Page 1

SOLDERING

PASTE FLUX

E

L

E

For Safety and ease of faucet

replacement, Moen recommends the

use of these helpful tools.

Para la seguridad y facilidad de

repuesto de la mezcladora, Moen

recomienda las siguientes herramientas.

Par mesure de sécurité et pour faciliter

l’installation, Moen suggère l’utilisation

des outils suivants.

INS288

HELPFUL TOOLS HERRAMIENTAS UTILES OUTILS UTILES

ENGLISH ESPAÑOL FRANÇAIS

COMMERCIAL TRANSFER VALVE

INSTALLATION INSTRUCTIONS

MODELS 8341, 8342, 8343, 8360

ROBINET COUPLEUR COMMERCIAL

DIRECTIVES D’INSTALLATION

Modèles 8341, 8342, 8343, 8360

INSTRUCCIONES PARA LA INSTALACIÓN

DE LA VÁLVULA MEZCLADORA COMERCIAL

MODELOS 8341, 8342, 8343, 8360

KEEP INSTRUCTIONS FOR

FUTURE REFERENCE

Thank you for purchasing a quality MOEN valve.

With simple care and maintenance, it will provide

you with many years of reliable performance.

Please read all instructions before installation.

TIPS FOR REMOVAL OF OLD FAUCET:

CAUTION: Always turn water OFF before

removing existing faucet or disassembling

the valve. Open faucet handle to relieve

water pressure and ensure that complete

water shut-off has been accomplished.

GUARDE ESTAS INSTRUCCIONES PARA

REFERENCIA FUTURA

Gracias por comprar una válvula MOEN de alta

calidad. Con un cuidado y mantenimiento

sencillos, le brindará muchos años de servicio

fiable. Por favor lea todas las instrucciones antes

de instalar.

SUGERENCIAS PARARETIRAR LA VIEJA

MEZCLADORA:

ADVERTENCIA: Desconecte siempre el

agua antes de retirar la mezcladora

existente o desarmar la válvula. Abra los

manerales de la mezcladora para

desahogar la presión del agua y

asegurarse de que se ha logrado un corte

completo de la misma.

CONSERVER CES DIRECTIVES POUR

RÉFÉRENCE ULTÉRIEURE

Merci d’avoir acheté un soupape de qualité

MOEN. Avec un peu de soin et d’entretien, ce

robinet vous donnera plusieurs années de

rendement fiable. Lire attentivement toutes les

directives avant de débuter l’installation.

SUGGESTIONS POUR ENLEVER L’ANCIEN

ROBINET :

ATTENTION: Toujours couper l’alimentation

en eau avant d’enlever ou de démonter le

soupape. Ouvrir la poignée du robinet pour

libérer la pression d’eau et pour s’assurer

que l’alimentation en eau a bien été coupée.

© Moen Incorporated, 2000

Printed in U.S.A.

INS288 JUN00

!

Complies with ASME A112.18.1M and CSA B125Complies with ASME A112.18.1M and CSA B125 Conformément à ASME A112.18.1M et CSA B125

En cumplimiento de ASME A112.18.1M y CSA B125

SOLDERING

PASTE FLUX

SAFETY GLASSES

GAFAS DE SEGURIDAD

LUNETTES DE SÉCURITÉ

PLIERS

PINZAS

PINCES

DRILL

TALADRO

PERÇEUSE

TUBING CUTTER

CORTADOR DE TUBO

COUPE-TUYAU

SOLDER KIT

EQUIPO DE SOLDAR

NÉCESSAIRE À SOUDER

FLASHLIGHT

LINTERNA

LAMPE DE POCHE

TILE SEALER

SELLADOR DE BALDOSA

MASTIC DE CÉRAMIQUE

ADJUSTABLE WRENCH

LLAVE AJUSTABLE

CLÉ ANGLAISE

HEX WRENCH

LLAVE HEXAGONAL

CLÉ HEXAGONALE

TORCH

SOLDADOR

CHALUMEAU

HACKSAW

SIERRA DE ARMERO

SCIE À MÉTAUX

PHILLIPS SCREWDRIVER

DESTORNILLADOR DE ESTRELLA

TOURNEVIS À POINTE CRUCIFORME

FILE

LIMA

LIME

PLUMBER'S PUTTY

MASILLA DE PLOMERO

MASTIC DE PLOMBIER

FLATBLADED SCREWDRIV

DESTORNILLADOR DE PA

TOURNEVIS À TÊTE PLAT

!

!

