Moeller MV4-590-TA1, MV4-150-TA1, MV4-570-TA1, MV4-670-TA1, MV4-570-TA2 Hardware And Engineering

...Page 1

Hardware and Engineering

MV4-...

Display units and Operator Panels

07/01 AWB-C2700-1347GB

1st edition 1999, 01/99

2nd edition 1999, 11/99

3rd edition 2000, 05/00

4th edition 2000, 08/00

5th edition 2001, 07/01

© Moeller GmbH, Bonn

Author: Norbert Mausolf

Production: Ruth Walrafen

Page 2

Caution!

Dangerous electrical voltage!

Before commencing the installation

● Disconnect the power supply of the device.

● Ensure that the device cannot be

accidentally restarted.

● Verify isolation from the supply.

● Earth and short circuit.

● Cover or enclose neighbouring units

that are live.

● Follow the engineering instructions (AWA)

ofthe device concerned.

● Only suitably qualified personnel may work

on this device/system.

● Before installation and before touching

thedevice ensure that you are free of

electrostatic charge.

● Connecting cables and signal lines should

be installed so that inductive or capacitive

interference do not impair the automation

functions.

● Install automation devices and related

operating elements in such a way that they

are well protected against unintentional

operation.

● Suitable safety hardware and software

measures should be implemented for the

I/Ointerface so that a line or wire breakage

on the signal side does not result in

undefined states in the automation devices.

● Ensure a reliable electrical isolation of the

low voltage for the 24 volt supply. Only use

power supply units complying with

IEC60364-4-41 or HD 384.4.41 S2.

● Deviations of the mains voltage from the

rated value must not exceed the tolerance

limits given in the specifications, otherwise

this may cause malfunction and dangerous

operation.

● Emergency stop devices complying with

IEC/EN 60 204-1 must be effective in all

operating modes of the automation devices.

Unlatching the emergency-stop devices

must not cause uncontrolled operation

orrestart.

● Devices that are designed for mounting in

housings or control cabinets must only be

operated and controlled after they have been

installed with the housing closed. Desktop

orportable units must only be operated and

controlled in enclosed housings.

● Measures should be taken to ensure the

proper restart of programs interrupted after

avoltage dip or failure. This should not

cause dangerous operating states even for

ashort time. If necessary, emergency-stop

devices should be implemented.

All brand and product names are trademarks or

registered trademarks of the owner concerned.

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any otherprocess) or

processed, duplicated or distributed by means of

electronic systems without written permission of

Moeller GmbH, Bonn.

Subject to alterations without notice.

Page 3

Contents

Part 1 Device Description Page 1-1 to 1-26

MV4-150-TA1

MV4-450-TA1

MV4-170-TA1

MV4-470-TA1

Part 2 Device Description Page 2-1 to 2-21

MV4-570-TA1/2

MV4-590-TA1/2

Part 3 Device Description Page 3-1 to 3-29

MV4-670-TA1/2

MV4-690-TA1/2

Part 4 Communications Card Description Page 4-1 to 4-55

ZB4-601-IF1

ZB4-609-IF1

Part 5 Communications Card Description Page 5-1 to 5-15

ZB4-604-IF1

PROFIBUS-DP

Part 6 Communications Card Description Page 6-1 to 6-12

ZB4-606-IF1

DeviceNet

Moeller 07/01 AWB-C2700-1347GB

Page 4

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-1

Part 1

Touch Operator Panel

Device Description

MV4-150-TA1

MV4-450-TA1

MV4-170-TA1

MV4-470-TA1

Moeller 07/01 AWB-C2700-1347GB

Page 5

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-2

Proper use

The device must only be used for the applications described in this device description and only in conjunction

with the components recommended by Moeller.

Warning !

For the trouble-free and reliable operation of this product proper transport, storage,

assembly and mounting, as well as careful operation must be ensured.

Do not switch on the device when it is covered with condensation. When changing its

location from a cold to warm area, allow the device to acclimatise to the new conditions

before commissioning.

No warranty claims will be accepted for faults arising from the improper handling of the

device.

The device should not be used for the implementation of any safety functions relating to

the protection of personnel and machinery.

No liability is accepted for claims for damages arising from a failure or functional defect

in the device.

All data specified in this document does not represent legally binding guaranteed

specifications.

Safety instructions for the user

This device description contains the information required for the proper use of the

products described therein. Sections 1 to 12 are aimed at technically qualified persons

and sections 13 to 19 at persons requiring no specific technical qualification.

Qualified persons in relation to the safety instructions in this device description or the

product itself are persons who:

are either design personnel familar with the safety concepts of automation,

or are operating personnel who are instructed in the handling of automation systems

and have a good knowledge of the contents of this device description relating to

operation,

or are commissioning and service personnel that have been properly trained and

authorised in the repair of such automation devices, and to commission circuit

components or systems in accordance with the relevant safety standards.

Moeller 07/01 AWB-C2700-1347GB

Page 6

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-3

CONTENTS

1 Explanation of symbols............................................................................................................................ 1-4

2 Introduction.............................................................................................................................................. 1-5

3 Device Versions....................................................................................................................................... 1-5

3.1 Scope of Delivery.............................................................................................................................1-6

4 Device mounting...................................................................................................................................... 1-7

4.1 General mounting instructions ......................................................................................................... 1-7

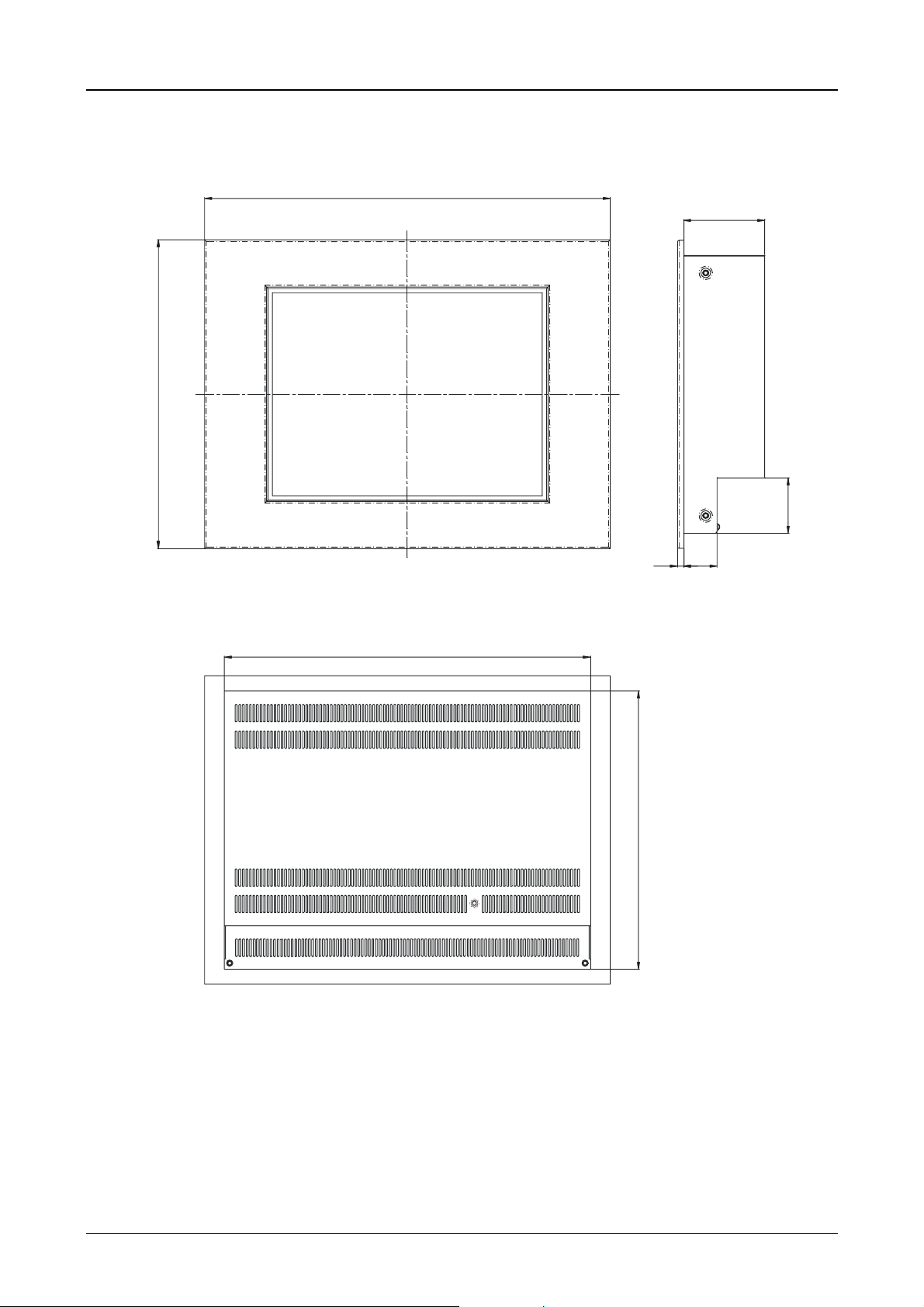

4.2 Dimensions of the 5.7″ devices MV4-150-TA1(-xx 1) , MV4-450-TA1(-xx1).....................................1-8

4.3 Front panel cutouts for 5.7″ devices ................................................................................................ 1-9

4.4 Dimensions of the 10,4″ devices MV4-170-TA1(-xx1), MV4-470-TA1(-xx1)................................ 1-10

4.5 Front panel cutouts for 10,4″ devices ............................................................................................ 1-10

5 Mounting instructions............................................................................................................................. 1-12

5.1 Mounting according to degree of protection IP 65 ......................................................................... 1-12

6 Connecting the system power supply.................................................................................................... 1-14

7 Connection to the communication interface.......................................................................................... 1-15

7.1 Preparing the connection cable (EMC).......................................................................................... 1-15

7.2 Preparing the shield connections................................................................................................... 1-16

8 Connection and function of the programming port (PROG PORT)....................................................... 1-17

9 Data transfer (Download Button)........................................................................................................... 1-18

9.1 Loading the runtime (GRSW)......................................................................................................... 1-18

9.2 Loading the project data (Download)............................................................................................. 1-19

10 Communications Cards and COM SLOT .......................................................................................... 1-20

11 Expansion and configuration options................................................................................................. 1-21

11.1 Additional 5 V power supply on programming port (PROG PORT)............................................... 1-21

12 Function and control LEDs ................................................................................................................ 1-21

13 Touch Screen..................................................................................................................................... 1-22

13.1 Basic Touch Screen function ......................................................................................................... 1-22

13.2 Power up function test.................................................................................................................... 1-22

13.3 Cleaning and maintenance of the Touch Screen........................................................................... 1-22

14 Display ............................................................................................................................................... 1-23

15 Maintenance and repair..................................................................................................................... 1-23

16 Disposal ............................................................................................................................................. 1-23

17 Technical Data................................................................................................................................... 1-24

18 EC Conformity.................................................................................................................................... 1-26

19 UL Listing........................................................................................................................................... 1-26

Moeller 07/01 AWB-C2700-1347GB

Page 7

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-4

1 Explanation of symbols

Danger warnings

The following warni ngs are provided t o ensure your personal safet y and to protect the produc t described or

connected devices from damage.

Safety instructions and warnings for the prevention of danger to the life and health of users or service

personnel, as well as the prevent ion of dam age to propert y are highli ghted througho ut this docum ent by t he

following symbols. This document always shows the different pictogrammes here for “Warnings” and “Notes”.

Warnings generally mean the following:

Indicates that death, s erious injur y or damage to propert y may occur if the r elevant pr ecautionar y measures

are not observed.

The individual Warning pictogrammes have the following meaning:

Caution ! General !

This type of warning must be observed in order to prevent hazards during the operation

of the device and at other times. Observe the correct procedure.

Danger ! Electric shock !

Voltages may occur in electrical installations that may be dangerous to persons. The

touching of live parts may cause electric shock.

Caution! Observe proper ESD protection measures !

Electrostatic discharge may destroy some components.

Notes generally mean the following:

This indicates important inf ormation on the prod uct or section of the op erating instructions t o which special

attention should be given.

The Note pictogramme has the following meaning:

Indicates important instructional information.

Moeller 07/01 AWB-C2700-1347GB

Page 8

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-5

2 Introduction

The Touch Operator Panel MV4 are visualisation units that are provided with touch zone functions for

medium to high complexity automation systems. They meet all the requirements placed on a modern

visualisation unit.

The Touch Operator Panel must be loaded with the necessary project data before it can be used. The project

data is created and loaded usin g a PC and the MV4-CFG-1 conf igurator sof tware (Ga lileo). This sof tware is

described in a separ ate documentation. The dat a transfer between the PC and the Touch Operator Panel

(Download) is implemented via a serial interface. The project data is then stored inside the device in a

retentive memory.

The Touch Operator Panel are provided with a slot for the communications card (see Section 10) which

manages the comm unication with the au tomation device. T he com munic ations cards are describe d in part 4

and 5.

This device description should be used as a reference for the installation, connections, technical data,

commissioning, operati on and maintenanc e of the units M V4-150-TA1(- xx1), MV4-450-T A1(-xx1), M V4-170TA1(-xx1), MV4-470-T A1(-xx1). The illustrati ons in this document are f or the 10.4″ version (see Sec tion 3)

unless stated otherwise. The desig nation and function of the term inals and signals are th e same, however,

for all versions.

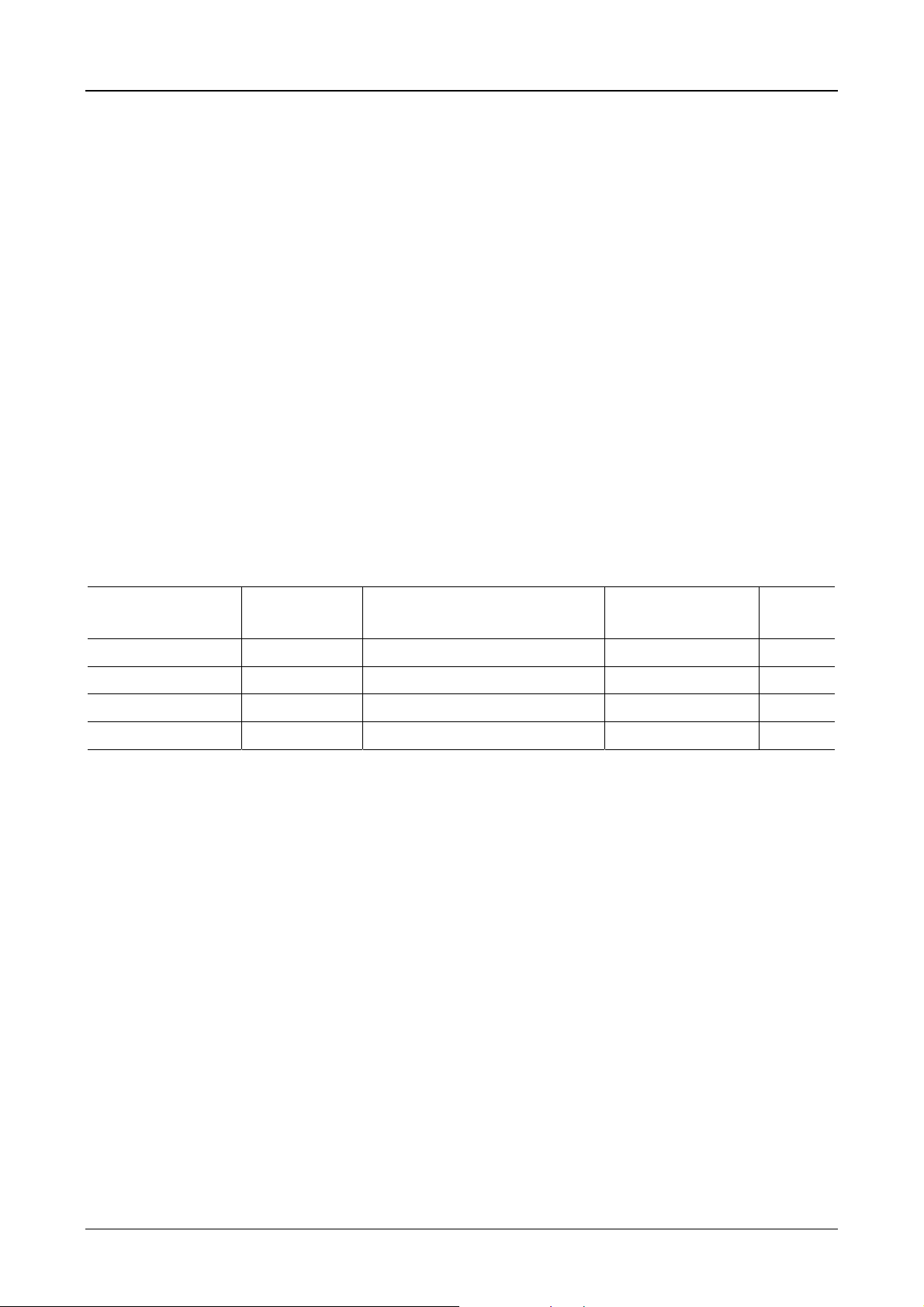

3 Device Versions

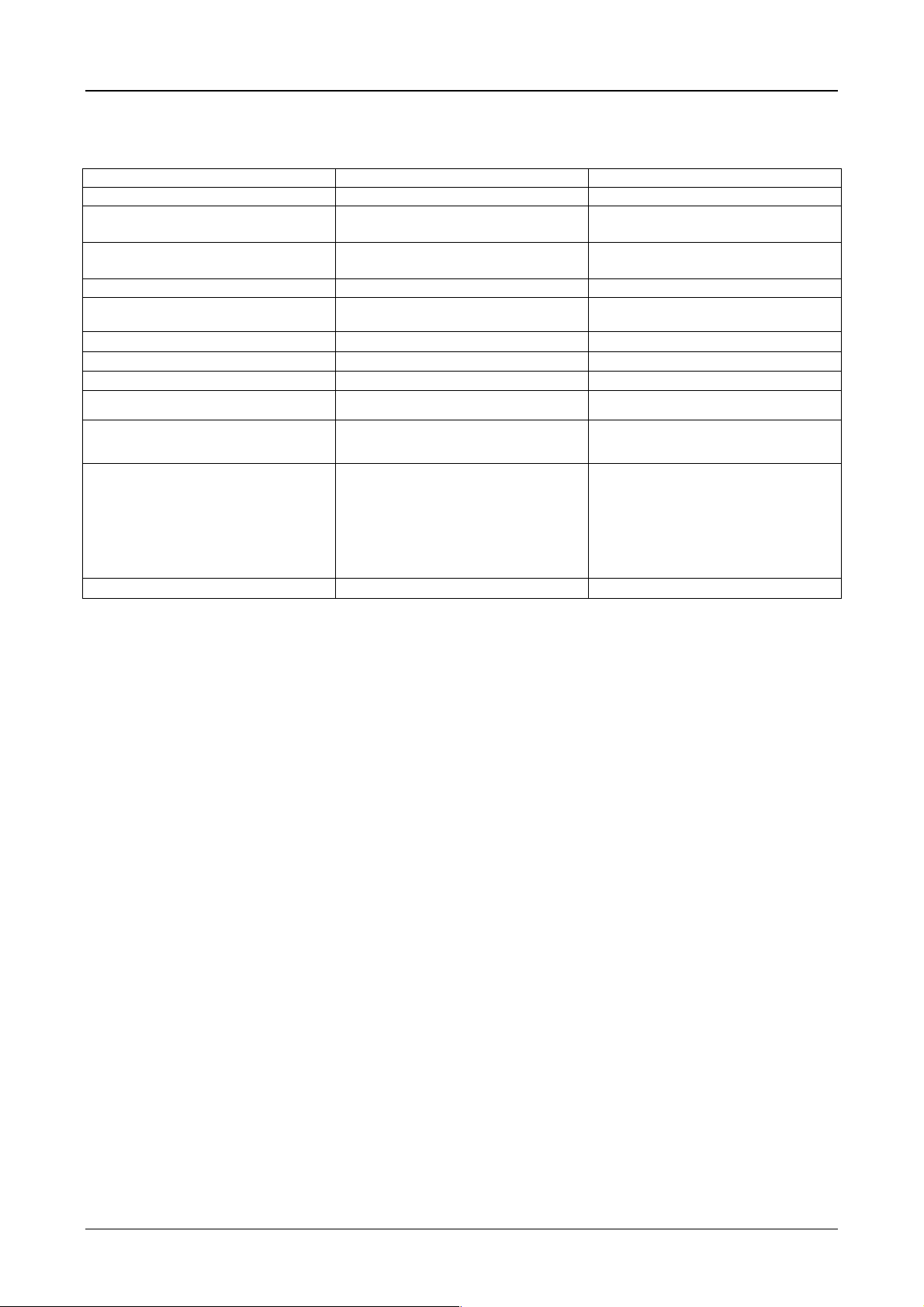

Type designation Display size Display technology Resolution Power

supply

MV4-150-TA1(-xx1)

