Page 1

Hardware and Engineering

DF5-...

09/01 AWB8230-1412GB

1st published 2001, edition 09/01

© Moeller GmbH, Bonn

Author: Holger Friedrich, Jörg Randermann

Editor: Michael Kämper

Translator: David Long

All brand and product names are trademarks or registered

trademarks of the owner concerned.

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any otherprocess) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alterations without notice.

Page 2

Warning!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50 110-1/-2 (VDE 0105 Part 100) may work on this

device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalisation. The system installer

is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for the

24 volt supply. Only use power supply units complying with

IEC 60 364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable

units must only be operated and controlled in enclosed

housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must be

implemented to ensure a safe operating state in the event of

a fault or malfunction (for example, by means of separate limit

switches, mechanical interlocks etc.).

• According to their degree of protection frequency inverters may

feature during operation live, bright metal, or possibly moving,

rotating parts or hot surfaces.

• The impermissible removal of the necessary covers, improper

installation or incorrect operation of motor or frequency

inverter may cause the failure of the device and may lead to

serious injury or damage.

• The relevant national regulations apply to all work carried on

live frequency inverters.

• The electrical installation must be carried out in accordance

with the relevant regulations (e. g. with regard to cable cross

sections, fuses, PE).

• All work relating to transport, installation, commissioning and

maintenance must only be carried out by qualified personnel.

(IEC 60 364 and HD 384 and national work safety regulations).

• Installations fitted with frequency inverters must be provided

with additional monitoring and protective devices in

accordance with the relevant safety regulations etc.

Modifications to the frequency inverters using the operating

software are permitted.

• Emergency stop devices complying with IEC/EN 60 204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

Moeller GmbH

Safety instructions

I

Page 3

• All shrouds and doors must be kept closed during operation.

• In order to reduce hazards to persons or equipment, the user

must include in the machine design measures that restrict the

consequences of a malfunction or failure of the drive

(increased motor speed or sudden standstill of motor).

These measures include:

– Other independent devices for monitoring safety-related

variables (speed, travel, end positions etc.).

– Electrical or non-electrical system related measures

(interlocks or mechanical interlocks).

– Live parts or cable connections of the frequency inverter

must not be touched after it has been disconnected from the

power supply due to the charge in capacitors. Appropriate

warning signs must be provided.

