Page 1

MIXED FUEL COOKER

MSC 5061 W

Page 2

2

Page 3

CONTENTS

Instructions for the user Instructions for the installer

Important Safety Information

Description of the appliance

Technical Features

Using the appliance

- Using the electric oven

- Using the electric grill

- Hints & Tips

- Using the Hob

Maintenance and Cleaning

Something Not Working

Service & Spare Parts

Customer Care

Guarantee conditions

Safety Advice

4

Electrical connection

5

Technical Data

6

Installation

7

7

8

9

10

12

14

15

15

16

- Positioning

- Ventilation

- Location

Gas connections

- Electrical connection

Conversion of gas

17

18

19

19

19

20

20

21

23

24

How to read the instruction book

The symbols below will guide you when reading the

instruction book

Safety instructions

Step by Step Operation

Advice and recommendations

Environmental Information

3

Page 4

IMPORTANT SAFETY INFORMATION

You MUST read these warnings carefully before installing or using the appliance. If you

need assistance, contact our Customer Care Department on 08705 950950.

Installation

• This cooker must be installed by qualified

personnel, according to the manufacturer’s

instructions and to the relevant British

Standards.

• This cooker is heavy. Take care when

moving it.

• Any gas installation must be carried out by a

registered CORGI installer.

• Remove all packaging before using the

cooker.

• Ensure that the gas and electrical supply

complies with the type stated on the rating

plate, located near the gas supply pipe.

• Do not attempt to modify the cooker in any

way.

Child Safety

• This cooker is designed to be operated by

adults. Do not allow children to play near or

with the cooker.

• The cooker gets hot when it is in use.

Children should be kept away until it has

cooled.

• Children can also injure themselves by

pulling pans or pots off the cooker.

During Use

• This cooker is intended for domestic cooking

only. It is not designed for commercial or

industrial purposes.

• When in use a gas cooker will produce heat

and moisture in the room in which it has

been installed. Ensure there is a continuous

air supply, keeping air vents in good

condition or installing a cooker hood with a

venting hose.

• When using the cooker for a long period

time, the ventilation should be improved, by

opening a window or increasing the extractor

speed.

• Do not use this cooker if it is in contact with

water. Do not operate the cooker with wet

hands.

• The grill pan will become hot during use,

always use oven gloves when removing or

replacing a hot grill pan.

• Ensure the control knobs are in the ‘OFF’

position when not in use.

• When using other electrical appliances,

ensure the cable does not come into contact

with the hot surfaces of the cooker.

• Unstable or misshapen pans should not be

used on the hob burners as unstable pans

can cause an accident by tipping or spillage.

• Never leave the cooker unattended when

cooking with oil and fats.

• This cooker should be kept clean at all

times. A build-up of fats or foodstuffs could

result in a fire.

• Never use plastic dishes in the oven or on

the hob burners. Never line any part of the

oven with aluminium foil.

• Always ensure that the oven vent, which is

located at the centre back of the hob, is left

unobstructed to ensure ventilation of the

oven cavity.

• Perishable food, plastic items and aerosols

may be affected by heat and should not be

stored above the cooker.

Service

• This cooker should only be repaired or

serviced by an authorised Service Engineer

and only genuine approved spare parts

should be used.

Environmental Information

• After installation, please dispose of the

packaging with due regard to safety and the

environment.

• When disposing of an old appliance, make it

unusable, by cutting off the cable.

Keep this instruction book for future

reference and ensure it is passed on to

any new owner.