MV4-450-TA1(-xx1)

MV4-170-TA1(-xx1)

MV4-470-TA1(-xx1)

Units with the extention –xx1 are equipped with an acid-proof stainless steel front. These devices are

installed from the rear using threaded bolts.

5.7″ (145 mm)

5.7″ (145 mm)

10.4″ (264 mm)

10.4″ (264 mm)

LCD passive monochrome (STN)

LCD passive color (STN)

LCD passive monochrome (STN)

LCD passive color (STN)

VGA (320 x 240)

¼ VGA (320 x 240)

VGA (640 x 480)

VGA (640 x 480)

24 V DC

24 V DC

24 V DC

24 V DC

Moeller 07/01 AWB-C2700-1347GB

Page 9

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-6

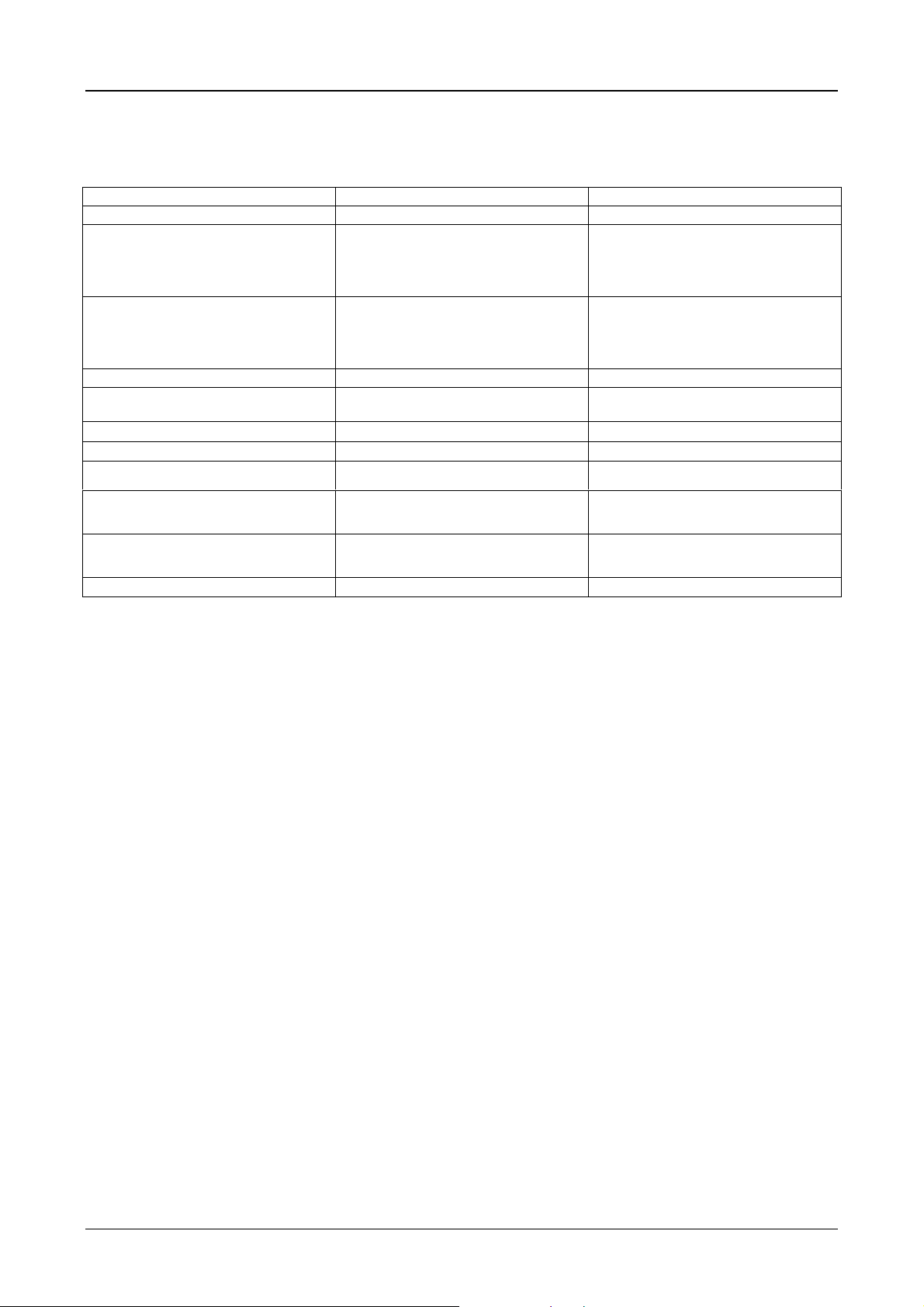

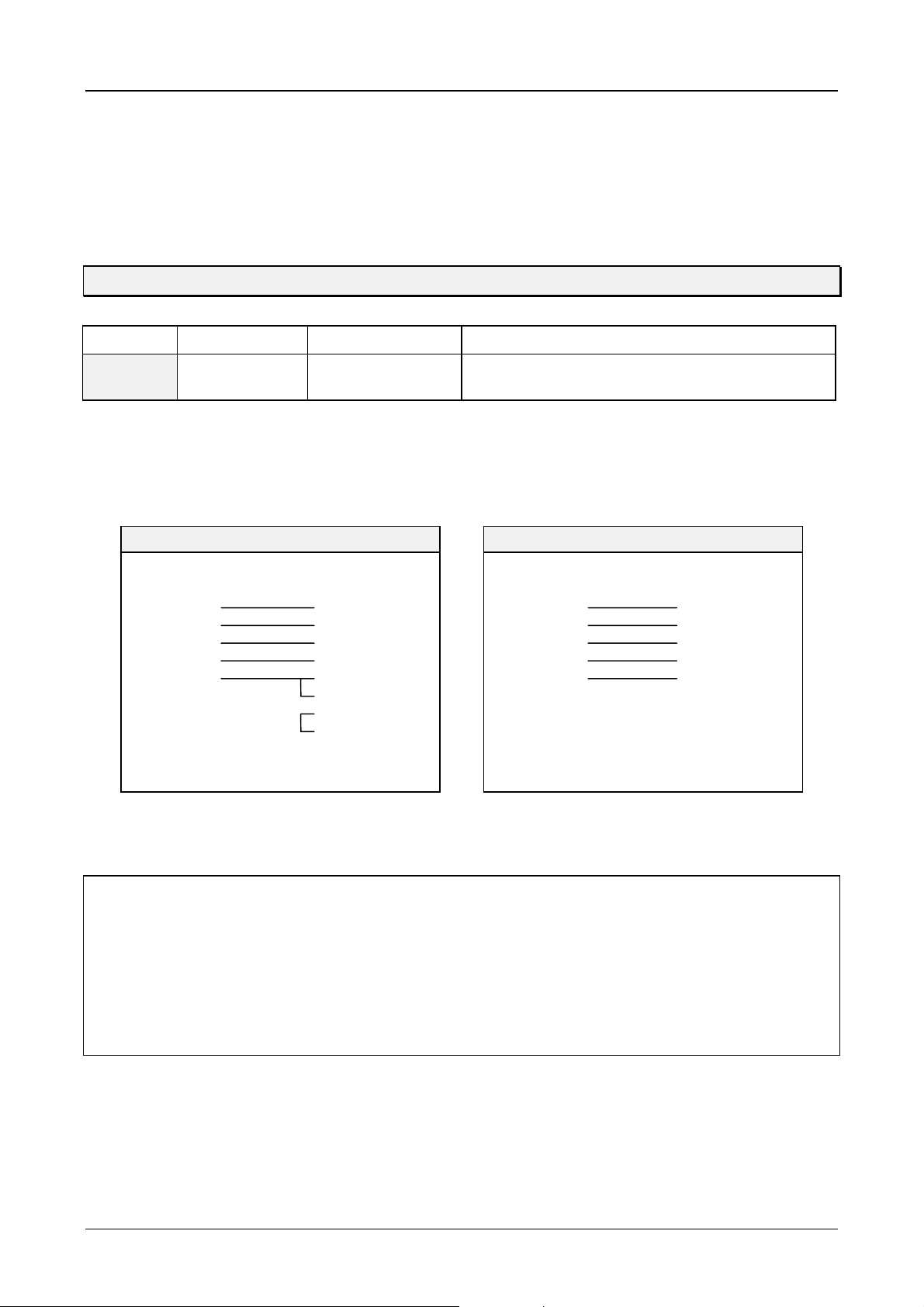

3.1 Scope of Delivery

Device version

MV4 with aluminium front

MV4 with stainless steel front

Accessories:

Fixing screws for unit installation (4 off,

countersunk)

Conter frame

Seal for mounting the unit

Device and blind plate with knurled screw

for COM slot

Nuts and washers

10 x M4 with 5.7“ units; 16 x M5 with 10.4”

units

Power supply plug connector (3-pole plugin screw terminal, Phoenix Contact, Type:

MSTB 2.5/3-ST-5.08)

AWA

MV4-150-TA1

MV4-450-TA1

MV4-170-TA1

MV4-470-TA1

MV4-150-TA1-xx1

MV4-450-TA1-xx1

MV4-170-TA1-xx1

MV4-470-TA1-xx1

•

•

• •

• •

•

• •

• •

Moeller 07/01 AWB-C2700-1347GB

Page 10

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-7

4 Device mounting

4.1 General mounting instructions

The Touch Operator Panels are suitable for insta llation in an enclosur e which is closed from the rear. The

unit is installed directl y from the fr ont with four counter sunk sc rews (standar d v ersion), or f rom the rear us ing

threaded bolts and nuts (stainless steel version).

After mounting the rear of the units must be accessible (Download button, see Section 9).

The mounting version allows protection in compliance with IP 65 (see Section 5.1).

The Touch Operator Panel can be operated at a n ambient tem perature of up to 50 °C ( see Secti on 17). T he

ambient temperature r efers to the ar ea d irectl y in t he vic init y of the l ower c ool ing slits of a ver tic all y m ounted

device provided with unhind ered air convection and m ounted at a locati on no more than 2000 m above sea

level. The cooling slits must always be kept clear to ensure the proper cooling of the system.

Mounting inside an enclosur e is possible provided that the perm issible ambient temperature is observed. A

clearance of at least 30 mm from all sides of the enc los ure m ust be obs erve d in or der to e nsur e suff icient a ir

circulation.

Avoid exposing the f lat screen to direct sunlight. T he radiation from the sun (UV component) redu ces the

lifespan of the LCD display.

The cooling slits must be kept clear to ensure the proper cooling of the system.

Avoid exposing the flat screen to direct sunlight.

After mounting the rear of the device must be accessible (Download button).

Moeller 07/01 AWB-C2700-1347GB

Page 11

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-8

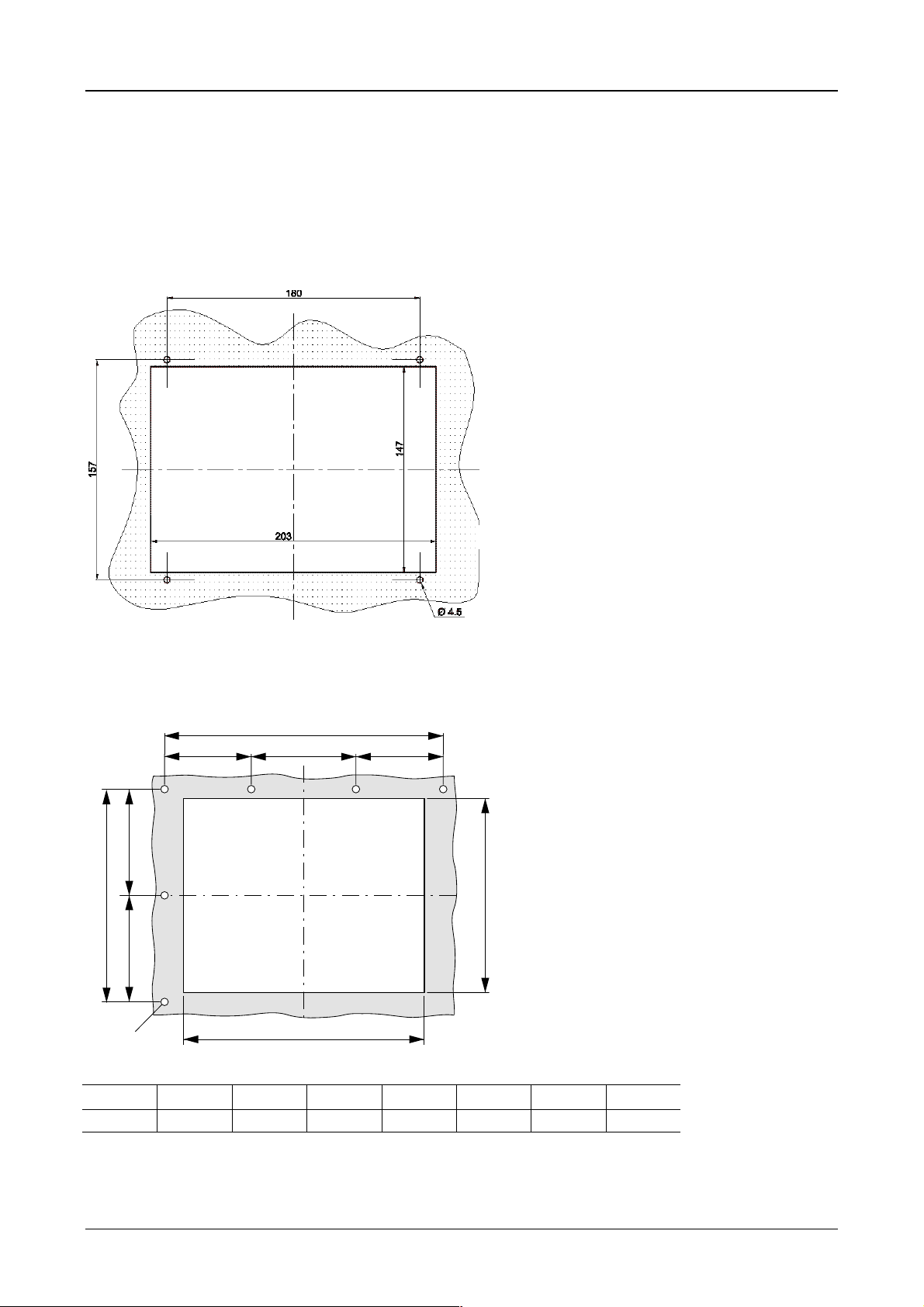

4.2 Dimensions of the 5.7″″″″ units MV4-150-TA1(-xx1), MV4-450-TA1(-xx1)

Note:

The standard unit with front hole mountin g is shown in this illustr ation. The dim ensions of the 5.7“ st ainless

steel units are ide ntical. Only the front panel cutout is different as a resu lt of the intended rear installation

with threaded bolts (refer to the following section).

Moeller 07/01 AWB-C2700-1347GB

Page 12

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-9

4.3 Front panel cutouts for 5.7″″″″ units

a) MV4-150-TA1, MV4-450-TA1

Front panel cutout : 203 mm XXXX 147 mm (centrally to fixing holes)

Fixing screws : M4 countersunk screw (supplied with unit)

b) MV4-150-TA1-xx1, MV4-450-TA1-xx1

lmhl

n

i

n

o

g

ghi kl mn

203 mm 211 mm 161 mm 147 mm 70.5 mm 70 mm 80.5 mm 4.5 mm

k

OOOO

Moeller 07/01 AWB-C2700-1347GB

Page 13

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-10

4.4 Dimensions of the 10.4″″″″ devices MV4-170-TA1(-xx1), MV4-470-TA1(-xx1)

Note:

The standard unit with front hole mountin g is shown in this illustr ation. The dim ensions of the 5.7“ st ainless

steel units are ide ntical. Only the front panel cutout is different as a resu lt of the intended rear installation

with threaded bolts (refer to the following section).