II

Page 4

09/01 AWB8230-1412GB

Contents

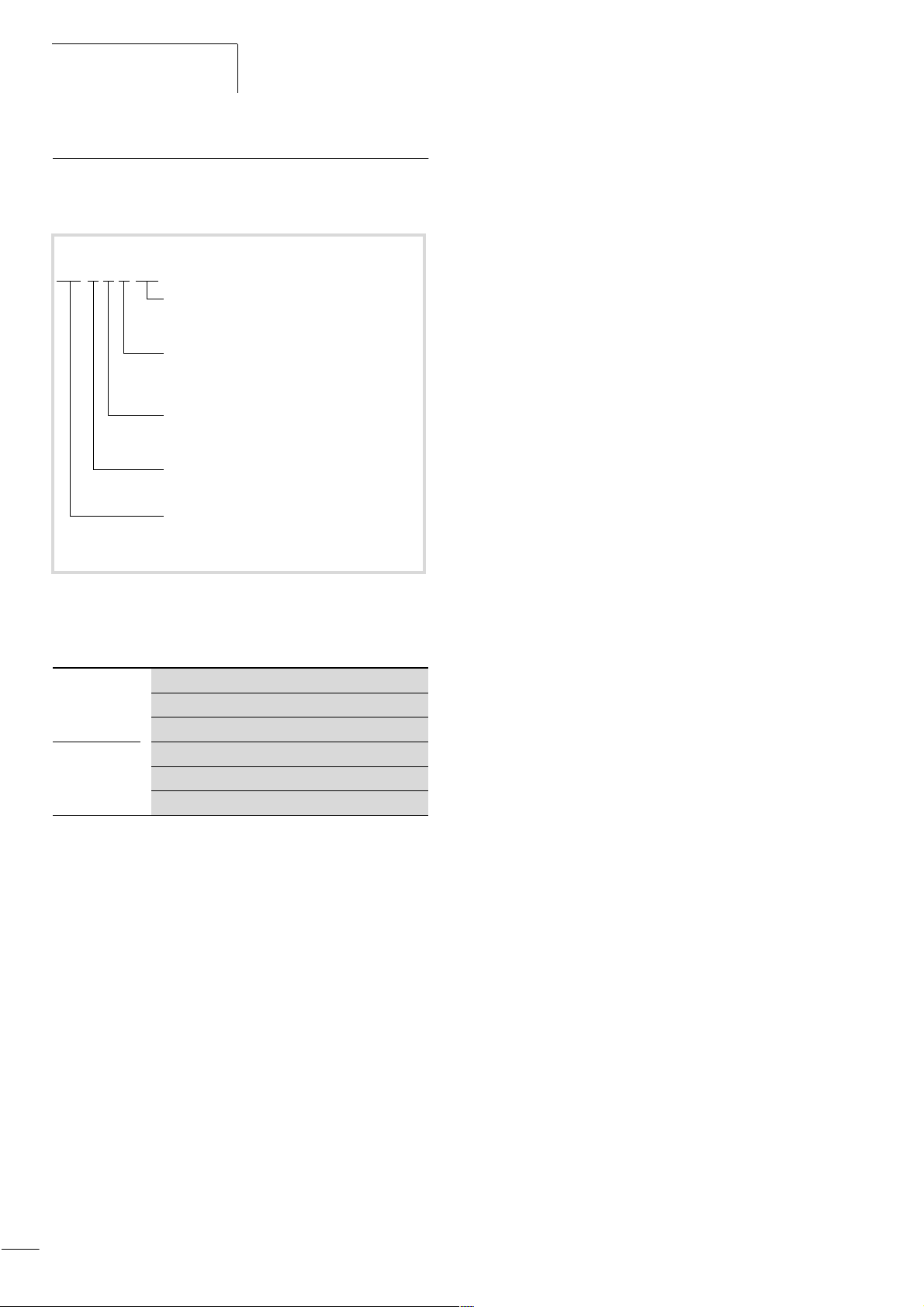

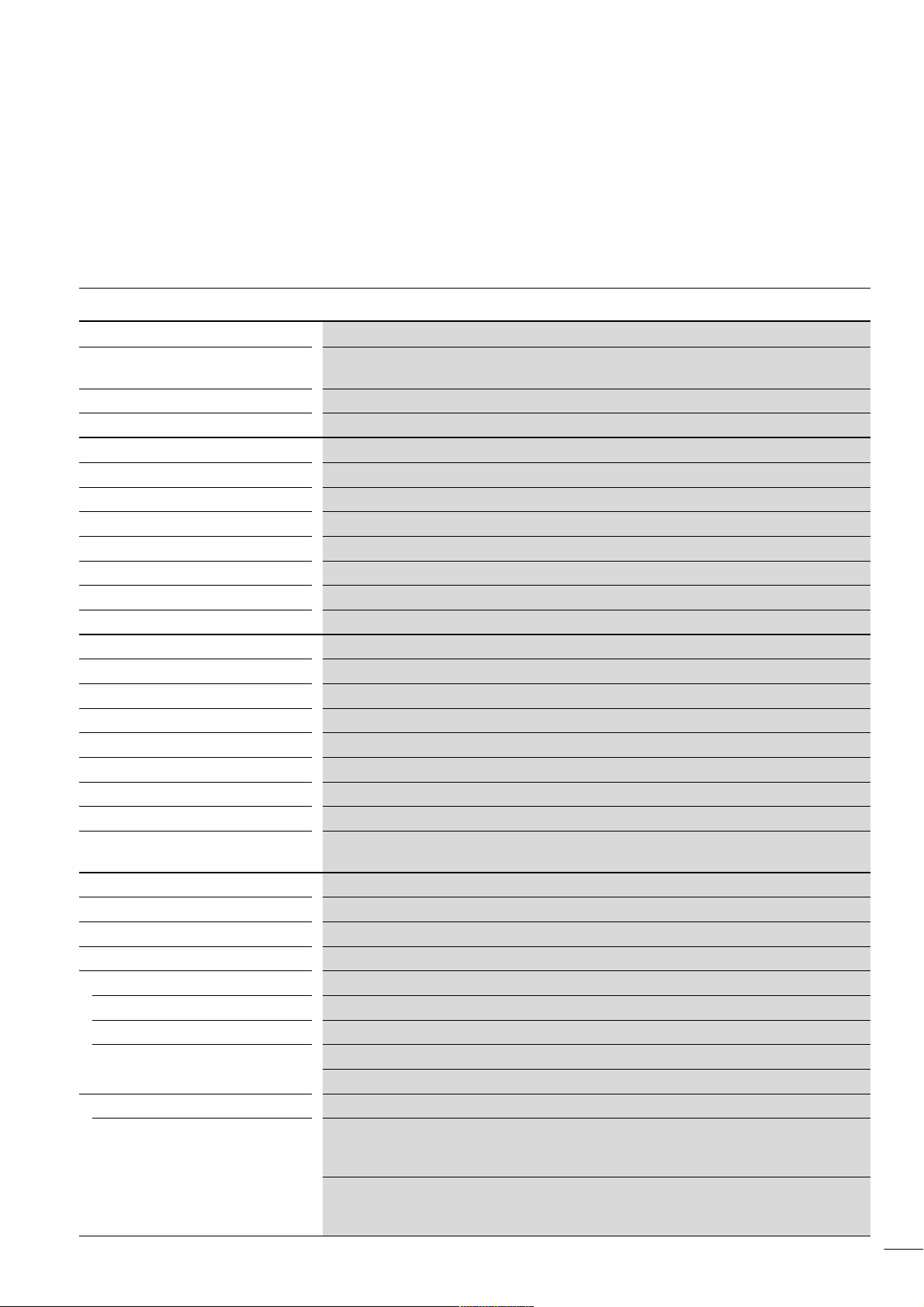

About this Manual 5

Abbreviations and symbols 5

1 About DF5 series frequency inverters 7

System overview 7

Type code 8

Inspecting the items supplied 9

Layout of the DF5 10

– Frequency inverter characteristics 11

Selection criteria 11

Intended use 12

Service and guarantee 12

2 Engineering 13

Features of the DF5 13

Connection to the mains 14

– Electrical grid types 14

– Mains voltage, Mains frequency 14

– Interaction with compensation devices 15

– Fuses and cable cross-sections 15

– Protection of persons and domestic animals

with residual-current protective devices 15

– Mains contactor 16

– Current peaks 16

– Mains choke 16

– Line filter, Radio interference filter 16

EMC guidelines 17

– EMC interference class 17

3 Installation 19

DF5 Installation 19

– Mounting position 19

– Installation dimensions 20

– DF5 attachment 21

EMC compliance 22

– EMC compliant installation 22

– Radio interference filter usage 22

– EMC measures in the control panel 23

– Grounding 24

– Screening 24

Electrical connection 26

– Connecting the power section 28

– Connecting the signalling relay 36

– Connecting the control signal terminals 38

1

Page 5

Contents

09/01 AWB8230-1412GB

4 DF5 Operation 43

Initial startup 43

LCD keypad 44

Operation with LCD keypad 44

– Menu overview 44

– Changing display and basic parameters 45

– Changing the parameters of the extended

parameter groups 46

Display after the supply voltage is applied 47

Operational warning message 48

5 Programming the control signal terminals 49

Overview 49

Frequency display FM 52

– Analog frequency display 52

– Digital frequency display 53

Programmable digital inputs 1 to 5 54

Start/Stop 55

Fixed frequency FF1 to FF4 selection 56

– Current setpoint value AT (4 to 20 mA) 58

– Second time ramp 2CH 59

– Controller inhibit and coasting of the

motor FRS (free run stop) 60

– External fault message EXT 61

– Restart inhibit USP 62

– Reset: RST 63

–Jog mode (JOG) 64

– PTC thermistor input: PTC 65

– Software protection SFT 66

Programmable digital outputs 11 and 12 67

Frequency value messages FA1/FA2 68

– RUN operational 70

– Overload message OL 71

– PID controller deviation message OD 72

– Error message AL 73

Signalling relay terminals K11, K12, K14 74

