Page 1

Page 2

THE MOJOTONE

BRITISH STYLE

WATT

18WATT TMB

1X 12 COMBO AMP / AMP HEAD

ojotone’s 18watt TMB Amplifier Kit addresses a

M

common mod made to a classic circuit, but with a few

new avors of our own. The 18watt TMB is based on the

circuit used in vintage Marshall models 1958, 1973, and

1974 (more affectionately known as the ‘18-watters’.)

These original Marshalls were only produced between the years

1965 and 1967, but were highly sought-after for having massive

sounding JTM-45-like tones in a smaller, more manageable

package. Because they were produced in comparatively low

quantities, these amps still remain a ‘lost ark’ today.

18-watters became popular studio amps for many players

and were used, at times, by everyone from Gary Moore, to

The Pretenders, to AC/DC. Over the years, some players have

reported having no use for the amp’s original tremolo channel

and have opted to replace the tremolo controls with a 3-band

EQ, since the original amps were only equipped with a

single tone control for each channel. In the Mojotone version,

we have done just this. We have integrated the entire preamp

section and the tone stack from our British 800 kit (based on

the original Marshall JCM 800 circuit) for a lean and mean,

hot-rodded gain sound. We have also integrated a master

volume control so this monstrous sound can be harnessed

and used in any size room.

Two EL84s give the amp’s normal channel a warm and

round character which, when the volume is pushed higher,

begins to break up into a smooth grind perfect for blues rock

and classic rock rhythm sounds. On the dirty channel, one

can access screaming lead tones perfect for everything from

dim dirty grunge all the way to saturated hair metal sustain!

With our TMB mod in place, this take on a classic beast

now has a normal channel with high sensitivity and low

sensitivity inputs as well as a single volume and single

tone control; the second channel has a single input with

volume, treble, middle, and bass controls. And don’t

forget about the master volume!

Page 3

CONTENTS

SECTION 1: SAFETY PG.3

SECTION 2: TOOLS PG.3

SECTION 3: PARTS INVENTORY PG.4

SECTION 4: COMPONENT IDENTITY & ORIENTATION PG.5

SECTION 5: CHASSIS ASSEMBLY PG.6

SECTION 6: TRANSFORMER WIRING PG.8

SECTION 7: COMPONENT WIRING PG.10

SECTION 8: BOARD ASSEMBLY & INSTALLATION PG.10

SECTION 9: WIRING THE SOCKETS, JACKS & POTS PG.12

SECTION 10: Rear panel component installation & wiring PG.14

SECTION 11: SPEAKER WIRING & INSTALLATION PG.15

SECTION 12: INITIAL CHASSIS TESTING PG.15

SECTION 13: CHASSIS INSTALLATION & final assembly PG.16

SECTION 14: SOUND TEST PG.17

SECTION 15: TROUBLESHOOTING PG.17

MORE FROM MOJOTONE PG.18

All content included in this book including text, graphics and images is the property of Mojotone, LLC and protected by U.S. and international copyright laws. The collection, arrangement and assembly of all

content in this book is the exclusive property of Mojotone, LLC and protected by U.S. and international copyright laws. You may not copy, reproduce, distribute, publish, display, perform, modify, create derivative works, transmit, or in any other way exploit any part of copyrighted material without permission from Mojotone, LLC .

Copyright © 2019 Mojotone, LLC

Page 4

SECTION 1:

SAFETY

SAFETY FIRST! ELECTRONICS CAN BE DANGEROUS AND MUST BE TREATED WITH RESPECT. ANY CIRCUIT THAT WORKS WITH 120 VAC POWER FROM AN

ELECTRICAL OUTLET IS ESPECIALLY DANGEROUS AND COULD POTENTIALLY KILL YOU. HERE ARE SOME SAFETY GUIDELINES TO KEEP YOU SAFE AS YOU WORK:

Never work on a circuit while power is applied.

Do not connect power to a circuit until the circuit

is nished and you have carefully checked your

work (twice).

If you smell anything burning, immediately

disconnect the power and examine your circuit to

nd out what went wrong.

Keep your work area dry and organized.

Be careful around large capacitors. They can

continue to hold voltage long after they are disconnected from power. Discharge electrolytic capacitors if power has been applied to the unit.

SECTION 2:

Be especially careful when you solder. A hot

soldering iron can easily burn you.

Always work in a well-ventilated space.

Have safety equipment such as a re extinguisher,

a rst-aid kit and a phone nearby.

Be Patient! Rushing through any type of techni-

cal work just leads to frustration and compounds

issues that can easily be avoided.

Tools

CERTAIN TOOLS ARE REQUIRED TO SUCCESSFULLY BUILD YOUR AMP. THE FOLLOWING TOOLS ARE RECOMMENDED TO COMPLETE YOUR PROJECT:

½” Nut Driver

Set of needle nose pliers (one with no grip and

one with serrated edge)

Wire Cutters

Wire Strippers

Soldering Iron & Solder

Adjustable Wrench

Phillips Head Screwdriver

Multimeter

NEED A TOOL? DO YOU SEE SOMETHING ON THIS LIST THAT YOU DON’T HAVE? TURN TO PAGE 20 FOR A FULL LIST OF TOOLS, PARTS AND KITS TO ADD TO YOUR WORK BENCH.

www.mojotone.com

3

Page 5

ECC83S

EL 84 EZ 81

SECTION 3:

PARTS INVENTORY *optional based on order

(1) Void Free Birch Head Cabinet*

(1) Faceplates (front & back)*

(1) Void Free Birch Combo Cabinet*

(1) Mojotone British Vintage

30w, 12“, 8Ω Speaker*

(2) (1)

(3)

Vacuum Tubes*

(1) British Style 18 Watt

Power Transformer

(6) 9 pin Tube Socket

(1) Aluminum Chassis

(1) British Style 18 Watt

Output Transformer

(3) Tube Shield for ECC836

(1) Turret Board

(3) Spring Retainer for

EL84 & EZ81

(3) Impedance Selector Switch

w/ hardware

4

Potentiometers

(1) 1MA (vol. / tone), (1) 250kl (treb.)

(1) 25kb (mid.), (4) 500ka (vol. / tone)

BUILD. MODIFY. REPAIR.

