Moeller Marine XControl PLC System User Manual

Hardware, Engineering and Function Description

XControl PLC System

XC-POW50(-XION)-UPS Base Module

XC-ADP(-XION) Power Supply Module

XC-NET-CAN CANopen Module

XC-NET-DP-M PROFIBUS-DP Module

XC-CPU601-E.M CPU Module

XC-SYS1 Operator Module

12/01 AWB2700-1428GB

1st edition 2001, edition date 12/01

© Moeller GmbH, Bonn

Author: Peter Roersch

Editor: Thomas Kracht

Translator: Terence Osborn

All brand and product names are trademarks or registered

trademarks of the owner concerned.

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any otherprocess) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alterations without notice.

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on

this device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalisation. The system installer

is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for the

24 volt supply. Only use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable

units must only be operated and controlled in enclosed

housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must be

implemented to ensure a safe operating state in the event of

a fault or malfunction (for example, by means of separate limit

switches, mechanical interlocks etc.).

Moeller GmbH

Safety instructions

I

12/01 AWB2700-1428GB

Contents

About This Manual 3

Structure 3

Abbreviations and symbols 3

1 Hardware and Engineering 5

Setup 5

Mounting 6

– Fitting/removing modules 6

– Fitting XI/ON base modules 8

Engineering 8

– Control cabinet design 8

– Ventilation 9

– Device arrangement 9

– Preventing interference 9

– Suppression of interference sources 9

– Shielding 9

– Lightning protection measures 9

Wiring example (overview) 10

Switching the power supply on/off 10

XC-ADP/XC-ADP-XION base modules 11

– General 11

– Task of the XC-ADP-XION module 11

– Task of the XC-ADP module 11

– Engineering the XC-ADP-XION base module 11

– Expansion with XI/ON modules 12

XC-POW50-UPS/XC-POW50-XION-UPS

power supply modules 12

– General 12

–Task 12

– Setup 12

– Engineering 12

XC-NET-DP-M PROFIBUS-DP module 12

– General 12

–Task 12

– Engineering 13

– Bus terminating resistors 14

XC-NET-CAN CANopen module 14

– General 14

– Task of the module 14

– Engineering 14

XC-SYS1 operator module 16

–Task 16

– Setup 16

XC-CPU601-E.M processor 17

–Task 17

– Setup 17

2 Establishing the Connection Between PC and XC600 19

Requirements of the Ethernet module in the PC 19

Configuring the Ethernet module 19

Configuring the XC600 20

Creating the connection between PC and XC600 20

1

Contents

12/01 AWB2700-1428GB

3 Creating an Example Project 23

Setting the target system 24

Configuring the XC600 controller 25

– Creating programs 27

PROFIBUS-DP expansion 28

– Adding a PROFIBUS-DP module

to the XC600 controller 28

– Adding a remote XI/ON gateway 28

– Creating a program for PROFIBUS-DP expansion 29

CANopen bus expansion 30

– Adding a CANopenmodule to the XC600 controller 30

– Creating a program for remote outputs

on the CANopen bus 32

4 Functions of the Operator Module 33

Initial PLC startup 33

Loading the program into the PLC 33

Starting up the PLC with a bootable and

activated program 34

Entering parameters or status modifications 34

Starting programs 35

Display programs on the hard disk (internal) and

on the CompactFlash card (external) 35

Startup with configuration scan 36

Error and event messages 36

General messages 37

– Deleting programs from the hard disk 37

Deleting programs from the working memory 37

– Reset function (initialisation of variables) 37

Handling several programs 38

Deleting programs 38

Copying programs 38

Editing programs on the CompactFlash card (CFC) 38

Password 39

Displaying text from the user program 39

– Shutting down the system 40

Switching off the power supply 40

5 Menu Overview of the Operator Module 41

Basic menu 42

– MAIN MENU 42

Appendix 47

Other error messages 47

Technical Data 48

Index 51

2

12/01 AWB2700-1428GB

About This Manual

Structure

The XC600 PLC is designed for the control of machines and

systems. This controller provides the basis for an extensive PLC

system using interfaces for the standard networks PROFIBUS-DP,

CANopen and ETHERNET, for connecting remote expansion

modules and intelligent devices.

The documentation for the PLC is divided into five sections:

• Hardware and engineering

• PC-XC600 connection

• Creating an example project

• Functions of the operator modules

• Menu overview of the operator module

The Chapter “Hardware and Engineering” provides information

on the installation and engineering of the PLC as well as on the

possible PLC settings.

In order to communicate with the PLC, the PC must be connected

to it via the Ethernet network. The configuration of the Ethernet

module and the XC600 is described in the Chapter “Creating the

connection between PC and XC600” from Page 20.

Use of the XSoft software is then explained using a simple

example. This will show you how to configure and program the

controller. After you have downloaded the project you can then

test it as described in a Chapter “Creating an Example Project”

on Page 23.

Abbreviations and symbols

The abbreviations and symbols used in this manual have the

following meaning:

MSS

OMS

X Indicates instructions on what to do

”Choose Online r Login” means: Activate the Login menu item in

the Online menu.

Except for the first page of chapters and empty pages at the end,

the top left of the page shows the chapter title and the top right

of the page shows the current section for greater clarity.

Menu selector switch

Operating mode selector switch

Important!

Indicates the possibility of minor material damage.

Caution!

Indicates the possibility of major damage to property or

slight injury.

Warning!

Indicates the possibility of major damage to property or

serious or fatal injury.

The program can be started or stopped via the PLC's operator

module. These functions, as well as how to use the operator

module, are described in the Chapter “Functions of the Operator

Module” from Page 33 .

Chapter “Menu Overview of the Operator Module” from Page 41

explains the structure of all the menus and the individual menu

items.

3

12/01 AWB2700-1428GB

4

12/01 AWB2700-1428GB

1 Hardware and Engineering

Setup

The XC600 PLC has a modular design. The basic unit consisting of

the base, power supply, CPU and operator modules can be

expanded with function modules for communication. Modules for

the standard PROFIBUS-DP and CANopen networks are therefore

provided for this purpose. They provide the controller with access

to the I/O devices that log process data signals and control

actuators.

The process signals can also be connected locally with XI/ON input

and output modules. This requires the use of the power supply

module with the integrated XI/ON interface and the base module

with the XI/ON adapter.

A module consists of a circuit board that is embedded in a frame.

The special frame design makes it possible to stack the modules

together, thus allowing compact functional units to be combined

to suit the requirements of the task at hand.

The circuit boards of the individual function modules meet the

requirements of the PC/104+ specification. In addition to dimensions, the specifications also stipulate the requirements of the

PC/104+ bus that connects the modules. This bus also carries the

power supplies from the power supply module to the individual

function modules.

A configuration containing XI/ON input/output modules must

always include theXC-ADP-XION base module with the

XC-POW50-XION-UPS power supply module. The power supply

module adapts the PC/104+ bus to the XI/ON module bus using

the XI/ON interface. This bus is connected out from the base

module. The adapter on the base module provides the interface to

the XI/ON modules. The 24 V DC field power supply of the XI/ON

modules is also connected to the base module.

