Operator’s Manual:

CT100B Series

TDR Cable Analyzers

For Software Version 2.15

Part No.: CT100B-M-OM-008

CAGE Code: 4JEE1

Revision Date: 2018.12.10

Copyright Notice

Copyright © 2008-2018 MOHR Test and Measurement LLC (MOHR). All rights reserved.

Reproduction of this manual in print and electronic form is authorized for U.S. Government

purposes only. This manual may not be reproduced, distributed, transmitted, displayed,

published, or broadcast in any form or medium by any other party without written permission

from MOHR.

MOHR products are covered by U.S. and foreign patents, issued and pending. Information in

this publication supersedes all previously published material. MOHR reserves the right to

change product specifications or pricing at any time without notice.

This manual contains trademarks and material copyrighted or patented by MOHR and other

third parties. All marks, copyrights, trade secrets, and patents should be considered to be the

property of their respective owners and all rights are reserved. Nothing contained herein shall be

construed by implication, estoppels, or otherwise as granting to the user a license under any

copyright, trademark, patent, or other intellectual property right of MOHR or any third party.

Statutory notice contained herein represents trademark status in the United States.

MOHR Test and Measurement LLC, 2105 Henderson Loop, Richland, WA 99354 USA

CT100B TDR Cable Analyzers Operator’s Manual i

Manual Updates

We at MOHR are always working to improve the written materials we offer to our valued

customers. Since our last printing, there may have been minor updates to this manual.

To view our most recent manual revision, open the accompanying CT Viewer 2 DVD, or visit us

online at www.mohrtm.com. (Please click on Products, CT100, Downloads.)

Date and Time Generated 10th Dec, 2018 2:21pm

CT100B TDR Cable Analyzers Operator’s Manual iii

Warranty

Purchase and/or use of this product signifies your agreement to the terms of this Warranty.

MOHR Test and Measurement LLC (MOHR) warrants that this product will be free from

defects in materials and workmanship for a period of one (1) year from the date of shipment

unless otherwise stated in writing by MOHR. If any such product proves defective during this

warranty period, MOHR, at its option, will either repair the defective product without charge

for parts and labor, or will provide a replacement in exchange for the defective product.

MOHR’s liability and Buyer’s remedies under this Warranty shall be limited solely to repair,

replacement, or credit.

In order to obtain service under this Warranty, customers must notify MOHR of the defect

before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customers shall be responsible for packaging and shipping the defective

product to MOHR with shipping charges prepaid. Customers shall be responsible for paying all

return shipping charges, duties, taxes, and other charges for units returned to any location.

Customers shall be responsible for removing and reinstalling the equipment and for any

decontamination procedures that may be necessary in preparation for shipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MOHR SHALL NOT BE LIABLE UNDER ANY CIRCUMSTANCES FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING BUT NOT LIMITED TO

LABOR COSTS OR LOSS OF PROFITS, DAMAGE TO PERSONS OR PROPERTY

ARISING IN CONNECTION WITH THE USE OF OR INABILITY TO USED PRODUCTS

PURCHASED FROM MOHR.

Specific limitations of this Warranty:

This Warranty only applies to normal and reasonable use of this product. Damage

to this product resulting from improper use, the determination of which is solely at

the discretion of MOHR, is specifically excluded from this Warranty.

Any electrical damage to this product resulting from connection of a cable or

device carrying a static electrical charge to the front panel BNC connector or SMA

connector without first properly grounding the conducting elements of the cable or

device is specifically excluded from this Warranty.

Any Electrical damage to this product resulting from connection of a cable or

device carrying an electrical signal or other non-zero electrical potential relative to

earth ground to the front panel BNC connector or SMA connector is specifically

excluded from this Warranty.

CT100B TDR Cable Analyzers Operator’s Manual v

Contacting MOHR

Phone

+1-888-852-0408

Mail

MOHR Test and Measurement LLC

2105 Henderson Loop

Richland, WA 99354

USA

E-mail

Sales: sales@mohrtm.com

Technical Support: techsupport@mohrtm.com

Web

www.mohrtm.com

CT100B TDR Cable Analyzers Operator’s Manual vii

Table of Contents

Copyright Notice i

Manual Updates iii

Warranty v

Contacting MOHR vii

Table of Contents ix

List of Figures xiii

List of Tables xv

1. General Information 1

1.1. Product Description . . . . . . . 1

1.2. Power Requirements . . . . . . . 1

1.3. Options and Accessories . . . . . 1

1.4. Unpacking and Initial Inspection 2

1.5. Repacking for Shipment . . . . . 2

2. Safety Summary 3

2.1. Terms in the Manual . . . . . . . 3

2.2. Terms on the CT100B . . . . . . 3

2.2.1. DANGER . . . . . . . . . 3

2.2.2. WARNING . . . . . . . . 3

2.2.3. CAUTION . . . . . . . . 3

2.3. Symbols in the Manual . . . . . . 4

2.4. Symbols on the CT100B . . . . . 4

2.5. Static Charge . . . . . . . . . . . 4

2.6. Fuses . . . . . . . . . . . . . . . . 5

2.7. AC Power Source . . . . . . . . . 5

2.8. Grounding the CT100B . . . . . 6

2.9. Danger Arising From Loss of

Ground . . . . . . . . . . . . . . 6

2.10. Explosive Atmospheres . . . . . . 6

2.11. Do Not Remove Covers or Panels 7

2.12. Connecting Cables to the Test Port 7

2.13. Battery Replacement and Disposal 7

3. Operating Instructions 9

3.1. Overview . . . . . . . . . . . . . 9

3.1.1. Handling . . . . . . . . . 9

3.1.2. Powering the CT100B . . 9

3.1.3. Caring for the Battery . . 10

3.1.4. Charging and Power Status 10

3.1.5. Batteries and Long-Term

Storage . . . . . . . . . . 10

3.1.6. Low Battery . . . . . . . 10

3.1.7. Nameplate . . . . . . . . 11

3.1.8. Discharge Warning Label 11

3.2. License Codes . . . . . . . . . . . 11

3.3. Preparing to Use the CT100B . . 11

3.4. Front Panel Controls and Con-

nectors . . . . . . . . . . . . . . . 12

3.5. Rear Panel Connectors and

Switches . . . . . . . . . . . . . . 13

3.6. Keyboard Alternate Controls . . 14

3.7. Setting up the CT100B . . . . . 14

3.7.1. Setting Date and Time . . 14

3.7.2. Navigating Dialog Boxes . 15

3.8. Display Features . . . . . . . . . 15

3.9. Menu Selections and Function

Buttons . . . . . . . . . . . . . . 16

3.9.1. M-FUNC Button . . . . . 16

3.9.2. SCAN Button Menu . . . 16

3.9.3. SELECT Button . . . . . 19

3.9.4. AUTOFIT/HELP Button 19

3.9.5. CURSOR Button . . . . . 19

3.9.6. FILE Button and Menu . 19

3.9.7. “Blue” MENU Button

and Top-Level Menu . . . 20

3.10. Test Preparations . . . . . . . . . 27

3.10.1. Connecting to the Ca-

ble or Device-Under-Test

(DUT) . . . . . . . . . . . 27

3.10.2. Change Velocity of Prop-

agation (Vp) . . . . . . . 28

3.10.3. Find an Unknown Veloc-

ity of Propagation (Vp) . 29

3.10.4. Smooth Settings . . . . . 29

3.10.5. Sample Resolution . . . . 30

3.10.6. Temperature Correction . 32

3.11. Test Procedures . . . . . . . . . . 32

3.11.1. Measure Distance-to-

Fault (DTF) . . . . . . . 32

CT100B TDR Cable Analyzers Operator’s Manual ix

Table of Contents

3.11.2. Relative Distance and

DTF Measurements . . . 33

3.11.3. Multi-Segment Cable

DTF Measurements . . . 34

3.11.4. Ohms-at-Cursor Mea-

surements . . . . . . . . . 35

3.11.5. Scan a Cable . . . . . . . 36

3.11.6. Select a Trace . . . . . . . 37

3.11.7. Store a Trace . . . . . . . 38

3.11.8. Load a Trace (Cable

Records) . . . . . . . . . . 39

3.11.9. Storing, Transferring,

and Deleting Traces . . . 41

3.11.10.Mask Testing . . . . . . . 42

3.11.11.Envelope Plot (Transient/Intermittent Fault

Detection) . . . . . . . . . 44

3.11.12.Difference (Subtraction)

Traces . . . . . . . . . . . 45

3.11.13.First Derivative (Slope)

Traces . . . . . . . . . . . 47

3.11.14.Second and Higher Order

Derivative Traces . . . . . 47

3.11.15.Vertical Reference (Vert.