(1) Indicator Lamp

w/ hardware

(1) 10‘ Removable Power Cord

(1) A/C Power Jack

Page 6

(8) Knobs

(1) 1/4'' Mono Plug

(1) Fuse Holder & Fuse

w/ hardware

(2) Toggle Switch

w/ hardware

Jacks w/ hardware

(4) J1 4-Lug Jack

(1) J2 2-Lug Jack

(2) Four-Lug Terminal

(2) Rubber

Grommets

(2) Ground

Tabs

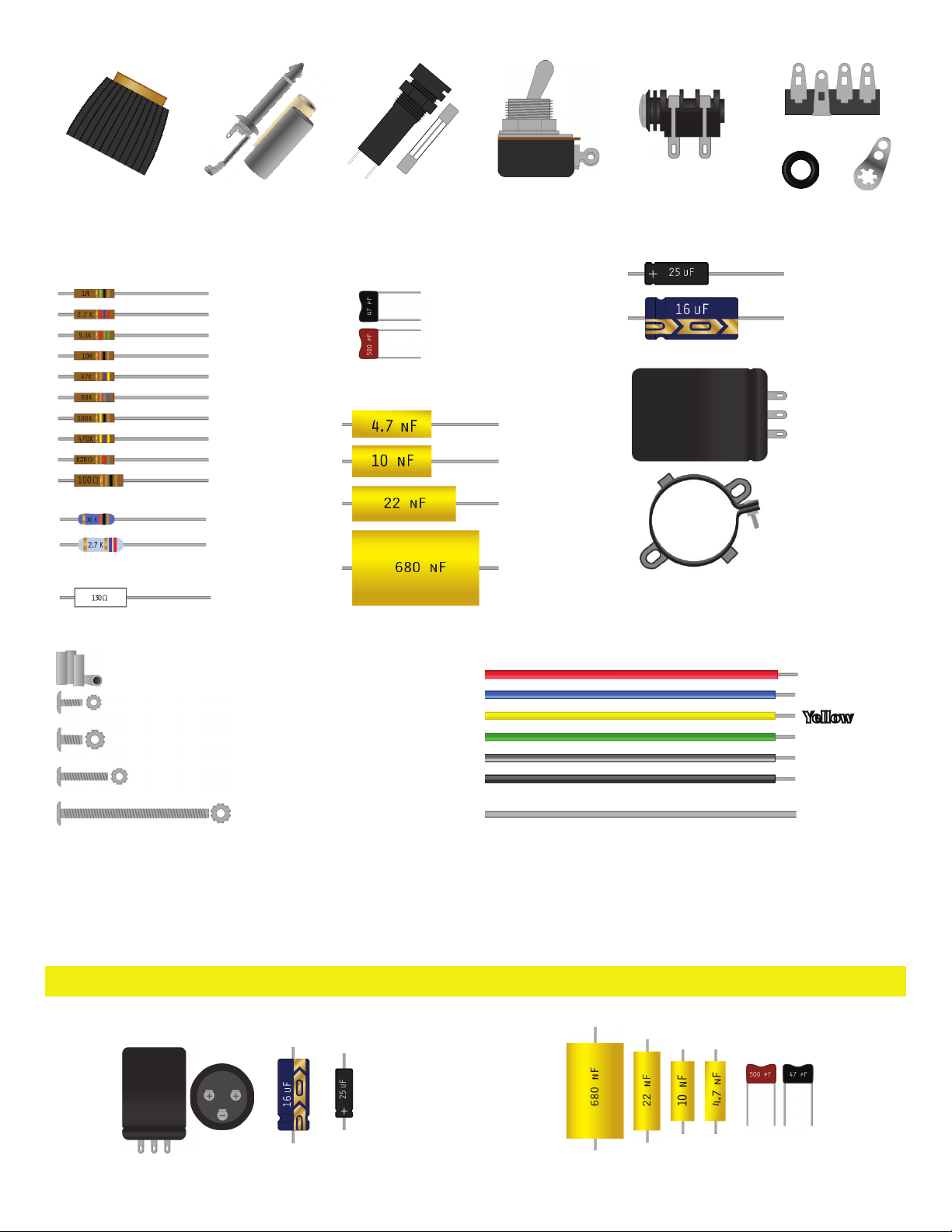

RESISTORS CAPACITORS

Carbon Composite

(2) 1/2W 1M

(1) 1/2W 2.7k

(2) 1/2W 5.1k

(1) 1/2W 10K

(1) 1/2W 47k

(3) 1/2W 68k

(7) 1/2W 100k

(7) 1/2W 470k

(3) 1/2W 820Ω

(2) 1W 100Ω

Metal Oxide

(2) 2W 10kΩ

(2) 2W 2.7k

Wire Wound

(1) 3W 130Ω

Silver Mica

Mojotone Dijon

HARDWARE

Standoffs for Turret Board

(20) 4-40 1/4'' Screw & Keps Nuts

(2) 8-32 1/4’’ Screw & Keps Nuts

(2) 6-32 1/2’’ Screw & Keps Nuts

(4) 10-32 11/2’’ Screw & Keps Nuts

(1) 47pf @ 500V

(2) 500pf @ 500V

(1) 4.7nf @ 630V

(4) 10nf @ 630V

(5) 22nf @ 630V

(1) 680nf @ 160V

WIRES

20 gauge Pre-Tinned PVC Coated Wire (4‘ of each color)

Copper Bus Wire (2‘)

(2) Sprague Atom

25µf @ 50V

(1) Mojotone

Electrolytic KingCap

16µf @ 475V

(2) Can Capacitor

32µf + 32µf

@ 500v

(2) Can Capacitor

Clamps

Red

Blue

Yellow

Green

Gray

Black

SECTION 4:

COMPONENT IDENTITY & ORIENTATION

ENSURE ALL POLARIZED CAPS ARE IN THE CORRECT ORIENTATION WHEN INSTALLING ONTO THE BOARD. THIS IS TYPICALLY DENOTED BY AN ARROW POINTING TOWARDS THE NEGATIVE

SIDE, OR A SMALL INDENTION ON THE POSITIVE SIDE.

SAFETY FIRST! A CAP IN THE WRONG ORIENTATION CAN EXPLODE! SO FOLLOW YOUR WIRING DIAGRAM AND PAY CLOSE ATTENTION WHEN ORIENTING YOUR POLARIZED CAPS.