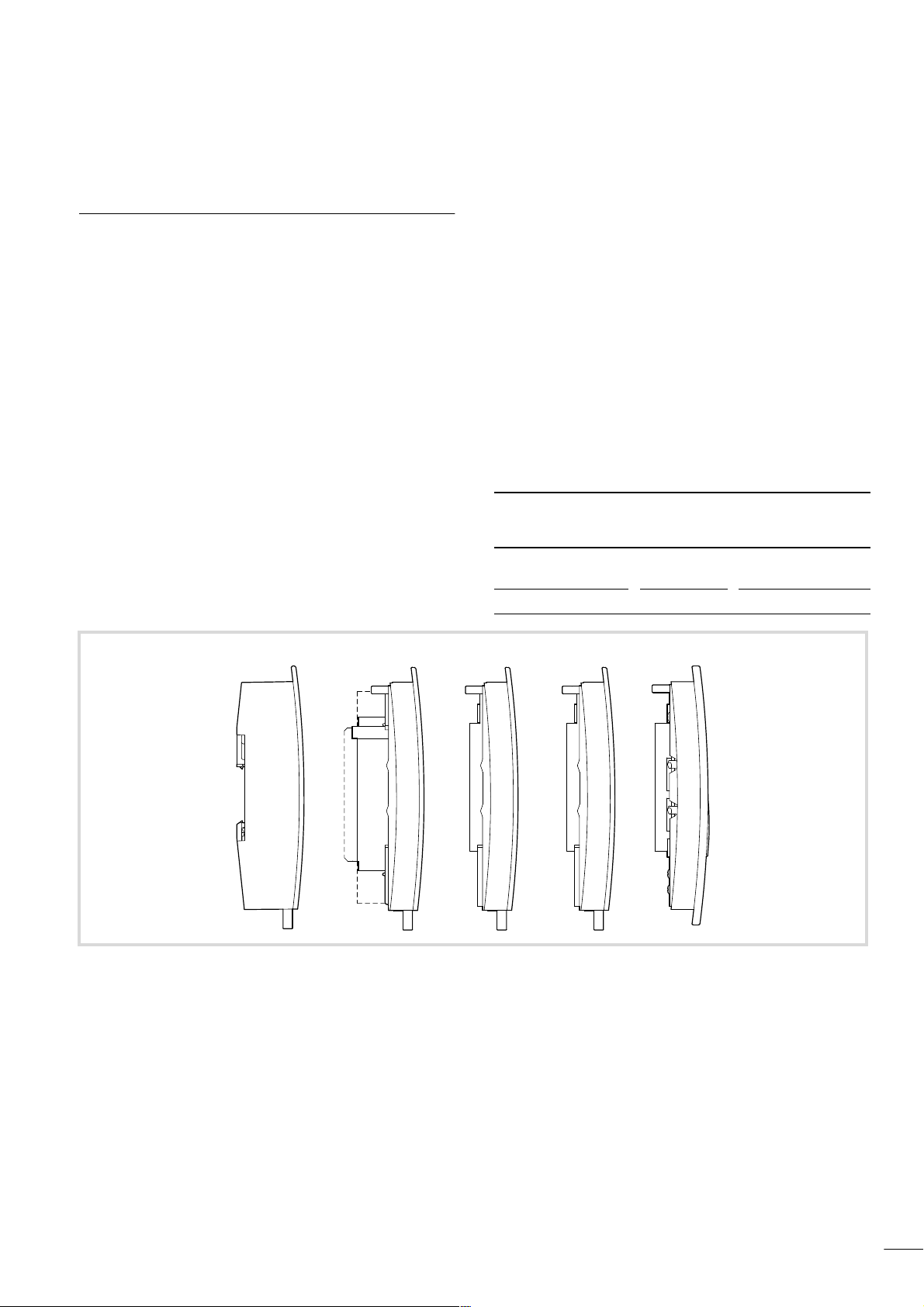

XC600 Base module Power supply

module

Without XI/ON

connection

With XI/ON connection XC-ADP-XION XC-POW50-XION-UPS

XC-ADP XC-POW50-UPS

c d e f g b a

Figure 1: Order of modules

a XC-ADP/XC-ADP-XION base module

b XC-POW50-UPS/XC-POW50-XION-UPS power supply module

c, d, e XC-NET-DP-M PROFIBUS-DP module*

or XC-NET-CAN CANopen module *

f XC-CPU601-ExM CPU module*

g XC-SYS1 operator module*

* Function modules

5

Hardware and Engineering

A maximum of three bus modules for PROFIBUS-DP and CANopen

can be fitted between the power supply and CPU module.

12/01 AWB2700-1428GB

Modules for the basic configuration: a, b, f, g

Bus modules: c, d, e

Mounting

Caution!

Only remove or fit modules with the power supply

switched off. Discharge yourself on any electrostatic

charge before touching a module.

Voltage peaks on the bus connector may cause

malfunctions or damage to the module.

The modules are supplied separately and must be fitted together.

Observe the order shown in Figure 1 and fit the base module first

of all on a horizontal mounting rail.

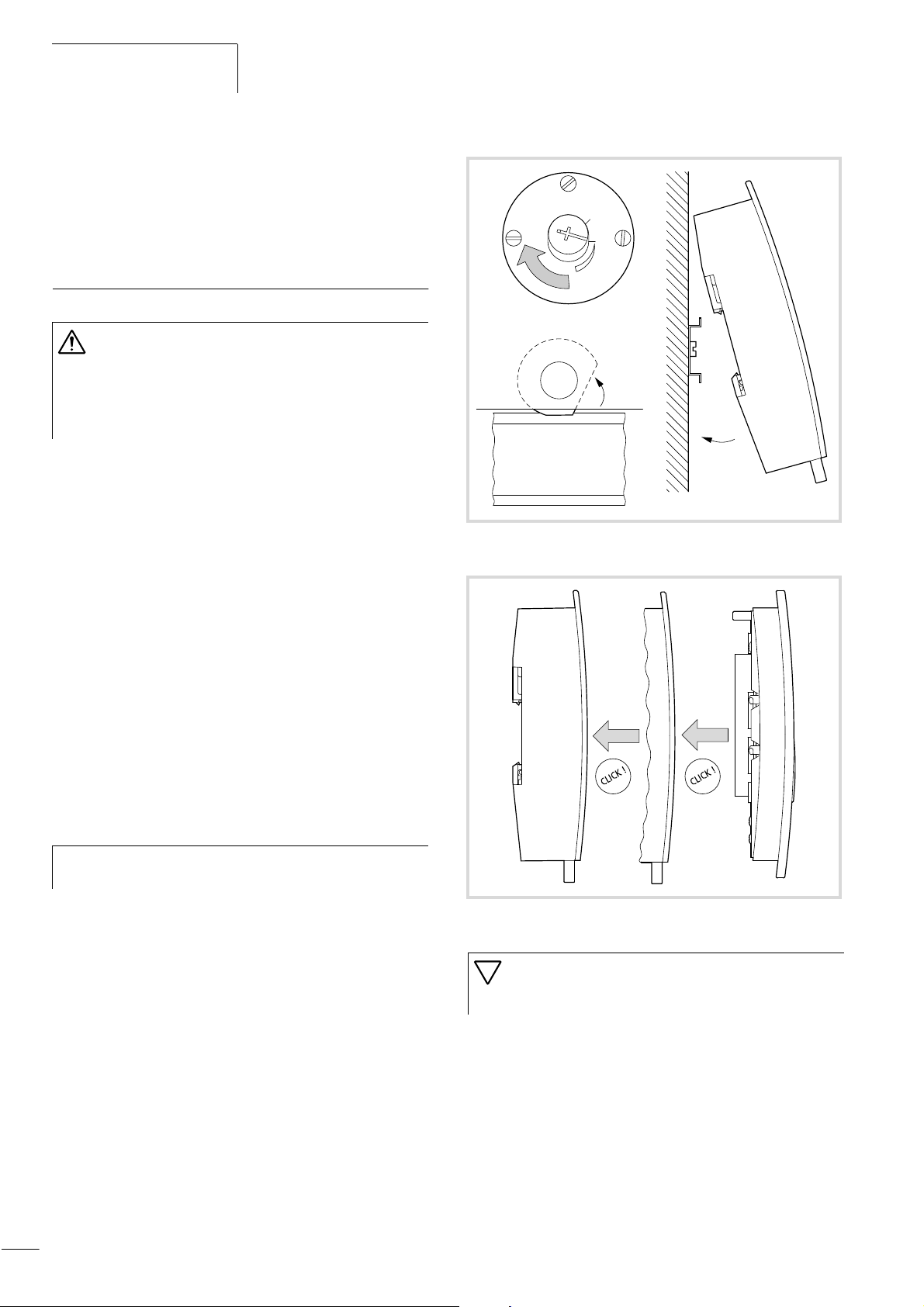

Fitting/removing modules

The back of the base module is provided with an eccentric plate.

Using a cheese head screwdriver, turn this plate so that it grips

underneath the mounting rail and secures the base module. The

front of the plate has number markings to ensure that it is positioned correctly.

0

1

Figure 2: Fitting the base module

X To fit the controller on the mounting rail, rotate the eccentric

plate until the longer slit is pointing to Position 1 (a Fig. 2).

X Hook the base module on the mounting rail (a Fig. 2).

X Turn the eccentric plate to the right until the base module is

secured firmly.

X Fit the power supply module and then the function modules.

The operator module is the last component to be fitted

(a Fig. 3).

