Page 1

30D

SERIES

G32D4/D5

(Digital Operation)

Service Manual

11 May 2015

Amendment 10

Page 2

MANUFACTURED BY

Moffat Limited

Rolleston 7675

New Zealand

INTERNATIONAL CONTACTS

AUSTRALIA

Moffat Pty Limited

Web: www.moffat.com.au

E.Mail: vsales@moffat.com.au

Main Office: (tel) +61 (03) 9518 3888

(fax) +61 (03) 9518 3833

Service: (tel): 1800 622 216

Spares: (tel): 1800 337 963

Customer Service: (tel): 1800 335 315

(fax): 1800 350 281

CANADA

Serve Canada

Web: www.servecanada.com

E.Mail: info@servecanada.com

Sales: (tel): 800 551 8795 (Toll Free)

Service: (tel): 800 263 1455 (Toll Free)

NEW ZEALAND

Moffat Limited

Web: www.moffat.co.nz

E.Mail: sales@moffat.co.nz

Main Office: (tel): 0800 663328

UNITED KINGDOM

Blue Seal

Web: www.blue-seal.co.uk

E.Mail: sales@blue-seal.co.uk

Sales: (tel): +44 121 327 5575

(fax): +44 121 327 9711

Spares: (tel): +44 121 322 6640

(fax): +44 121 327 9201

Service: (tel): +44 121 322 6644

(fax): +44 121 327 6257

UNITED STATES

Moffat

Web: www.moffat.com

Sales: (tel): 800 551 8795 (Toll Free)

Service:

REST OF WORLD

Moffat Limited

Web: www.moffat.co.nz

E.Mail: export@moffat.co.nz

(tel): +1 336 661 1556

(fax): +1 336 661 9546

(tel): 866 673 7937 (Toll Free)

(tel): +1 336 661 1556

(fax): +1 336 661 1660

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in writing

by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and design

without prior notice.

© Copyright Moffat Ltd. May 2015.

11 May 2015

Amendment 10

Page 3

Contents List

G32 Turbofan Convection Oven.

Model Numbers Covered in this Manual

G32D4 - Turbofan Oven - 4 Tray Convection Oven.

G32D5 - Turbofan Oven - 5 Tray Convection Oven.

Specifications ........................................................................................................................... 2

Installatio n ............................................................................................................................... 4

Installation Requirements

Unpacking

Location

Clearances

Stand Mounted Ovens

Electrical Connection

Gas Connection

Recommended Water Specifications

Water Connection

Positioning and Levelling of Oven

Stand Mounted Ovens

Initial Start-Up

Commissioning

Operation .................................................................................................................................. 7

Oven Control Panel (Up to Ser. No. 762119)

Oven Control Panel (From Ser. No. 762120)

Changing Operator Settings

Operator Settings

Parts Replacement ................................................................................................................. 10

5.1 Parts Replacement

5.2 Adjustment and Calibration

Controller Programming ........................................................................................................ 22

6.1 Viewing / Changing Service Parameters

6.2 Viewing / Changing Service Parameters (Up to Ser No. 762119)

6.3 Viewing / Changing Service Parameters (From Ser No. 762120)

E

Wiring Diagrams..................................................................................................................... 2

Exploded Parts Lists ............................................................................................................... 2

Accessories ............................................................................................................................ 3

Gas Conversion and S

Appendix 1 - Oven Door Reversal ........................................................................................... 39

WARNING:

11 May 2015

lectrical Schematics ............................................................................................................. 26

7

9

6

pecifications ........................................................................................ 37

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY QUALIFIED PERSONS ONLY.

IMPROPER INSTALLATION, ALTERATION, ADJUSTMENT, MAINTENANCE OR SERVICE MAY CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

ENSURE ELECTRIC AND GAS SUPPLIES ARE TURNED OFF BEFORE SERVICING.

ALWAYS TEST AFTER SERVICE REPAIRS

Amendment 10

Page 4

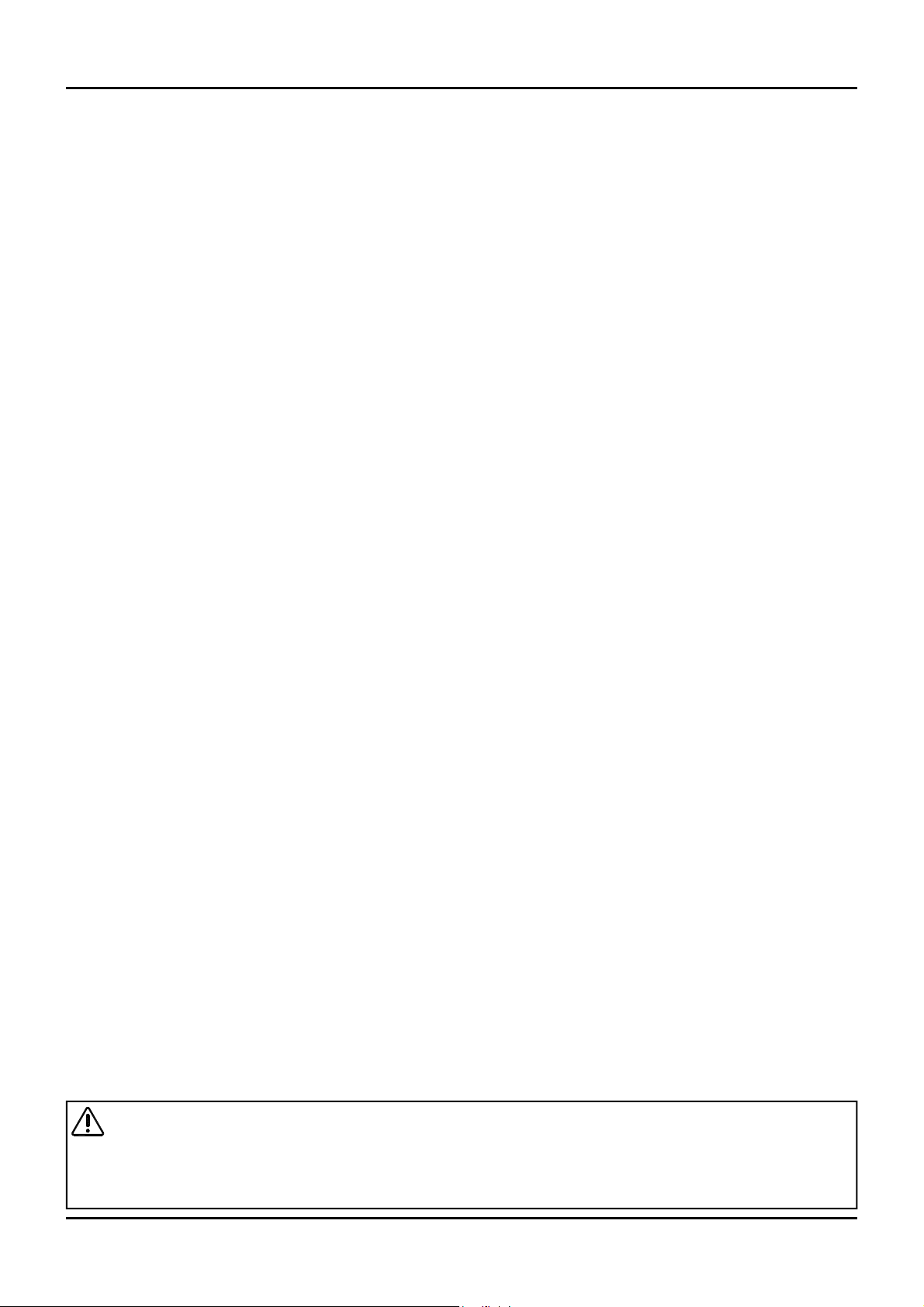

1 Specifications

G32D4/D5

11 May 2015

2

Amendment 10

Page 5

Oven Gas Supply Requirements and Specifications

G32D5 (110 - 120V):

Natural Gas LP Gas

Input Rating 35 MJ/hr. 35 MJ/hr.

Supply Pressure

1.75 kPa. 2.75 kPa.

Operating Pressure 1.05 kPa. 2.75 kPa.

Gas Connection ½” NPT.

Electrical Power Ratings 1 Phase, 110-120V, 60HZ, 220W.

Oven Tray Details

Water Connection

Tray Capacity

Tray Spacing

5 x US Full Pan.

85mm / 31/3”.

¾” BSP with ¾” GHT Adaptor supplied (80 psi / 550 kPa

maximum pressure).

Specifications 1

G32D4 (

240V) - UK Only:

Category: II

Flue Type: A

2H3P.

1.

Natural Gas Propane

Input Rating 10 kW 10 kW

Supply Pressure 20 mbar 30 - 37 mbar

Operating Pressure 10 mbar 25 mbar

Gas Connection ½” BSP Male.

Electrical Power Ratings 220-240V, 1P+N+E, 50/60HZ, 200W.

4, 18” x 26” / 460 x 660 Full Size Sheet Pan Capacity.

4, 600 x 400 Tray Capacity.

110mm.

Oven Tray Details

Tray Capacity

Tray Spacing

Water Connection ¾” BSP (80 psi / 550 kPa maximum pressure).

G32D4 (

220 - 240V) - All Other Markets:

Natural Gas LP Gas (Propane)

Input Rating 35 MJ/hr. 35 MJ/hr.

Supply Pressure 1.13 - 3.4 kPa. 2.75 - 5.0 kPa.

Operating Pressure 0.75 kPa. 2.35 kPa.

Gas Connection ½” BSP Male.

Electrical Power Ratings 220-240V, 1P+N+E, 50/60HZ, 200W.

Oven Tray Details

Tray Capacity

Tray Spacing

4 x US Full Pan / EN 600 x 400.

110mm.

Water Connection ¾” BSP (80 psi / 550 kPa maximum pressure).

11 May 2015

3

Amendment 10

Page 6

2 Installation

Installation Requirements

Important:

Installation shall comply with local gas, electrical and health and safety requirements.

It is most important that this oven is installed correctly and that oven operation is correct before use.

If you have any questions regarding the proper installation and / or operation of this oven, please contact your local

Turbofan distributor.

This installation of this appliance must conform with local codes, or in the absence of local codes, must conform to the National Codes shown

below covering gas and electrical safety.

Australia: - AS5601 - Gas Installations.

New Zealand: - NZS5261 - Gas Installation.

Australia / New Zealand: - AS/NZS3000 - Wiring Rules.

United Kingdom: - Gas Safety (Installation & Use) Regulations 1998.

Ireland: - IS 820 - Non - Domestic Gas Installations.

- BS6173 - Installation of Catering Appliances.

- BS5440 1 & 2 - Installation Flueing & Ventilation.

- BS7671 - Requirements for Electrical Installations.

Installation

Installations must be carried out by authorised persons only.

Failure to install equipment to the relevant codes and

manufacturers specifications shown above, will void the warranty.

This oven must be electrically earthed / grounded in accordance

with local codes.

Installation must allow for a sufficient flow of fresh air for the

combustion air supply. Combustion air requirements:

Natural Gas 10m³/hr.

LPG

Components having adjustments protected (e.g. paint sealed) by

manufacturer are only to be adjusted by an authorised service

agent. They are not to be adjusted by the installation person.

9m³/hr.

Unpacking

1. Remove all packaging and transit protection including all

protective plastic coating from the exterior stainless steel

panels.

2. Check the oven and supplied parts for damage. Report any

damage immediately to the carrier and distributo

3.

Check that the following parts have been supplied with yo

oven:

-

4 x Leg Adjustable.

Adaptor Brass.

Rubber Washer.

4. Report any deficiencies to the distributor who supplied yo

oven.

Securely fit the 4 legs supplied with the ov

5.

Check that the available gas and electrical supply is correct to

6.

that shown on the Technical Data Plate located on the fron

ri

ght hand side panel.

USA / Canada Only)

r.

en.

Refer to ‘Specifications’ section, ‘Oven

Specifi

cations Tables’.

ur

ur

t

11 May 2015

Technical Data Plate - Location

4

Amendment 10

Page 7

Installation 2

Location

1. This oven must be installed in an area of adequate air supply.

Adequate ven

of combustion products. DO NOT obstruct the

up

around

2. This oven must be fitted on supplied legs in all installations.

(When installed on a manufacturers stand, the le

to l

ocate the oven in the correct position.

3. All air for burner combustion is supplied from beneat

iance. Legs must always be fitted and no obstructions

appl

placed beneath or around the base of the applianc

structions will cause incorrect operation and / or failure

ob

the ap

4

. Installation must allow for a sufficient flow of fresh

ombustion air supply.

c

The area around the appliance must be kept free and cl

5.

from comb

6. Position the oven in its approximate working positi

should be positioned so that the control panel and ov

It

shelve

7

. Use a spirit level to ensure oven is level from side to si

t to back. (If this is not carried out, uneven cooking could

fron

occur).

The vent located on the top of the oven must NOT be

obstructed.

tilation is essential, to prevent dangerous buil

the ventilation slots.

gs are used

e.

plianc

ustibles.

s are easily reachable for loading and unloadi

Important:

Oven Vent

e, as

on.

d

air flow

h the

of

air for the

ear

en

ng.

de and

Electrical Connection

Warning

s oven must be earthed / grounded.

Thi

h oven should be connected to an adequately protected power

Eac

supply and an isolation switch mounted adjacent to, but not

behind the oven and must be readily accessible to the operator.

This switch must be clearly marked and readily accessible in case

of fire.

Check the electricity supply is correct to as shown on the

Technical Data Plate on the front right hand corner of the oven

side panel.

Ensure that the oven is fitted with the appropriate power cord and

plug.

Gas Connection

A ½" BSP or ½" N.P.T connection is provided at the bottom rear

of the oven.

A restraint chain anchor has been provided below the gas

connection point on the appliance, for fitment of a restraint chain.

It is important that adequately sized piping run directly to the

connection joint on the oven with as few tees and elbows as

possible to give maximum supply volume.

A suitable jointing compound which resists the break down action

of LPG must be used on every gas connection.

Check all gas connections for leakages using soapy water or other

gas detecting equipment.

Clearances

1. To ensure correct ventilation for the motor and controller, the

lowing minimum installation clearances are to be adhered

fol

to:

CLEARANCE FR

A minimum distance of 300mm (12”) from appliance sides

is required.

Top 600mm/24” 200mm/8”

Left / Right

Hand Side

Rear 75mm/3” 75mm/3”

NOTE: Fixed installations require at least 500mm clearance

OM SOURCE OF HEAT.

Combustible

Surface

75mm/3” 75mm/3”

at the right hand side of oven for service access.

Non Combustible

Surface

Warning

use a naked flame to check for gas leakages.

