AquaMax® 2000/4000

Microplate Washer

User Guide

0112-0151 K

June 2014

www.moleculardevices.com

This document is provided to customers who have purchased Molecular Devices, LLC

(“Molecular Devices”) equipment, software, reagents, and consumables to use in the

operation of such Molecular Devices equipment, software, reagents, and

consumables. This document is copyright protected and any reproduction of this

document, in whole or any part, is strictly prohibited, except as Molecular Devices

may authorize in writing.

Software that may be described in this document is furnished under a license

agreement. It is against the law to copy, modify, or distribute the software on any

medium, except as specifically allowed in the license agreement. Furthermore, the

license agreement may prohibit the software from being disassembled, reverse

engineered, or decompiled for any purpose.

Portions of this document may make reference to other manufacturers and/or their

products, which may contain parts whose names are registered as trademarks and/or

function as trademarks of their respective owners. Any such usage is intended only to

designate those manufacturers’ products as supplied by Molecular Devices for

incorporation into its equipment and does not imply any right and/or license to use

or permit others to use such manufacturers’ and/or their product names as

trademarks.

Molecular Devices makes no warranties or representations as to the fitness of this

equipment for any particular purpose and assumes no responsibility or contingent

liability, including indirect or consequential damages, for any use to which the

purchaser may put the equipment described herein, or for any adverse circumstances

arising therefrom.

For research use only. Not for use in diagnostic procedures.

The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These

trademarks may not be used in any type of promotion or advertising without the prior written permission of

Molecular Devices, LLC.

Product manufactured by Molecular Devices, LLC.

1311 Orleans Drive, Sunnyvale, California, United States of America 94089.

Molecular Devices, LLC is ISO 9001 registered.

© 2014 Molecular Devices, LLC.

All rights reserved.

Contents

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who This User Guide Is For . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instrument Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Robot and Stacker Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Microplate Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reagent and Waste Bottle Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Setting Up the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting to a StakMax

®

Plate Stacker . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Starting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Main Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Running Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stopping Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Shutting Down the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4: Operation: The Touch Screen Interface . . . . . . . . . . 37

Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Program Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Program Tab: Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . 39

Program Settings Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

0112-0151 K 3

AquaMax® 2000/4000 Microplate Washer User Guide

Program Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Program Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Program Stacker Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjust Dispense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Program Tab: Program Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

New Step Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dispense Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Aspirate Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wash Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

FastWash Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Shake Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Soak Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Repeat Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Purge Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Rinse Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Standby Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Prime Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Managing the Program Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Plates Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Plates Tab: Administrative Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Plate Definition Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Managing the Plate Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Options Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Advanced Options Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Options Tab: Administrative Mode . . . . . . . . . . . . . . . . . . . . . . . . . 76

Shutdown Options Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Managing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Automatic Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Restricting Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Chapter 5: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Purging the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Decontaminating the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Cleaning the Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Removing and Storing Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . 88

Cleaning Wash Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4 0112-0151 K

Contents

Moving an AquaMax® Microplate Washer . . . . . . . . . . . . . . . . . . . . 92

Preparing for Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 6: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

General Instrument Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

System Fluidics Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

System Pressure Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

External Communication Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Dispense Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Aspiration Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Wash Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Cell Wash Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Instrument Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 7: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

AquaMax® Microplate Washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix A: Microplate Library . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix B: Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix C: AquaMax Sterilant . . . . . . . . . . . . . . . . . . . . . . . . 115

Principle of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Materials Required but Not Provided. . . . . . . . . . . . . . . . . . . . . . 116

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Preparing the Reagent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Preparing the Complete Sterilant . . . . . . . . . . . . . . . . . . . . . . . . . 117

Using Reagent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Warnings, Precautions, and Limitations . . . . . . . . . . . . . . . . . . . . . 118

Sterilant Solution A Concentrate (4X). . . . . . . . . . . . . . . . . . . . . . 118

Sterilant Solution B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix D: Tips and Applications . . . . . . . . . . . . . . . . . . . . . . 119

Using the Washer for ELISA Based Applications . . . . . . . . . . . . . 119

Using the Washer for Cell Based Applications . . . . . . . . . . . . . . . 119

0112-0151 K 5

AquaMax® 2000/4000 Microplate Washer User Guide

Appendix E: Robot Command Interface . . . . . . . . . . . . . . . . . . 121

Instrument Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Hardware Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Host Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

No Error (OK) Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Error Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

General Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

User Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Program Management Commands . . . . . . . . . . . . . . . . . . . . . . . . . 132

Factory-defined Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Protocol (Program) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Edit/view Opened Protocol Steps . . . . . . . . . . . . . . . . . . . . . . . . . 136

Function-specific Step Arguments and Return Data . . . . . . . . . . . . 138

Plate Library Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

StakMax

Stacker Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Error Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Instrument Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

®

Robot Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

6 0112-0151 K

Who This User Guide Is For

This guide is intended for users of the AquaMax® 2000 and AquaMax

4000 Microplate Washers. The user guide contains setup, operation, and

general maintenance information.

Conventions

Within the scope of this user guide, the following typographical

conventions are used:

WARNING! A warning indicates an operation that can cause personal

injury if precautions are not followed.

CAUTION! Indicates an operation that might cause damage to the

instrument, device, or data, if the precautions are not followed.

Foreword

Note: Emphasizes significant information in a procedure or description.

Tip: Provides useful information or shortcuts, but is not essential to the

completion of a procedure.

0112-0151 K 7

AquaMax® 2000/4000 Microplate Washer User Guide

8 0112-0151 K

Introduction

The AquaMax® Microplate Washers from Molecular Devices can be easily

configured to meet your current application requirements. The modular

design provides affordable upgrade options when your lab requirements

change.

Instrument Features

AquaMax 2000 and AquaMax 4000 Microplate Washers can be

configured to process 96-well and 384-well microplates used in both

biochemical and cell-based assays.

• Wash heads are available in 96-well and 384-well configurations

• All wash heads are interchangeable. The software automatically

• The AquaMax Microplate Washer primes, cleans, and rinses the

• The AquaMax Microplate Washer processes all plate wells

• Whole-well dispensing and aspiration in 384-well plates result in

• The AquaMax Microplate Washer supports most microplate

• The AquaMax Microplate Washer is equipped with two

• All washer operations are controlled through an on-board

• The program library can store up to 3 factory-defined and 100

1

for both plate wash and cell wash.

detects which wash head is installed.

wash heads with the touch of a single button.

simultaneously during dispense, aspirate, and wash operations.

2 to 4 times faster plate processing than other commercially

available plate washers.

formats through its user-definable plate library. Up to 32 plate

types can be stored in the plate library.

(AquaMax 2000 washer) or four (AquaMax 4000 washer) reagent

ports to connect 2 or 4 different dispense bottles. Waste can be

drained into any waste bottle. Non-toxic waste can be drained

directly into a sink. The AquaMax Microplate Washer supports

4 L or 10 L bottles only.

touch-screen user interface.

user-defined programs. Each program can contain up to 50 steps.

0112-0151 K 9

AquaMax® 2000/4000 Microplate Washer User Guide

Robot and Stacker Compatibility

AquaMax Microplate Washers are compatible with Molecular Devices

StakMax® Microplate Handling System. Third party robots can be set up

to control the AquaMax Microplate Washers through a USB command

interface. The USB command interface is detailed in Robot Command

Interface on page 121.

Components

6

1

2

3

4

5

Table 1-1: AquaMax® 4000 Components

Item Description

1 4L reagent reservoirs

2 Back panel with USB and StakMax connectors

3 384-well wash head installed

4 96-well wash head

5 Microplate carriage with microplate

6 Touch screen

10 0112-0151 K

Introduction

Touch Screen

Figure 1-1: AquaMax® touch screen

Instrument operation is controlled through a touch-screen user interface.

The touch screen displays instrument status, provides access to

instrument settings and programs, and controls the optional StakMax

Plate Stacker.

Wash Heads

AquaMax wash heads have either 96 or 384 paired probes. The longer

probe of each pair is used for aspiration. The short probe is used for

dispensing. The plate wash heads have straight dispense probes and are

intended for thorough cleaning and aspiration. The cell wash heads have

angled dispense probes to minimize cell loss during washing.

The wash heads are interchangeable and can be removed and

re-attached using a simple lever mechanism.

0112-0151 K 11

AquaMax® 2000/4000 Microplate Washer User Guide

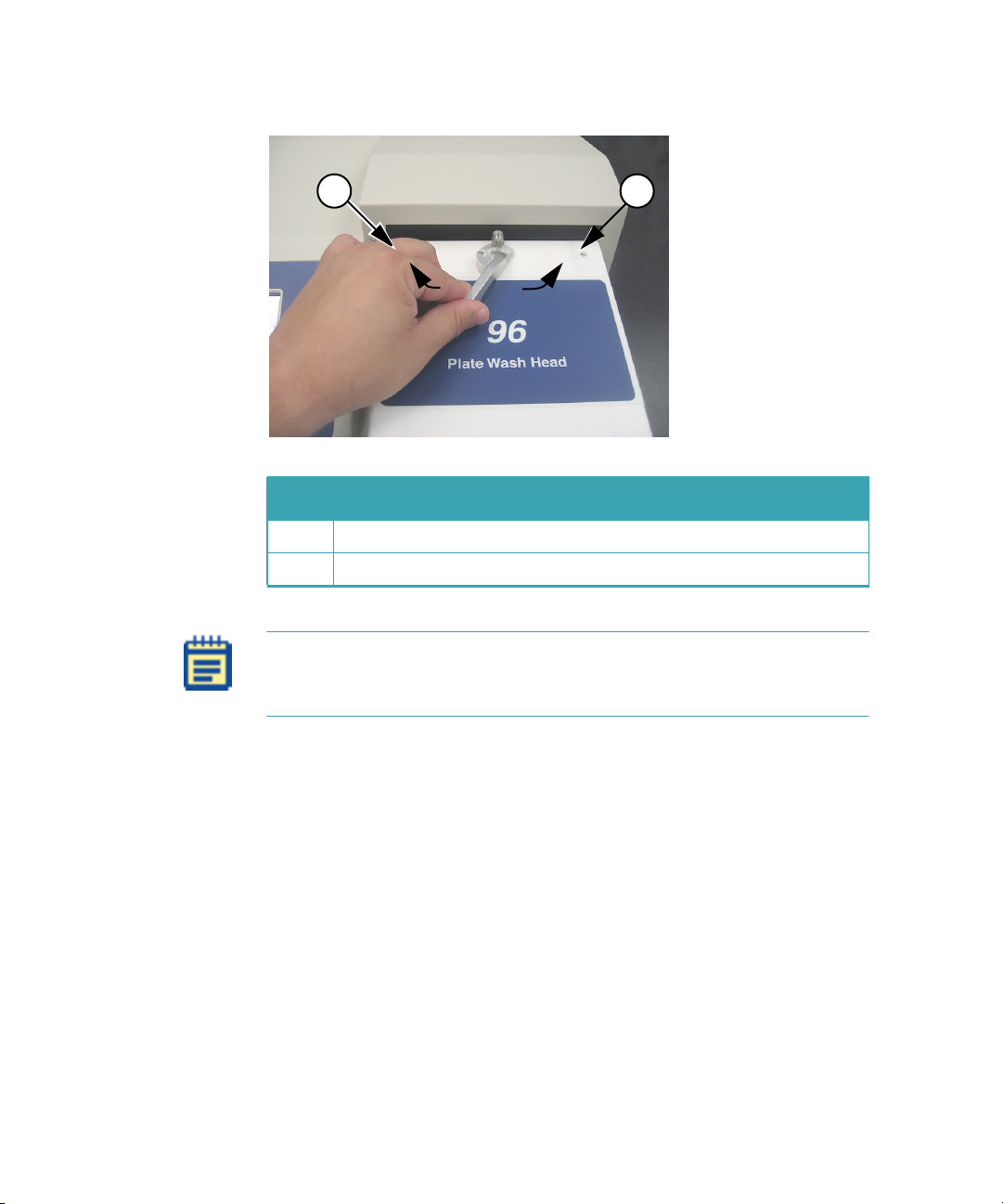

1 2

Table 1-2: 96-plate wash head lock

Item Description

1 Close

2 Open

Note: A mismatched wash head and microplate will cause a motor

pinch error when the wash head tries to descend toward the wells. A

mismatch should not damage the wash head.

