Page 1

Industrial AutomationBuilding Automation Systems

User Manual

MFD-CP4

Power supply/

Communication module

10/04 AWB2528-1548GB

Think future. Switch to green.

Page 2

All brand and product names are trademarks or registered

trademarks of the owner concerned.

st

published 2004, edition date 10/04

1

© Moeller GmbH, 53105 Bonn

Authors: Dieter Bauerfeind, Jörg Mattke

Editor: Thomas Kracht

Translator: Terence Osborn

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or

processed, duplicated or distributed by means of electronic

systems without written permission of Moeller GmbH, Bonn.

Page 3

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally

restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that

are live.

• Follow the engineering instructions (AWA)

of the device concerned.

• Only suitably qualified personnel in

accordance with EN 50110-1/-2

(VDE 0105 Part 100) may work on this

device/system.

• Before installation and before touching

the device ensure that you are free of

electrostatic charge.

• The functional earth (FE) must be

connected to the protective earth (PE) or

to the potential equalisation. The system

installer is responsible for implementing

this connection.

• Connecting cables and signal lines should

be installed so that inductive or capacitive

interference does not impair the

automation functions.

• Install automation devices and related

operating elements in such a way that they

are well protected against unintentional

operation.

• Suitable safety hardware and software

measures should be implemented for the

I/O interface so that a line or wire breakage

on the signal side does not result in

undefined states in the automation

devices.

• Ensure a reliable electrical isolation of the

low voltage for the 24 volt supply. Only

use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or

HD 384.4.41 S2.

• Deviations of the mains voltage from the

rated value must not exceed the tolerance

limits given in the specifications, otherwise

this may cause malfunction and dangerous

operation.

•Emergency stop devices complying with

IEC/EN 60204-1 must be effective in all

operating modes of the automation

devices. Unlatching the emergency-stop

devices must not cause restart.

• Devices that are designed for mounting in

housings or control cabinets must only be

operated and controlled after they have

been installed with the housing closed.

Desktop or portable units must only be

operated and controlled in enclosed

housings.

Moeller GmbH

Safety instructions

I

Page 4

• Measures should be taken to ensure the

proper restart of programs interrupted

after a voltage dip or failure. This should

not cause dangerous operating states even

for a short time. If necessary, emergencystop devices should be implemented.

• Wherever faults in the automation system

may cause damage to persons or property,

external measures must be implemented to

ensure a safe operating state in the event

of a fault or malfunction (for example, by

means of separate limit switches,

mechanical interlocks etc.).

II

Page 5

10/04 AWB2528-1548GB

Contents

About This Manual 3

Explanation of terms 3

Other manuals 4

Writing conventions 4

1 About the Display/Operator System 5

Target readership 5

Proper use 5

Overview 6

– Display/operator system at a glance 8

Type references 9

Operating principles 10

Main menu 11

2 Installation 13

Mounting 13

– Fitting the protective membrane 14

– Mounting the protective cover 16

– Mounting the display/operator unit

(front mounting) 19

– Removing the display/operator unit

(front mounting) 21

– Mounting the power supply/communication

module 22

– Removing the power supply/communication

module 23

Terminals 23

–Terminals 23

– Connecting the power supply 24

– Connecting the connection cable 25

1

Page 6

10/04 AWB2528-1548GB

3 Commissioning 29

Switching on 29

Initial Commissioning 30

4Use 31

Point-to-point connection 31

Net operation 32

Connection faulty 33

Graphic mode on the remotely operated device 33

5 Settings 35

Station selection 35

Setting the menu language 36

Changing the lighting 37

Changing the contrast 38

6 Appendix 39

Dimensions 39

– MFD-80.. display/operator unit 39

Technical data 40

– General ambient conditions 40

– MFD-80.. display/operator unit 42

– MFD-XM-80 protective membrane 44

– MFD-80-XS protective cover 44

– MFD-CP4 power supply/communication

module 45

Index 47

2

Page 7

10/04 AWB2528-1548GB

About This Manual

This manual describes the installation, commissioning and

possible settings on the display/operator system.

Explanation of terms The display/operator system described here consists of the

MFD-CP4 power supply/communication module, the

MFD-80.. display/operator unit and an MFD-CP4-...-CAB

connection cable for the easy basic units.

If the display/operator system is connected with an easy

basic unit it, can be used to read the text and status display

of the basic unit or operate the basic unit remotely via the

keypad.

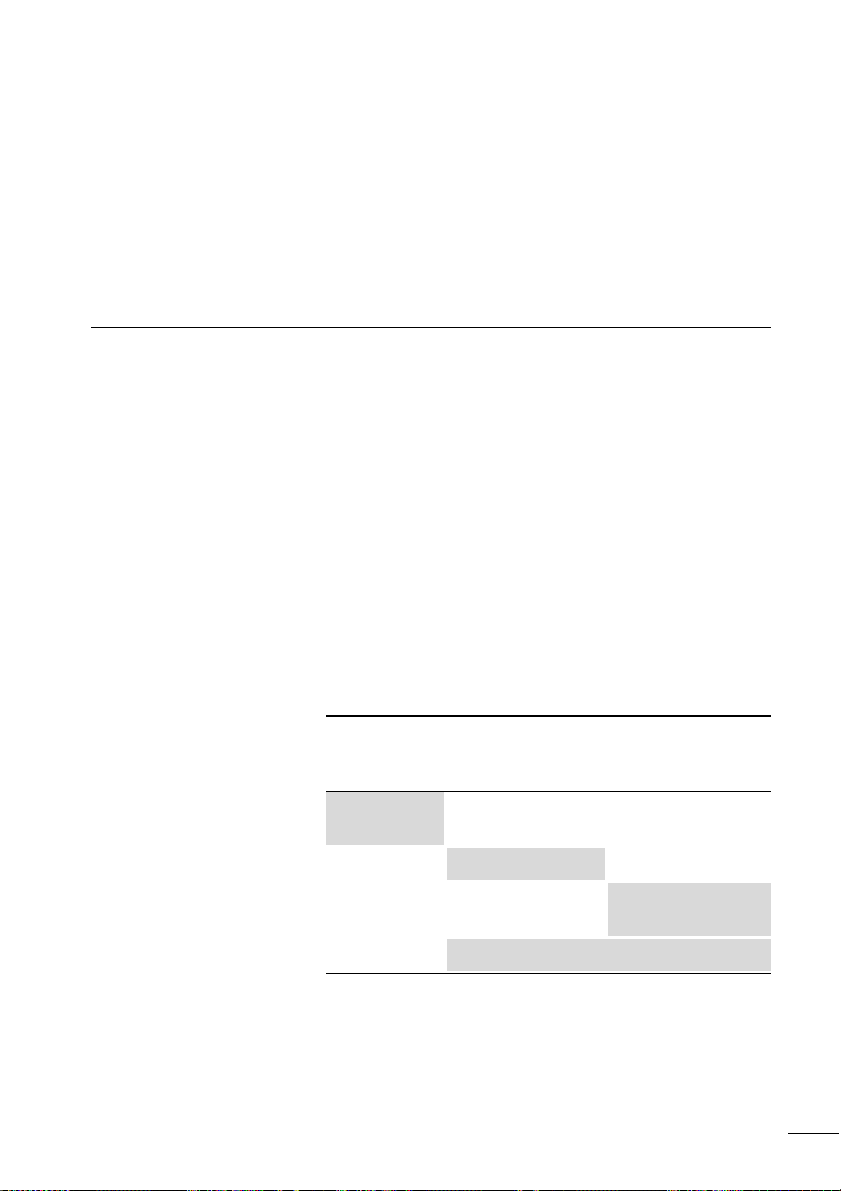

The following tables shows the individual components of the

display/operator system with their type designations.

