Page 1

E87 PROOFER

SERVICE

MANUAL

Revision 2/F3520

-1-

Page 2

CONTENTS

This manual is designed to take a more in depth look at the E87 prover for the purpose of making

the unit more understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for

completeness and those special cases where these settings are required to change, this manual

gives a full explanation as to how, and what effects will result.

SECTION PAGE NO.

1. SPECIFICATIONS .........................................................................................................5

2. INSTALLATION .............................................................................................................7

3. OPERATION ...................................................................................................................8

3.1 Description of Controls

3.2 Explanation of Control System

4. MAINTENANCE .............................................................................................................10

4.1 Cleaning

4.2 Routine Procedures

5. TROUBLE SHOOTING GUIDE ......................................................................................12

6. SERVICE PROCEDURES ..............................................................................................14

6.1 Fault Diagnosis

6.2 Access

6.3 Replacement

7. ELECTRICAL SCHEMATICS ........................................................................................20

8. ELECTRICAL WIRING DIAGRAMS ..............................................................................21

9. SPARE PARTS ..............................................................................................................22

10. ACCESSORIES / OPTIONS ..........................................................................................23

11. PARTS DIAGRAM .........................................................................................................24

11.1 Main Assembly

11.2 Control Panel Assembly

12. SERVICE CONTACTS ..................................................................................................27

IMPORTANT: MAKING ALTERATIONS MAY VOID WARRANTIES AND APPROVALS.

Revision 2/F3520

-3-

Page 3

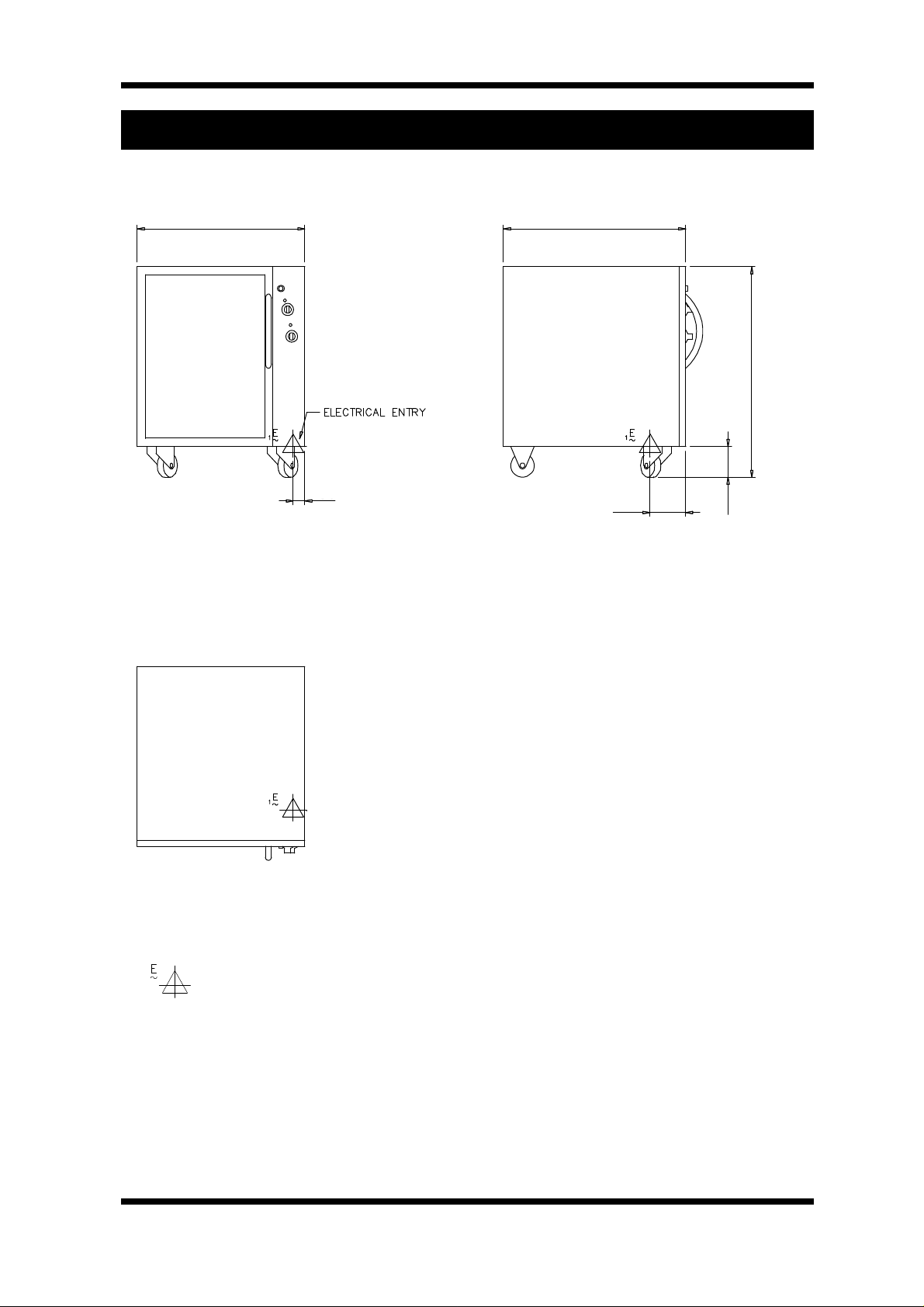

MODEL: E87

1. SPECIFICATIONS

FRONT

710

(28.0)

50

(1.95)

SIDE

770

(30.3)

150

(5.9)

890

(35.0)

