Page 1

Installation and Operation Manual

Electric Pasta Cooker

PC8140E

PC8140E-7

PCL8140E

PCL8140E-7

Date Purchased

Serial Number

Dealer

Service Provider

For use in GB & IE

232805-4

Page 2

MANUFACTURED BY

Moffat Limited

PO Box 10001

Christchurch

New Zealand

Ph: (03) 389 1007

Fax: (03) 389 1276

WORLD-WIDE BRANCHES

UNITED KINGDOM

Blue Seal

Unit 67, Gravelly Business Park

Gravelly Park

Birmingham

West Midlands

B24 8TQ

Ph: (121) 327 5575

Fax: (121) 327 9711

UNITED STATES

Moffat Inc

3765 Champion Blvd

Winston-Salem

North Carolina 27115

Ph: (336) 661 0257

Fax: (336) 661 9546

CANADA

Serve Canada

22 Ashwarren Road

Downview

Ontario M3J1Z5

Toll Free:800 263 1455

Ph: (416) 631 0601

Fax: (416) 631 0315

info@servecanada.com

www.servecanada.com

www.moffat.com

NEW ZEALAND

Christchurch

Moffat Limited Moffat Limited

PO Box 10-001 4 Waipuna Road

16 Osborne Street Mt Wellington

Christchurch Auckland

Ph: (03) 389 1007 Ph: (09) 574 3150

Fax: (03) 389 1276 Fax: (09) 574 3159

AUSTRALIA

Victoria

Moffat Pty Limited Moffat Pty Limited

740 Springvale Road 3/142 James Ruse Drive, Rose Hill

Mulgrave, Melbourne PO Box 913, Smithfield

Victoria 3171 Sydney, N.S.W. 2142

Ph: (03) 9518 3888 Ph: (02) 8833 4111

Fax: (03) 9518 3838 Fax: (02) 8833 4133

Western Australia

Moffat Pty Limited Moffat Pty Limited

67 Howe Street 30 Prosperity Place

Osbourne Park Geebung, Brisbane

WA 6017 Queensland 4034

Ph: (08) 9202 6820 Ph: (07) 3630 8600

Fax: (08) 9202 6836 Fax (07) 3630 8623

Auckland

New South Wales

Queensland

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless qualified previously in

writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. August 2009.

Page 3

Contents

PC(L)8140E ELECTRIC PASTA COOKER - (Single Tank - 40 Ltr)

Introduction ............................................................................................ 2

Specifications .......................................................................................... 3

Model Numbers Covered in this Specification

General

Optional Accessories

Electrical Supply Requirements

Electrical Connection

Water Supply Requirements

Dimensions ............................................................................................... 4

Installation ............................................................................................... 5

Installation Requirements

Unpacking

Location

Clearances

Assembly

Electrical Connection

Water Connection

Drainage Connection

Commissioning

Operation.................................................................................................. 8

Operation Guide

Description of Controls

Before Use

Filling the Tank

Operating the Pasta Cooker

Turning ‘OFF’ the Pasta Cooker

Cleaning and Maintenance ..................................................................... 11

General

Draining and Cleaning

After Each Use

Daily Cleaning

Weekly Cleaning

Periodic Maintenance

Fault Finding........................................................................................... 14

Wiring Schematic ................................................................................... 15

Replacement Parts List .......................................................................... 16

Page 4

Introduction

We are confident that you will be delighted with your WALDORF Electric Pasta Cooker and it will become a

most valued appliance in your commercial kitchen.

To ensure you receive the utmost benefit from your new WALDORF Appliance, there are two important

things you can do.

Firstly:

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly:

If you are unsure of any aspect of the installation, instructions or performance of your appliance,

contact your WALDORF dealer promptly. In many cases a phone call could answer your question.

CE Only:

These instructions are only valid if the country code appears on the appliance. If the code does not

appear on the appliance, refer to the supplier of this appliance to obtain the technical instructions for

adapting the appliance to the conditions for use in that country.

