Page 1

8000 Series Respirator

INSTRUCTION MANUAL

IMPORTANT NOTICE TO USERS

You are responsible to understand and follow all warnings,

restrictions and other information contained in this

instruction manual, before you enter a contaminated work

area. Failure to do so may result in sickness or death.

CONTENTS

g

s

Moldex

Moldex

y

s

s

e

n

®

8100 Organic Vapor Cartridge 17

®

8600 Organic Vapor Cartridge 19

s

e

s

AApppplliiccaattiioonns

RReessttrriiccttiioonns

TTeecchhnniiccaall SSeerrvviiccee LLiinne

SSeelleeccttiioonn GGuuiiddee

PPrree--IInnssppeeccttiioon

FFiittttiinng

Fitting Instructions 8

User Seal Check 10

Fit Tests 10

CCaarrttrriiddggees

Chemical Cartridge Service Life 11

Cartridge Replacement 11

Changeout Schedules 12

Cartridge Breakthrough Times 13

8000 Cartridge Change Schedule Worksheet 15

Estimated Cartridge Breakthrough Time for the

Estimated Cartridge Breakthrough Time for the

DDiisskkss//FFiilltteerrs

Disk/Filter Holder Assembly 21

Filter and Disk Service Life 21

Filter/Disk Replacement 22

Piggyback Replacement 23

MMaaiinntteennaanncce

Facepiece Service Life 24

Exhalation Valve Inspection 25

Cleaning 26

CCBBRRNN WWaarrnniinnggs

WWaarrrraanntty

26

31

APPLICATIONS

USE AGAINST

1. Contaminants specified on NIOSH approval label

on bag or cartridges or filters.

2. Contaminants with good warning properties, i.e. smell,

taste or irritation.

3

4

5

5

8

DO NOT USE AGAINST

1. Concentrations of contaminants which are unknown,

or are immediately dangerous to life or health.

2. Concentrations of contaminants which exceed the

maximum use concentration or 10 times the OSHA

Permissible Exposure Limit, whichever is lower.

3. Gases or vapors with poor warning properties or those

which generate high heats of reaction, or paint sprays

containing isocyanates, or sandblasting.

4. Oil-based mists with N filters.

WARNING TO USER

1. Follow all instructions and warnings on the use of these

respirators and wear during all times of exposure. Failure

to do so will reduce respirator effectiveness, wearer

protection, and may result in sickness or death.

2. For proper use, ask your supervisor or call 800/421-0668.

3. The user must first be trained by the employer in proper

respirator use, in accordance with applicable safety and

health standards, for the contaminant and exposure level

in the assigned work area.

4. The vapors, gases, dusts, mists, fumes, and other

contaminants which can be dangerous to your health

include those which you cannot see, taste, or smell.

5. Check with your supervisor for the appropriate cartridges

and/or filters for the contaminants in your work area.

3

Page 2

RESTRICTIONS

01. This respirator does not supply oxygen and must not be

used in atmospheres containing less than 19.5% oxygen.

02. Do not remain in contaminated area if any physical

distress occurs, for example breathing difficulty, dizziness

or nausea.

03. Leave contaminated area and replace respirator and/or

cartridge or filter if it is damaged, distorted, a proper fit

cannot be obtained, you taste, smell or become irritated

by contaminants, or breathing becomes difficult.

04. Do not alter, modify, or abuse this respirator.

05. Store respirator in sealed bag in a clean, dry,

non-contaminated area.

06. Dispose of facepiece, and/or cartridges and disks/filters

according to your employer’s policy and local regulations.

07. Filters are required for particulates.

WWhheerree ooiill mmiissttss aarree pprreesseenntt,

08.

combination with solid particulates, do not use the R or P

filters for longer than one eight-hour work shift. Dispose

no later than eight hours after first use. Do not exceed

10X PEL or a total of 200 mg loading per respirator,

whichever is lower. It is the user’s responsibility to know

the PEL and concentration of the contaminant, the maximum work rate of the employee, and any other work

site-specific information to calculate the loading of the

filter. Where oil mists are present do not use N filters.

09. Dispose of all cartridges, N, R, P filters no later than thirty

days after a) first use, and/or b) removing from sealed bag.

10. Use cartridges, filters, and facepieces before the “use by”

expiration date printed on box or bag.

,

either alone or in

TECHNICAL SERVICE LINE

Moldex maintains a toll-free Technical Service Line to answer

questions about the use of Moldex respirators, contaminants

and regulations. If you have any questions call

800/421-0668 ext. 512/550 or e-mail at:

tech@moldex.com. FAX 310/837-9563.