130

(5.1)

PLAN

LEGEND

- Electrical connection entry point

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 2/F3520

-5-

Page 4

LOCATION

To ensure correct operation the following

minimum installation clearances are to be

adhered to:

Rear: 25 mm / 1”

Left-hand side: 25 mm / 1”

Right-hand side: 25 mm / 1”

PROVER INTERNAL DIMENSIONS

Width: 460 mm / 18”

Height: 610 mm / 24”

Depth: 660 mm / 26”

Oven Volume: 0.19 m³ / 6.5 ft³

PROVER RACK SIZE

Width: 460 mm / 18”

Depth: 660 mm / 26”

No. of rack positions: 8

Rack position spacing: 75 mm / 3”

ELECTRICAL SUPPLY SPECIFICATION

OPTIONS

100-120 V AC 60 Hz, 12.5 A, 1.5 kW @ 120 V

220-240 V AC 50 Hz, 7.5 A, 1.8 kW @ 240 V

ELECTRICAL PLUG SPECIFICATION

REQUIREMENTS

Australia 3-pin 250V 10A, AS/NZ 3112

Canada 3-pin 250V 15A, NEMA 6-15

New Zealand 3-pin 250V 10A, AS/NZ 3112

United Kingdom 3-pin 250V 13A fused, BS

1363A

United States 3-pin 250V 15A, NEMA 6-15

Other Countries 3-pin 250V 10A minimum, type

to meet country standards

Revision 2/F3520

-6-

Page 5

2. INSTALLATION

WARNING: THIS APPLIANCE MUST BE GROUNDED.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

It is most important that the prover is installed

correctly and that the operation is correct

before use. Installation shall comply with local

electrical, health and safety requirements.

BEFORE CONNECTION TO POWER

SUPPLY

Unpack and check unit for damage and report

any damage to the carrier and dealer. Report

any deficiencies to your dealer. Fit the

castors which are packed inside the unit.

Check that the available power supply is

correct to that shown on the rating plate

located on the right-hand side panel.

220-240 V AC 50 Hz, 7.5 A, 1.8 kW @ 240 V

100-120 V AC 60 Hz, 12.5 A, 1.5 kW @ 120 V

LOCATION

To ensure correct operation the following

minimum installation clearances are to be

adhered to:

Rear 25mm / 1”

Left-hand side 25mm / 1”

Right-hand side 25mm / 1”

ELECTRICAL CONNECTION

E87 provers are supplied with pre-fitted cords.

Ensure unit is fitted with correct cord and plug

for the installation (refer to the specifications

section).

Should changing of the cord be necessary,

gain access to the electrical connection

terminal block and strain relief clamp by

removing the control panel.

ASSEMBLY OF CASTORS

1. Remove the castors from inside the

prover.

2. Remove side racks and water trough.

3. Lift and place the prover onto its back.

Attach the two swivel castors (with brake)

to the front of the prover with the screws

provided. Attach the two rigid castors to

the rear.

4. Lift the prover onto its castors and refit the

water trough and side racks.

DOUBLE STACKING UNITS

When it is desired to mount a Turbofan

Countertop Convection Oven on an E87

prover, a double stacking kit may be used.

Available from your dealer or Turbofan

distributor (see Spare Parts).

When mounting one prover on top of another,

a double stacking kit is also required.

RATING PLATE LOCATION

The rating plate for the E87 prover is located

at the bottom left corner of the RH side panel.

Rating Plate

Revision 2/F3520

Figure 2.2

Figure 2.1

-7-

Page 6

3. OPERATION

NOTE: A full user’s operation manual is supplied with the product and can be used for further

referencing of installation, operation and service.

