Moeller Marine XI-OC Signal Modules User Manual

Building Automation

Hardware and Engineering

XI/OC Signal Modules

05/02 AWB2725-1452GB

SystemsIndustrial Automation

All brand and product names are trademarks or registered

trademarks of the owner concerned.

st

published 2002, edition date 05/02

1

© Moeller GmbH, 53105 Bonn

Author: Peter Roersch

Editor: Thomas Kracht

Translator: Patrick Chadwick

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any otherprocess) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alteration without notice.

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on

this device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalisation. The system installer

is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for the

24 volt supply. Only use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable

units must only be operated and controlled in enclosed

housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must be

implemented to ensure a safe operating state in the event of

a fault or malfunction (for example, by means of separate limit

switches, mechanical interlocks etc.).

Moeller GmbH

Safety instructions

I

05/02 AWB2725-1452GB

Contents

About this Manual 3

Additional manuals 3

Intended users 3

Abbreviations and symbols 3

1 Signal modules 5

Overview 5

Accessories 6

Assembly 6

PLC connection 6

Slot assignment in the module racks 7

Mounting the module rack 8

– Mounting on the top hat rail 8

– Mounting on the mounting plate 8

Detaching the module rack 8

Mounting the signal modules 10

Detaching the signal modules 10

Fixing the terminal block 10

Wiring up the I/O signals 11

– Wiring up the screw terminal block 11

– Wiring up the spring-loaded terminal block 11

Wiring the digital input module (24 V DC) 11

Wiring up the digital output module (24 V DC) 12

– Wiring up the relay output module 12

– Wiring up the transistor output module 12

Wiring up the analogue module 13

Project planning 13

Dimensions 13

– Signal modules 13

– Module rack 13

2 Temperature acquisition module XIOC-4T-PT 15

Features 15

Wiring 15

Data evaluation 16

– Range 1: –50 to +400 °C (Pt100/Pt1000) 16

– Range 2: –20 to +40 °C (Pt100) 17

Conversion tables 17

Fault-finding 19

– Faults that affect a single channel 19

– Faults that affect more than one channel 19

3 Counter module 21

Wiring of the counter module 21

– Connect the incremental encoder to the counter input 21

– Connecting third-party equipment to the

comparator output 22

1

Contents

05/02 AWB2725-1452GB

4 Te chni cal data 23

XControl 23

Digital input modules 24

Digital output modules 25

– Transistor output modules 25

– Relay output module 26

Analogue input modules 27

Analogue output module 28

Temperature acquisition module 30

Counter module 31

– Mode (operating mode) switch 32

General technical data for the counter 34

Index 35

2

05/02 AWB2725-1452GB

About this Manual

This manual describes the XIOC signal modules for the expandable

PLC types XC-CPU100/200/400/600. In Chapter 1 you will find

information on mounting and wiring, which is applicable to all the

signal modules. Chapter 4 provides comprehensive technical data.

This chapter also starts with a general section. Specific features are

then dealt with separately or, there where it is more useful,

combined in groups. Chapter 2 and Chapter 3 include further

detailed information on the temperature acquisition module and

the counter module.

Additional manuals

The PLC types that are used in conjunction with the signal modules

are described in the following manuals:

PLC type Manual no. Article no.

XC-CPU100/200

XC-CPU400/600

These manuals are also available online as PDF files, under

“www.moeller.net l support”. Enter the manual number here as

the search text.

AWB27241453GB

AWB27001428GB

Abbreviations and symbols

The abbreviations and symbols used in this manual have the

following meanings:

I/O Input/Output

PLC

I

o

I

1

U

o

U

1

All dimensions are in millimetres, unless otherwise specified.

X Indicates instructions on what to do

h

h

i

Programmable Logic Controller

Input current

Output current

Input voltage

Output voltage

Draws your attention to interesting tips and

supplementary information

Important!

Indicates the risk of minor material damage.

Caution!

