Page 1

Building Automation SystemsIndustrial Automation

Hardware and Engineering

MI4

Display and Operator Panel

12/03 AWB-C27-1293-GB

Think future. Switch to green.

Page 2

All brand and product names are trademarks or registered

trademarks of the owner concerned.

st

1

published 1997, edition date 09/97

nd

2

edition 09/99

rd

3

edition 05/01

th

4

edition 03/03

th

5

edition 12/03

See revision protocol in the “About this manual“ chapter

© Moeller GmbH, 53105 Bonn

Author: Norbert Mausolf

Editor: Thomas Kracht

Translator: Dominik Kreuzer

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or

processed, duplicated or distributed by means of electronic

systems without written permission of Moeller GmbH, Bonn.

Subject to alteration without notice.

Page 3

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally

restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that

are live.

• Follow the engineering instructions (AWA)

of the device concerned.

• Only suitably qualified personnel in

accordance with EN 50110-1/-2

(VDE 0105 Part 100) may work on this

device/system.

• Before installation and before touching

the device ensure that you are free of

electrostatic charge.

• The functional earth (FE) must be

connected to the protective earth (PE) or

to the potential equalisation. The system

installer is responsible for implementing

this connection.

• Connecting cables and signal lines should

be installed so that inductive or capacitive

interference does not impair the

automation functions.

• Install automation devices and related

operating elements in such a way that they

are well protected against unintentional

operation.

• Suitable safety hardware and software

measures should be implemented for the

I/O interface so that a line or wire breakage

on the signal side does not result in

undefined states in the automation

devices.

• Ensure a reliable electrical isolation of the

low voltage for the 24 volt supply. Only

use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or

HD 384.4.41 S2.

• Deviations of the mains voltage from the

rated value must not exceed the tolerance

limits given in the specifications, otherwise

this may cause malfunction and dangerous

operation.

•Emergency stop devices complying with

IEC/EN 60204-1 must be effective in all

operating modes of the automation

devices. Unlatching the emergency-stop

devices must not cause restart.

• Devices that are designed for mounting in

housings or control cabinets must only be

operated and controlled after they have

been installed with the housing closed.

Desktop or portable units must only be

operated and controlled in enclosed

housings.

Moeller GmbH

Safety instructions

I

Page 4

• Measures should be taken to ensure the

proper restart of programs interrupted

after a voltage dip or failure. This should

not cause dangerous operating states even

for a short time. If necessary, emergencystop devices should be implemented.

• Wherever faults in the automation system

may cause damage to persons or property,

external measures must be implemented to

ensure a safe operating state in the event

of a fault or malfunction (for example, by

means of separate limit switches,

mechanical interlocks etc.).

II

Page 5

Contents

About This Manual 3

List of Modifications 3

MI4 documentation 3

Symbols used 3

1 Display Units And Operator Panels 5

Panel overview 5

Features 6

2 Engineering 9

Connections 9

Data connections 12

Connecting MI4 to PLC 13

Connecting a PC or printer to the MI4 20

Data interfaces of MI4-140-KF1 (hand-held) 23

Connect MI4 (hand-held) to PLC 26

Connecting the MI4 (hand-held) to

PC or printer (through CN2) 26

3 Installation 27

MI4 27

MI4-140-KF1 (hand-held) 29

Interface module 30

Replacing the battery 32

Insert labels 35

12/03 AWB-C27-1293GB

4Operation 37

Ambient conditions 37

Servicing and maintaining the panels 37

Configuration 38

Key functions 39

LED indicators 48

1

Page 6

Contents

Appendix 51

Dimensions 51

Communication cables 54

Technical data 56

Index 75

2

12/03 AWB-C27-1293GB

Page 7

About This Manual

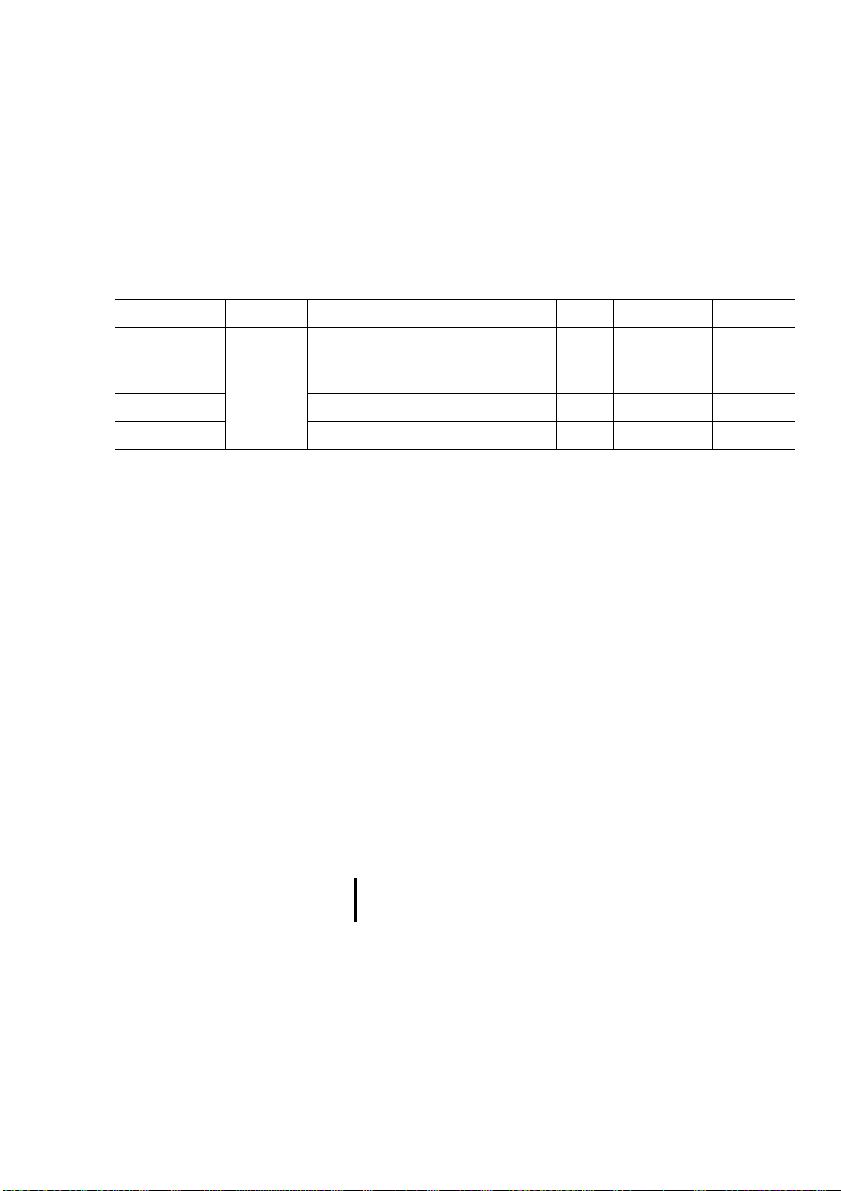

List of Modifications The following major changes have been made since

edition 09/99:

Edition Date Page Keywords New Modification Omitted

05/01 Complete

manual

03/03 MI4-140-TA1, MI4-170/570-KH1,

12/03 MI4-110-KD1, MI4-130-TA1

MI4 documentation This manual describes MI4 series display units and

New devices,

additional data interfaces

(Siemens MPI, DeviceNet, CANopen)

operator panels.

Additional manuals for the MI4 include the following:

Training Guide (AWB27-1302GB)

User Interface for MI4-CFG-1-GB Configuration

Software (AWB-C27-1294GB)

MI4-PLC Communication:

Application module and function blocks

(AWB-C27-1303GB)

Symbols used The following symbols are used in this manual:

왘 Indicates action to be taken.

Provides useful tips and additional information.

)

12/03 AWB-C27-1293GB

3

Page 8

4

12/03 AWB-C27-1293GB

Page 9

1 Display Units And Operator Panels

Panel overview The display units and operator panels are divided

into three groups:

Text operator panels

These are distinguished by

the type of display (text-based/graphicscapable),

the size of the display,

the number of interfaces,

the number of keys.

In addition, a hand-held unit and a device with

prepunched holes for electromechanical control

circuit devices are available.

Graphic operator panels with LCD display

These are distinguished by

the size and type of display

(colour or monochrome),

the number of keys.

12/03 AWB-C27-1293GB

Touch panels

These are distinguished by

the size and type of display

(colour or monochrome),

the number of additional buttons.

Depending on the device type, inputs are made

either using a keypad or a touch screen. In the latter

case, only slight pressure on the display triggers a

function (resistive touch technology).

All graphic/text/touch operator panels are equipped

with interfaces for configuration with a PLC or a PC.

Most of the units have a serial printer port.

5

Page 10

Display Units And Operator

Panels

Features Overview

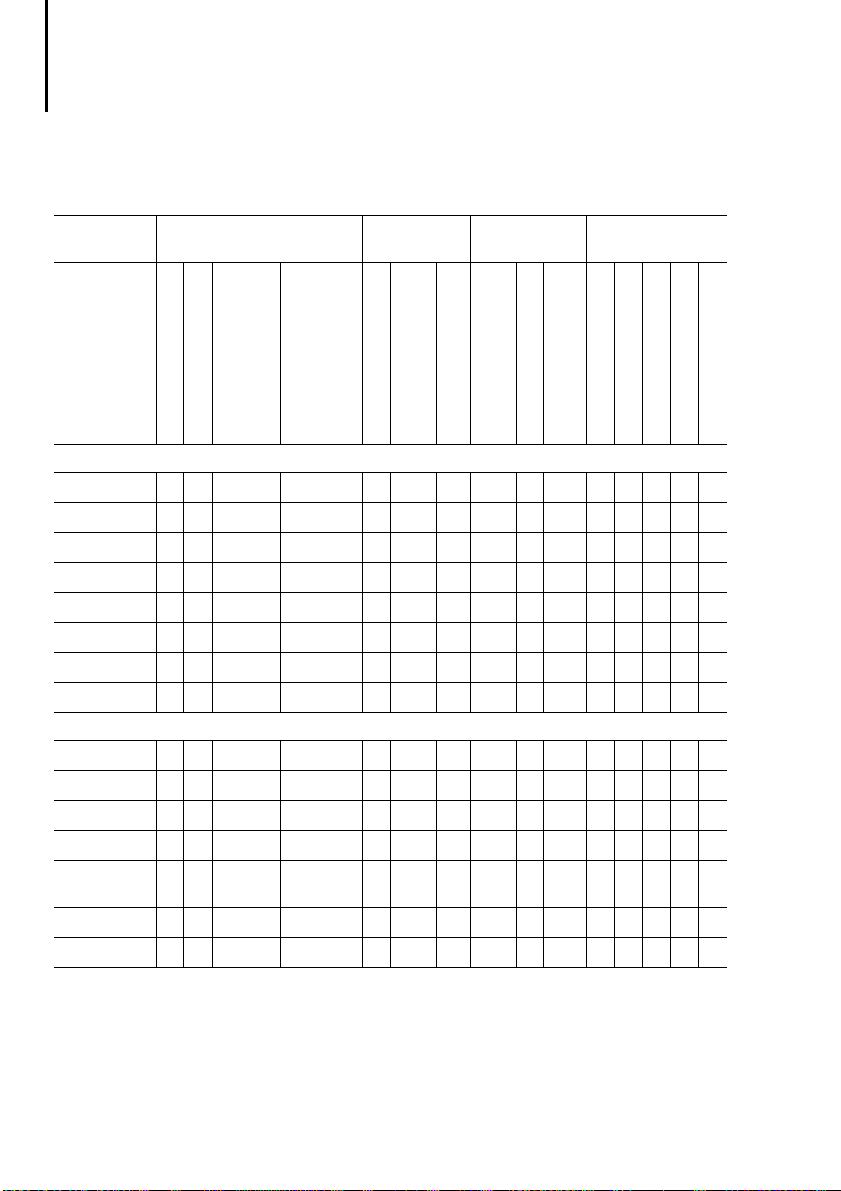

Table 1: Features of the text operator panels

MI4 Display Operator

LC display, text-based

LC display, graphics-capable

Rows x characters

Text operator panel (not graphics-capable)

MI4-100-KC1

MI4-101-KC1

MI4-100-KE1

MI4-101-KE1

MI4-110-KE1

MI4-111-KE1

MI4-130-KH1

MI4-131-KH1

Text operator panel (graphics-capable)

MI4-110-KC1 –

MI4-110-KD1 –

MI4-110-KG2 –

MI4-110-KG1 –

MI4-140-KF1

Handheld

MI4-140-KI1 –

MI4-140-KJ13) –

–2 20 – – 4 11

j

–2 20 – – 4 11

j

–2 20 –

j

–2 20 –

j

–4 20 –

j

–4 20 –

j

–4 40 –

j

–4 40 –

j

4 20 120 32 4 11

j

4 20 120 32 j 919j – –

j

4 20 120 32

j

4 20 120 32

j

–

8 20 120 64

j

8 40 240 64

j

8 40 240 64

j

Resolution in pixels

panel

Numeric keypad

F-keys with LED,

919j – –

j

919j – –

j

919 –

j

919 –

j

16 35 –

j

16 35 –

j

12 35

j

12 35 –

j

927 –

j

23 47 –

j

23 47 –

j

labelling facility

Interfaces

Total number of keys

j

j

j

j

1)

Plug-in

interface modules

Sucom A/configuration

(PLC PORT)

Sucom A (PLC PORT)

Configuration/printer

(PC/PRINTER PORT)

Suconet K (AUX PORT)2)PROFIBUS DP (AUX PORT)

– –

– –

jjjjj

jjjjj

jjjjj

jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

– –

jjjjj

jjjjj

– –

jjjjj

jj jjjjj

jj j–j

jj jjjjj

jj jjjjj

MPI (AUX PORT)

––

DeviceNet (AUX PORT)

CANopen (AUX PORT)

1) For explanation, see legend on next page

2) The MI4-101-KC1, MI4-1x1-KE1 and MI4-131-KH1

units are supplied with a fitted Suconet-K interface.