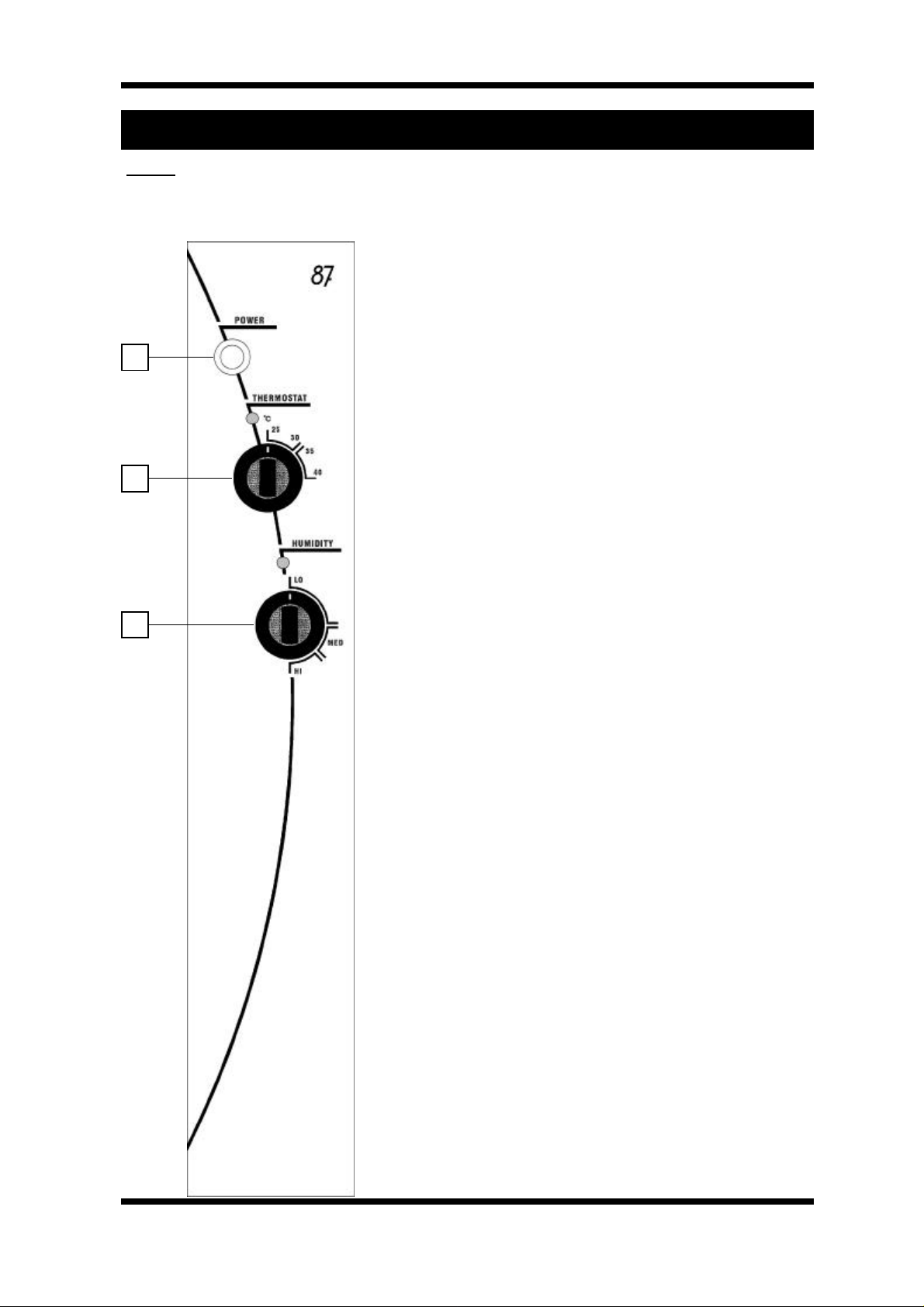

3.1 DESCRIPTION OF CONTROLS

1. POWER

Depress to switch power on or off (switch

illuminates when power is on).

2. THERMOSTAT

1

2

3

Temperature range 25 - 40°C (75 - 105°F).

Light illuminates when elements are cycling

ON to maintain set temperature.

Controls the prover air temperature.

3. HUMIDITY CONTROL

(Light illuminates when elements are cycling

ON to maintain set humidity).

Controls prover humidity.

LO - Humidity setting for butter based pastries

(croissants, Danish pastries etc).

MED / HI - Humidity setting for yeast based

breads and dough.

WATER

Open the prover door. Fill the water trough to

the halfway level in the trough front filling

snout, located on the right hand side.

Remember to top up the water trough when

the level is below the front snout.

Revision 2/F3520

-8-

Page 7

3.2 EXPLANATION OF CONTROL

SYSTEM

The E87 Prover has a power On/Off switch on

the control panel and isolates power to the

humidity and heating fan and light circuits

when switched Off. When switched On the

switch will illuminate to indicate that the unit is

On and operational. The air circulation fan is

On continuously on all E87 models when the

power switch is in an On position.

The proofing system operates on all models,

controls air temperature and humidity levels

by way of an air heating element controlled by

a mechanical bulb and capillary thermostat

and a water tank heating element controlled

by a mechanical bulb and capillary

thermostat.

The air heating element is positioned in the

bottom of the air circulation ducting inside the

cabinet and is directly controlled by the

user-adjustable thermostat mounted to the

control panel. The thermostat sensing bulb is

mounted inside the cabinet to control the

cabinet air temperature to the control panel

setting. An indicator light on the control panel

above this thermostat will illuminate when the

thermostat has the air heating element

operating and will cycling Off with the

thermostat to indicate when the temperature

reaches set point.

The water tank heating element controlled by

the humidity level thermostat mounted to the

control panel is used to heat the water tank

water and maintain water tank temperature

between 50°C (122°F) and 80°C (176°F).

This water tank temperature is controlled by

the humidity level thermostat setting between

the adjustments of low and high humidity.

The evaporation rate of the water in the water

tank dependent on its temperature, provides

humidity into the cabinet and accordingly the

setting of the humidity thermostat controls the

rate of evaporation and therefore the humidity

level in the cabinet.

An indicator light on the control panel above

the humidity dial illuminates when the water

tank element is On, and cycles Off when the

thermostat switches the heating element Off

to provide an indication of the humidity

control. The sensing bulb of the humidity

thermostat is mounted directly on the water

tank heating element which are both

immersed in the water tank. Should the water

tank level drop below the heating element the

humidity thermostat will cycle Off due to the

sensing bulb reacting to the radiated heat off

the heating element and will prevent the

humidity water tank heating element burning

out through excessive temperature.

E87 models require the operator to manually

fill the water tank and maintain the water tank

level as the water evaporates through

operation.

With all E87 models butter based products

such as croissants and danish pastries should

have the cabinet proofing temperature set

around 25°C (77°F) as higher proofing

temperatures will cause the butter to melt out

of the product, and for yeast based doughs

and breads the proofing temperature should

be set higher at around 40°C (105°F) in order

to activate the yeast in these products.

On all models the air circulation fan mounted

at the top of the air delivery ducting ensures

that the temperature and humidity throughout

the cabinet is even by creating a low velocity

air circulation system throughout the prover

cabinet. This system overcomes the natural

occurrence of hot air rising and therefore

higher humidity and temperature in the upper

positions of the cabinet as found with proofing

units without forced air circulation.

