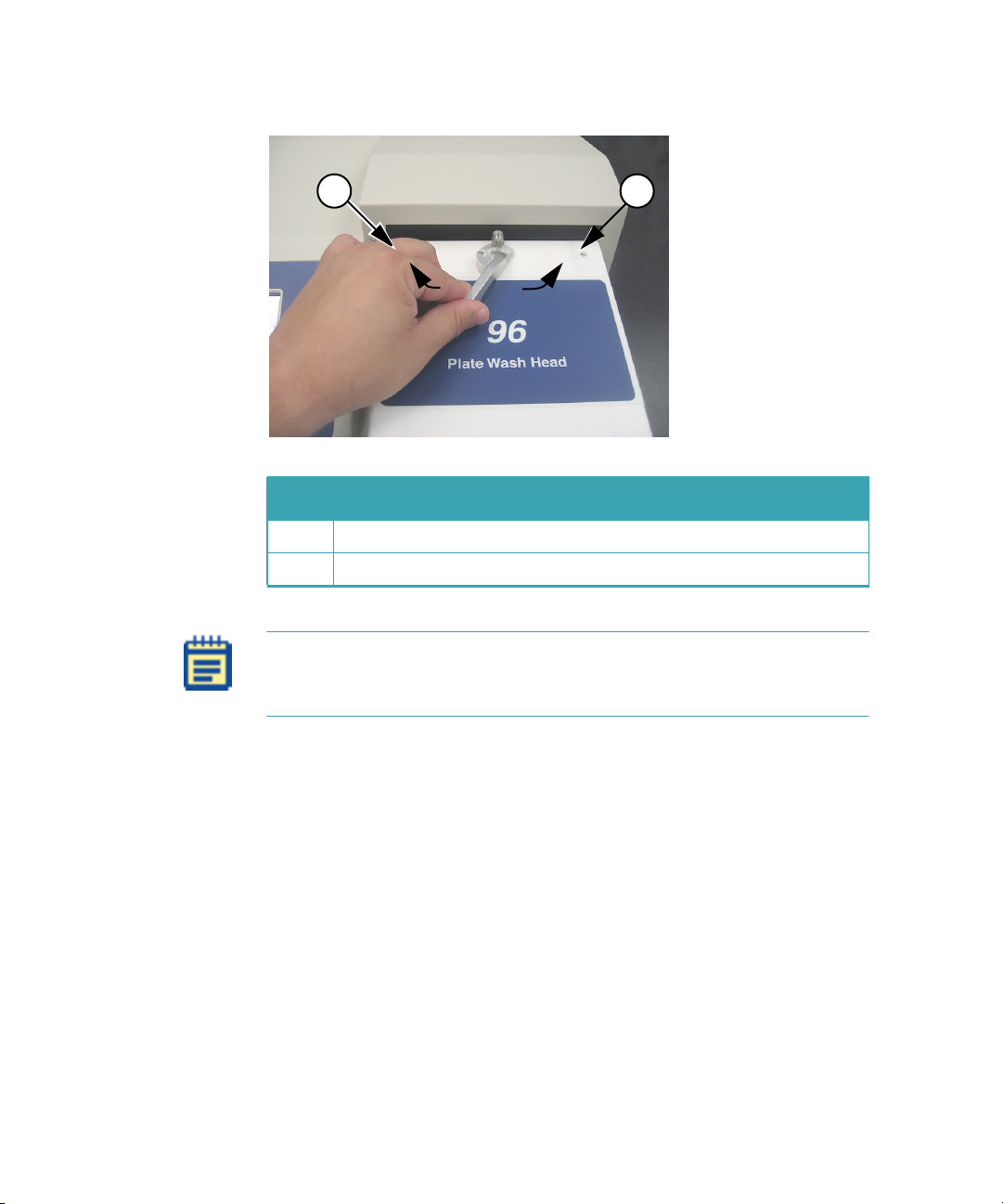

Wash Heads

AquaMax wash heads have either 96 or 384 paired probes. The longer

probe of each pair is used for aspiration. The short probe is used for

dispensing. The plate wash heads have straight dispense probes and are

intended for thorough cleaning and aspiration. The cell wash heads have

angled dispense probes to minimize cell loss during washing.

The wash heads are interchangeable and can be removed and

re-attached using a simple lever mechanism.

0112-0151 K 11

AquaMax® 2000/4000 Microplate Washer User Guide

1 2

Table 1-2: 96-plate wash head lock

Item Description

1 Close

2 Open

Note: A mismatched wash head and microplate will cause a motor

pinch error when the wash head tries to descend toward the wells. A

mismatch should not damage the wash head.