Components that can be ordered are indicated by a grey

background.

Table 1: Components of the display/operator system with type

designation and possible order combinations

Display/

operator unit

MFD-80

MFD-80-B

Power supply unit/

communication

module

MFD-CP4

MFD-CP4-500 or MFD-CP4-800

Connection cable to

easy basic unit

MFD-CP4-500-CAB5/

MFD-CP4-800-CAB5

3

Page 8

About This Manual

Other manuals The MFD-CP4 can be connected to easy500, easy700,

easy800 or MFD-CP8... basic units.

These easy basic units are described in separate manuals

(AWBs):

• easy500/700 (AWB2528-1508GB)

• easy800 (AWB2528-1423GB)

• MFD-Titan, multi-function display (AWB2528-1480GB).

All manuals can be downloaded as PDF files from the

Internet. To find the manual quickly, enter the

documentation number at http://www.moeller.net/support

Writing conventions Symbols used in this manual have the following meanings:

X Indicates actions to be taken.

Attention!

h

Warns of the possibility of slight damage.

10/04 AWB2528-1548GB

.

Caution!

i

j

h

4

Warns of the possibility of serious damage and slight

injury.

Warning!

Warns of the possibility of substantial damage, serious

injury or death.

Indicates interesting tips and additional information

For greater clarity, the name of the current chapter is shown

in the header of the left-hand page and the name of the

current section in the header of the right-hand page. This

does not apply to pages at the start of a chapter and empty

pages at the end of a chapter.

Page 9

10/04 AWB2528-1548GB

1 About the Display/Operator

System

Target readership The MFD-CP4 must only be installed and connected up by

trained electricians or persons familiar with the installation

of electrical equipment.

A specialist knowledge of electrical engineering is needed

for commissioning. When controlling active components

such as motors or pressure cylinders, parts of the system can

be damaged and persons put at risk if the MFD-CP4 is

connected or programmed incorrectly.

Proper use The MFD-CP4 must be properly installed before use.

• The MFD-80/MFD-80-B display and operator unit is

protected to IP65 and does not normally require any

special housing protection.

• The rear of the MFD-CP4 unit is designed as a mounting

unit and must be installed in an enclosure, control cabinet

or a service distribution board.

• The installation must comply with regulations for

electromagnetic compatibility (EMC).

• The power up of the MFD-CP4 must not cause any hazards

arising from activated devices, such as unexpected motor

startups or power ups.

5

Page 10

About the Display/Operator

System

10/04 AWB2528-1548GB

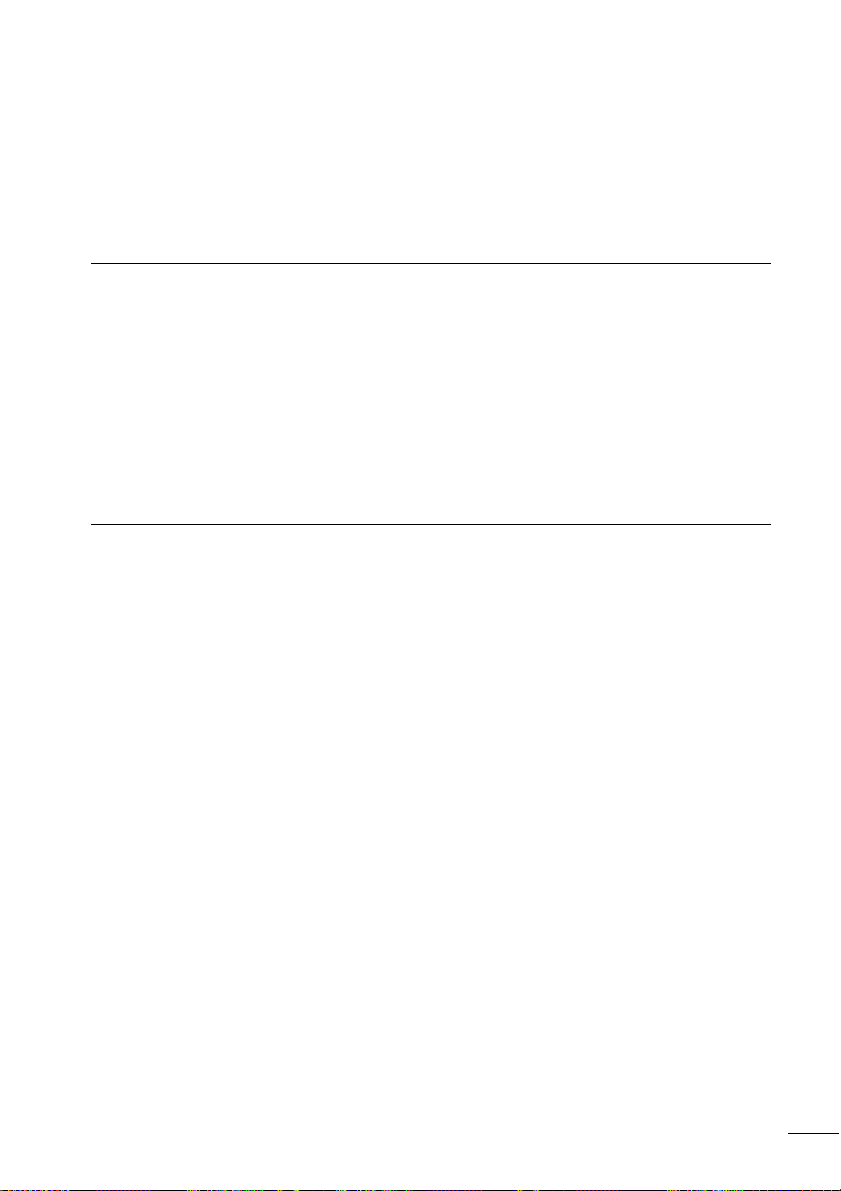

Overview The display/operator system can be connected with easy500,

easy700, easy800 or MFD-CP8... basic units to implement

the following tasks:

• Display on the MFD-CP4 of the status or text display of the

connected basic unit.

• Remote operation of the connected basic unit via the

MFD-CP4 keypad.

The devices can be linked together easily via the serial

interface.

If the display/operator system is connected to an easy basic

unit in the EASY-NET network, it is also possible to operate

any other device in the EASY-NET via the display/operator

unit and display its status, regardless of the device in the

EASY-NET to which the display/operator system is

connected.