Page 2

1 INS288

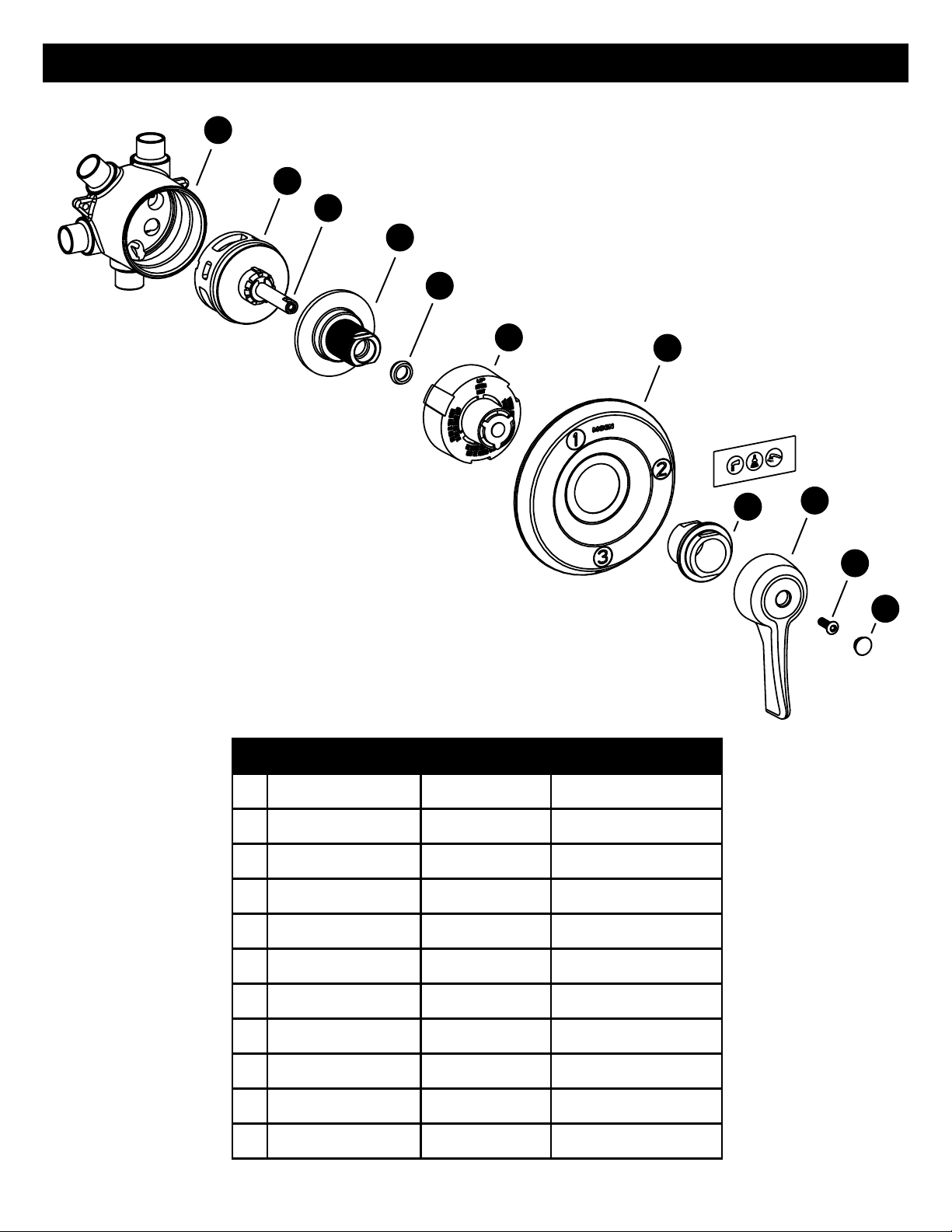

PARTS DIAGRAM DIÁGRAMA DE PIEZAS TABLEAU DES PIÈCES

ENGLISH

FRANÇAIS

ESPAÑOL

1

Valve Housing

Boîtier du robinet

Cuerpo de la válvula

2

Cartridge

Cartouche

Cartucho

3

Stem

Tige

Vástago

4

Top Plate

Plaque supérieure

Plancha superior

5

Handle Stem Bushing

Douille de tige de poignée

Manguito del vástago del maneral

6

Plaster Ground

Arrêt d’enduit

Plantilla de yeso

7

Escutcheon

Rosace

Chapetón

8

Mounting Sleeve

Manchon de montage

Manguito de montaje

9

Handle

Poignée

Monomando

10

#10-24 Torx Screw

Vis à six lobes 10-24

Tornillo de torsión

11

Plug Button

Bouton de finition

Botón de presión

1

2

3

4

5

6

7

9

10

8

11

Page 3

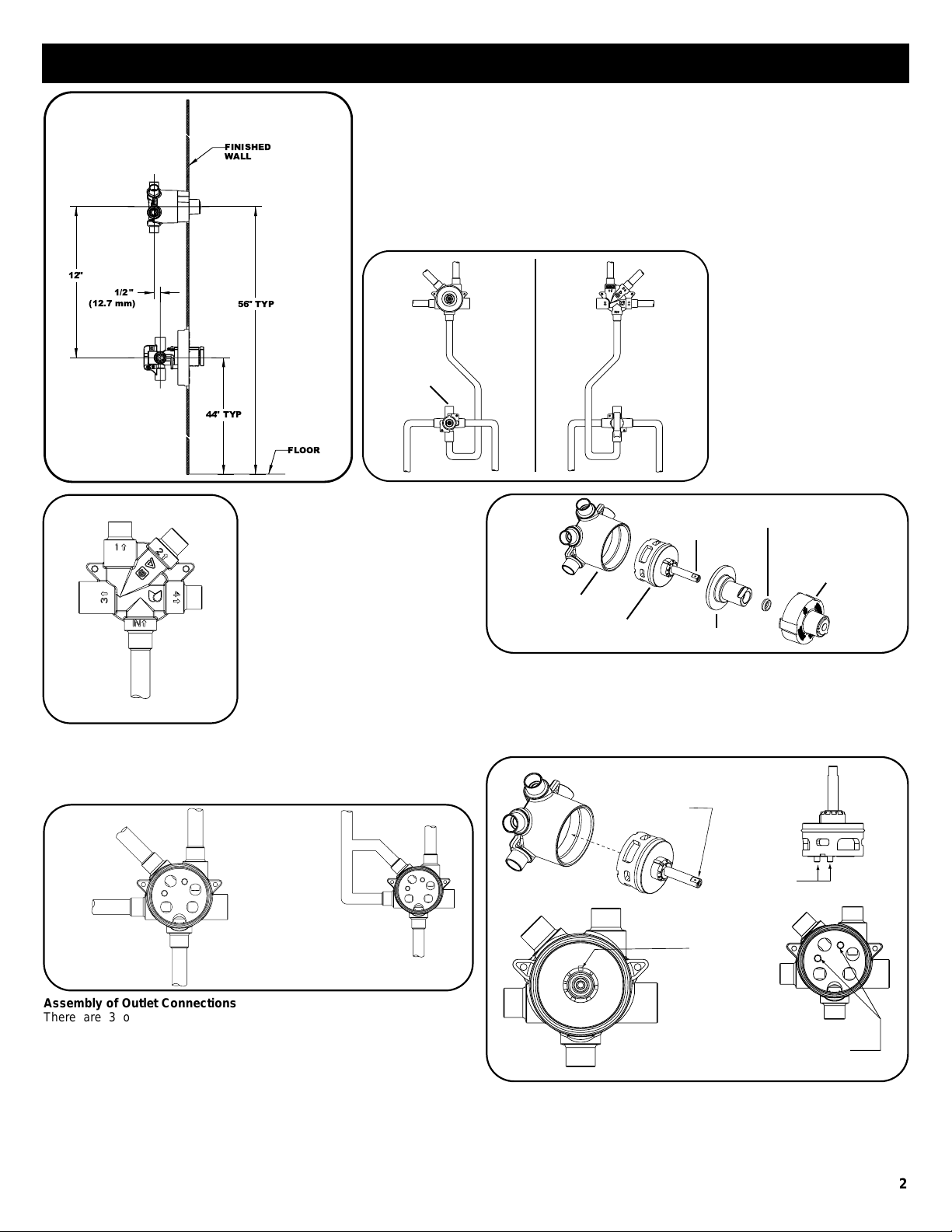

5. With the valve castings “IN” port facing

directly down, connect the outlet of the

main supply valve to the inlet of the

transfer valve using a 1/2” copper

water tube. If the supply valve has 2

outlets, one of these outlets must be

plugged.

CAUTION:

For CC (copper to copper)

installations, the cartridge must be

removed from the valve body before

heating the valve. Failure to do so will

result in cartridge damage. Please

refer to the instructions ‘Removing

Cartridge for CC Connection/

Servicing.’

Handle Stem Position for Handle Adapter/Handle Assembly

For correct handle position/outlet flow designation, make sure that the handle

stem flats locating mark is facing upwards and away (opposite direction) from

the inlet.

Rough-in Body Casting

1. The distance from the supply valve center to the center of the transfer valve must be a minimum

of 12” (305mm) to assure proper clearance of the transfer valve escutcheon and supply valve

escutcheon.

2. In the finished wall, make a minimum hole of 2-3/4” (70mm) diameter for the transfer valve

installation.

3. The plaster ground is used as a guide to help install the valve at the proper depth within the wall.

The plaster ground should be flush with the finished wall once the transfer valve is installed. The

inlet of the transfer valve may not be aligned with the outlet of the shower valve. For example,

the transfer valve installed with Posi-Temp has an offset as shown in the Figure at left.

INSTALLATION INSTRUCTIONS

"12

" TYP56

" TYP44

"

(12.7 mm)

1/2

FINISHED

WALL

FLOOR

2

Assembly of Outlet Connections