12 0112-0151 K

Introduction

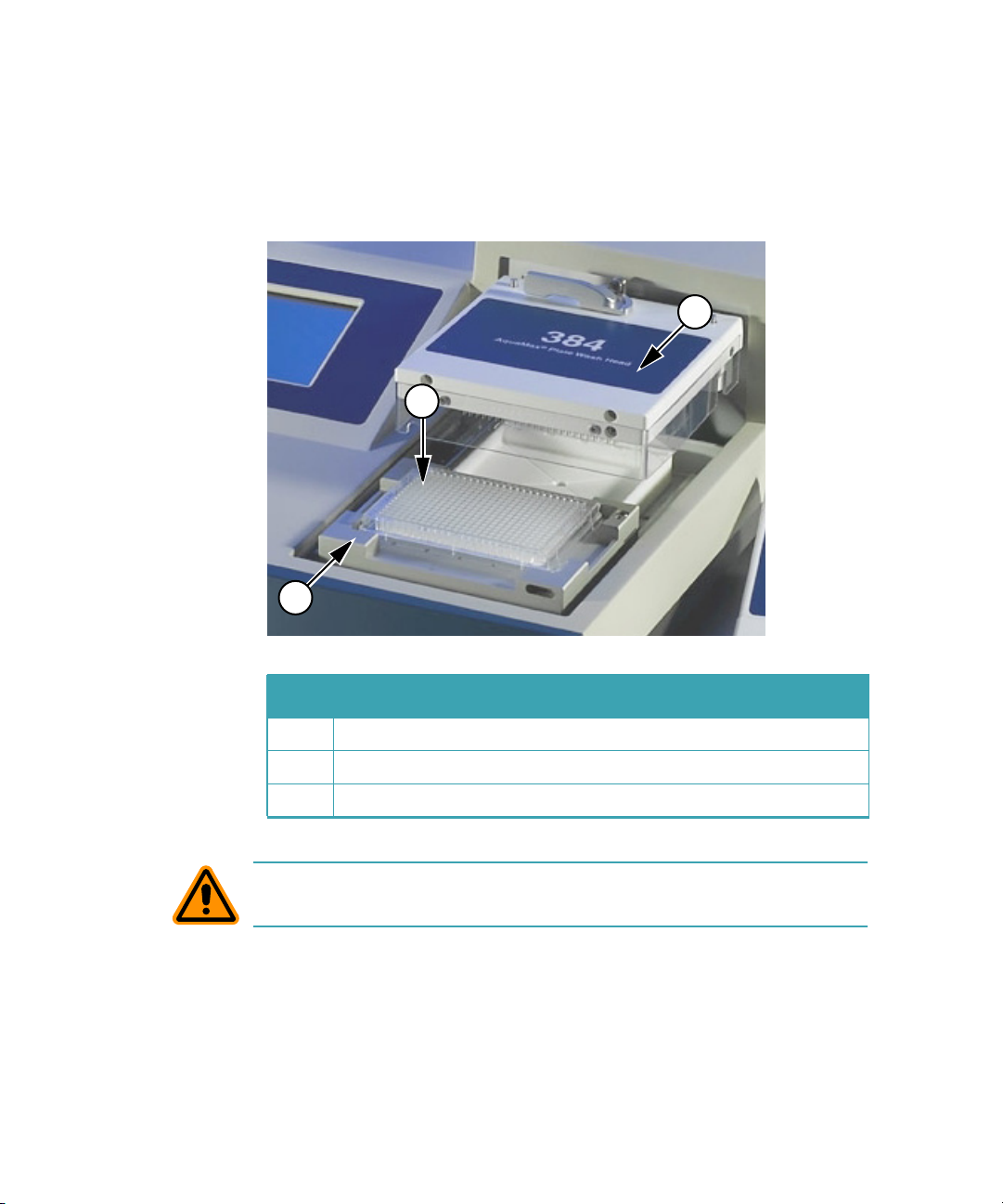

Each wash head has a clear plastic guard to protect the probes from

damage, and to prevent spills, sprays, and injury to users.

1

2

Table 1-3: 384-plate wash head and guard

Item Description

1 Plastic guard

2 Aspiration and dispensing probes on underside of wash head

0112-0151 K 13

AquaMax® 2000/4000 Microplate Washer User Guide

Microplate Carriage

The microplate carriage is located on the right side of the washer. The

plate carriage slides in and out of the washing chamber for loading and

unloading.

2

1

3

Table 1-4: Plate carriage

Item Description

1 Plate carriage, in eject position

2 384-well microplate

3 384 wash head

CAUTION! Do not obstruct the movement of the plate carriage during

operation. Obstruction can damage the instrument.

14 0112-0151 K

Introduction

Supported Microplates

AquaMax Microplate Washers accommodate rigid SBS-standard

polystyrene and polypropylene microplates with dimensions 128.2 mm

(L) × 86.0 mm (W), and heights ranging from 13.5 mm to 15.5 mm,

including:

• 96-well and 384-well standard formats (U-bottom, V-bottom, or

Flat)

• 96-well half area

• 96-well and 384-well small volume

Note: Some microplates with conical or tapered wells and some small

volume microplates are not compatible with bottom wash and aspirate

operations.

Note: 96-well “strip plates” fall outside SBS guidelines, and

compatibility of these plates with the AquaMax Microplate Washer

varies across brands. Plates with strips that are held firmly in a more

rigid frame and have smaller tabs are generally more washercompatible. Plates with strips that have large tabs and are held loosely

in a flexible frame, such as Nunc strip plates with C8 configuration,

should be avoided. If you are unsure whether a plate is compatible,

consult Technical Support or your sales representative before

proceeding.

The AquaMax Microplate Washer also supports magnetic bead washing

using the Dexter Magnetic Technologies LifeSep magnetic beadseparator adapter plates. For more details, refer to the Dexter Magnetic

Technologies website:

http://www.dextermag.com/lifesep.aspx.

The plate library includes eight commonly used microplates (4 each of

96-well and 384-well):

• Corning/Costar: 96 and 384

• BD/Falcon: 96 and 384

• Greiner: 96 and 384

• Nunc/Nalgene: 96 and 384

Detailed manufacturer numbers and dimensions for these default plate

types are listed in

0112-0151 K 15

Microplate Library on page 111.

AquaMax® 2000/4000 Microplate Washer User Guide

The plate library can store up to 32 plate types. For information about

adding a plate type, see Managing the Plate Library on page 73.

