Moffat E85-12HLD Service Manual

E85 PROOFER CABINETS

E85HLD PROOFER / HOLDING CABINETS

SERVICE

MANUAL

Revision 4/F3517

October, 2003

Manual P/N M0ME85

CONTENTS

This manual is designed to take a more in depth look at the E85 prover and E85HLD prover /

holding cabinets for the purpose of making the unit more understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for

completeness and thos e special cases where thes e settings are required to ch ange, this manual

gives a full explanation as to how, and what effects will result.

SECTION PAGE NO.

1. SPECIFICATIONS......................................................................................................... 5

2. INSTALLATION ............................................................................................................ 8

3. OPERATION..................................................................................................................9

3.1 Description of Controls - E85 Models

3.2 Description of Controls - E85HLD Models

3.3 Explanation of Control System

4. MAINTENANCE............................................................................................................. 13

4.1 Cleaning

4.2 Routine Procedures

5. TROUBLE SHOOTING GUIDE.....................................................................................15

6. SERVICE PROCEDURES............................................................................................. 17

6.1 Fault Diagnosis

6.2 Access

6.3 Replacement

7. ELECTRICAL SCHEMATICS........................................................................................ 27

8. ELECTRICAL WIRING DIAGRAMS ............................................................................. 29

9. SPARE PARTS.............................................................................................................. 33

10. ACCESSORIES / OPTIONS.......................................................................................... 34

11. PARTS DIAGRAM ........................................................................................................ 35

11.1 Main Assembly (N on HLD Only)

11.2 Main Assembly (HLD Only)

IMPORTANT: MAKIN G ALTERATIONS MAY VOI D WAR R ANTIES AND APPROVA LS.

Revision 4/F3517

-3-

11.3 Control Panel Assembly (Non HLD Only)

11.4 Control Panel Assembly (HLD Only)

12. SERVICE CONTACTS..................................................................................................43

13. APPENDIX A. Stacking Kit Instructions.................................................................... 45

14. APPENDIX B. Auto Water Fill Kit Instructions ......................................................... 47

Revision 4/F3517

-4-

1. SPECIFICATIONS

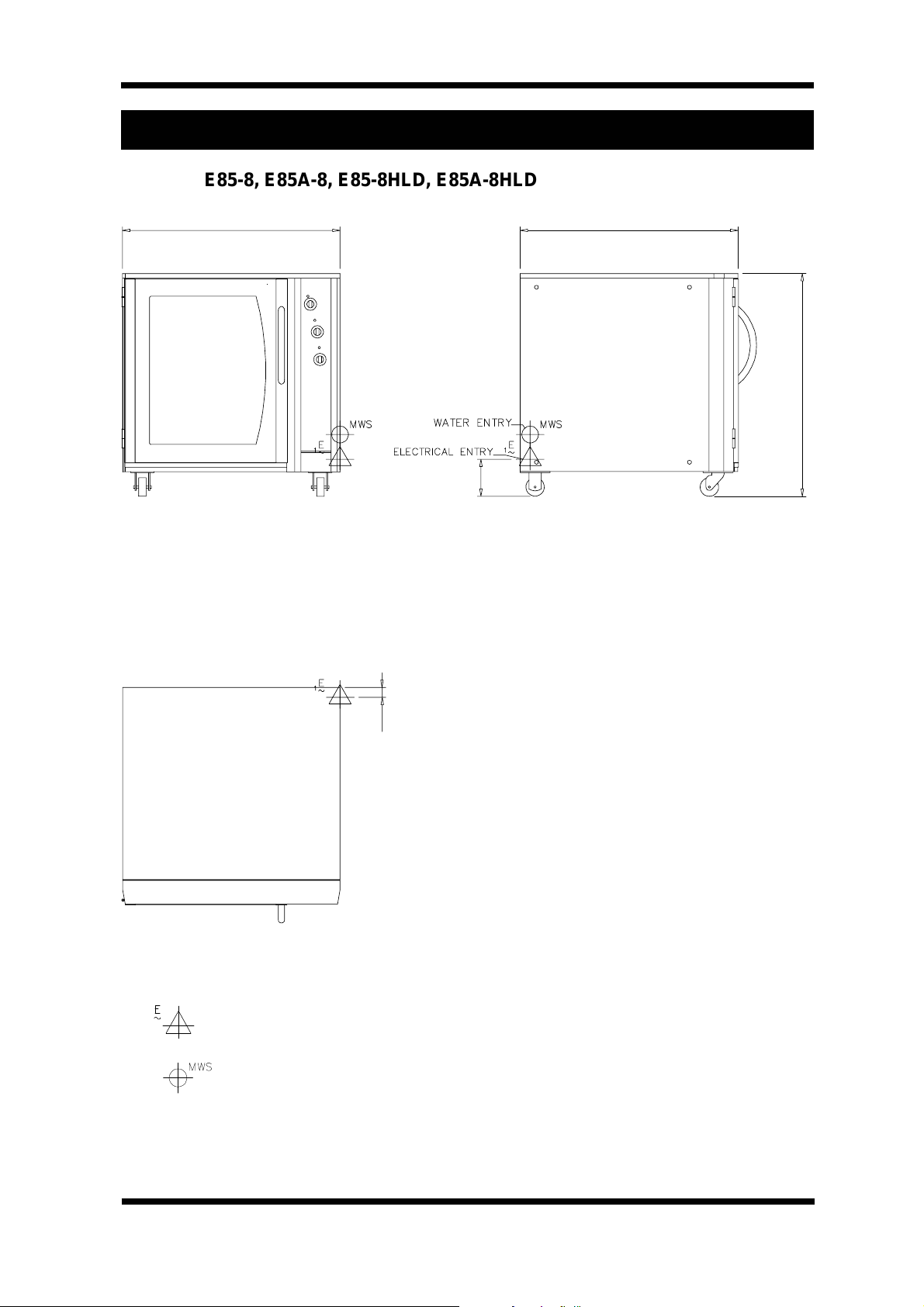

MODEL: E85-8, E85A-8, E85-8HLD, E85A-8HLD

880

(34.6)

FRONT

150

(5.9)

880

(34.6)

SIDE

902

(35.5)

40

(1.6)

PLAN

LEGEND

- Electrical connection entry point

- Water entry - ¾” BSP (Autofill models only)