SELECTION GUIDE

Use this Selection Guide to help you select the correct

respirator and/or cartridges and/or filters for the contaminant

in your work area. Check with your supervisor to determine if

you have the correct protection. Refer to the NIOSH label for

approval limitations. Call

access via website at

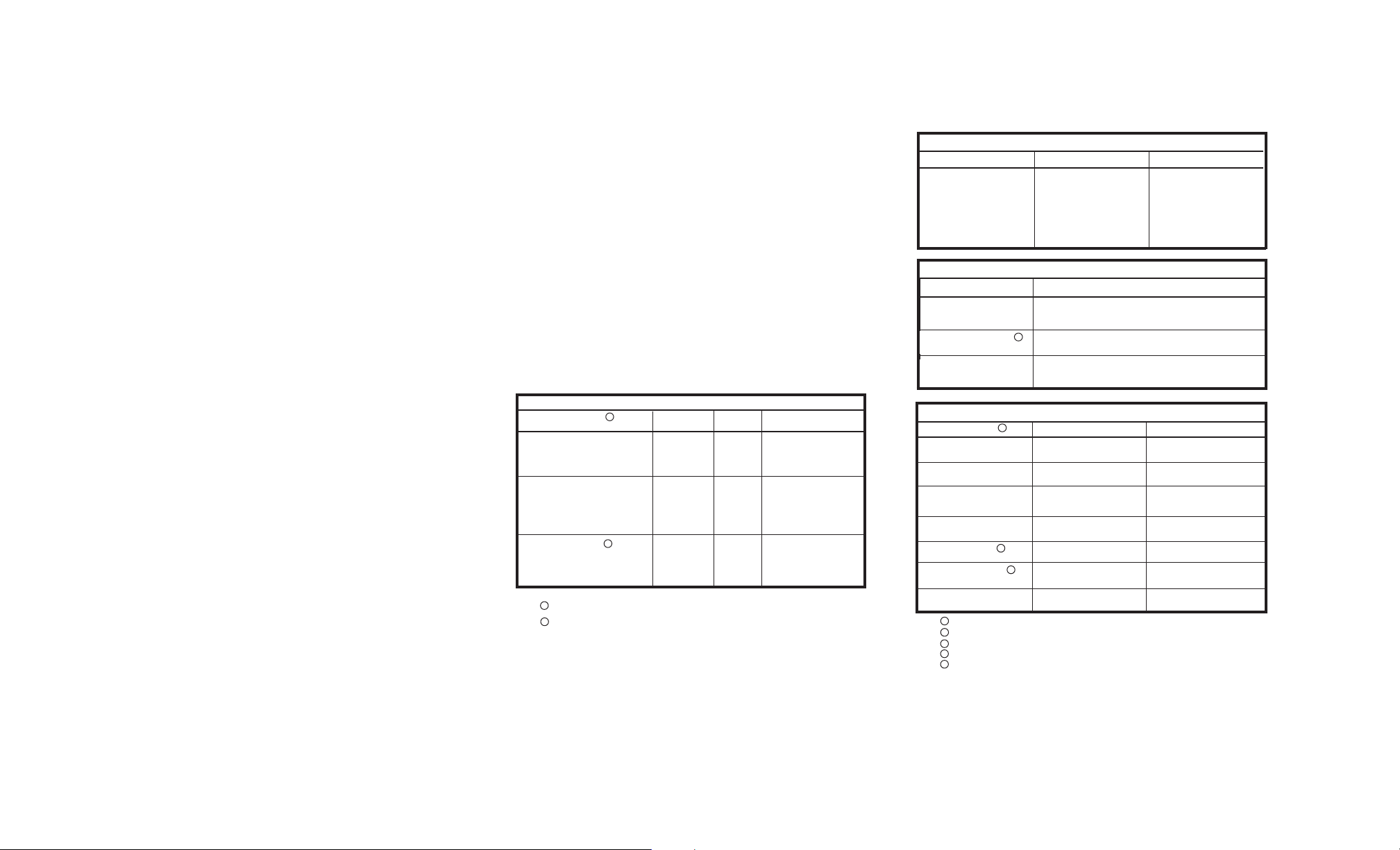

88000000 RREESSPPIIRRAATTOORR AASSSSEEMMBBLLYYWWIITTHH CCAARRTTRRIIDDGGEES

HHaazzaarrdd MMooddeell## SSiizzee AApppprroovvaall

Organic Vapor 8101 S

Paint Spray/Pesticide-

wwaatteerrbbaasseedd,, nnoonn ooiill oonnlly

(includes 8910N95 filters, 8020

retainers, 8100 cartridges)

Multi Gas/Vapor 8601 S

Smart®Cartridge 8602 M TC-23C-1809

1

Refer to NIOSH label for approval limitations.

2

OSHA regulations require gas-proof goggles, when used against Formaldehyde.

1

2

800/421-0668 for copy or you may

www.moldex.com.

8102 M TC-23C-1223

8103 L

8111N S

y

8112N M TC-84A-1337

8113N L

8603 L

S

FFAACCEEPPIIEECCEE OONNLLYY

DDeessccrriippttiioon

Facepiece Assembly

including head strap

harness and

exhalation valve

n

MMooddeell#

8001

8002

8003

#

RREETTAAIINNEERRSS//HHOOLLDDEERRSS//AADDAAPPTTEERRSS

DDeessccrriippttiioon

Retainer

Disk/Filter Holder

Piggyback Adapter

n

2

MMooddeell #

8020

8900

8920

#

RREEPPLLAACCEEMMEENNTT CCAARRTTRRIIDDGGEESS

1

d

HHaazzaarrd

Organic Vapor

Acid Gases

Organic Vapors/

Acid Gases

Ammonia/

Methylamine

Formaldehyde

Multi Gas/Vapor

®

Smart

P100 Particulates

1

Refer to NIOSH label for approval limitations.

2

Can be used with 8940, 8910, 8970, and 8755.

3

OSHA regulations require gas-proof goggles, when used against Formaldehyde

4

Can be used with all gas/vapor cartridges.

5

Nuisance OV (less than OSHA PEL).

3

3

Cartridge

#

MMooddeell #

AApppprroovvaal

8100 TC-23C-1223

8200

TC-23C-1224

8300 TC-23C-1225

8400 TC-23C-1369

8500 TC-23C-1409

8600 TC-23C-1809

8990 TC-84A-1443

SSiizze

S

M

L

e

l

.

4

5

6

Page 3

RREESSPPIIRRAATTOORR AASSSSEEMMBBLLYY

WWIITTHH PP110000 PPAARRTTIICCUULLAATTEE DDIISSKKSS

HHaazzaarrd

P100

d

MMooddeell#

8941

8942

8943

#

SSiizze

e

AApppprroovvaal

l

S

M

TC-84A-0117

L

RREESSPPIIRRAATTOORR AASSSSEEMMBBLLYY WWIITTHH NN9955++ NNUUIISSAANNCCEE OOVV

d

HHaazzaarrd

N95

Particulates Plus

Nuisance OV

5

MMooddeell#

8757

#

SSiizze

M

e

AApppprroovvaal

TC-84A-3901

l

88990000 DDIISSKK//FFIILLTTEERR SSEERRIIEESS

1

DDeessccrriippttiioon

n

N95 Particulates 8910 TC-84A-1343

N95

Particulates Plus

Nuisance OV

5

P100 Particulates

R95 Particulates

#

MMooddeell #

4

AApppprroovvaal

8755 TC-84A-3901

4

8940 TC-84A-0117

4

8970 TC-84A-4248

l

88000000 SSEERRIIEESS RREEPPLLAACCEEMMEENNTT PPAARRTTSS

DDeessccrriippttiioon

Head Strap Assembly

Exhale Valve

Assembly

including holder and

diaphragm

n

MMooddeell#

0082

0083

#

PPaacckkaaggiinng

g

4/Bag

5 Bags/Case

6/Bag

5 Bags/Case

PRE-INSPECTION

Inspect your respirator before and after wearing. Do not wear,

and return to your supervisor if:

1. Headstraps are torn, cut, or have lost elasticity.

2. Buckles or head cradle are missing, damaged or broken.

3. Facepiece is cracked, torn, distorted, dirty, or has holes.

4. Inhalation/Exhalation valves are missing, torn, damaged,

or not properly seated.

