Page 1

Circuit-Breaker IZM

Operating Manual

08/07 AWB1230-1407GB

Page 2

All brand and product names are trademarks or registered

trademarks of the owner concerned.

st

published 2001, edition date 03/01

1

nd

2

edition 10/02

rd

3

edition 06/05

st

4

edition 08/07

See revision protocol in the “About this manual“ chapter

© 2001 by Moeller GmbH

Production: Oliver Fiebag-Elias, Heidrun Riege, Ingo Meyer

Translation: Nigel Green, David Long

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alteration without notice.

Printed on bleached cellulose. 100 % free from chlorine and acid.

Page 3

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Danger if spring is charged! Discharge spring.

• Follow the engineering instructions (AWA/AWB) of the device

concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this

device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Deviations of the mains voltage from the rated value must not

exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60 204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency-stop devices must not

cause restart.

• The electrical installation must be carried out in accordance

with the relevant regulations (e. g. with regard to cable cross

sections, fuses, PE).

• All work relating to transport, installation, commissioning and

maintenance must only be carried out by qualified personnel.

(IEC 60364 and HD 384 and national work safety

regulations).

Moeller GmbH

Safety instructions

Page 4

Page 5

Contents

0 About this manual 0 - 1

1 Construction 1 - 1

Circuit-breaker 1 - 1

Withdrawable unit 1 - 2

2Labels 2 - 1

Circuit-breaker equipment label 2 - 1

Circuit-breaker label 2 - 1

Identification of the control unit 2 - 2

Rating plug label 2 - 3

Withdrawable unit label 2 - 3

3 Standards and regulations 3 - 1

4 Transport 4 - 1

5 Mounting 5 - 1

Installation 5 - 1

– Mounting position 5 - 1

– Mounting on horizontal surface 5 - 1

– Mounting on a vertical surface with mounting brackets 5 - 2

Safety clearances 5 - 4

– Use in IT systems 5 - 5

Connecting bars 5 - 7

– Horizontal connection 5 - 7

– Flange connection 5 - 7

– Front connection 5 - 8

– Vertical connection 5 - 10

Connection of main conductors 5 - 15

Auxiliary conductor connection 5 - 16

– Plug connector 5 - 16

– Sliding contact module 5 - 17

– Control circuit plug 5 - 17

Wiring on withdrawable unit 5 - 19

– Assembly with control circuit connections 5 - 19

– Order numbers 5 - 19

Connection of protective conductor 5 - 21

Changeover of fixed mounting circuit-breaker

into withdrawable circuit-breaker 5 - 21

Conversion 5 - 22

6 Commissioning 6 - 1

Preparation of withdrawable circuit-breaker 6 - 1

– Inserting the circuit-breaker in withdrawable unit 6 - 1

– Position of the circuit-breaker in the withdrawable unit 6 - 2

– Release racking handle/withdraw racking handle 6 - 3

– Circuit-breaker to connected (CONNECT) position 6 - 3

– Insert racking handle 6 - 3

Charging the spring 6 - 4

Checklist for commissioning 6 - 4

Closing 6 - 5

Switch off 6 - 5

Tripping by overcurrent release 6 - 6

Re-starting a tripped circuit-breaker 6 - 7

Switching off and discharging the storage spring 6 - 8

Troubleshooting 6 - 9

7 Frame sizes, dimension drawings 7 - 1

Overview external dimensions 7 - 1

IZM(IN)...1-..., fixed-mounting, 3- and 4-pole 7 - 2

IZM(IN)...1-..., withdrawable, 3- and 4-pole 7 - 4

IZM(IN)...2-..., fixed-mounting, 3 and 4 pole 7 - 6

IZM(IN)...2-..., withdrawable, 3 and 4 pole 7 - 8

IZM(IN)...3-..., fixed-mounting, 3- and 4-pole 7 - 10

IZM(IN)...3-..., withdrawable, 3- and 4-pole 7 - 12

External current transformer for N-conductor 7 - 14

Voltage transformers 7 - 14

Further dimension drawings 7 - 14

8 Circuit diagrams 8 - 1

Terminal assignment, accessories 8 - 1

Auxiliary and control switches 8 - 2

Signal switch 8 - 2

Voltage release/electrical switch-on inhibit 8 - 3

Closing release/electrical ON 8 - 3

Motor operator 8 - 4

Remote reset coil 8 - 4

Protection circuit for overcurrent release XZMU, XZMD 8 - 5

– With Breaker Status Sensor (XBSS) and metering

module XMH 8 - 5

– Only metering module XMH 8 - 6

– Breaker Status Sensor (XBSS) only 8 - 6

9 Electronic components 9 - 1

Overcurrent release 9 - 1

– Overview of functions 9 - 1

– Overcurrent release for system protection XZMA

(IZM…-A…) 9 - 2

– Overcurrent release with selective protection XZMV

(IZM…-V…) 9 - 5

– Overcurrent release for universal protection XZMU

(IZM…-U…) 9 - 8

– Digital release XZMD (IZM…-D…) 9 - 12

– Order numbers 9 - 14

– Indications 9 - 15

– Protective functions 9 - 16

– Displays 9 - 20

– Rated current module 9 - 35

– Earth-fault protection modules 9 - 36

– Removing the overcurrent release 9 - 39

– Internal self-test of the overcurrent tripping function

(XZMV, XZMU, XZMD) 9 - 42

– Sealing and locking equipment 9 - 43

Additional communication features 9 - 44

– System architecture 9 - 44

– Internal modules 9 - 45

– External expansion modules 9 - 57

Current transformer 9 - 65

– Retrofitting the internal neutral CT 9 - 65

– External current transformer for neutral conductor 9 - 67

– Voltage transformers 9 - 67

– External summation transformer 9 - 70

External supply voltage 9 - 71

Parameter assignment module 9 - 72

– Application 9 - 72

– Design 9 - 72

– Indications 9 - 72

– Connection versions 9 - 72

– Power supply 9 - 74

– Article numbers 9 - 74

Hand-held test unit 9 - 75

– Design 9 - 75

– Preparations 9 - 75

– Connection 9 - 76

– Power supply 9 - 76

– Mains voltage reconnection 9 - 77

– Operation 9 - 77

– Follow-up work 9 - 78

– Article numbers 9 - 78

08/07 AWB1230-1407D I

Page 6

10 Reclosing lockout and remote reset 10 - 1

Manual reset of the reclosing lockout 10 - 1

Automatic reset of reclosing lockout 10 - 2

Retrofitting automatic reset 10 - 3

– Installing reset mechanism 10 - 3

Retrofitting the remote reset option 10 - 4

– Fitting 10 - 4

– Connecting wires 10 - 6

– Function test 10 - 6

– Updating the options label 10 - 6

11 Control switch 11 - 1

Signalling switches 11 - 1

– Mounting signalling switches 11 - 2

– Mounting signalling switches at trip unit 11 - 2

Control switches 11 - 3

Communication switches 11 - 3

Connecting wires 11 - 3

12 Motor operator 12 - 1

Mechanical operations counter 12 - 2