2

Page 6

09/01 AWB8230-1412GB

Contents

6 Setting Parameters 75

Setting the display parameters 75

Basic functions 76

– Input/display frequency value 76

– Acceleration time 1 76

– Deceleration time 1 77

– Direction of rotation 77

Setting the frequency and start command parameters 78

– Definition of frequency setpoint value 78

– Start command 78

– Base frequency 79

– Maximum end frequency 79

Analog setpoint value matching 80

Voltage/frequency characteristics and boost 81

DC braking (DC-Break) 82

Operating frequency range 83

PID controller 84

– The PID closed-loop control 84

– Structure and parameters of the PID controller 87

– Example for setting K

and T

p

i

92

– Application examples 93

Automatic voltage regulation (AVR) 95

Time ramps 96

Automatic restart after a fault 97

Electronic motor protection 98

Current limit 99

Parameter protection 100

Magnetizing current 100

Other functions 101

– Carrier frequency 101

– Initialization 101

– Country version 101

– Frequency factor for display via PNU d07 101

– Inhibit of the OFF key 102

– Motor restart after cancellation of the FRS signal 102

– Display when a remote operating unit is used 102

7 Messages 103

Fault messages 103

Other messages 104

8 Fault correction 105

3

Page 7

Contents

09/01 AWB8230-1412GB

Appendix 107

Technical Data 107

Dimensions and weights 111

Cables and fuses 112

Mains contactors 113

Radio interference filter 115

Mains choke 116

Connection examples 117

– Operation through an external potentiometer 117

– Operation through an analog setpoint value 117

– Operation with fixed frequencies 118

Abbreviations of parameters and functions 119

Standard form for user defined parameter settings 120

®

UL

Caution, Warnings and Instructions 125

– Preparation for Wiring 125

– Determination of Wire and Fuse Sizes 125

– Terminal Dimensions and Tightening Torque 126

Index 127

4

Page 8

09/01 AWB8230-1412GB

About this Manual

This manual describes the frequency inverters of the DF5 series.

This manual contains special information which is required for

engineering, installation and operation of the DF5 series frequency

inverters. The features, parameters and functions are described in

detail and illustrated by the use of examples for the most important applications. All the details stated relate to the hardware and

software versions specified.