Indicates the risk of major damage to property, or slight

injury.

Intended users

Read this manual carefully, before you install the signal module

and start using it. We assume that you are familiar with basic

physical concepts and are experienced in reading technical

drawings and dealing with electrical equipment.

Warning!

j

Indicates the risk of major damage to property, or serious

or fatal injury.

For greater clarity, the chapter title is shown at the top left of the

page, and the current section at top right. Exceptions are the first

page of each chapter, and empty pages at the end.

3

05/02 AWB2725-1452GB

4

05/02 AWB2725-1452GB

1 Signal modules

Overview

• Digital input/output modules

• Analogue input/output modules

The signal modules for the expandable PLC types XC-CPU100/

• Function modules, such as counter and network modules

200/400/600 are divided into:

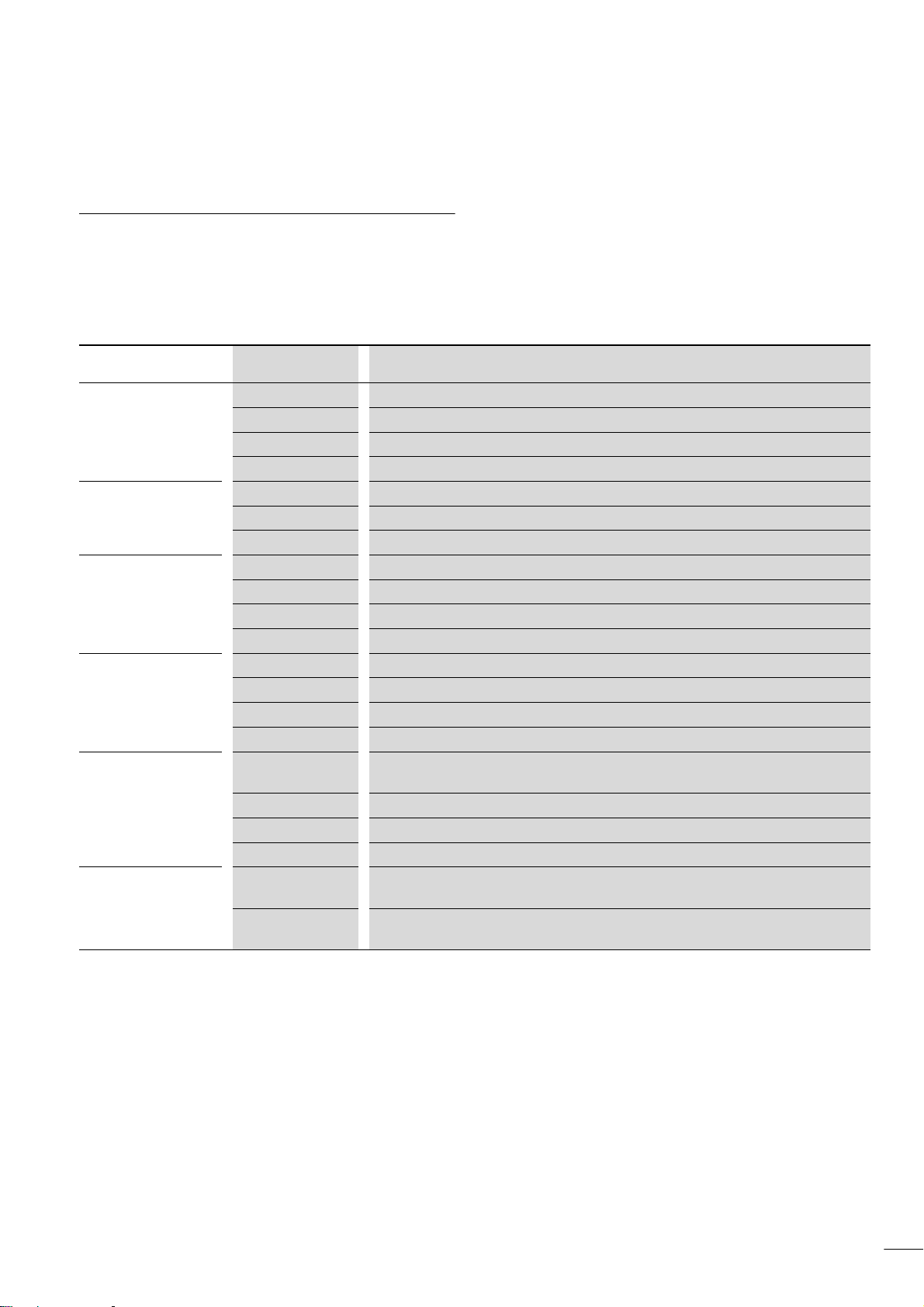

The following table provides an overview of the modules.

Table 1: List of signal modules

Designation

Module rack XIOC-BP-XC For CPU with power supply

Digital input module XIOC-8DI 8 channels, 24 V DC

Digital output module XIOC-8DO 8 channels, transistor output 12/24 V DC (source type)

