Page 1

INS237

MODEL 8301

Deck-mount (4-inch center) Non-Mixing Battery Powered

Electronic Faucet

MODELO 8301

Llave Electrónica De Baterías, No Mezcladora, Montaje En

Plataforma (4 Pulgadas Del Centro)

MODÉLE 8301

Robinet Elétronique À Pile, Montage Simple Sur Comptoir

(Entraxe De 4 po), Sans Mitigeur

For safety and ease of

faucet replacement, Moen

recommends the use of

these helpful tools.

Para la seguridad y

facilidad de repuesto de la

mezcladora, Moen

recomienda las siguientes

herramientas.

Par mesure de sécurité et

pour faciliter l’installation,

Moen suggère l’utilisation

des outils survants.

HELPFUL TOOLS HERRAMIENTAS UTILES OUTILS UTILES

ENGLISH ESPAÑOL FRANÇAIS

KEEP INSTRUCTIONS FOR

FUTURE REFERENCE

Thank you for purchasing a quality MOEN faucet.

With simple care and maintenance, it will provide

you with many years of reliable performance.

Please read all instructions before installation.

Questions During Installation?

1-800-BUY MOEN

(1-800-289-6636)

Toronto 905-829-3400

Rest of Canada 1-800-465-6130

TIPS FOR REMOVAL OF

OLD FAUCET:

CAUTION:

Always turn water OFF before

removing existing faucet or disassembling the

faucet. Open faucet handles to relieve water

pressure and insure that complete water shut-off

has been accomplished.

GUARDE ESTAS INSTRUCCIONES PARA

REFERENCIA FUTURA

Gracias por haber comprado una mezcladora de

alta calidad de MOEN. Con un cuidado y

mantenimiento sencillos, le brindará muchos

años de servicio fiable. Por favor lea todas las

instrucciones antes de instalar.

¿Preguntas durante la instalación?

(84) 88-08-26,

88-08-27,

o 91-800-84-345

SUGERENCIAS PARA QUITAR LA VIEJA

MEZCLADORA:

ADVERTENCIA: Siempre desconecte el agua

antes de desmontar o desarmar la mezcladora.

Abra las manijas de la mezcladora para

desahogar la presión del agua y asegurarse que

se ha logrado un cierre completo del agua.

CONSERVER CES DIRECTIVES POUR

RÉFÉRENCE ULTÉRIEURE

Merci d’avoir acheté un robinet de qualité MOEN.

Avec un peu de soin et d’entretien, ce robinet

vous donnera plusieurs années de rendement

fiable. Lire attentivement toutes les directives

avant de débuter l’installation.

Des questions lors de l’installation?

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U.: 1 800 289-6636

SUGGESTIONS POUR ENLEVER L’ANCIEN

ROBINET :

ATTENTION : Toujours couper l’alimentation en

eau avant d’enlever ou de démonter le robinet.

Ouvrir la poignée du robinet pour libérer la

pression d’eau et pour s’assurer que l’alimentation

en eau a bien été coupée.

Complies with CSA B125-98 En cumplimiento de CSA B125-98 Conformément à CSA B125-98

PLIERS

PINZAS

PINCES

5/8" DEEP WELL SOCKET

LLAVE A COPA DE 5/8"

CLÉ À DOUILLE

PROFONDE DE 5/8 PO

CHANNEL LOCKS

PINZAS DE EXTENSION

PINCES MULTIPRISES

FLEXIBLE SUPPLIES

LINEAS DE ALIMENTACION FLEXIBLES

CONDUITES D'ALIMENTATION SOUPLES

PENETRATING OIL

ACEITE PENETRANTE

HUILE DE DÉGRIPPAGE

SAFETY GLASSES

GAFAS DE SEGURIDAD

LUNETTES DE SÉCURITÉ

(2)

ADJUSTABLE WRENCH

LLAVE AJUSTABLE

CLÉ ANGLAISE

FLASHLIGHT

LINTERNA

LAMPE DE POCHE

BASIN WRENCH

LLAVE DE FREGADERO

CLÉ DE LAVABO

PIPE WRENCH

LLAVE DE TUBO

CLÉ DE LAVABO

7/32" HEX WRENCH

LLAVE HEXAGONAL

CLÉ HEXAGONALE

FLATBLADED SCREWDRIVER

DESTORNILLADOR DE PALA

TOURNEVIS À LAME PLATE

PHILLIPS SCREWDRIVER

DESTORNILLADOR DE ESTRELLA

TOURNEVIS À POINTE CRUCIFORME

! ! !