WARNING:

MPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

I

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS APPLIANCE.

WARNING:

REAT CARE MUST BE TAKEN BY THE OPERATOR TO USE THE EQUIPMENT SAFELY TO GUARD IT AGAINST

G

RISK OF FIRE.

• T

• I

• DO NOT

•

HE APPLIANCE MUST NOT BE LEFT ‘ON’, UNATTENDED.

T IS RECOMMENDED THAT A REGULAR INSPECTION IS MADE BY A COMPETENT SERVICE PERSON TO

ENSURE CORRECT AND SAFE OPERATION OF YOUR APPLIANCE IS MAINTAINED.

STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

C

AUTION

:

This appliance is;

•

For professional use and is to be used by qualified persons only.

•

Only authorised service persons are to carry out installation, and servicing

operations.

•

Components having adjustments protected (e.g. paint sealed) by the

manufacturer should not be adjusted by the user / operator.

•

DO NOT operate the appliance without the legs supplied, fitted.

2

Page 5

Model Numbers Covered in this Specification

Specifications

PC[1]8140E PASTA COOKER (10.5 kW).

PC[1]8140E-7 PASTA COOKER (7.0 kW).

NOTE: [1]: - - Standard Back Models.

L - Low Back Models.

General

A commercial heavy duty, electric, high performance Pasta Cooker designed for cooking in a

commercial high production output site. The boiling medium is contained within a heavy gauge

stainless steel tank, heated by a 3 coil heavy duty element within the tank.

This Pasta Cooker features an Over Temperature Safety Cut Out System.

An open tank design and pivoting element system to make cleaning a simple and easy task.

Optional Accessories

This appliance can be fitted with the following optional accessories, (refer to the 'Replacement Parts

List' for details).

• Plinth Kit.

• Basket 320 x 165 mm.

Electrical Supply Requirements

Standard Ex-Factory Model Convertible to:

PC8140E 10.5 kW 3P+N+E, L1=L2=L3 = 15A @ 240V 1P+N+E, 44A @ 240V

PC8140E-7 7.0 kW 1P+N+E, 30A @ 240V 3P+N+E, L1=L2=L3 = 10A @ 240V

Electrical Connection

WARNING:

HIS APPLIANCE MUST BE EARTHED. IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY A

T

SUITABLY QUALIFIED PERSON IN ORDER TO AVOID A HAZARD.

Electrical supply connection point is located 56 mm from the right hand side, 529 mm from the rear of

the appliance and 489 mm from the floor.

When connecting a this electric appliance to the mains supply, ensure that the following is carried

out:-

•

The supply cord shall not be lighter than ordinary tough rubber sheathed (oil

resistant) cord. e.g. H05 RN-F with sufficient current carrying capacity cable sizes.

•

The branch supply line shall be overload protected.

•

The point of connection shall be as close as practicable to the appliance and shall

have a

n isolating switch accessible during manual operation of the appliance.

• The supply cord shall be protected against any mechanical or thermal damage.

Refer to the appropriate wiring standards for the size of cable that is to be supplied to an appliance

for the current drawn on that line.

Water Supply Requirements

Cold water connection is 1/2" tube connection via 15 mm crox fitting located 49mm from the LH side,

556 mm from rear and 139 mm from the floor. This should be plumbed in, in accordance with

National / Local Codes covering installation.

Maximum water supply pressure 550 kPa (80 psi).

Tank capacity - 40 ltrs of water.