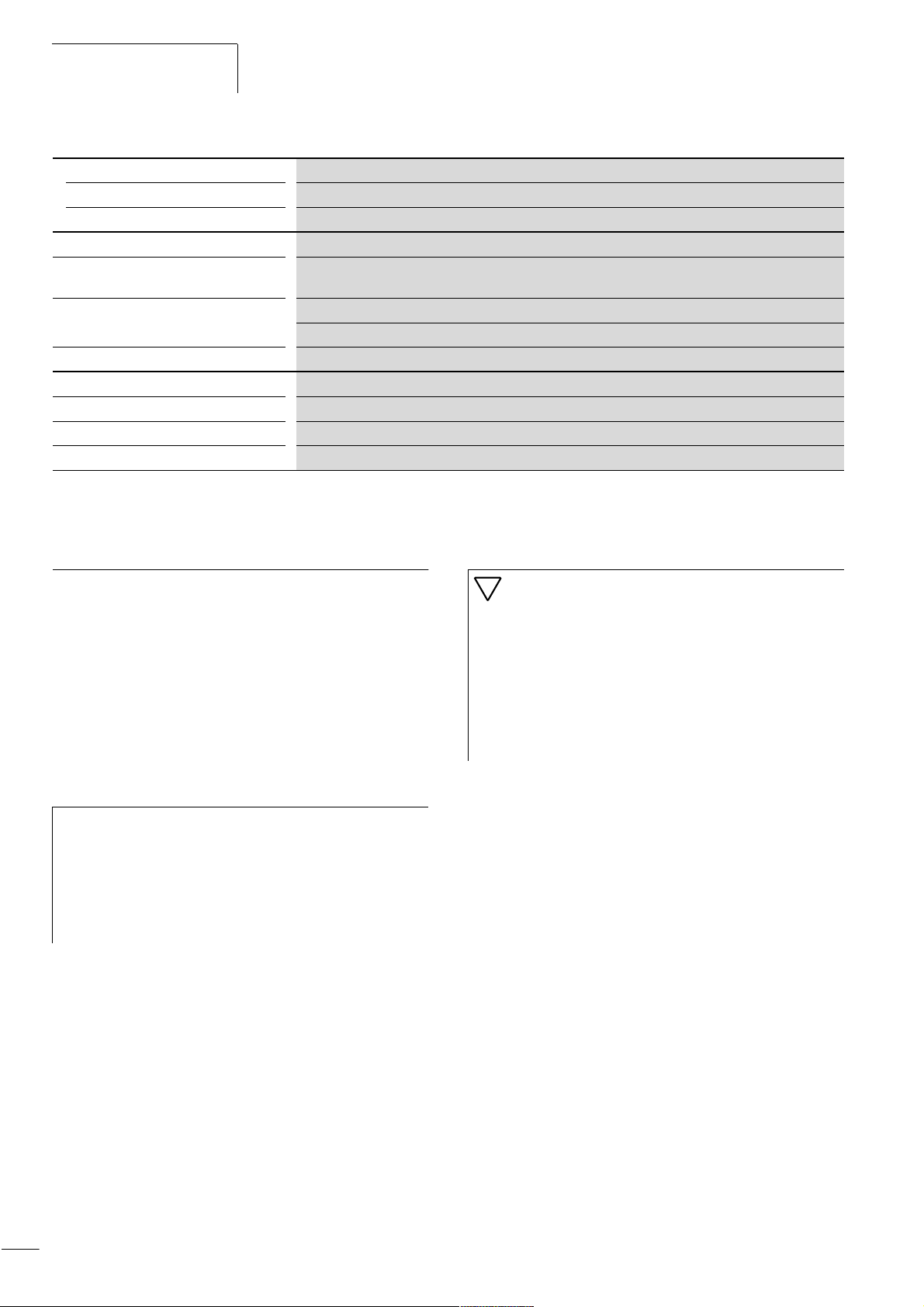

Abbreviations and symbols

Abbreviations and symbols with the following meanings are

described in this manual:

EMC: Electro Magnetic Compatibility

ESD: Electro static discharge

(Electro Static Discharge)

HF: High Frequency

IGBT: Insulated Gate Bipolar Transistor

PES: PE – connection (earth) of the screen (cable)

PNU: Parameter Number

WE: Factory default setting

All measurements are in millimeters unless otherwise stated.

In some of the illustrations, the enclosure of the frequency inverter

as well as other safety relevant parts may be omitted for the

purpose of improved visualization. However, the frequency

inverter must always be operated in the enclosure with all necessary safety relevant parts and components.

Read the manual carefully before you install and operate the

frequency inverter. We assume that you have a good knowledge

of engineering fundamentals and that you are familiar with the

electrical systems and the principles which apply, and are able to

read, understand and apply information contained in technical

drawings.

X indicates instructions to be followed

Makes you aware of interesting tips and additional

h

information

Caution!

warns about the possibility of minor material damage.

Warning!

warns about the possibility of major material damage and

minor injury.

Warning!

warns about the possibility of major material damage and

severe injury or death.

In order to improve the readability, the title of the chapter is indicated on the top of the left-hand page and the current section is

indicated on the top of the right-hand page. Pages where chapters

commence and blank pages at the end of the chapter are an

exception.