12 0112-0151 K

Introduction

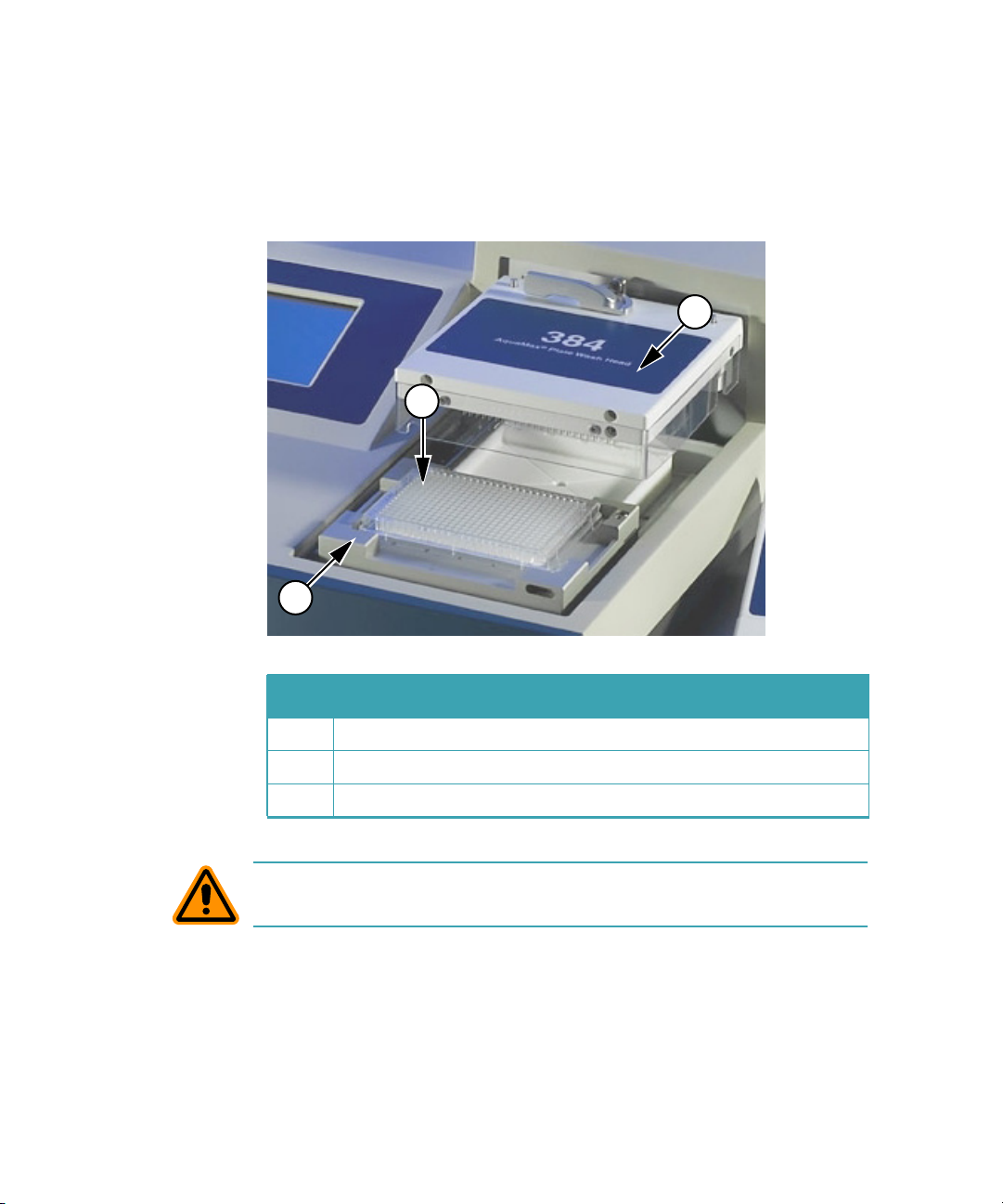

Each wash head has a clear plastic guard to protect the probes from

damage, and to prevent spills, sprays, and injury to users.

1

2

Table 1-3: 384-plate wash head and guard

Item Description

1 Plastic guard

2 Aspiration and dispensing probes on underside of wash head

0112-0151 K 13

AquaMax® 2000/4000 Microplate Washer User Guide

Microplate Carriage

The microplate carriage is located on the right side of the washer. The

plate carriage slides in and out of the washing chamber for loading and

unloading.

2

1

3

Table 1-4: Plate carriage

Item Description

1 Plate carriage, in eject position

2 384-well microplate

3 384 wash head

CAUTION! Do not obstruct the movement of the plate carriage during

operation. Obstruction can damage the instrument.

14 0112-0151 K

Introduction

Supported Microplates

AquaMax Microplate Washers accommodate rigid SBS-standard

polystyrene and polypropylene microplates with dimensions 128.2 mm

(L) × 86.0 mm (W), and heights ranging from 13.5 mm to 15.5 mm,

including:

• 96-well and 384-well standard formats (U-bottom, V-bottom, or

Flat)

• 96-well half area

• 96-well and 384-well small volume

Note: Some microplates with conical or tapered wells and some small

volume microplates are not compatible with bottom wash and aspirate

operations.

Note: 96-well “strip plates” fall outside SBS guidelines, and

compatibility of these plates with the AquaMax Microplate Washer

varies across brands. Plates with strips that are held firmly in a more

rigid frame and have smaller tabs are generally more washercompatible. Plates with strips that have large tabs and are held loosely

in a flexible frame, such as Nunc strip plates with C8 configuration,

should be avoided. If you are unsure whether a plate is compatible,

consult Technical Support or your sales representative before

proceeding.

The AquaMax Microplate Washer also supports magnetic bead washing

using the Dexter Magnetic Technologies LifeSep magnetic beadseparator adapter plates. For more details, refer to the Dexter Magnetic

Technologies website:

http://www.dextermag.com/lifesep.aspx.

The plate library includes eight commonly used microplates (4 each of

96-well and 384-well):

• Corning/Costar: 96 and 384

• BD/Falcon: 96 and 384

• Greiner: 96 and 384

• Nunc/Nalgene: 96 and 384

Detailed manufacturer numbers and dimensions for these default plate

types are listed in

0112-0151 K 15

Microplate Library on page 111.

AquaMax® 2000/4000 Microplate Washer User Guide

The plate library can store up to 32 plate types. For information about

adding a plate type, see Managing the Plate Library on page 73.