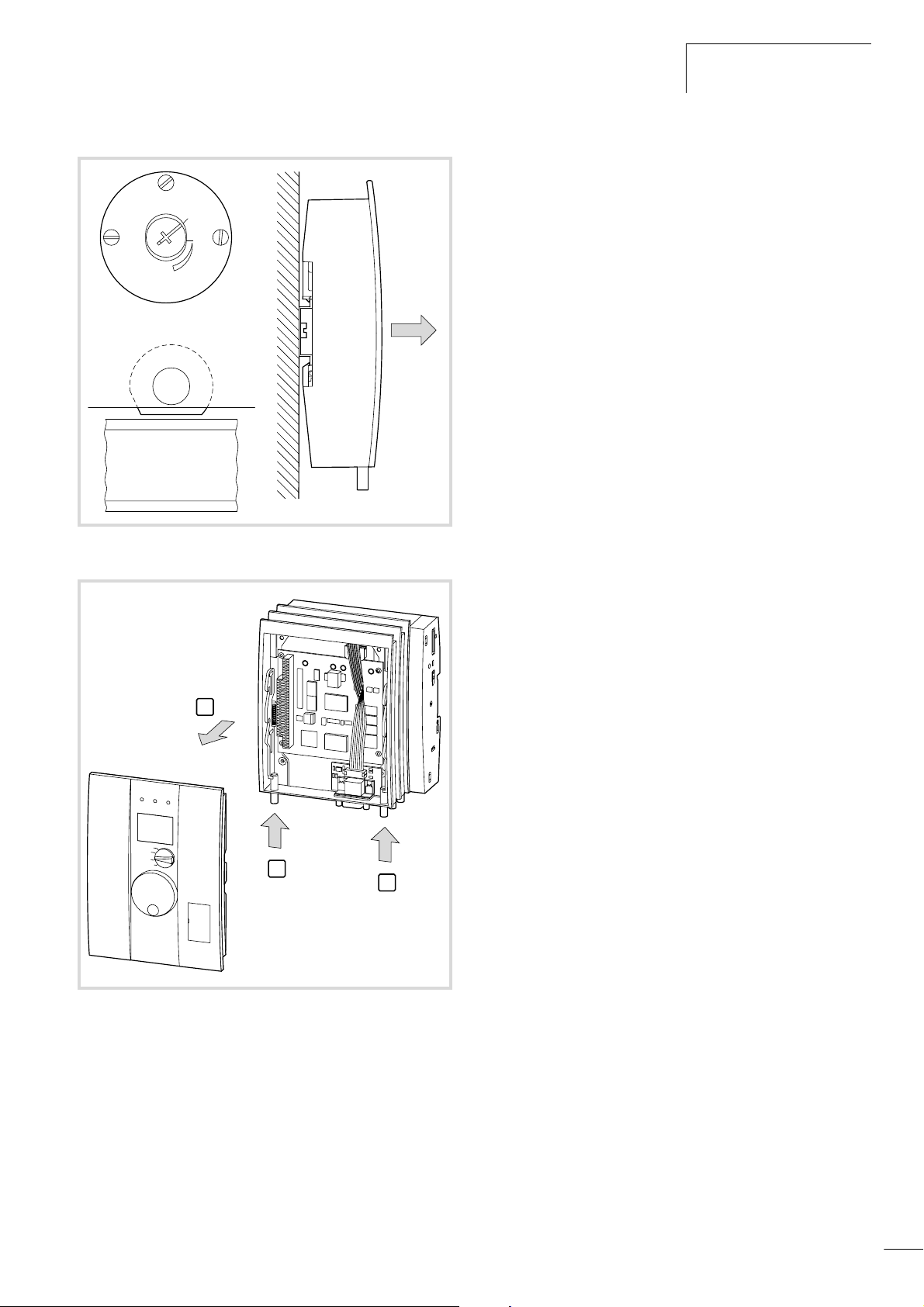

The modules are removed as shown in a Fig. 4 and

h

Fig. 5.

Figure 3: Fitting the modules together

Important!

When fitting the modules together, ensure that the socket

connectors fit exactly into the plug connectors.

6

12/01 AWB2700-1428GB

0

1

Mounting

Figure 4: Removing the base module

2

1

1

Figure 5: Detaching the modules

7

Hardware and Engineering

12/01 AWB2700-1428GB

Fitting XI/ON base modules

Further information on mounting and wiring is provided in

h

the XI/ON manuals, e.g. ”Hardware and Engineering” –

XI/ON PROFIBUS-DP (AWB2700-1394).

The XI/ON base modules are fitted on the right of the XC600

controller on the mounting rail:

X Fit the groove of the XI/ON base module onto the mounting rail

from underneath .

X Tilt the upper end back and press the base module against the

mounting rail until you can hear it snap into position

X Push the base module as far left as possible until the two snap

1

2

.

hooks on the side of the adapter or neighbouring base module

click into position .

X Fix the XI/ON modules using the end bracket and end plate on

3

the mounting rail.

2

Figure 6: Fitting XI/ON modules

Wire the base modules after they have been fitted and

h

before you have fitted the electronic modules!

X Once you have fitted all modules, switch on the 24 V power

supply on the XC-POW50-XION-UPS module in order to provide

the 5 V supply to the XI/ON modules.

X Check that the modules are working correctly (no fitting errors,

no gaps).

Only apply the field voltage on the XC600 controller base

h

module after the error-free state of the station is ensured.

3

1

Engineering

Control cabinet design

The arrangement of components in the control cabinet is an important factor in ensuring that system and machine functions are free

of interference. During the planning and design stages, as well as

during implementation, it must be ensured that the power and

control sections are separated. The power section includes the

following components:

• Contactors

• Coupling modules

• Transformers

• Frequency inverters

• Current converters

Dividing the control cabinet into to areas with different power and

interference levels is recommended as an effective prevention

against electromagnetic interference. In small control cabinets,

this can often be provided sufficiently by using separators in order

to reduce interference.

8

12/01 AWB2700-1428GB

Engineering

Ventilation

A minimum gap of 5 cm between passive components must be

provided in order to ensure sufficient ventilation. If active components (e.g. load power supply, transformers) are fitted next to each

other, a minimum gap of 7.5 cm must be ensured. Observe the

values specified in the technical data.

