Page 1

MOLDEX® DISPOSABLE RESPIRATORS

APPLICATIONS:

! WARNING TO USER:

1. Follow all instructions and warnings on the use of this respirator and wear during all times of exposure. Failure to do so will reduce

respirator effectiveness, wearer protection and may result in sickness or death.

2. Before use, the user must first be trained by the employer in proper respirator use, in accordance with applicable safety and health

standards, for the contaminant and exposure level in the assigned work area.

3. The particulates and other contaminants which can be dangerous to your health include those which you cannot see, taste, or smell.

4. Moldex industrial respirators have not been sold with warnings or use instructions for personnel involved in healthcare or related

situations, where there may be the possibility of contact with disease or biological hazards. If you are considering such uses, first call

the Moldex Technical Service Dept., +1 (310) 837-6500 or +1 (800) 421-0668 ext. 512/550 or select your respirator from our line of

healthcare and surgical respirators.

How do I choose an appropriate filter?

Respirators certified under 42CFR 84 are divided into filter types and efficiency levels.

An N95 would be 95% efficient in environments where no oils are present.

Filter Types: • N-Series: • R-Series: • P-Series:

Not for oil Resistant to oil Oil proof

Efficiency classes: • 95% • 99% • 100% (99.97%)

RESPIRATORS — COMMON APPLICATIONS

Lightweight, cost effective, comfortable protection.

N95, R95 and P95 Series

Grinding, Torch Cutting, Sanding, Metal Pouring, Sweeping, Metal Working, Bagging, Foundries, Stone Quarrying, Agriculture, Metal

Machining, Construction Sites, Cement, Ceramics Manufacturing, Underground Mining, Timber/Lumber Mills, Polishing, Buffing, Lime,

Poultry, Textiles, Welding, Brazing, Soldering.

N95 and R95 Plus Nuisance Levels of Ozone and Organic Vapors

Welding, Arc Cutting, Foundry Operations, Brazing, Plasma Spraying, Laser Beam Cutting/Welding, Laboratory Settings, Agriculture,

Petrochemical Manufacturing, Rendering Plants, Auto Repair, Mining Operations, Waste Disposal.

N95 and R95 Plus Nuisance Levels of Acid Gas Irritants

Aluminum Smelting, Glass Etching, Electroplating, Fiberglass Manufacturing, Paper Processing, Chemical Processing, Brewing

Operations, Fertilizer Production.

N99 Series

Welding, Soldering, Brazing, Metal Working, Grinding, Sanding, Cement Work, Metal Pouring, Underground Mining, Textile Manufacturing.

N100 and P100 Series

Metal Working, Grinding, Sanding, Sweeping, Bagging, Foundries, Pharmaceutical Operations, Power Plants, Environments where an

OSHA substance specific standard applies (e.g., lead, cadmium, inorganic arsenic, MDA).

USE AGAINST (N95 MODELS):

1. Particulate aerosols free of oil.

2. For 2400N95, 2800/1N95, 4800 N95 and M2800/1N95 only, nuisance levels (less than OSHA Permissible Exposure Limits) of Organic

Vapor Odors and/or Ozone.

3. For 2500N95 only, nuisance levels (less than OSHA Permissible Exposure Limits) of Acid Gas Irritants.

USE AGAINST (R95 and P95 MODELS):

1. Oil and non-oil particulate aerosols.

2. For 2840/1R95 only, nuisance levels (less than OSHA Permissible Exposure Limits) of Organic Vapor Odors and/or Ozone.

3. For 2940/1R95 only, nuisance levels (less than OSHA Permissible Exposure Limits) of Acid Gas Irritants.

DO NOT USE AGAINST (N95, N99 and N100 MODELS):

1. Concentrations of contaminants which are unknown, or are immediately dangerous to life or health.

2. Concentrations of particulates which exceed the maximum use concentration or 10 times the OSHA Permissible Exposure Limit,

whichever is lower.

3. Gases, vapors, asbestos, paint spray, sandblasting or particulate materials which generate harmful vapors.

4. Oil-based mists.

DO NOT USE AGAINST (R95, P95 and P100 MODELS):

1. Concentrations of contaminants which are unknown or are immediately dangerous to life or health.

2. Concentrations of particulates which exceed the maximum use concentration or 10 times the OSHA Permissible Exposure Limit,

whichever is lower.