Motor cut-off switch on the operating panel 12 - 3

Updating the options label 12 - 4

13 Voltage releases, closing coil, electrical ON 13 - 1

Overview 13 - 1

Retrofitting voltage releases 13 - 3

Fitting of optional signalling switch on the

voltage release 13 - 3

Setting delay times on undervoltage release 13 - 4

Installation of cut-off switch for overexcited

shunt release and closing coil 13 - 4

Retrofitting Electrical ON 13 - 5

Mechanical function test 13 - 6

Connecting wires 13 - 6

Finally 13 - 7

Electrical function test 13 - 7

Updating the options label 13 - 8

Capacitor storage device 13 - 8

14 Indicator and operating elements 14 - 1

Locking set 14 - 1

– Retrofitting of access inhibiter over mechanical

ON/OFF button 14 - 2

– Locking device for Mechanical OFF/ON button 14 - 2

Emergency-Stop mushroom-headed pushbutton 14 - 3

Retrofitting for key operation for mechanical ON or OFF 14 - 3

Electrical ON pushbutton 14 - 3

Mechanical operations counter 14 - 3

Motor cut-off switch 14 - 3

15 Locking devices 15 - 1

Safety locks 15 - 1

– Retrofitting the interlocking mechanism in the

OFF position (operating panel) – safe OFF 15 - 2

– Retrofitting safety lock for electrical ON 15 - 5

– Retrofitting for key operation for mechanical

ON or OFF 15 - 5

– Retrofitting locking device against moving from the

disconnected position 15 - 5

– Retrofitting device for locking in the

OFF-position (panel door) 15 - 10

– Retrofitting locking device for racking handle 15 - 11

– Retrofitting locking device for reset button 15 - 13

Equipment for padlocks 15 - 14

– Locking bracket for “Safe OFF” 15 - 15

– Locking device for shutters 15 - 16

– Locking device for guide rails 15 - 17

– Locking device for racking handle 15 - 18

– Locking device for spring charging lever 15 - 18

– Locking device for Mechanical OFF/ON button 15 - 18

16 Sealing fixtures 16 - 1

17 Locking devices 17 - 1

Locking device to prevent racking with panel door open 17 - 2

Panel door interlock 17 - 2

– Fit bolt 17 - 2

– Panel door interlock drill pattern 17 - 4

– Fitting catch on panel door 17 - 5

– Function check 17 - 5

Retrofitting access inhibiter over mechanical

ON and OFF button 17 - 6

18 Mutual mechanical interlocking 18 - 1

Configurations 18 - 3

– General notes 18 - 3

– Two circuit-breakers against each other 18 - 4

– Three circuit-breakers among each other 18 - 5

– Three circuit-breakers among each other 18 - 6

– Three circuit-breakers against each other 18 - 7

– Three circuit-breakers, two of them against

each other 18 - 8

Retrofitting interlocking module 18 - 9

– Installing intermediate shaft and coupling 18 - 9

– Installing interlocking module 18 - 11

– Mounting the Bowden cables 18 - 13

– Function test 18 - 15

19 Accessories for withdrawable unit 19 - 1

Shutters 19 - 1

– Retrofitting 19 - 1

Coding circuit-breaker - withdrawable unit 19 - 5

– Rated current coding 19 - 5

– Option-related coding 19 - 6

Position signalling switch for withdrawable unit 19 - 9

20 Phase barriers 20 - 1

21 Arc chute covers 21 - 1

Retrofitting 21 - 1

22 Door sealing frame IP41 22 - 1

23 Shrouding cover IP55 23 - 1

24 Maintenance 24 - 1

Preparation for maintenance 24 - 2

– Switch off and discharge the spring 24 - 2

– Remove the circuit-breaker from the withdrawable unit 24 - 3

Checking arc chutes 24 - 4

Check contact wear 24 - 6

Replacing pole assembly 24 - 6

– Remove front panel 24 - 6

– Remove arc chutes 24 - 6

– Removing pole assemblies 24 - 7

– Installing pole assemblies 24 - 10

– Article numbers on request 24 - 13

– Fitting front panel 24 - 13

– Mechanical function test 24 - 13

– Fitting arc chutes 24 - 13

Replacing operating system 24 - 13

25 Disposal 25 - 1

Disposal of IZM circuit-breakers 25 - 1

26 Forms 26 - 1

27 Abbreviations 27 - 1

28 Glossary 28 - 1

29 Index 29 - 1

II 08/07 AWB1230-1407D

Page 7

0 About this manual

List of modifications

Edition date Page Description

10/02 All Revision of complete manual

06/05 All Revision of complete manual

08/07 All Revision of complete manual

Note

These instructions do not purport to cover all details or variations in

equipment, nor to provide for every possible contingency to be met

in connection with installation, operation or maintenance.

Should further information be desired or should particular problems

arise which are not covered sufficiently for the Purchaser's

purposes, the matter should be referred to the local Moeller Sales

Office.

Our Field Service personnel are available for maintainance or retrofitting of your circuit-breakers. To contact Field Service:

a chapter 26

Danger

Hazardous voltage!

Can cause death or serious personal injury as well

as damage to device and equipment.

Before working on this device the system must be

switched off.

Danger if spring is charged!

Discharge spring.

Symbols

Warning

Dangerous electrical voltage!

Safety warning

Danger by crane transport

Warning against personal injury

Danger of injury

CE-mark

Flathead screwdriver

10 Nm

1

Crosstip screwdriverPhilips (PH),

PoziDriv (PZ)

Torx screwdriver (T)

Hexagon socket screwdriver

Tightening torque

Cable tie

Complete by hand

First step of action sequence

08/07 AWB1230-1407GB 0 – 1

Page 8

0 – 2 08/07 AWB1230-1407GB

Page 9

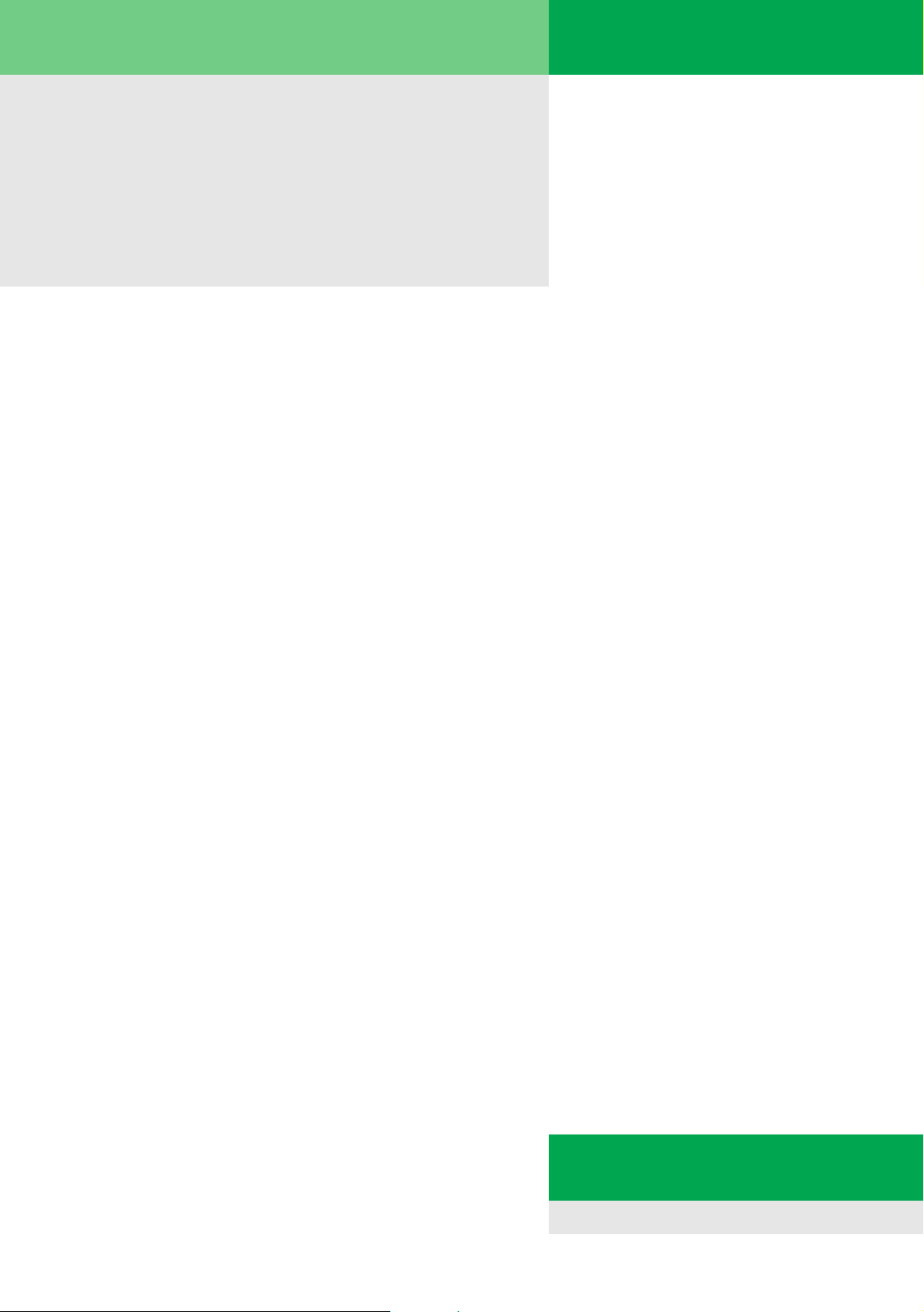

1 Construction

1.1 Circuit-breaker

(1) Arc chute a page 24 – 4

(2) Carrying handle

(3) Identification tags

(4) Motor cut-off switch (option) a page 14 – 3 or “Electrical ON”

(option) a page 14 – 3

(5) Circuit-breaker label a page2–1

(6) Stored-energy indicator a page 6 – 5

(7) “Mechanical ON” button

(8) Part no.

(9) Insertion pictograph

(10) Switching operations counter (option) a page 12 – 2

(11) Manual lever a page 6 – 4

(12) Crank handle a page 6 – 3

(13) Withdrawable unit transport shaft

(14) Options label a page 2 – 1

(15) Earthing terminal a page5–21

(16) Position indicator a page6–2

(17) Earth-fault tripping table (a page 9 – 17)

(18) Safety lock crank handle (option) a page 15 – 11

(19) Control rod (option) a page 15 – 3

(20) Overcurrent release a page9–1

(21) Rating plug a page 9 – 35

(22) Mechanical OFF button or Emergency-Stop pushbutton (option)

a page 14 – 3

(23) Ready-to-close indicator a page6–4

(24) Switch position indicator a page6–4

(25) Tripped indicator (Reset button) (a page6–6)