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 4/F3517

-5-

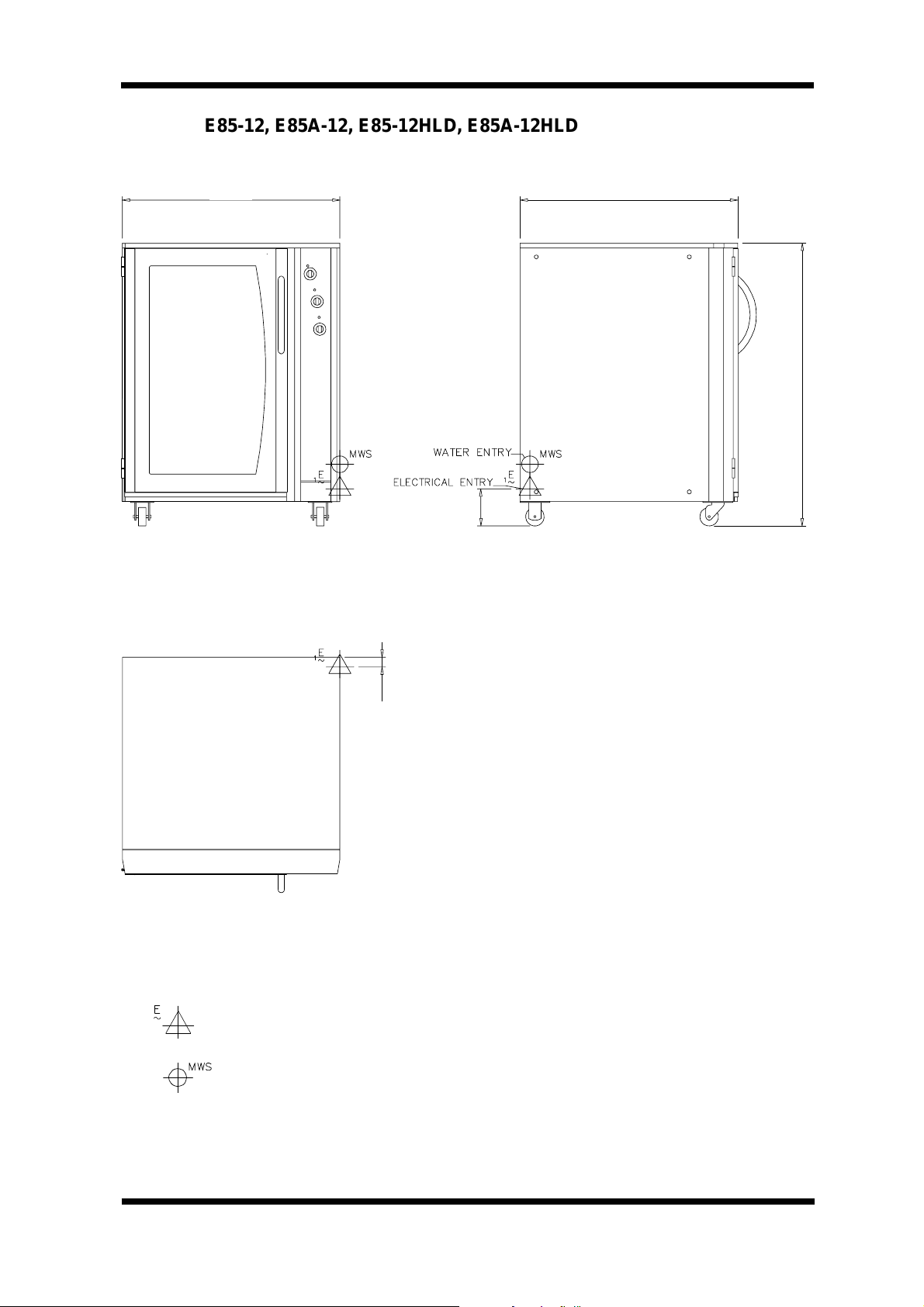

MODEL: E85-12, E85A-12, E85-12HLD, E85A-12HLD

880

(34.6)

FRONT

150

(5.9)

880

(34.6)

SIDE

1145

(45.1)

40

(1.6)

PLAN

LEGEND

- Electrical connection entry point

- Water entry - ¾” BSP (Autofill models only)

Dimensions shown in millimetres.

Dimensions in inches shown in brackets.

Revision 4/F3517

-6-

LOCATION

To ensure correct operation the following

minimum installation clearances are to be

adhered to:

Rear 0mm / 0”

Left-hand side 0mm / 0”

Right-hand side 25mm / 1”

Provision must be allowed for the door

opening.

PROVER INTERNAL DIMENSIONS

E85-8

Width 460mm / 18”

Height 700mm / 27

5

/8”

Depth 660mm / 26”

Prover Volume 0.21m³ / 7.5ft³

E85-12

Width 460mm / 18”

Height 945mm / 37

1

/4”

Depth 660mm / 26”

Prover Volume 0.29m³ / 10.1ft³

PROVER RACK/PAN SIZE CAPACITY

Width 460mm/18” or 405mm/16”

Depth 660mm/26” or 760mm/30”

RACK POSITIONS

Number - E85-8: 8

- E85-12: 12

Spacing 76mm/3”

ELECTRICAL SUPPLY SPECIFICATION

OPTIONS

100-120 Volts A.C. 60 Hz, 14.5 A, 1.6kW

220-240 Volts A.C. 50 Hz, 7.2 A, 1.65kW

ELECTRICAL PLUG SPECIFICATION

REQUIREMENTS

Australia 3-pin 250V 10A, AS/NZ 3112

Canada 3-pin 250V 15A, NEMA 6-15

New Zealand 3-pin 250V 10A, AS/NZ 3112

United Kingdom 3-pin 250V 13A fused, BS

1363A

United States 3-pin 25 0V 15 A, NEM A 6-1 5

Other Countries 3-pin 250V 10A minimum, type

to meet country standards

WATER SUPPLY CONNECTION

(Autofill Models Only)

Max Pressure 550 kPa / 5.5 bar / 80 psi

Min Pressure 100 kPa / 1.0 bar / 15 psi

Revision 4/F3517

-7-

2. INSTALLATION

WARNING: THIS APPLIANCE MUST BE GROUNDED.

