Page 1

Building Automation

Device Description

Embedded HMI

XVH-3x0

01/05 AWB2776-1559GB

SystemsIndustrial Automation

Page 2

All brand and product names are trademarks or registered

trademarks of the owner concerned.

st

1

published 2005, edition date 01/05

© Moeller GmbH, 53105 Bonn

Author:Peter Zuber

Production: Norbert Mausolf

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alteration without notice.

Page 3

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on

this device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalisation. The system installer

is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for the

24 volt supply. Only use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable

units must only be operated and controlled in enclosed

housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must be

implemented to ensure a safe operating state in the event of

a fault or malfunction (for example, by means of separate limit

switches, mechanical interlocks etc.).

Moeller GmbH

Safety instructions

I

Page 4

II

Page 5

Hardware Device Description Embedded HMI XVH-3x0

Notes

01/05 AWB2776-1559GB

© by Moeller GmbH

3

Page 6

Device Description Embedded HMI XVH-3x0 Hardware

Contents

Contents

1 Explanation of Symbols ..................................................................................... 5

2 Introduction......................................................................................................... 6

2.1 Benefits of the XVH-330/340-57 Systems...............................................................6

2.2 Aim and purpose of this document..........................................................................7

2.3 List of documents .................................................................................................... 7

3 Device Versions .................................................................................................. 8

3.1 Scope of delivery..................................................................................................... 8

3.2 Options.................................................................................................................... 8

4 Commissioning ................................................................................................... 9

4.1 Overview of the terminals........................................................................................ 9

4.2 General notes on cabling....................................................................................... 10

4.3 Connection to the power supply............................................................................ 10

4.4 Ethernet................................................................................................................. 11

4.5 USB device............................................................................................................ 12

4.6 Expansion module interfaces (ComModule) optional............................................ 13

4.6.1 CAN............................................................................................................................13

4.6.2 MPI.............................................................................................................................14

5 System Control Button (CTRL)........................................................................ 15

6 System settings ................................................................................................ 16

7 CompactFlash Slot ........................................................................................... 17

8 Expansion and Configuration Options ........................................................... 18

8.1 Device interventions ..............................................................................................18

9 Function and Control LEDs.............................................................................. 19

10 Mounting Instructions ...................................................................................... 21

10.1 General mounting instructions............................................................................ 21

10.2 Standard front..................................................................................................... 22

10.3 Mechanical dimensions......................................................................................23

10.4 Front panel cutout standard front....................................................................... 24

11 Notes on the Touch Screen.............................................................................. 25

11.1 Infra-Red Touch ................................................................................................. 25

11.2 Resistive Touch.................................................................................................. 26

12 Display Technology, Backlight........................................................................ 27

13 Maintenance and Repair................................................................................... 28

14 Disposal............................................................................................................. 29

15 Technical Data................................................................................................... 30

16 EU Conformity/Safety ....................................................................................... 32

16.1 EMC ................................................................................................................... 32

16.2 Explosion protection...........................................................................................32

16.2.1 Zone 22, Category 3D ............................................................................................. 32

17 Safety / North American Approvals................................................................. 33

4

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 7

Hardware Device Description Embedded HMI XVH-3x0

Explanation of Symbols

1 EXPLANATION OF SYMBOLS

Danger warnings

The following information is for your personal safety and the prevention of damage to the product

described or connected devices.

Safety instructions and warnings for the prevention of danger to the life and health of users or service

personnel, and for the prevention of damage are highlighted in this document by the following

pictograms. “Warning” and “Information” pictograms are shown in this document.

Warnings indicate the following:

Death, serious injury or substantial material damage may occur if the related safety measures are not

implemented.

The individual “Warning” pictograms have the following meaning:

Caution! General!

Is an instruction that must be strictly observed in order to protect oneself and the

device from hazards relating to the operation of the device and to ensure the proper

use of the device.

Caution! Dangerous voltage!

There is a danger of electric shock if a live part is touched.

Caution! Observe ESD measures!

Electrostatic discharge may damage or destroy electronic components.

Information pictograms indicate the following:

Important information about the product or the relevant section of the document, requiring the

particular attention of the reader.

The “Information” pictogram has the following meaning:

Indicates important and instructional information.

01/05 AWB2776-1559GB

© by Moeller GmbH

5

Page 8

Device Description Embedded HMI XVH-3x0 Hardware

Introduction

2 INTRODUCTION

2.1 BENEFITS OF THE XVH-330/340-57 SYSTEMS

The PANEL in conjunction with Galileo is a professional and powerful data management and

visualization system for machine and system building and for building services automation.

BENEFIT The device is a genuine communication professional. The onboard Ethernet and USB

Device interfaces, as well as the expansion slot for Com modules (CAN, RS 232, etc.)

can even be used as a gateway for different PLC and bus systems simultaneously.