Ref.) Calibration . . . . . 47

3.11.16.Cable Resistive Loss Cor-

rection . . . . . . . . . . . 48

3.11.17.Return Loss (S11) Traces 49

3.11.18.Return Loss (S11)Options 50

3.11.19.Improving S-Parameter

Measurements . . . . . . 54

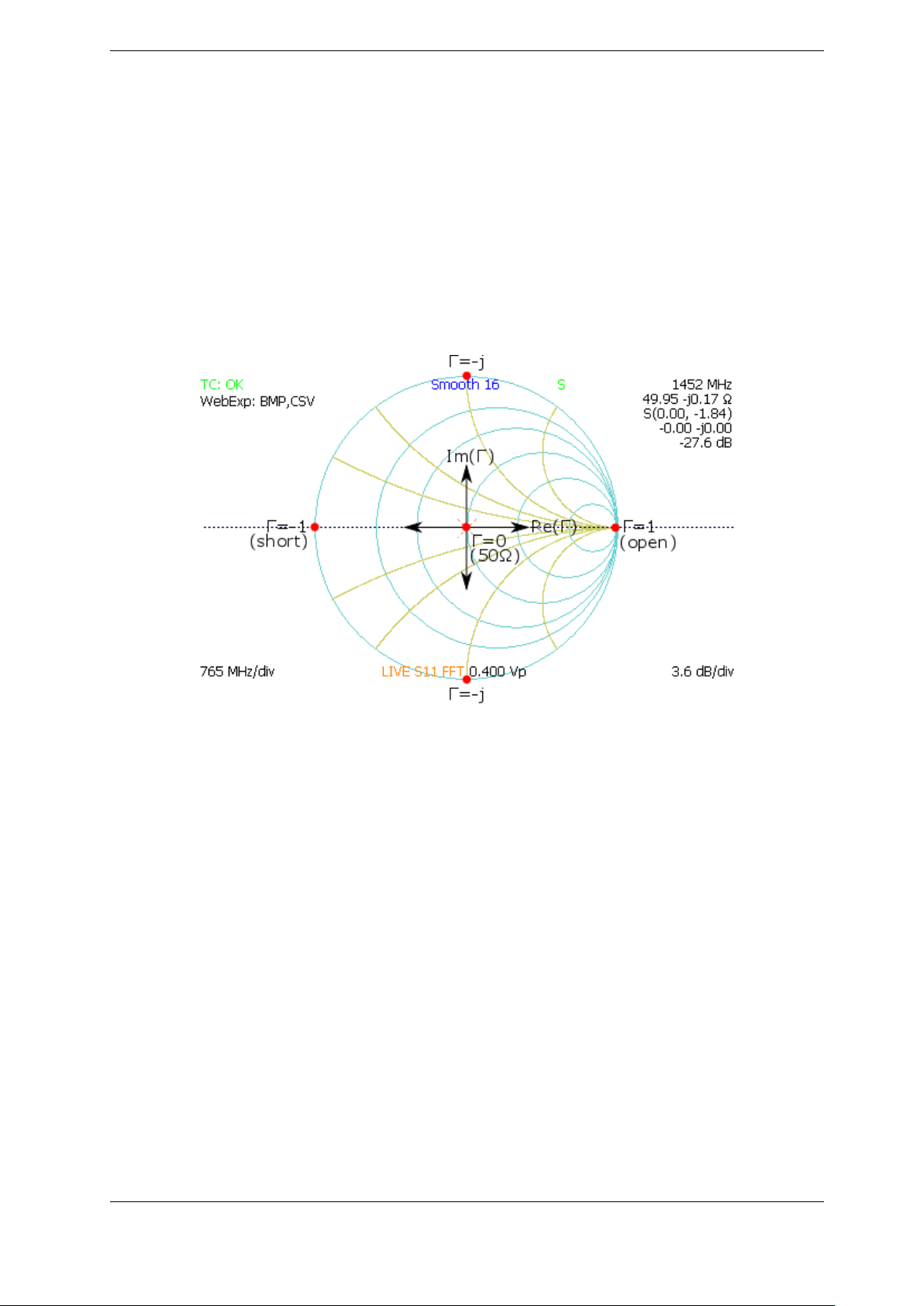

3.11.20.Smith Charts . . . . . . . 54

3.11.21.Normalized TDR Traces . 56

3.11.22.Vertical Units . . . . . . . 57

3.11.23.Layer Peeling (Dynamic

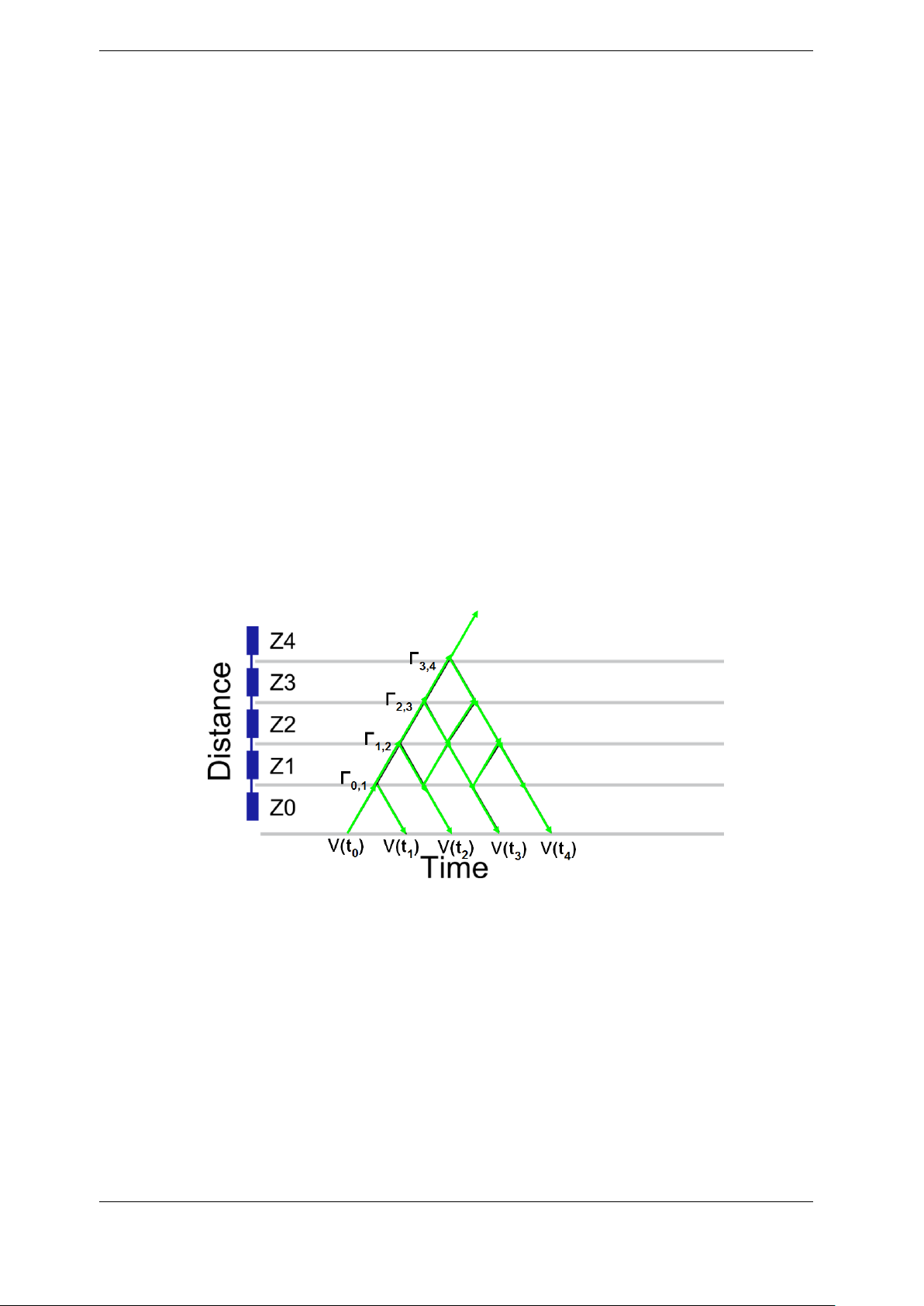

Deconvolution) Traces . . 58

3.11.24.Fast Fourier Transform

(FFT) Traces . . . . . . . 59

3.11.25.Web Export . . . . . . . . 59

3.11.26.Remote Control . . . . . . 60

3.11.27.Cable Type Library . . . 60

3.11.28.Other Measurement Set-

tings . . . . . . . . . . . . 60

3.11.29.User Configurations . . . 61

3.11.30.Take a Screenshot . . . . 62

4.1.2. Send Saved Traces over

USB . . . . . . . . . . . . 64

4.1.3. Send Saved Traces Using

Ethernet . . . . . . . . . . 64

4.1.4. Using Remote Control . . 66

4.1.5. Record and Playback

Real-Time TDR Trace

Movies . . . . . . . . . . . 66

5. TDR Measurement Theory 67

5.1. Time-Domain Reflectometry

(TDR) . . . . . . . . . . . . . . . 67

5.2. Reflection Coefficients . . . . . . 67

5.3. Common Types of TDR Cable

Faults . . . . . . . . . . . . . . . 68

5.4. Velocity of Propagation (VoP, Vp) 70

5.5. Distance-to-Fault (DTF) and

Cable Length . . . . . . . . . . . 71

5.6. Impedance . . . . . . . . . . . . . 71

5.7. Return Loss . . . . . . . . . . . . 72

5.8. VSWR . . . . . . . . . . . . . . . 73

5.9. Rise Time and Spatial Resolution 74

5.10. Timebase/Cursor/Horizontal

Resolution . . . . . . . . . . . . . 75

5.11. Frequency-Domain Measurements 76

5.11.1. Scattering Parameters . . 76

5.11.2. Return Loss (S11) . . . . 77

5.11.3. Insertion Loss (S21) . . . 77

5.11.4. Cable Loss (S21) . . . . . 77

5.12. Smith Charts . . . . . . . . . . . 78

5.13. Normalized TDR Traces . . . . . 78

5.14. Layer Peeling/Dynamic Decon-

volution . . . . . . . . . . . . . . 79

6. Options and Accessories 81

6.1. Options . . . . . . . . . . . . . . 81

6.2. Accessories . . . . . . . . . . . . 81

6.2.1. Service accessories

(CT100B / CT100HF) . . 81

6.2.2. Standard BNC Acces-

sories – CT100B (BNC) . 81

6.2.3. Standard SMA Acces-

sories – CT100B (SMA),

CT100HF . . . . . . . . . 82

6.2.4. Optional accessories . . . 82

4. CT Viewer 63

4.1. Sending Saved Traces to a Com-

puter . . . . . . . . . . . . . . . . 63

4.1.1. Send Saved Traces with a

Thumb Drive . . . . . . . 63

x CT100B TDR Cable Analyzers Operator’s Manual

A. Specifications 83

A.1. Electrical Specifications . . . . . 83

A.2. Environmental Specifications . . 84

A.3. Mechanical Specifications . . . . 84

A.4. Certifications and Compliances . 85

Table of Contents

B. Operating Performance Checks 87

B.1. General Information . . . . . . . 87

B.2. Required Equipment . . . . . . . 87

B.3. Getting Ready . . . . . . . . . . 88

B.4. Operator Performance Checks . . 88

C. Operator Troubleshooting 93

C.1. General Information . . . . . . . 93

C.2. Power On Test . . . . . . . . . . 93

C.3. Functional Block Diagram and

Troubleshooting Flowcharts . . . 93

C.4. Parts List . . . . . . . . . . . . . 104

D. Maintenance and Service Instructions 105

D.1. Cleaning and Lubrication . . . . 105

D.2. Cleaning and Lubrication Interval 105

D.3. Battery Removal/Replacement . 105

D.4. Calibration and Calibration In-

terval . . . . . . . . . . . . . . . 105

D.5. Install CT100B License . . . . . 106

D.6. Clean Storage . . . . . . . . . . . 106

E. Vpof Common Cables 107

E.1. Cable Types . . . . . . . . . . . . 107

E.2. Dielectric Material . . . . . . . . 107

E.3. RG Standards . . . . . . . . . . . 108

E.4. MIL-C-17 Standards . . . . . . . 108

E.5. Commercial Designations . . . . 109

E.6. Twisted Pair . . . . . . . . . . . 109

Glossary 111

Index 117

CT100B TDR Cable Analyzers Operator’s Manual xi

List of Figures

3.1. Example nameplate label found on back of a CT100B. . . . . . . . . . . . . . . . . 11

3.2. Diagram of the CT100B front panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3. Diagram of the rear panel of the CT100B/CT100HF. . . . . . . . . . . . . . . . . . 14

3.4. Screenshot showing typical features of the CT100B. . . . . . . . . . . . . . . . . . 16

3.5. Clip lead adapter and controlled impedance adapter . . . . . . . . . . . . . . . . . 28

3.6. Screenshot showing AUTOFIT result. . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.7. Use of the HORIZONTAL SCALE knob to improve Vp accuracy. . . . . . . . . . . 30

3.8. Final Vp of the cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

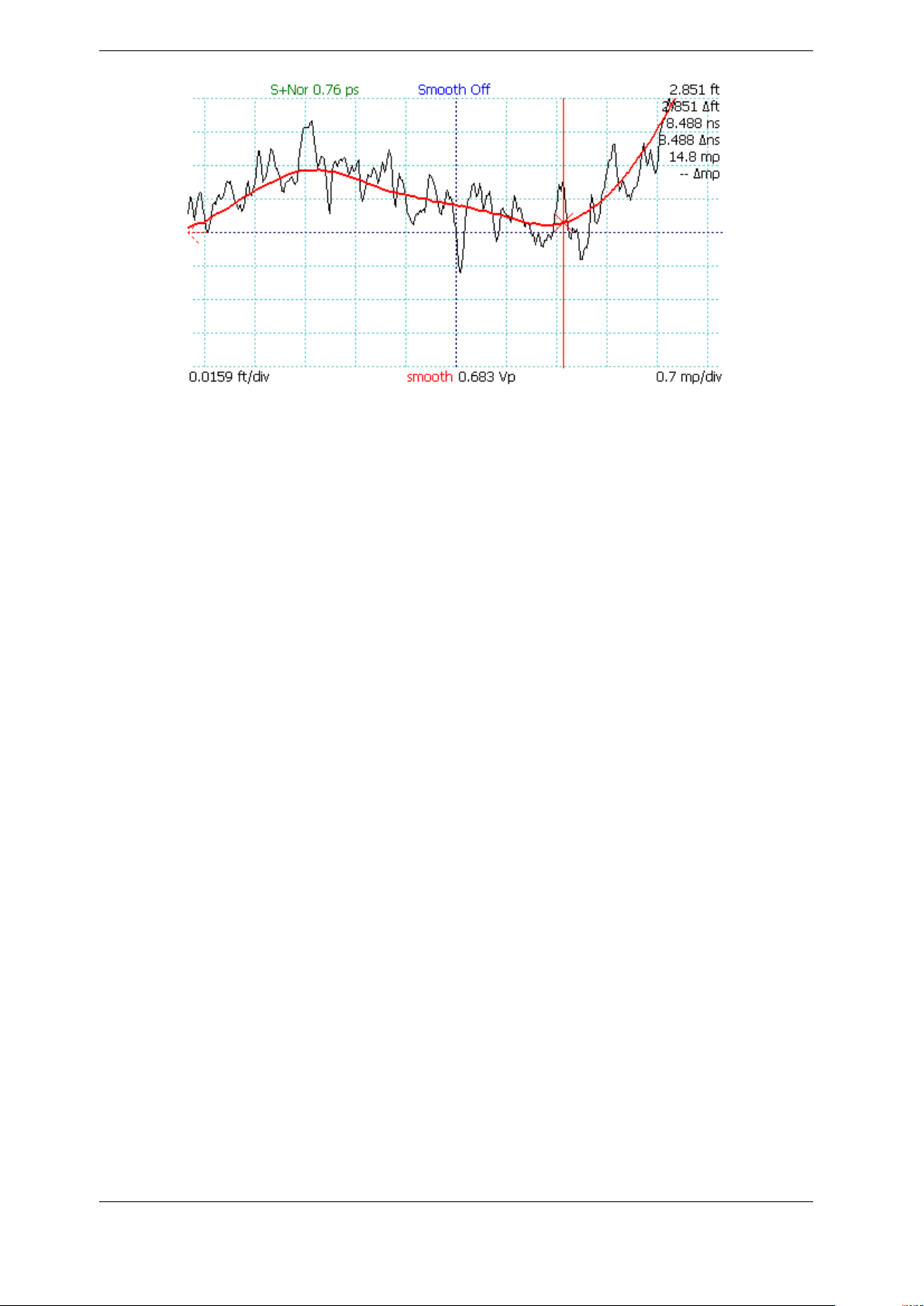

3.9. Smoothed vs. unsmoothed traces at very small vertical scales . . . . . . . . . . . . 31

3.10. A small fault in a long cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.11. AUTOFIT cable. The cable termination is a short. . . . . . . . . . . . . . . . . . . 33

3.12. Vertical scale used to emphasize cable fault. . . . . . . . . . . . . . . . . . . . . . . 33

3.13. A zoomed in view of the cable fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.14. Relative distance measurement between two small impedance “faults” caused by

BNC connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.15. Multi-segment cable segment with Vp of 0.400 . . . . . . . . . . . . . . . . . . . . . 35

3.16. Multi-segment cable segment with Vp of 0.850 . . . . . . . . . . . . . . . . . . . . . 36

3.17. Scan progress display with Cancel button. . . . . . . . . . . . . . . . . . . . . . . . 36

3.18. Scan of a portion of a cable, zoomed-in vertically. . . . . . . . . . . . . . . . . . . . 37

3.19. Selecting the live trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.20. Selecting a scanned trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.21. Selecting a difference trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.22. Using the on-screen keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.23. Loading a trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.24. A trace that passes the mask test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.25. A trace that fails the mask test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.26. Envelope Plot with Fill Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.27. Envelope Plot with Probability Density display. . . . . . . . . . . . . . . . . . . . . 45