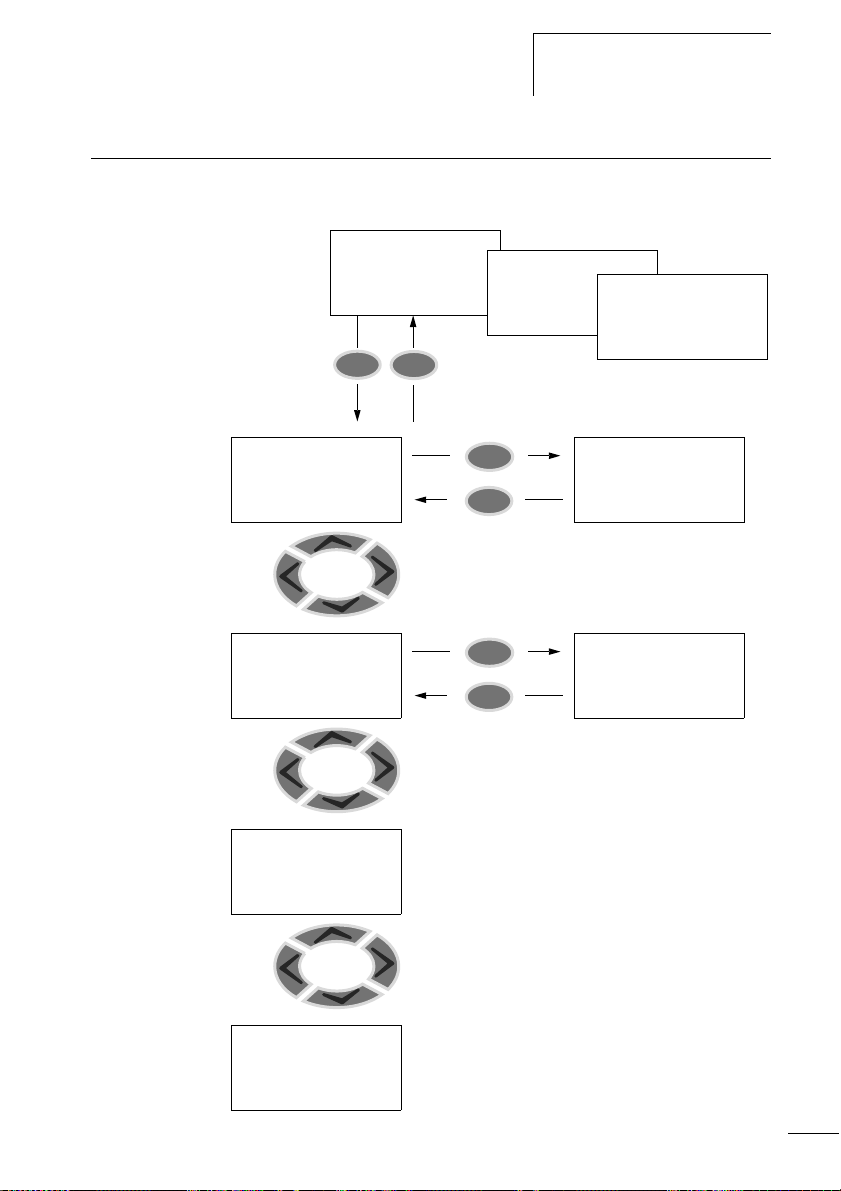

Legend for figure 1:

a easy500 basic units

b easy700 basic units

c MFD80-B/MFD-80 multi-function display

d Power supply/communication module with MFD-CP4-500

(above) or MFD-CP4-800 (below) connection cable

e easy800 basic units

6

Page 11

10/04 AWB2528-1548GB

Proper use

c

d

a

d

b

e

ALT

DEL

c

ESC

OK

Figure 1: System overview ( Legend a page 6)