INNOVATION State-of-the-art technologies such as FTP server, remote client/server, OPC

client/server, printing via Ethernet, UNICODE support and many additional features

fulfill every possible need.

BENEFIT The operating system, the application programs and data can be exchanged easily

without any other technical resources.

The PANELs use the benefits of a seamless Ethernet and IT-based (WEB-based) automation solution

and thus offer an unlimited range of possible applications.

6

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 9

Hardware Device Description Embedded HMI XVH-3x0

Introduction

2.2 AIM AND PURPOSE OF THIS DOCUMENT

This device description is a reference for the installation, the terminals, technical data, commissioning,

operating and maintenance.

2.3 LIST OF DOCUMENTS

Subject Document Doc. No.

[1]

Installation

[2]

Networks

[3]

Windows CE

(this list of documents is not final)

Installation instructions General wiring instructions AWB2776-1569

Networks in brief AWB2776-1568

PANEL with WindowsCE AWB2776-1553

01/05 AWB2776-1559GB

© by Moeller GmbH

7

Page 10

Device Description Embedded HMI XVH-3x0 Hardware

Device Versions

3 DEVICE VERSIONS

The XVH-330/340-57 Systems are available in the following versions:

Type Touch Front / Type of fixing

XVH-330-57XXX-x-13-x Resistive Standard / Fixing brackets

XVH-340-57XXX-x-13-x Infra-red Standard / Fixing brackets

3.1 SCOPE OF DELIVERY

Each device version is supplied with the following accessories:

Device version: XVH-330-57 XVH-340-57

-x-13-x

• •

• •

• •

• •

•

-x-13-x

Resistive touch Standard front

IR touch Standard front

Accessories (included)

4 fixing brackets for mounting the device

Sealing strip(for IP65)

Power supply plug connector

CompactFlash cover for the CompactFlash slot

Resistive touch pen

3.2 OPTIONS

OS Flash

Additional fixing brackets for IP65

• •

• •

8

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 11

Hardware Device Description Embedded HMI XVH-3x0

Commissioning

4 COMMISSIONING

4.1 OVERVIEW OF THE TERMINALS

Ethernet

ComModule plug

(e.g. CAN)

Supply

USB Device

ÎLED functions see chap. 9.

The Ethernet, ComModule (e.g. CAN) and Supply terminals are located on the right of the device

when viewed from the rear. The terminal for the USB interface is located on the left of the device.

01/05 AWB2776-1559GB

© by Moeller GmbH

9

Page 12

Device Description Embedded HMI XVH-3x0 Hardware

Commissioning

4.2 GENERAL NOTES ON CABLING

Cabling should be carried out with special care in order to ensure

interference-free operation.

The EMC values stated in the technical data can only be guaranteed if the

connections and cables are prepared according to the specifications stated.

The cabling must be laid separately from low-voltage cables or isolated with

double or reinforced insulation.

Î Further information: Installation instructions, General wiring instructions [1]