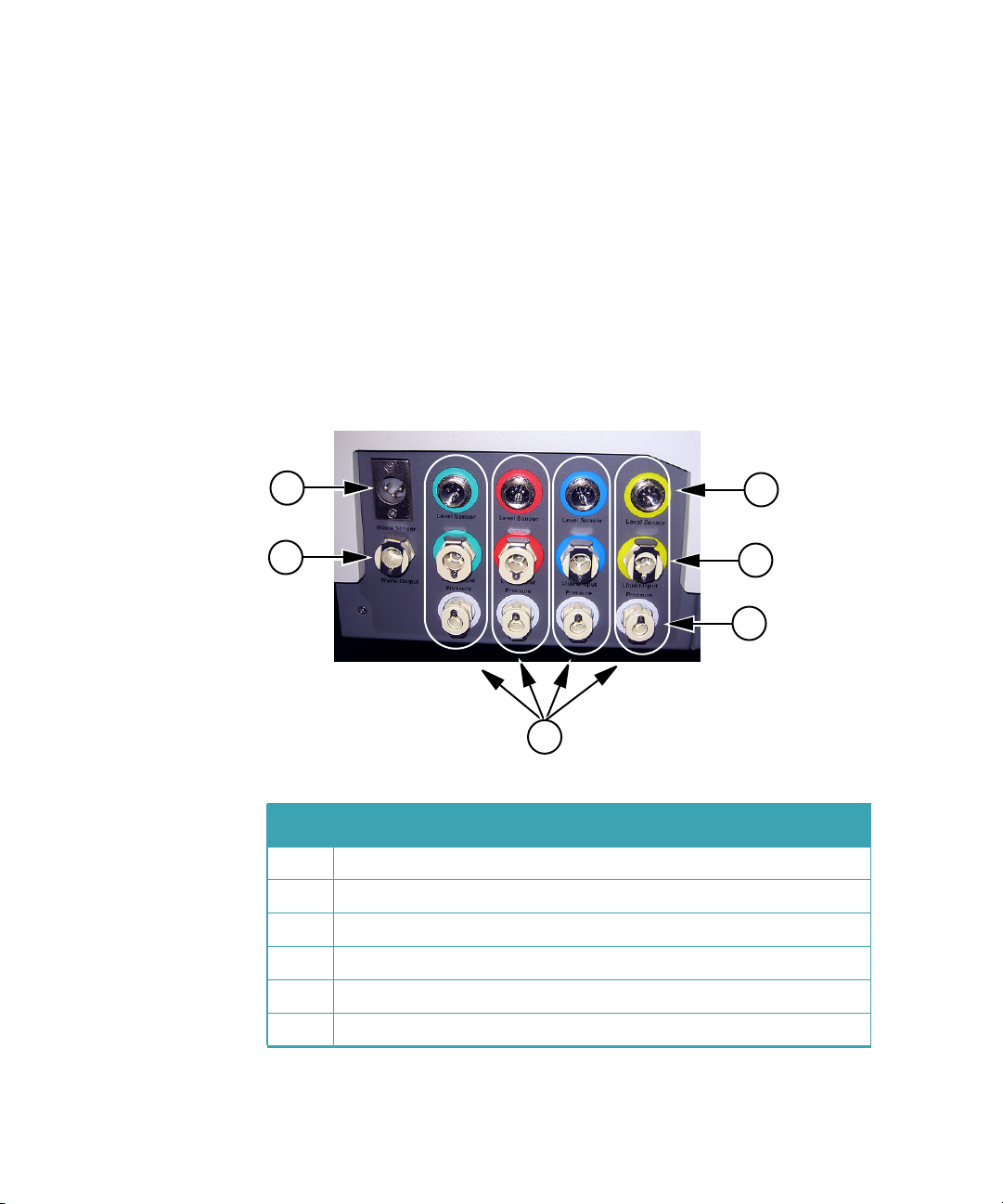

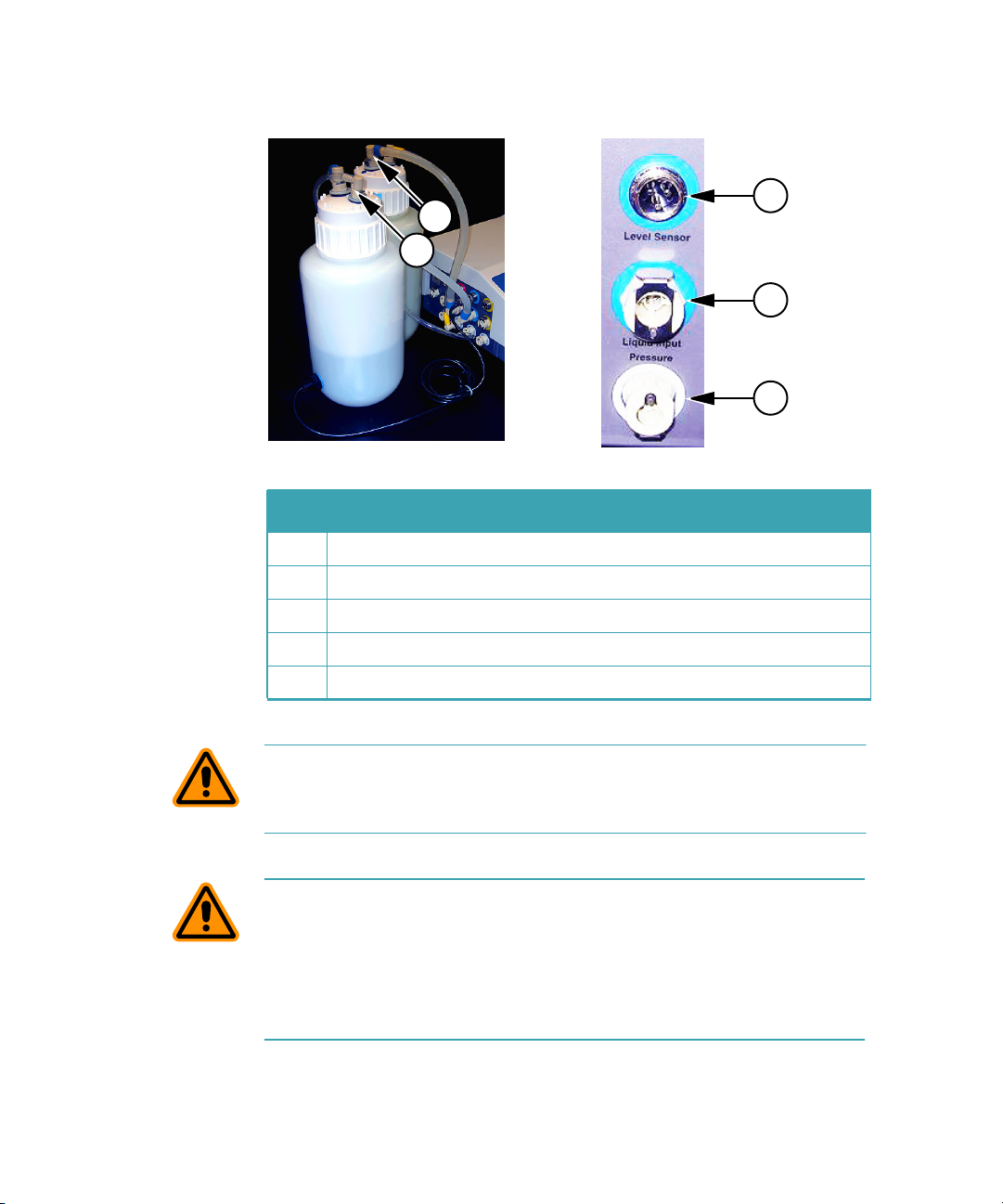

Reagent and Waste Bottle Ports

The source channels and waste connections are located on the left side

of the instrument. The AquaMax 2000 Microplate Washer has two

source channels, while the AquaMax 4000 Microplate Washer has four.

Each source channel can be connected to a reagent bottle, and is

composed of a fluid input, a pressure output, and an optional level

sensor connector. Waste can be drained into any waste bottle. A waste

sensor can be installed to detect a full waste bottle. Non-toxic waste can

be drained directly into a sink.

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

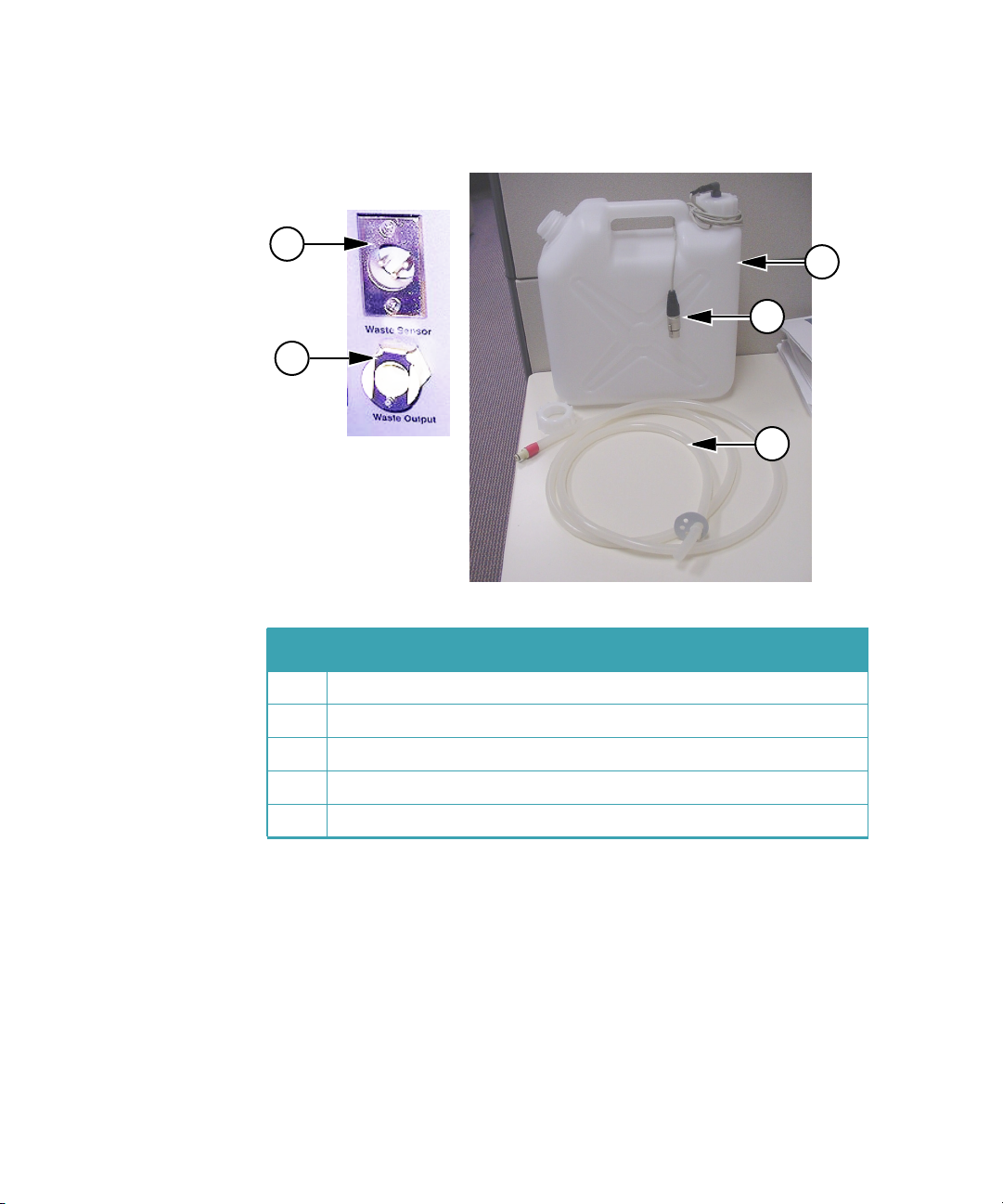

1

2

3

®

Table 1-5: Reagent ports for AquaMax

Item Description

1 Waste full sensor input

2 Waste fluid output

3 Source channels (green, red, blue, and yellow)*

4 Source bottle pressure outputs

5 Source bottle fluid inputs

6 Source bottle empty sensor inputs

4000 Microplate Washer.

6

5

4

16 0112-0151 K

Introduction

*The AquaMax 2000 Microplate Washer has only green and red inlets.