Do not

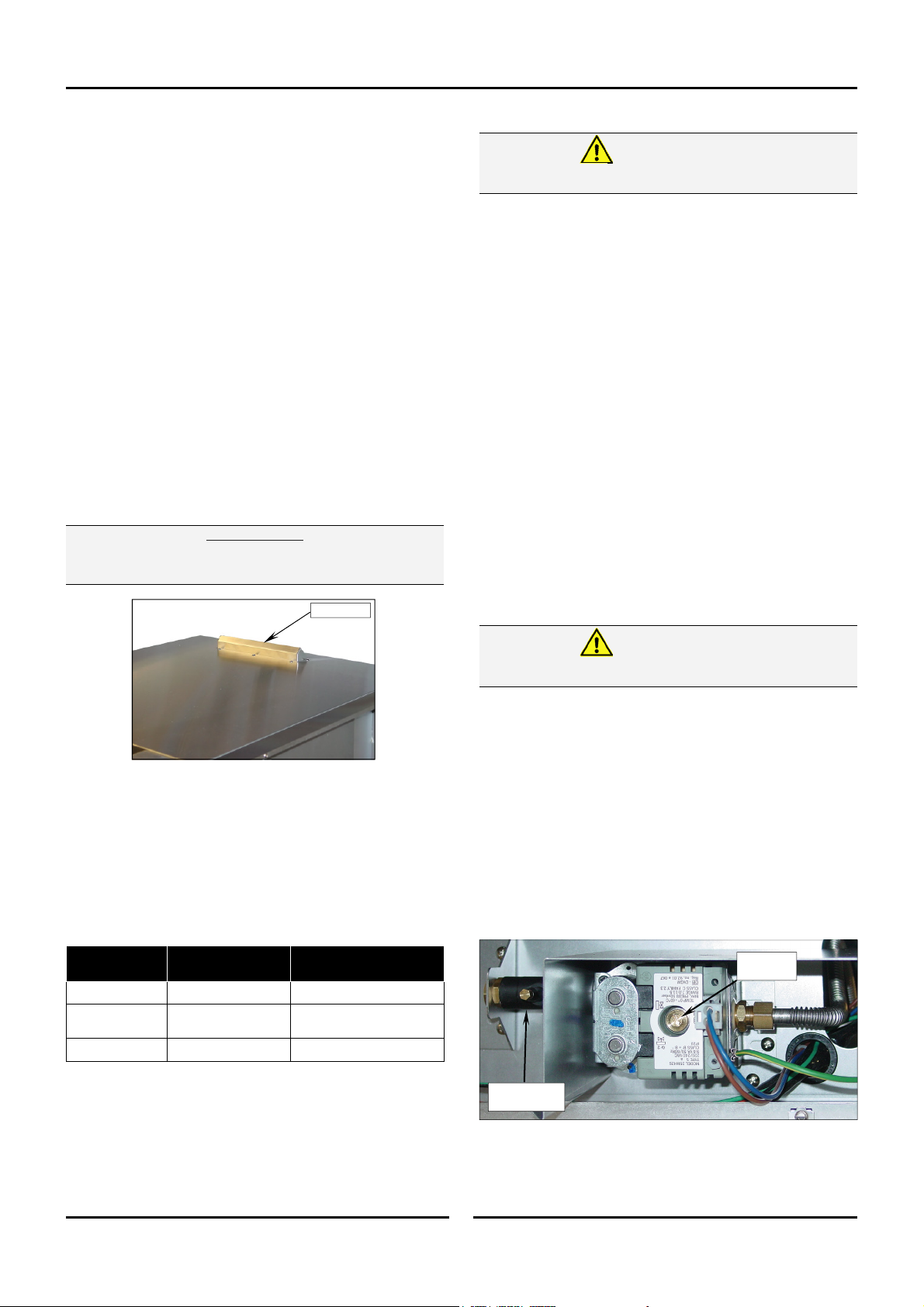

Check the technical data plate located on the front right hand

corner of the oven, for correct operating pressure and gas orifice

size for the gas being used, before operation.

The appliance combination gas valve is fitted with an internal

regulator for adjusting the operating pressure. To access, remove

appropriately marked service panel from beneath the oven door.

Unscrew and remove regulator cap from the gas valve. Adjust the

regulator to achieve the stated pressure. Also refer to the

‘Specifications’ section.

NOTE: The Pressure Test Point is located behind the front

Pressure Test

service panel beneath the oven door.

Regulator

Cap

Point

11 May 2015

5

Amendment 10

Page 8

2 Installation

Water Connection - Optional

NOTE: If the Moisture Mode cooking option is not required,

1. Tighten 2 screws securing water

2. Connect a cold water supply to th

3.

Recommended Water Specifications

In order to prevent corrosion or scaling in the oven and water

system due to supplying water that is either too soft or too hard,

the following recommendations should be used as a guideline.

Positioning and Levelling of Oven

1. Correctly locate the oven into its final operating position and

the oven does not need to be connected to a water

supply.

nection to rear of oven. (The

con

urposely been left loos

have p

prev

ent damage to the wate

nection during transit).

con

w

ater inlet (R ¾” Connector) on th

oven.

- Max Inlet Pressure 80psi / 550kPa.

Turn ‘On’ the water supply and check for leak

Hardness: Between 60 and 90ppm.

PH: Greater than 7.5.

Chlorides: Less than 30 ppm.

using a spirit level, adjust the oven feet so that the oven is

level and at the correct height.

r

e to

se

e

e

Tighten Screws.

s.

Stand Mounted Ovens

For ovens that are to be mounted to a stand, the oven legs are

used to level the oven on the stand. Refer to the

instructions supplied with separately ordered stands for mounting

details.

Initial Start-Up

Before using the new oven;

1. For first time use of the oven, operate the oven for about 1

hour at 200°C/ 400°F to remove any fumes or odours whic

be present.

may

2.

Please refer to the Operation Section of this manual for detail

on how t

Commissioning

Before leaving the new installation;

Check the oven functions in accordance with the operating

instructions specified in the ‘Operation’ section of this manual.

o correctly operate and shutdown the ov

en.

h

Lighting the oven.

Turning ‘Off’ the oven.

Ensure that the operator has been instructed in the areas of

correct lighting, operation, and shutdown procedure for the

appliance.

s

NOTE: If for some reason it is not possible to get the

appliance to operate correctly, shut off the gas

supply and contact the supplier of this appliance.

