Page 1

For Safety and ease of faucet

replacement, Moen recommends the

use of these helpful tools.

Para la seguridad y facilidad de

repuesto de la mezcladora, Moen

recomienda las siguientes herramientas.

Par mesure de sécurité et pour faciliter

l’installation, Moen suggére l’utilisation

des outils survants.

INS264

HELPFUL TOOLS HERRAMIENTAS UTILES OUTILS UTILES

ENGLISH ESPAÑOL FRANÇAIS

TWO-HANDLE LAVATORY FAUCET VALVE ONLY

MODEL 9300, 69300

ROBINET DE LAVABO À DEUX POIGNÉES SOUPAPE SEULEMENT

MODÉLES 9300, 69300

MEZCLADORA PARA LAVABO

DE DOS MANIJAS - SOLO VALVULA

MODELOS 9300, 69300

KEEP INSTRUCTIONS FOR

FUTURE REFERENCE

Thank you for purchasing a quality MOEN faucet.

With simple care and maintenance, it will provide

you with many years of reliable performance.

Please read all instructions before installation.

TIPS FOR REMOVAL OF OLD FAUCET:

CAUTION: Always turn water OFF before

removing existing faucet or disassembling

the valve. Open faucet handle to relieve

water pressure and ensure that complete

water shut-off has been accomplished.

GUARDE ESTAS INSTRUCCIONES PARA

REFERENCIA FUTURA

Gracias por haber comprado una mezcladora de

alta calidad de MOEN. Con un cuidado y

mantenimiento sencillos, le brindará muchos años

de servicio fiable. Por favor lea todas las

instrucciones antes de instalar.

SUGERENCIAS PARA QUITAR LA VIEJA

MEZCLADORA:

ADVERTENCIA: Siempre cierre el agua

antes de remover la mezcladora existente o

desarmar la válvula. Abra las manijas de la

mezcladora para aflojar la presión del agua

y para asegurar que el cierre completo del

agua ha sido logrado.

CONSERVER CES DIRECTIVES POUR

RÉFÉRENCE ULTÉRIEURE

Merci d’avoir acheté un robinet de qualité MOEN.

Avec un peu de soin et d’entretien, ce robinet v ous

donnera plusieurs années de rendement fiable.

Lire attentivement toutes les directives avant de

débuter l’installation.

SUGGESTIONS POUR ENLEVER L’ANCIEN

ROBINET :

ATTENTION :Toujours couper l’alimentation

en eau avant d’enlever ou de démonter le

robinet. Ouvrir la poignée du robinet pour

libérer la pression d’eau et pour s’assurer

que l’alimentation en eau a bien été coupée.

© Moen Incorporated, 2000

Printed in U.S.A.

INS264 FEB 00

!

Complies with ASME A112.18.1M and CSA B125Complies with ASME A112.18.1M and CSA B125 Conformément à ASME A112.18.1M et CSA B125

En cumplimiento de ASME A112.18.1M y CSA B125

SAFETY GLASSES

GAFAS DE SEGURIDAD

LUNETTES DE SÉCURITÉ

FLATBLADED SCREWDRIVER

DESTORNILLADOR DE PALA

TOURNEVIS À TÊTE PLATE

PLUMBER'S PUTTY

MASILLA DE PLOMERO

MASTIC DE PLOMBIER

PIPE WRENCH

LLAVE DE TUBO

CLÉ À TUYAU

FLASHLIGHT

LINTERNA

LAMPE DE POCHE

PHILLIPS SCREWDRIVER

DESTORNILLADOR DE ESTRELLA

TOURNEVIS À POINTE CRUCIFORME

7/32" HEX WRENCH

LLAVE HEXAGONAL

CLÉ HEXAGONALE

PLIERS

PINZAS

PINCES

!

!