Analogue input module XIOC-8AI-I2 Current input (channels 0 to 7) 4 to 20 mA, 12 bit

Analogue output module XIOC-2AO-U1-2AO-I2 Voltage output (channel 0 + 1) 0 to 10 V DC,

Counter module XIOC-1CNT-100kHz Input for fast counter, maximum frequency 100 kHz, 1 channel, switchable 1/2-phase,

1) With short-circuit protection

Type Technical data

XIOC-BP-XC1 For CPU with power supply, 1 signal module

XIOC-BP-2 For 2 signal modules

XIOC-BP-3 For 3 signal modules

XIOC-16DI 16 channels, 24 V DC

XIOC-16DI-AC 16 channels, 200 to 240 V AC

XIOC-16DO 16 channels, transistor output 12/24 V DC (source type)

XIOC-16DO-S

XIOC-12DO-R 12 channels, relay output

XIOC-8AI-U1 Voltage input (channels 0 to 7) 0 to 10 V DC,12 bit

XIOC-8AI-U2 Voltage input (channels 0 to 7) –10 to +10 V DC,12 bit

XIOC-4T-PT Pt100/1000 input (channels 0 to 3) 15 bit, signed

XIOC-2AO-U2 Voltage output (channel 0 + 1) –10 to 10 V DC

XIOC-4AO-U2 Voltage output (channels 0 to 4) –10 to 10 V DC

XIOC-4AO-U1 Voltage output (channels 0 to 4) 0 to 10 V DC

XIOC-2CNT-100kHz Input for fast counter, maximum frequency 100 kHz, 2 channels, switchable 1/2-phase,

1)

16 channels, transistor output 12/24 V DC (source type)

