Page 1

Manual

01/2017 MN048014 EN

XP-503

panel PC

Page 2

Company Information

Eaton Industries GmbH

Hein

D

Germany

www.eaton.eu

www.eaton.com

Region North America

Eaton Corporation

Electrical sector

1111 Superior Ave.

Cleveland,

United States

877

www.eaton.com

Other regions

Please contact your local distributor or send an e

mail to:

automation@eaton.com

All proprietary names and product designations are brand names or trademarks

registered to the relevant title holders.

Break-Down Service

Please call your local representative:

http://www.eaton.eu/aftersales

or

Hotline After Sales Service:

+49 (0) 1805 223822 (de, en)

AfterSalesEGBonn@eaton.com

Manufacturer

-Möller-Straße 7-11

-53115 Bonn

Support

OH 44114

-ETN-CARE (877-386-2273)

Original

The German-language edition of this document is the original manual.

Translation of the original version.

All editions of this document other than those in German language are translations of the original

manual.

4th edition 2017, publication date 01/2017

© 2014 by Eaton Automation GmbH, CH-9008 St. Gallen

Author: Ivo Hengartner

Editor: Antje Panten-Nonnen

All rights reserved, also for the translation.

No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, micro-filming, recording or otherwise, without

the prior written permission of Eaton Industries GmbH, Bonn.

-

2 XP-503 01/2017 MN048014 EN www.eaton.com

Subject to alteration.

Page 3

Danger!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA/IL) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on

this device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the

protective earth (PE) or to the potential equalisation. The

system installer is responsible for implementing this

connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair

the automation functions.

• Install automation devices and related operating elements

in such a way that they are well protected against

unintentional operation.

• Suitable safety hardware and software measures should

be implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for

the 24 volt supply. Only use power supply units complying

with IEC 60364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency-stop devices must not

cause restart.

• Devices that are designed for mounting in housings or

control cabinets must only be operated and controlled

after they have been installed with the housing closed.

Desktop or portable units must only be operated and

controlled in enclosed housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This

should not cause dangerous operating states even for a

short time. If necessary, emergency-stop devices should

be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must

be implemented to ensure a safe operating state in the

event of a fault or malfunction (for example, by means of

separate limit switches, mechanical interlocks etc.).

Eaton Industries GmbH

Safety instructions

1

Page 4

2

Page 5

Table of Contents

Table of Contents

1 General ............................................................................................................................... 5

1.1 Purpose of this manual ....................................................................................................... 5

1.2 Additional documents .......................................................................................................... 5

1.3 List of revisions ................................................................................................................... 6

2 Description of device ........................................................................................................ 7

2.1 Function .............................................................................................................................. 7

2.2 Intended use ....................................................................................................................... 7

2.3 Device models ..................................................................................................................... 8

2.4 Marking ............................................................................................................................. 10

2.5 Marine approvals ............................................................................................................... 11

3 Safety instructions .......................................................................................................... 12

3.1 Basics ................................................................................................................................ 12

3.2 Precautionary statements ................................................................................................. 13

3.3 Mandatory requirements, personnel requirements ........................................................... 14

3.3.1 Occupational safety ........................................................................................................... 14

3.3.2 Personnel qualifications .................................................................................................... 14

3.3.3 Manual .............................................................................................................................. 14

3.3.4 Installation, maintenance, and disposal ............................................................................ 14

3.3.5 Prohibited use ................................................................................................................... 14

3.3.6 Prerequisites for proper operation ..................................................................................... 15

3.4 Device-specific hazards .................................................................................................... 16

4 Installation ....................................................................................................................... 20

4.1 Safety instructions ............................................................................................................. 20

4.2 Unpacking and checking the package contents ................................................................ 20

4.3 Storage and transportation ................................................................................................ 20

4.4 Installing ............................................................................................................................ 20

4.4.1 Temperature ...................................................................................................................... 21

4.4.2 Aeration and de-aeration ................................................................................................... 21

4.4.3 Mounting position .............................................................................................................. 22

4.4.4 Installation cut-out ............................................................................................................. 22

4.4.5 Fixing and sealing ............................................................................................................. 23

4.4.6 Conditions for marine approval ......................................................................................... 25

4.5 Preparing the device for operation .................................................................................... 26

4.6 Connecting the power supply ............................................................................................ 27

4.7 Using peripheral devices ................................................................................................... 28

4.8 External connections ......................................................................................................... 29

4.8.1 Ethernet connections ........................................................................................................ 29

4.8.2 USB connections ............................................................................................................... 30

4.8.3 DVI-I interface ................................................................................................................... 30

4.8.4 Serial interfaces ................................................................................................................ 31

XP-503 01/2017 MN048014 EN www.eaton.com 3

Page 6

Table of Contents

5 Commissioning and operation ...................................................................................... 32

5.1 Adding expansions to the XP-503 ..................................................................................... 32

5.1.1 General prerequisites ........................................................................................................ 32

5.2 Connecting peripheral devices .......................................................................................... 34

5.2.1 Interfaces .......................................................................................................................... 34

5.2.2 Periphery ........................................................................................................................... 36

5.3 Using the storage media ................................................................................................... 37

5.3.1 CFast memory card ........................................................................................................... 37

5.4 Using the XP-503 .............................................................................................................. 39

5.5 Safety Warnings ................................................................................................................ 39

5.5.1 Commissioning .................................................................................................................. 41

5.6 XP-503 with Windows Embedded Standard 7 .................................................................. 44

5.6.1 Protect Mode (Operated with two drives, C:\ and D:\) ....................................................... 44

5.6.2 Managing Accounts and Auto Logon functionality ............................................................ 47

5.6.3 Touch parameters ............................................................................................................. 49

5.6.4 License Eaton Galileo-Open Runtime ............................................................................... 51

5.6.5 License Eaton Visual Designer Runtime ........................................................................... 51

6 Maintenance and repairs ................................................................................................ 53

6.1 Safety instructions ............................................................................................................. 53

6.2 Maintenance ...................................................................................................................... 53

6.2.1 Cleaning the capacitive touch panel ................................................................................. 53

6.2.2 Battery ............................................................................................................................... 53

6.3 Repairs .............................................................................................................................. 53

7 Storage, transport and disposal .................................................................................... 55

7.1 Safety instructions ............................................................................................................. 55

7.2 Storage .............................................................................................................................. 55

7.3 Transport ........................................................................................................................... 55

7.4 Disposal ............................................................................................................................ 56

8 Technical data ................................................................................................................. 57

8.1 Dimensions for XP-503 with 25.65 cm (10.1") display ...................................................... 57

8.1.1 Front dimensions ............................................................................................................... 57

8.1.2 Device dimensions ............................................................................................................ 58

8.1.3 Fitting dimensions ............................................................................................................. 59

8.2 Dimensions for XP-503 with 39.6 cm (15.6") display ........................................................ 60

8.2.1 Front dimensions ............................................................................................................... 60

8.2.2 Device dimensions ............................................................................................................ 61

8.2.3 Fitting dimensions ............................................................................................................. 62

8.3 Dimensions for XP-503 with 54.6 cm (21.5") display ........................................................ 63

8.3.1 Front dimensions ............................................................................................................... 63

8.3.2 Device dimensions ............................................................................................................ 64

8.3.3 Fitting dimensions ............................................................................................................. 65

8.4 General ............................................................................................................................. 66

8.5 Directives and standards ................................................................................................... 70

8.6 Approvals .......................................................................................................................... 71

4 XP-503 01/2017 MN048014 EN www.eaton.com

Page 7

1 General

CAUTION

Installation requires qualified electrician

Before working with

Chapter 3 contains important information regarding your own personal safety, and

must be read and understood by everyone who will be working with the device.

WARNING

Incomplete manual copies

Working with individual pages taken out from the manual may lead to bodily injury

and property damage due to missing safety information.

Always work with the full document.

1.1 Purpose of this manual

This manual contains all the information you will need in order to use the XP-503 panel PC safely and

effectively. The manual is considered an integral part of the device and must always be readily

available in the device's close proximity.