4

Page 5

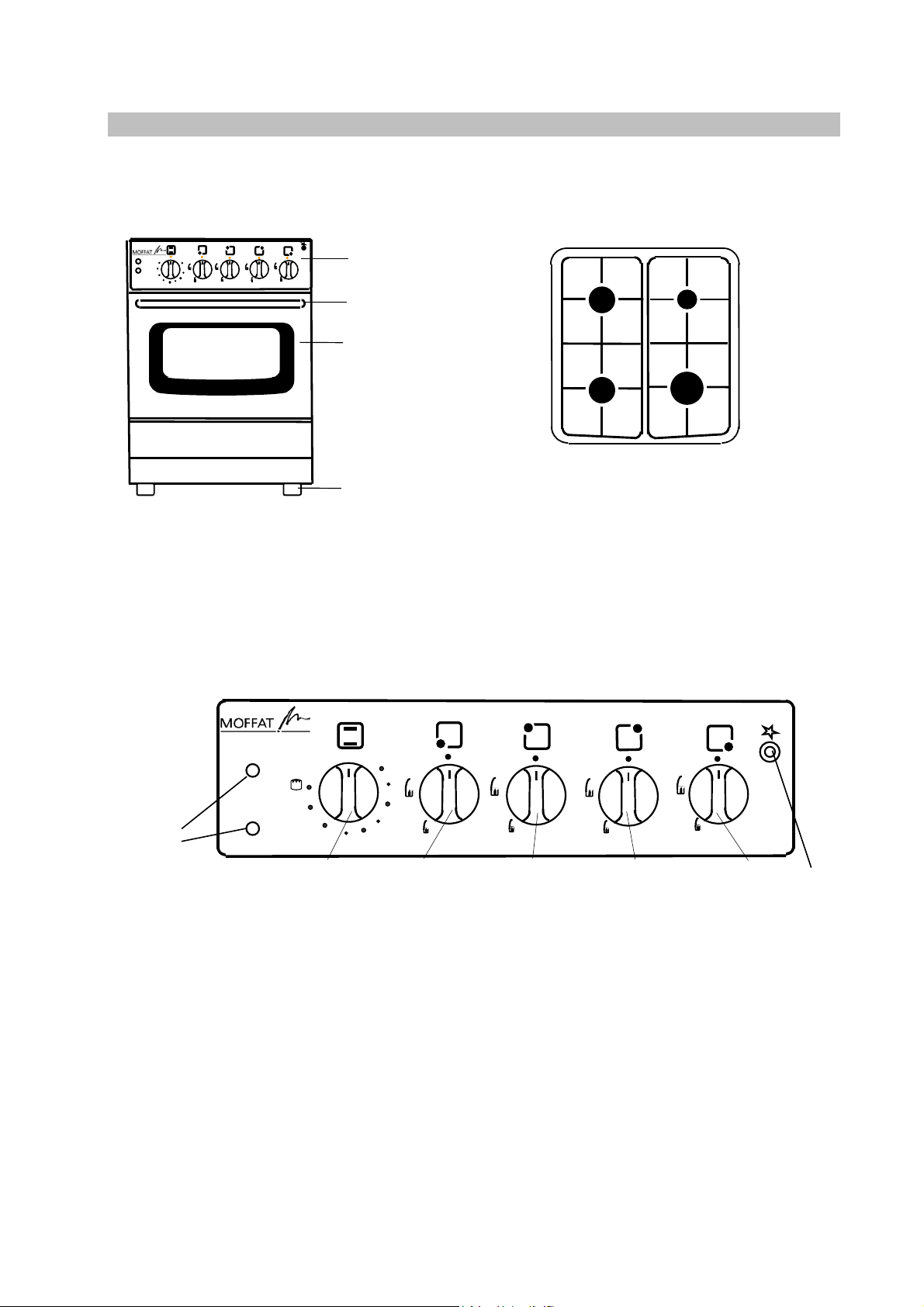

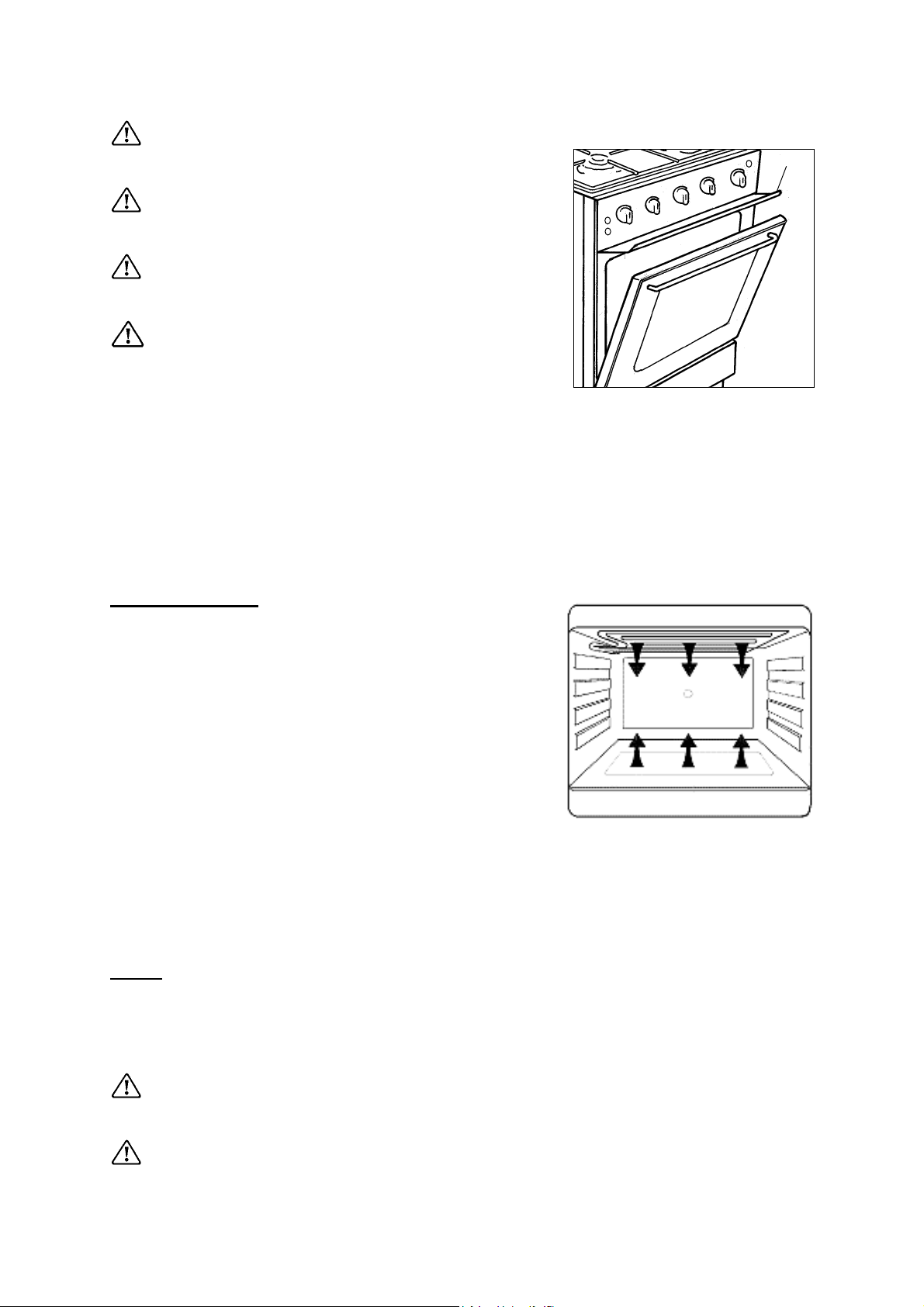

DESCRIPTION OF THE APPLIANCE

y

K

K

Hob

Control panel

Control panel

Handle door

Oven door with

glass

Adjustable

small feet

2,0kW

semi-rapid

1,0kW

auxiliar

2

1

semi-rapid

2,0kW

1. Front left burner (semi-rapid)

2. Back left burner (semi-rapid)

3. Back right burner (auxiliary)

4. Front right burner (rapid)

rapid

2,6kW

3

4

PILOT

LIGHT

MAIN

THERMOSTAT

250

200

OVEN

KNOB

Model : MSC 5061 W

normal

0

50

100

150

FRONT

LEFT

BURNER

CONTROL

KNOB

normal

BAC

LEFT

BURNER

CONTROL

KNOB

small rapid

BAC

RIGHT

BURNER

CONTROL

KNOB

MSC 5061 W

FRONT

RIGHT

BURNER

CONTROL

KNOB

IGNITION

SWITCH

5

Page 6

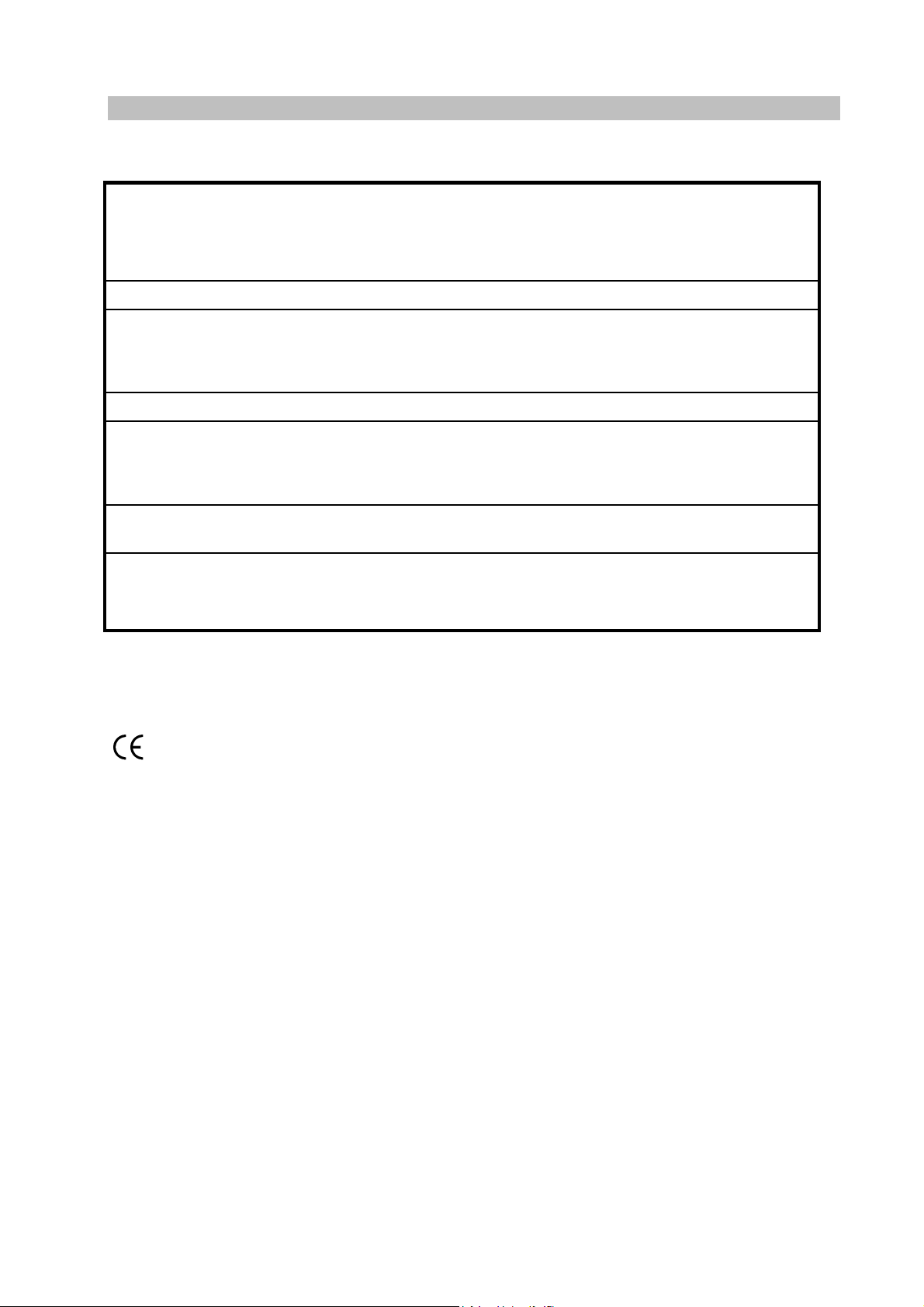

TECHNICAL FEATURES

Free standing Class 1

Hob Pan support

Front right

Back right

Front left

Back left

Total power 7,60 kW

Oven

Accessories

Supply

Dimensions Height to the hob

Oven

Oven power

Grill

Grill power

Total rating 1,80 kW

Oven grid

Roasting tray

Roasting grid

Protective screen

Rated voltage

Rated frequency

Width

Depth

Enamelled

Rapid

Auxiliary

Semi-rapid

Semi-rapid

Electric

1,70 kW

Electric

1,80 kW

Chromed

Enamelled

Chromed

Enamelled

880 - 890 mm

500 mm

600 mm

2,60 kW

1,00 kW

2,00 kW

2,00 kW

240 V

50 Hz

This appliance complies with the following

EEC Directives :

89/336 (Electromagnetical Compatibility

Directive) and subsequent modifications,