Page 2

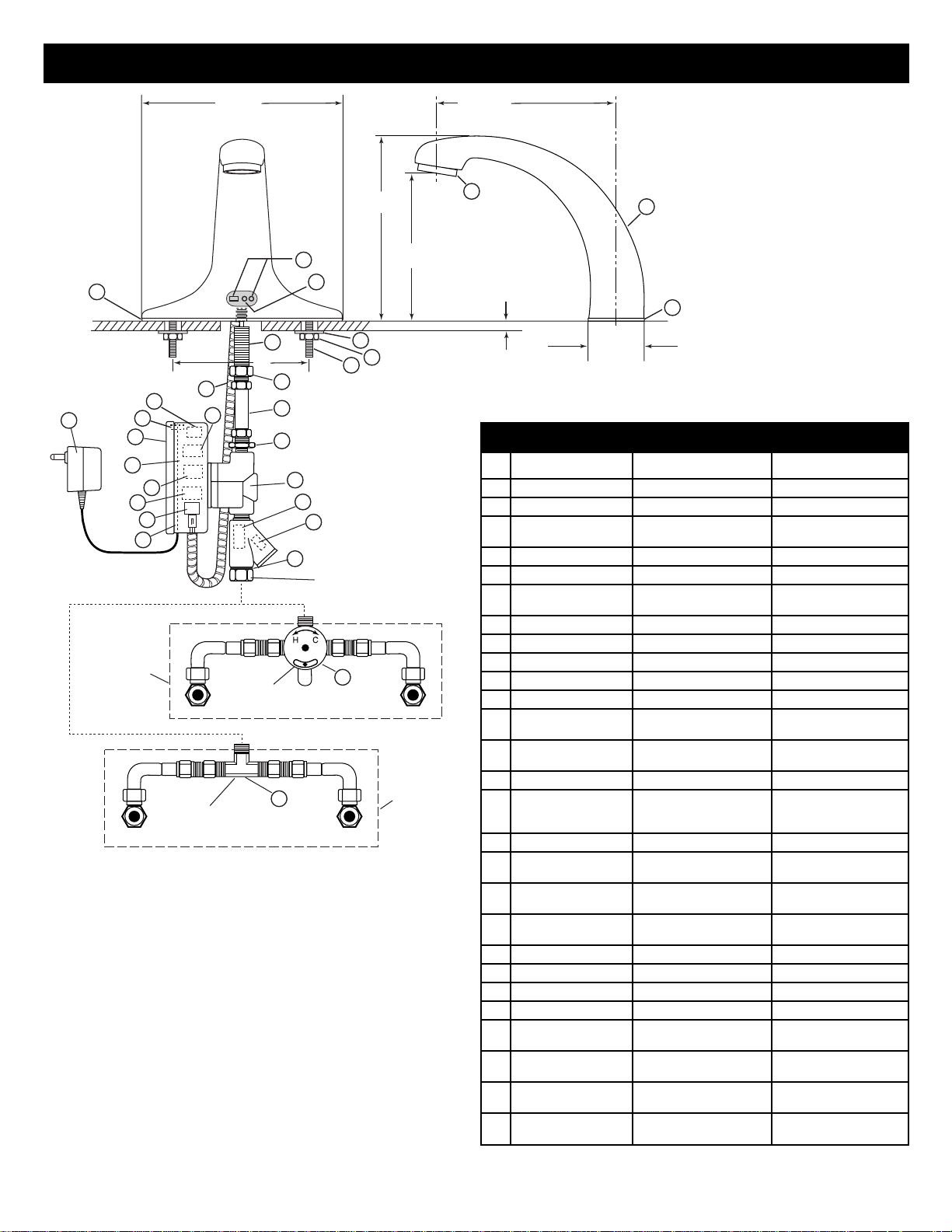

23

25

4

11

1

3

5

2

7

27

28

21

19

20

8

15

9

16

16

6

18

12

26

22

13

24

14

10

3

17

P/N 104424

4"

5 7/8" 4 3/4"

P/N 104425

4 1/2"

3 3/4"

2 1/4"

3/8" Female Compression Inlet

Entrada hembra de compresión

de 3/8 de pulgada

Entrée de compression femelle

3/8 po

Deck Application

Dependent

Dependiente de la

aplicación de la

plataforma

Varie selon l’installation

sur comptoir

Optional

installation

for tempered

water

Instalación

opcional para

agua templada

Installation

optionnelle pour

eau tempérée

Optional

installation

for tempered

water

Instalación

opcional para

agua templada

Installation

optionnelle pour

eau tempérée

2 INS237

PARTS DIAGRAM DI´ÁGRAMA DE PIEZAS TABLEAU DES PIÈCES

ENGLISH ESPAÑOL FRANÇAIS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Faucet body

Mounting bolt (2)

Gasket

Mounting slotted

washer (2)

Mounting nut (2)

Supply rod

Compression

adapter

Inline filter

Nylon washer

Control box

Aerator

Screws (4)

Control box lid

Rubber seal

Check valve

Mixing valve (104424)

Mixing tee (104425)

(optional)

Solenoid valve

Sensor eye cable

Sensor eye

pin receptor*

Sensor eye

pin connector

AC/battery receptor*

Batteries* (provided)

Sensors

Circuit board*

LED indicator

light

AC adapter

(optional)

Copper supply tube

Compression

reducer

Cuerpo de la llave

Perno de montaje (2)

Empaque

Arandela ranurada

de montaje (2)

Tuerca de montaje (2)

Tubo de suministro

Adaptador de

compresión

Filtro en-línea

Arandela

Caja de control

Aireador

Tornillos (4)

Tapa de la caja

Sello de hule

Válvula Check

Válvula mezcladora (104424)

T mezcladora (104425)

(opcional)

Válvula solenoide

Cable del ojo sensor

Receptor

del pin*

Conector

del pin

Receptor AC*

Baterías* (suministradas)

Sensores

Circuito impreso*

Luz indicadora

LED

Adaptador de corriente

alterna (opcional)

Tubo de suministro de

cobre

Adaptador de

compresión

Corps du robinet

Boulon de montage (2)

Joint d’étanchéité

Rondelle fendue

de montage (2)

Écrou de montage(2)

Tige d’alimentation

Adaptateur de

compression

Filtre de conduite

Rondelle en nylon

Boîtier de commande

Aérateur

Vis (4)

Couvercle du boîtier

de commande

Dispositif d’étanchéité

en caoutchouc

Clapet de non-retour

Robinet mélangeur(104424)

«T» mitigeur (104425)

(optionnel)

Électrovanne

Câble des yeux du

capteur

Récepteur de la goupille

des yeux du capteur

Raccord de la goupille

des yeux du capteur

Récepteur de pile/C.A.*

Piles* (fournies)

Capteurs

Carte à circuit imprimé*

Lumière du voyant

DEL

Adaptateur C.A.

(optionnel)

Tube d’alimentation

en cuivre

Réducteur de

compression

Parts

Provided

Partes

Suministradas

Pièces

Fournies

*: interior to control box

*: interior ha la caja de control

*: intérieur du boîtier de commande

OPCIONAL

Tope Angular provisto por otros

Líneas de Suministro provistas por otros

OPTIONNEL

Arrêt angulaire non inclus

Conduites d’alimentation non incluses

(Option de plate-forme)

