Page 1

TECHNICAL DATA SHEET FOR

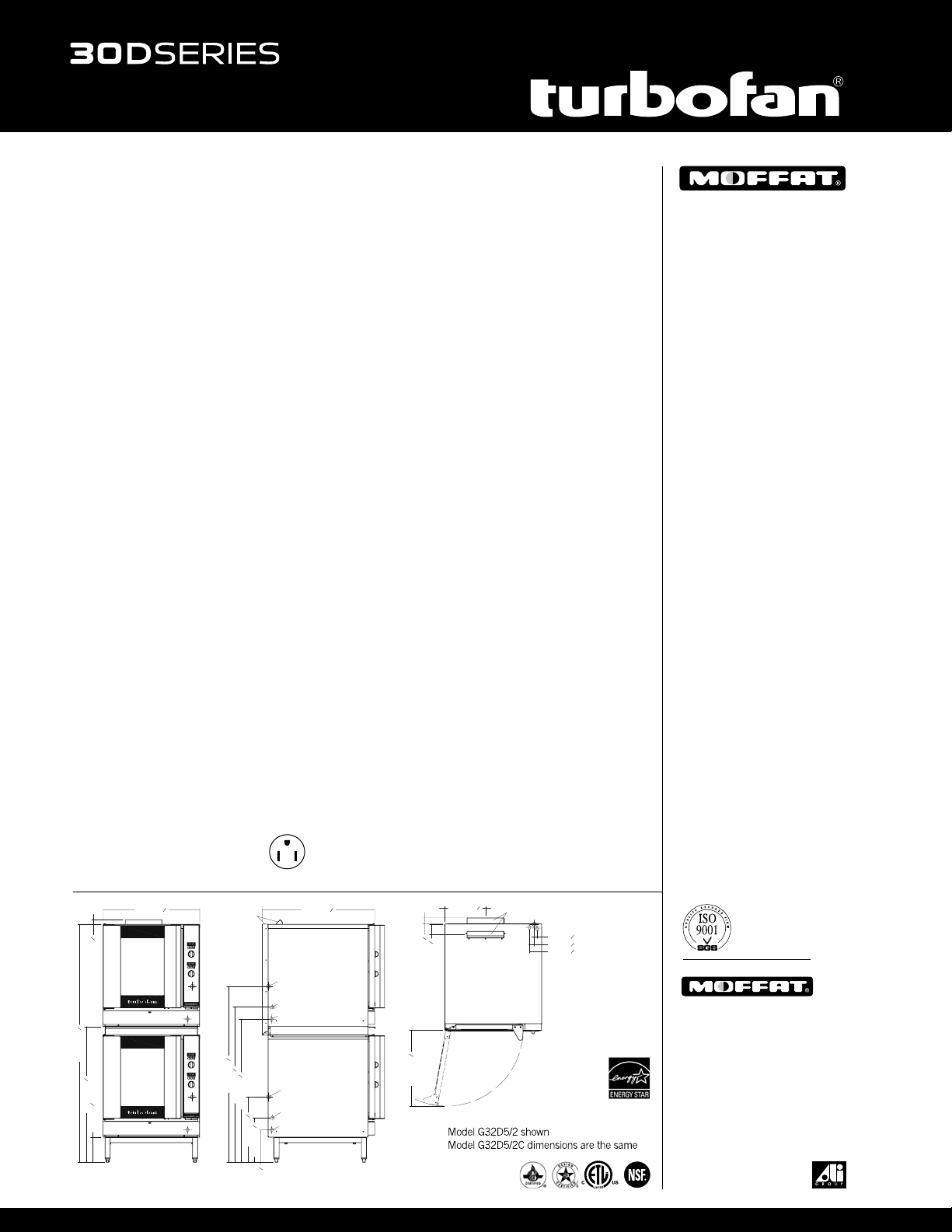

G32D5 DOUBLE STACKED

Full Size Digital / Gas Convection Ovens

Double Stacked on a Stainless Steel Base Stand

G32D5/2 - Double stack with adjustable feet base stand

G32D5/2C - Double stack with castor base stand

DOUBLE STACK FEATURES

• Two 5 full size sheet pan capacity ovens

• Compact 28

• Full stainless steel base stand

• Full stainless steel oven spacer frame

• Adjustable feet or castor models

OVEN FEATURES (each)