90/396 (Gas Appliance Directive)

93/68 (General Directives) and subsequent

modifications.

6

Page 7

USING THE APPLIANCE

Using the electric oven

Before the first use ensure that the

room is well ventilated: V.M.C.

(Mechanic ventilation) or opened

window.

Before the First Use of the Cooker

Remove all packaging both inside and

outside of the cooker, before using it.

Before first use, the oven should be heated

without food. During this time, an unpleasant

odour may be emitted. This is quite normal.

1. Remove the oven accessories.

2. Detach the adhesive labels, the foil

protection if there is.

3. Heat the oven the corresponding knob on

position “250” for about 45 min.

Clean the accessorie(s) with a mild detergent.

Rinse and dry carefully.

During cooking in the oven the oven

door is hot. Take care that children do

not play near it.

During use the appliance becomes

hot. Care should be taken to avoid

touching heating elements inside the

oven.

The electric oven is equipped with 3 heating

elements:

- 2 heating elements (top and bottom) for

using the oven with closed door (pastry,

cakes,roasts)

- 1 heating grill element, placed in the middle

of top for grilling with door half opened

(steaks , toast)

Use

The oven can be used in traditional cooking or

for grilling, but not simultaneously.

Control knob

It makes possible to choose the most appropriate

temperature and to select the elements radiating

heat one by one.