OPTIONAL

Angle Stop By Others

Supply Lines By Others

Page 3

OPERATIONS

INSTALLATION INSTRUCTIONS

3

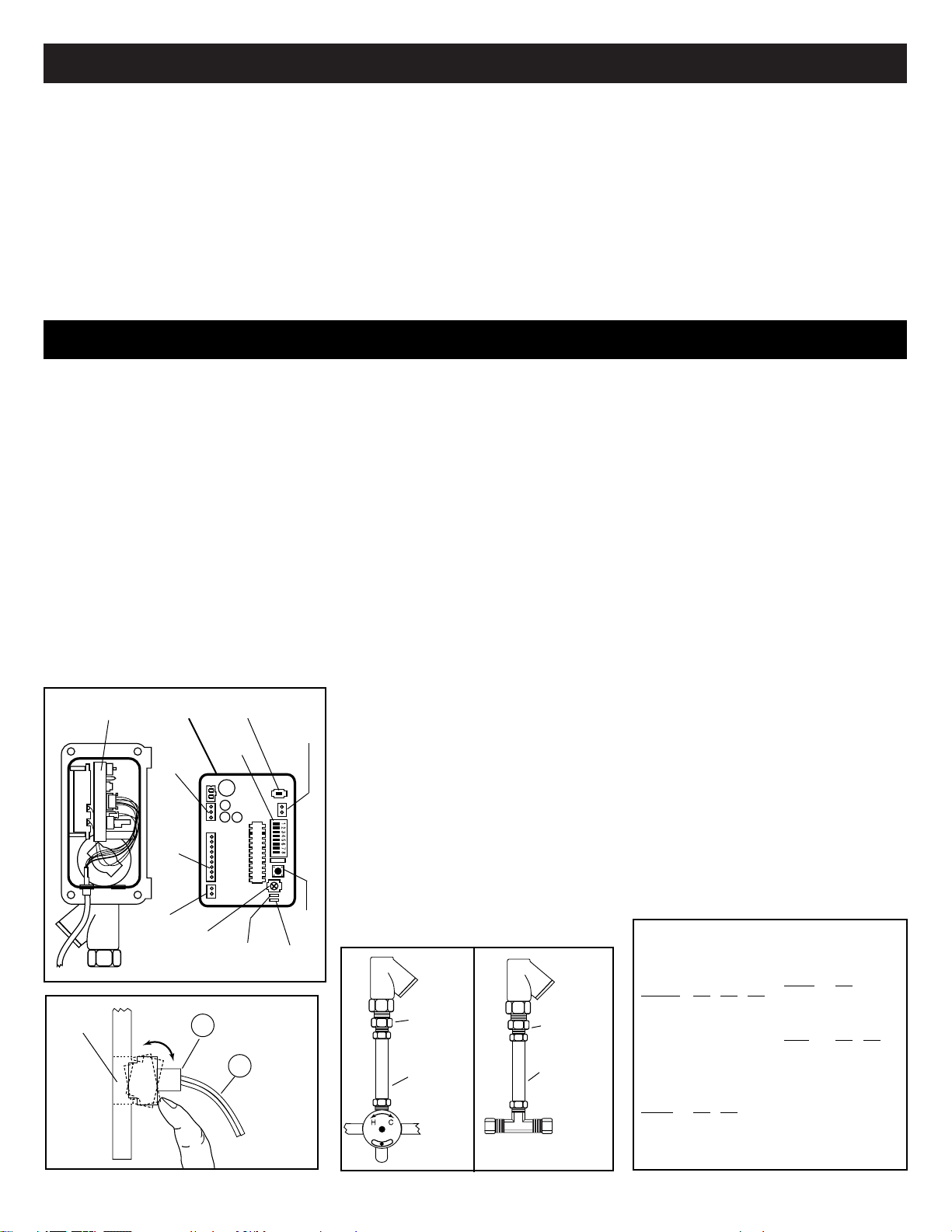

DRY TEST

ATTENTION: To insure proper operation, before

installing the faucet, a “DRY TEST” is

recommended.

1. Take off the control box lid (13) by removing

screws (12) with hex wrench.

2. Connect the sensor eye connector (20) at the

end of the sensor eye cable (18) onto the

circuit board (24) inside the control box (10)

Refer to illustration “A”.

3. Slide battery housing out of control box (10)

and install batteries (included) and slide

battery housing back into control box (10).

Insert the battery housing connector onto the

circuit board. The lights on the circuit board

should blink red/green/red.

4. Place your hand in front of the sensor (23) to

operate the faucet and listen for a “clicking”

sound.

5. Remove your hand and listen for a softer

“clicking” sound. The “clicking” sounds

indicate that the faucet is working properly. If

there is no light or sound, please contact

Moen at 1-800-289-6636.

6. The sensors are equipped with angular

adjustments. The factory setting is in the

center or straight position from the faucet.

Adjustment is most easily performed before

the faucet is installed. The adjustment is

located inside the faucet body (1) behind the

LED indicator light (25) Refer to illustration

“B”.

7. If you are ready to install the faucet,

disconnect the sensor eye connector (20) at

the end of the sensor eye cable (18) from the

circuit board (24).

8. Attach supply rod (6) into threads located at

the bottom of the faucet body (1). If needed,

snug the supply rod (6) with a “8 mm” hex

wrench. Attach compression reducer (28) to

the supply rod (6). Also attach compression

adapter (7) to the solenoid valve outlet.

9. Attach the mounting bolts (2) to the faucet

body. If needed, snug mounting bolts (2) with

Phillips screwdriver.

10. Slide gasket (3) over sensor eye cable and

onto faucet.

11. Set faucet on sink and install slotted washers

(4) and mounting nuts (5). Tighten mounting

nuts (5) to secure the faucet to the sink.

12. Connect the sensor eye connector (20) at the

end of the sensor eye cable (18) onto the

circuit board (24). Properly seat both the

sensor eye cable seal and cable into the

control box slot on the left. Reinstall control

box lid (13) and tighten screws (12) to insure

the control box is water-resistant. NOTE:

make sure that the rubber seal plug is in

installed in the AC adapter control box slot

(on the right).

13. Connect 3/8” copper tube (supplied) between

the supply rod (6) and the solenoid valve

(17). Tighten compression fittings.

14. Insert white nylon washer (9) into swivel nut

on filter body inlet.

15. A) For standard (pre-tempered or cold water)

installation, attach water supply to inlet of

in-line filter/check valve body.

B) If a tempered water installation is needed,

attach mixing/check valve (optional) to the

inlet of in-line filter/check valve body.

Connect water supply lines to

mixing/check valve. Refer to illustration

“C”. NOTE: USE TEFLON TAPE FOR ALL

THREADED CONNECTIONS.

C) Refer to Illustration D for the optional

mixing tee installation.

16. Turn on water and check for leaks. Place

hand in front of sensor to activate water.

Remove hands and the water should stop. If

not, refer to troubleshooting guide.

17. For timing adjustments, refer to instructions

on the inside of the control box lid. Refer to

Illustration E.

A) Note: Be sure to depress the re-set

button, located on the circuit board, after

each adjustment.

B) The factory settings are:

Sensor Distance Adjustment =

approximately 3.5 inches from the lens

Time Delay to shut-off after hands are

removed = 1 sec seconds

Auto – shutoff = 30 seconds

D

Sensor

Lens

Sensors

23

Sensor

Eye Cable

18

Optional

Supply

Tube

provided

by

installer

B

Compression

adapter

Optional

Supply

Tube

provided

by installer

Compression

adapter

C

Electronic Faucet

Operation and Installation

Instructions for Electronic

Faucets-Battery-Powered

The battery-powered faucet is designed for ease

of installation and provides a reliable, convenient,

economical and sanitary system for high-volume

users, such as hospitals, transportation terminals,

restaurants, schools, sports arenas, office

buildings and municipalities. It can be installed by

one tradesman without electrical hook-up.

Operation:

1. The faucet operates by emitting a continuous

infrared beam from the sensor.

2. As the user enters the beam’s effective

range, a red light flashes one time to alert the

user that the faucet will operate. As long as

the user is in the beam’s range, the beam is

reflected into the receiver circuitry and the

system will operate.

3. When the user exits out of range, the sensor

sends a signal to the solenoid for closure.

The sensor then automatically resets and is

ready for the next user.

4. Low battery indicator light comes on when

battery is low.

Caution: Avoid installing the faucet where

sensor faces a stainless steel wall or other

reflective surface within the active range of

sensors. Avoid facing another infrared sensor. It

may cause faucet to activate unnecessarily.

E

CONTROL BOX INSTRUCTIONS

ADJUSTMENTS: (DIP Switches):

1. Shut-off time delay

after hands are removed:

Time Delay SW1 SW2 SW3

1 Sec on on on

2 Sec on on off

3 Sec on off on

4 Sec on off off

5 Sec off on on

6 Sec off on off

7 Sec off off on

8 Sec off off off

2. Auto Time-Out Feature:

Time-Out SW4 SW5

0 Sec on on

15 Sec on off

30 Sec off on

60 Sec off off

3. Sensor Distance:

Distance

SW6

3.5 – 12" on

10 – 24" off

4. Faucet Setting:

Setting SW7 SW8

Faucet on off

SENSOR DISTANCE

ADJUSTMENT (SDA): Preset

at factory. If adjustment is

needed; Locate

potentiometer with Phillips

Head adjuster screw. Turn

adjuster screw clockwise to

increase SDA, counter

clockwise to decrease SDA.