1

/3” / 85mm tray spacing

• 3

• 110-120V plug-in

• 15A NEMA 5-15P cordset fitted

• Digital display Time and Temperature Controls

• Large easy view ¾” / 20mm high displays

• Electronic thermostat control

• Electronic burner ignition and safety control system

• Electronic timer with countdown or time count modes

Manual mode and Program mode

NEW

20 programs with 3 stage cooking and stage end alarms

NEW

Core Probe program cooking (optional Core Probe Kit)

NEW

• Moisture injection mode (5 levels) and manual injection

• Bi-directional reversing fan system

• 33,000 Btu/hr patented Infrared burner system

• Safe-Touch vented side hinged door (standard LH

hinge). Optional RH hinge (field convertible)

• Stay-Cool door handle

• Porcelain enameled oven chamber

• Plug-in continuous oven door seal

• Dual halogen oven lamps

• 5 oven wire racks supplied

ACCESSORIES

• Optional M236060 Core Temp Probe Kit

7

/8” / 735mm width

G32D5/2

G32D5/2C

Model G32D5/2C shown

G32D5/2 G32D5/2C

G32D5 ovens shall be Moffat gas heated Turbofan convection ovens NSF-4 and CSA listed. The ovens shall have a one piece porcelain enameled oven chamber,

stainless top and sides and safe touch vented easy clean side hinged door that offers field reversible hinging. Ovens shall have capacity for five full size sheet pans

each. The ovens shall be controlled by an electronic control having separate digital displays and adjusting knobs for time and temperature functions. The oven control

shall allow both manual and programmed operating modes with programmable moisture injection and 3 stage cooking. A core temperature probe M236060 is optional.

The units shall include dual halogen oven lamps. Ovens shall be fitted with a NEMA 5-15P cordset. Ovens shall be double stacked using Double Stacking Kits DSKG32

(adjustable feet option) or DSKG32C (castor option). Units shall be supplied in 100% recyclable shipping packaging.

Double stack models are supplied as two individual ovens and a double stacking kit for field assembly.

Page 2

G32D / 2

308 mm / 12

1

"

GAS

G32D5/2

G32D5/2C

G32D5/2 G32D5/2C Full Size Digital / Gas Convection Ovens

Double Stacked on a Stainless Steel Base Stand

CONSTRUCTION - OVENS

Porcelain enameled fully welded oven chamber

Stainless steel front, sides and top exterior

Stainless steel oven fan baffle

Removable 5 position stainless steel side racks

Oven racks chrome plated wire (5 supplied)

Stainless steel frame side hinged door

0.2” / 5mm thick door outer glass

0.2” / 5mm thick low energy loss door inner glass

Full stainless steel welded door handle

Stainless steel control panel

Aluminized coated steel base and rear panels

CONSTRUCTION - DOUBLE STACKING KIT

All stainless steel construction

Welded 1½” square base stand

4 adjustable feet on G32D5/2

4 dia. 3” / 76mm swivel castors with 2 front castors dual wheel

and swivel lock on G32D5/2C

Stainless steel oven spacer frame

Aluminized steel bottom oven flue extension

CONTROLS (each oven)

Electronic controls with Digital Time and Temperature display,

Manual or Program modes

Large ¾” / 20mm high LED displays

Two individual time and temperature setting control knobs

ON/OFF key

Oven Lights key

Timer Start/Stop key

Moisture Injection key (5 levels)

Programs select key

Actual temperature display key

Adjustable buzzer/alarm volume

Thermostat range 150-500°F / 50-260°C

Timer range from 180 minutes in countdown mode

Timer range up to 999 minutes in time count mode for holding,

slow cooking

Direct burner ignition control flame failure safety control

Optional Core Probe temperature range 122-194°F / 50-90°C

Over-temperature safety cut-out

CLEANING

Stainless steel top and side exterior panels

Porcelain enameled oven chamber

Fully removable stainless steel oven side racks

Removable stainless steel oven fan baffle

Easy clean door system with hinge out door inner glass (no tools

required)

Removable plug-in oven door seal (no tools required)