This manual describes all the lifecycle stages for the device: transportation, installation,

commissioning, operation, maintenance, storage, and disposal. It does not, however, go over its

operating system or application software.

Target group

This manual is intended for engineers, electricians, and automation technicians. Electrical

engineering and physics-related knowledge and skills will be required in order to be able to

commission the corresponding devices.

1 General

1.1 Purpose of this manual

1.2 Additional documents

The following documents may also be helpful in relation to the use of this device:

[1] MN05010009Z-DE System Description Networks in Brief

(information on networks in general and on how to integrate PCs and panels into

networks)

[2] IL0480006ZU XP-503 Instruction Leaflet

Download Center

To download the documents, go to the Download Center - Documentation page by clicking on the

Customer Support tab on the Eaton website and then selecting the appropriate option:

www.eaton.eu/doc (search for the document number using the search field on the home page)

the device, make sure to read chapter 3, "Safety instructions."

Product information

For up-to-date information, please consult the product page on the Internet.

www.eaton.eu/xp500

XP-503 01/2017 MN048014 EN www.eaton.com 5

Page 8

1 General

Publication

Page

Keyword

New

Modificati

Delete

07/2014

New edition

11/2015

ATEX accreditation

09/2016

Marine approvals

01/2017

Additional device models

1.3 List of revisions

1.3 List of revisions

The following table only lists major modifications.

date

✓

✓

✓

✓

on

d

6 XP-503 01/2017 MN048014 EN www.eaton.com

Page 9

2 Description of device

2.1 Function

XP-503 panels can be used as control and monitoring devices.

XP-503 devices are the answer to the growing demand of machine and system manufacturers for

high-precision, cost-effective HMI solutions featuring industrial-grade capacitive multi-touch

technology. These devices are available in three widescreen display sizes: 10.1", 15.6", and 21.5".

Their slim design, featuring a non-reflective glass front, delivers a modern look. The robust, scratchresistant front and open device concept on the Panel PCs make them suitable for use in almost all

branches of industry involved in mechanical and plant engineering.

2.2 Intended use

XP-503 panel PCs are primarily intended for use in machine and system building applications. They

are suitable for use in industrial environments and are typically used for automation purposes.

2 Description of device

2.1 Function

XP-503 01/2017 MN048014 EN www.eaton.com 7

Page 10

2 Description of device

Device type

Part no.

Article no.

10.1" widescreen industrial panel PC (Galileo)

• Galileo Open Runtime License

XP-503-10-A10-A00-1B

174474

15.6" widescreen industrial panel PC (Galileo)

• Galileo Open Runtime License

XP-503-15-A10-A00-1B

174475

21.5" widescreen industrial panel PC (Galileo)

• Galileo Open Runtime License

XP-503-21-A10-A00-1B

174476

10.1" widescreen industrial panel PC (VD)

• Visual Designer runtime license

XP-503-10-A10-A00-1V

174477

15.6" widescreen industrial panel PC (VD)

• Visual Designer runtime license

XP-503-15-A10-A00-1V

174478

2.3 Device models

2.3 Device models

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard 7

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• Min. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard 7

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard 7

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard 7

8 XP-503 01/2017 MN048014 EN www.eaton.com

Page 11

21.5" widescreen industrial panel PC (VD)

• PCT Multitouch

• Visual Designer runtime license

XP-503-21-A10-A00-1V

174479

15.6" widescreen industrial panel PC (Galileo)

• ATEX certification II 3D Ex tc IIIC T70°C U

XP-503-15-A10-A01-1B

184582

10.1" widescreen industrial panel PC (Galileo)

• ATEX certification II 3D Ex tc IIIC T70°C U

XP-503-10-A10-A01-1B

184926

21.5" widescreen industrial panel PC (Galileo)

• ATEX certification II 3D Ex tc IIIC T70°C U

XP-503-21-A10-A01-1B

184927

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard 7

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard

• Galileo Open Runtime License

2 Description of device

2.3 Device models

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard

• Galileo Open Runtime License

• PCT Multitouch

• 1.65 GHZ CPU

• 4 GB RAM

• M in. 32 GB of internal memory

• M in. 4 GB of CFast removable memory

• Windows Embedded Standard

• Galileo Open Runtime License

Tab. 1 Device model s

XP-503 01/2017 MN048014 EN www.eaton.com 9

Page 12

2 Description of device

2.4 Marking

2.4 Marking

Nameplate

The device has a nameplate on rear. This nameplate makes it possible to identify the device and

includes the following information:

Manufacturer

Part Number

Required power supply

Article No. (Part No. or Art. No.)

Serial No.

Certification marks and information concerning the corresponding certification/approval

Layout of interfaces and controls

To get fast and effective support, make sure to always provide Customer Service with the following

information from the nameplate:

Article No. (Part No. or Art. No.)

Serial No.

10 XP-503 01/2017 MN048014 EN www.eaton.com

Page 13

2.5 Marine approvals

Temperature

B - Ambient temperature: 0°C to +55°C

B - Relative humidity up to 100 % at all relevant temperatures.

Vibration

A - Bulkheads, beams, deck, bridge, Acceleration amplitude: 0.7 g

EMC

A* - All locations except bridge and open deck

Input

Required protection according to DNV-GL Rules shall be provided upon

Location class

interface

Installations

EMC B

Power supply

Place interference filter

EMC A

No additional installations

The gasket installed inside the enclosure cover at the factory must be present in order to

provide stability against vibrations.

Obtained type approvals

XP-503 panels have been granted the required shipping classification by Det Norsk Veritas /

Germanischer Lloyd (DNV GL)

• DNV GL-CG-0339 type approval, November 2015 edition,

"Environmental test specification for electrical, electronic and programmable equipment and

systems"

Certificate No.: TAA00000NC

Location classes

Humidity

2 Description of device

2.5 Marine approvals

B* - All locations (including bridge and open deck)

installation on board

* Filters / Ferrites maybe required to fulfil. See installation restrictions

Installation restrictions

• Install and commission referring to manuals

• Screened communication cables improve EMC behavior

• PE connection of communication cables improve EMC behavior

(e.g. earth-connection kit: EATON ZB4-102-KS1)

see section 4.4.64.4.6 Conditions for marine approval.

XP-503 01/2017 MN048014 EN www.eaton.com 11

Page 14

3 Safety instructions

Read this chapter before working with the device. It contains important information

regarding your own personal safety, and must be read and understood by everyone

who will be working with the device.

3.1 Basics

3 Safety instructions

3.1 Basics

The device has been designed according to the state of the art and all generally accepted safety

rules and standards. However, this alone cannot eliminate all potential hazards, which is why it is

necessary for you to be aware of all hazards and residual risks.

Do not run the device unless it is in perfect technical condition. Make sure to always operate it as

specified in this document.