(26) Locking device, “Safe OFF” position (option) a page 15 – 15

(27) Front panel a page 24 – 6

(28) Plug connector for auxiliary contacts a page 5 – 16

08/07 AWB1230-1407GB 1 – 1

Page 10

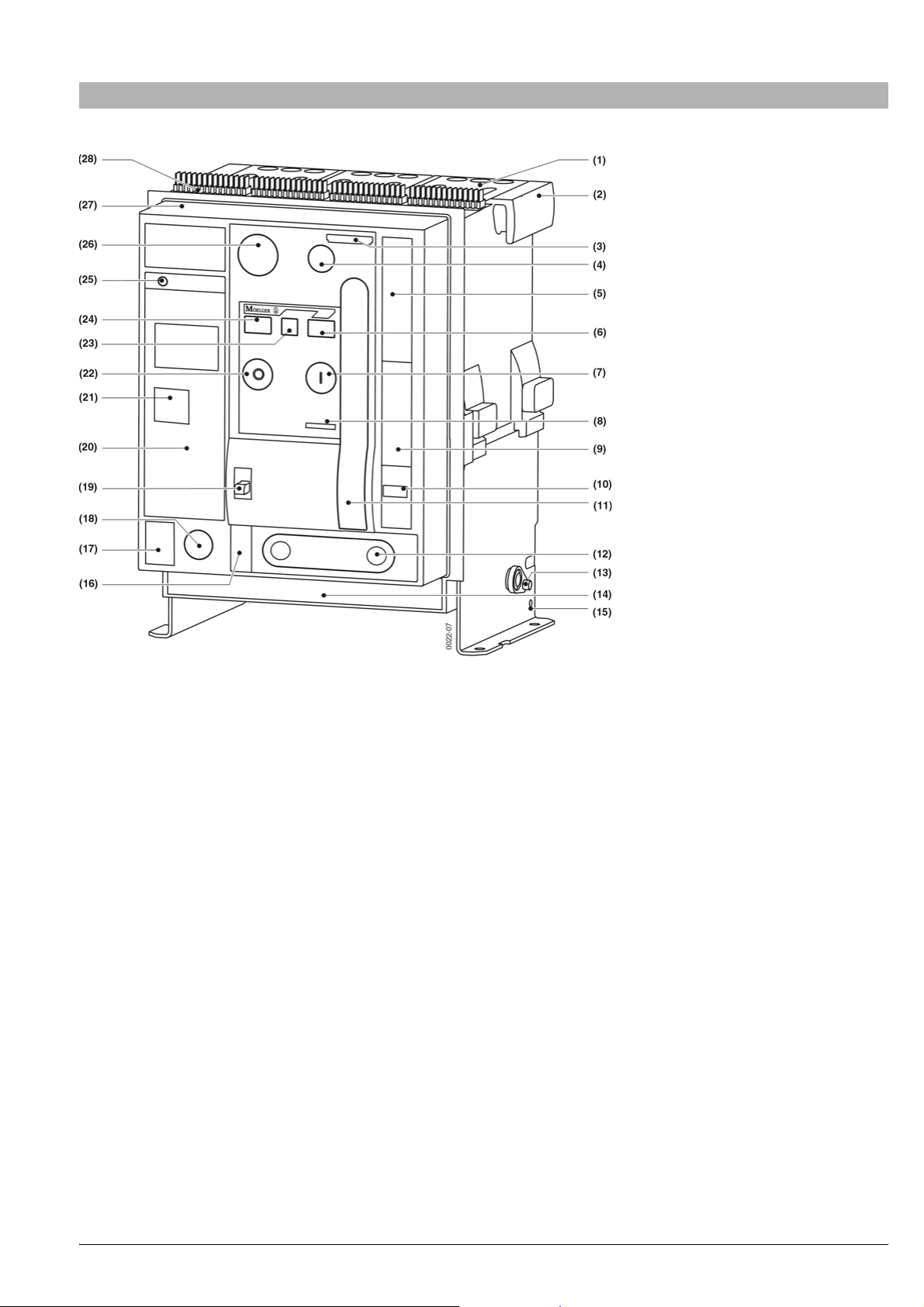

1.2 Withdrawable unit

(1)

(2)

(18)

(17)

(16)

(15)

(14)

(13)

(12)

(11)

(10)

(1) Arcing chamber cover (option) a page 21 – 1

(2) Outlets a page 5 – 19

(3) Hole for crane hook a page4–2

(4) Shutter (option) a page19–1

(5) Locking device shutter (a page 15 – 16)

(6) Withdrawable unit label a page2–3

(7) Laminated contacts (a page 5 – 11)

(8) Earthing terminal o 14 mm a page5–21

(9) Locking device guide rail a page 15 – 17

(10) Locking device to prevent racking with panel door open (option)

a page 17 – 2

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(11) Door locking withdrawable unit (option) a page 17 – 2

(12) Guide rail a page6–1

(13) Factory setting rated current coding a page 19 – 5

(14) Switch ground sliding contact (on request)

(15) Equipment dependant coding (option) a page 19 – 6

(16) Shutter actuator a page 19 – 2

(17) Position signalling switch (option) a page 19 – 9

(18) Auxiliary sliding contacts module (quantity depends on

configuration) a page 5 – 17

1 – 2 08/07 AWB1230-1407GB

Page 11

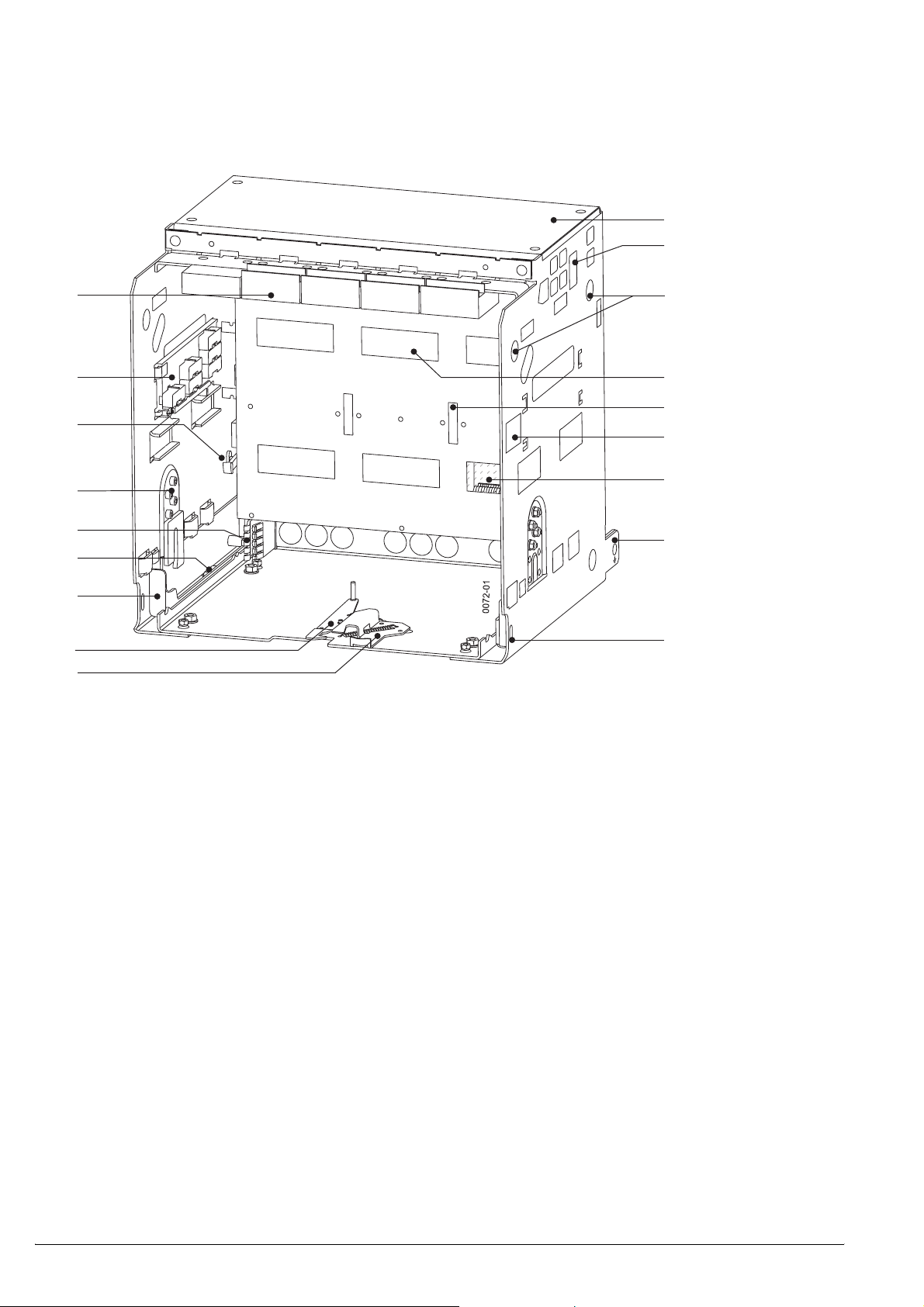

2 Labels

2.1 Circuit-breaker equipment label

(with terminal designations)

