Page 1

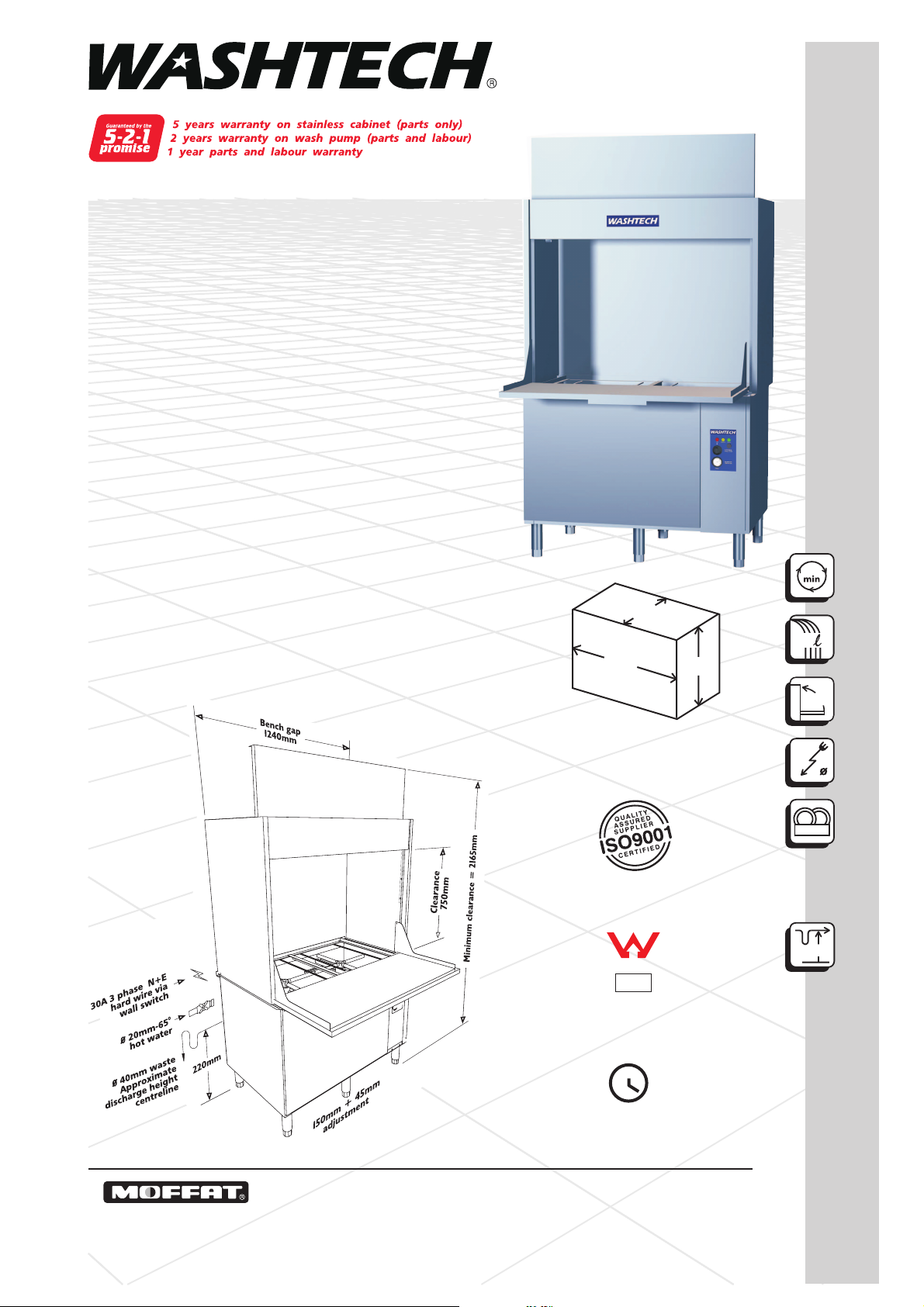

PW2 Wide Body Potwasher

With a wash compartment 1100 wide by 650 deep by 750mm high

the PW2 washes big volumes of utensils, racks, bowls, mats,

baking trays, crates, bins, small tables and many brands of 80 to

100 litre mixer bowls.

Operator may select 2, 4 or 6 minute cycles for rapid washing of a wide

range of soil levels.

Regardless of cycle time the high temperature sanitising rinse uses

only about 7 litres ofwaterpercycletoensure highly efficient operation,

minimising water,waste, power and chemical costs.