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

It is most important th at t he pr oof er is ins t al led

correctly and that the operation is correct

before use. Installation shall comply with local

electrical, health and safety requirements.

BEFORE CONNECTION TO POWER

SUPPLY

Unpack and check unit f or dam age and repor t

any damage to the c arrier and dealer . Repor t

any deficiencies to your dealer. Check that

the available power supply is correct to that

shown on the rating plate l ocated on the righthand side panel.

100-120 Volts A.C. 60 Hz, 14.5 A, 1.6kW

220-240 Volts A.C. 50 Hz, 7.2 A, 1.65kW

LOCATION

To ensure correct operation the following

minimum installation clearances are to be

adhered to:

Rear 0mm / 0”

Left-hand side 0mm / 0”

Right-hand side 25mm / 1”

Provision must be allowed for the door

opening.

ELECTRICAL CONNECTION

E85 models are suppli ed with pre-fitte d cords.

Ensure unit is f itted with corr ect cord an d plug

for the installation (refer specifications

section).

Should changing of the cord be necessary,

gain access to the electrical connection

terminal block and strain relief clamp by

removing the RH side panel.

DOUBLE STACKING UNITS

When it is desired to mount a Turbofan E35

convection oven on an E 85, a dou ble stack ing

kit must be used. Available from your dealer

or Turbofan distrib utor (see Sp are Parts ). For

stacking kit assembly instructions, refer

Appendix A.

NOTE:

United Kingdom and USA/Canada

models are supplied with a top panel fitted.

Other country models are pre-fitted with the

double stacking kit on the proofer for direct

stacking under E35 convection ovens.

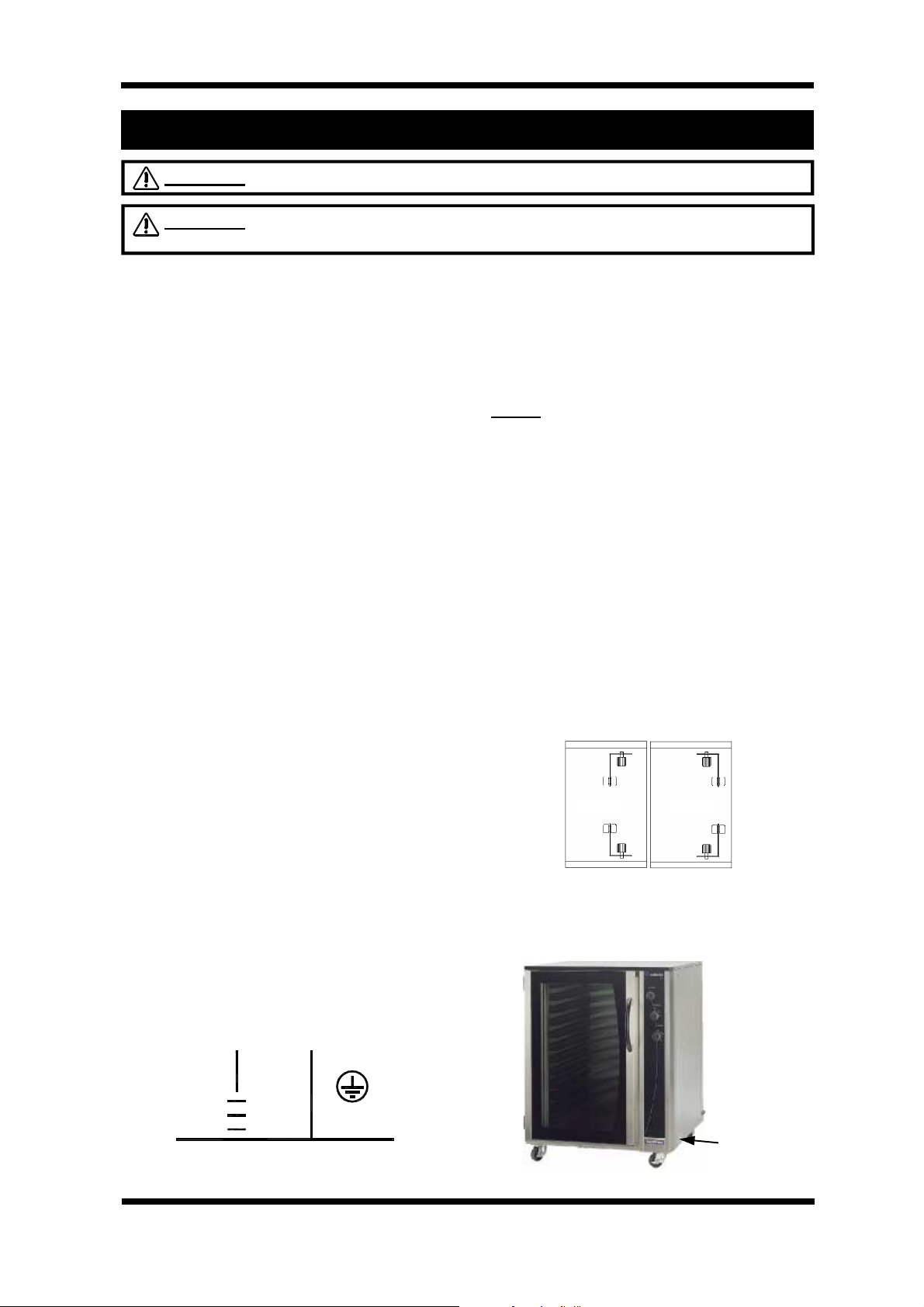

RACK WIDTH POSITIONS

The E85 models have an adjustable rack

width setting. This a llo ws f or the rac king to be

configured for 405mm / 16” or 460 / 18” wide

baking sheets/pans or racks.

To set width remove right hand side rack.

Unscrew and remove four thumbscrews at

bottom and top of c abin et. For 16” wi de tra ys,

turn the rack supports s uch that they face the

left side of the proofer. For 18” trays, turn the

rack supports to the right of the proofer.

16” trays

18” trays

Figure 2.2

RATING PLATE LOCATION

The rating plate f or the E85 prover is located

at the bottom left corner of the RH side panel.