12 XP-503 01/2017 MN048014 EN www.eaton.com

Page 15

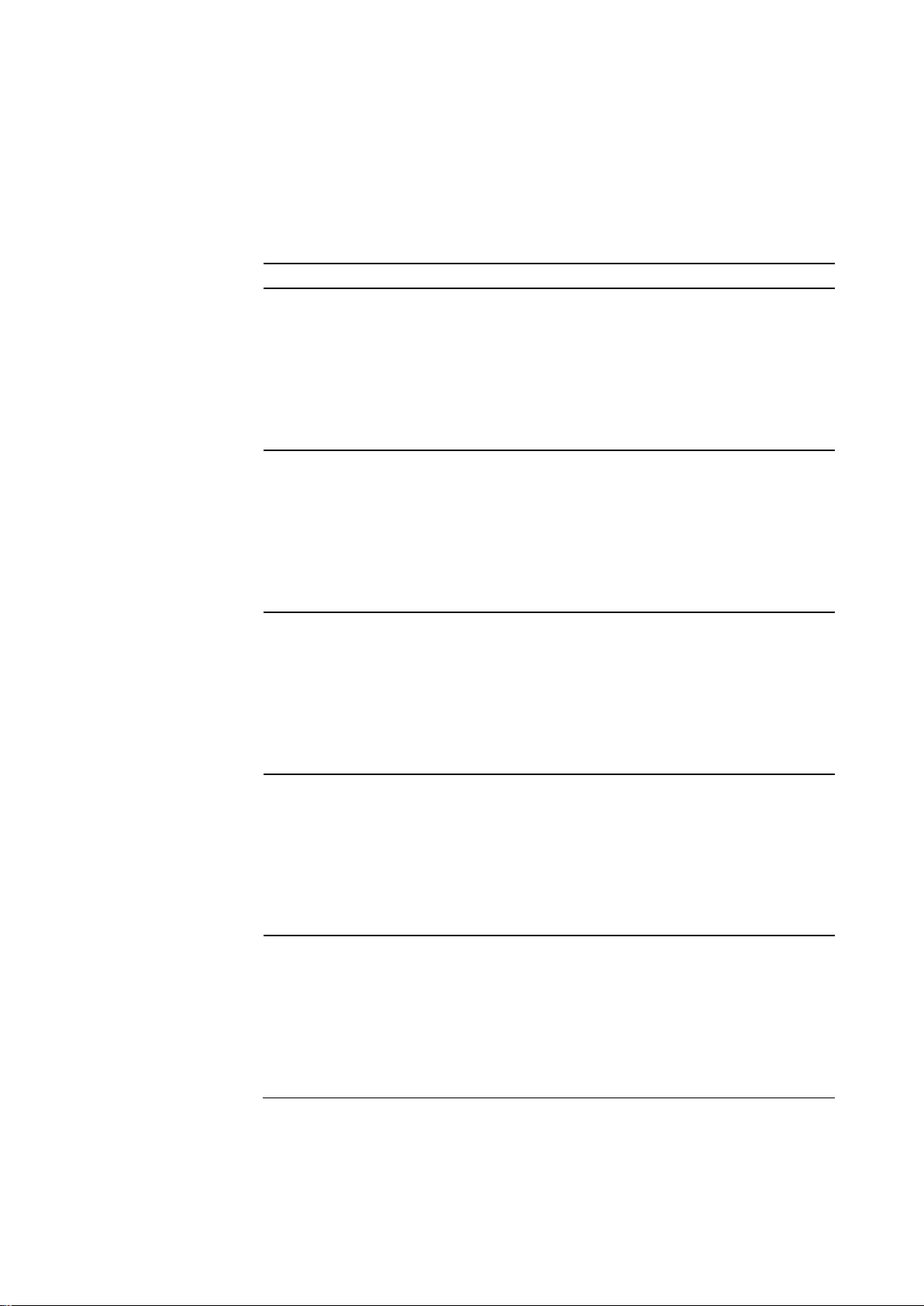

3.2 Precautionary statem ent s

Danger

DANG

Indicates an imminent hazardous situation that will result in death or serious injury if

it is not avoided.

WARNING

WARNING signal word

Indicates a potentially hazardous situation that could result in death or serious injury

if it is not avoided.

CAUTION

CAUTION signal word

Indicates a potentially hazardous situation that could result in minor or moderate

injury if it is not avoided.

CAUTION

CAUTION signal word without warning sign

Indicates a situation that could res

Used to highlight useful information.

ER signal word

3 Safety instructions

3.2 Precautionary statements

ult in property damage if it is not avoided.

The hazard symbol used and the corresponding text will provide information regarding the specific

hazard and how to avoid or prevent it.

XP-503 01/2017 MN048014 EN www.eaton.com 13

Page 16

3 Safety instructions

WARNING

Incomplete manual copies

Working with individual pages taken out from the manual may lead to bodily injury

and propert

Always work with the full document.

3.3 Mandatory requirements, personnel requirements

3.3 Mandatory requirements, personnel requirements

3.3.1 Occupational safety

All generally accepted occupational health and safety rules and standards (internal and national)

must be complied with.

3.3.2 Personnel qualifications

The personnel responsible for installation, operation, maintenance, and repairs must have the

necessary qualifications for the work they will be performing. They must be appropriately trained

and/or briefed and be informed of all hazards and risks associated with the device.

3.3.3 Manual

Make sure that every person who will be working with the device, regardless of the lifecycle stage

involved, has read and understood the relevant sections of this manual.

3.3.4 Installation, maintenance, and disposal

Make sure that the device is connected, installed, serviced, and disposed of professionally and

all relevant standards and safety rules.

with

3.3.5 Prohibited use

It is strictly prohibited to use the device in order to implement safety-relevant functions (in the sense

of personal and machine protection).

y damage due to missing safety information.

in line

14 XP-503 01/2017 MN048014 EN www.eaton.com

Page 17

3.3 Mandatory requirements, personnel requirements

For more information on repairs, please refer to chapter 6.3.1, "Repairs."

3.3.6 Prerequisites for proper operation

In order for the device to be able to meet the contractually stipulated terms, the following must be

observed:

Only qualified personnel should be allowed to work with the device.

The personnel working with the device must have read the manual and must follow all the

instructions in it.

The required ambient conditions must be met.

Maintenance work must be carried out correctly.

Potentially explosive area, zone 22, only device type XP-503-…-A10-A01-1B:

o The XP-503-…-A10-A01-1B are designed for installation in the front of enclosures in

protection type "tc" (alternatively "ta" or "tb"). This installation must be tested and certified

separately.

o The maximum surface temperature at the outer surface is set to 70°C at the maximum

ambient temperature of 50°C.

o For safe installation, comply with the specification to holding brackets and tightening torque in

the Instruction Leaflet.

o The ground resistance of accessible metal parts must be less than 10

3 Safety instructions

9

ohms

We assume no liability for damages, consequential damages, and/or accidents caused by the

following:

Failure to follow occupational health and safety rules and standards

Device failures or function disturbances

Improper use and/or handling

Failure to follow the instructions in this manual

Alterations, changes, and repairs to the device

XP-503 01/2017 MN048014 EN www.eaton.com 15

Page 18

3 Safety instructions

Danger

Explosion hazard

Death, serious injury, and property damage may occur if the device is being used in

a potentially explosive (classified) lo

connection is disconnected or the device is exposed to dangerous impacts or other

types of dangerous mechanical shock.

The XP

in protection type "tc" (al ter na tive ly "ta" or "tb" ). Th is insta ll atio n must be te sted a

certified separately. The maximum surface temperature at the outer surface is set to

70°C at the maximum ambient temperature of 50°C. The environment has to be

designed to avoid any bun ch di s cha rge . For s afe ins ta llat io n, compl y with the

specification to holding brackets and tightening torque in the Instruction Leaflet.

WARNING

Live parts inside the device

When the device is open, there will be an electric shock hazard if live parts are

touched.

WARNING

Stray currents

Large transient currents between the protective circuits of different devices may

result in fire or in malfunctions due to signal interference.

3.4 Device-specific hazards

3.4 Device-specific hazards

Use the device in the following environments only:

- Non-hazardous (non-explosive) area

- Hazardous (explosi ve) area , zo ne 22 (as defin ed in the AT E X Direc ti ve) ,

only device type:XP-503-15-A10-A01-1B (184582)

XP-503-10-A10-A01-1B (184926)

XP-503-21-A10-A01-1B (184927)

The ground resistance of accessible metal parts must be less than 109 ohms.

Make sure that the device is not exposed to dangerous impacts and other types

of dangerous mechanical shock.

De-energize the device before disconnecting plug connections.

Clean only with a clean soft antistatic damp cloth

When used in a potentially explosive atmosphere, zone 22

-503-…-A10-A01-1B are designed for insta llat io n in the fro nt of enc lo sures

cation and, during operation, an electrical plug

nd

16 XP-503 01/2017 MN048014 EN www.eaton.com

Do not open the device if it is not de-energized.

If necessary, route an equipotential bonding conductor, with a cross-sectional

area that is several times larger than that of the cable screen, parallel to the

cable.

Page 19

3 Safety instructions

CAUTION

Electrostatic discharge

E

CAUTION

Non

The device may be damaged by potential differences.

CAUTION

Data loss

If an SSD, HD, or CFast card is being written to and a voltage drop occurs or the

drive/card is removed, data may be lost or the SSD, HD, or CFast card may be

ruined.

