Moeller PS 416-CPU-400, PS 416-POW-400, PS 416-POW-410, PS 416-BGT-4 Series, PS 416-POW-420 Hardware And Engineering

...Page 1

Hardware and Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

PS 416-CPU-x00

Central Unit

PS 416-POW-4x0

Power Supply Card

PS 416-BGT-4xx

Rack

02/98 AWB 27-1208 GB

3rd edition 02/98

© Moeller GmbH, Bonn

Author: Werner Albrecht

Editor: Thomas Kracht

Translator: Terence Osborn

Page 2

Caution!

For Immediate Delivery call KMParts.com at (866) 595-9616

Dangerous electrical voltage!

Before commencing the installation

● Disconnect the power supply of the

device.

● Ensure that the device cannot be

accidentally restarted.

● Verify isolation from the supply.

● Earth and short circuit.

● Cover or enclose neighbouring units that

are live.

● Follow the engineering instructions

(AWA) of the device concerned.

● Only suitably qualified personnel may

work on this device/system.

● Before installation and before touching

the device ensure that you are free of

electrostatic charge.

● Connecting cables and signal lines

should be installed so that inductive or

capacitive interference do not impair the

automation functions.

● Install automation devices and related

operating elements in such a way that

they are well protected against

unintentional operation.

● Suitable safety hardware and software

measures should be implemented for

the I/O interface so that a line or wire

breakage on the signal side does not

result in undefined states in the

automation devices.

● Ensure a reliable electrical isolation of

the low voltage for the 24 volt supply.

Only use power supply units complying

with IEC 60 364-4-41 or HD 384.4.41 S2.

● Deviations of the mains voltage from the

rated value must not exceed the

tolerance limits given in the

specifications, otherwise this may cause

malfunction and dangerous operation.

● Emergency stop devices complying with

IEC/EN 60 204-1 must be effective in all

operating modes of the automation

devices. Unlatching the emergency-stop

devices must not cause uncontrolled

operation or restart.

● Devices that are designed for mounting

in housings or control cabinets must only

be operated and controlled after they

have been installed with the housing

closed. Desktop or portable units must

only be operated and controlled in

enclosed housings.

● Measures should be taken to ensure the

proper restart of programs interrupted

after a voltage dip or failure. This should

not cause dangerous operating states

even for a short time. If necessary,

emergency-stop devices should be

implemented.

IBM is a registered trademark of International

Business Machines Corporation.

All other brand and product names are

trademarks or registered trademarks of the

owner concerned.

All rights reserved, including those of the

translation.

No part of this manual may be reproduced in

any form (printed, photocopy, microfilm or

any otherprocess) or processed, duplicated

or distributed by means of electronic

systems without written permission of

Moeller GmbH, Bonn.

Subject to alterations without notice.

Page 3

List of revisions to AWB 27-1208-GB

For Immediate Delivery call KMParts.com at (866) 595-9616

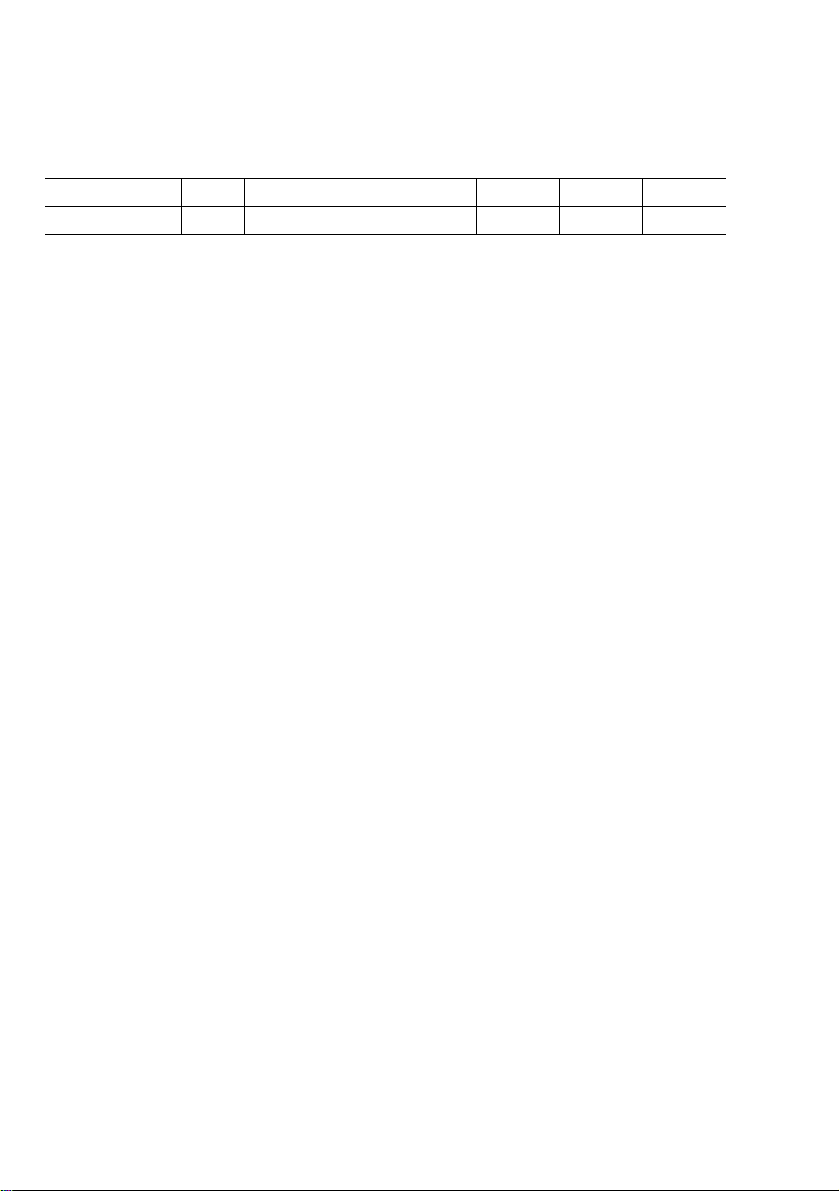

Edition Page Revision new Rev. n. a.

02/98 PS 416-CPU-200/-300 ҂

II

02/98 AWB 27-1208-GB

Page 4

Contents

For Immediate Delivery call KMParts.com at (866) 595-9616

About the manual

PS 416 system

PS 416-BGT-4.. racks

PS 416-POW-400/410/420

Power supply cards

PS 416-CPU-200/-300/-400 Central unit

3

PS 416 system PS 416-POW-4x0PS 416-BGT-4.. AppendixPS 416-CPU-200/-300/-400

5

21

35

57

Appendix

Index

02/98 AWB 27-1208-GB

129

141

1

Page 5

2

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 6

About This Manual

For Immediate Delivery call KMParts.com at (866) 595-9616

The rack, power supply card and the central

processing unit form the basis of the PS 416 system.

Their tasks and functions are described in this

manual.

There are various cards which you can integrate in

the modular system, depending on the requirements.

The functions of these cards are described in

separate manuals.

The communication between the stations in a

networked system is carried out via network cards.

These are the PS 416-CPU-300/-400 or the Suconet

K PS 416-NET-400 card if the stations are linked via

Suconet K. These cards manage the access to local

or remote input/output cards. This function is

explained in the “Suconet K Interface” manual

(AWB 27-1210-GB).

The Sucosoft S 40 programming software is used for

programming and configuration and is also

described in a separate documentation.

02/98 AWB 27-1208-GB

3

Page 7

4

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 8

PS 416 System

For Immediate Delivery call KMParts.com at (866) 595-9616

Contents

PS 416 system

1 System Description

Setup 7

Hardware/software requirements 7

Components 8

2 Configuration

Master 12

Slaves for remote I/O expansion 13

Intelligent slaves 15

3 Engineering

Electromagnetic compatibility (EMC) 17

Reaction times 17

Interference immunity 17

7

11

17

02/98 AWB 27-1208-GB

5

Page 9

6

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 10

1 System Description

For Immediate Delivery call KMParts.com at (866) 595-9616

Setup

Hardware/software

requirements

The PS 416 is a modular programmable controller.

The rack with an internal bus system for signal

transfer and slots for the connections of cards form

the basic unit. Interference-free supply cards supply

the system with a stabilised voltage. A central

processing unit with universal functions manages the

access to local and/or remote input/output cards or

enables an application process to be run separately

in the same rack. Various cards can be used for

detecting digital, analog and counter signals.

Networking and communication are implemented via

standard interfaces or standard bus protocols. The

Moeller Suconet K bus protocol is used as a system

bus for connecting remote inputs/outputs or an

expander rack. The Sucosoft S 40 software package

forms the user interface for user-friendly

programming, testing and commissioning.

A P S416 system has the following minimum

requirements:

PS 416 system

02/98 AWB 27-1208-GB

7

Page 11

System Description

For Immediate Delivery call KMParts.com at (866) 595-9616

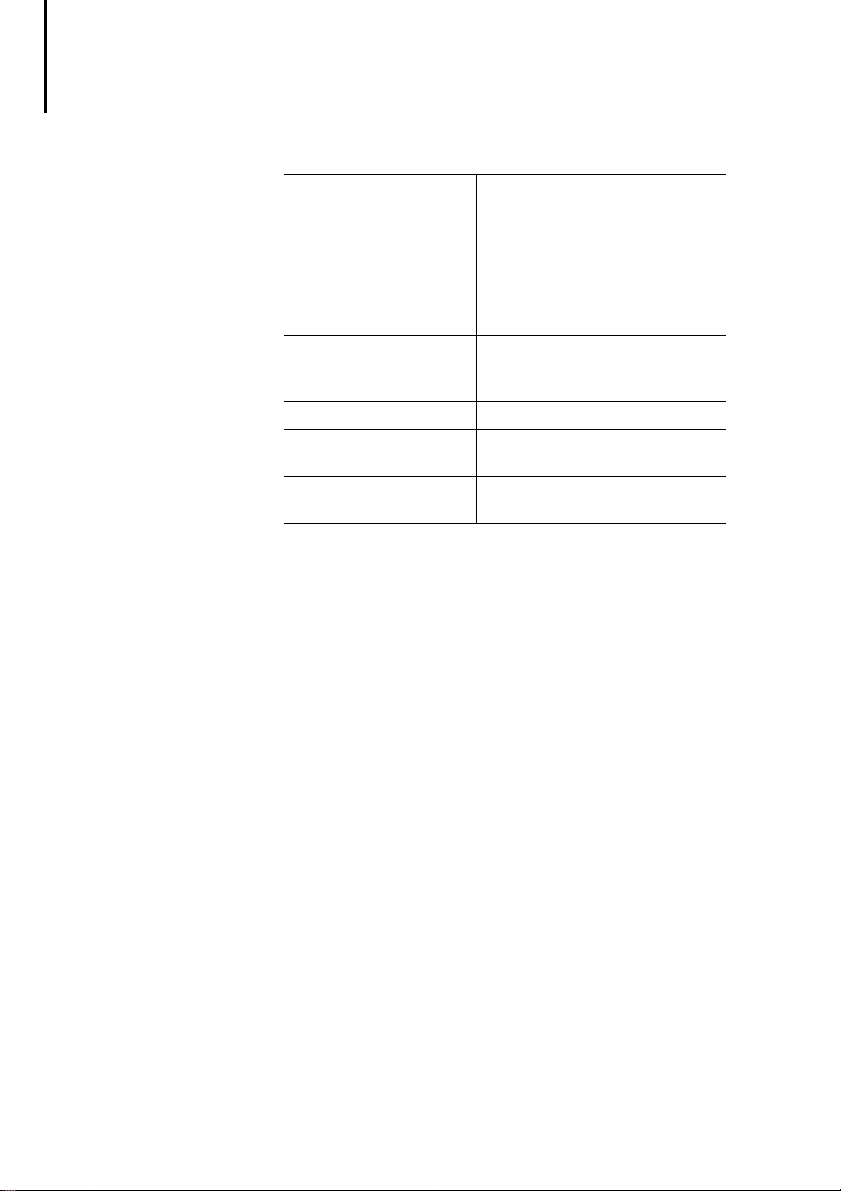

Table 1: Hardware and software requirements

Sucosoft

for PS 416-CPU-223

for PS 416-CPU-200/-300:

for PS 416-CPU 400:

Rack PS 416-BGT-400/410/420 or 421 with

Power supply units PS 416-POW-400/410/420

Central processing unit PS 416-CPU-200/300/400

Programming cable or

interface converter

1) Hardware and engineering of the

PS 416-CPU-223 see AWB 27-1243-GB

1)

:

Operating system from version 1.32

S 30-S 316-D/-GB/-F from

version 2.31

Operating system from version 2.0

S 40-D/-GB/-F from version 2.0

Operating system from version 1.0

S 40-D/-GB/-F from version 1.0

potential equalisation bar

PS 416-ZBX-401/402/403

PS 416-CPU-223

PS 416-ZBK-210 (PRG/RS 232)

UM 1.5 (PRG/RS 485)

1

The central unit is supplied without an operating

system. Sucosoft S 40 is required for loading the

operating system or a bootable memory card with a

loaded operating system. The prrogramming, test

and commissioning of the P S416 are described in

the relevant Sucosoft S 40 manuals.

