Moerch Tonearm DP-8 User Manual

H. H. MØRCH

DP-8

Instructions

Contents of the packing

In the packing of the tonearm you will find the arm base in which the bearings are encapsulated in a

heavy body. The bearings are the link between the moveable part of the tonearm and its support. This

support can move up and down in a bush, which is holding the arm base. A black pear shaped plate is

attached to the said bush with just one screw. This pear shaped plate is supporting the integrated

VTA device, the antiskating device and the lifter cylinder. The said bush is holding the arm base with a

big nut to the turntable chassis. A high quality cord is supplied for connecting the arm base to the

amplifier. In North America this cord is not included.

Further you will find one arm tube according to the choice that you have had from advice from your

dealer. Or you have seen the Cartridge Armtube Combination List (under Instructions) in our website.

There also will be 4 weights with O-rings, 4 weights with screws, finger lever with screws, knurled nut,

hexagon spanner, syringe with silicone fluid, a thin plexiglass rod and a narrow piece of thick paper.

The tonearm usually is supplied with the arm rest mounted on the pick-up lifter, but if desired a

separate arm rest could be supplied instead.

Spatial requirements

The vertical distance between the plane where the tonearm is mounted to the plane where the record

is placed should be between 28 mm (1 1/8”) and 40 mm (1 9/16”).

If the diameter of the turntable platter is larger than 32 cm (12 5/8”) then it is recommended to use a

12” armtube.

Mounting the bush

First it has to be decided exactly where to place the bush with the arm base. The center of the bush

should be at a distance of 212 mm (8 5/16'') from the center of the turntable platter and there has to

be room enough for the counterweight rod to move freely.