CAUTION

Stable mounting cut requ

An IP65 degree of protection will only be ensured if the control panel is stiff enough,

the device is properly mounted using its holding brackets, and the gasket has a

proper seat.

brackets included with the delivery must be used at its intended spot.

3.4 Device-specific hazards

lectrostatic discharges may damage or ruin assembly parts.

Do not touch components (e.g., pins) that are electrostatic-sensitive.

Discharge any static electricity from your body before touching the device

(e.g., by touching an earthed metal object).

-galvanically-isolated interfaces

The GND connections of all bus stations must be connected.

Insert SSDs, HDs, and CFast cards only when the device is

de-energized.

Avoid writing to SSDs, HDs, and CFast cards as much as possible. Reasons:

- The number of write cycles for SSDs, HDs, and CFast cards is limited

If there is a voltage drop while a write operation is in progress, data loss

-

is highly likely to occur.

Remove SSDs, HDs, and CFast cards only when the device is

de-energized.

Before switc hi ng off the dev i ce, m ake sur e th at th ere are no pro g ram s wri ting to

an SSD, HD, or CFast card.

Minimum sheet thickness of control panel panel where the device will be flush

mounted: 1.5 mm.

In order for the device to be properly mounted, every single one of the holding

.

ired

XP-503 01/2017 MN048014 EN www.eaton.com 17

Page 20

3 Safety instructions

CAUTION

Condensation in/on the device

If the device is or has been expose

fluctuations, air humidity), condensation may form on or inside the device,

short

CAUTION

UV light

Plastic

lifespan.

CAUTION

Cleaning the device

The device can be damaged by pointy or sharp objects, as well as by liquids.

3.4 Device-specific hazards

d to climatic fluctuations (temperature

-circuit hazard.

Do not switch on the device is there is condensation in or on it.

If the device has condensation in or on it, or if the device has been exposed to

temperature fluctuations, let the device settle into the existing ambient

temperature before switching it on do not expose the device to direct heat

radiation from heating appliances).

s may become brittle when exposed to UV light. This will reduce the device's

creating a

Protect the device from direct sunlight (UV radiation).

Do not use pointy or sharp objects (e.g., knives) to clean the

device.

Do not use any aggressive or abrasive cleaning products or

solvents.

Make sure that no liquids get into the device (short-circuit hazard).

18 XP-503 01/2017 MN048014 EN www.eaton.com

Page 21

3 Safety instructions

3.4 Device-specific hazards

XP-503 01/2017 MN048014 EN www.eaton.com 19

Page 22

4 Installation

Before installing and commissioning the device, make sure to read chapter 3, "Safety

instructions." Chapter 3 contains important information reg

safety.

Keep the original packaging so that you will be able to use it in the future if you need

to transport or ship the XP

the device.

If storing/transporting the device in cold weather conditions or in such a way that it

will be exposed to extreme differences in temperature, make sure that no

condensation forms on or inside the device.

The Panel PC XP

The following requirements and instructions must be observed without fail in order to

ensure that the XP-503 will run properly and will not be damaged.

4.1 Safety instructions

4 Installation

4.1 Safety instructions

4.2 Unpacking and checking the package contents

Unpacking

Check the XP-503's packaging for transit damage.

Carefully remove the packaging in order to avoid damaging the device.

-503. Make sure to also keep the documents enclosed with

arding your own personal

Verify

Check the package contents for visible transit damage.

Use the package insert to make sure that the contents are complete.

4.3 Storage and transportation

The XP-503 is sturdily built, but the components inside it are sensitive to excessively strong vibrations

and mechanical shock.

Accordingly, make sure to protect the XP-503 from excessively large mechanical loads.

The device should only be transported in its original packaging, complete with all shock-absorbing

parts.

4.4 Installing

-503 is approved for use in closed spaces.

When installing the XP-503, make sure to also consult the "Technical data" chapter.

20 XP-503 01/2017 MN048014 EN www.eaton.com

Page 23

4.4.1 Temperature

Abb. 1

Prior to commissioning:

- Slowly let the device settle into the existing ambient temperature.

- If there is condensation in or on the device, do not switch on the device until it is completely dry.

Avoid overheating during operation:

Do not expose the device to direct sunlight or other sources of heat.

The ambient air temperature during operation must not exceed the maximum limit value specified

in the "Technical data" chapter.

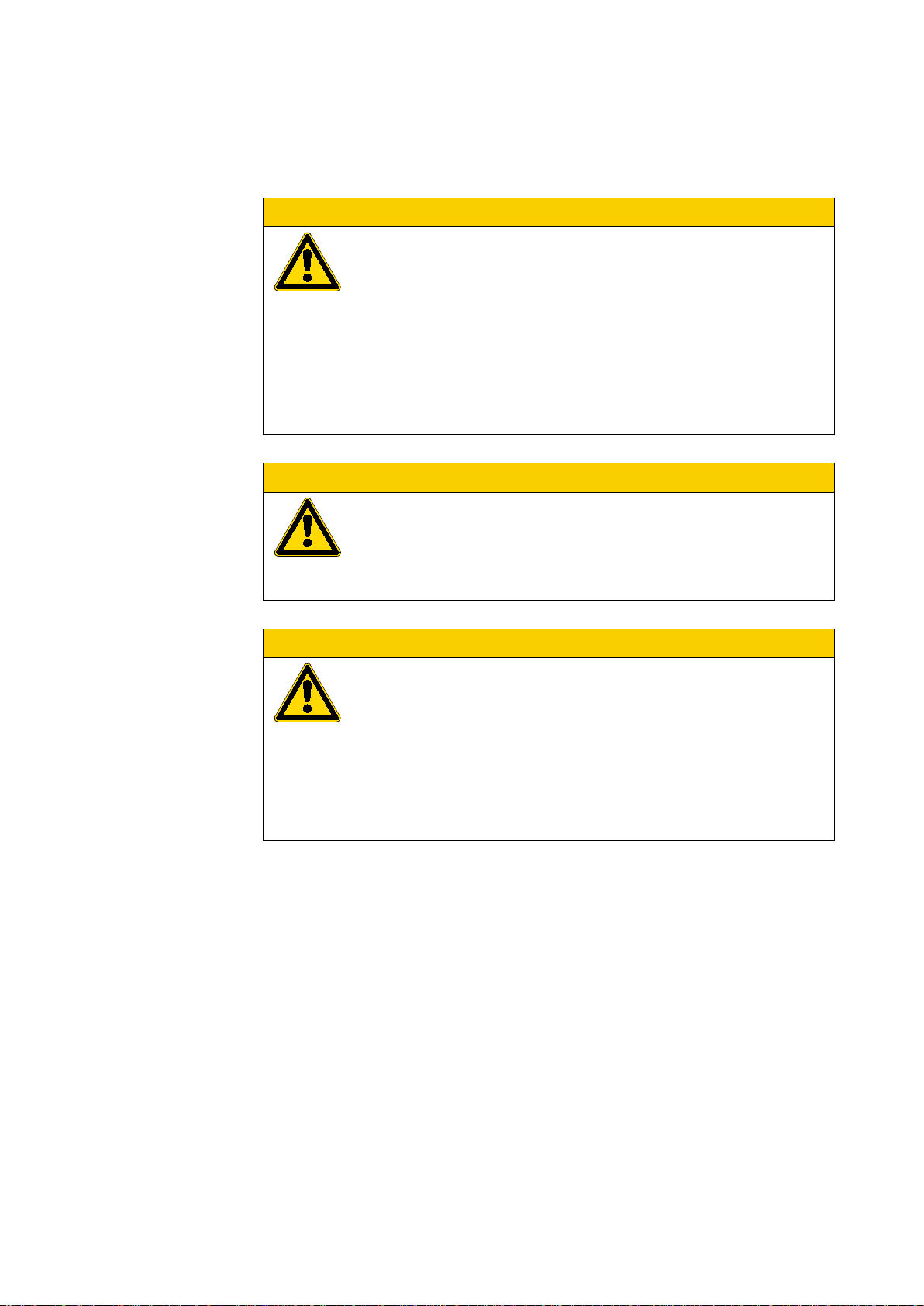

4.4.2 Aeration and de-aeration

Do not block the ventilation openings when mounting the device:

They are designed to allow air to circulate in order to cool the device.