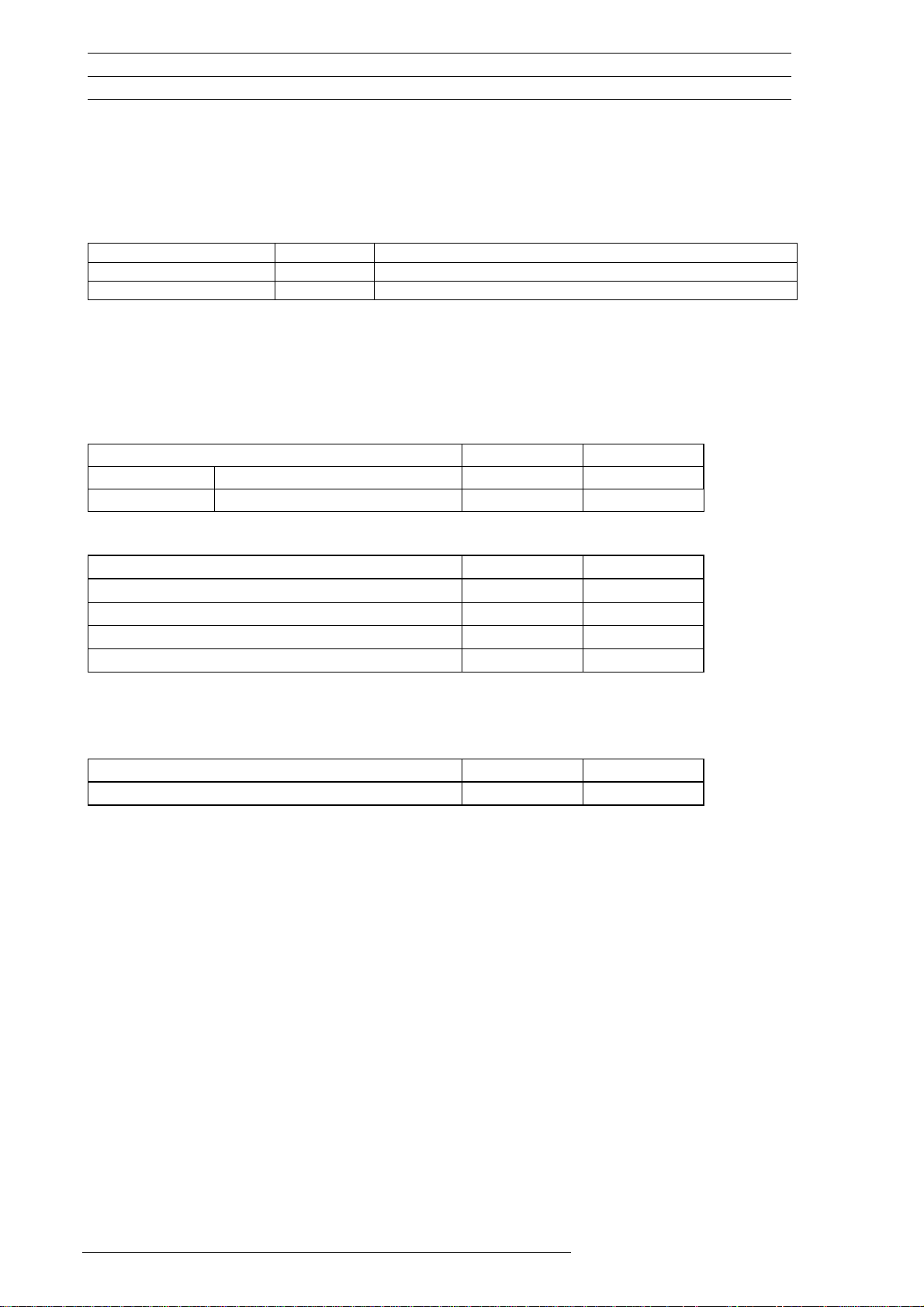

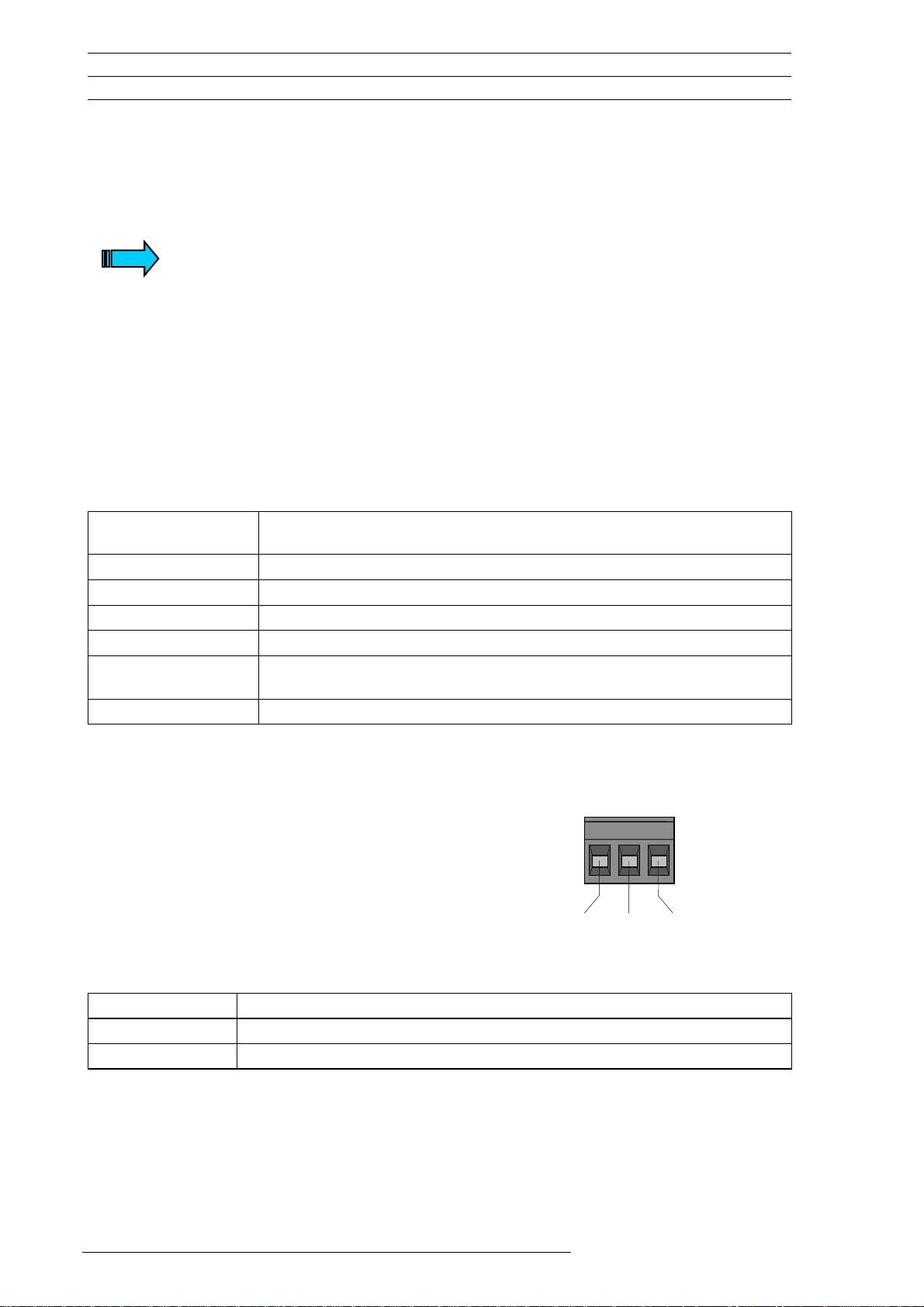

4.3 CONNECTION TO THE POWER SUPPLY

System supply 24 VDC SELV (safety extra low voltage)

Not isolated

Current consumption Î Chapter 15

Fuse / protection Internal fuse / protection against reverse polarity

Housing potential Connected to 0 V terminal

Terminal type Screw terminal (screwdriver No. 3), pluggable

Cross section min. 0.75 mm2 / max. 2.5 mm2 (lead or wire)

min. AWG24 / max. AWG12

Stripping length 7 mm

Î Further technical data: Chapter 15

Plug connector: Phönix MSTB 2.5/3-ST-5.08

Phönix Order No. 1757022;

Supplied with unit

(view from the wiring side)

+24 VDC +24 VDC power supply

GND Functional ground, connected with housing (connection not compulsory)

0 V 0 V power supply (connected with housing)

+24 VDC GND 0 V

10

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 13

Hardware Device Description Embedded HMI XVH-3x0

Commissioning

4.4 ETHERNET

RJ45 10/100 Mbit

Î LED functions: Chapter 9

Cabling

The network is implemented with shielded twisted pair cables (STP or UTP) and shielded RJ45 plug

connectors. The maximum permissible cable length is 100 m. See also the specification as per

EIA/TIA 568 TSB-36. When preparing the cables it must be ensured that the cable shield is correctly

connected to the connector housing.

A crossover cable must be used for connecting one device with another. A 1:1 cable must be used

when using a hub in the connection.

Î Further information: Installation instructions, General wiring instructions [1]

The IP addresses can be obtained from your system or network administrator.

IP addresses must be uniquely defined in an Ethernet network.

Further information: Networks in brief [2]

Î

01/05 AWB2776-1559GB

© by Moeller GmbH

11

Page 14

Device Description Embedded HMI XVH-3x0 Hardware

Commissioning

4.5 USB DEVICE

The XVH-330/340-57 supports USB 1.1.

A USB device interface is provided