L1 L2

Phase

RED

BROWN

BLACK

WARNING:

BE GROUNDED / EARTHED

Revision 4/F3517

Ground

Neutral

BLACK

BLUE

WHITE

THIS APPLIANCE MUST

Figure 2.1

GREEN

GREEN/YELLOW

Rating Plate

Figure 2.3

-8-

3. OPERATION

NOTE: A full user’s operation manual is supplied with the product and can be used for further

referencing of installation, operation and service.

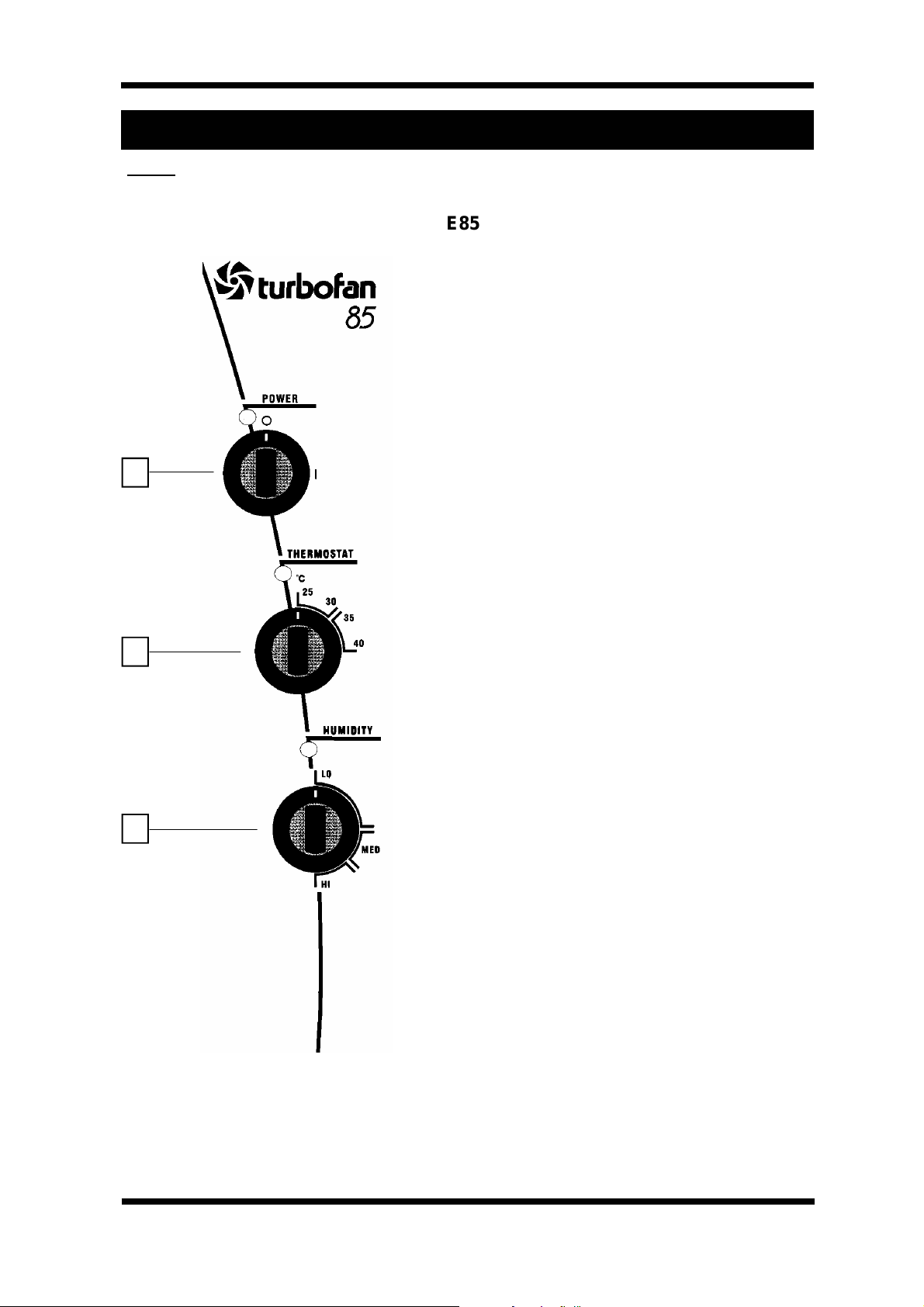

3.1 DESCRIPTION OF CONTROLS - E85 PROVERS

1. POWER

O UNIT IS OFF

I UNIT IS ON (Ind icator illu minates when

switched to this position)

2. THERMOSTAT

Temperature range 25 - 40°C (75 - 105°F).

Indicator illuminates when elements are

cycling ON to maintain set temperature.

1

2

3

Controls the proofer air temperature.

3. HUMIDITY CONTROL

(Indicator illuminates when water tank

elements are cycling ON to maintain set

humidity).

Controls proofer humidity.

LO - Humidity setting for bu tter bas ed pastr ies

(croissants, Danish pastries etc).

MED / HI - Humidity setting for yeast based

breads and dough.

WATER

Manual Water F ill Models: Open the proof er

door. Fill the water tank at the filling spout,

located at the front of the r ight h and side rac k ,

to approximately 20mm / ¾” from the top of

the tank. Rem ember to top up t he water ta nk

when the water level is below the halfway

level in the tank and before the heating

element is exposed.

Auto Water Fill Mo dels: Check that the water

tank is filling, and the heating e lement is well

covered. Unit must be switched on f or water

tank auto-fill system to operate.

CONDENSATE PAN (Auto water fill models

only)

A pan is provided on guides underside the

cabinet for the collec tion of cabinet and door

condensation. Where provided, remove the

drain plugs in the cabinet floor centre and

door condensate channel below the door, to

allow condensate collection in the pan.

Remove the pan daily for emptying.