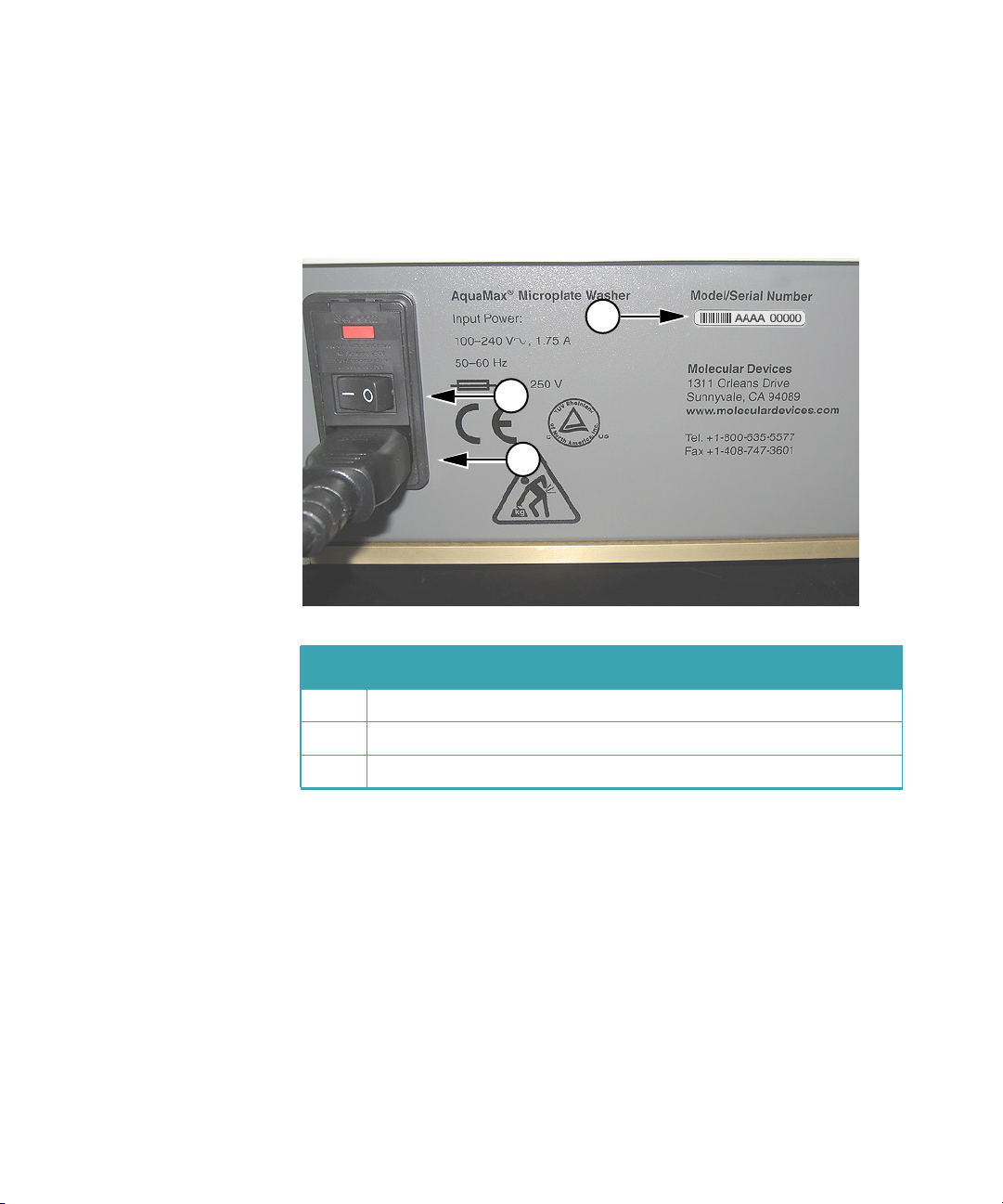

Back Panel

The power switch, power cord receptacle, communication ports, and

instrument information, are located on the back panel of the instrument.

3

1

2

Table 1-6: Back panel, right side

Item Description

1 Power switch

2 Power cord receptacle

3 Serial number

The power cord receptacle and power switch are located on the right

side of the instrument.

Labels and text next to the power switch provide important information

about the AquaMax Microplate Washer, such as line voltage rating and

serial number. Use the model/serial number on this label when

contacting Molecular Devices for technical support issues.

Two communication ports are located on the left side of the back panel.

0112-0151 K 17

AquaMax® 2000/4000 Microplate Washer User Guide

1

2

®

Table 1-7: AquaMax

Microplate Washer USB and StakMax® connectors

Item Description

1 USB port

2 StakMax® connector

The USB Type B port is designated for external robotic control. The

StakMax communication port is dedicated to control StakMax stacker

operations. The StakMax control cable is available with the StakMax

integration kit (Part Number: 0310-5454).

18 0112-0151 K

Installation

2

WARNING! Shock Hazard. To avoid electrical shock, always make sure

the power switch is in the OFF position, and the power cord is

removed, before installing or moving the instrument.

WARNING! Risk of fire, explosion, or shock. Do not operate the

instrument in an environment where potentially damaging liquids or

gases are present.

CAUTION! Do not operate the instrument in an environment with a

temperature below 15°C.

CAUTION! Do not touch or loosen any screws or parts unless specifically

instructed by Molecular Devices. Doing so can cause misalignment and

voids the instrument warranty.

0112-0151 K 19

AquaMax® 2000/4000 Microplate Washer User Guide

Unpacking

WARNING! Each AquaMax Microplate Washer weighs approximately

41 lbs (18.5 kg) and should be lifted with care.

The AquaMax® Microplate Washers are shipped in two specially designed

containers.

• The base unit box contains the washer unit and accessories

(manual, power cord, waste tube, and tubing label kit):

AquaMax 2000 Microplate Washer (Part Number: 0310-

5363)

AquaMax 4000 Microplate Washer (Part Number: 0310-

5227)

The tubing label kit contains 4×3 pieces of colored slip-on

plastic spiral wraps, one group of each color, for labeling

bottle connections (liquid, pressure, level sensor).

• The wash head box contains up to four wash heads, each in a

clamshell container:

96-Well Microplate Wash Head (Part Number: 0310-5216T)

96-Well Cell Wash Head (Part Number: 0310-5217T)

384-Well Microplate Wash Head (Part Number: 0310-5219T)

384-Well Cell Wash Head (Part Number: 0310-5218T)

The standard AquaMax Microplate Washer unit does not include any

bottles. If you have purchased bottles separately, check to make sure that

all bottles and tubing are present. Each reservoir bottle should contain a

cap, fluid tubing, and air tubing. The waste bottle should contain its own

waste tubing.

• Reagent and waste bottles:

4-Liter Reservoir without Level Sensor (Part Number:

5000801)

4-Liter Reservoir with Level Sensor (Part Number: 5000802)

10-Liter Reservoir (Part Number: 9000-0299)

10-Liter Waste Reservoir (Part Number: 9000-0296)

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

Keep all boxes and packing materials, including the clamshell containers

for the wash heads. Use the original packing materials for long-term

storage of the instrument. Original packing material must be used for

shipping if the unit is returned for repair.

20 0112-0151 K

Note: If a box has been damaged in transit, it is particularly important

that you retain it for inspection by the carrier in case there has also

been damage to the instrument.

Setting Up the Instrument

WARNING! Each AquaMax Microplate Washer weighs approximately

41 lbs (18.5 kg) and should be lifted with care.

Set up the instrument on a level surface, away from direct sunlight, dust,

drafts, and vibrations. Complete the following procedures:

• To turn on the instrument on page 21

• To connect a reagent bottle on page 21

• To connect a waste bottle on page 24

• To install the wash head on page 26

To turn on the instrument

Installation

Molecular Devices recommends that you use a surge protector between

the power cord and the grounded power outlet.

1. Connect the power cord to the back panel.

2. Connect the power cord to a surge protector or grounded power

outlet.

The instrument automatically detects the voltage setting.

To connect a reagent bottle

Each reagent bottle comes with two quick-connect fittings and tubing in

two sizes. The larger tubing is for fluid. The smaller tubing is for bottle

pressure.

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

0112-0151 K 21

AquaMax® 2000/4000 Microplate Washer User Guide

2

1

Table 2-1: Reagent bottles and connections fittings

Item Description

1 Small fitting for pressure connection

2 Large fitting for liquid input

3

4

5

3 Level sensor fitting on the instrument

4 Liquid input fitting on the instrument

5 Pressure connector on the instrument

CAUTION! The source bottle and waste fluid fittings are the same size.

Do not connect source bottles to the Waste Output, or damage to the

instrument can occur.

CAUTION! Pressurized bottles for the AquaMax Microplate Washer

provide up to 5 years of service. Eventually, they will show signs of aging

such as yellowing, plastic degradation, or thread wear. Therefore, it is

imperative to replace bottles at the earliest signs of aging. Use only

bottles supplied for use with the AquaMax 2000 and 4000 Microplate

Washers.

22 0112-0151 K

Installation

1. Fill the bottle with a reagent, and tighten the cap firmly.

Tip: For quick and accurate assembly of reagent bottles, use slip-

on rings to color-code all tubing and sensor connections.

2. Connect one end of the fluid tubing to the large fitting on the

bottle cap.

3. Connect the other end to a Liquid Input on the left side of the

instrument (green, red, blue, or yellow).

Tip: Push down on the metal fitting of the quick connector to

ease the fitting into place.

4. Connect one end of the pressure tubing to the small fitting on

the bottle cap.

5. Connect the other end to the Pressure fitting below the Liquid

Input.

6. If the bottle has an Empty sensor, connect the sensor to the Level

Sensor connector above the Liquid Input fitting used.

0112-0151 K 23

AquaMax® 2000/4000 Microplate Washer User Guide

To connect a waste bottle

1

2

Table 2-2: Waste bottle and connection fittings

Item Description

1 Waste sensor connector

2 Waste output fitting

3 Waste bottle

3

4

5

4 Waste full sensor

5 Waste tubing

24 0112-0151 K

Installation

1. Connect the quick connect fitting of the waste tubing to the

Waste Output fitting on the left side of the instrument.

2. Connect the free end of the tubing to any vented waste

container.

For non-toxic waste the free end of the tubing can be placed

directly into a sink. The open end of the waste tubing must be

below the level of the Microplate Washer, and must remain free

of obstruction.

CAUTION! An obstructed waste tubing can damage the

instrument.

3. If the bottle has a waste full sensor, connect the waste full sensor

to the Waste Sensor input fitting.

WARNING! Biohazard. Waste tubing must be connected during

operation. Waste fluid is ejected out of the waste port. If no

waste tubing is connected, waste will spray and spill from the

waste output port.

CAUTION! Waste containers must be vented. Connecting the

waste tubing to a pressurized or closed vessel will cause damage

to the waste pump.