Cabling

Only use USB standard cables with a shield. When preparing the cables it must be ensured that the

cable shield is correctly connected to the connector housing. The maximum permissible cable length

is 5 m.

Î Further information: Installation instructions, General wiring instructions [1]

12

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 15

Hardware Device Description Embedded HMI XVH-3x0

Commissioning

4.6 EXPANSION MODULE INTERFACES (COMMODULE) OPTIONAL

4.6.1 CAN

The CAN interface is isolated.

Connector assignment

1 - nc

6

7

8

9

9pole

DSUB male

Case Shield Cable shield (connected with housing)

Pin 3 and 6 (CAN_GND) are both connected internally with the CAN Ground. Pins 4, 5 and 8 must not

be connected. The CAN bus driver is fed internally.

Pin no. Signal Description

1

2

3

4

5

2 CAN-L Data signal Low

3 GND Signal Ground

4 - nc

5 - nc

6 GND 0 V power supply

7 CAN-H Data signal High

8 -

9 -

The CAN interface is isolated.

The max. baud rate is 1 Mbit/s.

The terminating resistor must be provided externally, e.g. in the connector, and is

not part of the device.

The CAN connector is not provided with a supply for third-party devices.

Î Further information: Installation instructions, General wiring instructions [1]

01/05 AWB2776-1559GB

© by Moeller GmbH

13

Page 16

Device Description Embedded HMI XVH-3x0 Hardware

Commissioning

4.6.2 MPI

The MPI interface is an isolated RS485 interface.

Connector assignment

1

1 - nc

6

2

3

4

5

Connector

DSub female 9 - nc

1) The 0V terminal must always be wired.

9pole

7

8

9

Pin no. Signal Description

2 - nc

3 LINE B Receive/Transmit Data B

4 REP CTL Repeater Control

5 0 V Reference potential for the terminating

6 5 V Power supply for the bus terminating

7 - nc

8 LINE A Receive/Transmit Data A

Case Shield Cable shield (connected with housing)

resistors and the potential equalisation

line 1)

resistors

The MPI interface is isolated.