3. Gases, vapors, asbestos, paint spray, sandblasting or particulate materials which generate harmful vapors. These respirators are NOT

approved for any vapors or gases, so when 2840/1R95 is used against Organic Vapor Odors and/or Ozone or 2940/1R95 is used

against Acid Gas Irritants, do not exceed the OSHA Permissible Exposure Limit.

4. Oil-based mists for longer than one 8 hour work shift.

RESTRICTIONS (N95, N99 and N100 MODELS):

1. This respirator does not supply oxygen and must not be used in atmospheres containing less than 19.5% oxygen.

2. Do not remain in contaminated area if any physical distress occurs, for example breathing difficulty, dizziness or nausea.

3. Leave contaminated area and replace respirator if it is damaged, distorted, a proper fit can not be obtained or breathing

becomes difficult.

4. Prior to each use, carefully inspect the entire respirator, including filter media and strap/weld attachment area for tears and damage.

Staple or strap/weld attachment perforations do not affect respirator performance.

5. Do not alter, modify, or abuse this respirator.

6. Store unused respirators in box/bag in a clean, dry, non-contaminated area.

7. Dispose of respirator according to your employer’s policy and local regulations.

8. Dispose no later than thirty days after first use.

9. Use respirator before the “use by” expiration date printed on box/bag.

10. If used for welding, wear appropriate eye and face protection.

RESTRICTIONS (R95, P95 and P100 MODELS):

1. This respirator does not supply oxygen and must not be used in atmospheres containing less than 19.5% oxygen.

2. Do not remain in contaminated area if any physical distress occurs, for example breathing difficulty, dizziness or nausea.

3. Leave contaminated area and replace respirator if it is damaged, distorted, a proper fit can not be obtained or breathing

becomes difficult.

4. Prior to each use, carefully inspect the entire respirator, including filter media and strap/weld attachment area for tears and damage.

Staple or strap/weld attachment perforations do not affect respirator performance.

5. Do not alter, modify, or abuse this respirator.

6. Store unused respirators in box/bag in a clean, dry, non-contaminated area.

7. Dispose of respirator according to your employer’s policy and local regulations.

8. Where oil mists are present dispose no later than 8 hours after first use. Where non-oil particulates only are present, dispose no

later than 30 days after first use.

9. Use respirator before the “use by” expiration date printed on box/bag.

10. If used for welding, wear appropriate eye and face protection.

ADDITIONAL INFORMATION FOR Healthcare PARTICULATE RESPIRATOR SURGICAL MASKS:

DESCRIPTION

The Moldex healthcare particulate respirator surgical mask models are designed to help provide respiratory protection for the wearer.

This product has been tested1 and certified by NIOSH as an N95 respirator and as having a filter efficiency level of 95% or greater

against particulate aerosols free of oil. It is fluid resistant,2 disposable and may be worn in surgery or throughout the hospital. These

models do not contain any components made from natural rubber latex.

INTENDED USE

The various models of Moldex type N95 Healthcare Particulate Respirator and Surgical Masks meet CDC Guidelines for TB exposure

control within healthcare facilities. These devices are also intended to be worn by healthcare personnel during surgical procedures to

protect both the patient and healthcare personnel from the transfer of microorganisms, body fluids and particulate material.

CONTRADINDICATIONS

1. Not for use with beards, or other facial hair that prevents direct contact between the face and sealing surface of the respirator.

2. Eyewear must not prevent direct contact between the face and sealing surface of the respirator.

3. Not to be used on children.

1 Tested in accordance with NIOSH 42 CFR 84.

2 Passed ASTM F 1862 @ 160mm Hg

Non-latex straps are used in the headbands of these respirators. However, individuals highly sensitive to natural rubber latex may have

an allergic reaction.

SUPPLEMENTAL HAZARD WARNINGS FOR MOLDEX PARTICULATE RESPIRATORS

These are Warnings and Limitations that all users must be made aware of in addition to all warnings and other information on the

outside of the Moldex respirator packaging or other published related information. You must read and comply with these Warnings

and Limitations at all times and if your employer has determined that it is appropriate to use this respirator.