Components

The PS 416 automation system consists of the

following components:

Basic elements

PS 416-BGT-4...rack

PS 416-POW-4x0 power supply card

PS 416-CPU-200/-300/-400/-223 central processing unit

8

02/98 AWB 27-1208-GB

Page 12

Components

For Immediate Delivery call KMParts.com at (866) 595-9616

Standard cards

Digital input/output cards

PS 416-INP-400/401

PS 416-OUT-400/410

Analogue input/output cards

PS 416-AIO-400/PS 416-AIN-400

PS 416-CNT-200 counter card

Networking/communications cards

PS 416-NET-210 Suconet K card

(only with PS 416-CPU-223 central unit)

PS 416-NET-400 Suconet K card

PS 416-NET-230 PROFIBUS card

PS 416-NET-220 Interbus S card

PS 416-COM-200 Communications card

PS 416-COM-200 Communications card

The basic elements, such as rack, power supply and

the central unit are described in this manual.

The hardware and programming of the

PS 416-CPU-223 are described in the

AWB 27-1243-GB.

PS 416 system

power supply

230 V AC

power

PS 416

POW-400

processing unit

not ready

change

run

ready

error

CPU-400

analog I/O

4xI, 4xQ, 12Bit

AIO-400

digital in

I

I

INP-400

digital out

Reset

Q

Q

OUT-400

network

16x0,5A

SUCOnet K

active

ready

ZAA

.0

error

.1

.2

.3

.4

.5

.6

.7

.0

.1

.2

.3

.4

.5

.6

.7

NET-400

16x0,3ms

.0

.1

.2

.3

.4

.5

.6

.7

.0

.1

.2

.3

.4

.5

.6

.7

COUNTER

14

1

GND

CH0

15

2

GND

CH0

16

3

GND

CH1

17

4

GND

CH1

18

5

GND

CH2

19

6

CH2

GND

7

20

CH3

5V

8

21

CH3

5V

9

22

CH4

5V

10

23

CH4

24V

11

24

CH5

24V

12

25

CH5

24V

13

CNT-200

network

PROFIBUS

NET-230

Bus

ERR

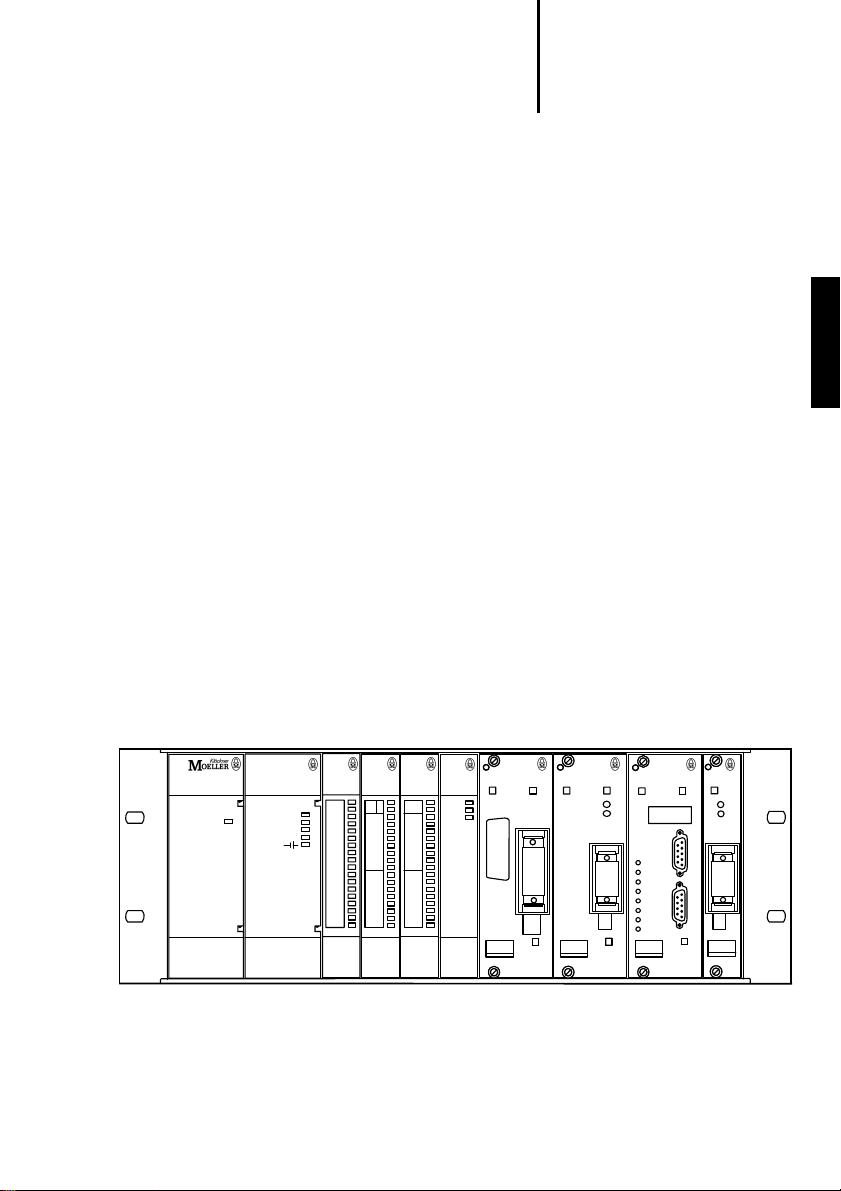

Figure 1: PS 416 automation system

02/98 AWB 27-1208-GB

network

InterBus-S

COM

NET-220

RxD/

TxD

ERR

C

F

G

S

U

C

O

n

e

t

S

COM200

diag.-code

ready

clear

out

run

bsa

con

rb

lb

mod

9

Page 13

10

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 14

2 Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Networks for different applications can be created

with the Suconet K system bus. The network stations

are configured according to their functions. The

following functions are possible:

PS 416 system

AIN

POW

PS 416-CPU-x00

INP

AIN

AIO

OUT

EM 4-201-DX2

POW

NET 400

LE 4116-DX1

AIN

Master

햲

Slaves for the expansion of the remote inputs/

outputs:

Expander rack

Expansion module

Intelligent slaves

햲

LE 4-

햴

116-XD1

INP

AIO

OUT

햳

햴

햵

INP

AIN

AIO

POW

NET 400 (E)

햵

OUT

햳

PS 416-CPU-400

*

Figure 2: Device configuration with Suconet K

*) This network line is not possible with the

PS 416-CPU-200.

02/98 AWB 27-1208-GB

11

Page 15

Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Master

The master manages the access to the remote input/

output cards. A master is any card that manages a

network line. In a PS 416 system the

PS 416-CPU-300/-400 and/or PS 416-NET-400 can

be implemented as master. Both cards have a

Suconet K interface. The configuration of the

operating mode and the stations is carried out in the

Sucosoft S 40 Topology Configurator.

A PS 416-CPU-300/-400 central unit can manage up

to nine bus lines. One line is integrated on the card,

whilst other lines can be formed using the

PS 416-NET-400 card.

A P S416-CPU-200 central unit can manage up to

eight bus lines, using the PS 416-NET-400 network

card to connect each line.

The current requirements must be calculated in all

cases for the number of bus lines to be used.

Up to 30 stations can be connected to each line. The

number depends on the memory requirements of

each station in the communication memory of the

master.

12

02/98 AWB 27-1208-GB

Page 16

Slaves for remote I/O

For Immediate Delivery call KMParts.com at (866) 595-9616

expansion

NET 400

NET 400

NET 400

1...30

1...30

NET 400

NET 400

1...30

1...30

1...30

NET 400

NET 400

NET 400

PS 416-CPU-x00

PS 416-POW-4x0

햲

123456789

햳

12345678

햴

1...30

1...30

1...30

1...30

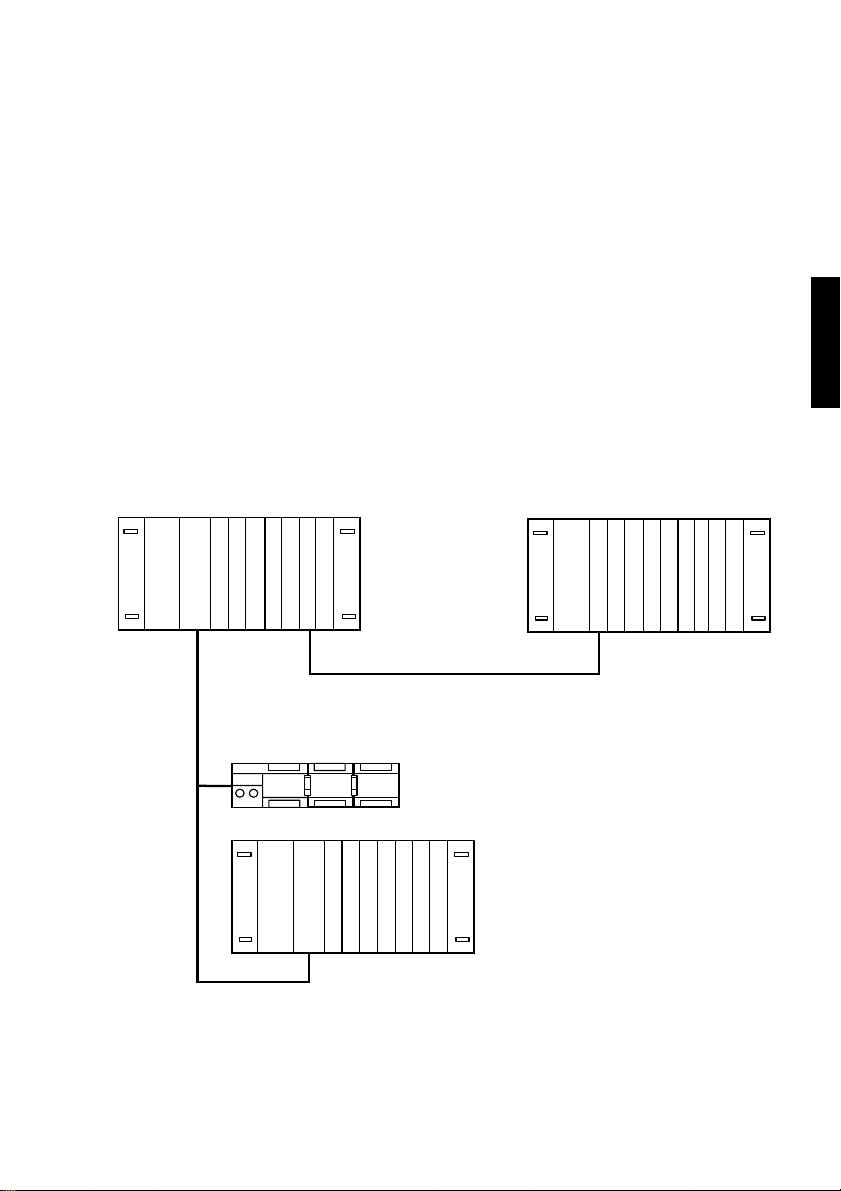

Figure 3: Maximum expansion

햲 Lines with PS 416-CPU-300/-400

Lines with

햳

햴 Stations

PS 416-CPU-200

PS 416 system

Slaves for remote I/O

expansion

Slaves for remote I/O expansion have no individual

central unit. They provide the master their data if

requested but cannot communicate with the master.