3

Page 6

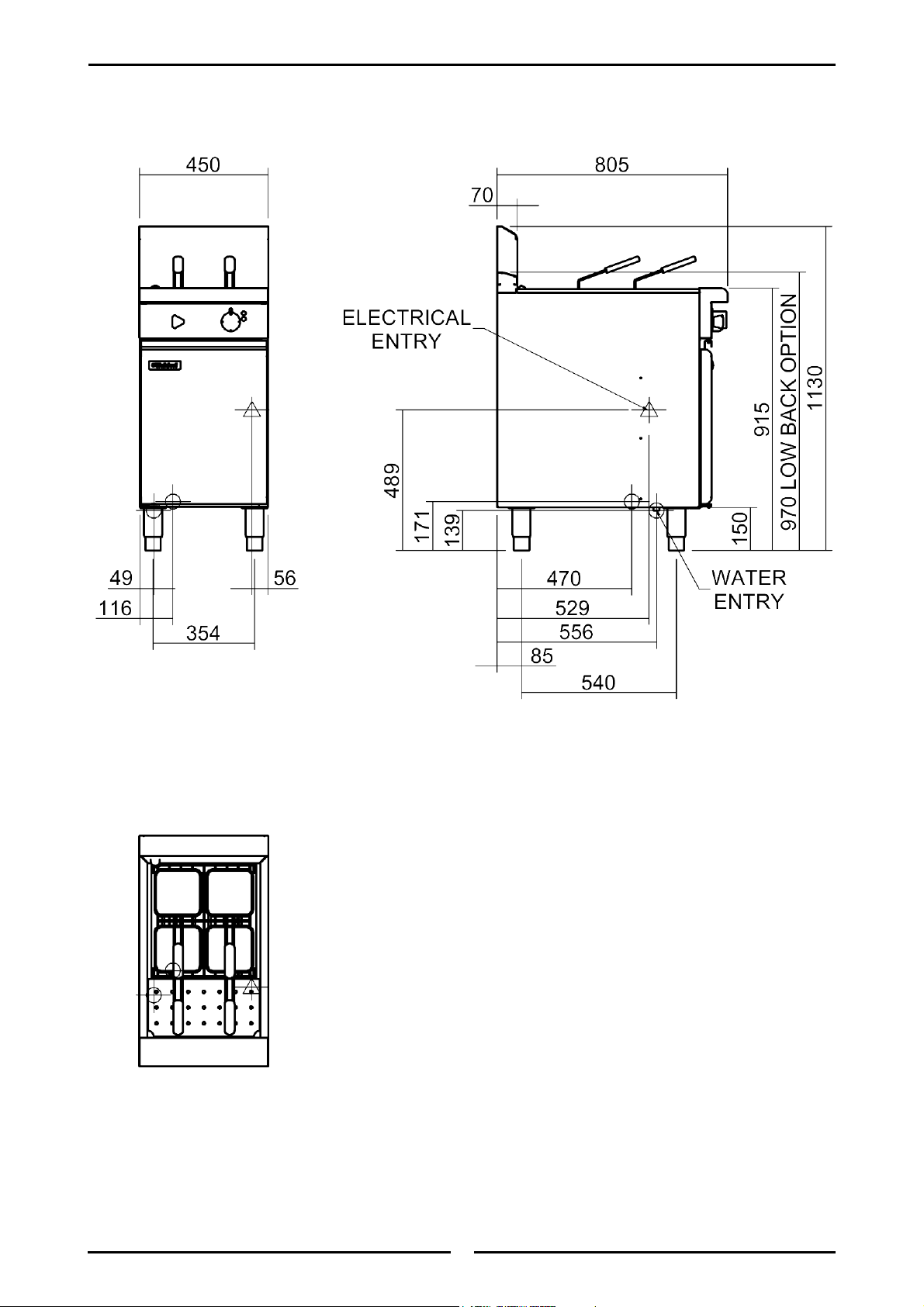

Dimensions

PC

(1)

8140E-Pasta Cooker

4

Page 7

Installation

Installation Requirements

NOTE:

• It is most important that this appliance is installed correctly and that operation is

correct before use. Installation shall comply with local, electrical health and safety

requirements.

Waldorf Electric Pasta Cookers are designed to provide years of satisfactory service and correct installation

is essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering electrical, fire safety and health and safety.

Australia / New Zealand: AS / NZS3000 - Wiring Rules.

United Kingdom: BS7671 - Requirements for Electrical Installations.

Installations must be carried out by qualified service persons only. Failure to install the

equipment to the relevant codes and manufacturer’s specifications shown in this section will

void the warranty.