AC/DC switch

Sensor

distance

adjustor

Reset

button

DIP

switches

Green

LED

DC receptor

Sensor

eye

cable pin

receptor

A

Circuit board

side view

Circuit board

front view

AC

receptor

Solenoid

pin

receptor

Red

LED

Page 4

Faucets made of leaded brass alloys may contribute small amounts of lead to water that is

allowed to stand in contact with the brass. The amount of lead contributed by any faucet is

highest when the faucet is new. The following steps may reduce potential exposure to lead

from faucets and other parts of the plumbing system:

• Always run the water for a few seconds prior to use for drinking or cooking

• Use only cold water for drinking or cooking

• If you wish to flush the entire plumbing system of water that has been standing in the pipes

or other fittings, run the cold water until the temperature of the water drops, indicating water

coming from the outside main

• If you are concerned about lead in your water, have your water tested by a certified

laboratory in your area

WARRANTY CONSUMER INFORMATION

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A. In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5S7

HELPLINE:

1 (800) BUY MOEN

[289-6636]

In the U.S. call our toll free Helpline number, for answers

to any product installation, or warranty questions.

In Canada:

Toronto: 905-829-3400;

Rest of Canada: 1-800-465-6130

In Mexico:

(84) 88-08-26, 88-08-27, o 91-800-84-345

4

TROUBLESHOOTING

Water not on.

Power supply failure.

Battery is weak.

Sensor distance too short into bowl.

Electronic circuit board is defective.

Sensor eyes are defective.

Solenoid valve is clogged.

In-line filter is clogged.

Solenoid coil is defective.

Faucet will

not turn on

Check water supply.

Check wires and connections.

Red indicator light stays on, no click.

Use hand/palm to find focal point.

Change batteries but no light or action.

Re-inserting battery, red light doesn’t

blink.

Solenoid is clicking but no water.

Open clean-out filter screen (8) and trap.

No clicking after re-inserting battery.

Turn on water supply.

Reconnect battery holder wires.

Replace batteries.

Adjust sensor distance

(see Table E).

Replace circuit board.

Replace sensor eyes and cable.

Clean solenoid and water pathway.

Clean the filter.

Replace solenoid coil.

Faucet will

not shut

off.

Remove battery. If faucet stops running, the problem is electronic (sensor is defective; replace sensor, or, sensor

distance adjustment is too long, adjust sensor distance adjustment). If the faucet continues to run, the problem is

mechanical. See below for remedy.

Solenoid valve is clogged or sticking.

Faucet

drips.

Open solenoid valve and check for debris. Clean solenoid valve and water pathway.

Replace piston, spring or disc.

For further assistance, call Moen at 1-800-289-6636.

Problem Possible Cause To Diagnose Remedy

Electronic Faucet-Troubleshooting Guide Battery Powered

Normal operation: When new batteries are inserted, the red indicator light on faucet and the lights on circuit board will blink. When a user’s

hands are placed under the spout, the red light will flash one time and water starts to flow. Water stops when hands are removed. Red

indicator light stays on when battery is low.

INS237

Moen products have been manufactured under the highest standards of quality and workmanship. Moen warrants

to the original consumer purchaser for as long as the original consumer purchaser owns their home (the “Warranty

Period” for homeowners), that this faucet will be leak and drip-free during normal use and all parts and finishes of this

faucet will be free from defects in material and manufacturing workmanship. All other purchasers (including

purchasers for industrial, commercial and business use) are warranted for a period of 1 year from the original date of

purchase (the “Warranty Period” for non-homeowners).

If this faucet should ever develop a leak or drip during the Warranty Period, Moen will FREE OF CHARGE provide the

parts necessary to put the faucet back in good working condition and will replace FREE OF CHARGE,

any part or finish that proves defective in material and manufacturing workmanship, under

normal installation, use and service. Replacement parts may be obtained by calling

1-800-289-6636 (Canada 1-800-465-6130), or by writing to the address shown. Proof of purchase (original sales

receipt) from the original consumer purchaser must accompany all warranty claims. Defects or damage caused by the

use of other than genuine Moen parts are not covered by this warranty. This warranty is applicable only to faucets

purchased after December 1995 and shall be effective from the date of purchase as shown on purchaser’s receipt.

This warranty is extensive in that it covers replacement of all defective parts and finishes. However, damage due to

installation error, product abuse, product misuse, or use of cleaners containing abrasives, alcohol or other organic

solvents, whether performed by a contractor, service company, or yourself, are excluded from this warranty. Moen will

not be responsible for labor charges and/or damage incurred in installation, repair or replacement, nor for any indirect,

incidental or consequential damages, losses, injury or costs of any nature relating to this faucet. Except as provided

by law, this warranty is in lieu of and excludes all other warranties, conditions and guarantees, whether expressed or

implied, statutory or otherwise, including without restriction those of merchantability or of fitness for use.

Some states, provinces and nations do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights and you may

also have other rights which vary from state to state, province to province, nation to nation. Moen will advise you of

the procedure to follow in making warranty claims. Simply write to Moen Incorporated using the address below.

Explain the defect and include proof of purchase and your name, address, area code and telephone number.

Page 5

Mezcladoras fabricadas con aleaciones de latón de plomo podrían contribuir pequeñas

contidades de plomo al agua que está en contacto con el latón. La cantidad de plomo

contribuida en cualquier mezcladora es mayor cuando esta mezcladora es nueva. Los

siquientes pasos podrían reducir la exposición potencial al plomo de las mezcladoras y otras

piezas del sistema de plomeria:

• Siempre deje correr el agua por unos segundos antes de usaria para tomar o cocinar

• Solamente use agua fría para tomar o cocinar

• Si usted desea limpiar el sistema completo de plomeria de agua estancada en las

tuberías y otros accessorios, deje correr el agua hasta que la temperatura de ésta baje,

indicando de que esta agua viene del suministro de afuera.

• Si usted tiene interés sobre el plomo en su agua, haga examinar su agua por un

laboratorio certificado en su área

Los productos Moen han sido elaborados bajo los más estrictos standard de calidad y mano de obra. Moen

garantiza al consumidor - comprador original por todo el tiempo que el consumidor - comprador original esté en

posesión de su casa (el “Período de Garantia” del propietario de casa), que esta mezcladora será libre de

infiltraciones y goteo durante su uso normal y que todas las piezas y el acabado de esta mezcladora serán libres

de defectos de material y mano de obra de fabricación. Todos los otros compradores (incluyendo compras para

uso industrial comercial y profesional) se garantizan por un período de 1 años desde la fecha original de compra

(el “Período de Garantía” para los que no son propietarios de casa).

En caso que esta mezcladora empiece en algún momento a gotear o infiltrarse durante el Período de Garantía,

Moen suministrará LIBRE DE CARGO las piezas que se necesiten para reponer la mezcladora en buena condición

de funcionamiento y reemplazará LIBRE DE CARGO, cualquier pieza o acabado que resulte ser defectuoso en

cuanto a material y elaboración, bajo instalación, uso y servicio normal. Las piezas de repuesto se pueden obtener

llamando al 1-800-289-6636 (Canadá 1-800-465-6130), o escribiendo a la dirección indicada. El comprobante de

compra (recibo original de la venta) del consumidor - comprador de origen debe acompañar todas las

reclamaciones de garantía. Esta garantía no ampara los defectos o daños ocasionados por un uso otro que de

piezas genuinas Moen. Esta garantía se extiende solamente a mezcladoras compradas después de Diciembre

1995 y será en efectividad desde la fecha de la compra como indique el recibo del comprador.