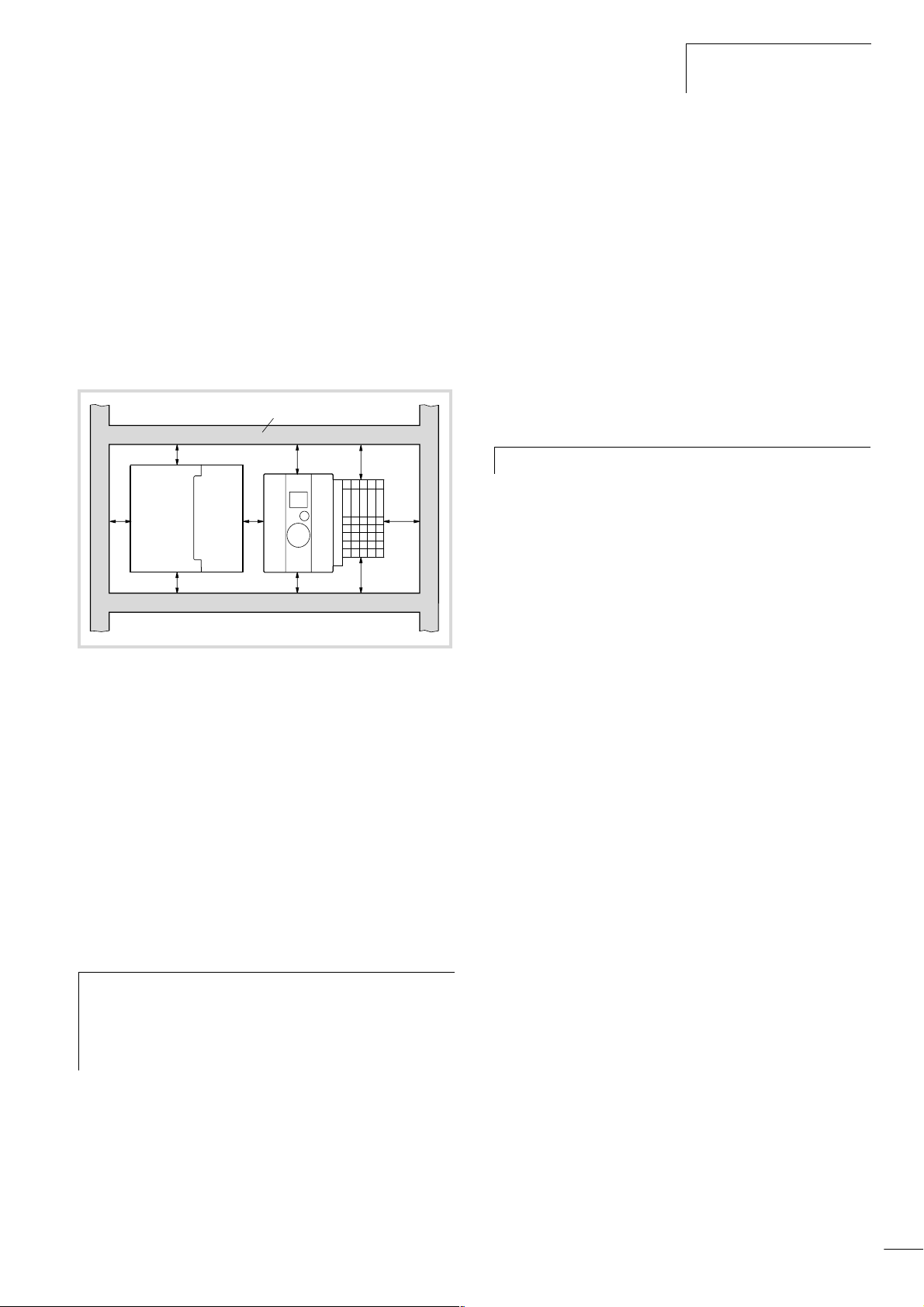

Device arrangement

Mount the UPS unit and the controller horizontally in the control

cabinet as shown in the following figure.

햴

햲

햵

햲

햲 햳

햲

햲

햲

햳

햳

X Observe the following minimum gaps:

– Between heavy current cables and signal cables at least

10 cm

– Between heavy current and data/analog cables at least

30 cm.

– Make sure that the supply and return cables belonging to

each circuit are laid together. The opposing direction of

current flow means that the sum of all the currents is zero, so

that any fields which are produced are compensated.

Suppression of interference sources

X Keep all suppressor circuits as close to the interference source

(contactor, relay, solenoid) as possible.

Switched inductive loads should always be suppressed.

h

Shielding

X Connections to data interfaces should be implemented with

shielded cables. General guideline: the lower the coupling

impedance, the better the shielding effect.

Figure 7: Arrangement in the control cabinet

a Gap > 50 mm

b Gap > 75 mm from active elements

c Cable duct

d UPS unit

Preventing interference

Cabling and wiring

The following cable types are required:

• Heavy current cables (e.g. power cables carrying high currents,

or cables to current converters, contactors, solenoid valves)

• Control and signal cables (e.g. digital input cables)

• Measuring and signal cables (e.g. fieldbus cables)

Keep heavy current cables, control cables and signal

h

cables as far apart from each other as possible. This will

prevent capacitive and inductive interference. If separate

cable routing is not possible, the interference cable must

be shielded.

Ensure correct cable routing inside and outside of the control

cabinet in order to keep interference to a minimum:

X Avoid laying cables with different power levels in parallel.

X Always separate AC from DC cables.

Lightning protection measures

External lightning protection

All cables linking buildings must be shielded. Metal conduits are

recommended as the most suitable means of protection. Signal

cables must be provided with overvoltage protection in the form of

varistors or other overvoltage arresters. This should be implemented as close as possible to the point where the cable is routed

into the building, and at least before the cable enters the control

cabinet.

Internal lightning protection

Internal lightning protection includes all measures that reduce the

effect of lightning current and its electrical and magnetic fields on

the metallic installation and electrical system inside a building

complex. This consists of:

• Lightning protection potential equalisation

• Shielding

• Use of overvoltage protective devices.

Further information on cabling and shielding is provided in the

following manuals:

• AWB27-1287 ”EMC Design Guide for Automation Systems”.

• TB27-001-GB ”The Electromagnetic Compatibility of

Automation Systems”.

• TB27-022-GB ”The Electromagnetic Compatibility (EMC) of

Machines and Plants”.

9

Hardware and Engineering

12/01 AWB2700-1428GB

Wiring example (overview)