7

Page 12

About the Display/Operator

System

10/04 AWB2528-1548GB

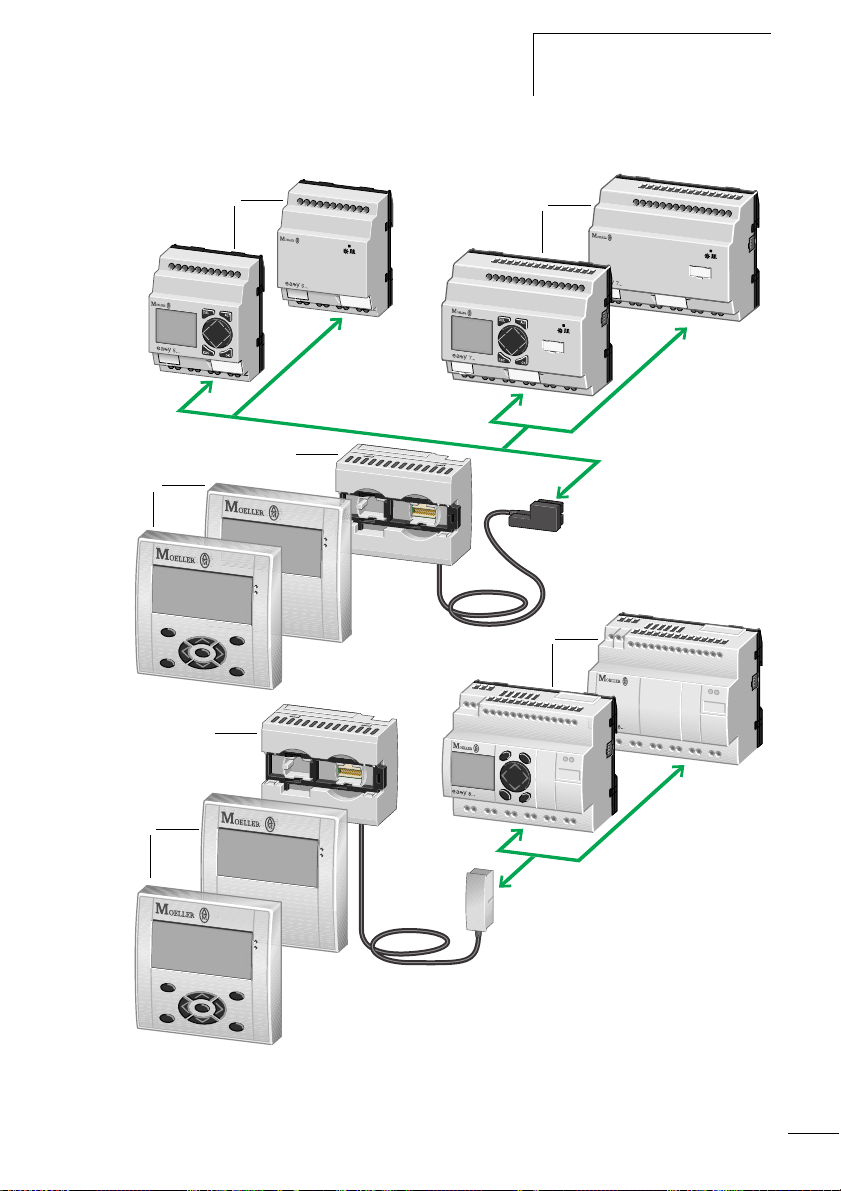

Display/operator system at a glance

The display/operator system consists of the power supply

unit/communication module and the display/operator unit

Display and operator unit

adb

i

h

Figure 2: Display/operator unit

a DEL button

b Graphic display

c ALT button

d LEDs for signalling

e Mode button

f Right, down cursor buttons

g OK button

h Left, up cursor buttons

i ESC button

c

efg

8

Page 13

10/04 AWB2528-1548GB

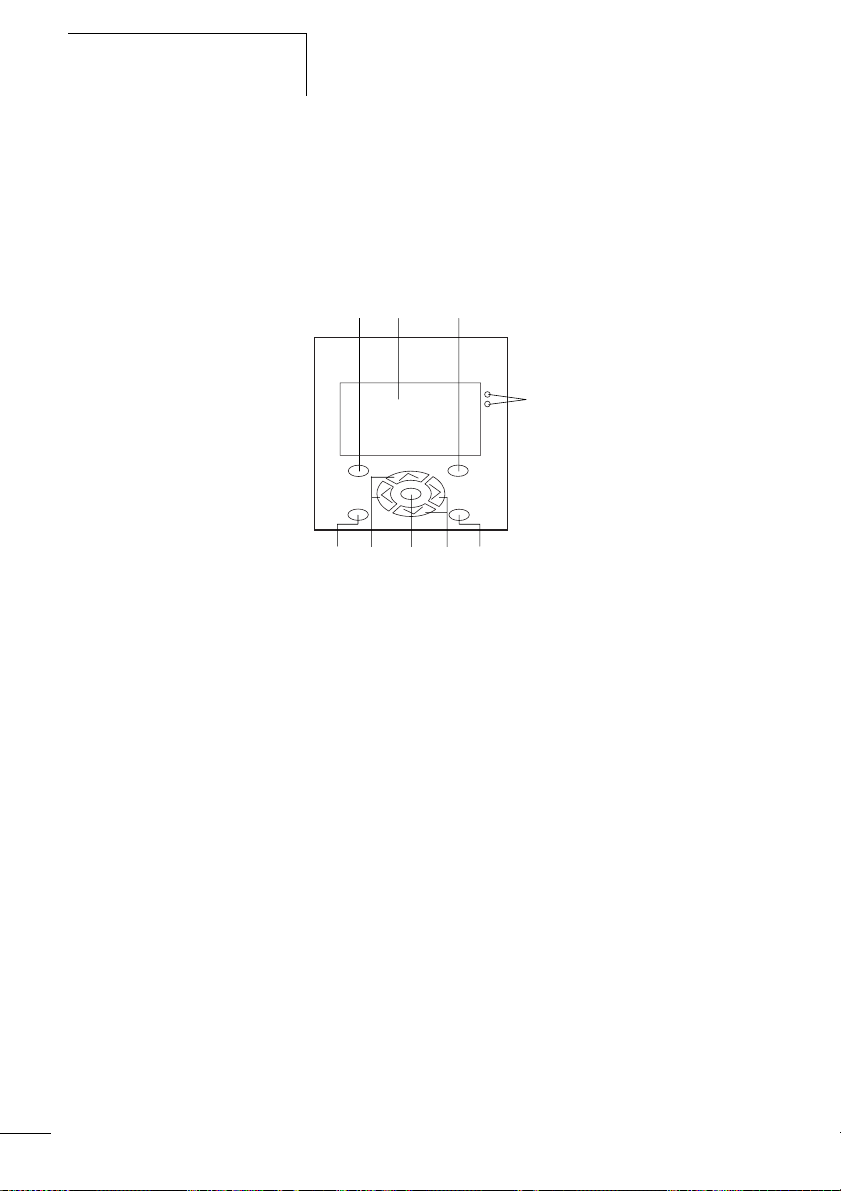

Type references

Power supply/communication module

a

b

Figure 3: Power supply/communication module

a Power supply

b Serial interface for point-to-point connection

Type references

MFD - CP4 - XXX

Supplied

connection cable for interface (optional)

500 = MFD-CP4-500-CAB5

800 = MFD-CP4-800-CAB5

CP4 = Power supply/

CPU rating 4

Multi-function display

9

Page 14

About the Display/Operator

System

10/04 AWB2528-1548GB

Operating principles The buttons of the display/operator unit have the following

functions:

Go to next menu level

OK

Select menu item

Activate, modify, save your entry

Return to last menu level

ESC

Cancel your entry since the last OK

Í Ú

Change menu item

Change value

Change place

ú í

Toggle between Terminal mode and main menu.

*

10

Page 15

10/04 AWB2528-1548GB

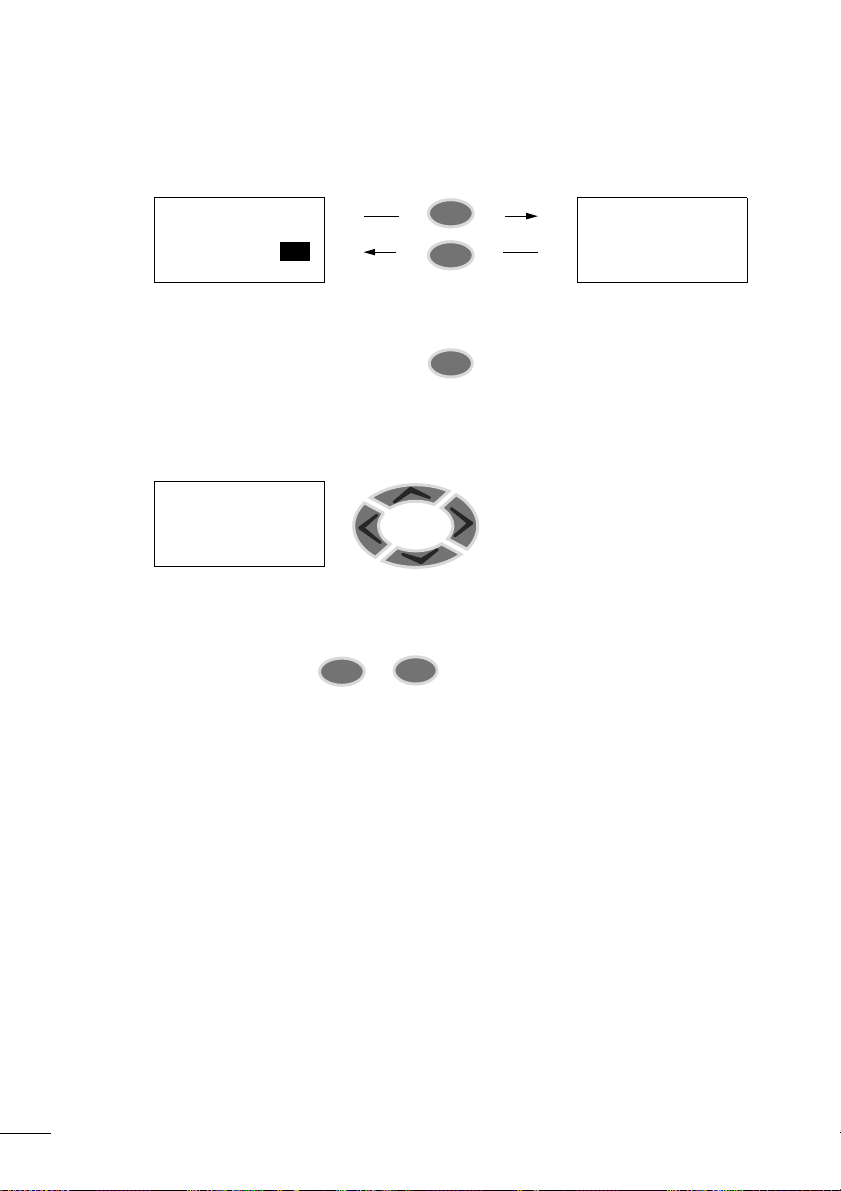

a

12

a

12

Main menu Status display

Connection

establishment

in progress...

*

*

Type references

I .2..5.......