3) Electromechanical keypads can be fitted

6

12/03 AWB-C27-1293GB

Page 11

Features

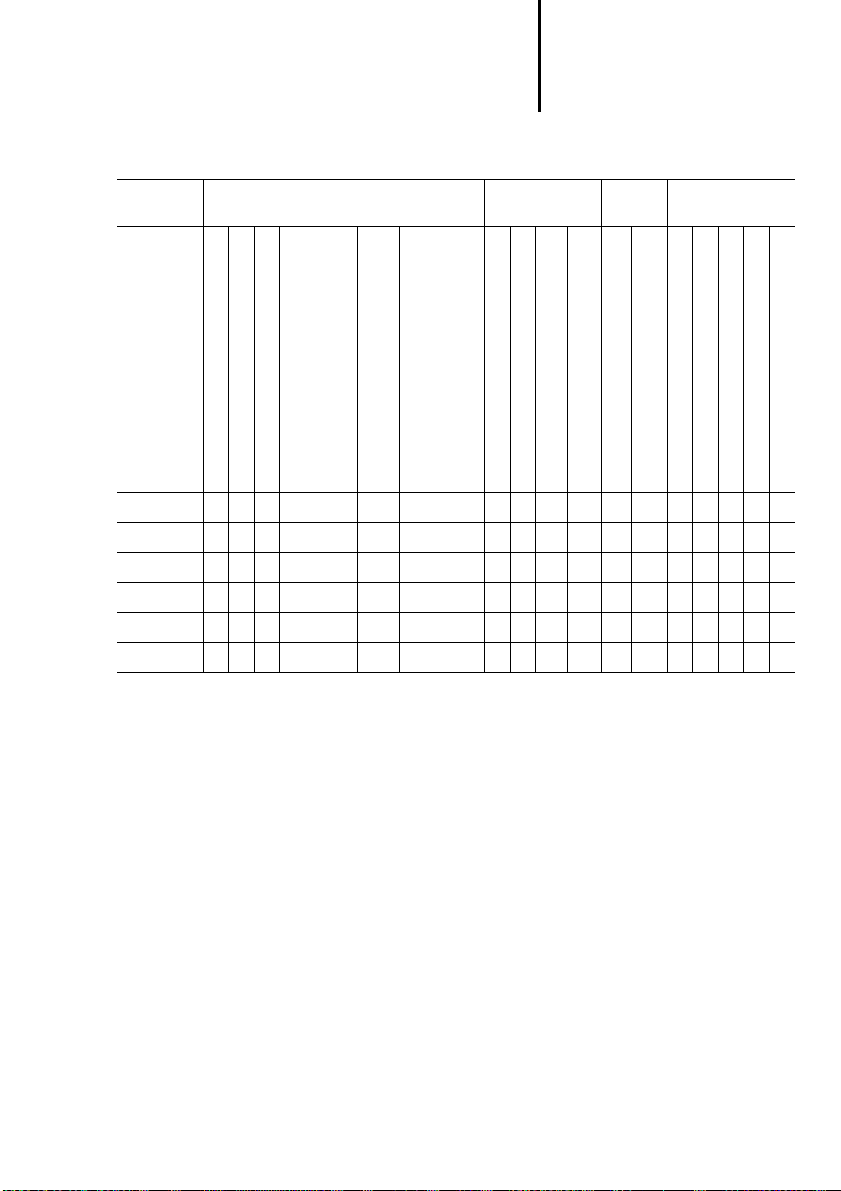

Table 2: Features of the graphic operator panels

MI4 Display Control panel Inter-

LCD passive monochrome

LCD passive colour

TFT

Rows x characters

MI4-151-KF1 j 16 40 5,6 320 240

MI4-451-KF1 j 16 40 5,6 320 240

MI4-150-KI1 j 16 40 5,6 320 240

MI4-450-KI1 j 16 40 5,6 320 240

MI4-170-KH1 j 30 80 10,4 640 480

MI4-570-KH1 j 30 80 10,4 640 480

Display size in inches

Resolution in pixels

1) A PC for uploading or downloading the configuration or

a printer can be connected to the PC/PRINTER PORT.

To the PLC PORT, the PLC for data transfer with the

Sucom A protocol is connected. On devices without

PC/PRINTER PORT, the PC or printer can also be

connected to this port with an adapter.

To the AUX PORT, the PLC for data transfer using the

respective bus protocol is connected.

2) The MI4-151-KF1 and MI4-451-KF1 units are supplied

with a fitted Suconet-K interface.

Resistive touch

Numeric keypad

10 37

j

10 37

j

33 57

j

33 57

j

23 50

j

23 50

j

faces

F-keys with LED, labelling facility

Total number of keys

Sucom A (PLC PORT)

j j jjjjj

j j jjjjj

j j jjjjj

j j jjjjj

j j jjjjj

j j jjjjj

Plug-in interface

1)

modules

Configuration/printer (PC/PRINTER PORT)

Suconet K (AUX PORT)2)PROFIBUS DP (AUX PORT)

MPI (AUX PORT)

DeviceNet (AUX PORT)

CANopen (AUX PORT)

12/03 AWB-C27-1293GB

7

Page 12

Display Units And Operator

Panels

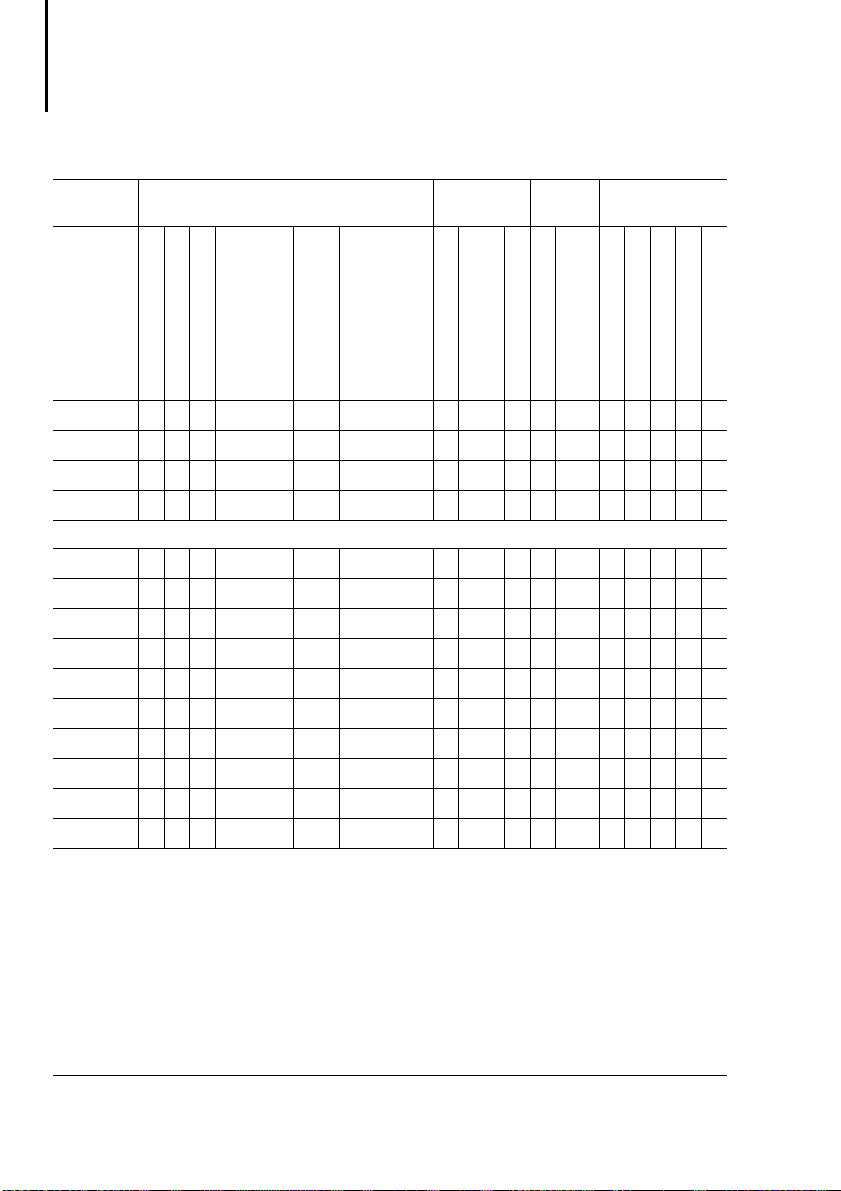

Table 3: Features of the touch operator panels

MI4 Display Control

LCD passive monochrome

LCD passive colour

LCD active TFT

Rows x characters

MI4-151-TA1 j 16 40 5,6 320 240

MI4-451-TA1 j 16 40 5,6 320 240

MI4-161-TC1 j 25 80 9,5 640 400

MI4-471-TC1 j 30 80 10,4 640 480

MI4-130-TA1 j 16 40 3,8 320 240

MI4-140-TA1 j 16 40 5,6 320 240

MI4-150-TA1 j 16 40 5,6 320 240

MI4-450-TA1 j 16 40 5,6 320 240

MI4-550-TA1 j 16 40 5,6 320 240

MI4-160-TA1 j 30 80 9,6 640 480

MI4-470-TA1 j 30 80 10,4 640 480

MI4-570-TA1 j 30 80 10,4 640 480

MI4-580-TA1 j 40 100 12,1 800 600

MI4-590-TA1 j 48 128 15 1024 768

1) A PC for uploading or downloading the configuration or a printer can be connected to

the PC/PRINTER PORT.

To the PLC PORT, the PLC for data transfer with the Sucom A protocol is connected. On

devices without

PC/PRINTER PORT, the PC or printer can also be connected to this port with an adapter.

To the AUX PORT, the PLC for data transfer using the respective bus protocol is

connected.

2) The MI4-151-TA1, MI4-451-TA1, MI4-161-TC1 and

MI4-471-TC1 units are supplied with a fitted Suconet-K interface.

3) Port can also be used for engineering.

Display size in inches

Resolution in pixels

panel

Resistive touch

––

j

––

j

29

j

29

j

–––

j

––

j

––

j

––

j

––

j

––

j

––

j

––

j

––

j

––

j

Inter-

1)

faces

F-keys with LED,

labelling facility

Total number of keys

Sucom A (PLC PORT)

Configuration/printer

(PC/PRINTER PORT)

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

3

–

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

jj jjjjj

Plug-in interface

modules

Suconet K (AUX PORT)2)PROFIBUS DP (AUX PORT)

MPI (AUX PORT)

DeviceNet (AUX PORT)

jjj

jj

CANopen (AUX PORT)