Components having adjustments protected (e.g. paint sealed) by manufacturer, are only

to be adjusted by an authorised service agent. They are not to be adjusted by the installation

person.

Unpacking

• Remove all packaging and transit protection from the appliance including all protective plastic

coating from the door outer panel and exterior stainless steel panels.

• Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

• Report any deficiencies to the distributor who supplied the appliance.

• Check that the available electrical supply is correct to that shown on the rating plate located on the

inside of the access door.

• Check that the following parts have been supplied with the appliance:

PC8140E / PC8140E-7

Baskets 165 x 165 mm 4

Basket Support Frame 1

Location

1. Any appliance requires adequate clearance and ventilation for optimum and trouble-free operation.

The minimum installation clearances shown below are to be adhered to.

2. Position the appliance in its approximate working position.

3. The legs must always be fitted. Ensure that the legs are securely attached.

Clearances

Combustible Surface Non Combustible Surface

Left / Right hand side 50 mm 0 mm

Rear 25 mm 0 mm

NOTE:

• Only non-combustible materials can be used in close proximity to this appliance.

• In order to facilitate easy operation, drainage and servicing of the appliance, a

minimum of 600 mm clearance should be maintained at the front of the appliance.

5

Page 8

Installation

Assembly

This model is delivered completely assembled. Ensure that the adjustable feet are securely attached.

NOTE:

• This appliance is fitted with adjustable feet to enable the appliance to be positioned

securely and level. This should be carried out on completion of the electrical

connection. Refer to the ‘Electrical Connection’ section below.

Electrical Connection

NOTE: ALL ELECTRICAL CONNECTIONS MUST ONLY BE CARRIED OUT BY A QUALIFIED

PERSON.

Each pasta cooker should be connected to an adequately protected power supply and isolation switch

mounted adjacent to, but not behind the pasta cooker. This switch must be clearly marked and readily

accessible in case of fire.

1. Check that the electricity supply is correct as shown on the Rating Plate attached to the inside of the

access door.

2. The supply terminal connections are located at the lower front of the pasta cooker.

3. Open the door and remove the service panel (4 screws) located below the control panel, to allow

connection access for the electrical supply.

4. Bring the supply cable up through the grommet at the back of the pasta cooker, and through the

compression type gland provided on the rear of the main electrical switchgear panel.

5. Connect the mains supply to L1, L2 and L3 switch connections for 3 phases.

6. Connect neutral and earth conductors to the appropriately marked terminals on the terminal block.

7. For all connections ensure that conductors are secure and appropriately terminated.

8. Tighten the cable gland to secure against tension on the cable.

NOTE:

• This appliance must be grounded / earthed.

• Fixed wiring installations must incorporate an all-pole disconnection switch.

Water Connection

NOTE: The water connection shall be installed in accordance with local water regulations in force

and the applicable standard / code, e.g. EN 1717 in UK / Ireland, PCA in Australia.

1

A cold water supply must be connected to the water inlet connection (R

/2" BSP), located 49 mm from

the LH side, 556 mm from rear and 139 mm from the floor.

The water inlet pressure must be as follows:-

Minimum water supply pressure 150 kPa (22 psi).

Maximum water supply pressure 550 kPa (80 psi).

6

Page 9

Installation

Drainage Connection

• The water is drained from the appliance by means of a valve located behind the front access door.

• A waste water tundish must be fitted below the appliance drain outlet. This should be a minimum of

127 mm (5”) major diameter.

• If required the drain outlet can be extended in order to exit above the tundish. All drain piping must

be with materials suitable for conveying boiling water.

• Drain connection is R1" BSP drain / overflow.

Commissioning

The following commissioning checks must be carried out before the pasta cooker is handed

over for use, to ensure that the unit operates correctly and the operator(s) understand the

correct operating procedure.

1. Before leaving the new installation;

a. Check the following functions in accordance with the operating instructions specified in the

'Operation' section of this manual.