The user-adjustable thermostat and humidity

controls are required to allow adjustment of

cabinet temperature and humidity levels for

the variations of temperature and humidity

that different product types require.

Two cabinet illumination lights are provided in

the E87 models and these 15 watt each

incandescent filament lamps are On

whenever the control panel power switch is

switched on.

To prevent the formation of condensation on

the aluminium frame around the front of the

cabinet and to assist in minimising the

condensation occurring on the door frame and

door glass inner face a resistance wire

heating element is fitted into the cabinet

aluminium extrusion frame. This heating wire

is on whenever the power switch is switched

on and will heat the aluminium frame to a

warm-to-touch temperature.

Revision 2/F3520

-9-

Page 8

4. MAINTENANCE

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

4.1 CLEANING

WARNING: ALWAYS TURN THE

POWER SUPPLY OFF BEFORE

CLEANING.

IMPORTANT: THIS UNIT IS NOT

WATER PROOF.

DO NOT USE A WATER JET SPRAY TO

CLEAN INTERIOR OR EXTERIOR OF

THIS UNIT.

CABINET

A good quality stainless steel cleaning

compound is recommended for cleaning the

inside and outside of the cabinet. Harsh

abrasive cleaners may damage the surface.

SIDE RACKS

To remove, take hold of the centre rung and

lift towards the prover top. To replace, hold

horizontally, engage in holes and push down.

DOOR

Open the door and lift up off its hinges. Wash

with warm water and detergent solution using

a soft sponge.

To refit the door, simply fit onto its hinges.

WATER TROUGH

Remove right hand side rack and remove

trough. Clean with warm, soapy water. Rinse

thoroughly.

WATER TROUGH ELEMENT

When the element becomes limed / scaled,

remove water trough and clean. Replace

water trough and half fill with white vinegar or

acetic acid then fill to the normal level with

water. Switch unit on. Set humidity control to

‘Hi’ and run for approximately 30 minutes.

Remove trough and clean element with damp

cloth when cooled. Wash out trough and refit

to unit.

This procedure is recommended to be done

once a week. Frequency of cleaning the

element may be increased or decreased

depending on the lime depositing on the

element.

Revision 2/F3520

-10-

Page 9

4.2 ROUTINE PROCEDURES

PROCEDURE INTERVAL

DOOR HINGES Check for wear. 12 months

DOOR CATCH Ensure that catch is adjusted such that the door

closes properly.

ELEMENTS Check that element resistances are correct to their

ratings. (refer 6.3.6, 6.3.7).