5. Cartridges are at the end of their service life, cracked,

damaged, or not properly seated.

FITTING

FFIITTTTIINNGG IINNSSTTRRUUCCTTIIOONNS

1. Users must follow instructions each time respirator is worn.

2. OSHA regulation 1910.134 (f) requires that the user be

fit tested.

3. Do not wear with any facial hair, such as beards, which

may prevent a proper fit.

4. If you cannot obtain a proper fit, do not enter the

contaminated area and see your supervisor.

S

Place respirator under the chin and

pull the cradle to the top of the head

so it rests on the crown.

See Separate (Matrix) Label for 42 CFR 84 NIOSH Approvals

7

8

Page 4

Attach the bottom straps behind

the neck.

Adjust top and bottom of strap

to obtain a secure and comfortable fit. Tighten by pulling on

ends, or loosen by pushing out

on buckle tab.

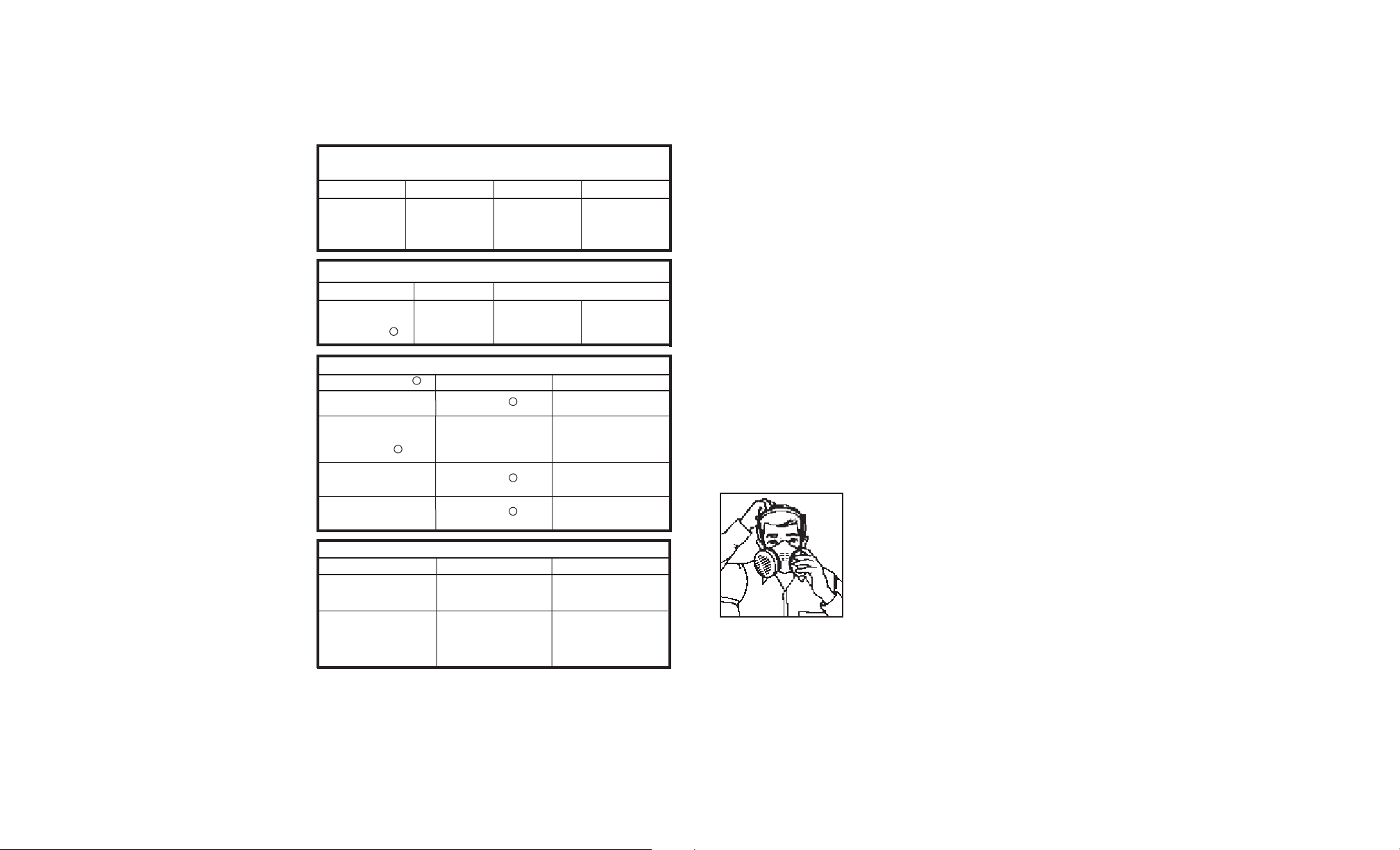

UUSSEERR SSEEAALLCCHHEECCK

K

Read instructions on respirator bag.

PPoossiittiivvee PPrreessssuurree SSeeaall CChheecckk:

Cover the exhalation valve vents,

and exhale gently to create a slight

positive pressure. If air leakage is

detected, re-adjust the position of the

facepiece, and the tension of both

headstraps, and repeat the seal check

until leakage is eliminated.

NNeeggaattiivvee PPrreessssuurree SSeeaall CChheecckk:

Cover both cartridges, and gently

inhale and hold your breath. The

facepiece should slightly collapse.

If air leakage is detected, re-adjust

the position of the facepiece, and

tension of both headstraps, and

repeat the seal check until leakage

is eliminated.

CARTRIDGES

CCHHEEMMIICCAALLCCAARRTTRRIIDDGGEE SSEERRVVIICCEE LLIIFFE

:

:

Leave contaminated area, and replace cartridges, if you

smell, taste, or feel any irritation, in your nose or throat.

Consult your supervisor. Replace according to your change-out

schedule per OSHA 1910.134, or no more than eight hours

after first use, or sooner if breakthrough occurs.