Moeller 07/01 AWB-C2700-1347GB

Page 14

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-11

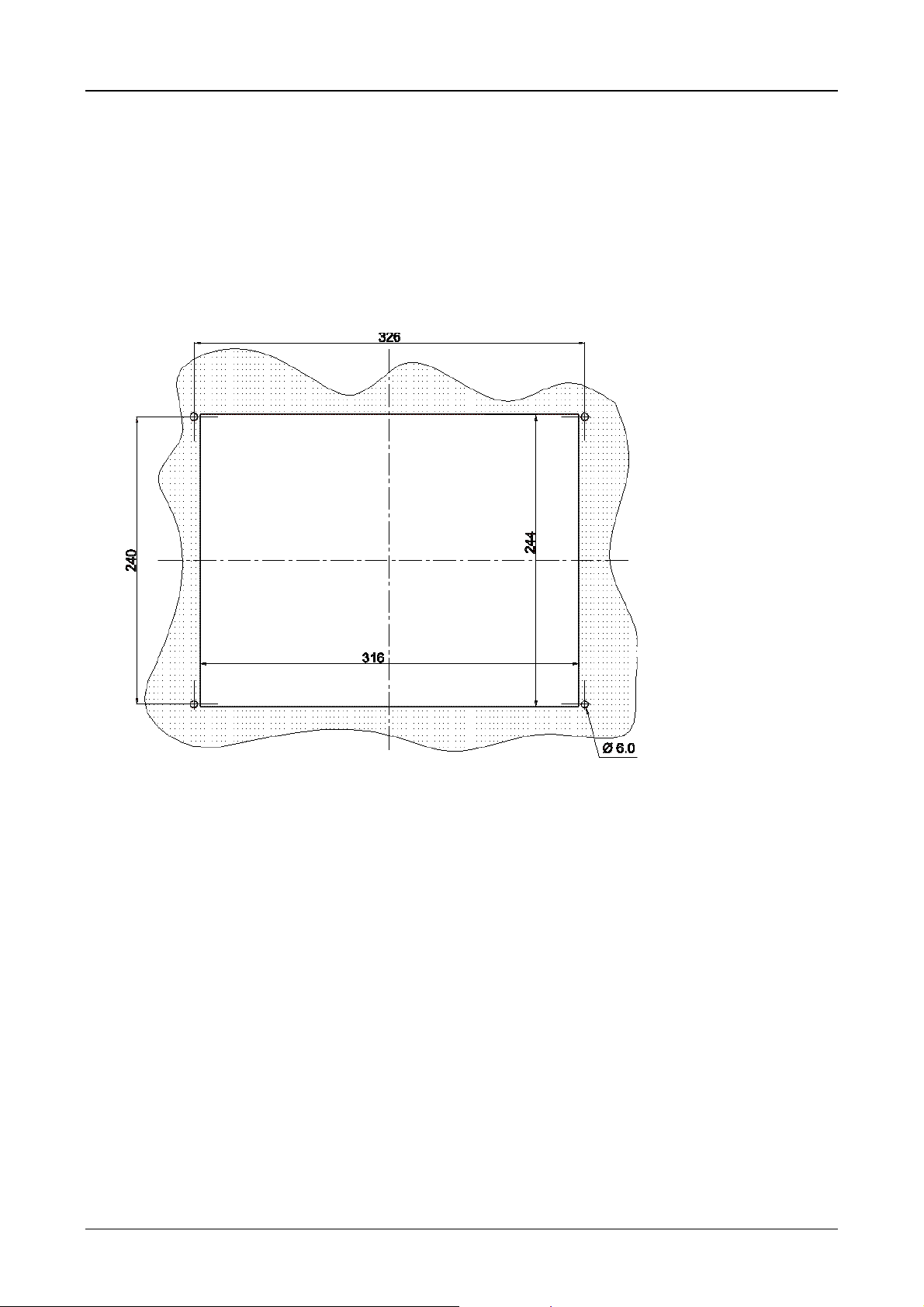

4.5 Front panel cutouts for 10.4″″″″ devices

a) MV4-170-TA1, MV4-470-TA1

Front panel cutout : 316 mm XXXX 244 mm (centrally to fixing holes)

Fixing screws : M5 countersunk screw (supplied with unit)

b) MV4-170-TA1-xx1, MV4-470-TA1-xx1

h

qqrr

p

i

po

o

g

ghi kopqr

316 mm 328 mm 256 mm 244 mm 86 mm 85 mm 66 mm 65 mm 6 mm

q

k

OOOO

Moeller 07/01 AWB-C2700-1347GB

Page 15

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-12

5 Mounting instructions

5.1 Mounting according to degree of protection IP 65

a) Installation of the unit with 4-hole aluminium front

For installation re quiring IP 65 com pliance the sup plied conter fr ame and seal m ust be used. These ens ure

that the necessary pressure is applied to the seal when mounting the unit in thin-walled front panels .

Special care should be taken during mounting to ensure correct sealing to IP 65.

1. Fit the front seal from the rear of the device.

2. Insert the unit into the panel cutout from the front (without any force).

3. The front seal must fit evenly between the front plate and the front panel.

4. Fit the conter frame from the rear of the device.

5. Tighten the countersunk screws on the device through the front panel onto the conter frame.

The countersunk screws must be tightened uniformly and securely.

6. Ensure the correct positioning and even pressure of the front seal.

Observe the general mounting instructions (see Section 4).

IP 65 can only be guaranteed with correct mounting.

Moeller 07/01 AWB-C2700-1347GB

Page 16

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-13

b) Installation of the units with a stainless steel front

Special care should be taken during mounting to ensure correct sealing to IP 65.

1. Slide the front seal from the rear over the unit cover onto the fixing bolts.

2. Place the device from the front into the housing cutout.

3. The front seal must be make flat and uniform contact between the front plate and front cover.

4. The nuts must be uniformly and securely tightened.

5. Ensure correct positioning and application of even pressure of the front seal.

Pay close attention to the mounting instructions (→ Section 4).

Moeller 07/01 AWB-C2700-1347GB

Page 17

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-14

6 Connecting the system power supply

The Touch Operator Panel is classified to protection class 3. The system power supply must be connected to

an SELV (safety extr a-low voltage) 24 V DC su pply (see Sec tion 17). T he power supp ly is not isolated. T he

0 V terminal is located directly on the housing potential. The power supply must be fuse protected

(2.5 A slow), (see Section 17). This can be accessed without having to open the device. The unit is protected

against reverse polarity, and the operation of the unit depends on correct polarity.

Observe the relevant regulations for the connection of the units.

Carry out the connection as follows:

– The cross-section of the supply cable must be between 0.75 mm² and 2.5 mm² .

– A lead or wire can be used for the connection.

– The power supply must be provided with the correct current rating (see Section 17), selectivity and

breaking capacity in accordance with the specified disconnection characteristics (see Section 17).

– A functional ground is no t compulsory for correc t operati o n. The GND is connected dir ectly to the housing

potential.

The connector (socket strip with screw terminals) is supplied with the device.

Connector assignment:

Designation Function

+24 V +24 V Power supply

GND Functional ground

0 V 0 V Power supply

+24 V GND 0 V

(Plug-in screw terminal: Phoenix Contact MSTB 2.5/3-ST-5.08)

ZB4-601-IF

III

GND

Section of the connector panel with a view of the system

power supply plug connector and the fuse.

Moeller 07/01 AWB-C2700-1347GB

Page 18

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-15

7 Connection to the communication interface

7.1 Preparing the connection cable (EMC)

The preparation of the data and signal cables is an important factor for the electromagnetic compatibility

(EMC) of the Touch Operator Panel, both in terms of interference immunity and emission.

All data cables on the Touch Operator Panel (PROG PORT ) and on the card in the slot (COM SLOT ) must

be shielded unless unshielded wiring is specified explicitly. Cables connected to the communications

interface must be laid s eparately to low-voltage cabl es when they come together (cable ducts in separate

partitions).

The cable shield must be made from copper braid. Only use a metal or metallised connector casing. Connect

the cable shield directly to the low-impedance connector casing on the unit. This ensures that the cable

shield is properl y connected to the housin g of the Touch Operat or Panel via the screws and t he protective

metal shroud of the plug connector (low-impedance).

The cables must also be shi eld ed if they are not co nnecte d at the other end and are onl y used , f or exam ple,

for commissioning and servicing.

Refer to the operating instruc tions of the devic e m anuf acturers concer ned as t o how to co nnect the s hie ld at

the other end. If no specifications are given, connect the cable shield also at this end to the metal or

metallised connector casing.

Avoid leaving the shield open. The data connec tio ns to b e s h iel de d i nvol ve t he hig h- s pee d trans f er of s igna ls

between two active systems . The cable shield onl y functions against as ymmetrical interf erence transients if

the shield is connected to the device earths (usually metallic device enclosure) at both ends.

Provide a potential eq ualis ation co nd uctor with a su itabl e cros s-s ection b etween poten tials ( contro l ca binets )

if the Touch Operat or Panel and the com munications partn er are installed in different contro l cabinets or at

different PE potent ials ( zero cond uctor po tentia ls) , and if the c able s hield at bot h ends is d irectl y or in direc tl y

connected to the protect ive e arth con ductor. This wil l prevent th e occ urrenc e of large com pens ation curr ents

on the shield and shield connections. T hese k inds of com pensation c urren ts of norm ally 50 H z eve n occur in

normal operation and do not represent a problem for data transmission. However, they may cause the

destruction of the shield terminals and contacts, particularly in the event of short-circuits in the environment.

Special care should be taken with the connection to ensure interference-free operation.

The EMC values stated in the technical data can only be guaranteed if the cables are

manufactured according to the specifications.

Moeller 07/01 AWB-C2700-1347GB

Page 19

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-16

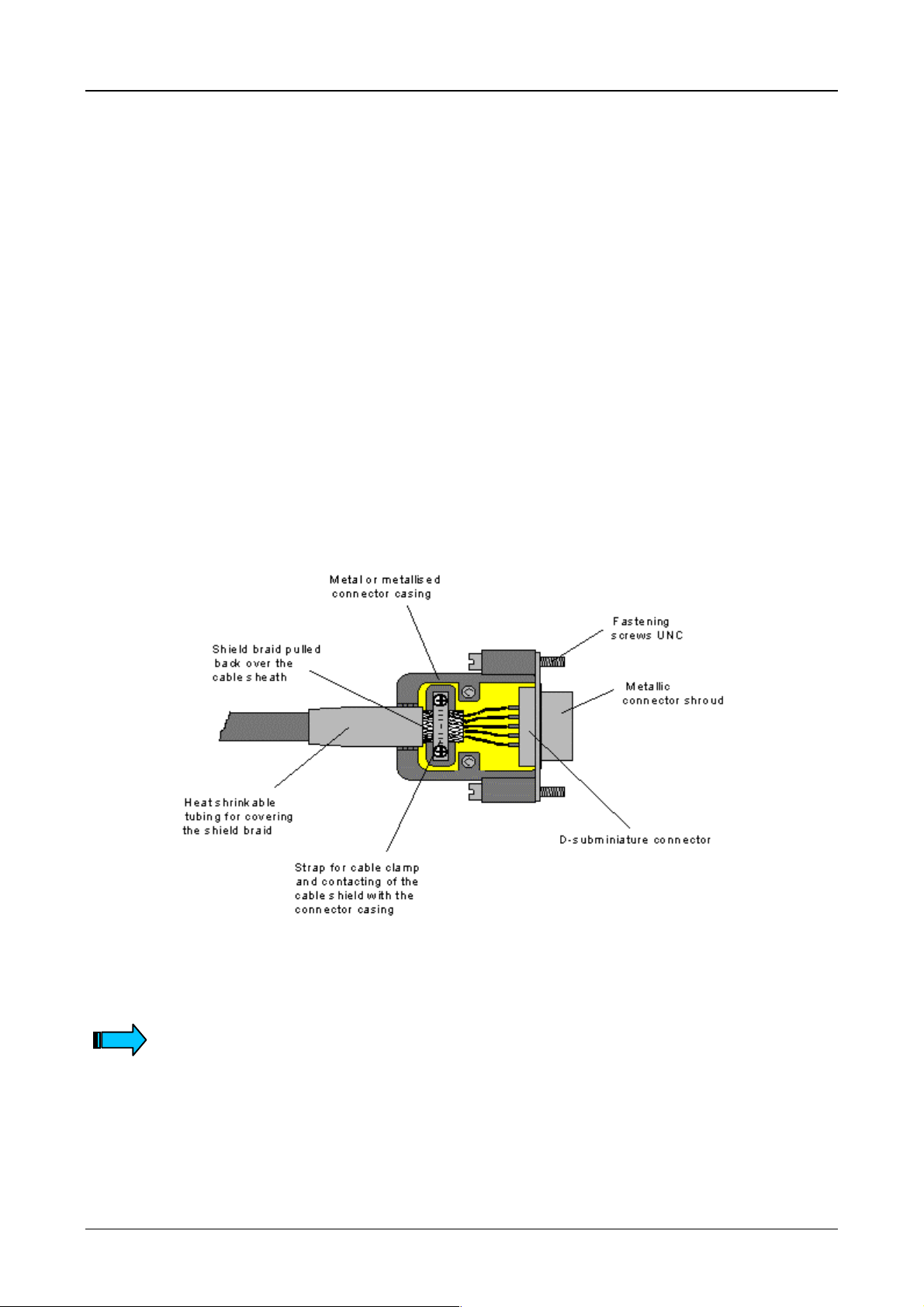

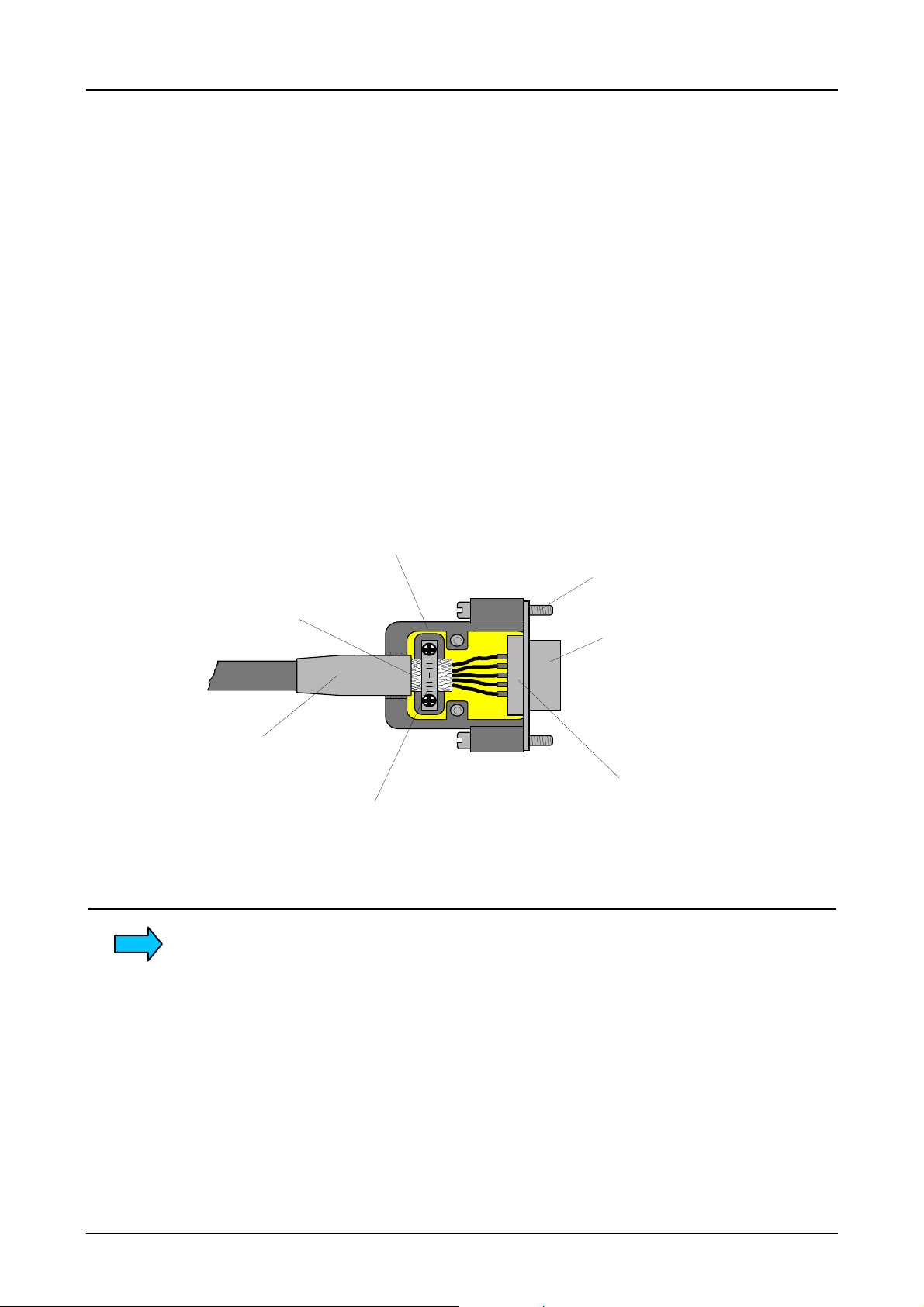

7.2 Preparing the shield connections

The connections on the Touch Operator Panel and especially the communications card are mostly

implemented with D-subm iniature connectors in accordanc e with DIN 41 652. Only us e metal or metallised

connector casings with a cab le clamp for strain relief f astened or c lamped o n o ne s ide of the con nector. T he

clamping of the cabl e shield ensures an optimum c ontact area and a low impedance c onnection with the

connector casing of the Touch Operator Panel.

The following procedure is recommended for making the low-impedance connection for the cable shield:

1. Strip the cable.

2. Shorten the exposed shield braid by approx. 3 cm.

3. Turn back the braid over the cable sheath.

4. Use a heat shrinkable t ubing or rubber grom met to cover the ex posed cable sheath with the f olded

back shield braid so that 5 to 8 mm of exposed c able shield is lef t at the sheath end an d is cleanly

covered at the back.