11 May 2015

6

Amendment 10

Page 9

Operation Guide

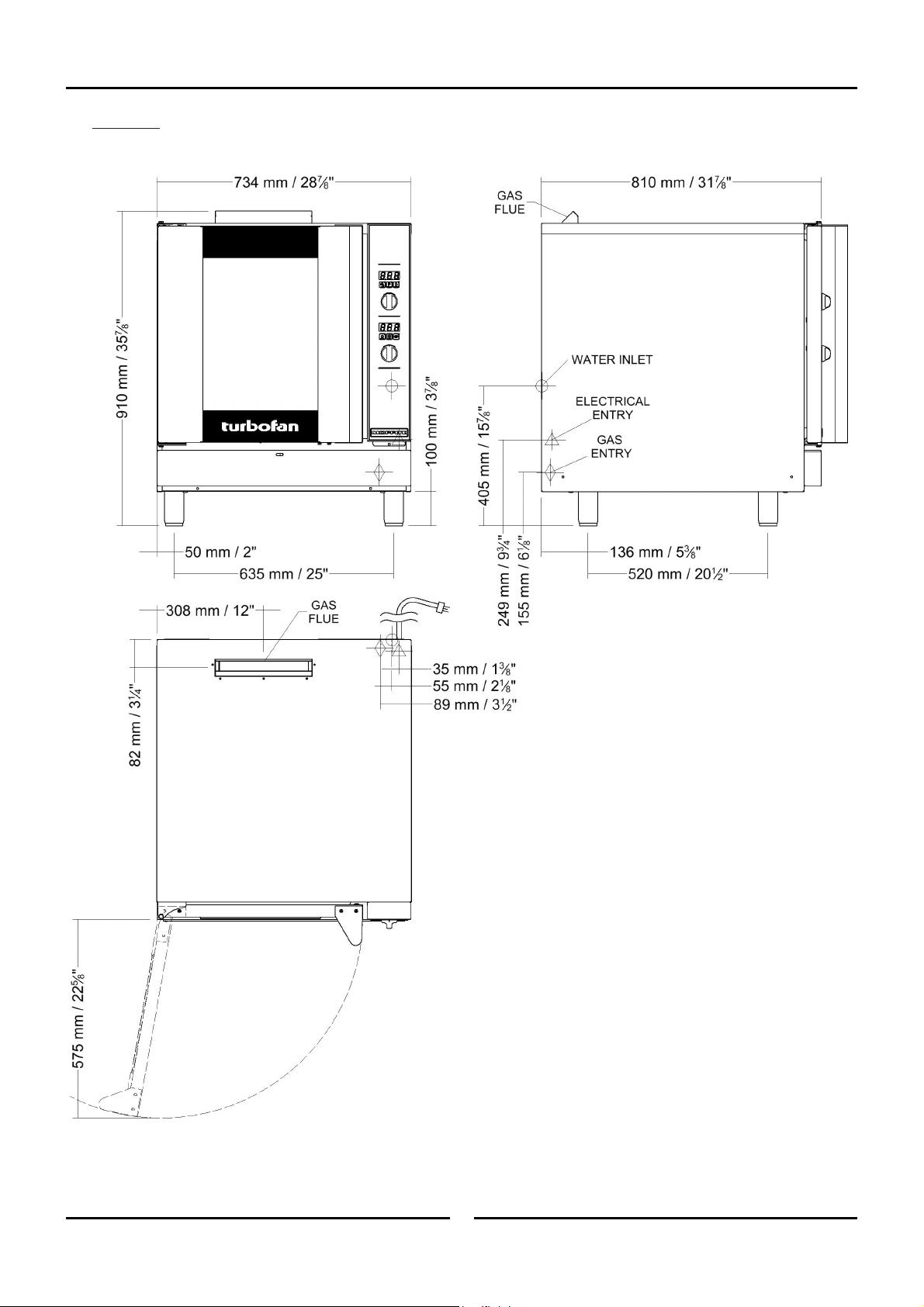

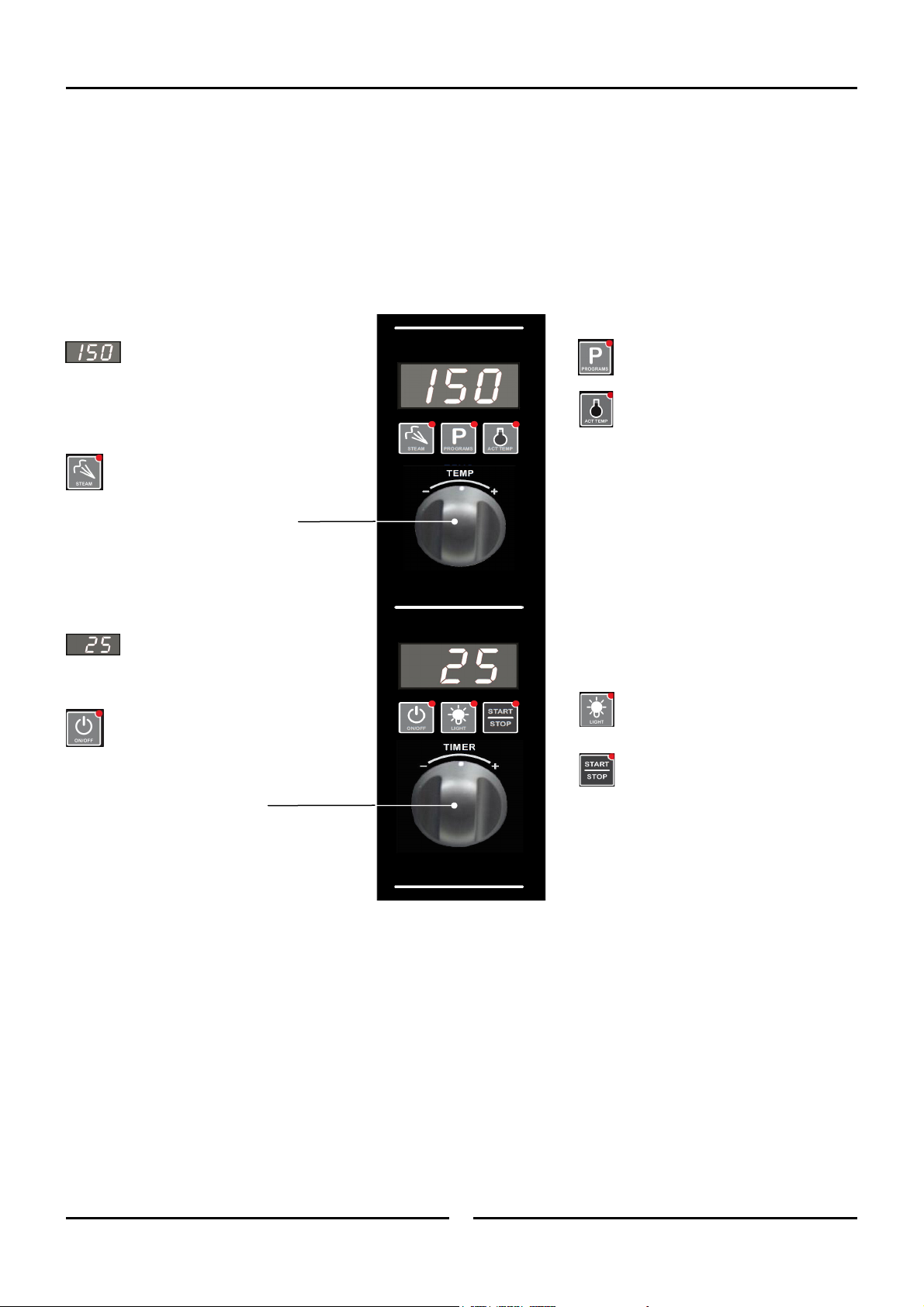

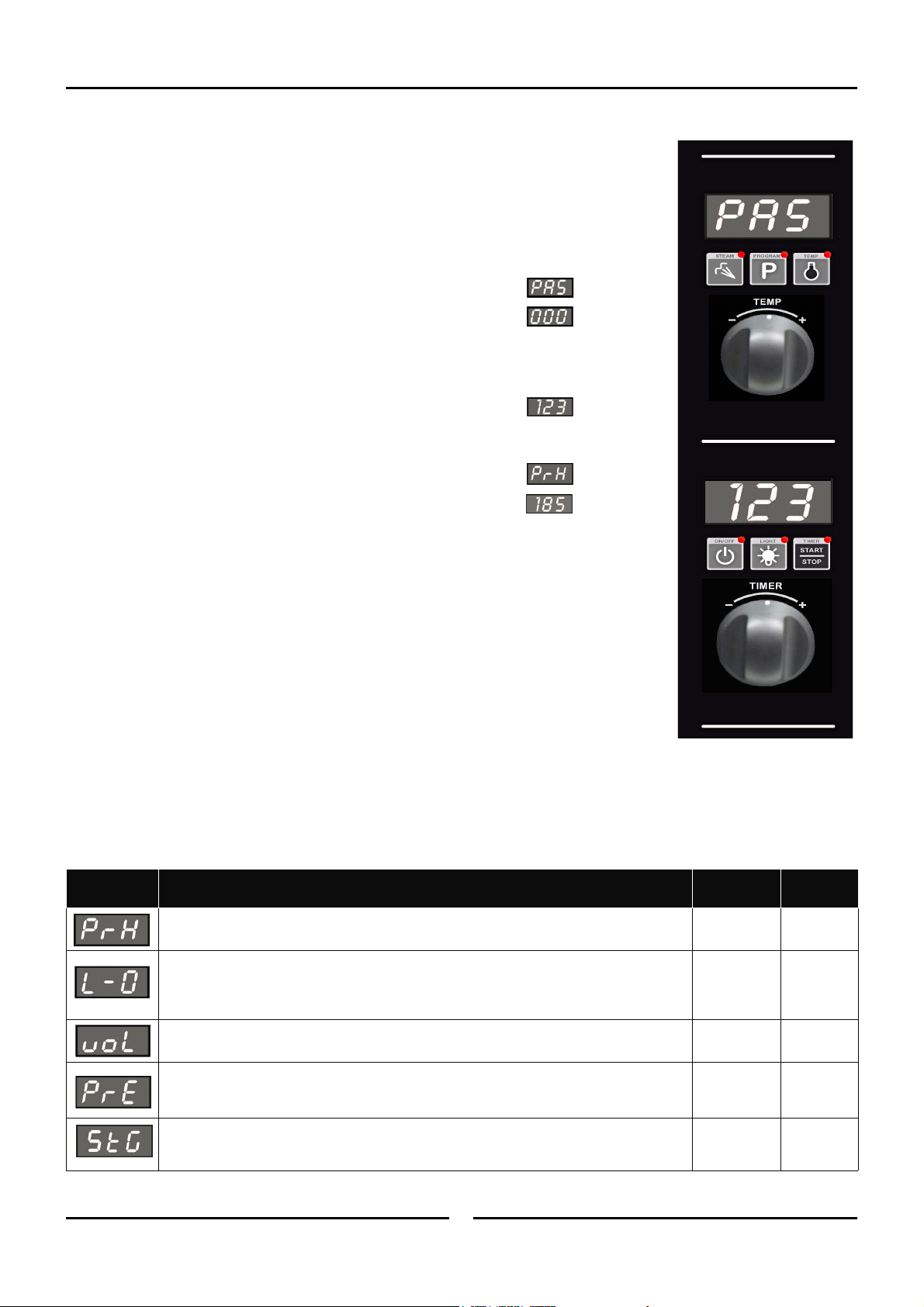

Oven Control Panel (Up to Ser. No. 762119)

Operation 3

Temperature Display - Shows

the preset chamber temperature.

When used with ‘Temperature’ button,

shows actual oven temperature for 5

seconds.

Shows Cooking Modes and Error Codes.

Steam Button and LED -

Activates the ‘Steam Mode’.

Temperature Adjustment Control.

Time Display - Shows cook

time in full minutes only from

180 - 1, and seconds for final

minute only.

On / Off / Stand-By Button and

LED - Press ‘On / Off’ button once

to turn the oven ‘On’.

Press and hold ‘On / Off’ button for

2 seconds to turn the oven ‘Off’.

Time Adjustment Control.

Programming Button and LED - Used

to enter the ‘Programming’ mode.

Temperature Button and LED - Shows

actual oven temperature for 5 seconds on

the Temperature Display.

LED ‘On’ when heating; LED flashes when

showing actual temperature.

Light On / Off Button and LED - Turns

oven light ‘On / Off’.

Start / Stop Button and LED - Pressing

the ‘Start / Stop’ button for 2 seconds,

when in the cooking cycle, will end the

cooking cycle.

11 May 2015

7

Amendment 10

Page 10

3 Operation

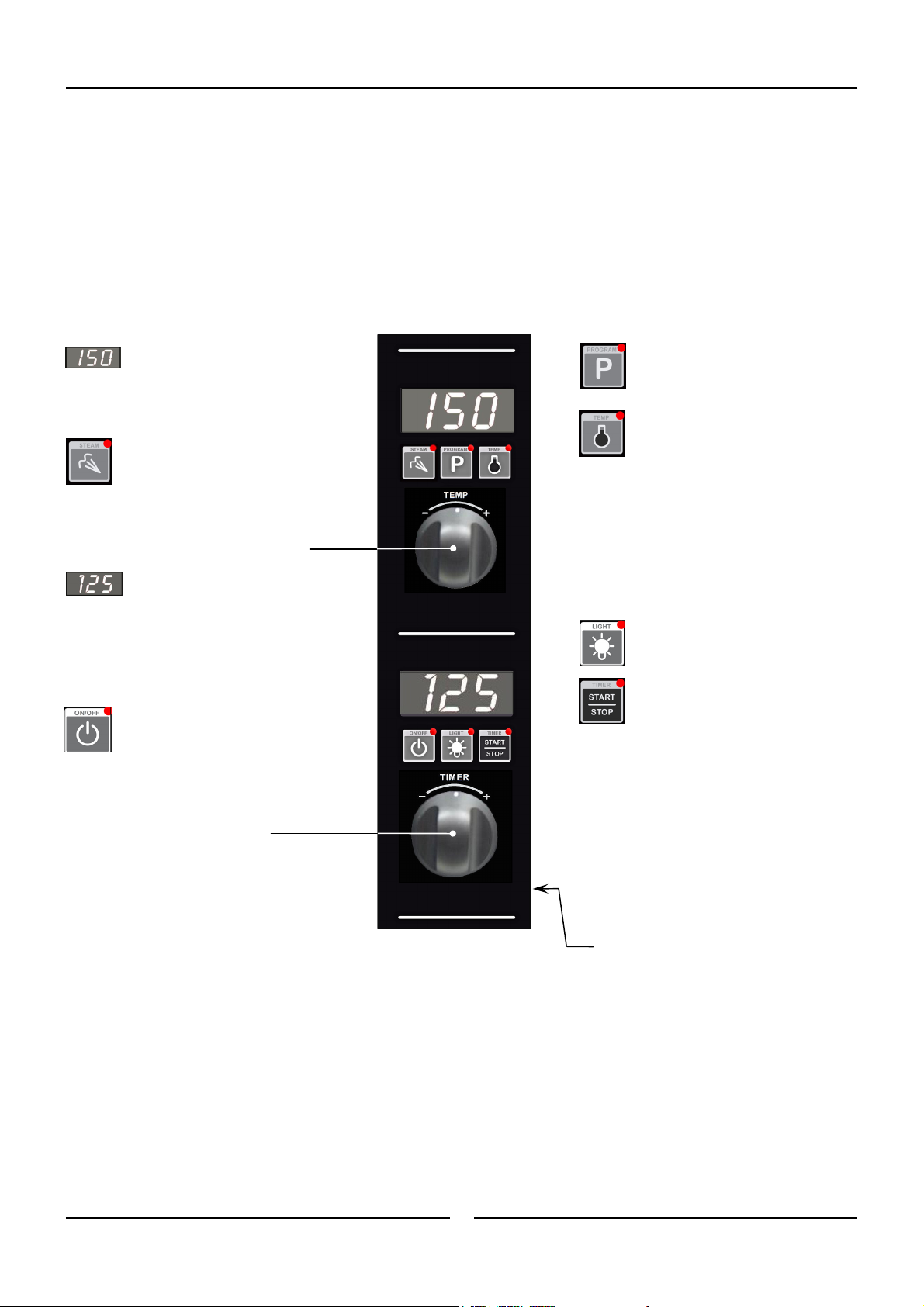

Oven Control Panel (From Ser. No. 762120)

Temperature Display -

Shows pre-set chamber temperature.

When used with the ‘Temp’ key, display shows

actual oven temperature for 5 seconds.

Shows cooking programs and error codes.

‘Steam’ Key and LED -

Used to set automated steam level or to

provide a manual steam injection when

in Manual Steam Mode.

LED is ‘On’ when automatic moisture injection is

set or when steam is manually injected.

Temperature Adjustment Control

Time Display -

Shows cook time in full minutes only

from 180 - 10, and in minutes and seconds for

the final 10 minutes.

NOTE:

In Core Temp Mode, time display alternates

between ‘CP’ and set core probe temperature.

‘On/Off’ Key and LED -

A dual-function key:

Press ‘On/Off’ key once to turn oven ‘On’.

Press and hold ‘On/Off’ key for

1.5 seconds to turn the oven ‘Off’.

Time Adjustment Control

NOTE: In Core Temp Mode, ‘Timer’ knob is

used to set core probe temperature.

‘Program’ Key and LED -

Used to select cooking programs, and to

set program parameters.

‘Temp’ Key and LED -

Displays actual oven temperature for

5 seconds on Temperature Display. LED

‘On’ when heating element is on

(heating indicator).

LED flashes when Upper Display is showing

actual temperature.

NOTE:

In Core Temp Mode, this key is used to

display Actual Oven Temperature (Upper

Display) and Core Probe Temperature (Lower

Display).

‘Light’ Key and LED -

Switches oven lights ‘On/Off’. LED is

‘On’ when oven lights are ‘On’.

‘Timer-Start/Stop’ Key & LED -

The ‘Timer-Start/Stop’ key is used to

control the following functions:-

Cancelling Alarm (All Modes).

Starting Core Temp Mode (Core Temp

Mode).

Starting Timer (Manual Mode).

Re-setting Timer (Manual Mode).

Starting Program (Program Mode).

Cancelling and Re-setting Program

(Pr

ogram Mode).

11 May 2015

Core Probe Connection Point

8

Amendment 10

Page 11

Changing Operator Settings

With the Oven in ‘Stand-By’ Mode (i.e. Power to oven but both displays blank).

1. ENTER OPERATOR PARAMETER MODE.

Press and hold 'Steam' and ‘Timer-Start/Stop’ keys together.

Operation 3

‘Upper’ Dis

‘Lower’ Display will flash ‘000’.

play will show ‘PAS’.

2. SETTING PASSWORD (Operator Password - 123).

otate ‘Timer Control’ to set password.

R

(123 - Operator Password)

Pres

s ‘Light’ key to confirm password.

‘Upper Display’ will show one of the Parameter Codes, eg.

‘Lower Display’ will show the parameter value.

3. SETTING THE PARAMETERS.

otate ‘Timer’ knob to the parameter required.

R

Press ‘Light’ key to confirm parameter required. ‘Lower Display’ will flash.

While ‘Lower Display’ is flashing, rotate ‘Timer’ knob to select value required.

Press ‘Light’ key to confirm value. ‘Lower Display’ will stop flashing.

4. EXITING THE PARAMETER MODE.

Pres

s ‘On/Off’ key, to return to Stand-By Mode.

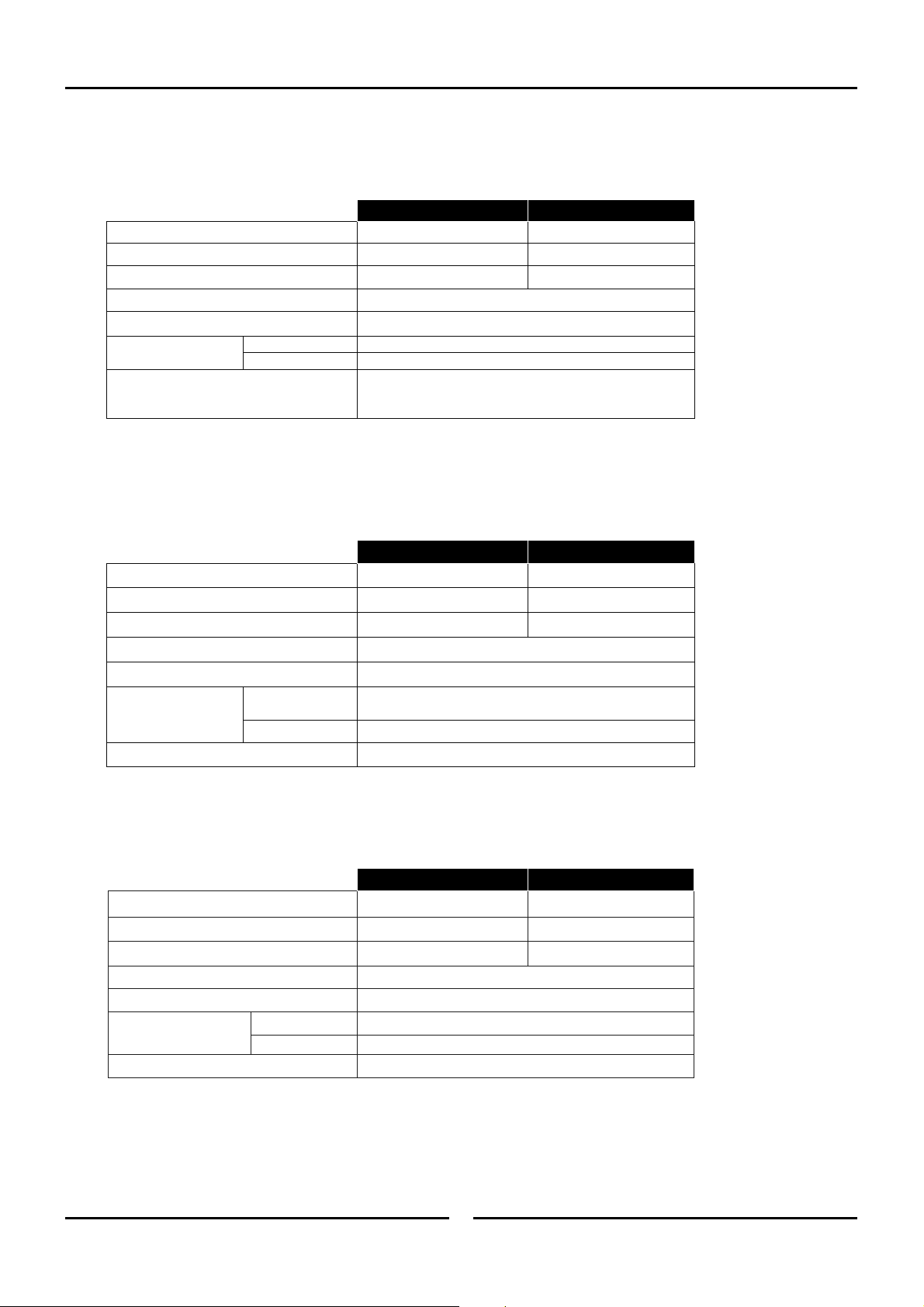

Operator Settings

Setting

Number

Oven Pre-Heat; - (Automatic Pre-Heat Temp on oven start-up).