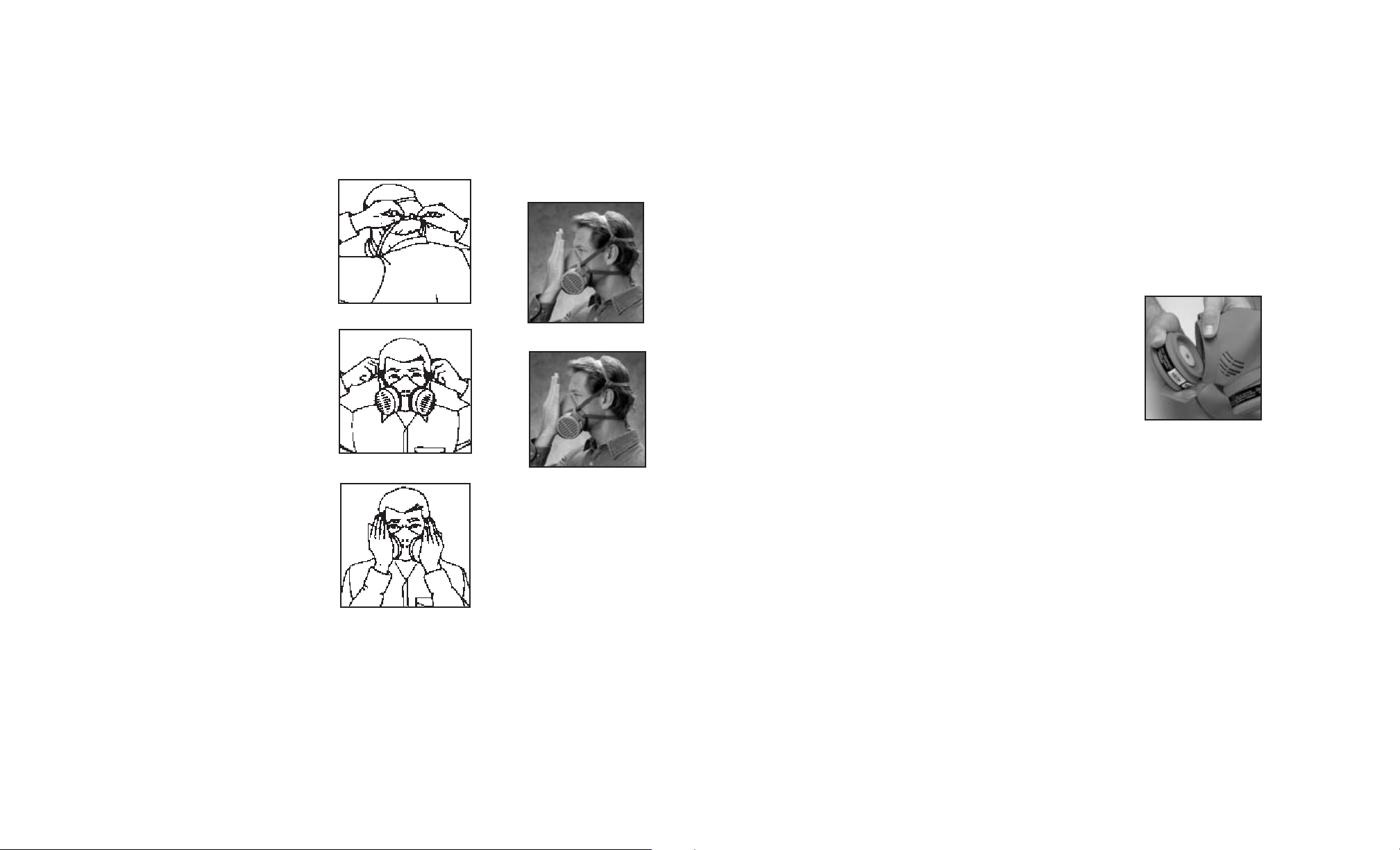

CCAARRTTRRIIDDGGEE RREEPPLLAACCEEMMEENNT

First inspect the facepiece to cartridge sealing surface to make sure

it’s clean and undamaged. Only use

cartridges from sealed bags. To

attach cartridge to facepiece, press

firmly into opening until both surfaces are tightly sealed together at

all points. Check to see that it is

seated properly, both on the inside and outside and flush

against the facepiece. Check the inhalation diaphragms for

dirt or damage and see that they are seated properly. To

remove cartridge, pull and lever out of the facepiece.

T

E

Seal check your respirator

each time you enter a

contaminated area.

9

WWAARRNNIINNGG::

contaminated area and see your supervisor.

FFIITT TTEESSTTS

A qualitative or quantitative fit test must be performed

before a respirator is assigned. Refer to current OSHA and/or

NIOSH regulations, current ANSI Standards, and all other

applicable regulations for complete details.

Qualitative fit testing can be performed using Bitrex

appropriate cartridges or filters. Quantitative fit testing can be

performed with cartridges fitted with probes. Call Moldex at

800/421-0668 for details or access our website at

www.moldex.com.

If you cannot obtain a proper fit, do not enter the

S

®

with

10

11

Page 5

CHANGEOUT SCHEDULES

OSHA 1910.134(d) requires that the employer implement a

change schedule for cartridges based on objective information or data that will ensure cartridges are changed before the

end of their service life (see OSHA1910.134 for complete

text). A cartridge’s useful service life is how long it provides

adequate protection from harmful chemicals in the air. The

service life of a cartridge depends on many factors, including

environmental conditions, breathing rate, cartridge filtering

capacity and the amount of contaminants in the air.

If you know what the chemical is and how much of it you are

exposed to, then you are ready to estimate how long your

respirator cartridges will work and apply the safety factor.

You must use some type of objective data to develop a

changeout schedule. Options for determining a cartridge’s

service life include:

1. Conducting experimental tests.

2. Using a mathematical model like the “Advisor Genius” or

“Breakthrough Software.”

3. Using the manufacturer

Estimated Cartridge Breakthrough Time in the Moldex

Chemical Selection Guide. This data is only provided as a

guide.)

For more detailed information on these methods, refer to

OSHA’s website at:

wwwwww..oosshhaa..ggoovv//SSLLTTCC//eettoooollss//rreessppiirraattoorryy//aaddvviissoorr__ggeenniiuuss_

wwoooodd//aaddvviissoorr__ggeenniiuuss..hhttmml

wwwwww..oosshhaa..ggoovv//SSLLTTCC//eettoooollss//rreessppiirraattoorryy//aaddvviissoorr__ggeenniiuuss_

wwoooodd//bbrreeaakktthhrroouugghh..hhttmml

’s recommendation. (Refer to the

_

l

_

l

Moldex has developed laboratory data for some of the

chemicals where we recommend the use of our 8000 Series

Respirator. You may use this information as a guide to

develop these schedules. Read the warnings and suggestions

on the next page before using this data to develop your

changeout schedule.