Page 2

1 INS264

ENGLISH

FRANÇAIS

ESPAÑOL

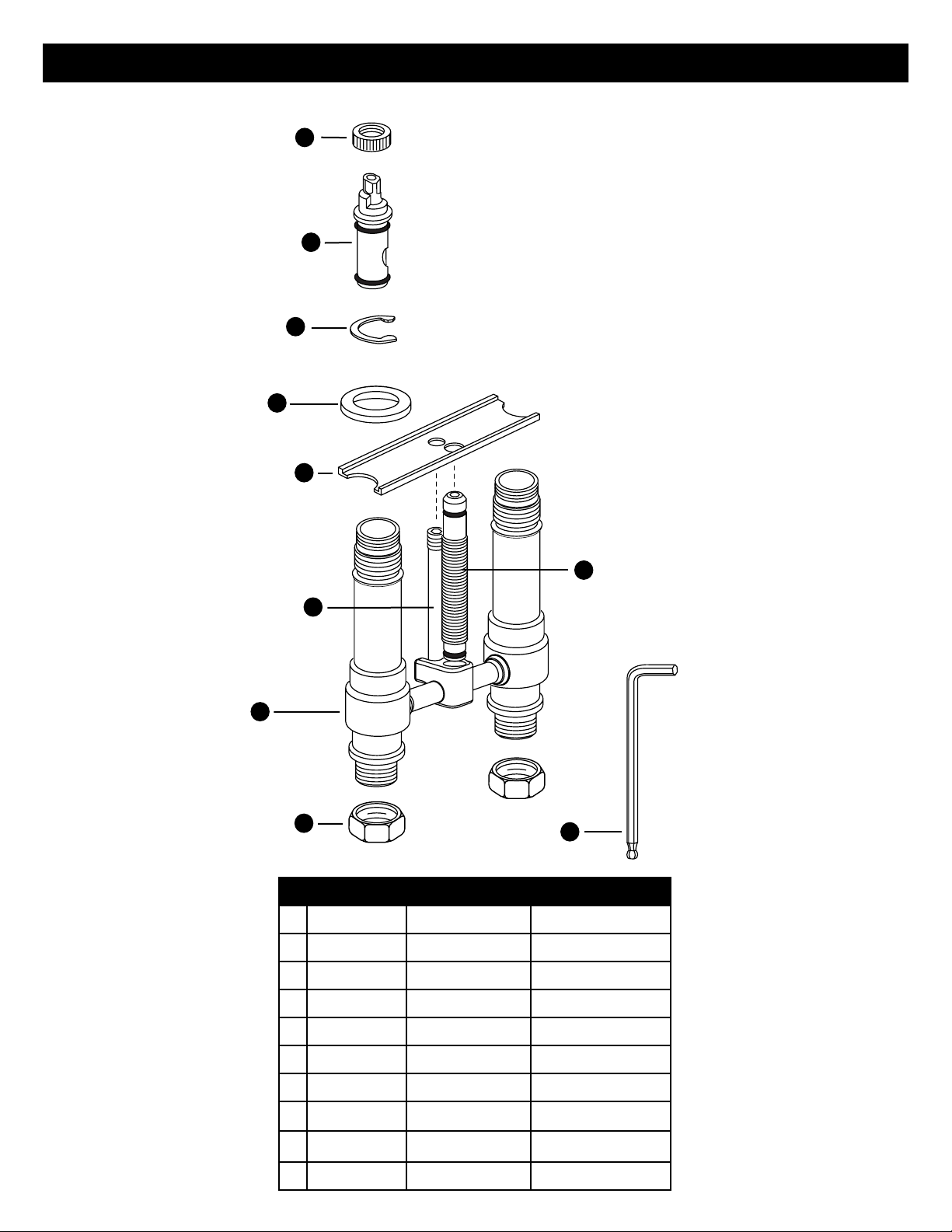

1

Cartridge Nut

Écrou de Cartouche

Tuerca de Cartucho

2

Cartridge

Cartouche

Cartucho

3

Retaining Clip

Bride

Presilla Retendora

4

Top Mounting Washer

Écrou de montage supérieur

Tuerca de montaje superior

5

Mounting Bracket

Support de Montage

Soporte de Montaje

6

Spout Bolt

Boulon de Bec

Tornillo de la Salida

7

Valve Body

Bâti de Soupape

Cuerpo de la Válvula

8

Spout Tube

Tube du bec

Tubo de Salida

9

Tailpiece Nut (not

included with all models)

Écrou de Queue (non compris

avec tous les modèles)

Tuerca de Colilla (no incluido

con todos los modelos)