Light Auto ‘Off’ Setting Time -

0 = ‘On/Off’.

1 = 1 minute auto ‘Off’.

2 = 2 minutes auto ‘Off’, etc.

Alarm Volume - Can be adjusted to suit operators preference.

Program Pre-Heating Condition - This setting allows for pre-heating ‘Ready’ temperature in

‘Program Mode’ Mode to be set higher than Program Set Temperature. Factory Default Setting

is ‘0’ (Equal to Program Setting).

Multi-Stage Enable (From Ser. No. 762120 only).- This setting enables multi-stage

programming. Factory Default Setting is ‘YES’, multi-stage programming is enabled.

Changing this setting to ‘no’ simplifies programming and program cooking.

11 May 2015

Description

9

Setting

Range

60 - 260°C

140 - 500°F.

0 - 60 mins.

0 - 10.

0 - 30°C

0 - 54°F.

‘YES’ or ‘no’.

Default

Setting

150ºC

302ºF

0

5

0

YES

Amendment 10

Page 12

5 Parts Replacement

5.1 Replacement

5.1.1

5.1.2 Cooling

5.1.3

5.1.4

5.1.5

5.1.6 Ignition Module /

5.1.7 Door Microswitch /

5.1.8 Gas Valve /

Oven Controller /

Encoder

Tr

Capacitor

Overtemp Thermostat /

Temperature

O

O

F

B

Microsw

Gas Burner /

I

............................................................................................................................................. 11

Fan /

ansformer /

.......................................................................................................................................... 12

Probe ........................................................................................................................... 13

ven Lamp Assy ............................................................................................................................... 14

ven Fan /

an Motor ......................................................................................................................................... 15

urner Overtemp (Thermal Switch) ................................................................................................. 16

itch Return Spring ............................................................................................................... 16

gnition Electrode Assembly ............................................................................................................. 17

5.1.9 Door Inner Glass /

5.1.10 Water Solenoid ................................................................................................................................. 19

Door /

Door

Hinges ...................................................................................................................................... 18

5.2 Adjustment & Calibration

5.2.1 Door Alignment

5.2.2 Door Catch / Latch Adjustment ........................................................................................................ 20

5.2.3

5.2.4

Microswitch .............................................................................................................................. 21

Door

T

emperature Calibration .................................................................................................................. 21

................................................................................................................................ 20

11 May 2015

10

Amendment 10

Page 13

5.1 Replacement

Parts Replacement 5

5.1.1 Oven Controller /

Encoder

Control Panel Screw

To Program the New Oven Controller

1. Check / adjust Parameters P01, P02 and P24 to the model

specific values shown belo

Model /

Revision

G32D

Rev 01

G32D

Rev 03

Encoder

1. With control panel removed from the oven, remove control

knob

from control panel.

2. Disconnect encoder plug from digital control board.

3. Remove oven controller if necessary.

4. Remove encoder from control panel by removing 2 securi

screws.

Key Identifiers PO1 PO2 P24

No Light Key.

Fan LO Key.

Square Lights in Oven.

Keys - New style graphics

w.

°C / °F

as reqd.

°C / °F

as reqd.

N/A

N/A

ng

To remo

1.

Remove screw on underside of control panel.

2.

Lift panel up to unhook at top.

Disconnect plugs from rear of control panel.

3.

ve the Digital Control Board:-

Note position of connectors before disconnecting plugs

from con

Disconnect earth connection at rear of control panel.

4.

5.

Undo the shake-proof securing nuts (8).

6. Remove digital control board from rear of control panel.

To replace the Digital

1

. Ensure 8 spacers are fitted to threaded studs on rear of contro

bo

2. Fit replacement digital control board to threaded studs

sec

3.

Re-connect plugs to control board, noting position

con

trol board.

Securing Nuts (8)

Control Board:-

ard before fitting new board.

and

ure with nuts supplied and tighten nuts hand tight.

of

nectors when re-fitting.

Securing

Screws

l

11 May 2015

11

Amendment 10

Page 14

5 Parts Replacement

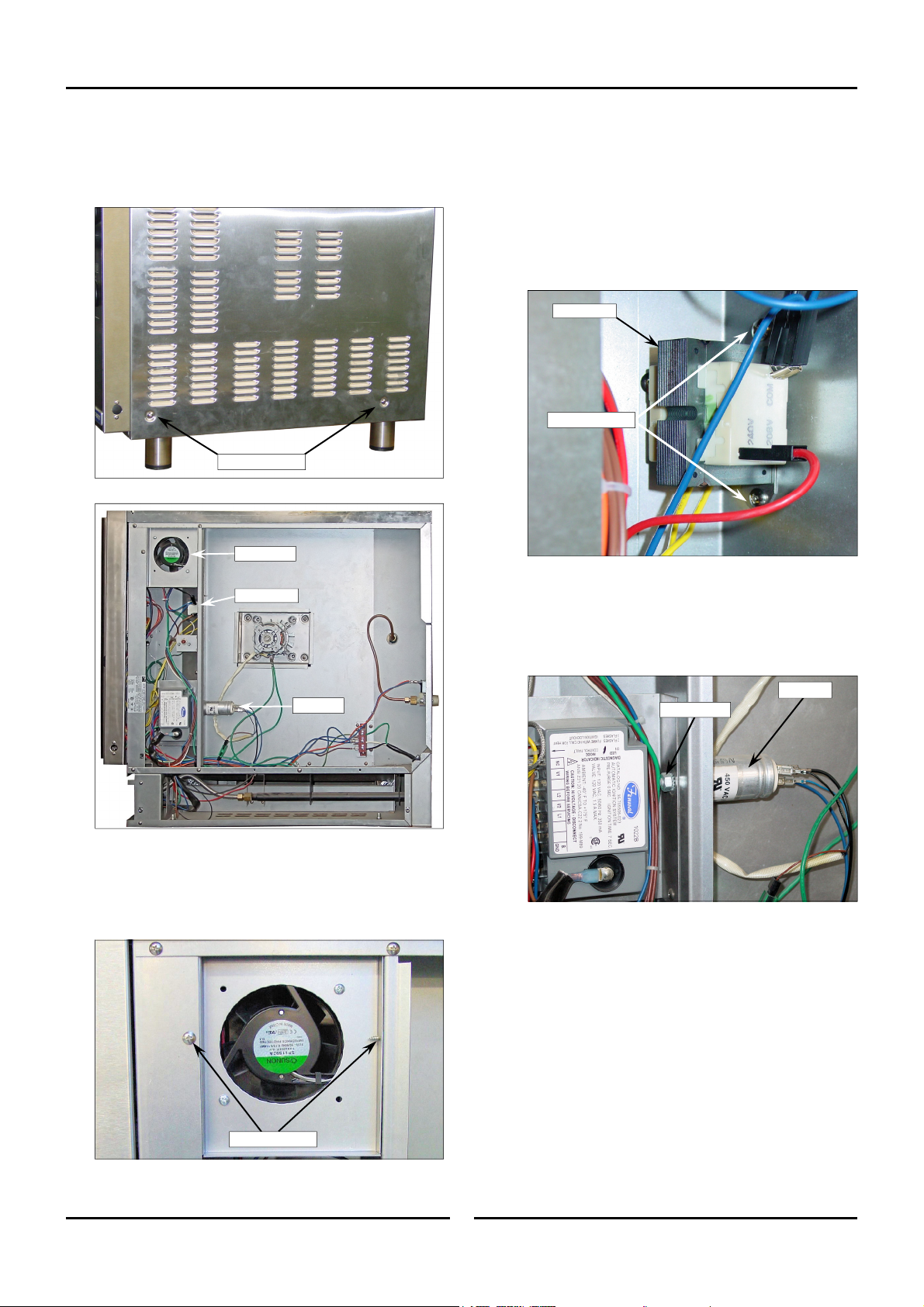

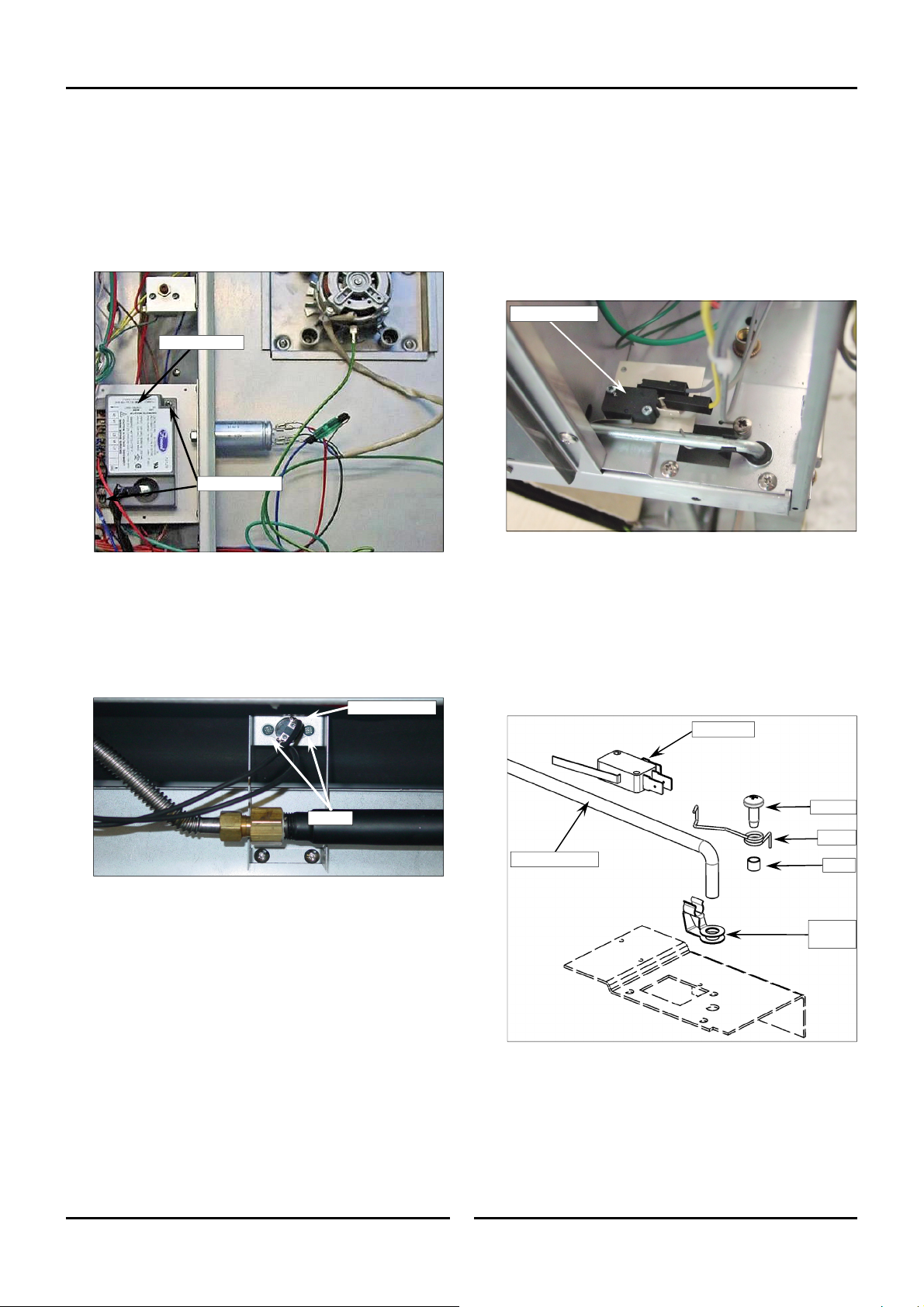

5.1.2 Cooling Fan / Transformer / Capacitor

1. Remove 2 screws on lower corners of side panel.

Pull bottom of panel out and away from bottom of oven.

2.

3. Pull down on panel to remove side panel.

Securing Screws

Cooling Fan

Transformer

Transformer

Disconnect electrical connections from transformer.

1.

2. Remove 2 screws securing transformer to oven chassis.

Transformer Specifications;

Primary; 200 - 208V / 220 - 240V.

Primary; 110 - 120V.

Secondary;

Transformer

Securing Screws

3.

Replace transformer and refit in reverse

12Vac.

order.

Capacitor

1.

Remove wires from rear of capacitor.

2. Remove capacitor securing nut.

Capacitor

Cooling Fan

Remove 2 screws securing cooling fan bracket.

1.

2. Rotate LH side inwards to remove fan assembly. Remove

ling fan from bracket.

coo

Securing Screws

Securing Nut

3. Replace capacitor(s) and refit in reverse or

3uF

s;

(208 - 240V).

Capacitor Specification

Motor Capacitor,

M

otor Capacitor, 12uF (110-120V).

Capacitor

der.

Replace in reverse order.

3.