Explanations of symbols:

0 Off positions

50-250 Temperature selection (bottom and top

heat)

Grill

To select the temperature turn the knob

clockwise until the pointer indicates the desires

temperature between 50°–250°C.

The temperature will be kept constant by the

thermostat.

250

200

0

50

100

150

7

Page 8

Electric grill

When grilling, the accessible parts of

the appliance are hot. Take care that

children do not play near it.

While the grill is in operation leave the

oven door half open and pull the

protective screen “A” into place.

During use the appliance becomes hot.

Care should be taken to avoid touching

heating elements inside the oven.

The grill pan will become hot during

use, always use oven gloves when

removing or replacing a hot grill pan.

The grill is used for grilling all kind of meat

(pork, beef…) which remain tender, toasts or

browning dishes already cooked.

If you place food directly on the grid, slide the

dripping pan directly under it to collect the

juices and fat.

For turning off the heating elements.

Turn the knob clockwise to position off “0”.

A

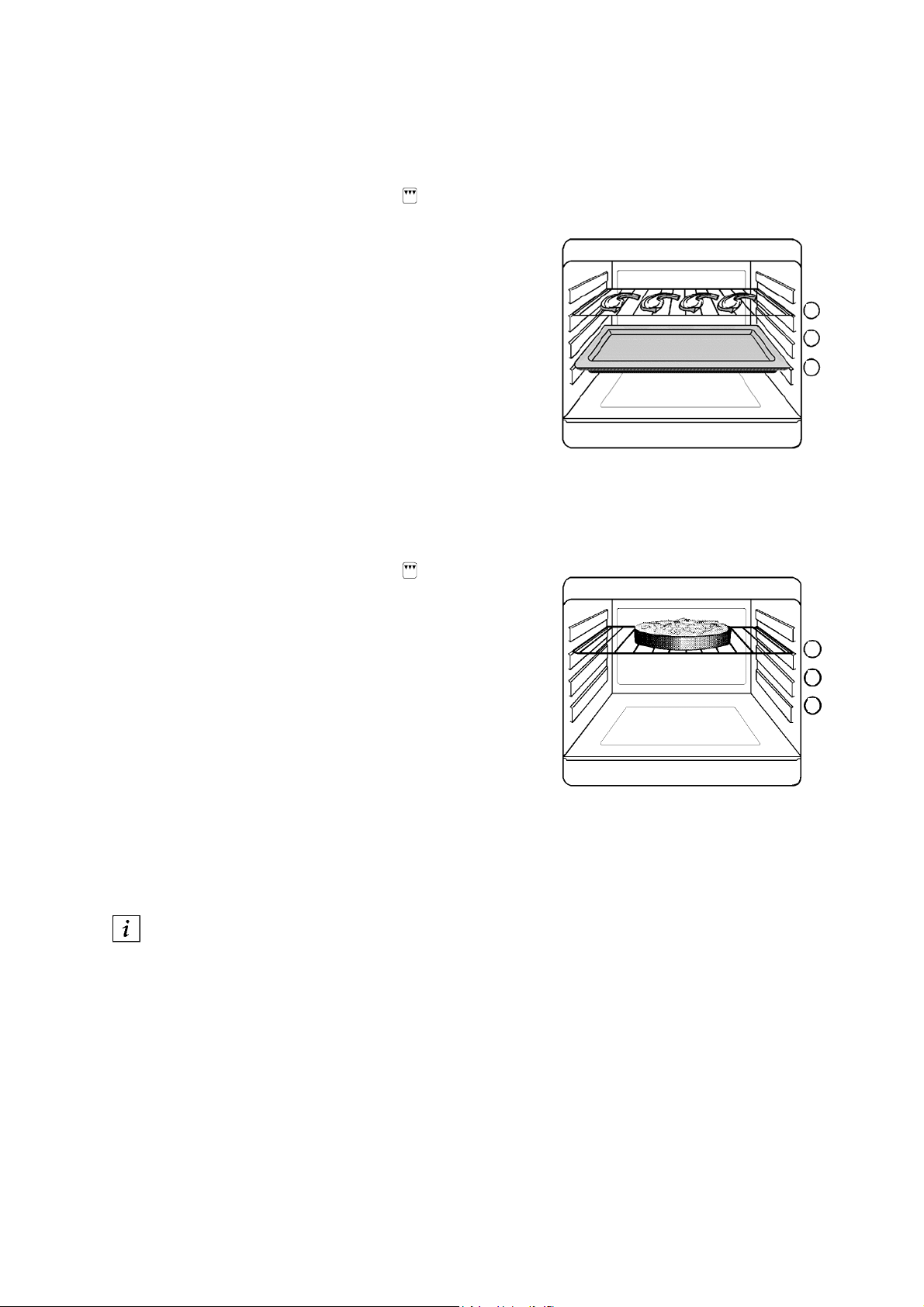

Cooking in the oven

Traditional cooking

Traditional cooking is made by natural

convection the heated air circulates on the

principle of ascending and descending draughts.

It is necessary to pre-heat the oven.

How to proceed ?

For small cakes, pastry, beaten mixture cakes in

moulds.

1. Preheat the oven the thermostat on

position chosen for cooking:

- about 8 min. for position 50°C to 150°C;

- about 15 min for position 175°C to 250°C;

2. Insert the meal.

Using the electric grill

Grilling

Heat comes from the top of the oven. It is

suitable for grilling meat (beef bacon, pork bacon

…) that remains tender, for toast or to brown

already cooked.

While the grill is in function leave the

oven door half open and pull the

protective screen “A” into place.

When grilling, the accessible parts of the

appliance are hot. Take care that

children do not play near it.

8

Page 9

Grilling

• Prepare the meat to be grilled, lightly brush it

with oil on both sides.

• Place it on the grill.

• Fix the protective screen.

• Turn the oven knob to the grill position

.

• Slide the dripping pan in the guide 1.

• Slide the pan support grid in the guide 2 or 3

depending on the thickness of the meat to be

grilled.