SPECIFICATIONS

Electrical Requirements (each oven)

110-120V, 60Hz, 1-phase, 1A

NEMA 5-15P cordset fitted

Gas Requirements (each oven)

33,000 Btu/hr / 35MJ/hr burner rating

Natural, Propane/Butane models

Unit supplied complete with gas type conversion kit

Gas Connection (each oven)

½” NPT male

Water Requirements (optional - each oven)

Cold water connection ¾” GHT male

80psi maximum inlet pressure / 20psi minimum inlet pressure

External Dimensions

Width 28

Height 71

Depth 33

7

/8” / 735mm

1

/4” / 1810mm

3

/4” / 856mm

Oven Internal Dimensions (each oven)

Width 18¼” / 465mm

Height 20¼” / 515mm

Depth 27½” / 700mm

Volume 6ft³ / 0.17m3

Oven Rack Dimensions

Width 18” / 460mm

Depth 26” / 660mm

Nett Weight (double stack complete)

546lbs / 248kg

Packing Data

Ovens (G32D5 each) Stacking Kit

289lbs / 131kg 47lbs / 22kg

25ft³ / 0.71m3 51lbs / 23kg (DSKG32C)

5.8ft³ / 0.16m3 (DSKG32)

4.1ft³ / 0.12m3 (DSKG32C)

Width 297/8” / 760mm Width 303/8” / 770mm

Height 39

Depth 36

3

/4” / 1010mm Height 35” / 890m

3

/8” / 925mm Depth 91/2” / 240mm (DSKG32)

6

Supplied CKD for assembly on site

INSTALLATION CLEARANCES

NON-COMBUSTIBLE COMBUSTIBLE

SURFACES SURFACES

Rear 3” / 75mm 3” / 75mm

LH Side 2” / 50mm 2” / 50mm

RH Side* 3” / 75mm 3” / 75mm

* For fixed installations a minimum of 20” / 500mm is required

for service

CLEARANCE FROM SOURCES OF HEAT

A minimum distance of 12” / 300mm from the appliance sides

is required

Double Stacking Kits

For after market double stacking two G32D5 convection ovens

DSKG32 - Double stacking kit - adjustable feet

DSKG32C - Double stacking kit - castor

(DSKG32)

3

/4” / 170mm (DSKG32C)

www.moffat.com

U.S.A.

Moffat Inc

3765 Champion Boulevard

Winston-Salem

North Carolina 27105

Ph Toll Free 1-800-551 8795

Ph 336-661 0257

Fax 336-661 9546

Email sales@moffat.com

www.moffat.com

Manufactured by:

Moffat Limited

16 Osborne Street PO Box 10-001

Christchurch 8081 New Zealand

7

735 mm / 28

"

8

"

8

3

1

/

m

m

5

3

"

4

1

1

7

/

mm

0

1

8

1

"

8

5

0

4

/

m

m

"

2

1

33

7

10

/

m

m

91

1

GAS

FLUE

WATER

CONNECTION

ELECTRICAL

ENTRY

GAS

ENTRY

"

8

5

2

5

"

2

/

1

"

m

8

46

7

m

/

2

8

4

WATER

m

/

3

3

CONNECTION

m

m

1

2

m

18

8

1

8

0

ELECTRICAL

1

ENTRY

"

2

1

GAS

19

"

8

ENTRY

/

3

3

m

1

/

m

m

96

4

m

40

3

"

4

3

9

/

m

m

46

2

856 mm / 33

3

"

4

"

4

3

1

1

/

mm

46

"

8

5

2

2

/

m

m

5

57

8

FLUE

"

4

3

/

m

m

2

8

35 mm / 1

55 mm / 2

92 mm / 3

3

"

8

1

"

8

5

"

8

Designed and manufactured by

ISO9001

All Turbofan products are designed and

manufactured by Moffat using the

internationally recognised ISO9001

quality management system, covering

design, manufacture and final inspection,

ensuring consistent high quality at all times.

In line with policy to continually develop

and improve its products, Moffat Limited

reserves the right to change specifications

and design without notice.

© Copyright Moffat Ltd

Moffat 1419 / 7.14

ISO9001

Quality

Management

Standard

Loading...

Loading...