Tripped signalling switch

Signalling switch 1st

Remote reset

voltage release

Charge condition signalling

(on request)

auxiliary contact

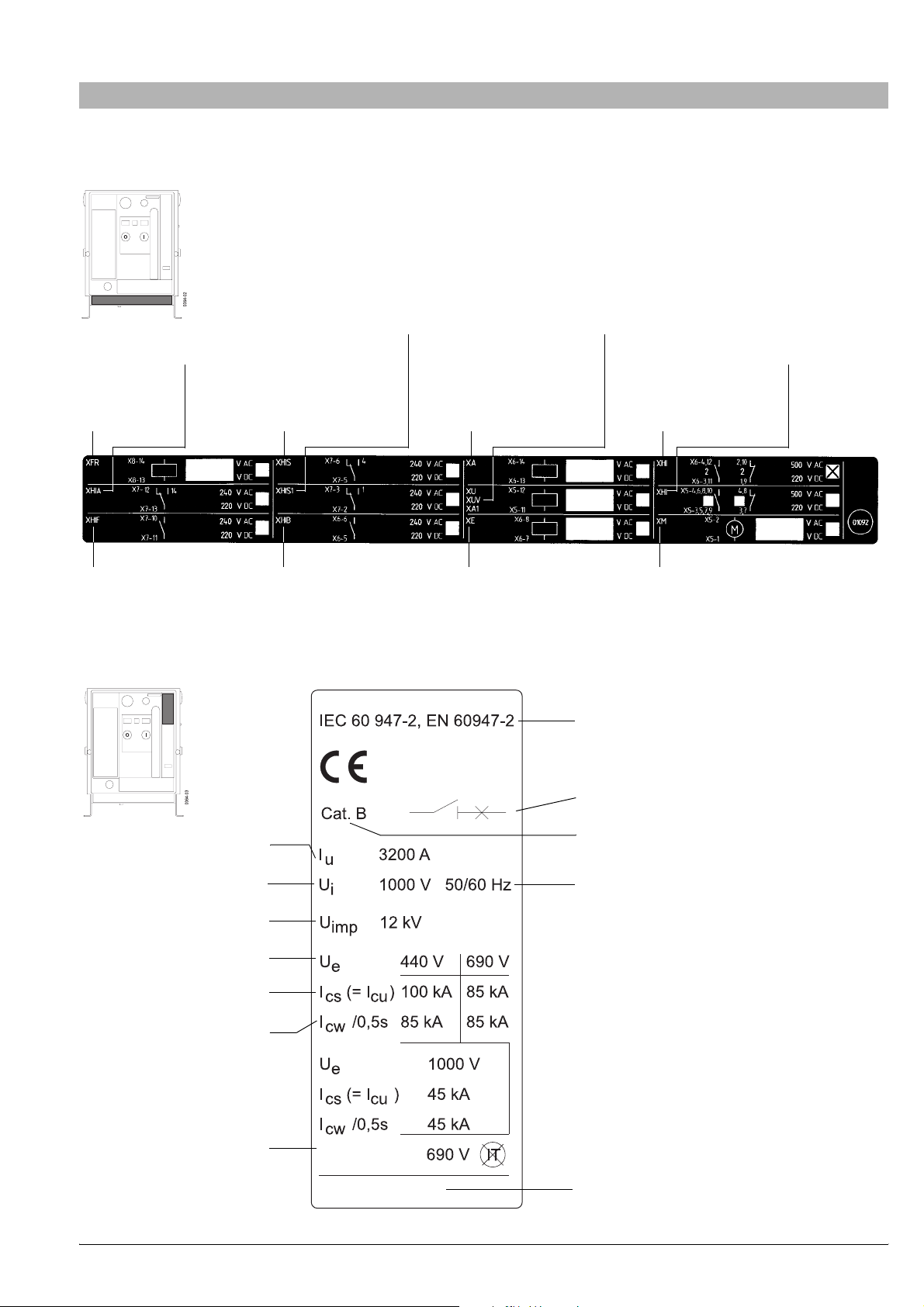

2.2 Circuit-breaker label

Signalling switch 2nd

voltage release

1st shunt release

(Delayed) undervoltage

release or 2nd shunt

release

Additional auxiliary contacts

Standard auxiliary

contacts

BA_01092

Motor operatorClosing releaseReady-to-close

Standards

Max. rated current of the

Rated insulation voltage

Rated impulse withstand voltage

Rated operational voltage

Rated short-circuit breaking capacity

Rated short-time withstand current

Direction for use in IT systems

circuit-breaker

ID-Nr. 4912...

Disconnected function

Utilization category

Rated frequencies

Ident-No. circuit-breaker

08/07 AWB1230-1407GB 2 – 1

Page 12

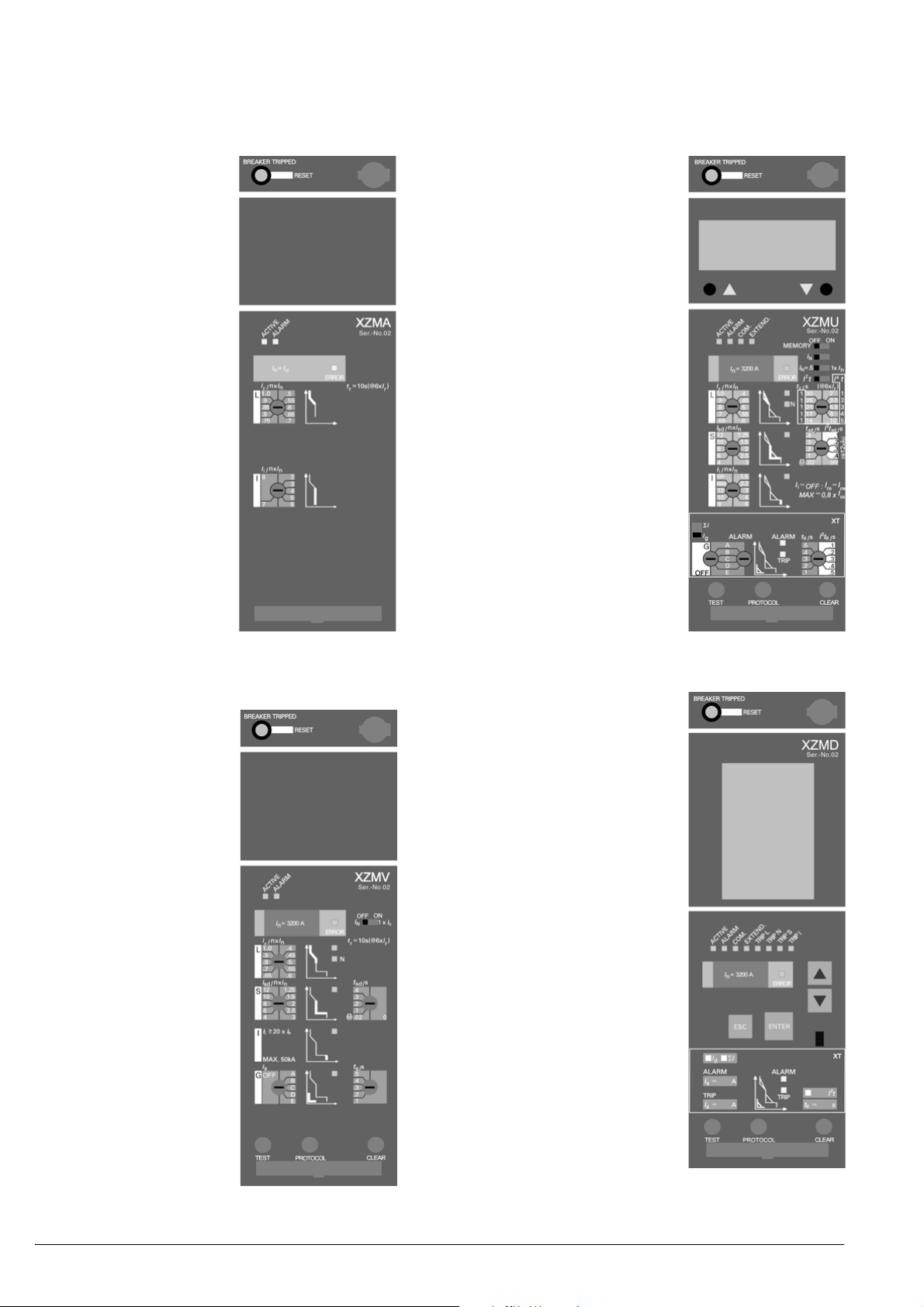

2.3 Identification of the control unit

IZM ...-A... Release for protection of systems

IZM ...-U... Release for universal protection

Options:

XT(A) Earth-fault

protection

N-conductor

protection

adjustable

XAM LCD-display

XCOM-DP Communication

interface

XMP(H) Measurement

module

IZM ...-V... Release for selectively-opening circuitbreakers

Options:

XT Earth-fault

protection

Neutral conductor

protection, can be

switched on/off

XZMA

XZMU

IZM...-D... Digital overcurrent release

Options:

XT(A) Earth-fault

protection

N-conductor

protection

adjustable

XCOM-DP Communication

interface

XMP(H) Measurement

module

XZMD+AMG

XZMV+T

2 – 2 08/07 AWB1230-1407GB

Page 13

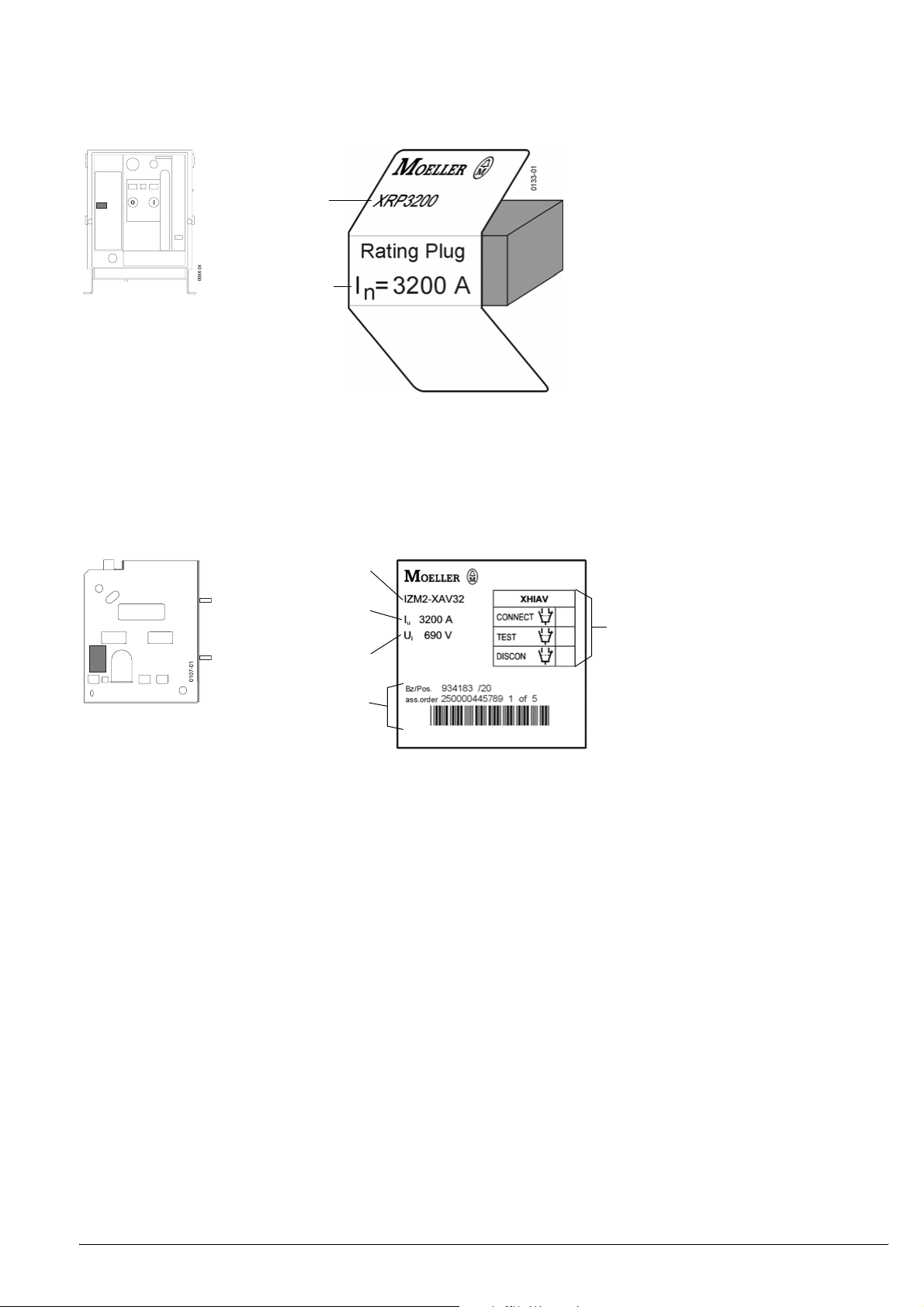

2.4 Rating plug label

Part no.

Rated current of the

circuit-breaker

2.5 Withdrawable unit label

Part no.

Withdrawable unit maximum

current rating

Rated insulation voltage

Internal handling numbers

Position signalling switch

0134

08/07 AWB1230-1407GB 2 – 3

Page 14

2 – 4 08/07 AWB1230-1407GB

Page 15

3 Standards and regulations

Danger

Dangerous voltage!

Can cause death, serious injury or damage to

material/property.

Only qualified personnel that are familiar with the

warning and safety notices and maintenance

instructions may work on the device.

Qualified personnel must have the skill and

experience in the operation of electrical equipment

and systems as well as their construction and

function. They should have taken part in safety

training concerning the dangers of electrical

equipment.

The effective and safe function of these devices is

dependant upon correct operation, installation,

handling and maintenance.

Qualified Personnel

For the purpose of this instruction manual and product

labels, a “qualified person” is one who is familiar with the

installation, construction and operation of the equipment

and the hazards involved. In addition, he has the following

qualifications:

a) Training or instruction in respectively, authorisation,

circuitry and device/systems in accordance with the

regulations for safe on and off switching, earthing and

identification.

b) Training or instruction in accordance with the regulations

for the safety features in care and application of

appropriate safety equipment.

c) Is trained in rendering first aid.

The circuit-breakers are suited for operation in enclosed spaces not

subject to operating conditions aggravated by dust, caustic vapours

or gases. Circuit-breakers to be installed in dusty or damp locations

must be appropriately enclosed.

The circuit-breaker is in conformity with the standards:

IEC 60947-2

EN 60947-2

DIN VDE 0660 Part 101

08/07 AWB1230-1407GB 3 – 1

Page 16

3 – 2 08/07 AWB1230-1407GB

Page 17

4 Transport

Unpack the circuit-breaker and inspect for damage. In case of later

installation of the circuit-breaker or withdrawable unit: They may be

stored and redispatched only in the original packing.

Transport packing

Red transport indicator

Arrow in the top half is partly or fully blue. Arrow in the top half is white

– Transport not according to instructions (switch was tilted or

overturned)

– Check circuit-breaker for transport damage

– Notify damages to forwarding agent

– Circuit-breaker was not tilted or overturned during transport

4.1 Overseas packing

Check humidity indicator Further storage

Pink Blue

Renew dessicant or seal tightly with dry plastic

Sealed packing ineffective. Check circuitbreaker for corrosion. Report damage to

transport company

Good

film Check packing regularly

4.2 Unpacking

Unpack the circuit-breaker and inspect for damages.

For later installation of circuit-breaker or withdrawable unit: Storage

and further shipment only in original packing.

CAUTION

Do not lay the circuit-breaker on it´s back!

08/07 AWB1230-1407GB 4 – 1

Page 18

4.3 Lifting by crane

m

Danger

Heavy device.

Incorrect lifting can cause death or serious

injury as well as damage to the device and

equipment.

Never lift a circuit-breaker, or a withdrawable

unit over a person. Follow the operating

instructions of the crane. Only use OSHA/

NIOSH tested crane harnesses. Use personnel

safety equipment to lift or move circuitbreakers and withdrawable unit.

Caution

Circuit-breaker Withdrawable unit

Do not put on the rear

side!

Frame size/No. of poles Weight

IZM(IN).1-... / 3

IZM(IN).1-... / 4

IZM(IN).2-... / 3

IZM(IN).2-... / 4

IZM(IN).3-... / 3

IZM(IN).3-... / 4

1) Hook cable above the label.

43 kg

50 kg

max. 64 kg

max. 77 kg

max. 90 kg

max. 108 kg

Circuit-breaker + Withdrawable

unit

o max. 12 m

m

1

f

m

1

f

25 kg

30 kg

max. 45 kg

max. 54 kg

max. 70 kg

max. 119 kg

o max 12 mm

1)

f

70 kg

84 kg

max. 113 kg

max. 136 kg

max. 166 kg

max. 227 kg

o max 12 mm

m

1

1)

4 – 2 08/07 AWB1230-1407GB

Page 19

5 Mounting

WARNING

Safe operation is dependent upon proper

handling and installation by qualified personnel

under observance of all warnings contained in

this instruction manual.

The general installation and safety regulations

for working on high current systems (e.g. DIN

VDE) and also standards concerning the

correct use of lifting equipment and tools and

the use of personal protection equipment

(safety glasses, etc.) should be especially

observed.

Non-observance can result in death, severe

personal injury or substantial property damage.

5.1 Installation

5.1.1 Mounting position

°

0

3

F

F

3

Danger

Heavy device.

Incorrect lifting can cause death or serious

injury as well as damage to the device and

equipment.

Never lift a circuit-breaker, or a withdrawable

unit over a person. Follow the operating

instructions of the crane. Only use OSHA/

NIOSH tested crane harnesses. Use personnel

safety equipment to lift or move circuitbreakers and withdrawable unit.

°

0

3

0

°

F

F

3

0

°

5.1.2 Mounting on horizontal surface

D h max. 1 mm

Fixing points

Non-removable nut

4 bolts M8-8.8

08/07 AWB1230-1407GB 5 – 1

4 bolts M8-8.8 + nuts + strain washers

If several withdrawable units are arranged one above the other in

cubicles without compartment bases we recommend the use of arc

chute covers (a page 21 – 1).

Page 20

5.1.3 Mounting on a vertical surface with mounting

brackets

For fixed-mounted circuit-breaker only.

Part no.

Mounting brackets (only for IZM(IN).1-... and

IZM(IN).2-...)

IZM1/2-XTW

4 bolts M10-8.8 + nuts + strain washers

Non-removable nut

4 bolts M8-8.8 + strain washers

Mounting dimensions

Representation of IZM(IN).2-... with front connection.