Proper use of this respirator may reduce but will not eliminate the risk of illness or death from exposure to some Chemical,

Biological, Radiological, or Nuclear (CBRN) hazards. CBRN hazards include, but are not limited to, bacteria, toxins, and viruses that

can cause death, serious bodily injury or disfigurement. The long-range and short-range risks of CBRN hazards and the amount and

manner of exposure that may produce such risks remain to a great extent unknown. Use of this respirator must be in accordance with

the Centers for Disease Control (CDC) Health Advisories or any other Local, State or Federal recommendations for use of respirators

against specific CBRN hazards. This respirator should not be used for many CBRN hazards.

There are more efficient models of respirators with a higher level of protection available from Moldex and other manufacturers. It is up to the employer, and not Moldex, to determine if a respirator should be worn and if so, which type, size, level of

protection, and model.

BACKGROUND

The National Institute for Occupational Safety and Health (NIOSH), a branch of the CDC and a U.S. Government agency, is responsible for

testing and certifying respirators for protection against hazardous industrial contaminants. Procedures for selecting and using proper respiratory protection are regulated by various governmental agencies, such as the Occupational Safety and Health Administration (OSHA).

NIOSH tests and certifies certain respirators for use against chemical warfare agents, biological warfare agents or biohazards and

provides advisory information for some biohazards, but OSHA and other government agencies have not set any exposure standards for

these agents or biohazards, in general.

Moldex does not make recommendations for any type of respirator to be used against CBRN hazards for workers or the

general public.

You should know that there may be no obvious warnings of the presence or release of CBRN hazards.

! WARNING TO ALL USERS:

• This respirator must only be used for substances having Permissible Exposure Limits (PELs) and only where deemed

appropriate by your employer.

• This respirator must be fit tested. If you cannot obtain a proper fit, do not use the respirator and do not enter the risk area.

• This respirator is not for use with beards or other facial hair that prevents direct contact between the face and sealing

surface of the respirator.

• Moldex respirators, when properly fitted and used as part of a comprehensive respiratory protection program, may reduce

wearer exposure to some airborne hazards, but not all.

• In the event of a sudden or unexpected CBRN hazard release, you may use this respirator for escape only if you have not

been provided with a more appropriate respirator for this type of situation. Do not remove the mask from the face until you

have left the contaminated area.

• Do not reuse or store for reuse or hang around neck unless your employer specifically authorizes reuse. Dispose of

respirator as a hazardous waste in accordance with your employer’s directions.

• Use other personal protective equipment, as directed by your employer. Where appropriate use protective gloves when

handling or removing respirator and dispose of respirator and then gloves in accordance with your employer’s directions.

• If CDC or other Local, State or Federal agency issues new or revised guidelines for respirator use against specific hazards,

users must strictly comply.

! WARNINGS FOR USE OF PARTICULATE RESPIRATORS AGAINST TB:

OSHA and CDC have recommended the use of any of the particulate respirators approved under 42CFR84 as a means of

providing help in complying with a program designed to reduce occupational exposure to tuberculosis.

The level of effectiveness of respiratory protection from tuberculosis cannot be determined with currently available data.

However, proper use of appropriate Moldex respirators in conjunction with a comprehensive respiratory protection program

may reduce, but will not eliminate, risk of infection.

• Be sure to read the Limitations outlined below and strictly follow all Warnings set forth under the WARNINGS FOR ALL USERS.

• When using any Moldex respirator, filter replacement and/or disposal must be handled in accordance with your Healthcare

Facility’s comprehensive respiratory protection program.

• If disinfectants are used to sanitize reusable facepieces, you must consult with your Healthcare Facility and run tests to

ensure the compatibility of any disinfectant with Moldex reusable facepiece materials. Use of disinfectants could impair

the efficiency of the respirator and result in a loss of protection.