current output (channel 2 + 3) 4 to 20 mA, 12 bit

2 open-collector outputs

2 open-collector outputs per channel

5

Signal modules

05/02 AWB2725-1452GB

Accessories

Designation Type Comments

Spring-loaded

terminal

Screw terminals

XIOC-TERM-18T For digital and analogue

I/O modules

XIOC-TERM-18S

Assembly

a

0 1 2 3

4 5 6 7

8 9 10 11

12 13 14 15

b

c

PLC connection

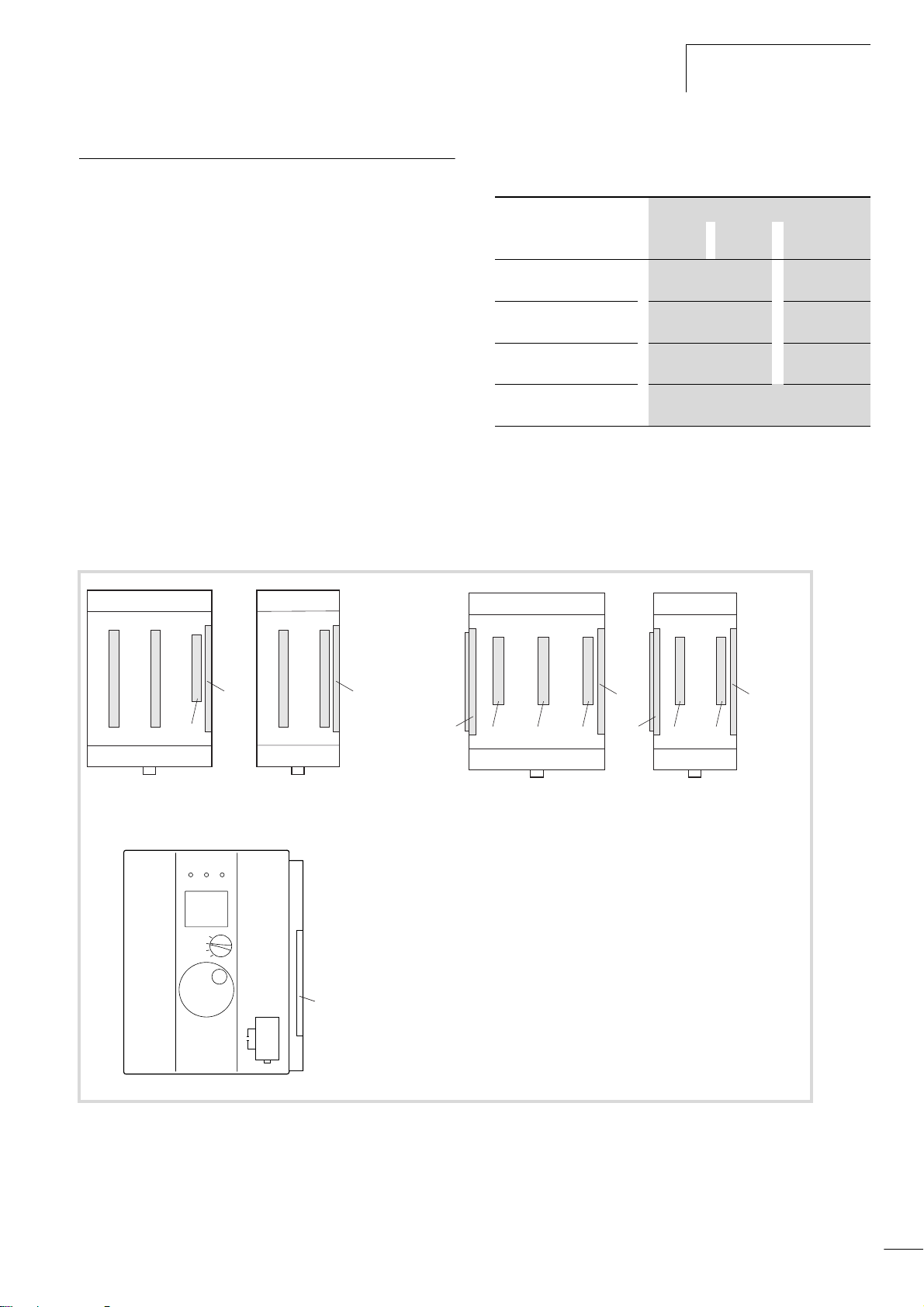

The XIOC modules are the I/O modules for the PLC types

XC-CPU100/200/400/600. The following diagrams show the

assembly of XIOC modules connected to a PLC.