There are 3 outlets of the transfer valve, providing 3 separate, discrete

functions. Suggested outlet designations are as follows:

• Outlet #1: Showerhead

• Outlet #2: Handshower (45° from the left of Outlet #1)

• Outlet #3: Un-used

• Outlet #4: Tub Spout, Additional Showerhead, or Handshower (90° from

the left of Outlet #1)

NOTE: Do not block any outlet. If any outlets are not to be used (i.e. tub spout), the outlet

should be plumbed into the line of one of the other outlets. This valve is not intended

to be used as a shut-off valve. Damage to the shower system may result if the valve

is used as a shut-off valve. To prevent the potential of cross flow, check valves must

be integral to the supply valve or installed in both hot and cold water supply lines.

Valve

Front

Hot Cold

Valve

Rear

Removing Cartridge for CC Connection/Servicing

1. Remove plaster ground but do not discard.

2. Using an adjustable wrench on the flats, remove the externally threaded

top plate by turning it counterclockwise (CCW).

3. Grasp the cartridge by the stem with pliers and pull the cartridge straight

out.

4. The Positemp Valve can be

connected to the Diverter Valve

in the configuration shown at

left. The top port (Shower Port)

on the Positemp Valve will

need to be capped.

Installing Cartridge Into Transfer Valve Body

1. Place the cartridge into the transfer valve body, positioning the 2 locating

pins on the bottom of the cartridge (Figure 1) into the 2 locating holes in

the transfer valve body (Figure 2). Assure (a) the locating key on the top

of the cartridge is facing upwards away from the inlet, and (b) that the

stem flats locating mark is facing upwards and away from the inlet

(Figure 3).

Cap

Shower Port

Rear

View

Outlet #1

Outlet #2

Outlet #4

Outlet #3 (un-used)

Inlet

Plumbing example for

un-used Outlet #4

Valve Housing

Stem

Handle Stem Bushing

Plaster Ground

Top Plate

Cartridge

Figure 1

Figure 2

Cartridge

Locating Pins

Valve Housing

Locating Holes

Stem Flats

Locating Mark

Figure 3

Inlet

Locating

Key

Page 4

INS288

3

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5s7

Attach The Handle

1. Place the Handle onto the valve stem as shown above. Test

the Handle rotation so that it comes to a stop at all three stop

locations on the Escutcheon. If this is not the case, remove the

handle, rotate it 180°, and replace the Handle onto the valve

stem.

