Page 1

®

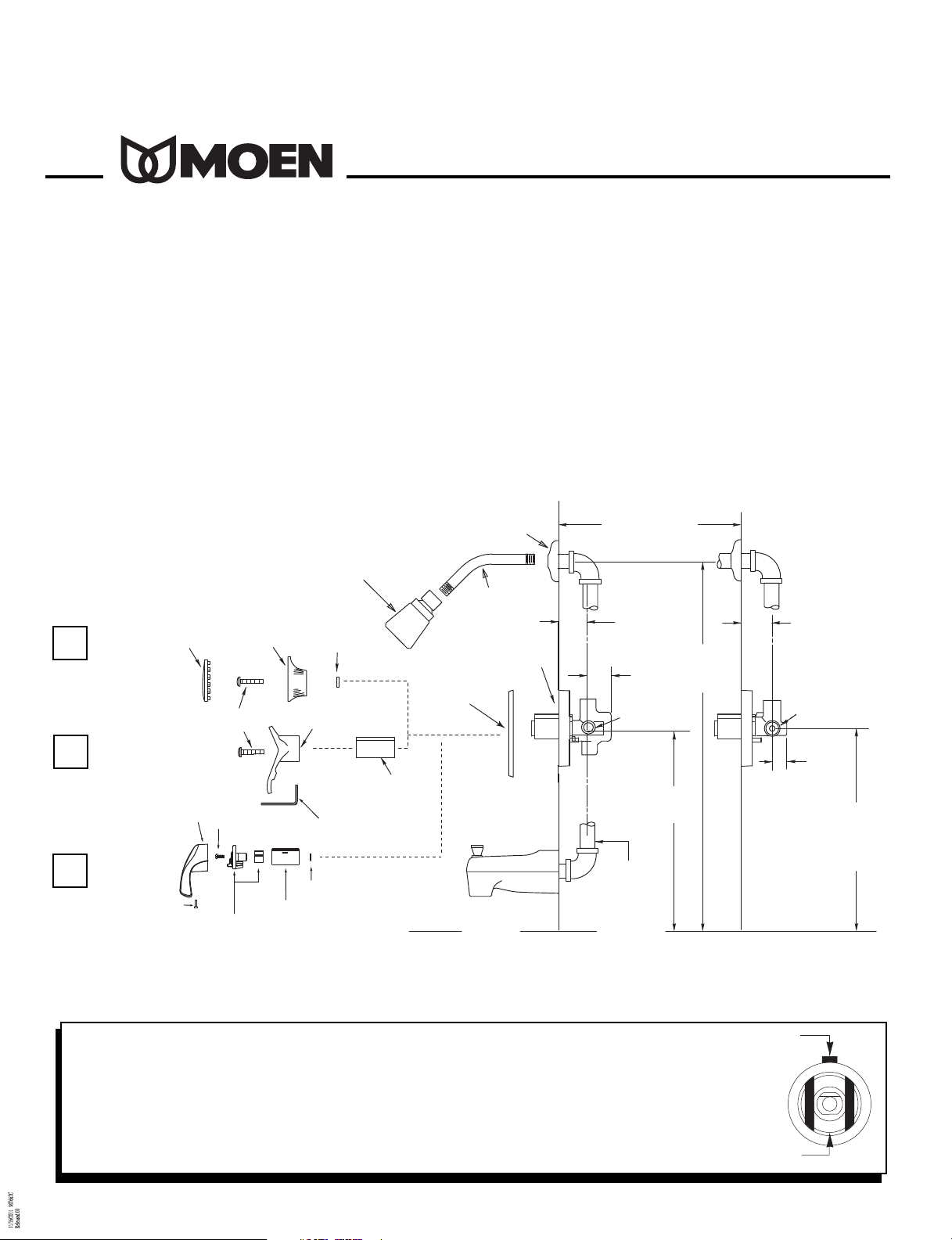

CLIP

EAR

HANDLE

COVER

HANDLE

KNOB

SHOWER

ARM

FLANGE

SHOWERHEAD

WASHER

HANDLE

SCREW

HANDLE

LEVER

STOP TUBE

ESCUTCHEON

PLASTER

GROUND

CAUTION

USE 1/2"

IRON PIPE

SIZE

MINIMUM

OR 1/2"

TUBING.