5. Fit the connector.

6. The cable is then fastened at the exposed shield braid and the cable sheath below it directly

underneath the cable clamp strap of the connector casing.

If plug connectors are used for communications cards (not D-subminiature plug

connectors to DIN 41 652), then follow the instructions in the relevant document

descriptions.

Moeller 07/01 AWB-C2700-1347GB

Page 20

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-17

8 Connection and function of the programming port (PROG PORT)

The project data is loaded into the Touch Operator Panel (Download) via the programming port (PROG

PORT). The programming port can also be used to connect a serial printer for printing reports from the

application or for the communication via SUCOM-A protocol (from MV4-Configurator MV4-CFG-1, V 3.03).

Refer to the documentation of the MV4-configurator design software for information on

the connection and operation of a printer (printer installation).

For SUCOM-A communication select the PLC type “Moeller...PRG (COM)” in the MV4-configurator. The

required SUCOM-A cables ZB4-237-KB1 (for PS4) and ZB4-233-KB1 (for PS416) must be used with an

adapter (9-pol. SUB-D fem ale connector to 9-pol. SU B-D female c onnector). This c an be ordered un der the

designation LT307.512.1 .

The programming port is a standard RS 232 interface.

The GND terminal is located directly on the housing potential (see Section 17). Cables connected to the

PROG PORT must be laid separately to low-voltage cables.

Pin 9 can be provided with an optional +5 V (see Section 11).

PROG PORT

D-Sub 9 Pol male

Pin-No. Assignment Function

1 – Not assigned

2 RxD Receive data

3 TxD Send data

4 DTR Data terminal ready

5 GND Ground

6 DSR Ready for operation

7 – Not assigned

8 – Not assigned

9 (+5 V) +5 V Power supply (see Section 11)

Case Shield Cable shield

Moeller 07/01 AWB-C2700-1347GB

Page 21

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-18

9 Data transfer (Download Button)

The Touch Operator Panel basic function is used to load the runtime program. This runtime program

(GRSW) contains the function for loading project data, and so this program must be loaded before the

loading of project data is possible.

Pressing the Download button ca lls up the functions for loading project data and/or the R untim e (Download)

(see Section 9.1 / 9.2).

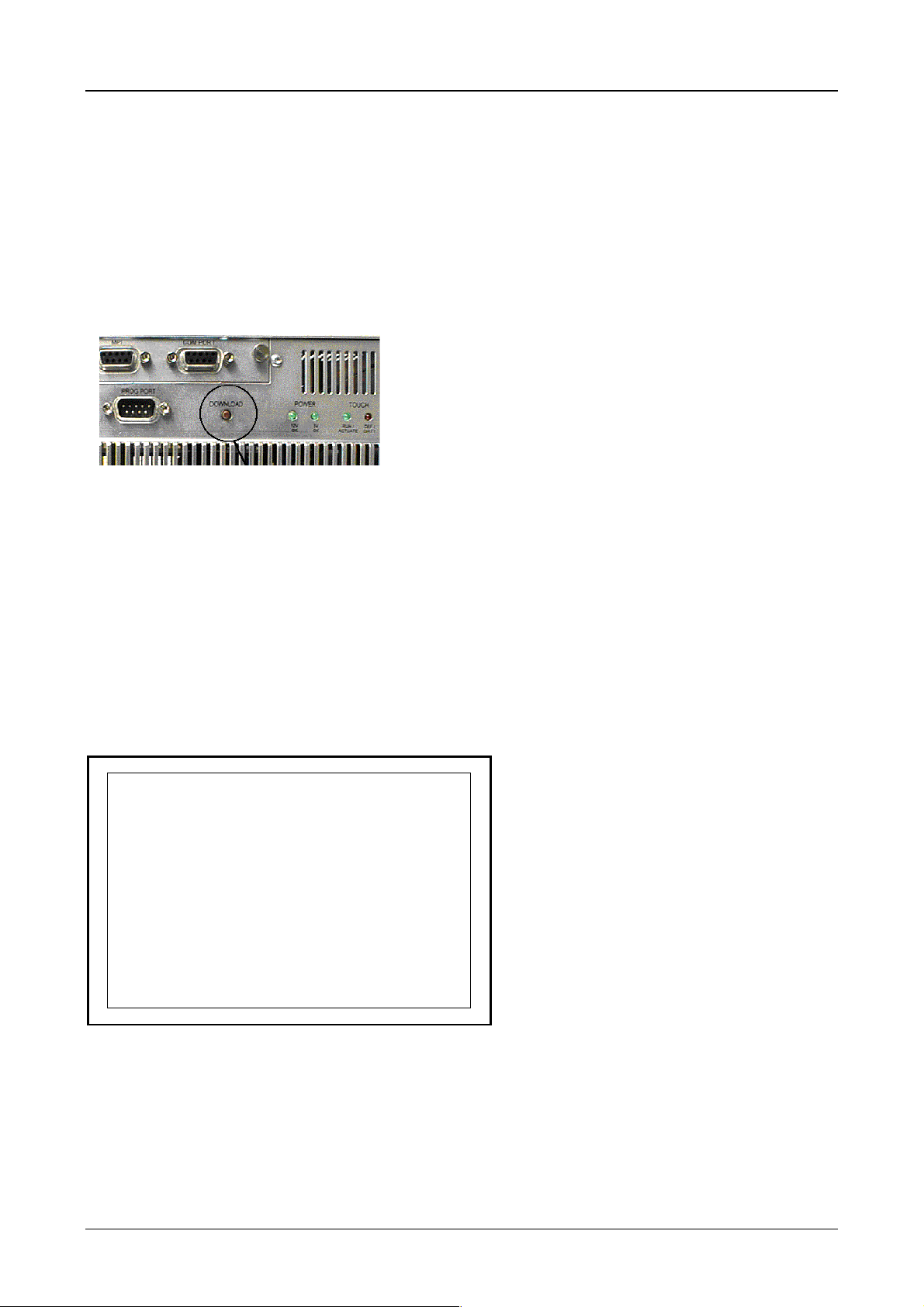

The Download button is located on the rear of the Touch Operator Panel:

9.1 Loading the runtime (GRSW)

The “APPLICATION LOADER”. system mask will appear when the s ystem is started. This applicatio n loader

is a fixed part of the firmware (basic function). When the system is started the application loader searches for

the runtime. T his is ind ic ated by the system m ess age “ search program...”. The message “ok” will ap pear

when the runtime program is found.

The integrity of the runtime program is then checked, and is indicated by the system message “check

GRSW.EXE” with date and tim e. If the runtime pr ogram is corr ect, the “ok” system m essage will appear and

the runtime program is started.

MAINBOARD FIRMWARE VERSION 3.XX (WIN32)

> APPLICATION LOADER <

----------------------------------------

- search program .. ok

- check GRSW.EXE

XX/XX/XX XX:XX .. ok

System mask “APPLICATION LOADER”

Moeller 07/01 AWB-C2700-1347GB

Page 22

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-19

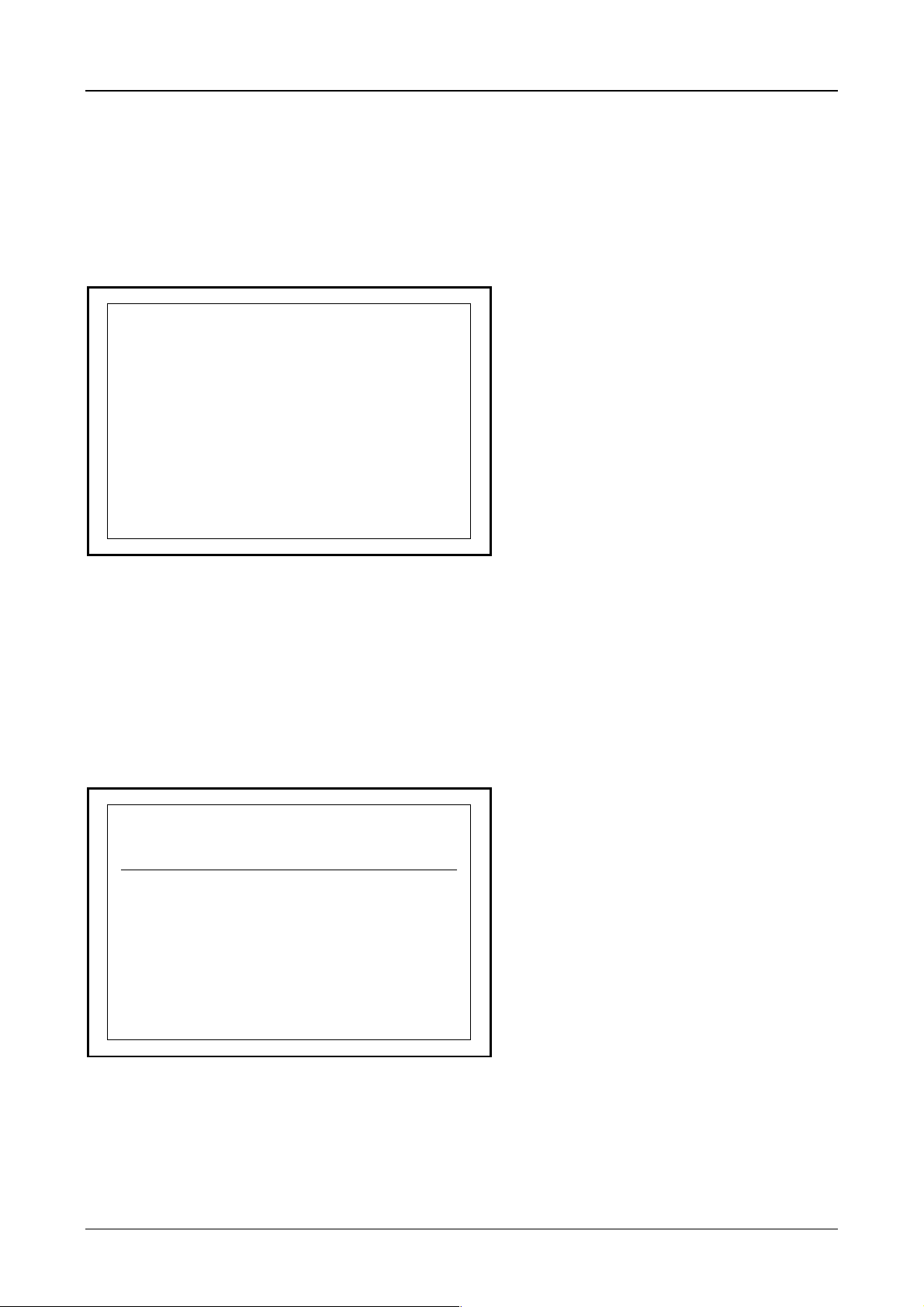

If the application loader does not find an integral runtime program, the unit switches to the

“SERIAL DOWNLOAD” system mask . In this mode the Touch Operator Panel will try to establish a c o nn ec tio n

to the PC via the programming port (PROG PORT). The runtime program can then be processed in

conjunction with the MV4-conf igur at or.

This mode can also be accessed by pressing the Download button. For this, press the Download button

while the Application Load er is searching for th e runtime program, i. e. whilst “search program...” is

showing in the “APPLICATION LOADER” system mask, and before the “ok” system message is shown.

The runtime program (a runtime program is already prese nt on the Touch Operator Pane l) can be updated

with the design software at any time when loading pr oj ect dat a (see Section 9.2).

MAINBOARD FIRMWARE VERSION 3.XX (WIN32)

> SERIAL DOWNLOAD <

----------------------------------------

- waiting for host ..

System mask for loading the runtime (GRSW)

9.2 Loading the project data (Download)

Pressing the Download button whilst the application is running accesses the system function for loading

project data and for reloading the runtime program. A short press of the Download button switches the

Touch Operator Panel to the “Serial Data Transfer PC<>Panel” system mask.

In this Download mode the Touch Operator Panel tries to establish a connection to the PC via the

programming port (PROG PORT). The MV4-configurator can then be used to load project data and/or to

reload the runtime program.

Error: <DOWNLOAD> button pressed...

Serial Data Transfer PC <> Panel

Waiting for serial download...

Press <DOWNLOAD> button to reboot

System mask for serial data transfer

The system also s witches to this Do wnload mode if the runtim e program does not find an exec utable pr oject

or in the event of a f atal er ror. T he s ystem indicat es the re ason f or the c hange t o Down load mode in the first

line of the screen.

To quit Download mode press the Download button or briefly interrupt the power supply.

Moeller 07/01 AWB-C2700-1347GB

Page 23

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-20

10 Communications Cards and COM SLOT

The Touch Operator Panel has one slot for a communications card (see Section 17). The link to the

automation equipment (e. g. PLC) or the fieldbus system is implemented using one of the several cards

available. Further information see part 3 and 4 of this documentation.

Safety precautions concerning electrostatic discharge (ESD) must be observed

when handling cards !

Never plug in the cards with the power supply switched on.

Only operate the communications card once it has been fully screwed into position.

Do not run any non-Moeller components in the slots.

Only original hardware from Moeller may be used.

Refer to the relevant communication card descriptions for information on protocols,

configuration, cable lengths etc.

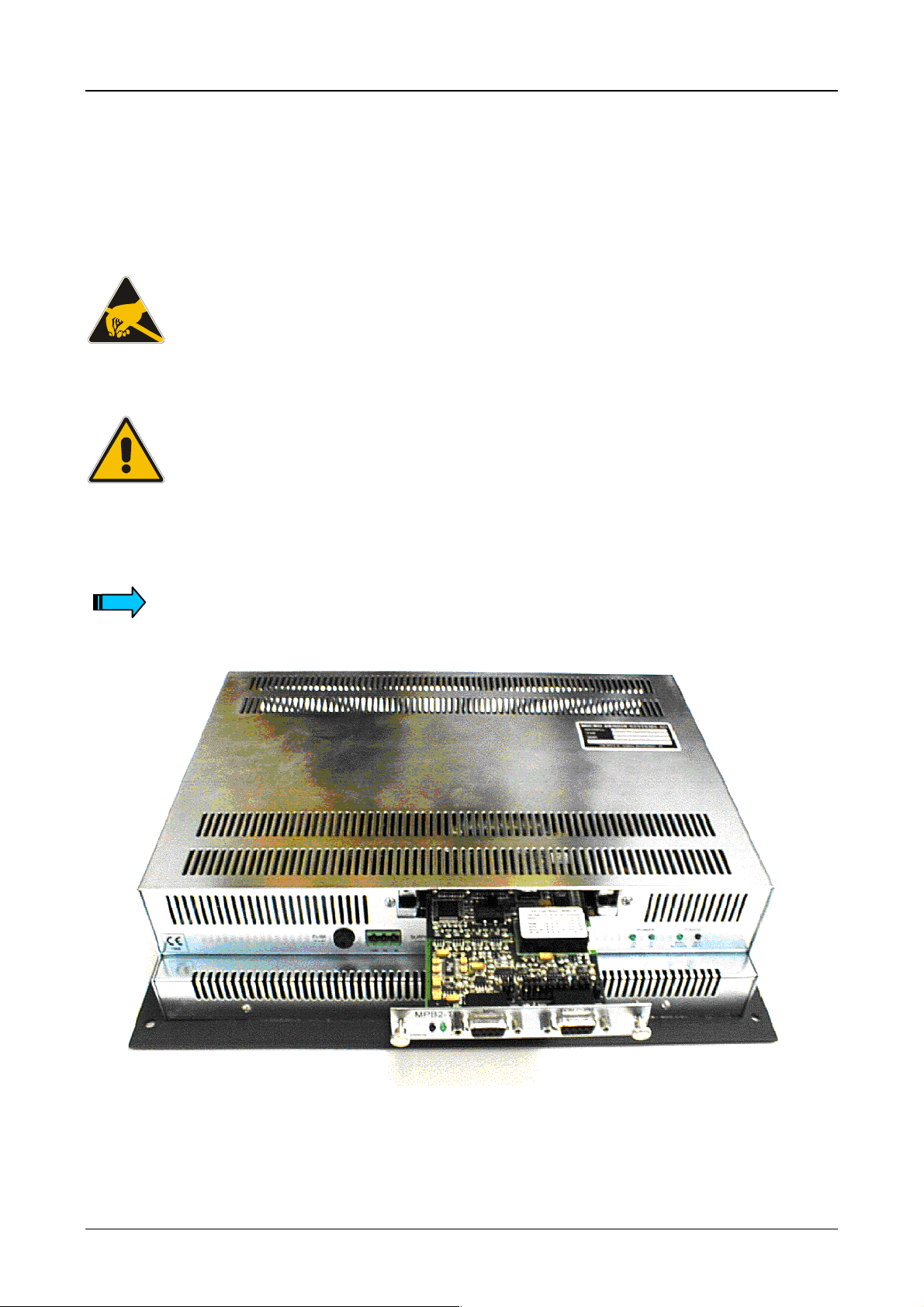

Communications card in COM SLOT of the Touch Operator Panel

Moeller 07/01 AWB-C2700-1347GB

Page 24

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-21

11 Expansion and configuration options

11.1 Additional 5 V power supply on programming port (PROG PORT)

Pin 9 of the PROG PORT (see Sec t ion 8) c an als o be us e d f or the po wer s upp l y (+5 V) of ex tern al additional

hardware (jumper J7 on the m ain board set to position A). This is not short-circuit proof and not overload

protected and mus t only be used in conj unction with origin al Moel ler hard ware. The po wer supp ly c annot b e

used for non-Moeller products.

12 Function and control LEDs

The Touch Operator Panel provides two LEDs for monitoring the f unctions of the touch control ler (

and two other LEDs for monitor ing the system voltages (

POWER

). They are located un derneath the COM

TOUCH

SLOT.

TOUCH

DEF/DIRTY

The LED (red) is lit if dur ing the power up f unct ion tes t of th e T ouch Sc ree n th e sign al

level of one or several IR channels is below the minimum level (see Section 13.2).

A reduction of the s ignal level is caused b y the contaminati on of the IR transpar ent

plastic frame or the failure of an optical elem ent. If this LED is lit, clean the plastic

frame on the device front (see Section 13.3).

RUN/ACTUATE

The LED (green) remains unlit whe n the system voltage is s witched on. It will light u p

once the initialisation of the touch controller has been successfully completed.

