Moen 8303 User Manual

MODEL 8303

CHANNEL LOCKS

PINZAS DE EXTENSION

PINCES MULTIPRISES

ADJUSTABLE WR ENCH

LLAVE AJUSTAB LE

CLÉ ANGLAISE

PENETRATING OIL

ACEITE PENETRANTE

HUILE DE DÉGRIPPAGE

FLASHLIGHT

LINTERNA

LAMPE DE POCHE

PLIERS

PINZAS

PINCES

FLEXIBLE SUPPLIES

LINEAS DE ALIMENTACION FLEXIBLES

CONDUITES D'ALIMENTATION SOUPLES

BASI N WRENC H

LLAVE DE FREGADERO

CLÉ DE LAVABO

(2)

SAFETY GLASSES

GAFAS DE SEGURIDAD

LUNETTES DE SÉCURITÉ

5/8" DEEP WELL SOCKET

LLAVE A COPA DE 5/8"

CLÉ À DOUILLE

PROFONDE DE 5/8 PO

PIPE WRENCH

LLAVE DE TUBO

CLÉ DE LAVABO

FLATBLADED SCREWDRIVER

DESTORNILLADOR DE PALA

TOURNEVIS À LAME PLATE

PHILLIPS SCREWDRIVER

DESTORNILLADOR DE ESTRELLA

TOURNEVIS À POINTE CRUCIFORME

7/32" HEX WRENCH

LLAVE HEXAGONAL

CLÉ HEXAGONALE

C O M M E R C I A L

Single Deck-mount, Non-mixing, Battery Powered

Electronic Faucet

MODELO 8303

Llave Electrónica (Electrónica) De Baterías Sin Mezcladora,

Montaje En Plataforma Sencilla

MODÈLE 8303

Robinet Elétronique À Pile, Montage Simple Sur Comptoir,

Sans Mitigeur

HELPFUL TOOLS HERRAMIENTAS UTILES OUTILS UTILES

For safety and ease of

faucet replacement, Moen

recommends the use of

these helpful tools.

INS 238

ENGLISH ESPAÑOL FRANÇAIS

KEEP INSTRUCTIONS FOR

FUTURE REFERENCE

Thank you for purchasing a quality MOEN faucet.

With simple care and maintenance, it will provide

you with many years of reliable performance.

Please read all instructions before installation.

Questions During Installation?

1-800-BUY MOEN

(1-800-289-6636)

Toronto 905-829-3400

Rest of Canada 1-800-465-6130

GUARDE ESTAS INSTRUCCIONES PARA

REFERENCIA FUTURA

Gracias por haber comprado una mezcladora de

alta calidad de MOEN. Con un cuidado y

mantenimiento sencillos, le brindará muchos

años de servicio fiable. Por favor lea todas las

instrucciones antes de instalar.

¿Preguntas durante la instalación?

(84) 88-08-26,

88-08-27,

o 91-800-84-345

CONSERVER CES DIRECTIVES POUR

RÉFÉRENCE ULTÉRIEURE

Merci d’avoir acheté un robinet de qualité MOEN.

Avec un peu de soin et d’entretien, ce robinet

vous donnera plusieurs années de rendement

fiable. Lire attentivement toutes les directives

avant de débuter l’installation.

Des questions lors de l’installation?

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U.: 1 800 289-6636

Para la seguridad y

facilidad de repuesto de la

mezcladora, Moen

recomienda las siguientes

herramientas.

Par mesure de sécurité et

pour faciliter l’installation,

Moen suggère l’utilisation

des outils survants.

TIPS FOR REMOVAL OF

OLD FAUCET:

CAUTION: Always turn water OFF before

removing existing faucet or disassembling the

faucet. Open faucet handles to relieve water

pressure and insure that complete water shut-off

has been accomplished.

Complies with CSA B125-98 En cumplimiento de CSA B125-98 Conformément à CSA B125-98

SUGERENCIAS PARA QUITAR LA VIEJA

MEZCLADORA:

ADVERTENCIA: Siempre desconecte el agua

antes de desmontar o desarmar la mezcladora.

Abra las manijas de la mezcladora para

desahogar la presión del agua y asegurarse que

se ha logrado un cierre completo del agua.

SUGGESTIONS POUR ENLEVER L’ANCIEN

ROBINET :

ATTENTION : Toujours couper l’alimentation en

eau avant d’enlever ou de démonter le robinet.