The number of data bytes which the slaves occupy in

the communication memory of the master is

predefined. This therefore does not have to be

specified in the configuration.

The slaves are addressed in a 5-point notation based

on the spatial configuration of the stations. The

stations are configured in the Topology Configurator

of Sucosoft S 40. Expander racks or expansion

modules are used as slaves for the remote expansion

of the inputs/outputs.

02/98 AWB 27-1208-GB

13

Page 17

Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Expander racks

The remote expansion of the inputs/outputs in a

PS 416 system is implemented with racks which do

not have a CPU (expander racks). The required

configuration parameters of the local inputs/outputs

of these racks are sent to the PS 416-NET-400 card

via the master.

The address set on the card must comply with the

address set in the Sucosoft Topology Configurator.

You will find detailed information on the

PS 416-NET-400 card in the Suconet K Interface

manual, AWB 27-1210-GB.

The PS 416 automation system can process up to

30 expander racks on one line. Up to nine/eight lines

(depending on the CPU) can be managed on each

basic unit. The total permissible number of cards

that can be used on the rack depends on the total

current consumption of the individual cards and the

power supply card used (current consumption

calculation). The standard cards can be used as

components of the expander rack. The

communication is carried out via Suconet K. The

following settings are possible depending on the

application at hand:

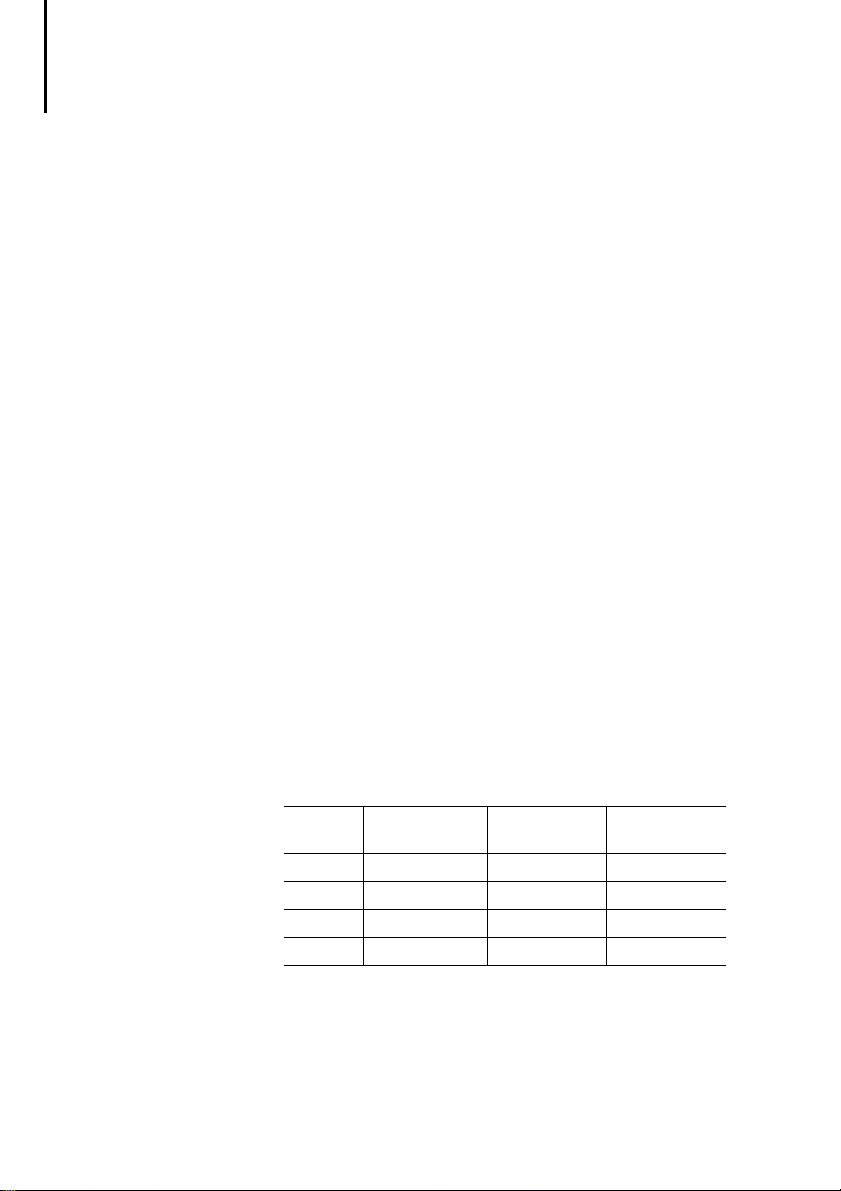

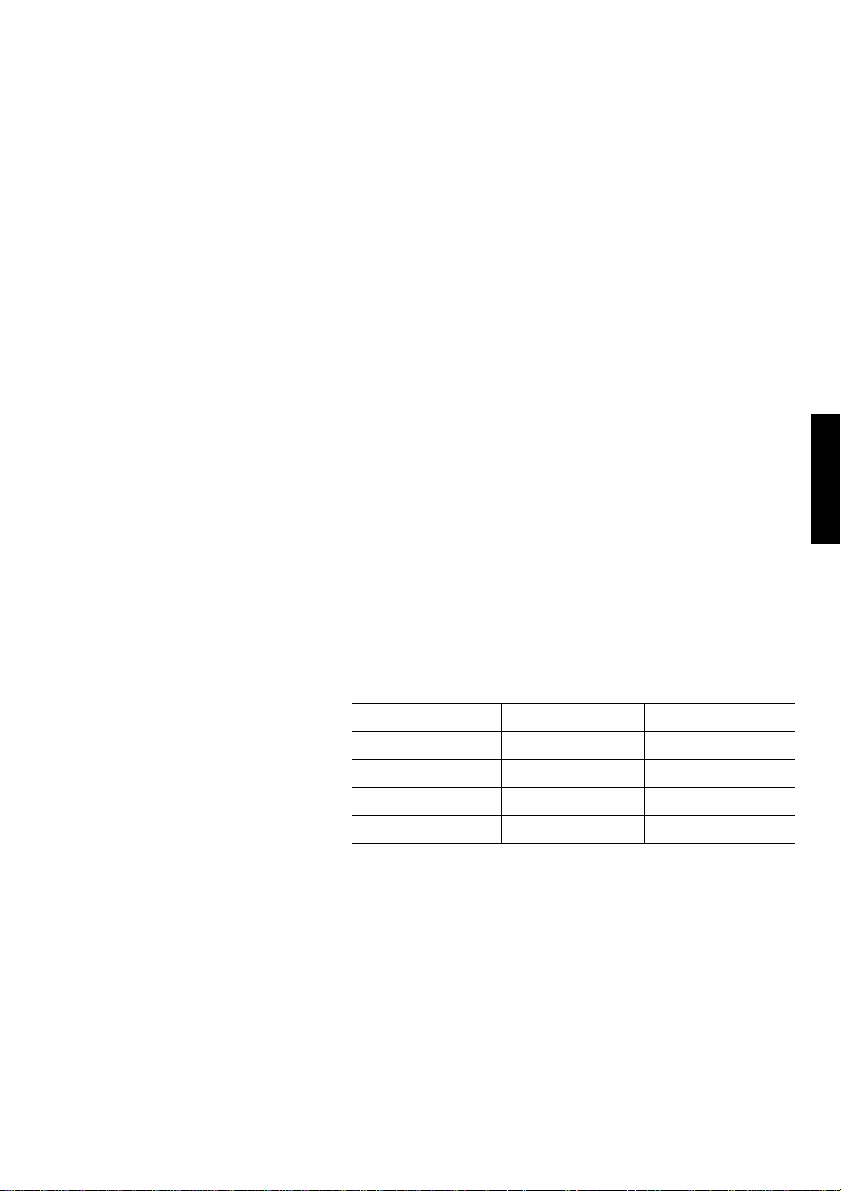

Table 2: Application criteria

Baud rate

(Kbaud)

187.5 no 600 m good

187.5 yes 600 m very good

375 no 300 m good

375 yes 300 m very good

1) These bus lengths can only be implemented with the

CRC16 check max. bus

cable listed under Accessories in the appendix.

length

1)

Data saving

14

02/98 AWB 27-1208-GB

Page 18

Intelligent slaves

For Immediate Delivery call KMParts.com at (866) 595-9616

784 bytes of memory are available for the

communication with all connected stations of a line

on the PS 416-CPU-300/-400. The following table

shows the memory assignment of the cards to be

used.

Table 3: Memory assignment of the cards of an expander

rack

Card Input byte Output byte

PS 416-INP-400/401 2 –

PS 416-OUT-400/410 – 2/1

PS 416-AIN-400 16 –

PS 416-AIO-400 8 8

PS 416-CNT-200 12 –

Expansion modules

Expansion modules of the EM... compact series are

usually used for the expansion of remote inputs/

outputs. They do not have their own central unit.

PS 416 system

Intelligent slaves

Intelligent slaves have their own central unit and are

thus able to process their own user program. The

communication between the master and intelligent

slaves is carried out in both directions. The number

of send and receive data bytes for intelligent slaves

must be defined in the Sucosoft S 40 Topology

Configurator. The memory size depends on the type

of slave.

The following components can be used as intelligent

slaves:

02/98 AWB 27-1208-GB

15

Page 19

Table 4: Data exchange memory of intelligent slaves

For Immediate Delivery call KMParts.com at (866) 595-9616

Components Usable memory

PS 416-CPU-300/-400 784 bytes

PS 416-NET-400 1492 bytes

PS 4-101-DD1

PS 4-111-DR1/DR5

PS 4-201-MM1

PS 4-141-MM1

PS 4-151-MM1

PS 4-401-MM2 168 bytes

1) The available memory size depends on the number of

connected slaves on a line. The values stated in the

table apply with the maximum utilization of the line.

6 bytes Master 씮 Slave

7 bytes Slave 씮 Master

Total I/O 78 bytes

1)

The station is addressed by the user program in bit,

byte, word or double word format depending on the

station. The operations with the possible operands

and function blocks are described in the

Sucosoft S 40 programming software.

16

02/98 AWB 27-1208-GB

Page 20

3 Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Electromagnetic

compatibility (EMC)

Reaction times

Interference immunity

Observe the engineering instructions in the manual

“EMC Engineering Guidelines for Automation

Systems” (AWB 27-1287-GB)

The shortest reaction time can be implemented with

local cards that are addressed by the central unit via

the internal bus. Only the program cycle time and the

input/output delays of the cards determine the

reaction time.

If remote stations are connected via Suconet K, the

reaction time depends on the number of stations on

the line, the data volume and the data transfer rate.

Further information on the calculation of the reaction

time is given in the Appendix.

The PS 416 system is designed for industrial

applications.

Provide the supply cable of the power supply card

with a ferrite ring. Mounting should be carried out as

close to the card as possible. No further connections

to other devices may be implemented beyond this

point.

PS 416 system

The ferrite ring is not delivered with the cards.