The max. baud rate is 1 Mbit/s.

The terminating resistors must be provided externally, e.g. in the connector, and

are not part of the device.

The 5V must not

be used as a power supply for systems of other suppliers.

Î Further information: Installation instructions, General wiring instructions [1]

14

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 17

Hardware Device Description Embedded HMI XVH-3x0

System Control Button (CTRL)

5 SYSTEM CONTROL BUTTON (CTRL)

The Control button (CTRL) is used to activate the system functions of the operating system.

Î Further information on the exact functions: PANEL with WindowsCE [3]

The Control button is located on the side of the CompactFlash slot and the Test LED. Ensure the

accessibility of the device when it is mounted. Viewed from the rear, the Control button is accessible

on the left.

Control button

01/05 AWB2776-1559GB

© by Moeller GmbH

15

Page 18

Device Description Embedded HMI XVH-3x0 Hardware

System settings

6 SYSTEM SETTINGS

This is where network, display, date/time settings etc. are entered.

These can be set via Start ⇨ Programs ⇨ Control Panel.

Î Further information: PANEL with WindowsCE [3]

16

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 19

Hardware Device Description Embedded HMI XVH-3x0

CompactFlash Slot

7 COMPACTFLASH SLOT

The XVH-330/340-57 is provided with a slot for a Type I or II CompactFlash card in compliance with

CF Specification 1.4. These cards store the project data and the operating system required for running

the XHV.

The CompactFlash card is not

We recommend the use of the CompactFlash cards supplied by Moeller in

order to ensure interference-free operation.

Moeller cannot offer support and does not accept any liability for

consequential damage arising from the use of CompactFlash cards offered

by other suppliers.

Viewed from the rear, the CompactFlash slot is accessible on the left.

View without cover

Ejector button CF ACT

supplied with the Panel .

View with cover

The CompactFlash card must only be inserted / removed when the red CF ACT

LED is not

Removing the CompactFlash card when the CF ACT LED is lit (access to

CompactFlash card in progress) may lead to data being lost or destroyed.

The device should only be operated with the CompactFlash cover fitted. The

CompactFlash card may otherwise fall out during operation.

lit.

01/05 AWB2776-1559GB

© by Moeller GmbH

17

Page 20

Device Description Embedded HMI XVH-3x0 Hardware

Expansion and Configuration Options

8 EXPANSION AND CONFIGURATION OPTIONS

8.1 DEVICE INTERVENTIONS

The measures described in this section require the housing cover to be removed. When the device is

opened, parts are accessible that may carry dangerous voltages. Removing the housing cover and

interventions on the internal parts of the device must only be carried out after the power supply has

been switched off and the power supply connector has been removed. Interventions and modifications

to the device that are not described in this document will invalidate the warranty agreement.

The housing cover is fixed with Torx T10 screws. In order to remove the cover, this must be pushed a

few millimetres against the LEDs after undoing the screws (4 screws).

Interventions on the device must only be carried out after the power supply has

been switched off. During operation device components carry dangerous voltage.

Safety precautions concerning electrostatic discharge (ESD) must be observed

when making interventions on the device.

18

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 21

Hardware Device Description Embedded HMI XVH-3x0

Function and Control LEDs

9 FUNCTION AND CONTROL LEDS

The XVH is provided with different LEDs for monitoring functions on the unit:

Supply SUPPLY OK

Touch Controller TOUCH ERROR and TOUCH ACT

ComModule CMM ACT

CompactFlash CF ACT

Ethernet ACT and LINK

5 4 3 2 1

CF ACT CMM

ACT

TOUCH

ACT

TOUCH

ERROR

SUPPLY

OK

Cutout of the XVH with a view of the Control LED with CF cover.

(accessible from the rear left)

Power supply

1 SUPPLY OK (green)

TOUCH (IR type)

2 TOUCH ERROR (red)

3 TOUCH ACT green)

CMM (ComModule)

4 CMM ACT (green)

CF card

5 CF ACT (red)

Lit Internal system voltage present

Lit

Dark

Lit

Flashing

Dark

Lit

Flashing

Lit briefly Bus active (data traffic)

Lit briefly (chap. 7) CF card access

During startup

When touch function ready

Error

Contamination

or wrong calibration

During startup

When touch function ready

On touch actuation

(cleaning IR touch frame, chap. 11.1)

(res.touch, chap.11.2)

ETHERNET

6 LINK (green)

7 ACT (yellow)

6

01/05 AWB2776-1559GB

© by Moeller GmbH

Lit Active network connected and detected

Flashing Ethernet active (data traffic)

7

19

Page 22

Device Description Embedded HMI XVH-3x0 Hardware

Function and Control LEDs

Cutout of the XVH with a view of the FlashCard and Control LED without the CompactFlash cover.