POLARIZED

www.mojotone.com

NON-POLARIZED

5

Page 7

500 K 25 K 250 K 500 K 500 K

1 M

500 K

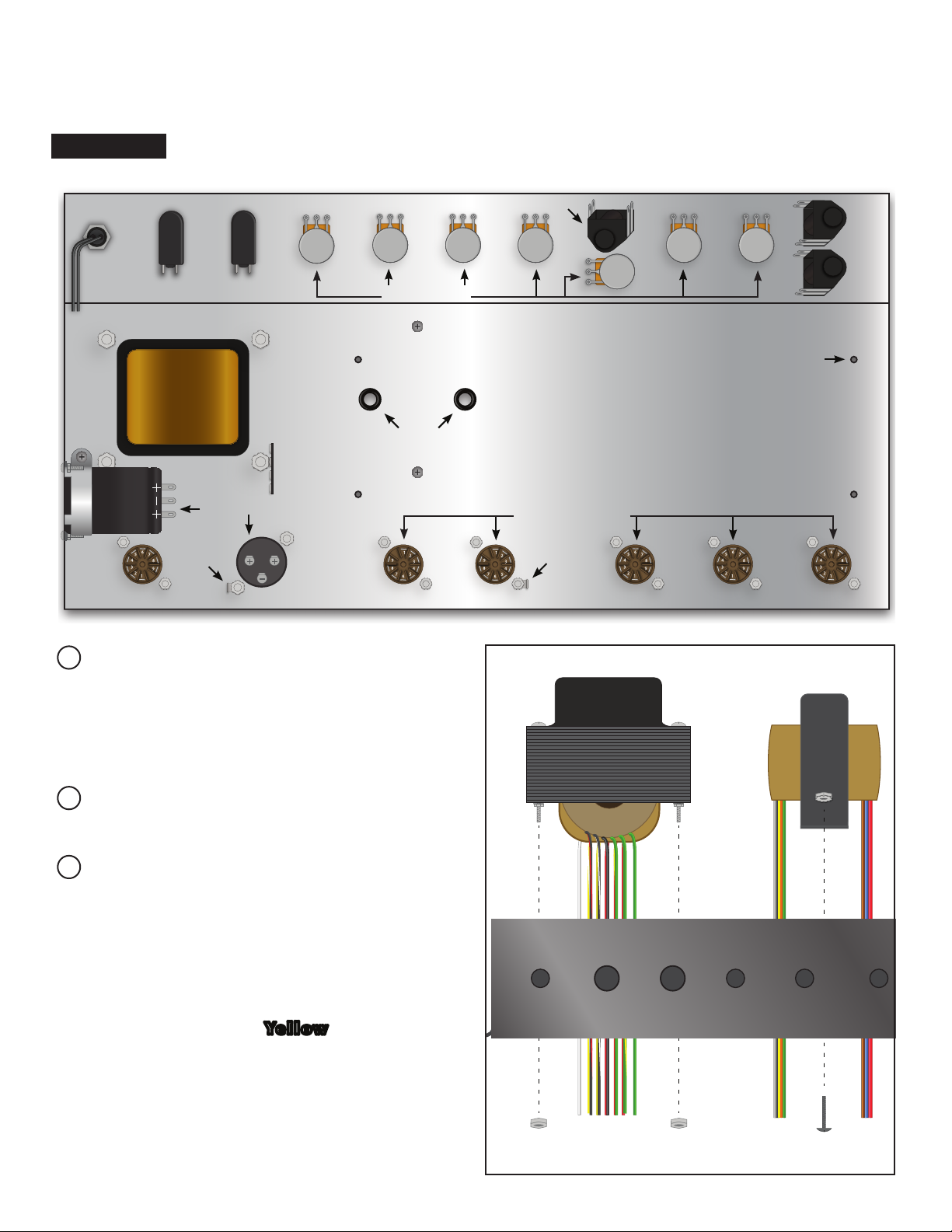

SECTION 5:

Chassis ASSEMBLY

PLEASE NOTE: ALL PARTS LISTED IN THE CHASSIS PREP SECTION STARTS AT ONE END OF THE CHASSIS AND COMPLETES ON THE OPPOSITE END, BOTH TOP AND BOTTOM.

FLATTENED VIEW OF INSIDE OF CHASSIS

INDICATOR

LAMP

MAINS SWITCH

STANDBY

J1 JACK

J1 JACK

POTENTIOMETERS

POWER TRANSFORMER

OUTPUT TRANSFORMER

RUBBER

GROMMETS

4 LUG

TERMINAL

CAN CAPACITOR

GROUND

TAB

9-PIN SOCKET

Mount the power transformer using its

pre-assembled hardware and your adjustable wrench. The transformer will be recessed through the rectangular cutout in the

“belly” of the chassis.

9-PIN TUBE SOCKETS

GROUND

TAB

J1 JACK

FOR TURRET BOARD MOUNTING

Install rubber grommets in holes for output

transformer leads.

Mount the output transformer using the (2)

8-32 x 1⁄4” screws and corresponding keps

nuts onto the outside of the chassis next to

the power transformer (output transformer

is not recessed). Install the transformer so

that the Red, Blue and Brown wires go

through the grommet furthest from the power transformer. The Yellow, Black, Green

and Orange go through the grommet closest to the power transformer. The screws

will go through the outside of the chassis,

and the nuts will be installed in the inside.

Use a screwdriver and adjustable wrench

to tighten.

6

BUILD. MODIFY. REPAIR.

Page 8

CHASSIS CROSS-SECTION FOR COMPONENT ASSEMBLY

POWER & STANDBY

SWITCH

FACEPLATE

CHASSIS

INDICATOR

LAMP

POTENTIOMETER

& KNOB

The faceplate will be secured by the washers and

nuts from the components being mounted through

it. Ensure the faceplate is straight before tightening

down the components and installing the knobs.

Mount indicator lamp using its pre-assembled

hardware. Unthread the hardware from the component and insert it through the chassis and corresponding faceplate cut out. Reapply hardware

and tighten with adjustable wrench and pliers.

INPUT JACKS 9-PIN

SOCKET

CHASSIS CROSS-SECTION FOR CAN CAP. ASSEMBLY

MOUNTING FROM

OUTSIDE CHASSIS

Mount your Main and Standby switches using

their pre-assembled hardware.

Mount potentiometers using their pre-assembled

hardware and 1/2” nut driver. Make sure potentiometers are mounted with their lugs facing up

towards the open end of the chassis.

PRO Tip: When mounting the pots, make sure the

toothed locking washer goes between the potentiometer and the chassis. The at washer will go on

the outside of the chassis and the nut will tighten

down.

Once you have the pots securely installed, turn the

shaft of the pot all the way counter-clockwise. Install the knob on each pot, making sure the pointer of the knob is pointing to “0” on the faceplate.

Use a small at head screwdriver to tighten the set

screw in the back of the knob securely on the pot

shaft. If the knob isn’t moving smoothly, loosen the

set screw, back the knob off of the pot 1/16‘‘ and

re-tighten.

MOUNTING FROM

INSIDE CHASSIS

Mount J2 input jacks using their pre-assembled

hardware and an adjustable wrench. Pay close

attention to the orientation of the jacks on the

wiring diagram.

PRO Tip: Pre-install and solder any resistors on the

jacks before mounting it to the chassis wherever

possible.

Mount 9-pin tube sockets using (4) 4-40 1⁄4” (for the

preamp tube sockets) and 4-40 x 3/8” (for the power

tube sockets and spring retainers) screws and keps

nuts and tighten down with adjustable wrench and

screwdriver. Be sure to mount the retainer springs on

the EL84 and EZ81 sockets and the ground tab.

Mount can capacitors using (4) 6-32 1/2“ screws and

keps nuts and tighten down with adjustable wrench

and screwdriver. Be sure to mount the ground tab.

www.mojotone.com

7

Page 9

SECTION 6:

TRANSFORMER WIRING

1M

68K

500 K 25 K 250 K 500 K 500 K

FROM OUTPUT TRANS.

10 K

2.7 K

RECTIFIER

TUBE SOCKET

EZ81

Twist all matching pairs of wires coming out of the

power transformer.

Measure length needed for each wire, allow yourself extra lead and cut to length. This will eliminate

excess wire and free up space in your chassis. Apply

this principle to all leads.

Prepare the two Red wires from the power trans-

former (HV secondary). Connect one wire to pin 1

and the other to pin 7 of the rectier tube socket.

NOTE: These wires carry AC voltage, so either

wire can go to either pin 1 or 7.

Prepare the Yellow and White wires from the

power transformer (5v rectier lament). Connect

the Yellow to pin 5 and White to pin 4 of the

rectier tube socket.

POWER

TUBE SOCKETS

EL84/6BQ5

socket closest to the power transformer.

Prepare the Black wire and connect to the mains

switch on the lug furthest from the power transformer.

Prepare the Green wire with the Yellow stripe.

Prepare the Red with the Yellow stripe and con-

nect both wires to the grounded lug on the terminal

strip.

Prepare the Black wire with the Red stripe and

connect it to an empty, non-grounded lug on the

terminal strip.

Prepare the Yellow wire with the White stripe

and connect it to an empty, non-grounded lug on

the terminal strip.

1 M

PHASE INVERTER

TUBE SOCKET

ECC83/12AX7

500 K

1M

PREAMP

TUBE SOCKETS

ECC83/12AX7

PRO Tip: On stranded wire, twist the stranded end

tight before tinning. This will make it easier to put

through the lug.

Prepare the two Green wires from the power

transformer (6.3v tube filament) and connect

them to the 5 and 4 pins on the power tube

8

Run the Black wire with the White stripe toward

the back panel of the chassis where the power plug

will be installed.

BUILD. MODIFY. REPAIR.

Page 10

On the output transformer the Red, Blue and Brown

wires are the primary and the Black, Yellow, Green

and Orange are the secondary.