3.28. Envelope Plot with Fill Mode, showing the range of impedance values . . . . . . . 46

3.29. Difference trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

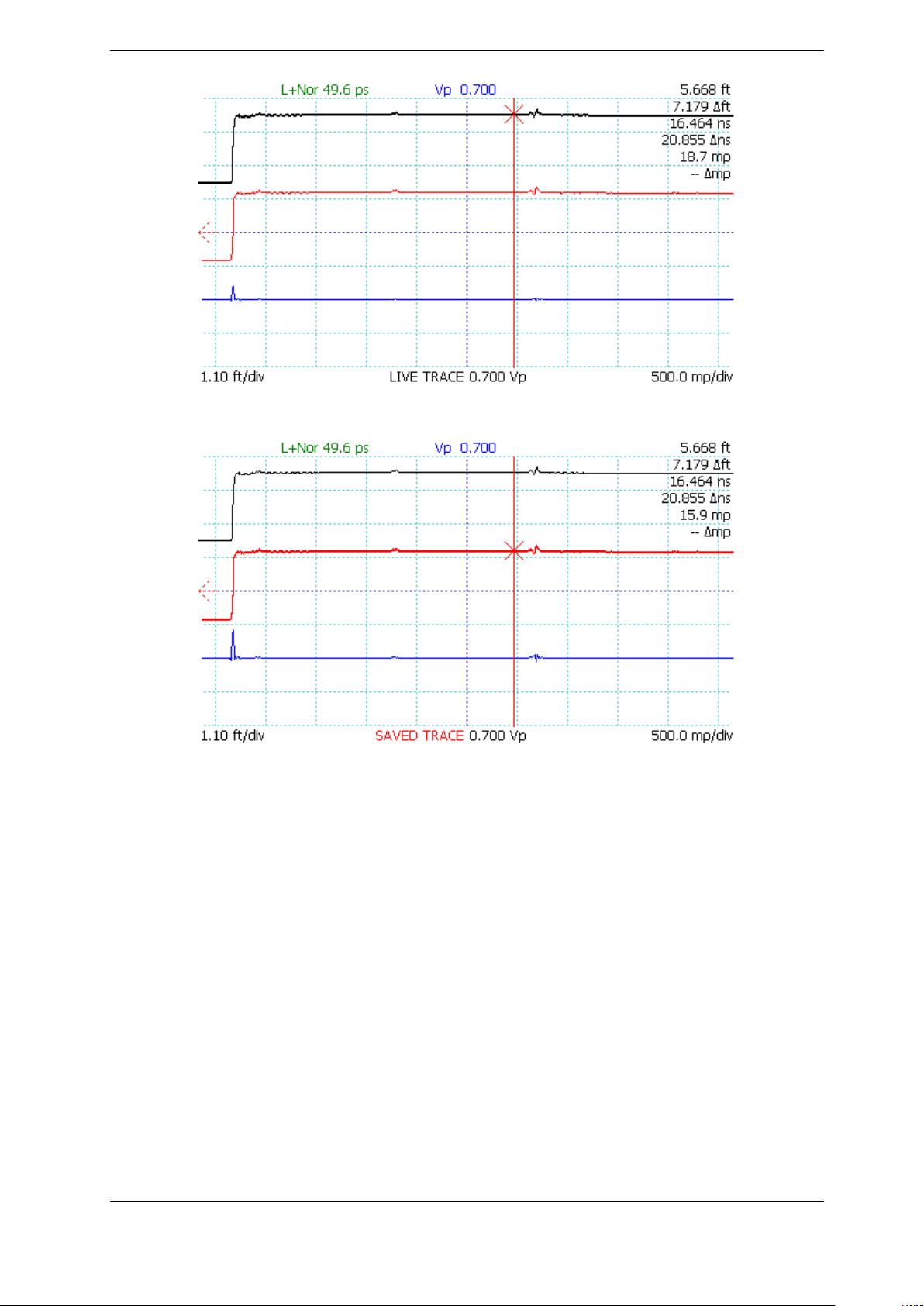

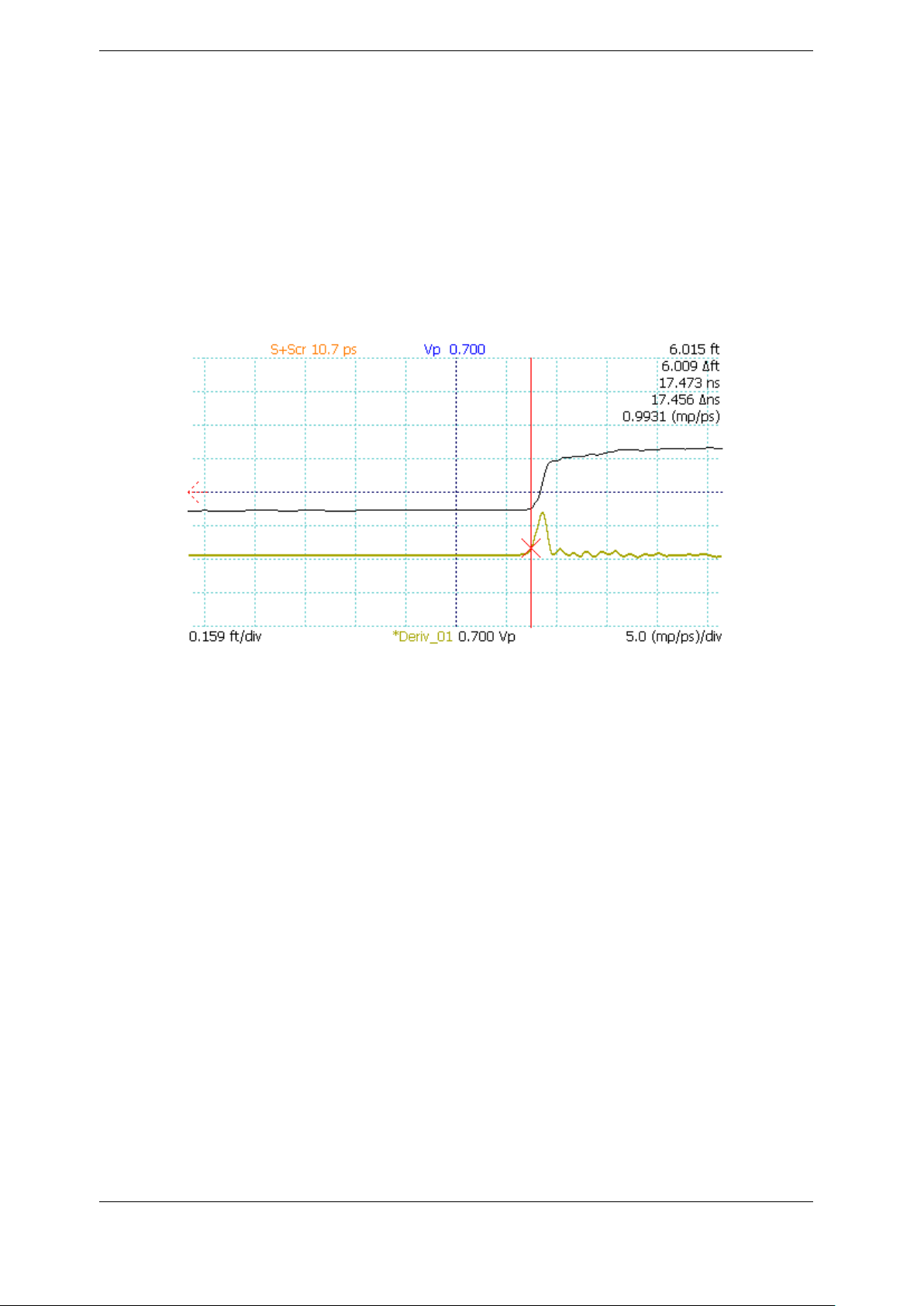

3.30. First-derivative trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.31. Resistive cable loss correction, before. . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.32. Resistive cable loss correction, after. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

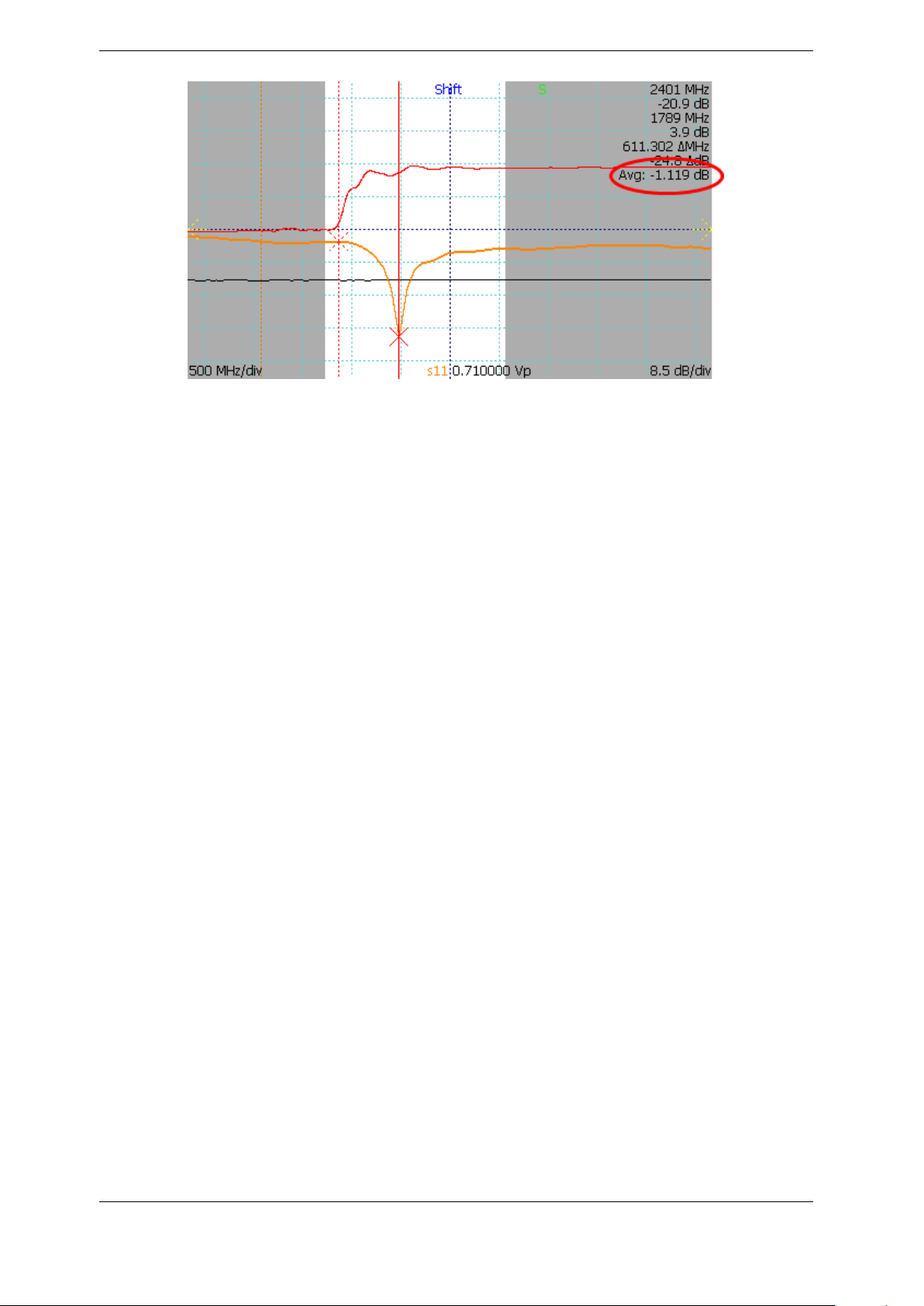

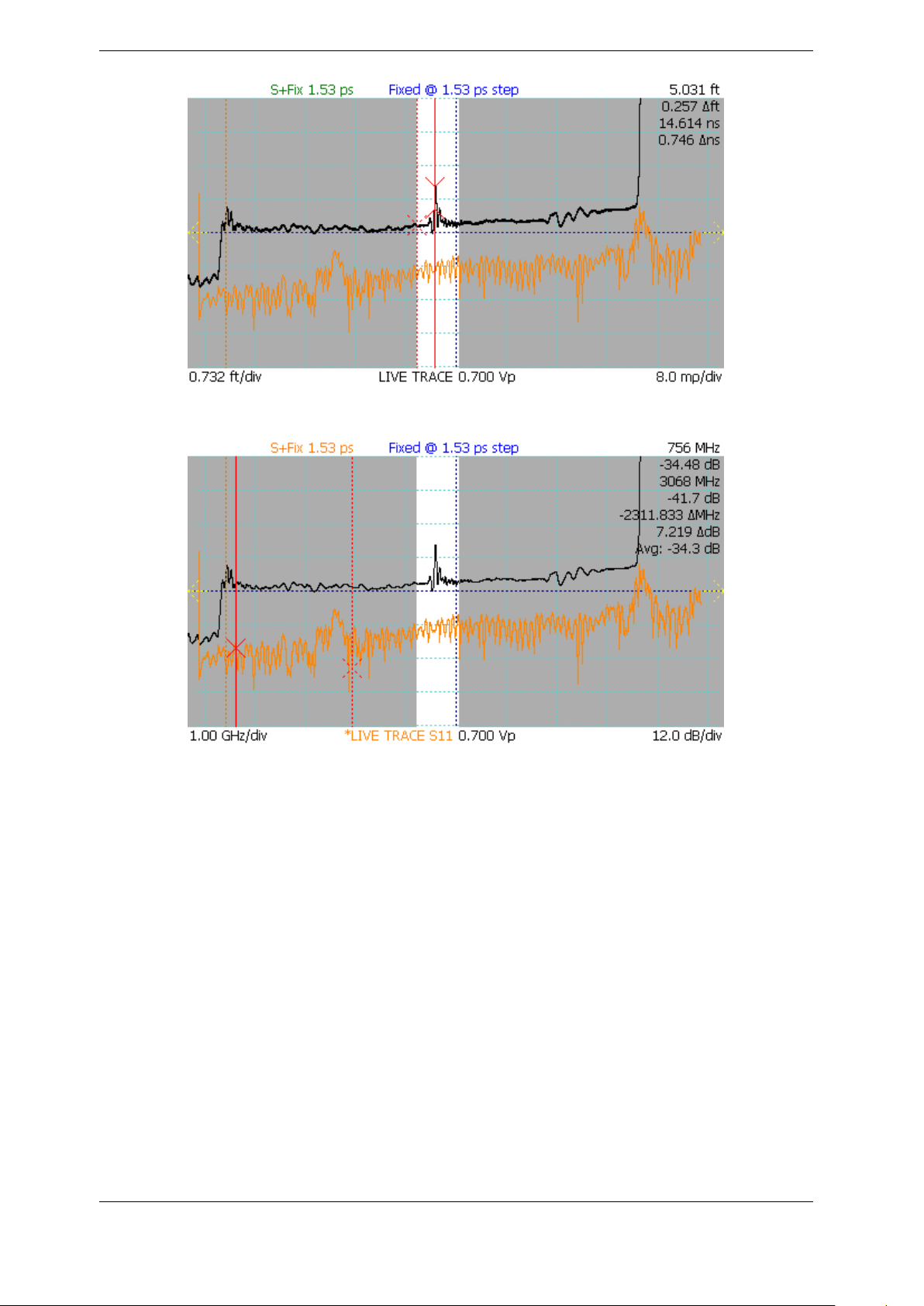

3.33. S11return loss plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.34. S11between cursors bracketing an SMA barrel adapter on the TDR trace. . . . . . 53

3.35. S11between cursors with tightened connector . . . . . . . . . . . . . . . . . . . . . 53

3.36. S11between cursors with loosened connector . . . . . . . . . . . . . . . . . . . . . . 54

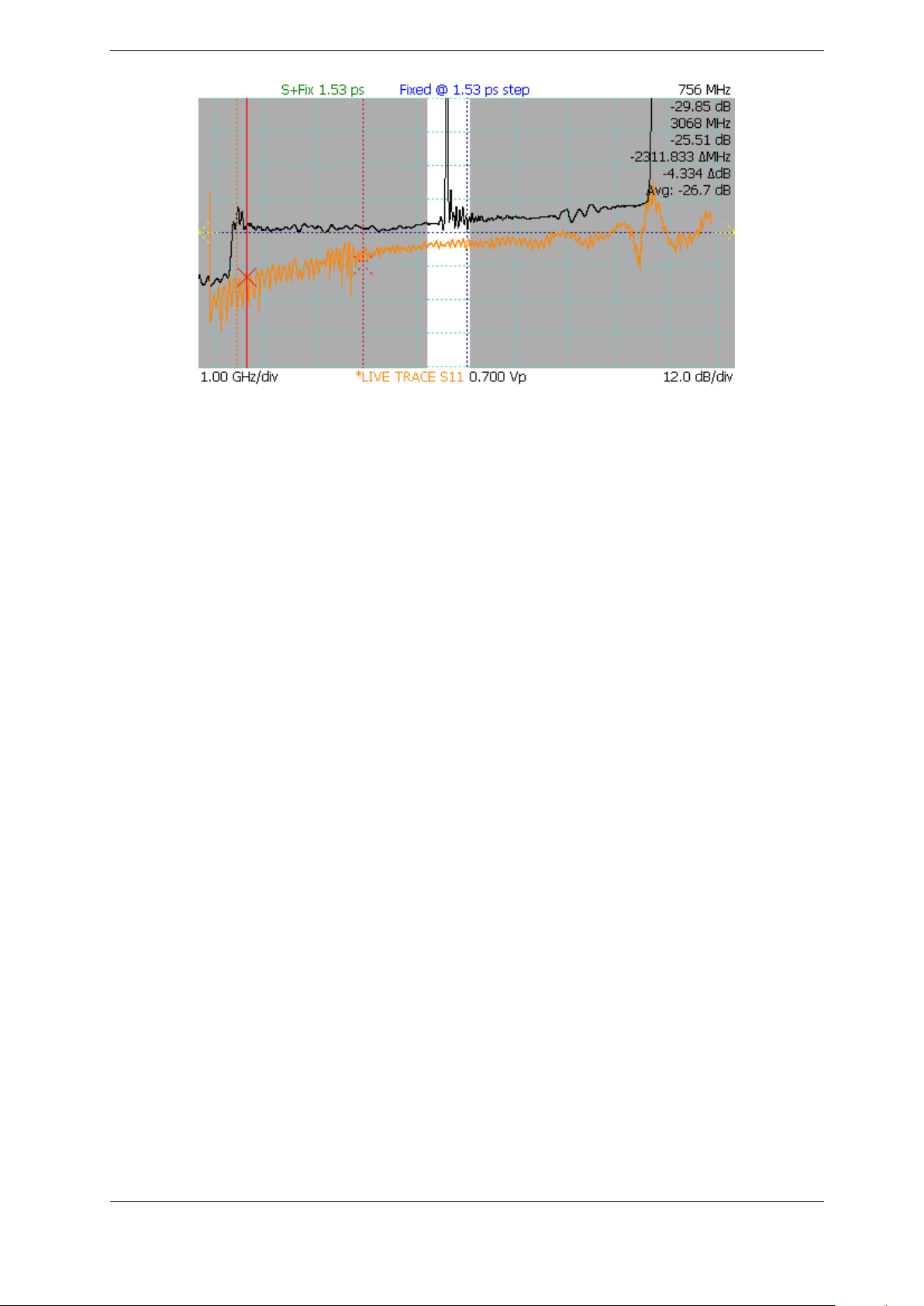

3.37. Using a phase stable cable to improve S-parameter measurements . . . . . . . . . . 55

3.38. Smith chart representation of open fault . . . . . . . . . . . . . . . . . . . . . . . . 55

3.39. Smith chart representation of short fault . . . . . . . . . . . . . . . . . . . . . . . . 56

3.40. Smith chart representation of a 50 ohm resistive load . . . . . . . . . . . . . . . . . 56

3.41. Smith chart of reactive 200 ohm load . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.42. Normalized trace showing short fault in a 50 ohm cable. . . . . . . . . . . . . . . . 57