0112-0151 K 25

AquaMax® 2000/4000 Microplate Washer User Guide

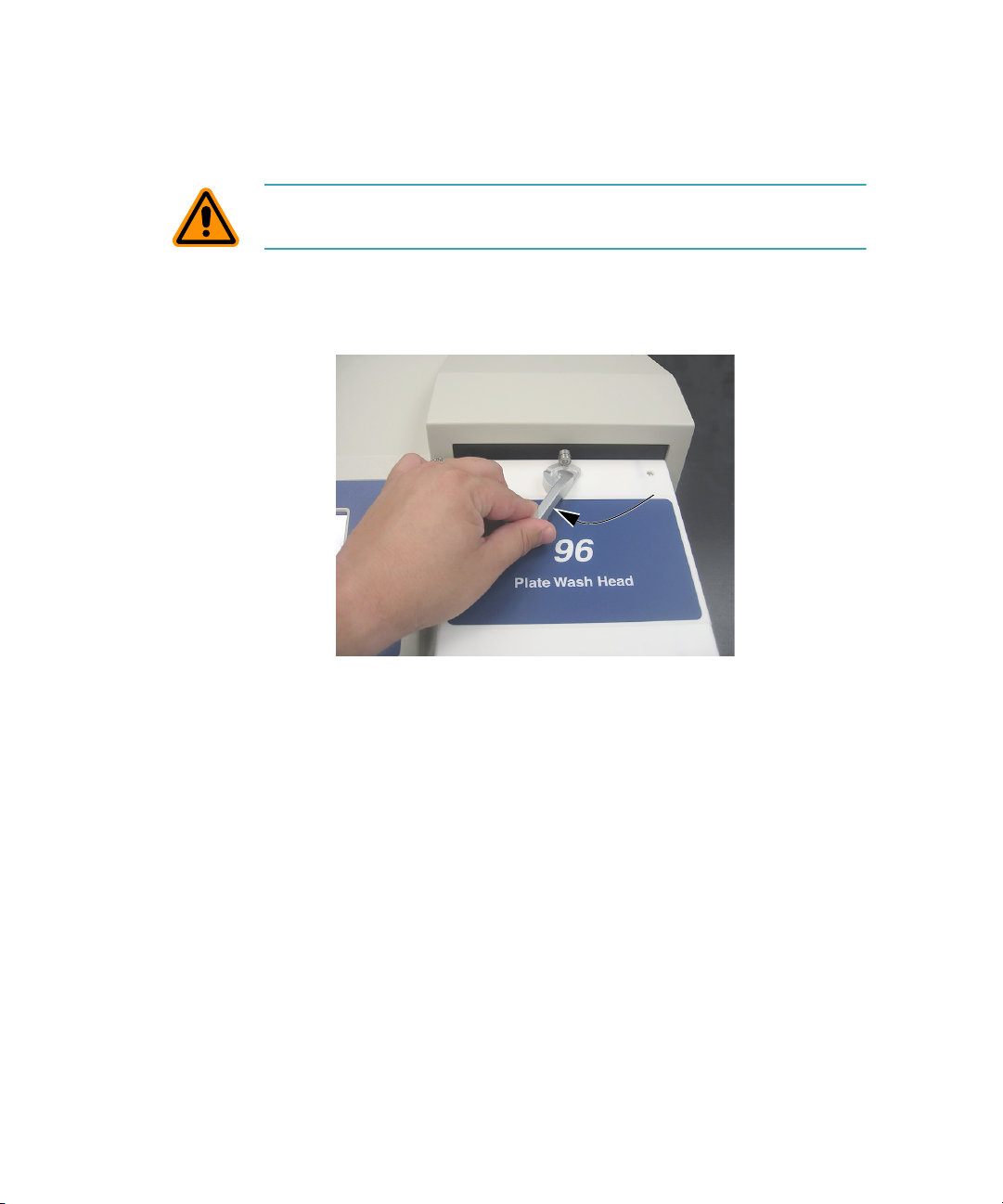

To install the wash head

CAUTION! The probes on the underside of the wash head are delicate.

Take care when handling the wash heads.

1. Install the wash head (96 or 384) of choice. Wash heads are

shipped pre-qualified and will work with any base unit.

2. Move the lever to the left to lock the wash head in place.

Figure 2-1: Wash head lock

3. Turn ON the instrument power switch located on the back panel.

The following operations occur as the instrument initializes when

turned on:

The wash head rises to prepare for plate loading.

The touch screen turns on and displays instrument status.

The plate carriage and wash head motor find home and

return to eject positions.

26 0112-0151 K

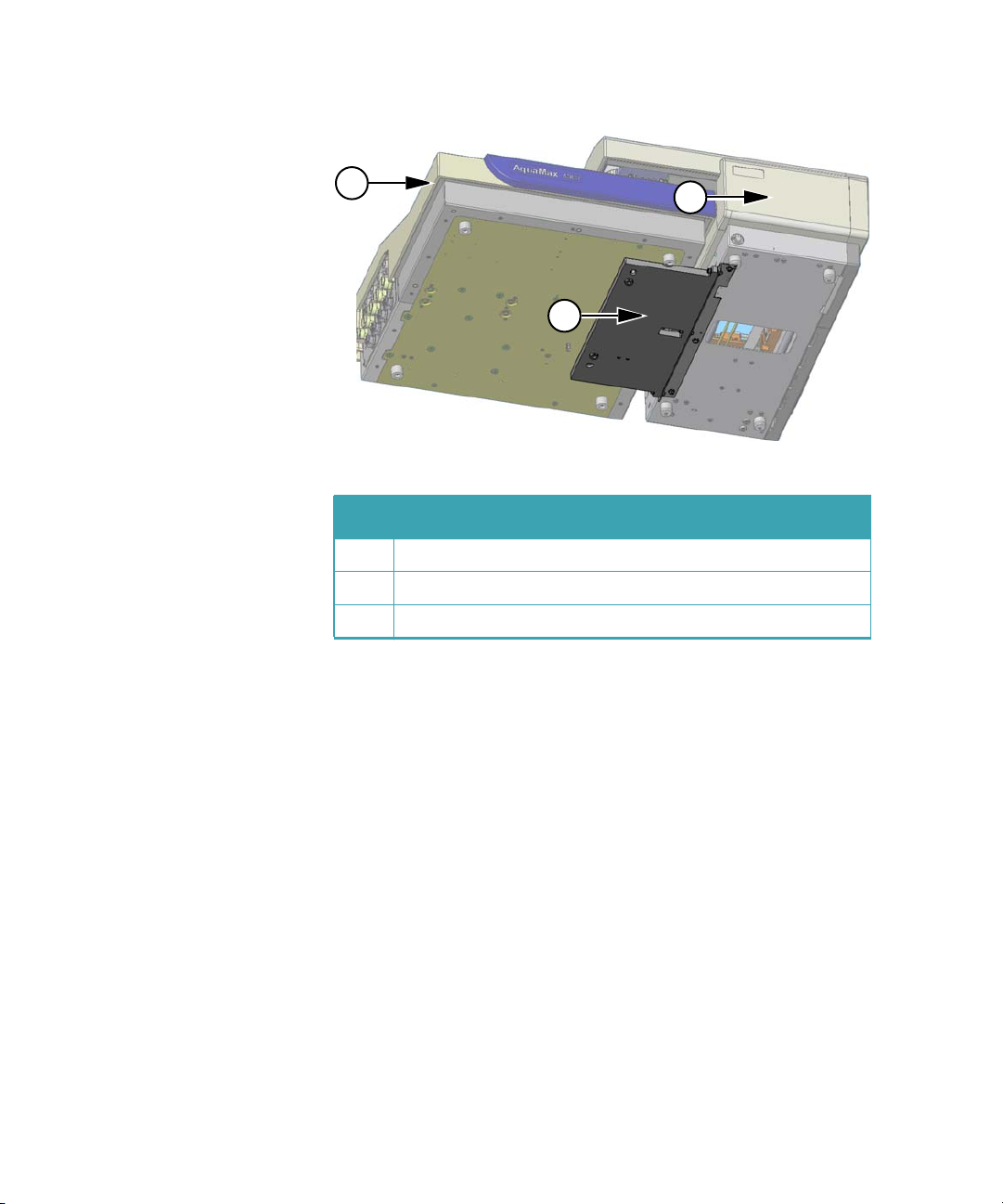

Connecting to a StakMax® Plate Stacker

®

Table 2-3: AquaMax

installed

Microplate Washer with StakMax® Plate Stacker

Installation

1

88

Item Description

1 StakMax® Plate Stacker

To connect the AquaMax Microplate Washer to the StakMax® Plate

Stacker you will need the StakMax integration kit (Part Number: 0310-

5454). The integration kit consists of a StakMax/AquaMax base plate,

bolts for the base plate, a tool for the bolts, a StakMax communication

cable, and an integration manual.

To set up a StakMax® Plate Stacker with an AquaMax® Microplate Washer

For more detailed instructions, see the integration manual.

1. Make sure that both the AquaMax Microplate Washer and the

StakMax Plate Stacker are turned off and that the power cords

are disconnect from the power supply.

2. Use the StakMax/AquaMax base plate to connect the StakMax

Plate Stacker to the AquaMax Microplate Washer (

0112-0151 K 27

Figure 2-4).

AquaMax® 2000/4000 Microplate Washer User Guide

1

2

3

Table 2-4: StakMax

®

Plate Stacker to AquaMax® Microplate

Washer adapter plate

Item Description

1 AquaMax® Microplate Washer

2 StakMax® Plate Stacker

3 Adapter plate

3. Connect the StakMax communication cable to the serial port on

the back of the StakMax Plate Stacker.

4. Connect the StakMax communication cable to the StakMax port

on the back panel of the AquaMax Microplate Washer. See

Back

Panel on page 17.

5. Turn on both the AquaMax Microplate Washer and the StakMax

Plate Stacker.

The StakMax Plate Stacker automatically detects that it is

connected to the AquaMax Microplate Washer.

The AquaMax Microplate Washer detects the StakMax Plate

Stacker.

28 0112-0151 K

Installation

Figure 2-2: StakMax Stacker indicator

The washer controls the stacker through its on board programs.

For information about using the stacker in a program, see

Program Stacker Settings on page 43.

0112-0151 K 29

AquaMax® 2000/4000 Microplate Washer User Guide

30 0112-0151 K

Getting Started

This chapter provides the information required to get started with the

AquaMax® 2000 and AquaMax 4000 Microplate Washers.

• Starting the Instrument on page 31

• Main Tab on page 32

• Running Programs on page 34

• Stopping Programs on page 35

• Shutting Down the Instrument on page 36

Starting the Instrument

To turn on the instrument, use one of the following procedures:

• If the instrument is in shutdown mode, touch anywhere on the

screen to wake the instrument up. For information about

shutdown mode, see Shutdown Options Dialog on page 78.

• If the instrument has been turned off, turn ON the instrument

power switch located on the back panel.

The instrument automatically performs diagnostic checks to

make sure that it is functioning correctly. When the diagnostic

checks are complete, the touch screen displays the Main tab.

3

Figure 3-1: Main tab

0112-0151 K 31

AquaMax® 2000/4000 Microplate Washer User Guide

Main Tab

The Main tab is used to execute stored programs. It features quick access

buttons for the one-touch maintenance programs and a list of

user-defined programs.

1

2

3

7

4

5

6

Table 3-1: Main tab

Item Description

1 Function Tabs–The Main tab is selected.

2 Run–Runs the selected program in the list.

3 Stacker Attached–Indicates that the StakMax® Plate Stacker is

attached.

4 Prime–Runs the one-touch prime program.

The one-touch prime program performs a full prime on the wash

head and internal fluidics from the default user-prompted fluid inlet.

5 Clean–Runs the one-touch cleaning program.

The one-touch clean program cleans and decontaminates internal

fluid paths. The system primes with the cleaning solution, pauses for

5 minutes to allow the cleaning solution to soak in the system, and

follows with 3 rinse cycles using the rinse solution. The default

program uses the red inlet for cleaning and the green inlet for rinsing.

The system is purged at the end of this program.

See Table B-1: AquaMax® Microplate Washer Compatible and

Incompatible Cleaning Solutions on page 113.