Twist the Blue and Brown wires together and run

them between the two output sockets.

output tube socket furthest from the power transformer.

Prepare and connect the Red wire to the left

(+) terminal of the can capacitor that is installed

between the rectier socket (EZ81) and the power

tube socket (EL84).

Prepare and connect the Brown wire to the 7 pin of

the output tube socket closest to the power transformer.

Prepare and connect the Blue wire to the 7 pin of the

POWER TRANSFORMER SCHEMATIC OUTPUT TRANSFORMER SCHEMATIC

RED (12”)

290V @ 120MA

BLACK/RED (12”)

240V

RED/YELLOW (12”)

290V @ 120MA

BLACK/WHITE (12”)

120V

0V

BLACK (12”)

FOR 120V OPERATION: USE BLACK LEAD AND BLACK/WHITE LEAD

FOR 240V OPERATION: USE BLACK LEAD AND BLACK/RED LEAD

RED (12”)

GREEN (12”)

GREEN/YELLOW (12”)

GREEN (12”)

WHITE (12”) 6V 2A

YELLOW/WHITE (12”) 5V 2A

YELLOW(12”) 0V

6.3V @ 3A

Run the secondary wires toward the rear panel

where the impedance selector will be installed.

Double check wiring and begin soldering.

BLUE (12”)

RED (12”)

BROWN (12”)

ORANGE 16Ω (12”)

GREEN 8Ω (12”)

YELLOW 4Ω (12”)

BLACK 0 (12”)

pro tip: SOLDERING BASICS

SOLDERING IS AN ESSENTIAL SKILL FOR EVERY LEVEL OF AMP BUILDER. HERE ARE A FEW TIPS FROM THE AMP PROS AT MOJOTONE.

SAFETY FIRST! THE SOLDERING IRON TIP REACHES A TEMPERATURE OF 400˚

HEATED. ALWAYS WORK IN A WELL VENTILATED AREA.

Prepare the joint to be soldered. Strip PVC coating

1

/2 ‘‘ from end of wire, hook your leads into lugs or

turrets, twist leads together, etc.

Tin (apply solder to) the tip of the soldering iron.

This will keep it from oxidizing and prolong the life

of your soldering tip. Wipe excess on sponge.

Clean the tip often while soldering. This will help

the iron heat more consistently and evenly.

Be sure to use clamps or tweezers if needed to

hold the components to be soldered in place.

www.mojotone.com

C

SO NEVER DIRECTLY TOUCH IT OR ANY COMPONENT THAT YOU ARE SOLDERING WHEN IT IS

Touch the iron directly on the joint to be soldered

for about two seconds to get it hot enough to melt

the solder.

Touch the solder to the joint. As it melts let it ow

onto the joint to create a solid bond.

Lift the solder off rst and then remove the iron

from the component.

Another method is to tin the stripped wire and then

touch it directly to the heated component. Some

wires will be pre-tinned. They will have a shiny

silver layer twisted around the wire.

9

Page 11

SECTION 7:

500 K 25 K 250 K 500 K 500 K

1 M

500 K

2.7 K

68K

10 K

10 K

1M

Component wiring

Connect The 10k metal oxide resistor between the

Positive (+) terminals on the can capacitor mounted

from the inside, and the 2.7k metal oxide resistor be-

tween the positive (+) terminals on the can capacitor

mounted from the outside.

Prepare the White and Yellow wire and twist to-

gether for the standby switch. Connect the Yellow

wire from the LEFT terminal of the switch to the

3 pin on the rectier tube socket. White from the

right terminal to the LEFT (+) terminal on the can

capacitor mounted from the outside of the chassis.

Prepare the Black wire for the mains switch. Con-

nect to the left terminal of the switch and run it to

where the fuse holder will be installed.

Connect one wire from the indicator lamp to the

RIGHT terminal on the mains switch. Run the other

wire to where the power plug will be installed.

Prepare the Blue and Green wire for the can capacitor mounted from the inside of the chassis. Connect

the Blue wire from the RIGHT positive (+) terminal

to an open, non-grounded, lug on the terminal strip.

Connect the Green wire from the Bottom negative (-)

terminal to the grounded lug on the terminal strip.

Prepare bare wire and connect from the BOTTOM

negative (-) terminal on the can capacitor mounted

from the outside of the chassis to the closest ground

lug. Connect a 10k metal oxide resistor from the

RIGHT positive (+) terminal to the same lug the

Blue wire is connected to on the terminal strip.

Double check wiring and solder.

SECTION 8:

BOARD ASSEMBLY & INSTALLATION

SAFETY FIRST! BE SURE TO TAKE NOTE OF POLARIZED CAPA CITOR ORIENTATIO N FOR THE 16 UF CAP, AND (2) 25UF CAPS.

Begin by applying traces (or “jumper wires”) to

the board.

PRO Tip: Utilize the different sections on the post

of the turret when attaching your wires and components. This makes for easier soldering and repair.

Once jumper wires are in place, follow wiring diagram

to create leads where necessary. These will be the wires

that go out from the component board to other compo-

10

BUILD. MODIFY. REPAIR.

nents in the circuit. Insert these leads down through the

front of the board and bend around back to secure.

PRO Tip: Use the included Wiring Diagram to

approximate lead lengths.

Starting at one end of the front side of the board,

identify the necessary components for each turret

connection and begin placing the leads into the

hole on top of the turret.

Page 12

10 nF

4.7 nF

22 nF

22 nF

22 nF

100K

100K

820Ω

10K

47K

470K

470K

470K

470K

16uF

22 nF

22 nF

680 nF

500 pF

500 pF

25uF

+

2.7 K

820Ω

100K

100K

2.7 K

PRO Tip: When a capacitor and resistor are both

running between the same turrets, you can twist

their leads, one around the other, and solder to

Once all components, jumpers, and leads are in

place, start at one end of the board and begin sol-

dering every turret.

form a solid mechanical connection.

Make Sure you don’t have any bad or “cold” solder

joints by lightly pulling each wire after solder has set.

CROSS-SECTION OF TURRET BOARD CAPACITOR AND RESISTOR TWISTED TOGETHER

JUMPER WIRES AND LEADS TO CHASSIS COMPONENTS

COMPLETED TURRET BOARD

470K

5.1K

470K

5.1K

47K

130 Ω

+

25uF

100 Ω

10 nF

100 Ω

100K

47 pF

100K

10 nF

10 nF

470K

22 nF

22 nF

22 nF

500 pF

470K

820Ω

100K

47K

500 pF

100K

22 nF

470K

470K

820Ω

2.7 K

10K

16uF

470K

22 nF

100K

4.7 nF

10 nF

100K

www.mojotone.com

2.7 K

680 nF

25uF

+

11

820Ω

Page 13

Locate the four small pre-drilled holes in the

COMPLETED

TURRET BOARD

STANDOFFS

chassis for mounting the turret board. Install

a turret board standoff on each hole using the

1/4‘‘ 4-40 screws.

Line the mounting holes on the turret board with

the turret board standoffs and secure using the

1/4‘‘ 4-40 screws.