WET ELEMENT Remove scaling (refer section 4.1). As required

HOTWIRE Check that hotwire is working. 12 months

12 months

12 months

Revision 2/F3520

-11-

Page 10

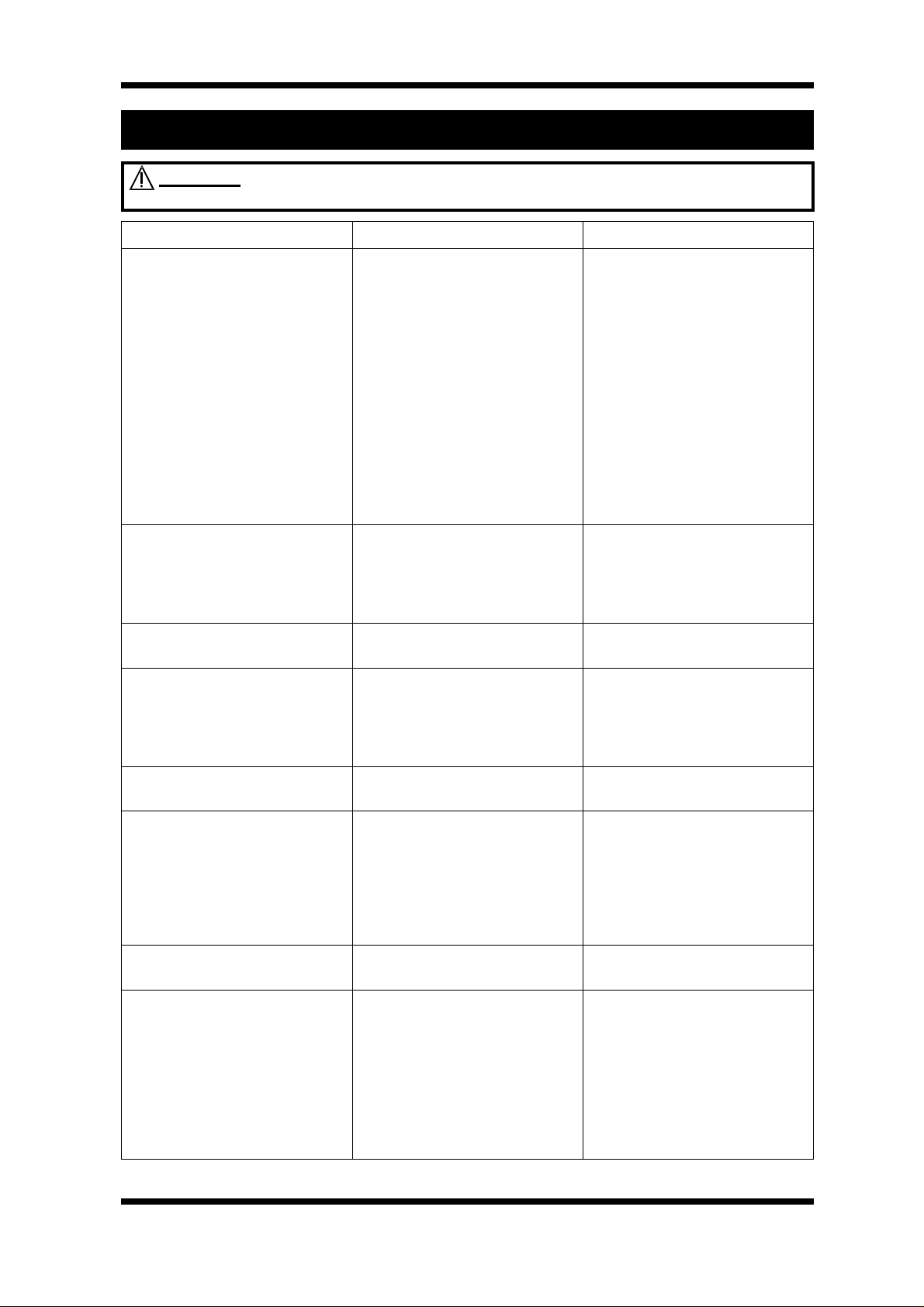

5. TROUBLE SHOOTING

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

FAULT POSSIBLE CAUSE REMEDY

THE PROVER DOES NOT

OPERATE / START

OVEN LIGHT NOT

ILLUMINATING

FAN DOES NOT OPERATE Faulty fan.

The prover is not plugged into

the wall socket.

The mains isolating switch on

the wall, circuit breaker or fuses

are “off” at the power board.

The power switch on the prover

is off.

Incorrect electrical supply.

(Refer fault diagnosis 6.1.1)

Power switch on unit faulty.

(Refer fault diagnosis 6.1.1)

Blown bulb.

No power to light.

(Refer fault diagnosis 6.1.2)

(Refer fault diagnosis 6.1.3)

Plug in.

Turn on.

Depress switch. Switch will

illuminate.

Ensure electrical supply correct.

Replace.

(Refer service section 6.3.3)

Replace.

(Refer service section 6.3.1)

Correct fault.

Replace.

(Refer service section 6.3.8)

NO HEAT Thermostat faulty.

(Refer fault diagnosis 6.1.4)

Element blown.

(Refer fault diagnosis 6.1.4)

NO TEMPERATURE

CONTROL

NO HUMIDITY No water in trough.

NO HUMIDITY CONTROL Faulty thermostat.

SLOW RECOVERY Overloading of prover.

Faulty thermostat.

(Refer fault diagnosis 6.1.5)

Faulty thermostat.

(Refer fault diagnosis 6.1.6)

Element blown.

(Refer fault diagnosis 6.1.6)

(Refer fault diagnosis 6.1.7)

Door opened unnecessarily.

Electrical supply incorrect.

Fan faulty.

(Refer fault diagnosis 6.1.3)

Replace.

(Refer service section 6.3.4)

Replace.

(Refer service section 6.3.6)

Replace.

Refer service section 6.3.4)

Fill trough with water.

Replace.

(Refer service section 6.3.5)

Replace.

(Refer service section 6.3.7)

Replace.

(Refer service section 6.3.5)

Reduce batch size.

Do not open unnecessarily.

Check supply voltage is as per

rating plate voltage.

Replace.

(Refer service section 6.3.8)

Revision 2/F3520

-12-

Page 11

FAULT POSSIBLE CAUSE REMEDY

NO HEATING / HUMIDITY

INDICATOR

CONDENSATION ON TOP OF

FRAME

DOOR DOES NOT CLOSE Tray in way of door.

Indicator faulty.

(Refer fault diagnosis 6.1.8)

Hot wire faulty.

(Refer fault diagnosis 6.1.9)

Damaged door magnet.

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.12)

Correctly position tray in rack.

Replace.

(Refer service section 6.3.11)

Revision 2/F3520

-13-

Page 12

6. SERVICE PROCEDURES

WARNING: ENSURE POWER SUPPLY IS SWITCHED OFF BEFORE SERVICING.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

SECTION PAGE NO.

6.1 FAULT DIAGNOSIS ..............................................................................................................15

6.1.1 Prover Does Not Operate / Start .........................................................................15

6.1.2 Prover Lights Not Illuminating .............................................................................15

6.1.3 Fan Does Not Operate ........................................................................................15

6.1.4 No Heat ...............................................................................................................15

6.1.5 No Temperature Control ......................................................................................15

6.1.6 No Humidity ......................................................................................................... 15

6.1.7 No Humidity Control ............................................................................................15

6.1.8 No Heating / Humidity Indicator ...........................................................................15

6.1.9 Condensation On Top Of Frame .........................................................................15

6.2 ACCESS ................................................................................................................................16

6.2.1 Control Panel .......................................................................................................16

6.2.2 Control Panel (Rear) ............................................................................................16

6.3 REPLACEMENT ...................................................................................................................16

6.3.1 Light Bulb / Glass ................................................................................................16

6.3.2 Indicator Light ......................................................................................................16

6.3.3 Power Switch .......................................................................................................16

6.3.4 Thermostat ...........................................................................................................17

6.3.5 Humidity Thermostat ...........................................................................................17

6.3.6 Dry Element .........................................................................................................18

6.3.7 Wet Element ........................................................................................................18

6.3.8 Fan Motor ............................................................................................................18

6.3.9 Door .....................................................................................................................19

6.3.10 Door Hinges ......................................................................................................... 19

6.3.11 Magnetic Catch ....................................................................................................19

6.3.12 Hotwire .................................................................................................................19

Revision 2/F3520

-14-

Page 13

6.1 FAULT DIAGNOSIS

6.1.1 PPOVER DOES NOT OPERATE

Incorrect electrical supply

Check that the voltage across phase and

neutral (L1 and L2) terminals of terminal block

is the voltage as stated on the unit’s electrical

rating plate.