SUPPLY

SUPPLY

45"

(1143mm)

48"

(1219mm)

1-1/4"

(32mm)

6' 6"

(1981mm)

32"

(813mm)

FINISHED WALL

LINE

2-1/16"

(52mm)

2-1/16"

(52mm)

TUB FILLER

OR SHOWER

TUB/SHOWER

COMBINATION

FLOOR

15/16"

(24mm)

HANDLE LEVER

HANDLE SCREW

HEXAGONAL

WRENCH

SET SCREW

HANDLE ADAPTER &

BRAKE ASSEMBLY

STOP TUBE

WASHER

MODELS 2600, 2700, 5401, 62600, 62700, 72615, 72700 and MODEL SERIES T471,

T473, T555, T666, T777, T888, TL470, TL471, TL473, L2600, L2700

INSTALLATION INSTRUCTIONS

TUB AND SHOWER VALVES

Available with three or four port castings, with and without stops.

Connections are either 1/2 inch I.P.S. pipe or 1/2 inch copper sweat connections.

If the Moen Slip Fit spout is used, a 1/2 inch copper drop and lookout may be used.

Measurements

These are shown in the drawings. The depth measurement is critical.

Use the front face of the plaster ground as a reference point for the finished wall position, including tile (2-1/16" [52mm]). The center line of

the supply and discharge piping should be a maximum of 2-3/16" (56mm)

and a minimum of 1-7/16" (37mm) behind the finished wall surface.

MT662C

THESE INSTRUCTIONS MUST BE

LEFT WITH HOMEOWNER

IMPORTANT: SEE FLUSHING

INSTRUCTIONS PAGE 2

A

B

C

CAUTION:

Before turning water on during either rough-in or trim-out, make sure that cartridge retainer clip is in place. The

cartridge and retainer clip were properly installed and tested before leaving the factory. Although it is unlikely, it

is nevertheless possible that through the handling of the valve by any number of persons the retainer clip may

not be properly installed. This should be carefully checked at time of rough-in and trim-out. If the retainer clip

is not properly installed, water pressure could force the cartridge out of the casting. Personal injury or water

damage to the premises could result.

Always turn water off before installing or disassembling the valve. Open

valve handle to relieve water pressure and to insure that complete water

shut-off has been accomplished.