8

12/03 AWB-C27-1293GB

Page 13

2 Engineering

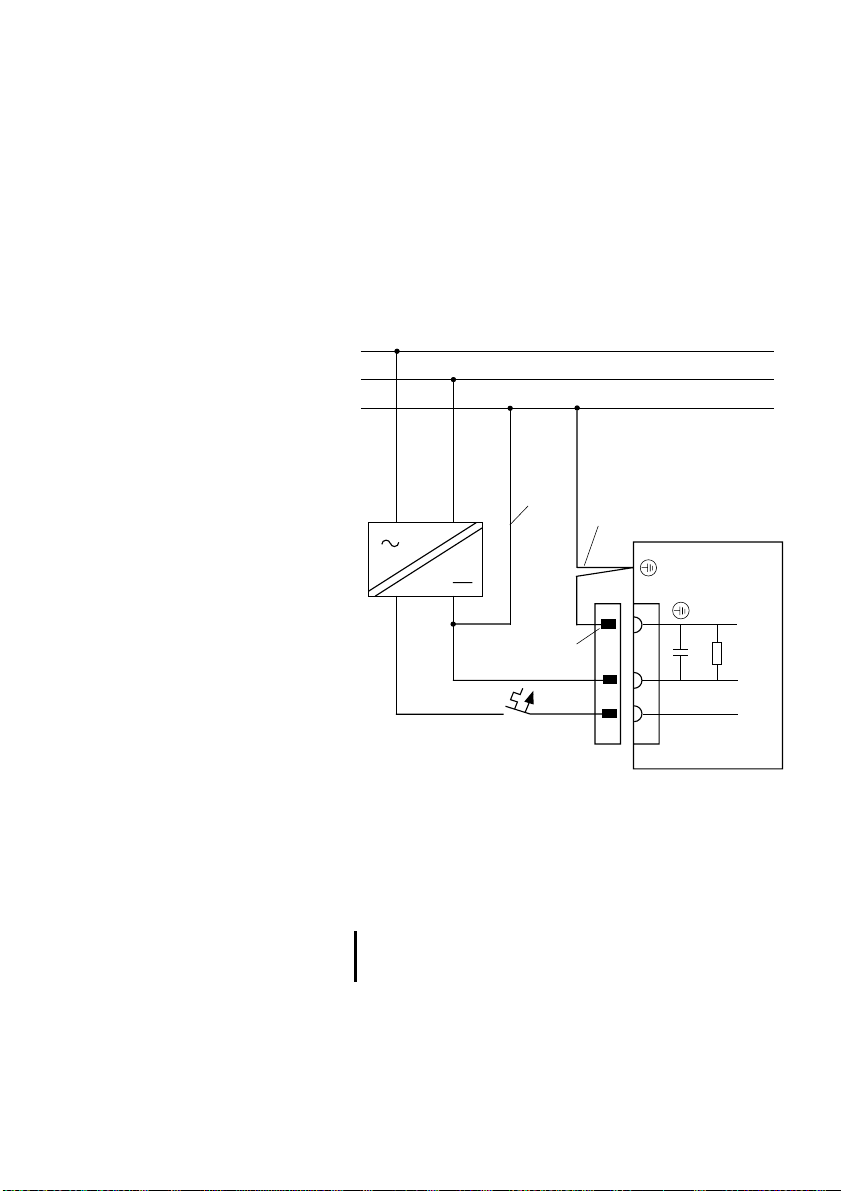

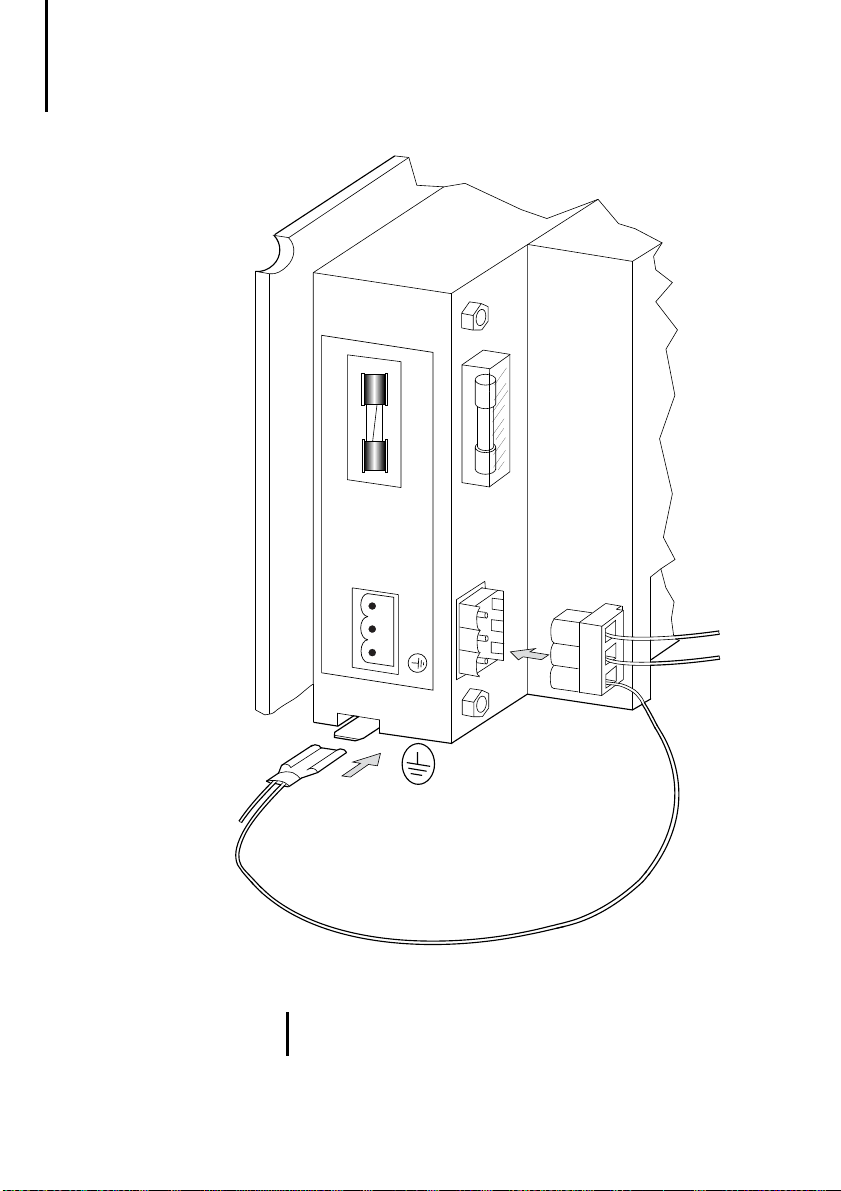

Connections Power supply and grounding

왘 Connect the units as shown in the following

diagrams.

L1

N

PE

햲

햳

MI 4-...

12/03 AWB-C27-1293GB

)

+24 V

Figure 1: Connection diagram

햲 Earth connection for 0 V line

햳 Device housing earth connection

햴 Power supply plug earth connection

0 V

햴

0 V

+24 V

For further explanation of the diagram legend,

see page 11.

9

Page 14

Engineering

2A R

24V DC

햴

1

2

0V 24V

3

10

햳

Figure 2: Connecting the power supply and earthing

Not all devices are fitted with a 2 A fuse.

)

12/03 AWB-C27-1293GB

Page 15

Connections

햲 Earthing the 0 volt cable (see Fig. 1)

The units can be operated earthed or unearthed. An

isolation monitoring device must be used for

unearthed operation.

햳 Panel housing earth connection

The panel housing must always be earthed. The

earth connection is located next to the connector

sockets for the power supply. It is indicated by a

sticker bearing the symbol for earth. Use a 6.3 mm

fast-on plug for the power connection.

햴 Power supply plug earth connection

In all cases, connect the earth connection of the plug

to earth. It is connected internally to the 0 V plug

connection through a capacitor-resistor combination

(10 nF, 100 V/1 M⍀).

Data plug earthing

The data plug housings for MI4 units are earthed.

12/03 AWB-C27-1293GB

11

Page 16

Engineering

Data connections MI4 units are equipped with several connection

ports. The panels differ in their housing design,

electrical data and the protocol they use. The

following illustrations show the pin and socket

assignments of the cable connections to the PC,

printer and PLC.

If you are not using standard cables, you may

)

only allocate those cable plug pins or sockets

required for the interface in question. Otherwise,

malfunctions may occur.

Overview

Use the table to determine the required connection

type:

Connection type MI4-PORT Page

MI4 to PLC through ...

Sucom A PLC 13

Suconet K AUX 14

PROFIBUS-DP AUX 16

Siemens MPI AUX 17

DeviceNet AUX 18

CANopen AUX 19

MI4 to PC or printer PC/PRINTER 21

PLC (with adapter) 22

MI4 (hand-held) to PLC through ...

Sucom A CN3 26

Suconet K CN1 26

Siemens MPI CN1 26

MI4 (hand-held) to PC or printer CN2 26

12

12/03 AWB-C27-1293GB

Page 17

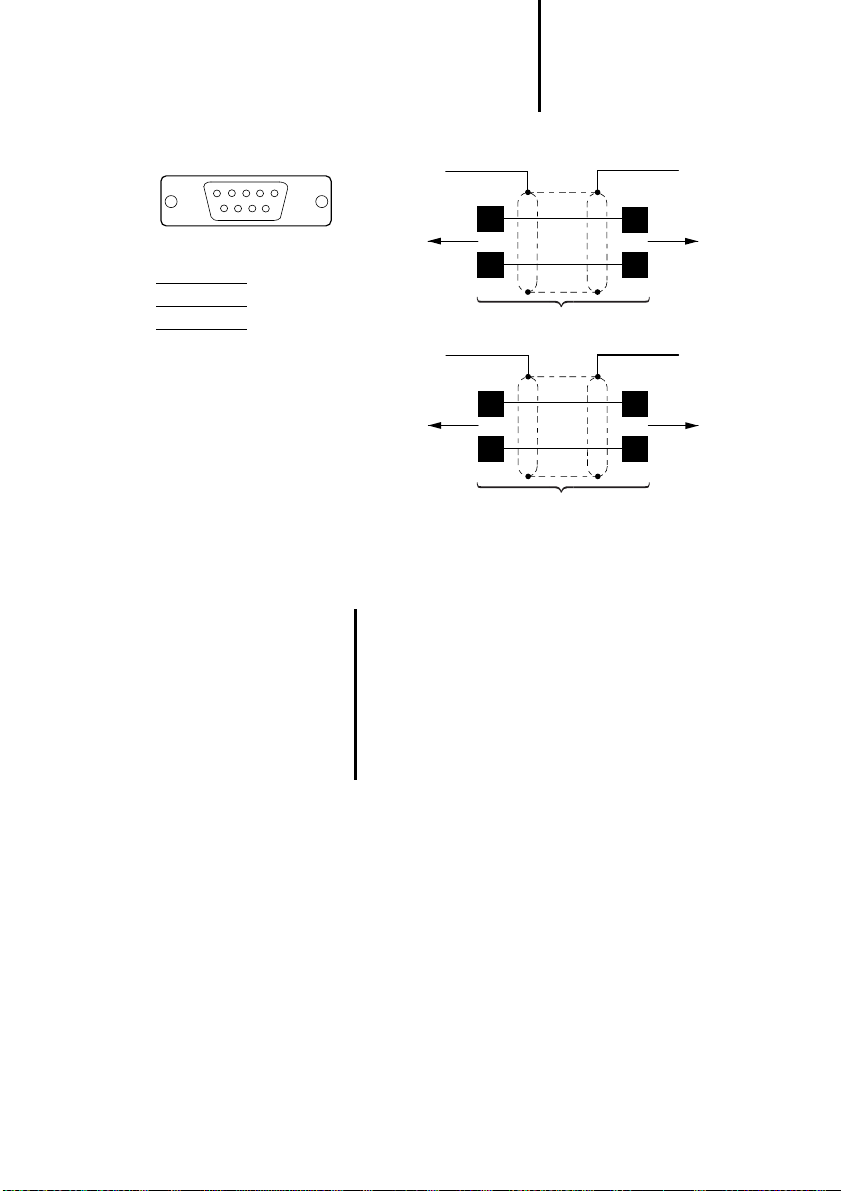

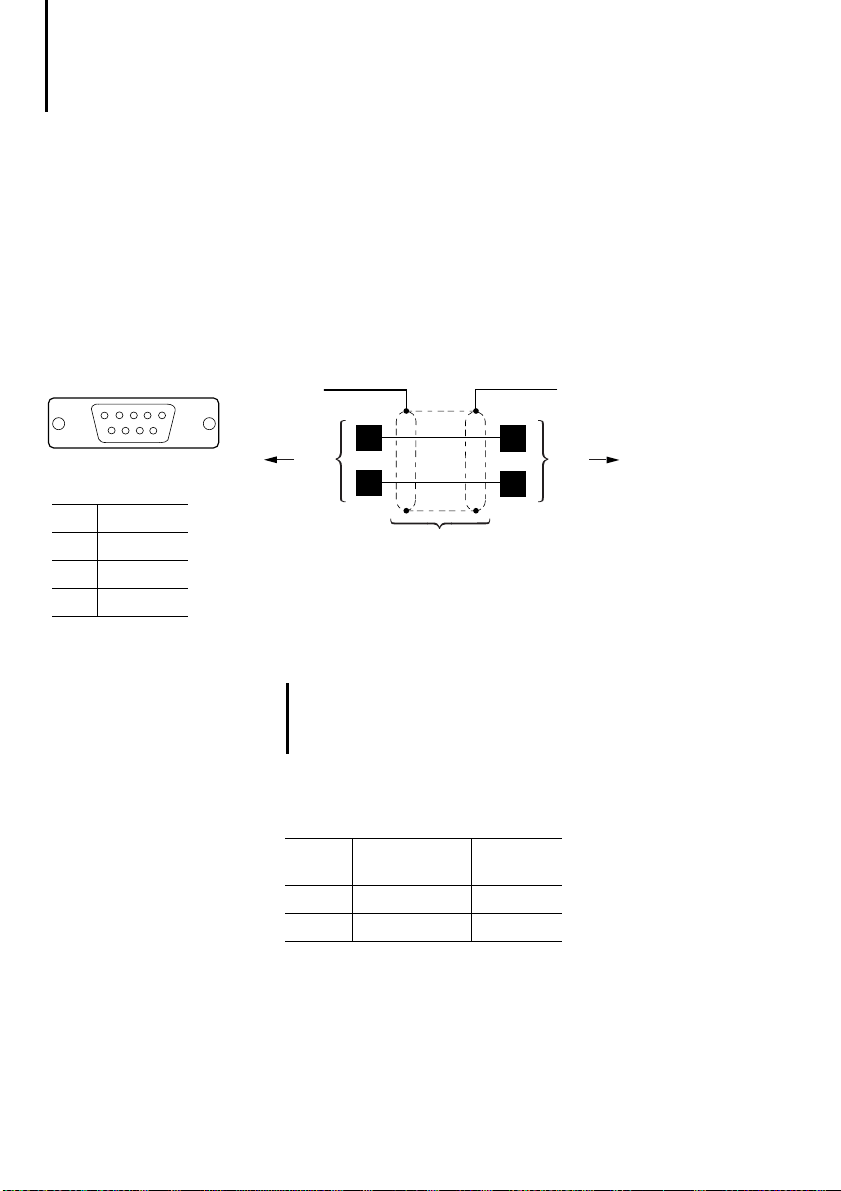

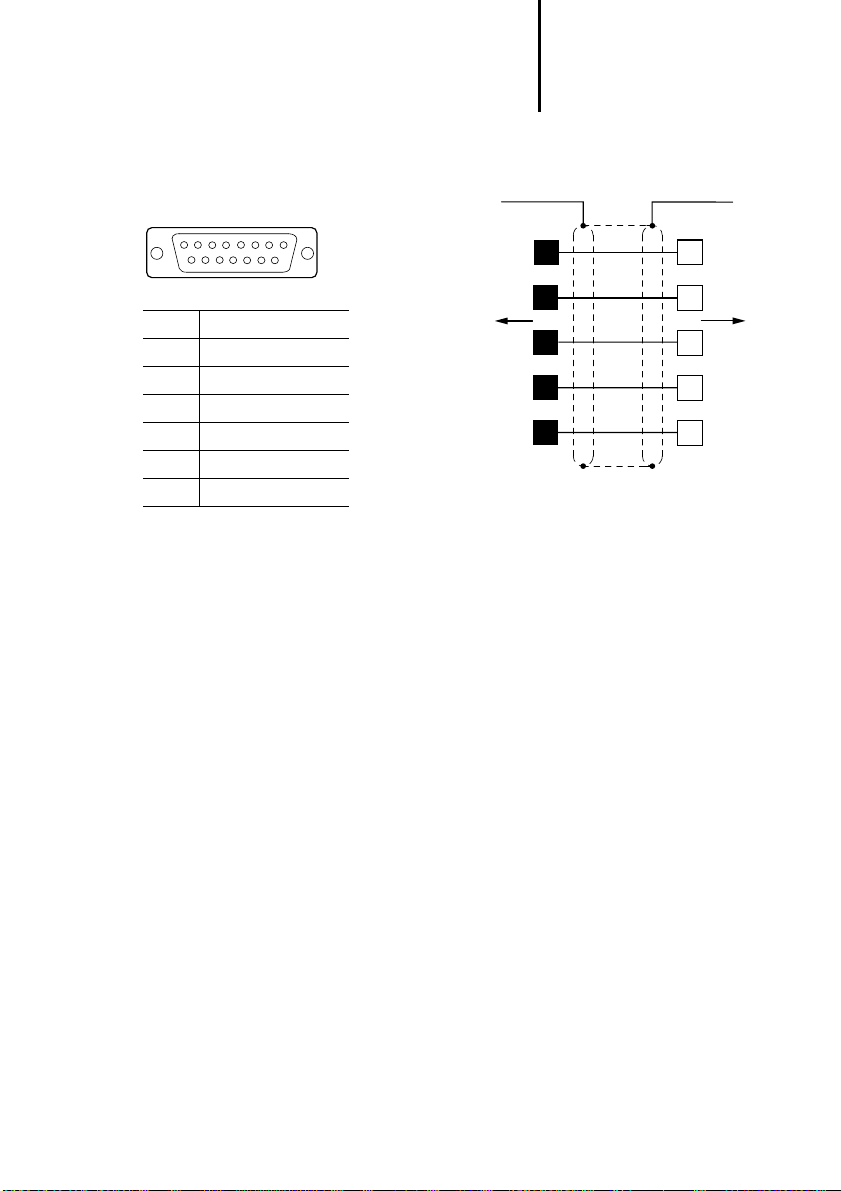

Connecting MI4 to PLC SUCOM-A protocol

For serial communication with various PLC systems,

use the PLC PORT of the MI4. The PLC PORT

supports RS 232, RS 485, RS 422 and Current Loop

20 mA. Please use only the specified data cable.