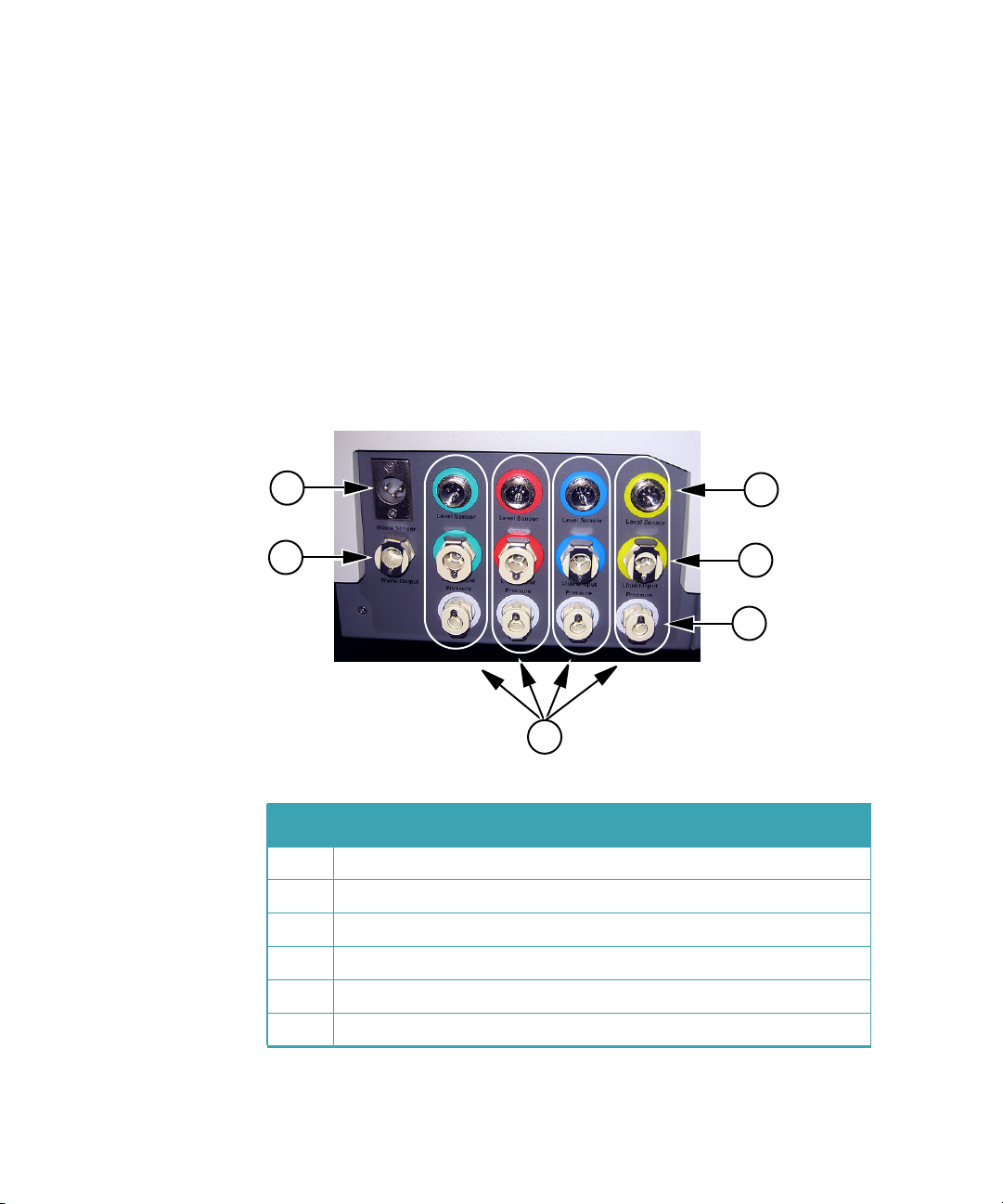

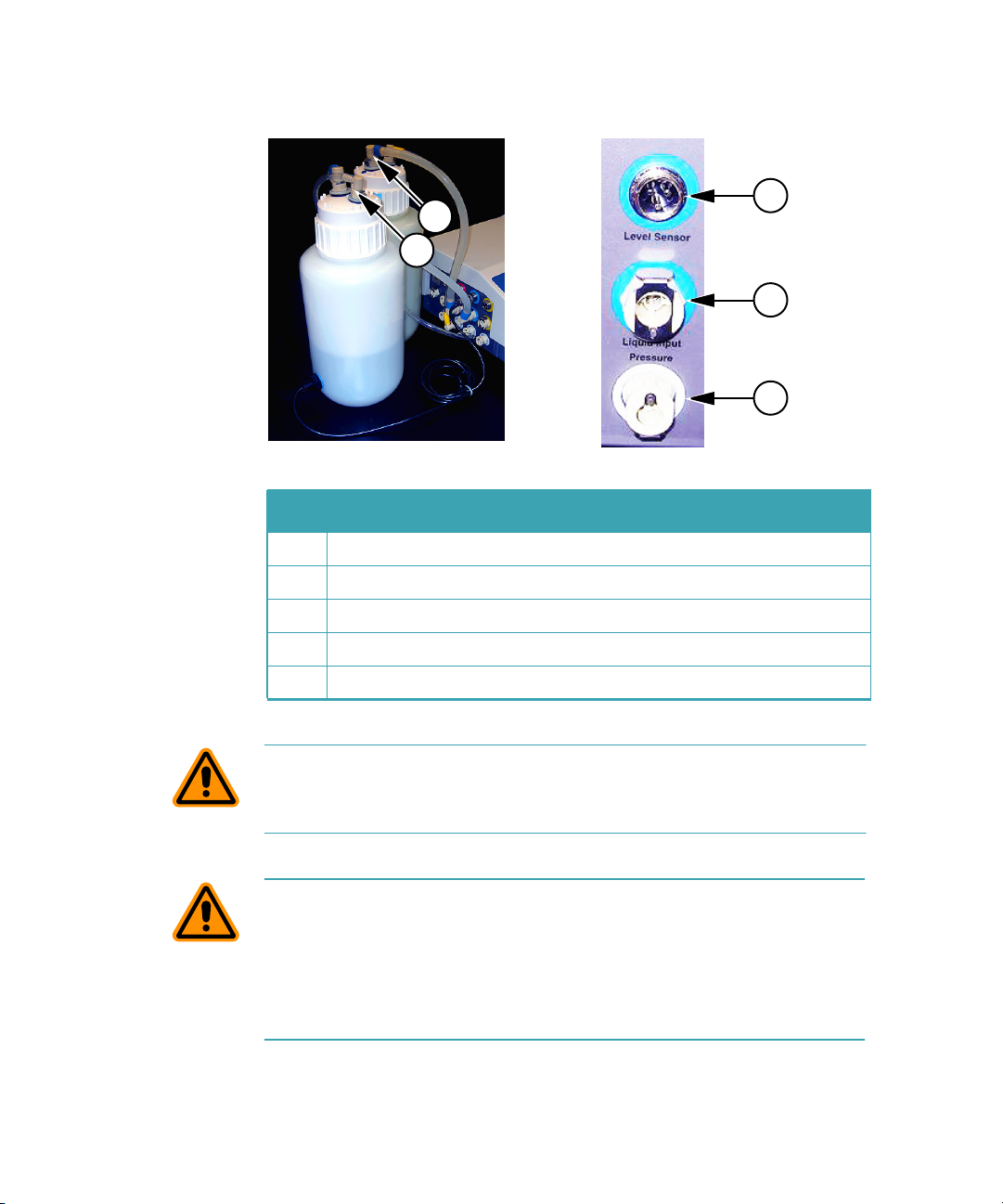

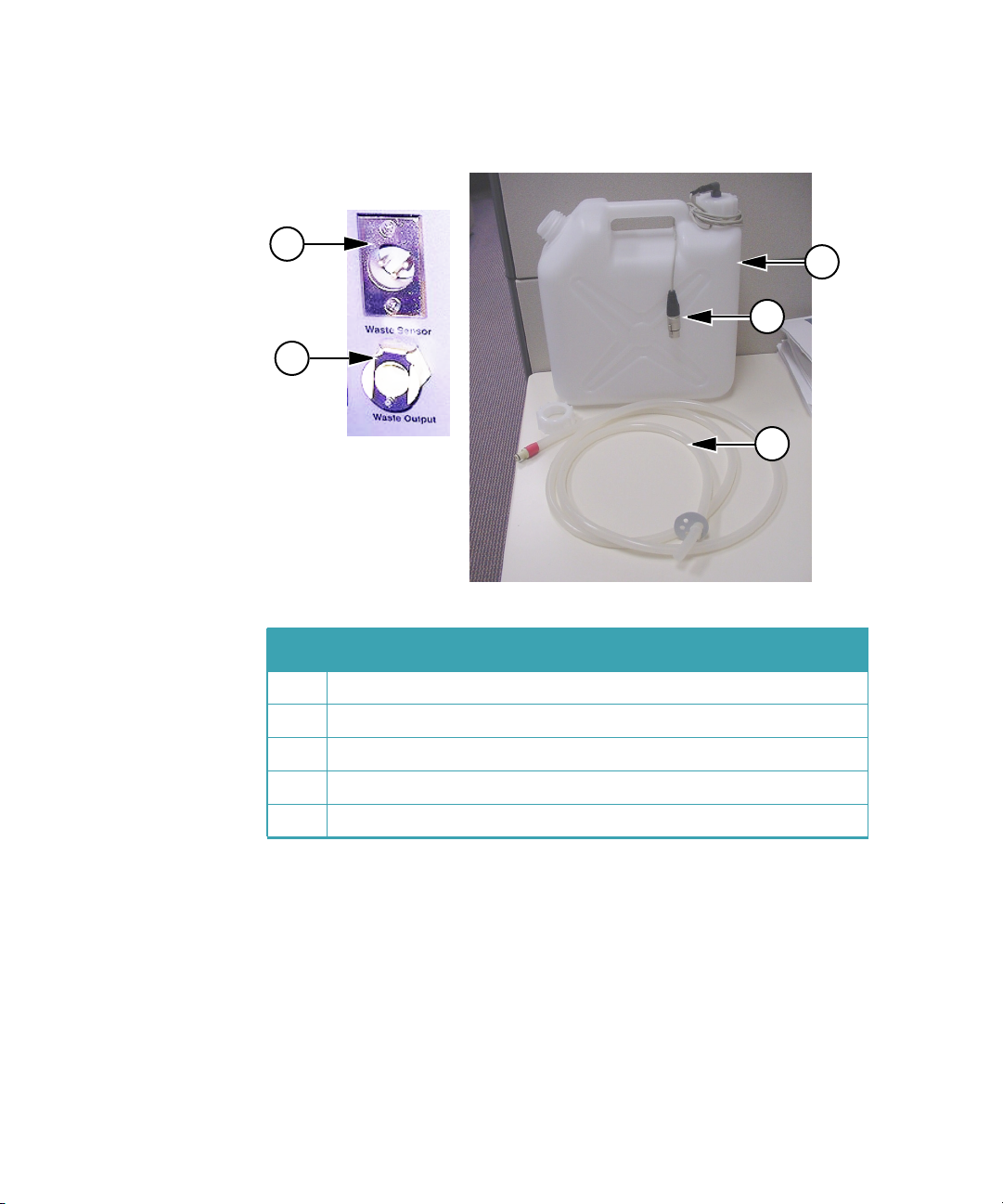

Reagent and Waste Bottle Ports

The source channels and waste connections are located on the left side

of the instrument. The AquaMax 2000 Microplate Washer has two

source channels, while the AquaMax 4000 Microplate Washer has four.