11 May 2015

12

Amendment 10

Page 15

Parts Replacement 5

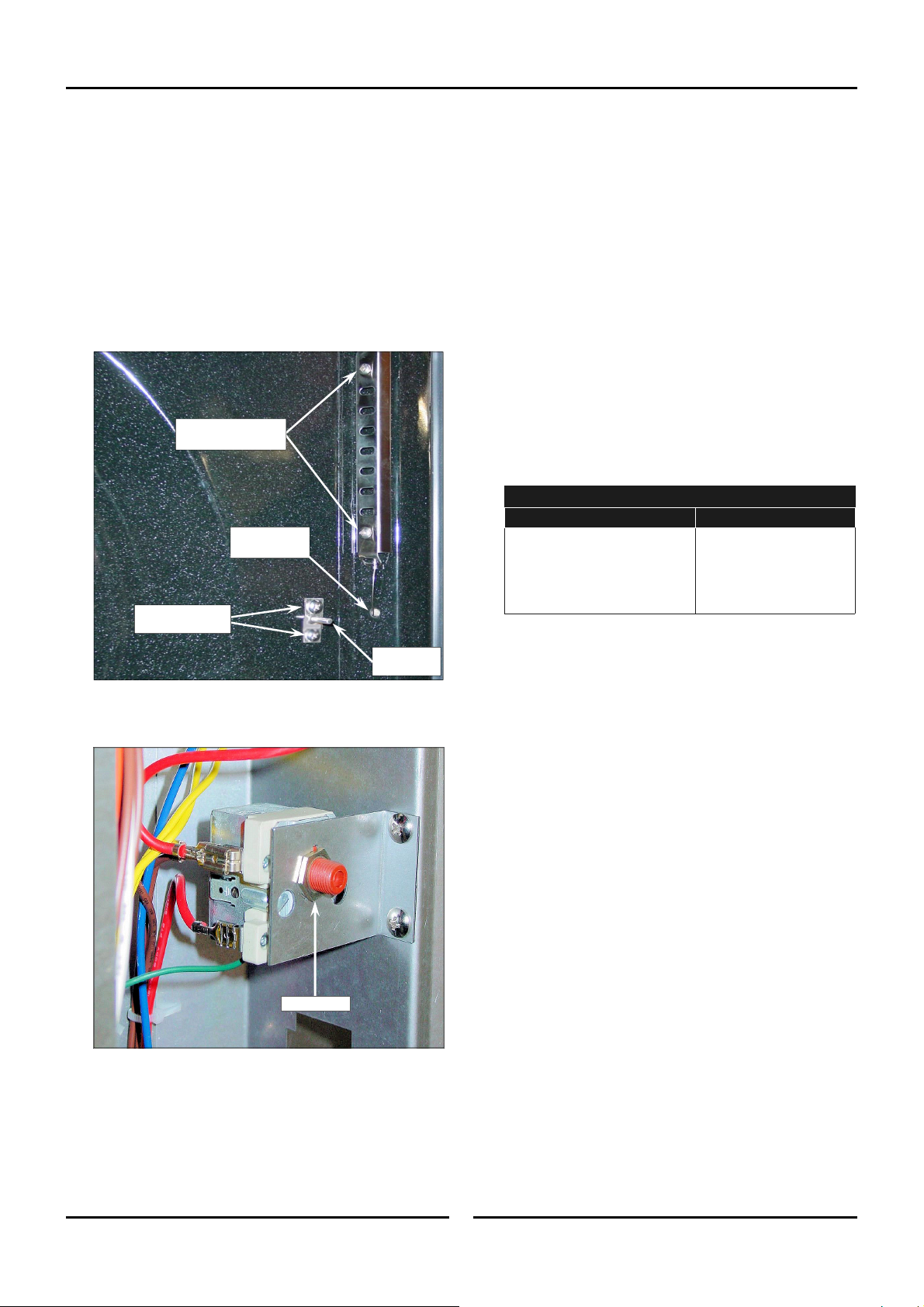

5.1.3 Overtemp Thermostat /

Temperature Probe

1. Remove RH louvered side panel.

2. Inside oven remove side oven rack

Overtemp Th

1.

From inside the oven, remove overtemp phial ho

ermostat

.

lder (two

screws).

Withdraw phial through oven cavity

2.

Remove wires from overtemp thermostat, noting positions.

3.

4.

Remove mounting nut securing overtemp to mounting bracke

and remove th

e overtemp.

Overtemp Phial Holder

Securing Screws

Seal hole with

RTV Silicone

Temperature Probe

Securing Screws

.

Temperature

1. Remove

connect temperature probe cable from controller.

2. Dis

Probe

control panel.

3. From inside oven, remove RH side oven rack.

4. Undo temperature probe securing screw(s).

t

5. Withdraw probe and cable through oven cavity

6.

Clean off any existing silicone from around the te

p

robe opening in the oven inner wall.

7. Fit the new gasket to the rear of the new temperature prob

and f

eed the probe cable through oven cavity

8.

Connect temperature probe cable to oven controller

9.

Secure temperature probe to oven using the supplied screws

1

0. Refit the control panel.

Carry out a functional check of temperature probe using th

11.

oven con

troller.

.

mperature

e

.

.

.

e

Temperature Probe Type PT1000

Temperature oC (oF) Resistance ± 5%

0 (30) 1000 Ω

50 (122) 1194 Ω

100 (212) 1385 Ω

150 (302) 1573 Ω

180 (356) 1685 Ω

Temperature

Probe

5. When replacing the overtemp use RTV silicone sealant to seal

the hole in the oven liner.

Mounting Nut

6. Refit overtemp in reverse order.

11 May 2015

13

Amendment 10

Page 16

5 Parts Replacement

5.1.4 Oven Lamp Assy

Oven Lamps (Up to Ser. No. 762119)

1. Remove the oven rack and LH side rack fr

2.

Unscrew and remove the lamp glass (anti-clockwise) from

oven.

3

. Remove the light bulb which is a push fit into the light hold

4.

ace if requir

and repl

Remove seal fitted between lamp glass and holder and replac

uired

if req

.

ed.

om oven.

the

er

Oven Lamps (From Ser. No. 762120)

Oven Lamp / Oven Lamp Glass / Oven Lamp Seal /

Oven Lamp Housing

1. Remove LH side rack from ov

. Remove 4 screws securing the lamp support frame.

e

2

3. Remove support frame, glass lens and gasket

. Remove light bulb if required (this is a push fit into housing).

4

en.

.

Screws

Remove th

5.

panel

6. Disco

connections to the oven lamp

assy being replaced.

7. Pull back the insulation

reveal the rear of the lamp

assembly.

8.

Depress the 3 spri

load

rear of the light assy and

p

ush the assembly into

oven and

9. Refit oven light

reverse order.

1

0. Ensure the insulation

re-pos

of t

1

1. Refit the LH side rack and

oven rack to the oven.

12. Refit the LH oven side panel.

e LH Oven side

.

nnect the electrical

ed locking tabs

remove.

itio

ned around the rear

he lamp assembly

ng

assy in

to

on the

the

is

.

Disconnect

Securing Tabs (3)

To replace Oven Lamp Housing:

1.

Remove oven non louvered side panel.

2. Pull back insulation to reveal rear of lamp assy

Disconnect electrical connections on rear of lamp assy.

3.

4. Depress spring loaded locking tabs on rear of light assembly

and push assembly into oven and remove.

Depress Spring

Tabs

Disconnect Electrical

Connections (3)

.

11 May 2015

14

5.

Refit oven lamp assembly in reve

rse order.

Amendment 10

Page 17

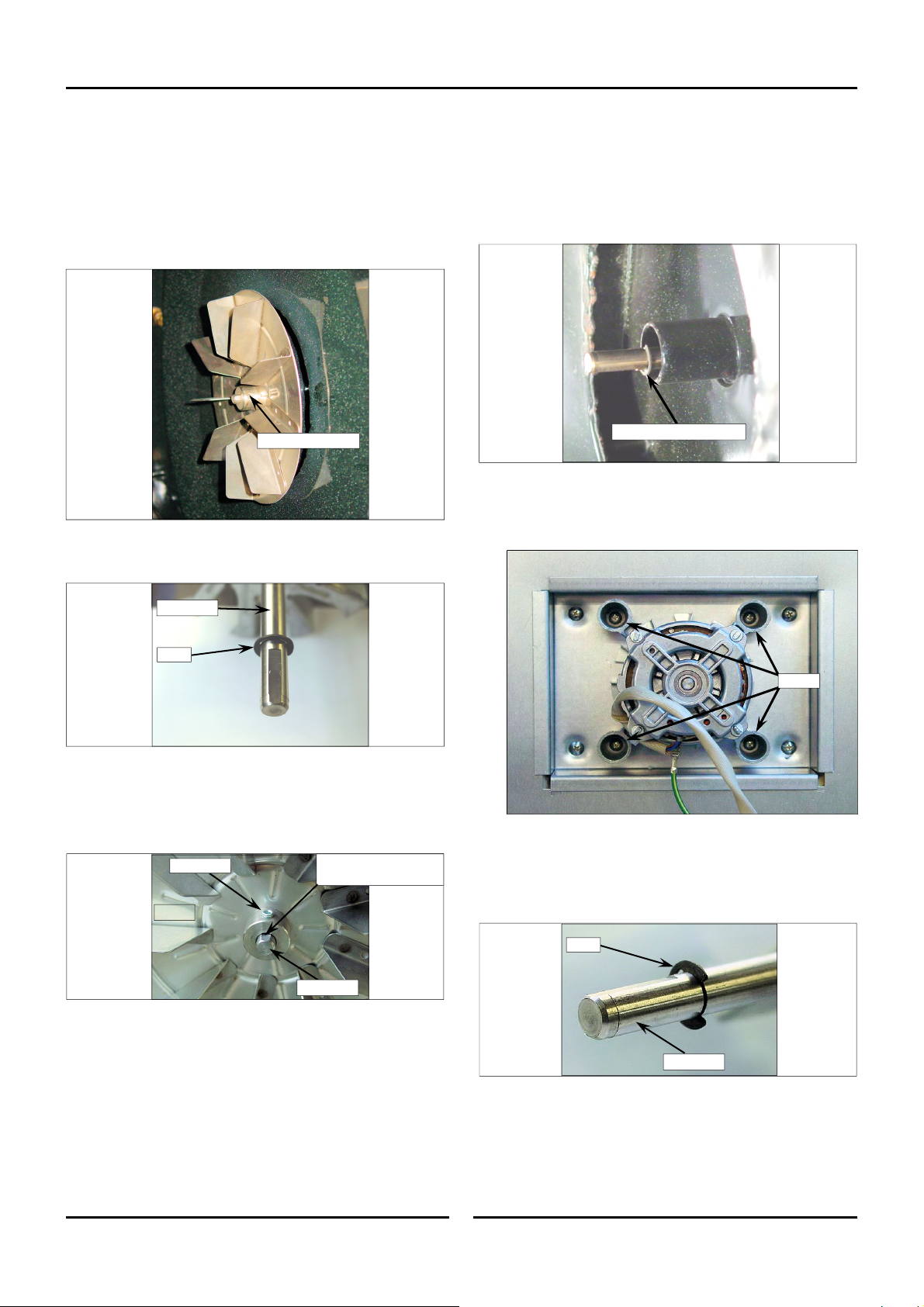

5.1.5 Oven Fan / Fan Motor

1. Remove RH louvered side panel.

Parts Replacement 5

Oven Fan

Inside oven remove RH Side oven rack

1.

2.

Remove the 2.5mm grub screw securing the oven

an motor shaf

f

3.

Remove the oven fan from inside the oven.

t.

.

fan to the

2.5mm Grub Screw

NOTE: Ensure the E-Clip is still fitted to the motor shaft

before replacing the oven fan.

Motor Shaft

Fan Motor

1.

Remove the oven fan as shown opposite.

2. Remove and retain the E-Clip fitted to the motor shaft.

Remove and Retain E-Clip

3. Disconnect motor wires from motor connection block, no

wire p

Remove Motor mounting screws and remove the motor

4.

osition

s.

the oven.

te

from

E-Clip

3. Refit oven fan, pushing fan back against the E-Clip

4

. Rotate the fan until the fan securing grub screw is located

.

over the flat of the motor shaft.

5. Securely tighten the grub screw onto the ‘D’ section of th

m

otor shaft to secure the fan to motor shaft.

Grub Screw

Fan

Note Flat on Motor Shaft

for Grub Screw location.

Motor Shaft

Screws

e

5.

Replace motor and secure with 4 screws

. Reconnect motor wires to connection block, note wi

6

po

sitions.

From inside the oven refit the E-Clip into the groo

7.

m

otor shaf

. Refit oven fan as shown opposite.

8

t.

E-Clip

Motor Shaft

.

re

ve on the

9. Refit RH oven side panel.

11 May 2015

15

Amendment 10

Page 18

5 Parts Replacement

5.1.6 Ignition Module /

Burner Overtemp (Thermal Switch)

1. Remove RH louvered side panel.

Ignition Module

1.

Disconnect plug connections from Ignition Module.

2. Remove and replace Ignition Module

Re-connect the plug connections to the Ignition Module.

3.

Ignition Module

Securing Screws

.

Burner Overtemp (Thermal Switch)

Remove RH side panel.

1.

2.

Remove wires from burner overtemp

Remove securing screws and replace burner overtemp.

3.

.

4. Refit replacement burner overtemp and connect up wi

temp

over

.

Burner Overtemp

res to

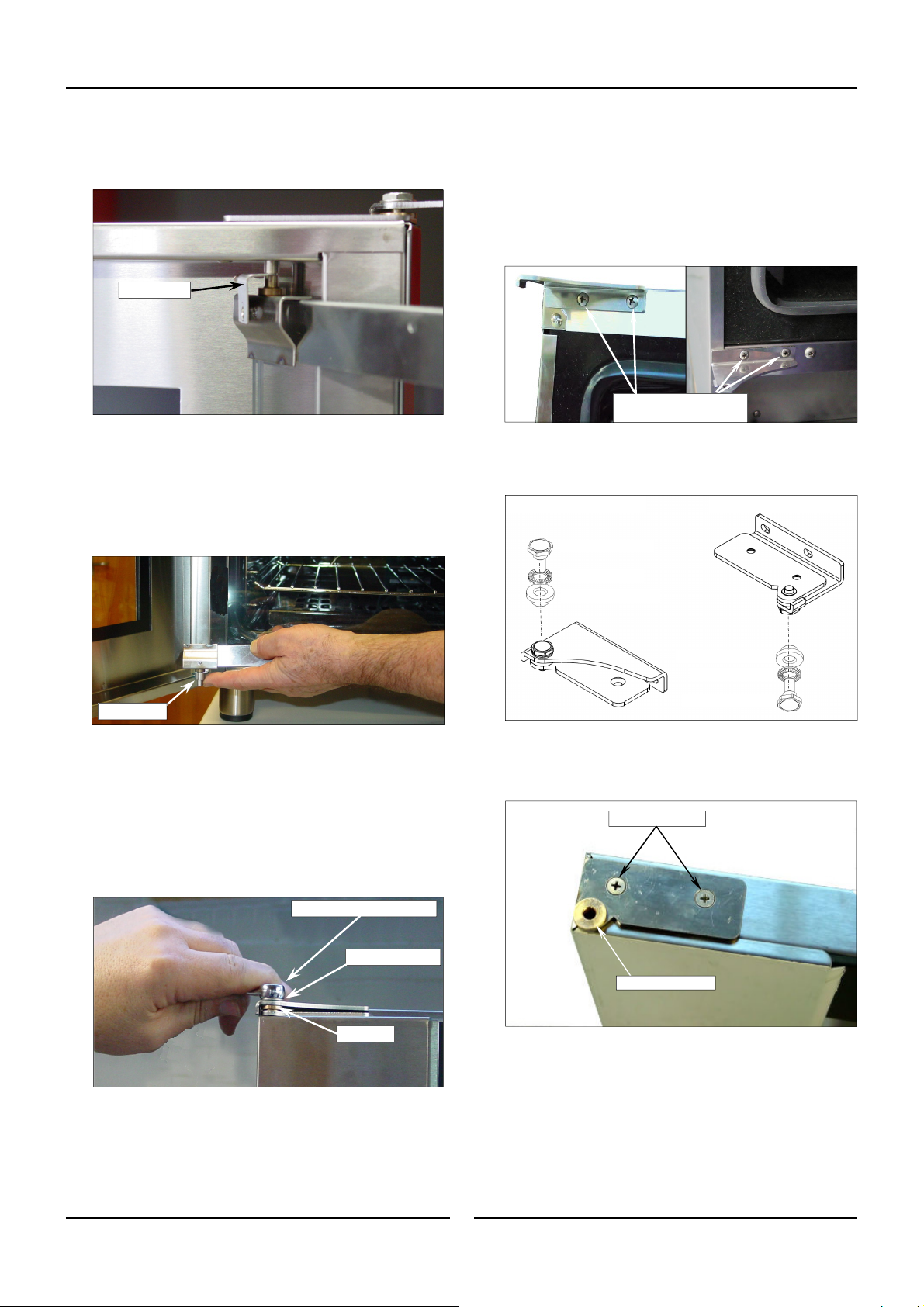

5.1.7 Door Microswitch /

Microswitch Return Spring.