5

Page 9

09/01 AWB8230-1412GB

6

Page 10

09/01 AWB8230-1412GB

1 About DF5 series frequency inverters

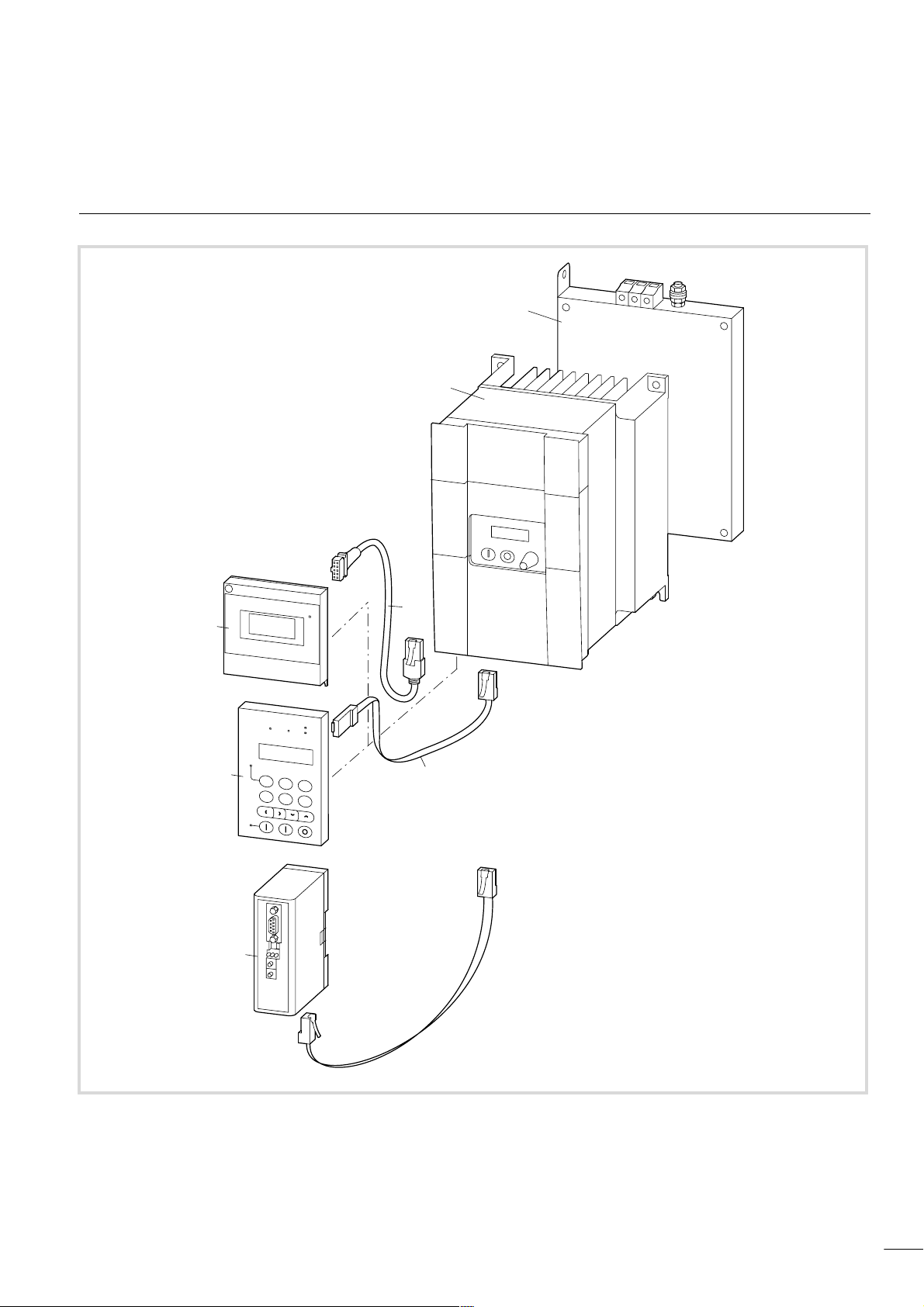

System overview

a

b

g

f

c

d

e

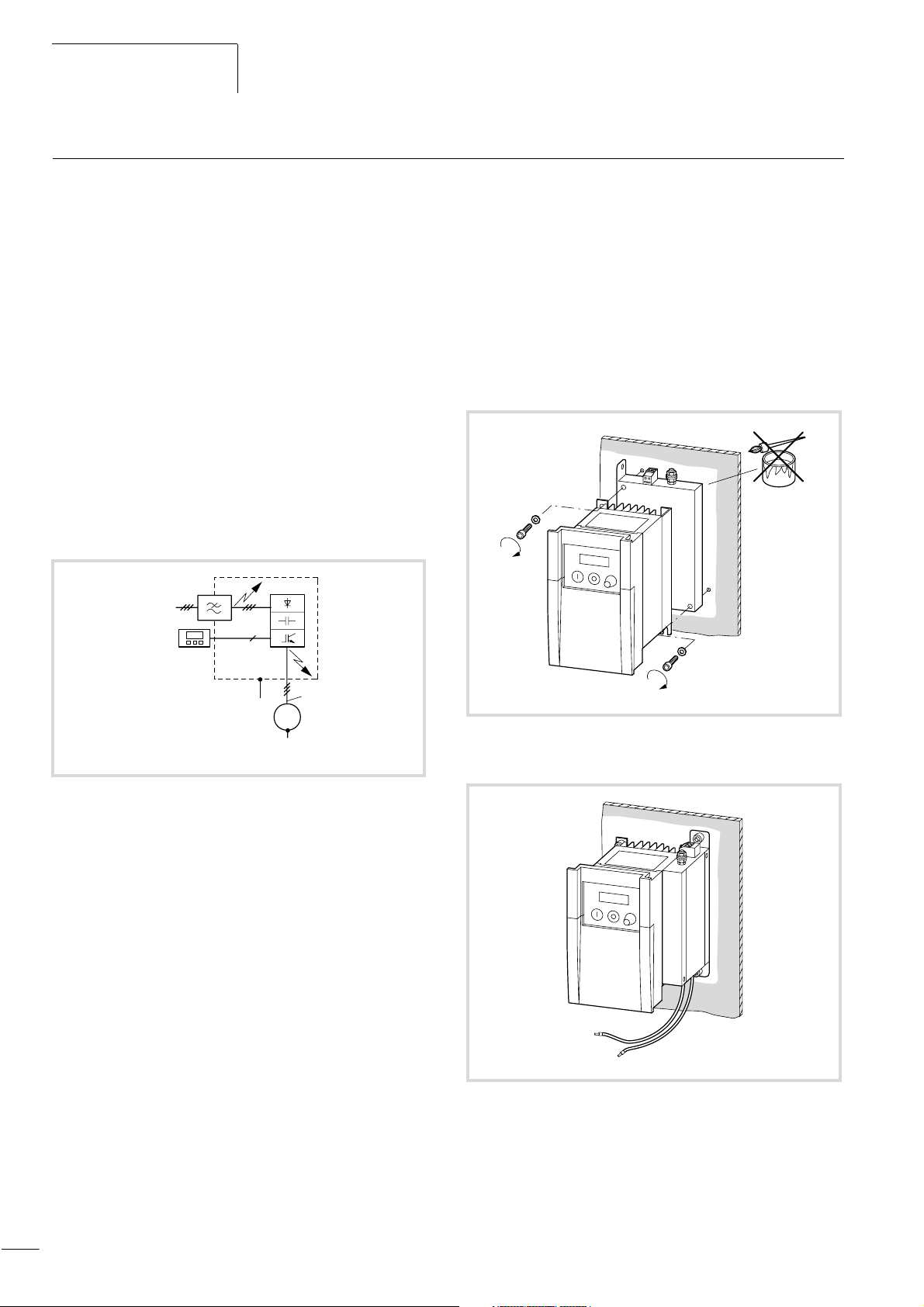

Figure 1: System overview

a DF5 series frequency inverters-...

b DE5-LZ... RFI filter

c DE5-CBL-...-ICL connection cable

d DEX-CBL-...-ICS connection cable

e DE5-NET-DP interface module for PROFIBUS-DP

f DEX-DEY-10 external keypad

g DE5-KEY-RO3 external display module

7

Page 11

About DF5 series frequency

inverters

Type code

Type code and type designation of the DF5 series frequency

inverter:

09/01 AWB8230-1412GB

DF5-xxx-yyy

Motor rating code

Incoming supply: EU rated voltage (230 V/400 V)

Version and model number

0 = basic version

1 = system devices

2 = voltage code suffix

Supply connection, voltage code (EU rated value)

2 = 230 V (180 V – 0 % to 252 V + 0 %)

4 = 400 V (342 V – 0 % to 506 V + 0 %)

Supply connection, phase code

1 = single-phase

3 = three-phase

Family name:

Drives Frequency Inverter, Generation 5

Figure 2: Type code DF5 series frequency inverters

Examples:

DF5-322-075

DF5-340-5K5

Frequency inverters of the DF5 series

Single-phase or three-phase supply: 230 V

Assigned motor rating: 0.75 kW at 230 V

Frequency inverters of the DF5 series

Three-phase mains supply voltage: 400 V

Assigned motor rating: 5.5 kW at 400 V

8

Page 12

09/01 AWB8230-1412GB

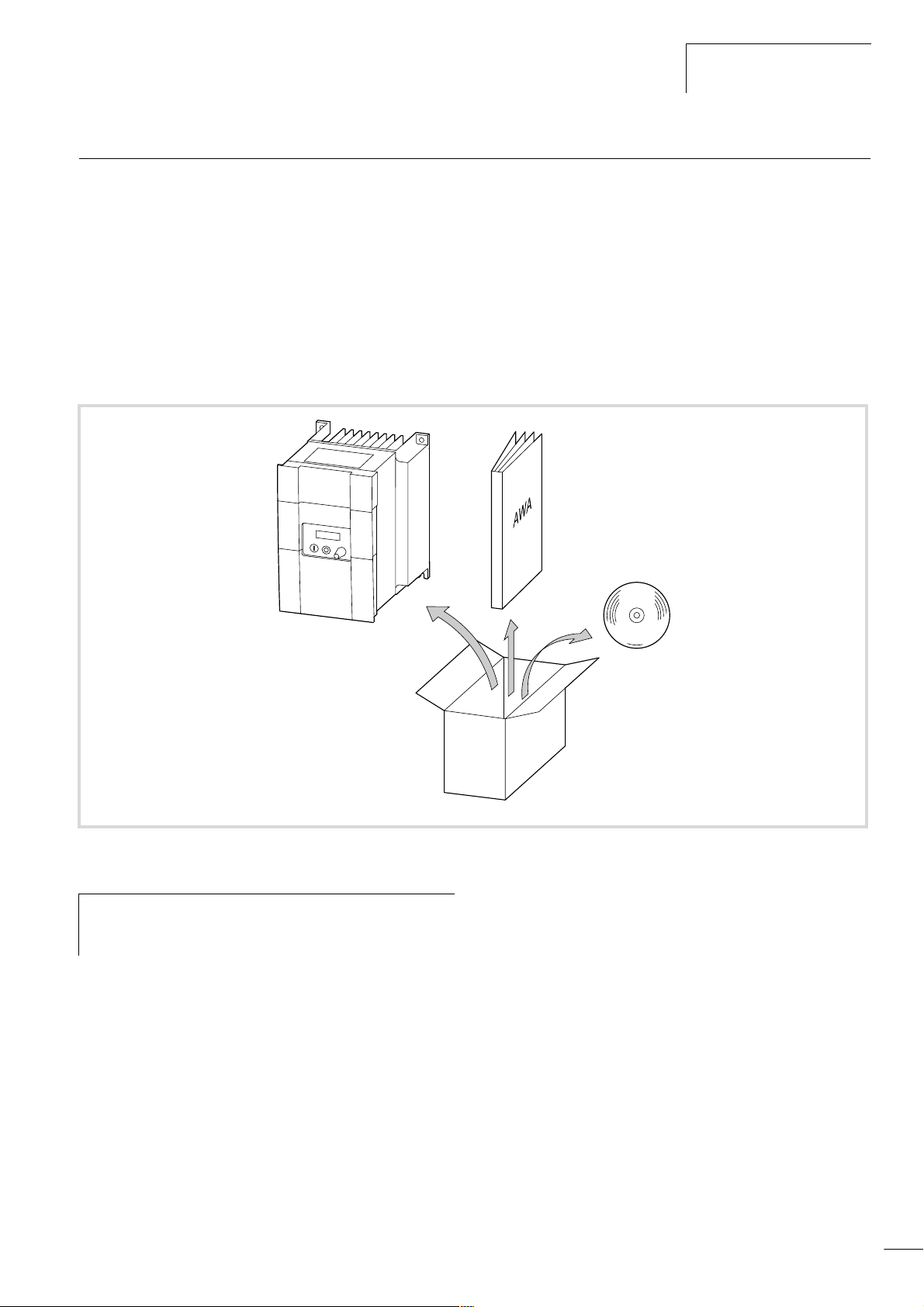

Inspecting the items supplied

Inspecting the items supplied

Frequency inverters of the DF5 series frequency inverters are carefully packed before delivery. The device may be transported only in

its original packaging with a suitable transport system (see weight

details). Observe the instructions and the warnings on the side of

the packaging. This also applies after the device is removed from

the package.

Open the packaging with suitable tools and inspect the contents

immediately after delivery to ensure that they are complete and

undamaged. The package must contain the following items:

• a DF5 series frequency inverter,

• the installation instructions AWA8230-1935,

• a CD with:

– this manual in PDF format as well as in further languages

– the parameter definition software;

the requirements are: A PC with Windows 95, 98, ME, 2000,

NT and the DEX-CBL-2M0-PC connection cable

Figure 3: Equipment supplied

Using the nameplate attached to the frequency inverter,

h

check to ensure that the frequency inverter is the type

which you have ordered.

9

Page 13

About DF5 series frequency

inverters

Layout of the DF5

09/01 AWB8230-1412GB

m e

Figure 4: Designations of the DF5

a Front cover, can be opened without tools

b Integrated keypad

c Terminal shroud

d Front cover flap with keypad

e Signalling relay terminals

f Heat sink

g Optional radio interference filter

e

j

k

l

cab

i

h

h Power terminals

i Screw for opening the front enclosure

j Control signal terminals

k Enclosure

l Earth connection (PE)