10

7/32" Hex Wrench

Clé Hexagonal de 3.175mm

Llave hexagonal de 3.175mm

6

7

8

10

9

1

2

3

5

4

PARTS DIAGRAM DIÁGRAMA DE PIEZAS TABLEAU DES PIÈCES

Page 3

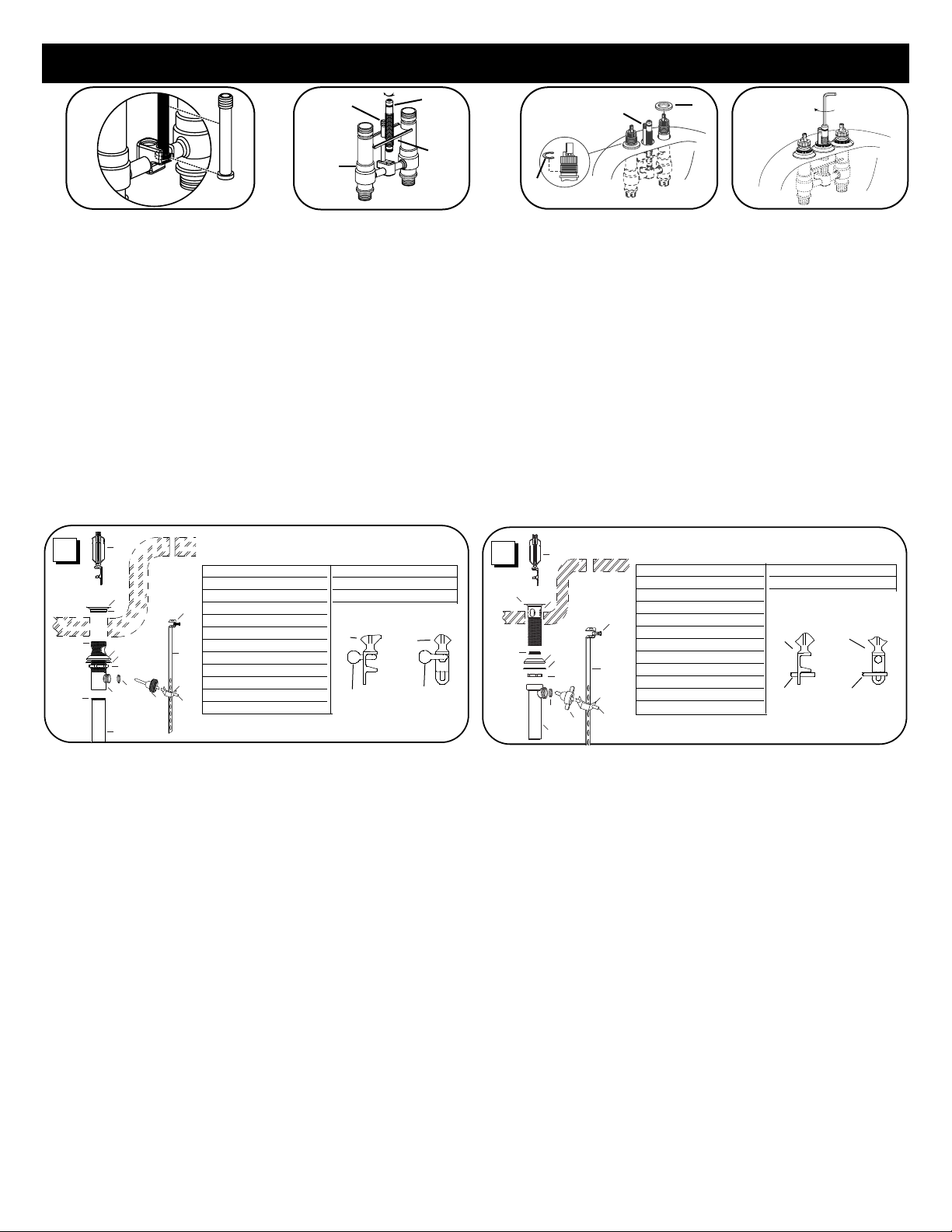

Before installing new faucet make sure that the cartridge nuts are in place.

The cartridge and car tridge nuts were properly installed and tested before

leaving the factory. Although it is unlikely, it is nevertheless possible that

through the handling of the valve by any number of persons the cartr idge

nuts may not be properly installed.This should be carefully checked at time

of installation.If the cartridge nuts are not properly installed, water pressure

could force the cartridge out of the casting.Personal injury or water damage

to the premises could result.

1.Insert head of spout bolt (6) into the slot at the back of the valve body (7).

With the ears of the mounting bracket (5) facing up, screw in the spout

tube (9) with the longer unthreaded end up. Mounting bracket (5) should

be approximately 1/2" up from spout tube (9). A 7/32" hex wrench is

supplied. Lubricate both spout tube o-rings (A) with silicone grease

supplied, position the mounting bracket over spout bolt and insert spout

tube into valve body.

INSTALLATION INSTRUCTIONS

2.Apply plumber’s putty (not supplied) to bottom of top

mounting washers (4). Center washers over holes in deck.

Slide valve assembly from under the deck up through

sink/deck holes, washers.Insert retaining clips (3) into lower

grooves on valve assembly. Release valve assembly down

until it rests on top of the washers. Place the 7/32" hex key

wrench into the tube bolt (6) and tighten mounting bracket

securely.

1

2

2

A. Lavatory Waste Installation

Instructions

1) Thoroughly clean around drain

opening of lavatory sink.

2) Apply plumbers putty under seat

(2).

3) Thread mounting nut (5),

mounting washer (4) and bottom

gasket (3) onto drain body (6).

Wrap top threaded end of drain

body with Teflon tape (15).

4) Position drain body up through

drain opening and screw seat

onto drain body.

5) Align drain body so that pivot rod

opening faces the rear of the

sink and tighten the mounting

nut snug.

6) Apply T eflon tape to the threaded

end of the tailpiece (12) and

screw into the drain body.

Tighten firmly by hand.

7) Drop in plug base (1) and install

pivot rod in one of the following

ways:

I. Vandal proof: Prevent

unauthorized removal of drain

plug.Place pivot rod seat (7) into

opening of drain body as shown.

Place the pivot rod (14) into the

opening and position the pivot

rod through the upper hole of the

pop-up base as shown in

installation (a).Slide the pivot n ut

onto the pivot rod and thread

snugly onto the drain body, be

careful not to over tighten.

II. Easy removal: After inserting

drain plug into waste tube, turn

drain plug 90 degrees. For quick

removal of drain plug for

cleaning, follow the instructions

above except position parts as

shown in illustration (b) above.

Do not insert pivot rod into

opening of pop-up base.

8) Connect the pivot rod (14) to lift

rod strap using spring clip (11)

as shown above.

To disassemble waste assembly,

reverse steps as listed above. In

order to remove seat cover, use

screwdriver to bend snap features

back from the inside as shown in

picture. Do not try to lift seat cover

with tool from the outside.

B. Lavatory Waste Installation

Instruction

1) Thoroughly clean around drain

opening of lavatory sink.

2) Apply plumbers putty under seat

(2).

3) Drop seat into the drain opening

in sink.

4) From underneath the sink. Slide

bottom gasket (3), mounting

washer (4) and mounting nut (5)

onto drain seat and hand tighten.

5) Fit seal (12) inside the drain

tailpiece (6).

6) Install the tailpiece and hand

tighten.Align the entire assembly

so that the pivot rod is facing the

rear of the sink, hand tighten the

mounting nut (5) until snug.

7) Drop in plug base (1) and install

pivot rod in one of the following

ways:

III. Vandal proof: Prevent

unauthorized removal of drain

plug. Place pivot rod seat (2) into

opening of drain body as shown.

Place the pivot rod (14) into the

opening and position the pivot

rod through the upper hole of the

pop-up base as shown in

installation (a).Slide the pivot nut

onto the pivot rod and thread

snugly onto the drain body, be

careful not to over tighten.

IV. Easy removal: For quick

removal of drain plug for

cleaning, follow the instructions

above except position parts as

shown in illustration (b) above.

Do not insert pivot rod into

opening of pop-up base.

8) Connect the pivot rod (14) to lift

rod strap using spring clip (11)

as shown above.

To disassemble waste assembly,

reverse steps as listed above. In

order to remove seat cover, use

screwdriver to bend snap features

back from the inside as shown in

picture below. Do not tr y to lift seat

cover with tool from the outside.