02/98 AWB 27-1208-GB

Please order separately:

Type PS 416-ZBX-405

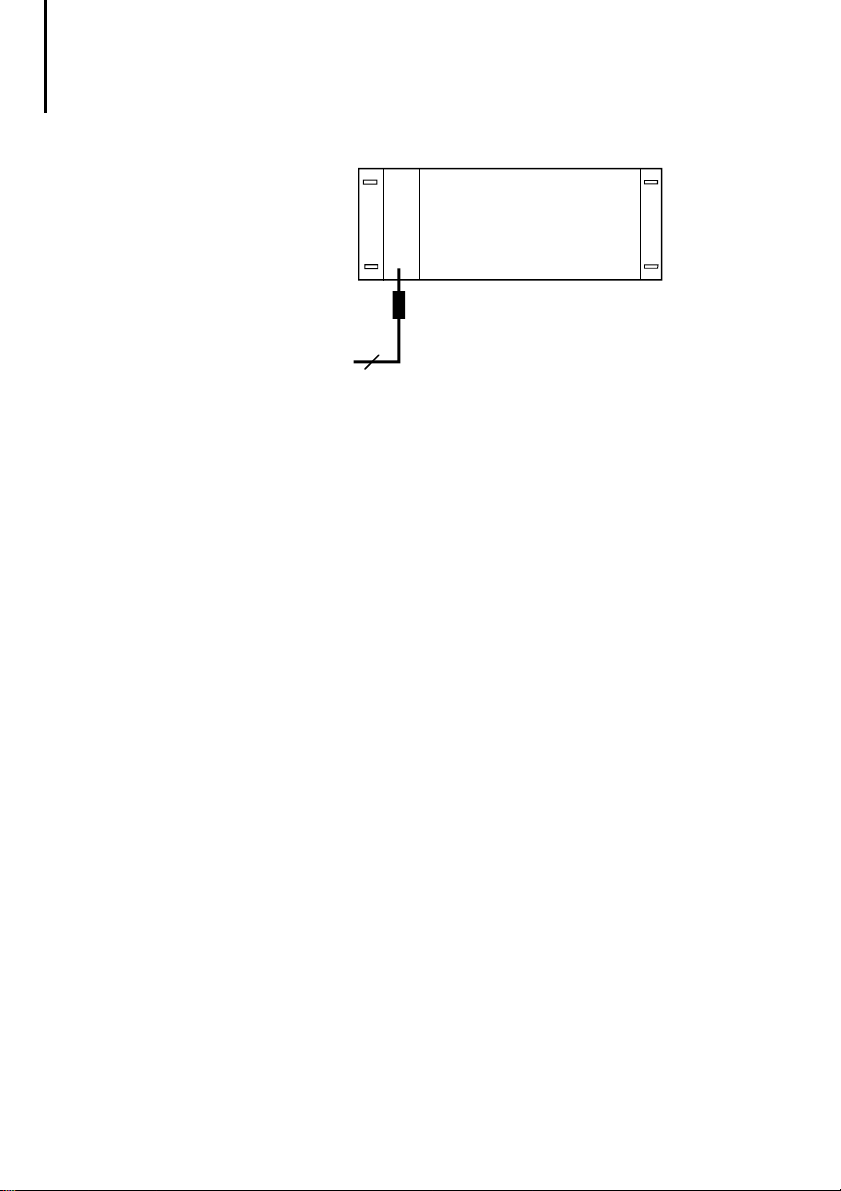

The following figure shows the use of the ferrite ring,

using the PS 416-POW-400 as an example:

17

Page 21

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

PS 416

POW-400

Ferrite ring

230 V AC

3

Ensure that all signal cables of communications and

analog cards are laid separately from power and

control cables in order to prevent interference.

Radiated interference

Interference is either caused by radiation or via

electromagentic fields or by static discharges.

Interference signals coming from

fields

can affect signal cables. This can be prevented

by screening these cables. The screen braid here

intercepts the interference potential. The screen

discharge to earth is implemented via high-frequency,

low-impedance connections.

electromagnetic

The screen earth should

be located as close as possible to the most sensitive

location of the system, e. g. on the inputs of the

cards. A potential equalisation bar can therefore be

fitted on the racks of the PS 416 system (see

Appendix). The screen must not be interrupted so

that the conductive plugs and mounting components

which do not belong to the signal circuit on the card

are connected with the screen. They are earthed via

the protective conductor on the rack which is

connected with the central reference point.

Installation notes, see chapter “Racks”.

18

02/98 AWB 27-1208-GB

Page 22

Interference immunity

For Immediate Delivery call KMParts.com at (866) 595-9616

Static discharges

may cause a system fault via

conductive components which do not belong to the

operating circuit (e. g. plugs, switches, mounting

components). All freely accessible components

which are not covered by a flap or covering are

electrically connected to the rack. The guide rails of

the card are provided with contact springs. Ensure

that these contact elements function correctly.

Note

Ensure that you are free of electrostatic charge

when working with operating elements and

components that are covered. This especially

applies to the battery, the memory card and the

operating switches of the CPU.

Line-conducted interference

Line-conducted interference may be due to galvanic,

capacitive and inductive coupling. All cards of the

PS 416 system have appropriate suppressor

elements which ensure the correct functioning of the

cards according to the relevant interference class.

The engineering of the system should not involve any

switchgear with higher interference levels.

Interference sources of this kind must be eliminated

via an appropriate installation or suppressor

elements.

PS 416 system

02/98 AWB 27-1208-GB

19

Page 23

20

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 24

PS 416-BGT-4.. Racks

For Immediate Delivery call KMParts.com at (866) 595-9616

Contents

1 Racks

Task 23

System description 23

Setup 24

2 Engineering

Coupling the racks 27

Assignment of the rack 27

3 Installation

Fixing the potential equalisation bar 29

Connecting the protective earth 29

Fitting/removing cards 29

4Operation

Monitoring 33

23

PS 416-BGT-4..

27

29

33

02/98 AWB 27-1208-GB

21

Page 25

22

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 26

1 Racks

For Immediate Delivery call KMParts.com at (866) 595-9616

Task

System description

The PS 416-BGT-4.. racks are used for the assembly

of PS 416 programmable controllers.

The racks house mechanically and electrically house

the individual cards. They provide protection against

mechanical and electromagnetic interference. An

internal bus is used for the power supply and the

signal exchange between the cards. An integrated

monitoring element monitors the 5 V system voltage

and the bus activity and generates an Enable signal

(ENA) for the cards.

Fully mounted devices for installation on a mounting

plate are available in three different sizes as well as a

rack for front installation. The following table shows

the mounting type and the number of the freely

available slots in the individual racks.

Table 5: Type overview of racks

Type Installation type Number of free slots

PS 416-BGT-400 Mounting plate 9

PS 416-BGT-410 Mounting plate 13

PS 416-BGT-420 Mounting plate 19

PS 416-BGT-421 Front mounting 19

PS 416-BGT-4..

02/98 AWB 27-1208-GB

23

Page 27

Racks

For Immediate Delivery call KMParts.com at (866) 595-9616

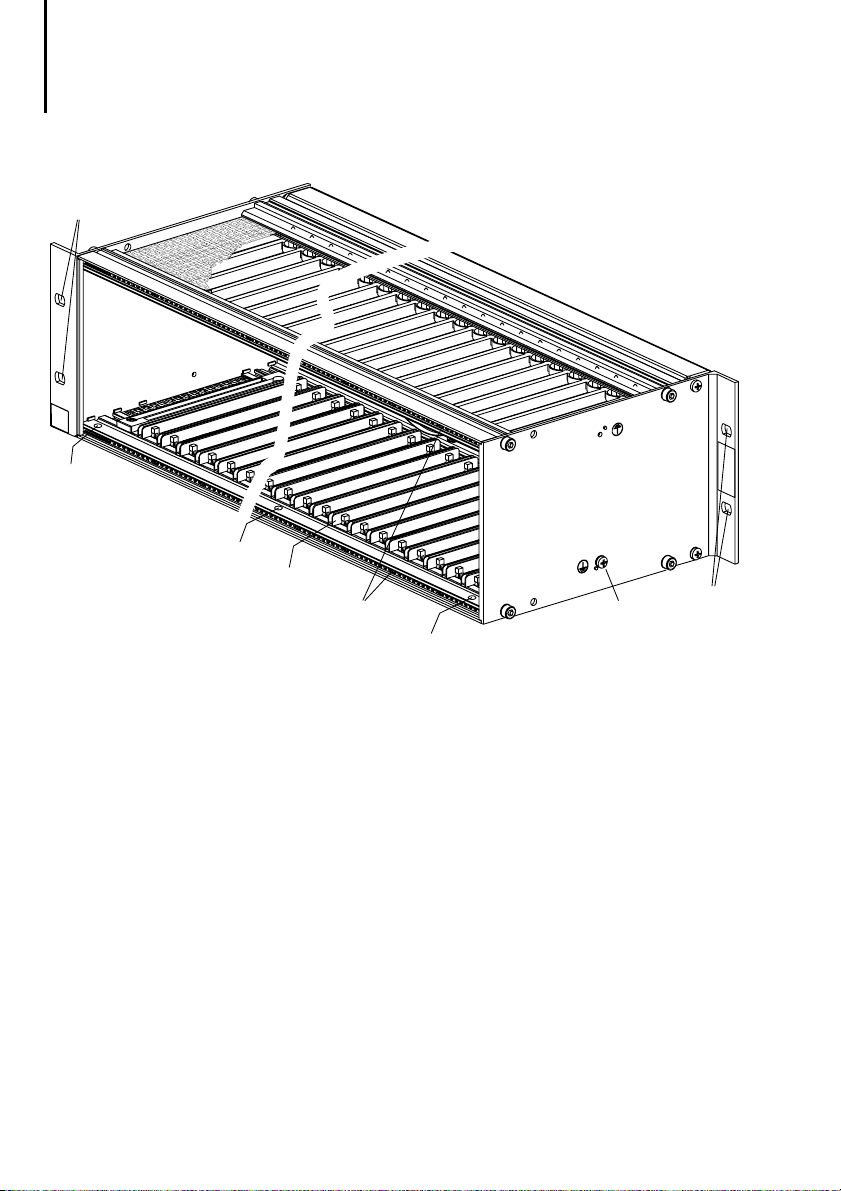

Setup

햲

햴

햴

햶

햵

햴

햳

햲

Figure 4: Setup of the racks for mounting plate installation

(left) and front mounting (right)

햲 Fixing holes for mounting/installation of the rack

햳 Protective earth connection (PE)

햴 Fixing holes for the potential equalisation bar

햵 Fast-release lock for fixing the card

햶 Rails for inserting the card

24

02/98 AWB 27-1208-GB

Page 28

PS 416-BGT-4xx

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

햳

M4

8

´

Setup

Potential equalisation bar

A suitable potential equalisation bar is supplied with

each rack as an accessory. The bar is used for

connecting the cable screens to the protective earth.

Table 6 shows an overview of potential equalisation

bars for the individual racks.

Table 6: Type overview potential equalisation bars

Racks Potential equalisation bar

PS 416-BGT-400 PS 416-ZBX-403

PS 416-BGT-410 PS 416-ZBX-402

PS 416-BGT-420, PS 416-BGT-421 PS 416-ZBX-401

PS 416-ZBX-40x

M4

´

12

PS 416-BGT-4..

햴

PS 416-ZBX-404

Figure 5: Setup and mounting of the potential equalisation

bar

햲 Cable

햳 Screen

햴 Marking strip

02/98 AWB 27-1208-GB

25

Page 29

26

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 30

2 Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

All racks can be used as a basic unit (with central

unit) or as an expander rack (without central unit).

Each rack must be fitted with a power supply card

which must always be fitted in the left "POW" slot.

The other slots can be used as required.