CT100B TDR Cable Analyzers Operator’s Manual xiii

List of Figures

3.43. TDR trace with impedance vertical units demonstrating vertical scale in ohms . . 58

3.44. Example layer peeling trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

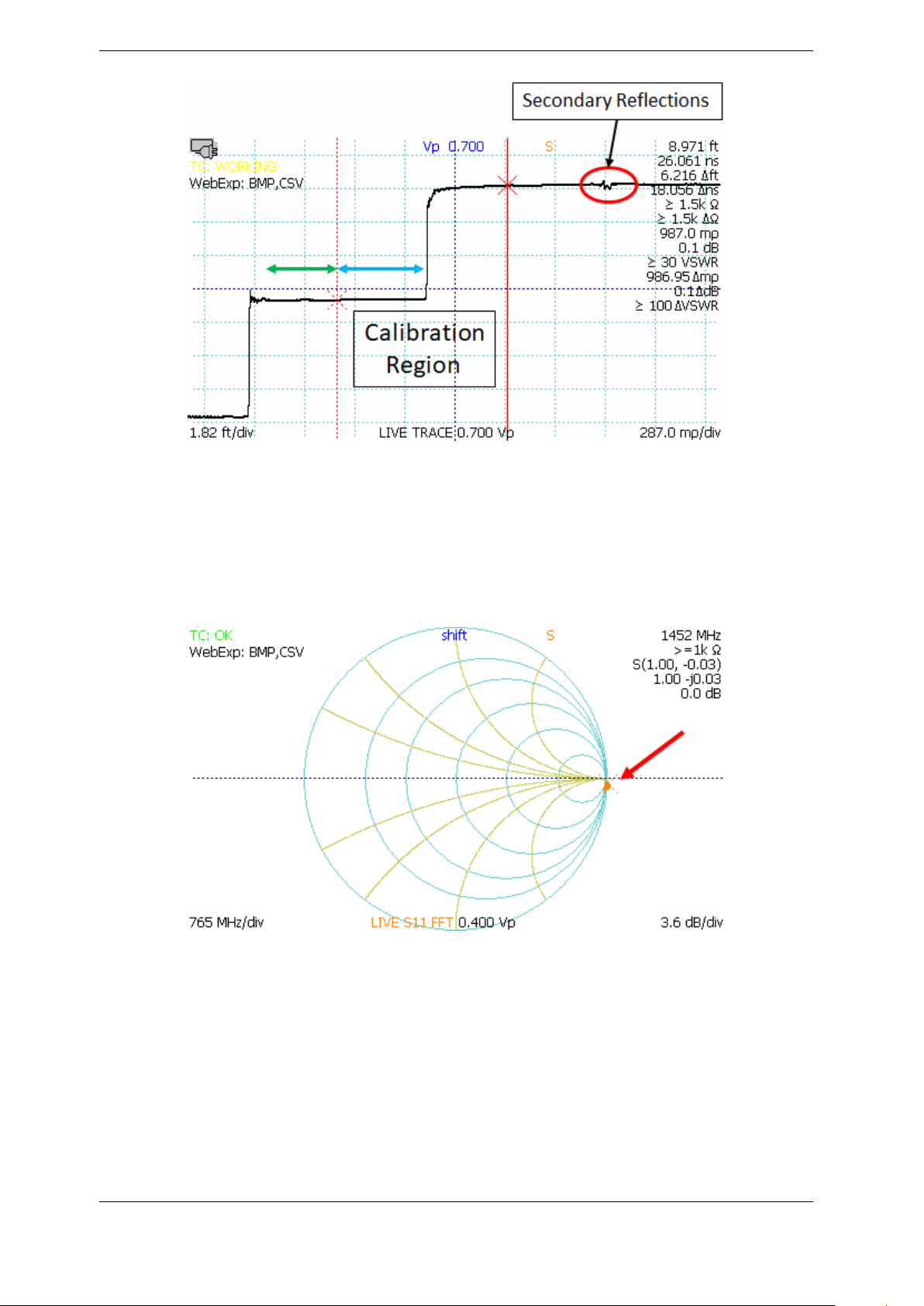

4.1. Options under the Connect to CT Viewer menu. . . . . . . . . . . . . . . . . . . . 65

4.2. Selecting Manual Connect in the Connect to CT Viewer menu will bring up a server

menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

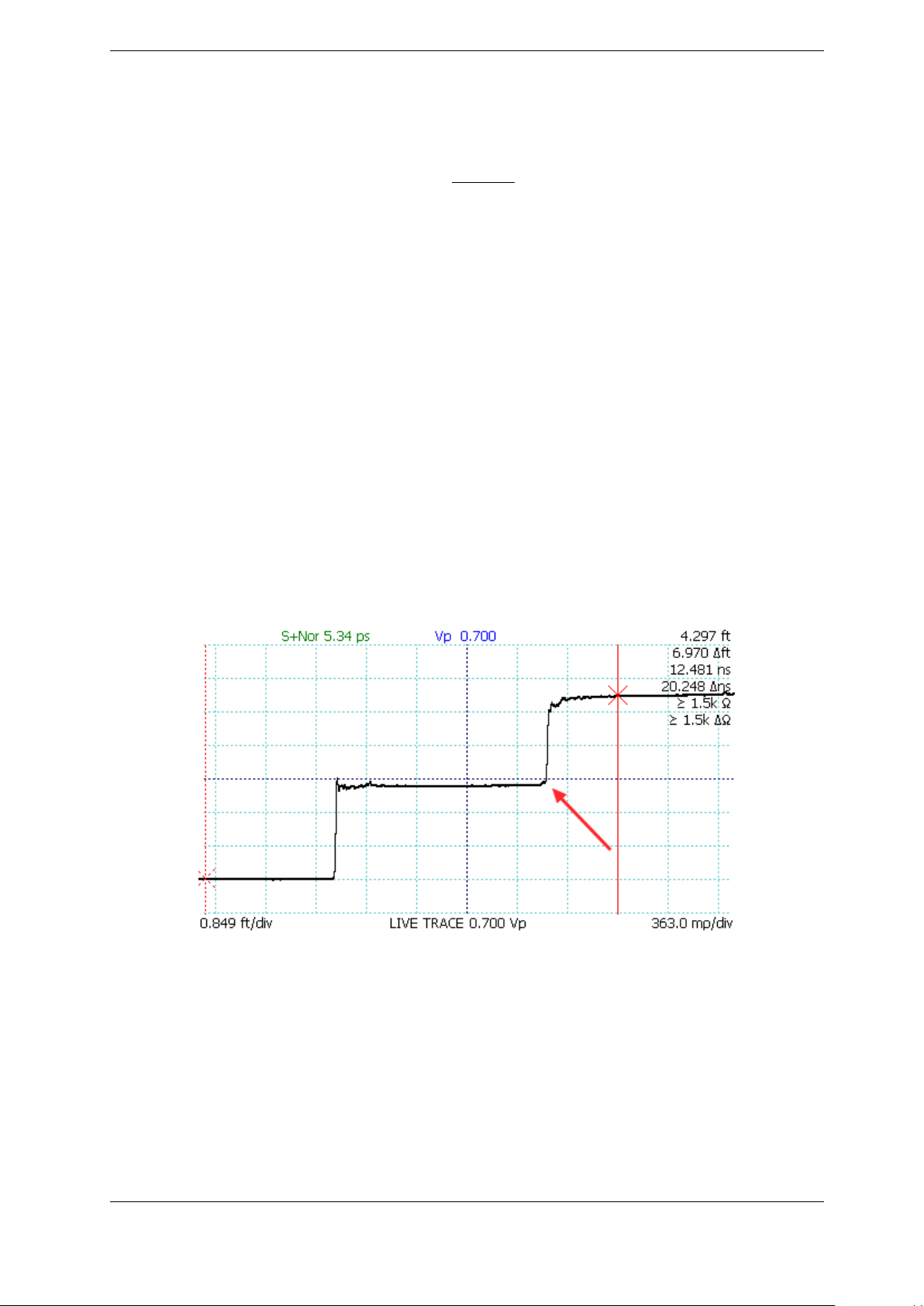

5.1. An open cable fault shows an upward step edge at the location of the fault. . . . . 68

5.2. A short cable fault shows a downward step edge at the location of the fault. . . . . 69

5.3. An open cable fault at 824 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

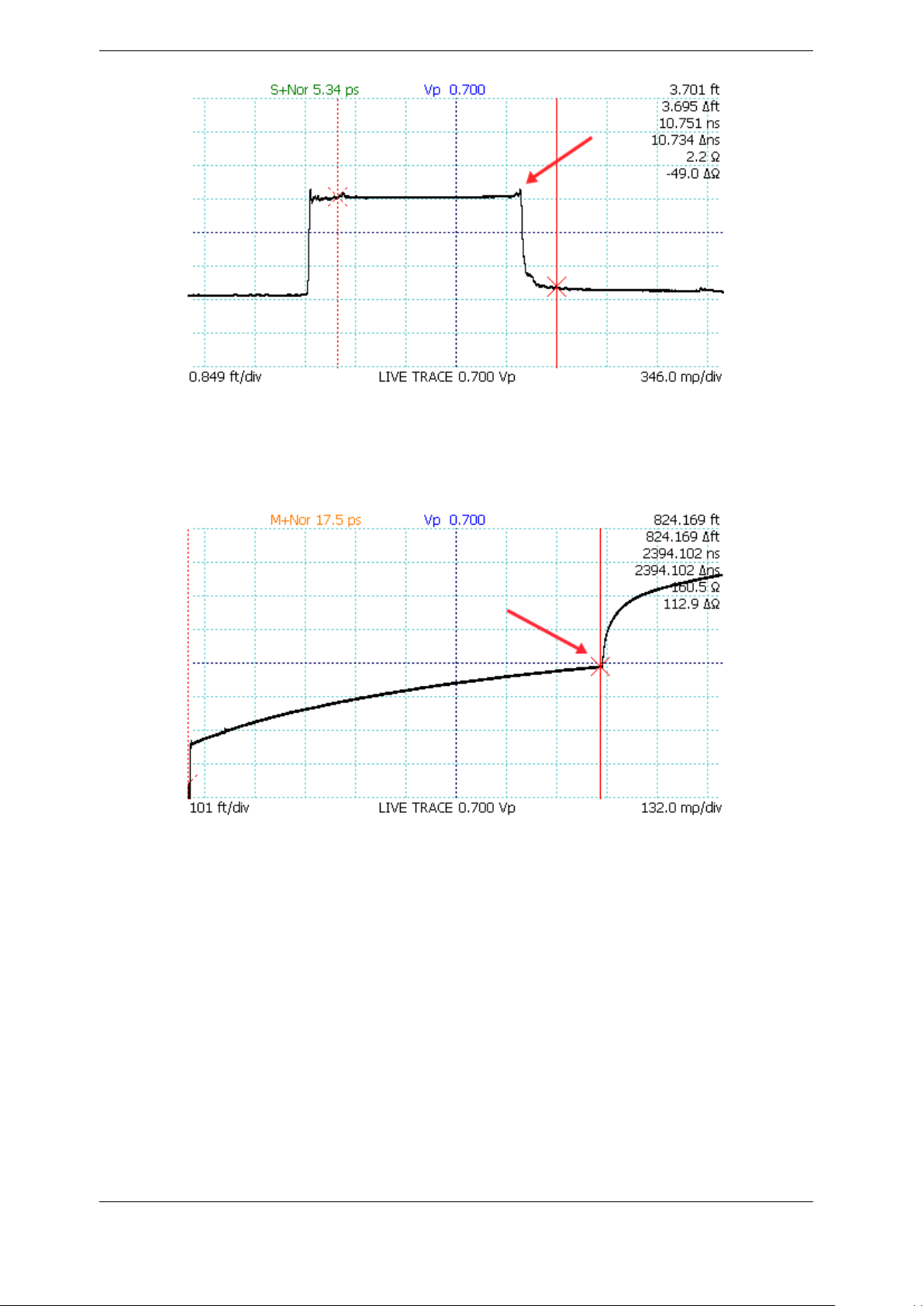

5.4. Normal SMA female barrel interconnect measuring 52.1 ohms. . . . . . . . . . . . 70

5.5. Comparison of typical SMA and BNC coaxial cable interconnects. . . . . . . . . . 70

5.6. Relationship of impedance to reflection coefficient . . . . . . . . . . . . . . . . . . . 72

5.7. Relationship of return loss to reflection coefficient. . . . . . . . . . . . . . . . . . . 73

5.8. Relationship of voltage standing wave ratio to reflection coefficient. . . . . . . . . . 74

5.9. Simulated comparison of a 90 ps rise time TDR and an 800 ps TDR . . . . . . . . 75

5.10. Comparison of S11return loss of a 2.4 GHz WiFi patch antenna. . . . . . . . . . . 77

5.11. Impedance Smith chart relationships. . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.12. Layer peeling scattering diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

xiv CT100B TDR Cable Analyzers Operator’s Manual

List of Tables

3.1. SCAN Button and Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2. Math Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3. FILE Button and Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4. MENU Button and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

B.1. Required Performance Check Equipment for CT100B . . . . . . . . . . . . . . . . . 87

B.2. Required Performance Check Equipment for CT100HF and CT100B with SMA

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

C.1. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

E.1. Vp of Common Dielectric Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

E.2. Vp of RG Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

E.3. Vp of MIL-C-17 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

E.4. Vp of Commercial Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

E.5. Vp of Twisted Pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

CT100B TDR Cable Analyzers Operator’s Manual xv

1. General Information

1.1. Product Description

The MOHR CT100B TDR Metallic Cable Analyzer uses a form of closed-circuit radar known as

time-domain reflectometry (TDR) to test cables for defects or “faults”. The instrument applies a

fast rise time broadband step signal to the cable under test and then measures the reflected

voltage at very short time intervals. The resultant TDR trace allows the operator to identify

changes in impedance along the length of the cable indicating the presence of faults such as

opens, shorts, kinks, defects in the shield or conductor, foreign substances such as water,

thermal damage, among others. The CT100B provides sophisticated signal processing software

that lets users analyze the frequency-domain characteristics of the TDR trace, replacing a

handheld vector network analyzer (VNA) or frequency domain reflectometer (FDR) for many

applications. With the CT100B TDR Cable Analyzer a user can detect, localize, and

characterize almost any cable fault in both the time and frequency domains.

Please note that with the release of the CT100B, the CT100HF instrument has been updated

with the CT100B hardware, firmware, and software improvements. Any reference to the

CT100B in this manual also applies to the CT100HF unless specifically stated.

1.2. Power Requirements

The CT100B may be operated using either the supplied AC adapter or internal NiMH batteries

(for a minimum six hours operating time, typical use). The internal NiMH battery charges

under AC during normal operation.

The external AC power adapter (pn CT100-AC-PS) operates on 100-240V AC at 50-60 Hz and

draws a maximum current of 1.5A. Use of a grounded AC socket (US 3-prong or EU 3-prong) is

essential for safe operation of the CT100B with the included AC power adapter. Review the

Safety Summary section before operating the CT100B.

1.3. Options and Accessories

Options and accessories available for the CT100B are described in Section 6, Options and

Accessories.

CT100B TDR Cable Analyzers Operator’s Manual 1

1. General Information

1.4. Unpacking and Initial Inspection

Before opening the shipping package containing the CT100B, first inspect it for signs of damage.

If there is evidence of damage to the shipping package, notify both the shipping carrier and

MOHR.

The shipping container should contain the CT100B and standard accessories, including this

Operator’s Manual, front panel cover, external AC adapter and power cord, soft transit case,

and calibration fixture(s). If the shipping container is intact but there are missing items or if the

CT100B is damaged, defective, or does not meet operational requirements, contact a

MOHR-authorized sales representative.

1.5. Repacking for Shipment

In the event that the CT100B needs to be shipped to a MOHR-authorized service center for

repair, calibration, or other service, contact MOHR for an RMA number. Affix a label to the

outside of the shipping container indicating:

• RMA number

• name, address, phone, and email of the owner

• name of the MOHR service representative who was contacted regarding the shipment

• serial number of the instrument

• description of the problem with the instrument and/or the desired service or maintenance

Optimally, the original shipping carton and packing material should be used to repack the

CT100B for shipment. Otherwise, the following steps should be taken:

1. Place CT100B in ESD-safe (Electro Static Discharge) Bag.

2. Wrap with 3 in. of anti-static bubble wrap or non-movable foam cushioning. DO NOT

USE packaging peanuts.

3. Place in a sturdy cardboard box and fill any additional void with packaging material. DO

NOT USE packaging peanuts.

4. Include any Purchase Orders, Work Orders, or special instructions with shipment.

5. Write the RMA number on outside packaging.

2 CT100B TDR Cable Analyzers Operator’s Manual

2. Safety Summary

The safety information presented in this brief summary is only intended for operators of the

CT100B. Safety information relating to specific circumstances is present throughout this manual

and is not necessarily present in this summary. Please read this manual in its entirety before

using the CT100B and take note of safety information not included in this summary.

2.1. Terms in the Manual

WARNING: Refers to conditions or practices that could result in personal

injury or loss of life.

CAUTION: Refers to conditions or practices that could result in damage to this product or other products and in some cases could void the

Warranty.

2.2. Terms on the CT100B

2.2.1. DANGER

Indicates an injury hazard immediately accessible.

2.2.2. WARNING

Indicates an injury hazard not immediately accessible.