MO 08:00

Q..34.... RUN

NT1 P-

Text display

Status or text display of the

connected device

Main menu

Current

selection

flashes in

the

MFD-CP4

menu

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

Cursor

Í Ú

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

Cursor

Í Ú

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

Cursor

Í Ú

page

OK

ESC

OK

ESC

STATION ID: 0

BAUDRATE: 9600B

ENGLISH a

DEUTSCH

FRANCAIS

ESPANOL b

ITALIANO

PORTUGUES

NEDERLANDS

SVENSKA

POLSKI

TÜRKCE

MAGYAR

CESKY

RUSSKIJ

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

page

11

Page 16

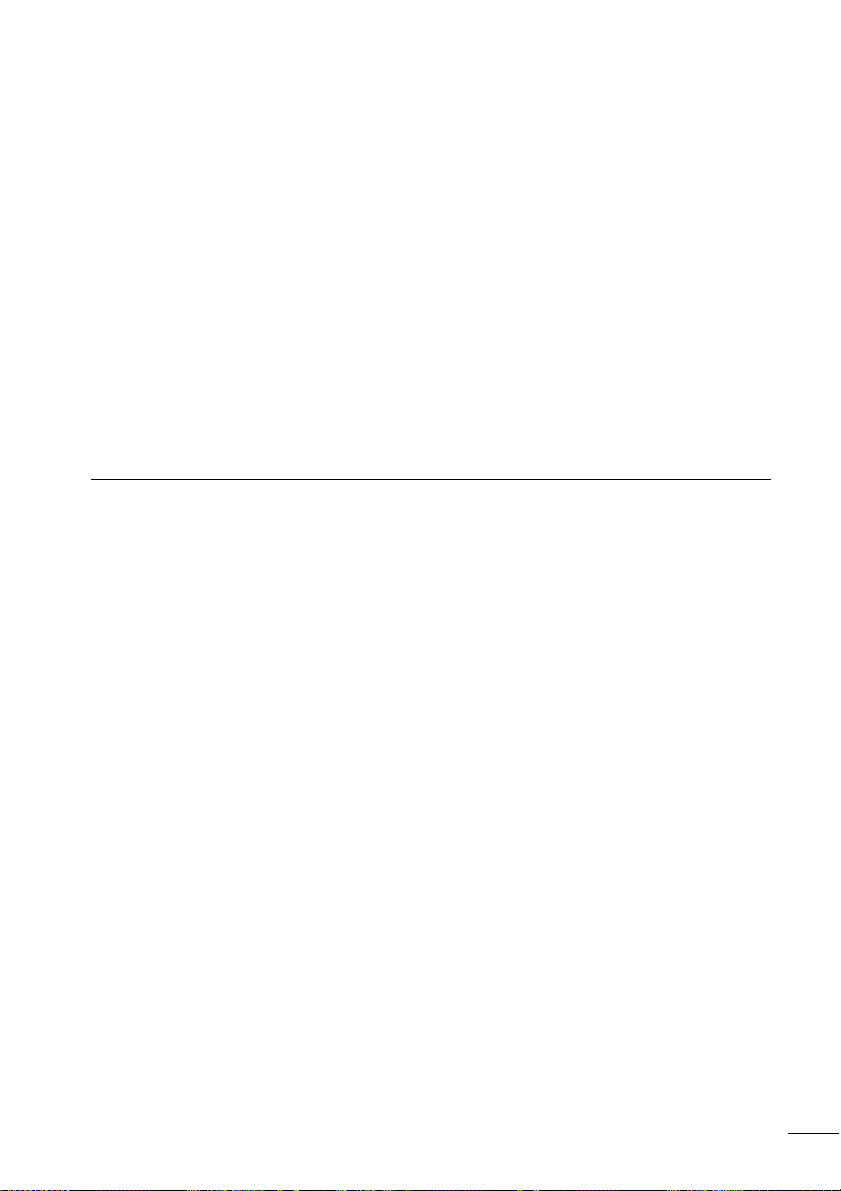

Setting values

10/04 AWB2528-1548GB

COM...

MENU LANGUAGE...

LIGHTING 60%

CONTRAST: +2

Selection mode:

Black rectangle flashing

OK

OK

or

ESC

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

Entry mode:

Number flashing

Press OK to toggle between Selection and Entry modes.

Press OK or ESC to move from Entry mode to Selection mode of the main menu

COM...

Í Ú Change value

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

The result of the value change is immediately visible

Special function

ALT

+

If the remotely operated device is an

ESC

MFD device in graphic mode, this

button combination can be used to

close the graphic mode on this device.

The “*” button on the remotely

operated MFD device has the same

local function when pressed.

12

Page 17

10/04 AWB2528-1548GB

2 Installation

The MFD-CP4 must only be installed and connected up by

trained electricians or a person familiar with the installation

of electrical equipment.

The MFD-CP4 is installed in the following order:

• Mounting,

• Connecting the serial interface,

• Connecting the power supply.

Mounting Install the display/operator unit in the front of a control

cabinet, a service distribution board, operator panel or in an

enclosure. You can protect the display/operator unit with a

protective membrane or cover, depending on the

environment in which it is to be used. This must be fitted

before the MFD-CP4 is mounted and is therefore described

in the next section.

The MFD-CP4 power supply/communication module must be

mounted in such a way that all the terminals are protected

against direct contact, liquids and dust during operation.

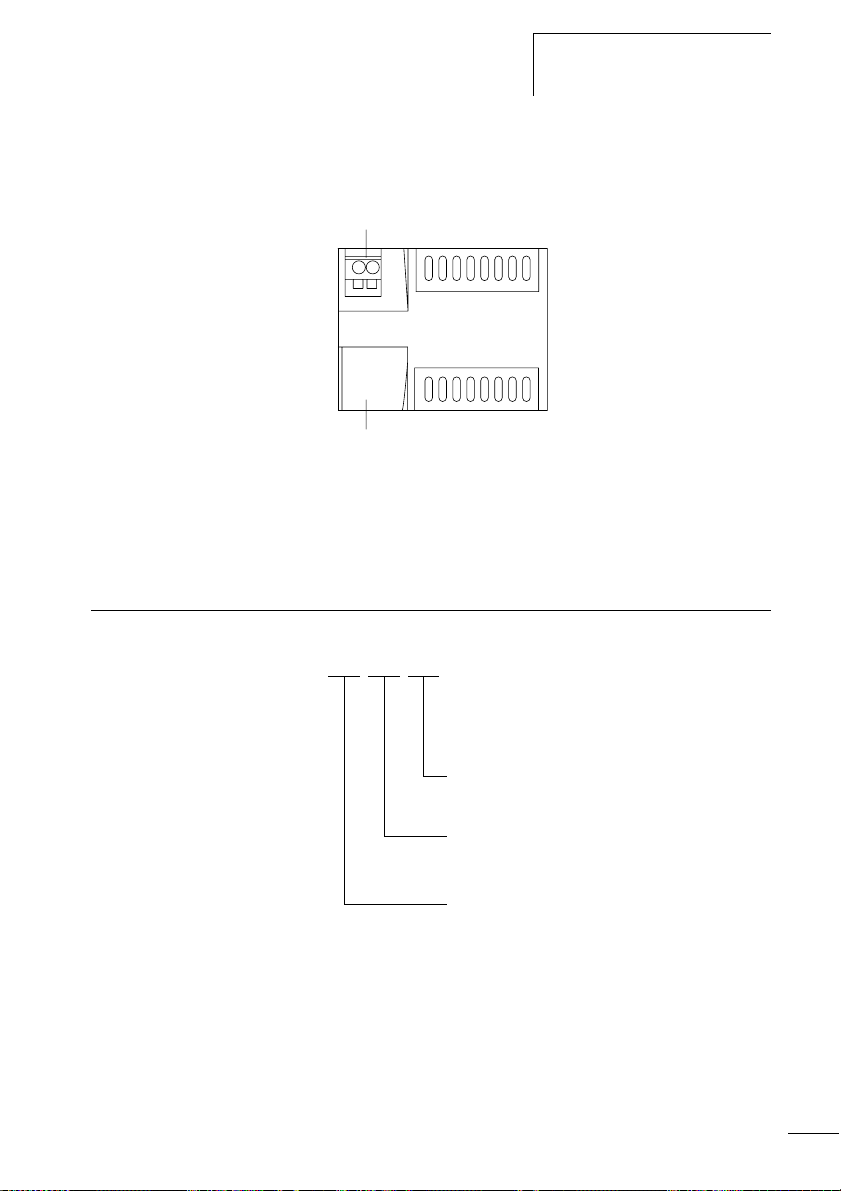

For sufficient heat circulation around the device, the rear of

the MFD-CP4 and the terminals must have a clearance of at

least 3 cm from the wall or adjacent devices.