A

B

1

2

4

3

6

7

8

9

14

10

11

12

5

13

15

15

1 Drain Plug Base Part

2 Seat

3 Bottom Gasket

4 Mounting Washer

5 Mounting Nut

6 Drain Body

7 Pivot Rod Seat

8 Pivot Nut

9 Lift Rod Strap

10 Lift Rod Strap Screw

11 Spring Clip

12 Tailpiece

13 Plumbers Putty

14 Pivot Rod

15 Teflon Tape

4

18

18

(a)

(b)

4

1 Drain Plug Base Part

2 Seat

3 Bottom Gasket

4 Mounting Washer

5 Mounting Nut

6 Tail Piece

7 Pivot Rod Seat

8 Pivot Nut

9 Lift Rod Strap

10 Lift Rod Strap Screw

11 Spring Clip

12 Seal

13 Plumbers Putty

14 Pivot Rod

4

18

18

(a)

(b)

4

1

2

4

3

6

7

8

12

9

10

11

5

14

13

7

6

5

9

4

6

3

Page 4

INS264

Faucets made of leaded brass alloys may contribute small amounts of lead to

water that is allowed to stand in contact with the brass. The amount of lead

contributed by any faucet is highest when the faucet is new. The following steps

may reduce potential exposure to lead from faucets and other parts of the

plumbing system:

• Always run the water for a few seconds prior to use for drinking or cooking

• Use only cold water for drinking or cooking

• If you wish to flush the entire plumbing system of water that has been standing

in the pipes or other fittings, run the cold water until the temperature of the water

drops, indicating water coming from the outside main

• If you are concerned about lead in your water, have your water tested by a

certified laboratory in your area

Moen products have been manufactured under the highest standards of quality and

workmanship. Moen warrants to the original consumer purchaser for as long as the original

consumer purchaser owns their home (the “Warranty Period” for homeowners), that this

faucet will be leak and drip-free during normal use and all parts and finishes of this faucet will

be free from defects in material and manufacturing workmanship. All other purchasers

(including purchasers for industrial, commercial and business use) are warranted for a period

of 5 years from the original date of purchase (the “Warranty Period” for non-homeowners).

If this faucet should ever develop a leak or drip during the Warranty Period, Moen will FREE

OF CHARGE provide the parts necessary to put the faucet back in good working condition and

will replace FREE OF CHARGE, any part or finish that proves defective in material and

manufacturing workmanship, under normal installation, use and service. Replacement parts

may be obtained by calling 1-800-289-6636 (Canada 1-800-465-6130), or by writing to the

address shown. Proof of purchase (original sales receipt) from the original consumer

purchaser must accompany all warranty claims. Defects or damage caused by the use of other

than genuine Moen parts are not covered by this warranty. This warranty is applicable only to

faucets purchased after December 1995 and shall be effective from the date of purchase as

shown on purchaser’s receipt.

This warranty is extensive in that it covers replacement of all defective parts and finishes.

However, damage due to installation error, product abuse, product misuse, or use of cleaners

containing abrasives, alcohol or other organic solvents, whether performed by a contractor,

service company, or yourself, are excluded from this warranty. Moen will not be responsible

for labor charges and/or damage incurred in installation, repair or replacement, nor for any

indirect, incidental or consequential damages, losses, injury or costs of any nature relating to

this faucet. Except as provided by law, this warranty is in lieu of and excludes all other

warranties, conditions and guarantees, whether expressed or implied, statutory or otherwise,

including without restriction those of merchantability or of fitness for use.

Some states, provinces and nations do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from

state to state, province to province, nation to nation. Moen will advise you of the procedure to

follow in making warranty claims. Simply write to Moen Incorporated using the address below.

Explain the defect and include proof of purchase and your name, address, area code and

telephone number.

MOEN LIFETIME LIMITED WARRANTY CONSUMER INFORMATION

3

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A. In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5s7

HELPLINE:

1 (800) BUY-MOEN

[289-6636]

In the U.S.call our toll free Helpline number, for answers

to any product installation, or warranty questions.

In Canada:

Toronto: 905-829-3400;

Rest of Canada: 1-800-465-6130

In Mexico:

(84) 88-08-26, 88-08-27,

o 91-800-84-345

Page 5

Antes de instalar una mezcladora nueva, cerciórese de que las tuercas de los

cartuchos estén en sus sitios. El car tucho y sus tuercas se instalan y prueban

en fábrica. Aunque es sumamente improbable que el manejo de la válvula por

varias personas cause la instalación incorrecta de las tuercas del cartucho,

puede ocurrir, y la instalación correcta de dichas tuercas se debe verificar

cuidadosamente al hacer la instalación, porque si están mal instaladas, la

presión del agua puede hacer al cartucho salirse de su sitio y así causar

lesiones físicas o daños al local.

1.Inserte la cabeza del perno de la salida (6) en la ranura de la parte trasera del

cuerpo de la válvula (7). Con las orejas del soporte de montaje (5) hacia

arriba, enrosque el tubo de la salida (9), con su extremo sin rosca más largo

hacia arriba. El soporte de montaje (5) debe estar a unos 12 mm hacia arriba

del tubo de la salida (9). Se suministra una llave hexagonal de 5.55 mm.

Lubrique ambos anillos O del tubo de la salida (A) con la grasa de silicón

provista, sitúe el soporte de montaje sobre el perno de la salida e inser te el

tubo de la salida al cuerpo de la válvula.

1 Pieza de la base del tapón de

drenaje

2 Asiento

3 Empaque de más bajo

4 Arandela de montaje

5 Tuerca de montaje

6 Cuerpo de drenaje

7 Asiento de la varilla de pivote

8 Tuerca de pivote

9 Banda de la varilla elevadora

10 Tornillo de la banda de la

varilla elevadora

11 Presilla de resorte

12 Tuerca de colilla

13 Masilla de plomero

14 Varilla de pivote

15 Cinta de teflón

2. Aplique masilla de plomero (no suministrada) a la base de las

arandelas de montaje de encima (4) y al chapetón de la salida. Centre

las arandelas y el chapetón sobre los hoyos en el fregadero. Deslice el

ensamble de la válvula desde debajo de la cubierta hacia arriba a

través de los ho yos del fregadero/cubierta, las arandelas y el chapetón

de la salida. Inserte la presilla retenedora (3) en las ranuras inferiores

del ensamble de la válvula. Libere el ensamble de la válvula hacia

abajo hasta que descance sobre las arandelas.Coloque la mezcladora

hexagonal de 7/32" en el perno del tubo (6) y apriete la abrazadera de

montaje seguramente.