Revision 4/F3517

-9-

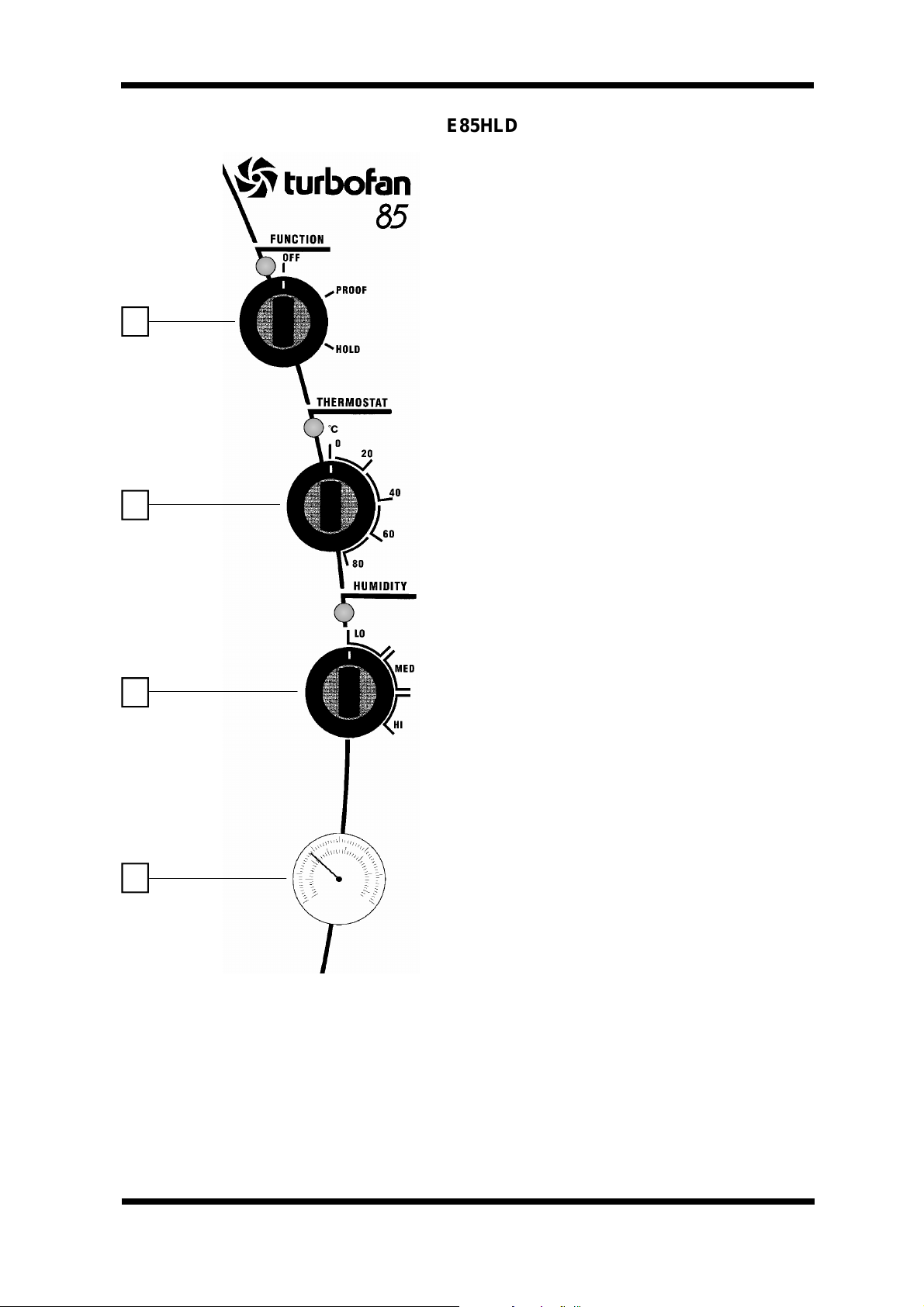

3.2 DESCRIPTION OF CONTROLS - E85HLD PROVER/HOLDING CABINETS

1. FUNCTION

OFF Unit is off.

PROOF Unit is in proofing m ode. (Indicator

illuminates when switched to this position)

HOLD Unit is in holding mode. (Indicator

illuminates when switched to this position)

1

2

3

4

2. THERMOSTAT

Temperature range 0 - 80°C (32 - 176°F).

Indicator illuminates when elements are

cycling ON to maintain set temperature.

Controls the proofer air temperature.

3. HUMIDITY CONTROL

Proofing function only, redundant in hold

mode. (Indicator illuminates when elements

are cycling ON to maintain set humidity).

Controls proofer humidity.

LO - Humidity setting for bu tter bas ed pastr ies

(croissants, Danish pastries etc).

MED / HI - Humidity setting for yeast based

breads and dough.

4. THERMOMETER

Dual Centigrade and Fahrenheit scale.

Indicates cabinet temperature.

WATER

Manual Water F ill Models: Open the proof er

door. Fill the water tank at the filling spout,

located at the front of the r ight h and side rac k ,

to approximately 20mm / ¾” from the top of

the tank. Rem ember to top up t he water ta nk

when the water level is below the halfway

level in the tank and before the heating

element is exposed.

Auto Water Fill Mo dels: Check that the water

tank is filling, and the heating e lement is well

covered

.

Revision 4/F3517

CONDENSATE PAN (Auto water fill models

only)

A pan is provided on guides underside the

cabinet for the collec tion of cabinet and door

condensation. Where provided, remove the

drain plugs in the cabinet floor centre and

door condensate channel below the door, to

allow condensate collection in the pan.

Remove the pan daily for emptying.

-10-

3.3 EXPLANATION OF CONTROL

SYSTEM

The E85 Prover and Prover/Holding Cabinets

feature operator controls and an electrical

circuit for which a d irect un derstand in g of their

operation is required before carrying out any

service work or f ault repair work . The control

device functions and electrical circuit are

explained as follows:

A rotary switch on the control panel of thes e

models functions as the p ower On/Off switch

of the unit by isolating the Line 1 phase

supply.

E85 Prover onl y models thi s s witch is a 2 pole

device, with 1 pole isolating power to the air

circulation fan motor and the other pole

isolating power to the water tank heating

element controls and the dry heat ing element

controls.

On E85HLD Prover/Holding Cabinet models

this switch is a 3 position, 4 pole, multifunction switch whic h in t he O ff pos itio n o pens

circuits all poles and isolates power from all

control and heating systems .

In the ‘Proof’ position poles P3 and P4 are

closed, operating the electrical circuit

functions as follows:

P3 – Humidity control thermostat

P4 – Air heating thermostat, air circulation

motor and control panel power indicator.

In the ‘Hold’ funct ion positi on pole P 4 rem ains

closed, pole P3 opens to isolate the humidit y

control, and pole P2 c loses. Power to pole P2

is fed from the air heating thermostat and

switches power thr ough to the addit ional hold

heating element.