CLIP

EAR

Page 2

Stop Operation

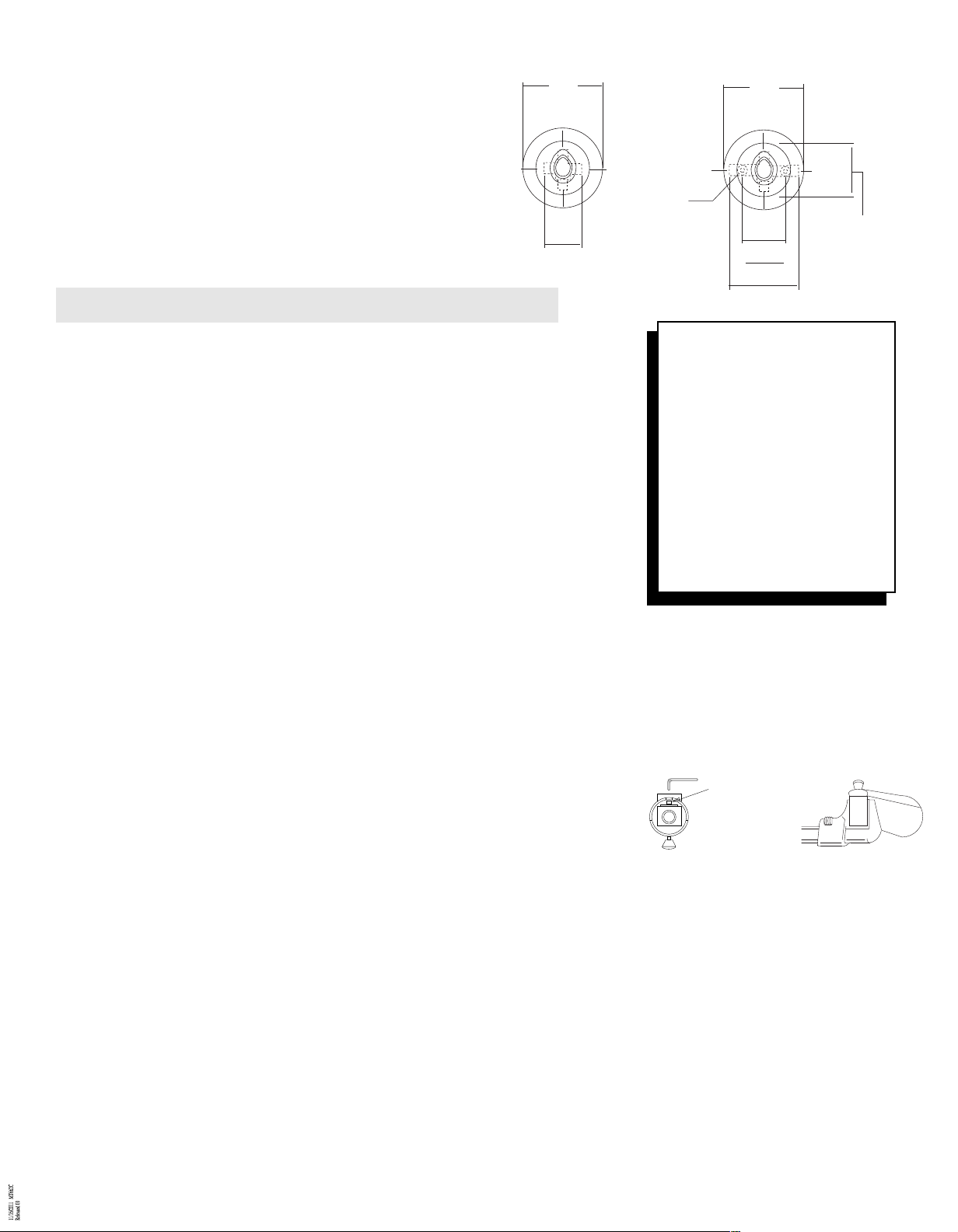

7" DIA

(178mm)

SHOWER

TUB

2" CC

(51mm)

2-3/16" IPS

(56mm)

SUPPLY

SUPPLY

‰

‰

‰

‰

‰

‰

‰

‰

7" DIA

(178mm)

SHOWER

TUB

2-1/8" CC

(54MM)

3-3/4" IPS

(95MM)

4-5/8" FOR C.C.

(117mm)

6" FOR I.P.S.

(152mm)

SUPPLY

SUPPLY

‰

‰

‰

‰

‰

‰

‰

‰

‰

‰

‰

‰

‰

4-1/2"

(114mm)

PLASTER GROUND

SIZE AND WALL

OPENING

WITHOUT STOPS WITH STOPS

‰

RUBBER STOP VALVE

(WITH SCREW DRIVER SLOT)

RETAINER

CLIP

CARTRIDGE

EAR

NOTCHED FLAT

ON STEM

STOP

TUBE

WASHER

ALWAYS KEEP POINTER UP

HANDLE

KNOB

HANDLE

SCREW

HANDLE

COVER

HANDLE

LEVER

SCREW

SET

SCREW

HANDLE

LEVER

STOP TUBE

HANDLE ADAPTER &

BRAKE ASSEMBLY

C

H

CC - This type is integral with casting, actuated by screwdriver, and require a

90° turn to open or close. When the screwdriver slot is vertical, the rubber

stop is closed, and when the slot is horizontal, the rubber stop is open.

IPS - This type has been added to the basic shower casting and is actuated

by screwdriver. The stop is opened by rotating in a counterclockwise direction until it stops and closed by rotating in a clockwise direction until it bottoms.

Rough-In

MAKE SURE ALL WATER SUPPLIES ARE OFF.

4- port: (2700 SERIES): Install casting with "UP" at the top (arrow pointing up). If the valve is to be used

for both a shower and a tub, connect the top outlet to the shower (36" minimum riser) and the bottom outlet to the tub (6" minimum drop), using 1/2" iron pipe size or 1/2" copper water tube, 5/8" O.D. (If the valve

is to be used for a shower only or a tub only, plug the outlet not being used.)