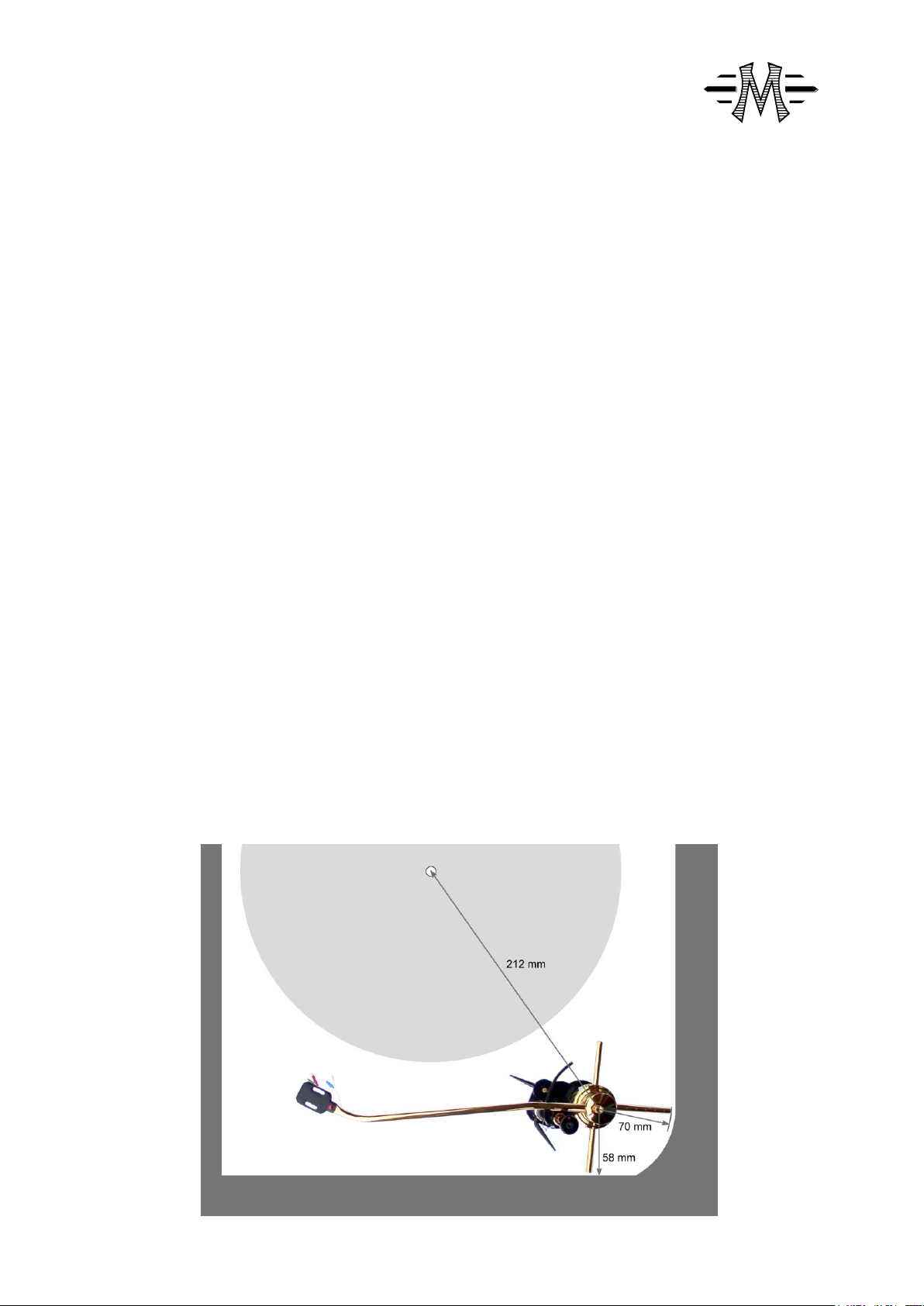

Fig. 1. The outline of the white area is indicating the room needed for the tonearm.

Page 1

The counterweight rod is having a rear overhang of 70 mm (2 3/4”) as to the center of the said bush. If

there is plenty of room for the counterweight rod consideration should be taken as to where the arm

base should be positioned to give a convenient position for the armtube when resting in the arm rest.

(See fig. 1)

If a separate arm rest is used, it should be placed so that the armtube when resting on it is at a suitable distance from the record.

Mark the center of the hole for the bush and check that the distance to the center of the turntable

platter is 212 mm (8 5/16"). Then drill a 20 mm (13/16") hole with center in this mark. Also, if separate

arm rest is used, drill a 10 mm (13/32") hole for the bush for the arm rest about 155 mm (6 1/8") in

front the 20 mm hole.

Accommodate the bush with the heavy central body of the tonearm in the 20 mm hole so that the

“narrow” end of the black pear shaped plate is pointing forwards. Then pull out the piece of rubber,

which is squeezed in under this heavy body.

Put the armtube on top of the arm base with the 5 pins in the flange of the armtube inserted into the 5

holes in the plexiglass. Secure the armtube with the knurled nut screwed onto the thread going

through the flange of the armtube.

The position of the black pear shaped plate must be adjusted so that the armtube can move in a

suitable angle over the turntable platter and so that the armtube can rest in the arm rest in a suitable

distance from the turntable platter: Move the armtube resting on the girder of the raised pick-up lifter

all the way to the end of the girder. Then turn the pear shaped plate, so that the position of the stylus

is on line with the direction from the center of knurled nut holding the armtube to the center of the

turntable spindle.

Then put the big nut onto the thread of the bush and tighten it - making sure that the bush with the

pear shaped plate does not turn (Fig. 1).

Mounting the cable to the amplifier

Put the plug of the tonearm cord into the socket inside the bottom of the arm pillar. Make sure that the

big nut holding the arm base is tightened before pushing the connector of the tonearm cord into the

arm base. Try to avoid bending the cable too sharply right next to the tonearm connector. If the

turntable has a floating sub chassis, the cable should not be restricted in any way, and it should be

arranged in a suitable arc, so that it does not limit the free movements of the suspension. Remember

that the ground wire should always be connected to the chassis (ground terminal) of the amplifier. The

chassis of the turntable in most cases also has to be electrically connected to the arm base.

Putting on the side weights

First the weights for the side rods should be put on. Take the smaller of the weights with screws and

hang one on each side rod (without tightening the screws). Then likewise take the bigger weights with

screws and hang one on each side rod (Fig. 2).

Fig. 2. All the weights with screws hanging on the side rods.

Page 2

Push the armtube towards the turntable spindle so that one of the side rods touches the VTA spindle.

Push the weights in this side towards the VTA device while holding the enclosed thick paper between

the VTA device and the smaller weight. With the smaller weight in this position put the hexagon key

into the screw of this weight. Still with this weight pushing on the paper turn the weight so that the

hexagon key is pointing backwards and about 30O down from horizontal (Fig. 3) and then tighten the

screw of this weight slightly. The width of the thick paper is the same as the distance from the smaller

weight to the heavy body, where the side rod is attached.

Fig. 3. Tighten the screw of the smaller weight with the paper as a spacer.

Move the weights on the other side rod so that they hang symmetrically as to the center line of said

heavy body.. Then with the paper check that the smaller of the weights hanging here has the same

distance from the body as the same weight on the other side (Fig. 4).

Fig. 4. The paper fits the spacing of the smaller weight adjusted at the

VTA device and is used as spacing for the smaller weight on the other

side.

With this distance and with the hexagon key pointing backwards and about 30O down (Fig. 5) tighten

the screw slightly.

Page 3

Loading...

Loading...