2.2.3. CAUTION

Indicates a hazard to property including the product.

CT100B TDR Cable Analyzers Operator’s Manual 3

2. Safety Summary

2.3. Symbols in the Manual

2.4. Symbols on the CT100B

2.5. Static Charge

Any cable or wire can carry a significant static electric charge that could damage the sensitive

internal electronics of the CT100B. For this reason, it is essential to discharge the electrical

conductors of any cable or device-under-test (DUT) by shorting them to each other or to earth

ground before connection is made to the CT100B’s sampling circuitry.

CT100B instruments supplied with a front panel BNC test port are equipped with a built-in

internal self-grounding connection that briefly shorts the conductors of the DUT to each other,

dissipating stored charge, before completing the connection to the CT100B’s sensitive internal

sampling circuitry. For this reason, the last cable connection should always be made to the

CT100B test port. For example, if the DUT is a cable assembly, all internal connections within

the cable assembly should be made before connection is made to the CT100B BNC test port.

This ensures that all stored charge in the DUT is discharged during the connection to the

CT100B BNC test port.

Sometimes it is convenient to insert a patch cable between the CT100B BNC test port and the

DUT. In this case, it is recommended that all cable connections, including the connection of the

patch cable to the DUT, be made before connecting the patch cable to the CT100B BNC test

port. Otherwise, the BNC test port self-grounding safety feature is circumvented.

If for some reason the last connection cannot be made at the CT100B test port, then the

conductors of the DUT should be discharged (shorted) manually using an industry-standard

shorting cap termination or equivalent direct electrical connection.

Note that CT100B instruments equipped with SMA or other front panel test ports do not have

internal self-grounding protection. Therefore, when using these instruments, the conductors of

the cable under test/DUT should always be shorted to each other or to earth ground prior to

connection to the CT100B’s test port.

4 CT100B TDR Cable Analyzers Operator’s Manual

2. Safety Summary

CAUTION: Failure to properly ground the cable/device under test prior

to connecting it to the front panel connector, either directly or indirectly,

could result in damage to the sampling electronics and will void the Warranty.

2.6. Fuses

There are no external fuses or breakers accessible to the user. However, there are two internal

automatic thermal breakers that disconnect the power from the charger and battery to the rest

of the system. These thermal breakers make an audible click when they actuate, and the

CT100B turns off. One of the circuit breakers automatically resets after time. When this

breaker cools, the CT100B can be restarted, but the CT100B should be serviced by qualified

personnel. There is also an internal breaker on the power board. If tripped, this breaker must

be reset manually and the instrument should be serviced by qualified personnel.

CAUTION: If the thermal breakers trip, the instrument should be evaluated by qualified service personnel for maintenance.

2.7. AC Power Source

The CT100B is intended to operate only from a 120 VAC or 240 VAC RMS power source using

the CE- and UL-approved 24 VDC external power supply/adapter (pn: CT100-AC-PS)

provided with the instrument.

WARNING: Only use the power cord supplied with the instrument, and

then only if the cord is in good condition. Refer all maintenance regarding

the power supply or power cord to qualified service personnel.

CAUTION: Use of any power source other than the supplied external

power adapter(s) could damage the instrument and may void the Warranty. Use only MOHR-approved accessories.

WARNING: To reduce the risk of electric shock, disconnect all external

cables before connecting the 24 VDC external power supply.

CT100B TDR Cable Analyzers Operator’s Manual 5

2. Safety Summary

2.8. Grounding the CT100B

When the CT100B is connected to the external AC adapter, the CT100B chassis, front panel

USB, screen, and controls are grounded through the grounding conductor of the power cord. To

avoid electrical shock, it is essential that the protective ground connection is present when

operating the unit under AC power. When disconnected from external power, the CT100B is

floating relative to earth ground, unless one of the USB ports is connected to a grounded device.

In this case, the ground of the USB device is common with the CT100B chassis, screen, and

electronic controls. An isolated ground power supply is an optional accessory available upon

request.

At all times, the front panel BNC or SMA connector is floating and is isolated by at least 500

VDC from the remainder of the CT100B. This eliminates measurement errors caused by

common-mode noise and slight ground-potential differences in the cable/device under test.

However, care should be taken with respect to electrical safety, as the front panel BNC or SMA

shield is never safely grounded unless connected to a safely grounded cable or device and can be

considered a second live conductor if connected to a cable or device carrying a non-zero

electrical potential relative to earth ground. This situation carries the risk of electric shock.

WARNING: The BNC or SMA connector shield represents a floating

ground and is never safely grounded even with the use of a properly

grounded AC adapter. Never use the CT100B to test any cable or device carrying a non-zero electrical potential relative to earth ground, as

this could render an electric shock.

2.9. Danger Arising From Loss of Ground

When disconnected from the AC power adapter, the CT100B is no longer grounded unless

connected to a grounded USB device at the front panel host USB port. Because the test port

connector shield is floating relative to the remainder of the instrument, the test port connector

may be operating at an elevated voltage even when the AC adapter is connected. Therefore, the

test port connector should never be used to test any cable or device with an electrical potential

relative to earth.

WARNING: Upon loss of the protective-ground connection, all accessible

parts, including the screen, knobs, and connectors, can render an electric

shock.

2.10. Explosive Atmospheres

Do not operate the CT100B in an explosive atmosphere unless your unit has been specifically

certified for that condition. Explosive Atmospheres: MIL-STD 810G, Method 511.5, Procedure I

(+55◦C, sea level to 4600 m).

6 CT100B TDR Cable Analyzers Operator’s Manual

2. Safety Summary

2.11. Do Not Remove Covers or Panels

To avoid personal injury and risk of electric shock, do not open the CT100B case unless

replacing the battery and do not operate unless the case is fully intact.

WARNING: Disconnect power, USB, Ethernet, and test cables prior to

opening the CT100B case to replace the battery. Failure to do so can

render an electric shock.

2.12. Connecting Cables to the Test Port

To avoid damage to the CT100B and the very sensitive sampling electronics associated with the

front panel BNC or SMA connector, do not connect it to any cable or device that can be driven

by active circuitry or is subject to transient voltage spikes.

WARNING and CAUTION: The instrument should never be used to test

any cable or device carrying live electrical signals, as this carries a risk of

electric shock. This could also damage the sampling electronics and will

void the Warranty.

CAUTION: Always properly ground the conductor(s) of any cable or

wiring to remove any static charge prior to connecting it, either directly

or indirectly through attachment to another cable, to the CT100B’s front

panel test port connector. Failure to do so can damage the instrument’s

sensitive sampling electronics and will void the Warranty.

2.13. Battery Replacement and Disposal

The CT100B contains an internal battery pack. The internal battery pack is 2700 mAh, NiMH,

12 AA cells, 14.40 volts, 38.88 Wh. There is also a 120 mAh lithium button cell of 2.8 volts and

0.336 Wh. Depending on the state or local jurisdiction, these batteries may require special

disposal and/or recycling. Contact your local authorities for safe disposal in your area, or you

may return them to MOHR for recycling.

WARNING: The battery pack must be replaced with MOHR pn: CT100AC-B2700. Use of any other battery pack will damage the instrument and

pose a danger of fire.

CAUTION: User replacement of components is limited. Multiple warranty seals are installed on components within the CT100B. Removal or

damage of these seals voids warranty.

CT100B TDR Cable Analyzers Operator’s Manual 7

3. Operating Instructions

3.1. Overview

If you would like a detailed explanation of TDR measurement theory and applications before

using the CT100B, please read Section 5, TDR Measurement Theory.

3.1.1. Handling

The CT100B is designed to meet the rigors associated with normal instrument use both in the

field and on the benchtop. Care should be taken to protect it from excessive mechanical shock,

vibration, static electrical charges, and water hazards.

The CT100B front panel is protected from impact by a snap-on front cover. The carrying

handle rotates 360° and can be used to support the instrument for bench-top use.

The CT100B is not watertight and must be protected against water spray. If the unit is

subjected to water spray, first turn off the unit with the battery-disconnect power switch on the

rear panel and then drain all of the excess water from the case and allow it to dry completely.

As noted in the Safety Summary and elsewhere, the CT100B is sensitive to damage introduced

by electrostatic discharge. Always properly ground the conductors of a cable to each other or to

earth ground before attaching it, either directly or indirectly, to the front panel BNC, SMA, or

other test port. Failure to do so could damage the sampling electronics and void the Warranty.

The CT100B can be stored in temperatures of between -20°C to +60°C with or without a

battery installed and can be operated from 0°C to +50°C.

3.1.2. Powering the CT100B

The CT100B can be powered through the included 120/240 VAC (RMS) to 24 VDC external

power adapter. This adapter has sufficient capacity to charge the internal battery from a dead

battery state while the unit is under operation. The internal battery will allow the unit to

operate using power conservation techniques for periods of at least 6 hours under typical use.

Automatic power-down occurs after a variable amount of time of inactivity, selectable in

software by the user. The screen also can be set to turn off after a set amount of inactivity. A

heavily discharged battery will require 4 hours to reach full charge.

Fusing is internal and based on thermal reset switches and a manual-reset breaker. If one of

these fuses trips, it may indicate that a hardware malfunction has occurred and the instrument

should be evaluated by qualified personnel.

CT100B TDR Cable Analyzers Operator’s Manual 9

3. Operating Instructions

3.1.3. Caring for the Battery

The CT100B has an intelligent battery-charging circuit that dynamically determines the

optimum charge rate and reverts to low-level trickle charge when the battery is fully charged.

Charging is automatic and there are no charge-length restrictions.

The battery should be charged between 0◦C and +45◦C. Battery operation should be limited to

between 0◦C and +50◦C. Batteries should be stored between -20◦C and +60◦C. If the battery

pack is older, it may not show a 100% charge capacity even when the maximum battery charge

is obtained.

CAUTION: Do not attempt to charge the battery pack below 0◦C or above

+45◦C. Batteries should not be stored below -20◦C or above +60◦C.

3.1.4. Charging and Power Status

The CT100B operates from a 24 volt power adapter or the internal battery pack.

In the Power menu, a submenu of the Settings menu, the user can set power save and shutdown

timers. Different timeout values can be set for when the CT100B is using the AC/DC converter

or batteries. In power save mode, the screen goes blank and only enough power is used to

monitor for user input. When input is received, the CT100B resumes normal operation. When

the shutdown timer expires, the CT100B will turn off.

A battery indicator can be toggled on or off with the Power Display menu option in the Power

menu. The indicator will show the level of charge in the battery. It will also show if the 24 volt

adapter is attached and providing power.

3.1.5. Batteries and Long-Term Storage

The CT100B has NiMH internal batteries. These batteries will drain if the CT100B is left in

storage over long periods. To preserve battery charge for as long as possible during storage,

make sure the power switch on the back of the CT100B is set to the OFF position. After several

months of storage, the internal batteries may be completely drained. Allow up to 4 hours for the

first recharge of the CT100B after coming out of long-term storage.

3.1.6. Low Battery

When a low battery condition is first encountered, the CT100B alerts the user. Internal

Battery Low text appears on-screen in red when the battery percentage left drops below 20

percent.

10 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

3.1.7. Nameplate

The CT100B has a nameplate label affixed on the back of the case. See Figure 3.3 for

positioning. The nameplate includes Cage Code, Model Number, Serial Number, NSN, a

warranty expiration date, electrical input information, and a 2D barcode containing the

identifying information. See Figure 3.1 for an example nameplate label.

Figure 3.1. Example nameplate label found on back of a CT100B.

3.1.8. Discharge Warning Label

The CT100B has a warning label above the test port on the front of the instrument. This label

warns the user to discharge any cable or device before connecting it to the test port.

See Figure 3.2 for location and contents of the label.

3.2. License Codes

Each CT100B requires a unique license code to operate. Without the correct code, menus and

buttons still function, but there will be no live trace displayed on the screen. The correct code

for a particular device can be requested from MOHR. Installation instructions will be included

with the license code.

Depending on how it was purchased, the instrument may be supplied with either a 30-day

demonstration license or permanent license. Current license information can be found by

pushing the blue MENU button and navigating to Settings → Info → License → License Info.

A dialog showing license date and active features will appear. When the CT100B has a

permanent license installed, appropriate options will be active. When the instrument has a

demonstration license, the dialog will show a future license date and the instrument will provide

appropriate warnings to the user as the expiration date gets closer. If your CT100B has a

license with pending expiration and you are unsure how to upgrade to a permanent license,

please contact MOHR.

3.3. Preparing to Use the CT100B

Before using the CT100B, make sure you have read and understand the Safety Summary section

and power requirements described in Section 3.1.2 through Section 3.1.6. If you would like a

detailed explanation of TDR measurement theory and applications before using the CT100B to

test cables, please read Section 5, TDR Measurement Theory.

CT100B TDR Cable Analyzers Operator’s Manual 11

3. Operating Instructions

Otherwise, remove the front cover and turn on the power. You are ready to test cables using the

most versatile and sophisticated portable TDR instrument on the market.

3.4. Front Panel Controls and Connectors

The following numbered items describe the controls and connectors identified in the front panel

diagram (Figure 3.2) and described in the text below.

Figure 3.2. Diagram of the CT100B front panel.

1. POWER (red) button. Pressing this button turns the instrument on when the main

power switch on the rear panel is in the ON position. Pressing the POWER button when

the unit is on will turn the unit off after verification that you really wish to power down. If

the POWER button is held in for several seconds, the unit will turn off regardless.

2. H1 function button. Function depends on menu.

3. H2 function button. Function depends on menu.

4. H3 function button. Function depends on menu.

5. H4 function button. Function depends on menu.

6. MENU (blue) button. Push to display the top-level menu screen. If a menu is already on

the screen, this button will clear the menu. The previous menu will be displayed. This

button also activates on-screen help when held down while pressing other buttons.

7. VERTICAL POSITION knob. Controls the vertical position of the currently selected

trace. Trace selection is controlled by the SELECT button (14).

8. VERTICAL SCALE knob. Controls the vertical scale, which is displayed on the bottom of

the screen. This control modifies the appearance of the currently selected trace. The scale

is expanded about the vertical center of the screen.

9. HORIZONTAL POSITION knob. Controls the horizontal position of the active cursor.

Displayed trace positions are moved horizontally if the cursor is moved toward the edge of

the screen to keep the cursor on-screen.

10. HORIZONTAL SCALE knob. Controls the horizontal scale of displayed traces. The scale

is expanded about the active cursor.

12 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

11. BNC or SMA test port. This connects to the cable to be tested. Be sure to properly

ground the cable before connecting it to test port in order to prevent electrostatic damage

to the CT100B’s sensitive sampling circuitry.

CAUTION: All static charge must be drained from the cable to be tested

prior to connecting to the test port (11). This is done by shorting the cable

center conductor to the cable sheath/ground return. If this procedure is

not fol lowed, the sampling electronics can be damaged and will void the

Warranty.

12. Host USB port. This USB (V1.1) connection can be used to interface to a client USB

device such as a barcode reader, keyboard, or flash drive.

13. FILE button. Opens the File menu, which contains a database of user configurations,

saved cable records (scans), and a Vp database for known cable types.

14. SELECT button. Used to select between traces on the screen. It has no effect if there are

no other traces. Note: When the SELECT button is held down, press the M-FUNC

button. The CT100B will generate a screenshot that can be saved to a USB drive.

15. CURSOR button. This button is used to toggle between the two available cursors.

Pressing and holding the CURSOR button for one second and then releasing the button

will bring both cursors onto the screen.

16. SCAN button. Displays a specialized soft-menu that brings up the Scan menu.

17. AUTOFIT/HELP (orange) button. Opens the on-screen help library along with Autofit

soft-menu options.

18. M-FUNC (multifunction) button. The function of the M-FUNCTION knob (19) is set by

this button. The current operation is displayed on the screen (top-center).

19. M-FUNCTION (multifunction) knob. This knob adopts the function selected through the

use of the M-FUNC button (18). It also allows users to scroll through dialog box options.