With both E85 Prover and E85HLD Prover/

Holding Cabinets this power and power

function switch wil l also switch p ower on Auto

water-fill models to the water solenoid

switching relay.

The air circulation fan and control panel power

indicator are On continuously on all E85

models when the power or power/function

switch are in an On position.

The proofing system operates on all models,

controls air temperature and humidity levels

by way of an air heating element control led by

a mechanical bulb and capillary thermostat

and a water tank heating element controlled

by a mechanical bulb and capillary

thermostat.

The air heating element is positioned in the

bottom of the air circulati on ducting inside the

cabinet and is direc tly controlled by the user adjustable thermostat mounted to the control

panel. The thermostat sensing bulb is

mounted inside the cabinet to control the

cabinet air temperature to the control panel

setting. An indic ator lig ht on th e control panel

above this therm ostat will illuminate when th e

thermostat has the air heating element

operating and will cycling Off with the

thermostat to indicate when the temperature

reaches set point.

The water tank heati ng element controlled b y

the humidity level thermostat mounted t o the

control panel is used to heat the water tank

water and maintain the water tank

temperature between 50°C (122°F) and 80°C

(176°F). This water tank temperature is

controlled by the humidity level thermostat

setting between the adjustments of low and

high humidity. The evaporation rate of the

water in the water tank dependent on its

temperature, provides humidity into the

cabinet and accordingly the setting of the

humidity thermostat controls the rate of

evaporation and therefore the humidity level in

the cabinet.

An indicator light on the control panel above

the humidity dial illuminates when the water

tank element is On, and cycles Off when the

thermostat switches the heating element Off

to provide an indication of the humidity

control. The sensing bulb of the humidity

thermostat is mounted directly on the water

tank heating element which are both

immersed in the water tank . Sh ould t he water

tank level drop bel ow the heating elem ent the

humidity thermostat will cycle Off due to the

sensing bulb reacting to th e radiated heat off

the heating element and will prevent the

humidity water tank heating element burning

out through excessive temperature.

E85 Auto-Water fill models provide for a

mains cold water supply connection for automatic water t ank filling and le vel c ontrol. NonAuto water-fill m odels require the operator to

manually fill the water tank and maintain the

water tank level as the water evaporates

through operation.

On auto water-fill models, an electric water

Revision 4/F3517

-11-

solenoid, float switch and relay maintain the

water level in the humidity tank. The float

switch is mounted at the rear of the water

tank, and when below the full water level

position, it open c ircuits, re moving po wer from

the relay coil, and therefore allowing power

through the normally closed contact of the

relay to energise the water solenoid. As the

water reaches the full level position the float

switch will close circuit, energising the relay

and therefore removing power from the

normally closed position of the relay, thus

turning off the water solenoid.

Ensuring that the power or power function

switch is in the Off position is necessary

whenever removing the removable water tank

for cleaning, as when the water tank is

removed the float switc h drops and the water

solenoid valve will be ope ned if the electrical

circuit is switched On. Therefore as a

precaution the mains water supply should also

be switched Off whene ver removing the water

tank.

E85HLD Prover/Holding C abinets are able to

be operated both as a proof ing cabinet and as

a holding cabinet.

As explained in earlier paragraphs, when th e

power function switch on these models is

selected to the ‘Hold’ position the humidity

control circuit is turned Off and an additional

air heating element is connected into the air

temperature thermostat circuit. In this mode

the air temperature t hermostat operates as it

does in the proofing mode, however, in this

case there is an addit ional air he ating e lem ent

switched On and Of f to provide extra heating

power in this m ode. The additional air heating

element in these models is also mounted in

the air circulation ducting.

E85HLD Prover/Holding Cabinets are also

provided with a thermometer dial on the

control panel to provide an indication of the

cabinet temperature and the sensing bulb of

this thermometer dial is mounted next to the

sensing bulb of the m ain ther m ostat inside th e

cabinet.

On E85 Prover only models the main

thermostat is adjustable up to 40°C (105°F)

whereas on E85HLD Prover/Holding Cabinet

models the main thermostat is adjustable up

to 80°C (175°F).

With both models butter b ased products such

as croissants and dan is h p as tr ies s ho uld have

the cabinet proofing temperature set around

the 25° C (77° F) as higher proofing

temperatures will cause t he butter to melt out

of the product. F or yeast based doughs an d

breads the proofing temperature should be set

higher at around 40°C (105°F) in order to

activate the yeast in these products. On

E85HLD models temperatures higher than

this are used for holding food at required

serving temperatures and the thermometer

dial on the control panel of these models is

provided to indicate and verify the actual

cabinet temperature and assist with the

thermostat setting.

On all models the air circulation fan mounted

at the top of the air delivery ducting ensures

that the temperature and h umidity throughout

the cabinet is ev en by creating a lo w velocity

air circulation system throughout the prover

cabinet. This system overcomes the natural

occurrence of hot air rising and therefore

higher humidit y and temperature in the upper

positions of the cabi net as f ound with pro ofing

units without forced air circulation.

The user-adjustable thermostat and humidity

controls are required to allow adjustment of

cabinet temperature and humidity levels for

the variations of temperature and humidity

that different product types require .

Revision 4/F3517

-12-

4. MAINTENANCE

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

4.1 CLEANING

WARNING: ALWAYS TURN THE

POWER SUPPLY OFF BEFORE

CLEANING.

IMPORTANT: THIS UNIT IS NOT

WATER PROOF.

DO NOT USE A WATER JET SPRAY T O

CLEAN INTERIOR OR EXTERIOR OF

THIS UNIT.

CABINET

A good quality stainless steel cleaning

compound is recommended for cleaning the

inside and outside of the cabinet. Harsh

abrasive cleaners may damage the surface.

SIDE RACKS

To remove, tak e hold of the centre rung and

lift towards the pr oofer top. To replace, hold

horizontally, engage in holes and push down.

DOOR

Wash with warm water and det ergent solut ion

using a soft sponge in straight lines up and

down the door.

Rinse with clean, warm water to remove

detergent. Dry off.

WATER TROUGH

Remove right hand side rack and remove

trough. Clean with warm , soapy water. Rinse

thoroughly.