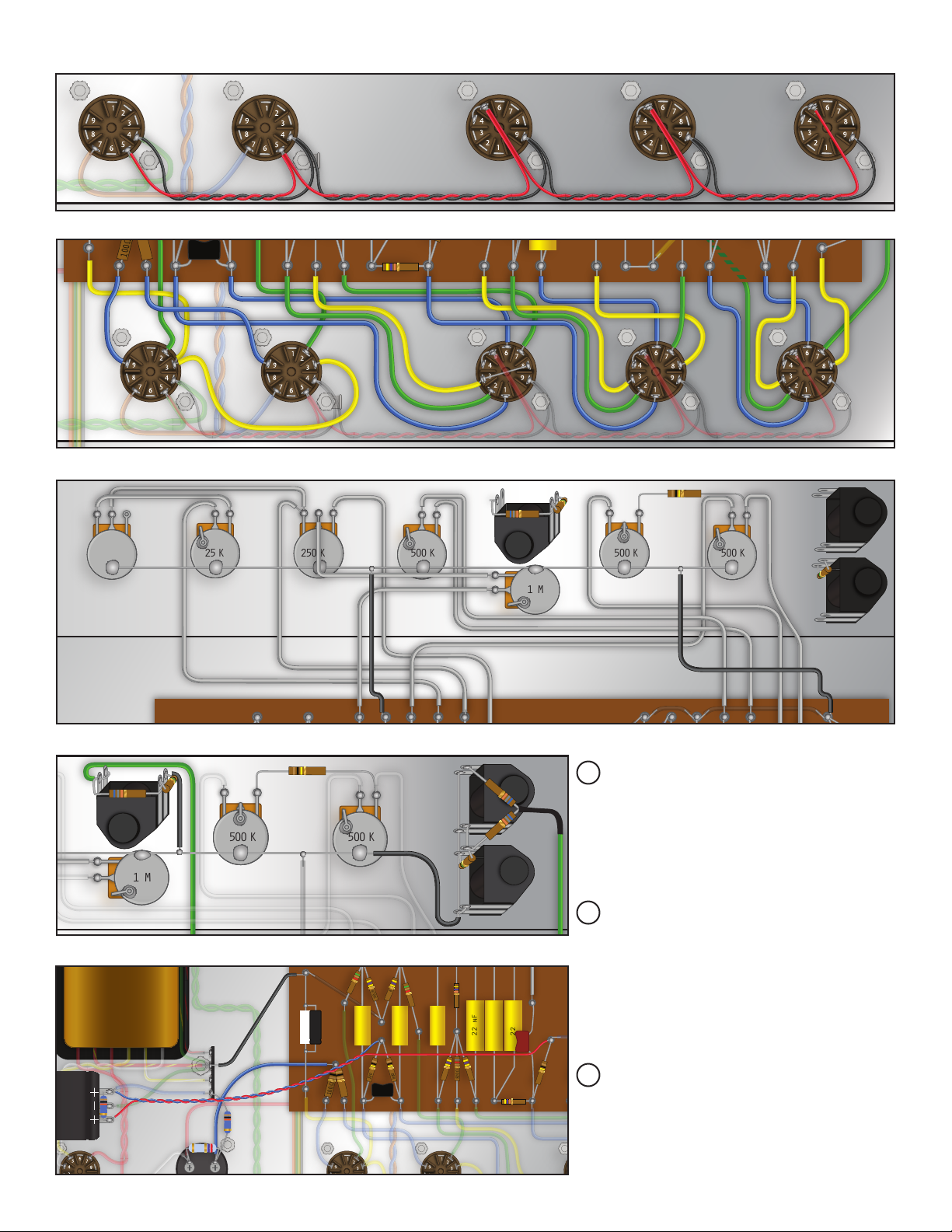

SECTION 9:

WIRING THE SOCKETS, JACKS & POTS

TUBE SOCKET FILAMENT WIRING:

Pro Tip: This is a high gain preamp and is more

sensitive to lament hum from wiring lead dress. Take

care that signal wires are routed away from the lament

wirings and previous gain stages.

Twist tightly together a length of about 3’ of Red and

Black wire to start wiring the tube laments. Starting

with the power tube that is closest to the rectier tube,

prepare and connect the twisted wire between the tube

sockets.

PRO Tip: Make sure the power tube laments are “in

phase”. This means that the lament wires (Red and

Black twisted wire running between the power tubes

sockets) must connect to the corresponding pins between the sockets. Pin 4 to pin 4, Pin 5 to pin 5. Preamp

tubes do not have to be in phase.

When wiring the preamp tubes, Be sure to keep the

Red wires close together and centered when running

them across the tube socket to pin 5. Also note that there

is a jumper between pins 4 & 5.

PRO Tip: Since there is a wire connected to the 5 pin,

you can achieve the jumper wire to the 4 pin by stripping the wire back further, running it through the 5 pin

and reach to the 4 pin. Solder the wire to both pins. Use

this method on any jumper on the tube sockets.

“INPUTS” jacks. Connect the other from pin 2 and

run toward the “MASTER” jack.

POTENTIOMETER WIRING:

Prepare the bus wire that will mount across the back of

all the pots. Start from the “BASS” control on the left side

and solder the wire on the back of each pot. This will

provide a place to run to ground since the pots are all

grounded to the chassis.

Prepare the two Black wires and connect from

the board to the ground buss wire that is installed

on the back of the pots.

Follow the wiring diagram and begin wiring the pots on the

front of the chassis. Start from the left “BASS” control and

work your way across the chassis towards the input jacks.

INPUT JACK WIRING:

Prepare the Green signal wire from pin 2 of the

preamp tube and connect it to the rear left lug on

the “MASTER” input jack.

Prepare the three jumper wires and connect to the

“INPUTS” input jacks as shown.

Prepare the two Black ground wires and connect

to the “INPUTS” input jacks as shown.

TUBE SOCKET WIRING:

Follow the wiring diagram and begin wiring the tubes

sockets starting from the power tubes and work your

way across the chassis towards the preamp tubes.

Prepare two Green wires and connect one to pin

7 of the far right preamp tube and run toward the

12

Prepare the two 68K resistors and connect to the

“INPUTS” input jacks as shown. Then twist the other ends together.

Prepare the Green signal wire from pin 7 of the preamp tube and connect at the junction of the two 68K

resistors. Trim the excess wire from the 68K resistors.

BUILD. MODIFY. REPAIR.

Page 14

1 M

500 K

10 nF

10 nF

10 nF

10 nF

4.7 nF

22 nF

22 nF

22 nF

100K

100K

100K

100K

820Ω

820Ω

10K

47K

47K

470K

470K

470K

470K

470K

470K

470K

5.1K

16uF

22 nF

22 nF

680 nF

47 pF

500 pF

500 pF

25uF

+

100 Ω

100 Ω

25uF

+

130Ω

2.7 K

5.1K

820Ω

100K

100K

2.7 K

68K

100K

1M

68K

68K

1M

500 K 25 K 250 K 500 K 500 K

1 M

500 K

10 nF

4.7 nF

100K

820Ω

10K

470K

470K

470K

16uF

22 nF

22 nF

680 nF

500 pF

25uF

+

2.7 K

820Ω

100K

100K

2.7 K

68K

100K

1M

68K

68K

1M

1 M

500 K

10 nF

10 nF

10 nF

10 nF

4.7 nF

22 nF

22 nF

22 nF

100K

100K

100K

100K

820Ω

820Ω

10K

47K

47K

470K

470K

470K

470K

470K

470K

470K

5.1K

16uF

22 nF

22 nF

680 nF

47 pF

500 pF

500 pF

25uF

+

100 Ω

100 Ω

2.7 K

5.1K

820Ω

100K

100K

2.7 K

68K

100K

1M

68K

68K

1M

TUBE SOCKET FILAMENT WIRING

TUBE SOCKET WIRING

POTENTIOMETER WIRING

1M

68K

100K

INPUT JACK WIRING

CAN CAPACITOR WIRING

500 K 25 K 250 K 500 K 500 K

1 M

CAN CAPACITOR WIRING:

10 K

68K

1 M

100K

500 K

470K

130 Ω

5.1K

25uF

+

100Ω

100Ω

10 nF

100K

47 pF

5.1K

470K

10 nF

10 nF

100K

1M

500 K

10 K

2.7 K

www.mojotone.com

68K

68K

1M

47K

22 nF

470K

470K

820Ω

22 nF

22 nF

47K

500 pF

100K

500 K

1M

Prepare the Blue wire and connect

from the can cap mounted between

the rectier tube and power tube, to

the turret where the two 100 Ohm 1

watt resistors meet.