2. Fasten the Handle to the valve stem using the supplied torx

screw.

3. Push the Plug Button into the Handle hole until it snaps into

place.

Faucets made of leaded brass alloys may contribute small amounts of lead to

water that is allowed to stand in contact with the brass. The amount of lead

contributed by any faucet is highest when the faucet is new. The following steps

may reduce potential exposure to lead from faucets and other parts of the

plumbing system:

• Always run the water for a few seconds prior to use for drinking or cooking

• Use only cold water for drinking or cooking

• If you wish to flush the entire plumbing system of water that has been standing

in the pipes or other fittings, run the cold water until the temperature of the

water drops, indicating water coming from the outside main

• If you are concerned about lead in your water, have your water tested by a

certified laboratory in your area

Moen products have been manufactured under the highest standards of quality and

workmanship. Moen warrants to the original consumer purchaser for as long as the original

consumer purchaser owns their home (the “Warranty Period” for homeowners), that this

faucet will be leak and drip-free during normal use and all parts and finishes of this faucet will

be free from defects in material and manufacturing workmanship. All other purchasers

(including purchasers for industrial, commercial and business use) are warranted for a period

of 5 years from the original date of purchase (the “Warranty Period” for non-homeowners).

If this faucet should ever develop a leak or drip during the Warranty Period, Moen will FREE

OF CHARGE provide the parts necessary to put the faucet back in good working condition and

will replace FREE OF CHARGE, any part or finish that proves defective in material and

manufacturing workmanship, under normal installation, use and service. Replacement parts

may be obtained by calling 1-800-289-6636 (Canada 1-800-465-6130), or by writing to the

address shown. Proof of purchase (original sales receipt) from the original consumer

purchaser must accompany all warranty claims. Defects or damage caused by the use of other

than genuine Moen parts are not covered by this warranty. This warranty is applicable only to

faucets purchased after December 1995 and shall be effective from the date of purchase as

shown on purchaser’s receipt.

This warranty is extensive in that it covers replacement of all defective parts and finishes.

However, damage due to installation error, product abuse, product misuse, or use of cleaners

containing abrasives, alcohol or other organic solvents, whether performed by a contractor,

service company, or yourself, are excluded from this warranty. Moen will not be responsible

for labor charges and/or damage incurred in installation, repair or replacement, nor for any

indirect, incidental or consequential damages, losses, injury or costs of any nature relating to

this faucet. Except as provided by law, this warranty is in lieu of and excludes all other

warranties, conditions and guarantees, whether expressed or implied, statutory or otherwise,

including without restriction those of merchantability or of fitness for use.

Some states, provinces and nations do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from

state to state, province to province, nation to nation. Moen will advise you of the procedure to

follow in making warranty claims. Simply write to Moen Incorporated using the address below.

Explain the defect and include proof of purchase and your name, address, area code and

telephone number.

MOEN LIFETIME LIMITED WARRANTY CONSUMER INFORMATION

HELPLINE:

1 (800) BUY-MOEN

[289-6636]

In the U.S. call our toll free Helpline number, for answers

to any product installation, or warranty questions.

In Canada:

Toronto: 905-829-3400;

Rest of Canada: 1-800-465-6130

In Mexico:

(84) 88-08-26, 88-08-27,

o 91-800-84-345

1. Prior to Escutcheon installation, verify that the plaster ground has been removed from

the valve so that the trim will fit properly.

2. Screw on the Mounting Sleeve passing through the Escutcheon such that the outer rim

of the sleeve presses up firmly against the Escutcheon, holding it in place against the

wall.

Note:

• The orientation of the Mounting Sleeve is dependent upon whether the valve was

installed closer or further from the finished wall.

Optional

An optional decal sheet was included with the packaging.

These decals on this sheet can be used in place of the

numbers on the Escutcheon according to the valve position

function.

2. Re-assemble the top plate to the transfer valve body by turning it clockwise until handtight (take caution when handling

the top plate threads) and then turn an additional 1/2 turn with a wrench.

Note:

• The proper torque of the top plate into the transfer valve body is 25 in-lbs. (2.8 N-m).

3. If the trim is to be installed at a later time, re-install the plaster ground to protect the valve.

Handle Stem Position for Handle Adapter/Handle Assembly

For correct handle position/outlet flow designation, make sure that the handle stem flats locating mark is facing upwards

and away (opposite direction) from the inlet.

Top Plate

Remove

Plaster Ground

Escutcheon

Mounting Sleeve

(Reversible — see

illustration above)

Mounting Sleeve

(Reversed)

Page 5

5. Con las piezas de fundición de la

válvula marcadas "IN" (ENTRADA)

directamente hacia abajo, conecte la

salida de la válvula de suministro

principal a la entrada de la válvula

mezcladora usando un tubo de cobre

para agua de 1/2" (1,27 cm). Si la

válvula de suministro tiene dos salidas,

una de ellas debe ser taponada.

ADVERTENCIA: Para instalaciones CC

(cobre a cobre), debe retirarse el

cartucho del cuerpo de la válvula

antes de calentarla. De no hacerlo el

cartucho se dañará. Por favor vea las

instrucciones ‘Para retirar el cartucho para Conexión y Servicio CC’.

Posición del vástago del monomando para armar el conjunto del

adaptador y el monomando

Para designar correctamente la posición del monomando y del flujo de salida,

asegúrese de que la marca chata de ubicación del vástago del monomando

esté hacia arriba y en dirección opuesta a la entrada.