20

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 23

Hardware Device Description Embedded HMI XVH-3x0

Mounting Instructions

10 MOUNTING INSTRUCTIONS

10.1 GENERAL MOUNTING INSTRUCTIONS

All devices are mounted from the front, i.e. in a control panel.

Standard front

The device is fixed from the rear with 4 fixing brackets (M4 threaded pin with type 2 hexagon). Four

additional fixing brackets are required for mounting to IP 65.

The devices can be run at a maximum ambient temperature of 50°C. This refers to the area directly

next to the lower cooling slots when the device is mounted vertically. A clearance of 3 cm must be

maintained at the cooling slots to ensure unobstructed air convection.

Hot components such as a heavily loaded transformer must have a clearance of at least 15 cm.

Avoid the exposure of the flat screen to direct sunlight. The sunlight (UV component) reduces the

lifespan of the LCD crystals.

The temperature inside the XVH can be scanned via the Control Panel.

Î Further information: PANEL with WindowsCE [3]

The cooling slots must always be free in order to ensure the proper cooling of the

system.

Avoid the exposure of the flat screen to direct sunlight.

Ensure that operating elements (Control button, CF card) and terminals are still

accessible when the device is mounted.

The front panel should not exceed a maximum thickness of 5 mm, due to the

clamping range of the fixing brackets.

01/05 AWB2776-1559GB

© by Moeller GmbH

21

Page 24

Device Description Embedded HMI XVH-3x0 Hardware

Mounting Instructions

10.2 STANDARD FRONT

1. Insert the supplied sealing strip in the cut out groove of the front plate. Cut the tape to a suitable

length so that the joint is tight.

2. Push the device from the front into the cutout of the front panel.

3. Fix the device at two corners on the top and the bottom with the 4 fixing brackets supplied.

4. Additional fixing brackets are required for mounting to IP 65 (optional) or in the Ex Zone 22. These

brackets are positioned in the middle of each side.

22

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 25

Hardware Device Description Embedded HMI XVH-3x0

Mounting Instructions

10.3 MECHANICAL DIMENSIONS

Einbautiefe

156

55

196

185

140

212

Standard front Resistive touch

01/05 AWB2776-1559GB

© by Moeller GmbH

23

Page 26

Device Description Embedded HMI XVH-3x0 Hardware

Mounting Instructions

10.4 FRONT PANEL CUTOUT STANDARD FRONT

Front panel cutout: 198.0 +1/-0 mm x 142.0 +1/-0 mm

142.0 +1/-0

198.0 +1/-0

The front panel should not exceed a maximum thickness of 5 mm, due to the

clamping range of the fixing brackets.

24

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 27

Hardware Device Description Embedded HMI XVH-3x0

Notes on the Touch Screen

11 NOTES ON THE TOUCH SCREEN

11.1 INFRA-RED TOUCH

Basic touch screen function

The touch screen operates using an active light matrix in the infra-red range. The optical elements of

the light matrix are located behind the IR transparent plastic frame in the front panel of the device.

They are located in such a way that their radiation extends slightly out of the front pane. Each emitter

is assigned a receiver that is located on the other side. A touch on the screen is detected by the

simultaneous interruption of one or several channels on the X or Y axis.

Repeated touch actuations and those that cover an area greater than 20 mm x 20 mm are not

evaluated by the touch controller. Continuously interrupted channels caused by severe contamination

and dirt, or by the failure of an optical element are detected by the touch controller and are no longer

included in the evaluation.

Function test

A function test of the touch screen is permanently active. This test measures the signal levels of all IR

channels and compares them with initial signal values. The initial values are determined before the

device is delivered and stored in a retentive memory.

If the signal of one or several channels is below a minimum level relative to the initial values, this will

be indicated by an error message on the screen and the

signal level of this kind is normally due to severe contamination of the IR transparent plastic frame

which consequently has to be cleaned. The touch screen, however, remains fully functional.

Only a further increase in the contamination of the screen will lead to the continuous interruption of

one or several IR channels. IR channels that are continuously interrupted will be detected by the touch

controller and no longer included in the evaluation. In extreme cases, this may mean that individual

zones cannot be touch activated.

TOUCH ERROR LED (flashing). A reduced

Cleaning the Touch Screen

For proper operation ensure that the signal levels of the channels are not so severely reduced or

interrupted due to excessive contamination through dirt.

Clean the inside of the plastic frame on the device front regularly with a damp soft cloth. Ensure that

the surface is not scratched or scoured, especially when removing hard deposits and abrasive dust.

Do not expose the front of the device to solvents which may corrode and destroy the plastic frame and

foil (frame material: polycarbonate (PC); Foil material: polyester (PET); Display pane: non-reflective

glass; Carrier plate: aluminum).