• Check the current draw and loading for the equipment. Refer to the ‘Specifications’ section

of this manual for the correct electrical requirements.

• Check that all the connections are correct and that all panels have been re-fitted.

• Check that the unit functions in accordance with the operating instructions.

• Ensure that this instruction manual is left with the appliance.

• Ensure that all the relevant details and contacts have been added to the front of this

manual.

b. Ensure that the operator has been instructed in the correct operation and shutdown procedure

for the appliance.

2. This manual must be kept by the owner for future reference and a record of Date of Purchase, Date

of Installation and Serial Number of Unit recorded and kept with this manual. (These details can be

found on the Rating Plate fitted to the inside of the access door and in the 'Specifications' section of

this manual.

NOTE:

• If for some reason it is not possible to get the unit to operate correctly, disconnect the

electrical power supply and contact a qualified service person. The supplier of this

unit will be able to recommend a suitable person.

• Make sure that the electrical supply is disconnect before any service or maintenance

work is carried out.

7

Page 10

Operation

Operation Guide

C

AUTION

•

This appliance is for professional use and is only to be used by qualified

persons.

•

Only qualified service persons are to carry out installation and servicing

operations.

•

Components having adjustments protected (e.g. paint sealed) by the

manufacturer should not be adjusted by the user / operator.

:

1. Waldorf Pasta Cookers have been designed to provide simplicity of operation and 100% safety

protection.

2. Improper operation is therefore almost impossible, however bad operation practices can produce a

poor quality product. To use this pasta cooker correctly please read the following sections carefully;

• Description of Controls.

• Before Use.

• Filling the Tank.

• Operating the Pasta Cooker.

• Turning ‘Off’ the Pasta Cooker.

• Cleaning and Maintenance.

Description of Controls

• A commercial heavy duty, electric pasta cooker using a 3 coil heavy duty, pivoting element system.

• Available in single model type.

• This model is fitted with single 3 coil heavy duty, pivoting element and is controlled by a 4 position

switch and a thermostat for variable speed and temperature control.

• Open tank and pivotal element system design to simplify cleaning operation.

PC-8140E Pasta Cooker Controls

Element Control Knob

O OFF Position

SIMMER

1

BOIL

2

RAPID

3

Power Indicator Neon

(Green)

Heating Indicator Neon

(Amber)

Fig 1

Thermostat Knob

(Behind Access Door)

Overtemp Reset

(Behind Access Door)

Water Control Valve

8

Page 11

Operation

Before Use

WARNING:

REAT CARE MUST BE TAKEN BY THE OPERATOR TO USE THE PASTA COOKER SAFELY, TO GUARD AGAINST

G

THE RISK OF INJURY AND FIRE.

• DO NOT

• DO NOT

• DO NOT

• DO NOT

COOKER WHILST THE PASTA COOKER IS STILL HOT.

1. Check that the electrical supply is switched ‘On’.

2. Check that there are no foreign articles in the tank.

Filling the Tank

LEAVE THE PASTA COOKER UNATTENDED DURING OPERATION.

OVER FILL THE WATER IN THE PASTA COOKER ABOVE THE UPPER FILL LEVEL MARK.

ALLOW THE WATER IN THE PASTA COOKER TO FALL BELOW THE LOWER LEVEL MARK.

USE FLAMMIBLE SOLVENTS AND CLEANING AIDS ON OR IN CLOSE PROXIMITY TO THE PASTA

CORRECT LEVEL FOR WATER WHEN

COOKING, KEEP TOPPED UP.

INDICATES MINIMUM (SAFE) LEVEL.

WATER LEVEL SHOULD BE TOPPED UP.

Fig 2

NOTE: Tank capacity - 40 Ltrs of water.

1. Before filling the tank, always check that the drain valve behind the access door is closed. A locking

slide is provided on the valve and this should always be locked in position during use. (See Fig 3

and 4 in the ‘Cleaning and Maintenance’ section).