LIMITATIONS

• Respirators may reduce but do not eliminate wearer exposure to airborne hazards or the risk of contracting any disease or

infection. Only use this respirator as part of a comprehensive respiratory protection program. You will receive no respiratory

protection if this respirator is not properly fitted and worn. Additionally, potentially hazardous particles, including infectious

agents, smaller than the particle sizes used in NIOSH certifications are likely to exist in certain environments. Some published

data indicates that these smaller particles may not be filtered out as effectively as the particle sizes used by NIOSH [N Series

Count Median Diameter (CMD) 0.075 ± .02µm Geometric Standard Deviation 1.86 (GSD) and R & P Series CMD 0.185 ± .02µm

1.6 (GSD)] when certifying respirators. It is imperative that you determine the size and potential hazards of the particles that

may be present in the environment before selecting appropriate respiratory protection, and that you refer to CDC guidelines

when selecting and using any respirator, particularly in environments where smaller types of particles, such as those referenced above, may be present.

• If the respirator comes in contact with blood or fluids, including body fluids, leave contaminated area as soon as possible

and discard and replace the respirator.

• Moldex respirators must not be used on children.

For further information on use of respirators contact Moldex at +1 (800) 421-0668 or +1 (310) 837-6500 ext. 554, your Employer, or

CDC at www.cdc.gov or +1 (800) 311-3435 or +1 (404) 498-1515.