Figure 2: XC-CPU400/600 with XIOC signal modules

d

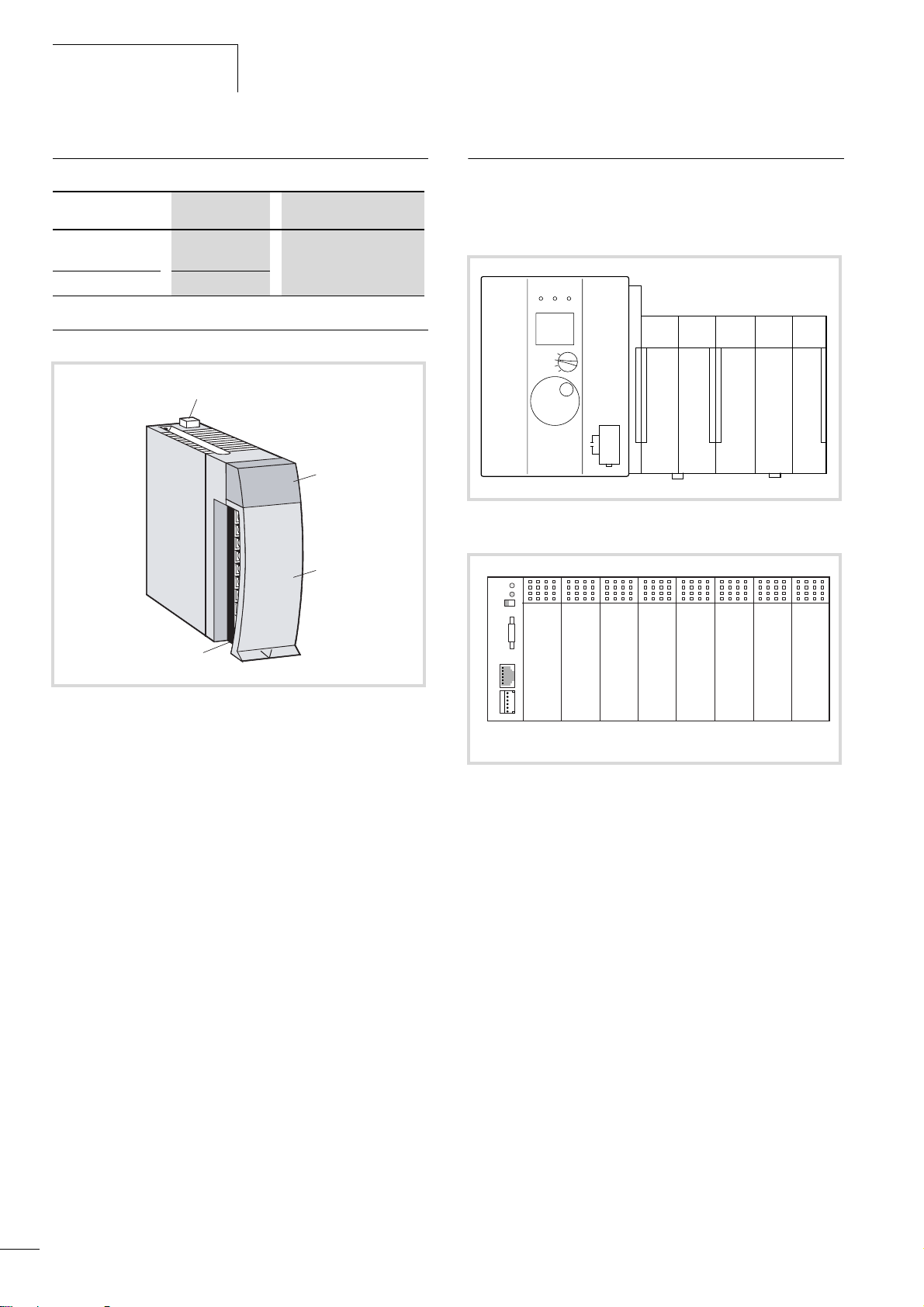

Figure 1: Assembly of a signal module

a Catch

b LED display

c I/O cover

d Terminal block

Figure 3: XC-CPU100/200 with XIOC signal modules

6

05/02 AWB2725-1452GB

Slot assignment in the module racks

Slot assignment in the module rack s

The XIOC modules are plugged onto module racks that provide the

connection to the PLC. The modules are also interconnected

through the module rack.