Remember this data is only valid for the Moldex 8100 and

8600 cartridges. Use the correct chart for the respective

cartridge. Use any data provided with caution as each

workplace has its own unique variables.

Be sure to read all footnotes provided at the end of each chart.

CARTRIDGE BREAKTHROUGH TIMES

RREEAADD TTHHIISS WWAARRNNIINNG

The following pages contain laboratory generated breakthrough times for some of the chemicals that Moldex suggests

its 8100 and 8600 cartridges to be used against. These

breakthrough times were developed by Miller-Nelson Research

under specific laboratory conditions. Tests were run at 72

degrees F (22 degrees C), 50% relative humidity, and 25 liters

per minute for a pair of cartridges. Miller-Nelson Research

used a challenge concentration of 1000 ppm for certain representative chemical families and was then able to calculate

estimated breakthrough times at other concentrations for various chemicals. These are laboratory generated breakthrough

times and should only be used as a tool in developing your

own changeout schedules. No claims can be made as to their

relationship to actual use conditions. There are other factors

that must be considered in developing changeout schedules

specific to your workplace. These factors include but are not

limited to actual employee work rate, ambient temperature,

ambient relative humidity, whether or not the challenge

G

chemicals have good warning properties, whether other contaminants are also present, use patterns, and maintenance.

Use this data only as a tool to develop your own changeout

schedules. It is the employer’s responsibility to ensure that

the appropriate type of respiratory protection is chosen for

use against a particular contaminant, and that respirators are

used in accordance with a comprehensive respiratory protection program in compliance with 29 CFR 1910.134 or any

other regulation with which you may be required to comply.

Finally, OSHA has on its website other means of calculating

breakthrough times for various chemicals. You may also wish

to consider use of this website in developing your changeout

schedules. Be advised that actual service life can vary considerably from those calculated using these models. These

models only provide rough estimates. Some of the data you

will need specific to the Moldex cartridges in order to use the

models on the OSHA website are:

• 8100 has an average of 36.7 grams Organic Vapor Carbon,

its height is 2.13 cm, inside diameter is 7.85 cm.

• 8600 has an adsorbing equivalent of 28 grams Organic

Vapor Carbon as calculated by Miller-Nelson Research,

it’s height is 2.34 cm, inside diameter is 7.85 cm.

These weights were estimated by Miller-Nelson using methods based on his tests. It is suggested that you use default

values provided by OSHA for the other cartridge specific

parameters. Lastly, in order for the OSHA models to be used

you may have to provide other pertinent data on the challenge agent which may be found on the MSDS or from the

chemical manufacturer. These models can be found at

www.osha.gov/SLTC/etools/respiratory/advisor_genius_w

oods/advisor_genius.html.

and “Breakthrough Applications.” As with the following table,

They are called “Advisor Genius”

12

13

14

Page 6

your use of these models are only as a tool in the development of your own changeout schedule which must consider

all of the factors set forth in the preceding paragraphs.

Moldex suggests that you use both this table, the OSHA

models, or other means provided by OSHA. Moldex always

recommends that you utilize the most conservative (shortest)

breakthough times. Moldex recommends that you use any of

the methods only for the contaminants contained in this guide.

If you have any questions please feel free to call Moldex

Technical Services at 800-421-0668 x700.

8000 CARTRIDGE CHANGE SCHEDULE WORKSHEET

Duties / Job Classification:

Location:

WORKSITE CONDITIONS

Maximum Expected Temperature (ºC):

Maximum Expected Relative Humidity (%):

Work Rate:

Number of Shifts/Week:

Hours Cartridge Used/Shift:

8000 CARTRIDGE DATA

# of Cartridges:

8100 Absorbing Equivalent (grams):

8100 Cartridge Bed Height (cm):

8600 Absorbing Equivalent (grams):

8600 Cartridge Bed Height (cm):

8100 & 8600 Bed Diameter (cm):

Service Life Estimate:

2

36.7

2.13

28.0

2.34

7.85

CHEMICAL INFORMATION

(FROM MSDS OR MANUFACTURER)

Chemical:

Exposure Limit:

Basis Used:

Cartridge Change Schedule Every Hours

After Each Shift:

Other:

Maximum Concentration:

Boiling Point:

Molecular Weight:

Liquid Density:

Vapor Pressure:

This form may be used to assist you in developing a changeout schedule when

using 8100 or 8600 cartridges for protection against organic vapors. Be advised,

this is simply a tool to help you collect some of the pertinent data in developing

a changeout schedule. It is your responsibility to ensure the accuracy of the

schedules that you develop for each operation and work site.

Molecular Polarization:

Refractive Index:

15 16

Page 7

ESTIMATED CARTRIDGE BREAKTHROUGH TIME FOR

ESTIMATED CARTRIDGE BREAKTHROUGH

TIME FOR THE MOLDEX

®

8600

MULTI-PURPOSE VAPOR CARTRIDGE

MEDIUM WORK RATE, 22ºC AND LESS THAN 65% RH

Chemical CAS No. ESTIMATED CARTRIDGE SERVICE LIFE* IN HOURS AT

10 50 100 500 1000

ppm ppm ppm ppm ppm

Acetone 67-64-1 26 8.7 5.5 1.9 1.2

1.5

2.4

3.5

3.5

2.7

4.0

2.7

0.5

2.5

2.6

2.8

2.5

3.2

2.9

3.8

3.1

1.1

0.4

2.4

3.1

3.3

Acrylonitrile 107-13-1 34 11 7.2 2.5

Benzene 71-43-2 53 18 11 3.8

Butylamine 109-73-9 76 26 16 5.5

Chlorobenzene 108-90-7 77 26 17 5.6

Cumene 98-82-8 59 20 13 4.3

Cyclohexanone 108-94-1 87 30 19 6.3

Cyclohexene 110-83-8 59 20 13 4.3

Dimethylamine 124-40-3 12 4.0 2.5 0.9

2-Ethoxyethanol 110-80-5 56 19 12 4.1

2-Ethoxyethlyacetate 111-15-9 58 20 12 4.2

Ethyl Benzene 100-41-4 61 21 13 4.4

Heptane 142-82-5 54 18 12 3.9

2-Heptanone 110-43-0 70 24 15 5.1

3-Heptanone 106-35-4 63 21 13 4.6

2-Methoxyethanol 109-86-4 84 29 18 6.1

2-Methoxyethylacetate 110-49-6 67 23 14 4.9

Methyl Acetate 79-20-9 24 8.1 5.1 1.7

Methylamine 74-89-5 8.3 2.8 1.8 0.6

Nonane 111-84-2 52 18 11 3.8

Toluene 108-88-3 68 23 15 4.9

m-Xylene 108-38-3 72 24 15 5.2

ESTIMATED CARTRIDGE BREAKTHROUGH

TIME FOR THE MOLDEX

®

8100

ORGANIC VAPOR CARTRIDGE

MEDIUM WORK RATE, 22ºC AND LESS THAN 65% RH

Chemical CAS No. ESTIMATED CARTRIDGE SERVICE LIFE* IN HOURS AT

10 50 100 500 1000

ppm ppm ppm ppm ppm

Acetone 67-64-1 37 13 8.0 2.7 1.7

2.3

3.5

5.1

5.1

3.9

5.8

4.0

0.8

3.7

3.8

4.0

3.6

4.7

4.2

5.6

4.5

1.6

0.6

3.5

4.5

4.7

Acrylonitrile 107-13-1 50 17 11 3.6

Benzene 71-43-2 76 26 16 5.6

Butylamine 109-73-9 111 38 24 8.1

Chlorobenzene 108-90-7 112 38 24 8.1

Cumene 98-82-8 85 29 18 6.2

Cyclohexanone 108-94-1 127 43 27 9.3

Cyclohexene 110-83-8 87 30 19 6.3

Dimethylamine 124-40-3 17 5.8 3.7 1.2

2-Ethoxyethanol 110-80-5 81 27 17 5.9

2-Ethoxyethlyacetate 111-15-9 84 29 18 6.1

Ethyl Benzene 100-41-4 88 30 19 6.4

Heptane 142-82-5 79 27 17 5.7

2-Heptanone 110-43-0 102 35 22 7.4

3-Heptanone 106-35-4 92 31 20 6.7

2-Methoxyethanol 109-86-4 121 41 26 8.8

2-Methoxyethylacetate 110-49-6 97 33 21 7.1

Methyl Acetate 79-20-9 35 12 7.4 2.5

Methylamine 74-89-5 12 4.1 2.6 0.9

Nonane 111-84-2 77 26 16 5.6

Toluene 108-88-3 98 33 21 7.2

m-Xylene 108-38-3 104 35 22 7.5

THE MOLDEX

®

8600 ORGANIC VAPOR CARTRIDGE

MEDIUM WORK RATE, 22ºC AND LESS THAN 65% RH

17

*When used in pairs.

Bold print numbers represent experimental 1% breakthrough

data point obtained in the 1970’s adjusted for a medium work

rate and the increased carbon volume and capacity of current

cartridge technology. This data is applicable for ambient conditions at 22ºC, relative humidities from 0 to 65% and a medium work rate (25 LPM). The other breakthrough times were

calculated from Equation 2 taken from Nelson, G.O. and A.N.

Correia, “Respirator Cartridge Efficiency Studies: VIII

Summary and Conclusions” Am. Ind. Hyg. Assoc. J. 37: 514

(1976). These tests and calculations assume no safety factor.

For temperatures at 32ºC, multiply breakthrough times by 0.8.

For temperatures at 12ºC, multiply breakthrough times by 1.2.

For relative humidities between 65 and 80%, multiply breakthrough times by 0.9. For relative humidities between 80 and

95%, multiply breakthrough times by 0.8.

For heavy work rates (35 LPM), multiply breakthrough times

by 0.7. For light work rates (15 LPM), multiply breakthrough

times by 1.7.

These tests were performed under laboratory conditions and

not under actual use conditions. Miller-Nelson Research Inc.

makes no warranties concerning protection by these air purifying respirator devices. These are estimates and the user

should determine the suitability of the devices under actual

field conditions.

Compiled by Miller-Nelson Research Inc., 8 Harris Ct., Suite

C-6, Monterey, CA 93940

18

ESTIMATED CARTRIDGE BREAKTHROUGH TIME FOR

THE MOLDEX

®

8100 ORGANIC VAPOR CARTRIDGE

MEDIUM WORK RATE, 22ºC AND LESS THAN 65% RH

*When used in pairs.

19

Page 8

Bold print numbers represent experimental 1% breakthrough

data point obtained in the 1970’s adjusted for a medium work

rate and the increased carbon volume and capacity of current

cartridge technology. This data is applicable for ambient conditions at 22ºC, relative humidities from 0 to 65% and a medium work rate (25 LPM). The other breakthrough times were

calculated from Equation 2 taken from Nelson, G.O. and A.N.

Correia, “Respirator Cartridge Efficiency Studies: VIII

Summary and Conclusions” Am. Ind. Hyg. Assoc. J. 37: 514

(1976). These tests and calculations assume no safety factor.

For temperatures at 32ºC, multiply breakthrough times by 0.8.

For temperatures at 12ºC, multiply breakthrough times by 1.2.

For relative humidities between 65 and 80%, multiply breakthrough times by 0.9. For relative humidities between 80 and

95%, multiply breakthrough times by 0.8.

For heavy work rates (35 LPM), multiply breakthrough times

by 0.7. For light work rates (15 LPM), multiply breakthrough

times by 1.7.

These tests were performed under laboratory conditions and

not under actual use conditions. Miller-Nelson Research Inc.

makes no warranties concerning protection by these air purifying respirator devices. These are estimates and the user

should determine the suitability of the devices under actual

field conditions.

Compiled by Miller-Nelson Research Inc., 8 Harris Ct., Suite

C-6, Monterey, CA 93940

DISKS/FILTERS

DDIISSKK//FFIILLTTEERR HHOOLLDDEERR AASSSSEEMMBBLLY

Before assembling disk filter holder,

inspect the facepiece sealing surface,

to make sure it is clean and undamaged. To attach holder to facepiece,

press firmly into opening until both surfaces are tightly sealed together at all

points. Check to see that the holder is properly sealed, both

on the inside and the outside, and flush against the facepiece. Insert disk or filter into retainer ring, so that

iinnddiiccaatteedd iiss aawwaayy ffrroomm ffaaccee.