INSTRUCCIONES PARA LA INSTALACION

4

"12

" TYP56

" TYP44

"

(12.7 mm)

1/2

FINISHED

WALL

FLOOR

Armado de las conexiones de las salidas

Existen tres salidas de la válvula mezcladora; cada una provee funciones

separadas y diferentes. Se sugieren las siguientes designaciones para dichas

salidas:

•Salida #1: Regadera

•Salida #2: Regadera manual (45° a la izquierda de la Salida #1)

•Salida #3: sin uso

•Salida #4: Surtidor de la tina, regadera fija o manual adicional (90° a la

izquierda de la Salida #1)

NOTA: No bloquee ninguna salida. Si alguna de ellas no va a ser utilizada ( por ej. el surtidor

de la tina) la salida debe ser conectada con cañería a la línea de una de las otras. Esta

válvula no debe ser utilizada como válvula de corte. Si se la usa a tal efecto pueden

causarse daños al sistema de regadera. Para evitar la posibilidad de flujo cruzado, las

válvulas checadoras deben estar integradas a la válvula de suministro o instaladas

tanto en la línea de suministro de agua fría como en la de agua caliente.

Frent de

la válvula

Frío Caliente

Parte

posterior

de la

válvula

4. La Válvula Positemp puede ser

conectada a la válvula

mezcladora en la configuración

que se muestra a la izquierda.

El puerto superior (Puerto de

regadera) de la Válvula

Positemp debe taparse.

Instalación del cartucho en el cuerpo de la válvula mezcladora

1. Coloque el cartucho dentro de la mezcladora, ubicando los dos pasadores de

ubicación en el fondo del mismo (Figura 1) dentro de los dos orificios de

ubicación en el cuerpo de la válvula (Figura 2). Asegúrese de que (a) la llave

de ubicación en la parte de arriba del cartucho esté hacia arriba y en dirección

opuesta a la entrada, y (b) que la marca de ubicación de las partes chatas del

vástago esté hacia arriba y en dirección opuesta a la entrada (Figura 3).

Tape el

puerto de la

regadera

Vista

posterior

Salida #1

Salida #2

Salida #4

Salida #3 (sin uso)

Entrada

Ejemplo de cañero para

Salida #4 sin uso

Bastidor de la

válvula

Vástago

Manguito del vástago

del monomando

Plantilla de

yeso

Plancha superior

Cartucho

Figura 1

Figura 2

Cartucho

pasadores de

ubicación

Orificios de ubicación

del bastidor de la válvula

Marca de

ubicación de

la parte chata

del vástago

Figura 3

Entrada

Llave de

ubicación

PARED

TERMINADA

PISO

Empotrado de la válvula

1. La distancia del centro de la válvula de suministro al centro de la válvula mezcladora debe tener

un mínimo de 12" (305 mm) para asegurar el espacio correcto para los chapetones de dichas

válvulas.

2. En la pared terminada, haga un orificio de diámetro mínimo de 2-3/4" (70 mm) para instalar la

válvula mezcladora.

3. La plantilla de yeso se usa como guía para ayudar a instalar la válvula a la profundidad correcta

dentro de la pared. Una vez instalada la válvula, la plantilla debe quedar a ras de la pared

terminada. La entrada de la válvula mezcladora puede no quedar alineada con la salida de la

válvula de la regadera. Por ejemplo, la válvula mezcladora instalada con Posi-Temp tiene una

diferencia como se muestra en la figura de la izquierda.

Para retirar el cartucho para Conexión y Servicio CC

1. Retire la plantilla de yeso sin deshacerse de ella.

2. Usando una llave ajustable en las partes chatas, retire la plancha superior con rosca

externa haciéndola girar hacia la izquierda.

3.

Agarre el cartucho por el vástago con unas pinzas y retírelo tirando derecho hacia afuera.

4. La Válvula Positemp puede ser conectada a la válvula mezcladora en la

configuración que se indica a la izquierda. El puerto superior (Regadera) de la

Válvula Positemp deberá taparse.

Page 6

INS288

5

Las mezcladoras fabricadas con aleaciones de latón al plomo pueden contaminar

el agua que entra en contacto con ellas con pequeñas cantidades de plomo.

Estas cantidades son más altas cuando la mezcladora es nueva. Los siguientes

pasos pueden reducir la exposición potencial al plomo causada por las

mezcladoras y otras piezas del sistema de plomería:

• Deje correr el agua por unos segundos antes de usarla para beber o cocinar.

• Use solamente agua fría para beber o cocinar.

• Si desea limpiar el sistema completo de plomería para eliminar el agua

estancada en las tuberías y otros accesorios, deje correr el agua hasta que

la temperatura de ésta disminuya, indicando que esta agua proviene del

suministro exterior.

• Si le preocupa la presencia de plomo en el agua de su hogar, haga examinar

una muestra de la misma en un laboratorio certificado en su zona

Los productos Moen han sido elaborados bajo las más estrictas normas de calidad y mano de

obra. Moen garantiza al consumidor - comprador original durante el tiempo en que éste esté en

posesión de su casa (el "Período de Garantía" del propietario), que esta mezcladora no presentará

infiltraciones ni goteo durante su uso normal y que ni las piezas ni el acabado de la misma

presentarán defectos de material ni de fabricación. Cualquier otro comprador, (incluyendo aquellos

que la adquieran para uso industrial, comercial y profesional) recibirá una garantía por un período de

5 años desde la fecha original de compra ("Período de Garantía" para los no propietarios).