The integrated bus system ensures interference-free transmission

between the individual slots on the bus. In addition, the bus

system supplies the individual modules with the voltage that is

required for internal signal processing.

The supply voltage for the I/O electronics is applied directly to the

corresponding I/O modules.

Four different module racks are available:

XIOC-BP-XC1 XIOC-BP-XC

Table 2: Slot assignment in the module racks

Module rack Slots

1 2 3

XIOC-BP-XC

(Basic module rack)

XIOC-BP-XC1

(Basic module rack)

XIOC-BP-2

(Expansion module rack)

XIOC-BP-3

(Expansion module rack)

CPU with power

supply

CPU with power

supply

I/O module –

I/O module

–

I/O module

As a rule, the first module rack, which is used to take the CPU type

XC-CPU100/200, is a basic module rack. You can add on several

expansion module racks to the right side. The module racks must

be arranged so that one CPU module and a maximum of 7 XIOC

signal modules can be planned (a fig. 4).

XIOC-BP-3 XIOC-BP-2

d

adba

XC400/XC600

bc

d

d

ee

Figure 4: top left: expandable basic module rack

bottom left: expandable XC-CPU400/600

top right: expansion module rack

a Slot 1

b Slot 2

c Slot 3

d Bus expansion connector (socket)

e Bus expansion connector (plug)