Ouvrir la poignée du robinet pour libérer la

pression d’eau et pour s’assurer que l’alimentation

en eau a bien été coupée.

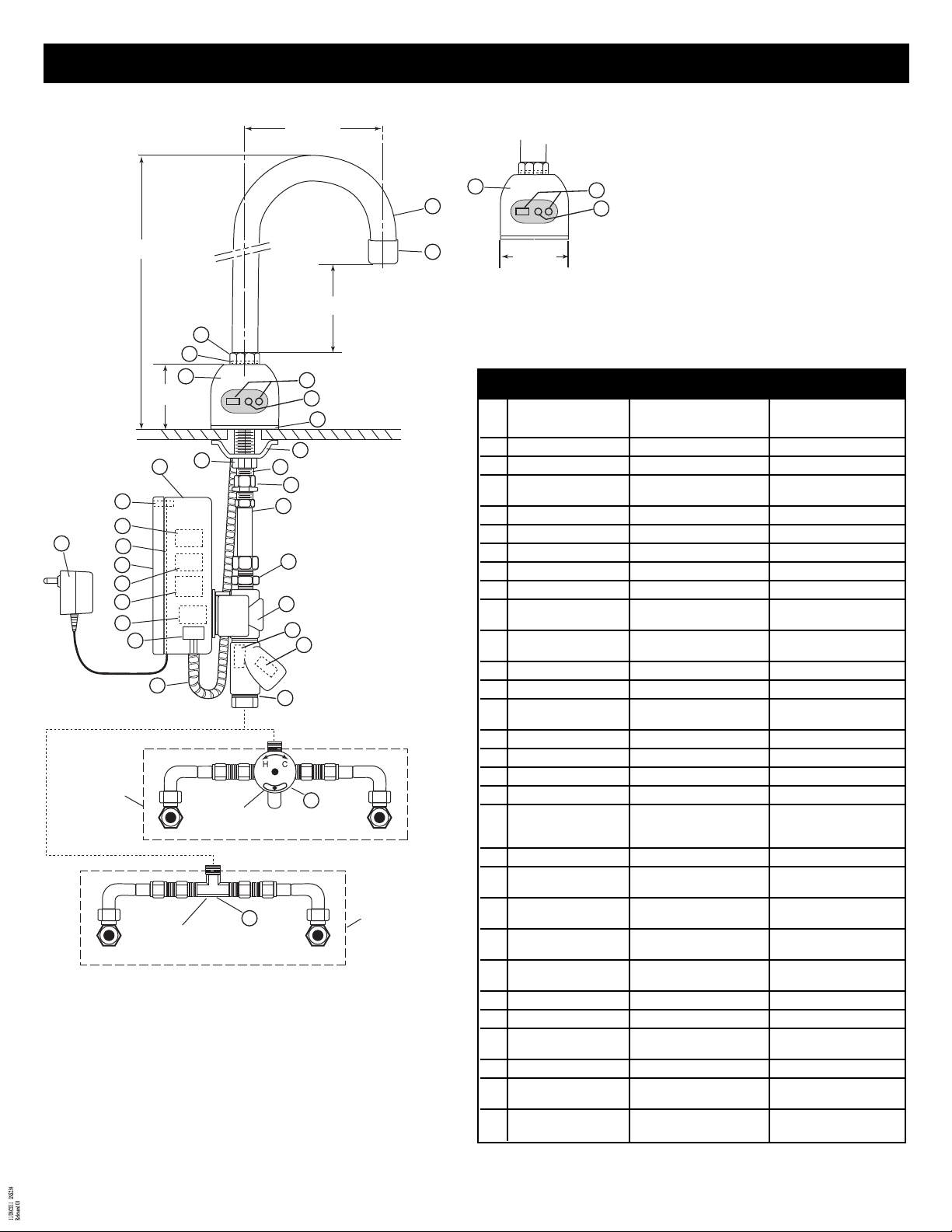

2 "

5 3/8"

2 3/8"

6"

12 1/4"