2. Turn the water supply 'On'. Open the appliance water valve and fill the tank with water.

3. The water level will remain at a constant height as there is an overflow at the front of the tank.

4. During cooking, the water level will reduce as it evaporates as steam when boiling and when it

overflows as loaded baskets are dropped into the tank.

5. To maintain the correct water level, the water tap should be adjusted to give a water flow out of the

water supply nozzle that just causes water to continually flow out of the overflow.

This method provides:

• A maintained water level for cooking.

• Skimming or flushing effect to prevent the cooking water becoming gummed up with pasta

residue.

9

Page 12

Operation

Operating the Pasta Cooker

C

AUTION

Do NOT turn ‘On’ the element if the tank is empty (No Water). Ensure that the

tank is filled to the correct level before turning ‘On’ the element.

:

1. Ensure that the pasta cooker tank is full of water to the upper fill mark.

2. Check that the electrical supply is turned ‘On’ at the mains supply.

3. Select the ‘power’ level on the element control knob to either Simmer / Boil / or Rapid as required.

The ‘green’ power indicator will illuminate.

4. Rotate the thermostat knob to the desired temperature. The ‘amber’ heating indicator will illuminate

until the temperature is reached.

NOTE: It will take approximately 28 minutes to heat the water in the tank from 20°C to 100°C. (This

time has been calculated for the PC8140E Pasta Cooker that is fitted with the 10.5kW

element).

Turning 'Off' the Pasta Cooker

1. Rotate the element control knob to the ‘O’ position, to turn ‘Off’ the pasta cooker.

2. The ‘green’ power indicator and the ‘amber’ heating indicators will extinguish.

10

Page 13

Cleaning and Maintenance

General

WARNING:

DO NOT

WHILST THE COOKER IS STILL HOT.

USE FLAMMIBLE SOLVENTS AND CLEANING AIDS ON OR IN CLOSE PROXIMITY TO THE PASTA COOKER

C

AUTION

:

Always turn off the electrical supply at the mains supply before cleaning.

This appliance is not water proof.

Do not use water jet spray to clean interior or exterior of this appliance.

Clean the pasta cooker regularly. A clean pasta cooker looks better, will last longer and will perform

better. A dirty pasta cooker will hinder the transfer of heat from the cooking surface to the food.

This will result in loss of cooking efficiency and food quality.

C

AUTION

:

If cleaning detergents are allowed to enter the inner parts of the appliance,

rusting will occur on the pipe work, installation elements, heating

elements, gas fittings and electrical components, this will cause premature

failure of the appliance.

NOTE:

• DO NOT clean the appliance using high pressure water or steam jets.

• DO NOT pour water directly over the appliance.

• DO NOT use wire brushes. Clean the pan regularly after each use.

• DO NOT use combustible liquids to clean the appliance.

• DO NOT use harsh abrasive detergents, sharp scrapers, strong solvents or caustic

detergents as they will damage the appliance.

• DO NOT use any chloric or bleaching detergents to clean the appliance.

• Ensure that any detergent or cleaning material has been completely removed after

each cleaning operation.

• DO NOT use saline or sulfuric acid preparations for descaling the appliance.

• Ensure that protective gloves are worn during the cleaning process.

• Clean the pan regularly after each use.

Draining and Cleaning

Opening the Drain Valve

a. Unlock the locking slide on the valve handle by pushing the locking slide away from the valve

body to release the valve handle (See Fig 3) and rotate the valve handle downwards

(anticlockwise) to open the drain valve (See Fig 4).

b. On completion of the draining and cleaning operation, to close the valve, ensure that the locking

slide is in the unlocked position (See Fig 4) and rotate the valve handle upwards (clockwise) to

close the drain valve.

c. When the valve is closed, slide the locking slide back over the valve handle to prevent accidental

opening of the valve.

NOTE: The valve handle can be secured in the locked position by inserting a padlock through the

holes in the locking handle and locking slide to prevent the valve handle from being

inadvertently opened.