INSTRUCCIONES PARA LA INSTALACION

A. Instrucciones de instalación del

desagüe del lavatorio

1) Limpie completamente alrededor de

la abertura de drenaje de la pileta

del lavatorio.

2) Aplique masilla de plomero debajo

de la marca (2).

3) Enrosque la tuerca de montaje (5),

la arandela de montaje (4) y el

empaque de más bajo (3) al cuer po

de drenaje (6). Envuelva la parte de

arriba del extremo roscado del

cuerpo de drenaje con cinta Teflón

(15).

4) Posicione el cuerpo de drenaje

hacia arriba a través de la abertura

de drenaje y atornille el asiento al

cuerpo de drenaje.

5) Alinee el cuerpo de drenaje de

modo que la abertura de la varilla de

pivote haga cara a la parte de atrás

del fregadero y apriete

ajustadamente la tuerca de montaje.

6) Aplique cinta de Teflón al extremo

roscado de la tuerca de colilla (12) y

atornille al cuerpo de drenaje.

Ajuste firmemente con la mano.

7) Deje caer la base del tapón (1) e

instale la varilla de pivote en una de

las siguientes maneras:

I) A pr ueba de vandalismo: Previene

la remoción no autorizada del tapón

de drenaje. Coloque el asiento de la

varilla elevadora (7) en la abertura

del cuerpo de drenaje como se

muestra. Coloque la varilla de

pivote (14) dentro de la abertura y

posicione la varilla de pivote a trav és

del hoyo de arrriba de la base de

liberación automática como se

muestra en la instalación (a).

Deslice la tuerca de pivote dentro de

la varilla de pivote y enrosque

firmemente al cuerpo de drenaje,

tenga cuidado de no apretar

demasiado.

II) Remoción fácil: Después de

insertar el tapón de drenaje en el

tubo de desagüe, voltee el tapón de

drenaje 90 grados. Para remover

fácilmente el tapón de drenaje para

limpieza, siga las instrucciones de

arriba, pero posicione las piezas

como se muestra en la ilustración

(b) de arriba. No inserte la varilla de

pivote en la abertura de la base de

liberación automática.

8) Conecte la varilla de pivote (14) a la

banda de la varilla elevadora

usando la presilla de resorte (11)

como se muestra arriba.

Para desarmar el ensamble de

desagüe, invierta los pasos como se

indican arriba. Para remover el cobertor

del asiento, use un destornillador para

doblar hacia atrás, desde adentro, el

mecanismo de cierre a presión, como

se muestra en el dibujo de abajo. No

trate de levantar el cobertor del asiento

con la herramienta desde afuera.

A

1 Pieza de la base del tapón de

drenaje

2 Asiento

3 Empaque de más bajo

4 Arandela de montaje

5 Tuerca de montaje

6 Tuerca de colilla

7 Asiento de la varilla de pivote

8 Tuerca de pivote

9 Banda de la varilla elevadora

10 Tornillo de la banda de la

varilla elevadora

11 Presilla de resorte

12 Sello

13 Masilla de plomero

14 Varilla de pivote

4

B

4

18

18

(a)

(b)

4

B) Instrucciones de Instalación del

desagüe del lavatorio

1) Limpie completamente alrededor

de la abertura de drenaje del

fregadero del lavatorio.

2) Aplique masilla de plomero debajo

del asiento (2).

3) Deje caer el asiento en la abertura

de drenaje en el fregadero.

4) Desde debajo de la pileta. Deslice

el empaque de más bajo (3), la

arandela de montaje (4) y la tuerca

de montaje (5) sobre el asiento del

drenaje y apriete a mano.

5) Calce el sello (13) dentro de la

tuerca de colilla del drenaje (6).

6) Instale la tuerca de colilla y apr iete

a mano. Alinee el ensamble entero

de modo que la varilla de pivote

haga cara a la parte de atrás del

fregadero, apriete a mano la tuerca

de montaje (5) hasta que quede

ajustada.

7) Deje caer la base del tapón (1) e

instale la varilla de pivote en una

de las siguientes maneras:

III) A prueba de vandalismo:

Previene la remoción no

autorizada del tapón de drenaje.

Coloque el asiento de la varilla

elevadora (2) en la abertura del

cuerpo de drenaje como se

muestra. Coloque la varilla de

pivote (15) dentro de la abertura y

posicione la varilla de pivote a

través del hoyo de arrriba de la

base de liberación automática

como se muestra en la instalación

(a). Deslice la tuerca de pivote

dentro de la varilla de pivote y

enrosque firmemente al cuerpo de

drenaje, tenga cuidado de no

apretar demasiado.

IV) Remoción fácil: Para remover

fácilmente el tapón de drenaje para

limpieza, siga las instrucciones de

arriba, pero posicione las piezas

como se muestra en la ilustración

(b) de arriba. No inserte la varilla

de pivote en la abertura de la base

de liberación automática.

8) Conecte la varilla de pivote (15) a

la banda de la varilla elevadora

usando la presilla de resorte (12)

como se muestra arriba.

Para desarmar el ensamble de

desagüe, invierta los pasos como se

indican arriba. Para remover el

cobertor del asiento, use un

destornillador para doblar hacia atrás,

desde adentro, el mecanismo de cierre

a presión, como se muestra en el

dibujo de abajo. No trate de levantar el

cobertor del asiento con la herramienta

desde afuera.