Connecting MI4 to PLC

PLC PORT

1

15

SUB D

Pin Function

1 Frame Earth

2RxD

3TxD

4+5 V output (F 100 mA)

5GND

6CHA–

7CHB–

8 Tx+ 20 mA

9 Tx– 20 mA

10 RTS

11 CTS

12 Rx+ 20 mA

13 Rx- 20 mA

14 CHA+

15 CHB+

햲 Connection to the data plug

housing

Q Plug qSocket

a

MI4

PLC PORT

a

MI4

PLC PORT

햲

MI4

PLC PORT

2

3

5

2

3

5

6

14

RS 232

ZB4-2B7-KB1

RS 232

ZB4-2B3-KB1

RS 485

ZB4-2B3-KB2

a

5

2

3

PS4-150

PS4-200

PS4-300

a

3

2

5

PS416

햲

7

PS416

3

Figure 3: Sucom A communication cable

12/03 AWB-C27-1293GB

13

Page 18

Engineering

Suconet K protocol

Precondition: To operate MI4 units with Suconet K,

the ZB4-501-IF1 interface module must be

connected. The following MI4 units are delivered in

that state:

MI4-101-KC1 MI4-151-KF1 MI4-161-TC1

MI4-101-KE1 MI4-451-KF1 MI4-471-TC1

MI4-111-KE1 MI4-151-TA1

MI4-131-KH1 MI4-451-TA1

For all other devices, the Suconet K interface module

must be ordered and fitted separately (see

Section “Interface module”, page 30).

The connection to a PLC with the Suconet K protocol

is made through the AUX PORT of the MI4. The AUX

PORT supports RS 485 communication.

14

12/03 AWB-C27-1293GB

Page 19

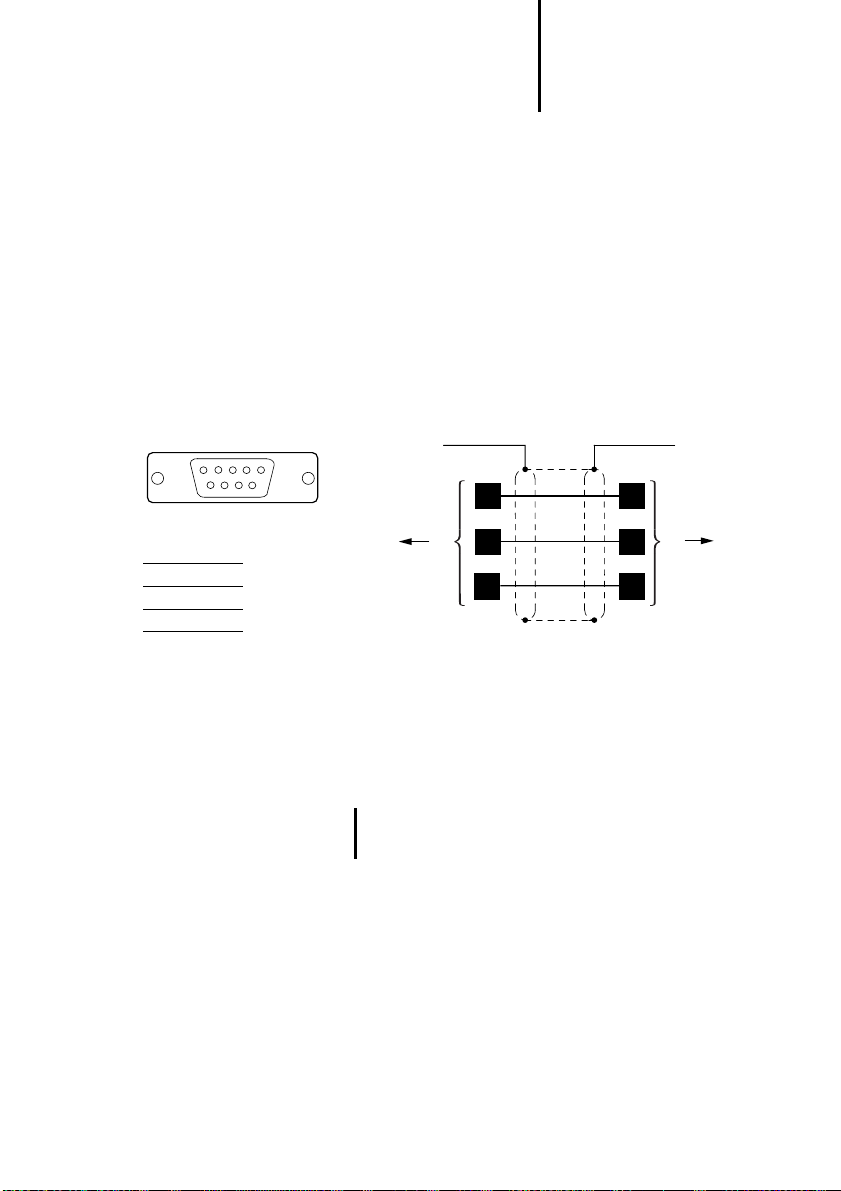

Connecting MI4 to PLC

AUX PORT

9

SUB D

3A

7B

햲 Connection to the data

plug housing

1

Q Plug

)

a

MI4

AUX PORT

a

MI4

AUX PORT

Figure 4: Assignment of the Suconet K communication

cable (cable with plug)

RS 485

7

3

ZB4-231-KB1

RS 485

3

7

ZB4-233-KB2

a

1

4

PS4-150

PS4-200

PS4-300

a

3

7

PS416

Bus termination with Suconet K

If the MI4 is the last station on a Suconet line, a

bus terminating resistor should be provided for

this device. The bus terminating resistor for the

MI4 is supplied as a plug and can be ordered

under the type designation ZB4-043-AD1

(Order No. 203512).

12/03 AWB-C27-1293GB

15

Page 20

Engineering

PROFIBUS-DP protocol

Precondition: To use the MI4 units with

PROFIBUS-DP, the ZB4-504-IF1/-IF2 interface

module must be connected (see Section “Interface

module”, page 30).

The connection to a PLC with the PROFIBUS-DP

protocol is made through the AUX PORT of the MI4.

The AUX PORT supports RS 485 communications.

AUX PORT

9

3RxD/TxD-P

5DGND

6VP (+5 V)

8RxD/TxD-N

1

SUB D

)

a

MI4

AUX PORT

햲 Connection to data plug housing

햳 ZB4-209-DS2

쎱 Plug

b

Figure 5: PROFIBUS-DP communication cable

RS 485

3

8

ZB4-900-KB1

Non-designated pin connectors may not be

assigned because they are specified in the

PROFIBUS-DP standard.

Cables and plugs must be ordered and assembled

separately.

Typ e

designation

Cable ZB4-900-KB1 206983

Plug ZB4-209-DS2 206982

3

8

Article No.

a

b

PS416-NET-440

LE4-504-BS1

16

12/03 AWB-C27-1293GB

Page 21

Connecting MI4 to PLC

Siemens MPI

Precondition: For communication through MPI, the

firmware version of the MI4 units must be 4.25 or

later. In addition, the ZB4-505-IF1/-IF2 interface

module (with/without potential isolation) must be

connected (see Section “Interface module”,

page 30).

The connection to a PLC with the MPI protocol is

made through the AUX PORT. The MI4 AUX PORT

supports RS 485 communication.

AUX PORT

9

SUB D

3B

5GND

8A

)

MI4

AUX PORT

a

5

bb

8

3

1

Figure 6: Siemens MPI communication cable

햲 Connection to data plug housing

햳 ZB4-209-DS2 plug

쎱 Plug

a

5

8

3

SPS/PLC/API

For communication through MPI, the

PROFIBUS-DP cable can also be used.

12/03 AWB-C27-1293GB

17

Page 22

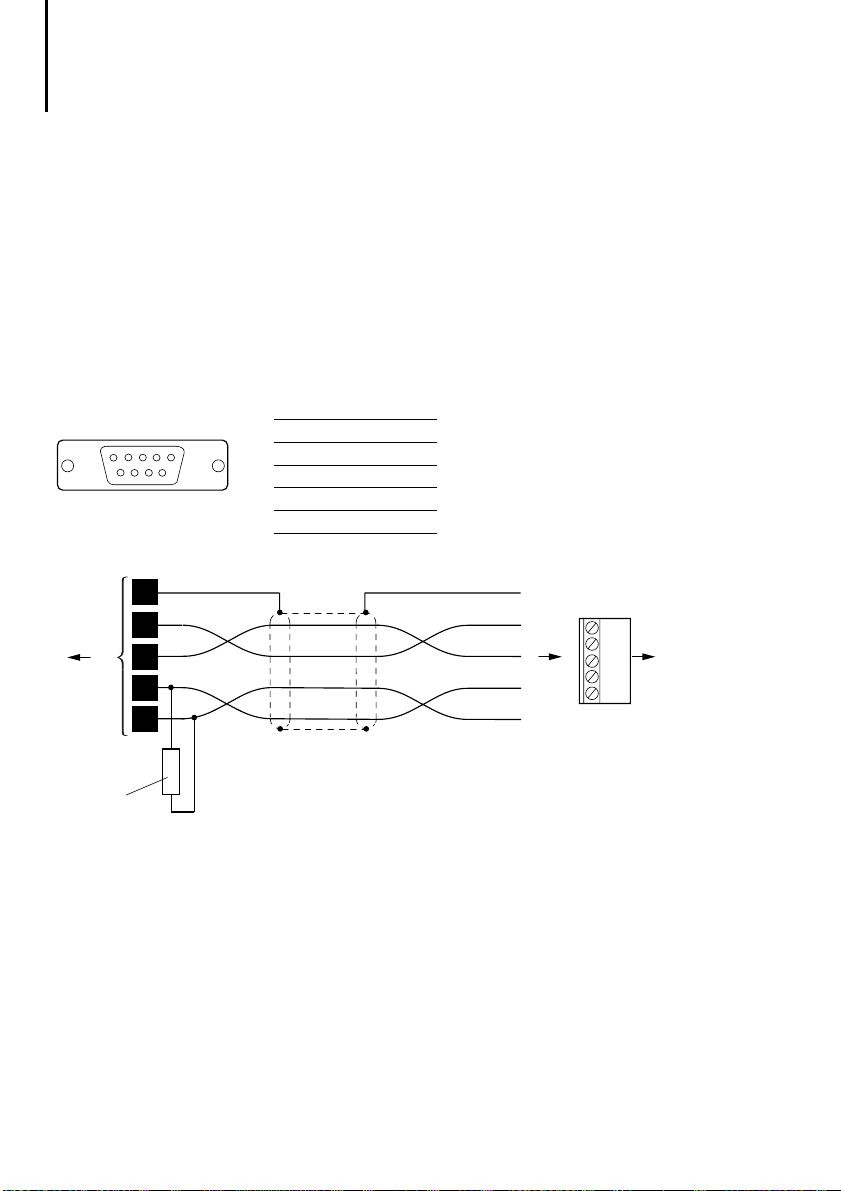

Engineering

DeviceNet

Precondition: For communication through

DeviceNet, the firmware version of the MI4 units

must be 4.40 or later. In addition, the ZB4-506-IF1

interface module must be connected (see

Section “Interface module”, page 30).

The connection to a PLC with the DeviceNet protocol

is made through the AUX PORT of the MI4. The AUX

PORT supports RS 485 communications.