13

Page 18

Installation

10/04 AWB2528-1548GB

30

30

30

Figure 4: Minimum clearance to MFD-CP4

Fitting the protective membrane

For special applications such as in the food industry, the

operator unit must be protected against the ingress of dust,

liquids etc. In this case fit the protective membrane over the

display/operator unit.

14

h

Fit the protective membrane before mounting the display/

operator unit.

Page 19

10/04 AWB2528-1548GB

Mounting

b

a

Figure 5: Fitting the protective membrane

a Protective membrane

b Display and operator unit

Caution!

Ensure that the membrane fits snugly in the groove of the

display/operator unit.

Otherwise a proper seal cannot be guaranteed and

particles may enter underneath the membrane. This may

cause malfunctions in the keypad.

In food industry applications, there is the risk of bacteria

building up underneath the membrane.

15

Page 20

Installation

10/04 AWB2528-1548GB

Figure 6: Correct position of the protective membrane

h

h

If the protective membrane has to be replaced, the display/

operator unit has to be removed. Replace the membrane

and refit the device.

Mounting the protective cover

The protective cover is provided for using the device in

aggressive environments. This protects the display and the

operator unit against mechanical damage or destruction.

Protection to IP 65 is maintained.

The protective cover can be opened so that the operator

buttons can be used.

The protective cover can be closed with a sealing facility to

provide protection against unauthorised operation.

Fit the protective cover before mounting the display/

operator unit.

16

Page 21

10/04 AWB2528-1548GB

Mounting

X First remove the front frame before mounting.

Figure 7: Removing the front frame

The protective cover can be mounted in two different

positions.

X Choose the position that is most suitable for the

application at hand and your requirements.

Figure 8: Position of the protective cover

17

Page 22

Installation

10/04 AWB2528-1548GB

X Mount the protective cover as shown in the figure.

18

Figure 9: Mounting the protective cover

Sealing the protective cover

Figure 10: Sealing the protective cover

The grip handle of the protective cover is provided with holes

that can be used in any mounting position. You can fit a wire

or similar material through these holes in order to seal the

cover. The cover is sealed properly if the wire is provided

with a lead seal. The cover can then only be opened by

breaking the seal or the wire.

Page 23

10/04 AWB2528-1548GB

Mounting

Mounting the display/operator unit (front mounting)

h

The protective membrane or the protective cover must be

fitted beforehand.

X Drill and punch out two 22.5 mm diameter holes in the

front plate. The diameter is the same as is normally

required for control circuit devices.

h

Observe the following technical requirements:

• The hole spacing is 30 mm.

• The maximum thickness of the front plate for mounting

the power supply/CPU module must not be more than

6 mm.

• Ensure minimum clearances for the power supply/CPU

module a page 14

• In order to ensure protection to IP 65, the surface of the

mounting front must be even and smooth.

22.5

Figure 11: Drill holes for the MFD

30

19

Page 24

Installation

10/04 AWB2528-1548GB

X Fit the display/operator unit in the punched fixing holes.

20

Figure 12: Mounting the display/operator unit

X Tighten the display/operator unit with the M22-MS

combination box spanner (a Figure 13).

The tightening torque must be between 1.2 and 2 Nm

h

Ensure that the correct torque is used. If the tightening

torque is too low or high, this may impair the seal.

Page 25

10/04 AWB2528-1548GB

Mounting

2 x

Figure 13: Screw fastening the display/operator unit

Figure 14: Rear of the mounted display/operator unit

Removing the display/operator unit (front mounting)

X Unscrew the fixing element and remove the display/

operator unit.

21

Page 26

Installation

10/04 AWB2528-1548GB

Mounting the power supply/communication module

22

Figure 15: Mounting the power supply/communication module

Page 27

10/04 AWB2528-1548GB

Terminals

Removing the power supply/communication module

Use a screwdriver with a 100 x 3.5 mm slot width.

X Insert the screwdriver into the lug of the fixing shaft

catch.

1

X Lever out the slide catch.

X Pull out the power supply/CPU module from the fixing

shafts.

3

2

3

2

Figure 16: Releasing the fixing shaft

Terminals Terminals

The MFD-CP4 is fitted with cage clamp terminals for

connecting the power supply and the connection cable to the

serial interface.

Tool for cage clamp terminals

Slot-head screwdriver, width 3.5 mm x 0.6 mm.

Connection cross-sections of the MFD cage clamp

terminal cables

• Power supply terminal:

0.08 to 2.5 mm

• Interface terminal

0.14 to 0.5 mm

1

2

(AWG 28 – 12)

2

(AWG 26 – 20)

23

Page 28

Installation

10/04 AWB2528-1548GB

Connecting the power supply

h

The required connection data for the MFD-CP4 is provided

in the Section “Technical data”, Page 40.

DC power supply MFD-CP4

L01+ L02+

L01–

> 1 A

Ue = 24 V H

(20.4 – 28.8 V H)

Ie = 150 mA

0.6 x 3.5 x 100

Figure 17: Power supply on the MFD

h

The MFD-CP4 is protected against polarity reversal. Ensure

0V24V

the correct polarity of the terminals to ensure that the

MFD-CP4 functions correctly.

Cable protection

Provide cable protection (F1) of at least 1 A (slow) on the

MFD-CP4.

24

h

When the MFD-CP4 is switched on for the first time, its

power supply circuit behaves like a capacitor. Use a

suitable device for switching on the power supply and do

not use any reed relay contacts or proximity switches.

With the power supply ensure that the response threshold

for the short-circuit current is higher than the inrush

current of the MFD-CP4.

Page 29

10/04 AWB2528-1548GB

Terminals

Connecting the connection cable

The MFD-CP4 is provided with a serial interface. This is used

for point-to-point communication between the MFD-CP4

and an easy500, easy700, easy800 or MFD-CP8.. if there is

no PC connected to these devices.

Selecting a suitable connection cable

Different connection cables are required depending on

which device is connected to the MFD-CP4:

Table 2: Selecting connection cables

MFD-CP4 connected to ... Connection cable

easy500 (from device version 01) MFD-CP4-500-CAB5

easy700 (from device version 01)

easy800 (from device version 04)

MFD-CP8.. (from device

version 01)

MFD-AC-CP8.. (from device

version 01)

MFD-CP4-800-CAB5

The MFD-CP4-500-CAB5 and MFD-CP4-800-CAB5

connection cables are 5 m long.

h

In order to ensure correct EMC, the MFD-CP4-500-CAB5

and MFD-CP4-800-CAB5 connection cables must not be

lengthened.

25

Page 30

Installation

10/04 AWB2528-1548GB

Connecting the connection cable

X Remove the interface cover carefully.

X Use a screwdriver to press down the recess next to the

terminal and connect the wires of the connection

2

cable to the terminals in the order stated . Proceed

1

3

accordingly in the reverse order to remove the connection

cable .

4

X Refit the interface cover.

5

26

MFD-CP4-..-CAB5

Figure 18: Connecting the connection cable

X1 = grey, X2 = brown, X3 = yellow, X4 = white, X5 = green

2

X5

X4

X3

X2

X1

15

3

4

Page 31

10/04 AWB2528-1548GB

Terminals

X Fit the connection cable plug into the easy basic unit.

Figure 19: Fitting the connection plug a to the easy basic unit

Left:easy800/MFD, right: easy500/700

27

Page 32

10/04 AWB2528-1548GB

28

Page 33

10/04 AWB2528-1548GB

3 Commissioning

Switching on Before switching on check that the power supply and the

connection cable are properly connected:

– Terminal +24 V: voltage +24 V

– Terminal 0 V: voltage 0 V

If you have already integrated devices into a system, secure

any parts of the system connected to the working area to

prevent access and ensure that no-one can be injured if, for

example, motors start up unexpectedly.