• Use guide 3 for the thin pieces to be roasted

(toasts, pork bacon, sausage, small fish…)

• Use guide 2 for thick pieces to be roasted (beef

bacon, large fish, poultry).

• When the first side is brown, turn the meat

without pricking it in order that the juices are

not lost.

• Grill the second side.

• Salt when ending the cooking.

Cooking time has to determined by the thickness of

the piece to be grilled not by its weight.

Browning

3

2

1

• Fix the protective screen.

• Turn the oven knob to the grill position

.

• Place the dish on the grid and slide it in the

guide 2 or 3.

• Leave the dish under the radiation of the grill for

a few minutes.

Main pilot light

This light will illuminate when the oven/grill knob is

turned on and remains lit while the oven is in

operation.

Oven thermostat pilot light

This light will illuminate when a temperature is

selected and remain lit until the selected

temperature has been reached. It then cycles on

and off to indicate that the temperature is being

maintained.

Hints and Tips

Condensation and steam

When food is heated it produces steam in the

same way as a boiling kettle. The oven vents

allow some of this steam to escape. However,

always stand back from the oven when

opening the oven door to allow any build up of

steam or heat to release.

If the steam comes into contact with a cool

surface on the outside of the oven, e.g. a trim, it

will condense and produce water droplets. This is

quite normal and is not a fault with the oven.

To prevent discolouration, regularly wipe away

condensation and also soilage from surfaces.

3

2

1

9

Page 10

Cookware

Use any ovenproof cookware, which will

withstand temperatures of 250

°

C.

Oven dishes, etc. should not be placed

directly on the oven base.

Oven Cooking

• Turn off the oven 5 minutes before the end of

cooking time, and use residual heat to

complete the cooking.

• The thickness, the material and the colour of

the pan will influence the cooking results.

• When cooking, certain dishes increase in

volume, ensure the pan is large enough.

• To prevent fat dripping when roasting use tall

rim pans proportional to the item being

roasted.

• Prick the skin of poultry and sausages with a

fork before cooking to avoid spitting.

Use heatproof glass dishes for soufflés.

Using the Hob

The Hob Burners

The symbol on the knob corresponds to a symbol

on the control panel (See description of appliance).

The effects of dishes on cooking results

Dishes and tins vary in their thickness,

conductivity, colour, etc. which affects the way

they transmit heat to the food inside them.

A Aluminium, earthenware, oven glassware

and bright shiny utensils reduce cooking and

base browning.

B Enamelled cast iron, anodised aluminium,

aluminium with non-stick interior and coloured

exterior and dark, heavy utensils increase

cooking and base browning.

Off

Maximum level

Minimum level

Use the maximum level for boiling and the

minimum for simmering.

Always choose positions between the minimum

and maximum, never between maximum and off.

Ignition of the burners

• Push the knob and turn it left to the “large

flame” symbol.

• At the same time, push the electronic

ignition knob (see fig). Keep it pushed untill

the gas ignites (1 spark / second).

• Release the knob and watch that the burner

has ignited.

• Upon ignition, adjust the flame as required.

OR

Lack of power

• Push the corresponding knob in completely

and turn it left to the “large flame” symbol and

ignite with a match.

• Release the knob and watch that the burner

has ignited. Upon ignition, adjust the flame as

required.

• If for any reason the flame should extinguish

turn off the relevant control know, leave for at

least one minute and then re-ignite.

Extinguishing of burners

Turn the knob clockwise to mark «

».

Do not put anything on the hob that is

10

Page 11

liable to melt.

(

)

Selecting the Correct burner

Above every knob there is a symbol for the

corresponding burner.

For good cooking results, always choose pans,

which correctly fit to the diameter of the burner

used (see figs). Choose thick, flat bottom pots.

We recommend the flame is lowered as soon as

the liquid starts boiling.

For a correct ignition always keep the burner ring

and the spark plugs clean.

The following diameter pans can be used:

Burner Power

Diameter (mm)

(kW) min. max.

Rapid 2,60 165 260

SemiRapid

2,00 140 220

Auxiliary 1,00 120 160

Accessories delivered with the

appliance

Good use

Bad use

Power waste

The following accessories are supplied with your

appliance.

• Shelf for placing dishes on (roast, pastry

mounds)

The dish should be put in the middle of the

shelf to balance the weight.

• A roasting tray with roasting grid on it.

It is used to collect juice when cooking in it,

place it on the shelf 2.

If you do not use the roasting tray, remove it

from the oven.

• A protective screen.

It is used for when using the grill.

In addition to the accessories supplied we

recommend you only use heatproof dishes/pans

(according to the instructions of the manufacturer).

11

Page 12

MAINTENANCE AND CLEANING

The oven should be kept clean at all

times. A build-up of fats or other

foodstuffs could result in a fire,

especially in the grill pan.

Before cleaning, ensure all control

knobs are in the OFF position, and the

appliance has cooled completely.

Before any maintenance or cleaning

can be carried out, you must

DISCONNECT the cooker from the

electricity supply.

Cleaning materials

Before using any cleaning materials on your

oven, check that they are suitable and that their

use is recommended by the manufacturer.

Cleaners that contain bleach should

NOT be used as they may dull the

surface finishes. Harsh abrasives

should also be avoided.

locking parts

External cleaning

Regularly wipe over the control panel, oven door

and door seal using a soft cloth well wrung out in

warm water to which a little washing up liquid

has been added.

To prevent damaging or weakening the

door glass panels avoid the use of the

following:

• Household detergent and bleaches

• Impregnated pads unsuitable for non

stick saucepans

• Brillo/Ajax pads or steel wool pads

• Chemical oven pads or aerosols

• Rust removers

• Bath/Sink stain removers

Oven Door

- The door can be dismantled for cleaning as

follows:

- Open the door completely

- Revolv the two locking parts on the hinge

arms completely upwards.

- Partially close the door, to a 30

- Lift the door and pull out

The internal

removed for cleaning. For this purpose

remove the 2 fixing screws.

and inner

water. Should the inner door glass become

heavily soiled it

cleaning

Keepers Friend be used.