MI4

AUX PORT

121 O G1 %

0.25 W

AUX PORT

9

a

b

SUB D

5

9

3

7

2

1

2CAN_L

3GND

5 CAN_SHLD

7CAN_H

9 +24 V (Input)

Bare

3

V+(red)

V-(black)

CAN_H(white)

CAN_L(blue)

1

5

2

1

3

4

4

5

2

DeviceNet

Figure 7: DeviceNet communication cable

햲 ZB4-209-DS1 plug

햳 Bus terminating resistor

18

12/03 AWB-C27-1293GB

Page 23

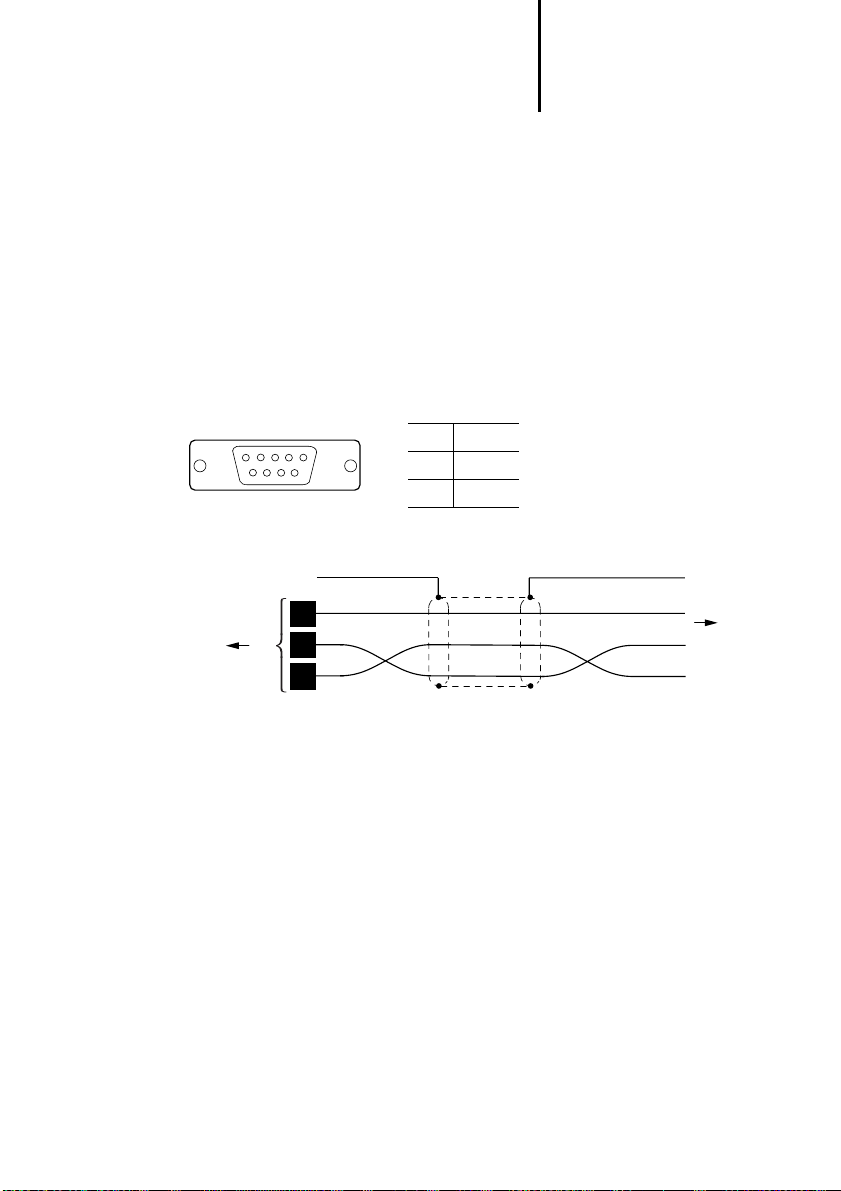

Connecting MI4 to PLC

CANopen

Precondition: For communication through CANopen,

the firmware version of the MI4 units must be 4.40 or

later. In addition, the ZB4-507-IF1 interface module

must be connected (see Section “Interface module”,

page 30).

The connection to a PLC with the CANopen protocol

is made through the AUX PORT of the MI4. The AUX

PORT supports RS 485 communications.

9

MI4

AUX PORT

AUX PORT

SUB D

a

1

2 CAN_L

6GND

7 CAN_H

FG

9

6

7

2

Figure 8: CANopen communication cable

햲 ZB4-209-DS1

FG

GND

CAN_H

CAN_L

CANopen

12/03 AWB-C27-1293GB

19

Page 24

Engineering

Connecting a PC or printer to the MI4

Depending on the device model, PCs are connected

either to the PC/PRINTER PORT or the PLC PORT of

the MI4. The different connection types are

described in the following sections.

The PC is connected to the interface for uploading or

downloading the configuration. To be configured

with a PC, the MI4 panels must be in configuration

mode.

Projects can also be downloaded to the graphic or

touch operator panels’ SSFDC memory card through

the ZB4-510-EG1 SSFDC charging device. This has

the advantage that the download is very fast.

The printer can be connected only to the

PC/PRINTER PORT. To connect a printer, set the

communication parameters in the MI4 Configurator

under “Project ➞ Report On Panel Printer ➞ Printer

Setup”.

20

12/03 AWB-C27-1293GB

Page 25

PC-/PRINTER PORT

Connecting a PC or printer

to the MI4

PC/PRINTER PORT

15

SUB D

Pin Function

2RxD

3TxD

a

1

PC/PRINTER PORT

PLC PORT*

10

RS 232

2

3

5

a

3

2

5

8

4 + 5 V (max. 100 mA)

5GND

11

7

10 RTS

11 CTS

ZB4-24A-KP1

햲 Connection to the data plug housing

* On MI4 units without PC/PRINTER PORT, the PC is connected to the PLC PORT

(see next section)

Q Plug qSocket

Figure 9: Assignment of the programming cable

PC

12/03 AWB-C27-1293GB

21

Page 26

Engineering

PLC PORT

On the following units, connect the PC to the PLC

PORT:

MI4-100-KC1, MI4-101-KC1, MI4-110-KC1,

MI4-110-KD1

MI4-100-KE1, MI4-101-KE1

MI4-110-KG1, MI4-130-TA1

Use the ZB4-24A-KP1 standard cable to connect the

PC. The required adapter is supplied as standard

with the cable.

PLC PORT

1

2

RxD

3

GND

5

RTS

10

11

CTS

TxD

SUB D

햲

MI 4

15

10

11

Adapter

2

3

5

RS 232

ZB 4-24A-KP1

Figure 10: MI4 – PC connection with adapter

햲 Connection to the data plug housing

QPlug qSocket

햲

3

2

PC

5

8

7

22

12/03 AWB-C27-1293GB

Page 27

Data interfaces of

MI4-140-KF1 (hand-held)

Data interfaces of

MI4-140-KF1

(hand-held)

Arrangement and assignment of the adapter extensions

The adapter extensions in the MI4 hand-held are

arranged as shown in the diagram below. For the

assignments of the adapter extensions, see Table 4:

CN2

CN1

CN5

123456789

10

123412 34 567 89

1234 123456789

10

10

CN3

CN4

12/03 AWB-C27-1293GB

Figure 11: Arrangement of the adapter extensions in the

MI4-140-KF1

23

Page 28

Engineering

)

Table 4: Assignment of the adapter extensions in the MI4

hand-held

The green fields indicate the adapter number

used for each connection.

Plug

No.

1

2

3

4

5

6

7

8

9

10

CN1 (AUX PORT)

Suconet K MPI

GND (brown/pink) CHA+ Reserved +24 V DC

+5 V output (max. 100 mA)

(orange/pink)

A (yellow/pink) B (yellow/pink) + 5 V output

B (green/pink) GND (grey) GND (black) – –

1)

A CHB– Reserved PE DM Left

CN2

(PC/PRINTER

PORT)

CHA– Reserved Common

CHB+ Reserved Reserved DM Left (cyan)

(max. 100 mA)

(green)

RxD (orange) RxD (blue/red) – –

CTS (brown) CTS (purple/

TxD (white) TxD (blue/black) – –

RTS (pink) RTS (purple/

1) The assignment of the AUX PORT depends on the

connected interface module. Currently, these are the

interface modules for Suconet K and Siemens MPI

(electrically isolated). For further information, please read

the next section.

CN3

(PLC PORT)

+ 5 V output

(max. 100 mA)

(red)

red)

black)

CN4

Power

(red)

(black)

––

––

––

CN5

Additional

signals

DM Right

(blue)

DM Right

(blue-black)

(cyan-black)

24

Delivery state

As supplied, the MI4 hand-held is prewired for

Suconet K and Sucom A communication. The unit is

supplied with a 5 m long cable. The respective

communication module must be ordered separately!

12/03 AWB-C27-1293GB

Page 29

CN2

123456789

Data interfaces of

MI4-140-KF1 (hand-held)

10

CN1

10

12341234 56789

CN5

CN3

1

10 9 8 74321 6 5432

CN4

a

c

b

Figure 12: Wiring of the MI4 hand-held as supplied

햲 PE, cable screen

햳 Emergency-Stop switch, only for voltages up to

48 V DC (wire yellow and green cable and brown and

orange cable together)

햴 Ferrite ring required for fault-free device function

12/03 AWB-C27-1293GB

25

Page 30

Engineering

Connect MI4

(hand-held) to PLC

Sucom A (through CN3)

PLC connection through Sucom A is preset (see

Section “Delivery state” above). The terminal

assignment on the PLC side is identical to that of the

PLC PORT; see page 13.

Suconet K (through CN1)

PLC connection through Suconet K is preset (see

Section “Delivery state” above). The terminal

assignment on the PLC side is identical to that of the

AUX PORT; see page 14.

CN 1.1 ------- (brown-pink) --------CN 1.2 ------- (orange-pink) -------CN 1.5 ------- (yellow-pink) ----------- Suconet K.3

CN 1.6 -------- (green-pink) ------------ Suconet K.7

Siemens MPI (through CN1)

If the ZB4-505-IF1 MPI communication cable is

connected, the CN1 AUX PORT must be rewired as

follows:

Plug No. 6 (green/pink) to plug No. 4 (see Section

“Delivery state” above)

The terminal assignment on the PLC side is identical

to that of the AUX PORT; see page 17.

Connecting the MI4 (hand-held) to PC or printer (through CN2)

26

CN 1.1 ------- (brown-pink) --------- MPI.5

CN 1.2 ------- (orange-pink) -------CN 1.4 ------- (yellow-pink) ----------MPI.8

CN 1.5 -------- (green-pink) -----------MPI.3

The PC connection is preset (see Section “Delivery

state” above).

The terminal assignment on the PC side is identical

to that of the PC/PRINTER PORT or the PLC-PORT;

see page 21.

12/03 AWB-C27-1293GB

Page 31

MI4

MI4-110-KC1

MI4-110-KD1

MI4-100-KC1

MI4-101-KC1

MI4-130-TA1

3 Installation

a

b

e

12/03 AWB-C27-1293GB

1/3

d

All other MI4-...

series

a

c

햲 Installation cut-

out

햳 Rectangular

gasket

햴 Narrow gasket

햵 Wide gasket

(prefitted on

some devices)

햶 Clamping

bracket (if not

present, see next

page)

27

Page 32

Installation

Devices without clamping bracket are mounted with

a frame and four screws.

햲 Frame

햶 Gaskets

햷 Washers

햹 Nuts

햺 Gasket

햹

햹

햷

햶

햺

햲

The drilling dimensions are listed in the table on

page 52.

28

12/03 AWB-C27-1293GB

Page 33

MI4-140-KF1

(hand-held)

MI4-140-KF1 (hand-held)

12/03 AWB-C27-1293GB

29

Page 34

Installation

Interface module MI4...

During installation of the interface module, the

)

MI4 must be voltage-free and its reverse side

freely accessible.

왘 Remove the fixing screws on the back of the MI4

and lift off the cover. On some models, the cover

has to only be levered off with a screwdriver.

왘 If a module is already fitted, remove it.

왘 Plug the required interface module into the red

connector.

왘 Refit the back cover with the two screws, or snap

the cover back into place.

왘 Attach the accompanying marking label over the

plate labelled AUX PORT.

30

ZB4-5xx-IF1/2

3

4

2

Figure 13: Installing the interface module

1

12/03 AWB-C27-1293GB

Page 35

Interface module

MI4-140-KF1 (hand-held)

왘 Undo the screws and remove the back of the

housing.

왘 Turn the back of the housing towards you and

replace the interface module.

2

4

12/03 AWB-C27-1293GB

3

ZB4-501-IF1

ZB4-505-IF1

1

31

Page 36

Installation

Replacing the battery The battery is used for maintaining the following data

in the event of a power supply failure:

Real-time clock (date and time)

Events list

Recipes

The MI4-101-KC1, MI4-100-KC1, MI4-101-KE1,

)

MI4-100-KE1, MI4-110-KC1 and MI4-110-KG2

units are not battery backed-up.

The battery life is about one year. The MI4 units

indicate a low battery charge level in several ways:

Flashing red front plate “FAULT”, “FLT” or

LEDs (depending on device model)

Display in the system menu in the “Battery” field

(BATTERY OK or LOW)

Indication in the control panel status word, bit S 6

(bit S 6 = signal 1)

Replace the battery immediately if any of these

displays is activated. Battery type: Duracell DL 2430

(ZB4-280-BT1, Order No. 203515).

32

)

An internal capacitor will maintain the power

supply for 30 seconds while the battery is being

replaced. If this time is exceeded, data will be

lost.

Replacing the battery of the MI4

왘 Switch off the power supply to the device.

왘 Undo the four screws at the back of the

expansion housing.

왘 Remove the housing.

12/03 AWB-C27-1293GB

Page 37

Replacing the battery

2

1

왘 Replace the battery.

3

ZB4-280-BT1

왘 Screw the housing back in place.

왘 Switch the power supply back on and check the

battery voltage.

12/03 AWB-C27-1293GB

33

Page 38

Installation

Replacing the battery of the MI4 hand-held

왘 Switch off the power supply.

왘 Undo the four screws at the back.

왘 Remove the housing.

2

34

1

왘 Replace the battery (see next page).

왘 Screw the housing back in place.

왘 Switch the power supply back on and check the

battery voltage.