The two 1.5 kW wash pumps recirculate approximately 1600 litres of

water per minute through dual upper and lower stainless steel wash

systems. Double filtration in the deep wash tank isolates solid soil on

easily removable scrap trays.

Powerful rinse boosterelements ensure rapid recovery between cycles

for high capacity.

PW2

PW2

WIDE BODY POTWASHER

Counterbalanced insulated two piece doorwith safety stop switch.

Easy to keep clean with FASTCLEAN rounded wash tank, uncluttered

internal design, double filtration and removable wash and rinse armend

plugs.

Electrical requirement is 30 amps per phase 3 phase, with neutral and

earth.

Supplied with two 500mm cupracksand two cup covers.

650

1100

Wash Chamber

Over 25 years Washtech has earned the position of

Australasia's leadingwash equipmentmanufacturer

by providing robust, reliable machines designed for

ease of service and years of effective, efficient

operation.

ISO 9001 certified and audited since 1993 - our

equipment complies with all local hygiene, electrical

and plumbingregulations includingWATERMARK.

WaterMark

ATS5200.101

Cert 08603

SAI GLOBAL

Washtech products are supported nationwide by the

MOFFAT Service Network to ensure long term

access to parts and after sales support and service

including preventativemaintenance programmes.

750

TM

2,4,6

7

750

30A

3

500

330

Installation drawing and detail overleaf.

Australia Moffat Pty Limited

www.moffat.com.au

24 HOUR SERVICE

1800 622 216

REPLACEMENT PARTS

1800 337 963

Victoria/Tasmania

740 Springvale Road

Mulgrave, Victoria 3170

Telephone 03 9518 3888

Facsimile 03 9518 3833

Email vsales@moffat.com.au

www.moffat.com.au

In linewith policyto continuallydevelop andimprove

it's products Moffat reserves the right to change

specifications anddesign withoutnotice.

New South Wales

Telephone 02 8833 4111

Email nswsales@moffat.com.au

South Australia

Telephone 03 9518 3888

Email vsales@moffat.com.au

24

6

18

12

7

SERVICE & SUPPORT

Queensland

Telephone 07 3630 8600

Email qldsales@moffat.com.au

Western Australia

Telephone

08 9202 6820

Email

bgarcia@moffat.com.au

Effective November 2007

Page 2

PW2 Wide Body Potwasher

PW2

Installer must be suitably qualified and ensure

compliance with all local codes and standards

including AS/NZS 3500.1. Failure to comply even

partially with installation instructions may void the

warranty. Install machine on sound waterproof selfdraining floor and use adjustable feet to level

machine. Allow room for detergent to one side of

machine or in adjacent cupboard. 20 litre container

requires about 450H x 250W x 350D, but smaller

containers are available from manysuppliers.

Water Supply

Water temperature 65°C ± 5°C

Connection 20 mm (3/4" BSP) male

Pressure 200-350 kPa = 30-50 psi

Flow rate minimum 20litres per minute

Hot water consumption 7 litres per cycle approx

Backflow prevention Dual Check Valve supplied

Pressure limiter may be required. Don't use small

diameter plastic supply lines. FLUSH supply line

before connection. Poor quality supply or excessive

water hardness may affect performance or damage

machine - filtration and/or softening is

recommended. Optional rinse booster pump

available for very low pressuresupply.

Waste

40mm gravity drain - refer to point B in the

installation diagram - run waste directly behind the

machine.

Power

Electrical supply required is 5 wire, 3 Phase,

Neutral and Earth, 30A/Ph, 415V, 50Hz

permanently wired via wall switch mounted adjacent

to the machine. Wash pump rotation must be

checked after installation to ensure correct direction

(excessive noise and damage with incorrect

direction)

Detergent

If detergent pump is fitted insert pump inlet hose into

container of commercial low foam detergent. Open

machine door and switch machine on. Press and

hold detergent prime switch behind front cover until

chemical flows into machine. Commercial

detergents can be hazardous - read instructions and

handle with care.

Commissioning

Connect all services as above. Ensure that all

internal components such as filterand drain upstand

are in place. Turn on water and switch on power.

Close machine door and switch on machine by

selecting any cycle. When machine stops filling

switch off machine at wall and remove front panel.

Switch on commissioning switch by breaking label

over same. Turn power on at wall and close the front

panel.

Loading...

Loading...