Esta garantía es amplia puesto que cubre el repuesto de todas piezas y acabados defectuosos. Sin embargo,

los daños causados por un error de instalación, abuso del producto, mal uso del producto o el uso de limpiadores

que contengan abrasivos, alcohol u otros solventes orgánicos, ya sean ejecutados por un contratista, Cía. de

servicio o Ud. mismo se excluyen de esta garantía. Moen no será responsable de costos laborales y/o daños

producidos durante la instalación, reparación o cualquier daño incidental o consiguiente, pérdidas, heridas u

costos de cualquier naturaleza relacionados con esta mezcladora. Salvo como previsto por la ley, esta garantía

reemplaza y excluye todas las otras garantías, condiciones y afirmaciones, ya sea expresadas o implícitas, legales

u otras, incluyendo sin restricción alguna aquellas de comercialización o aptitud para el uso.

Algunos estados, provincias y naciones no permiten la exclusión o limitación de daños incidentales o

consiguientes, y por este motivo las sobrecitadas limitaciones posiblemente no le afectan. Esta garantía le otorga

derechos legales expecíficos y Ud. posiblemente también tiene otros derechos que cambian de un estado a otro,

de una provincia a otra, de una nación a otra. Moen le avisará cual procedimiento debe seguir en cuanto haga

una reclamación bajo garantía. Escriba nada más a Moen Incorporated a la dirección indicada a continuación.

Explique el defecto e incluya la prueba de compra así como su nombre, dirección, código y número de teléfono.

GARANTIA LIMITADA DE VIDA INFORMACION AL CONSUMIDOR

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5S7

LINEAS TELEFONICAS

DE SERVICIO:

Para Aclarar sus dudas relacionadas con la instalacion,

refacciones, partes y/o garantia de nuestras llaves,

llamenos por cobrar a los siquientes telefonos: (84) 88-0826, 88-08-27, o 91-800-84-345. FAX (84) 88-08-04.

En los Estados Unidos: 1-800-289-6636

6

INS237

PROBLEMAS Y SOLUCIONES

LA LLAVE

NO SE

ENCIENDE

LA LLAVE

NO SE

CIERRA

LA

LLAVE

GOTEA

Para mayor asistencia, llame a MOEN al (84) 88-08-26, 88-08-27, o 91-800-84-345. FAX (84) 88-08-04.

PROBLEMA CAUSA POSIBLE PARA DIAGNOSTICAR REMEDIO

GUÍA PARA LA SOLUCIÓN DE PROBLEMAS DE LA LLAVE ELECTRONICA DE BATERÍAS

Opción Normal: Cuando de insertan nuevas baterias, la luz roja del indicador de la llave y la luz en el circuíto impreso se encienden

parpadeándo. Cuando las manos del usuario se colocan debajo de la boquilla, la luz roja parpadeará una vez y el agua empezará a fluir. El

agua se detiene cuando las manos se quitan de ahí. La luz roja del indicador permanece encendida cuando la batería está baja.

El agua no está abierta.

Falla en el suministro de energía.

La batería está débil.

La distancia del sensor es

demasiada corta dentro del lavabo.

El circuíto impreso electrónico está

defectuoso.

Los ojos del sensor están

defectuosos.

La válvula Solenoide está obstruída.

El filtro en-línea estáobstruído.

La espiral de la válvula Solenoide

está defectuosa.

Revise el suministro de agua.

Revise los alambres y conecciones.

La luz roja del indicador se queda

prendida, no hace "click".

Use la mano/palma para encontrar el

punto focal.

Reemplace las baterias pero no hay luz ni

acción.

Re-inserte las baterias, la luz roja no

parpadéa.

La válvula Solenoide hace "click" pero no

sale el agua.

Abra y limpie la malla del filtro (11) y el

sifón.

No hay ningún "click" después de reinsertar las baterias.

Abra el suministro de agua.

Conecte nuevamente los cables del

compartimento de las baterias.

Reemplace las baterias.

Ajuste la distancia del sensor.

(Vea la ilustración E)

Reemplace el circuíto impreso.

Reemplace los ojos del sensor y los

cables.

Limpie la válvula Solenoide y el drenaje.

Limpie el filtro.

Reemplace la espiral Solenoide.

Quite la batería. Si la llave déja de gotear, el problema es elecrtrónico (el sensor está defectuoso; reemplace el

sensor, o, la distancia del sensor pude ser demasiada grande, ajuste la distancia del sensor). Si la llave continúa

goteándo, el problema es mecánico. Véa abajo para varios remedios.

La válvula Solenoide está obstruída o

se está atascando.

Abra la válvula Solenoide y revise a ver si

está sucia.

Limpie la válvula Solenoide y el drenaje.

Reemplace el pistón, el resorte o el disco.

Page 6

7

FONCTIONNEMENT

DIRECTIVES D’INSTALLATION

ESSAI À SEC

ATTENTION : Pour assurer le bon

fonctionnement du robinet, il est recommandé

d’effectuer un ESSAI À SEC avant l’installation.

1. Retirer le couvercle du boîtier de commande

(13) en enlevant les vis (12) à l’aide d’un clé

hexagonale.

2. Raccorder le raccord des yeux du capteur

(20) à l’extrémité du câble des yeux du

capteur (18) sur la carte à circuit imprimé (24)

à l’intérieur du boîtier de commande (10).

Voir l’illustration A.

3. Faire glisser le compartiment à piles pour

l’enlever du boîtier de commande (10) et

installer les piles (incluses). Pour le remettre

en place, le faire glisser dans le boîtier de

commande (10). Insérer le raccord du

compartiment à piles dans la carte à circuit

imprimé. La lumière de la carte à circuit

imprimé devrait clignoter rouge/verte/rouge.

4. Placer votre main devant le capteur (23) pour

faire fonctionner le robinet. Vous devriez

entendre un « clic ».

5. Retirer votre main de devant le capteur et

écouter s’il y a un autre « clic » mais plus

doux cette fois. Ce son indique que le robinet

fonctionne correctement. S’il n’y a pas de clic

et pas de voyant, contacter Moen au Aux É.U. :1 800 289-6636

6. Les capteurs sont munis d’ajustements

angulaires. Les paramètres établis en usine

correspondent à une position centrale ou

directe du robinet. Il est plus facile d’ajuster le

capteur avant que le robinet ne soit installé.

Le dispositif d’ajustement est situé dans le

corps du robinet (1) derrière la lumière du

voyant DEL (25). Voir l’illustration B.

7. Pour installer le robinet, déconnecter d’abord

le raccord des yeux du capteur (20) situé à

l’extrémité du câble des yeux capteur (18) de

la carte à circuit imprimé (24).

8. Fixer la tige d’alimentation (6) sur les

filetages situés au bas du corps du robinet (1)

Si requis, serrer la tige d’alimentation (6)

avec une clé hexagonale de 88 mm. Fixer le

réducteur de compression (28) à la tige

d’alimentation (6). Fixer aussi l’adaptateur de

compression (7) à la sortie de l’électrovanne.