20. V1 function button. Function depends on menu.

21. V2 function button. Function depends on menu.

22. V3 function button. Function depends on menu.

23. V4 function button. Function depends on menu.

3.5. Rear Panel Connectors and Switches

The following numbered items describe the connectors and switches identified in the rear panel

diagram (Figure 3.3) and described in the text below.

24. 24 VDC power adapter plug. The provided 24 VDC AC adapter plugs into this port. Only

MOHR-approved positive center tip, 24V adapters may be used.

25. Client USB connection. Allows the CT100B to be connected to a host computer for data

transfer and PC control.

26. RJ-45 Ethernet port. This is a 10/100 Mb Ethernet port that can be used for data

transfer and remote PC control.

27. Power switch. This is a manual ON/OFF power switch that turns the device off and

disconnects the power from the internal electronics so the unit can be stored and/or

shipped safely.

CT100B TDR Cable Analyzers Operator’s Manual 13

3. Operating Instructions

Figure 3.3. Diagram of the rear panel of the CT100B/CT100HF.

3.6. Keyboard Alternate Controls

If a keyboard is plugged into the front panel USB port, alternate hotkey controls are available

for all front panel buttons and knobs.

1. F1-F4 map to H1-H4.

2. F5-F8 map to V1-V4.

3. F9 maps to the blue MENU button.

4. F10-F12 map to the M-FUNC, SCAN, and SELECT buttons.

5. Shift F10-F12 map to AUTOFIT/HELP, CURSOR, and FILE.

6. Vertical arrow keys adjust the VERTICAL POSITION knob.

7. Horizontal arrow keys adjust the HORIZONTAL POSITION knob.

8. Shift vertical arrow keys adjust the VERTICAL SCALE knob.

9. Shift horizontal arrow keys adjust the HORIZONTAL SCALE knob.

10. Shift F7 rotates the M-FUNCTION knob counter-clockwise.

11. Shift F8 rotates the M-FUNCTION knob clockwise.

Note: Some functions may require multiple button pushes to take effect.

3.7. Setting up the CT100B

3.7.1. Setting Date and Time

The date, time, and time zone must be accurately set for saved data in the CT100B to be

correctly time-stamped.

1. Change the date and time by pressing the MENU button. This calls up the Main menu.

2. Select the Settings soft-menu option and then select the Info menu.

3. Select the Time menu option. The Time menu appears.

4. Select the Set Time Zone menu option. A dialog box listing all time zones appears on the

screen.

5. Use the M-FUNCTION knob to scroll through the list of time zones. Highlight the correct

time zone.

14 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

6. Choose the Select menu option. The CT100B may prompt you to restart. If so, restart the

unit and return to the Time menu. The CT100B is now set to the correct time zone.

7. Ensure the menu option for daylight savings reads Daylight Savings On, indicating that

this setting is on. If the option reads Daylight Savings Off, then press the menu button to

toggle it. The CT100B may prompt you to restart. If so, restart the unit and return to

the Time menu. The CT100B will automatically adjust for daylight savings on the correct

dates.

8. Select the Time/Date menu option. A dialog box used to set the date and time appears.

See Section 3.7.2 for methods of navigating and entering data into a dialog box.

9. Press the OK menu option when the correct time and date have been entered.

3.7.2. Navigating Dialog Boxes

For an example of a dialog box with multiple entries, press the blue MENU button, then

Settings, then Info, then Time, and then Time/Date. Scroll through the different entry boxes

with the M-FUNCTION knob. With an entry box selected, press the Show Keyboard menu

option to call up an on-screen keyboard.

With the on-screen keyboard chosen, select the desired characters with the M-FUNCTION

knob, pressing the Select Highlighted menu option for each one. Get more character options by

selecting the Shift menu option. Delete the character before the cursor with the Backspace menu

option.

With the keyboard open, accept the current entry with the Hide Keyboard menu option or

revert to the original entry with the Cancel menu option. Both options remove the on-screen

keyboard from the screen.

With the keyboard off the screen, select the OK menu option to accept all changes to the

current dialog box and close the dialog box. Select the Cancel menu option to close the dialog

box while canceling all changes.

With a USB keyboard attached, entries can be changed directly. Use the Tab key to scroll down

through entry boxes and hold down Shift and press Tab to scroll up through entry boxes. Use

Backspace to delete the character before the cursor and use the arrow keys to move the cursor

left or right. Press Enter for OK or Escape for Cancel.

3.7.2.1. Scrolling Dialog Boxes

Some dialog boxes present a list of items to be selected. For an example of this type of dialog

box, press the FILE button, and then press Cable Scan Records (see 3.11.8 and Figure 3.23).

Use the M-FUNCTION knob to highlight individual items for selection, and then use the Select

option to choose the highlighted item. Where appropriate, multiple items can be marked for

selection using the options on the right-side menu: Toggle Selected, Clear All, and Mark All.

When an individual item is marked, it will appear in a different color.

3.8. Display Features

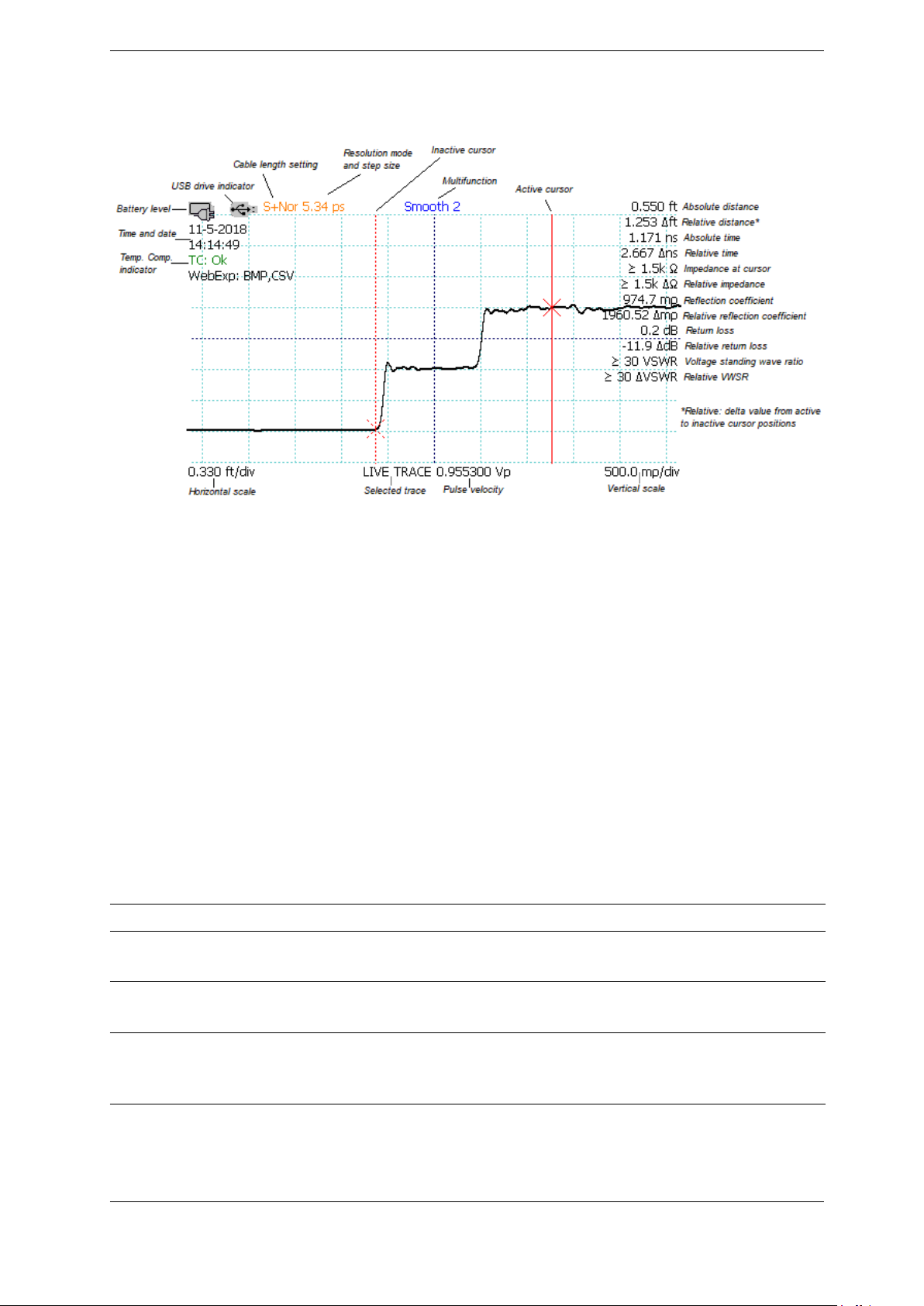

The CT100B screen provides the operator with numerous features that may be useful in

different cable testing situations. Figure 3.4 shows some of the typical features you will

CT100B TDR Cable Analyzers Operator’s Manual 15

3. Operating Instructions

encounter during use. Many other features are available, however, and most of them are

configurable by the user. These features are described in detail in the following sections.

Figure 3.4. Screenshot showing typical features of the CT100B.

3.9. Menu Selections and Function Buttons

3.9.1. M-FUNC Button

The M-FUNC button is used to switch between functions Shift, Smooth, and Vp (and

Fine/Coarse Vp) shown in the Multifunction indicator at the top of the display screen.

3.9.2. SCAN Button Menu

The SCAN button displays menu selections associated with saving and managing TDR traces

and cable scan records. SCAN menu selections are shown in Table 3.1.

Table 3.1. SCAN Button and Menu.

Menu Selection Purpose/Action

Save/Rename Saves selected trace to internal storage. Renames

previously saved traces.

Show Sel. Trace Only Turns all traces invisible except the currently

selected trace. Select again to set all traces visible.

Hide All Traces Hides all traces except the live trace. (If traces were

previously saved, they can be recalled from the FILE

menu; see Section 3.9.6)

16 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.1 (Continued) SCAN Button and Menu.

Menu Selection Purpose/Action

Hide Selected Trace Hides the selected trace. (If trace was previously

saved, it can be recalled from the FILE menu; see

Section 3.9.6)

Start Scan Initiates cable scan.

Cursor/Snapshot Switches between scan modes:

Cursor ........................... Creates a new scan of the portion of trace between

cursors using the current resolution and smooth

settings.

Snapshot ......................... Saves trace as currently displayed on screen.

Math See Table 3.2: Math Menu.

Table 3.2. Math Menu

Menu Selection Purpose/Action

FFT Tools

FFT Settings

Window Sets window type (Hann, Hamming, etc.).

size FFT buffer size.

Frequency Cut-Off Range FFT display frequency cut-off.

Hide Selected Trace Hides the selected trace.

Apply FFT Creates FFT trace from selected trace data.

View Live FFT Creates live FFT trace from live TDR trace.

Apply VSWR Creates VSWR (voltage standing wave ratio) trace

from a selected complex division or S11trace.

Set Base Sets base trace for complex FFT trace division.

Complex Division Creates complex division FFT: Divides selected FFT

by base FFT. Equivalent to uncalibrated S11trace

when base FFT is of a shorted test port.

Phase Creates phase angle trace from selected FFT trace.

Smith Chart Toggle Smith Chart display for selected complex

division FFT or S11trace.

SParam & Normalize Tools

S11Calibration Performs Open-Short-Load S11calibration and

creates S11trace.

Normalize Pulse Rise Time Sets the rise time to apply to the selected normalized

trace.

S11Options

CT100B TDR Cable Analyzers Operator’s Manual 17

3. Operating Instructions

Table 3.2 (Continued) Math Menu

Menu Selection Purpose/Action

Pre-Filter Options Changes the filter options that smooth the

aberrations of the base traces.

Post-Filter Options Changes the filter options that limit the noise of the

base traces.

Other S11Options

OSL Bases Visible When enabled, causes the Open, Short, and Load

traces to not appear on-screen. Helps eliminate

excess on-screen clutter.

Align Base Traces When enabled, the Open, Short, Load, and DUT

traces may be aligned to each other based on the

common part of the beginning of the trace.

Calibration Standards Brings up a table of Calibration Standard Kits

Coefficients. There is the option to change and apply

the standards.

S11→ USB (.csv) Creates a CSV (Comma Separated Value) file of the

selected S11trace and outputs that file to a

connected USB drive.

Phase Corr. Off/On Toggles the Phase Correction On/Off.

Phase Corr. Start Using the active time-domain cursor, sets a new

start point for the Phase Correction.

Between Cursor Off/On /Hold Toggle S11Between Cursors mode:

Off............................ Between Cursors Off.

On............................. Between Cursors On – the active section will adjust

with time-domain cursor movement.

Hold .......................... Between Cursors Hold – the active section will

remain regardless of cursor movement.

Hide Selected Trace Hides the selected trace.

Reapply S

11

Adjusts the time-domain settings to match those

used for the selected live S11trace.

Apply Normalization Create normalized TDR trace based on the selected

S11trace.

Cable Loss Changes selected S11trace to Cable Loss

(S21/insertion loss) trace. Terminate cable with

precision short adapter for meaningful results.

Smith Chart Toggle Smith Chart display for selected complex

division FFT or S11trace.

Layer Peeling Create layer peeling trace from selected trace.

Assumes active cursor (layer peel start) is set at 50

ohms.

Hide Selected Trace Hides the selected trace.

18 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.2 (Continued) Math Menu

Menu Selection Purpose/Action

Set Base Sets selected trace as the base (denominator) trace

for math operations.

Difference Creates subtraction trace from selected trace and

base trace (Difference = Selected – Base).

1st Derivative Creates first derivative trace from selected trace.

Der. Smooth Off/On Toggles first derivative trace smoothing.

3.9.3. SELECT Button

The SELECT button switches which trace on-screen is the active trace. See Section 3.11.6 for

more information on selected traces.

3.9.4. AUTOFIT/HELP Button

The AUTOFIT/HELP button calls up the online help library and AUTOFIT soft-menu

options. Use the M-FUNCTION knob and Select menu option to scroll through and select the

help library content. When you select the AUTOFIT menu option, the CT100B looks for the

TDR signature of an open or short-terminated cable and selects appropriate horizontal and

vertical scale values to display the entire cable on the screen. By default the cursors are

positioned approximately to the beginning and end of the cable.

If Vertical Recenter is selected then only vertical scale and position are affected.

3.9.5. CURSOR Button

Toggles between cursors, making the active cursor inactive and the inactive cursor active.

Pressing and holding the CURSOR button for one second then releasing will reposition any

cursors not visible on the screen to the screen.

3.9.6. FILE Button and Menu

Use this menu to access the user library of configurations, cable types, and cable records. FILE

button menu selections are shown in Table 3.3.

Table 3.3. FILE Button and Menu

Menu Selection Purpose/Action

Custom Cable Types Use to add, select, or delete an entry from the

custom cable type library:

Add New .......................... Enter in new cable type information.

Delete............................ Delete selected cable type from the library.

Select............................ Select the highlighted custom cable type. Instrument

settings change to reflect the cable Vp setting.

CT100B TDR Cable Analyzers Operator’s Manual 19

3. Operating Instructions

Table 3.3 (Continued) File Menu

Menu Selection Purpose/Action

Reference Cable Types Use to select a built-in cable type from the standard

cable type library. Instrument settings change to

reflect the cable Vp setting.

Cable Scan Records Use to select, delete, or USB save a previously saved

TDR trace. (See Section 3.11.8 for more.)

Config Entries Use to add, select, or delete an entry from the user

configuration library.

Export CSV → USB Export selected TDR trace as a CSV file to USB

drive.

Save Scan Saves selected trace to internal storage.

Masks

Create Mask From Trace Generates mask or test limit based on the selected

trace.

Change Vertical Margin Adjusts vertical pass/fail criteria of the mask.

Change Horizontal Margin Adjusts the horizontal pass/fail criteria of the mask.

Clear Mask Removes the current mask from the display.

Masks Use to add, select, or delete a mask from the mask

library.

Print Screen Prints directly to a PCL3 compatible printer via

USB.

3.9.7. “Blue” MENU Button and Top-Level Menu

If no menu is displayed, the blue MENU button loads the main top-level menu. If the top-level

menu is displayed, it closes the menu. If a submenu is displayed, it displays the parent menu.