To replace Door Microswitch:

1. Remove

control panel.

2. Remove oven RH side panel.

3. Remove electrical connections from door microswitch.

4. Remove

Check adjustment when new door microswitch is fitted. Refe

5.

Sec

microswitc

h.

tion 5.2. ‘Adjustment & Calibration’.

Door Microswitch

To replace Door Microswitch Return Spring:

croswitc

croswitc

control panel.

curing screw and spacer from

h bracket.

rod and

h bracket.

e order.

Microswitch

1. Remove

2.

Unscrew and remove spring se

mi

3.

Unclip and remove return spring from microswitch

mi

Refit replacement spring in revers

4.

r

5.

Refit RH side and Gas Control panels

11 May 2015

.

Screws

16

Microswitch Rod

Screw

Spring

Spacer

Retaining

Clip

Amendment 10

Page 19

Parts Replacement 5

5.1.8 Gas Valve / Ignition Electrode

Assembly / Gas Burner

1. Remove gas control panel.

Gas Valve &

1. Remove gas control

Remove cover bracket, 1 screw.

2.

Remove earth and power connectors.

3.

4. Disconnect gas inlet pipe to Gas Valv

Power

Connector

. Remove injector and securing nut.

5

Burner Injector

panel.

Earth Connector

e.

Screw

Gas Inlet Pipe

Ignition Electrode Assembly

1. Remove burner access panel.

2. Disconnect wires from the Ignition Electrode Assembly to th

Ignition Module.

3

. Remove 2 slotted screws securing Ignition Electrode Assemb

he oven

to t

Withdraw the ignition electrode assembly and replac

4.

Before fitting the new ignition electrode assembly,

5.

spark ele

2 ‘Adjustment and Calibratio

5.

Re-connect wires from the new Ignition Electrode Assembly

6.

the I

.

ctrode / flame sensor gaps are as shown

n’.

gnition Module.

Screws

e.

check the

in Section

e

ly

to

Burner Bracket

Screws

6.

Remove securing screws and remove gas valve with bracket.

7. Replace and refit in reverse or

8.

Remove screw cap and fit correct spring for the gas type bein

Injector & Nut

der.

used.

Screw Cap

. Adjust operating pressure as shown in Section 9. ‘G

9

Conversion and Specifications’ section.

Gas Burner

Remove Ignition Electrode Assembly as sh

1.

Remove burner bracket screws (2).

2.

3. Carefully withdraw

Fit replacement

g

4.

burner.

burner and refit in reverse order.

own above.

as

11 May 2015

17

Amendment 10

Page 20

5 Parts Replacement

5.1.9 Door Inner Glass / Door / Door Hinges

To replace Door Inner Glass:

1. Undo inner glass retaining clip.

Retaining Clip

2. Lift inner glass up and pull bottom outwards to free bottom

pivot.

NOTE: Pivot spacer is a loose fit over pivot and may fall

out.

3. Lower inner glass to free top pivot and remove glass.

To replace Door Hinges:

1. Remove door and inner glass complete. (as shown previous

2.

Remove 2 Hinge Plate Screws

Remove the upper and lower hinge plates

3.

Refit replacement door hinge plates.

4.

5. Refit door and inner glas

: The Door Hinge Assembly can be ordered as a

NOTE

.

.

s.

Remove Top or Bottom

Hinge Plate Screws.

complete Door Hinge Replacement Kit or as

separate items as shown below.

Door Top Hinge Assemby.

Door Hinge Pivot Pin.

Nord-Lock Washer.

Door Hinge Pivot Bush.

Door Bottom Hinge Assemby.

).

Pivot Spacer

4. Replace and refit door inner glas

to ref

it Pivot Spacer to bottom hing

s in reverse order, remember

e.

To replace Door:

1. Remove door inner glass (as above).

2. Whilst supporting door, unscrew and remove top door hi

pi

vot bolt from the door top hinge assembly

3.

Remove the Nord-Lock Washer.

4.

Lift door off the bottom hinge.

.

Remove Door Top Pivot Bolt.

Nord-Lock Washer.

Pivot Bush

nge

Door Hinge Pivot Bush.

Nord-Lock Washer.

Door Hinge Pivot Pin.

To replace Door Hinge Pivot Bushes:

Remove door complete

1.

2.

Unscrew and remove top and bottom plates from the door

3.

Tap out the old Door Hinge Pivot Bushes and discard.

4. Gently Tap in the new pivot bushes

. Refit the oven door as shown opposite.

5

.

Unscrew 2 Screws

Door Hinge Pivot Bush.

.

.

5.

Refit door in reve

11 May 2015

rse order.

18

Amendment 10

Page 21

5.1.10 Water Solenoid.

1. Remove control panel.

2. Remove oven RH side panel.

3.

Turn Off wa

Remove wires from water sole

4.

Disconnect water pipes.

5.

6. Remove Nylock nuts (7mm) and mounting screws

7

. Remove water solenoid.

ter.

noid.

Parts Replacement 5

.

8.

Replace water soleno

Nylock Nuts

id and refit in reverse order.

11 May 2015

19

Amendment 10

Page 22

5 Parts Replacement

5.2 Adjustment & Calibration

5.2.1 Door Alignment.

Ensuring Door is Square to Oven.

Check alignment and operation of the door. Ensure that the door

is correctly aligned horizontally and vertically.

There should be a

nominal gap of 6mm from edge of door to side of control

panel.

Slacken these screws to adjust door vertically - horizontally.

1. Slacken off the upper and lower hinge plates and correctly

align the door. Re-tighten both hinge plates on completion.

NOTE:

Check the nominal gap from front edge of door to side

of control panel. This should be 6mm.

If door is adjusted for correct alignment, ensure that

the door closes correctly. Check door closes correctly

as shown below at Section 5.2.2 ‘Door Catch / Latch

Adjustment’.

Check Gap between Door

and Control Panel at top

and bottom of Door.

Should be 6mm nom.

3. To adjust door catch, loosen the locking nut on the door catch.

4. If paper withdraws easily,

turn

and repeat test above until adjusted correctly.

5. If paper cannot be withdrawn and door springs open,

door catch ‘Out’ by ½ a turn

il adjusted correctly.

unt

6.

Tighten the locking nut on the door catch.

Ensuring Door Latches Closed Properly:

1. Check that the door closes and latches correctly by push

the door clo

ithout springing open.

w

2. If the door is hard to close and springs open,

sed and ensuring that the door remains clos

catch ‘Out’ by ½ a turn

adjusted corre

If the door closes and feels loose once latched closed,

3.

ctly.

door catch ‘In’ by ½ a turn

oor is adjusted correctly.

d

4.

Tighten the locking nut on the door catch.

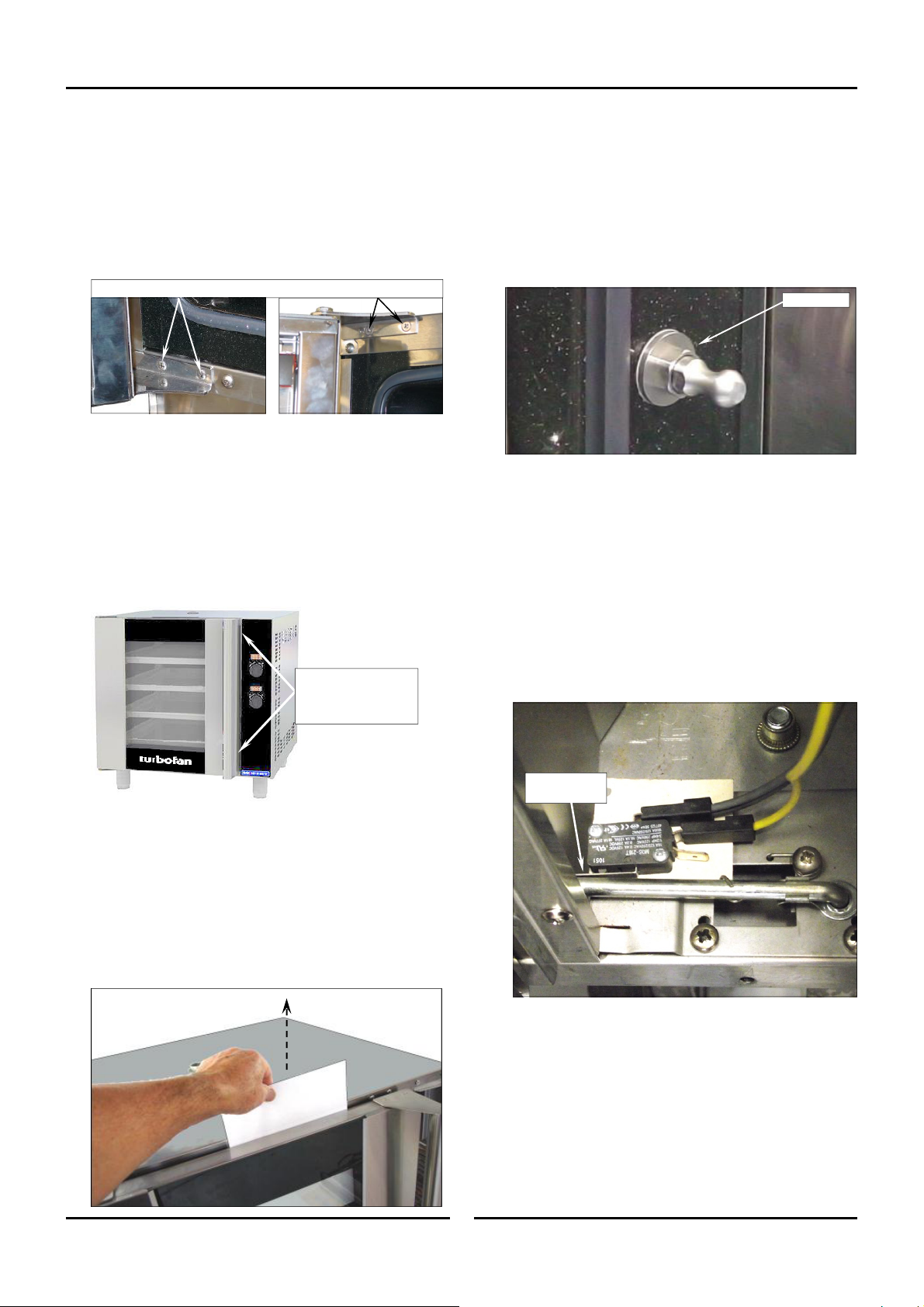

5.2.3 Door Microswitch

screw door catch ‘In’ by ½ a

screw

and repeat the test above

Locking Nut

ing

ed

screw door

and repeat test above until door is

screw

and repeat the test above until

5.2.2 Door Catch / Latch Adjustment.

Ensuring Door Seals Properly:

If the door sealing requires adjustment, carry out the following to

adjust the door catch:-

1. Check that the door seals correctly when closed, by plac

s

heet of paper between the door and the seal

. Close the door on the paper and attempt to withdraw

2

paper by

pull out with some resistance but without tearing.

11 May 2015

firmly tugging on the paper. The paper should just

.

ing a

the

Microswitch

Activation Arm

1. Remove control panel.

Bend the microswitch activation arm so switch open circuits

2.

when door is open.

Check adjustment when door is opened and closed

3.

20

.

Amendment 10

Page 23

5.2.4 Temperature Calibration

1. Place temperature probe in the centre of the oven.

2. Close the door and allow temperature to stabilise.

3. Enter service parameters settings menu on control panel

che

ck P10 Temperature Offset (refer to Sectio

ing / Changing Service Para

‘View

meters’).

n 6.

5.2.5 Spark Electrode Adjustment.

The recommended gap settings for the ignition electrodes are

given in the diagram below.

‘a’ 18.3mm (+0.5mm, -0mm).

3

/4” (+1/64”, -0”).

‘b’ 4.5mm (+0.5mm, -0mm).

3

/16” (+1/64”, -0”).

FLAME SENSER

EARTH / GROUND

Parts Replacement 5

and

‘a’

‘b’

SPARK

11 May 2015

21

Amendment 10

Page 24

6 Controller Programming

6.1 Viewing / Changing Service Parameters

With the Oven in ‘Stand-By’ Mode (i.e. Power to oven but both displays blank).

1. ENTER SERVICE PARAMETER MODE.

Press and hold 'Steam' and ‘T

‘Upper’ Display will show ‘PAS’.

The ‘Lower’ Display will flash.

imer-Start/Stop’ keys together for 3 seconds.

2. SET PASSWORD (Service / Factory Password - 321).

Rotate ‘Timer Control’ to set password;

321 - Service Password).

(

Press ‘Light’ key to confirm password.

‘Upper’ Display will show one of the Parameter Codes.

‘Lower’ Display will show the parameter value.

3. SETTING THE PARAMETERS.

Rotate ‘T

Pres

imer’ Knob to the parameter required.

s ‘Light’ key to confirm parameter. ‘Lower Display’ will flash.

While ‘Lower Display’ is flashing, rotate ‘Timer’ Knob to select value required.

Press ‘Light’ key to confirm value. ‘Lower Display’ will stop flashing.

4. EXITING THE PARAMETER MODE.

Press ‘T

imer-Start/Stop’ to, to return to ‘Stand-By’ mode.

11 May 2015

22

Amendment 10

Page 25

Controller Programming 6

6.2 Viewing / Changing Service Parameters (up to Ser. No. 762119)

Parameter

Number

P1 Temperature Scale

Description Min Max Default Value S / O

˚F ˚C

˚C

---- S

P2 Oven Model. 31 32 32 ---- S

P3 Minimum Temperature Setpoint. 0(32) 300(572) 60(140) ˚C(˚F) S

P4 NOT SHOWN WHEN P2 SET TO 32

Maximum Temperature Setpoint

P5

PrH NOT SHOWN WHEN P2 SET TO 32.

H Temperature preset.