a

L1

L2

L3

N

PE

b

c

c

d

N

L1

PE

0 V

5

24 V

6

~

+24 V 0 V

f

e

1

1

1

C

24 V

XC-ADP-XION

0 V

XI/ON-Modul

XC600

0

0 V

XC-POW50-

UPS-XION

1

0

24 V

2

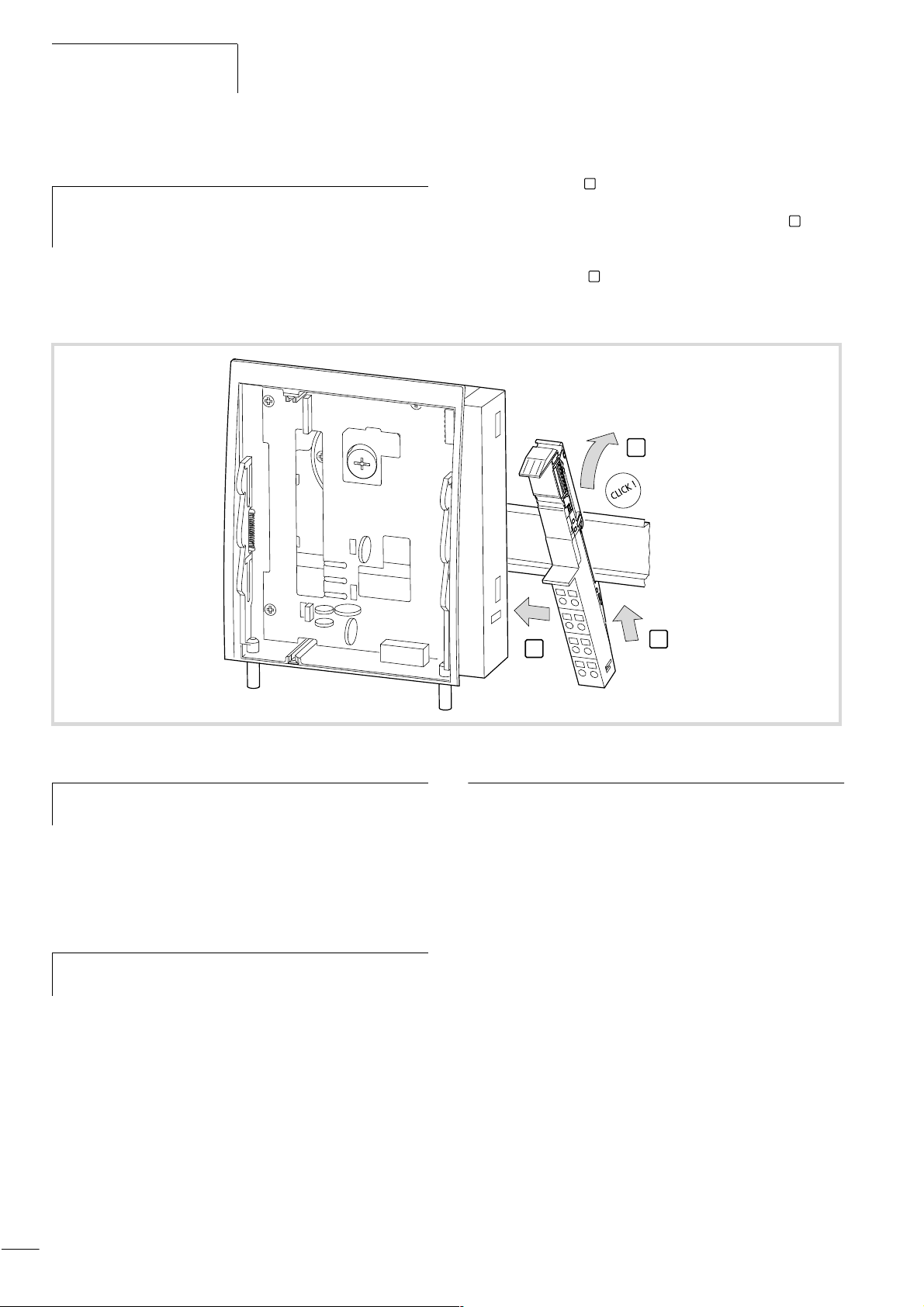

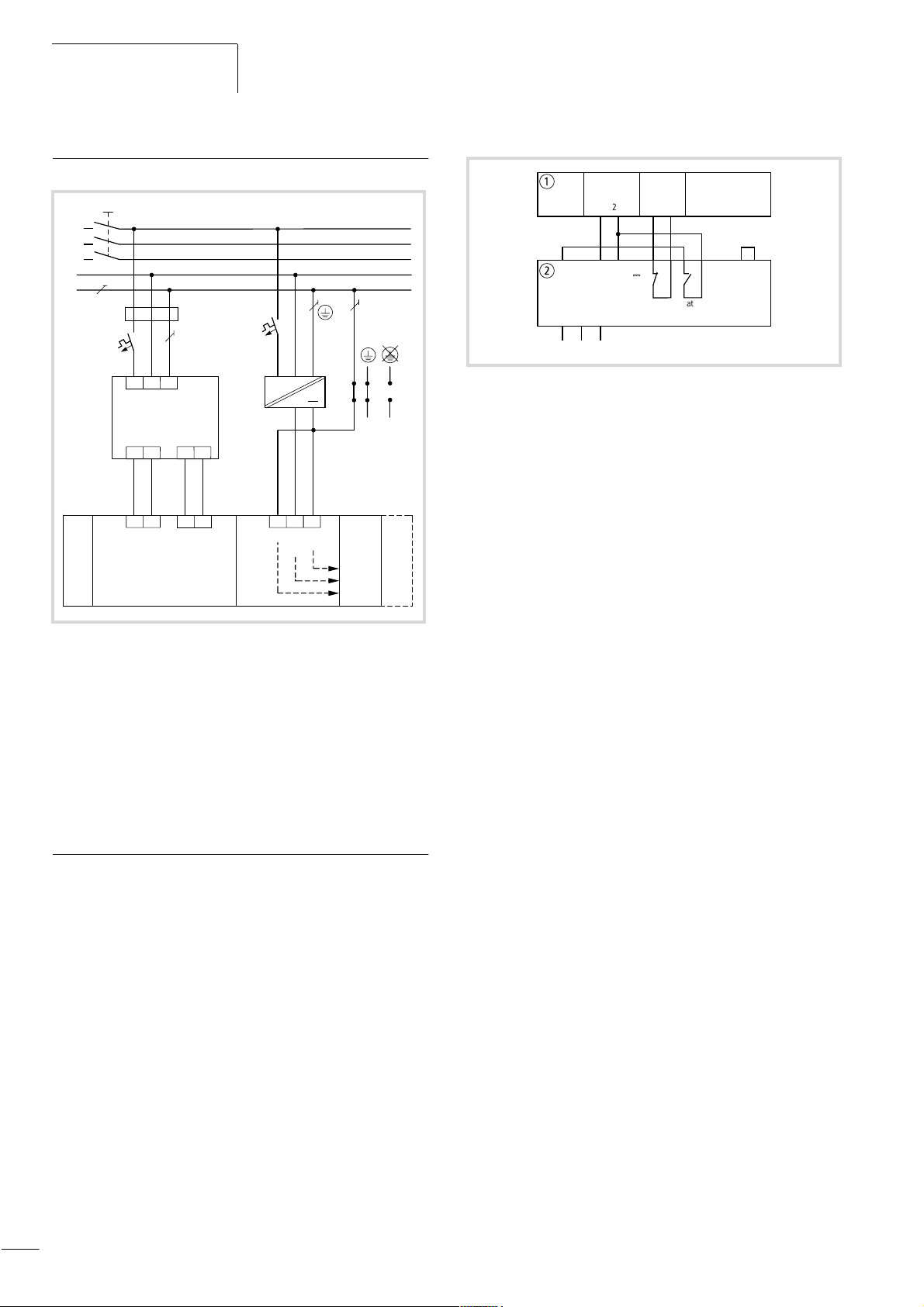

Figure 8: Example of wiring

a Main switch

b Delayed switching of the power supply (a Fig. 10)

c Miniature circuit-breaker

d UPS device

e Wiring between UPS device and the XC600 power supply module

(a Fig. 9)

f Non-grounded control circuits must be provided with insulation

monitoring.

Switching the power supply on/off

The UPS ensures that the XC600 controller is switched off properly

in the event of a power supply failure. This requires the inputs/

outputs of the UPS device and the other devices to be wired as

shown below.

a

1

245

b

Batt.

0 V

off

L1 N PE

0 V

Power

Supply

0

3

0 V

24 V

24 V

Power

Fail

0

12

6 7 8 9 10 11 12

H

C1 C2

Power

Supply

Battery

2 min.

UPS

Release

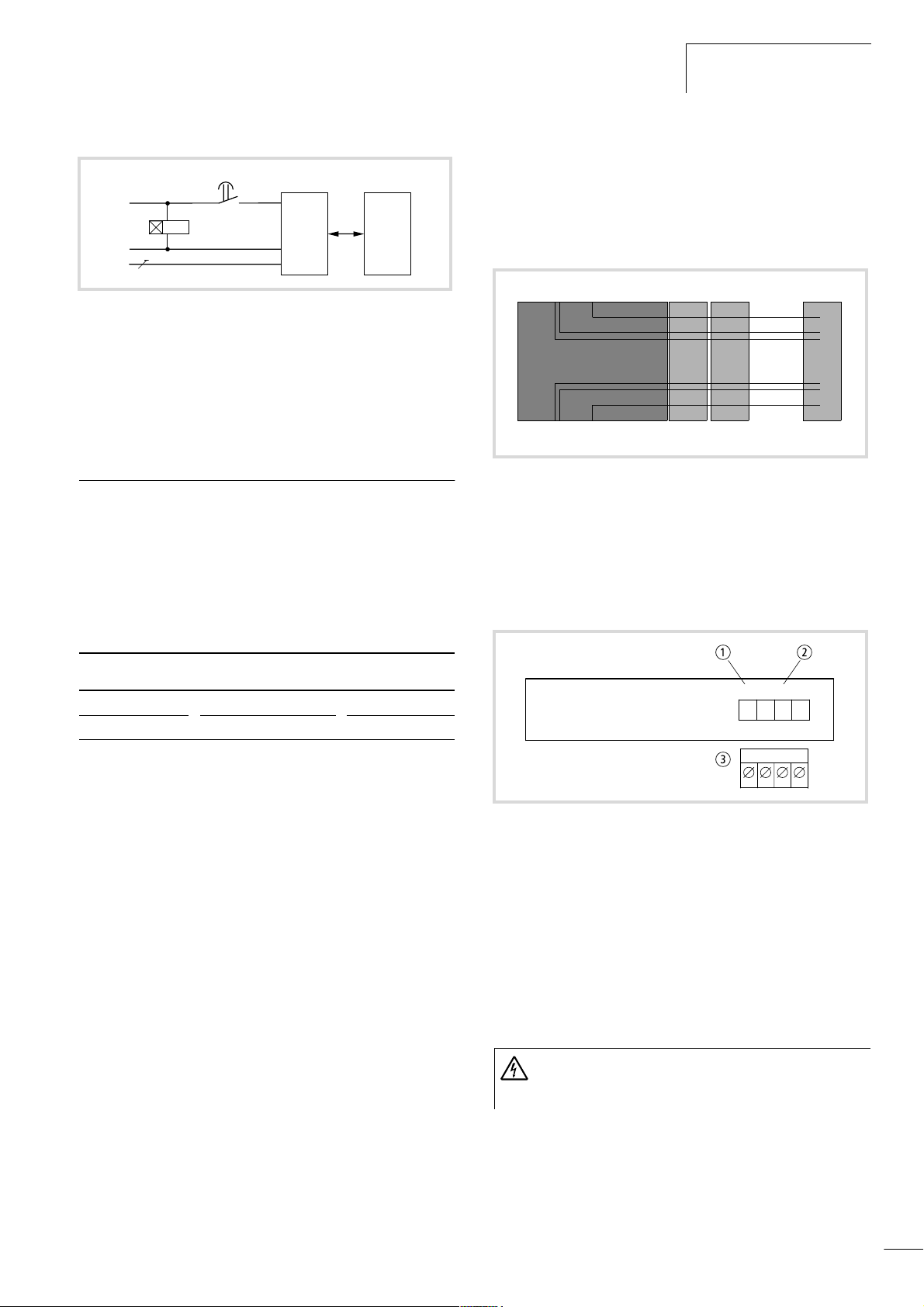

Figure 9: Wiring between UPS device and the XC600 power

supply module

a XC600 (XC-POW50-(XION-)UPS)

b UPS device

If the supply voltage to the UPS device drops, the controller is

supplied with the battery supply voltage. The contact ”C1” in the

UPS device opens and the circuit at the Power Fail input of the

power supply module is interrupted. This will cause the controller

to initiate the PFI signal, which will cause the system to shut down.