Each source channel can be connected to a reagent bottle, and is

composed of a fluid input, a pressure output, and an optional level

sensor connector. Waste can be drained into any waste bottle. A waste

sensor can be installed to detect a full waste bottle. Non-toxic waste can

be drained directly into a sink.

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

1

2

3

®

Table 1-5: Reagent ports for AquaMax

Item Description

1 Waste full sensor input

2 Waste fluid output

3 Source channels (green, red, blue, and yellow)*

4 Source bottle pressure outputs

5 Source bottle fluid inputs

6 Source bottle empty sensor inputs

4000 Microplate Washer.

6

5

4

16 0112-0151 K

Introduction

*The AquaMax 2000 Microplate Washer has only green and red inlets.

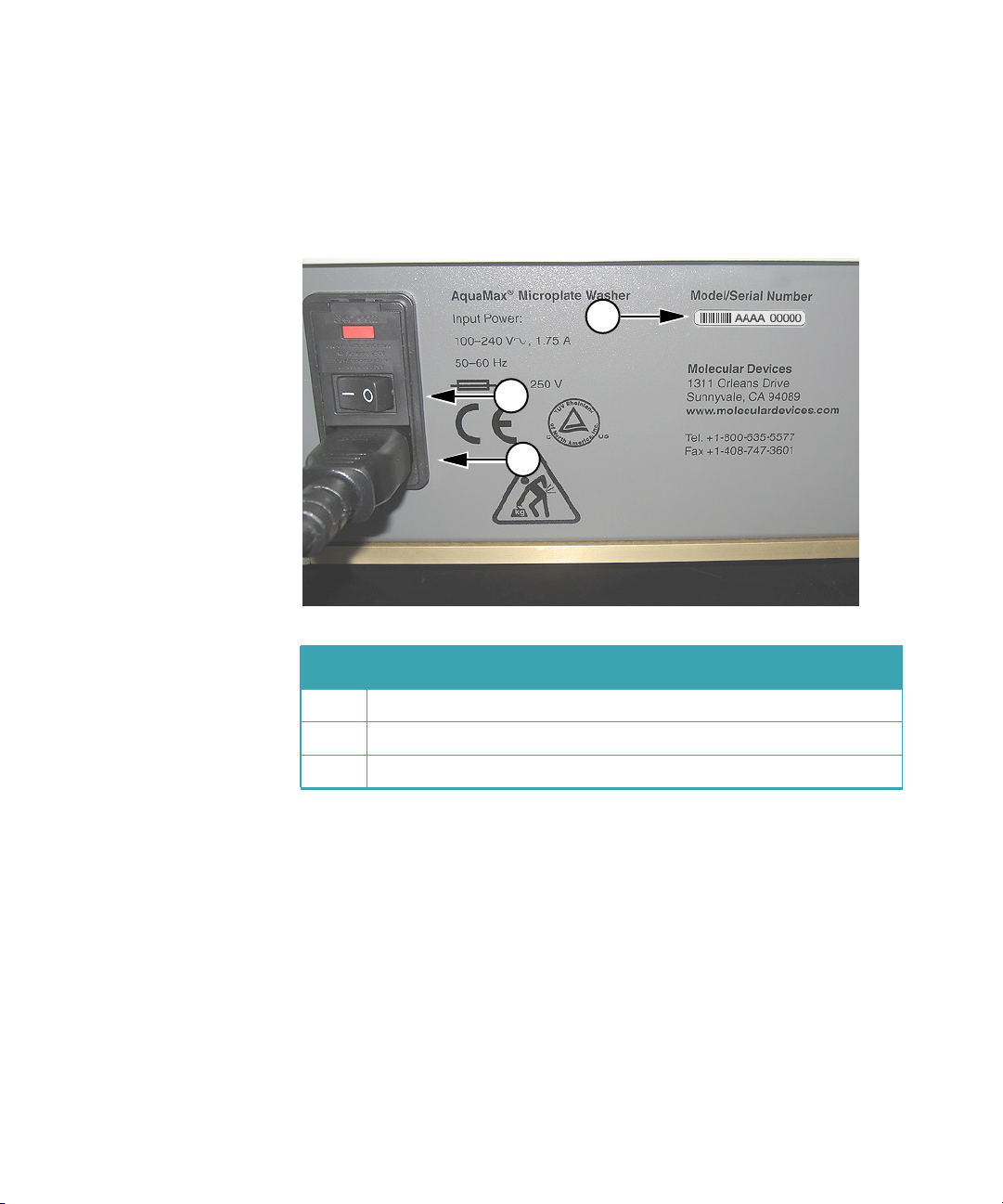

Back Panel

The power switch, power cord receptacle, communication ports, and

instrument information, are located on the back panel of the instrument.

3

1

2

Table 1-6: Back panel, right side

Item Description

1 Power switch

2 Power cord receptacle

3 Serial number

The power cord receptacle and power switch are located on the right

side of the instrument.

Labels and text next to the power switch provide important information

about the AquaMax Microplate Washer, such as line voltage rating and

serial number. Use the model/serial number on this label when

contacting Molecular Devices for technical support issues.

Two communication ports are located on the left side of the back panel.