If incorrect, check electrical connection of

supply wiring and / or check electrical supply.

Power switch faulty

Check if power switch latches. If the switch

does not latch, then switch is faulty—replace.

With switch latched, check voltage across

terminal 1 to terminal 3. If there is no voltage,

check for fault in wiring.

Check voltage across terminal 2 to terminal 3.

If there is no voltage, then switch is faulty—

replace.

NOTE: When power switch is latched, it

should illuminate if operating correctly.

6.1.2 PROVER LIGHTS NOT ILLUMINATING

No power to light

Check voltage across light bulb terminals. If

there is no voltage then check wiring. If there

is voltage then the lamp is faulty - replace.

6.1.3 FAN DOESN’T OPERATE

Fan motor faulty

Check the supply voltage across the motor

terminals. If there is no voltage then check

the electrical connections of supply wiring.

If voltage is correct then check the oven fan

for free rotation. Remove any obstruction.

If fan is free to spin and the voltage supply is

correct, then the motor is faulty—replace.

6.1.4 NO HEAT

Thermostat faulty

With cold prover, set thermostat to 40°C /

105°F. Check power to terminal 1 of top

thermostat. If there is no power then check

wiring.

Check power at terminal 2. If there is no

power then the thermostat is faulty - replace.

Element blown

With thermostat on and heating check voltage

across dry element terminals. If there is no

voltage check wiring. If voltage is correct,

element is faulty - replace.

6.1.5 NO TEMPERATURE CONTROL

Thermostat faulty

With thermostat in off position (fully counterclockwise), the heating indicator should be off.

If not, then the thermostat is faulty - replace.

6.1.6 NO HUMIDITY

Thermostat faulty

With cold prover, set humidity to ‘HI’. Check

power to terminal 1 of bottom thermostat. If

there is no power then check wiring.

Check power at terminal 2. If there is no

power then the thermostat is faulty - replace.

Element blown

With humidity thermostat on and heating

check voltage across wet element terminals.

If there is no voltage check wiring. If voltage

is correct, element is faulty - replace.

6.1.7 NO HUMIDITY CONTROL

Humidity thermostat faulty

Switch the prover on and set the humidity to

‘LO’. Check that the humidity thermostat

cycles on/off, and using a suitable probe

measure the temperature of the water in the

trough. The water temperature should be 50°

C/120°F ± 10%. If the temperature continues

to rise above this then the humidity thermostat

is faulty - replace.

6.1.8 NO HEATING / HUMIDITY

INDICATOR

Indicator faulty

Check voltage across indicator terminals with

controls on and appropriate thermostat turned

on fully. If the voltage is correct, and the

indicator is not illuminating then the indicator

is faulty - replace. If there is no voltage then

check wiring.

6.1.9 CONDENSATION ON TOP OF FRAME

Hotwire faulty

Check voltage across hotwire. If there is no

voltage then the hotwire is faulty - replace.

Revision 2/F3520

-15-

Page 14

6.2 ACCESS

6.3 REPLACEMENT

6.2.1 CONTROL PANEL

1) Undo the one screw on top of control

panel.

One Screw

Figure 6.2.1

2) Panel is now free to hinge at bottom.

When closing the panel ensure wires and

capillary tube are clear of metal or other

terminals.

6.2.2 CONTROL PANEL—REAR

Power Switch

6.3.1 LIGHT BULB / GLASS

1) Open the prover door.

2) Pull off lamp cover.

Lamp Covers

Figure 6.3.1

3) Unscrew bulb out of fitting.

4) Screw in replacement bulb.

5) Refit lamp cover.

6.3.2 INDICATOR LIGHT

1) With control panel open (refer 6.2.1)

remove the wires from the back of the

neon.

Dry Heating Indicator

Dry Thermostat

Wet Heating Indicator

Wet Thermostat

Neon Wires

Figure 6.3.2

2) From back push neon through front of

panel rotating clockwise.

3) Push new neon in from front of panel, and

reconnect wires.

6.3.3 POWER SWITCH

1) With control panel open (refer 6.2.1)

remove the wires from the back of the

switch, noting their positions.

Power Switch

Wires

Revision 2/F3520

Figure 6.2.2

Figure 6.3.3

-16-

Page 15

2) From back push switch through front of

panel.

3) Push new switch in from front of panel, and

reconnect wires.

6.3.4 THERMOSTAT

1) Pull knob off front of thermostat

2) Open control panel (refer 6.2.1) and undo

2 screws securing thermostat.

Two Screws

Figure 6.3.4

3) Transfer wires to new thermostat.

4) With door open, remove right hand side

rack. Undo thermostat support bracket

screw and remove bracket.

6.3.5 HUMIDITY THERMOSTAT

1) Pull knob off front of thermostat

2) Open control panel (refer 6.2.1.) and undo

2 screws securing thermostat.

Two Screws

Figure 6.3.7

3) Transfer wires to new thermostat.

4) With door open, remove right hand side

rack and water trough. Undo thermostat

support bracket screw and remove

bracket. Remove clips holding capillary to

element.

Support

Bracket

Screw

Support

Bracket Screw

Figure 6.3.5

5) Withdraw old thermostat phial through

side of prover.

6) Remove plastic sleeving from old

thermostat and fit to replacement

thermostat.

Thermostat Phial

Plastic Sleeving

Figure 6.3.6

7) Insert new thermostat.