5 – 2 08/07 AWB1230-1407GB

Page 21

Dimension diagram, mounting brackets

o 13.5

o 20

43

9

113

342

172.5

20

o 9

23 402

16+0.5

452

30

16

20

o 11

455

400

20

34

40

17

17.5

152.5

212

337 5

08/07 AWB1230-1407GB 5 – 3

Page 22

5.1.4 Safety clearances

5.1.5 Safety clearance to earthed parts

Rated operational

voltage

[V AC] [mm] [mm] [mm]

IZM(IN).1-..., Fixed mounting

440 75

690 75

IZM(IN).1-..., Withdrawable, without arc chute cover

440 50

690 50

IZM(IN).1-..., Withdrawable, with arc chute cover

440 0 0

690 0 0

IZM(IN).2-..., Fixed mounting

440 75

690 75

1000 180 0 0

IZM(IN).2-..., Withdrawable, without arc chute cover

440 50

690 50

1000 100 0 0

IZM(IN).2-..., Withdrawable, with arc chute cover

440 0 0

690 0 0

IZM(IN).3-..., Fixed mounting

440 75

690 75

1000 180 0 0

IZM(IN).3-..., Withdrawable, without arc chute cover

440 50

690 50

1000 100 0 0

IZM(IN).3-..., Withdrawable, with arc chute cover

440 0 0

690 0 0

1) Value for plates, 0 mm for supports and grills.

2) 40 mm (IZM(IN).2-...: 70 mm) for plates that cover openings in drawer frame.

above control

circuit plug

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

Side (each) Rear

00

00

00

00

2)

2)

0

0

00

00

00

00

2)

2)

0

0

00

00

00

00

2)

2)

0

0

All safety clearances above the circuit-breaker are from the top

edge of the control circuit plug not the top edge of the arc chute!

a dimension drawings

5.1.5.1 Safety clearances to live parts

Rated operational

voltage

[V AC] [mm] [mm] [mm]

IZM(IN).1-..., Fixed mounting

440 150 20 20

690 300 50 125

IZM(IN).1-..., Withdrawable, without arc chute cover

440 150 20 14

690 300 50 14

IZM(IN).1-..., Withdrawable, with arc chute cover

440 14 100 14

690 14 100 14

IZM(IN).2-..., Fixed mounting

440 250 50 20

690 600 100 140

1000 430 100 125

IZM(IN).2-..., Withdrawable, without arc chute cover

440 250 50 14

690 600 100 30

1000 350 100 14

IZM(IN).2-..., Withdrawable, with arc chute cover

440 14 50 14

690 14 225 14

IZM(IN).3-..., Fixed mounting

440 75 20 20

690 500 100 125

1000 430 100 125

IZM(IN).3-..., Withdrawable, without arc chute cover

440 50 20 14

690 500 100 14

1000 350 100 14

IZM(IN).3-..., Withdrawable, with arc chute cover

440 14 50 14

690 14 200 14

above control

circuit plug

Side (each) Rear

5 – 4 08/07 AWB1230-1407GB

Page 23

5.1.6 Use in IT systems

5.1.7 Regulations

In IEC 60947-2 or EN 60947-2 “Low voltage switchgear Part 2:

circuit-breakers” for the use of circuit-breakers in an unearthed or

impedance earthed network (IT systems) an extra test to IEC

60947-2 Appendix H is required.

Subsequently the tests with 1.2 times the highest setting of the

short time delayed overcurrent trip (S trip) or the undelayed

overcurrent trip ( I trip) when no S trip is available, as single pole

short-circuit switch-off capacity I

maximum of 50 kA. The tests are to carried out with the phase

voltages of the highest rated operating voltage Ue for use in the

network.

With this the worst case fault that could occur in the IT system is

covered, with a double earth fault on the load and incoming sides

See following illustration:

are to be verified. This is for a

IT

e

690 V AC

L1

L2

L3

b

d

690 V

a

c

햲 Fault 1

햳 Fault 2

햴 Frame

햵 Impedance

햶 Transformer

Explanation:

– After fault 1 fault 2 then occurs.

– With that there is then a double earth fault on the load and

incoming sides.

– On the main contacts in phase L1 is then the full phase voltage of

e.g. 690 V.

– At the same time the contact must carry a high short-circuit

current.

08/07 AWB1230-1407GB 5 – 5

Page 24

5.1.7.1 Conditions for use in IT Systems

The IZM circuit-breaker fulfills the requirements for use in IT

systems with the standard IEC 60947-2 Appendix H demanded

maximum values with consideration of the following options and

safety clearances (blow-out space).

The details for the blow-out space above the control circuit plug is

based on the necessary blow-out space over the arc chute and

serves as additional information to users who want to bring their

Overview circuit-breaker IZM in IT systems

safety clearances to the appropriate highest point of the device

(control circuit plug). The short-circuit breaking capacity shown in

the table I

corresponds to the maximum demanded value in the

IT

standard IEC 60947-2 Appendix H , to fulfill an acceptibility in the IT

systems with the respective rated operating voltage U

The circuit-breakers of type IZM1 cannot be used in 690 V IT

systems, here the option IZM...-X1000 V is generally suitable.

to IEC 60947-2 or EN 60947-2 Appendix H

Type (3/4-pole)

IZM1 IZM2 IZM3

Rated operating voltage Ue F 440 V

– Single pole short-circuit breaking capacity I

IT

kA 23 50 50

– neccessary options – – –

– minimum required blow-out space above arc chute. mm 100 100 50

– corresponding minimum blow-out space above control circuit plug.

mm 70/40 70/40 20/0

(fixed/withdrawable)

– labelling to IEC 60947-2 Appendix H 690 V 690 V 500 V

ITIT ITIT ITIT

Rated operating voltage Ue F 500 V

– Single pole short-circuit breaking capacity IIT kA 23 50 50

– neccessary options – – –X1000 V

– minimum required blow-out space above arc chute. mm 150 150 50

– corresponding minimum blow-out space above control circuit plug.

mm 120/90 120/90 65/0

(fixed/withdrawable)

– labelling to IEC 60947-2 Appendix H 690 V 690 V 1000 V

ITIT ITIT ITIT

Rated operating voltage Ue F 690 V

– Single pole short-circuit breaking capacity IIT kA – 50 50

– neccessary options – –X1000 V

2)

–X1000 V

– minimum required blow-out space above arc chute. mm – 50 50

– corresponding minimum blow-out space above control circuit plug.

mm – 65/0 65/0

(fixed/withdrawable)

– labelling to IEC 60947-2 Appendix H 690 V 1000 V 1000 V

ITIT ITIT ITIT

.

e

1)

1)

1) –X1000 V ist option IZM...-X1000 V for rated operating voltage Ue = 1000 V AC

2) Exception: IZM...2-(4-)A(V)800...1600, this circuit-breaker fulfills the

requirement for 690V IT networks corresonding to IEC 60947-2, Appendix H

(contrary to the details on the rating label: )

ITIT

5.1.8 Labelling of the IZM circuit-breaker

The standard IEC 60947-2 Appendix H demands the labelling of

devices that are in their existing features not suitable for IT

networks for all values of the rated operating voltage and the

corresponding types or sizes. The following symbol must be directly

behind the rated operating voltage e.g. 690 V .

ITIT

The labelling for single sizes and voltages can be seen in the above

table.

5 – 6 08/07 AWB1230-1407GB

Page 25

5.2 Connecting bars

a Frame sizes, dimension drawings (page 7 – 1)

5.2.1 Horizontal connection

The horizontal connection is up to 5000 A including the standard

connection for fixed-mounted circuit-breakers and withdrawable

unit.

o 13.5 mm

For withdrawable unit only:

a Retrofit installation of horizontal connections (page 5 – 12)

5.2.2 Flange connection

(only for withdrawable)

M 12

The mounting of the flange connection is similar to the mounting of

the vertcal and horizontal connections (a page 5 – 12)

70

± 4 Nm

X

08/07 AWB1230-1407GB 5 – 7

Screw-in depth:

x = 18...24 mm

Page 26

5.2.3 Front connection

Note

When front connections are used, a partition between busbar and

arcing space must be fitted on the system side.

Fixed-mounted circuit-breaker

Two variations are offered:

(1) Standard version: single-hole fitting

(2) Version double-hole fitting

(3) Holes o 13.5

(1)

(2)

(3)

Fastening connecting bars:

(1) (2)

85 Nm

Size 5

8 Nm

(1) For

IZM(IN).1-...

IZM(IN).2-...

(2) For

IZM(IN).1-...

IZM(IN).2-...

IZM(IN).3-...

(3) Long connecting bar

(4) Short hexagon socket screw ISO 4762 M6 with strain washer

(5) Short spacer

(6) Coach screw DIN 603 M12 with strain washer and nut

(7) Long distance sleeve

(8) Long hexagon socket screw ISO 4762 M6 with strain washer

(9) Short connecting bar

F 1000 A and

F 2000 A

1600 A

2500 A, 3200 A

4000 A

(3)

(4)

(5)

(6)

(7)

(8)

(9)

85 Nm

Size 5

8 Nm

5 – 8 08/07 AWB1230-1407GB

Page 27

Withdrawable unit

Two variations are offered:

(1) Standard version: single-hole fitting

(2) Version double-hole fitting

(3) Slots for phase separation walls; mounting position as shown!