The device uses natural convection-based passive cooling,

i.e., it does not use CPU or system fans.

The CPU and the power supply unit's power semiconductors are directly thermally connected to

the back of the display housing by means of a heat spreader or heat sink.

Make sure that there will be enough volume for air changes inside the control panel, etc. There

must be a clearance of at least 50 mm around the XP-503. The clearance behind it can be

reduced to 20 mm if necessary.

Make sure that there is enough air recirculation.

Example: XP-503-15

Th e following also applies t o other device versions as applicabl e.

4 Installation

4.4 Installing

Aeration and de-aeration

XP-503 01/2017 MN048014 EN www.eaton.com 21

Page 24

4 Installation

Abb. 2

Make sure that there is also sufficient clearance for removing the XP

mounting cutout.

4.4 Installing

4.4.3 Mounting position

The device is designed to be flush mounted in landscape mode.

It can be mounted in a perfectly vertical position or at an angle of up to ±10° in the directions shown

below.

If the device is not mounted in a perfectly vertical position, make sure that air will still be able to

circulate properly through the openings in the housing.

Example: XP-503-21

Th e following also applies t o other device versions as applicabl e.

Permissible mo unt i ng pos it io ns

4.4.4 Installation cut-out

The dimensions for the mounting cutout can be found in the"Fitting dimensions" section (for the

relevant device) of the "Mechanical dimensions" chapter

22 XP-503 01/2017 MN048014 EN www.eaton.com

-503 from the

Page 25

4.4.5 Fixing and sealing

CAUTION

Stable mounting cut required

An IP65 degree of protectio

the device is properly mounted using its holding brackets, and the gasket has a

proper seat.

brackets included with the delivery must be used at its intended spot.

Abb. 3

Flush mounting in cabinets, etc.

The XP-503 is designed to be flush mounted in control panels and swing frames.

The mounting cutout must be located in a position that ensures that webs or other

reinforcing elements in the control panel, etc. will stabilize it. If necessary, reinforcing

elements must be installed/added.

Minimum sheet thickness of control panel panel where the device will be flush

In order for the device to be properly mounted, every single one of the holding

4 Installation

4.4 Installing

n will only be ensured if the control panel is stiff enough,

mounted: 1.5 mm.

Example: XP-503-15

Th e following also applies t o other device versions as applicabl e.

Device holding br ack et s

Polyurethane foam gasket

Fixing and seali ng

XP-503 01/2017 MN048014 EN www.eaton.com 23

Page 26

4 Installation

Abb. 4

Abb. 5

4.4 Installing

IP65-tight flush mounting

- Peripheral gasket at the back of the front frame on the display housing

Polyurethane foam gasket

Material: RAKU-PUR 31-3117, black

Polyurethane foam gask et

Device holding bracket

- The purpose of the device holding brackets is to secure the flush-mounting panel PC onto a

control panel, etc. To this end, the brackets must be hooked into the display housing sideways

and screwed against the control panel door.

- Together with the polyurethane foam gasket, these holding brackets are the main element

involved in achieving an IP65 degree of protection.

- The holding brackets' intended locations have been selected in such a way as to ensure that the

brackets will push against the center of the peripheral polyurethane foam gasket.

- The holding brackets are included as accessories with the device.

1-mm stainless steel sheet

M4 x 25 DIN 914 Allen set sc rew, galvani zed

Device holding br ac ket

When tightening the M4 x 25 DIN 914 Allen set screw with torque: 0.6 – 0.7 Nm

24 XP-503 01/2017 MN048014 EN www.eaton.com

Page 27

4.4.6 Conditions for marine approval

Abb. 6 Power supply with EMC filter

The following DNV GL rules for shipping classification in accordance with DNV GL-CG-0339 type

approvals must be observed:

1 Complete and proper installation and commissioning in accordance with DNV GL rules and

Eaton requirements and specifications.

2 Installation of radio interference suppression filters for the 24-V-DC-supply.

Radio interference suppression filter for the 24-V-DC-supply

Additional interference filters must be installed for the power supply in order to adhere to the EMC B

provisions.

Integrate a radio interference suppression filter into the wiring.

Depending on the output, the following filters can be used:

• XT-FIL-1 radio interference suppression filter for 24-V-DC supply up to 2.2 A (Eaton article no.

285316) or

• XT-FIL-2 radio interference suppression filter for 24-V-DC supply up to 12 A (Eaton article no.

118980)

4 Installation

4.4 Installing

Grounding is ensured either by using

the filter's integrated contact fields onto a grounded metal plate

or using

a separate line to the filer's PE connection.

Depending on the current consumption or configuration, several filters may be used as well.

XP-503 01/2017 MN048014 EN www.eaton.com 25

Page 28

4 Installation

CAUTION

Interference

For all signal connections, use screened cables and metal connectors only.

All plug

This will improve their electrical shielding.

Signal cables must not be routed in the same cable duct with

Before commissioning the system, check all cable connections.

Make sure that all voltages and signals have the required values.

CAUTION

Safely diverting electrical interference currents

The device and the control panel must be conne

short a conductor length as possible.

The connection between the device and the control panel must have as low a

resistance as possible.

The earth connection must be implemented using a green and yellow cable with a

minimum cross-sectional area of 6 mm².

Emitted interference as per EN 55022:2010 Class A and EN 61000

WARNING

D

The device should only be run with safety extra

voltage with protective separation).

The power transformer must meet all applicable standards.

4.5 Preparing the device for operation

4.5 Preparing the device for operation

-proof connections for undisturbed operation

-in connections must be screwed or locked into place.

power cables.

cted to a central earth point with as

-6-4:2007

evices with a 24 V DC supply

-low voltage (functional extra-low

26 XP-503 01/2017 MN048014 EN www.eaton.com

Page 29

4.6 Connecting the power supply

CAUTION

Control required

Does the voltage fall within the permissible input range?

Functional earth: Connect the earth point to the cabinet's eart

M6 x 12 earthing stud on the back of the display housing

CAUTION

S

24 V DC (18

The applied voltage must meet the requirements for s

(SELV) set forth in IEC 60950 and

requirements for a low

Pay attention to the polarity!

Abb. 7

Before connecting the power supply

Supply voltage 24 V DC

afety extra-low voltages (SELV) necessary

– 36 V DC) supply for integrated DC/DC converter.

4 Installation

4.6 Connecting the power supply

h!

afety extra-low voltages

– in connection with the UL listing – the

-voltage source set forth in UL 508!

Example: XP-503-15

Th e following also applies t o other device versions as applica ble.

Bottom of ho using:

Connecting the 24 V DC supply voltage

Connection cable

For the power supply connection:

Copper conductor: 60° / 70°C

Cross section: 0.75 – 2.5 mm²

Tightening torque of 0.56 to 0.79 Nm (screws on plug section)

XP-503 01/2017 MN048014 EN www.eaton.com 27

Page 30

4 Installation

1 + +24 V DC

Supply voltage +24 V DC

2

N.C.

N.C.

not used

3 – 0V

Supply voltage 0 V

CAUTION

Disturbances

When using commercially available peripheral devices (e.g., with the USB port), it is

important to keep in mind that their EMC interference immunity parameters will

normally be designed

These devices are not suitable for operation in industrial environments!

4.7 Using peripheral devices

Plug-in connection for 24 V DC

On the back of the device, at the bottom of the housing:

Tab. 2 Plug-in connection for 24 V DC

Basic enclosur e MSTBA 2.5/ 3-G-5.08

3-pole, grid: 5.08 mm

Connector section MSTB 2.5/ 3-ST-5.08

Pin Signal Connection Configuration

Phoenix Cont act article no.: 1757255

3-pole, grid: 5.08 mm

Screw connection

Phoenix Cont act article no.: 1757022

Included as an acces s ory with the dev i ce!