8) Re-assemble in reverse order.

Capillary

Clips

Figure 6.3.8

5) Remove rubber bush in side wall, withdraw

old thermostat phial through side of prover.

6) Remove fibreglass sleeving from old

thermostat and fit to replacement

thermostat

Fibreglass Sleeve

Thermostat Phial

Figure 6.3.9

7) Insert new thermostat.

8) Re-assemble in reverse order.

Revision 2/F3520

-17-

Page 16

6.3.6 DRY ELEMENT

1) Open control panel (refer 6.2.1), remove

wires from element terminals noting

position.

Element

Terminals

Figure 6.3.10

2) With door open, remove right hand side

rack

3) Unscrew the element from inside control

housing. Pull element carefully to remove

from inside of prover.

4) Open control panel (refer 6.2.1) and

remove wires from element terminals,

noting their positions.

5) Unscrew the element from inside control

housing.

Element

Screws

Figure 6.3.13

6) Pull element carefully from the inside of

prover to remove .

7) Replace and re-assemble in reverse

order.

Wet Element Ratings

110 - 120 Volt 20.1 ohms

220 - 240 Volt 71.5 ohms

Element

Screws

Figure 6.3.11

4) Replace and re-assemble in reverse

order.

Dry Element Ratings

110 - 120 Volt 20.5 ohms

220 - 240 Volt 70.5 ohms.

6.3.7 WET ELEMENT

1) With door open, remove right hand side

rack and water trough.

2) Undo thermostat support bracket screw

and remove bracket.

3) Remove clips holding capillary to element.

Support

Bracket

Screw

6.3.8 FAN MOTOR

1) Open control panel (refer 6.2.1), and

remove wires from fan motor terminals,

noting positions.

Fan Motor

Terminals

Figure 6.3.14

2) Loosen retaining bracket screw. Slide

bracket down to bottom position.

Retaining

Bracket Screw

Capillary

Clips

Revision 2/F3520

Figure 6.3.12

Figure 6.3.15

3) Slide out motor.

4) Replace and re-assemble in reverse

order, ensuring bracket is secured in

highest position.

-18-

Page 17

6.3.9 DOOR

6.3.11 MAGNETIC CATCH

1) Open prover door.

2) Lift door vertically off hinges.

3) Remove door handle and door catch plate

(two bolts).

Two Bolts

Figure 6.3.16

4) Drill out rivets securing hinges to old door

frame (two per hinge).

Rivets

Figure 6.3.17

5) Secure door handle and catch plate to

new door.

6) Rivet hinges to new door frame.

7) Re-hang door on E87 prover.

6.3.10 DOOR HINGES

1) Open prover door.

2) Open control panel.

3) Unscrew two screws securing magnetic

door catch to prover.

Two Screws

Figure 6.3.19

NOTE: A spanner may be required to hold

the nuts located inside the control panel,

behind the magnetic catch.

4) Replace magnetic catch and re-assemble

in reverse order.

6.3.12 HOTWIRE

1) Open control panel (refer 6.2.1) and

prover door.

2) Remove silicone extrusion seal strips from

prover door frame.

Silicone

Extrusion

Strips (3)

1) Open prover door.

2) Lift door vertically off hinges.

3) Drill out rivets securing hinges to door and

E87 prover (two rivets per hinge), and remove hinges.

Door

Hinges

Hinge

Rivets

Figure 6.3.18

4) Rivet new hinges to door and E87 prover.

5) Re-hang door on prover.

Revision 2/F3520

Figure 6.3.20

3) Remove hotwire retaining sleeves (9) from

prover frame.

Retaining

Sleeves (9)

Figure 6.3.21

4) Remove hotwire from prover, noting

wiring positions.

5) Replace and re-assemble in reverse

order.

-19-

Page 18

7. ELECTRICAL CIRCUIT SCHEMATIC

Revision 2/F3520

-20-

Page 19

8. ELECTRICAL WIRING DIAGRAM

Revision 2/F3520

-21-

Page 20

9. SPARE PARTS

PART NO DESCRIPTION

CONTROLS

021473 Switch - Power (220-240V)

021514 Switch - Power (110V)

014233 Thermostat (Temperature)

015485 Thermostat (Humidity)

020823 Knob - Thermostats

020849 Neon Indicator

014218 Oven Lamp Bulb - 15W (220-240V)

014219 Oven Lam p Bulb - 15W (110V)

015539 Heating Wire - 100W (220-240V)

015538 Heating Wire - 100W (110V)

MOTOR & ELEMENTS

013998 Motor and Fan (220-240V)

013999 Motor and Fan (110V)

014001 Dry Element (220-240V)

015759 Dry Element (110V)

015224 Wet Element (220-240V)

015230 Wet Element (110V)

DOOR

021461 Door Assembly

021468 Handle

017575 Hinge

018947 Magnetic catch

RACKS

015477 Side Rack

STACKING KIT

21547 Double Stacking Kit

Revision 2/F3520

-22-

Page 21

10. ACCESSORIES

DOUBLE STACKING KIT (PART NO

021547) - For use with E32 / G32 con-

vection ovens

6” LEG OPTION (PART NO 15274)

DRIP TROUGH (PART NO 15295)