(4) Support

(5) Holes o 13.5

Fastening connecting bars:

(1)

(2)

(3)

(4)

(5)

(1) (2)

(3)

85 Nm

(4)

(5)

Size 5

10 Nm 10 Nm

(1) For

IZM(IN).1-...

IZM(IN).2-...

(2) For

IZM(IN).1-...

IZM(IN).2-...

IZM(IN).3-...

(3) Hexagon socket screw ISO 4762 M6 with strain washer

(4) Support; mounting position as shown!

(5) Coach screw DIN 603 M12 with strain washer and nut

F 1000 A and

F 2000 A

1600 A

2500 A, 3200 A

4000 A

85 Nm

Size 5

Conversion from vertical or flange connection to front

connection requires installation of horizontal connection first!

a (page5–11)

08/07 AWB1230-1407GB 5 – 9

Page 28

5.2.4 Vertical connection

Fixed-mounted circuit-breaker

Size

IZM(IN).1-... 1000 A

1) 2 connection bars per main connection,

above and below fixing by offset slot,

a Picture for IZM(IN).2-...

Rated current

1)

1600 A

.

Size

IZM(IN).2-...

Rated current

2500 A1)

3200 A

1) 1 connect bar per main connection, middle fixing,

a Picture for IZM(IN).1-...

1 × M12-8.8 + nut

+ spring washer (above + below)

2 × o 13.5 mm

3 × M12-8.8 + nut

+ spring washer (above + below)

3 × o 13.5 mm

85 Nm

85 Nm

Size

IZM(IN).3-...

Rated current

5000 A

4 × M12-8.8 + nut

+ spring washer (above + below)

4 × o 13.5 mm

85 Nm

5 – 10 08/07 AWB1230-1407GB

Page 29

Withdrawable unit

Size

IZM(IN).1-... 1000 A, 1600 A

Size

IZM(IN).3-... 6300 A

Rated current

1 × M 6

2 x o 13.5

Rated current

Size

IZM(IN).2-... 2000 A, 2500 A

Rated current

A

3200

2 × M 6

3 x o 13.5

Size

IZM(IN).3-... 5000 A

Vertical connections left and right

asymmetric

Rated current

2 × M 6

4 x o 13.5

Removal of lamelle contacts

Rear side of withdrawable unit

2

3

1

08/07 AWB1230-1407GB 5 – 11

Page 30

Removing horizontal connection

Rear drawer area

2

Size 5

Combination

screw M6x20

Installing vertical connection

Rear drawer area Combination screw M6x20

1

3

2

4

1

8 Nm

3

Mounting steps for installation of horizontal or flange connection are similar.

Note

The lamelle blocks for circuit-breaker IZM(IN).3-..., 4000 A, are not

fully equiped with lamelle.

4

ATTENTI O N

Only use similarly equiped lamelle blocks for assembly.

5 – 12 08/07 AWB1230-1407GB

Page 31

Order numbers

Connecting bars fixed-mounted circuit-breaker Frame size Rated current I

F 1000 A (+)IZM1-XAT1F10-0

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XAT1F16-0

F 2000 A (+)IZM2-XAT1F20-0

Front connection (single-hole fitting) top

IZM(IN).2-...

2500 A (+)IZM2-XAT1F25-0

3200 A (+)IZM2-XAT1F32-0

IZM(IN).3-... F 4000 A (+)IZM3-XAT1F40-0

F 1000 A (+)IZM1-XATF10-0

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XATF16-0

F 2000 A (+)IZM2-XATF20-0

Front connection (double-hole fitting) top

IZM(IN).2-...

2500 A (+)IZM2-XATF25-0

3200 A (+)IZM2-XATF32-0

IZM(IN).3-... F 4000 A (+)IZM3-XATF40-0

F 1000 A (+)IZM1-XAT1F10-U

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XAT1F16-U

F 2000 A (+)IZM2-XAT1F20-U

Front connection (single-hole fitting) bottom

IZM(IN).2-...

2500 A (+)IZM2-XAT1F25-U

u

Part no.

Front connection (double-hole fitting) bottom

Vertical connection

1)IZM1-XATV16 = 2x IZM1-XATV10

2)IZM2-XATV32 = 2x IZM2-XATV25

3200 A (+)IZM2-XAT1F32-U

IZM(IN).3-... F 4000 A (+)IZM3-XAT1F40-U

F 1000 A (+)IZM1-XATF10-U

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XATF16-U

F 2000 A (+)IZM2-XATF20-U

IZM(IN).2-...

2500 A (+)IZM2-XATF25-U

3200 A (+)IZM2-XATF32-U

IZM(IN).3-... F 4000 A (+)IZM3-XATF40-U

F 1000 A (+)IZM1-XATV10

IZM(IN).1-...

1600 A (+)IZM1-XATV16

1)

F 2500 A (+)IZM2-XATV25

IZM(IN).2-...

3200 A (+)IZM2-XATV32

2)

IZM(IN).3-... F 5000 A (+)IZM3-XATV50

08/07 AWB1230-1407GB 5 – 13

Page 32

Connecting bars withdrawable unit Frame size Rated current I

F 1000 A (+)IZM1-XAT1F10-AV

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XAT1F16-AV

Front connection (single-hole fitting)

When these connections are ordered individually, additional

supports must also be ordered.

IZM(IN).2-...

F 2000 A (+)IZM2-XAT1F20-AV

2500 A (+)IZM2-XAT1F25-AV

3200 A (+)IZM2-XAT1F32-AV

IZM(IN).3-... F 4000 A (+)IZM3-XAT1F40-AV

u

Part no.

Front connection (double-hole fitting)

When these connections are ordered individually, additional

supports must also be ordered.

3-pole for 3 front

Supports for front connections with

connections

withdrawable unit

2 supports per switch required

4-pole for 4 front

connections

Vertical connection

IZM(IN).1-...

F 1000 A (+)IZM1-XATF10-AV

1250 A...1600 A (+)IZM1-XATF16-AV

F 2000 A (+)IZM2-XATF20-AV

IZM(IN).2-...

2500 A (+)IZM2-XATF25-AV

3200 A (+)IZM2-XATF32-AV

IZM(IN).3-... F 4000 A (+)IZM3-XATF40-AV

IZM(IN).1-... F 1600 A IZM1-XATFS

IZM(IN).2-... F 3200 A IZM2-XATFS

IZM(IN).3-... F 4000 A IZM3-XATFS

IZM(IN).1-4-... F 1600 A IZM1-XATFS4

IZM(IN).2-4-... F 3200 A IZM2-XATFS4

IZM(IN).3-4-... F 4000 A IZM3-XATFS4

F 1000 A (+)IZM1-XATV10-AV

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XATV16-AV

F 2000 A (+)IZM2-XATV20-AV

IZM(IN).2-...

2500 A (+)IZM2-XATV25-AV

3200 A (+)IZM2-XATV32-AV

Flange connection

IZM(IN).3-... F 5000 A (+)IZM3-XATV50-AV

F 1000 A (+)IZM1-XATA10-AV

IZM(IN).1-...

1250 A...1600 A (+)IZM1-XATA16-AV

F 2000 A (+)IZM2-XATA20-AV

IZM(IN).2-...

F 2500 A (+)IZM2-XATA25-AV

F 3200 A (+)IZM2-XATA32-AV

IZM(IN).3-... F 4000 A (+)IZM3-XATA40-AV

5 – 14 08/07 AWB1230-1407GB

Page 33

5.3 Connection of main conductors

Main conductor - minimum cross section:

Frame size Rated current

I

u

[A] [mm2]

Cross section Cu bars

bare/bare black/bare

1)

630 1 × 40 × 10 1 × 40 × 10

800 1 × 50 × 10 1 × 60 × 10

IZM(IN).1-...

1000 1 × 60 × 10 1 × 60 × 10

1250 2 × 40 × 10 2 × 40 × 10

1600 2 × 50 × 10 2 × 50 × 10

800 1 × 50 × 10 1 × 50 × 10

1000 1 × 60 × 10 1 × 60 × 10

1250 2 × 40 × 10 2 × 40 × 10

IZM(IN).2-...

1600 2 × 50 × 10 2 × 50 × 10

2000 3 × 50 × 10 3 × 50 × 10

2500 2 × 100 × 10 2 × 100 × 10

3200 3 × 100 × 10 3 × 100 × 10

4000 4 × 100 × 10 4 × 100 × 10

IZM(IN).3-...

5000 5 × 100 × 10 5 × 120 × 10

6300 6 × 120 × 10 6 × 120 × 10

1) Other Cu bar sizes possible, but the total Cu cross section must not be less.

2) Aluminium bars - please enquire.

2)

[mm2]

1)

Cleaning the copper bars

Steel-wire brush

Bolt tight line-side bars

Bracing the main conductors

Metal cuttings

Remove

ATTENTION

On 4-pole circuit-breakers, the neutral conductor must

always be connected all on the left (front view).

Otherwise this can cause malfunctions of the electronic

overcurrent release.