11

Page 14

Cleaning and Maintenance

Locking Slide

locked position

Locking Slide

unlocked position

Fig 3

Fig 4

After Each Use

WARNING:

OT WATER WILL SCALD - DO NOT RUSH THIS JOB.

H

1. Clean the interior of the pan regularly after each use. Do not use wire brushes on the pan. Clean

using a mild detergent and a hot water solution using soft cloth or a soft bristled brush. Dry the

appliance thoroughly using a dry clean cloth.

Daily Cleaning

WARNING:

O NOT ATTEMPT TO MOVE THE PASTA COOKER WHILST THE COOKER IS FULL OF WATER.

D

EFORE ATTEMPTING TO MOVE THE PASTA COOKER, ENSURE THAT ALL THE WATER HAS BEEN DRAINED FROM

B

THE TANK. REFER TO THE INFORMATION ON THE PREVIOUS PAGE, ON HOW TO DRAIN THE WATER FROM THE

ASTA COOKER.

P

1. The water should be drained and re-filled regularly. Open the drain valve slowly to minimise

splashing. Waste water will drain into the tundish fitted below the appliance drain outlet.

2. When the tank is empty, open the drain valve fully and check for any particles or residue lodged in

the valve. Clean out with a stiff nylon brush. Do not use a wire brush or metal rods as these

damage the seating in the valve and will eventually lead to valve leakage.

3. If the obstruction in the valve cannot be removed with a brush, use a wooden probe to dislodge any

obstruction.

4. Clean the control panel using a damp cloth lightly moistened with a solution of mild detergent and

hot water. Dry the control panel thoroughly using a dry clean cloth.

5. Clean the interior and exterior of the pasta cooker regularly at the end of each day. Do not use wire

brushes on the pan. Clean using a mild detergent and a hot water solution using soft cloth or a soft

bristled brush. Dry the appliance thoroughly using a dry clean cloth.

6. Once the daily cleaning operation is completed, ensure that the drain valve has been closed.

12

Page 15

Cleaning and Maintenance

Weekly Cleaning

WARNING:

O NOT ATTEMPT TO MOVE THE PASTA COOKER WHILST THE COOKER IS FULL OF WATER.

D

EFORE ATTEMPTING TO MOVE THE PASTA COOKER, ENSURE THAT ALL THE WATER HAS BEEN DRAINED FROM

B

THE TANK. REFER TO THE INFORMATION ON THE PREVIOUS PAGE, ON HOW TO DRAIN THE WATER FROM THE

ASTA COOKER.

P

NOTE:

• If the pasta cooker usage is very high, we recommend that the weekly cleaning

procedure is carried out on a more frequent basis.

• Ensure that protective gloves are worn during the cleaning process.

• DO NOT use harsh abrasive detergents, strong solvents, sharp scrapers or caustic

detergents as they will damage the surface of the pasta cooker.

• Ensure that the water circuit is free of ferrous particles. Any such particles deposited

in the bottom of the tank may cause it to rust.

Thoroughly clean the interior and exterior of the pasta cooker regularly. Do not use wire brushes on the

pan. Clean using a mild detergent and a hot water solution using soft cloth or a soft bristled brush. Dry

the appliance thoroughly using a dry clean cloth.

NOTE: In order to prevent the forming of rust on the steel components, ensure that the detergent

or cleaning material has been entirely removed after each cleaning process.

Stainless Steel Surfaces

a. Clean the control panel with a damp lightly moistened cloth using hot water and a mild detergent

solution. Note that the gas control knobs are a push fit onto the gas and water control valve

spindles and can be removed to allow cleaning of the front of the control panel.

b. Clean the interior and exterior surfaces of the pasta cooker with hot water, a mild detergent

solution and a soft scrubbing brush.

c. Baked on deposits or discolouration may require a good quality stainless steel cleaner or stainless

steel wool. Always apply cleaner when the appliance is cold and rub in the direction of the grain.

d. Dry all components thoroughly with a dry cloth and polish with a soft dry cloth.

Periodic Maintenance

NOTE: All maintenance operations should only be carried out by a qualified service person.