The LED will be deactivated for approx. 0.3 seconds when the touch screen is

pressed.

POWER

12 V OK

5 V OK

When lit the LEDs indicate the presence of the system voltages (+12 V and +5 V).

If the LEDs are not lit when the system voltage is applied, check the fuse.

When the system voltage is switched on, both Touch LEDs are activated for approx. 0.3 seconds as a

function check.

COM SLOT

)

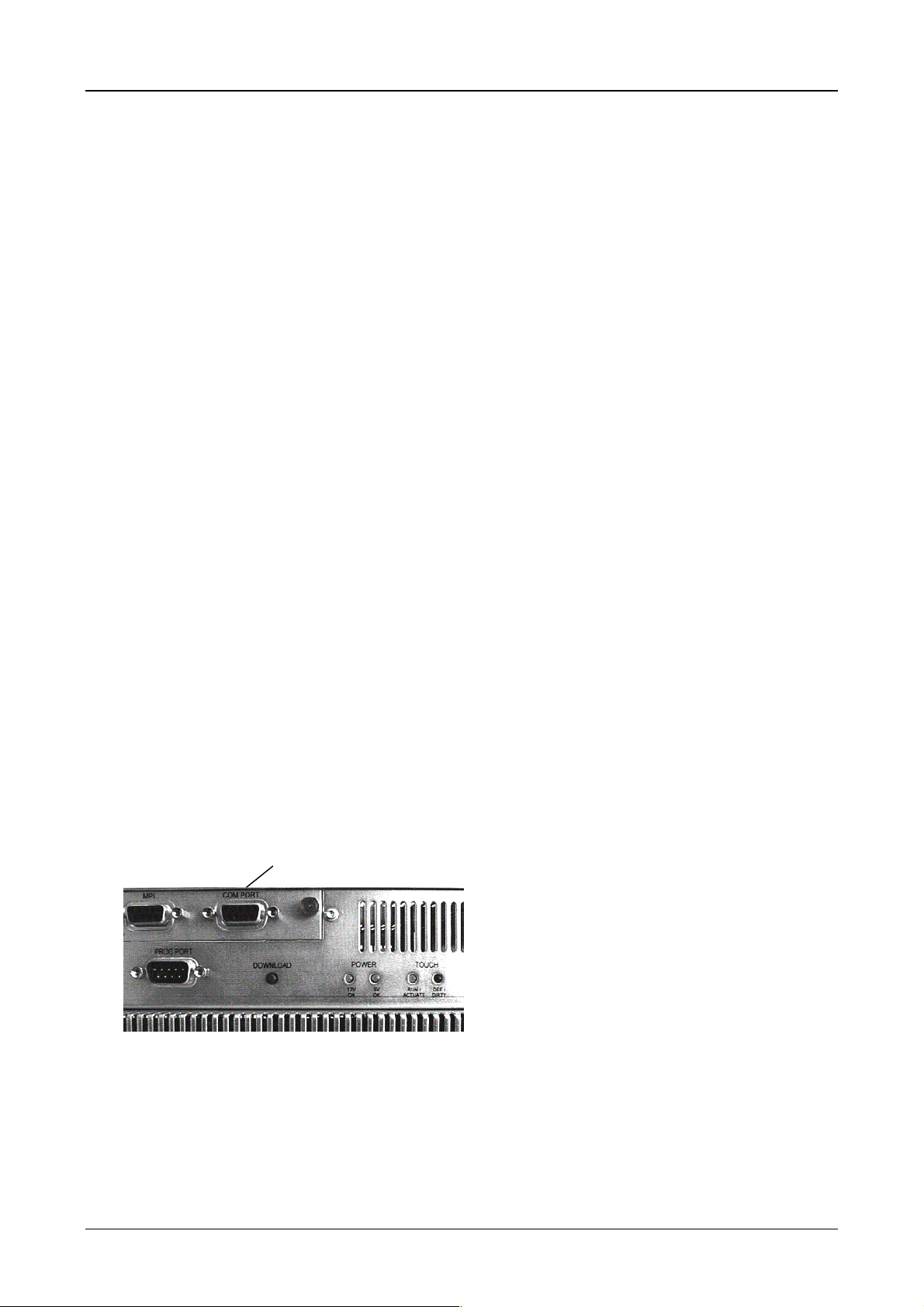

Section of the connector panel with a view of the control LED, the PROG PORT and the COM SLOT

Moeller 07/01 AWB-C2700-1347GB

Page 25

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-22

13 Touch Screen

13.1 Basic Touch Screen function

The Touch Screen operates on the ac tive lig ht matr ix princi ple in the infrared r ange. T he optical elem ents of

the light matrix are located behind the IR transpar ent plastic fr ame in the front pa nel of the de vice. The y are

located in such a way that their radiation extends s lightly out of the fr ont pane. Each emitter is ass igned a

receiver that is loc ated on the other side. In this way 40 closel y positioned IR channe ls are pro vided on the

5.7″ unit and 70 IR chann els on the 10.4″ unit (see Section 17). A touch on th e screen is detected by the

simultaneous interruption of one or several channels in the X or Y axis.

Repeated touches and to uches that cover an area greater than 20 mm x 20 mm are not evaluated by the

controller. Continu ously interrupted channe ls caus ed by s e ver e c ont amination and dirt, or by the failure of an

optical element are detected by the touch contr o ller and are no longer inclu ded in the eval uat ion .

13.2 Power up function test

The Touch Operator P anel carries o ut a functio n test of the to uch screen with eac h power up of the dev ice.

This test measures the signal levels of all IR channels and compares them with initial values. The initial

values are determined before the device is delivered and stored in a retentive memory.

If the signal of one or several channels is below a minimum level relative to th e initial values, this will b e

indicated by an error message on the screen and the

of this kind is nor mally due to sever e contamination of the IR transparent plas tic frame which conseque ntly

has to be cleaned (see Section 13.3). The Touch Screen, however, remains fully functional.

Only an increase in the contam ination of the sc reen will lead t o the cont inuous interrupti on of one or se veral

IR channels. IR channels that are continuousl y interrupted will be detect ed by the Touch Contro ller and no

longer included in the evaluation . In ex trem e cas es, this m ay mean that i ndiv idual zo nes c annot be ac tivated

by touch.

Do not touch the screen whilst the system is being started up, and wait tillyour

application has started.

During the startup the Touch Screen carries out a function test in which the signal

levels of the IR channels are measured.

DEF/DIRTY

LED (see Section 12). A r ed uc ed s i gna l le vel

13.3 Cleaning and maintenance of the Touch Screen

For operation ensure that the s ignal lev els of th e channe ls are not s o severe ly redu ced or int errupted d ue to

excessive contamination through dirt (see Section 13.1).

Clean the inside of the plastic f rame of the dev ice regular ly (see S ection 15) with a damp soft c loth. Ensure

that the surface is not scratched or scoured, especially when removing hard deposits and abrasive dust.

Do not expose the front of the device to solvents which m ay corrode and destroy the p lastic frame (frame

material: polymethylmethacrylate, PMMA).

Moeller 07/01 AWB-C2700-1347GB

Page 26

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-23

14 Display

The different vers ions of the T ouch Oper ator Pan el are avail able with dif fer ent d ispla y t echno logies . Pas sive

LCD, monochrome or color screens are available.

The individual pixels of an LCD displ ay are not actively illuminated. The im age is produced by illum inating

the screen by a backlight which is varied in colour and intensity by means of the individual LCD cells (pixels).

The light of this backlight is provided b y a cold cathod tu be. The lifespan of these tubes ( see Section 17) is

limited and depends on the operating conditions at hand. The brightness setting of the backlight and the

number of switch-on cycles will determine the lifespan of the screen. Reducing the brightness can

significantly increas e the lif espan of the LCD dis play. Fr equent sw itching, es pecially at low tem peratures will

reduce the lifespan.

Therefore avoid frequent switc hing on and of f of the back light or the ent ire s ystem. Reducing th e brightness

to a minimum setting is better than frequently switching the display on and off.

Particularly with LCD displays the image contr ast depends on the view ing angle. T he operating t emperature

also has a direct influence on the contrast and consequently also on the viewing angle. Any detrimental

influences caused b y temperature are reduc ed by an additiona l circuit in the device (part ial compensation) .

The contrast (contras t voltage) ma y need to be adjusted due to the viewing angle requ irements of different

people or changes in the ambient temperature. This can be carried out on the Touch Panel by the operator.

Further information on adjusting the brightness of the backlight and the contrast is provided in the

documentation of the MV4-configurator.

15 Maintenance and repair

The Touch Operator Panels are maintenance-free.

The inside of the device front panel should be cleaned regularly to ensure trouble-free IR touch screen

operation (see Section 13.3).

Repairs to the units must only be carried out by the manufacturer.

Modifications made to the device that are not described in this document are not permitted and no liability will

be accepted for them.

16 Disposal

Touch Operator Panels that are no longer used must be disposed of properly or returned to the manufacturer

for disposal.

Special note:

– The clock module contains a sealed lithium battery.

(Real Time Clock, Dallas DS12887 or STMicroelectronics M48T86PC1)

– The backlights for units with LCD displays are provided by fluorescent tubes that contain mercury.

Moeller 07/01 AWB-C2700-1347GB

Page 27

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-24

17 Technical Data

Display

Technology MV4-450-TA1(-xx1)

MV4-470-TA1(-xx1)

MV4-150-TA1(-xx1)

MV4-170-TA1(-xx1)

Resolution

5.7″

10.4″

Display area

5.7″

10.4″

Number colours/greyscale 256

Contrast ratio (normally) MV4-450-TA1(-xx1)

MV4-150-TA1(-xx1)

MV4-470-TA1(-xx1)

MV4-170-TA1(-xx1)

Brightness (normally) MV4-450-TA1(-xx1)

MV4-150-TA1(-xx1)

MV4-470-TA1(-xx1)

MV4-170-TA1(-xx1)

Lifespan if backlight

MV4-450-TA1(-xx1) 25,000 Operating hours

(only LCD/without backlight saver) MV4-150-TA1(-xx1)

MV4-470-TA1(-xx1)

MV4-170-TA1(-xx1)

Operation

MDS TCL2

Optical light matrix in the infrared range (IR Touch, see Section 13)

Resolution physical

5.7″ device

10.4″ device

Resolution logic

5.7″ device

10.4″ device

LCD passive colour (STN)

LCD passive colour (STN)

LCD passive monochrome (STN)

LCD passive monochrome (STN)

320 x 240 pixels

640 x 480 pixels

115 x 86 mm

212 x 158 mm

2

2

25

24

30

18

110 cd/m

140 cd/m

70 cd/m

75 cd/m

2

2

2

2

20,000 Operating hours

25,000 Operating hours

25,000 Operating hours

24 x 16 (13 x 15 pixels)

40 x 30 (16 x 16 pixels)

47 x 31 (7 x 8 pixels)

79 x 59 (8 x 8 pixels)

System memory

Prog Port

Ambient conditions

Protection type

Front panel

Technology Flash

Basic unit 4 MByte (permanently soldered)

RS 232, non-isolated (see Section 8)

Operating climate 0 to 50 °C, 10 to 85 % rel. air humidity,

non-condensing (see Section 4)

Storage climate –20 to 60 °C, 10 to 85 % rel. air humidity,

non-condensing

Mech. shock IEC 60068-2-27 (1 shock, half-sinus 50 g/20 ms)

Vibration IEC 60068-2-6 (10 to 200 to 10 Hz/1.5 g)

EMC IEC/EN 61000-4-2, 6 kV/8 kV

IEC/EN 61000-4-3, 10 V/m

IEC/EN 61000-4-4, 2 kV

IEC/EN 61000-4-6, 10 V

EMF

IEC/EN 61000-4-8, 10 A/m

Radio interference CISPR 11, EN 55011, Class A

Front IP 65 (NEMA 12), to IEC/EN 60529

Rear IP 20

5.7″

10.4″

Glass 2.0 mm, non-reflective (etched)

Glass 3.0 mm, non-reflective (coated)

Weight

5.7″

10.4″

approx. 2.2 kg

approx. 3.6 kg

Moeller 07/01 AWB-C2700-1347GB

Page 28

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-25

Dimensions

System supply

Fuse protection

Front

Rear

5.7″ device

10.4″ device

5.7″ device

10.4″ device

220 x 170 mm

342 x 270 mm

201 x 144 x 83 mm

310 x 240 x 81 mm

Rated voltage SELV 24 V DC, Safety extra-low voltage (see Sec. 6)

Voltage range 24 V DC to EN 61131-2

20.4 to 28.8 V DC effective,

absolute value with ripple 18.5 to 30.5 V

35 V DC for < 100 ms

Voltage dips 5 ms max., at 20.4 V DC to 0 V DC, repetition rate 1 s

Reverse polarity protection Yes

Isolation No

0 V and PE connection to housing potential

Power consumption

(incl. comms. card)

5.7″ device

10.4″ device

Inrush current 1.5 A

Current consumption

(incl. comms. card)

5.7″ device

10.4″ device

2

s

0.7 A (normally)

0.7 A (normally)

20 W

20 W

Internal 2.5 A slow, to EN 60127-2/2

(externally accessible, see Section 6)

Maximum disconnection

35 A (see Section 6)

capacity

Interfaces

1 slot for communications card (see Section 10)

Moeller 07/01 AWB-C2700-1347GB

Page 29

Device Description MV4-150-TA1, MV4-450-TA1, MV4-170-TA1, MV4-470-TA1 1-26

18 EC Conformity

The Touch Operator P anel meets the requirem ents specified b y the EC Council Dir ectives for har monizing

the regulations of EC member states relating to electrom agnetic compatibility (89/336/EEC) a nd electrical

safety (Low-Vol tage Directive 73/23/EEC).

The generic standards below were use d to assess the electrom agnetic compatibility of the Touch Operat or

Panels:

EN 50 081-2 (Emission)

EN 50 082-2 (Immunity)

The following standard was used to assess the electrical safety of the Touch Operator Panels:

EN 60 950

1999

Manufacturer: Moeller GmbH

Hein-Moeller-Straße 7 – 11

D-53115 Bonn

Federal Republic of Germany

19 UL Listing

The Touch Operator Panel is listed by Underwriters Laboratories Incorporated (UL). File E208621.

Representative sam ples of the units have been evaluated b y Underwriters Laboratories Incorporated and

meet the applicable United States and Canadian safety standards.

To assess the safety of the Touch Operator Panel the safety standard UL 1950 (Safety of Information

Technology Equipment, Including Electrical Business Equipment) was used.

Moeller 07/01 AWB-C2700-1347GB

Page 30

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-1

Part 2

Touch Operator Panel

Device Description

MV4-570-TA1/2

MV4-590-TA1/2

Moeller 07/01 AWB-C2700-1347GB

Page 31

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-2

CAUTION !

The device should only be installed by qualified personnel,

observing the instructions given in section 12 (Installation

Instructions) of this document.

Only qualified personnel shall be allowed to repair this device.

Removing parts of the housing from this device exposes parts of the

system carrying a dangerous voltage. Only operate the de vice in its

original condition with all parts of the housing firmly fastened.

To avoid damage to the electronics do not switch on the device

when condensation is present. When changing its location from a

cold to a warm area, allow the device to adjust temperature before

commissioning.

No guarantee claims will be recognised for faults arising from the

improper handling of the device.

The device should not be used for the implementation of any safet y

functions relating to the protection of personnel and machinery.

No liability is accepted for claims fo r damages arising from a failure

or functional defect in the device.

All data specified in this document does not represent legally

binding guaranteed specifications.

Moeller 07/01 AWB-C2700-1347GB

Page 32

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-3

CONTENTS

1 Introduction.............................................................................................................................................. 2-4

2 Device version......................................................................................................................................... 2-4

3 Scope of delivery..................................................................................................................................... 2-5

4 EC Conformity .........................................................................................................................................2-6

5 Technical Data......................................................................................................................................... 2-6

6 Dimensions, Views, Front Plate Cutout................................................................................................... 2-8

6.1 General mounting instructions ......................................................................................................... 2-8

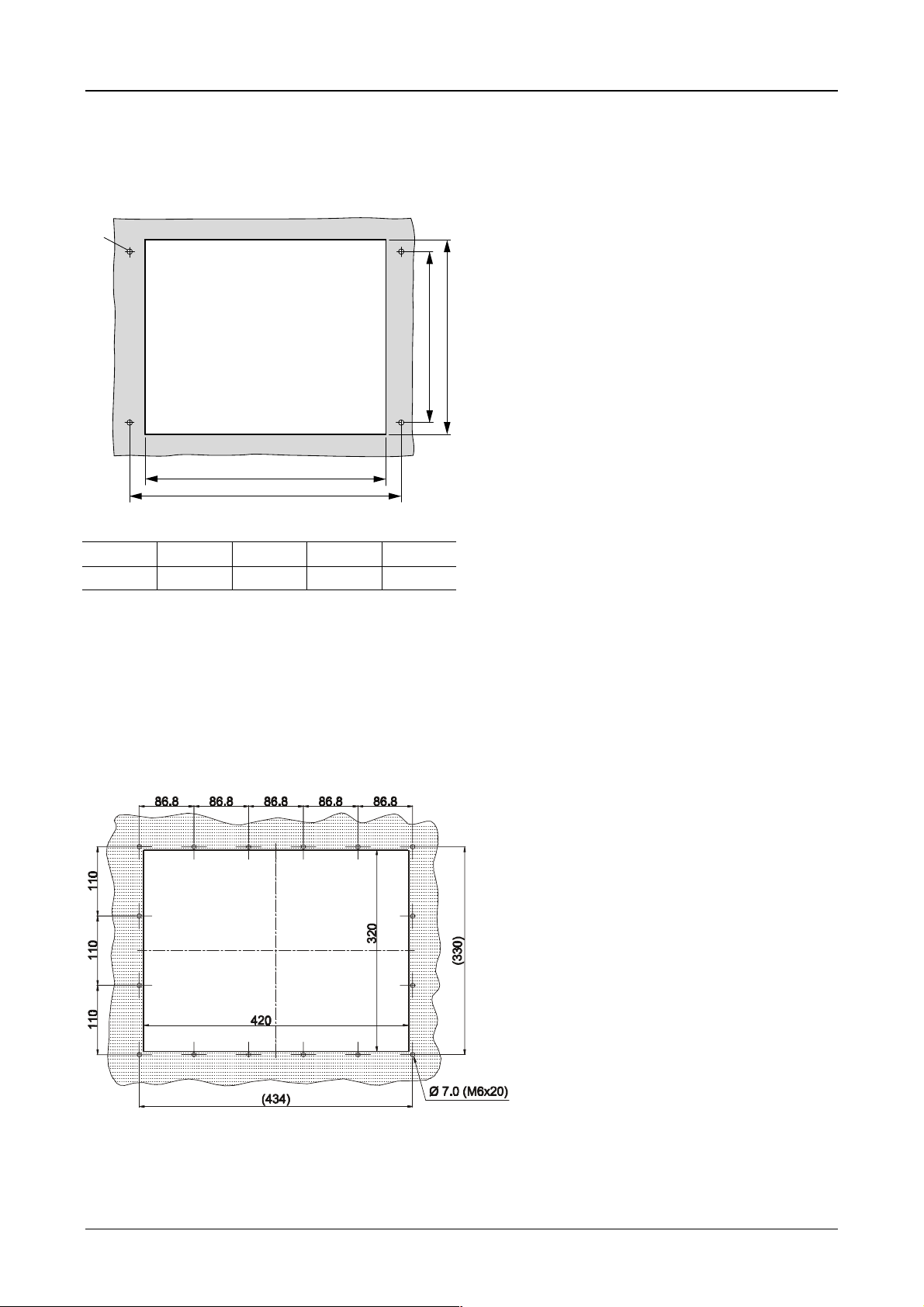

6.2 Dimensions 10.4″- unit MV4-570-TA1/2(-xx1) ................................................................................. 2-9