12/03 AWB-C27-1293GB

Page 39

Insert labels

3

ZB4-280-BT1

Insert labels The insert labels are used for labelling the keys. You

can write on the labels and slide them beneath the

keys (row of keys). The insertion slit for the labels is

at the rear of the front panel. Depending on the

device type, two different labelling strip kits are

available:

12/03 AWB-C27-1293GB

ZB4-301-BS1 (Order No.

206859) for ...

MI4-100-KC1 MI4-110-KC1, -KD1

MI4-101-KC1 MI4-110-KG1

MI4-100-KE1 MI4-110-KG2

MI4-101-KE1 MI4-140-KI1

MI4-110-KE1 MI4-140-KJ1

MI4-130-KH1 MI4-150-KI1

MI4-131-KH1 MI4-450-KI1

MI4-151-KF1 MI4-170-KH1

MI4-151-KF1 MI4-570-KH1

MI4-451-KF1 MI4-140-TA1

MI4-151-TA1 MI4-150-TA1

MI4-451-TA1 MI4-450-TA1

MI4-161-TC1 MI4-550-TA1

MI4-471-TC1 MI4-160-TA1

ZB4-301-BS2 (Order No.

230610) for ...

MI4-470-TA1

MI4-570-TA1

MI4-580-TA1

MI4-590-TA1

35

Page 40

Installation

On delivery, blank label strips are fitted to each unit.

With the accompanying labelling software, you can

create user-specific labels and then print them on a

laser printer. The labelling software is included as

standard with the MI4 Configurator and can be

loaded via the Moeller homepage.

36

12/03 AWB-C27-1293GB

Page 41

4 Operation

Ambient conditions Do not expose the equipment to direct sunlight for

extended periods, as this could result in premature

aging of the membrane. Do not let the equipment

come into contact with corrosive substances.

Servicing and maintaining the panels

Do not use tools to operate the keyboard

(screwdriver or similar). To clean the equipment, use

a soft cloth and a neutral soap product. Do not use

solvents.

12/03 AWB-C27-1293GB

37

Page 42

Operation

Configuration Irrespective of the MI4 model, configuration of the

MI4 panels is always carried out using the MI4

configurator software. The completed configuration

is loaded into the MI4. The following conditions

apply:

The MI4 unit is in configuration mode

state).

The PC is connected to the MI4 unit.

The PC port (PORT) COM 1, COM 2, COM 3 or

COM 4 must first be selected in the Configurator

“Options/Communication” menu and the

communications parameters “Baud rate”,

“Parity” and “Stop bit” specified. Transfer rates of

9600, 19200 and 38400 bit/s

can be preselected:

1) If the device is not already in configuration mode,

do the following: Press the Enter key for three

seconds and, in the menu, select Config. On touch

operator panels, touch the screen for three seconds

and select Config.

1)

(delivery

38

)

With the ZB4-510-EG1 SSFDC downloader

(Order No. 230617), which can be connected to

the PC’s parallel port, the configuration settings

can be downloaded to the SSFDC memory card

in just a few seconds.

12/03 AWB-C27-1293GB

Page 43

Key functions

Key functions This section contains a listing of the possible key

functions of all MI4 panels.

Table 5: Possible key functions and their meaning

Keys/

symbols

Enter – Depending on the mode

Clr –

Info – Help

Clear – Delete

Ins – Insert

⫾

Designation Function

ESC Returns to page mode without

selecting ROW or EXIT in the system

menu

PG_UP In page mode, this function can be

defined with the help of the macro

editor

PG_DOWN

HOME

DATIME Date/time

PASSWORD Enter password

PRINT Print

– +/– Input a positive or negative value

12/03 AWB-C27-1293GB

With the numeric keys 0 to 9, you can input numerical

values. Some of the keys contain an additional

symbol. Depending on the operating mode, either

the numeric keypad or the symbols are active.

39

Page 44

Operation

)

Key functions depending on the operating mode

The functions are dependent on the operating mode.

Only the standard functions are described here.

These functions – with the exception of functions

available in configuration mode – can be modified,

deleted or extended in the MI4 Configurator using

the keyboard macro editor.

Some panels do not have a “Clear” key; the

corresponding function can, however, be called

up by simultaneously pressing the “←” and “→”

keys.

Configuration mode (CONFIG)

1

Enter

Enter Pressed for 2 seconds:

1

If you have programmed the Enter key by mistake, change

to configuration mode as follows:

On MI4 with touchscreen: With a finger of the left hand,

press the centre of the left half of the touchscreen. Keep

the finger on the touchscreen and switch the power supply

on. With a finger of the right hand, tap the right half of the

touchscreen once every second until configuration mode is

selected.

On MI4 without touchscreen: Keep any three keys pressed

at the same time and switch the 24 V power supply on.

Keep the keys pressed until the MI4 is in configuration

mode.

View the type and version of the

communication driver

Return to application mode, provided a

communication driver which is ready for

operation and a valid project have been

saved in the device (the key must be

pressed for two seconds).

40

12/03 AWB-C27-1293GB

Page 45

Key functions

Page mode (PAGES)

Scroll page up

Scroll page down

Previous page

Next page

Enter Pressed for 2 seconds:

Ins1) Data input mode

1)

Prn

1) Not all models have this key. The corresponding

function can be assigned with the keyboard macro

editor.

Recall the command menu

Print page/cancel printing

Command menu (COMMAND)

Selection up

Selection down

Selection left

Selection right

Enter Activate selection

Clear Return to page mode

12/03 AWB-C27-1293GB

41

Page 46

Operation

System menu (SYSTEM)

Selection up

Selection down

Activate command

Activate command

Enter Return to page mode if EXIT was selected

Clear Return to page mode

1) Numeric keys are not available on all models. A

numeric value can be entered in these cases using the

arrow keys and the keyboard macro editor. To do this,

use the left and right arrow keys to select the required

digits and change them with the up and down arrows.

42

12/03 AWB-C27-1293GB

Page 47

Key functions

Data entry mode

Select a data input field:

Go to field in the previous row

Go to field in the next row

Previous field

Next field

Ins (0 to 9)

Enter Select field for data input

Clear Cancel input and return to page mode

Value input:

0 to 9

Enter Confirm input and return to page mode

Clear Cancel input and return to page mode

1) If not present, see legend on page 42

1)

Preselection of data input field

Increase value/scroll up ASCII character set/select

previous message

Reduce value/scroll down ASCII character set/select

next message

Move cursor to the left in ASCII fields

Move cursor to the right in ASCII field

1)

Numerical input

12/03 AWB-C27-1293GB

Alarm mode (ALARMS)

Previous alarm in the list

Next alarm in the list

Enter Confirm current alarm (press for 2 seconds)

Clear Return to page mode

1)

Prn

1) Not all models have this key. The corresponding

function can be defined with the keyboard macro

editor.

Print/cancel alarm list

43

Page 48

Operation

Events mode (EVENTS)

Scroll up

Scroll down

Clear Return to page mode

1)

Prn

1) Not all models have this key. The corresponding

function can be defined with the keyboard macro

editor.

Print/close event list

Password input mode (PASSWORD)

Increases number

Decreases number

Next number

1)

0 to 9

Enter Confirms password

Clear Cancel input

1) If not present, see legend on page 42

Input of numerical password

44

Time and date input mode (TIME)

Increase field value

Decrease field value

Enter Select field

Clear Return to page mode

12/03 AWB-C27-1293GB

Page 49

Key functions

Direct page selection mode (DIRECT PAGE SELECTION)

Decreases page

Increases page

1)

0 to 9

Enter Confirm input, go to selected page

Clear Cancel input, return to page mode

1) If not present, see legend on page 42

Page number input

Direct access mode (ACCESS)

The status of individual marker bytes is shown in

hexadecimal and binary format.

Decrease offset

Increase offset

0 to 9 Numerical offset input

Enter Select next page, confirm offset input

Clear Cancel numerical offset input and return to

page mode

12/03 AWB-C27-1293GB

45

Page 50

Operation

Special features of models MI4-151-KF1 and

MI4-451-KF1

In addition to the ten function keys (which have insert

labels) these two models have another four function

keys located on the left of the display. Their

numbering is shown in the following drawing.

F14

F13

F12

F11

F1 F2 F3 F4 F5

F6 F7 F8 F9 F10

Figure 14: Additional function keys

46

12/03 AWB-C27-1293GB

Page 51

Key functions

Special features of models MI4-161-TC1/

MI4-471-TC1

F1/F3

F2/F4

shift

Figure 15: Additional function keys of MI4-161-TC1/

MI4-471-TC1

The configuration of the function keys is shown in the

diagram.

12/03 AWB-C27-1293GB

When the shift function is inactive, the top two

function keys are configured as F1 and F2.

When shift is activated they are configured as F3

and F4.

The shift function is activated or deactivated with the

Shift key. An illuminated LED in the shift key

indicates the activated state.

The LEDs of the two function keys can be configured

as required.

47

Page 52

Operation

LED indicators MI4-100-KC1/MI4-101-KC1

MI4-151-KF1/MI4-451-KF1

MI4-161-TC1/MI4-471-TC1

Designation Colour Status Function

DL FL(T)

(one LED)

– Off No key pressed/hardware

Green Flashing Communication error

On Key pressed

Red Flashing Battery low

On Hardware fault

MI4-100-KE1/MI4-101-KE1 MI4-110-KE1/MI4-111-KE1 MI4-130-KH1/MI4-131-KH1

Designation Colour Status Function

DL Green Off No key pressed

Flashing Communication error

On Key pressed

FLT/fault Red Off Hardware OK

Flashing Battery low

On Hardware fault

OK

48

MI4-151-TA1/MI4-451-TA1

Designation Colour Status Function

DL Green Off No keys pressed

On Key pressed

12/03 AWB-C27-1293GB

Page 53

LED indicators

Various models

LED indicators which are marked with a symbol or

text:

Symbol Designation Colour Status Function

Alarm Red Off No alarm active

On Alarm active

Flashing Alarm (confirmation required)

Com Green On Communication OK

Flashing Communication error

– Green – Programmable with macro editor

Run Green Off Hardware fault

On OK

Fault – Off Hardware OK

On Hardware fault

Flashing Battery low

Red Off Hardware OK

On Hardware fault

Flashing Battery low

Green Off No key pressed

On Key pressed

12/03 AWB-C27-1293GB

49

Page 54

Operation

The values in the table refer to the letters in the

drawings shown on the next page:

abcdef

MI4-110-KC1 149 109 60 5 136 96

MI4-110-KD1 149 109 53 5 136 96

MI4-110-KG1 141 176 76 5 128 163

MI4-110-KG2 141 176 76 5 128 163

MI4-140-KI1 220 176 71 5 207 163

MI4-140-KJ1 275 220 77 5 262 207

MI4-150-KI1 275 220 80 5 262 207

MI4-450-KI1 275 220 80 5 262 207

MI4-170-KH1 311 276 80 5 292 257

MI4-570-KH1 311 276 80 5 292 257

MI4-130-TA1 149 109 61 5 136 96

MI4-140-TA1 187 147 79 5 176 136

MI4-150-TA1 187 147 91 5 176 136

MI4-450-TA1 187 147 91 5 176 136

MI4-550-TA1 187 147 91 5 176 136

MI4-160-TA1 287 232 91 5 276 221

MI4-470-TA1 287 232 91 5 276 221

MI4-570-TA1 287 232 91 5 276 221

MI4-580-TA1 337 267 91 5 326 256

MI4-590-TA1 392 307 101 5 381 296

50

12/03 AWB-C27-1293GB

Page 55

Dimensions

Device dimensions

)

Appendix

See the left-hand page for the values

corresponding to device types.

b

Fitting dimensions

12/03 AWB-C27-1293GB

a

f

e

cd

51

Page 56

Operation

a

b

d

i

c

Panel Unit dimensions in mm Panel cutout

in mm

abcdef ghi

1)

MI 4-100-KC1

MI 4-101-KC1

MI 4-100-KE1

149 109 64 5 136 96 – – –

1)

195 98 74 8 174 78 184 87 4.2

MI 4-101-KE1

MI 4-110-KE1

195 98 74 8 174 78 184 87 4.2

MI 4-111-KE1

MI 4-130-KH1

MI 4-131-KH1

MI 4-151-KF1

1)

311 165 80 9 292 147 – – –

1)

216 168 74 8 195 147 205 157 4.2

MI 4-451-KF1

MI 4-151-TA1

216 168 74 8 195 147 205 157 4.2

MI 4-451-TA1

MI 4-161-TC1

MI 4-471-TC1

1)

311 220 80 9 292 202 – – –

1)

e

f

g

Drilling dimensions

[mm]

h

52

1) These models are secured with screw brackets and

have a fixed frame; the remaining models have a free

frame and are fastened with four screws.

12/03 AWB-C27-1293GB

Page 57

MI4-140-KF1

a

Dimensions

d

12/03 AWB-C27-1293GB

c

b

abcd

116 86 102 239

53

Page 58

Operation

Communication cables Text operator panel (without PC/PRINTER PORT)

RS 232/RS

485

PLC PORT MI4 AUX PORT

햲 Sucom A Suconet K

ZB4-24A-KP1

RS 232 RS 232 RS 232 RS 485 RS 485 RS 485

PC PS416-CPU PS4-150

ZB4-2B3-KB1

ZB4-2B7-KB1

PS416-CPU PS4-150

PS4-200

PS4-300

햲 Adapter, supplied as standard with ZB4-24A-KP1

cable.

햳 Other interface module can be connected in place of

the Suconet K interface module:

PROFIBUS-DP ZB4-504-IF1/-IF2

Siemens MPI ZB4-505-IF1/-IF2

DeviceNet ZB4-506-IF1

CANopen ZB4-507-IF1

For cable assignments of these interfaces, see section

“Engineering”. For an overview, see page 12.