Page 2

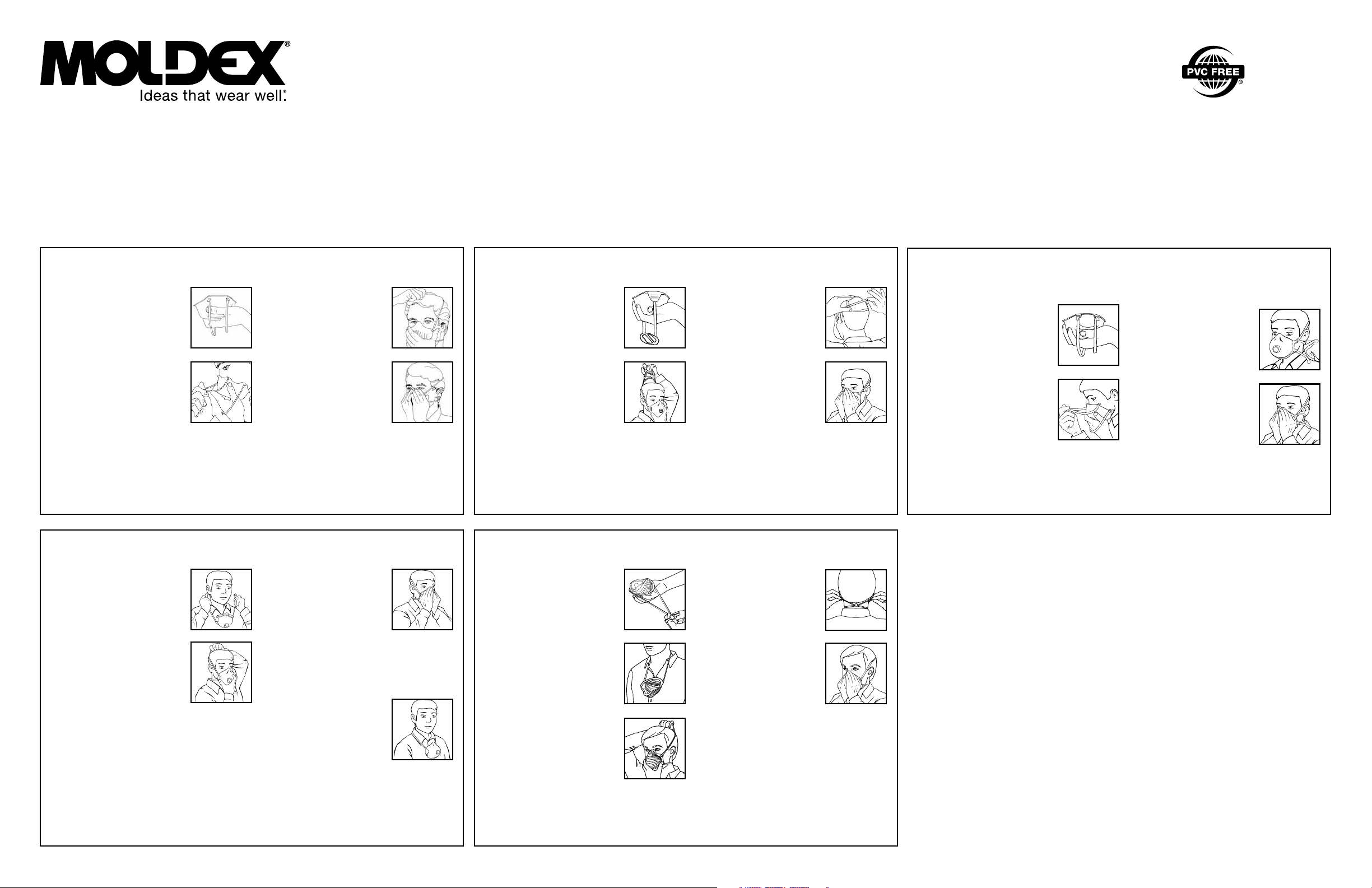

FITTING INSTRUCTIONS

1. Users must follow instructions each time respirator is worn.

2. It’s the wearer’s responsibility to obtain a proper fit.

3. To choose the correct model/size Moldex Respirator you must fit test and

user seal check.

4. If you cannot obtain a proper fit do not enter the contaminated area.

5. OSHA regulation 29 CFR 1910.134 (f) requires that the user must be fit

tested before being assigned a respirator and annually thereafter.

2-Strap Disposable Respirators

Hold respirator in hand with molded

1

nose contour (narrow end) at finger

tips, allowing headstraps to fall below

hand.

Place respirator under chin with

2

molded nose contour (narrow end)

up. Nose cushion must be uncreased

inside respirator. Raise top strap to

top back of head. Pull shorter bottom strap over head, below ears, to

around neck. Do not wear with only

one strap. When changing from any model/size to

another respirator, you must fit test.

Adjust respirator for

3

comfortable fit.

Each time user enters con-

4

taminated area seal should be fit

checked. Cover front of respirator

by cupping both hands. INHALE

SHARPLY. A negative pressure

should be felt inside respirator. If

any leakage is detected at respirator edges, adjust straps by pulling back along the

sides and/or reposition respirator. Repeat until sealed

properly, otherwise see your supervisor. Entry into a

contaminated area with an improper fit may result in

sickness or death.

6. Use Moldex Qualitative Fit Test Kit. User must be clean-shaven. Any facial

hair, such as beards or long sideburns, may prevent the respirator from

fitting properly.

7. Eyewear must not interfere with face to facepiece seal.

8. Re-fit test when there are any changes to the wearers physical condition that

may affect fit.

EZ-ON® Series Respirators

Hold respirator in hand with molded

1

nose contour (narrow end) at finger

tips, allowing head harness to fall

below hand.

Place respirator under chin with

2

molded nose contour (narrow end)

up. Nose cushion must be uncreased

inside respirator. Pull head harness to

top of head so it rests at the crown.

When changing from any model/

size to another respirator, you

must fit test.

Adjust tension by pulling on each

3

side of strap within the head

harness to provide a tight and

comfortable seal.

Each time before entering a con-

4

taminated area, perform a user

seal check. Cover front of respirator by cupping both hands. INHALE

SHARPLY. A negative pressure

should be felt inside respirator.

If any leakage is detected at respirator edges, adjust

strap by pulling back (on head harness) and/or reposition respirator. Repeat until sealed properly, otherwise

see your supervisor. Entry into a contaminated area

with an improper fit may result in sickness or death.

Adjustable Strap Respirators

2360P100 & 2315 N99

Untwist straps. Thread bottom strap

1

through bottom buckle and repeat

for top strap. Hold respirator in hand

with nose contour (narrow end) at

finger tips, allowing headstraps to fall

below hand.

Place respirator under chin with

2

molded nose contour (narrow end)

up. Nose cushion must be uncreased

inside respirator. Raise top strap to

top back of head. Pull shorter bottom strap over head, below ears, to

around neck. Do not wear with only

one strap. When changing from any model/size to

another respirator, you must fit test.