Coupling the racks

Assignment of the rack

The coupling between the basic unit and expander

rack is carried out via the Suconet K field bus. The

internal bus in the basic unit is operated by the

central unit, in the expander by the PS 416-NET-400

Suconet K card. You will find a detailed description

of coupling with PS 416-NET-400 in the “Suconet K

interface” manual AWB 27-1210-GB.

All card types can be used in a rack.

The PS 416-NET-400 card is used in the expander

rack for coupling to the basic unit and for controlling

the internal bus. Only standard cards must be used

in an expander rack:

Digital input/output cards

Analogue input/output cards

Counter card

PS 416-BGT-4..

02/98 AWB 27-1208-GB

27

Page 31

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Figure 6 shows the possible assignments of the rack

for the individual cards.

햲

PS 416-POW-4x0

PS 416-CPU-

200/-300/-400

PS 416-...

햳

PS 416-POW-4x0

PS 416-NET-400

PS 416-...

POW

234 10 14 20

PS 416-BGT-420/421

PS 416-BGT-410

PS 416-BGT-400

234 10 14 20

POW

... ... ...

... ... ...

Figure 6: Slot assignment in the basic unit 햲 and the

expander rack 햳

1 slot = 4 space units (1 space unit = 5.08 mm)

28

02/98 AWB 27-1208-GB

Page 32

3 Installation

For Immediate Delivery call KMParts.com at (866) 595-9616

The PS 416-BGT-400/410/420 racks are directly

installed on a mounting plate in a control cabinet. The

PS 416-BGT-421 rack can be installed via the

mounting brackets on the front in a 19-inch mounting

rail system or swing frame.

Use type M6҂25 screws for installing the rack on

the mounting plate or for front installation.

PS 416-BGT-4..

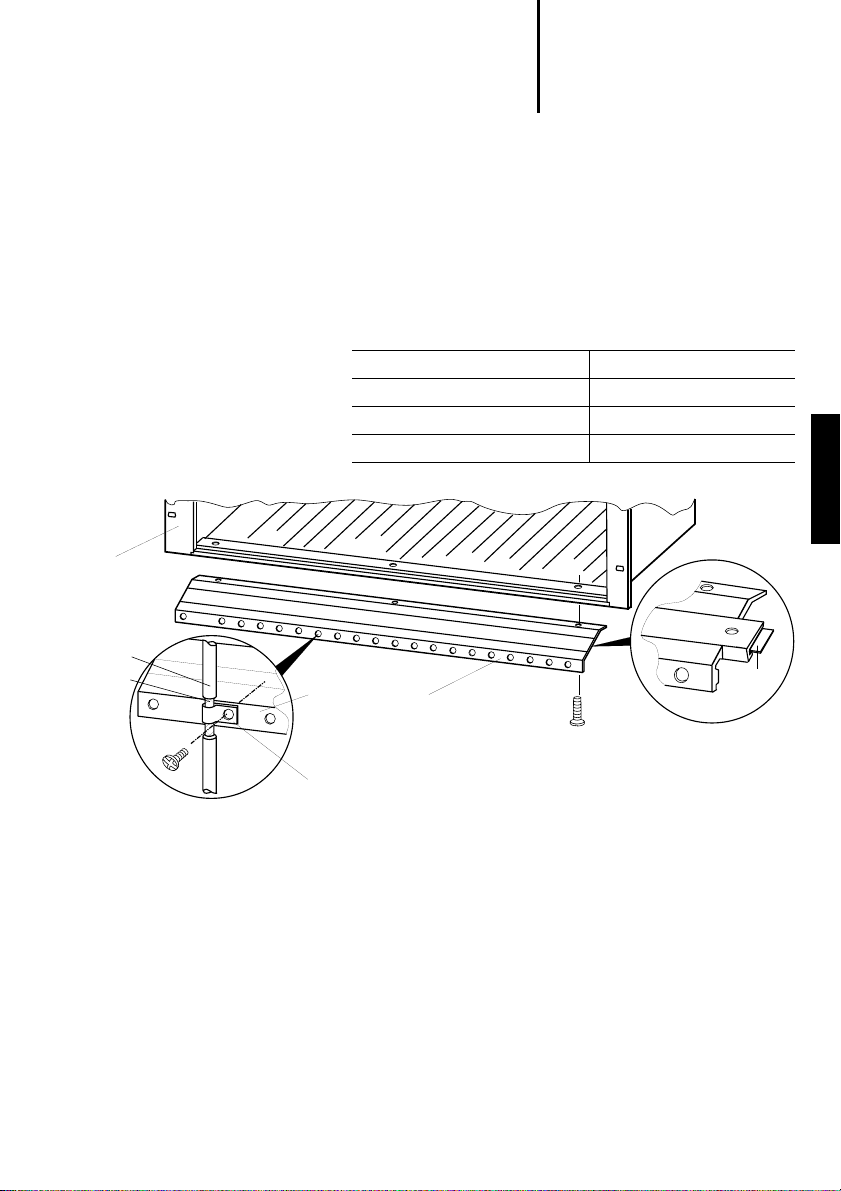

Fixing the potential

equalisation bar

Connecting the

protective earth

Fitting/removing cards

Fix the equalisation bar with three M4҂12 screws

왘

on the bottom of the rack before mounting.

The protective earth (PE) can be connected on the

side of each rack.

Connect the protective earth via the M4҂4 screw

왘

(see also section “Interference immunity”).

Note

Only fit or remove the cards with the PLC

switched off.

Voltage peaks on the bus connector may otherwise

cause interference or may damage the controller or

the card.

02/98 AWB 27-1208-GB

29

Page 33

Installation

For Immediate Delivery call KMParts.com at (866) 595-9616

Installation

Fit the cards into the rack:

왘

the PS 416-POW-4x0 power supply card

into the “POW” slot,

the PS 416-CPU-200/-300/-400 central unit

into the slots 2 and 3, the Suconet K card

into the slot 2,

all other cards into any available slot.

Insert the card into the rack until you hear the

왘

spring lug snap into position.

Wire the card. Refer to the “Hardware and

왘

Engineering” manual for the card concerned.

Removing

Open the front cover.

왘

Remove the cables.

왘

Unlock the spring lug by pressing the lever

왘

(see arrow in Figure 7).

Pull the card forward towards you.

왘

30

02/98 AWB 27-1208-GB

Page 34

Fitting/removing cards

For Immediate Delivery call KMParts.com at (866) 595-9616

PS 416-BGT-4..

L1

N

PE

A

C

B

Figure 7: Installing/removing cards. The PS 416-POW-400

power supply card as an example

02/98 AWB 27-1208-GB

31

Page 35

32

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 36

4 Operation

For Immediate Delivery call KMParts.com at (866) 595-9616

Monitoring

During operation, the rack monitors the 5 V system

voltage. The function cards are disabled if the system

voltage falls below the permissible minimum of

4.75 V.

The rack also monitors the control of the internal bus

by the central unit (basic unit) or the

PS 416-NET-400 Suconet K card (expander rack).

The voltage is switched off and the function cards are

disabled if no activity is on the bus for approx.

100 ms. In both cases all outputs are reset.

PS 416-BGT-4..

02/98 AWB 27-1208-GB

33

Page 37

34

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 38

PS 416-POW-400/410/420

For Immediate Delivery call KMParts.com at (866) 595-9616

Power Supply Cards

Contents

1 About the power supply card

Task 37

Setup 37

2 Engineering

Number of power supply cards 42

Mains filter 42

Connection assignment 42

Wiring PS 416-POW-400/-420 44

Wiring PS 416-POW-410 47

Cabling 49

3 Installation

Connecting the mains supply 51

4Operation

Function of the card 53

5 Diagnostics

37

41

PS 416-POW-4x0

51

53

55

02/98 AWB 27-1208-GB

35

Page 39

36

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 40

1 Power Supply Card

For Immediate Delivery call KMParts.com at (866) 595-9616

Task

Setup

The PS 416-POW-4x0 power supply card generates

the 5 V stabilised system voltage required for the

operation of the PS 416 automation system from the

connected mains supply. The power supply card

also monitors the power supply for voltage failures.

The PS 416-POW-4x0 power supply card can be

operated in all racks of the PS 416 automation

system.

PS 416-POW-4x0

02/98 AWB 27-1208-GB

37

Page 41

Power Supply Card

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

햵

L

1

햴

N

P

E

햳

Figure 8: Setup of the PS 416-POW-400 and

PS 416-POW-420 cards

햲 Spring lug

햳 Front cover

햴 Screw terminal for power supply

PS 416-POW-400 L1/N: 230 V AC

PS 416-POW-420 L1/N: 115 V AC

PS 416-POW-400/420 PE: protective earth

햵 LED for mains supply

38

02/98 AWB 27-1208-GB

Page 42

Setup

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

햵

02/98 AWB 27-1208-GB

2

4

V

0

햴

V

햳

Figure 9: Setup of the PS 416-POW-410 card

햲 Spring lug

햳 Front cover

햴 Screw terminal for power supply

24 V/0 V: 24 V DC

PE: protective earth

햵 LED for mains supply

PS 416-POW-4x0

39

Page 43

40

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 44

2 Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Ensure that the relevant safety regulations and

accident prevention requirements (EN, IEC

regulations) are observed if required.

With 24 V supplies the low voltages must be isolated

electrically. Only power supply units produced

according to IEC 364-4-41 must be used.

Emergency-stop devices according to

EN 60204/IEC 204 must be functional in all operating

modes of the controller. Unlocking the Emergencystop device must not cause an uncontrolled or

undefined restart.

02/98 AWB 27-1208-GB

Please observe the technical data of the

PS 416-POW-4x0 card (see Appendix) when

engineering.

PS 416-POW-4x0

41

Page 45

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Potential isolation

Number of power

supply cards

Overvoltage

Filter

L1

N

PE

Power

PS 416-POW-400/420

Figure 10: Block diagram for the PS 416-POW-4x0 power

supply card

protection

Control

unit

HF

transformer

Overvoltage

protection

Power Fail Indicator

Each rack requires one power supply card. The fitting

of several power supply cards on one rack is not

possible.

5 V/

8 A

Mains filter A mains filter is not required due to filter measures

already integrated.

42

02/98 AWB 27-1208-GB

Page 46

Connection assignment

For Immediate Delivery call KMParts.com at (866) 595-9616

Connection

assignment

The card is connected to the mains supply via a

3-pole screw terminal which is located behind the

front cover.

2

4

L

1

N

P

E

Figure 11: Terminal for mains supply

Left: Terminal block for a voltage of

230 V AC (PS 416-POW-400)

115 V AC (PS 416-POW-420)

Right: Terminal block for a voltage of

24 V DC (PS 416-POW-410)

Table 7: Meaning of the connections

PS 416-POW-... Connection Meaning

... 400 L1, N

PE

... 410 24 V, 0 V댸Rated voltage 24 V DC,

... 420 L1, N

PE

V

0

V

Rated voltage 230 V AC, single

phase,

195 to 264 V AC/47 to 400 Hz

Rated current max. 0.5 A

Protective conductor

19.2 to 30 V DC

Rated current approx. 3 A

Protective conductor

Rated voltage 115 V AC, single

phase,

98 to 132 V AC/47 to 400 Hz

Rated current approx. 1 A

Protective conductor

PS 416-POW-4x0

02/98 AWB 27-1208-GB

43

Page 47

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Wiring

PS 416-POW-400/-420

Figure 12 shows the direct connection of the mains

supply to the PS 416-POW-400/420 power supply

cards.

L1

L2

L3

N

PE

F1

PS 416-POW-400/420

PS 416

L1

N

햲

Figure 12: Direct connection of the mains supply 230 V

or 115 V AC

PE

햲 PS 416-ZBX-405 ferrite ring

Mounting see “Cabling” on page 49.

The ferrite ring is not supplied with the card.

Please order separately.