1

2

4

3

6

7

8

9

1

12

5

13

15

15

1

2

4

3

6

7

8

12

9

10

11

5

14

13

18

18

(a)

(b)

4

4

1

2

7

6

5

9

4

6

3

Page 6

5

INS264

Mezcladoras fabricadas con aleaciones de latón de plomo podrían contribuir pequeñas

contidades de plomo al agua que está en contacto con el latón. La cantidad de plomo

contribuida en cualquier mezcladora es mayor cuando esta mezcladora es nueva. Los

siquientes pasos podrían reducir la exposición potencial al plomo de las mezcladoras y

otras piezas del sistema de plomeria:

• Siempre deje correr el agua por unos segundos antes de usaria para tomar o cocinar

• Solamente use agua fría para tomar o cocinar

• Si usted desea limpiar el sistema completo de plomeria de agua estancada en las

tuberías y otros accessorios, deje correr el agua hasta que la temperatura de ésta

baje, indicando de que esta agua viene del suministro de afuera.

• Si usted tiene interés sobre el plomo en su agua, haga examinar su agua por un

laboratorio certificado en su área

Los productos Moen han sido elaborados bajo los más estrictos standard de calidad y mano de

obra. Moen garantiza al consumidor - comprador original por todo el tiempo que el consumidor comprador original esté en posesión de su casa (el “Período de Garantia” del propietario de casa),

que esta mezcladora será libre de infiltraciones y goteo durante su uso normal y que todas las piezas

y el acabado de esta mezcladora serán libres de defectos de material y mano de obra de fabricación.

Todos los otros compradores (incluyendo compras para uso industrial comercial y profesional) se

garantizan por un período de 5 años desde la fecha original de compra (el “Período de Garantía” para

los que no son propietarios de casa).

En caso que esta mezcladora empiece en algún momento a gotear o infiltrarse durante el Período

de Garantía, Moen suministrará LIBRE DE CARGO las piezas que se necesiten para reponer la

mezcladora en buena condición de funcionamiento y reemplazará LIBRE DE CARGO, cualquier pieza

o acabado que resulte ser defectuoso en cuanto a material y elaboración, bajo instalación, uso y

servicio normal. Las piezas de repuesto se pueden obtener llamando al 1-800-289-6636

(Canadá 1-800-465-6130), o escribiendo a la dirección indicada. El comprobante de compra (recibo

original de la venta) del consumidor - comprador de origen debe acompañar todas las reclamaciones

de garantía. Esta garantía no ampara los defectos o daños ocasionados por un uso otro que de piezas

genuinas Moen. Esta garantía se extiende solamente a mezcladoras compradas después de

Diciembre 1995 y será en efectividad desde la fecha de la compra como indique el recibo del

comprador.

Esta garantía es amplia puesto que cubre el repuesto de todas piezas y acabados defectuosos. Sin

embargo, los daños causados por un error de instalación, abuso del producto, mal uso del producto

o el uso de limpiadores que contengan abrasivos, alcohol u otros solventes orgánicos, ya sean

ejecutados por un contratista, Cía. de servicio o Ud. mismo se excluyen de esta garantía. Moen no

será responsable de costos laborales y/o daños producidos durante la instalación, reparación o

cualquier daño incidental o consiguiente, pérdidas, heridas u costos de cualquier naturaleza

relacionados con esta mezcladora. Salvo como previsto por la ley, esta garantía reemplaza y excluye

todas las otras garantías, condiciones y afirmaciones, ya sea expresadas o implícitas, legales u otras,

incluyendo sin restricción alguna aquellas de comercialización o aptitud para el uso.

Algunos estados, provincias y naciones no permiten la exclusión o limitación de daños

incidentales o consiguientes, y por este motivo las sobrecitadas limitaciones posiblemente no le

afectan. Esta garantía le otorga derechos legales expecíficos y Ud. posiblemente también tiene otros

derechos que cambian de un estado a otro, de una provincia a otra, de una nación a otra. Moen le

avisará cual procedimiento debe seguir en cuanto haga una reclamación bajo garantía. Escriba nada

más a Moen Incorporated a la dirección indicada a continuación. Explique el defecto e incluya la

prueba de compra así como su nombre, dirección, código y número de teléfono.

MOEN GARANTIA LIMITADA DE VIDA INFORMACION AL CONSUMIDOR

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

In Canada Moen Inc. • 2816 Bristol Circle • Oakville,Ontario L6H5s7

LINEAS TELEFONICAS

DE SERVICIO:

Para Aclarar sus dudas relacionadas con la instalacion,

refacciones, partes y/o garantia de nuestras llaves,

llamenos por cobrar a los siquientes telefonos: (84) 88-0826, 88-08-27, o 91-800-84-345. FAX (84) 88-08-04.

En los Estados Unidos: 1-800-289-6636

Page 7

6

DIRECTIVES D’INSTALLATION

2. Mettre du mastic de plombier (non compris) sur le dessous des

rondelles de montage supérieures (4) et rosace de bec. Centrer les

rondelles et la rosace sur les ouvertures de la plate-forme. Faire glisser

vers le haut, l’assemblage de soupape par en dessous de la plate-forme

et en passant par les ouvertures de l’évier/de la plate-forme, les

rondelles et la rosace du bec. Insérer les étriers (3) dans les rainures

inférieures de l’assemblage de soupape.Faire descendre l’assemblage

de soupape jusqu’à ce qu’il repose sur le dessus des rondelles. Placer

la clé hexagonale de 7/32" sur le boulon du tube (6) et bien serrer le

support de montage.