Adjust tension on both top and

3

bottom straps to provide a tight

and comfortable seal. To tighten,

pull ends of straps. To loosen,

push open hinge of buckle with

thumb and pull on strap.

Each time user enters work

4

area, the respirator must be seal

checked. Cover front of respirator

by cupping both hands. INHALE

SHARPLY. A negative pressure

should be felt inside respirator.

If any leakage is detected at

respirator edges, adjust straps by pulling back along

the sides and/or reposition the respirator. Repeat until

sealed properly, otherwise do not enter work area and

see your supervisor. Entry into a contaminated area

with an improper fit may result in sickness or death.

®

HandyStrap

Attach buckle behind neck with shell

1

against chest.

a) Fit mask to face and pull top of

2

strap to crown of head. Nose

cushion must be uncreased inside

respirator.

b) Always use top and bottom

2

part of strap. Adjust tension for a

comfortable fit. When changing from any

model/size to another respirator, you

must fit test.

CAUTION: If used against biohazards discard immediately after

removing from face and do not hang around neck.

Respirators

Each time user enters contami-

3

nated area respirator must be seal

checked. Cover front of respirator

by cupping both hands. INHALE

SHARPLY. A negative pressure

should be felt inside respirator. If

any leakage is detected at respirator edges, adjust strap by pulling back along the

sides and/or reposition respirator. Repeat until sealed

properly, otherwise see your supervisor. Entry into a

contaminated area with an improper fit may result in

sickness or death.

To hang around neck:

4

a) Undo buckle.

b) Allow strap to fall around neck.

c) Pull mask down to chest.

OR

a) Pull top strap forward away

from head.

b) Adjust tension to allow mask to hang freely.

SmartStrap® Respirators

Pull adjustment clip and strap fully

1

below the bottom of the mask.

Place strap around neck so outside of

2

shell is against chest.

a) Fit mask to face and pull top of

3

strap to crown of head. Nose

cushion must not be creased

inside of respirator.

b) Always use both top and bottom

straps.

To tighten pull both strap tabs.

4

To loosen, grasp both sides of

neck strap and pull.

Each time user enters contami-

5

nated area respirator must be seal

checked. Cover front of respirator

by cupping both hands. INHALE

SHARPLY. A negative pressure

should be felt inside respirator. If

any leakage is detected at respirator edges, tighten or adjust strap by pulling back

along the sides and/or reposition respirator. Repeat

until sealed properly, otherwise see your supervisor.

Entry into a contaminated area with an improper fit

may result in sickness or death.

To hang around neck, pull top strap away from head,

6

then pull mask down.

TECHNICAL HELP LINE

For technical assistance call Moldex Technical Service Department +1 (310) 837-6500, ext. 512/550 or

+1 (800) 421-0668, ext. 512/550.

LIMITED WARRANTY

IMPORTANT NOTICE TO PURCHASER

This limited warranty is made in lieu of the warranties of merchantability, fitness for particular purposes and

all other warranties, express or implied. There are no other warranties which extend beyond the description on

the face hereof. The physical standards and specifications of Moldex will be met by products sold. Exclusive

Remedies: damages for the breach of this limited warranty are limited to the replacement of such quantity of

Moldex products proved to be defectively manufactured. Except as provided above, Moldex shall not be liable or

responsible for any loss, damage, or liability, direct, indirect, incidental, special, or consequential, arising out of

sale, use, or misuse, or the inability to use products by the user.

MOLDEX-METRIC, INC.

10111 W. Jefferson Blvd., Culver City, CA 90232

Tel: +1 (800) 421-0668 or +1 (310) 837-6500 Fax: +1 (310) 837-9563

Email: sales@moldex.com www.moldex.com

Moldex Technical Service Department: +1 (800) 421-0668 or +1 (310) 837-6500 ext. 512/550

Moldex, Ideas that wear well, SmartStrap, EZ-ON, HandyStrap, Dura-Mesh, Softspun and Ventex

are registered trademarks. Made in U.S.A.

ATTENTION: If this respirator is used against any contaminants it must be used in accordance with the

appropriate local, state and federal regulations including 29CFR1910.134 as a minimum.

9702-773 REV H 12/14

Loading...

Loading...