8

9

10

32 0112-0151 K

Getting Started

Table 3-1: Main tab (cont’d)

Item Description

6 Rinse–Runs the one-touch rinse program.

The one-touch rinse program runs the standard rinse cycle three

times to flush the internal fluidics with rinse solution from the default

green inlet. At the end of the rinse program, the system drains the

rinse solution from the fluid paths.

7 Program List–Displays a list of the user-defined programs in the

program library. The number to the right of the program name (96 or

384) refers to the plate type used.

• Red indicates that the program uses a plate type that has been

changed since the program was last saved. When you run a red

program, an error message prompts you to accept the plate

parameter change before the program runs.

• Gray indicates that the program is not compatible with the

installed wash head. You cannot run gray programs.

8,10 Up Arrow and Down Arrow–Scroll the list if the number of programs

exceeds the display area.

9 Head–Identifies the installed wash head or cell head:

• PW96: 96-well plate wash head

• PW384: 384-well plate wash head

• CW96: 96-well cell wash head

• CW384: 384-well cell wash head

Note: One-touch programs can be edited and copied like any other

programs, but they cannot be renamed or deleted.

Note: Only program settings applicable to the installed wash head are

available in the on-screen menus.

0112-0151 K 33

AquaMax® 2000/4000 Microplate Washer User Guide

Running Programs

To run a stored program

Note: Gray programs are not compatible with the installed wash head.

You cannot run a gray program.

Note: Red programs indicate a change in the plate type. When you run

a red program, the message “Plate parameters changed” appears. Click

OK to acknowledge the changes and return to the program list. The red

is removed and you can run the program as usual. Click Cancel to exit

the program without changing the red status indicator.

1. Make sure that all appropriate reagent bottles are connected to

Liquid Input and Pressure fittings on the left side of the

instrument.

2. Make sure that the waste tubing is connected to the Waste

Output fitting and the Waste bottle.

3. Load the appropriate microplate in the plate carriage.

4. On the Main tab, touch the program from the list and touch Run.

When a program is running, the touch screen displays a status

dialog.

Figure 3-2: Status dialog

34 0112-0151 K

To run a one-touch maintenance program

Stopping Programs

To interrupt a program in non-emergency conditions

Getting Started

1. Make sure that all appropriate reagent bottles are connected to

Liquid Input and Pressure fittings on the left side of the

instrument.

2. Make sure that the waste tubing is connected to the Waste

Output fitting and the Waste bottle.

3. On the Main tab, touch the appropriate one-touch program

button.

When a program is running, the touch screen displays a status

dialog. (See

Note: For information about one-touch program defaults, see

Program Tab on page 38. One-touch programs can be copied and

edited.

Figure 3-2.)

When you run a program, the touch screen displays a status dialog. (See

Figure 3-2.)

• For non-emergency stops touch Cancel.

Cancel stops the program when appropriate. It turns off the

pumps, resets the wash head, moves the plate carriage to the

plate load position, and performs program clean up before

returning control to the touch screen.

To interrupt a program in emergency conditions

When you run a program, the touch screen displays a status dialog. (See

Figure 3-2.)

1. For emergency stops touch Stop.

Stop halts the program immediately. It turns off all pumps and

motors, closes valves, and releases system pressure.

2. Touch OK to recover and remove the plate.

A software reset is performed before returning control to the

touch screen.

0112-0151 K 35

AquaMax® 2000/4000 Microplate Washer User Guide

3. If fluid remains in the trough, then in the Options tab, touch

Purge.

Note: The wash head must be re-primed to continue.

Shutting Down the Instrument

The AquaMax Microplate Washer supports the following shutdown

options:

• For general use with short periods of inactivity, use Automatic

Shutdown. Automatic Shutdown puts the instrument in a low

power mode after a user-specified time of inactivity. It turns off

the screen, releases system pressure, and shuts off all motors

and valves. The shutdown process can include a rinse and purge

cycle. For information about automatic shutdown options, see

Shutdown Options Dialog on page 78.

• For longer periods of inactivity, for example if the instrument is

not used every day, turn off the instrument. For information, see

To turn off the instrument on page 93.

• For storage or shipping, rinse and purge the instrument and

remove the wash head before turning off the power. For

information, see To prepare the wash head for storage on

page 94.

36 0112-0151 K

Operation: The Touch Screen Interface

Operation of the AquaMax® Microplate Washer is controlled by the onboard touch screen.

This chapter provides information about the functions that are available

on each tab of the interface.

• Administrative Mode on page 37

• Program Tab on page 38

• Managing the Program Library on page 61

• Plates Tab on page 70

• Managing the Plate Library on page 73

• Options Tab on page 74

• Managing the Software on page 79

For information about the Main tab and about running programs, see

Getting Started on page 31.

Administrative Mode

The default operating mode of the touch-screen interface allows all users

to access all program functions, plate functions, and options.

You can restrict access to editing functions and system options by setting

an administrator passcode. (See

setting an administrator passcode, you must use the administrator

passcode to access the following functions and options:

Restricting Functions on page 80.) After

4

• New (Program, Plates) • Copy (Program)

• Rename (Program) • Restack (Options)

• Delete (Program, Plates) • Change passcode (Options)

• Calibrate screen (Options) • Shutdown options (Options)

• Edit (Program, Plates)

You can access the restricted functions by touching the Admin button

and entering the administrator passcode. There is only one passcode for

the instrument, but the passcode must be entered separately on each

tab.

0112-0151 K 37

AquaMax® 2000/4000 Microplate Washer User Guide

The passcode is not required to run existing programs, view program

details and plate details, or access Depressurize, Purge, and Shutdown on

the Options tab.

Program Tab

The Program tab contains the functions to manage the program library.

1

2

3

7

4

5

6

Table 4-1: Program tab, general access to all functions

Item Description

1 Function Tabs–The Program tab is selected.

2 New–Creates a new program.

3 Edit–Opens the selected program for review and editing.

4 Rename–Renames the selected program.

5 Copy–Copies the selected program.

6 Delete–Deletes the selected user-defined program.

The one-touch programs cannot be deleted.

7 Program List–Displays a list of programs in the program library.

The number to the right of a user-defined program (96 or 384) refers

to the plate type used. Red indicates that the program uses a plate

type that has been changed since the program was last saved.

8

9

10

11

8,11 Up Arrow and Down Arrow–Pages up and down through the program

list if the list exceeds the display area.

38 0112-0151 K

Operation: The Touch Screen Interface

Table 4-1: Program tab, general access to all functions (cont’d)

Item Description

9,10 Move Up and Move down–Moves the selected program up or down

in the program list.

The one-touch programs cannot be moved. They are always listed at

the top of the program list.

Program Tab: Administrative Mode

In administrative mode, general users have access only to the View

button and the Admin button. The Admin button and the administrator

passcode access the program editing options.

1

2

3

Table 4-2: Program tab with administrator passcode

Item Description

1 View–Opens the selected program so that you can view the settings

and steps.

2 Admin–Opens the passcode dialog to access the program editing

options.

3 Admin–Indicates that the AquaMax® Microplate Washer is in

administrator mode, and exits administrator mode when

programming changes are complete.

For information about the program editing buttons, see

Program Tab on

page 38.

0112-0151 K 39

AquaMax® 2000/4000 Microplate Washer User Guide

For information about restricting access to editing functions, see

Restricting Functions on page 80.

Program Settings Dialog

The Program Settings dialog controls step-independent program

information. It appears automatically when you create a new program

and is the first item in the program after the program has been saved.

See To access the Program Settings dialog for a program on page 41.

1

2

3

Table 4-3: Program Settings

Item Description

1 Plate–Lists the plates in the plate library. The highlighted option is the

option used for the current program. Plate type is not required for

programs involving only maintenance steps such as Prime, Soak,

Clean, Rinse, and Standby. Select no plate for maintenance programs.

Gray indicates that the plate is not compatible with the installed wash

head and is not available for selection.

2 Program Options–Opens the Program Options dialog with additional

program specific options.

3 Up/Down Arrows–Page through the list plates in the plate library.

Note: Program options and menus are optimized for the installed wash

head. Plate types that are not compatible with the installed wash head

are disabled.

40 0112-0151 K

Operation: The Touch Screen Interface

To access the Program Settings dialog for a program

1. Touch the Program tab.

2. Select a program from the list.

3. Touch Edit.

4. Touch Program Settings at the top of the list of program steps.

5. Touch Edit.

Program Options

Access Program Options from the Program Settings dialog. Messages,

stacker settings, and dispense accuracy adjustments are program

specific.

1

2

3

Table 4-4: Program Settings

Item Description

1 Messages–Opens the Messages dialog where you can set Program

Start and Program Done messages for the current program.

2 Stacker–Opens the stacker functions dialog for the current program.

3 Adjust Dispense–Opens the Adjust Dispense dialog for the current

program.

0112-0151 K 41

AquaMax® 2000/4000 Microplate Washer User Guide

Program Messages

You can set up the program to display a message before and after

running the steps of the program. Messages are optional.

1

2

Table 4-5: Messages dialog

Item Description

1 Program Start Message–Opens the keypad where you can enter a

message to display on the touch panel when the current program is

run. Running a program that has a Program Start Message defined

displays the message first. The user must confirm the message before

the program can run.

2 Program Done Message–Opens the keypad where you can enter a

message to display on the touch panel when all the steps of the

current program have been run.

To access the messages options for the current program

1. Select Program Settings from the list of steps.

2. Touch Edit.

3. Touch Program Options.

4. Touch Messages.

42 0112-0151 K

Operation: The Touch Screen Interface

Program Stacker Settings

In the stacker settings dialog you can enable stacker options for the

current program. Stacker settings are optional. See To access the stacker

options for the current program on page 44.

With the stacker enabled, plates are supplied from the stacker input.

Each plate is washed using the same program and then placed in the

stacker output. The program ends when the input stack is empty.

Table 4-6: Program stacker settings

Item Description

1 Enable Stacker–Enables and disables the plate stacker. The stacker is

enabled when the button is highlighted.

2 Restack at End–Transfers the plates back to the input stack at the end

of the program.

The stacker options are available when a stacker is not attached to the

washer. If you run a program with the stacker functions enabled and no

stacker, the washer displays a warning with instructions to add a plate

manually.

0112-0151 K 43

AquaMax® 2000/4000 Microplate Washer User Guide

To access the stacker options for the current program

1. Select Program Settings from the list of steps.

2. Touch Edit.

3. Touch Program Options.

4. Touch Stacker.

Adjust Dispense

The Adjust Dispense dialog lets you optimize the accuracy of the

dispense volumes based on the specific requirements of the individual

program. For more information, see To adjust dispense accuracy for a

program on page 68.

Figure 4-1: Adjust dispense

44 0112-0151 K

Operation: The Touch Screen Interface

Program Tab: Program Editing

The Program Tab contains the functions to manage the steps in the

current program. See To access program details on page 46.