Install the enclosed plug on a two-conductor cable and plug it into the socket at the bottom of the

housing. Pay attention to the polarity.

Connect the power supply cable to a 24-V power supply that meets the requirements for safety

extra-low voltages (SELV) set forth in IEC 60950 and – in connection with the UL listing – the

requirements for a low-voltage source set forth in UL 508!

The device is now ready to run on 24 VDC.

4.7 Using peripheral devices

With their peripheral ports, Eaton's devices make it possible to connect a variety of components.

in EMC

with office environments in mind.

28 XP-503 01/2017 MN048014 EN www.eaton.com

Page 31

4.8 External connections

The external interfaces described below can be accessed on the back of the device, at

the bottom of the housing.

1

TxD +

Transmit +

O

2

TxD –

Transmit –

O

3

RxD +

Receive +

I

4

N.C.

not used

---

5

N.C.

not used

---

6

RxD –

Receive –

I

7

N.C.

not used

---

8

N.C.

not used

---

LED yellow

Link

LED green

Activity

1

DB +

Bi-directio nal data B +

I/O

2

DB –

Bi-directio nal dat a B –

I/O

3

DA +

Bi-directio nal data A +

I/O

4

DD +

Bi-directio nal data D +

I/O

5

DD –

Bi-directio nal dat a D –

I/O

6

DA –

Bi-directio nal dat a A –

I/O

7

DC +

Bi-directional data C +

I/O

8

DC –

Bi-directio nal dat a C –

I/O

LED yellow

Link

LED green

Activity

2 x Ethernet

4.8.1 Ethernet connections

Two Ethernet connections, each with its own RJ45 port. The Ethernet controllers support transfer

rates of 10 Mbit/s, 100 Mbit/s, and 1 Gbit/s.

Configuration for the 10 Mbit/s and 100 Mbit/s operating modes

RJ 45 socket

8-pole, 2 LEDs

(CAT5e/6)

4 Installation

4.8 External connections

Pin Signal Description Input/Output

Tab. 3 Ethernet [10/100 Base-T]

Pinout for the 1000 Mbit/s operating mode

RJ 45 socket

8-pole, 2 LEDs

(CAT5e/6)

Tab. 4 Ethernet [1000 Bas e-T]

Pin Signal Description Input/Output

XP-503 01/2017 MN048014 EN www.eaton.com 29

Page 32

4 Installation

1

USB VCC

+5 V Power

2

USB –

Data –

3

USB +

Data +

4

GND

Ground

5

SS_RX –

twisted with RX +

6

SS_RX +

Data transmiss ion dev i ce to hos t

7

GND_DRAIN

Shield

8

SS_TX –

twisted with TX +

9

SS_TX +

Data transmission host t o device

2 x USB 3.0

1

Data 2 –

9

Data 1 –

17

Data 0 –

2

Data 2 +

10

Data 1 +

18

Data 0 +

3

Data 2/4 Shield

11

Data 1/3 Shield

19

Data 0/5 Shield

4

Data 4 –

12

Data 3 –

20

Data 5 –

5

Data 4 +

13

Data 3 +

21

Data 5 +

6

DDC Clock

14

+5v

22

Clock Shield

7

DDC Data

15

Ground (for +5V)

23

Clock +

8

VSYNC

16

Hot Plug Detect

24

Clock –

C1

Red

C3

Blue

C5

Ground

C2

Green

C4

HSYNC

4.8 External connections

4.8.2 USB connections

Two 9-pole USB ports, Type A, for connecting USB peripherals.

Type A USB

9-pole

Tab. 5 USB 3.0

4.8.3 DVI-I interface

DVI-I interface, conforming to the DVI-I (dual-link) standard, for connecting (with a digital or analog

signal) an external display unit.

DVI-I socket

(24+5)-pole

(dual link)

Pin Signal Description

Pin Signal Pin Signal Pin Signal

30 XP-503 01/2017 MN048014 EN www.eaton.com

Tab. 6 DVI-I

Page 33

4.8.4 Serial interfaces

1

DCD

TX –

DATA –

2

RXD

TX +

DATA +

3

TXD

RX +

N.C.

4

DTR

RX –

N.C. 5 GND

GND

GND 6 DSR

N.C.

N.C. 7 RTS

N.C.

N.C.

8

CTS

N.C.

N.C.

9

RI

N.C.

N.C.

Default setting: half

1

DCD

Data Carrier Detect

I

2

RXD

Receive Data

I

3

TXD

Transmit Data

O

4

DTR

Data Termin al Ready

O

5

GND

Signal Ground

---

6

DSR

Data Set Ready

I

7

RTS

Request to Send

O

8

CTS

Clear To Send

I

9

RI

Ring Indicator

I

RS 485/232

One serial interface on a 9-pole SUB-D plug that can be used as an RS 232, RS 422, or RS 485

port, configurable in the BIOS.

4 Installation

4.8 External connections

SUB-D plug

9-pole

Tab. 7 RS 485/232

Pin RS 232 RS 422 RS 485

-duplex RS 485

RS 232

One serial interface on a 9-pole SUB-D plug that can be used as an RS 232 port.

SUB-D plug

9-pole

Pin Signal Description Input/Output

Tab. 8 RS 232

XP-503 01/2017 MN048014 EN www.eaton.com 31

Page 34

5 Commissioning and operation

CAUTION

All cards and assembly parts are electrostatic

Follow all ESD safety instructions.

The symbol to the left is used to indicate the use of electrostatic

components.

CAUTION

Electronic a

Because of this, it is necessary to take precautions whenever handling the cards.

Please refer to the guidelines for electrostatic

information (ESD guidelines).

CAUTION

Please note:

Only service personnel should be allowed to open the XP

5.1 Adding expansions to the XP-503

5 Commissioning and operatio n

5.1 Adding expansions to the XP-503

5.1.1 General prerequisites Limitation of Liability

All technical data, certifications, and approvals will cease to apply/be void if expansions other than

those approved by Eaton are used.

We will not assume liability for functional limitations resulting from the use of third-party devices and

components.

Precautions

-sensitive.

-sensitive

ssembly parts are extremely sensitive to electrostatic discharges.

Before plugging in or disconnecting components or expansion modules,

disconnect the XP-503 from the power supply.

Before plugging in the cables, you will need to bring the static charge on your body

to the same potential as the charge on the XP-503 and the cables.

To do this, briefly touch the metal housing.

Discharge the electrostatic charge on your tools.

Wear an anti-static wrist strap when handling components.

Leave components and expansion modules in their packaging until

right before you install them.

Grab components and expansion modules from the edge only –

do not touch connection pins or traces.

Never run the XP-503 with the housing open.

-sensitive components for more

-503.

32 XP-503 01/2017 MN048014 EN www.eaton.com

Page 35

5 Commissioning and operation

Abb. 8

Note on marine approvals

The gasket installed inside the enclosure cover at the factory must be present in order to

provide stability against vibrations.

5.1 Adding expansions to the XP-503

Before opening

Shut down the operating system.

Disconnect the power supply.

Disconnect all connection cables from the XP-503.

Remove the CFast card

Open

Example: XP-503-15, The following also applies to other device versions as applicable.

Unscrew the four screws on the housing cov er :

Torx pan head s crews without plain unthreaded sh ank

RHS TORX Zn M3 x 5 ISO 7380-1

Opening the d evice

Close

Remove the cover from th e housing.

Please note:

The CFast adapter is screwed onto the cover and wir ed to

the board.

All service-relevant assembly parts, such as RAM,

mSATA, the CMOS battery, and the opti onal HDDs or

SSDs, can be accessed fro m the inside of the housing.

When closing the device, follow the same steps you used to open it, but in opposite order.

XP-503 01/2017 MN048014 EN www.eaton.com 33

Page 36

5 Commissioning and operation

Abb. 9

Do not plug in or disconnect any plugs during operation!

Before connecting peripherals, make sure they are designed for use in industrial

environments!

For the ports' layout, see the nameplate on the back of the housing.

The connections are standard contacts with the corresponding standard pinouts.

5.2 Connecting peripheral devices

5.2 Connecting peripheral devices

5.2.1 Interfaces Connection locations

The ports used to connect peripherals are located on the back of the housing.