Caution!

The MFD-CP4 allows you to operate a device that may be

positioned far from your actual location. All access rights

that you would also require "locally" are granted to you.

It is not always possible to obtain a view of the situation

“locally”. Use of this operating mode and the execution of

any changes to device settings should only be carried out

with the utmost caution.

h

You can also carry out settings locally on the device whilst

you are operating a device remotely via the keypad. In this

case, the local operation on the device is always faster

than the remote operation in Terminal mode. Bear in mind

that this may lead to conflicts that may trigger faults or

unforeseen events.

A MFD-CP4 makes its display and operator unit available

to the connected device. Only data for the display and the

status of the buttons is sent via the connection. This

ensures that the local data of the connected device is not

destroyed in the event of a communication fault.

29

Page 34

Commissioning

10/04 AWB2528-1548GB

Initial Commissioning When you switch on the display/operator system for the first

time, you will be asked to select the menu language.

X Select the required menu language and confirm the

setting by pressing the OK button.

X Press ESC to exit language selection.

Connection

establishment

in progress...

h

If you do not set the language, the display/operator system

will display this language menu every time you switch on,

and wait for you to select a language.

You can change the language setting at a later time as

required, (see a Section “Setting the menu language”,

Page 36).

If the device was switched on for the first time, the display/

operator system will try to establish a connection with the

default settings to a connected device. The status and text

display of the remotely operated device is displayed as soon

as the connection can be established.

30

Page 35

10/04 AWB2528-1548GB

Point-to-point connection

4Use

You can use the display/operating system for a point-topoint connection or in the easy-NET network. easy-NET

operation is only possible in combination with easy800/MFD

devices.

easy5..

easy7..

easy8..

MFD-CP4

D

E

L

E

CS

MFD-CP4-500-CAB5

A

L

T

O

K

ED

L

A

L

T

E

CS

O

K

MFD-CP8..

MFD-CP4-800-CAB5

Figure 20: Possible point-to-point connection via the serial

interface

31

Page 36

Use

Net operation

10/04 AWB2528-1548GB

MFD-CP4

EASY 8..

EASY 8..

MFD-CP4

EASY 8..

MFD-CP8..

MFD-CP8..

EASY 8..

PC

32

h

h

Communication via EASY-SOFT is not possible if a network

station (easy800 or MFD-CP8) is connected with a PC and

an MFD-CP4 is accessing this device. This also applies to

program uploads and downloads.

To enable communication simply set a different station ID

in the main menu of the CP4 in the COM menu

(a page 11).

Avoid data conflicts between the connected devices!

Page 37

10/04 AWB2528-1548GB

Graphic mode on the remotely operated device

Connection faulty If the connection is faulty or interrupted, the MFD-CP4 will

display the message “Connection establishment in

progress...” continuously. This message may, however, also

be due to an incorrect COM setting (a section “Main

menu”, page 11).

Connection

establishment

in progress...

Graphic mode on the

remotely operated device

If the display/operator system is connected with another

MFD device which is in Graphic mode, this graphic will not

be shown by the display/operator system. You can terminate

graphic mode from the display/operator system by pressing

ALT + ESC. The same thing can be achieved by pressing the

“*” button on the remotely operated MFD device as long

another function was not assigned to this button

(a section “Special function”, page 12).

33

Page 38

10/04 AWB2528-1548GB

34

Page 39

10/04 AWB2528-1548GB

5 Settings

The following settings to the connected basic unit can be

made via the display/operator system.

Station selection Pressing the “*” activates the main menu of the display/

operator system.

X Press the “*” button.

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

STATION ID: 0

BAUDRATE: 9600B

h

STATION ID: 0

BAUDRATE: 9600B

h

The main menu will appear.

X Select the COM menu item and press the OK button.

The Station ID menu will appear.

X Press the OK button and select the station number with Í

and

Ú.

X Confirm with OK.

Station ID 0 is always assigned to the device directly

connected via the interface. All other station IDs are

assigned to the NET-IDs of the individual NET stations in

an EASY-NET.

X Press the OK button and select the baud rate using Í and

Ú.

X Confirm with OK.

The transfer rate for easy500 and easy700 is limited to

9600 baud. The maximum baud rate for easy800 and

MFD-CP8 is 19200 baud.

35

Page 40

Settings

10/04 AWB2528-1548GB

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

Connection

establishment

in progress...

Setting the menu language

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

ENGLISH a

DEUTSCH j

FRANCAIS

ESPANOL b

X Exit the COM menu with ESC.

You can leave the main menu at any time by pressing the

“*” button.

When the main menu is left, the MFD-CP4 tries to establish

connection to the selected device. The status and text

display of the remotely operated device is displayed as soon

as the connection can be established.

If the main menu of the display/operator system is not active,

press the “*” button to enter the menu.

X Use the Í and Ú buttons to select the Menu language

menu item.

X Confirm with OK.

X Use the cursor buttons Í or Ú to select the language

required.

–English

–German

–French

–Spanish

– Italian

–Portuguese

–Dutch

–Swedish

– Polish

–Turkish

– Hungarian

–Czech

– Russian

36

X Press OK to confirm your choice and press ESC to exit the

menu.

You can leave the main menu at any time by pressing the

“*” button.

Page 41

10/04 AWB2528-1548GB

Setting the menu language

Changing the lighting If the main menu of the display/operator system is not active,

press the “*” button to enter the menu.

COM...

MENU LANGUAGE...

LIGHTING: 60%

CONTRAST: +2

h

COM...

MENU LANGUAGE...

LIGHTING: 70%

CONTRAST: +2

X Use the Í and Ú buttons to select the Lighting menu

item.

The cursor moves to the percentage value of the lighting.

When Selection mode is active, the cursor appears as

black flashing rectangle. Pressing OK will activate Edit

mode in which the cursor will disappear and the number

will flash. In Edit mode, use the

Í and Ú to change the

value. The changes are displayed immediately.

X Press OK.

Now change the value in 10% steps with the

X Press the Í or Ú buttons to change the value.

X Press OK or ESC to exit Edit mode

Í and Ú.

If Selection mode is active, you can exit the main menu at

any time by pressing the “*” button.

37

Page 42

Settings

10/04 AWB2528-1548GB

Changing the contrast If the main menu of the display/operator system is not active,

press the “*” button to enter the menu.

COM...

MENU LANGUAGE...

LIGHTING: 70%

CONTRAST: +2

h

COM...

MENU LANGUAGE...

LIGHTING: 70%

CONTRAST: +1

X Use the Í and Ú buttons to select the Contrast menu

item.

The cursor moves to the percentage value of the contrast.

When Selection mode is active, the cursor appears as

black flashing rectangle. Pressing OK will activate Edit

mode in which the cursor will disappear and the number

will flash. In Edit mode, use the

Í and Ú to change the

value. The changes are displayed immediately.

X Confirm with OK.

Use the

Í and Ú buttons to change the value between -2

and +2 in increments of 1.

X Press the Í or Ú buttons to change the value.

X Press OK or ESC to exit Edit mode

If Selection mode is active, you can exit the main menu at

any time by pressing the “*” button.

38

Page 43

10/04 AWB2528-1548GB

6Appendix

Dimensions MFD-80.. display/operator unit

32 17

86.5

g0.2

28.25 28.25

MFD-80-XM protective membrane

30

62

86.5

+0.4

22.3

30

MFD-CP...