With applications which must meet the EN 60204-1

requirements the connection is carried out via a

control transformer. Figure 13 shows the external

wiring of the P S416-POW-400/420 power supply

cards with earthed operation, figure 14 with

unearthed operation.

44

02/98 AWB 27-1208-GB

Page 48

For Immediate Delivery call KMParts.com at (866) 595-9616

Wiring

PS 416-POW-400/-420

An isolation monitoring device must be

implemented with unearthed mains supply

(EN 60 204-1).

L1

L2

L3

N

PE

Q1

I > I > I >

MM

F1

PS 416-POW-4x0

PS 416

햲

Figure 13: Connection of the mains supply 230 or 115 V AC

via control transformer with earthed operation

햲 PS 416-ZBX-405 ferrite ring

Mounting see “Cabling” on page 49.

The ferrite ring is not supplied with the card.

Please order separately.

02/98 AWB 27-1208-GB

PS 416-POW-400/420

L1

N

PE

45

Page 49

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

L1

L2

L3

N

PE

F3

Q1

I > I > I >

S1

K1

MM

F2

F1

P1

PS 416

햲

S2

P1

K1

Isolation

monitoring

PS 416-POW-400/420

L1

N

PE

Figure 14: Connection of the mains supply 230 or 115 V AC

via control transformer with unearthed operation

햲 PS 416-ZBX-405 ferrite ring

Mounting see “Cabling” on page 49.

The ferrite ring is not supplied with the card.

Please order separately.

46

02/98 AWB 27-1208-GB

Page 50

Wiring PS 416-POW-410

For Immediate Delivery call KMParts.com at (866) 595-9616

Wiring

PS 416-POW-410

Figure 15 shows the external wiring of the

PS 416-POW-410 power supply card with earthed

operation; figure 16 with unearthed operation.

An isolation monitoring device must be

implemented with unearthed mains supply

(EN 60 204-1).

L1

L2

L3

N

PE

Q1

G1

I >I >I >

3

0 V

+24 V

PS 416-POW-4x0

F1

Figure 15: Connection of the 24 V DC mains supply,

earthed operation

02/98 AWB 27-1208-GB

PS 416-POW-410

PS 416

24 V

0 V

47

Page 51

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

L1

L2

L3

N

PE

F3

Q1

I > I > I >

S1

K1

G1

S2

Isolation

monitoring

24 V

0 V

P1

K1

3

0 V

+24 V

F2

F1

P1

PS 416-POW-410

PS 416

Figure 16: Connection of the 24 V DC mains supply,

unearthed operation

48

02/98 AWB 27-1208-GB

Page 52

Cabling

For Immediate Delivery call KMParts.com at (866) 595-9616

Cabling Use a 3-core cable (with protective conductor) for

the connection of the mains supply.The core cross-

2

section must not exceed 1.5 mm

(solid or flexible).

왘 Connect twisted mains cables and with a

sufficient distance to power cables in order to

prevent inductive interference.

왘 Fit ferrite rings to the voltage supply cables of the

AC power supply cards PS 416-POW-400 and

PS 416-POW-420. Fit these ferrite rings as close

to the card as possible directly underneath the

potential equalisation bar.

햲

PS 416-POW-4x0

햳

PS 416-POW-400/420

PS 416-CPU-X00

햶

햵

Figure 17: Mounting the ferrite ring on the

PS 416-POW-400 und P S416-POW-420 cards

Rack

햲

Ferrite ring

햳

Cable binder

햴

Supply cable

햵

Potential equalisation bar

햶

02/98 AWB 27-1208-GB

햴

49

Page 53

50

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 54

3 Installation

For Immediate Delivery call KMParts.com at (866) 595-9616

Connecting the mains

supply

Observe the following safety instructions before

connecting the power supply card!

Caution

Ensure that the mains connection cables are

de-energized before connecting them to the

power supply card. Always connect the

protective earth conductor. A protective

conductor that is not connected may be

dangerous to persons and machine/system!

Connect the protective conductor and the mains

왘

supply cables to the 3-pole terminal block of the

power supply card. Ensure that the polarity is

correct.

Secure the connection by the integrated screws.

왘

Note

Only operate the card with the permissible rated

voltage (see Technical data), otherwise the card

may be destroyed!

Re-check the wiring before switching on the

왘

supply!

PS 416-POW-4x0

02/98 AWB 27-1208-GB

51

Page 55

52

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 56

4 Operation

For Immediate Delivery call KMParts.com at (866) 595-9616

Function of the card

The power supply card generates the 5 V DC

stabilised system voltage once the mains supply is

switched on. The regulated voltage is potentially

isolated from the mains supply. The card operates as

a switched mode power supply unit in compliance

with protection class 1. The output current is 1.5 to

8 A (PS 416-POW-400/420) and 1.5 to 10 A

(PS 416-POW-410). The voltage output of the card is

short-circuit and idle-proof.

During operation the card monitors the connected

mains supply. The card generates a warning signal

(PFI = Power Fail Indication) for the central unit in the

event of a mains supply failure that lasts more than

13 ms. This signal initiates a data backup in the

retentive memory of the central unit.

PS 416-POW-4x0

02/98 AWB 27-1208-GB

53

Page 57

54

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 58

5 Diagnostics

For Immediate Delivery call KMParts.com at (866) 595-9616

The LED on the front is lit if the connected supply is

active.

If the LED is not lit, check whether:

the mains supply is switched on

the fuse for the supply voltage has blown

the wiring is correct.

If the LED indicates that the mains supply is present,

and the system voltage is missing, this may be due

to the following:

the power supply card is not fitted properly in the

rack.

Switch off the mains supply and insert the

왘

card until you hear the card snap into position.

the card has a short-circuit or fault

Switch off the mains supply.

왘

Contact your Moeller sales office.

왘

PS 416-POW-4x0

The system voltage is not directly indicated via a

LED. If none of the LED on all the cards (except

power supply card) fitted in the rack are lit and the

mains supply is correctly applied to the power supply

card, the system voltage is missing.

02/98 AWB 27-1208-GB

55

Page 59

56

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 60

PS 416-CPU-200/-300/-400

For Immediate Delivery call KMParts.com at (866) 595-9616

Central Unit

Contents

1 About the Central Unit

Task 59

Setup 59

2 Engineering

Slot 69

Power supply 69

Interfaces 69

PRG interface 69

SBI interface (only PS 416-CPU-300/-400) 75

Screening/potential equalisation 78

3 Hardware Configuration

Setting the PRG address 79

Selecting the PRG interface 81

Switching on the PRG terminating resistors 81

Selecting SBI interface

(PS 416-CPU-300/-400 only) 83

4 Installation

ESD measures 87

Fitting the backup battery 87

Changing the backup battery 87

Fitting/removing the memory card 88

Changing the reserve battery 90

Changing the MC battery 91

59

69

79

PS 416-CPU-200/-300/-400

87

5Operation

ESD measures 93

Memory elements 97

Memory card 98

Function 99

Startup behaviour 102

02/98 AWB 27-1208-GB

93

57

Page 61

Contents

For Immediate Delivery call KMParts.com at (866) 595-9616

Stop of the user program 103

Restart behaviour 103

6 Test/Commissioning/Diagnostics

LED display 105

Self test 105

Loading the operating system 105

Loading the user program 106

Error messages 107

Acknowledging errors on NOT-READY 108

Clearing the diagnostic status word 108

Saving data after a battery failure 108

Checking the connection between

PLC and PRG 109

7 Direct Communication with Data Terminal

Units via the COM Function Block

Structure of the COM function block 112

Inputs of the COM function block 113

Outputs of the COM function block 114

Addressing the COM function block 114

Refreshing inputs/outputs 117

Reset behaviour 117

Startup behaviour 118

Data transfer 118

Transparent mode 1 118

Data block length 119

Setting COM function block parameters 119

Starting a job 120

Sending data 120

Receiving data 121

Monitoring a job 122

Aborting a job 122

Test and commissioning 124

Testing the user program 124

Error diagnostics 124

SlotError 125

Error messages 126

105

111

58

02/98 AWB 27-1208-GB

Page 62

1 Central Unit

For Immediate Delivery call KMParts.com at (866) 595-9616

Task

Setup

The central unit controls and monitors the

automation process. It stores and processes the user

program and manages the data exchange with the

connected slaves. The central unit is provided with

the required interfaces for communication,

programming and data exchange.

The central unit consists of two printed circuit boards

and occupies two slots in the rack (= 8 space units).

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

59

Page 63

Central Unit

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

PS 416-ZBB-410

PS 416-CPU-200

햵

PS 416-ZBB-410

햴

햳

햶

Figure 18: Setup of the PS 416-CPU-200

햲 Plug-in backup battery (on the front)

햳 Spring lug

햴 Switch for bus terminating resistors (PRG: RS 485)

햵 Plug-in reserve battery (internal)

햶 Address switch (PRG)

60

02/98 AWB 27-1208-GB

Page 64

Setup

For Immediate Delivery call KMParts.com at (866) 595-9616

햲 Plug-in backup battery (on the front);

for saving the data if the operating voltage fails (see

sections “Installation”, “Operation”).

햳 Spring lug: Push down before removing

햴 Switch for bus terminating resistors (PRG: RS 485);

for activating/de-activating the bus terminating

resistors if the PRG interface is operated in RS 485

mode (see section “Hardware configuration”).

햵 Plug-in reserve battery (internal);

used as fail-safe battery of the backup battery

(see sections “Installation”, “Operation”).

햶 Address switch (PRG);

for setting the station address under which the central

unit is addressed by the programming device if the

interface is operated in the RS 485 mode

(see section “Hardware configuration”).

Maximum capacity of the

user memory

:

PS 416-CPU-200 256 Kbyte

The operating system has a permanently reserved

memory range.

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

61

Page 65

Central Unit

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

햳

SET

햴

햻

햺

¬

232

®

485

M

E

M

O

R

Y

C

A

R

D

RUN

READY

NOT READY

ERROR

CHANGE

PRG-BUS-ADDR.

햵

햶

햷

햸

햹

HALT

RUN

PRG

RUN

M-RESET

Figure 19: Setup of the PS 416-CPU-200 central unit

(front view)

햲 Plug-in backup battery

햳 Multi-function button

햴 LED display

햵 Front cover

햶 Space for marking strip

햷 Socket for memory card

햸 Eject button for memory card

햹 Operating mode selector switch

햺 Selector switch for PRG interface (RS 232/RS 485)

햻 PRG interface

62

02/98 AWB 27-1208-GB

Page 66

Setup

For Immediate Delivery call KMParts.com at (866) 595-9616

햳 Multi-function button;

enables several system functions in conjunction with

the operating mode selector switch

(see section “Operation”).

햴 LED display;

indicates the states of the CPU (see section “Test/

Commissioning/Diagnostics”).

햵 Space for marking strip;

the currently set PRG bus address can be written here

(see “Hardware configuration”).

햶 Socket for memory card;

can be used for different functions. Fitting/removing is

described in section “Installation”, the function is

described in section “Operation”.

햷 Eject button for memory card;

pressing this button ejects the memory card.

햸 Operating mode selector switch;

defines the start behaviour of the central unit

(see section “Operation”).

햹 Selector switch for PRG interface (RS 232/RS 485);

with this switch you control whether the connection

to the programming device is carried out via a point-topoint connection (RS 232) or in the RS 485 mode

(see section “Hardware configuration”).

햺 PRG interface;

for the connection to a programming device

(see chapter “Engineering”).

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

63

Page 67

햲

For Immediate Delivery call KMParts.com at (866) 595-9616

PS 416-ZBB-410

PS 416-CPU-300/-400

햵

PS 416-ZBB-410

햴

햳

햶

햷

Figure 20: Setup of the PS 416-CPU-300/-400

central unit

햲 Plug-in backup battery (front)

햳 Spring lug

햴 Switch for bus terminating resistors (PRG: RS 485)

햵 Plug-in reserve battery (internal)

햶 Switch for bus terminating resistors (SB: RS 485)

햷 Address switch (PRG)

64

02/98 AWB 27-1208-GB

Page 68

햲 Plug-in backup battery (on the front);

For Immediate Delivery call KMParts.com at (866) 595-9616

for saving the data if the operating voltage fails (see

sections “Installation”, “Operation”).