Always support the door while removing the

glass panel as the door may spring closed due

to its lighter weight.

oven door glass can be

door glass using warm soapy

is recommended that a

product such as Hob Brite, or Bar

o

angle

Clean the outer

DO NOT clean the oven door while the

glass panels are warm. If this

precaution is not observed the glass

panel may shatter.

If the door glass panel becomes

chipped or has deep scratches, the

glass will be weakened and must be

replaced to prevent the possibility of

the panel shattering.

Contact your local Service Centre who

will be pleased to advise further.

IMPORTANT: The inner door glass must be in

place when using the oven.

12

Page 13

Oven Cavity

The enamelled oven cavity is best cleaned

whilst the oven is still warm.

Wipe the oven over with a soft cloth soaked in

warm soapy water after each use. From time to

time it will be necessary to do a more thorough

cleaning, using a proprietary oven cleaner.

Hob

After every use wipe with a soft cloth well wrung

out in warm water to which a little washing up

liquid has been added, avoiding any leakage

through the holes of the hob. Rinse and dry with

a soft cloth.

To remove more stubborn stains, wet and leave

to dissolve, do not scratch and avoid the use of

abrasive or caustic products that could damage

the enamel.

Burner cap

Burners

The burner caps and crowns can be removed

for cleaning.

Wash the burners caps and crowns using hot

soapy water, and remove marks with a mild

paste cleaner. A well-moistened soap

impregnated steel wool pad can be used with

caution, if the marks are particularly difficult to

remove.

After cleaning, be sure to wipe dry with a soft

cloth.

Burner

ring

Ignition

13

Page 14

SOMETHING NOT WORKING

If the appliance is not working correctly, please carry out the following checks, before contacting your

local Service Force Service Centre.

IMPORTANT: If you call out an engineer to a fault listed below, or to repair a fault caused by

incorrect use or installation, a charge will be made even if the appliance is under guarantee.

Symptoms Solutions

1. No burner ignition

2. The gas ring burns unevenly

3. The oven does come on

4. Cooking results are not satisfactory

5. The oven smokes

Check that:

• Gas supply is completely open

• The position of gas pipe is right

• The burner is not wet

• The burner cap and ring burner have been

replaced correctly after cleaning

Check that:

• The main jet is not blocked and the ring

burner is clean of food particles

• The burner cap and ring burner have been

replaced correctly after cleaning

Check that:

• a cooking function/temperature have been

selected;

Check that:

• the thermostat is placed correctly;

• the cooking time is adapted;

Check that:

• the oven does not need cleaning;

• the meal does not overflow;

• there is no excessive fat / juice projection on

the oven sides.

6. The oven does not work

If after these checks, the appliance still does not operate correctly, contact your local Service Force

Centre. When you contact the Service Force Centre you will need to give the following details:

1. Your name, address and post code.

2. Your telephone number

3. Clear and concise details of the fault

4. The model and serial number of the appliance (found on the rating plate*)

5. The purchase date

* The rating plate can be found on the lower left hand corner of the front frame of the cavity.

Please note that a valid purchase receipt or guarantee documentation is required for in-guarantee

service calls.

14

Check that:

• the appliance is not unplugged;

• there is no power break.

• the fuse connections are intact.

Page 15

SERVICE AND SPARE PARTS

In the event of your appliance requiring service, or if you wish to purchase spare parts, please contact

your local Service Force Centre by telephoning:-

08705 929929

Your telephone call will be automatically routed to the Service Force Centre covering your post code

area.

For the address of your local Service Force Centre and further information about Service Force, please

visit the website at www.serviceforce.co.uk

Before calling out an engineer, please ensure you have read the details under the heading “Something

Not Working” and have the model number and purchase date to hand.

In-guarantee customers should ensure that the checks under the heading “Something Not

Working” have been made as the engineer will make a charge if the fault is not a mechanical or

electrical breakdown. Please note that it will be necessary to provide proof of purchase for any inguarantee service calls.

Moffat has an agreement with Electrolux who will undertake all servicing requirements for your appliance.

CUSTOMER CARE

For general enquiries concerning your Moffat appliance and or for further information on our products,

contact our Customer Care Department by letter or telephone as follows:

Customer Care Department

Moffat

55-77 High Street

Slough

Berkshire

SL1 1DZ

Tel : 08705 950 950 (*)

(*) calls to this number may be recorded for training purposes.

15

Page 16

GUARANTEE CONDITIONS

Standard Guarantee Conditions

We Moffat undertake that if, within 12 months of the date of the purchase, this Moffat appliance or any

part thereof is proved to be defective by any reason only of faulty workmanship or materials, we will, at

our option, repair or replace the same FREE OF ANY CHARGE for labour, materials or carriage on

condition that:

• The appliance has been correctly installed and used only on the gas and electricity supply stated on

the rating plate.

• The appliance has been used for normal domestic purposes only, and in accordance with the

manufacturer's instructions.

• The appliance has not been serviced maintained, repaired, taken apart or tampered with by any

person not authorised by us.

• All service work under this guarantee must be undertaken by an Electrolux Service Force Centre.

• Any appliance or defective part replaced shall become the Company's property.

• This guarantee is in addition to your statutory and other legal rights.

Home visits are made between 8.30am and 5.30pm Monday to Friday. Visits may be available outside

these hours, in which case a premium will be charged.

Exclusions

This guarantee does not cover:

• Damage or calls resulting from transportation, improper use or neglect, the replacement of any light

bulbs or removable parts of glass or plastic.

• Costs incurred for calls to put right an appliance which is improperly installed or calls to appliance

outside the United Kingdom.

• Appliances found to be in use within a commercial or similar environment, plus those, which are the

subject to rental agreements.

• Products of Moffat manufacture which are not marketed by Moffat.

European Guarantee

If you should move to another country within Europe then your guarantee moves with you to your new

home subject to the following qualifications:

• The guarantee starts from the date you first purchased your product.

• The guarantee is for the same period and to the same extent for labour and parts as exist in the new

country of use for this brand or range of products.

• This guarantee relates to you and cannot be transferred to another user.

• Your new home is within the European Community (EC) or European Free Trade Area.