Pr

P3 P5 150(325) ˚C(˚F) O

0(32) 300(572) 260(500) ˚C(˚F) S

P8 Hysteresis Temperature Gap. 1 10 1 ˚

P9

Temperature Regulation Offset. 0 10 0 ˚

Chamber Temperature Offset.

P

10

(This offset is always added to the raw temperature measurement,

in order to correct the value. The value shown on display is the

-25(-45) 25(45) 0(0) ˚C(˚F) S

corrected value).

P11 Maximum Timer Setpoint. 1 180 180 Min S

P12 Timer Preset. 1 P11 0 Min S

L-O Time Light stays on. 0 60 0 Min O

InJ Steam Injection Time

0 10 0 Sec O

P15 Cooling Fan Timeout. 0 60 10 Min S

P16 Oven Fan Rotation Time

P17 Oven Fan Inversion Pause Time

1 999 120 Sec S

5 10 10 Sec S

VoL Buzzer Volume 0 10 5 ---- O

P19 NOT SHOWN WHEN P2 SET TO 32

20 Thermal switch NO or NC contacts 0 1 1 ---- S

P

P21 Program Mode - Pre-heat temp condition. 0(0) 30(54) 20(36) ˚C(˚F) O

P22 Door open time—Program Mode Only. 30 180 60 Sec S

S

S

1) To change the parameter turn the timer encoder knob.

2

) To enter the parameter, to change it’s value, press the light button.

3)

To change the value turn the timer encoder knob

) To enter the value press the light button.

4

5)

Press ‘On / Off’ button to exit.

.

11 May 2015

23

Amendment 10

Page 26

6 Controller Programming

6.3 Viewing / Changing Service Parameters (from Ser. No. 762120)

: All units produced after this point are G32r03 Units, but older units can fit the new controller as a spares item, in which

NOTE

case Parameter Number ‘P02’ is set to ’G32r01’.

Parameter

Number

P01

P02

P03

P04

P05

P06

PrH

P08

P09

P10

P11

P12

L-O

P13

P14

InJ

P15

Description Min Max

Temperature Scale.

Defines temperature scale used

(C = °C, F = °F). Changing scale from °F to °C will reset all

temperature parameters to their default values.

Oven Model and Software Revision.

Minimum Oven Temp Set Point.

The minimum temperature

that the oven can be set to.

Maximum Oven Temp Set Point.

The maximum temperature

that the oven can be set to.

Minimum Core Temp Set Point.

The minimum core

temperature that can be set.

Maximum Core Temp Set Point.

The maximum core

temperature that can be set.

Oven Default Preheat Temp.

The temperature that the oven

will pre heat to on start-up.

Hysteresis Temperature Gap.

The temperature drop from

the Set Point before the heating cycles back ‘On’.

Temperature Regulation Offset.

The temperature below set

point that the oven heating turns off. i.e. If P9 is set to 5 and

oven temperature is set to 180, oven heating will turn ‘Off’ at

175. This is intended to allow for thermal over-run in the oven

cavity

.

Oven Temperature Offset.

This offset is always added to the

raw temperature measurement, to correct the value. Value

shown on display is the corrected value).

Maximum Timer Set Point.

Core Temp Verification Time.

Maximum time that can be set.

Time required for Core Probe

to be at or above the Set Temperature before the cooking done

alarm sounds.

Time Light stays On.

Duration of time for which light stays

‘On’. Pressing ‘Act Temp/Light Key will turn oven light ‘On / Off’

in all settings. If 1-60min set, oven light will turn off after set

time elapsed. If ‘0’ is set, key must be pressed to turn lights ‘Off’.

Steam Cycle Time.

The time duration in minutes for each

steam cycle.

Steam Injection Pulse Time.

The time duration in seconds

for each steam pulse within the steam cycle (P13).

Note;- The number of steam injections per cycle is

determined by the humidity level set by the user, e.g. H1

= 1 Injection Pulse of (P14) seconds every (P13)

minutes.

Steam Injection Time (sec).

Cooling Fan Timeout.

The time that the cooling fan will

continue running after the ‘On/Off’ key has been pressed.

Default

G32R01 G32R03

˚C ˚F ˚C

E31 r01 G32 r03

0 (32) 300 (572) 60 (140) ˚C (˚F) S

0 (32) 300 (572) 260 (500) ˚C (˚F) S

0 (32) 150 (302) N/A 50 (122) ˚C (˚F) S

0 (32) 150 (302) N/A 90 (194) ˚C (˚F) S

P3 P4 150 (300) N/A ˚C (˚F) U

1 (2) 10 (18) 1 (2) °C / °F S

0 (0) 10 (18)

-25 (-45) 25 (45) 0 (0) 0 (0) ˚C (˚F) S

1 180 180 180 min S

1 120

0

1 5

0 5

0 10 0 N/A sec U

0 60 min S

G32r01 --- S

0

N/A 30

60 0 0 min U

N/A

N/A

10

˚C

G32r03

60 (140)

260 (500)

1 (2)

U o M

Pass

--- S

0

°C / °F S

sec S

2 min S

1 sec S

10

0

(0) Defines the password level of the parameter (S = Service / Factory. Password level 321)

User. Password level 123)

(U =

24

11 May 2015

.

Amendment 10

Page 27

Controller Programming 6

Viewing / Changing Service Parameters (from Ser. No. 762120) (Cont.d)

Parameter

Number

P16

P17

voL

P20

PrE

P22

P25

StG

Description Min Max

Oven Fan Rotation Time.

The time the fan will rotate in one

direction before changing direction.

Oven Fan Reversing Pause Time.

The time between the fan

stopping and re-starting in the opposite direction.

Buzzer Volume.

Volume of buzzer can be adjusted between ‘

O’ - No Buzzer and ‘10’ - Maximum Volume.

Thermal switch NO or NC contacts

Program Preheating Offset.

In Program Mode only. The

temperature above ‘Set Temperature’ that the oven will pre-heat

to. (To allow for heat loss during door opening and cold product

loading

). Note;- Upon starting the Program, Oven Set

Temperature will revert to the Set Temperature.

Maximum Door Open Time - Program Mode Only.

This is the time allowance for door open when loading oven, to

avoid Pre-Heating state re-activating once the door is closed.

Note: If door has been open longer than the time set (60)

and actual temperature has dropped below the set

temperature for that program, when the door is closed, the

oven will revert to the Pre-heating Mode.

Core Probe Temperature Offset.

This offset is always added to

the raw temperature measurement, to correct displayed value.

(Value shown on display is the corrected value).

Enable Multi-Stage Cooking.

This new parameter will control

whether or not the oven can program with multiple stages. Setting

defaults to ‘No’ ensuring programming for single stage ios as in

previous revision (No decimal numbers e.g. 1.1, 1.2 to indicate

stages).

Default

G32R01 G32R03

1 999 120 120 sec S

5 10 10 10 sec S

0 10 5 5 --- U

0 1 1

0 (0) 30 (54) 20 (36) 0 ˚C (˚F) U

30 180

25 (-45) 25 (45) N/A 0 ˚C (˚F) S

no YES N/A YES ---- U

60 60

1

U of M

--- S

sec S

Pass

0

P26

(0) Defines the password level of the parameter (S = Service / Factory Password level 321)

Maximum number of stages.

User Password level 123)

(U =

2 5 N/A 3 —- S

.

11 May 2015

25

Amendment 10

Page 28

7 Electrical Schematics

Circuit Schematic G32D Turbofan Oven, 220 - 240V.

Circuit Schematic G32D Turbofan Oven, 110 - 120V

11 May 2015

26

Amendment 10

Page 29

Wiring Diagrams 8

Wiring Diagram G32D4 Turbofan Oven, 220 - 240V

Round Lamps (Up to Ser. No. 762119)

Square Lamps (From Ser. No. 762120)

11 May 2015

27

Amendment 10

Page 30

Wiring Diagram G32D5 Turbofan Oven, 110 - 120V

Round Lamps (Up to Ser. No. 762119)

Square Lamps (From Ser. No. 762120)

11 May 2015

28

Amendment 10

Page 31

Exploded Parts Lists 9

Outer Assembly

Item Part No. Description

1

2

3

4

5

6

7

M234223

M232912

M232961

M232210

M233986 FOOT 4”/100mm ADJ

M233533

M234583

SIDE COVER LH

TOP PANEL

VENT SHIELD

SIDE COVER RH

SILL

DOOR ASSEMBLY(COMPLETE)

11 May 2015

29

*RPL

D

D

D

D

D

D

C

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

Amendment 10

Page 32

9 Exploded Parts Lists

Motor, Lamp & Racks

Round Lamps

(up to Ser. No. 762119)

Square Lamps (from Ser. No. 762120)

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

Item

8

9

9a

9b

9c

Part No. Description

M232666

M233863

M231814

M233884

M233883

M233115

DOOR SEAL E27/32

OVEN LAMP ASSY G9 (COMPLETE)

LAMP BULB G9 25W 230V HALOGEN 208-240V

LAMP BULB G9 25W 120V HALOGEN 110-120V

OVEN LAMP SEAL

OVEN LAMP LENS

10 — OVEN LAMP ASSY - STEAM SEALED

10a

10b

10c

10d

10e

13

14

15

M236214

M231814

M233884

M021354

M021352

GLASS LENS A

M021353

M234656

M234658

M234660

M233552 THUMBSCREW

M234666 SIDE RACK RH 4 TRAY

LAMP HOLDER (Bulb Included) B

LAMP BULB G9 25W 230V HALOGEN 208-240V A

LAMP BULB G9 25W 120V HALOGEN 110-120V A

GASKET A

SUPPORT FRAME A

SIDE RACK LH 4 TRAY

SIDE RACK LH 5 TRAY

SIDE RACK LH 3 TRAY D

M234667 SIDE RACK RH 5 TRAY

M238561 SIDE RACK RH 3 TRAY D

16

M232904 FAN MOTOR 208-240V, 50/60Hz

M232905 FAN MOTOR 120V, 60Hz

17

18

19

M234726

M232903

M234460

M234461

M233649

M235277

M235278

E-CLIP (NOT SHOWN) D

FAN 7”/175mm

COOLING FAN 230V 50/60Hz

COOLING FAN 115V 50/60HZ

OVEN RACK

DOOR ROLLER CATCH STRIKE PIN

STRIKE LOCKING NUT

*RPL

B

A

A

A

B

B

D

D

B

D

D

B

B

C

B

B

D

C

D

11 May 2015

30

Amendment 10

Page 33

Exploded Parts Lists 9

Electrical Components

Item Part No. Description *RPL

20

21

22

23

24

25

Not shown

26

27

29

M021057

M234774

M015292

M013215

M020869

M020851

M021617

M025922

M021527

M233870

M026160

M232964

SPRAY NOZZLE ASSEMBLY C

WATER TUBE D

SEAL WASHER D

NUT BRASS D

FEMALE CONNECTOR D

WATER SOLENOID 240V B

WATER SOLENOID 110V B

ADAPTOR BRASS ¾” BSP. (USA / CANADA ONLY) D

WASHER RUBBER. (USA / CANADA ONLY) A

CABLE CLAMP PA107 D

TERMINAL BLOCK FV110B D

THERMAL SWITCH 110°C C

30 ------ DOOR MICROSWITCH ASSY (Refer following Page)

31

32

33

34

M234459

IGNITION MODULE 110-120V

M232552

M025400

M234430

CAPACITOR 12uF 110-120V

OVERTEMP THERMOSTAT 360C

TRANSFORMER 110/120V x 12VAC SEC 15VA

A

A

B

C

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

11 May 2015

31

Amendment 10

Page 34

9 Exploded Parts Lists

Oven Main Assembly - Microswitch Details

Up to Ser. No. 744429.

1

2

3

4

5

6

7

8

9

Item Part No Description *RPL

1

2

3

4

5

6

7

8

9

10

M021637

M013610

M021638

M234403

M024802

M041043

M235354

M003397

M017929

M232911

Microswitch Button D

Pivot Bush Plated D

Pin Circlip D

Microswitch Rod D

Door Microswitch B

Screw M5 x 12 Taptite Phil D

Microswitch Return Spring C

Spacer - Plated D

Damper Rod Clip D

Microswitch Bracket B

10

From Ser. No. 744430.

13

12

11

14

15

16

17

18

Item Part No Description *RPL

11

12

13

14

15

16

17

18

19

M236880

M236885

M236886

M024802

M041043

M235354

M003397

M017929

M232911

Microswitch Button Assy D

Microswitch Button Gasket D

Microswitch Rod D

Door Microswitch A

Screw M5 x 12 Taptite PHIL D

Microswitch Return Spring E32 C

Spacer Plated D

Damper Rod Clip D

Microswitch Bracket D

19

M237437

11 May 2015

Microswitch Button Kit - Upgrade

32

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

Amendment 10

Page 35

Exploded Parts Lists 9

Gas Components

Item Part No. Description

BURNER

35

36

37

38

39

42

43

45

46

47

49

M004952

SPARK ELECTRODE

M024127

FLAME SENSOR

M025071

M022909

M032170

M032270

M025093

LOCKNUT M14X1

M234266

M015311

M234458

M015627

M016405

M021288

M024156

M233548

IGNITION ELECTRODE ASSEMBLY (COMPLETE)

INJECTOR 1.7mm - LPG / BUT

INJECTOR 2.70mm - NAT UK US CA

G32 INJECTOR PIPE ASSY - USA/CAN US CA JP ONLY

PRESSURE TEST POINT PLUG US CA JP ONLY

GAS VALVE G32 110-120V

LPG SPRING KIT (NOT SHOWN)