1

2

7

8

3

9

4

5

6

Table 4-7: Program details

Item Description

1 New–Opens the New Step dialog where you can select the type of

new step to add to the current program.

2 Edit–Opens the selected step for editing.

3 Copy–Copies the selected step.

4 Delete–Deletes the selected step.

5 Test–Runs through the steps in the current program.

6 Done–Closes the current program and returns to the list of programs.

7 Displays the name of current program.

8 Program Settings–Opens the Program Settings dialog.

To view and change the details, select Program Settings and touch

Edit.

9 Program Details–Lists the steps that make up the program.

Details for the steps are noted to the right. To change the details,

select the step and touch Edit.

0112-0151 K 45

AquaMax® 2000/4000 Microplate Washer User Guide

To access program details

1. Touch the Program tab.

2. Touch a program.

3. Touch Edit.

New Step Selection

The New Step dialog lists the steps that can be included in the current

washer program. Steps that are not compatible with the currently

installed equipment options appear gray.

Each program can have up to 50 steps.

Note: Before creating or editing a program, make sure that the

equipment is configured for the operations you want to program. The

system detects the installed options and tailors menus and program

options.

Figure 4-2: Steps that can be included in a program

The following sections detail the settings for each step type:

• Dispense Settings on page 47

• Aspirate Settings on page 49

• Wash Settings on page 50

• FastWash Settings on page 53

• Shake Settings on page 54

• Soak Settings on page 55

46 0112-0151 K

Operation: The Touch Screen Interface

• Repeat Settings on page 56

• Purge Settings on page 57

• Rinse Settings on page 58

• Standby Settings on page 59

• Prime Settings on page 60

Dispense Settings

The Dispense step dispenses fluid into a microplate using predefined

parameters. Fluid dispense occurs at the top of the wells to prevent

contamination to the probes.

1

2

3

4

Table 4-8: Dispense settings

Item Description

1 Inlet–Liquid to be used for this step.

Available options correspond to the color-coded reagents connected

to the washer.

2 Prompt–Indicates that system will pause before dispensing and wait

for the user to specify the inlet.

3 Rate–Dispense rate.

See Table 4-9: Plate Wash and Cell Wash Dispense Rates.

0112-0151 K 47

AquaMax® 2000/4000 Microplate Washer User Guide

Table 4-8: Dispense settings

Item Description

4 Volume–Volume to be dispensed.

Use 5 to 150 μL for 384-well plates and 20 to 400 μL for 96-well

plates. The volume must be within the specified range for the plate or

the program cannot be saved or run.

Note: You should never dispense a greater volume than is

listed by the plate manufacturer.

Table 4-9: Plate Wash and Cell Wash Dispense Rates

Plate wash

96 plate wash 384 plate wash

dispense

rate

1 150 18300 150 21600

2 200 22100 200 25600

3 250 25400 250 26200

4 350 31300 350 35600

5 450 36600 450 41400

Cell wash

(mmHg) (μL/plate/sec) (mmHg) (μL/plate/sec)

96 cell wash 384 cell wash

dispense

rate

1 75 7200 150 19400

2 100 9100 200 23000

3 150 12400 250 26300

4 250 17800 350 32100

5 350 22500 450 37400

(mmHg) (μL/plate/sec) (mmHg) (μL/plate/sec)

Tip: Best dispense volume accuracy and precision are achieved at the

highest rate (Rate 5) and volume.

48 0112-0151 K

Operation: The Touch Screen Interface

Dispense accuracy is set to specification during manufacturing. The

following factors can affect dispense accuracy:

• Types of reagent.

• Locations and size of reagent bottles.

The AquaMax Microplate Washer supports 4 L or 10 L bottles

only.

• Level of reagent in bottles (too full or too low).

To adjust dispense factors, see

To adjust dispense accuracy for a program

on page 68.

Aspirate Settings

The Aspirate step removes fluid from a microplate using predefined

parameters.

1

2

3

4

5

Table 4-10: Aspirate settings

Item Description

1 Mode–Aspiration from Center, Edge, or Crosswise (from front to back

of wells).

Edge and Crosswise aspiration are supported for flat bottom wells

only.

2 Rate–Aspiration rate.

See Table 4-11: Aspiration Rates.

3 Descent speed–The speed at which the probes enter the wells.

4 Dwell time–Dwell time at the final probe position. The default value is

1 second. Range is 0-30 seconds.

0112-0151 K 49

AquaMax® 2000/4000 Microplate Washer User Guide

Table 4-10: Aspirate settings

Item Description

5 Probe height–final probe height above the bottom of the well. The

range is 0 to the top of well. The maximum probe height is the well

depth specified in the plate library.

To avoid damage to probes and plate bottom, the AquaMax®

Microplate Washer has a “no touch” feature. If the height is set to

0mm, the aspiration pins are offset from the well bottom by a

minimum clearance.

Table 4-11: Aspiration Rates

AQ 4000 AQ 2000 96 (μL/well/sec) 384 (μL/well/sec)

5 Fast 270 70

4 240 60

3 200 50

2 Gentle 80 20

15010

Tip: For plate washing, minimal residual volume is best achieved using

Crosswise aspiration, a rate of 5, a fast descent speed, a 1 second dwell time,

and 0 mm to 0.2 mm probe height.

Wash Settings

The Wash step washes a microplate using predefined parameters.

Note: To prevent overflow when using the Wash function with a plate wash

head, add a surfactant such as Tween to wash solutions.

50 0112-0151 K

Operation: The Touch Screen Interface

1

2

3

4

5

Table 4-12: Wash settings

Item Description

1 Inlet–Liquid to be used for this step.

The available options correspond to the color-coded reagents

connected to the washer.

2 Prompt–Indicates that the system will pause before dispensing and

wait for the user to specify an inlet.

3 Rate–Wash rate (see Table 4-13: Wash Rates). This option is available

for the AquaMax® 4000 Microplate Washer only.

4 Volume–Volume of wash fluid used per well. Use 50 μL to 3000 μL.

5 Wash position–Position of aspiration probes during the wash.

• Bottom: The aspiration probes aspirate to the bottom of the well,

then wash with the specified amount of wash fluid at that

position. Bottom washing results in partially empty wells at the

end of the wash.

• Top: The aspiration probes remain just below the top of the well,

then wash with the specified amount of wash fluid at that

position. Top washing results in full wells at the end of the wash.

Table 4-13: Wash Rates

Model # Options 96 (μL/well/sec) 384 (μL/well/sec)

AQ 4000 Fast 270 70

Gentle 200 60

0112-0151 K 51

AquaMax® 2000/4000 Microplate Washer User Guide

Table 4-13: Wash Rates

Model # Options 96 (μL/well/sec) 384 (μL/well/sec)

AQ 2000 (no option) 270 70

Tip: Wash volume should not exceed 10x the well volume.

Tip: The wash step leaves the wells partially empty (bottom wash) or

full (top wash). To empty the wells, add an aspiration step.

52 0112-0151 K

Operation: The Touch Screen Interface

FastWash Settings

The FastWash step is designed for rapid microplate washing using

multiple aspirate-dispense cycles with predefined parameters. FastWash

performs a final aspiration after the last cycle. All aspirations use a rate of

5 and a fast descent speed. See Table 4-11: Aspiration Rates.

1

3

4

6

7

Table 4-14: FastWash settings

Item Description

1 Inlet–Liquid to be used for this step.

The available options correspond to the color-coded reagents

connected to the washer.

2 Prompt–Indicates that the system will pause before dispensing and

wait for the user to specify an inlet.

3 Rate–Dispense rate.

See Table 4-9: Plate Wash and Cell Wash Dispense Rates.

4 Volume–Volume of wash fluid to be dispensed per well in each cycle.

Use 5 to 150 μL for 384-well plates and 20 to 400 μL for 96-well

plates.

2

5

5 Cycles–Number of times the volume is dispensed.

6 Dwell Time–Duration in seconds (0 to 30) that the probe rests at the

final probe position. The default value is 1 second.

7 Probe Height–Final probe height above the bottom of the well during

aspiration.

The range for plate wash heads is 0 mm to the top of the well.

0112-0151 K 53

AquaMax® 2000/4000 Microplate Washer User Guide

Shake Settings

The Shake step shakes a microplate in the carriage using predefined

parameters.

1

2

Table 4-15: Shake settings

Item Description

1 Shake speed–Speed of shaking (Slow, Medium, or Fast).

A fast shake is vigorous and generally mixes the wells in 10 to 30

seconds.

2 Time–Duration of shake. Acceptable range is 1 to 600 seconds.

54 0112-0151 K

Operation: The Touch Screen Interface

Soak Settings

The Soak step pauses the program for a specified duration. During a Soak

step, probes are removed from the microplate wells. No other operations

are performed for the duration.

1

\

Table 4-16: Soak settings

Item Description

1 Time–Duration of soak, in minutes and seconds. Acceptable range is 1

second to 120 minutes.

0112-0151 K 55

AquaMax® 2000/4000 Microplate Washer User Guide

Repeat Settings

1. The Repeat step repeats a set of previous program steps.

1

2

Table 4-17: Repeat settings

Item Description

1 Repeat from step–The numbered step at which to start the

repetition.

The list contains the previous steps in the current program.

2 Repetitions–The number of extra cycles to be performed. For

example, setting repetitions to 5 means that the specified step would

be executed once from the original program, and then repeated 5

more times in the Repeat step, for a total of 6 cycles.

Note: One Repeat step counts as just one step in the 50-step program

limit, regardless of the number of steps or cycles repeated. The system

will not allow a Repeat step within another Repeat step.

56 0112-0151 K

Operation: The Touch Screen Interface

Purge Settings

The Purge step evacuates liquids from the installed wash head. It has no

programmable parameters.

Figure 4-3: Purge screen (no settings)

Tip: Run a Purge step when the washer will not be used again

immediately. Purging prevents needle clogging or mold growth when

the instrument is idle.

Tip: Run a Purge step before removing the wash head.

0112-0151 K 57

AquaMax® 2000/4000 Microplate Washer User Guide

Rinse Settings

The Rinse step flushes the selected reagent through the internal fluidics

and the installed wash head.

1

2

Table 4-18: Rinse settings

Item Description

1 Inlet–Liquid to be used for this step.

The available options correspond to the color-coded reagents

connected to the washer.

2 Prompt–Indicates that the system will pause before dispensing and

wait for the user to specify an inlet.

After rinsing with a harsh reagent, such as a cleaning solution, rinse with

water several times to fully remove any harmful residues. Rinsing does

not empty the wash head completely. Follow the rinse with a Purge step

before you remove the wash head or shutdown the system.

58 0112-0151 K

Operation: The Touch Screen Interface

Standby Settings

Use Standby mode to keep wash fluid in the head without the need to

prime the head if there is a delay between uses.