The controller requires approximately two minutes to do this.

By connecting the Battery off input of the UPS to contact C2, the

UPS device can switch off the battery supply voltage after two

minutes. The battery is then used only for these two minutes so

that further battery backup protection is ensured occur. If power

is restored after two minutes, the controller will start up again

according to how the operating mode selector switch is set.

A different routine is followed if the power supply to the UPS

returns within two minutes: while the power to the UPS device has

failed, the controller is at first initially supplied by the battery

voltage until power is restored. As the UPS device signals the

power failure to the controller (Power Fail input), the controller

starts a system shutdown (2 minutes). The following message will

be shown on the display: ”PFI shut down in progress”.The operation ends with the message ”TURN OFF YOUR CONTROLLER” on

the display.

In this case, the controller has not detected a power failure. When

the PLC is restarted, the power supply of the UPS system must be

switched off and on again. If the start is to take place automatically, an on-delayed timer must be used to lengthen the interruption to more than 2.5 minutes (a Fig. 10).

10

In the event of a power failure the PLC will then shut down after

two minutes and will restart automatically after 2.5 minutes.

12/01 AWB2700-1428GB

ab

a

L1

K1T

N

PE

Figure 10: Delayed switching of the power supply

a UPS device

K1T

L1

N

PE

XC600

These functions were implemented by adapting the UPS device

supplied by Konzept to the power supply modules of the XC600.

When using a different UPS device, the wiring must be adapted

accordingly.

XC-ADP/XC-ADP-XION base modules

General

A base module and a power supply module form one unit. The

following table shows the combination possibilities of both

modules. The modules only differ in their capability for expansion

with XI/ON modules.

Base module Power supply module Expansion

XC-ADP/XC-ADP-XION base

modules

Engineering the XC-ADP-XION base module

Power supply for the XI/ON modules

The 24 V DC power supply required for the load supply of the XI/

ON modules is connected to the base module (a also ”Power

supply module”). The maximum current consumption is 10 A.

XI/ON modulesXC-ADP-XION

cd

Figure 11: Connections between the XC-ADP-XION base module

and the XI/ON modules

a 5 V DC from the power supply module

b Data from the supply module

c Field supply 24 V DC

d C rail connection

Connections

ab

XC-ADP XC-POW50-UPS XI/ON

XC-ADP-XION XC-POW50-XION-UPS –

A base module provides the platform for the other function

modules that are fitted on. The complete unit is then fitted on the

mounting rail.

Task of the XC-ADP-XION module

The module controls the XI/ON data bus and provides the power

supply (5 V) to the XI/ON modules. The base module has a separate connection for the 24 V DC field power supply of the XI/ON

modules. It also has a C connection to which the potential for the

C rails of the XI/ON modules can be connected.

How to expand the controller with XI/ON modules is described in

the XI/ON manuals, ”Hardware and Engineering”, e.g.

AWB2700-1394.

Task of the XC-ADP module

This is used as a platform for other modules.

24V 0V11C

1

Field

Supply

c

Figure 12: 24 V DC and C1 connections of the XC-ADP-XION

a 24 V DC connection

b C rail connection

c Plug-in terminals, connection cross-sections:

– flexible with ferrule 0.5 mm

– solid 0.5 mm2 to 2.5 mm

2

to 2.5 mm

2

2

The C1 connection is routed to the XI/ON modules. It is used for

providing an additional common potential, e.g. PE.

XI/ON modules that have a C in their designation, e.g. S4T S-B-CS, require the provision of a common C rail.

Warning!

The maximum load on the C rail and C1 connection is

24 V!

11

Hardware and Engineering

12/01 AWB2700-1428GB

Expansion with XI/ON modules

The following XI/ON base modules can be connected directly to

the XC-ADP-XION base module:

• Modules with tension clamp connection

• Modules with screw connections without C rail

Bus refreshing modules and power feeding modules cannot be

connected directly.

XC-POW50-UPS/XC-POW50-XION-UPS power supply modules

General

A base module and a power supply module form one unit. The

following table shows the combination possibilities of both

modules. The only difference between the modules is their expansion capability with XI/ON modules.

Base module Power supply module Expansion

XC-ADP XC-POW50-UPS XI/ON

XC-ADP-XION XC-POW50-XION-UPS –

24 V

Power

Fail

24 V

H

H

XC-POW50-XION-UPS

24 V

H

Power

Fail

Diagnostics

XI/0N

ISA Interface

XC- ADP-XION

5 V

+12 V

–12 V

ISA-BUS

USV

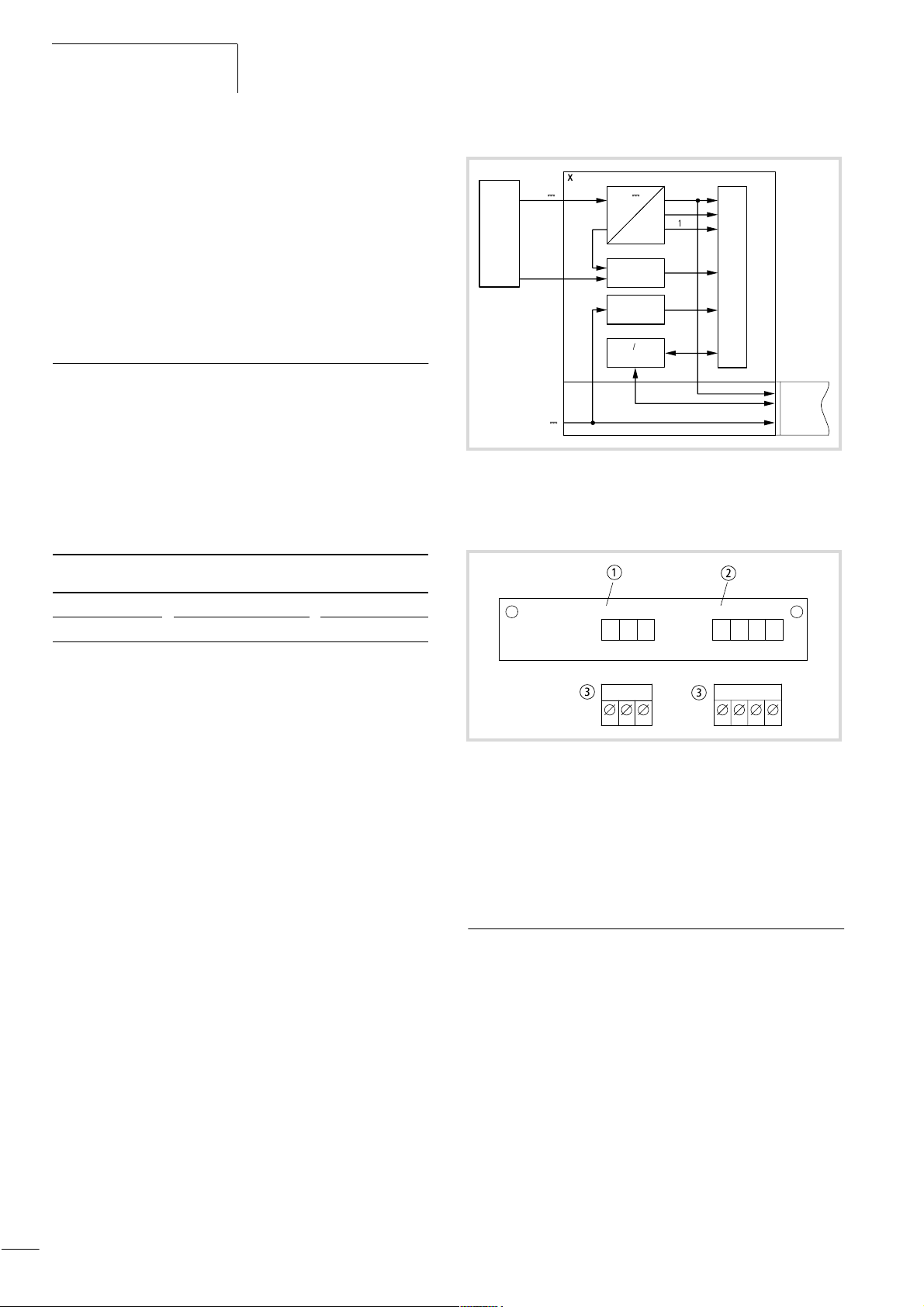

Figure 13: Block diagram of the power supply module

Engineering

a

12 24Vo 0Vo

Power Fail

Power

b

Supply

XI/ON

Modulebus

Fieldbussupply

Task

The modules convert the 24 V DC power supply to +5 V DC,

+12 V DC and –12 V DC (for XC-POW50-XION-UPS) supplies, and

provide the voltages for the function modules via the PC/104+

bus. The XC-POW50-XION-UPS power supply module also

provides a 5 V DC supply to XI/ON modules via the XI/ON module

bus.