(ZB4-501-IF1)

ZB4-2B3-KB2

PS4-200

PS4-300

ZB4-231-KB1

Other

interface

modules

ZB4-233-KB2

PS416 XC100/

200/600

NonMoeller

devices

햳

54

12/03 AWB-C27-1293GB

Page 59

Communication cables

Text operator panel (with PC/PRINTER PORT) Graphic/touch operator panel

RS 232 RS 232/RS 485

PC/PRINTER

PORT

ZB4-24A-KP1

RS 232 RS 232 RS 232 RS 485 RS 485 RS 485

PC PS416-CPU PS4-150

MI4 PLC PORT AUX PORT

Sucom A Suconet K* Other

ZB4-2B3-KB1

PS4-200

PS4-300

ZB4-2B7-KB1

PS416-CPU PS4-150

ZB4-2B3-KB2

PS4-200

PS4-300

ZB4-231-KB1

interface

modules

PS416 XC100/

햲

ZB4-233-KB2

200/600

Non-

Moeller

devices

12/03 AWB-C27-1293GB

햲 Other interface modules can be connected in place of

the Suconet K module:

PROFIBUS-DP ZB4-504-IF1

Siemens MPI ZB4-505-IF1/-IF2

DeviceNet ZB4-506-IF1

CANopen ZB4-507-IF1

For cable assignments of these interfaces, see section

“Engineering”. For an overview, see page 12.

* The following units are supplied with a fitted Suconet-K

interface (ZB4-501-IF1):

MI4-101-KC1

MI4-101-KE1/MI4-111-KE1

MI4-131-KH1

MI4-151-KF1/MI4-451-KF1

MI4-151-TA1/MI4-451-TA1

MI4-161-TC1/MI4-471-TC1

55

Page 60

Operation

Technical data

General

Standards EN 61 131-2, EN 50 178

Shock resistance 15 g/11 ms

Vibration resistance Constant 1g, f = 0 to 150 Hz

Cable cross-section 0.22 to 1.5 mm

EMC See below

Ports

PC/PRINTER PORT

Type RS 232

Transmission rate 600 to 38400 kbit/s

Plug type 15-pin, Sub-D socket

PLC PORT

PLC/PC PORT

Type RS 232, RS 485

Plug type 15-pin, Sub-D plug

AUX PORT

Type Depending on connected

interface module

Plug type 9-pin, Sub-D socket

2

General electromagnetic compatibility (EMC) data for automation devices

Emitted interference EN 55 011/22 Class A

Interference immunity

ESD EN 61 000-4-2 Contact discharge

RFI EN 61 000-4-3 AM/PM 10 V/m

Burst EN 61 000-4-4 Network/digital I/O

Surge EN 61 000-4-5 Digital O/O, asymmetrical

Line-conducted

interference

EN 61 000-4-6 AM 10 V

Air discharge

Analog I/O, field bus

Network DC, asymmetrical

Network DC, symmetrical

Network AC, asymmetrical

Network AC, symmetrical

56

4 kV

8 kV

2 kV

1 kV

0.5 kV

1 kV

0.5 kV

2 kV

1 kV

12/03 AWB-C27-1293GB

Page 61

12/03 AWB-C27-1293GB

Text operator panel (not graphics-capable)

MI4-...

100-KC1 101-KC1 100-KE1 101-KE1 110-KE1 111-KE1 130-KH1 131-KH1

Display Monochrome

Backlighting LED LED LED LED LED LED LED LED

Contrast adjustment Software Software Software Software Software Software Software Software

Graphics capability No No No No No No No No

Number of colours/

grey levels

Rows x characters 2 x 20 2 x 20 2 x 20 2 x 20 4 x 20 4 x 20 4 x 40 4 x 40

Display dimensions in

mm

Scaleable font No No No No No No No No

User-definable

characters

Keys

Numeric keypad – – Yes Yes Yes Yes Yes Yes

F-keys (with LED),

labelling facility

Total no. of userprogrammable keys

User LEDs 4499991616

Touch function––––––––

LCD

––––––––

80 x 16 80 x16 72 x 16 72 x 16 72 x 24 72 x 24 138 x 28 138 x 28

88888888

4499991616

10 10 19 19 19 19 35 35

57

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Technical data

Page 62

58

MI4-...

100-KC1 101-KC1 100-KE1 101-KE1 110-KE1 111-KE1 130-KH1 131-KH1

Memory

Flash project memory 128 kb (32 kb reserved for protocol)

Recipe memory – – – – 16 kb 16 kb 16 kb 16 kb

Project memory

expansion

Special features

Battery – – – – Yes Yes Yes Yes

Number of alarm

messages

Number of history

memory messages

Number of variables per

page

Pa ss wo rd Ye s Ye s Yes Ye s Ye s Ye s Ye s Yes

Real-time clock Yes, without battery back-up Yes Yes Yes Yes

Screen saver––––––––

Buzzer ––––––––

Printer port ––––YesYesYesYes

– – – – 512 kb 512 kb 512 kb 512 kb

256 256 256 256 1024 1024 1024 1024

– – – – 256 256 256 256

Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

Operation

12/03 AWB-C27-1293GB

Page 63

12/03 AWB-C27-1293GB

Ports

RS 232C/RS 485 combination port for:

- Sucom A Yes Yes Yes Yes Yes Yes Yes Yes

- Configuration Yes Yes – – Yes Yes – –

RS232C port for:

- Configuration – – Yes Yes Yes Yes

- Printer connection – – – – Yes Yes Yes Yes

1 fieldbus interface, plug-in modules for:

- Suconet K Yes Yes, plugged inYes Yes, plugged inYes Yes, plugged inYes Yes, plugged

- PROFIBUS-DP Yes Yes Yes Yes Yes Yes Yes Yes

- Siemens MPI Yes Yes Yes Yes Yes Yes Yes Yes

- DeviceNet Yes Yes Yes Yes Yes Yes Yes Yes

- CANopen Yes Yes Yes Yes Yes Yes Yes Yes

Power supply

Rated voltage 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC

Permissible range (V DC) 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8

Reverse polarity

protection

Rated current 250 mA 250 mA 250 mA 250 mA 250 mA 250 mA 400 mA 400 mA

Fuses Electronic Electronic 2 A

59

MI4-...

100-KC1 101-KC1 100-KE1 101-KE1 110-KE1 111-KE1 130-KH1 131-KH1

in

Yes Ye s Ye s Ye s Ye s Yes Ye s Ye s

replaceable

2 A

replaceable

2 A

replaceable

2 A

replaceable

2 A

replaceable

2 A

replaceable

Technical data

Page 64

60

MI4-...

100-KC1 101-KC1 100-KE1 101-KE1 110-KE1 111-KE1 130-KH1 131-KH1

General

Weight in kg 0.8 0.8 1 1 1 1 1.9 1.9

Degree of protection

(front) IP65

Ambient temperature in °C0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50

Storage temperature in °C–20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70

Yes Ye s Ye s Ye s Ye s Yes Ye s Ye s

Operation

Keyboard lifespan

(keystrokes)

Touchscreen lifespan

(operations)

Cable cross-section in

mm²

Connection type: Plug-in

screw terminal

Dimensions W x H x D in mm149 x 109 x 64149 x 109 x 64195 x 98 x 74195 x 98 x 74195 x 98 x 74 195 x 98 x 74 311 x 165 x 80311 x 165 x

12/03 AWB-C27-1293GB

> 3 million > 3 million > 3 million > 3 million > 3 million > 3 million > 3 million > 3 million

––––––––

1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5

Yes Ye s Ye s Ye s Ye s Yes Ye s Ye s

80

Page 65

12/03 AWB-C27-1293GB

Graphics-capable text operator panel

MI4-...

110-KC1 110-KD1 110-KG2 110-KG1 140-KF1 140-KI1 140-KJ1

Display Monochrome

Backlighting LED LED LED LED LED LED LED

Contrast adjustment Software Software Software Software Software Software Software

Graphics capability Yes Yes Yes Yes Yes Yes Yes

Number of colours/grey

levels

Rows x characters 4 x 20 4 x 20 4 x 20 4 x 20 8 x 20 8 x 40 8 x 40

Resolution in pixels 120 x 32 120 x 32 120 x 32 120 x 32 120 x 64 240 x 64 240 x 64

Display dimensions 70 x 21 mm 70 x 21 mm 70 x 21 mm 70 x 21 mm 66 x 33 mm 127 x 34 mm 127 x 34 mm

Scaleable font Yes Yes Yes Yes Yes Yes Yes

User-definable

characters

Keys

Numeric keypad – Yes Yes Yes Yes Yes Yes

F-keys (with LED),

labelling facility

Total number of userprogrammable keys

Electromechanical

keypads can be fitted

User LEDs 4 1013 13212432

61

Touch function

LCD

––– ––––

256 256 256 256 256 256 256

4 9 12 12 9 23 23

11 19 35 35 27 46 46

––– –––Yes

––– ––––

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Monochrome

LCD

Technical data

Page 66

62

MI4-...

110-KC1 110-KD1 110-KG2 110-KG1 140-KF1 140-KI1 140-KJ1

Memory

Flash project memory 512 kb 512 kb 512 kb 512 kb 512 kb 512 kb 512 kb

Recipe memory – 16 kb – 16 kb 16 kb 16 kb 16 kb

Project memory

expansion

Special features

Ba tt er y – Yes – Yes Yes Yes Ye s

Number of alarm

messages

Number of history

memory messages

Number of variables per

page

Pa ss wo rd Ye s Yes Yes Ye s Yes Yes Yes

Real-time clock Yes, without

Screen saver––– ––––

Buzzer ––– ––––

Printer port – – – Yes Yes Yes Yes

– – 512 kb 512 kb – 512 kb 512 kb

256 1024 256 1024 1024 1024 1024

– 256 – 256 256 256 256

Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

back-up

Yes Yes, without

back-up

Yes Yes Yes Yes

Operation

12/03 AWB-C27-1293GB

Page 67

12/03 AWB-C27-1293GB

Ports

RS232C/RS485 combination port for:

- Sucom A Yes Yes Yes Yes Yes Yes Yes

- Configuration Yes Yes Yes – – – –

RS232C port for:

- Configuration – – – Yes Yes Yes Yes

- Printer connection – – – Yes Yes Yes Yes

1 fieldbus interface, plug-in modules for:

- Suconet K Yes Yes Yes Yes Yes Yes Yes

- P R O F IBUS-D P Yes Yes Ye s Yes No Ye s Yes

- Siemens MPI Yes Yes Yes Yes Yes Yes Yes

- D e v i ceNet Ye s Yes Yes Yes No Yes Yes

- C A N o p en Yes Ye s Yes Yes No Ye s Yes

Power supply

Rated voltage 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC

Permissible range (V DC) 18 to 30 18 to 30 18 to 30 18 to 30 18 to 30 18 to 30 18 to 30

Reverse polarity

protection

Rated current 250 mA 250 mA 300 mA 300 mA 300 mA 400 mA 400 mA

Fuses Electronic Electronic Electronic Electronic Electronic Electronic Electronic

MI4-...

110-KC1 110-KD1 110-KG2 110-KG1 140-KF1 140-KI1 140-KJ1

Technical data

Yes Ye s Ye s Ye s Yes Ye s Ye s

63

Page 68

64

MI4-...

110-KC1 110-KD1 110-KG2 110-KG1 140-KF1 140-KI1 140-KJ1

General

Weight in kg 1 1 1.1 1.1 1.5 incl. cable 2 2

Degree of protection

(front) IP65

Ambient temperature in °C0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50

Storage temperature in °C–20 to +70 –20 bis +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70

Yes j a Ye s Ye s Yes Ye s Ye s

Operation

Keyboard lifespan

(keystrokes)

Touchscreen lifespan

(operations)

Cable cross-section in

mm²

Connection type, plug-in

screw terminal

Dimensions in mm 149 x 109 x 60149 x 109 x 58141 x 176 x 76 141 x 176 x 76116 x 239 x

12/03 AWB-C27-1293GB

> 3 million > 3 Mio > 3 million > 3 million > 3 million > 3 million > 3 million

––– ––––

1 x 1.5 1 x 1,5 1 x 1.5 1 x 1.5 Open

cable end

Yes j a Ye s Ye s – Ye s Ye s

102

1 x 1.5 1 x 1.5

220 x 176 x 71275 x 220 x

77

Page 69

12/03 AWB-C27-1293GB

Graphic operator panels

MI4-151-KF1 MI4-451-KF1 MI4-150-KI1 MI4-450-KI1 MI4-170-KH1 MI4-570-KH1

Display Monochr. LCD Colour LCD-STN Monochr. LCD Colour LCD-STN Monochr. LCD TFT

Backlighting CCFL CCFL CCFL CCFL CCFL CCFL

Contrast adjustment Autom. Autom. Software Software Software Software

Graphics capability Yes Yes Yes Yes Yes Yes

Number of colours/grey levels – 16 – 16 – 256

Rows x characters 16 x 40 16 x 40 16 x 40 16 x 40 30 x 80 30 x 80

Resolution in pixels 320 x 240 320 x 240 320 x 240 320 x 240 640 x 480 640 x 480

Display dimensions in mm 121 x 91/5.6" 121 x 91/5.6" 121 x 91/5.6" 121 x 91/5.6" 212 x 159/10,4“

Scaleable font Yes Yes Yes Yes Yes Yes

User-definable characters 256 256 256 256 256 256

Keys

Numeric keypad Yes Yes Yes Yes Yes Yes

F-keys (with LED), labelling facility 10 10 33 (24 – 33 no LED) 23 23

65

Total number of user-programmable

keys

User LEDs 10 10 24 24 24 24

Touch function – – – – – –

Memory

Flash project memory 512 kb (64 kb reserved for protocol) 8 MB SSFDC card 8 MB SSFDC card