9. Fixer les boulons de montage (2) au corps du

robinet. Si requis, serrer les boulons de

montage (2) à l’aide d’un tournevis à tête

cruciforme.

10. Faire glisser le joint d’étanchéité (3) sur le

câble des yeux du capteur et sur le robinet.

11. Placer le robinet sur l’évier et installer les

rondelles fendues de montage (4) et les

écrous de montage (5). Serrer les écrous de

montage pour bien fixer le robinet à l’évier.

12. Raccorder le raccord des yeux du capteur

(20) situé à l’extrémité du câble des yeux du

capteur (18) sur la carte à circuit imprimé

(24). Bien placer le joint d’étanchéité du

câble des yeux du capteur et le câble dans le

boîtier de commande à gauche. Réinstaller le

couvercle du boîtier de commande (13) et

visser les vis (12) pour s’assurer que le

boîtier de commande est imperméable.

NOTE : s’assurer que le bouchon

d’étanchéité en caoutchouc est installé dans

la fente du boîtier de commande de

l’adaptateur C.A. (à droite).

13. Raccorder le tube en cuivre de 3/8 po (fourni)

entre la tige d’alimentation (6) et

l’électrovanne (17). Serrer les raccords de

compression.

14. Insérer une rondelle en nylon blanc (9) dans

l’écrou pivotant sur l’entrée du corps du filtre

de conduite.

15. A) Pour une installation standard (eau

prétempérée ou froide ), fixer la conduite

d’alimentation sur l’entrée du filtre de

conduite/du corps du clapet de nonretour.

B) Pour une installation d’eau tempérée,

fixer le clapet mitigeur/de non-retour

(optionnel) à l’entrée du filtre de

conduite/corps du clapet de non-retour.

Raccorder les conduites d’alimentation de

l’eau au clapet mitigeur/de non-retour.

Voir l’illustration C. NOTE : UTILISER UN

RUBAN EN TÉFLON POUR TOUS LES

RACCORDS.

C) Voir l’illustration D pour une installation

optionnelle « T » avec mitigeur.

16. Ouvrir l’eau et vérifier s’il y a des fuites.

Placer les mains devant l’œil du capteur du

robinet pour faire couler l’eau. Retirer les

mains pour que l’eau s’arrête de couler.

Sinon, consulter le guide de résolution de

problèmes.

17. Pour régler la durée, consulter les directives

à l’intérieur du couvercle du boîtier de

commande. Voir l’illustration E.

A) Note : Après chaque réglage, s’assurer

d’appuyer sur le bouton de rétablissement

(re-set) situé sur la carte à circuit imprimé.

B) Les paramètres définis en usine sont les

suivants :

Ajustement de la distance du capteur :

environ 3,5 pouces de la lentille.

Temporisation pour la fermeture après

avoir ôter les mains : 1 seconde

Autofermeture : 30 secondes

Robinet elétronique

Directives pour le

fonctionnement d’un robinet

elétronique à pile

Le robinet à pile est conçu pour être facile à

installer et il fournit un système fiable, pratique et

économique pour les endroits très achalandés

comme les hôpitaux, les gares terminales, les

restaurants, les écoles, les arénas, les tours à

bureaux et les bureaux municipaux. Il peut être

installé par une personne de métier sans besoin

de raccordement électrique.

Fonctionnement

1. Le robinet fonctionne en émettant un

faisceau continu provenant du capteur.

2. Lorsque l’utilisateur entre dans la portée

active du faisceau, une lumière rouge

clignote une fois pour l’avertir que le robinet

va se mettre en marche. Aussi longtemps

que l’utilisateur reste dans la portée active du

capteur, le faisceau se réfléchit dans la

circuiterie du récepteur et le système

fonctionne.

3. Lorsque l’utilisateur s’éloigne de la portée du

capteur, celui-ci envoie un signal de

fermeture au solénoïde. Le capteur se met à

zéro automatiquement et est prêt pour la

personne suivante.

4. La lumière du voyant pour la pile s’allume

lorsque la pile est faible.

AVERTISSEMENT : Éviter d’installer le

robinet dans les endroits où le capteur fait face à

un mur en acier inoxydable ou à toute autre

surface réfléchissante se trouvant dans la portée

active du capteur. Cela peut causer le mauvais

fonctionnement du robinet.

D

Lentille du

capteur

Capteur

23

Câble des

yeux du

capteur

18

Tube

d’alimentation

optionnel

fourni par

l’installateur

B

Adaptateur de

compression

C

Tube

d’alimentation

optionnel

fourni par

l’installateur

Adaptateur de

compression

E

AJUSTEMENTS : (Commutateurs DIP) :

1. Temporisation de fermeture

après avoir ôter les mains :

Temporisation Com1 Com2 Com3

1 Sec on on on

2 Sec on on off

3 Sec on off on

4 Sec on off off

5 Sec off on on

6 Sec off on off

7 Sec off off on

8 Sec off off off

2. Caractéristique d’autofermeture :

Fermeture Com4 Com5

0 Sec on on

15 Sec on off

30 Sec off on

60 Sec off off

3. Distance du capteur:

Distance SW6

3.5 – 12 po on

10 – 24 po off

4. Réglage du robinet:

Réglage

SW7 SW8

Robinet on off

AJUSTEMENT DE DISTANCE DU

CAPTEUR : Prédéfini en usine.

Si un ajustement est requis,

trouver le potentiomètre avec la

vis d’ajustement à pointe

cruciforme et tourner la vis

d’ajustement dans le sens des

aiguilles d’une montre pour

augmenter la distance ou dans

le sens contraire des aiguilles

d’une montre pour la diminuer.

Directives du boîtier de commande

Interrupteur

CA/courant

continu

Commutateur DIP

Récepteur/CA

Récepteur

de la

goupille

du câble

des yeux

du

capteur

A

Vue latérale de

la carte à

circuit imprimé

Vue frontale de la carte

à circuit imprimé

Récepteur/

courant

continu

Ajustement de

distance du capteur

Bouton de

rétablissement

DEL rouge

DEL

verte

Récepteur de la

goupille des

électrovanne

Page 7

5

OPERACIONES

INSTRUCCIONES DE INSTALACION

PRUEBA EN SECO.

ATENCION: Para asegurarse que la llave

funcione apropiadamente, antes de instalarla, se

recomienda efectuar una “PRUEBA EN SECO”.

1. Destape la caja de control (13)

desenroscando los tornillos (12) con un llave

hexagonal.

2. Conecte el conector del sensor óptico (20) al

extremo del cable del sensor óptico (18) en el

circuito impreso (24) dentro de la caja de

control (10). Véa la ilustración “A”.

3. Saque la caja de las baterías de la caja de

control (10) e instale las baterías (que vienen

incluídas) y meta nuevamente la caja de las

baterías a la caja de control (10). Inserte el

conector de la caja de baterías en el circuito

impreso. La luz en el circuito impreso deberá

parpadear rojo/verde/rojo.

4. Ponga su mano frente al sensor (23) para

hacer operar la llave y escuche un sonido de

“click”.