0112-0151 K 17

AquaMax® 2000/4000 Microplate Washer User Guide

1

2

®

Table 1-7: AquaMax

Microplate Washer USB and StakMax® connectors

Item Description

1 USB port

2 StakMax® connector

The USB Type B port is designated for external robotic control. The

StakMax communication port is dedicated to control StakMax stacker

operations. The StakMax control cable is available with the StakMax

integration kit (Part Number: 0310-5454).

18 0112-0151 K

Installation

2

WARNING! Shock Hazard. To avoid electrical shock, always make sure

the power switch is in the OFF position, and the power cord is

removed, before installing or moving the instrument.

WARNING! Risk of fire, explosion, or shock. Do not operate the

instrument in an environment where potentially damaging liquids or

gases are present.

CAUTION! Do not operate the instrument in an environment with a

temperature below 15°C.

CAUTION! Do not touch or loosen any screws or parts unless specifically

instructed by Molecular Devices. Doing so can cause misalignment and

voids the instrument warranty.

0112-0151 K 19

AquaMax® 2000/4000 Microplate Washer User Guide

Unpacking

WARNING! Each AquaMax Microplate Washer weighs approximately

41 lbs (18.5 kg) and should be lifted with care.

The AquaMax® Microplate Washers are shipped in two specially designed

containers.

• The base unit box contains the washer unit and accessories

(manual, power cord, waste tube, and tubing label kit):

AquaMax 2000 Microplate Washer (Part Number: 0310-

5363)

AquaMax 4000 Microplate Washer (Part Number: 0310-

5227)

The tubing label kit contains 4×3 pieces of colored slip-on

plastic spiral wraps, one group of each color, for labeling

bottle connections (liquid, pressure, level sensor).

• The wash head box contains up to four wash heads, each in a

clamshell container:

96-Well Microplate Wash Head (Part Number: 0310-5216T)

96-Well Cell Wash Head (Part Number: 0310-5217T)

384-Well Microplate Wash Head (Part Number: 0310-5219T)

384-Well Cell Wash Head (Part Number: 0310-5218T)

The standard AquaMax Microplate Washer unit does not include any

bottles. If you have purchased bottles separately, check to make sure that

all bottles and tubing are present. Each reservoir bottle should contain a

cap, fluid tubing, and air tubing. The waste bottle should contain its own

waste tubing.

• Reagent and waste bottles:

4-Liter Reservoir without Level Sensor (Part Number:

5000801)

4-Liter Reservoir with Level Sensor (Part Number: 5000802)

10-Liter Reservoir (Part Number: 9000-0299)

10-Liter Waste Reservoir (Part Number: 9000-0296)

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

Keep all boxes and packing materials, including the clamshell containers

for the wash heads. Use the original packing materials for long-term

storage of the instrument. Original packing material must be used for

shipping if the unit is returned for repair.

20 0112-0151 K

Note: If a box has been damaged in transit, it is particularly important

that you retain it for inspection by the carrier in case there has also

been damage to the instrument.

Setting Up the Instrument

WARNING! Each AquaMax Microplate Washer weighs approximately

41 lbs (18.5 kg) and should be lifted with care.

Set up the instrument on a level surface, away from direct sunlight, dust,

drafts, and vibrations. Complete the following procedures:

• To turn on the instrument on page 21

• To connect a reagent bottle on page 21

• To connect a waste bottle on page 24

• To install the wash head on page 26

To turn on the instrument

Installation

Molecular Devices recommends that you use a surge protector between

the power cord and the grounded power outlet.

1. Connect the power cord to the back panel.

2. Connect the power cord to a surge protector or grounded power

outlet.

The instrument automatically detects the voltage setting.

To connect a reagent bottle

Each reagent bottle comes with two quick-connect fittings and tubing in

two sizes. The larger tubing is for fluid. The smaller tubing is for bottle

pressure.

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

0112-0151 K 21

AquaMax® 2000/4000 Microplate Washer User Guide

2

1

Table 2-1: Reagent bottles and connections fittings

Item Description

1 Small fitting for pressure connection

2 Large fitting for liquid input

3

4

5

3 Level sensor fitting on the instrument

4 Liquid input fitting on the instrument

5 Pressure connector on the instrument

CAUTION! The source bottle and waste fluid fittings are the same size.

Do not connect source bottles to the Waste Output, or damage to the

instrument can occur.

CAUTION! Pressurized bottles for the AquaMax Microplate Washer

provide up to 5 years of service. Eventually, they will show signs of aging

such as yellowing, plastic degradation, or thread wear. Therefore, it is

imperative to replace bottles at the earliest signs of aging. Use only

bottles supplied for use with the AquaMax 2000 and 4000 Microplate

Washers.

22 0112-0151 K

Installation

1. Fill the bottle with a reagent, and tighten the cap firmly.

Tip: For quick and accurate assembly of reagent bottles, use slip-

on rings to color-code all tubing and sensor connections.

2. Connect one end of the fluid tubing to the large fitting on the

bottle cap.

3. Connect the other end to a Liquid Input on the left side of the

instrument (green, red, blue, or yellow).

Tip: Push down on the metal fitting of the quick connector to

ease the fitting into place.

4. Connect one end of the pressure tubing to the small fitting on

the bottle cap.

5. Connect the other end to the Pressure fitting below the Liquid

Input.

6. If the bottle has an Empty sensor, connect the sensor to the Level

Sensor connector above the Liquid Input fitting used.

0112-0151 K 23

AquaMax® 2000/4000 Microplate Washer User Guide

To connect a waste bottle

1

2

Table 2-2: Waste bottle and connection fittings

Item Description

1 Waste sensor connector

2 Waste output fitting

3 Waste bottle

3

4

5

4 Waste full sensor

5 Waste tubing

24 0112-0151 K

Installation

1. Connect the quick connect fitting of the waste tubing to the

Waste Output fitting on the left side of the instrument.