6.3 Front panel cutouts for 10.4″ units................................................................................................. 2-10

6.4 Dimensions for 13.8″ unit - MV4-590-TA1/2(-xx1) ......................................................................... 2-12

6.5 Front cover cutout for 13.8″ units................................................................................................... 2-13

7 Connection Assignment ........................................................................................................................ 2-14

7.1 System power supply for AC Versions (100 to 240 V AC, TA2 units) ........................................... 2-14

7.2 System power supply for DC Versions (24 V DC, TA1-units)........................................................ 2-14

7.3 System Port (Function, Assignment).............................................................................................. 2-15

8 Memory Card Slot.................................................................................................................................. 2-15

9 The Touch Screen................................................................................................................................. 2-16

9.1 Basic function of the Touch Screen ............................................................................................... 2-16

9.2 Power up function test.................................................................................................................... 2-16

9.3 Cleaning and care of the Touch Screen......................................................................................... 2-16

10 Function and control LEDs ................................................................................................................ 2-17

11 Communication Modules and System Expansion (Slot 0, Slot 1) ..................................................... 2-18

12 Installation Instructions ...................................................................................................................... 2-19

12.1 Device installation .......................................................................................................................... 2-19

12.2 Mounting to IP 65 ........................................................................................................................... 2-19

12.3 Preparation of the connection cables (EMC) ................................................................................. 2-20

12.4 Preparing the shield connections................................................................................................... 2-21

Moeller 07/01 AWB-C2700-1347GB

Page 33

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-4

1 Introduction

The MV4 Touch Oper ator Panels are visualisat ion units provided with t ouch zone functions for medium to

high complexity automation systems, meeting all the requirements placed on a modern visualisation unit.

The Touch Operator Pane ls must be loaded befor e use with the appropriat e project data. This is s tored in

the external plug-in memory card (PC car d). The memory card in the MV4 can be loade d with project data

via a download or directly on the PC (PC card slot). The project data is created using the MV4-CFG-1

configurator software (Galileo).

The Touch Operator Panels provide two slots for communication modules (see Section 11). The

communication card handles the connection to the automation system. They are described in Part 4 and 5.

This device descr iption is a ref erence for technical data, information on installing, terminals, com missioning

and operating of the MV4-570-TA1/2(-xx1) and MV4-590-TA1/2(-xx1) device versions. The illustrations in

this documentation refer to the 10.4″ Versions (see Section 2), unless otherwise noted. Lettering and

function of the terminals and indicators are the same for all device versions.

2 Device version

Type designation Display size Display techn olo gy Resolution Supply voltage

MV4-570-TA1(-xx1)

MV4-570-TA2(-xx1)

MV4-590-TA1(-xx1)

MV4-590-TA2(-xx1)

Units with the extention –xx1 are equipped with an acid-proof stainless steel front. The standard devices

have an aluminium front.

10.4″ (264 mm)

10.4″ (264 mm)

13.8″ (351 mm)

13.8″ (351 mm)

LCD active color

(TFT)

LCD active color

(TFT)

LCD active color

(TFT)

LCD active color

(TFT)

VGA (640 x 480) 24 V DC

VGA (640 x 480)

VGA (640 x 480) 24 V DC

VGA (640 x 480)

100 to 240 V AC,

50/60 Hz

100 to 240 V AC,

50/60 Hz

Moeller 07/01 AWB-C2700-1347GB

Page 34

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-5

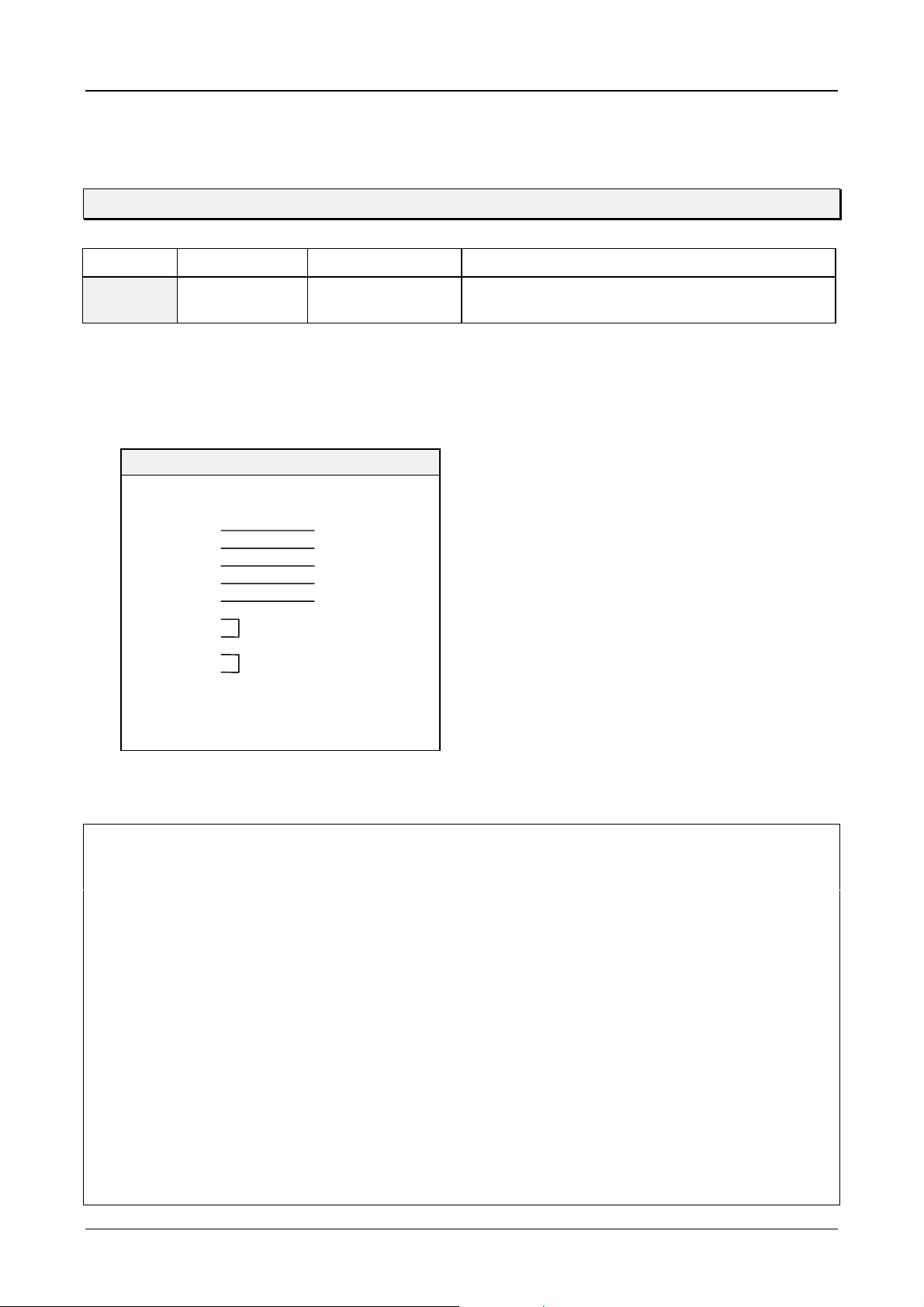

3 Scope of delivery

Device version

MV4 with aluminium front

MV4 with stainless steel front

Accessories:

Fixing screws for device installation (4 off,

countersunk)

Conter frame

Seal for device installation

PC card retaining device

Two blind plates with knurled screws for

System Slot 1 and System Slot 2

Nuts and washers

16 x M5 with 10.4“ units; 16 x M6 with 13.8“

units

Power supply plug

– DC Version MV4-570/590-TA1(-xx1):

plug-in screw terminal (3 pole)

(Phoenix Contact, Type: MSTB 2.5/3-ST-

5.08)

– AC Version MV4-570/590-TA2(-xx1):

Standard appliance plug

AWA

MV4-570-TA1/2

MV4-590-TA1/2

MV4-570-TA1/2-xx1

MV4-590-TA1/2-xx1

•

•

• •

• •

• •

•

• •

• •

Moeller 07/01 AWB-C2700-1347GB

Page 35

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-6

4 EC Conformity

The Touch Operator Panels meet the requirements specified by the Directives of the EC Council for

harmonizing the regul ati ons of EC member states relat ing to e lec tromagnetic com patibi lity (89/336/EEC) a nd

electrical safety (Low-Voltage Directive 73/23/EEC).

The following basic standards were used to assess the electromagnetic compatibility of the units:

EN 50 081-2 (Emission)

EN 50 082-2 (Immunity)

The following standard has been used as a basis for assessing the units with respect to its electrical safety:

EN 60 950

1998

Manufacturer: Moeller Gm bH

5 Technical Data

Display

Operation

Technology

(fully graphic)

Resolution 640 x 480 pixels

Colours 256

Contrast ratio min. 100

Display area

Luminance

Lifespan of backlight

(without backlight saver)

Optical light matrix in infrared range (IR Touch)

Resolution physical

Resolution logical

LCD active colour (TFT)

10.4″

13.8″

10.4″

13.8″

10.4″

13.8″

10.4″

13.8″

10.4″

13.8″

212.2 x 158.4 mm

281.0 x 208.0 mm

250 cd/m

180 cd/m

25,000 Operating hours min.

10,000 Operating hours min.

40 x 30 (16 x 16 pixels)

46 x 34 (14 x 14 pixels)

79 x 59 (8 x 8 pixels)

91 x 67 (7 x 7 pixels)

2

2

2

2

Memory Card Slot

PC-card to JEIDA/PCMCIA Type

I

or Type

II

Technology – Flash linear, 5 V/5 V or 5 V/12 V, max. 64 MB

– ATA-Flash (from Mainboard Firmware Version 1.10)

System Port

RS 232, non-isolated (see Section 7.3)

Moeller 07/01 AWB-C2700-1347GB

Page 36

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-7

Ambient conditions

Front

Weight

Dimensions

Operation 0 to 50 °C, 10 to 90 % rel. air humidity,

non-condensing

Storage –20 to 60 °C, 10 to 90 % rel. Air humidity,

non-condensing

Mech. shock IEC 60 068-2-27 (1 shock, half sinus 50 g/20 ms)

Vibration IEC 60 068-2-6 (10 TO 200 TO 10 HZ/1.5 G)

EMC compliance IEC/EN 61 000-4-2, 6 kV/8 kV

IEC/EN 61 000-4-3, 10 V/m

IEC/EN 61 000-4-4, 2 kV

IEC/EN 61 000-4-5, 1 kV/2 kV (AC Version only)

IEC/EN 60 801-6, 10 V

EMF

IEC/EN 61 000-4-8, 10 A/m

Radio interference voltage CISPR 11, EN 55 011, Class A (AC Version only)

Emitted interference CISPR 11, EN 55 011, Class A

Degree of protection (front) IP 65 (NEMA 12), to IEC/EN 60 529

Degree of protection, rear IP 20

Glass 3.0 mm, anti-reflective

10.4″

13.8″

Front

approx. 4.8 kg

approx. 6.9 kg

10.4″ Device

13.8″ Device

342 x 270 mm

460 x 350 mm

System power AC Versions (MV4-570/590-TA2)

supply

Rated voltage

100 to 240 V AC

Voltage range 85 to 264 V AC

Rated frequency 50 to 60 Hz

Power consumption 40 W max.

Fuse 1.0 AT, externally access ible

DC Versions (MV4-570/590-TA1)

Rated voltage 24 V DC

Voltage range 24 V DC to DIN EN 61 131-2

20.4 to 28.8 V DC effective,

absolute value with ripple 18.5 to 30.5 V

Power consumption 40 W max.

Current consumption 1.0 A norm.

Fuse 4.0 AT, externally access ible

Inrush current 3.0 A

Interfaces/Slots

2 slots for communication modules (Slot 0, Slot 1)

2

s max.

Moeller 07/01 AWB-C2700-1347GB

Page 37

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-8

6 Dimensions, Views, Front Plate Cutout

6.1 General mounting instructions

The Touch Operator Panels are suitable for insta llation in an enclosur e which is closed from the rear. The

unit is installed directl y from the fr ont with four counter sunk sc rews (standar d v ersion), or f rom the rear us ing

threaded bolts and nuts (stainless steel version). For correc t installation of all var iants, the thicknes s of the

front cover must be sufficient, and the installation must be performed according to the defined installation

procedure (refer to section 12).

The installation variants enable installation according to IP 65 degree of protection (see section 12).

The Touch Operator Panel can be operated at an ambient temperature of up to 50 °C. The ambient

temperature refers to the area direct ly in the vicin ity of the lower c ooling slits of a vertica lly mounted device

provided with unhindered air convection and mounted at a location no more than 2000 m above sea leve l.

The cooling slits must always be kept clear to ensure the proper cooling of the system.

Mounting inside an enclosur e is possible provided that the perm issible ambient temperature is observed. A

clearance of at least 30 mm from all sides of the enc los ure m ust be obs erve d in or der to e nsur e suff icient a ir

circulation.

Avoid exposing the f lat screen to direct sunlight. T he radiation from the sun (UV component) re duces the

lifespan of the LCD display.

The cooling slits must be kept clear to ensure the proper cooling of the system.

Avoid exposing the flat screen to direct sunlight.

After mounting the rear of the device must be accessible (Download button).

Moeller 07/01 AWB-C2700-1347GB

Page 38

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-9

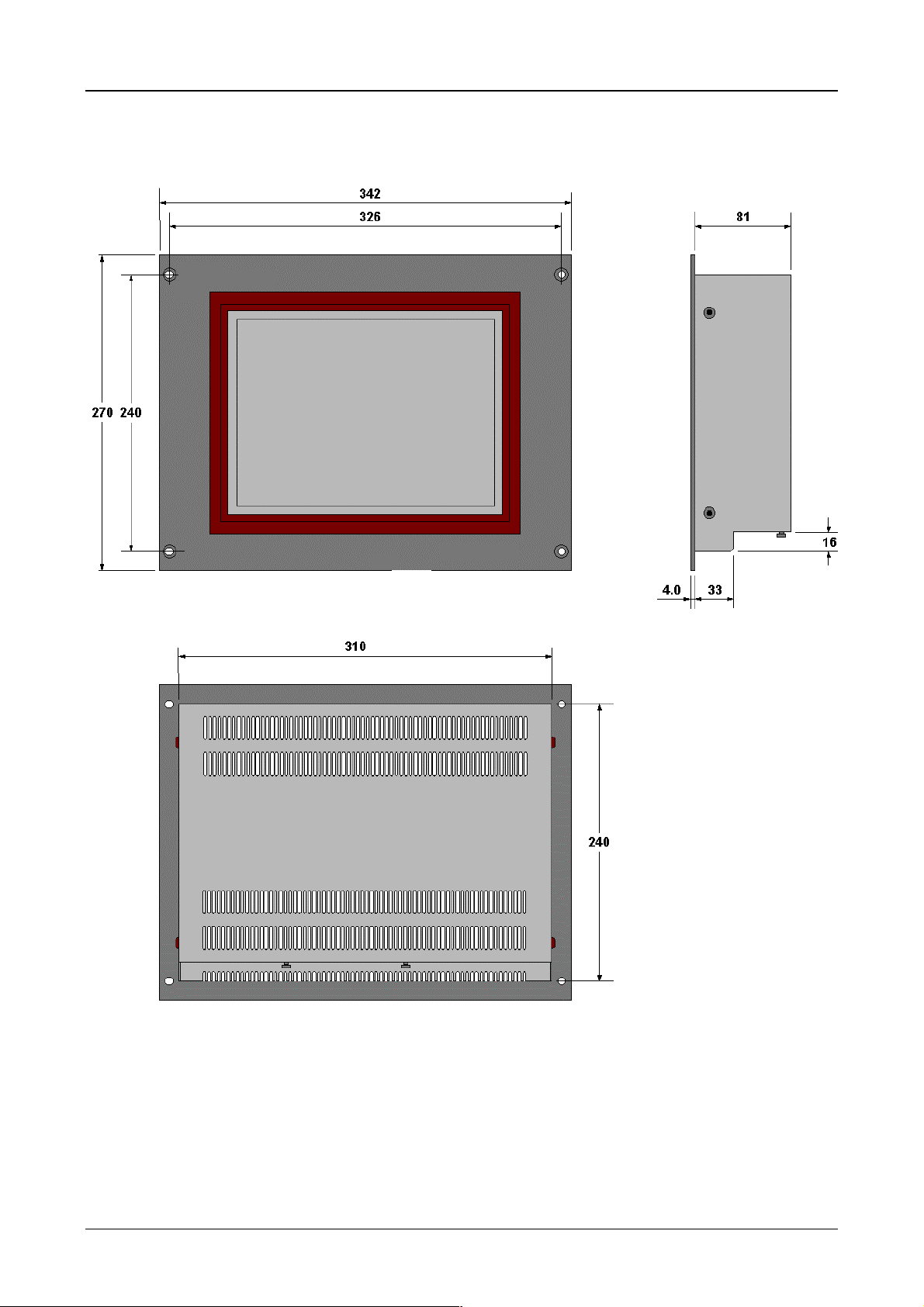

6.2 Dimensions 10.4″″″″- unit MV4-570-TA1/2(-xx1)

342

326

GF-1

240270

81

310

MICRO DESIGN

Farbe : MFS RAL 7016

16

4.0 33

240

Note:

The standard unit with front hole m ounting is s hown in th is il lustration. The dim ensions of the 10.4“ stainles s

steel units are ide ntical. Only the front panel cutout is different as a resu lt of the intended rear installation

with threaded bolts (refer to the following section).