As the XC600 controller is PC-based, it must be ensured that the

program is closed and the operating system shut down properly

before the device is switched off. The supply of the power supply

module must therefore be backed up by means of an uninterruptible power supply (UPS). If the supply voltage drops, the UPS sends

a Power Fail signal to the PLC which then initiates a shutdown of

the system. The UPS unit will then keep the output voltage

constant for at least two minutes in order to ensure the troublefree completion of the shutdown.

Setup

The module contains a board with the PC/104+ bus. Another

board provides the interface for the XI/ON modules and connects

the power supply module with the base module.

c

c

Figure 14: Connections of the XC-POW50-UPS/

XC-POW50-XION-UPS

a Power Fail connection

b 24 V DC connection

c Plug-in terminals, connection cross-sections:

– flexible with ferrule 0.5 mm

– solid 0.5 mm2 to 2.5 mm

2

2

to 2.5 mm

2

XC-NET-DP-M PROFIBUS-DP module

General

The module provides the interface between the CPU module and

the PROFIBUS-DP bus that is compliant with industrial standard

EN 50170 Vol. 2.

Task

12

The module provides the master function for PROFIBUS-DP. It

organises and operates the data exchange between the user

program and the connected slaves. Up to 31 slaves can be

connected to one line. Several sections can be connected together

using repeaters, enabling up to 125 slaves to be connected.

12/01 AWB2700-1428GB

XC-NET-DP-M PROFIBUS-DP

module

The PROFIBUS-DP module can be fitted between the power supply

module and the CPU module.

Engineering

PROFIBUS-DP interface

Connect the module to the PROFIBUS-DP bus via the isolated

RS 485 interface (9-pole SUB-D socket/plug connector).

Use the special ZB4-209-DS2 PROFIBUS-DP plug. It

h

provides the wiring required for trouble-free operation up

to 12 Mbit/s.

Figure 15: Connections of the PROFIBUS-DP module

5

9

4

8

3

7

2

6

1

Devices that are still connected with the PLC will continue to be

interrogated.

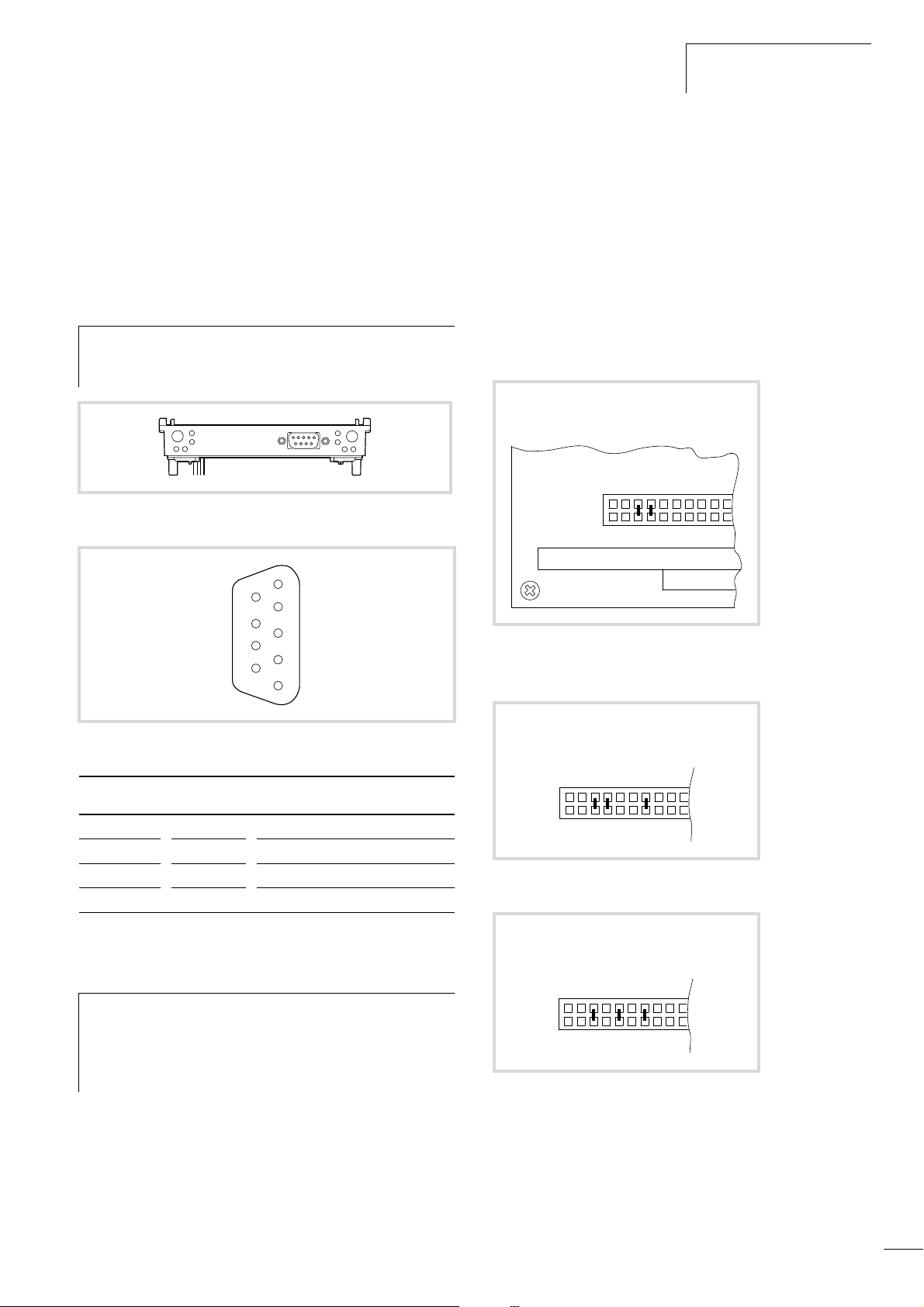

Configuring the module address

Up to three XC-NET-DP-M (PROFIBUS-DP) or XC-NET-CAN

(CANopen) modules can be used in any combination. Reserve a

memory range for each module in the CPU by defining a module

address for each one:

Setting the address on the device

X Set the address for each module using jumpers on the jumper

field in the jumper area 13 to 19 (a following figures).

1. r CE000*

110

0111

19 18 17 16 15 14 13

Figure 17: Address setting of module 1

* Factory setting

Figure 16: Pin assignment of the PROFIBUS-DP interface

SUB-D plug Signal Meaning

3 RxD/TxD-P Receive/send data P

5 DGND Data reference potential

6 VP Supply voltage plus pole

8 RxD/TxD-N Receive/send data N

Power supply

The power supply module provides the 5 V supply to the modules

via the PC/104+ bus.

Set up the system power supply so that the connected

h

remote stations on the PROFIBUS-DP line are switched on

simultaneously or before the controller. This prevents any

errors occurring during the starting of the PROFIBUS-DP

line.

Start/Stop behaviour

Setting the OMS to the STOP position will cause all the outputs of

the remote devices to be set to 0.

An interruption on the DP line will cause all inputs of the disconnected devices (receive data) to be interpreted by the PLC as 0

signals and the outputs set by the PLC in the output module to be

reset.