3-port (2600 SERIES): These models may be used as either a shower or a tub filler. Since they are factory set in the shower position, with the outlet up, you must reverse the position of the cartridge retainer

clip when using the valve as a tub filler. Accomplish this change during the assembly process. Remove

the stop tube, pull the clip out from the bottom of the casting, rotate cartridge stem 180° and replace clip in

the top, then proceed with assembly, using 1/2" iron pipe size or 1/2" copper water tube.

WARNING: Secure all pipes and the shower and tub drop ells. Use thread seal tape on all threads.

Use a plain ell on the tub drop. A twin ell is not needed. CHECK SYSTEM FOR LEAKS BEFORE

CLOSING WALL.

These valves are equipped with

Moen's long-life 1225 cartridge,

designed for smooth, trouble free

operation. When soldering, do not

heat valve any higher than necessary to flow the solder. Overheating

may damage the cartridge or rubber

stop valves. Following this direction will allow you to solder without

removing the cartridge or rubber

stop valves.

WARNING: The cartridge and rubber stop valves MUST be removed

CAUTION

before either brazing or resistance

(electric) soldering. For stop valve

Install Shower Arm & Tub Spout

removal instructions, see last page.

MAKE SURE ALL WATER SUPPLIES ARE OFF.

SHOWER: Install flange on long end of arm. Wrap threads on both ends of shower arm with thread seal tape.

Screw long end of shower arm into wall. Do not install showerhead prior to flushing (see Flushing).

C.C. SPOUT: The Moen Slip Fit spout is designed with an O-ring seal. It is specifically designed for installation with copper water tube. Lookout must

be free from burrs inside and out. The edge must not be rolled inward from a dull tubing cutter. The outside surface must be free from nicks and scratches.

Press and twist the spout onto the lookout upside down. Tighten the clamp screw with a 5/32" hex wrench until it just starts to bind. Turn spout upright into

position against the wall and finish tightening the clamp screw by hand. The use of pliers or another wrench on the hex wrench is not necessary.

Do not overtighten.

IPS SPOUT:

CAUTION: This spout is A.B.S. plastic and will crack when in contact with some pipe thread compounds.

Please read the pipe compound label to be certain. We recommend using thread seal tape thread sealant.

C.C.

I.P.S.

CLAMP SCREW

Screw tub spout onto pipe and tighten by hand. If final turn by wrench is needed, use small wrench with smooth

jaws; otherwise, pad wrench teeth with rag. Pull outward on spout while tightening to avoid scratching the wall.

DO NOT INSERT TOOL INTO SPOUT END TO TURN SPOUT.

Flushing

IMPORTANT: Before closing all wall openings, pressure test valve and complete system using

flushing instructions

IMPORTANT:

Pipe chips, sand, stones, and other solids found in new or renovated plumbing can damage the sealing surface of the cartridge and cause a leak. To avoid damage, DO NOT TURN ON SUPPLY VALVES until instructed below:

MT662C

1. Break off the protective cap on the plaster ground at the top end of the stop tube cover (see illustration page 3). Place a flat bladed screwdriver into

one of the slots near a support tab and twist to break. Repeat at remaining tabs.

2. Use pliers to operate cartridge.

3. Open the cartridge in the full cold position (notched flat pointing to the right) and turn on the cold supply for 15 seconds. Without closing the

cartridge, turn to the full hot position (notched flat pointing to the left) and turn on the hot supply for 15 seconds.

4. Turn the cartridge to the mixed position (notched flat pointing up), divert water to the shower and run for an additional 15 seconds.

5. Close cartridge.

6. Install showerhead.

Page 3

RETAINER

CLIP

CARTRIDGE

EAR

NOTCHED FLAT

ON STEM

STOP

TUBE

WASHER

ALWAYS KEEP POINTER UP

HANDLE

KNOB

HANDLE

SCREW

HANDLE

COVER

HANDLE

LEVER

SCREW

SET

SCREW

HANDLE

LEVER

STOP TUBE

HANDLE ADAPTER &

BRAKE ASSEMBLY

C

H

Plaster Ground

TO REMOVE STOP TUBE COVER:

Place a flat bladed screwdriver into the slot at the base of the

stop tube cover near a support tab as you did when removing protective cap.