STANDOFF KIT (PART NO 21336) -

Enables prover to take 16” wide trays

Revision 2/F3520

-23-

Page 22

11.1 MAIN ASSEMBLY

11. PARTS DIAGRAMS

Revision 2/F3520

-24-

Page 23

Pos Part No. Description

1 015236 WRAPPER

2 015253 SUPPORT DISC

3 ---------- INSULATION

4 015483 LINER

5 018738 LINER SUPPORT

6 015244 RACK MOUNTING PLATE

7 015278 FAN LOCATING BRACKET

8 013998 FAN/MOTOR ASSEMBLY - 240V

013999 FAN/MOTOR ASSEMBLY - 110V

9 015243 FAN CLAMP BRACKET

10 015242 FAN COVER

11 015241 DUCTING

12 018947 MAGNETIC CATCH

13 015249 CAPILLARY BRACKET

14 021342 LAMP HOLDER ASSEMBLY

014218 BULB (15w, 240V)

014219 BULB (15w, 110V)

15 015248 DUCTING HEAT SHIELD

16 014001 DRY ELEMENT (600w, 240V)

015759 DRY ELEMENT (600w, 110V)

17 015224 WET ELEMENT (800w, 240V)

015230 WET ELEMENT (800w, 110V)

18 012272 CLAMP TOP

19 012271 CLAMP BOTTOM

20 014725 HANGER STUD

21 015474 WATER TROUGH

22 002138 CABLE CLAMP

23 002441 INSULATOR

24 018737 BASE STIFFENER

25 015237 SPACER TUBE

26 015235 BACK PANEL

27 015234 BASE PANEL

28 017858 CABLE CLAMP

29 013885 CASTOR - 5" RIGID

30 013890 CASTOR - 5" SWIVEL

31 015240 CONTROL HOUSING

32 013586 MAINS TERMINAL BLOCK

33 015477 SIDE RACK

34 015481 HANGER SPACER

35 016650 FRAME

36 015539 HEATING WIRE (100w, 240V)

015538 HEATING WIRE (100w, 110V)

37 015238 STRIP INSERT - SHORT

38 015239 STRIP INSERT - LONG

39 021464 CATCH PLATE

40 021461 DOOR ASSEMBLY

41 021468 DOOR HANDLE

42 ---------- CONTROL PANEL ASSEMBLY (REFER TO SECTION 11.2)

43 015295 DRIP TROUGH (OPTIONAL EXTRA)

44 017575 DOOR HINGE

Revision 2/F3520

-25-

Page 24

11.2 CONTROL PANEL ASSEMBLY

Pos Part No. Description

1 004726 CONTROL PANEL BAKBAR ºC

004805 CONTROL PANEL BLUE SEAL °C

004724 CONTROL PANEL MOFFAT ºF

2 021473 POWER SWITCH (240V)

021514 POWER SWITCH (110V)

3 020849 PILOT LIGHT (240V)

023857 PILOT LIGHT (110V)

4 021472 KNOB - HUMIDITY

5 020823 KNOB - THERMOSTAT

6 015485 THERMOSTAT 50-80ºC (120-175°F)

7 014233 THERMOSTAT 0-40ºC (32 - 105°F)

Revision 2/F3520

-26-

Page 25

11. SERVICE CONTACTS

AUSTRALIA

VICTORIA - MOFFAT PTY

HEAD OFFICE AND MAIN WAREHOUSE

740 Springvale Road Tel (03) 9518 3888

Mulgrave VIC 3170 Fax (03) 9518 3838

Spare Parts Department Free Call 1800 337 963

Fax (03) 9518 3895

NEW SOUTH WALES - MOFFAT PTY

Unit 8/142 James Ruse Drive

Rosehill NSW 2142

Spare Parts Free Call 1800 337 963

Fax (03) 9518 3895

QUEENSLAND - MOFFAT PTY

30 Prosperity Place

Geebung QLD 4034

Spare Parts Free Call 1800 337 963

Fax (03) 9518 3895

SOUTH AUSTRALIA - MOFFAT PTY

Suite 8/71 Fullarton Rd Tel (08) 8431 0522

Kent Town SA 5067

Spare Parts Free Call 1800 337 963

WESTERN AUSTRALIA - MOFFAT PTY

PO Box 689 Tel (08) 9305 8855

Joondalup Business Centre WA 6027

Spare Parts Free Call 1800 337 963

NATIONAL COVERAGE FOR 24 HOUR SERVICE OR MAINTENANCE DIAL

FREE CALL 1800 622 216 (AUSTRALIA ONLY)

CANADA

Lessard Agencies Limited Tel (416) 766 2764

PO Box 97 Fax (416) 760 0394

Stn “D” Free Call 1 888 537 7273

Toronto, ONT M6P 3J5

NEW ZEALAND

CHRISTCHURCH - MOFFAT LTD

16 Osborne St Free Call 0800 Moffat

PO Box 10-001 (0800 663 328)

Christchurch

Spare Parts Tel (03) 389 1007

Fax (03) 389 1276

AUCKLAND - MOFFAT LTD

4 Waipuna Road Tel (09) 574 3150

Mt Wellington Fax (09) 574 3159

Auckland

Spare Parts Free Call 0800 Moffat

(0800 663 328)

Revision 2/F3520

-27-

Page 26

UNITED KINGDOM

BLUESEAL LTD

Units 6-7 Mount St Tel 0121-327 5575

Business Park Fax 0121-327 9711

Birmingham B7 5QU

England

UNITED STATES OF AMERICA

MOFFAT INC.

3765 Champion Blvd

Winston-Salem Tel 1-800-551 8795

NC27115 Fax 336 661 9546

NATIONAL COVERAGE FOR SERVICE OR MAINTENANCE DIAL

FREE CALL 1800 551 8795 (USA ONLY)

Revision 2/F3520

-28-

Loading...

Loading...