These connections are accessible at the bottom of the housing (the housing does not need to be

opened in order to access these ports).

Example: XP-503-15, The following also appl ies to other device versi ons as applicable.

Interfaces:

2 x Ethernet, 2 x USB 3.0, DVI-I, RS 485, RS 232

Connection locations

34 XP-503 01/2017 MN048014 EN www.eaton.com

Page 37

5 Commissioning and operation

Abb. 10

3

Ethernet (LAN 2)

RJ 45 socket, 8-pole, 2 LEDs

6

Serial interfac e RS 48 5

Sub-D plug, 9-pole

5.2 Connecting peripheral devices

Connections layout

The connections listed below are the external interfaces on the computer board installed in the XP-

503. They can be found on the back of the device, at the bottom of the housing.

Example: XP-503-15, The following also appl ies to other device versi ons as applicable.

Bottom of housing:

Connections f or peripherals

No. Interface Plug design

1 DVI-I display port (digital/analog) DVI-I socket, (24+5)-pole

2 Ethernet (LAN 1) RJ 45 socket, 8-pole, 2 LEDs

4 USB 3.0 Port USB Type A, 9-pole

5 USB 3.0 Port USB Type A, 9-pole

7 Serial interface RS 232 Sub-D plug, 9-pole

Tab. 9 Interfaces

XP-503 01/2017 MN048014 EN www.eaton.com 35

Page 38

5 Commissioning and operation

Connect

(for industrial environments!).

An external keypad can be used simultaneously with the touch panel.

5.2 Connecting peripheral devices

5.2.2 Periphery

Keypad

The XP-503 has been designed to work with the following keypads:

USB keypad

A USB keypad can be connected to one of the USB interfaces.

It may be necessary to install a USB keypad driver the first time you use the keyboard.

Mouse

The XP-503 has been designed to work with a variety of mouse types:

Serial mouse

A serial mouse can be connected to the serial ports (RS 232). The matching mouse driver must be

installed and configured before being able to use the mouse.

USB mouse

A USB mouse can be connected to one of the USB ports.

It may be necessary to install a USB mouse driver the first time you use the mouse.

ed devices must have the CE mark

Printer

A printer can be connected to one of the USB ports and used once the corresponding printer driver

has been installed.

USB flash drive

A USB stick can be plugged into one of the USB interfaces.

Display

An external display unit can be connected to the DVI-I interface.

Ethernet network

The XP-503 can be connected to various computer networks using the two RJ45 ports that serve as

Ethernet ports.

Ethernet is a standard used for local networks, and requires twisted-pair cables in order to connect

the computers.

36 XP-503 01/2017 MN048014 EN www.eaton.com

Page 39

5.3 Using the storage media

Note the specification for the CFast memory, at least 4GB.

Cover

Knurled screw

Abb. 11

CAUTION

Before changing the card, the device must be disconnected from the power

supply

A cover must be used to prot

The card will come out from the bottom of the slot!

The CFast card can be inserted and changed without opening the housing.

5.3.1 CFast memory card

The CFast slot can be accessed at the bottom of the housing. The card adapter is screwed onto the

housing's cover and is connected to a SATA interface on the board. A cover prevents the card itself

from falling out. The card will come out from the bottom of the slot!

Before changing the card, the device must be disconnected from the power supply.

Example: XP-503-15, The following also appl ies to other device versi ons as applicable.

5 Commissioning and operation

5.3 Using the storage media

CFast memory card locati on

XP-503 01/2017 MN048014 EN www.eaton.com 37

ect the card from falling out.

Page 40

5 Commissioning and operation

Loosen the thumbscrew (k nurled head screw) and remove

Abb. 12

5.3 Using the storage media

Changing the CFast memory card

Example: XP-503-15, The following also appl ies to other device versi ons as applicable.

the CFast slot's cover.

To insert a card, push it in until you feel it lock int o place.

38 XP-503 01/2017 MN048014 EN www.eaton.com

To remove a card, push on the card so that it will be

released and will jump out of the chase.

Changing the CFast memor y card

Page 41

5.4 Using the XP-503

WARNING

Malfunctions when using a touch panel with multi

There is always the p

panel. These errors may result in bodily injury or property damage.

The following precautions will help prevent the accidental use of the malfunctions:

Before performing maintenance work, disconnect it from the power supply.

WARNING

Incorrectly using the multi

Performing ge

errors and, consequently, in bodily injury.

Before using the device, make sure you are thoroughly familiar with the Windows

operating system's multi

using and its functions. Make sure that the gestures you perform on the multi

display will be recognized by the application. It may be necessary to practice certain

gestures beforehand.

Touch panel

Projected capacitive touch panel (PCT)

Multi-touch capable

4-point touch operation

2-point touch operation when using the EMC touch sensitivity setting

The device features a touch panel with multi-touch capabilities. It is controlled by means of touching,

inching, and gestures, all of which require the operator to touch the screen with their fingertips. More

specifically, gestures can be carried out using multiple fingers at the same time.

5.5 Safety Warnings

Using the XP-503 entails additional risks associated with using a touch panel device with multi-touch

capabilities

5 Commissioning and operation

5.4 Using the XP-503

Observe the following instructions in order to keep you and others safe and avoid property damage.

-touch capabilities

ossibility of an operator making errors when using the touch

Do not, under any circumstance, use the touch panel to control safety-relevant

functions.

Before cleaning the device, switch to a safe operating mode.

-touch functions

stures incorrectly on the touch panel can result in system operation

-touch functions, as well as with the application you will be

-touch

XP-503 01/2017 MN048014 EN www.eaton.com 39

Page 42

5 Commissioning and operation

WARNING

Risk of functions being

soiling

If the device's touch panel is soiled, any conductive material present in the dirt may

trigger unexpected operator actions. When functions are triggered incorrectly in the

system, bodily injury and

Keep the touch panel clean at all times and take suitable measures in order to

protect it from soiling.

Before using the device, check which types of potential soiling may accumulate on

the touch panel and which functions may be triggered incorrectly as a result.

WARNING

Potential damage when installing and operating the device

Scratches and other damage on the device's glass panel may trigger unexpected

operator actions. When functions are triggered incorrectly in the sy

injury and property damage may occur.

Make sure that the glass panel is not damaged during installation or use.

WARNING

Dangerous currents when installing and connecting the device

Connecting the device incorrectly may result in dange

being produced.

Always connect the protective conductor before anything else.

5.5 Safety Warnings

triggered accidentally by conductive material in

property damage may occur.

rous currents and overvoltage

stem, bodily

40 XP-503 01/2017 MN048014 EN www.eaton.com

Page 43

5 Commissioning and operation

WARNING

Performing gestures incorrectly on the touch panel with multi

capabilities

If gestures are performed incorrectly on the touc

they may not be recognized or they may be recognized incorrectly. When this

occurs, the device will either not respond to the operator's input or will respond in a

wrong or unexpected way.

Observe the following when u

you have entered.

Note:

Taking appropriate precautions will make it possible to prevent other malfunctions

while the device is running.

5.5 Safety Warnings

-touch

sing the touch panel with multi-touch capabilities:

The touch panel responds to contact on its surface, not to pressure.

If using a stylus:

Make sure to specifically use a capacitive touch panel stylus.

If using your fingers:

- Make sure to only use your fingertips.

- Do not use your fingernails to operate the touch panel.

Do not use thick gloves when operating the touch panel,

e.g., work gloves.

You may wear the following types of gloves:

- Thin cotton gloves,

- Rubber-coated gloves

- Latex gloves

- Capacitive touch panel gloves

Touch the touch panel perpendicularly, not at an angle.

Make sure you do not touch the screen accidentally,

e.g., with your knuckles or by leaning against the display or using it for support.

Make sure to always keep the touch panel clean.

Always check to make sure that the device has recognized the operator actions

h panel with multi-touch capabilities,

5.5.1 Commissioning Windows operating system

XP-503 01/2017 MN048014 EN www.eaton.com 41

Page 44

5 Commissioning and operation

CAUTION

Updating the display required

If the hibernation function is used, the image shown on the device may change aft

the device wakes up from hibernation.