2. Connect the free end of the tubing to any vented waste

container.

For non-toxic waste the free end of the tubing can be placed

directly into a sink. The open end of the waste tubing must be

below the level of the Microplate Washer, and must remain free

of obstruction.

CAUTION! An obstructed waste tubing can damage the

instrument.

3. If the bottle has a waste full sensor, connect the waste full sensor

to the Waste Sensor input fitting.

WARNING! Biohazard. Waste tubing must be connected during

operation. Waste fluid is ejected out of the waste port. If no

waste tubing is connected, waste will spray and spill from the

waste output port.

CAUTION! Waste containers must be vented. Connecting the

waste tubing to a pressurized or closed vessel will cause damage

to the waste pump.

0112-0151 K 25

AquaMax® 2000/4000 Microplate Washer User Guide

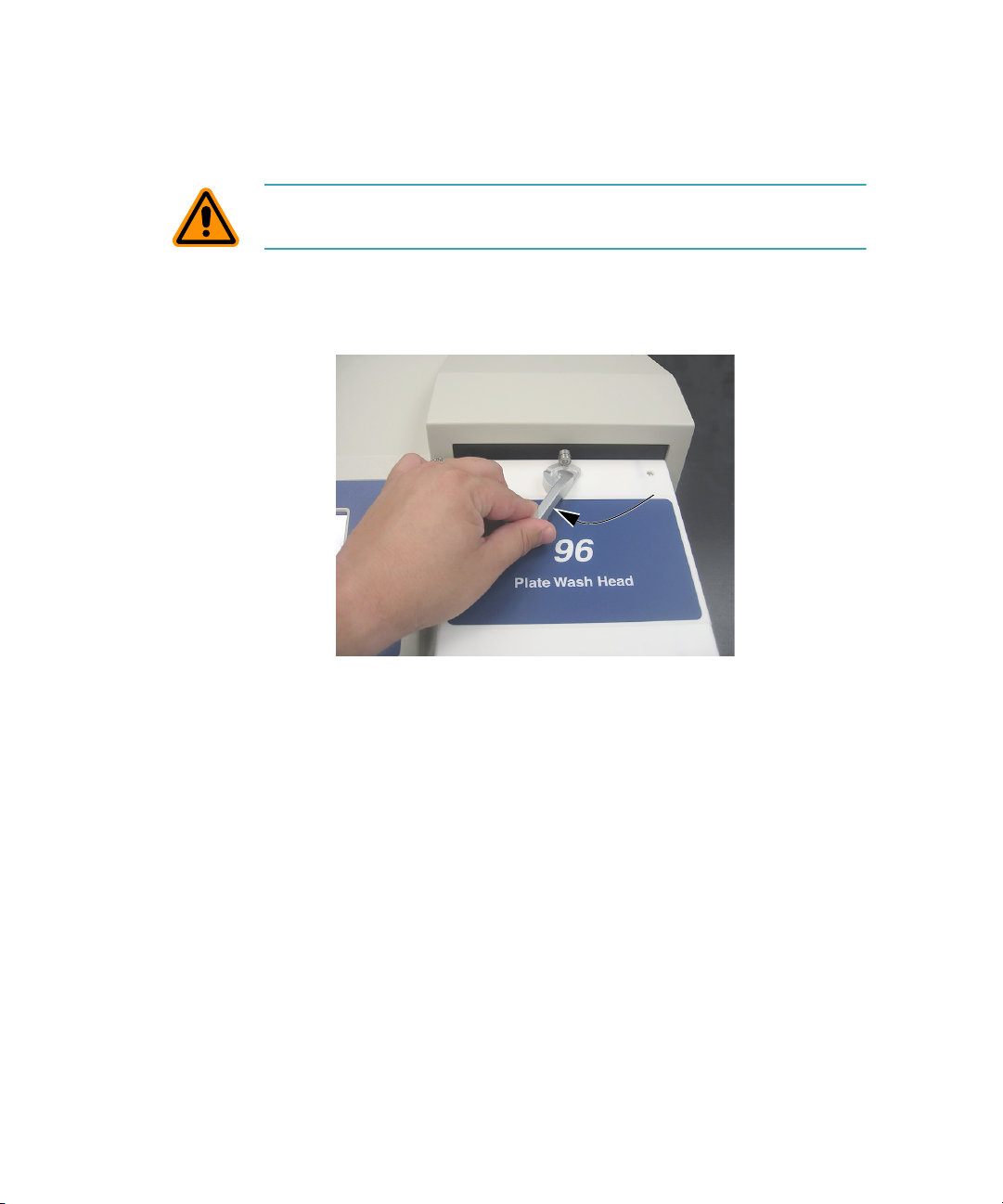

To install the wash head

CAUTION! The probes on the underside of the wash head are delicate.

Take care when handling the wash heads.

1. Install the wash head (96 or 384) of choice. Wash heads are

shipped pre-qualified and will work with any base unit.

2. Move the lever to the left to lock the wash head in place.

Figure 2-1: Wash head lock

3. Turn ON the instrument power switch located on the back panel.

The following operations occur as the instrument initializes when

turned on:

The wash head rises to prepare for plate loading.

The touch screen turns on and displays instrument status.

The plate carriage and wash head motor find home and

return to eject positions.