Check to see that disks or filters are properly seated. Check

the inhalation diaphragms for dirt or damage and see that

they are properly seated.

WWaarrnniinngg:

disk/filter series or 8755. Only

adapter with 8940 or 8980 disk/filters. Failure to do so may

result in sickness or death.

FFIILLTTEERR AANNDD DDIISSKK SSEERRVVIICCEE LLIIFFE

tridges, if they become damaged, soiled, torn, or if you experience increased breathing resistance.

Where oil mists may be present in the work area you must

follow page 4 point 8 and also points 9 and 10 for important

restrictions on the use of these filters.

:

Only use 8900 disk/filter holders with 8900

Leave contaminated area and replace filters, disks or car-

Y

tthhee ssiidde

.

use 8920 disk piggyback

E

UUssee RReessttrriiccttiioonnss:

e

:

FFIILLTTEERR RREEPPLLAACCEEMMEENNT

To remove the old filter, gently pull

off the filter retainer. Place a new filter

inside the retainer so that

iinnddiiccaatteedd iiss aawwaayy ffrroomm ffaacce

Replace the retainer.

WWaarrnniinngg::

retainer with the 8910 or 8970 filters

only. Failure to do so may result in sickness or death.

FFIILLTTEERR//DDIISSKK RREEPPLLAACCEEMMEENNT

To remove the old filter or disk,

gently pull off the filter/disk retainer

ring. Discard old filter or disk. Inspect

and clean the retainer ring and the

holder sealing ring each time disk is

changed. If seal is worn, cracked or

damaged the disk holder must be

replaced. Place a new filter or disk

inside the retainer ring so that

ffrroomm ffaacce

inspection of retainer ring seal to holder to ensure it is fully

sealed.

disk/filter series or with 8755 mini pleat N95 filter. Failure to

do so may result in sickness or death.

Use the 8020 filter holder

e

. Replace retainer ring. Make a careful visual

WWaarrnniinngg::

T

e

tthhee ssiidde

e

.

T

tthhee ssiiddee iinnddiiccaatteedd iiss aawwaay

Only use 8900 disk/filter holder with 8900

y

20

21

22

Page 9

PPIIGGGGYYBBAACCKK RREEPPLLAACCEEMMEENNT

To remove the old disk, gently pull

off the disk retainer ring. Discard old

disk. Then gently pull off disk piggyback adapter. Inspect and clean the

piggyback adapter and retainer ring

each time the disk is changed. If seal

is worn, cracked or damaged the piggyback adapter must be replaced. To

remove the cartridge, gently pull and lever out of the facepiece. Before replacing with a new cartridge, inspect the facepiece to cartridge sealing surface, to make sure it is clean and

undamaged. Only use replacement cartridges from sealed

bags. To attach cartridge to facepiece, press firmly into opening

until both surfaces are tightly sealed together at all points.

Check to see that it is seated properly, both on the inside and

the outside and flush against the facepiece.

Check the inhalation diaphragms for dirt or damage and see

that they are seated properly. Replace the piggyback adapter

on the new cartridge. Place a new disk inside the retainer ring

tthhee ssiiddee iinnddiiccaatteedd iiss aawwaayy ffrroomm ffaaccee.

so that

retainer ring. Make a careful inspection of retainer ring seal to

piggyback adapter to ensure it is fully sealed.

T

.

Replace the

MAINTENANCE

FFAACCEEPPIIEECCEE SSEERRVVIICCEE LLIIFFE

The effective life of the facepiece will be influenced by

the use conditions and contaminants to which it is exposed.

This includes concentration of the contaminants (e.g. ketones

and aromatic solvents will increase the rate of deterioration),

duration of exposure, ambient temperature, etc.

Do not use solvents to wipe or clean the facepiece as these

will reduce the life of the respirator and pose a health hazard

to the user. If the material shows any signs of cracking, wrinkling, or aging, then discard the facepiece immediately. Do

not expose to high ambient temperatures (above 160° F) as

this will distort the facepiece, and may affect fit.

RREEPPLLAACCEEMMEENNTT PPAARRTTS

Use only Moldex replacement parts for Moldex respirators.

E

S

WWaarrnniinngg:

8940 disk/filters. Failure to do so may result in

sickness or death.

:

use 8920 disk piggyback adapter with

Only

23

24

Page 10

EEXXHHAALLAATTIIOONN VVAALLVVEE

p

uup

toward you.

N

e

iinnssiidde

IINNSSPPEECCTTIIOON

Pull out plastic diaphragm holder

from the inside of the facepiece.

Clean and check the diaphragm for

dirt, leaks, distortion, or any other

damage. To wash the exhalation

valve diaphragm, remove from the

holder. After washing and/or inspection, replace diaphragm

holder and check to see that it is

fully seated.

Diaphragm holder must be inserted

as indicated by arrows. When holder is correctly inserted guidepins will

face

If the exhalation valve does not

function properly, or cannot be

properly maintained, then replace

diaphragm or discard respirator

immediately.

CCLLEEAANNIINNG

Your respirator should be cleaned after each day’s use, or

more frequently if necessary.

Remove the filters, cartridges, exhalation valve cover, and

headstrap from the facepiece. Gently scrub the facepiece

with a soft brush in a mild germicidal detergent.

Rinse in fresh water and air dry. Inspect components and

reassemble, or replace respirator if worn, damaged or

deformed. Use only warm water for machine washing.

SUPPLEMENTAL HAZARD WARNINGS

FOR MOLDEX

These are

made aware of in addition to all warnings and other information on the outside of the Moldex respirator packaging or

other published related information.

ccoommppllyy wwiitthh tthheessee WWaarrnniinnggss aanndd LLiimmiittaattiioonnssaatt aallll ttiimmees

and if your employer has determined that it is appropriate to

use this respirator.

Proper use of this respirator may reduce but will not

eliminate the risk of illness or death from exposure to

some Chemical, Biological, Radiological, or Nuclear

(CBRN) hazards.

to, bacteria, toxins, and viruses that can cause death, serious

bodily injury or disfigurement. The long-range and shortrange

risks of CBRN hazards and the amount and manner of exposure that may produce such risks remain to a great extent

unknown. Use of this respirator must be in accordance with

the Centers for Disease Control (CDC) Health Advisories or

any other Local, State or Federal recommendations for use of

respirators against specific CBRN hazards. This respirator

should not be used for many CBRN hazards.