Recipe memory 32 kb 32 kb 32 kb 32 kb 32 kb 32 kb

37 37 56 56 50 50

Technical data

Page 70

66

MI4-151-KF1 MI4-451-KF1 MI4-150-KI1 MI4-450-KI1 MI4-170-KH1 MI4-570-KH1

Project memory expansion 512 kb 512 kb – – – –

Special features

Battery Yes Yes Yes Yes Yes Yes

Number of alarm messages 1024 1024 1024 1024 1024 1024

Number of history memory messages 1024 1024 1024 1024 1024 1024

Number of variables per page Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

Password Yes Yes Yes Yes Yes Yes

Real-time clock Yes Yes Yes Yes Yes Yes

Screen saver Yes Yes Yes Yes Yes Yes

Buzzer – – – – – –

Printer port Yes Yes Yes Yes Yes Yes

Ports

RS232C/RS485 combination port for:

- Sucom A Yes Yes Yes Yes Yes Yes

- Configuration – – – – – –

RS232C port for:

- Configuration Yes Yes Yes Yes Yes Yes

- Printer connection Yes Yes Yes Yes Yes Yes

1 fieldbus interface, plug-in modules for:

- Suconet K Plugged in Plugged in Yes Yes Yes Yes

- PROFIBUS-DP Yes Yes Yes Yes Yes Yes

- Siemens MPI Yes Yes Yes Yes Yes Yes

- DeviceNet Yes Yes Yes Yes Yes Yes

Operation

12/03 AWB-C27-1293GB

Page 71

12/03 AWB-C27-1293GB

- CANopen Yes Yes Yes Yes Yes Yes

Power supply

Rated voltage 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC

Permissible range 20.4 to 28.8 V DC20.4 to 28.8 V DC 18 to 30 V DC 18 to 30 V DC 18 to 30 V DC

Reverse polarity protection Yes Yes Yes Yes Yes Yes

Rated current 500 mA 500 mA 600 mA 600 mA 700 mA 700 mA

Fuses 2 A replaceable 2 A replaceable 2 A replaceable 2 A replaceable electronic electronic

General

Weight in kg 1.4 1.4 1.9 1.9 2.5 2.5

Degree of protection (front) IP65 Yes Yes Yes Yes ja ja

Ambient temperature in °C 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50 0 – 50

Storage temperature in °C –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70

Keyboard lifespan (keystrokes) > 3 million > 3 million > 3 million > 3 million > 3 million > 3 million

Touchscreen lifespan (operations) – – – – – –

Cable cross-section in mm² 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5

Connection type

(plug-in screw terminal)

Dimensions W x H x D in mm 216 x 168 x 74 216 x 168 x 74 275 x 220 x 80 275 x 220 x 80 311 x 276 x 80 311 x 276 x 80

MI4-151-KF1 MI4-451-KF1 MI4-150-KI1 MI4-450-KI1 MI4-170-KH1 MI4-570-KH1

Technical data

Yes Yes Yes Yes Yes Yes

67

Page 72

68

Touch operator panels

MI4-...

151-TA1*

451-TA1**

161-TC1 471-TC1 130-TA1 140-TA1*

150-TA1*

450-TA1**

160-TA1*

470-TA1**

570-TA1***

550-TA1***

Display Monochr.*

colour STN**

Backlighting CCFL CCFL CCFL LED LED*

Contrast adjustment autom. Software Software Software Software*

Monochrome colour TFT Monochr. Monochr. *

colour STN**

colour TFT***

,

CCFL**

–***

***

Monochr.*

colour STN**

colour TFT***

CCFL CCFL

,

**

Software*, **

–***

Graphics capability Yes Yes Yes Yes Yes Yes Yes

Number of colours/grey levels –*

16**

256 256 – –*

16**

–*

256**

,

***

256***

Rows x characters 16 x 40 25 x 80 30 x 80 16 x 40 16 x 40 30 x 80 40 x 100*

Resolution in pixels 320 x 240 640 x 400 640 x 480 320 x 240 320 x 240 640 x 480 800 x 600*

Display dimensions in mm 121 x 91

5.6“

194 x 121

9.6"

212 x 159

10.4"

77 x 58

3.8“

121 x 91

5.6“

196 x 147.6/9.6“ *

218 x 159/10.4“ **

,

***

Scaleable font Yes Yes Yes Yes Yes Yes Yes

User-definable characters 256 256 256 256 256 256 256

Operation

580-TA1*

590-TA1**

colour TFT

–

256

48 x 128**

1024 x 768**

246 x 184/12.1“ *

304 x 228/15“ **

12/03 AWB-C27-1293GB

Page 73

12/03 AWB-C27-1293GB

MI4-...

151-TA1*

451-TA1**

161-TC1 471-TC1 130-TA1 140-TA1*

150-TA1*

450-TA1**

160-TA1*

470-TA1**

570-TA1***

550-TA1***

Keys

Numeric keypad – – – – – – –

F-keys (with LED), labelling

–22–– – –

facility

Total no. of user-

–99–– – –

programmable keys

User LEDs – 3 3 – – – –

Touch function Resistive Resistive Resistive Resistive Resistive Resistive Resistive

Memory

Flash project memory 512 kb 512 kb 8 MB SSFDC

Karte

512 kb 8 MB SSFDC

Karte

8 MB SSFDC Karte 8 MB SSFDC Karte

64 kb reserved for protocol

Recipe memory 32 kb 32 kb 32 kb 32 kb 32 kb 32 kb 32 kb

Project memory

expansion

1)

512 kb 512 kb 512 kb – – – –

Special features

2)

Battery

Yes Yes Ye s – Ye s Ye s Yes

Number of alarm messages 1024 1024 1024 1024 1024 1024 1024

Number of history memory

1024 1024 1024 256 1024 1024 1024

messages

Number of variables per page unlimited unlimited unlimited unlimited unlimited unlimited

Pa ss wo rd Ye s Yes Yes Ye s Yes Yes Ye s

69

Real-time clock Yes Yes Yes Yes Yes Yes Yes

580-TA1*

590-TA1**

Technical data

Page 74

70

MI4-...

151-TA1*

451-TA1**

Screen saver Yes Yes Yes Yes Yes Yes Yes

Buzzer Yes Yes Yes – Yes Yes Yes

Pri n t er port Yes Ye s Ye s – Ye s Yes Yes

Ports

RS232C/RS485 combination

port for:

- Sucom A Yes Yes Yes Yes Yes Yes Yes

- Configuration – – – Yes – – –

RS232C port for:

- Configuration Yes Yes Yes – Yes Yes Yes

- Printer connection Yes Yes Yes – Yes Yes Yes

1 fieldbus interface, plug-in

modules for:

- Suconet K Plugged in Plugged in Plugged in Yes Yes Yes Yes

-PROFIBUS-DP Yes Yes Yes Yes Yes Yes Yes

- Siemens MPI Yes Yes Yes Yes Yes Yes Yes

- DeviceNet Yes Yes Yes Yes Yes Yes Yes

- CANopen Yes Yes Yes Yes Yes Yes Yes

Power supply

Rated voltage 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC

Permissible range (V DC) 20.4 to 28.8 20.4 to 28.8 20.4 to 28.8 18 to 30 18 to 30 18 to 30 18 to 30

161-TC1 471-TC1 130-TA1 140-TA1*

150-TA1*

450-TA1**

550-TA1***

160-TA1*

470-TA1**

570-TA1***

Operation

580-TA1*

590-TA1**

12/03 AWB-C27-1293GB

Page 75

12/03 AWB-C27-1293GB

MI4-...

151-TA1*

451-TA1**

161-TC1 471-TC1 130-TA1 140-TA1*

150-TA1*

450-TA1**

160-TA1*

470-TA1**

570-TA1***

550-TA1***

Reverse polarity protection Yes Yes Yes Yes Yes Yes Yes

Rated current 500 600 1000 400 600 600*

700**

,

***

Fuses 2 A replaceable Electronic Electronic Electronic

General

Weight in kg 1.4 2.7 2.7 1 1.4 2.25 2.85*, 3.85**

Degree of protection (front)

Yes Ye s Ye s Yes Yes Yes Ye s

IP65

Ambient temperature 0 – 50 °C 0 – 50 °C 0 – 50 °C 0 – 50 °C 0 – 45 °C 0 – 45 °C 0 – 45 °C

Storage temperature in °C –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70 –20 to +70

Keyboard lifespan (keystrokes) – – – – – – –

Touchscreen lifespan

(operations)

> 1 million > 1 million > 1 million > 3

million

> 3 million > 3 million > 3 million

Cable cross-section in mm² 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5 1 x 1.5

Connection type (plug-in

Yes Ye s Ye s Yes Yes Yes Ye s

screw terminal)

Dimensions W x H x D in mm 216 x 168 x 74311 x 220 x 80311 x 220 x 80149 x 109

187 x 147 x 96

3)

287 x 232 x 96 337 x 267 x 96*

x 61

580-TA1*

590-TA1**

800*

1200**

Technical data

392 x 307 x 106**

1 Upgradeable with ZB4-512-SF1 memory module

2 3 V lithium, non-rechargeable, lifespan about 1 year, replaceable, replacement item ZB4-280-BT1

3 Bei MI4-140-TA1: T = 79 mm

71

Page 76

Operation

New features

All the new features available in MI4 models from

firmware version 4.40 and 4.50, are listed in the

following table.

1)

Device firm ware

Trend displays and pointer-type instruments

Pop-up keypads

Variables

Min./Max. variable setpoint values

Expanded font support

Recipe back-up

SSFDC memory card

Automatic firmware upgrade

Pixel and vector graphics

MI4-100-KC1 32 jj

MI4-101-KC1 32 jj

MI4-110-KC1 32 jj

MI4-110-KD1 52 jj

MI4-100-KE1 32 jj

MI4-101-KE1 32 jj

MI4-110-KE1 32 jj

MI4-111-KE1 32 jj

MI4-110-KG1 32 jj

MI4-110-KG2 32 jj

MI4-130-KH1 32 jj

MI4-131-KH1 32 jj

MI4-140-KI1 32 jj

MI4-140-KJ1 32 jj

MI4-140-KF1 32 jj

MI4-151-KF1 33 jj

72

12/03 AWB-C27-1293GB

Page 77

Technical data

Device firm ware

Trend displays and pointer-type instruments

Pop-up keypads

Variables

Min./Max. variable setpoint values

Expanded font support

Recipe back-up

SSFDC memory card

MI4-151-TA1 33

MI4-161-TC1 33 jj

MI4-451-KF1 37 jj

MI4-451-TA1 37 jj

MI4-150-KI1 38

MI4-450-KI1 38

MI4-170-KH1 58

MI4-570-KH1 58

MI4-471-TC1 38

MI4-130-TA1 53

MI4-140-TA1 38

MI4-450-TA1 38

MI4-150-TA1 38

MI4-550-TA1 58

MI4-570-TA1 58

MI4-470-TA1 58

MI4-160-TA1 58

MI4-580-TA1 58

MI4-590-TA1 58

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

jj

jj

jj

jj

jj

j

j

j

j

j

jj

jj

jj

jj

jj

jj

j

j

j

j

j

j

j

j

j

j

j

j

j

jj

jj

j

j

j

j

jj

jj

jj

jj

jj

jj

1)

Automatic firmware upgrade

j

j

j

j

j

j

j

j

Pixel and vector graphics

12/03 AWB-C27-1293GB

1) from firm ware 4.50

73

Page 78

74

12/03 AWB-C27-1293GB

Page 79

Index

A

Ambient conditions ........................................................ 37

AUX PORT

Function ........................................................................ 7

Terminal assignment .......................... 14, 16, 17, 18, 19

B

Baud rate ....................................................................... 38

Bus termination with Suconet K .................................... 15

C

Cleaning ......................................................................... 37

Communication cables, overview .................................. 54

CONFIG ......................................................................... 40

Configuration ................................................................. 38

Connection diagram ........................................................ 9

Connections ..................................................................... 9

D

Data connections, MI4 ................................................... 12

Data interface, MI4 hand-held ....................................... 23

Data transfer rate ........................................................... 38

Date input mode ............................................................ 44

Delivery state, MI4 hand-held ........................................ 24

Device dimensions ................................................... 51, 52

Dimensions .................................................................... 51

DL ................................................................................... 48

Documentation, MI4 ........................................................ 3

Drilling dimensions ......................................................... 52

12/03 AWB-C27-1293GB

E

Earthing

0 volt cable ................................................................. 11

Data plug .................................................................... 11

Panel housing ............................................................. 11

Power supply plugs .................................................... 11

Electromagnetic compatibility ....................................... 56

Engineering ...................................................................... 9

75

Page 80

Index

F

Features ............................................................................ 6

Fitting dimensions .......................................................... 51

FLT ................................................................................. 48

Function keys, additional

MI 4-151-KF1, MI 4-451-KF1 ..................................... 46

MI 4-161-TC1, MI 4-471-TC1 ..................................... 47

G

Grounding ......................................................................... 9

I

Insert labels .................................................................... 35

Installation

Interface module ......................................................... 30

MI4 .............................................................................. 27

MI4 (hand-held) ........................................................... 29

Installing the interface module .......................................30

K

Key assignment

In alarm mode (ALARMS) ........................................... 43

In configuration mode ................................................. 40

In data entry mode ...................................................... 43

In direct access mode (ACCESS) ............................... 45

In events mode (EVENTS) ........................................... 44

In page mode .............................................................. 41

In page selection mode, direct ................................... 45

In password input mode ............................................. 44

In the Command menu ............................................... 41

In the System menu .................................................... 42

In time input mode ...................................................... 44

Key functions .................................................................. 39

76

L

LEDs ............................................................................... 48

Lifespan, battery ............................................................. 32

M

Maintaining ..................................................................... 37

O

Operation ........................................................................ 37

12/03 AWB-C27-1293GB

Page 81

Index

P

Panel cutout ................................................................... 52

Panel overview ................................................................. 5

PASSWORD ................................................................... 44

PC, connecting .............................................................. 20

PC/PRINTER PORT

Function ........................................................................ 7