5. Retire su mano y escuche un sonido de“click”

más suave. Los sonidos de “click” indican

que la llave está operando apropiadamente.

Si no se escucha el click o la luz no se

enciende, llame a Moen al número 1-800289-6636.

6. Los sensores están equipados con ajustes

angulares. El ajuste de fábrica se hizo en la

posición central o directamente enfrente de la

llave. Cualquier ajuste puede efectuarse más

facilmente antes instalar la llave. El sistema

de ajuste está colocado dentro del cuerpo de

la llave (1) detrás del luz indicadora LED (25).

Véa la ilustración “B”.

7. Si usted está listo para instalar la llave,

desconecte el conector del sensor óptico

(20), que se encuentra al extremo del cable

del sensor óptico (18), del circuito impreso

(24).

8. Conecte la varilla del suministro (6) en la

rosca localizada en la parte inferior del

cuerpo de la llave (1). Si lo necesita apriete la

varilla de suministro (6) con una llave

exagonal de 8 milímetros. Fije el reductor de

compresión (28) a la varilla de suministro (6).

También fije el adaptador de compresión (7)

a la salida de la válvula solenoide.

9. Fije los pernos de montaje (2) al cuerpo de la

llave. Si lo necesita, apriete los pernos de

montaje (2) con un desarmador Phillips.

10. Deslice el empaque (3) sobre el alambre del

sensor óptico y en la llave.

11. Ponga la llave en el lavabo e instale las

rondanas ranuradas (4) y las tuercas de

montaje (5). Apriete las tuercas de montaje

(5) para fijar la llave al lavabo.

12. Enchufe el conector del sensor óptico (20) al

extremo del cable del sensor óptico (18) al

circuito impreso (24). Coloque

apropiadamente tanto el sello del cable del

sensor óptico como el cable en la ranura que

se encuentra al lado izquierdo de la caja de

control. Reinstale la tapa de la caja (13) y

apriete los tornillos (12) para asegurarse que

no le entre agua a la caja de control. NOTA:

asegúrese de que el tapón del sello de hule

este instalado en la ranura del adaptador de

corriente alterna de la caja de control (parte

derecha de la caja).

13. Conecte el tubo de cobre de 3/8” (incluído)

entre la varilla de suministro (6) y la válvula

solenoide (17). Apriete todas las tuercas de

presión.

14. Meta la rondana de nylon blanco (9) en la

tuerca giratoria a la entrada del cuerpo del

filtro.

15. A) Para instalaciones estandard (agua fria o

pre-templada), conecte el suministro de agua

a la entrada del cuerpo en-línea del

filtro/válvula check.

B) Si se requiere hacer instalación para agua

templada, conecte la válvula check de

mezclado (opcional) a la entrada del

cuerpo de la válvula filtro/check que se

encuentra alineada. Conecte las líneas de

suministro de agua a la válvula

check/mezcladora. Vea la ilustración “C”.

NOTA: USE CINTA DE TEFLON EN

TODAS LAS UNIONES ROSCADAS.

C) Vea la ilustración “D” para la instalación

de la mezcladora T opcional.

16. Abra la llave de agua y cheque las fugas.

Ponga la mano frente al sensor para activar

la llave. Cuando quite las manos el agua

deberá dejar de correr. Si no ocurre así, vea

la guía de problemas.

17. Para ajustar el tiempo al que abre la llave,

vea las instrucciones en la parte de adentro

de la tapa de la caja de control. Vea la

ilustración “E”.

A) Nota: Asegúrese de presionar el botón de

restablecimiento, localizado en el circuito

impreso, después de cualquier ajuste.

B) Los ajustes de fábrica son:

Ajuste de distancia del sensor =

aproximadamente 3.5 pulgadas del lente.

Tiempo de cerrado de la llave después de

retirar las manos = 1 segundo.

Apagado-automático = 30 segundos.

Llave Electrónica

Operacion e Instalación

Instrucciones para llaveselectrónicas-operadas-porbaterías.

La llave operada por batería esta diseñada para

instalarse en forma sencilla, y proporciona un

sistema sanitario confiable, conveniente, y

económico, para utilizarse en aplicaciones de alta

demanda de agua tales como hospitales,

estaciones de transporte, restaurantes, escuelas,

instalaciones deportivas, oficinas, y edificios

municipales. Puede ser instalada por un técnico

sin necesidad de hacer una instalación eléctrica.

Operación:

1. La llave funciona emitiendo un haz de luz,

del sensor infra-rojo, en forma continua.

2. Cuando el usuario interrumpe el haz de luz,

una luz roja se enciende y apaga, para

alertar al usuario que la llave va a operar.

Mientras el usuario se encuentre

interumpiendo el haz de luz, este haz se

refleja hacia el circuito receptor haciendo

funcionar la llave.

3. Cuando el usuario deja de interumpir el haz

de luz, el sensor emite una señal hacia la

válvula de solenoide haciéndola que cierre.

El sensor restablece su operación

automaticamente dejando la llave lista para

ser usada por el siguiente usuario.

4. La luz indicadora de bateria baja se enciende

cuando es necesario reemplazar la bateria.

Precaución: Evite instalar la llave en una

posición en la que el sensor este frente a una

pared de acero inoxidable u otra superficie

reflectora, dentro del rango de operación del

sensor. Evite colocar la llave frente a otro sensor

infrarrojo. Esto puede ocasionar un uso

innecesario de la llave.

D

Lente del

sensor

Sensores

23

Cable del

sensor

óptico

18

Tubo de

suministro

opcional

suministrado

por el

instalador

B

Adaptador de

compresión

Tubo de

suministro

opcional

suministrado

por el

instalador

Adaptador de

compresión

C

E

AJUSTES: (DIP Switches):

1. Retraso de apagado después

de retirar las manos:

Tiempo de retraso SW1 SW2 SW3

1 Seg on on on

2 Seg on on off

3 Seg on off on

4 Seg on off off

5 Seg off on on

6 Seg off on off

7 Seg off off on

8 Seg off off off

2. Opción de Time-out automático:

Time-Out SW4 SW5

0 Seg on on

15 Seg on off

30 Seg off on

60 Seg off off

Instrucciones de la caja de control

AJUSTE DE DISTANCIA DEL

SENSOR (SDA): Preseleccionado

en la fábrica. Si se necesita

ajustar: Localice el tornillo del

potenciómetro y ajústelo con un

desarmador Philips. Gire el

tornillo en el sentido de las

manecillas del reloj para

incrementar SDA, y en el sentido

inverso de las manecillas del reloj

para disminuir el SDA.

3. Distancía del sensor:

Distancía SW6

3.5 – 12" on

10 – 24" off

4.