01/05 AWB2776-1559GB

© by Moeller GmbH

25

Page 28

Device Description Embedded HMI XVH-3x0 Hardware

Notes on the Touch Screen

11.2 RESISTIVE TOUCH

Basic touch screen function

Resistive touch panels are based on two resistive foils or glass panels that are kept apart by means of

small spacers. The foils are contacted at the edges and thus connected to the evaluation circuit. A

slight touch pressure causes an electrical contact. Due to the voltage divider principle, a specific

current or resistance value is generated according to where the touch actuation occurred. A controller

evaluates these changes on touch contact and thus determines the touch position.

Actuation

The resistive touch panel must only be actuated with a special pen (supplied with the accessories) or

with a finger. When wearing gloves, these must be clean and must not be covered with abrasive dust

or sharp particles. The touch panel must not be operated with pointed objects or any writing

equipment (pens, pencil etc.).

Calibration

The resistive touch panel has to be calibrated on initial startup. In a dialog, the marked position must

be touched with the supplied pen

This calibration is carried out via the Control Panel.

Î Further information: PANEL with WindowsCE [3]

. The touch panel can be recalibrated as required.

Function test

Not yet specified

Cleaning the Touch Screen

Only clean the touch foil with a non

-abrasive cleaning material. Do not expose the front of the device

to solvents which may corrode and destroy the foil (foil material: polyester (PET); Carrier plate:

aluminum).

The touch panel must only be actuated with a special pen or with a finger.

26

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 29

Hardware Device Description Embedded HMI XVH-3x0

Display Technology, Backlight

12 DISPLAY TECHNOLOGY, BACKLIGHT

An STN color LCD (passive) is used for the display. The image is produced by means of a backlight

that varies in color and intensity on account of the individual LCD cells (pixels).

The light of the backlight is produced by means of cold cathode tubes. The lifespan of the tubes is

limited, and depends on the actual operating conditions. The intensity of the brightness and the

number of start cycles are major factors in determining the lifespan of the tubes. Reducing the

brightness can considerably increase the lifespan of the device. Frequent switching, particularly at low

temperatures, will reduce the lifespan of the unit.

Therefore avoid the frequent switching on and off of the backlight or the entire system. Minimising the

brightness required is more effective than reducing the frequent on/off switching.

Î Further information: PANEL with WindowsCE [3]

.

01/05 AWB2776-1559GB

© by Moeller GmbH

27

Page 30

Device Description Embedded HMI XVH-3x0 Hardware

Maintenance and Repair

13 MAINTENANCE AND REPAIR

Cleaning the screen

Regular cleaning of the plastic frame of the device front is recommended to ensure trouble-free

operation of the IR touch screen. (Î Chap. 11.1)

Repairs

Repairs should only be carried out by the manufacturer or authorized repair centres. In this case,

please contact your local PANEL dealer or the Technical Support at

Moeller.(www.moeller.net/Support)

The warranty is not applicable if any modifications are made to the device that are not described in

this document.

Transport

Only the original packaging must be used for transporting the device.

28

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 31

Hardware Device Description Embedded HMI XVH-3x0

Disposal

14 DISPOSAL

Devices that are no longer used, must be properly disposed of or returned to the manufacturer or

sales for their proper disposal.

Special note:

• The device contains a soldered lithium battery.

• The LCD unit is fitted with a fluorescent tube for the backlight. This contains mercury.

Materials Device

Housing: Galvanized sheet steel

Front plate: Aluminum, Peraluman 101 anodized

IR frame: Polycarbonate (PC);

Front glass: Non-reflective glass

Foil: Autotype polyester (PET);

Materials Packaging

Boxes: Cardboard

Transport protection: TFL foam (polyethylene)

Plastic bag: Polyethylene

01/05 AWB2776-1559GB

© by Moeller GmbH

29

Page 32

Device Description Embedded HMI XVH-3x0 Hardware

Technical Data

15 TECHNICAL DATA

Display

Resolution 320 x 240 pixels(1/4 VGA)

Number of colors 256 colors

Display area 115 mm x 86 mm

Backlight 1xCCFL dimmable via softwarer

Contrast ratio Normally 35

Brightness normally 150cd/m2

Lifespan of backlight min. 25'000 h / normally. 50'000h

Front plate IR: Glass, non-reflective, scratchproof

Operation

Resolution 47x 31 log.