G

®

PARTICULATE RESPIRATORS

WWaarrnniinnggss aanndd LLiimmiittaattiioonns

CBRN hazards include, but are not limited

s

that all users must be

YYoouu mmuusstt rreeaadd aannd

d

s

There are more efficient models of respirators with a higher level of protection available from Moldex and other

manufacturers. It is up to the employer, and not Moldex,

to determine if a respirator should be worn and if so, which

type, size, level of protection, and model.

BACKGROUND

The National Institute for Occupational Safety and Health

(NIOSH), a branch of the CDC and a U.S. Government

agency, is responsible for testing and certifying respirators

for protection against hazardous industrial contaminant's.

Procedures for selecting and using proper respiratory

protection are regulated by various governmental agencies,

such as the Occupational Safety and Health Administration

(OSHA).

NIOSH tests and certifies certain respirators for use against

chemical warfare agents, biological warfare agents or biohazards and provides advisory information for some biohazards, but OSHA and other government agencies have not set

any exposure standards for these agents or biohazards, in

general.

Moldex does not make recommendations for any type of

respirator to be used against CBRN hazards for workers

or the general public.

You should know that there may be no obvious warnings of

the presence or release of CBRN hazards.

WARNINGS FOR ALL USERS

• This respirator must only be used for substances having

Permissible Exposure Limits (PELs) and only where

deemed appropriate by your employer.

25

26

27

Page 11

There are more efficient models of respirators with a

higher level of protection available from Moldex and other

manufacturers. It is up to the employer, and not Moldex,

to determine if a respirator should be worn and if so, which

type, size, level of protection, and model.

BACKGROUND

The National Institute for Occupational Safety and Health

(NIOSH), a branch of the CDC and a U.S. Government

agency, is responsible for testing and certifying respirators

for protection against hazardous industrial contaminant's.

Procedures for selecting and using proper respiratory

protection are regulated by various governmental agencies,

such as the Occupational Safety and Health Administration

(OSHA).

NIOSH tests and certifies certain respirators for use against

chemical warfare agents, biological warfare agents or biohazards and provides advisory information for some biohazards, but OSHA and other government agencies have not set

any exposure standards for these agents or biohazards, in

general.

Moldex does not make recommendations for any type of

respirator to be used against CBRN hazards for workers

or the general public.

You should know that there may be no obvious warnings of

the presence or release of CBRN hazards.

WARNINGS FOR ALL USERS

• This respirator must only be used for substances having

Permissible Exposure Limits (PELs) and only where

deemed appropriate by your employer.

• This respirator must be fit tested. If you cannot obtain a

proper fit, do not use the respirator and do not enter the

risk area.

• This respirator is not for use with beards or other facial hair

that prevents direct contact between the face and sealing

surface of the respirator.

• Moldex respirators, when properly fitted and used as part of

a comprehensive respiratory protection program, may reduce

wearer exposure to some airborne hazards, but not all.

• In the event of a sudden or unexpected CBRN hazard

release, you may use this respirator for escape only if you

have not been provided with a more appropriate respirator

for this type of situation. Do not remove the mask from the

face until you have left the contaminated area.

• Do not reuse or store for reuse or hang around neck unless

your employer specifically authorizes reuse. Dispose of respirator as a hazardous waste in accordance with your

employer’s directions.

• Use other personal protective equipment, as directed by your

employer. Where appropriate use protective gloves when

handling or removing respirator and dispose of respirator and

then gloves in accordance with your employer's directions.

• If CDC or other Local, State or Federal agency issues

new or revised guidelines for respirator use against specific

hazards, users must strictly comply.

WARNINGS FOR USE OF PARTICULATE

RESPIRATORS AGAINST TB

OSHA and CDC have recommended the use of any of the

particulate respirators approved under 42CFR84 as a means

of providing help in complying with a program designed to

reduce occupational exposure to tuberculosis.

The level of effectiveness of respiratory protection from tuberculosis cannot be determined with currently available data.

However, proper use of appropriate Moldex respirators in conjunction with a comprehensive respiratory protection program

may reduce, but will not eliminate, risk of infection.

• Be sure to read the Limitations outlined below and strictly

follow all Warnings set forth under the WARNINGS FOR

ALL USERS.

• When using any Moldex respirator, filter replacement and/or

disposal must be handled in accordance with your Healthcare

Facility’s comprehensive respiratory protection program.

• If disinfectants are used to sanitize reusable facepieces,

you must consult with your Healthcare Facility and run tests

to ensure the compatibility of any disinfectant with Moldex

reusable facepiece materials. Use of disinfectants could

impair the efficiency of the respirator and result in a loss

of protection.

28

29

30

Page 12

LIMITED WARRANTY

IIMMPPOORRTTAANNTT NNOOTTIICCEE TTOO PPUURRCCHHAASSEER

TThhiiss lliimmiitteedd wwaarrrraannttyy iiss mmaaddee iinn lliieeuu ooff tthhee wwaarrrraannttiiees

ooff mmeerrcchhaannttaabbiilliittyy,, ffiittnneessss ffoorr ppaarrttiiccuullaarr ppuurrppoossees

aanndd aallll ootthheerr wwaarrrraannttiieess,, eexxpprreessss oorr iimmpplliieedd.

no other warranties which extend beyond the description

on the face hereof. The physical standards and specifications of Moldex will be met by products sold.

EExxcclluussiivvee RReemmeeddiieess:

:

damages for the breach of this

limited warranty are limited to the replacement of such

quantity of Moldex products proved to be defectively

manufactured. Except as provided above, Moldex shall

not be liable or responsible for any loss, damage, or

liability, direct, indirect, incidental, special, or consequential, arising out of sale, use, or misuse, or the inability to

use products by the user.

MOLDEX-METRIC, INC.

10111 West Jefferson Blvd., Culver City, CA 90232

310/837-6500 or 800/421-0668 Fax 310/83

www.moldex.com sales@moldex.com

U.S. Patent #5,505,197, #5,736,041, #D326,540 and Patents Pending.

Moldex is a registered trademark

Made in U.S.A. 8000-710 REV Q 1/06

R

7-9563

s

.

There are

NOTES

s

31 32

Loading...

Loading...