7

18

8

20

5

6

9

29

4

30

2

15

3

1

16

17

12

25

10

11

24

28

23

22

21

13

14

1

26

27

26

27

19

19

P/N 104424

P/N 104425

Optional

installation

for tempered

water

Instalación

opcional para

agua templada

Installation

optionnelle pour

eau tempérée

Optional

installation

for tempered

water

Instalación

opcional para

agua templada

Installation

optionnelle pour

eau tempérée

PARTS DIAGRAM DI´ÁGRAMA DE PIEZAS TABLEAU DES PIÈCES

Parts

Provided

OPTIONAL

Angle Stop By Others

Supply Lines By Others

OPCIONAL

Tope Angular provisto por otros

Líneas de Suministro provistas por otros

OPTIONNEL

Arrêt angulaire non inclus

Conduites d’alimentation non incluses

1 INS238

(Option de plate-forme)

ENGLISH ESPAÑOL FRANÇAIS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Faucet Body

Aerator

Gasket

Mounting bolt/

supply rod

Mounting washer

Mounting nut

Inline filter

Nylon washer

Control box

Rubber seal

Control box lid

Screws (4)

Supply tube

Compression

adapter

Spout

Spout nut

Spout o-ring

Check valve

Mixing valve (104424)

Mixing tee (104425)

(optional)

Solenoid valve

Sensor eye cable

Sensor eye

pin connector

Sensor eye

pin receptor*

AC/battery

receptor*

Batteries* (provided)

Sensors

LED indicator

light

Circuit board*

AC adapter

(optional)

Compression

reducer

*: interior ha la caja de control

*: intérieur du boîtier de commande

Partes

Suministradas

Cuerpo de la

Mezcladora

Aireador

Empaque

Perno de Montaje

Arandela de Montaje

Tuerca de Montaje

Filtro En-Línea

Arandela

Caja Contenedora

Sello de Hule

Tapa de la caja

Tornillos (4)

Tubo de Suministro

Adaptador de

Compresión

Boquilla

Tuerca de la boquilla

O-ring de la boquilla

Válvula Check

Válvula mezcladora (104424)

T mezcladora (104425)

(opcional)

Válvula solenoide

Cable del Ojo

Sensor

Conector del Pin

Receptor del Pin*

Receptor de bateria de

Corriente Alterna*

Baterías* (suministradas)

Sensores

Luz Indicadora

LED

Circuito Impreso

Adaptador de Corriente

Alterna (opcional)

Reductor de

Compresión

*: interior to control box

Pièces

Fournies

Corps de robinet

Aérateur

Joint d’étanchéité

Boulon de montage/

tige d’alimentation

Rondelle de montage

Écrou de montage

Filtre de conduite

Rondelle en nylon

Boîtier de commande

Dispositif d’étanchéité

en caoutchouc

Couvercle du boîtier

de commande

Tube d’alimentation

Adaptateur de

compression

Écrou de bec

Joint torique de bec

Clapet de non-retour

Robinet mélangeur(104424)

«T» mitigeur (104425)

(optionnel)

Électrovanne

Câble des yeux du

capteur

Raccord de la goupille

des yeux du capteur

Récepteur de la goupille

des yeux du capteur*

Récepteur de

pile/C.A.*

Piles* (fournies)

Capteurs

Lumière du voyant

Carte à circuit imprimé*

Adaptateur C.A.

(optionnel)

Réducteur de

compression

Vis (4)

Bec

DEL

OPERATIONS

Electronic Faucet

Operation and Installation

Instructions for Electronic

Faucets-Battery-Powered

The battery-powered faucet is designed for ease

of installation and provides a reliable, convenient,

economical and sanitary system for high-volume

users, such as hospitals, transportation terminals,

restaurants, schools, sports arenas, office

buildings and municipalities. It can be installed by

one tradesman without electrical hook-up.