Prepare the Black wire and con-

nect from the grounded lug terminal,

mounted by the power transformer,

to the turret closest to the front of

the chassis where the 130 Ω resistor

/ 25uf capacitor are mounted.

Prepare the Blue and Red wires

and connect from the can capacitor mounted on the left side of the

chassis to the two points on the

board as shown.

13

Page 15

500 K 25 K 250 K 500 K 500 K

1 M

PREAMP TUBE

9 PIN SOCKET

12AX7

PHASE INVERTER

9 PIN SOCKET

12AX7

POWER TUBE

9 PIN SOCKETS

EL84

RECTIFIER TUBE

9 PIN SOCKET

EL84

CAN CAPACITOR

32µF + 32µF

@500V

BRITISH STYLE 18watt

POWER TRANSFORMER

INDICATOR LIGHT

MAINS SWITCH STANDBY SWITCH

GAINTREBEL

MASTER

BASS

J2 INPUT JACK

10 nF

10 nF

10 nF

22 nF

22 nF

22 nF

100K

100K

100K

100K

820Ω

820Ω

10K

47K

47K

470K

470K

470K

470K

470K

470K

5.1K

16uF

22 nF

47 pF

500 pF

500 pF

100 Ω

100 Ω

2.7 K

2.7 K

5.1K

68K

100K

10 K

10 K

1M

130 Ω

25uF

+

CAN CAPACITOR

32µF + 32µF

@500V

SECTION 10:

REAR PANEL COMPONENT INSTALLATION AND WIRING

FROM INDICATOR LAMP

FROM MAINS SWITCH

FROM POWER TRANSFORMER

TO GROUND TAB TO GROUND TAB

FUSE HOLDER

A/C POWER JACK

Install rear faceplate, fuse holder, impedance se-

lector and speaker jacks on the back of the chassis

using included hardware. Make sure the impedance

selector is snug so that it does not rotate when you

are switching between different output impedances.

Snap in A/C Power Jack into chassis with the center

pin oriented closest to the inside of the chassis.

FROM OUTPUT TRANSFORMER

IMPEDANCE SELECTOR

J1 SPEAKER JACK

J2 SPEAKER JACK

IMPEDANCE

SELECTOR

SWITCH

A/C POWER

JACK

Follow the wiring diagram and begin with wiring

the fuse holder and working to the right towards

the speaker jacks.

Install the knob on the impedance selector, Note which

color wire that the selector tab is pointing to, and align

the knob to that number on the back panel, tighten the

set screw. (Yellow 4 Ω, Green 8 Ω, Orange 16 Ω).

SECTION 11:

FUSE HOLDER

& FUSE

Use a small at head screw driver to remove the

fuse holder cap. Install the fuse into the cap and

reinstall into the fuse holder, push in and twist to

the right about a quarter turn.

SPEAKER WIRING & INSTALLATION (For Combo Amp only)

SPEAKER WIRE HARNESS ASSEMBLY:

Twist the two 15” lengths of black and white 18

gauge stranded wire together.

Push the insulation back about 1⁄2” from both wires

on one end and tin them.

Install the clear plastic shielding over the wiring,

then install the cover on the jack.

On the other end of the wiring harness, push back

the insulation on the wires by 1⁄2”, twist and tin them.

SPEAKER WIRE HARNESS ASSEMBLY

Unscrew the cover off of the 1⁄4” plug. Solder the

white wire to the tip terminal. Solder the black wire

to the sleeve as shown in the illustration.

Bend the two retaining tabs over to hold the wires

to the jack.

14

BUILD. MODIFY. REPAIR.

Page 16

With a pair of needle nose pliers, take the tinned

wire and make a small “hook” on both the white &

black wires.

Insert the white wire “hook” into the positive (+)

terminal on the back of the speaker. Use the needle nose pliers to carefully crimp the “hook” on the

terminal, forming a mechanical connection. Then

solder the wire to the terminal. Repeat the same process with the black wire on the negative (-) terminal.

SPEAKER INSTALLATION:

Remove the four mounting screws from the speaker bafe.

With the cabinet laying face down, place the

speaker on the bafe, line up the speaker mounting

holes with the holes on the bafe.

Finger tighten the mounting speaker screws. Starting with the top left screw, tighten with a screwdriver, then tighten the screw diagonally from it.

Then tighten the remaining screws in the same way.

Remove the upper and lower back panel of the

cabinet.

Mounting holes for the chassis have already been

drilled on the upper back panel.

SECTION 12:

INITIAL CHASSIS TESTING

Reinstall the lower back panel.

Starting from the left side of the chassis, ensure

all solder joints and connections are good. Physically

inspect every tube socket closely, making sure there

are not any extra wires touching other pins.

Look and listen for loose hardware by shaking chassis.

Ensure chassis is free from debris before plugging

in. Check for pinched or burnt wire insulation.

Adjust lead dress so it is easy to see components.

Power on amp without the tubes installed.

Using a multimeter set to AC voltage, check the

power transformer secondary AC voltages (at tube

www.mojotone.com

socket for laments). This will be pins 4 and 5 and pin

9 on the preamp tubes and pins 4 and 5 on the EL84’s.

Turn off the amp and install the EZ81/6CA4 rectier tube.

Turn on amp, do NOT turn on the Standby switch yet, and

allow it to warm up (approximately one minute). Watch

for any kind of arcing or smoke from any component

or transformer. If you see anything, shut down the amp

immediately. Disconnect the amplier from wall socket,

check voltages on the lter capacitors (DC voltage), make

sure they are drained, and then recheck your wiring.

Check the B+ voltages on pin 3 on the rectier socket.

Turn the Standby Switch to ON. Watch for any kind of

15

Page 17

ECC83S ECC83SECC83S

ONBASSMIDDLETREBLEGAINTONEVOLUME

MASTERINPUTS

STANDBYONMAINS

INDICATOR

EL 84EL 84

EZ 81

arcing or smoke from any component or transformer.

If you see anything, shut down the amp immediately. Disconnect the amplier from wall socket, check

voltages on the lter capacitors (DC voltage), make

sure they are drained, and then recheck your wiring.

SAFETY FIRST! THERE ARE NOW HIGH VOLTAGES

PRESENT IN THE AMPLIFIER.

the Standby switch to ON. Check the B+ voltages

on pin 1 and pin 6 of the preamp tubes.

Turn the amp back to Standby and then turn off the

amp. Install the output tubes. Plug in the speaker.

Turn the amp on and check for proper lament operation.

Set your multimeter to its highest DC Voltage setting.