The Standby step fills the prime/soak trough with a wash fluid and leaves

the dispense/aspirate probes in the wash fluid.

You can use the touch screen buttons to select the source bottle for the

wash fluid and to program the wash fluid to automatically change at

specific time intervals.

To discontinue the Standby step and continue using the AquaMax

Microplate Washer, touch Cancel. This drains the trough and dispenses a

small amount of the wash fluid through the dispense needles.

1

2

3

Table 4-19: Standby settings

Item Description

1 Inlet–Liquid to be used for this step.

The available options correspond to the color-coded reagents

connected to the washer.

2 Prompt–Indicates that the system will pause before dispensing and

wait for the user to specify an inlet.

3 Change solution every–Drains and refills the solution in the soaking

trough at the specified refresh interval.

0112-0151 K 59

AquaMax® 2000/4000 Microplate Washer User Guide

Prime Settings

The Prime step primes the internal fluidics and installed wash head with

the selected reagent. During the Prime step, the needles are immersed in

the priming liquid to wash the outsides of the needles. This is a

maintenance step and does not require a microplate to run.

1

2

3

Table 4-20: Prime settings

Item Description

1 Inlet–Liquid to be used for this step.

The available options correspond to the color-coded reagents

connected to the washer.

2 Prompt–Indicates that the system will pause before dispensing and

wait for the user to specify an inlet.

3 Mode–Level of priming fluid.

• Maintenance: Uses 150 mL of the reagent to prepare the

instrument after long periods of system inactivity.

• Full: Uses 400 mL of the reagent to prepare the instrument after

a wash head installation, reagent exchange, or system purge.

60 0112-0151 K

Managing the Program Library

All programs can be modified. Factory-provided one-touch programs can

be edited, but not renamed or deleted.

Note: Program options and menus are optimized for the installed wash head.

Before creating or editing a program, make sure that the appropriate wash head

is installed. Do not remove the wash head until your program changes have

been saved. Removing the wash head resets the touch screen. Any unsaved

program changes are lost.

To create a new program

1. On the Program tab, touch New.

Operation: The Touch Screen Interface

Figure 4-4: Program tab

Tip: You can also create a new program by copying an existing program

(see To copy a program on page 64).

2. Type a name for the new program on the keypad, and touch OK.

The Program Settings dialog opens automatically.

0112-0151 K 61

AquaMax® 2000/4000 Microplate Washer User Guide

3. In the Program Settings dialog, touch a plate type from the Plate

list.

Figure 4-5: Program settings

Note: Plates that are not compatible with the installed wash

head appear gray.

4. If applicable, click Program Options to add Program Start and

Program Done messages to the program (see

Program Messages

on page 42), enable stacker options for the program (see

Program Stacker Settings on page 43), or adjust the dispense rate

accuracy for the program.

Figure 4-6: Program options

62 0112-0151 K

Operation: The Touch Screen Interface

Note: Test dispense accuracy separately and use the results to

adjust the settings in your program. For more information, see

adjust dispense accuracy for a program on page 68.

5. Touch OK to save your changes and close the Program Settings

dialog.

6. Add steps to the program. For more information see

To add a

step to a program on page 65.

7. Touch Done to exit programming mode.

8. Touch Yes to confirm your changes.

To

0112-0151 K 63

AquaMax® 2000/4000 Microplate Washer User Guide

To copy a program

1. On the Program tab, touch the program to be copied, and touch

Copy.

2. In the Copy Program dialog type the name of the new program.

The default name of the copy is the name of the existing

program followed by an asterisk (*).

3. In the Program Settings dialog, select a plate type and touch OK.

4. Edit the steps in the program as required:

Add a step

Copy a step

Edit a step

Delete a step

5. Touch Move Up and Move Down to rearrange program steps

within the list.

6. Touch Done to exit programming mode.

7. Touch Yes to confirm your changes.

To edit a program

1. Select the program to be edited, and touch Edit.

2. Touch New to add new steps, or touch Edit, Copy, or Delete to

modify existing ones.

3. Touch Move Up and Move Down to rearrange program steps

within the list.

4. After all program steps have been set up, touch Te st to execute a

test run, or touch Done to exit programming mode.

5. Touch Yes to confirm your changes.

64 0112-0151 K

Operation: The Touch Screen Interface

To rename a program

1. Select the program to be renamed, and touch Rename.

2. Type a new name for the program.

3. Touch OK to save the change.

Note: One-touch programs cannot be renamed.

To delete a program

Note: A deleted program cannot be recovered.

1. Select the program to be deleted, and touch Delete.

2. Touch OK to confirm the deletion.

Note: One-touch programs cannot be deleted.

To change the plate type for a program

1. Select the program to be edited, and touch Edit.

2. In the program details area, touch Program Settings and touch

Edit.

3. Select the plate type.

4. Touch OK to exit the Program Settings dialog.

5. Touch Done to exit programming mode and OK to confirm your

changes.

To add a step to a program

1. Select the program to be edited and touch Edit. The Program tab

displays the details for the selected program.

0112-0151 K 65

AquaMax® 2000/4000 Microplate Washer User Guide

Figure 4-7: Program tab, program editing

2. To add a step, touch New and touch the type of step you want to

add. The parameters dialog for the selected step type appears.

3. Complete the parameters dialog and touch OK when finished.

The newly-created program step appears in the program list.

Note: For information about step types and associated

parameters, see New Step Selection on page 46.

4. For each additional program step, repeat

Step 2 and Step 3

5. Touch Move Up and Move Down to rearrange program steps

within the list.

6. To test run the program, touch Test.

7. Touch Done to exit programming mode.

8. Touch Yes to confirm your changes.

66 0112-0151 K

Operation: The Touch Screen Interface

To edit a step in a program

1. Select the program to be edited and touch Edit.

The Program tab displays the details for the selected program.

2. Select the step you want to work with and choose one of the

following options:

To edit the selected step, touch Edit and change the

parameters in the associated dialog as required. Touch OK to

close the dialog.

To copy the selected step, touch Copy. The copied step is

added to the end of the program.

To delete the selected step, touch Delete.

Note: For information about step types and associated

parameters, see New Step Selection on page 46.

3. Touch Move Up and Move Down to rearrange program steps

within the list.

4. To test run the program, touch Test.

5. Touch Done to exit programming mode.

6. Touch Yes to confirm your changes.

0112-0151 K 67

AquaMax® 2000/4000 Microplate Washer User Guide

To adjust dispense accuracy for a program

Dispense accuracy in the AquaMax Microplate Washer is set to

specification during manufacturing. However, various installation

configurations can also affect accuracy, such as location and size of

reagent bottles, types of reagent, and so on. These adjustment are

specific and individual to every program. However, after you determine

an adjustment for a given set of parameters, you can use the same

setting whenever that combination is used (Liquid type, Head type, and

so on).

The AquaMax Microplate Washer supports 4 L or 10 L bottles only.

For best results test dispense accuracy in a separate program and use the

results to adjust your working program.

1. Make sure that the system is set up to match the parameters of

your working program.

2. Create a new program and in the Program Settings dialog, touch

Program Options.

3. Touch Adjust Dispense.

Figure 4-8: Adjust dispense options

4. In the Adjust Dispense dialog, set the adjustment to 0% for the

chosen fluid inlet.

5. Weigh an empty plate.

6. Complete the program with a dispense function from the fluid

inlet of choice: 300 μL/well/96-well plate or 100 μL/well/384-well

plate.

7. Run the program.

68 0112-0151 K

Operation: The Touch Screen Interface

8. Weigh the plate after the dispense to measure the amount of

liquid dispensed.

9. Divide the fluid mass by the fluid density and number of wells to

get the measured volume per well:

Measured volume per well

Fluid mass Fluid density§

---------------------------------------------------------------=

Number of wells (96 or 384)

10. Determine the fractional dispense accuracy using the equation

below:

Measured Volume

Dispense accuracy 100

---------------------------------------

Expected Volume

100–=

11. Round up this value to the nearest integer and type it in the

Adjust Dispense dialog for the chosen fluid inlet. Use whole

numbers in the range of 50% to 200%.

12. Repeat

Step 3 to Step 11 for each fluid intake that needs

adjusting.

13. Enter the results in the Adjust Dispense dialog of your working

program.

0112-0151 K 69

AquaMax® 2000/4000 Microplate Washer User Guide

Plates Tab

The Plates tab contains the functions for managing the plate library.

1

5

2

3

4

Table 4-21: Plates tab

Item Description

1 New–Creates a new plate type.

2 Edit–Opens the details of the selected plate type for editing.

3 Delete–Deletes the selected plate type.

4 Plate List–Lists the plate types stored in the library.

5 Up Arrow and Down Arrow–Moves up and down through the plate

list if the list exceeds the display area.

70 0112-0151 K

Operation: The Touch Screen Interface

Plates Tab: Administrative Mode

In administrative mode, general users have access to only the View

button and the Admin button. The Admin button and the administrator

passcode access the plate editing options.

1

2

3

Table 4-22: Plates tab with administrative mode

Item Description

1 View–Opens the selected plate so that you can view the plate details.

2 Admin–Opens the passcode dialog to access the plate editing options.

3 Admin–Indicates that the AquaMax® Microplate Washer is in

administrator mode, and exits administrator mode when your

changes are complete.

For information about the plate editing buttons, see

Plates Tab on

page 70.

For information about restricting access to editing functions, see

Restricting Functions on page 80.

0112-0151 K 71

AquaMax® 2000/4000 Microplate Washer User Guide

Plate Definition Dialog

A plate definition details the parameters used by the instrument during

operations. The plate definition controls the position of the plate and the

probes. Inaccurate settings can cause some operations to run incorrectly.

1

2

3

4

5

6

Table 4-23: Plate definition

Item Description

1 Name–Name of the plate type. The name can be up to 20 characters.

2 Wells–Number of wells in the plate (96 or 384).

3 Bottom–Bottom profile of the wells:

• Flat: plates with full-size flat-bottom wells. Crosswise and edge

aspiration are supported for Flat plates only.

• U: plates with round-bottom wells.

• V: plates with tapered wells.

• Small Vol: Small volume or half-area plates.

4 Plate Height (mm)–Distance in millimeters from the plate base to the

top of the wells.

When using a magnetic bead-washing insert (LifeSep 96F or 384F

biomagnetic separators), the plate height is the total height of the

carriage insert and plate stack.

Note: Carriage inserts cannot be used with robotics.

72 0112-0151 K

Table 4-23: Plate definition (cont’d)

Item Description

5 Well Depth (mm): Distance in millimeters from the bottom of the well

to the top of the well. Well depth is critical to reliable instrument

operation. An incorrect well depth can result in inefficient plate

aspiration, plate and wash head damage, or “Vertical Error 225”

appearing on the screen.

6 Auto–Calibrates the well depth.

See To calibrate the well depth on page 73.

Managing the Plate Library

To create a plate type