WATER TROUGH ELEMENT

When the element becomes limed / scaled,

remove water trough and clean. Replace

water trough and half fill with white vinegar or

acetic acid then fill to the normal level with

water. Switch unit o n. Set hum idity co ntrol to

‘Hi’ and run for approximately 30 minutes.

Remove trough and cle an element with dam p

cloth when cooled. Wash out trough and refit.

This procedure is recommended to be done

once a week. Frequency of cleaning the

element may be increased or decreased

depending on the lime depositing on the

element.

Revision 4/F3517

-13-

4.2 ROUTINE PROCEDURES

PROCEDURE INTERVAL

WET ELEMENT Remove scaling (refer section 4.1). As required

DOOR SEALS

(E85HLD models only)

DOOR HINGES Check for wear. 12 months

ELEMENTS Check that elements are operating. 12 months

Inspect door seals on door inside for wear and tear. 6 months

Revision 4/F3517

-14-

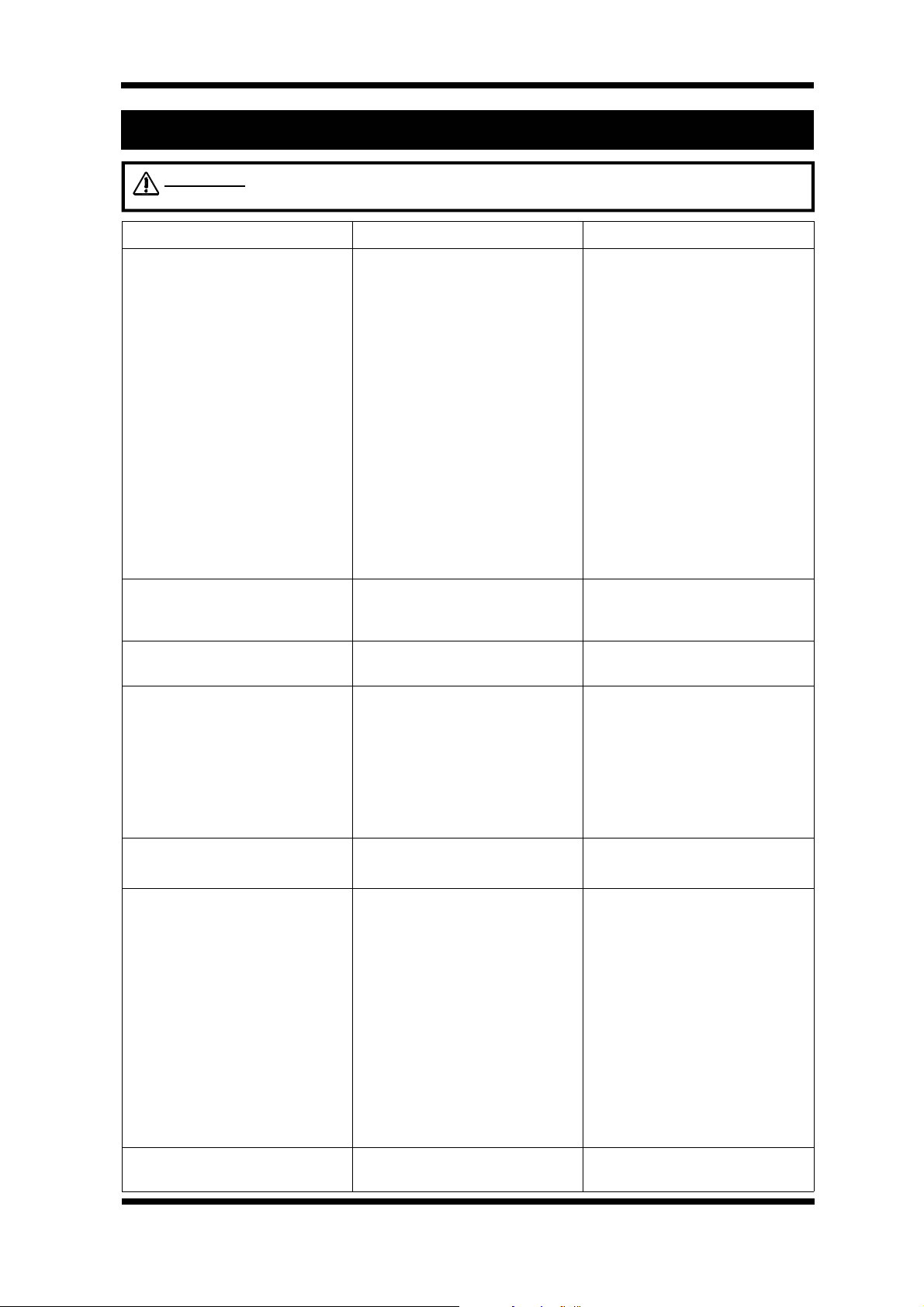

5. TROUBLE SHOOTING

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

FAULT POSSIBLE CAUSE REMEDY

THE UNIT DOES NOT

OPERATE / START

PROOFING OR HOLDING

MODE NOT WORKING

(E85HLD models only)

FAN DOES NOT OPERATE Faulty fan motor.

NO HEAT Thermostat faulty.

NO TEMPERATURE

CONTROL

The unit is not plugged into the

wall socket.

The mains isolating switch on

the wall, circuit breaker or fuses

are “off” at the power board.

The power switch on the unit is

off.

Incorrect electrical supply.

(Refer fault diagnosis 6.1.1)

Power switch faulty (E85).

(Refer fault diagnosis 6.1.1)

Function switch faulty (E85HLD)

(Refer fault diagnosis 6.1.1)

Power / selector switch faulty.

(Refer fault diagnosis 6.1.2)

(Refer fault diagnosis 6.1.3)

(Refer fault diagnosis 6.1.2)

Function switch faulty (E85HLD)

(Refer fault diagnosis 6.1.2)

Element blown.

(Refer fault diagnosis 6.1.4)

Faulty thermostat.

(Refer fault diagnosis 6.1.5)

Plug in.

Turn on.

Depress switch. Switch will

illuminate.

Ensure electrical supply correct.

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.8)

Replace.

(Refer service section 6.3.3)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.5)

Replace.

(Refer service section 6.3.3)

NO HUMIDITY No water in trough.

(Manual fill models)

Auto-fill system faulty.

(Auto-fill models only)

Faulty thermostat.