Attach the ground / common probe to the metal chassis. With one hand, take the positive (Red) probe and

carefully measure the voltages on the (+) terminals on

the can capacitors. Then measure the voltage at the 16uf

capacitor on the board. The voltages will be higher than

the voltage readings on the wiring diagram due to the remaining tubes not being installed in the circuit. If you do

not have voltages at these points, power down the amplier, allow the capacitors to drain, DO NOT short them to

ground as this can damage the capacitors or cause them

to explode. Test with your multimeter to make sure the

voltages are below 10V DC before working on the amp.

Turn the amp to Standby and then turn off the amp.

REMEMBER, if you have not drained the capacitors, there are still high voltages present.

Install the preamp tubes, then power up the ampli-

er and ensure the laments are working. Then turn

Turn the Standby switch to ON. Check the voltages at

the test points on the wiring diagram. Check the voltage

on pin 2 of each EL84 tube. Ensure the voltage reading

is near 0V +/- 50mV to avoid “red-plating” of the tubes.

PRO Tip: Red plating occurs when too much cur-

rent is applied to the plate (anode) of a vacuum

tube. It will overheat and glow cherry red. Turn the

power off immediately if this happens.

Let the amp idle on for half an hour or so for the

chassis to be warm and do the bump test.

PRO Tip: A bump test is exactly what it means. Use a non

conductive tool, such as a wooden handle of hammer or

plastic handle of a screw driver, to hit the edge of the chassis or pick your amp up about an inch and drop it. Don’t

worry it won’t harm your amp. This helps you test for bad

solder joints and any loose hardware as well as lets you

know if there is a physical problem with one of your tubes.

Turn the amp back to Standby and then turn the amp off.

SECTION 13:

CHASSIS INSTALLATION & FINAL ASSEMBLY

COMBO CABINET

Turn the chassis over so that the open end is fac-

ing up. If you still have the tubes installed be VERY

careful not to break the tubes. Take the top back

panel and line up the pre-drilled mounting holes

with the hole on the wings of the chassis.

Secure the back panel to the chassis using the four

1-1/2” 10-32 screw and keps nuts.

Secure the EL84 power tubes and EZ81 rectier

with the spring retainers.

the back of the combo cabinet using the four machine

Install the preamp tube shields. Align the pins on the

tube base with the grooves in the tube shield. Press

them on to the tubes and turn a quarter turn to the right.

Install the back panel, with the controls facing up, into

16

BUILD. MODIFY. REPAIR.

screws that originally held the back panel in place.

Set the Impedance selector on the back of the

chassis to match the impedance of the speaker in-

stalled in the cabinet.

Page 18

Plug the speaker into the speaker jack closest to the im-

ECC83S ECC83SECC83S

ONBASSMIDDLETREBLEGAINTONEVOLUME

MASTERINPUTS

STANDBYONMAINS

INDICATOR

EL 84EL 84

EZ 81

ECC83S ECC83SECC83S

ONBASSMIDDLETREBLEGAINTONEVOLUME

MASTERINPUTS

STANDBYONMAINS

INDICATOR

EL 84EL 84

EZ 81

ECC83S ECC83SECC83S

EL 84EL 84

EZ 81

MAINS FUSE

MAINS INPUT

IMPEDANCE

4 8

16

SPEAKERS

pedance selector.

Carefully slide the chassis into the cabinet until the front

faceplate is ush against the front panel of the cabinet.

Plug in the power cord into the A/C jack on the back of

the chassis.

HEAD CABINET

Using a screwdriver, remove the four screws holding

the back panel on the cabinet.

SECTION 14:

SOUND TEST

Carefully turn the cabinet so that it is facing down.

Locate the mounting holes on the bottom of the cabinet.

Install the four 1-1/2” 10-32 screws into the bottom of

the cabinet, through the mounting holes in the chassis.

Secure the screws with the 10-32 keps nuts.

Re-install the rear panel on the cabinet. Plug in power

cord into A/C outlet.

SECTION 15:

TROUBLESHOOTING

Turn on the amp and let it warm up.

After warm-up, ensure the tubes are not “red plating.”

Rotate all controls fully and listen for noise. It

is normal to have some noise at high volume levels.

Plug in an instrument cable and listen for any

crackle, pops, strange oscillations or feedback.

Leave on for a while so the tubes and compo-

nents can “burn in” - (not literally)

ROCK OUT!!

CONGRATULATIONS!! YOU HAVE JUST BUILT YOUR VERY OWN MOJOTONE

18WATT TMB. THERE IS ONLY ONE ON THE PLANET THAT IS LIKE YOURS. WE HOPE

YOU HAVE ENJOYED THIS EXPERIENCE AND GAINED KNOWLEDGE TO HELP YOU

BECOME MORE CONFIDENT TO BUILD MANY MORE AMPS AND SPREAD YOUR

KNOWLEDGE.

DEPENDING ON THE ISSUE YOU HAVE, YOU WILL NEED TO DIAGNOSE WHICH PART

OF THE CIRCUIT IS FAULTY. TRY TO WORK THE PROBLEM ANALYTICALLY, YOU

CAN MAKE PROBLEMS WORSE OR CREATE NEW ONES BY DOING UNNECESSARY

REPAIRS. 99% OF THE TIME IT IS SIMPLE - A BAD SOLDER JOINT, NO SOLDER ON

JOINT, CAPACITOR IN BACKWARDS, ETC.

RESOURCE WEBSITES

www.ampwares.com The best resource with the most

extensive info on most vintage amps.

RESOURCE LITERATURE

Tube Guitar Amplier Essentials and All About

Vacuum Tube Guitar Ampliers by Gerald Weber

Truly must read books by Gerald Weber for any amp

tech. You can purchase these at Mojotone.

The Tube Amp Book By Aspen Pitman.

A great resource for schematics and basic tube info.

Comes with DVD that has over 800 schematics of vintage tube amp technology.

RCA Tube Receiving Manual

This is one of the books that really started the guitar amp craze.

Leo Fender used this very book to develop his rst amps.

SHARE YOUR BUILD WITH US WE WANT TO SEE YOUR FINISHED

AMP. SEND PHOTOS TO: SALES@MOJOTONE.COM

OR TAG US!!! @ MOJOTONE

@ MOJOTONE

www.mojotone.com

CONTACT MOJOTONE’S PRO TECHS

800-927-6656

tech @ mojotone.com

17

Page 19

Ready for your next build?

TWEED CHAMP 5F1 STYLE COMBO

Mojotone’s Tweed Champ Style Amp Kit is based on the beloved 5 watt amp from the

1950s. These amps were perfect for recording and were featured on a wide array of recordings from Joe Walsh’s “Rocky Mountain Way” all the way to Derek & the Dominos’

“Layla.” Modeled after the historic Class-A 6V6 platform, this amp delivers warm tones

that are harmonically rich and have a beautiful low volume crunch. SKU # G1TCK910

Class Type: Single Ended Class A All Tube Amplifier

Output: ~5W

Circuit: 5F1

TWEED DELUXE 5E3 STYLE COMBO

Mojotone’s Tweed Deluxe Style Amp is based on the popular 5E3 circuit from the 1950s and

is by far our most popular amplier. These amps were originally designed as medium power

amps that would allow a musician to plug in more than one amplied instrument at a time.