20 13.7

88.5

88.5

MFD-80-XS protective cover

95

86.5

22.5

25

39

Page 44

Appendix

10/04 AWB2528-1548GB

MFD-CP4 power supply/communication module

58

22.5

30

75

22.5

36.2

Technical data General ambient conditions

Climatic conditions

(damp heat constant to IEC 60068-2-78; cyclical to

IEC 600618-2-30)

(cold to IEC 60068-2-1, heat to IEC 60068-2-2)

Ambient temperature

Installed horizontally/vertically

Condensation Prevent condensation with

Display legibility °C, (°F) –5 to 50, (–23 to 122)

Storage/transport temperature °C, (°F) –40 to 70, (–40 to 158)

Relative humidity (IEC 60068-2-30), non-condensing % 5 to 95

Air pressure (operation) hPa 795 to 1080

°C, (°F) –25 to 55, (–13 to 131)

suitable measures

40

Page 45

10/04 AWB2528-1548GB

Ambient mechanical conditions

Pollution degree

Power supply/CPU module 2

Display/operator unit 3

Degree of protection (EN 50178, IEC 60529, VBG4)

Power supply/CPU module IP20

Display/operator unit IP65

Display/operator unit with protective cover IP65

Display/operator unit with protective membrane IP65

Oscillations (IEC 60068-2-6)

Constant amplitude 0.15 mm Hz 10 to 57

Constant acceleration 2 g Hz 57 to 150

Shocks (IEC 60068-2-27) semi-sinusoidal 15 g/11 ms Shocks 18

Drop (IEC 60068-2-31) Drop

height

Free fall, when packed (IEC 60068-2-32) m 1

Electromagnetic compatibility (EMC)

Electrostatic discharge (ESD),

(IEC/EN 61000-4-2, severity level 3)

Air discharge kV 8

Contact discharge kV

Electromagnetic fields (RFI),

(IEC/EN 61000-4-3)

Radio interference suppression (EN 55011, EN 55022), limit class

Burst (IEC/EN 61000-4-4, severity level 3)

Power cables kV 2

Signal cables kV

High energy pulses (Surge) MFD

(IEC/EN 61000-4-5, severity level 2), power cable

symmetrical

Line-conducted interference (IEC/EN 61000-4-6) V

Technical data

mm 50

6

V/m 10

B

2

kV 1

10

41

Page 46

Appendix

10/04 AWB2528-1548GB

Dielectric strength

Overvoltage category II

Measurement of the air clearance and creepage distance EN 50178, UL 508,

CSA C22.2, No 142

Dielectric strength EN 50178

Tools and cable cross-sections

Power supply terminal

Solid and flexible with ferrule, minimum to

maximum

2

mm

0.08 to 2.5

AWG 28 to 12

Interface terminal

Flexible, tin-coated, minimum to maximum mm

2

0.14 to 0.5

AWG 26 to 20

Slot-head screwdriver, width mm 3.5 x 0.5

inch 0.14 x 0.02

MFD-80.. display/operator unit

Front dimensions W x H x D

With buttons mm 86.5 x 86.5 x 21.5

Without buttons mm 86.5 x 86.5 x 20

Overall dimensions with fixing shaft W x H x D

With buttons mm 86.5 x 86.5 x 43

Thickness of fixing wall (minimum; maximum) mm 1; 6

Weight g 130

42

/

inches 3.41 x 3.41 x 0.85

inches 3.41 x 3.41 x 0.79

inches 3.41 x 3.41 x 1.69

inches 0.04; 0.24

lb 0.287

Page 47

10/04 AWB2528-1548GB

Technical data

Mounting

Maximum tightening torque of the fixing rings [Nm]

Power supply By means of MFD-CP4 power

LCD display

Type Graphic/monochrome

Visible area W x H mm 62 x 33

Size of pixels mm 0.4 x 0.4

Number of pixels (W x H) 132 x 64

Spacing (pixel centre to pixel centre) mm 0.42

LCD backlight Yes

Backlight colour Yellow/green

The backlight can be used and programmed in

visualization applications

LEDs

Number of LEDs 2

Operating buttons

Number 9

Pushbutton illumination (LED)

Number 5

Colour Green

2 22.5 mm (0.886 in) holes

Display fastened with two

fixing rings

1.2 to 2

supply/communication

module

Yes

43

Page 48

Appendix

10/04 AWB2528-1548GB

MFD-XM-80 protective membrane

Dimensions W x H x Dmm88 x 88 x 25

inches 3.46 x 3.46 x 0.98

Weight g 25

lb 0.055

Mounting Is fitted over the

display/keypad

(with Titan front ring)

MFD-80-XS protective cover

Dimensions W x H x Dmm86.5 x 94 x 25

inches 3.41 x 3.41 x 0.98

Weight g 36

lb 0.079

Mounting Is fitted over the

display/keypad

(without Titan front

ring)

44

Page 49

10/04 AWB2528-1548GB

Technical data

MFD-CP4 power supply/communication module

Dimensions W x H x Dmm75 x 58 x 36.2

inches 2.95 x 2.28 x 1.43

Weight g 164

lb 0.362

Mounting Fitted on the fixing

shaft of the display

Power supply

Rated voltage

Rated value V DC,

(%)

Permissible range V DC 20.4 to 28.8

Residual ripple % F 5

Input current

with 24 V DC, MFD-CP4,

MFD-80.., normally

Voltage dips, IEC/

EN 61131-2

Heat dissipation

with 24 V DC, MFD-CP4,

MFD-80.., normally

mA 150

ms 10

W 3.6

24, (+20, –15)

45

Page 50

10/04 AWB2528-1548GB

46

Page 51

10/04 AWB2528-1548GB

Index

B Baud rate ............................................................11

C Cable protection ..................................................24

Commissioning ....................................................29

Communication via EASY-SOFT ...........................32

Connecting the connection cable .........................25

Connecting the power supply ..............................24

Connection

Connection cable ..........................................25

Power supply ................................................24

Connection faulty ................................................33

Connection plug ..................................................27

Contrast ..............................................................38

D Dimensions ..........................................................39

Dimensions, easy .................................................42

Display and operator unit ......................................8

Drill holes ............................................................19

F Fitting the protective membrane ..........................14

G Graphic mode ................................................12, 33

K Keypad ............................................................8, 10

L Language setting .................................................30

Lighting ...............................................................37

M Main menu

Selection ......................................................11

Menu language ...................................................30

Minimum clearances, to MFD-CP4 .......................14

47

Page 52

Index

10/04 AWB2528-1548GB

Mounting

Display/operator unit .................................... 19

Power supply/communication module .......... 22

Protective cover ...........................................16

Protective membrane ...................................14

Mounting the display/operator unit .....................19

Mounting the power supply/communication module

22

N Net operation ......................................................32

Network operation ................................................ 6

P Point-to-point connection ....................................31

Power supply ........................................................9

Protective cover

Mounting .....................................................16

Sealing .........................................................18

48

S Sealing the protective cover ................................18

Serial interface ......................................................9

Setting the menu language .................................36

Setting values .....................................................12

Settings ...............................................................35

Station ID

....................................................................11

Station selection ..................................................35

Status display ................................................11, 12

Switching on .......................................................29

System menu

Selection ......................................................11

System overview ...................................................7

T Task ......................................................................6

Terminals ............................................................23

Transfer rate .......................................................35

Type references .....................................................9

Page 53

10/04 AWB2528-1548GB

Index

U Use ........................................................................5

49

Page 54

10/04 AWB2528-1548GB

50

Loading...

Loading...