(Refer fault diagnosis 6.1.6)

Function switch faulty (E85HLD)

(Refer fault diagnosis 6.1.2)

Water tank element blown.

(Refer fault diagnosis 6.1.6)

NO HUMIDITY CONTROL Faulty thermostat.

(Refer fault diagnosis 6.1.7)

Revision 4/F3517

-15-

Fill trough with water.

(Refer Fault: Auto-fill not

working)

Replace.

(Refer service section 6.3.4)

Replace.

(Refer service section 6.3.2)

Replace.

(Refer service section 6.3.6)

Replace.

(Refer service section 6.3.4)

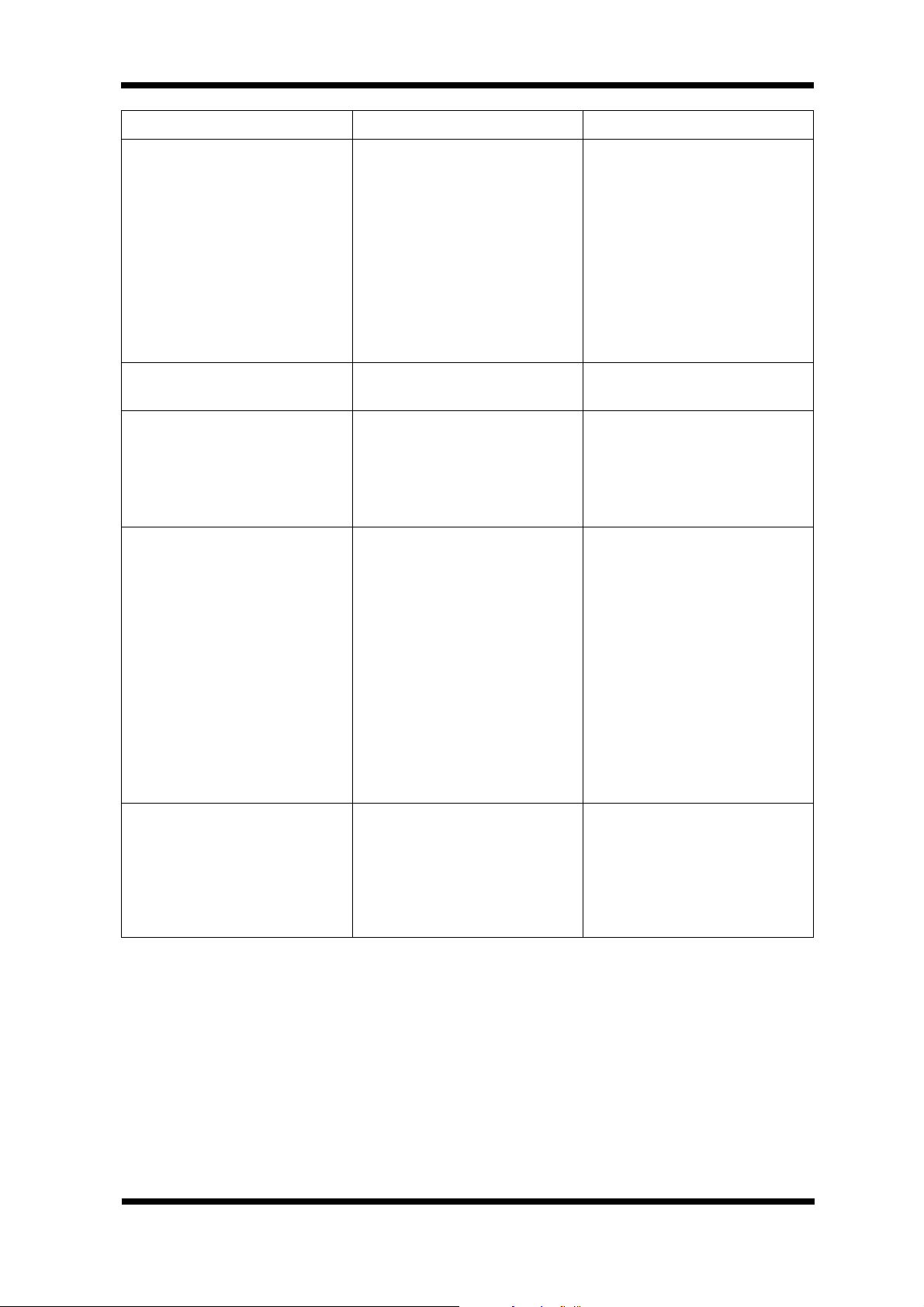

FAULT POSSIBLE CAUSE REMEDY

SLOW RECOVERY Overloading of product.

Door opened unnecessarily.

Electrical supply incorrect.

Door seals deteriorated.

(E85HLD models only)

Fan motor faulty.

(Refer fault diagnosis 6.1.3)

NO HEATING / HUMIDITY

INDICATOR

DOOR DOES NOT CLOSE Tra y in way of door.

AUTOFILL WATE R NOT

FILLING

(Autofill models only)

AUTOFILL WATER OVERFLOWING

(Autofill models only)

Indicator faulty.

(Refer fault diagnosis 6.1.8)

Interference with door.

Hinges damaged.

Water supply not turned on.

Blockage in water supply.

Water connection filter blocked.

Water solenoid faulty.

(Refer fault diagnosis 6.1.9)

Solenoid relay faulty.

(Refer fault diagnosis 6.1.9)

Water level float switch faulty.

(Refer fault diagnosis 6.1.9)

Water level float switch faulty.

(Refer fault diagnosis 6.1.9)

Solenoid relay faulty.

(Refer fault diagnosis 6.1.9)

Water tank not fitted.

Reduce batch size.

Do not open unnecessarily.

Check supply voltage is as per

rating plate voltage.

Inspect and replace.

Replace.

(Refer service section 6.3.8)

Replace.

(Refer service section 6.3.1)

Correctly position tray in rack .

Inspect and repair.

Replace.

(Refer service section 6.3.10)

Turn water supply on.

Disconnect water supply and

inspect.

Clean filter.

Replace.

(Refer service section 6.3.14)

Replace.

(Refer service section 6.3.13)

Replace.

(Refer service section 6.3.15)

Replace.

(Refer service section 6.3.15)

Replace.

(Refer service section 6.3.13)

Fit water tank.

Revision 4/F3517

-16-

Loading...

Loading...