• The product is installed and used in accordance with our instructions and is only used domestically,

i.e. a normal household

• The electrical supply complies with the specification given in the rating label.

• The product is installed taking into account regulations in your new country.

Before you move, please contact your nearest Customer Care Centre, listed below, to give them details of

your new home. They will then ensure that the local Service Organisation is aware of your move and able

to look after you and your appliances.

France Senlis +33 (0) 3 44 62 20 13

Germany Nürnberg +49 (0) 800 234 7378

Italy Pordenone +39 (0) 800117511

Sweden Stockholm +46 (0) 20 78 77 50

UK Slough +44 (0) 1753 219898

16

Page 17

INSTRUCTIONS FOR THE INSTALLER

d

d

d

d

d

SAFETY ADVICE

• Before installation ensure that the local

distribution conditions (gas type and pressure)

and the pre-setting of the appliance are

consistent.

• This appliance must be installed only in a

room with good ventilation.

• This appliance must not connected to a flu. It

has to be installed and connected in

accordance with the rules in force. Special

attention should be paid to the applicable

disposal concerning ventilation.

• The adjacent furniture panels have to be heat

proof or protected by such material.

• The adjusting conditions of this appliance are

mentioned on the rating plate.

Connection to gas supply.

Check that the gas flow and the diameter of the

supply pipe is sufficient to supply all the

appliances of the installation.

• Check that all connections are tight.

• Install an accessible and visible gas tap to

isolate the appliance.

- Installation of flues and ventilation for gas

appliances of rated input not exceeding

60 kW (1

st

, 2

n

and 3

r

family gases) – Part

2 Specification for installation of

ventilation for gas appliances – BS 5440;

- Gas burning appliances – Part 3 Domestic

cooking appliances burning gas – BS

5386;

- Specification for installation of low

pressure gas pipe work of up to 20mm

(R1) in domestic premises (2

n

family gas)

– BS 6891;

- Pipe threads for tubes and fittings where

pressure-tight joints are made on the

threads (metric dimensions) – BS 21:

1985;

- Flexible hoses, end fittings and sockets

for gas burning appliances – BS 669;

Installation of domestic gas cooking

appliances (1

st

, 2

n

and 3

r

family gases) – BS

6172: 1990;

Electric connection

Check that:

• the power of the installation is enough;

• the supplying lines are in good conditions;

17

Page 18

ELECTRICAL CONNECTIONS

Any electrical work required to install

this cooker should be carried out by a

qualified electrician or competent person, in

accordance with the current regulations.

THIS COOKER MUST BE EARTHED.

The manufacturer declines any liability

should these safety measures not be

observed.

This cooker is designed to be connected to a 230240V, 50Hz AC electrical supply.

Before switching on, make sure the electricity

supply voltage is the same as that indicated on

the cooker ratin plate. The rating plate is located

on the oven frame.

The cooker is supplied with a 3 core flexible

supply cord incorporating a 13amp plug fitted.

In the event of having to change the fuse, a

13amp ASTA approved (BS 1362) fuse must be

used. Should the plug need to be replaced for

any reason, the wires in the mains lead are

coloured in accordance with the following code:

A cut off plug inserted into a 13 amp

socket is a serious safety (shock) hazard.

Ensure that the cut off plug is disposed of

safety.

Permanent Connection

In the case of a permanent connection, it is

necessary that you install a double pole switch

between the cooker and the electricity supply

(mains), with a minimum gap of 3 mm, between

the switch contacts and of a type suitable for the

required load in compliance with the current

electric regulations.

The switch must not break the yellow and green

earth cable at any point.

Ensure that the cooker supply cord

does not come into contact with surfaces

with temperatures higher than 50° C.

Green and Yellow - Earth

Blue

- Neutral

Brown - Live

- Connect the green and yellow (earth) wire to

the terminal in the plug which is marked with

the letter 'E' or the earth symbol or coloured

green and yellow.

- Connect the blue (neutral) wire to the

terminal in the plug which is marked with the

letter 'N' or coloured black.

- Connect the brown (live) wire to the terminal

in the plug which is marked with the letter 'L'

or coloured red.

Upon completion there must be not cut, or stray

strands of wire present and the cord clamp must

be secure over the outer sheath.

18

Page 19

TECHNICAL DATA

Table no.1

(Cat : II

2H3+

)

Burner

Normal

power

(kW)

Economic

power

(kW)

By-

pass

(mm)

Natural Gas

RAPID 2.60 0.72 0.42

Butane

Propane

SEMIRAPID

2.00 0.43 0.32

Natural Gas

Butane

Propane

Natural Gas

AUXILIARY 1 .0 0 0 .3 5 0 .2 9

Butane

Propane

INSTALLATION

Positioning

Remove all the packaging and install the cooker

in a dry, ventilated room not near curtains,

paper, alcohol, petrol etc. (See figure).

The appliance must be set on a heatproof floor.

This appliance is approved to class “X”

regarding overheating of surrounding surfaces.

Gas Type

660 mm

Pressure

(mbar)

20 mbar

28-30mbar

37mbar

20 mbar

28-30mbar

37mbar

20 mbar

28-30mbar

37mbar

150 mm

Nozzle

diameter

(mm)

1.12

0,86

0,86

0.96

0,71

0,71

0.70

0,50

0,50

Cons

m3/h g/h

0.248

188,8

0.191

145,2

0.093

72,6

610 mm

The cooking appliance must be fitted

with a stability chain firmly secured to

the wall (see fig)

Firmly fix

chain to rear

of cooker

Stability

chain

Stability

hook

Chain to be as

short as

practicable

19

Page 20

Ventilation

3

3

2

3

3

The room containing the cooker should have an

air supply in accordance with B.S. 5440: Part 2:

Current Editions.

The following requirements for ventilation must

be met.

The cooker should not be installed in a bed

sitting room with a volume of less than 20m

is installed in a room of volume less 5m

vent of effective area of 110cm

is required; if it

, if it

an air

is installed in a room of volume between 5m

and 10m3, an air vent of effective area 50cm2 is

required, while if the volume exceeds 11m

no

air vent is required. However, if the room has a

door, which opens directly to the outside, no air

vent is required even when the volume is

between 5m

3

and 11m3.