26 0112-0151 K

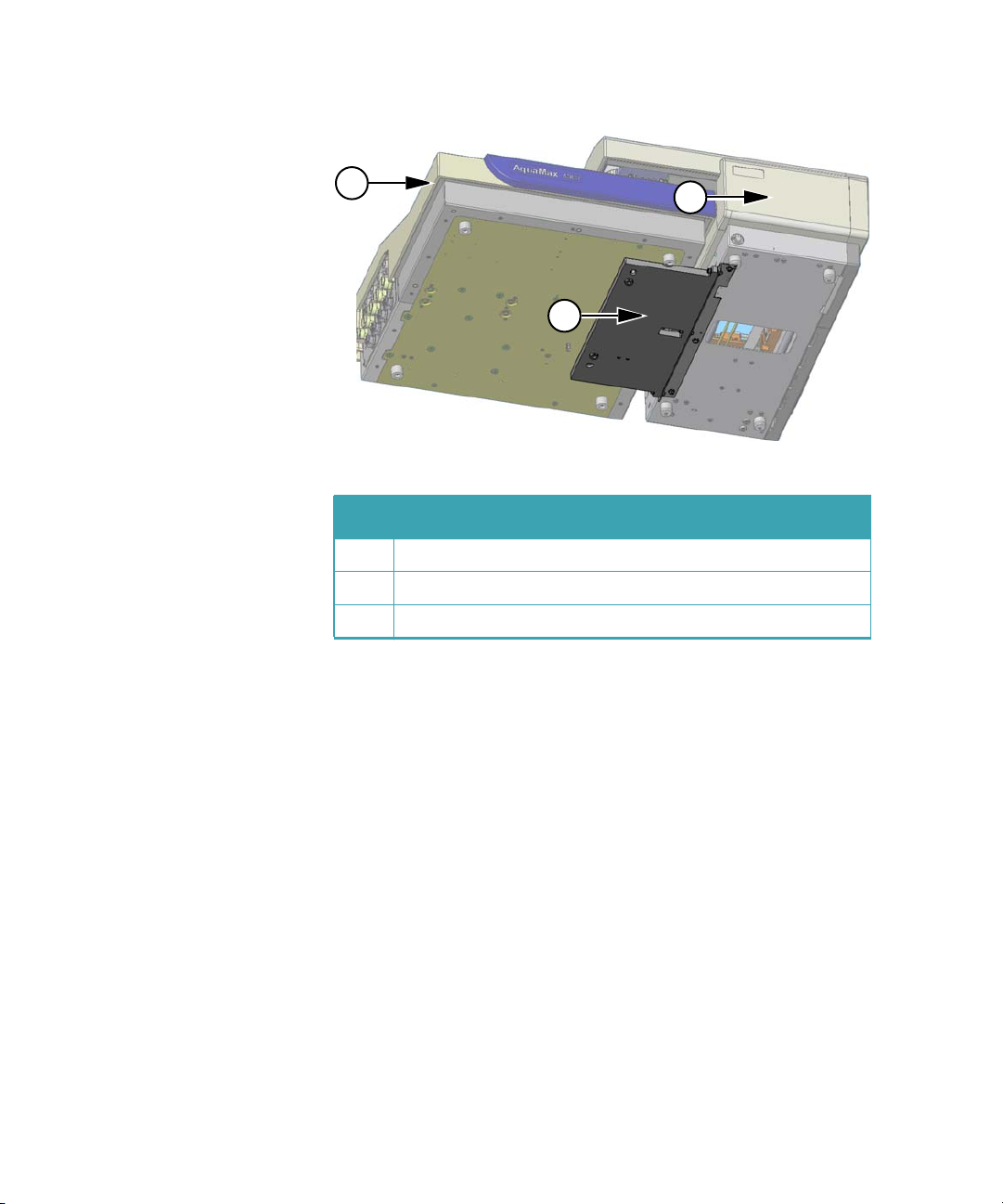

Connecting to a StakMax® Plate Stacker

®

Table 2-3: AquaMax

installed

Microplate Washer with StakMax® Plate Stacker

Installation

1

88

Item Description

1 StakMax® Plate Stacker

To connect the AquaMax Microplate Washer to the StakMax® Plate

Stacker you will need the StakMax integration kit (Part Number: 0310-

5454). The integration kit consists of a StakMax/AquaMax base plate,

bolts for the base plate, a tool for the bolts, a StakMax communication

cable, and an integration manual.

To set up a StakMax® Plate Stacker with an AquaMax® Microplate Washer

For more detailed instructions, see the integration manual.

1. Make sure that both the AquaMax Microplate Washer and the

StakMax Plate Stacker are turned off and that the power cords

are disconnect from the power supply.

2. Use the StakMax/AquaMax base plate to connect the StakMax

Plate Stacker to the AquaMax Microplate Washer (

0112-0151 K 27

Figure 2-4).

AquaMax® 2000/4000 Microplate Washer User Guide

1

2

3

Table 2-4: StakMax

®

Plate Stacker to AquaMax® Microplate

Washer adapter plate

Item Description

1 AquaMax® Microplate Washer

2 StakMax® Plate Stacker

3 Adapter plate

3. Connect the StakMax communication cable to the serial port on

the back of the StakMax Plate Stacker.

4. Connect the StakMax communication cable to the StakMax port

on the back panel of the AquaMax Microplate Washer. See

Back

Panel on page 17.

5. Turn on both the AquaMax Microplate Washer and the StakMax

Plate Stacker.

The StakMax Plate Stacker automatically detects that it is

connected to the AquaMax Microplate Washer.

The AquaMax Microplate Washer detects the StakMax Plate

Stacker.

28 0112-0151 K

Installation

Figure 2-2: StakMax Stacker indicator

The washer controls the stacker through its on board programs.

For information about using the stacker in a program, see

Program Stacker Settings on page 43.

0112-0151 K 29

AquaMax® 2000/4000 Microplate Washer User Guide

30 0112-0151 K

Loading...

Loading...