To achieve the best results cleaning must be regular and thorough and all controls and mechanical parts

should be checked and adjusted periodically by a qualified service person. If any small faults occur, have

them attended to promptly. Don't wait until they cause a complete breakdown. It is recommended that

the appliance is serviced every 6 months.

If the appliance is not used for long periods, disconnect the mains supply to the pasta cooker and clean

the appliance thoroughly.

The appliance should be inspected by an authorized service person at least every 6 months.

13

Page 16

Fault Finding

This section provides an easy reference guide to the more common problems that may occur during the

operation of your equipment. The fault finding guide in this section is intended to help you correct, or

at least accurately diagnose problems with your equipment.

Although this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorised service agent who will

make every effort to help you identify and resolve the problem. Please note that the service agent will

require the following information:-

• The Model Trade Name and the Serial Number of the Appliance. (both can be found

on the Technical Data Plate located on the appliance.

Fault Possible Cause Remedy

Elements do not heat up. Check the mains power is supplied

to the unit and that a circuit

breaker or fuse has not tripped /

blown.

Check that the element is flat and

that the tilt microswitch is closed.

Check that the thermostat setting

is correct and that the control

knob is set to the 'ON' position.

Over-temperature thermostat cuts

out.

Over-temperature thermostat

faulty.

Control thermostat not

maintaining set temperature.

a. Thermostat out of calibration.

b. Thermostat does not open on

temperature rise.

Turn ‘ON’ the power. Reset the

circuit breaker or replace the

blown fuse.

Adjust the microswitch so that the

microswitch is activated when the

element is fully down in the flat

(cooking position).

Replace the thermostat.

Call service provider.

If the element cuts out and the

power indicator light also drops

below 100ºC, replace the

over-temperature thermostat.

Check continuity through the

thermostat leads, on temperature

rise. If circuit does not open,

replace the thermostat.

Call service provider.

14

Page 17

PC8140E Pasta Cooker

Wiring Schematic

ELEMENTS

2.3KW each (PC8140-7)

3.5KW each (PC8140)

Electrical Supply Requirements

Standard Ex-Factory Model Convertible to:

PC8140E 10.5 kW 3P+N+E, L1=L2=L3 = 15A @ 240V 1P+N+E, 44A @ 240V

PC8140E-7 7.0 kW 1P+N+E, 30A @ 240V 3P+N+E, L1=L2=L3 = 10A @ 240V

15

Page 18

Replacement Parts List

Replacement Parts List

IMPORTANT:

Only genuine authorized replacement parts should be used for the servicing and

repair of this appliance. The instructions supplied with the parts should be followed

when replacing components.

For further information and servicing instructions, contact your nearest authorized

service branch (contact details are as shown on the reverse of the front cover of this

manual).

When ordering spare parts, please quote the part number and the description as listed below. If the part

required is not listed below, request the part by description and quote model number and serial number

which is shown on the rating plate.

Controls

231776 Element Assembly 10.5kW (PC8140E).

232605 Element Assembly 7.0kW (PC8140E-7).

232744 Element Retaining Pin.

232750 Element ‘O’ Ring.

232746 Bulkhead ‘O’ Ring.

232740 Overtemp Thermostat (Reset Switch).

232741 Thermostat.

015561 Thermostat Knob.

229703 Water Valve.

232733 Control Panel.

227962 Neon Green.

227963 Neon Orange.

232736 Element Control Switch.

227401 Element Control Knob.

232775 Terminal Block.

231738 Contactor.

232748 Microswitch.

General

229836 Pasta Cooker Basket 165 x 165mm.

229682 Basket Support Frame.

227856 Door Magnet.

229804 Water Filler Spout.

019390 Water Drain Valve.

229823 Overflow Hose.

229822 Drain ‘Y’ Junction.

228933 Basin Connector.

227850 Adjustable Leg - 150mm.

Accessories (Optional)

228793 Plinth Kit.

229837 Pasta Cooker Basket 320 x 165mm.

16

Page 19

Loading...

Loading...