Top-level menu selections are listed below in Table 3.4. Holding down the MENU button while

pressing any button (or the M-FUNCTION knob) will display a help dialog for that button’s

current menu selection (known as “blue button help”).

Table 3.4. MENU Button and Menus

Menu Selection Purpose/Action

Cable Len Adjust the pulse timing for different length cables:

Short............................. For cables of up to approximately* 300 ft. (90 m)

long.

Medium............................ For cables up to 1500 ft. (450 m) long.

Long.............................. For cables up to 6,000 ft. (1,800 m) long.

[Note: Access Extra Long mode in the

Measurement submenu. Use Extra Long mode for

cables over a mile (2 km) in length.]

*The exact length will depend on the Vp setting.

20 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Resolution Sets TDR trace horizontal sampling resolution (in

picoseconds):

Normal............................ A setting suitable for connector level detail for each

of the cable length modes. Short is nominally 5.32 ps

(< 1 mm). Medium is nominally 17.5 ps (~2 mm).

Long is nominally 49.6 ps (~1/2 inch). Extra Long is

nominally 381 ps (~2 inches). The actual setting is

dependent on horizontal scale, but will be at least as

good as the nominal value. If the user adjusts the

Horizontal Scale to zoom in to a very short section of

cable, the resolution setting will automatically adjust

to a finer scale. Multiple measurements may map to

a single horizontal offset on the display. This allows

you to easily see flaws in the cable or connectors

even when looking at long sections (see Figure 3.10).

Screen............................ Screen resolution (1 sample/pixel) varies

dynamically with the current horizontal scale.

Fixed............................. Allows user to set a specific value no matter the

cable length setting.

File (Load/Save) Calls up the FILE button menu. Use it to add,

select, or delete an entry from the cable type, user

configuration, and/or cable record libraries.

Connect to CT Viewer

Find CT Viewer Search the local area network looking for running

CT Viewer 2 programs. If successful, it establishes a

connection.

Manual Connect A dialog with a list of PCs that have previously been

added is displayed.

Add PC.......................... Enter in new server IP information.

Edit............................ If connected to CT Viewer 2, allows user to edit PC

name.

Delete.......................... Delete selected server from the library.

Select.......................... Connect to the highlighted server.

Cancel.......................... Cancel out of the connection menu.

See Section 4: CT Viewer for instructions on

connecting the CT100B to CT Viewer 2.

Use USB Go to the PC on which you are running CT Viewer

2 and use that program to connect to the CT100B.

SParam Tools Tools for creating S-parameter traces and normalized

traces. See Return Loss (S11) Traces in

Section 3.11.17 on page 49.

Measurement

Vert. Ref.

CT100B TDR Cable Analyzers Operator’s Manual 21

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Vert. Ref Off/On Toggles VR (Vertical Reference) mode on/off.

Set Vert. Ref. Performs VR calibration using short/open

terminators. When setup is complete, a green

vertical line indicates start of VR measurements.

Vert. Ref. Center Imp. Adjusts VR calibration to use impedance matching

adapters and baluns.

Vert. Ref. Start Sets start of VR at the position of the active cursor.

Vert. Ref. End Sets end of VR at the position of the active cursor.

Cable Segments

Add New Segment Create a new segment boundary at the active cursor.

The selected segment will be split in two, each with

the same initial Vp.

Delete Segment Delete the currently selected segment. The segment

will be merged with the segment to the left.

Delete All Segments Delete all segments. The CT100B will return to

normal operation. A single Vp now applies to the

entire trace.

Prev Segment Select the segment to the left of the currently

selected segment.

Next Segment Select the segment to the right of the currently

selected segment.

Reset All Vp Reset the Vp of all segments to 1.000.

Restore All Vp Restore Vp of all segments to the previous values.

Extra Long Mode Extra Long Mode allows the CT100B to obtain

traces out to 40,000 ft. (12,000 m) (assumes

Vp=0.66). Extra Long Mode is slower than other

cable lengths and some instrument features are not

available. When in Extra Long Mode, the Cable

Length menu option will indicate Extra Long Mode

On. Selecting the cable length menu item will switch

off Extra Long Mode.

Vert. Units Select vertical units for a time-domain trace from

reflection coefficient (mρ), impedance (Ω) or voltage

standing wave ratio (VSWR). A few features of the

CT100B only work with the reflection coefficient

setting.

Envelope Plot Captures transient cable and connector faults.

Envelope Plot Off/On Enable/disable envelope plot mode. When turned on

the CT100B begins capturing trace data and

displaying envelope plot information.

22 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Reset Deletes/restarts captured TDR trace envelope data.

Fill Mode Off/On Toggles between fill and probability density plot

mode. Use fill mode to find magnitude of impedance

change and highlighting fault location. Use

probability density plot mode to find infrequent

transient faults.

Hold Off/On When Hold is on, trace controls are locked for an

envelope plot. When Hold is off, trace controls work

normally.

Clear Historic As trace controls are used to change an envelope

plot, the envelope plot preserves a record of the trace

from previous positions. Clear Historic erases this

history, leaving only the plot from the current

position.

(Horizontal Units) Toggles through horizontal units (meters, inches,

feet, yards, centimeters)

Meas. Settings

Horiz. Units Toggles through horizontal units (meters, inches,

feet, yards, centimeters)

RRC Classic/1502C Mode Classic: Referenced to amplitude at inactive cursor.

1502C: Referenced to amplitude at test port.

Vp 3/6 Sig Figs Toggle Vp significant digits from 3 to 6 digits.

Vertical Correction

Adjust mρ Offset Allows manual vertical measurement offset

adjustments. This allows advanced users to

manually calibrate impedance measurements at a

particular location to a known value.

When activated the M-FUNCTION knob adjusts

the vertical offset. The blue M-FUNC indicator

shows the offset in mρ (millirho).

Cancel mρ Offset Use this option to cancel a manual mρ (millirho)

correction. Automatic temperature adjustment will

resume auto-correction of the vertical measurements.

Adjust Ω/(unit) Use the M-FUNCTION knob to change the ohms

per unit distance resistive loss setting until the cable

shows no upward or downward trend across its

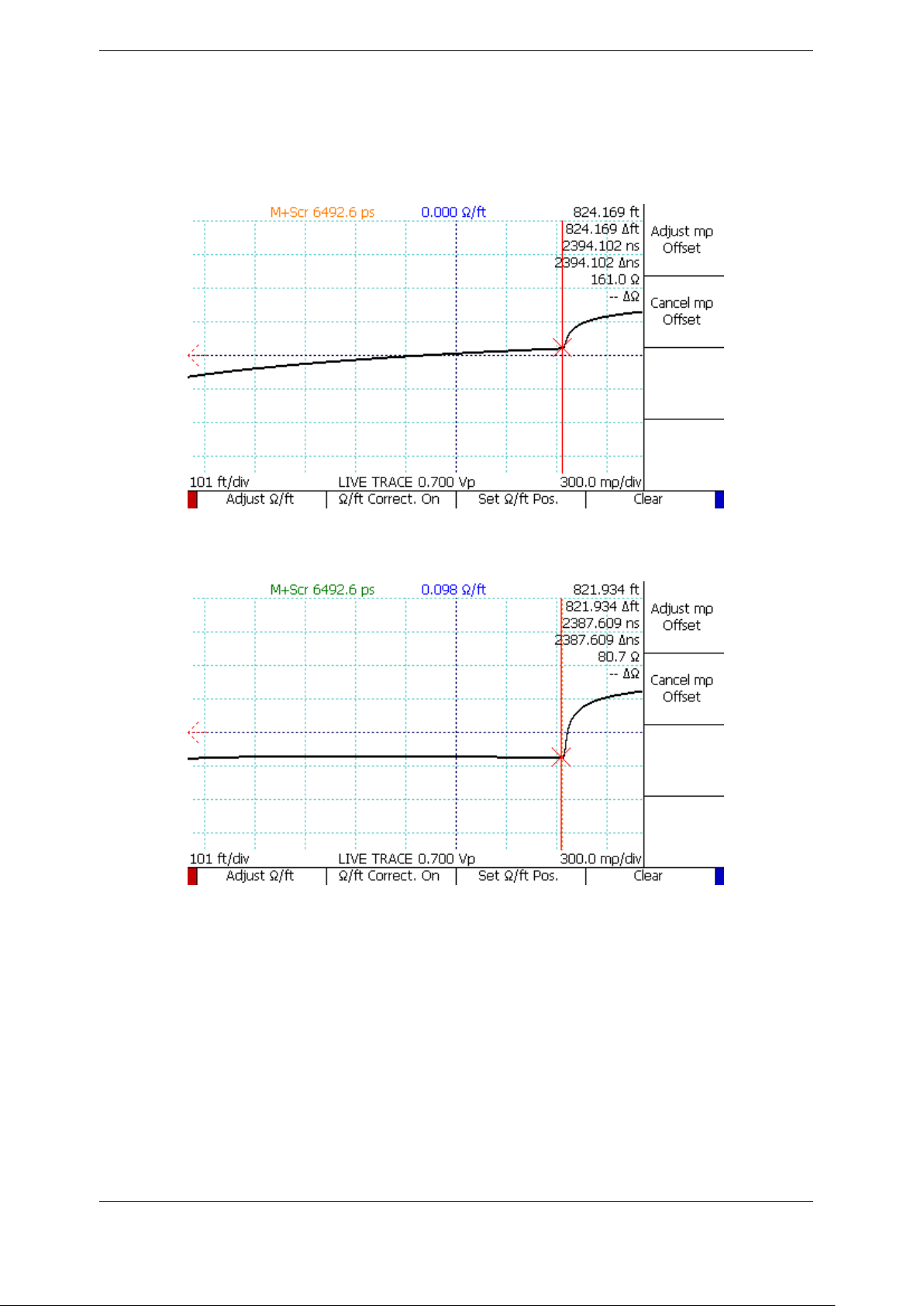

length.

Ω/(unit) Correct. On/Off Toggle resistive cable loss correction on/off, as

described above. If the end point of the correction

has not been set, then it will be set to the position of

the active cursor.

CT100B TDR Cable Analyzers Operator’s Manual 23

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Set Ω/(unit) Pos. Set the position of the ohms/(unit distance) position

to that of the active cursor.

Clear Reset all Ω/(unit) settings.

Math See Table 3.2: Math Menu.

Settings

Meas. Settings See Meas. Settings under Measurement menu above.

Network Settings

Static Network Settings Modify static network settings (if DHCP inactive):

IP Address . . . . . . . . . . . . . . . . . . . . . IP address (xxx.xxx.xxx.xxx)

Netmask . . . . . . . . . . . . . . . . . . . . . . . . Subnet for CT100B

Gateway (optional) . . . . . . . . . . . Gateway server setting

Nameserver 1 and 2

(optional) . . . . . . . . . . . . . . . . . . . . . . . . . .

Nameserver settings

DHCP on/off Toggles DHCP on/off.

Show IP Config. Displays current Ethernet configuration.

Web Export On/Fast/Off Activates and toggles function of web server into

three states: On, Fast Mode, and Off. The web

server provides .csv format files as well as screen

capture bitmaps. See Section 3.11.25 for more

details on accessing data using web export.

On............................. Normal operation (~2 frames/sec).

Fast Mode..................... Fast refresh (~7 frames/sec).

Off............................ Web server not active.

[Note: See Section 4 for more information on using

CT Viewer 2 to acquire TDR traces. See

www. mohrtm. com for information on the CT100B

Python programming library and binary programming

protocol for Ethernet CT100B interface.]

Selected .csv Options Opens a dialog for adding additional data columns

in the .csv trace export file.

Set Listen Ports This dialog box allows you to define a different RPC

port # and a different Remote Control Port # for

use with the CT Viewer 2 application (default 12347)

SP232 Protocol On / Off Toggles SP232 emulation on/off. A USB to serial

adapter is required for SP232 emulation. Press this

button while emulation is on to switch the baud rate.

Power

DC Power Save Sets the inactivity timeout for power save mode

while the device is running on external DC supply.

DC Shutdowns Sets the inactivity timeout for shutdown while the

device is running on external DC supply.

24 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Battery Power Save Sets the inactivity timeout for power save mode

while the device is running on batteries.

Battery Shutdown Sets the inactivity timeout for shutdown while the

device is running on battery.

Battery Icon Toggles battery icon display on/off.

Power Display Toggles the on-screen power status display on/off.

Diagnostics

Analog Run automated diagnostics on the analog trace

acquisition circuit board. Results are displayed

on-screen in a message box.

Database Clean Database: CAUTION! Not for routine

use. This option defragments the database, freeing

up unused space, then turns off the CT100B. Use

this option only when the CT100B is plugged into an

external power supply. Do not shutdown the

CT100B while the Clean Database command is in

progress.

Front Panel Check This item opens the front panel button and knob

check screen. Hit each button once and turn every

knob in each direction. Press the red power button

to exit when finished.

Jitter Jitter measures signal noise, jitter, rise time, and

sampling efficiency of the trace. These values are

used as part of the calibration checkout for the

CT100B, and results of interest are explained in

Appendix B: Operating Performance Checks.

Calibration Performs vertical and horizontal calibration.

Info

License

License Info This option gives information about the license

installed on the CT100B.

License from USB Use this option to load a license code from a USB

flash drive.

Enter License Manually load a license code. This is useful for

operators who are unable to connect to CT Viewer 2

or use a flash drive.

Web Update When a CT100B is connected to the Internet, this

item will automatically update the CT100B if newer

software is available.

Update From USB Drive Will run an update from the connected USB drive.

CT100B TDR Cable Analyzers Operator’s Manual 25

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Web Update Address View/set the web address to query for updated

software. Normally this setting should not be

changed.

Processor Displays CPU information.

Contact Contact information for MOHR.

Auto Update On/Off Toggles Auto-Update on/off. With Auto-Update on,

the CT100B will automatically check to see if it is

running the current software version and notify the

user if a new version exists.

Software Version Display software and firmware version information.

This also serves to verify the communications links

between the micro-controllers.

Hardware Info Display hardware information.

Usage Display instrument usage in hours.

Time Time and date settings:

Time Date Set the current date and time.

Set Time Zone Change the time zone.

Daylight Savings On Off Sets adjustment for daylight savings time on/off.

Display

Change Screen Profile Toggles screen background (black, gray, white).

Ohms/Rho Toggles display of impedance (ohms) and reflection

coefficient (millirho) at cursor and between cursors.

VSWR Toggles display of VSWR (voltage standing wave

ratio) at cursor.

Trace Labels On/Off Toggles display of the trace labels directly below the

traces.

Time/Date Toggles time/date display.

Distance/ns Toggles display of distance and time (ns) at cursor.

Temp Comp Toggles display of Temp Comp autocalibration

status.

Min/Max Display Toggles display of min/max values for high

resolution sampling.

Horiz. Vert. Ruler Toggles display of horizontal and vertical rulers.

Noise Value Toggles display of noise value at cursor for diagnostic

purposes.

Vert. Shift Correction Toggles the Vertical Shift Correction option. When

on, corrects the vertical shift that can happen when

changing the DUT.

26 CT100B TDR Cable Analyzers Operator’s Manual

3. Operating Instructions

Table 3.4 (Continued) MENU Button and Menus

Menu Selection Purpose/Action

Time of Flight Show Time of Flight time measurements. The

standard nanoseconds display shows electrical time

for a pulse to reach a point and then return to the

CT100B.

Time of Flight is exactly half that value. It is the

one-way transmission time.

Vert Centering On/Off When on, changes to vertical scale will center on the

point where the cursor intersects the selected trace.

When off, changes to vertical scale will center on the

center of the screen.

Draw Internal Cable Bkgrnd Changes the background of the trace beginning from

the start of the trace to the end of the internal cable.

Auto Smooth Reset On Off When on the CT100B will automatically reset

smoothing when a change in load is detected by the

device.

Scale Toggles display of horizontal, vertical scales, and Vp.

Intersection Toggles display of cursor-trace intersection.

Decibels Toggles display of decibel (dB) values at cursor.