Type Resistive-touch

Resolution 4-wire

Ethernet

USB Device

Connection Type B (4pole)

CAN (optional)

MPI (optional)

Connection Sub-D 9-pole male

CompactFlash Slot

Technology ATA 3.3V

NVSRAM

Flash

Power supply

Voltage range 24 VDC to DIN 19240

Voltage dips 20ms from rated voltage (24V)

Protection agains reverse

Fuse protection Yes (internal fuse)

Potential isolation No

Power consumption max. 14W / 24VDC

Technology 5,7” STN color LCD

Res: Polyester-foil

Type Infra-red touch

Type Fast Ethernet 100Base-TX IEEE 802.3u

(100 MBit/s)

Ethernet 10Base-T IEEE 802.3 (10 MBit/s)

Connection RJ45 female

Type 1 x USB 1.1 not isolated

Type CAN, isolated

Connection CiA, Sub-D 9-pole male

Type MPI, isolated

Type CompactFlash Card Type I/II

(CompactFlash Spec. 1.4)

Type 32 Kbyte (without battery)

Type 1.5 Mbyte

Rated voltage 24 VDC SELV, safety extra low voltage

20.4...28.8 VDC absolute value with ripple

19.2...30.0 VDC 35.0 VDC for a duration of

< 100ms

2ms from undervoltage (19.2V)

Yes

polarity

The 0V- connection is directly connected to

the housing potential (GND)

Inrush max. 2.5A2s

30

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 33

Hardware Device Description Embedded HMI XVH-3x0

Real-time clock

Battery type CR2032 (190mA/h) maintenance-free

(battery backup) Data retention >10 years (in de-energized state)

Weight

Approx. 1,6 kg

Dimensions

W x H x D 212 x 156 x 79 mm (mounting depth 55mm)

Cutout 198 x 142 mm (+1/-0mm)

Degree of protection

Front IP 65 (to EN 60529)

(nur mit mitgelieferter Dichtung und 8

Halteklammern)

Ambient conditions

Operating climate 0...50°C, 10...95% rel. Air humidity, non-

condensing

Storage climate -20...60°C, 10...95% rel. Air humidity, non-

condensing

Vibration / Shock / Fall test Vibration: IEC68-2-6

Shock: IEC68-2-27

Fall test: IEC68-2-32

EMC (CE)

EN 61000-6-2, EN 61000-6-4

EN 61000-6-3

EN 61131-2

Safetyt

EN60950

UL60950 (UL)

Explosion protection

(CE)

All standard devices Zone 22, Category 3D

Product standards

EN 50178, Electrical equipment for use in

electrical installations

Technical Data

01/05 AWB2776-1559GB

© by Moeller GmbH

31

Page 34

Device Description Embedded HMI XVH-3x0 Hardware

EU Conformity/Safety

16 EU CONFORMITY/SAFETY

16.1 EMC

The XVH meets the requirements specified by the EC Council Directives for harmonizing the

regulations of EC member states relating to electromagnetic compatibility (89/336/EEC).

16.2 EXPLOSION PROTECTION

16.2.1 ZONE 22, CATEGORY 3D

The XVH-330-340-5.7 Systems meet the requirements specified by the EC Council Directives for

harmonizing the regulations of EC member states for the proper use of devices and protective

systems in hazardous areas (94/9/EEC) for Zone 22, Category 3D.

Information on the nameplate

II 3D X

T 70°C

EEx II

IP5x

Applicable standards:

EN 50014 Electrical apparatus for potentially explosive atmospheres

EN 60079-0 Electrical apparatus for explosive gas atmospheres. General requirements

EN 50281-1-1 Electrical apparatus for use in the presence of combustible dust

Part 1-1: Electrical apparatus with protection by enclosures – design and testing

EN 13463-1 Non-electrical equipment for potentially explosive atmospheres

The X on the nameplate stands for:

Must not be subjected to dangerous blows and nor erected in the tracks of

cranes.

In order to achieve protection compliant with IP5x, installation must be carried

out with the supplied seal and the optional retaining bracket kit for IP65. (see

also Chap. Fehler! Verweisquelle konnte nicht gefunden werden.)

Ambient temperature range 0°C ≤Ta ≤ +50°C

32

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 35

Hardware Device Description Embedded HMI XVH-3x0

Safety / North American Approvals

17 SAFETY / NORTH AMERICAN APPROVALS

The standards EN60950-1 and UL60950 were used for the assessment of electrical safety.

The XVH-330/340-57 Systems are approved for the USA and Canada.

UL60950 (UL File No. E208621)

01/05 AWB2776-1559GB

© by Moeller GmbH

33

Page 36

Device Description Embedded HMI XVH-3x0 Hardware

Safety / North American Approvals

34

01/05 AWB2776-1559GB

© by Moeller GmbH

Page 37

Hardware Device Description Embedded HMI XVH-3x0

01/05 AWB2776-1559GB

© by Moeller GmbH

35

Page 38

Device Description Embedded HMI XVH-3x0 Hardware

Moeller GmbH

Industrial Automation

Hein-Moeller-Str. 7-11

D-53115 Bonn

Tel : +49 (0) 228-602-0

Fax : +49 (0) 228-602-2275

E-Mail : info@moeller.net

Internet : http://www.moeller.net

36

01/05 AWB2776-1559GB

© by Moeller GmbH

Loading...

Loading...