Moeller 07/01 AWB-C2700-1347GB

Page 39

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-10

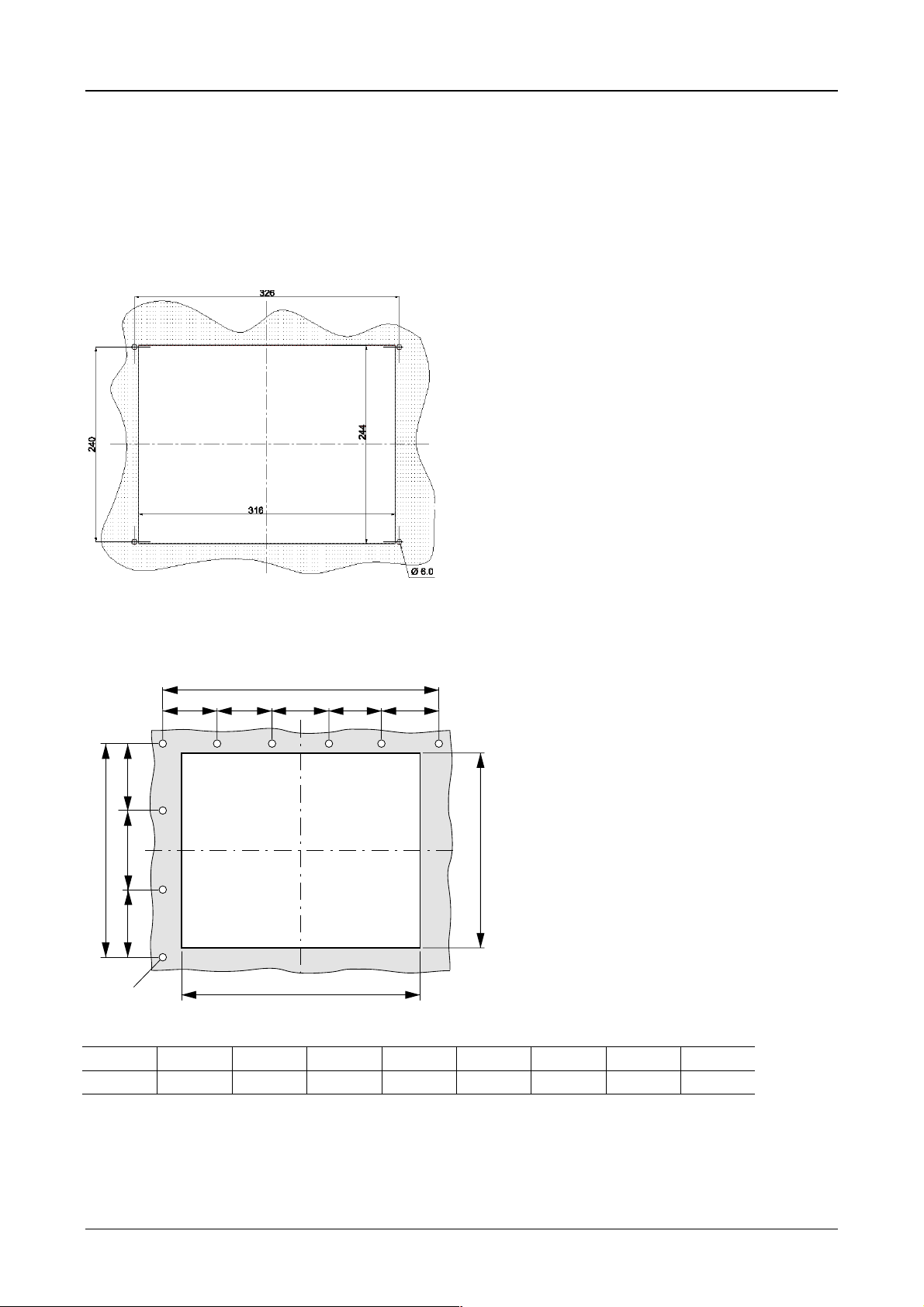

6.3 Front panel cutouts for 10.4″″″″ units

a) 10.4″″″″ units for 4-hole front mounting - MV4-570-TA1, MV4-570-TA2

Front panel cutout: 316 mm XXXX 244 mm (centrally to fixing holes)

Fixing screws : M5 countersunk screws (suppl ied wit h unit)

Moeller 07/01 AWB-C2700-1347GB

Page 40

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-11

b) 10.4″″″″ unit stainless steel version - MV4-570-TA1-xx1, MV4-570-TA2-xx1

Front panel cutout: 316x244 mm (centrally to fixing holes)

Moeller 07/01 AWB-C2700-1347GB

Page 41

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-12

460

6.4 Dimensions for 13.8″

GF-1

290350

″ unit - MV4-590-TA1/2(-xx1)

″ ″

430

MICRO DESIGN

94

50

412

4.0 38

Farbe : MFS RAL 7016

314

Note:

The standard unit with front 4-hole mounting is shown in this illustration. The dimensions of the 13.8“

stainless steel units are identical. Only the front panel cutout is different as a result of the intended rear

installation with threaded bolts (refer to the following section).

Moeller 07/01 AWB-C2700-1347GB

Page 42

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-13

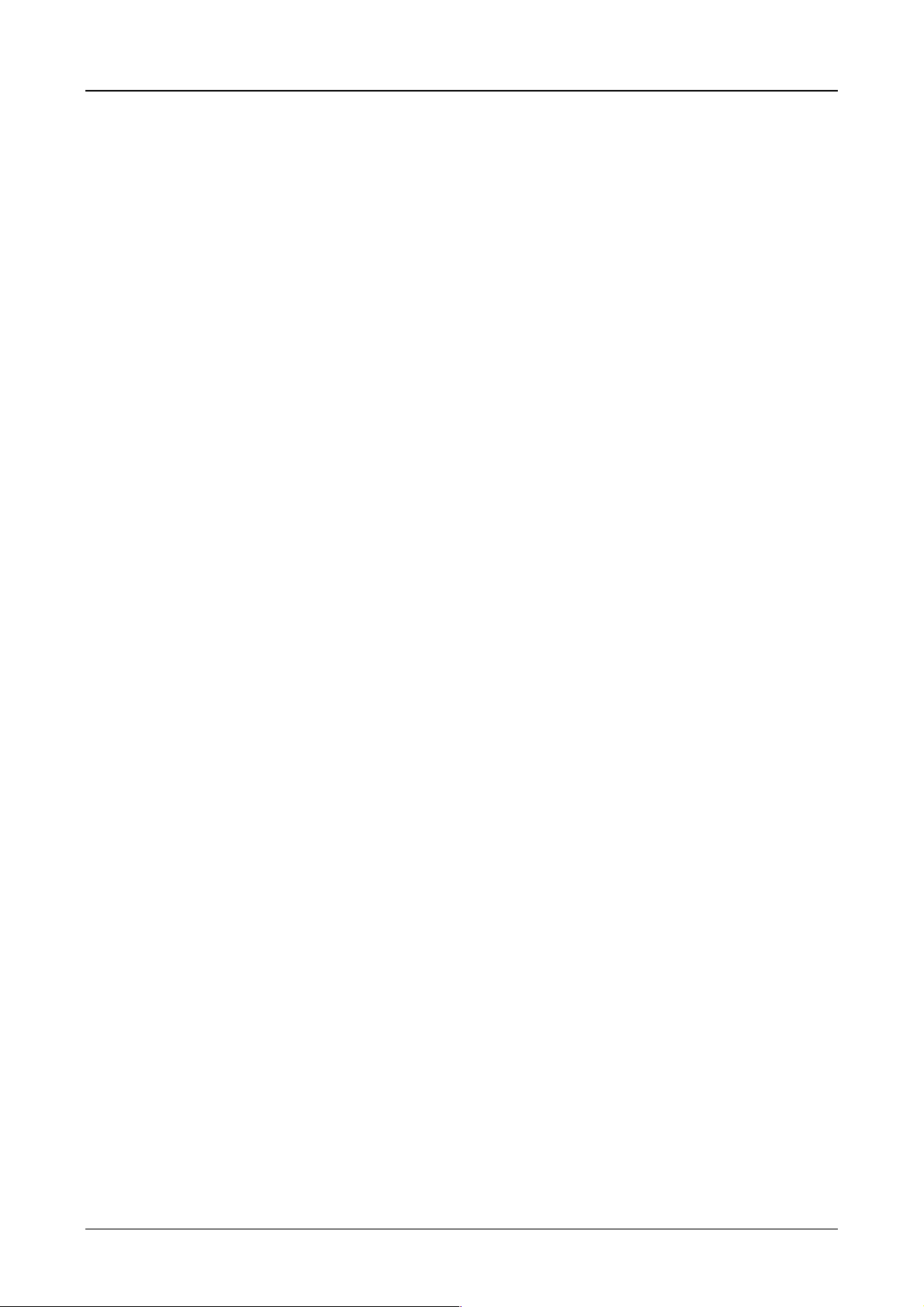

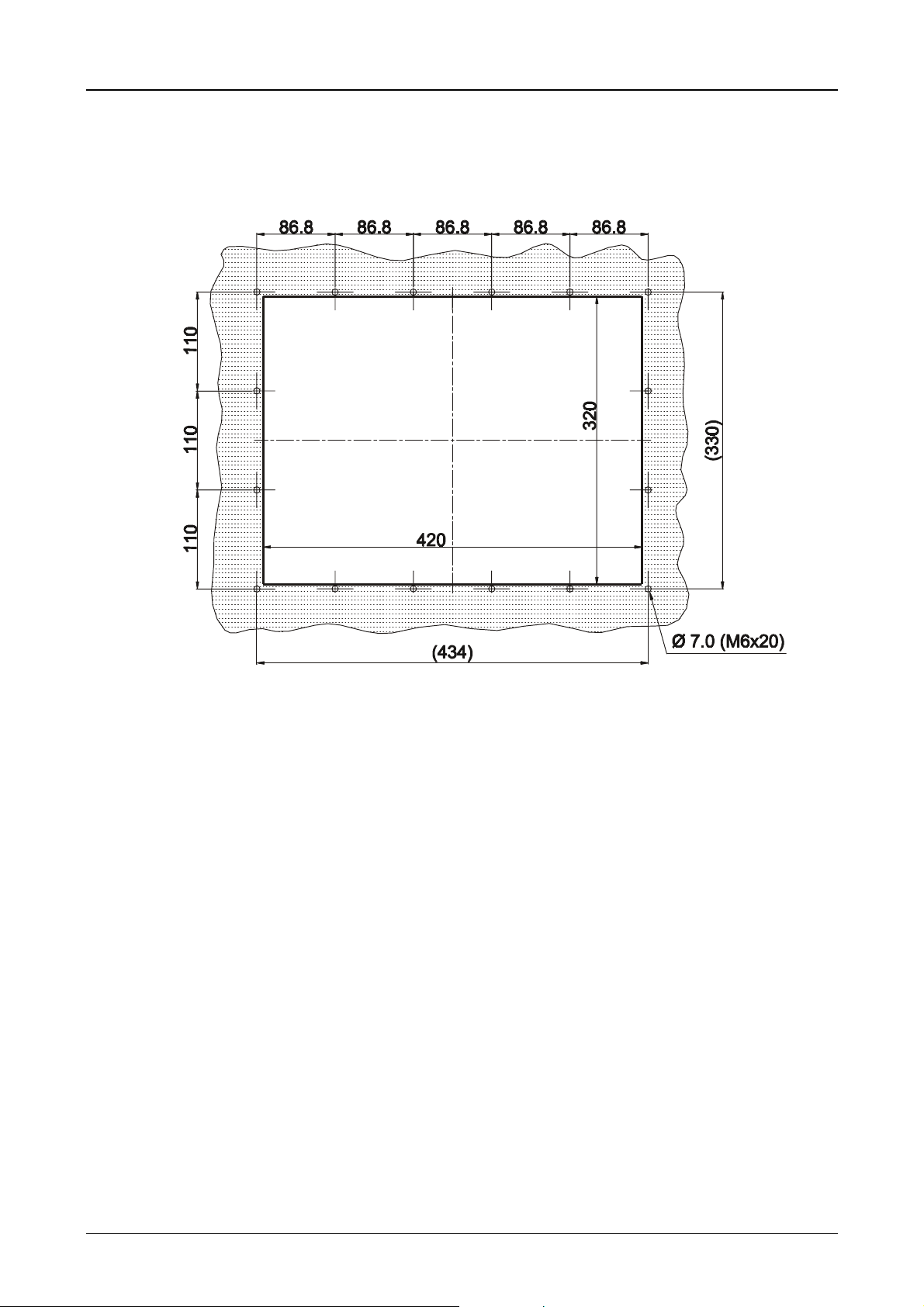

6.5 Front cover cutout for 13.8″″″″ units

a) 13.8″″″″ units for 4-hole front mounting - MV4-590-TA1, MV4-590-TA2

o

i

k

g

h

ghi k

OOOO

420 mm 430 mm 290 mm 320 mm 7 mm

Front panel cutout: 420 mm XXXX 320 mm (centrally to fixing holes)

Fixing screws : M6 countersunk screws (suppl ied wit h unit)

b) 13.8″″″″ stainless steel version units - MV4-590-TA1-xx1, MV4-590-TA2-xx1

Front panel cutout: 420 mm XXXX 320 mm (centrally to fixing holes)

Moeller 07/01 AWB-C2700-1347GB

Page 43

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-14

7 Connection Assignment

7.1 System power supply for AC Versions (100 to 240 V AC, TA2 units)

The power supply is connected using a stan dard appl iance socket. T he fuse f or protecting the de vice is a lso

integrated in the socket for easy replacement without having to open the device.

A standard plug for the connection is supplied with the unit.

SUPPLY

100-240 VAC

50/60 Hz

40 W

1997

PE LN

Section of the connector panel, showing the appliance socket for the

system power supply with integrated fuse

FUSE

1 AT

4.0 AT

WARNING !

TO AVOID ELECTRIC SHOCK THE

POWER CORD PROTECTIVE

GROUNDING CONDUCTOR MUST

BE CONNECTED TO PROTECTIVE

EARTH (PE).

DO NOT REMOVE ANY COVER WITH

PLUGED IN POWER CONNECTOR.

REFER SERVICING TO QUALIFIED

PERSONNEL.

Connector assignment

L ➞ Phase conductor

(Live)

N ➞ Zero conductor

(Neutral)

PE ➞ Protective conductor

(Protective Earth)

CAUTION ! To avoid the risk of electric shock the protective earth (PE) conductor

must be connected to the protective conductor potential of the power supply.

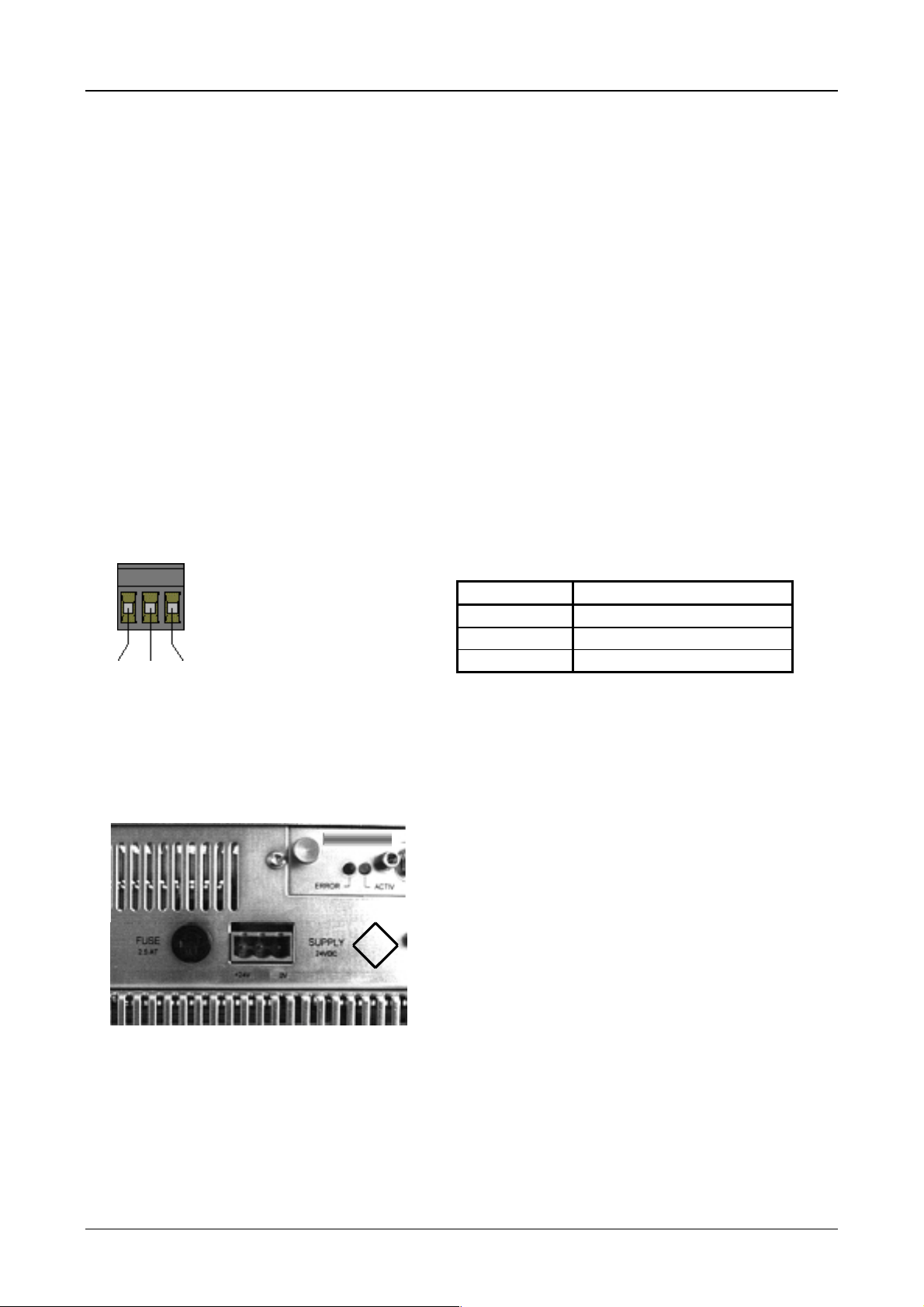

7.2 System power supply for DC Versions (24 V DC, TA1-units)

The system power suppl y of the Touch Operat or Panel is implemented via a plug-in screw terminal. T he

power supply is isolated and non-earthed (galvanically isolated), and is also fused. This can be replaced

without opening the device.