Ajuste de la mezcladora:

Ajuste

SW7 SW8

Mezcladora

on off

Switch AC/DC

Switches

DIP

Contacto/AC

Contacto

de puntas

del cable

del

sensor

óptico

A

Vista lateral

del circuito

impreso

Vista frontal del

circuito impreso

Contacto/DC

Ajuste de

distancia del sensor

Botón de

restablecimiento

LED

rojo

LED

verde

Receptor

del pin

Page 8

Robinets fabriqués à partir d'alliages de laiton de plomb pourraient contribuer des petites quantités de

plomb à l'eau qu'on laisse stagner en contact avec ledit laiton. La quantité de plomb contribuée par

n'importe quel robinet est supérieure lorsque le robinet est neuf. Les procédés qui suivent peuvent

réduire l'exposition au plomb provenant de robinets et autres pièces du système de tuyauterie:

• Toujours faire couler l'eau pendant quelques secondes avant de s'en servir pour boire ou cuire

• Utiliser uniquement l'eau froide pour boire ou cuire

• En cas ou l'on désire purger le sysème entier de plomberie de l'eau stagnante dans les tuyaux ou

autres montages, laisser couleur l'eau jusqu'à ce que la température de l'eau tombe, indicant ainsi

que l'eau provient du conduit extérieur

• Si la teneur en plomb de votre eau vous inquiète, la faire tester par un laboratoire régional certifié.

Les produits Moen ont été fabriqués selon les normes de qualité et de main-d’œuvre les plus élevées.

Moen garantit à la personne ayant acheté le robinet originalement, aussi longtemps qu’elle reste propriétaire

de la maison, (période de garantie pour propriétaires), que ce robinet sera libre de toute fuite ou

d’égouttement pendant son usage normal et que toutes les pièces et tous les finis de ce robinet ne

présenteront aucun défaut de matériel et de main-d’œuvre en usine. L’achat par tout autre consommateur

(acheteur à des fins industriels, commerciales et d’affaires) sera garanti pendant 1 ans à compter de la date

d’achat originale (période de garantie pour non-propriétaires).

Si ce robinet fuit ou dégoutte durant la période de garantie, Moen remplacera GRATUITEMENT les pièces

de remplacement requises pour remettre le robinet en parfait état et remplacera GRATUITEMENT toute pièce

ou tout fini dont le matériel, la fabrication ou la main-d’œuvre, lors d’une installation, d’un usage et d’un

service normaux, s’avère défectueux. On peut obtenir les pièces de remplacement en composant le

1 800 465-6130, ou en écrivant à l’adresse indiquée sous la preuve d’achat. Le reçu de vente original du

consommateur ayant acheté le robinet initialement, doit accompagner toute réclamation. Les défauts ou les

dommages causés par l’utilisation de pièces non fournies par Moen ne sont pas couvertes par cette garantie.

Cette garantie s’applique uniquement aux robinets achetés après décembre 1995 et entre en vigueur à

compter de la date d’achat indiquée sur le reçu de caisse du consommateur.

Cette garantie est vaste car elle couvre le remplacement de toute pièce ou de tout fini défectueux.

Cependant, les dommages causés par une erreur l’installation, un abus du produit, une mauvaise utilisation

du produit ou l’utilisation de nettoyeurs contenant des agents abrasifs, de l’alcool ou des solvants

organiques, qu’ils soient utilisés par un entrepreneur, une entreprise de service ou le consommateur, sont

exclus de cette garantie. Moen n’est pas responsable des frais de main-d’œuvre ni de tous dommages

survenus durant l’installation, la réparation ou le remplacement, ni des dommages indirects ou consécutifs,

des pertes, des blessures ou des coûts connexes à ce robinet. Sauf lorsque prévu par la loi, cette garantie

remplace et exclut toute autre garantie et condition, qu’elles soient exprimées ou sous-entendues,

obligatoires ou autres, y compris sans restriction, celle de commercialisation ou d’aptitude d’utilisation.

Certains pays, certains États et certaines provinces, ne permettent aucune exclusion, ni limitation suite

aux dommages indirects ou consécutifs. Les limitations ou les exclusions ne s’appliquent donc pas dans

ces cas. Cette garantie accorde des droits juridiques et il est possible que d’autres droits soient applicables

selon l’état, la province ou le pays précis. Moen avisera le consommateur de la procédure à suivre pour

soumettre une réclamation. Il suffit d’écrire à Moen incorporée, d’expliquer le défaut et d’inclure une preuve

d’achat, d’inscrire son nom, adresse ainsi que code régional et numéro de téléphone.

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

Au Canada, Moen inc., 2816 rue Bristol, Oakville (Ontario), L6H 5S7

APPELER SANS FRAIS NOTRE

SERVICE À LA CLIENTÈLE

Appeler notre Service à la clientèle pour obtenir des

renseignements sur nos produits, leur l’installation ou sur

notre garantie.

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U. :1 800 289-6636

Au Mexique :

(84) 88-08-26, 88-08-27,

o 91-800-84-345

GARANTIE À VIE LIMITÉE DE MOEN INFORMATION POUR LE CONSOMMATEUR

8

RESOLUTION DE PROBLEMS

L’alimentation en eau n’est pas

ouverte

Panne d’électricité

La pile est faible

La distance du capteur est trop

courte

La carte électronique est défectueuse

Les yeux du capteur sont défectueux

L’électrovanne est bloquée

Le filtre de conduite est bloqué

La bobine de solénoïde est

défectueuse

LE ROBINET

NE

FONCTIONNE

PAS

Vérifier l’alimentation en eau

Vérifier les fils et les connexions

La lumière rouge du voyant reste allumée,

aucun clic

Utiliser la main/paume pour trouver le

point de focalisation

Remplacer la pile mais aucune lumière ni

action

Réinsérer la pile, la lumière rouge ne

clignote pas

L’électrovanne clique mais il n’y a pas

d’eau

Ouvrir et nettoyer le filtre de conduite (11)

et le couvercle

Aucun clic après avoir réinséré la pile

Ouvrir l’alimentation en eau

Ouvrir l’alimentation en eau

Reconnecter les fils du boîtier des piles

Remplacer les piles

Régler la distance du capteur

(voir l’illustration E)

Remplacer la carte à circuit imprimé

Remplacer les yeux du capteur et le

câble

Nettoyer l’électrovanne et la conduite

d’eau

Nettoyer le filtre

Remplacer la bobine de solénoïde

LE

ROBINET

NE SE

FERME PAS

Enlever la pile. Si le robinet continue à couler, il est possible qu’il s’agisse d’un problème électronique (le capteur est

défectueux; le remplacer; ou la distance du capteur est trop longue, ajuster la distance). Si le robinet coule toujours, le

problème est d’ordre mécanique. Voir ci-dessous pour une solution.

L’électrovanne est bouchée ou elle

colle

LE

ROBINET

FUIT

Ouvrir l’électrovanne et vérifier s’il y a des

débris

Nettoyer l’électrovanne ou la conduite

d’eau. Remplacer le piston, le ressort ou

le disque

Pour obtenir de plus amples renseignements, appeler Moen au Aux É.-U. :1 800 289-6636

Probléme Cause Possible Diagnostic Solution

GUIDE DE RÉSOLUTION DE PROBLÈMES POUR LES ROBINETS ELÉTRONIQUE À PILE

Fonctionnement normal : après avoir inséré une nouvelle pile, le voyant rouge clignote rapidement et la lumière de la carte à circuit imprimé

clignote. Si on place les mains sous le robinet, le voyant rouge clignote une fois et l’eau commence à couler. Si on retire les mains, l’eau

s’arrête de couler. Le voyant rouge reste allumé lorsque la pile est presque épuisée.

Loading...

Loading...