En caso de que esta mezcladora comenzara a gotear o presentase pérdidas durante el Período de

Garantía, Moen suministrará LIBRE DE CARGO las piezas necesarias para restaurar el buen

funcionamiento de la misma y reemplazará LIBRE DE CARGO cualquier pieza o acabado que resulte

ser defectuoso en cuanto a material y elaboración, en condiciones de instalación, uso y servicio

normal.

Las piezas de repuesto se pueden obtener llamando al 1-800-289-6636 (Canadá 1-800-465-

6130), o escribiendo a la dirección indicada. El comprobante de compra (recibo original de la venta)

del consumidor - comprador de origen debe acompañar todas las reclamaciones de garantía. Esta

garantía no cubre defectos o daños ocasionados por el uso de piezas que no sean Moen genuinas.

Esta garantía se extiende solamente a mezcladoras compradas después de Diciembre de 1995 y será

efectiva desde la fecha de la compra indicada en el recibo del comprador.

Esta es una garantía amplia que cubre la reposición de todas las piezas y acabados defectuosos.

Sin embargo, quedan excluidos de esta garantía los daños causados por un error de instalación,

abuso del producto, mal uso del producto o el uso de limpiadores que contengan abrasivos, alcohol

u otros solventes orgánicos, ya sean responsabilidad de un contratista, Cía. de servicio o de Ud.

mismo. Moen no se hará responsable de costos laborales y/o daños producidos durante la

instalación, reparación o cualquier daño incidental o consiguiente, pérdidas, heridas o costos de

cualquier naturaleza relacionados con esta mezcladora. Salvo en los casos previstos por la ley, esta

garantía reemplaza y excluye todas las otras garantías, condiciones y resguardos, ya sea expresos o

implícitos, legales u otros, incluyendo sin restricción alguna aquellos de comercialización o aptitud

para el uso.

Algunos estados, provincias y naciones no permiten la exclusión o limitación de daños

incidentales o consiguientes, y por este motivo las limitaciones citadas pueden no afectarlo a Ud. Esta

garantía le otorga derechos legales específicos y posiblemente tenga también otros derechos que

varían de un estado a otro, de una provincia a otra, de una nación a otra. Moen le informará sobre el

procedimiento a seguir cuando haga una reclamación bajo garantía. Escriba a Moen Incorporated a

la dirección indicada a continuación. Explique el defecto e incluya la prueba de compra así como su

nombre, dirección, código y número de teléfono

LÍNEAS TELEFÓNICAS

DE SERVICIO:

Para Aclarar sus dudas relacionadas con la

instalación, refacciones, partes y/o garantía de

nuestras llaves, llámenos por cobrar a los

siguientes teléfonos: (84) 88-08- 26, 88-08-27, o

91-800-84-345. FAX (84) 88-08-04.

En los Estados Unidos: 1-800-289-6636

MOEN GARANTÍA LIMITADA DE POR VIDA INFORMACIÓN AL CONSUMIDOR

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A. In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5s7

Colocación del monomando

1. Coloque el monomando sobre el vástago de la válvula como

se muestra arriba. Pruebe la rotación del monomando para

verificar que se detenga en los tres puntos del chapetón. Si

no lo hace, retire el monomando, hágalo girar 180°, y vuelva a

colocarlo sobre el vástago de la válvula.

2. Ajuste el monomando al vástago de la válvula con el tornillo

de torsión provisto.

3. Apriete el botón de presión en el orificio en el monomando

hasta que quede fijo en su sitio.

1. Antes de instalar el chapetón, verifique que se haya retirado la plantilla de yeso de la

válvula para que la terminación quepa correctamente.

2. Atornille el manguito de montaje pasando a través del chapetón de modo que el borde

exterior del manguito presione firmemente contra el mismo, manteniéndolo en su lugar

contra la pared.

Nota:

• La orientación del manguito de montaje depende de si la válvula fue instalada más

cerca o más lejos de la pared terminada.

Optativo

Se ha incluido una hoja de calcomanías optativas en el

paquete. Dichas calcomanías pueden ser utilizadas en

lugar de los números del chapetón de acuerdo a la función

de cada posición de la válvula.

2. Vuelva a colocar la plancha superior en el cuerpo de la válvula mezcladora enroscándolo hacia la derecha y ajustándolo

con la mano (tenga cuidado de no dañar las roscas de la plancha) y luego ajuste _ vuelta adicional con una llave.

Nota:

•La torsión apropiada para la plancha superior dentro del cuerpo de la válvula mezcladora es de 25 in-lbs. (2.8 N-m).

3. Si se va a instalar la terminación más tarde, reinstale la plantilla de yeso para proteger la válvula.

Posición del vástago del monomando para armar el conjunto del adaptador y el monomando

Para designar correctamente la posición del monomando y del flujo de salida, asegúrese de que la marca chata de

ubicación del vástago del monomando esté hacia arriba y en dirección opuesta a la entrada.

Plancha superior

Retire la

plantilla de

yeso

Chapetón

Manguita de

montaje (dado

vuelta)

Manguito de

montaje

(dado vuelta)

Page 7

5. S’assurer que l’orifice « IN » de la pièce

coulée est dirigé vers le bas, raccorder la

sortie de la soupape d’alimentation

principale à l’entrée du robinet coupleur à

l’aide d’un tube d’eau en cuivre de 12,7

mm. Si la soupape d’alimentation est

munie de deux sorties, l'une d'elles doit

être bouchée.

ATTENTION :

Pour les installations en cuivre (cuivre à

cuivre), il faut enlever la cartouche du

corps de la soupape avant de la faire

chauffer. Sinon, la cartouche risque

d’être endommagée. Consulter les

directives « Retrait de la cartouche pour un raccord CC/Réparation ».