INSTALLATION INSTRUCTIONS

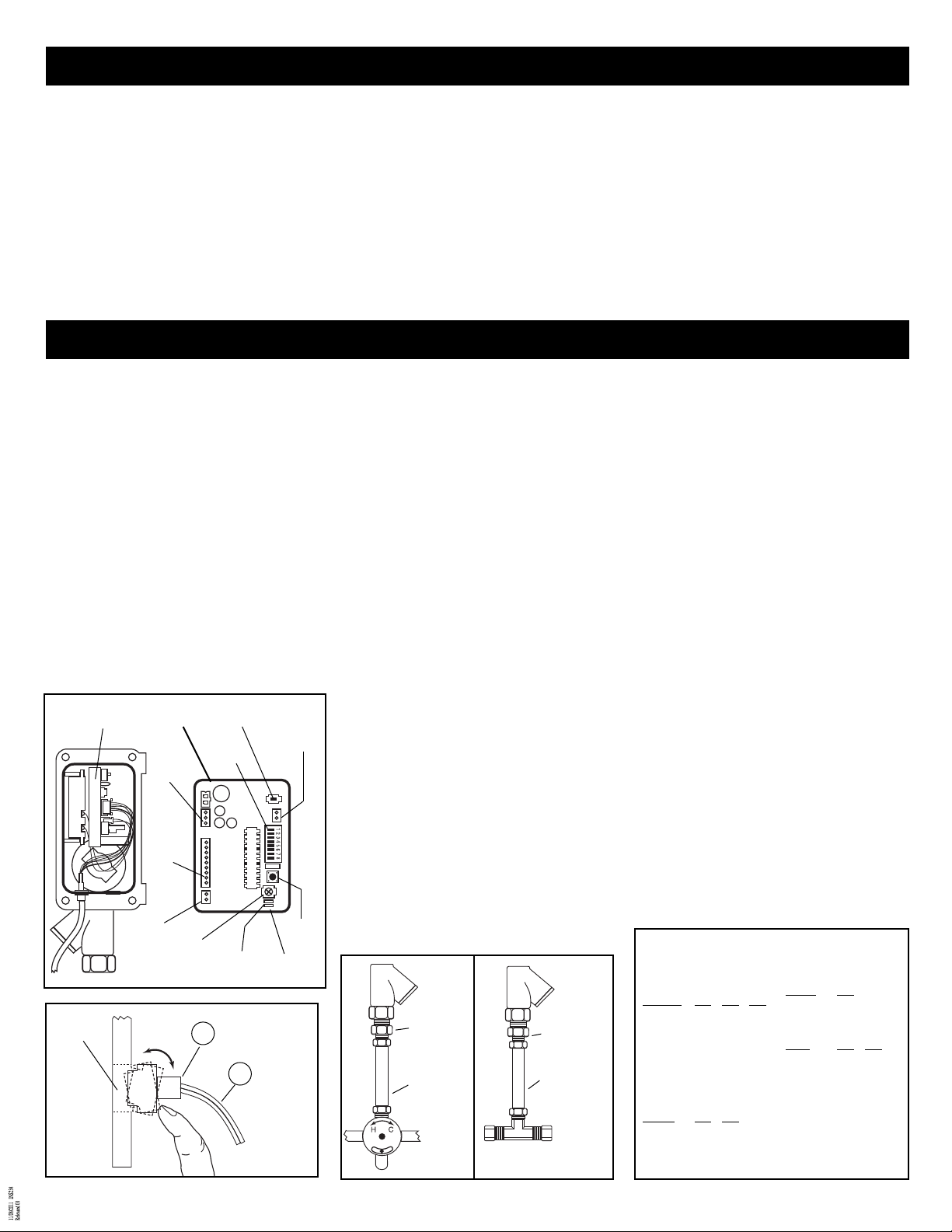

DRY TEST

ATTENTION: To insure proper operation, before

installing the faucet, a “DRY TEST” is

recommended.

1. Take off the control box lid (11) by removing

screws (12) with hex wrench.

2. Connect the sensor eye connector (22) at the

end of the sensor eye cable (21) onto the

circuit board (28) inside the control box (9)

Refer to illustration “A”.

3. Slide battery housing out of control box (9)

and install batteries (included) and slide

battery housing back into control box (9).

Insert the battery housing connector onto the

circuit board (28). The lights on the circuit

board should blink red/green/red.

4. Place your hand in front of the sensor (27) to

operate the faucet and listen for a “clicking”

sound.

5. Remove your hand and listen for a softer

“clicking” sound. The “clicking” sounds

A

Sensor

Lens

Circuit board

side view

Sensor

eye

cable pin

receptor

Solenoid

pin

receptor

Circuit board

front view

AC

receptor

Sensor

distance

adjustor

26

DIP

switches

Sensors

AC/DC switch

DC receptor

Green

LED

Sensor

21

Eye Cable

Reset

button

Red

LED

B

Operation:

1. The faucet operates by emitting a continuous

infared beam from the sensor.