Twist the screwdriver until tab breaks. Repeat for remaining tabs.

TO REMOVE THE PLASTER GROUND:

SNAP ON STYLE

Insert a flat bladed screwdriver into the screw hole access. Push the retaining arm

towards the outside of the plaster ground until it disengages from the valve body.

Repeat for other side and remove plaster ground.

SCREW STYLE

Remove screw holding plaster ground in place. Discard plaster ground.

Assembly

Use pliers to operate the cartridge. Turn on water and check system

for leaks. If there are no leaks, turn OFF water.

For style A & B : Install escutcheon plate and stop tube.

The notched flat on the cartridge stem must point UP. Install

handle parts as shown in the exploded parts view.

A

STOP

TUBE

COVER

PROTECTIVE

CAP

SCREW

HOLE

ACCESS

For style C :

Attach stop tube to the valve body. Next, attach the

B

escutcheon using provided hardware. Place the washer on the

cartridge stem and attach the adapter and brake assembly using

the screw. Attach handle using set screw.

C

IMPORTANT FINAL CHECK - ALL INSTALLATIONS: If above instructions have been followed correctly there will be clearance between the handle and the

escutcheon when the handle is pushed into the closed position, otherwise the valve will not shut off.

TO UTILIZE THE MAXIMUM TEMPERATURE LIMIT FEATURE AVAILABLE WITH THE STYLE C LEVER MODELS,

SEE INSTRUCTIONS ON BACK PAGE.

To Remove Stop Valve

Always turn water supply OFF before disassembly. Open faucet to relieve pressure.

Removal of stop valve:

1. Remove handle assembly as shown above and escutcheon.

2. Using snap ring pliers, remove retaining ring from valve body.

3. Grip stop valve stem with pliers and rotate slightly to remove from valve body.

Re-Installation of new stop valve:

1. Check to be sure that stop valve stem is fully seated in plug.

2. Insert stop valve until fully seated beyond retaining ring groove in valve body.

3. Using snap ring pliers, place retaining ring in valve body, making sure that ring is fully seated.

4. Check orientation of stop valve for water flow. (Stop is in the off position when screwdriver slot is vertical).

5. Turn water supply on.

Page 4

®

CLIP

EAR

®

HANDLE

COVER

HANDLE

KNOB

SHOWER

ARM

FLANGE

SHOWERHEAD

WASHER

HANDLE

SCREW

HANDLE

LEVER

STOP TUBE

ESCUTCHEON

PLASTER

GROUND

CAUTION

USE 1/2"

IRON PIPE

SIZE

MINIMUM

OR 1/2"

TUBING.

SUPPLY

SUPPLY

45"

(1143mm)

48"

(1219mm)

1-1/4"

(32mm)

6' 6"

(1981mm)

32"

(813mm)

FINISHED WALL

LINE

2-1/16"

(52mm)

2-1/16"

(52mm)

TUB FILLER

OR SHOWER

TUB/SHOWER

COMBINATION

FLOOR

15/16"

(24mm)

HANDLE LEVER

HANDLE SCREW

HEXAGONAL

WRENCH

SET SCREW

HANDLE ADAPTER &

BRAKE ASSEMBLY

STOP TUBE

WASHER

Remove handle knob or handle lever and handle parts (see "Disassembly"). Turn valve stem around so that the notched flat is turned one half turn or

180 degrees. Re-install handle parts and handle knob or lever. Tighten handle screw securely; replace handle parts.

MT662C MAR01

To Eliminate Cross-Piping On Back-To-Back Installations or To Correct

Reversed Rough-In Where Hot and Cold Positions Are Reversed:

HELPLINE: Call our toll free Helpline number,

(800) BUY-MOEN

for answers to any product, installation, replacement

parts, or warranty questions.

25300 Al Moen Dr., North Olmsted, OH 44070-8022 U..S.A.

(289 - 6636)

© Moen Incorporated 1996

Printed in U.S.A.

Loading...

Loading...