A screw terminal for the connection is supplied with the unit.

+24V PE 0V

FUSE

4.0 AT

1997

SUPPLY

24VDC

+24 V 0 V

Section of the connector panel of the unit, showing the c onnector for t he

system power supply and the fuse

Connection assignment

of supply connector

Moeller 07/01 AWB-C2700-1347GB

Page 44

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-15

7.3 System Port (Function, Assignment)

Use the System Port to

• load project data to the memory card of the Touch Oper ator Panels (Do wnload, serial link with the host

PC), as an alternative to loading project data to the memory card on the PC

• connect a serial printer for report printouts from the application

• communicate via the SUCOM-A protocol (from MV4 Configurator, V 3.03).

For SUCOM-A communic ation s elect the PLC t ype “Moe ller... PRG ” (COM) in the

MV4 Configurator. The required SUCOM-A cables ZB4-237-KB1 (for PS4) and

ZB4-233-KB1 (for PS416) must be used with an adapter (9-pol. SUB-D fem ale

connector to 9-pole SUB-D female connector).. This can be ordered under the

designation LT307.512.1 .

The programming port is a standard RS 232 interface.

CAUTION ! The system port is not isolated and is not earth-free!

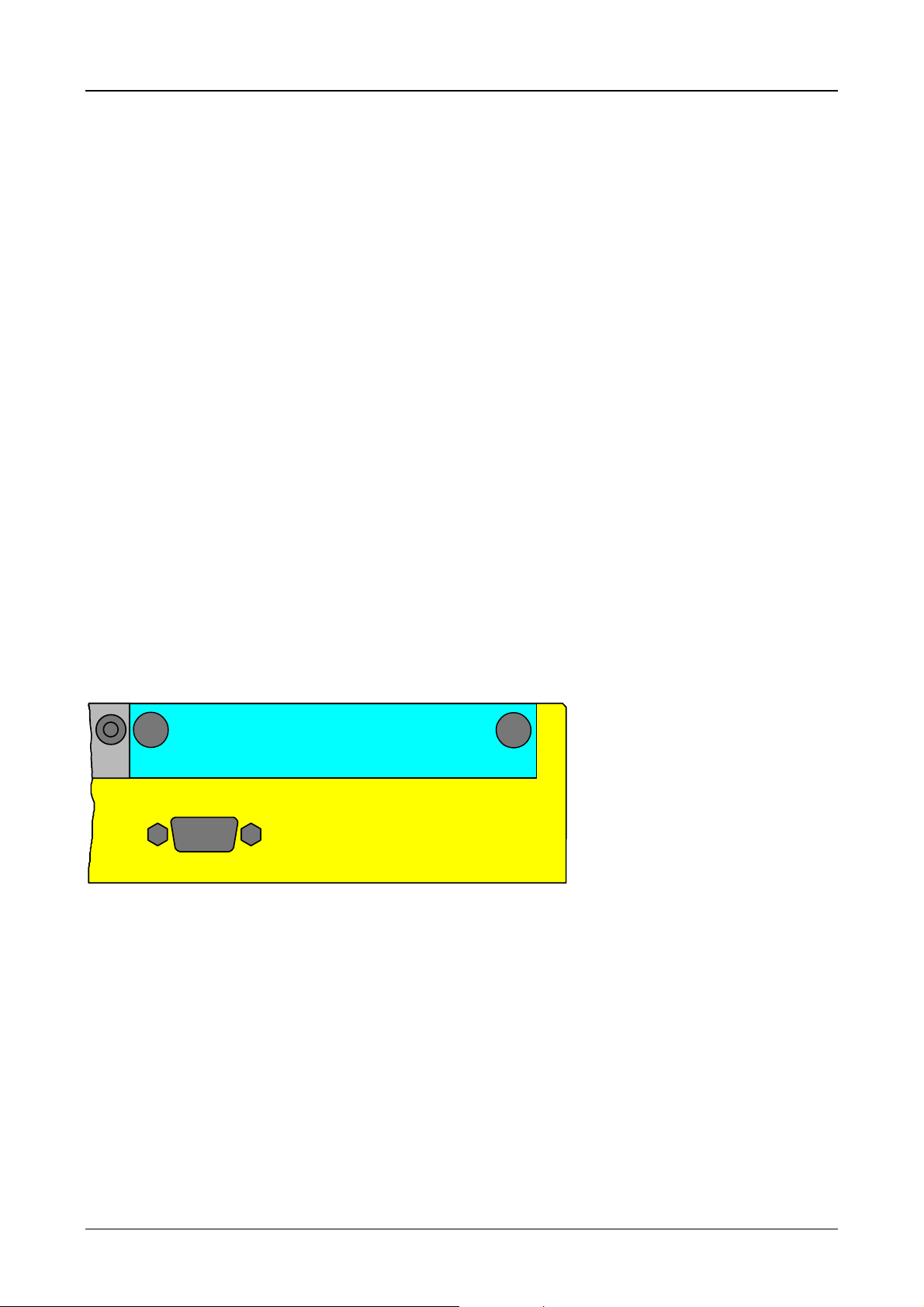

8 Memory Card Slot

SYSTEM PORT

D-Sub 9 Pol male

Pin No Assignment

1 DCD

2RxD

3TxD

4DTR

5Gnd

6DSR

7RTS

8CTS

9RI (+5 V)

Case Shield

The project data for operating the T ouch Operator Panel is stored on the m emory card in the m emory card

slot. The project data is cr eate d o n P C us i ng t he re levant design software for the configurator sof t ware. If the

PC has a PC card drive, t he project dat a can be trans ferred direc tly to the m emory card. T he memor y card,

in turn, is then sim ply fitted in the memory card slot of the device. The application ca n then be started up

after switching on the system power supply.

If the PC does not have a PC card drive, a direct program downloa d on W indows 95 is possible v ia the CO M

PORT of the MV4 unit. The program download via the COM PORT is very long. With Windows NT a

download via the COM PORT is not possible.

Refer to the MV4 documentation for further information.

The Memory Card is not supplied with the Touch Operator Panel.

SYSTEM SLOT 0

MEMORY CARD SLOT

Section of the connector panel on the device, showing the Memory Card Slot and the open System Slot 0

CAUTION ! When operating Touch Operator Panel secure the memory card

by using the card retaining device supplied!

The secure fitting of the memory card in the slot cannot be guaranteed

without the use of the retaining device, especially when the device is fitted

in the normal vertical position.

Card retaining device for the memory card slot

Moeller 07/01 AWB-C2700-1347GB

Page 45

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-16

9 The Touch Screen

9.1 Basic function of the Touch Screen

The function of T ouch Screen is based o n the active light m atrix principle in the infrared range. The optical

elements of the light m atrix are located behind the IR transparent plastic f rame in the front of the device.

They are located in such a way that their radiation extends slightly out of the front plate. Each emitter is

assigned a receiver that is located on the other side. In this way a total of 70 IR channels are arranged

closely together. A touch on the screen is detected by the simultaneous interruption of one or several

channels in the X or Y axis.

Repeated touches and touches that c over an area greater t han 20 mm ⫻ 20 mm are not evaluated by the

touch controller. Continuously interrupted channels caused by severe contamination and dirt, or by the failure

an optical element, are detected by the touch controller and are no longer included in the evaluation.

9.2 Power up function test

The device runs through a function test of the Touch Screen with ever y start-up. All the IR cha nnels are

evaluated and their si gnal levels c ompared with t hose of the init ial values. T he initial va lues are determ ined

before the device is delivered and stored in a retentive memory.

If one or several channel signa ls is below a minim um relative t o the initia l level, this will be indicate d on the

screen with an error m essage and the

this kind is norm ally due to se vere co ntam ination of the IR tr anspa rent pl astic f ram e which c ons equent ly has

to be cleaned (see Section 9.3). The Touch Screen, however, remains fully functional.

Only an increase in the contam inat ion of the s c r een will le ad t o th e c ont in uous inter ru pti ons of on e or s e vera l

IR channels. IR channels tha t are continuously interrupted will be detected by the touch controller and no

longer included in the evaluation . In ex trem e cas es, this m ay mean that i ndiv idual zones c annot be ac tivate d

by touch.

DEF/DIRTY

LED will be lit (see Section 10). A reduced signal leve l of

CAUTION ! Do not touch the screen whilst the system is being started up,

and wait till your application has started.

The Touch Screen carries out a function test during the start up in which

the signal levels of the IR channels are measured.

9.3 Cleaning and care of the Touch Screen

For operation ensure that the s ignal lev els of th e channe ls are not s o severe ly redu ced or int errupted d ue to

excessive contamination through dirt (see Section 9.1).

Clean the inside of the plastic fram e of the device r egular ly wit h a dam p s oft c loth. Ensur e that t he surf ace is

not scratched or scoured, especially when removing hard deposits and abrasive dusts.

Do not expose the front of the device to solvents which m ay corrode and loosen the plast ic frame (frame

material: polymethylmethacrylate, PMMA).

Moeller 07/01 AWB-C2700-1347GB

Page 46

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-17

!

!

!

!

!

!

10 Function and control LEDs

The device features 3 LEDs for the function control of the touch controller (TOUCH) and one LED for

monitoring the system voltages (SUPPLY). These are arranged underneath the system slot 1.

TOUCH

DEF/DIRTY

COM

ERROR

INIT/COM

POWER

SUPPLY OK

The LED is activat ed if during th e po wer up f unctio n test of the T ouch Sc ree n th e

signal level of one or several IR channels goes below the minimum value

(see Section 9.2). A reduced signal level is cause d b y the contam inatio n of the IR

transparent plastic frame or the failure of an optical element.

If this LED is lit, clean the plastic frame at the front of the device

(see Section 9.3).

This LED is lit if there are any communication problems between the touch

controller and the system electronics. If the LED is lit intermittently or

continuously, this indicates a system fault. During nor mal operation this LED is

off.

The LED stays dark when the power supply is switched on. It becomes active

when the initialisation of the touc h controller h as been succ essfully com pleted b y

the system electronics.

Pressing the Touch Screen will deact iv ate the LED for about 0.3 seconds.

When lit, this LED indicates that the system voltages (+12 V and +5 V) are

present.

If the LED is not lit, altho ugh the s upply volt age has b een switc hed on, chec k the

fuse.

When the supply voltage is switched on, all 3 Touch Screen monitoring LEDs ar e activated for 0.3 seconds

for a functional check.

SYSTEM PORT

! ! !

! ! ! !

Section of the device connector panel, showing the control LEDs, the SYSTEM PORT and the SYSTEM SLOT 1 with blind plate

SYSTEM SLOT 1

! !

SUPPLY

OK

INIT /

COM

TOUCHPOWER

COM

ERROR

DEF /

DIRTY

Moeller 07/01 AWB-C2700-1347GB

Page 47

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-18

11 Communication Modules and System Expansion (Slot 0, Slot 1)

The Touch Operator provides two slots for communication modules.

The different comm unication modules ava ilable allow the Touch Sc reen to be connected t o the automation

system or the field bus system required. The us e of two com munication m odules allo ws two com municatio n

systems to be operative at the same time.

For further information refer to Parts 3 and 4 (Communication cards).

CAUTION ! Do not handle the plug-in cards (modules) without observing the relevant

safety measures concerning electrostatic discharge (ESD).

Do not fit the modules with the power supply switched on.

Only operate the modules once they have been screwed into position.

Do not operate non-Moeller components in the slots.

Only the original Moeller hardware must be used.

Moeller 07/01 AWB-C2700-1347GB

Page 48

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-19

12 Installation Instructions

12.1 Device installation

When installing the Touch Operator Panel, a minimum distance of 10 cm must be ensured between the

device and any other components, so that the cooling of the system is not impaired. The cooling slits must

not be covered by cables or other objects.

The specified operating temperature (see Section 5) is based on a vertical mounting with unhindered air

convection and a location of no more than 2000 m above sea level.

Avoid the exposure of the flat screen to direct sunlight. The radiation from the sun (UV component)

reduces the lifespan of the liquid crystal.

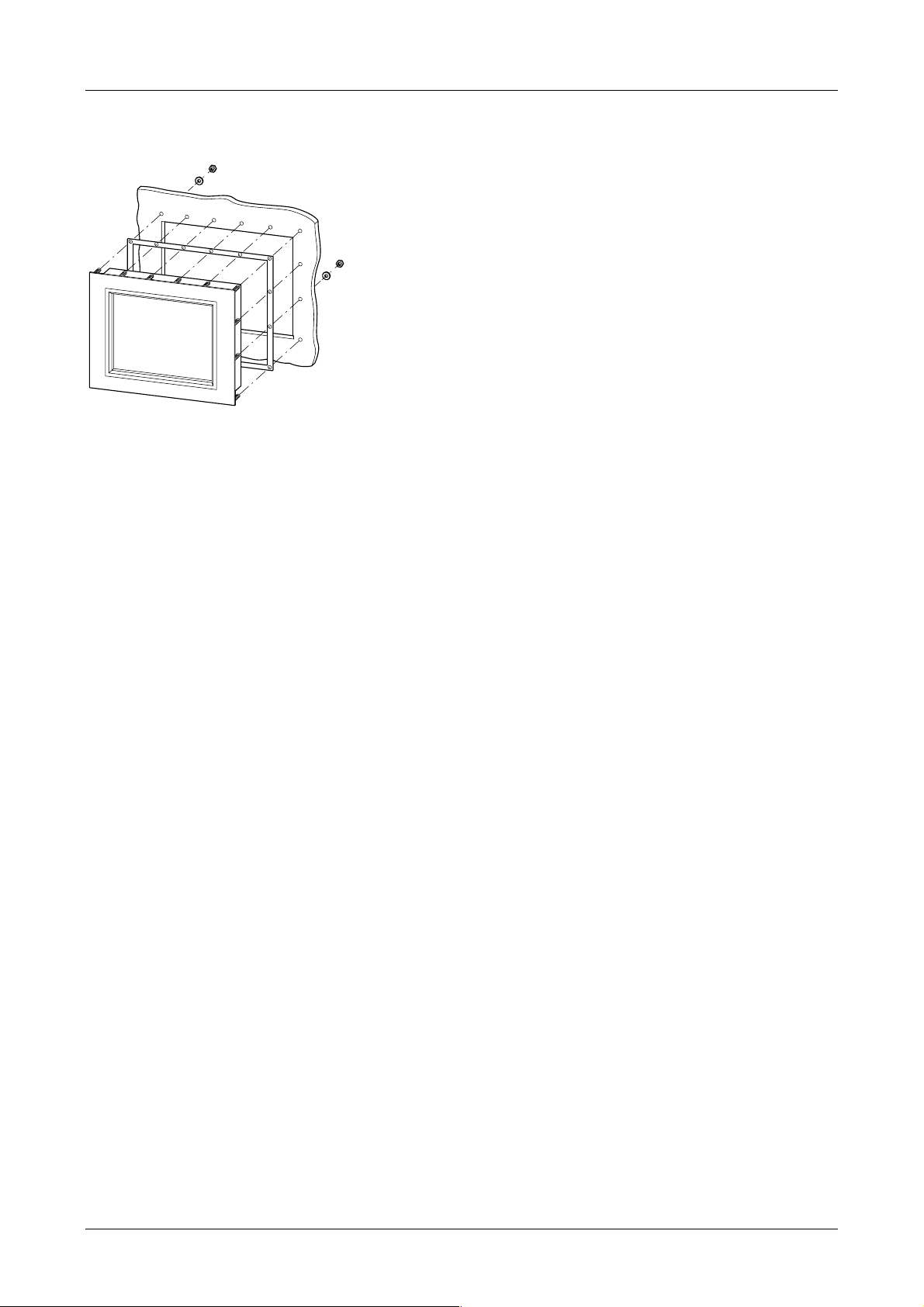

12.2 Mounting to IP 65

a) Installation of the unit with 4-hole aluminium front

For installations requiring IP 65 compliance the supplied conter frame and seal must be used.

These ensure the necessary pressure required for mounting in thin panels.

Special care should be taken during mounting to ensure correct sealing to IP 65.

1. Fit the front seal from the rear of the device.

2. Insert the unit into the panel cutout from the.

3. The front seal must fit evenly between the front plate and the front panel.

4. Fit the conter frame from the rear of the device.

5. Tighten the countersunk screws on the device through the front panel onto the conter frame.

The countersunk screws must be tightened uniformly and securely.

6. Ensure the correct positioning and even pressure of the front seal.

Observe the general mounting instructions (refer to section 6.1).

Moeller 07/01 AWB-C2700-1347GB

Page 49

Device Description MV4-570-TA1/2, MV4-590-TA1/2 2-20

b) Installation of the units with a stainless steel front

Special care should be taken during mounting to ensure correct sealing to IP 65.

1. Slide the front seal from the rear over the unit cover onto the fixing bolts.

2. Place the device from the front into the housing cutout.

3. The front seal must be make flat and uniform contact between the front plate and front cover.

4. The nuts must be uniformly and securely tightened.

5. Ensure correct positioning and application of even pressure of the front seal.

Pay close attention to the mounting instructions (refer to section 6.1).

12.3 Preparation of the connection cables (EMC)

The preparation of the data and signal cables is an important factor in the electromagnetic compatibility