2. r CC000

110

0110

19 18 17 16 15 14 13

Figure 18: Address setting of module 2

3. r D4000

110

1010

19 18 17 16 15 14 13

Figure 19: Address setting of module 3

Setting the address in XSoft

Assign the input/output address range (%IB/%QB) to the modules

in the PLC configuration in XSoft. The modules are integrated in

turn into the PLC configuration:

13

Hardware and Engineering

12/01 AWB2700-1428GB

X Assign the memory range beginning with start address CE000

to the first module (CANopen or PROFIBUS-DP) to be

configured.

The input/output devices assigned to this module are connected to

the module bus system via address CE000.

X Assign the range starting with address CC000 to the second

module and D4000 to the third.

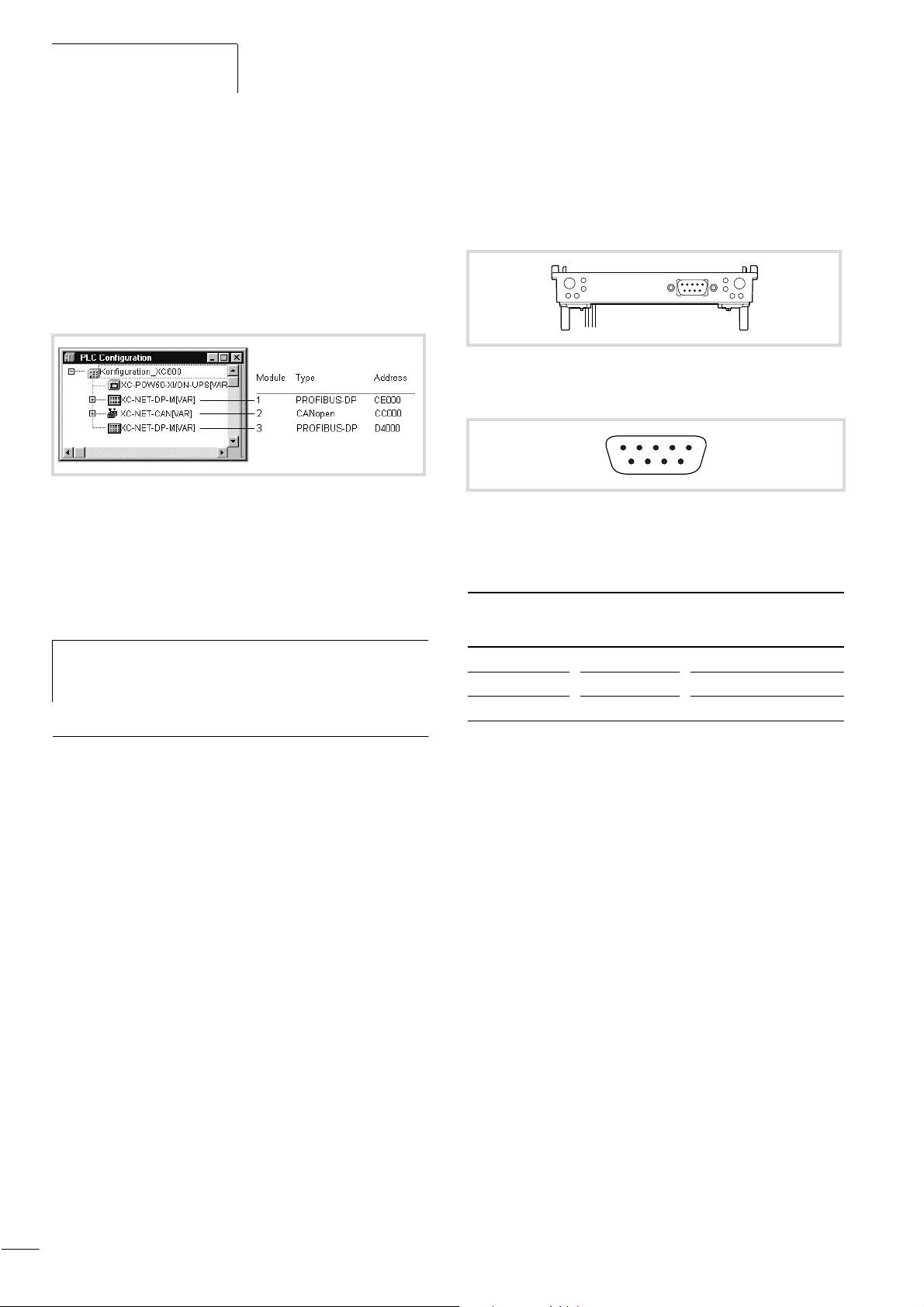

Figure 20: Example configuration with three modules and the

assigned addresses

Bus terminating resistors

Bus terminating resistors must be provided at both ends of the

cable.

Engineering

CANopen interface

The module can be connected to the CANopen bus via the isolated

ISO 11898 interface.

Figure 21: CANopen interface

Pin assignment

34125

8967

Figure 22: Pin assignment of the CANopen interface

Connector assignment in accordance with the CiA DS 102

(CAN Physical Layer for Industrial Applications) standard.

SUB-D plug

connector

Signal Meaning

When using the ZB4-209-DS2 PROFIBUS plug, the bus

h

terminating resistor can be enabled or disabled via the

slide switch on the plug.

XC-NET-CAN CANopen module

General

The module provides the ISO 11898 interface between the CPU

module and the CANopen bus.

Task of the module

The module provides the master function for CANopen bus. It

organises and operates the data exchange between the user

program and the connected slaves. Up to 126 nodes can be

connected to a line.

The CANopen modules can be fitted between the power supply

module and the CPU module. Up to three modules (PROFIBUS-DP

or CANopen) can be fitted.

2 CAN_L CAN_L bus cable

3 CAN_GND CAN reference potential

7 CAN_H CAN_H bus cable

Power supply

The power supply module provides the 5 V supply to the modules

via the PC/104 bus.

Set the system power supply so that the connected remote stations

on the CANopen line are switched on simultaneously or before the

controller. This prevents any errors occurring during the starting of

the CANopen line.

Start/Stop behaviour

Setting the OMS to the STOP position will cause all the outputs of

the remote devices to be set to 0.

An interruption on the line will cause all inputs of the disconnected

devices (receive data) to be interpreted by the PLC as 0 signals and

the outputs set by the PLC in the output module to be reset.

Devices that are still connected with the PLC will continue to be

interrogated.

Configuring the module address

Up to three XC-NET-DP-M (PROFIBUS-DP) or XC-NET-CAN

(CANopen) modules can be used in any combination. Reserve a

memory range for each module in the CPU by defining a module

address for each one:

14

X Set the address for each module using the jumpers in the

jumper field from range 13 to 17 (a following figures).

12/01 AWB2700-1428GB

1. r CE000*

14

13

111

Figure 23: Address setting of module 1

* Factory setting

171615

00

XC-NET-CAN CANopen module

Figure 26: Example configuration with three modules and the

assigned addresses

Bus terminating resistors

120 O bus terminating resistors must be provided at the ends of

the networks. Standard plugs are available that allow the bus

terminal resistor to be enabled or disabled via a slide switch on the

plug, e.g. the SUBCON-PLUS-CAN plug from Phoenix Contact,

Order No. 2744694

2. r CC000

14

13

011

171615

00

Figure 24: Address setting of module 2

3. r D4000

14

13

010

171615

10

Figure 25: Address setting of module 3

Assign the input/output address range (%IB/%QB) to the module

in the PLC configuration in XSoft:

The modules are integrated in turn into the PLC configuration:

Only use CANopen-approved cable with the following features:

• Ripple resistance 108 to 132 O

• Capacitance < 50 pf/m

CAN_H

CAN_L

CAN_GND

120 O

Figure 27: CANopen cable

Baud rate

[kbits/s]

F Length

[m]

Cable cross-section

2

[mm

]

20 1000 0.75 to 0.80 16 O/km

125 500 0.50 to 0.60 40 O/km

250 250 0.50 to 0.60 40 O/km

500 100 0.34 to 0.60 60 O/km

1000 40 0.25 to 0.34 70 O/km

120 O

Loop

resistance

CAN_H

CAN_L

CAN_GND

Assign the memory range beginning with start address CE000 to

the first module (CANopen or PROFIBUS-DP) to be configured. The

input/output devices assigned to this module are connected to the

module bus system via address CE000. Assign the range starting

with address CC000 to the second module and D4000 to the third.

15

Loading...

Loading...