2. As the user enters the beam’s effective

range, a red light flashes one time to alert the

user that the faucet will operate. As long as

the user is in the beam’s range, the beam is

reflected into the receiver circuitry and the

system will operate.

3. When the user exits out of range, the sensor

sends a signal to the solenoid for closure.

The sensor then automatically resets and is

ready for the next user.

indicate that the faucet is working properly. If

there is no light or sound, please contact

Moen at 1-800-289-6636.

6. The sensors are equipped with angular

adjustments. The factory setting is in the

center or straight position from the faucet.

Adjustment is most easily performed before

the faucet is installed. The adjustment is

located inside the faucet body (1) behind the

LED indicator light (27) Refer to illustration

“B”.

7. If you are ready to install the faucet,

disconnect the sensor eye connector (22) at

the end of the sensor eye cable (21) from the

circuit board (28).

8. Slide gasket (3) over sensor eye cable and

onto faucet.

9. Set faucet on sink and install mounting

washer (5) and mounting nut (6). Tighten

mounting nut (6) to secure the faucet to the

sink.

10. Attach compression reducer (30) to the

supply rod (4). Also attach compression

adapter (14) to the solenoid valve outlet.

11. Connect the sensor eye connector (22) at the

end of the sensor eye cable (21) onto the

circuit board (28). Properly seat both the

sensor eye cable seal and cable into the

control box slot on the left. Reinstall control

box lid (11) and tighten screws (4) to insure

the control box is water-resistant. NOTE:

make sure that the rubber seal plug is in

installed in the AC adapter control box slot

(on the right).

12. Connect 3/8” copper tube (supplied) between

the supply rod (4) and the solenoid valve

(20). Tighten compression fittings.

C

Compression

adapter

Optional

Supply

Tube

provided

by

installer

D

Compression

adapter

Optional

Supply

Tube

provided

by installer

4. Low battery indicator light comes on when

battery is low.

Caution: Avoid installing the faucet where

sensor faces a stainless steel wall or other

reflective surface within the active range of

sensors. Avoid facing another infrared sensor. It

may cause faucet to activate unnecessarily.

NOTE: The reset button must be pressed

after changing the battery in order to ensure the

faucet functions properly.

13. Insert white nylon washer (8) into swivel nut

on filter body inlet.

14. A) For standard (pre-tempered or cold water)

installation, attach water supply to inlet of

in-line filter/check valve body.

B) If a tempered water installation is needed,

attach mixing/check valve (optional) to the

inlet of in-line filter/check valve body.

Connect water supply lines to

mixing/check valve. Refer to illustration

“C”. NOTE: USE THREAD SEAL TAPE

FOR ALL THREADED CONNECTIONS.

C) Refer to Illustration D for the optional

mixing tee installation.

15. Mount faucet spout (15) to faucet body (1)

and secure with spout o-ring (17) and spout

nut (16).

16. Turn on water and check for leaks. Place

hand in front of sensor to activate water.

Remove hands and the water should stop. If

not, refer to troubleshooting guide.

17. For timing adjustments, refer to instructions

on the inside of the control box lid. Refer to

Illustration E.

A) Note: Be sure to depress the re-set

button, located on the circuit board, after

each adjustment.

B) The factory settings are:

Sensor Distance Adjustment =

approximately 3.5 inches from the lens

Time Delay to shut-off after hands are

removed = 1 sec seconds

Auto – shutoff = 30 seconds

CONTROL BOX INSTRUCTIONS

E

ADJUSTMENTS: (DIP Switches):

1. Shut-off time delay

after hands are removed:

Time Delay SW1 SW2 SW3

1 Sec on on on

2 Sec on on off

3 Sec on off on

4 Sec on off off

5 Sec off on on

6 Sec off on off

7 Sec off off on

8 Sec off off off

2. Auto Time-Out Feature:

Time-Out SW4 SW5

0 Sec on on

15 Sec on off

30 Sec off on

60 Sec off off

3. Sensor Distance:

Distance SW6

3.5 – 12" on

10 – 24" off

4. Faucet Setting:

Setting SW7 SW8

Faucet on off

SENSOR DISTANCE ADJUSTMENT

(SDA): Preset at factory. If

adjustment is needed; Locate

potentiometer with Phillips Head

adjuster screw. Turn adjuster screw

clockwise to increase SDA, counter

clockwise to decrease SDA.

2

Loading...

Loading...