bc

adba

7

Signal modules

05/02 AWB2725-1452GB

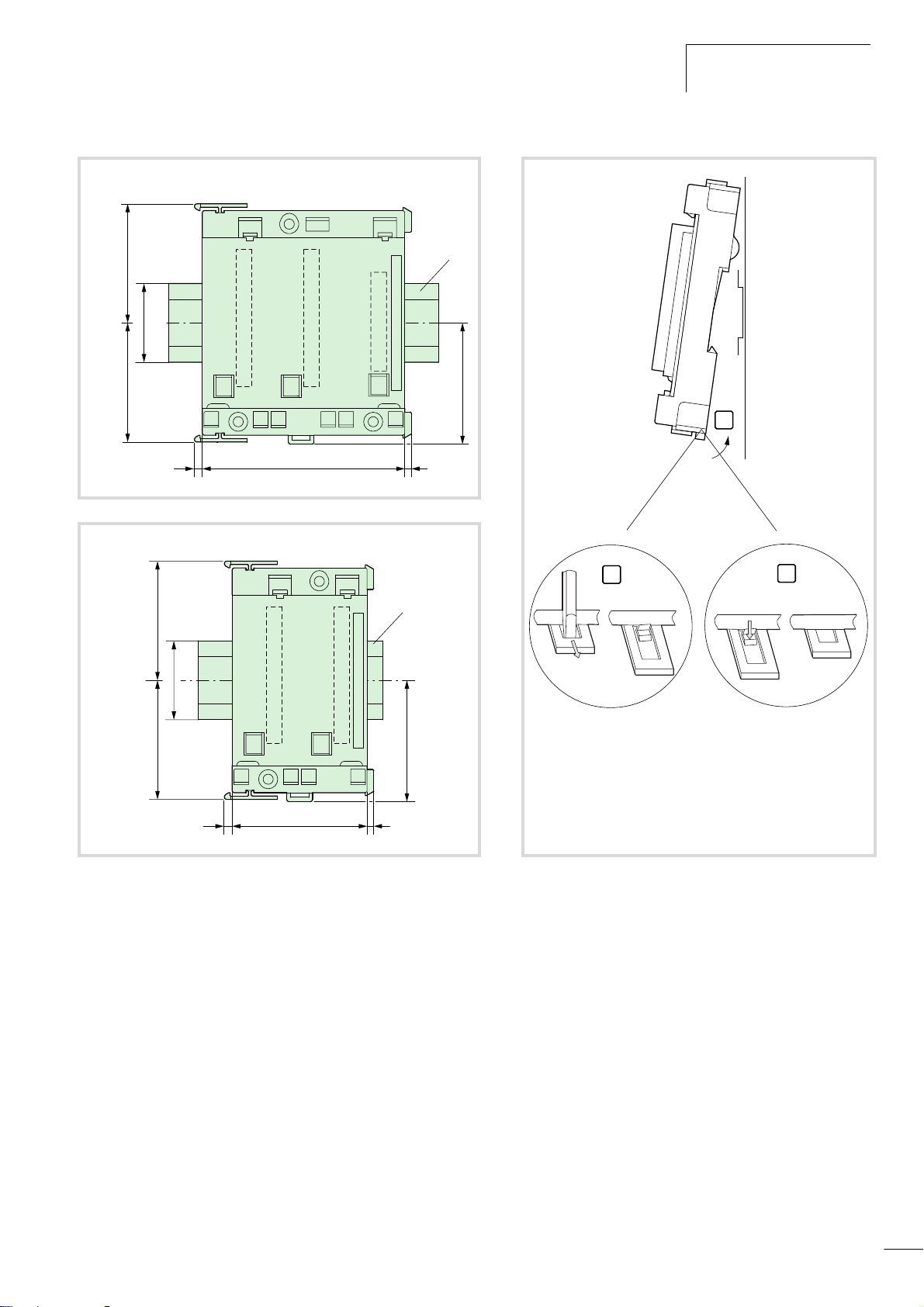

Mounting the module rack

The module rack can either be snapped onto a top hat (DIN) rail,

or screwed directly onto the mounting plate.

Caution!

i

The expansion module rack must only be plugged in or

pulled out when the power is switched off. FIrst detach

the CPU or I/O modules that were plugged into the

module rack. Discharge yourself from any electrostatic

charge before touching electronic modules. Voltage peaks

on the bus connector may cause malfunction or damage

to the modules.

Read the manual AWB2700-1428D for information on

h

mounting the XC-CPU400/600, and manual

AWB2724-1453D for the XC-CPU100/200.

Mounting on the top hat rail

X Use a screwdriver to pull out the locking bar until the catch

snaps into position. The locking bar is then held in this

position .

X Place the module rack on the top hat mounting rail so that the

1

top edge of the rail fits into the slot, and then slide the module

rack into the correct position .

X Press down the catch of the locking bar. The bar snaps in behind

2

the edge of the mounting rail. Check that the module rack is

firmly seated .

X If you want to fit an expansion module rack: push it to the left,

3

until the bus connector of the expansion module rack can be

plugged into the bus connector socket of the XC-CPU400/600

or the basic or expansion module rack. Take care that the bus

connectors of the module racks are completely engaged, in

order to ensure reliable electrical contact.

Mounting on the mounting plate

The spring contacts that protrude from the back of the module

rack are intended to provide a ground for the modules. They must

have a reliable electrical contact with the mounting plate.

Take care that the contact areas are protected from corrosion and

– if you are using painted mounting plates – that the paint layer is

removed from the contact areas.

X Plug the bus connector of the expansion module rack into the

bus connector of the XC-CPU400/600 or the basic or expansion

module rack. Take care that the bus connectors of the module

racks are completely engaged, in order to ensure reliable

electrical contact.

Detaching the module rack

X Use a screwdriver to pull out the locking bar until the catch

snaps into position. The locking bar is then held in this

position .

X Only with expansion module racks: Slide the expansion module

1

rack along the top hat rail to the right, until the bus connectors

are disengaged.

X Take the module rack off the rail.

8

05/02 AWB2725-1452GB

35

Detaching the module rack

a

53.5 53.5

3.5 390

53.5

35

53.5

3.5 360

a

54.5

54.5

2

1

3

Figure 5: Mounting on a 35 mm top hat (DIN) rail,

top left: XIOC-BP-XC1, (XIOC-BP-3)

bottom left: XIOC-BP-XC, (XIOC-BP-2)

a 35 mm top hat rail

See also dimensions on Page 14.

9

Loading...

Loading...