Disabling hibernation

To disable hibernation in the Windows operating system, go to

"Start

the appropriate options.

CAUTION

If the touch panel is displaying available functions before the screen saver starts

running, this first contact may cause the corresponding functions to be triggered.

Disabling the screen saver

To disable the screen saver in the Windows operating system, go to

"Start

through the appropriate options.

CAUTION

Make sure that important operating fun

multiple fingers at the same time

Important operating functions must be programmed in such a way that they can only

be triggered by gestures requiring multiple fingers on the touch panel at the same

time.

5.5 Safety Warnings

SleepTime

Screen saver

Control PanelHardware and SoundPower Options" and navigate through

Not intended triggeringing of functions

A wake-up event will cause the operating system to resume and the screen saver

to stop running. In devices with multi-touch capabilities, touching the touch panel

once will cause the operating system to resume (i.e., trigger a wake-up event).

Control PanelAppearance and PersonalizationDisplay" and navigate

er

ctions can only be triggered by using

42 XP-503 01/2017 MN048014 EN www.eaton.com

Page 45

Static touch panel contact

CAUTION

Time out

Contacts and gestures in which fingers do not move on the touch panel for more

than 10 seconds will be recognized as "static contact."

If the device detects this type of contact, the desired function will

no longer b

disruptions caused by soiling on the touch panel (e.g., saline solution on the glass

panel).

Avoiding static contact and continuing to run intended functions

move your finger(s) slightly during the process.

CAUTION

If you do touch it, make sure to move your finger(s) slightly!

5 Commissioning and operation

5.5 Safety Warnings

e carried out after approx. 10 seconds. This is intended to prevent

After approx. 10 seconds, touch the corresponding icon on the touch panel again

and check the results.

If you will be using an operator action for an extended continuous period of time,

Static contact during booting

If there is static contact on the touch panel during booting, this may result in

functional restrictions.

This can be prevented by taking the following measures:

Do not touch the touch panel during booting!

XP-503 01/2017 MN048014 EN www.eaton.com 43

Page 46

5 Commissioning and operation

5.6 XP-503 with Windows Embedded Standard 7

5.6 XP-503 with Windows Embedded Standard 7

The XP-503 standard devices are pre-installed with the Microsoft Windows Embedded Standard 7

operating system. If your XP-503 is not a standard device or is operated with a different operating

system these operating system specific descriptions may or may not apply to your device.

The general functions of the Windows Embedded Standard 7 operating system can be found in the

®

open-access system descriptions from Micro soft

.

The following instructions describe only specific functions of the XP-503 standard devices operating

with the Windows Embedded Standard 7 operating system.

5.6.1 Protect Mode (Operated with two drives, C:\ and D:\)

The Eaton XP-503 family of products running the Windows Embedded Standard 7 operating system

have a unique and exclusive Protect Mode™ feature that safeguards the integrity of files stored on

the C:\ drive of your operating system. This feature ensures that data and operating system files

cannot be modified by anyone or corrupted by unexpected power disruptions. As a result, you can be

confident that the XP-503 meets your rigorous industrial environmental requirements and can be

protected against all unauthorized alterations.

If Protect Mode is enabled, file write operations such as "delete," "edit," and "create new" will be

executed in temporary memory only. When the device is restarted, these write operations will be

deleted and the protected data storage medium will have all its original data intact, i.e., the device will

always start in its original state. This means that any file changes that need to be made on drive C:\

(operating system settings, installed software) must be carried out either with Protect Mode disabled

or using the appropriate special Protect Mode functions in order to save the changes permanently.

This applies to the following settings:

Operating system functionality

Time/date data

Ethernet port settings

Windows registry settings

Windows driver installations

Visualization runtime software and communications drivers

Visualization project files

The Protect Mode feature is based on the Windows Embedded EWF (Enhanced Write Filter)

function. Descriptions of the detailed manual operations can be found on the Internet.

44 XP-503 01/2017 MN048014 EN www.eaton.com

Page 47

5 Commissioning and operation

If Protect Mode is active and extensive changes are made to the C:

software installations), volatile memory may become full resulting in system errors.

Extensive changes to C:

Mode disabled.

5.6 XP-503 with Windows Embedded Standard 7

Protect-Mode data organization

C:\ drive

Protected by Protect Mode when enabled

Files to be installed and changed only at initial device setup and should remain unchanged under

normal operation.

Other drives (such as D:\)

Not protected, even when Protect Mode is enabled

Files to be stored through normal operations: process data, trends, recipes, alarm lists, ...

\ drive (e.g.

Protect Mode Save Operation

When the Protect Mode is active the unit is protected against any changes to data stored on the C:\

drive. In order to save desired data changes to the C:\ drive the Protect Mode Save operation must

be run

\ drive (software installations) must be executed with Protect

It is good practice to shut down and re-start the XP-503 in preparation of making permanent changes

to the C:\ drive. This step will ensure that all data stored in volatile memory is cleared so that no

unexpected corruption or changes will take place on your C:\ drive. Once the XP-503 has been

restarted, make your changes and then save the changes by selecting “StartAll

ProgramsEatonProtect Mode Manager”. From the Protect Mode Manager window select the

“Protect Mode Save” tab and click on the “Commit” button.

Once the Protect Mode Save operation has been launched, the changes that affect the C:\ drive will

be saved and then the device will automatically shut down and then restart, back in Protect Mode.

XP-503 01/2017 MN048014 EN www.eaton.com 45

Page 48

5 Commissioning and operation

We recommend to operate the device always with protect mode activated.

5.6 XP-503 with Windows Embedded Standard 7

Disabling Protect Mode

Protect Mode is active and enabled at the factory but it is possible for the user to disable the Protect

Mode feature. Reasons for doing so include the need to install a software program that is very large

or one that requires multiple reboots to complete its installation.

To do so, open Protect Mode Manager by selecting “StartAll ProgramsEatonProtect Mode

Manager”. From the Protect Mode Manager window select the “Advanced” tab and click on the

“Disable Protect Mode Save” button. The system will then reboot and flush any pending changes to

the protected C:\ drive. Upon reboot Protect Mode will be disabled and while in this mode the XP unit

will behave like any other Windows PC, meaning that it is subject to all forms of malware including

viruses, and adware and it must be shut down through the normal Windows shutdown mechanism to

prevent potential corruption of the operating system.

It is recommended that the XP-503 unit be removed from any plant network while Protect Mode is

disabled and that all media used for software installation to be connected to the unit are scanned for

malware prior to attachment.

Enabling Protect Mode

Once all desired changes have been made the user should place the XP unit back in Protect Mode

through the Advanced tab of the Protect Mode Manager utility (StartAll ProgramsEaton

Protect Mode Manager) by clicking on the “Enable Protect Mode Save” button. This will force a

reboot and return the XP-503 unit to its normal protected state.

46 XP-503 01/2017 MN048014 EN www.eaton.com

Page 49

5.6 XP-503 with Windows Embedded Standard 7

All changes made to the C:

saved or committed so that the next time the XP

changes will be retained. Refer to the “Protect Mode” section for additional

information.

5.6.2 Managing Accounts and Auto Logon functionality

Managing Accounts

There is an “Administrator” user account set up on your Eaton XP-503 unit when shipped from the

factory.

User: „Administrator“

Password: „Administrator“ (passwords are case sensitive)

The XP-503 is set up to automatically log in to the Administrator account, which is why the normal

Windows Security dialog box does not appear upon boot-up.

Modifying an Account Name or Password

You can modify the “Administrator” and any other account name password from the “User Accounts”

utility in “Control Panel” (Start Control PanelUser Accounts).

Once the Administrator password has been successfully modified you must follow the Account Auto

Logon Feature section in order to continue to automatically log in to the Administrator account at

boot-up.

\ drive when Protect Mode is active must be

5 Commissioning and operation

-503 is restarted the

Account Auto Logon Feature

The Account Auto Logon function can be used if you want the device to start directly with a user

profile already logged in so that application software can be used right away. When you use this