NAT SPRING KIT (NOT SHOWN) C

MALE CONNECTOR ASSY 3/8" x 3/8" BSPT

FLEXTUBE DORMONT T6x12

G32 SUPPLY PIPE ASSY - NPT US CA JP ONLY

11 May 2015

33

*RPL

C

A

A

B

C

C

D

D

D

B

C

D

D

D

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

Amendment 10

Page 36

9 Exploded Parts Lists

Door Assembly

DOOR HINGE ASSEMBLY KIT - 234930

HINGE PIVOT KIT - 234752

46

Item Part No. Description *RPL

45

46

---

M235275

M234930

M234752

DOOR OUTER GLASS ASSEMBLY C

DOOR HINGE ASSEMBLY KIT - which includes:- B

Door Hinge Assy Bottom

Door Hinge Assy Top

HINGE PIVOT KIT - which includes the following:-

Door Hinge Pivot Pin

Washer M8 Nord-Lock T316

Door Hinge Pivot Bush

47

48

49

50

51

53

54

55

56

57

58

59

60

M234725

M041045

M234779

M234757

M234767

M235105

M235104

M235278

M235277

M234580

M234818

M234835

M234581

DOOR CATCH BLANKING PLATE C

SCREW 8 x ⅜" TRUSS HD PHL NP D

INNER GLASS RETAINING CLIP C

DOOR INNER GLASS ASSY C

INNER GLASS PIVOT SPACER D

DOOR STRIKE ESCUTCHEON WASHER C

DOOR STRIKE PIN ESCUTCHEON C

STRIKE LOCKING NUT C

DOOR ROLLER CATCH STRIKE PIN C

DOOR ROLLER CATCH C

INNER GLASS LATCHING BUSH D

DOME PLUG D

DOOR HANDLE WA D

*Recommended Parts Level

RPL

Number of units in service

A 1-5

B 5-10

C 10-50

D 50+

11 May 2015

34

Amendment 10

Page 37

Exploded Parts Lists 9

Controller

72

11 May 2015

Item Part No. Description *RPL

61

62

63

64

65

66

67

68

69

70

71

72

Not Shown

73

74

75

M237139

M236256

M237447K

M236885

M234450K

M235846

M236192

M228132

M233865

M234447

M041425

M236060

CONTROL PANEL LAMINATED G32D D

DIGITAL CONTROL KIT E31D E32D G32D E33D B

TEMP PROBE PT1000 31D/32D/33D B

TEMP PROBE GASKET B

ENCODER MOMENTARY B

PAN

DOME PLUG 15.9 D

BADGE CLIP C

BADGE MOFFAT D

KNOB TFAN INDEX C

SCREW M4 X 6 PAN HD PHIL NP D

CORE TEMP PROBE KIT (

M235845

M235847

M236486

M748019

SCREW M4 x 10 TAPTITE PAN POZI ZP D

EL SOCKET CORE TEMP - D SERIES C

which includes:-

) B

Core Temp Probe (PT1000)

Dust Cap Core Temp Socket

Core Temp Probe Holder

35

*Recommended Parts Level

Number of units in service

RPL

B

D

C

A 1-5

B 5-10

C 10-50

D 50+

Amendment 10

Page 38

10 Accessories

SK STANDS

SK32 — Stand for G32

735mm/29”(W) x 650mm/25½”(D) x 900mm/35½”(H)

Accepts US ½ and US full pan

DSK Double Stacking Kit

GAS TYPE CONVERSIONS

235433 G32D Gas Conversion Kit AU/NZ/XP

235434 G32D Gas Conversion Kit UK

235435 G32D Gas Conversion Kit US/CA

11 May 2015

36

Amendment 10

Page 39

Instruction Sheet for the Assembly of the Base Stand for

the Turbofan Series Ovens

SERVICE WORK ONLY TO BE CARRIED OUT BY QUALIFIED PERSONS

Suitable for the following models:

Stand SK23 for E22 / E23 Ovens. Stand SK2731U for E27 / E28 / E31 Ovens.

Stand SK32 for E32 / G32 Ovens. Stand SK2731N for E27 / E28 / E31 Ovens.

Important - For G32 Appliances Only:

For G32 appliances installed on castors (on base stand, double stacked or on proofer), the appliance is

to be fitted with a restraint at the location provided below the gas connection point.

Adequate means must be provided to limit the movement of the appliance without depending on the

gas connector and the quick-disconnect device or its associated piping to limit the appliance movement.

This installation shall comply with the applicable local codes / standards, e.g. for USA / Canada Only:-

ANSI Z21.69 • CSA 6.16 - Connectors f

ANSI Z21.41 • CSA 6.9, (2) - Quick Disconnect Devices for use with Gas Fuel.

or Moveable Gas Appliances.

Unpacking and Assembly:

Check that the kit includes the correct parts and quantities for the stand purchased as listed overleaf.

1. Place Frame (A) on flat surface and fit Shelf Runners

(B) to Frame with 4 Screws (E). Only loosely tighten all

screws until Top Plates (C) are fitted.

Base of Stand

Restraining Anchor Point

(E)

(E)

(A)

Position for Shelf Runners

(‘L’ Shaped) when Stand is sat

on castors.

(B)

B

a

s

e

o

f

S

t

a

n

d

Correct

T

o

p

o

f

S

t

a

n

d

(A)

(E)

(B)

(E)

3. Fit Castors (F) to one Frame (A). Fit Castors (G) to

second Frame (A) and tighten hand tight. Ensure

both Locking Castors are fitted to the same

Frame.

(G)

Frame.

Top of Stand

(F)

(F)

2. Turn stand upside down and fit second Frame (A) and

attach to Shelf Runners (B), secure with 4 Screws (E).

Ensure Shelf Runners (B) are fitted correctly.

20 January 2011

1

(A)

Part No 234246-3

Page 40

Instruction Sheet for the Assembly of the Base Stand for the Turbofan Series Ovens.

4. Fit Top Plates (C) with 4 Screws (E). Fit Oven Location

Pins (D) with 4 Screws (E). Refer ‘Pin Fitting Locations’

figures overleaf for correct pin location for oven type.

Tighten all screws securely.

Correct

Position with Shelf

Runner upright sitting

behind Top Plate.

Note position

of Screw (E).

(C)

(D)

(E)

(D)

(E)

(C)

Pin Location for E31 Ovens Only

NOTE: For E31 Ovens Only, pin location should be as

shown below with Locking Castors at front of

stand and Rear Locating Pins fitted in holes

nearest front of stand.

d

n

a

t

S

f

o

t

n

o

r

F

NOTE: Position of

Rear Locating Pins.

For Stands SK23 / SK32

Pin Location for E22 / E23 & G32 / E32 Ovens

Pin Fitting Locations:

For Stands SK2731U / SK2731N

Pin Location for E27 / E28 Ovens

Parts List:

Frame (A) - Qty 2.

Top Plate (C) - Qty 2.

Stand Oven Locating Pin (D) - Qty 4.

Screw M6 x12 (E) - Qty 17 (1 spare).

Castor 75 mm (F) - Qty 2.

Shelf Runners (B) - Qty 2.

20 January 2011

Castor Braked 75 mm (G) - Qty 2.

2

Part No 234246-2

Page 41

Page 42

Page 43

Gas Conversion and Specifications 9

Conversion Procedure

Caution

Ensure that the appliance is isolated from

the electrical and gas supply before

commencing servicing.

NOTE:

These conversions should only be carried out by qualified

persons. All connections must be checked for leaks before

re-commissioning the appliance.

Adjustment of components that have adjustments /settings

sealed (e.g. paint sealed) can only be adjusted in

accordance with the following instructions and shall be

re-sealed before re-commissioning this appliance.

For all relevant gas specifications refer to the table at the

end of this section.

Procedure:

1. Remove the lower service panel to allow access to the gas

trol valv

con

Unscrew and remove screw cap from regulator incorporated in

2.

the gas control.

3.

Remove regulator spring from the gas control valve. Replace

with correct spring supplied with the conversion kit.

e.

Screw Cap

Gas Type Identification Label

On completion of the gas conversion, replace gas type

identification labels, located at:-

- The rear of the appliance, above the gas connection point.

Commissioning

Before leaving the converted installation;

1. Check all gas connections for leakages using soapy water or

other gas detecting equipment.

2. Check the following functions in accordance with the operating

instructions specified in the ‘Operation’ section of this manual.

Ensure that all the oven controls operate correctly.

Ensure that the operating pressure remains correct.

3. Ensure any adjustments done to components that have the

adjustments / settings sealed (e.g. paint sealed), are

re-sealed.

NOTE: If it is not possible to get the appliance to operate

correctly, shut ‘off’ the gas supply and contact the

supplier of this appliance.

9 Gas Conversion and

Specifications

- US / Canada Only:

4. Unscrew and remove the main burner injector and replac

with appropriate item.

5. Connect gas and electrical supplies.

6.

Main Burner Injector

7

. Carry out a full leak test of the converted oven prior to placing

it into operation.

e

Table of Gas Specifications

Operate oven and adjust regulator to achieve correct pressure

pressure test point (front

at

Orifice Size

Regulator Spring (Colour)

Supply Pressure

Operating Pressure

RH corner).

Natural Gas LP Gas

#36 Drill (2.70mm) #51 Drill (1.70mm)

Green Spring Blue Spring

7” w.c.

4.2” w.c. 11” w.c.

11” w.c.

Do not use a naked flame to

8. Refit the service panels.

11 May 2015

Warning

check

for gas l

eakages.

37

Amendment 10

Page 44

Appendix A Reversing Oven Door

Reversing the Oven Door

NOTE: This operation should only be carried out by a

suitably competent person.

Remove the Oven Door Inner Glass.

Open the oven door and open the

1.

door inner glass.

2. Remove screw securing in

gl

ass retaining clip and remove

clip

.

ner

Remove Screw

and Retaining

3. Lift up inner glass and remove,

ing that pivot spac

ensur

removed from

vot and retained.

pi

lower inner gla

4. Remove black plastic plugs from

top and bottom of door and fit

s where inner glass pivots

hole

were removed fr

Remove t

he Oven Door.

5. Remove the door roller catch and blanking plate from th

nside of the door and swap these over.

i

om.

er is

ss

to

Fit Blanking Plugs.

e

11. Remove inner glass latching

s and fit to opposite side of

stud

door using Loctite 243 to secu

Turn door handle over and fit to other end of d

12.

s were removed from. Ensure Flat of handle is to

hinge

out

side.

re.

Remove Latching Studs

oor where

the

Remove Upper and Lower Door Hinges and Door Catch.

13. Remove bottom door pivot bolt

and spacers and fit pivot bolt to

top door hinge assembly (as th

ll be swapped over and fitt

wi

to b

ottom of other side of oven).

ed

is

Bottom Door Pivot

Bolt and Spacers.

Swap Roller Catch and

Blanking Plate over.

6. Whilst supporting door, unscr

and remo

ve top door pivot bolt

ew

from top door hinge assembly.

7. Remove door and lay on a flat

ce or workbench.

surfa

8. Unscrew screws securing th

door handle rem

ove door handle.

e

9. Remove top door hinge and fit to

bottom opposite corner of door.

Remove Top

Door Pivot Bolt.

Remove Handle

Securing Screws

14.

Remove the 4 blanking screws

from front of oven.

15.

Remove Hinge Plate from

ven and fit diagonally opposite,

o

to lower corn

er.

Remove screws top and bottom

and fit to where hinges removed

from.

top of

Remove these screws to remove

top and bottom hinges.

Remove bottom door hinge and

10.

fit to top opposite corner of door

11 May 2015

Remove Top Door Hinge

.

39

16.

Remove Hinge Pl

ottom of oven and

b

di

agonally opposite, to

corner.

Fit screws removed at It

17.

above to wher

tted.

fi

ate from

fit

e hinges

upper

em 14

were

Amendment 10

Page 45

Appendix A Reversing Oven Door

18. Remove Blanking Screw and Door Catch from front of oven

and swap around (refer ‘Adjusting Door Catch’).

Locking Nut

19. Fit door spacers removed at Item 13 previously, to lower hi

pi

vot bolt.

Oven Door Re-Fitting

Fit the Door.

1. Refit oven door by locating bott

oor onto bottom hinge plat

of d

pi

vot bolt and spac

Fit top of door into top hinge pl

2.

and s

ecure with top pivot bolt

Fit Inner Glas

NOTE: It is important to ensure that the inner glass is fitted

3. Fit pivot spacer removed at Item 3 on previous page, to th

4. Locate top pivot of inner glass into

5. Lift inner glass up onto locking

correctly and that the glass pivots at the hinge end

of the door and not the handle end.

ower inner glass pivot and locate inner glass lower pivot into

l

position on inside of door.

top of door and secure in position

with inner glass retaining clip.

catch to lock glass into position

Door Catch

ers.

s to Door.

om

e

ate

.

.

Blanking Screw

nge

Top Door Pivot Bolt.

e

Screw and Retaining Clip.

Inner Glass Locking Catch

Adjust Door for Correct Alignment.

Check alignment and operation of the

door. Ensure that the door is

correctly aligned horizontally and

vertically.

To align, slacken off

1.

lower hinge plate

alig

n the door. Re-tighten bo

hinge plates.

Check that the roller ca

2.

corre

ctly retains door in the closed

position.

3. To adjust, slightly loosen screws

securing roller catch and close the

door. The roller catch wi

entralise itself.

c

4. Open door and tighten roller ca

securing screws.

Adjusting Door Catch

If the door sealing requires adjustment, carry out the following to

adjust the door catch:-

1. Check that the door seals correctly when closed, by plac

s

heet of paper between the door

and the seal

2.

Close the door on th

pt to withdraw the paper by

attem

firmly tugging on the paper.

hould just pull out wi

paper s

s

ome resistance but without

tearing the paper.

3. To adjust the door catch, loosen the locking nut on the door

ch:

cat

-

If the paper withdraws easily,

a.

by ½ a turn

ctly.

corre

b. If the paper cannot be withdrawn and the door springs

open,

screw the door catch ‘Out’ by ½ a turn

eat the test above until adjusted correctly.

rep

Tighten the locking nut on the door catch.

4.

the upper and

s and correc

.

e paper and

tch

tly

th

Slacken these screws to adjust

door vertically - horizontally.

ll

tch

The

th

screw the door catch ‘In’

and repeat the test above until adjusted

ing a

and

11 May 2015

40

Amendment 10

Page 46

Page 47

P

SERIES

P8M/P10M/P12M Series

Proofer/Holding Cabinets

(Manual Operatio

Service Manual

n)

26 July 2013

Amendment 2

Page 48

MANUFACTURED BY

Moffat Limited

Christchurch

New Zealand

INTERNATIONAL CONTACTS

AUSTRALIA

Moffat Pty Limited

E.Mail: vsales@moffat.com.au

Main Office: (tel) (03) 9518 3888

(fax) (03 9518 3833

Service: (tel): 1800 622 216

Spares: (tel): 1800 337 963

Customer Service: (tel): 1800 335 315

(fax): 1800 350 281

CANADA

Serve Canada

Web: www.servecanada.com

E.Mail: info@servecanada.com

Sales: (tel): 800 551 8795 (Toll Free)

Service: (tel): 800 263 1455 (Toll Free)

NEW ZEALAND

Moffat Limited

Web: www.moffat.co.nz

E.Mail: sales@moffat.co.nz

Main Office: (tel): 0800 663328

UNITED KINGDOM

Blue Seal

Web: www.blue-seal.co.uk

E.Mail: sales@blue-seal.co.uk

Sales: (tel): 0121 327 5575

(fax): 0121 327 9711

Spares: (tel): 0121 322 6640

(fax): 0121 327 9201

Service: (tel): 0121 322 6644

(fax): 0121 327 6257

UNITED STATES

Moffat

Web: www.moffat.com

Sales: (tel): 800 551 8795 (Toll Free)

Service:

REST OF WORLD

Moffat Limited

Web: www.moffat.co.nz

E.Mail: export@moffat.co.nz

(tel): 336 661 1556

(fax): 336 661 9546