If there are other fuel burning appliances in the

same room, B.S. 5440: Part. 2: Current Editions

should be consulted to determine the requisite

air vent requirements.

Location

The cooker may be located in a kitchen, a

kitchen/diner or bed sitting room but not in a

bathroom or shower room.

For information regarding the fitting of flexible

supply pipes, the highest temperature at the rear

of this cooker which may come into contact with

the supply pipe is 70°C above ambient.

When the appliance has been installed there

must be enough space for the hotplate lid (when

present) to open fully.

Levelling

Fix the support with two legs with the washer

and nuts, delivered with the cooker, see the

figure.

• Unscrew the legs as far as possible (approx.

16mm from fully screwed in).

• Place the plinth (pos.3) so that the springs

(pos.2) reach the threaded area of the legs

and the clamp of the plinth (pos.4) is in front

of the holes (pos.5) on the under side of the

structure.

• Push the plinth towards the appliance with

both hands until the springs fasten on the

legs and the clamps go into the

corresponding holes.

• Adjust the legs as necessary.

4

5

3

2

1

20

Page 21

GAS CONNECTIONS

Your cooker is delivered adjusted for the kind of

gas stated on the rating plate

If the appliance is supplied with natural gas and

the pressure for natural gas is 20mbar. The

following methods of connection to the gas

supply must be used:

BACK OF THE COOKER

Right Hand Connection (from front)

Ensure that the rubber hose is not in contact

with any part of the hatched area shown in the

diagram and that the loop of the hose when

connected is not in contact with the floor when

the appliance is in position.

Left Hand Connection (from front)

Ensure that the rubber hose is not in contact

with any part of the hatched area shown in the

diagram and the hose is retained in the clamp

provided, it will be necessary to fit the maximum

length hose when using this method.

Rigid Connection

Where it is not possible to make the connection

using a rubber hose, a rigid pipe work

connection must be used.

connection

of flexible

hose

power cord

clamps

BACK OF THE COOKER

power cord

connection

of flexible

hose

clamps

Recommendations when using an appliance

flexible connector are as follows:

- For NATURAL the gas installation pipes to the

termination point shall comply with:

Specification for installation of low-pressure

gas pipe work of up to 20mm (R1) in

domestic premises (2nd family gas) – BS

6891;

Connection shall be by means of an appliance

flexible connector for use with a self-sealing

plug-in device, complying with:

Flexible hoses, end fittings and sockets for

gas burning appliances – BS 669;

21

Page 22

The appliance flexible connector should not be

subjected to undue forces either in normal use

or whilst connected or disconnected;

- The socket which the plug of the appliance

flexible connector fits should be permanently

attached to a firmly fixed gas installation

pipe and positioned such that the appliance

flexible connector hose hangs freely

downwards (see fig.);

22

- The appliance flexible connector should be

positioned such that it will not suffer

mechanical damage, e.g. abrasion from the

surrounding kitchen furniture, which may be

moved in use such as a drawer or door, or

by being trapped by any stability device.

The plug-in-connector should be accessible

for disconnection after moving the

appliance.

Page 23

Electrical connection

Important

In any connection way the appliance

has to be grounded, in accordance with the

national rules in force. We decline any

responsibility in case of accidents due to no

grounding or wrong grounding.

Fuse capacity: 10A

NOTE: The earth wire should be about 2 cm

longer than the live and neutral wires.

Note:

Check on the rating plate the value for the total

connection power for establishing the fuse

power.

The supply cord must be positioned in such a

way as it does not reach in any point a

temperature higher by 50ºC than the room

temperature.

Before connecting check that:

Warning

It is forbidden to route the supply cord

across the back of the oven.

YES

power cord

NO

power cord

• fuse and household electric installation can

bear the charge of the appliance (see rating

plate);

• The plug used for connection is easily

reachable when the appliance is installed.

Important

If the supply cord is damaged it must be

replaced by the manufactuer or its service

agent or a similarly qualifid person in order

to avoid a hazard.

23

Page 24

CONVERSION OF GAS

Your cooker is designed to work with natural gas,

propane or butane. It is not designed for butane

or propane air.

The LPG conversion kit is available from your

Service Force Centre and must be fitted by a

Corgi Registered engineer.

For changing the gas type it is necessary to:

• replace the nozzles (hob);

• adjust the minimum level (hob);

• check the gas connection;

Replace the nozzles of the hob burners

Every appliance has spare nozzles for every type

of gas. The whole length of every nozzle is

marked in millimetres on the nozzle.

Hob burners

• Remove the pan support;

• Remove the caps and the burner crowns;

• Using a No 7 socket spanner unscrew the

nozzles and replace them with those required

for the type of gas in use (see table no. 1).

• Reassemble the parts following the same

procedure in reverse.

These burners do not need any primary air

regulation.

Stick the label supplied with the

appliance (in the nozzles bag) corresponding

to the gas type utilised.

Adjustment of minimum level for the hob

burners

The burner is correctly adjusted when the flame

is stable silent and goes out without any noise.

When changing the type of gas check that the

minimum level is correct. The air admission is

correct when the flame is about 4 mm in length.

The top burners do not need adjustment of

primary air.

Check that, turning the knob quickly from the

maximum position to the minimum one, the flame

does not go out.

Hob burners

To adjust the minimum level:

• Light the burner

• Turn the knob to the position of the minimum

flame;

• Remove the knob;

• Unscrew or screw the by-pass screw (on the

left above of tap shaft) until a regular small

flame is reached.

• For LPG screw completely the by-pass screw.

• Reassemble the parts following the same

procedure in reverse.

Check that, when turning the knob quickly from

the maximum position to the minimum one, the

flame does not go out.

AFTER COMPLETATION OF ANY REPAIRS,

ADJUSTMENTS OR CONVERSION THE

STATUTORY SAFETY TESTS MUST BE CARRIED

OUT.

24

Page 25

252627

Page 26

Page 27

Page 28

342 737 614

28

Loading...

Loading...