Position de la tige de poignée pour l’assemblage de l’adaptateur de

poignée/poignée

Pour s’assurer que le débit de sortie et la désignation de poignée sont corrects,

s'assurer que le repère des parties plates de la tige de poignée est dirigé vers le

haut et dans la direction opposée de l’entrée.

6

DIRECTIVES D’INSTALLATION

"12

" TYP56

" TYP44

"

(12.7 mm)

1/2

FINISHED

WALL

FLOOR

Assemblage des raccords de sortie

Trois des sorties du robinet coupleur offrent trois fonctions distinctes. Voici les

désignations de sortie suggérées :

•Sortie 1 : Pomme de douche

•Sortie 2 : Douche à main (45o à gauche de la sortie 1)

•Sortie 3 : Non utilisée

•Sortie 4 : Bec de baignoire, pomme de douche additionnelle ou douche à

main (90o à gauche de la sortie 1)

NOTE : Ne bloquer aucune sortie. Si l'une des sorties n’est pas utilisée (p. ex., le bec de

baignoire), la raccorder à la conduite de l’une des autres sorties. Cette soupape ne

doit pas être utilisée comme robinet de sectionnement car cela risquerait

d'endommager la plomberie de la douche. Pour éliminer les risques de débits

croisés, s’assurer que les soupapes sont intégrées à la soupape d’alimentation ou

installées dans les conduites d’alimentation en eau chaude et en eau froide.

Soupape

Devant

Chaud Froid

Soupape

Arrière

Retrait de la cartouche pour raccord CC/réparation

1. Enlever l’arrêt d’enduit mais ne pas le jeter.

2. À l’aide d’une clé anglaise placée sur les parties plates, ôter la plaque

supérieure filetée extérieure en tournant dans le sens contraire des

aiguilles d’une montre.

3. Saisir la cartouche par la tige à l’aide de pinces et tirer bien droit sur la

cartouche.

4. La soupape Posi-Temp peut

être raccordée à l’inverseur,

comme le montre le schéma à

gauche. L’orifice supérieur

(orifice de douche) sur la

soupape Posi-Temp devra être

bouché.

Installation de la cartouche dans le corps du robinet coupleur

1. Placer la cartouche dans le corps du robinet coupleur en insérant les

deux broches repères du fonds de la cartouche (illustr. 1) dans les deux

trous repères du corps du robinet coupleur (illustr. 2). S’assurer (a) que la

clé repère sur le dessus de la cartouche est dirigée vers le haut dans la

direction opposée à l’entrée et que (b) le repère des parties plates de tige

est dirigé vers le haut dans la direction opposée de l’entrée (illustr. 3).

Boucher

l’orifice de

douche

Vue

arrière

Sortie 1

Sortie 2

Sortie 4

Sortie 3

(non utilisée)

Entrée

Exemple de la plomberie d’entrée

si la sortie 4 n’est pas utilisée

Boîtier de soupape

Tige

Douille de tige de poignée

Arrêt d’enduit

Cartouche de

plaque supérieure

Cartouche

Illustr. 1

Illustr. 2

Broches

repères de la

cartouche

Trous repères du

boîtier de la soupape

Repères des

parties plates

de tige

Illustr. 3

Entrée

Clé

repère

TYP 56

TYP 44

PLANCHER

MUR

FINI

(12,7 mm)

1/2

12

Pièce moulée principale

1. La distance entre les centres de la soupape d’alimentation et du robinet coupleur doit être d’au

moins 305 mm pour qu'il y ait l’espace nécessaire à l’installation des rosaces de robinet coupleur

et de soupape d’alimentation.

2. Dans le mur fini, faire un trou d’au moins 70 mm de diamètre pour l’installation du robinet coupleur.

3. Utiliser l’arrêt d’enduit comme guide pour installer le robinet à la profondeur appropriée dans le

mur. L ’arrêt d’enduit doit être égal au mur fini lorsque le robinet coupleur est installé. Il est possible

que l’entrée du robinet coupleur ne soit pas alignée avec la sortie de la soupape de douche. Par

exemple, le robinet coupleur installé avec Posi-Temp a un double coude, comme l'illustre l’image

à gauche.

Page 8

INS288

Les robinets fabriqués à partir d’alliages de laiton et de plomb pourraient ajouter de

petites quantités de plomb à l’eau si celle-ci était stagnante et qu’elle touchait au laiton.

La quantité de plomb ajoutée par tout robinet est plus élevée lorsque le robinet est

nouveau. Les directives suivantes peuvent aider à réduire l’exposition au plomb

provenant du robinet et d’autres parties de la tuyauterie :

• T oujours faire couler l’eau pendant quelques secondes avant de s’en servir pour boire

ou cuire.

• Utiliser uniquement de l’eau froide pour boire ou cuire.

• Si on désire rincer l’eau stagnante de la tuyauterie et des raccords, faire couler l’eau

froide jusqu’à ce que sa température baisse, indiquant ainsi que l’eau provient

maintenant de la conduite d’eau extérieure.

Si la quantité de plomb dans votre eau vous inquiète, la faire tester par un laboratoire

local certifié.

Les produits Moen ont été fabriqués selon les normes de qualité et de main-d’œuvre les plus élevées.

Moen garantit à la personne ayant acheté le robinet originalement, aussi longtemps qu’elle reste propriétaire

de la maison, (période de garantie pour propriétaires), que ce robinet sera libre de toute fuite ou

d’égouttement pendant son usage normal et que toutes les pièces et tous les finis de ce robinet ne

présenteront aucun défaut de matériel et de main-d’œuvre en usine. L’achat par tout autre consommateur

(acheteur à des fins industriels, commerciales et d’affaires) sera garanti pendant 5 ans à compter de la date

d’achat originale (période de garantie pour non-propriétaires).