A

1 Pièce de base de la bonde

2 Siège

3 Joint d’étanchéité inférieur

4 Rondelle de montage

5 Écrou de montage

6 Corps de la blonde

7 Siège de la tige de pivot

8 Écrou de pivot

9 Courroie de la tige de

levage

10 Vis de la courroie de la

tige de levage

11 Bride à ressort

12 About

13 Mastic de plombier

14 Tige de pivot

15 Ruban en Téflon

4

18

18

(a)

(b)

4

B

1 Pièce de base de la bonde

2 Siège

3 Joint d’étanchéité inférieur

4 Rondelle de montage

5 Écrou de montage

6 Siège de la tige de pivot

7 About

8 Courroie de la tige de

levage

9 Écrou de pivot

10 Vis de la courroie de la tige

de levage

11 Bride à ressort

12 Dispositif d’étanchéité

13 Mastic de plombier

14 Tige de pivot

4

18

18

(a)

(b)

4

A) Directives d’installation de la

bonde de lavabo

1) Bien nettoyer la surface entourant

l’orifice d’écoulement de l’évier du

lavabo.

2) Appliquer du mastic de plombier

sous le siège (2).

3) Fileter l’écrou de montage (5), la

rondelle de montage (4) et le joint

d’étanchéité inférieur (3) dans le

corps du drain (6). Envelopper

l’extrémité filetée du corps de la

bonde d’un ruban Téflon (15).

4) Placer verticalement le corps de la

bonde dans l’ouverture du drain et

visser le siège dans le corps de la

bonde.

5) Aligner le corps de la bonde pour

que la tige de pivot soit dirigée

vers l’arrière de l’évier et bien

serrer l’écrou de montage.

6) Envelopper de ruban Téflon

l’extrémité filetée de l’about (12) et

visser dans le corps de la bonde.

Serrer fermement à la main.

7) Placer la pièce de base de la

bonde (1) et installer la tige de

pivot de l’une des façons suivantes :

I) À l’épreuve du vandalisme pour

prévenir le retrait non autorisé

de la bonde : Placer le siège de la

tige de pivot (7) dans l’ouverture

du corps de la bonde comme

illustré. Placer la tige de pivot (15)

dans l’ouverture et la placer dans

l’orifice supérieur de la base

mécanique comme illustré cidessus (a). Insérer l’écrou de pivot

sur la tige de pivot et bien fileter

dans le corps du drain sans trop

serrer.

II) Retrait facile : après avoir inséré

la bonde dans le tube de vidage,

tourner la bonde de 90 degrés.

Pour retirer rapidement la bonde

pour le nettoyage, suivre les

directives précitées mais placer

les pièces comme dans

l’illustration (b) ci-dessus. Ne pas

insérer la tige de pivot dans

l’orifice de la base mécanique.

8) Raccorder la tige de pivot (14) à la

courroie de tige de levage à l’aide

de la bride à ressort (11). Voir

l’illustration ci-dessus.

Pour démonter l’assemblage de

bonde, inverser l’ordre des étapes cidessus. Pour enlever le couvert du

siège, utiliser un tournevis pour

courber, de l’intérieur, les parties

comme illustré ci-dessous. Ne pas

essayer de soulever, de l’extérieur, le

couvercle du siège avec un outil.

B) Directives d’installation de la

bonde de lavabo

1) Bien nettoyer la surface entourant

l’orifice d’écoulement de l’évier du

lavabo.

2) Appliquer du mastic de plombier

sous le siège (2).

3) Placer le siège dans l’ouverture du

drain du lavabo.

4) Sous le lavabo, faire glisser le joint

d’étanchéité inférieur (3) la

rondelle de montage (4) et l’écrou

de montage (5) dans le siège de la

bonde et serrer à la main.

5) Placer le dispositif d’étanchéité

(12) dans l’about de bonde (6).

6) Installer l’about et serrer à la main.

Aligner tout l’assemblage pour

que la tige de pivot soit dirigée

vers l’arrière du lavabo. Bien

serrer l’écrou de montage (5) à la

main.

7) Insérer la base de la bonde (1) et

installer la tige de pivot selon l’une

des méthodes suivantes :

III) À l’épreuve du vandalisme pour

prévenir le retrait non autorisé

de la bonde : Placer le siège de la

tige de pivot (2) dans l’ouverture

du corps de la bonde comme

illustré. Placer la tige de pivot (14)

dans l’ouverture et la placer dans

l’orifice supérieur de la base

mécanique comme illustré cidessus (a).Insérer l’écrou de pivot

sur la tige de pivot et bien fileter

dans le corps de bonde sans trop

serrer.

IV) Retrait facile : pour retirer

rapidement la bonde pour le

nettoyage, suivre les directives

précitées mais placer les pièces

comme dans l’illustration (b) cidessus. Ne pas insérer la tige de

pivot dans l’orifice de la base

mécanique.

8) Raccorder la tige de pivot (14) à la

courroie de tige de levage à l’aide

de la bride à ressort (11). Voir

l’illustration ci-dessus.

Pour démonter l’assemblage de

bonde, inverser l’ordre des étapes cidessus. Pour enlever le couvert du

siège, utiliser un tournevis pour

courber, de l’intérieur, les parties

comme illustré ci-dessous. Ne pas

essayer de soulever, de l’extérieur, le

couvercle du siège avec un outil.

Avant d’installer un nouv eau robinet, s’assurer que les écrous de cartouche sont bien

en place. La cartouche et les écrous de car touche ont été correctement installés et

testés avant leur sortie d’usine. Bien que ceci soit peu probable, il est toutefois

possible que suite à la manutention de la soupape par diverses personnes, les

écrous de cartouche ne soient plus correctement installés. Vérifier avec soin cette

possibilité avant de procéder à l’installation. Si les écrous de cartouche ne sont pas

installés correctement, la pression d’eau risque de propulser la cartouche hors de sa

forme et ainsi causer des blessures et des dégâts d’eau sur les lieux de travail.