Connection of cables directly on the circuit-breaker

connections is not permissible.

Cleaning the main conductor connection

Circuit-breaker

08/07 AWB1230-1407GB 5 – 15

Page 34

5.4 Auxiliary conductor connection

Retrofitting

Terminal assignment:

a Circuit diagrams (page 8 – 1)

Cross section connection type

1 x 2 x

Strip conductors

Screw terminals

0.5 – 2.5 mm

AWG 20...14

+

7 mm

Spring-loaded

terminals

Wire end ferrule

0.5 – 2.5 mm

AWG 20...14

+

Wire end ferrule

7 mm

1) 1 x up to 2.5 mm2 tubular without plastic sheath to DIN 46228 T1

1 x up to 1.5 mm

2 x up to 1.5 mm

2) 2 x up to 2.5 mm

2 x up to 1.5 mm

2

tubular with plastic sheath to DIN 46228 T2

2

tubular with plastic sheath, twin ferrules

2

tubular without plastic sheath to DIN 46228 T1

2

tubular with plastic sheath to DIN 46228 T2

2

1)

2

2)

0.5 – 1.5 mm

AWG 20...15

+

Wire end ferrule

0.5 – 2.5 mm

AWG 20...14

+

Wire end ferrule

2

2

1

3

(2)

(1)

2

1)

2)

(1) Blanking cover

(2) Plug connector

Only for circuit-breakers, 1000 V version

0173-06

4

5.4.1 Plug connector

Arrangement

COM-DP

(1) Arc chute

(2) Plug connector

5

(3)

(1)

(2)

X6X7X8

X5

0173-09

6

PH 1

0.7 N

m

(3) Knife-contact rail adapter for higher arc chute

5 – 16 08/07 AWB1230-1407GB

Page 35

Spring-loaded terminals

3.0 × 0.6

5.4.3 Control circuit plug

Screw terminals

Connecting wires

5.4.2 Sliding contact module

Retrofitting

(2)

3.0 × 0.6

Spring-loaded terminals

(1)

3.0 × 0.6

2 terminals in parallel per contact

Attach guide tongues

(fixed-mounted circuit-breaker only)

2

1

(1) Connection area with sliding contact modules

(2) Sliding contact module

A single piece sliding contact module is also available with standard

screw terminals.

3.0 × 0.6

Single-piece sliding contact modules don´t require a control circuit

plug. The cable is directly connected to the sliding contact module.

Back side of

auxiliary connector

0769

08/07 AWB1230-1407GB 5 – 17

Page 36

Coding (only fixed-mounted circuit-breakers)

3

2

(1)

1

click

(1) Groove

(2) Guide

(3) Modul labelling (here X5; must show at front)

(4) Module X5

Fitting auxiliary connectors

L

(1)

X6.

X5

X6.

X5

0100-01_nu

X6.

X5

(2)

(3)

(4)

1

2

(2)

(1) Control circuit plug

(2) Fixed mounting: Knife contact rail

Withdrawable: Sliding contact module

5 – 18 08/07 AWB1230-1407GB

Page 37

5.4.4 Wiring on withdrawable unit

a

Danger

Impermissible area for wires:

Wires could be damaged.

Arcing space*)

Carrying h

Outlets

Interlocks

*)When arc chute cover is used control circuit wires must not be laid on this cover..

5.4.5 Assembly with control circuit connections

Terminal X6 always available. Depending upon the equiping of the

circuit-breaker with additional accessories other terminals are

necessary.

If necessary, with additional accessories the corresponding knife

contact rail, control circuit plug and for connection area also sliding

contact module must be retrofitted.

Ter mina l Optional accessories

X5 – Motor drive with storage with mechanical and electrical

X7 – Activated- signalling switch S24

X8 – Overcurrent release XZMU, XZMD (internal System

release.

– 2. Auxillary release (shunt release F2, undervoltage

release F3, delayable undervoltage release F4)

– Control circuit switch S3 + S4 or S7 + S8 or S3 + S8

– Motor cut-off switch S12 (only possible when motor

drive selected)

– Stored condition indication S21

– Electrical ON pushbutton S10

st

– Signalling switch on 1

– Signalling switch on 2

bus)

– Connection for external current transformer for

overload protection in N conductor and earth fault

protection

– Current transformer mounted in N conductor

– Current transformer mounted in star point of

transformer

– Remote reset magnet F7

– External voltage transformer

release S22

nd

release S23

5.4.6 Order numbers

Auxiliary conductors Order numbers

A Control circuit plug with screw terminals IZM-XKL-HS

B Spring-loaded terminals auxiliary

conductor

C Sliding contact module screw fixing /

standard (only for withdrawable)

D Sliding contact module optional (only for

withdrawable)

E Knife contact rail spring fixing IZM-XKL-ML

F Blanking cover (instead of a plug

connector)

G Coding set for fixed mounting for 4 control

circuit plugs (not necessary for

withdrawable)

H For 1000 V withdrawable the following

device is addditionally necessary:

Additional knife contact rail for adpation on

higher arc chute

IZM-XKL-HZ

IZM-XKL-SS

IZM-XKL-SK

IZM-XKL-B

IZM-XKL-C

IZM-XKL-AML1000V

08/07 AWB1230-1407GB 5 – 19

Page 38

Connection possibilities of the control circuit connections

C

ith

S

Fixed mounted

Connection with screw terminals

(standard)

Screwless connection (springloaded terminals) (option)

Withdrawable units

IZM-XKL-HS

NSE0_00975a

Plug connector on basic unit

IZM-XKL-ML

onnection w

(option)

IZM-XKL-HZ

NSE00978

screw terminals

NSE0_00976a

crewless connection (spring-

loaded terminals) (option)

IZM-XKL-C

Coding

(only for fixed

mounting)

NSE00974

NSE00973

Sliding contact module with screw fixing for

withdrawable (standard)

0769_1

IZM-XKL-SS

IZM-XKL-HS

Plug connector on basic unit

NSE00978

IZM-XKL-ML

NSE0_00975a

IZM-XKL-HZ

Sliding contact module for withdrawable

(option)

IZM-XKL-SK

N S E 0 _ 0 0 9 7 7 a

NSE0_00976a

5 – 20 08/07 AWB1230-1407GB

Page 39

5.5 Connection of protective conductor

5.5.1 Fixed-mounted circuit-breaker

5.5.2 Withdrawable unit

o 14 mm

o 14 mm

5.6 Changeover of fixed mounting circuit-breaker into withdrawable circuit-breaker

Note

For the changeover of your circuit-breaker our Field Service can be

used.

To contact Field Service: a chapter 26.

– Switching off and discharging the storage spring

(a page 24 – 2)

– Remove fixed-mounted circuit-breaker(a page5–1)

– Remove terminals other than horizontal terminals

(a page5–7)

– Remove front panel (a page 24 – 6)

– Remove overcurrent release (a page 9 – 39)

– Install rated current coding on the new circuit-breaker feet and on

the withdrawable unit (a page 19 – 5)

08/07 AWB1230-1407GB 5 – 21

Page 40

5.6.1 Conversion

Replacing circuit-breaker feet

2

Size 4

1

Size 4

3

10 Nm

4

1 Loosen and remove 3 M6x20 countersunk screws

2 Remove foot of fixed-mounted circuit-breaker

3 Replace by foot for withdrawable circuit-breaker

4 Attach the circuit-breaker foot with 3 countersunk M6x20 screws

Size 5

*Nm

2

1 Install racking mechanism

2 When threaded holes exist bolt the racking mechanism tight with

M6x12 cheese-head screw, strain washer and 6x18x3 washer.

When no screw thread exists grease a self-tapping screw and

screw in.

*) Tightening toque :machine screw 6 Nm

self-tapping screw 5 Nm

Installing racking shaft

Installing racking mechanism

1

1

3

2

1 Insert racking shaft

2 Fit crank

3 Secure crank handle with circlip DIN 471-17x1

5 – 22 08/07 AWB1230-1407GB

Page 41

Knock out front panel

1

1 Knock-out section from operating panel; use suitable support

2 Deburr the edges

2

Conversion kit part numbers

Conversion kit for fixed-mounted into withdrawable circuit-breaker.

Frame size Part no.

IZM(IN).1-... IZM1-XUS-AV

IZM(IN).1-4-... IZM1-XUS4-AV

IZM(IN).2-... IZM2-XUS-AV

IZM(IN).2-4-... IZM2-XUS4-AV

IZM(IN).3-... IZM3-XUS-AV

IZM(IN).3-4-... IZM3-XUS4-AV

Note

Conversion kits can only be ordered using the part no. shown above

and also giving the Indent no. of the circuit-breaker.

Fix adhesive label at the front panel

Then:

– Fit control gate(a page 15 – 3)

– Install overcurrent release (a page 9 – 39)

– Install front panel (a page 24 – 13)

– Assemble the required terminals on the withdrawable unit (must be

ordered separately) (a page5–7)

– Install withdrawable unit (a page5–1)

– Insert the circuit-breaker in the withdrawable unit and rack into

connected position (a page 6 – 1)

08/07 AWB1230-1407GB 5 – 23

Page 42

5 – 24 08/07 AWB1230-1407GB

Loading...

Loading...