Si ce robinet fuit ou dégoutte durant la période de garantie, Moen remplacera GRATUITEMENT les pièces

de remplacement requises pour remettre le robinet en parfait état et remplacera GRATUITEMENT toute pièce

ou tout fini dont le matériel, la fabrication ou la main-d’œuvre, lors d’une installation, d’un usage et d’un

service normaux, s’avère défectueux. On peut obtenir les pièces de remplacement en composant le

1 800 465-6130, ou en écrivant à l’adresse indiquée sous la preuve d’achat. Le reçu de vente original du

consommateur ayant acheté le robinet initialement, doit accompagner toute réclamation. Les défauts ou les

dommages causés par l’utilisation de pièces non fournies par Moen ne sont pas couvertes par cette garantie.

Cette garantie s’applique uniquement aux robinets achetés après décembre 1995 et entre en vigueur à

compter de la date d’achat indiquée sur le reçu de caisse du consommateur.

Cette garantie est vaste car elle couvre le remplacement de toute pièce ou de tout fini défectueux.

Cependant, les dommages causés par une erreur l’installation, un abus du produit, une mauvaise utilisation

du produit ou l’utilisation de nettoyeurs contenant des agents abrasifs, de l’alcool ou des solvants

organiques, qu’ils soient utilisés par un entrepreneur, une entreprise de service ou le consommateur, sont

exclus de cette garantie. Moen n’est pas responsable des frais de main-d’œuvre ni de tous dommages

survenus durant l’installation, la réparation ou le remplacement, ni des dommages indirects ou consécutifs,

des pertes, des blessures ou des coûts connexes à ce robinet. Sauf lorsque prévu par la loi, cette garantie

remplace et exclut toute autre garantie et condition, qu’elles soient exprimées ou sous-entendues,

obligatoires ou autres, y compris sans restriction, celle de commercialisation ou d’aptitude d’utilisation.

Certains pays, certains États et certaines provinces, ne permettent aucune exclusion, ni limitation suite

aux dommages indirects ou consécutifs. Les limitations ou les exclusions ne s’appliquent donc pas dans ces

cas. Cette garantie accorde des droits juridiques et il est possible que d’autres droits soient applicables selon

l’état, la province ou le pays précis. Moen avisera le consommateur de la procédure à suivre pour soumettre

une réclamation. Il suffit d’écrire à Moen incorporée, d’expliquer le défaut et d’inclure une preuve d’achat,

d’inscrire son nom, adresse ainsi que code régional et numéro de téléphone.

APPELER SANS FRAIS NOTRE

SERVICE À LA CLIENTÈLE

Appeler notre Service à la clientèle pour obtenir des

renseignements sur nos produits, leur l’installation ou sur

notre garantie.

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U. :1 800 289-6636

Au Mexique :

(84) 88-08-26, 88-08-27,

o 91-800-84-345

GARANTIE À VIE LIMITÉE DE MOEN POUR ROBINETS INFORMATION POUR LE CONSOMMATEUR

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

Au Canada, Moen inc., 2816 rue Bristol, Oakville (Ontario), L6H 5S7

Installation de la poignée

1. Placer la poignée sur la tige de soupape, comme illustré ci-

dessus. Essayer de tourner la poignée pour s’assurer qu’elle

s’arrête aux trois arrêts prévus sur la rosace. Sinon, enlever la

poignée, la faire pivoter de 180o et la replacer sur la tige de

soupape.

2. Visser la poignée sur la tige de poignée à l’aide de la vis à six

lobes fournie.

3. Pousser sur le bouton de finition dans le trou de poignée

jusqu'à ce qu’il s’enclenche.

1. Avant d’installer la rosace, s’assurer que l’arrêt d’enduit a été retiré de la soupape pour

installer la garniture correctement.

2. Visser le manchon de montage en le passant par la rosace pour que le bord extérieur

du manchon soit fermement appuyé contre la rosace en le gardant bien en place contre

le mur.

Note :

•L’orientation du manchon de montage varie selon la distance qui sépare la soupape

installée du mur fini.

Facultatif

Une feuille de décalcomanie optionnelle est incluse dans

l’emballage. Il est possible d’utiliser les autocollants fournis

au lieu des numéros sur la rosace, selon la fonction de la

position de la soupape.

2. Réassembler la plaque supérieure sur le corps du robinet coupleur en la faisant pivoter à la main dans le sens des

aiguilles d’une montre jusqu’à ce qu’elle soit bien fixée (manipuler les filetages de la plaque supérieure avec grand soin)

et la resserrer d’un autre demi-tour à l’aide d’une clé.

Note :

•La plaque supérieure doit être serrée au couple (à 11,3 kg) dans le corps du robinet coupleur. (2.8 N-m).

3. Si la garniture doit être installée plus tard, réinstaller l’arrêt d’enduit pour protéger la soupape.

Position de la tige de poignée pour l’assemblage de l’adaptateur de poignée/poignée

Pour que le débit de sortie et la désignation de poignée soient corrects, s'assurer que le repère des parties plates de la

tige de poignée est dirigé vers le haut dans la direction opposée de l’entrée.

Plaque

supérieure

Retrait de

l’arrêt d’enduit

Rosace

Manchon de montage

(réversible - voir

l’illustr. ci-dessus)

Machon de

montage

(inversé)

Loading...

Loading...