햳 Spring lug: Push down before removing

햴 Switch for bus terminating resistors (PRG: RS 485);

for activating/de-activating the bus terminating

resistors if the PRG interface is operated in RS 485

mode (see section “Hardware configuration”).

햵 Plug-in reserve battery (internal);

used as fail-safe battery of the backup battery

(see sections “Installation”, “Operation”).

햶 Switch for bus terminating resistors (SBI: RS 485);

for activating/de-activating the bus terminating

resistors if the SBI interface is operated in RS 485

mode (see section “Hardware configuration”).

햷 Address switch (PRG);

for setting the station address under which the central

unit is addressed by the programming device if the

interface is operated in the RS 485 mode

(see section “Hardware configuration”).

Maximum capacity of the

user memory

PS 416-CPU-300 512 Kbyte

PS 416-CPU-400 1 MByte

The operating system has a permanently reserved

memory range.

02/98 AWB 27-1208-GB

:

PS 416-CPU-200/-300/-400

65

Page 69

Central Unit

For Immediate Delivery call KMParts.com at (866) 595-9616

햲

SET

햽

햻

햺

¬

232

®

485

PRG

¯

SBI

HALT

RUN

RUN

M-RESET

M

E

M

O

R

Y

C

A

R

D

RUN

READY

NOT READY

ERROR

CHANGE

PRG-BUS-ADDR.

Figure 21: Setup of the PS 416-CPU-300/-400

central unit (front view)

햳

햴

햵

햶

햷

햸

햹

햲 Plug-in backup battery

햳 Multi-function button

햴 LED display

햵 Front cover

햶 Space for marking strip

햷 Socket for memory card

햸 Eject button for memory card

햹 Operating mode selector switch

햺 SBI-Interface

햻 Selector switch for PRG interface (RS 232/RS 485)

햽 PRG interface

66

02/98 AWB 27-1208-GB

Page 70

Setup

For Immediate Delivery call KMParts.com at (866) 595-9616

햳 Multi-function button;

enables several system functions in conjunction with

the operating mode selector switch

(see section “Operation”).

햴 LED display;

indicates the states of the CPU (see section “Test/

Commissioning/Diagnostics”).

햶 Space for marking strip;

the currently set PRG bus address can be written here

(see “Hardware configuration”).

햷 Socket for memory card;

can be used for different functions. Fitting/removing is

described in section “Installation”, the function is

described in section “Operation”.

햸 Eject button for memory card;

pressing this button ejects the memory card.

햹 Operating mode selector switch;

defines the start behaviour of the central unit

(see section “Operation”).

햺 SBI Interface;

for connecting to the Suconet K/K1 fieldbus (see

section "“Engineering” on page 69). A DTE unit can be

connected here in Transparent mode.

햻 Selector switch for PRG interface (RS 232/RS 485);

with this switch you control whether the connection

to the programming device is carried out via a point-topoint connection (RS 232) or in the RS 485 mode

(see section “Hardware configuration”).

햽 PRG interface;

for the connection to a programming device

(see chapter “Engineering”).

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

67

Page 71

68

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 72

2 Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Slot

Power supply

Interfaces

PRG interface

The slots 2 and 3 are provided for the central unit.

The central unit is supplied by the power supply unit

in the rack. Power consumption, see Technical data

in the Appendix.

PS 416-CPU-200

A programming (PRG) interface is located on the

front of the card. It is isolated for increased

interference immunity.

PS 416-CPU-300/-400

Two interfaces are provided on the front of the card

for programming and networking. They are isolated

for increased interference immunity.

The central unit is connected to the programming

device via the PRG interface. The PRG interface can

be set as an RS 232/RS 485 interface according to

the application at hand (see section “Hardware

configuration”).

PS 416-CPU-200/-300/-400

PRG interface/RS 232

A point-to-point connection with the programming

device (PRG) is possible via the RS 232 interface.

Transfer security is restricted due to possible direct

coupling with the earth potential so that faults may

occur with high transfer speeds. The parameters for

the transfer rate (baud rate) are set via the connection

window in the Test and Commissioning tool of

02/98 AWB 27-1208-GB

69

Page 73

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Sucosoft S 40. 9600 bit/s is recommended as a

standard value.

A prepared cable is offered as connection cable in

the Accessories.

PC

PS 416-CPU-200/-300/-400

Figure 22: Point-to-point connection

Interface parameters:

The parameters required for operating the interface

are set directly in the Connection List window of the

Sucosoft S 40 test and commissioning tool. For this

the required PLC is selected and opened via Device

Interface Parameters in the Interface Settings

씮

dialog box.

The data format is defined with:

Data bit = 8

Parity = none

Stop bit = 1

70

02/98 AWB 27-1208-GB

Page 74

PRG interface

For Immediate Delivery call KMParts.com at (866) 595-9616

Possible settings are: 2400, 4800, 9600 19200,

38400 and 57600 bit/s. If the CPU is started via a

cold start, the PRG is automatically connected

with the selected baud rate and transfers the new

parameters. If no communication is posible with

these parameters, the connection is aborted and

the CPU must be restarted with new values.

A delay function can be implemented and set in

milliseconds. This can be used for adaptions to

poor connections, such as signal delays

occurring during remote diagnostics via modem.

Figure 23: Setting parameters of the COM1 interface

PRG interface/RS 485

Longer distances can be bridged between the

programming device and the PS 416 controller when

using the RS 485 mode of the PRG interface

(see Technical data in the Appendix).

In this case the interface converter U M1.5 must be

connected in series in order to create a connection

between the RS 485 interface on the CPU and the

RS 485 interface of the programming device.

02/98 AWB 27-1208-GB

PS 416-CPU-200/-300/-400

71

Page 75

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

If the RS 485 interface cable is lengthened, the

UM1.5 interface converter must be provided a

separate 5 V DC power supply.

PC

UM 1.5

Figure 24: Connection between programming device and

PS 416 controller in RS 485 mode

Pin assignment

PRG

5

+5 V

TB/RB

9

8

7

6

4

3

2

1

SGND

PGND

TxD/TA/RA

RxD

Figure 25: Programming interface, top view

72

02/98 AWB 27-1208-GB

Page 76

PRG interface

For Immediate Delivery call KMParts.com at (866) 595-9616

The table shows the meaning of the signals

depending on the selected interface.

Note

Pin 9 is assigned to the + 5V internal power

supply and Pin 5 is assigned to ground (internal

chassis). These pins must not be connected

otherwise this will destroy the card.

Table 8: Meaning of signals

Pin RS 232 RS 485 Function

1–––

2 RxD – Receive data

3TxD

TA/RA

4 – PGND Potential ground over 100 Ω

5 SGND SGND Signal ground for interface

6–––

7 – TB/RB Send/receive data

8–––

9 – +5 V Voltage for interface converter

Send data

Send/receive data

converter UM 1.5

UM 1.5

PS 416-CPU-200/-300/-400

Wiring

PRG interface/RS 232:

The following figure shows how the PRG interface/

RS 232 on the CPU is connected with the RS 232

interface of the programming device.

02/98 AWB 27-1208-GB

73

Page 77

PRG/RS232

For Immediate Delivery call KMParts.com at (866) 595-9616

Programming device

PRG/RS 485

Signal

TB/RB

TA/RA

PGND

I/O

I/O

I/O

Signal Signal

RxD

TxD 3

SGND

I/O

Pin

I

2

O

–

5

Screen

TxD

RxD

SGND

(sender)

(receiver)

Figure 26: Wiring of the central unit and programming

device via PRG/RS 232

PRG interface/RS 485:

If the PRG interface on the central unit is used as a

RS 485 interface, the UM 1.5 interface converter

must be used in the connection between the RS 485

interface and the RS 232 interface of the

programming device.

햲

UM 1.5

Pin

7

3

4

–

Screen

Signal Signal

Receiver/

sender

Receiver/

sender

PGND

(if required)

+5 V ext.

NG 31

+5 V DC 220 V AC

RxD

TxD

SGND

Programming device

Signal

(sender)

TxD

(receiver)

RxD

SGND

Figure 27: Wiring of the central unit and the programming

device via PRG/RS 485

햲 Required for lengthening the RS 485 interface

74

02/98 AWB 27-1208-GB

Page 78

SBI interface

For Immediate Delivery call KMParts.com at (866) 595-9616

(only

PS 416-CPU-300/-400)

The communication with the Suconet K stations or

data terminal units is carried out via the SBI interface

of the central unit. Transparent or Suconet K mode

can be set for the SBI interface (see Hardware

configuration), depending on the application at hand.

Suconet K mode

In the Suconet K mode the central unit is operated as

a station of a Suconet K line. The station type

(master/slave) is defined in the Sucosoft S 40

Topology Configurator. The central unit can also

connect expander racks when operating as a master.

You will find further information in the Suconet K

interface manual (AWB 27-1210-GB) or in the

relevant manuals for the remote expansion modules.

Transparent mode

This operating mode provides a serial interface for

the point-to-point communication with a data

terminal unit. The communication is carried out via

the COM function block which is integrated in the

central unit and can be called up via Sucosoft S40.

PS 416-CPU-200/-300/-400

The signal level conversion for other interfaces must

be carried out with appropriate converters. The

UM 1.5 converter is available for an RS 485/RS 232

coupling. The addressing of the interface by the

software is described in section “Operation”.

02/98 AWB 27-1208-GB

75

Page 79

Engineering

For Immediate Delivery call KMParts.com at (866) 595-9616

Pin assignment

SBI

5

+5 V

TB/RB

Figure 28: SBI interface, top view

Table 9: Meaning of signals

Pin RS 485 Function

1 ––

2 ––

3 TA/RA Send/receive data

4 PGND Potential ground over 100 Ω

5 SGND Signal ground for UM 1.5 interface converter

6 ––

7 TB/RB Send/receive data

8 ––

9 +5 V Voltage for UM 1.5 interface converter

9

8

7

6

SGND

4

PGND

3

TA/RA

2

1

Wiring

Figure 26 and 27 show the usual wiring between the

SBI interface on the central unit and the R S485

interface of a Suconet K station or the RS 232

interface of a data terminal unit (RS 232).

76

02/98 AWB 27-1208-GB

Page 80

SBI interface (only PS 416-

For Immediate Delivery call KMParts.com at (866) 595-9616

CPU-300/-400)

.

Note

Pin 9 is assigned to the + 5V internal power

supply and Pin 5 is assigned to ground (internal

chassis). These pins must not be connected

otherwise this will destroy the card.

SBI/RS485

Signal

TB/RB

TA/RA

PGND

I/O

I/O

I/O

SBI/RS 485

Signal

TB/RB

TA/RA 3

PGND

I/O

I/O

I/O

–

Pin

7

4

Screen

Suconet K Stn.

Receiver/sender

Receiver/sender

PGND (if required)

Figure 29: Wiring of central unit and Suconet K station

via SBI/RS 485

햲

UM 1.5

Pin

7

3

4

–

Screen

Signal

Receiver/

sender

Receiver/

sender

PGND

(if required)

+5 V ext.

Signal

RxD

TxD

SGND

NG 31

+5 V DC 220 V AC

Data terminal unit

TxD

(sender)

RxD

(receiver)

SGND

PS 416-CPU-200/-300/-400

Figure 30: Wiring of central unit and data terminal unit

via SBI/RS 485

햲 Required for lengthening the RS 485 interface

02/98 AWB 27-1208-GB

77

Page 81

Screening/potential

For Immediate Delivery call KMParts.com at (866) 595-9616

equalisation

Connect the screen of the data cables with the

왘

potential equalisation bar in order to prevent

interference (for mounting instructions see

chapter “Interference immunity”).