1. Insérer le boulon du bec (6) dans la fente à l’arrière du corps du robinet (7).En

plaçant les oreilles du support de montage (5) vers le haut, visser le tube du bec

(9) en plaçant l’extrémité non filetée la plus longue vers le haut. Le support de

montage (5) devrait être à environ 1/2 po plus haut que le tube du bec (9).Une clé

hexagonale de 7/32 po est fournie.Lubrifier les deux joints toriques du tube de bec

(A) avec la graisse de silicone fournie. Placer le support de montage sur le boulon

du bec et insérer le tube du bec dans le corps du robinet.

1

2

4

3

6

7

8

9

14

10

11

12

5

13

15

15

1

2

4

3

6

7

8

12

9

10

11

5

14

13

1

2

7

6

5

9

4

6

3

Page 8

INS264

Robinets fabriqués à partir d'alliages de laiton de plomb pourraient contribuer des petites quantités de

plomb à l'eau qu'on laisse stagner en contact avec ledit laiton. La quantité de plomb contribuée par

n'importe quel robinet est supérieure lorsque le robinet est neuf. Les procédés qui suivent peuvent

réduire l'exposition au plomb provenant de robinets et autres pièces du système de tuyauterie:

• Toujours faire couler l'eau pendant quelques secondes avant de s'en servir pour boire ou cuire

• Utiliser uniquement l'eau froide pour boire ou cuire

• En cas ou l'on désire purger le sysème entier de plomberie de l'eau stagnante dans les tuyaux ou

autres montages, laisser couleur l'eau jusqu'à ce que la température de l'eau tombe, indicant ainsi

que l'eau provient du conduit extérieur

• Si la teneur en plomb de votre eau vous inquiète, la faire tester par un laboratoire régional certifié.

Les produits Moen ont été fabriqués selon les normes de qualité et de main-d’œuvre les plus élevées.

Moen garantit à la personne ayant acheté le robinet originalement, aussi longtemps qu’elle reste propriétaire

de la maison, (période de garantie pour propriétaires), que ce robinet sera libre de toute fuite ou

d’égouttement pendant son usage normal et que toutes les pièces et tous les finis de ce robinet ne

présenteront aucun défaut de matériel et de main-d’œuvre en usine. L’achat par tout autre consommateur

(acheteur à des fins industriels, commerciales et d’affaires) sera garanti pendant 5 ans à compter de la date

d’achat originale (période de garantie pour non-propriétaires).

Si ce robinet fuit ou dégoutte durant la période de garantie, Moen remplacera GRATUITEMENT les pièces

de remplacement requises pour remettre le robinet en parfait état et remplacera GRATUITEMENT toute pièce

ou tout fini dont le matériel, la fabrication ou la main-d’œuvre, lors d’une installation, d’un usage et d’un

service normaux, s’avère défectueux. On peut obtenir les pièces de remplacement en composant le

1 800 465-6130, ou en écrivant à l’adresse indiquée sous la preuve d’achat. Le reçu de vente original du

consommateur ayant acheté le robinet initialement, doit accompagner toute réclamation. Les défauts ou les

dommages causés par l’utilisation de pièces non fournies par Moen ne sont pas couvertes par cette garantie.

Cette garantie s’applique uniquement aux robinets achetés après décembre 1995 et entre en vigueur à

compter de la date d’achat indiquée sur le reçu de caisse du consommateur.

Cette garantie est vaste car elle couvre le remplacement de toute pièce ou de tout fini défectueux.

Cependant, les dommages causés par une erreur l’installation, un abus du produit, une mauvaise utilisation

du produit ou l’utilisation de nettoyeurs contenant des agents abrasifs, de l’alcool ou des solvants

organiques, qu’ils soient utilisés par un entrepreneur, une entreprise de service ou le consommateur, sont

exclus de cette garantie. Moen n’est pas responsable des frais de main-d’œuvre ni de tous dommages

survenus durant l’installation, la réparation ou le remplacement, ni des dommages indirects ou consécutifs,

des pertes, des blessures ou des coûts connexes à ce robinet. Sauf lorsque prévu par la loi, cette garantie

remplace et exclut toute autre garantie et condition, qu’elles soient exprimées ou sous-entendues,

obligatoires ou autres, y compris sans restriction, celle de commercialisation ou d’aptitude d’utilisation.

Certains pays, certains États et certaines provinces, ne permettent aucune exclusion, ni limitation suite

aux dommages indirects ou consécutifs. Les limitations ou les exclusions ne s’appliquent donc pas dans

ces cas. Cette garantie accorde des droits juridiques et il est possible que d’autres droits soient applicables

selon l’état, la province ou le pays précis. Moen avisera le consommateur de la procédure à suivre pour

soumettre une réclamation. Il suffit d’écrire à Moen incorporée, d’expliquer le défaut et d’inclure une preuve

d’achat, d’inscrire son nom, adresse ainsi que code régional et numéro de téléphone.

APPELER SANS FRAIS NOTRE

SERVICE À LA CLIENTÈLE

Appeler notre Service à la clientèle pour obtenir des

renseignements sur nos produits, leur l’installation ou sur

notre garantie.

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U.:1 800 289-6636

Au Mexique :

(84) 88-08-26, 88-08-27,

o 91-800-84-345

GARANTIE À VIE LIMITÉE DE MOEN INFORMATION POUR LE CONSOMMATEUR

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

Au Canada, Moen inc.,2816 rue Bristol, Oakville (Ontario), L6H 5S7

Loading...

Loading...