At higher volumes, this amp produces saturated tones that were adopted as signature tones

for the likes of Billy Gibbons, Neil Young, Don Felder, and Larry Carlton. SKU # G1FTD819

Class Type: Class A/B all Tube Amplifier

Output: ~15 watts

Circuit:5E3

MOJOTONE TWEED BASSMAN 5F6-A STYLE COMBO

Mojotone’s Tweed Bassman Style Amp is based on the late 50s 5F6-A circuit which seems

to be the most commonly used of the Bassman circuits. These 40 Watt amps are known

for their bold and pristine clean sounds as well as their classic unmistakable dirt. The

Bassman is extremely versatile and has been used by tons of iconic guitarists from Mike

McCready, of Pearl Jam fame, all the way to Stevie Ray Vaughan himself. SKU # G1TWK942

Class Type: A/B all Tube Amplifier

Output: ~40 watts

Circuit: 5F6-A

Bias Type: Cathode Biased

Build time: 4 hours

Difficulty:

Bias Type: Cathode Biased

Build Time: 5 hours

Difficulty:

Bias Type: Fixed

Build Time: 6 hours

Difficulty:

18

BLACKFACE Princeton REVERB® STYLE COMBO

The Blackface Princeton Reverb has been a staple in guitar tone since its inception in 1964.

The Princeton Reverb was essentially all the good parts of its predecessor, the Tweed Princeton, but with a long-spring reverb and tube-driven tremolo circuit added. Over the years the

Princeton Reverb has worked its way into the gear repertoire of many renowned guitarists

such as Ryan Adams, Larry Carlton, Glen Campbell, and Tommy Tedesco. SKU # G1BPR108

Class A/B All Tube Amplifier

Output: ~12-15 Watts

Circuit: AA1164

BLACKFACE DELUXE REVERB® STYLE COMBO

One of our most popular amps, the Mojotone Deluxe Reverb Style Kit, is based on arguably the most widely used guitar amp of all time. Just about every iconic guitarist imaginable has played through a Deluxe Reverb at some point or another, but this amp has been

specically touted by artists such as Mike Campbell, Vince Gill, Jackson Brown, and even

Elvis Costello. SKU # G1BDR092

Class Type: A/B All Tube Amplifier

Output: ~22 Watts

Circuit: AB763

BUILD. MODIFY. REPAIR.

Bias Type: Fixed

Build Time: 5 hours

Difficulty:

Bias Type: Fixed with an adjustable bias potentiometer

Build Time: 7 hours

Difficulty:

Page 20

BRITISH 18 WATT STYLE 1X12 COMBO

If you are looking for an amplier that is compact, lightweight, but powerful, this is the

jewel for you. It produces beautiful cleans and one of the best distortion tones ever produced. The 18 watt amplier is the epitome of perfect vintage Marshall® tone. SKU # G1BCK212

Class TYPE: A/B All Tube Amplifier

Output: ~18 Watt

Circuit: 1974

This kit produces similar tones to a 81-90 Marshall® JCM800 2204. SKU # G1800969

Class TYPE: A/B Tube Amplifier

Output: ~50 Watts

Circuit: 2204

This was the rst amplier Marshall® ever built, based off of the 5F6A circuit. Favored

by blues and rock guitarists, this amp can produce a warm sustain and elegant clean

tones, with a pronounced rectier “sag.” Played by guitar greats such as Angus Young

and Gary Moore. SKU # G145C228

Class TYPE: A/B all Tube Amplifier

Output: ~45 watts

Circuit: M45

Cathode Biased

Build Time: 6 hours

Difficulty:

Fixed Bias with an adjustable bias potentiometer

Build Time: 7 hours

Difficulty:

Bias Type: Fixed Bias w/ adjustable potentiometer

Build Time: 6 hours

Difficulty:

BRITISH 800 STYLE AMP

BRITISH 45 STYLE 2X12 COMBO

BLACKFACE SUPER REVERB® STYLE COMBO

Few amps have rivaled the commanding image and sound of the Super Reverb. Since

its introduction in 1963, the Super Reverb has remained highly sought-after due to its

unique tonal qualities and extreme versatility. Having a use on stages of all sizes and in

any studio situation, the Mojotone Super Reverb style amp has the potential to handle

literally any task at hand. SKU # G1BSR125

Class TYPE: A/B Tube Amplifier

Output: ~40 Watts

Circuit: AB763

Our Brownface Deluxe Style kits are modeled after the brown era model 6G3 from the

earlier 1960s. Great for recording or small gigs. The amp can go from a tweed clean/

dirty to a British style overdrive with the turn of the volume knob. Includes bias modulated tremolo. SKU # G1BFD067

Class TYPE: AB all tube amplifier

Output: ~15 watts

Circuit: 6G3

Bias Type: Fixed Bias w/ adjustable bias potentiometer

Build Time: 8 hours

Difficulty:

Bias Type: Fixed Bias

Build Time: 5 hours

Difficulty:

TWEED TWIN 5E8-A LOW POWER STYLE COMBO

Mojotone’s Tweed Twin Low Power Style Amp Kit is a complete tonal powerhouse.

Sporting 45 Watts of power, the amp has all the sweet, vocal qualities and rich dynamic

response as the original. Known for being a plug-and-play amp, the 5E8-A circuit has

been used most notably by Eric Clapton and has been said to ‘cut’ more than its higher

powered counterpart (Tweed Twin High Power). SKU # G1TTL031

Class Type: AB all Tube Amplifier

Output: ~45 watts

Circuit: 5E8-A

Bias Type: Fixed

Build Time: 6 hours

Difficulty:

BROWNFACE DELUXE STYLE COMBO

www.mojotone.com

19

Page 21

the

Workbench

Tools the Pros use

WORKBENCH TESTED. AMP PRO APPROVED. YEARS OF EXPERIENCE AND ENDLESS PASSION HAVE DRIVEN

OUR TEAM AT MOJOTONE TO CREATE THE QUALITY PRODUCTS THAT WE OFFER. NOW YOU CAN USE THE TOOLS

THAT WE DO IN YOUR SEARCH FOR THE PERFECT TONE.

MOJOTONE AMPLIFIER CHASSIS STAND

SKU# N4CHS021

KESTER ‘’44’’ ROSIN CORE SOLDER

SKU# 1000015a

WELLER ANTI-STATIC DE-SOLDER

PUMP SKU# N4TOL085

WELLER WTCPT TEMPERATURE

CONTROLLED SOLDERING STATION

SKU# N4TOL110

XCELITE 6-PIECE PRECISION

SCREWDRIVER SET SKU# N4TOL125

XCELITE ELECTRICAL CUTTING AND

STRIPPING PLIERS SKU# N4TOL113

MOJOTONE SYG A830L DIGITAL

MULTIMETER SKU# 4152015

GROOVETECH JACK/POT WRENCH

SKU# Q2GTJPT1757

XCELITE SERRATED LONG REACH PLIERS

SKU# N4TOL116

MOJOTONE PICKUP WINDING

MACHINE SKU# 4152015

RENE MARTINEZ 24-PIECE

MICRO-TIP SCREWDRIVER SET

SKU# Q2GTJPT1757

XCELITE 6” LONG NEEDLE NOSE PLIERS

SKU# N4TOL124

CONTACT & ORDERING INFO Follow

800-927-6656 sales@ mojotone.com

or

www.mojotone.com

Disclaimer: Mojotone, LLC makes no representations or warranties of any kind as to the information, content, procedures, materials or operation of this book. To the full extent permissible by applicable law,

MojoTone, LLC disclaims all warranties, expressed or implied, including but not limited to, implied warranties of merchantability or tness for any particular purpose. Mojotone, LLC will not be liable for dam-

ages of any kind arising from the use of this book, including but not limited to direct, indirect, incidental punitive and consequential damages.

137 WORTH BEVERAGE DR., BURGAW, NC 28425

Loading...

Loading...