Potential equalisation must be provided between the

two cards when using R S485 interfaces if the

potential difference is greater than 7 V. In this case

use a data cable with at least one additional line. This

potential equalisation line is to be connected with the

PGND connection (pin 4).

Take into account the current carrying capacity of

the additional cables.

78

02/98 AWB 27-1208-GB

Page 82

3 Hardware Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Setting the PRG

address

The default address of the programming device

interface is set to 1. The interface can be connected

with the programming device (PRG) if you have

configured an appropriate communication relation in

Sucosoft S40.

Proceed as follows if you wish to use an address for

addressing the programming device:

Set the address via the address switch

왘

(see coding table).

Write the set address on the supplied label and

왘

stick it on the back of the front cover.

Enter the same address in the Sucosoft S 40

programming software as you have set via the

DIP switch on the CPU.

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

79

Page 83

Hardware Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Table 10: Address coding

Address Switch

12345678

1 10000000

2 01000000

3 11000000

4 00100000

5 10100000

6 01100000

7 11100000

8 00010000

9 10010000

10 01010000

11 11010000

12 00110000

13 10110000

14 01110000

15 11110000

16 00001000

17 10001000

18 01001000

19 11001000

20 00101000

21 10101000

22 01101000

23 11101000

24 00011000

25 10011000

26 01011000

27 11011000

28 00111000

29 10111000

30 01111000

31 11111000

80

02/98 AWB 27-1208-GB

Page 84

Selecting the PRG

For Immediate Delivery call KMParts.com at (866) 595-9616

interface

Example

The switch for a CPU with the address 4 is set as

follows:

ON

23456781

Figure 31: Switch position for address 4

Selecting the PRG

interface

Switching on the PRG

terminating resistors

Set the selector switch for the PRG interface as

follows:

Push the switch to the left to connect the

왘

controller directly with the PRG (RS 232).

Push the switch to the right to connect the

왘

controller with the PRG via an interface (RS 485).

RS 232

RS 485

Figure 32: Selector switch in RS 232 setting

In the RS 485 mode the terminating resistors on the

CPU must be switched on (ON). In all other cases the

bus terminating resistors must be inactive (OFF).

PS 416-CPU-200/-300/-400

02/98 AWB 27-1208-GB

81

Page 85

Hardware Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Set the poles 1 and 2 of the switch for bus

왘

terminating resistors to position ON.

21

Figure 33: Activated bus terminating resistors

Note

Both poles must always be in the same position

in order to ensure the correct functioning of

the card.

82

02/98 AWB 27-1208-GB

Page 86

Selecting SBI interface

For Immediate Delivery call KMParts.com at (866) 595-9616

(PS 416-CPU-300/-400

only)

Selecting SBI interface

(PS 416-CPU-300/-400

only)

Set the address and the baud rate in the Sucosoft

S 40 Topology Configurator. The following baud

rates are available:

Suconet K mode: 187.5/375 Kbaud

Transparent mode:

300/600/1200/2400/4800/9600/19200 bit/s

Figure 34: Setting the baud rate in Suconet K mode

02/98 AWB 27-1208-GB

PS 416-CPU-200/-300/-400

83

Page 87

Hardware Configuration

For Immediate Delivery call KMParts.com at (866) 595-9616

Figure 35: Setting the baud rate in Transparent mode

84

02/98 AWB 27-1208-GB

Page 88

Selecting SBI interface

For Immediate Delivery call KMParts.com at (866) 595-9616

(PS 416-CPU-300/-400

only)

Switching on the SBI terminating resistors

(PS 416-CPU-300/-400 only)

The terminating resistors of the physically first and

last bus station must be switched on (ON) when the

SBI is run in Suconet K mode. In all other cases the

bus terminating resistors must be inactive (OFF).

Set the poles 1 and 2 of the switch for the bus

terminating resistors to position ON.

21

Figure 36: Activated bus terminating resistors

Note

Both poles of the switch must always be in the

same position in order to ensure correct

functioning of the card.

02/98 AWB 27-1208-GB

PS 416-CPU-200/-300/-400

85

Page 89

86

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 90

4 Installation

For Immediate Delivery call KMParts.com at (866) 595-9616

ESD measures

Fitting the backup

battery

Changing the backup

battery

Before touching operating elements, interfaces and/

or data connectors during the installation, make sure

that you are free of electrostatic charge by touching

a surface with a good earth (control cabinet, device

frame).

Ensure the following during normal operation ("RUN"

mode):

the front covers should be closed

the front covers should be snapped into position

Proceed as follows to fit the backup battery:

Open the front cover

왘

Insert the battery into the space provided until the

왘

retaining clip snaps into position

Close the front cover

왘

Note

Ensure that a reserve battery is present before

changing the battery in order to prevent data

loss. The reserve battery must be changed every

five years.

PS 416-CPU-200/-300/-400

It is always possible to change the battery with the

operating voltage switched on. If the battery is

changed with the operating voltage switched off, the

voltage must only be switched on with the battery

fitted; otherwise a cold start is initiated and all

programs and data are lost.

02/98 AWB 27-1208-GB

87

Page 91

Installation

For Immediate Delivery call KMParts.com at (866) 595-9616

Open the front cover

왘

Push the retaining clip downwards

왘

Remove the battery

왘

Insert the new battery into the space provided

왘

until the retaining clip snaps into position

Close the front cover

왘

Fitting/removing the

memory card

Fitting

Insert the memory card into the socket until the

왘

eject button appears.

Correct mounting is ensured by a mechanical

lock.

88

02/98 AWB 27-1208-GB

Page 92

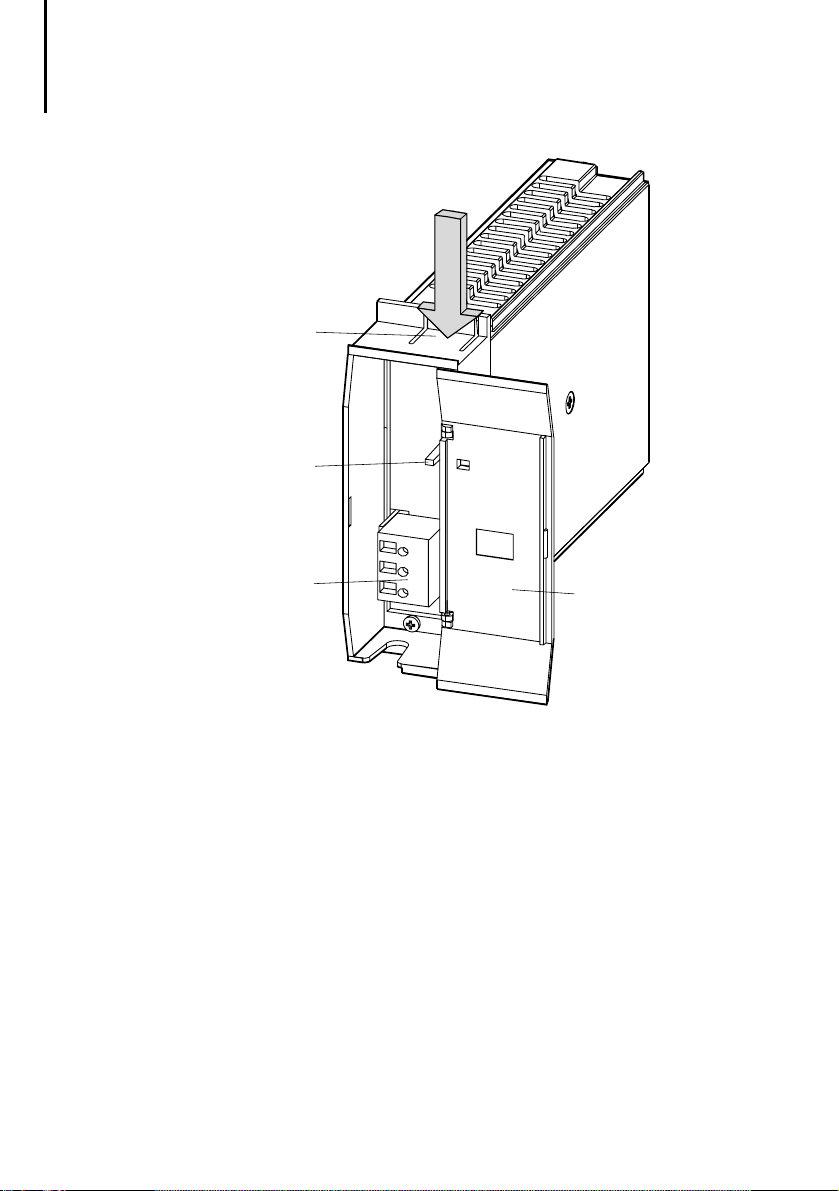

Removing

For Immediate Delivery call KMParts.com at (866) 595-9616

Press the eject button and remove the memory

왘

card.

PS 416-ZBB-410

Fitting/removing the

memory card

PS 416-CPU-400

SET

232

485

M

E

M

O

R

Y

C

A

R

D

PRG

SBI

PS 416-MEM-430/440

Figure 37: Fitting/removing the memory card and backup

battery

02/98 AWB 27-1208-GB

HALT

RUN

M-RESET

RUN

PS 416-CPU-200/-300/-400

89

Page 93

Installation

PS 416-ZBB-410

For Immediate Delivery call KMParts.com at (866) 595-9616

Changing the reserve

battery

The reserve battery is not discharged during normal

operation and has a very long lifespan. The battery

must be changed every five years since the central

unit is not provided with a monitoring device for the

battery.

Figure 38: Fitting/removing the reserve battery

90

02/98 AWB 27-1208-GB

Page 94

Changing the MC battery

For Immediate Delivery call KMParts.com at (866) 595-9616

Changing the MC

battery

Proceed as follows to change the MC battery on the

memory card :

1.

2.

PS 416-ZBB-300

3.

4.

PS 416-CPU-200/-300/-400

Figure 39: Changing the MC battery

02/98 AWB 27-1208-GB

91

Page 95

92

For Immediate Delivery call KMParts.com at (866) 595-9616

02/98 AWB 27-1208-GB

Page 96

5 Operation

For Immediate Delivery call KMParts.com at (866) 595-9616

ESD measures

PS 416-CPU-200

Before touching operating elements, interfaces and/

or data connectors during the installation, make sure

that you are free of electrostatic charge by touching

a surface with a good earth (control cabinet, device

frame).

Ensure the following during normal operation ("RUN"

mode):

the front covers should be closed

the front covers should be snapped into position

Realtime

Memory

card

512 KBytes

or

1 MByte

Bus

interface

ASIC

DPR

PS 416

User

program

memory

256 KBytes

Control

processor

RS 485

or

RS 232C

Operating

system

memory

512 KBytes

Voltage

monitoring

System bus

PRG

clock

pluggable/

optional

PS 416-CPU-200/-300/-400

Figure 40: Block diagram of the PS 416-CPU-200

02/98 AWB 27-1208-GB

93

Page 97

Operation

For Immediate Delivery call KMParts.com at (866) 595-9616

The PS 416-CPU-200 contains the following

elements required for the operation of the PS 416

automation system:

Control processor for program processing

Memory elements for operating system,

programs and data

Real-time clock

Interface to parallel bus and bit bus

Batteries for data backup in the event of voltage

drops

Monitoring device for battery function

94

02/98 AWB 27-1208-GB

Page 98

ESD measures

For Immediate Delivery call KMParts.com at (866) 595-9616

PS 416-CPU-300

Memory

card

512 KBytes

or

1 MByte

Bus

interface

ASIC

DPR

User

program

memory

512 KBytes

Control

processor

PS 416

RS 485

or

RS 232C

Operating

system

memory

512 KBytes

System bus

PRG

I/O