Temperature Toggles display of instrument internal temperatures.

AutoSmooth On Off When on, the CT100B will automatically pick a

smoothing value based on the observed noise.

When off, the CT100B will use the user-entered

smoothed value.

3.10. Test Preparations

If you would like a detailed explanation of TDR measurement theory and applications before

using the CT100B to test cables, please read Section 5, TDR Measurement Theory, or go to

www.mohrtm.com.

3.10.1. Connecting to the Cable or Device-Under-Test (DUT)

The first and most important decision to make when testing a cable or device-under-test (DUT)

is how to connect to the DUT. Because the connection to the DUT acts as a filter for the test

signal into and out of the DUT, it is very important that the connection have the highest

bandwidth and least aberration possible.

Controlled impedance connections are recommended whenever possible. Controlled impedance

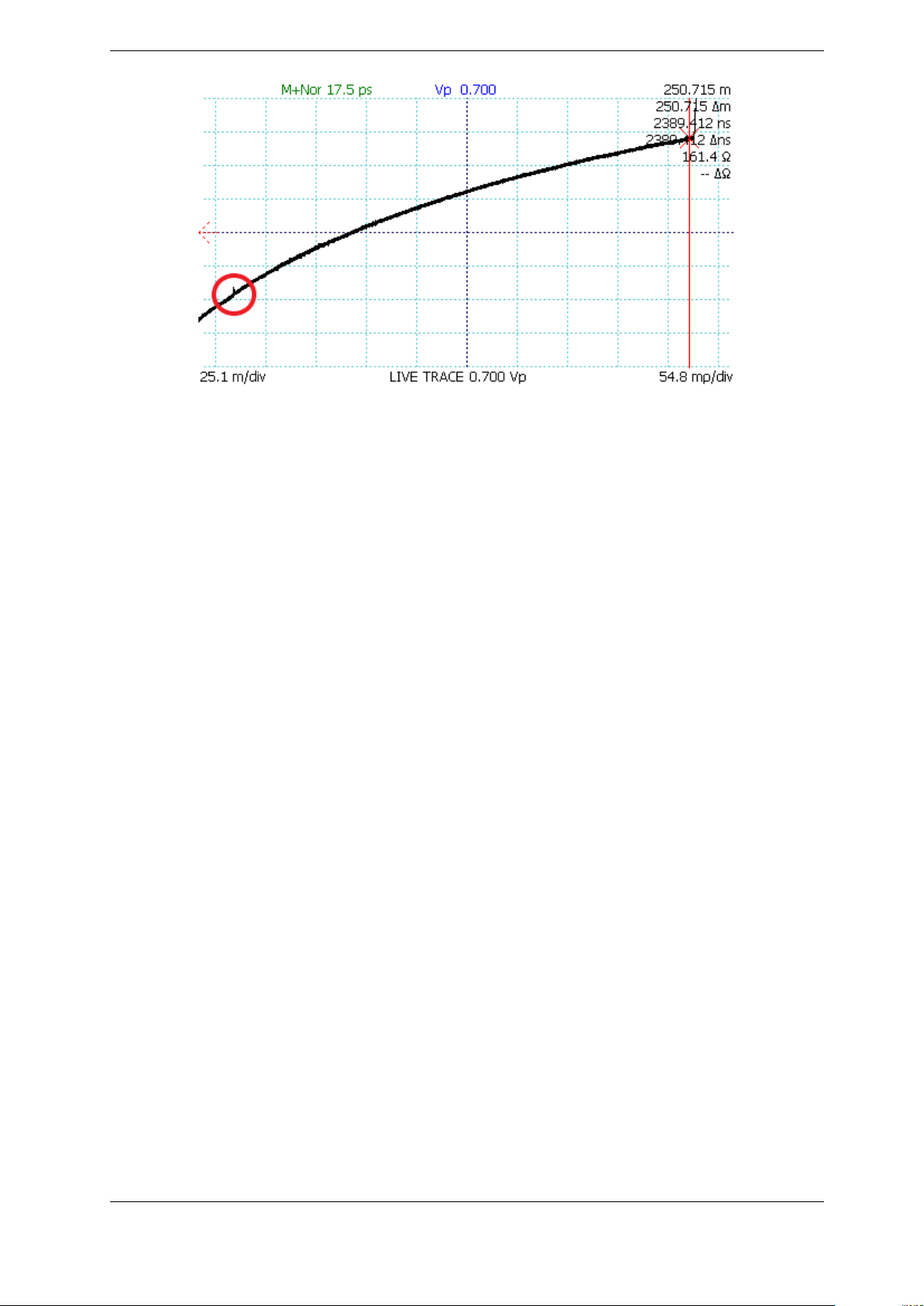

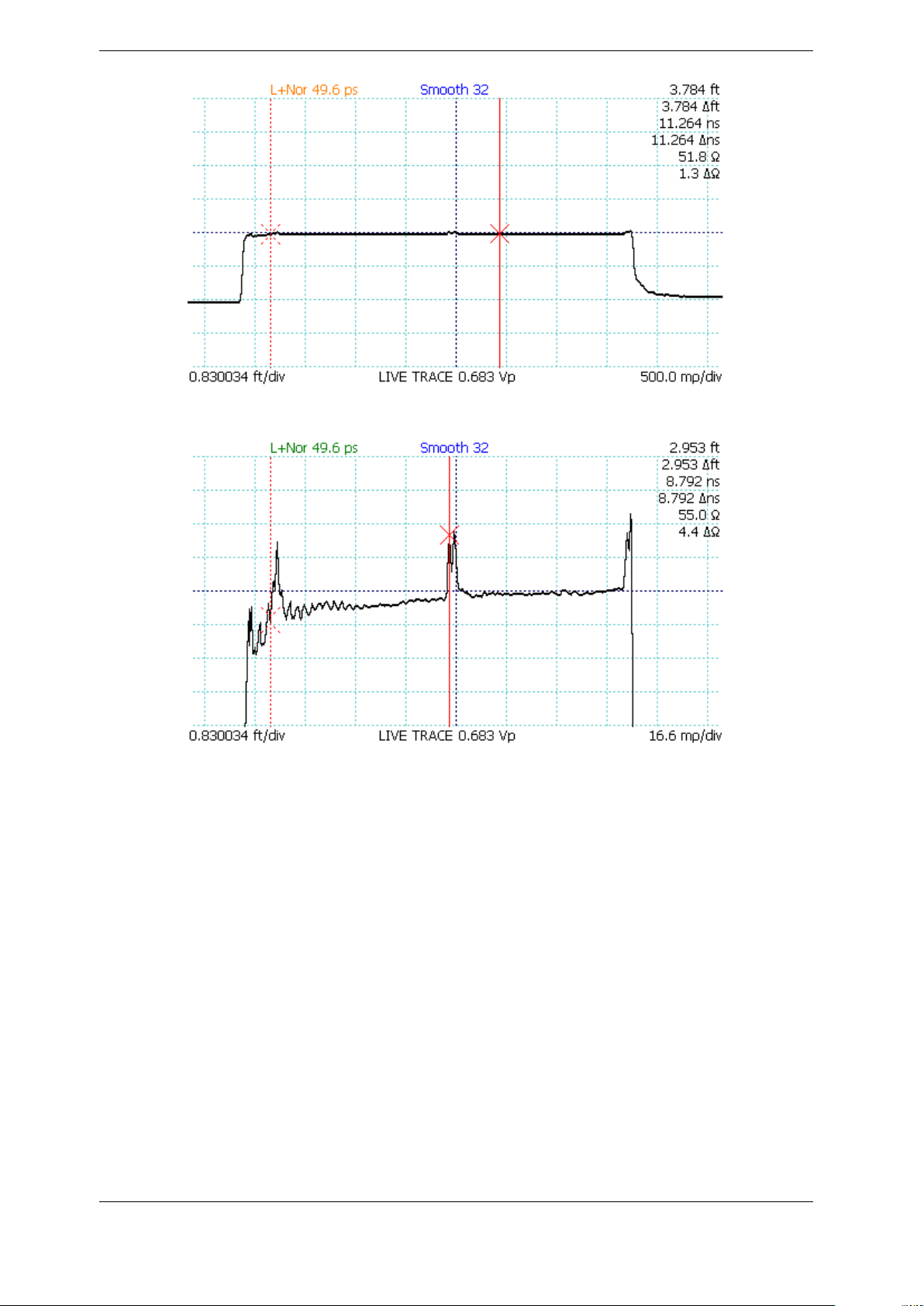

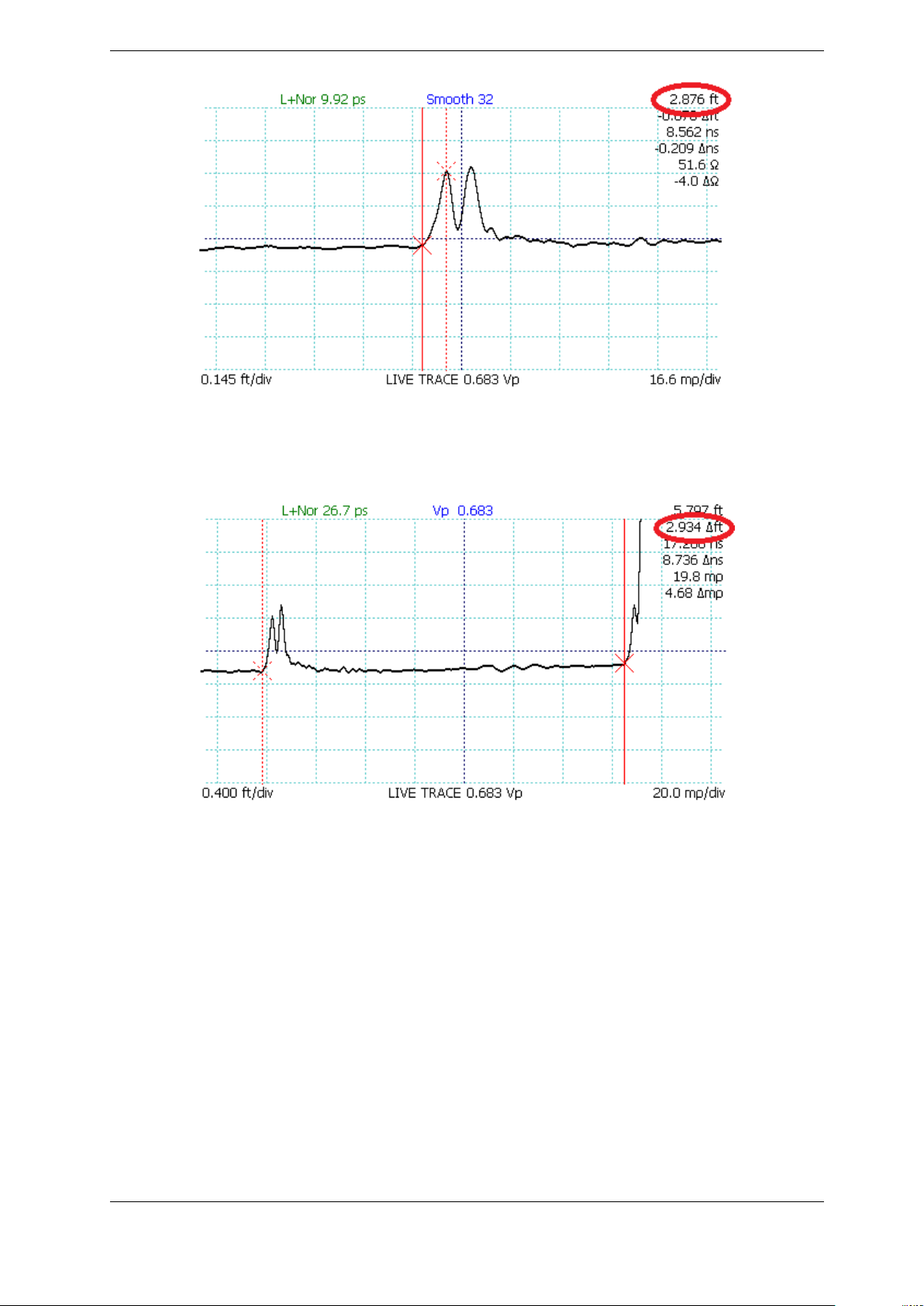

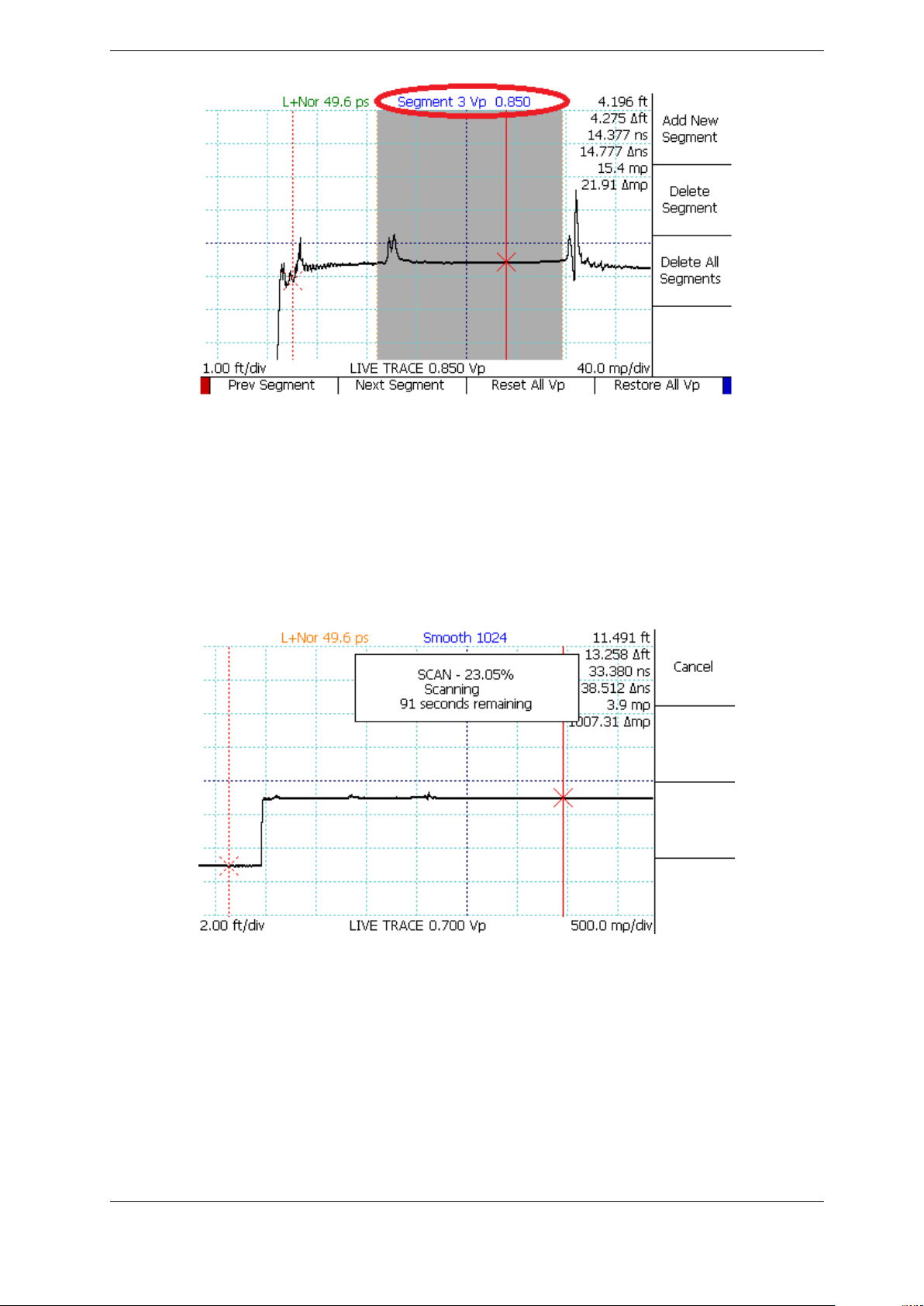

connections have conductors with uniform geometry and dielectric properties that do not change