m Interface connection

e

d

f

g

10

Page 14

09/01 AWB8230-1412GB

Selection criteria

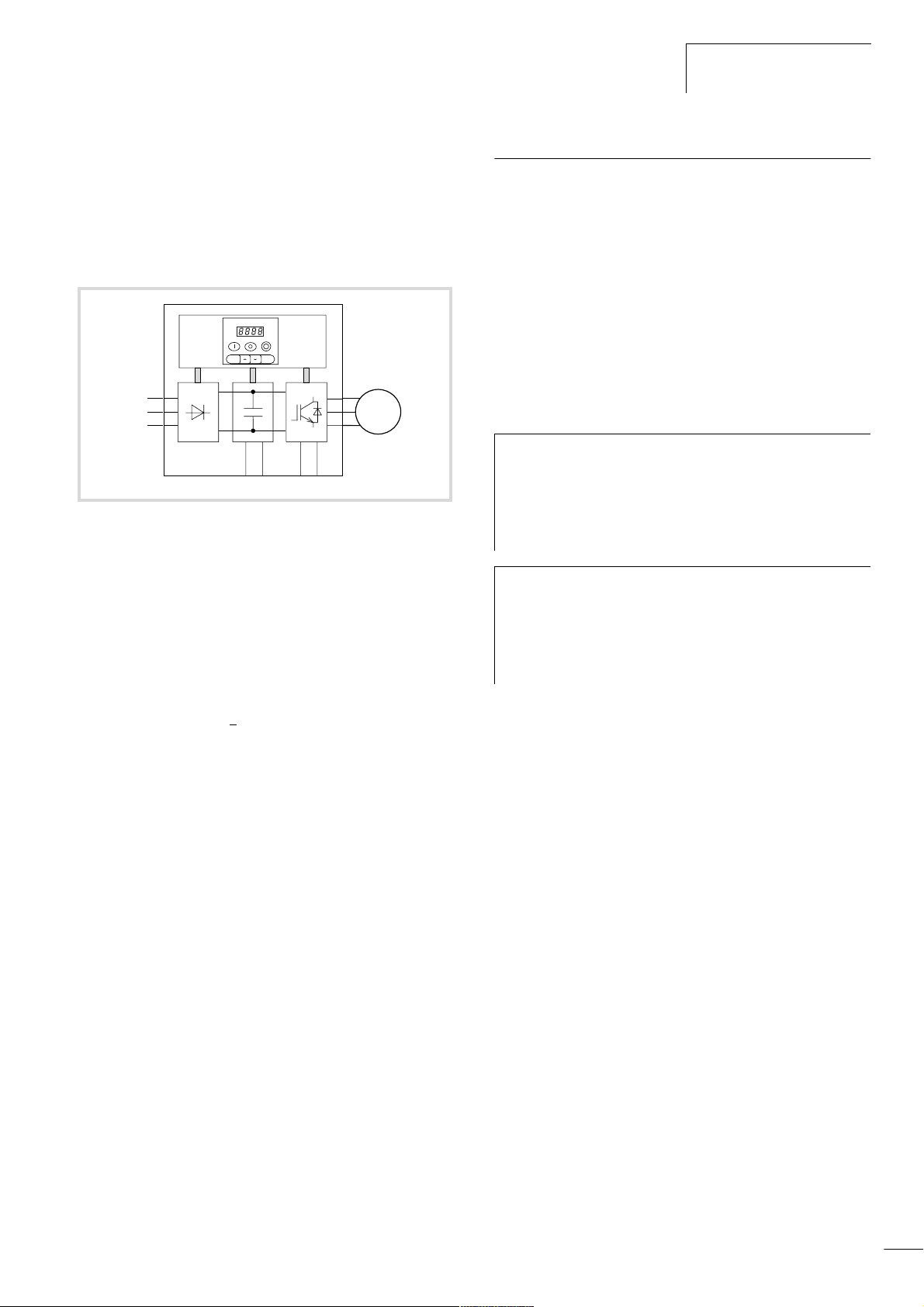

Frequency inverter characteristics

The DF5 series convert the voltage and frequency of an existing

three-phase supply to a DC voltage and use this voltage to generate a three-phase supply with adjustable voltage and frequency.

This variable three-phase supply allows stepless variability of

three-phase asynchronous motors.

f

h

a

bc d

Figure 5: Functional diagram of the frequency inverter

a Supply via an interference suppressor

Mains voltage U

-322 1/3 AC 230 V, 50/60 Hz

DF5

-340 3 AC 400 V, 50/60 Hz

DF5

b The bridge rectifiers convert the AC voltage of the electrical supply to

a DC voltage.

c The DC link contains a charging resistor, smoothing capacitor and

switched-mode power supply unit. It enables coupling of the DC bus

voltage and the DC current supply:

DC bus voltage (U

d IGBT power inverter:

The power inverter converts the DC voltage of the DC link to a variable

three-phase alternating voltage with variable frequency.

e Output voltage (U

three-phase, variable AC voltage, 0 to 100 % of the input voltage

)

(U

LN

Output frequency (f

Variable frequency, 0.5 to 360 Hz

Output rated current (I

1.8 to 22.5 A with about 1.5 times the starting current for 60 s, with

a switching frequency of 5 kHz and with an ambient temperature of

40 °C

Motor connection, assigned shaft output (P

0.18 to 2.2 kW at 230 V

0.37 to 7.5 kW at 400 V

f Programmable control section with keypad and interface.

(EU-rated voltage):

LN

) = W2 x mains voltage (ULN)

ZK

), motor connection:

2

):

2

):

2N

2

M

3

˜

e

):

Selection criteria

The frequency inverter is selected to suit the rated motor current.

The output rated current of the frequency inverter must however,

be greater than or equal to the rated motor current.

The following drive data is assumed to be known:

• type of motor (three-phase asynchronous motor),

• mains voltage = supply voltage of the motor (e.g. 3 ~ 400 V),

• rated motor current (guide value, dependent on the circuit type

and the supply voltage),

• load torque (quadratic, constant, with 1.5-times the starting

torque),

• ambient temperature (maximum temperature 40 °C).

With the parallel connection of multiple motors to the

h

output of a frequency inverter, the motor currents are

subject to vector addition, i.e. the active in-phase current

and reactive current components are added separately.

Select the frequency inverter rating to ensure that the

total current can be supplied by the frequency inverter.

If a motor switches during operation on the output of a

h

frequency inverter, the motor draws a multiple of its rated

current. Select the rating of the frequency inverter to

ensure that the starting current plus the sum of the

currents of the running motors does not exceed the rated

output current of the frequency inverter.

The rated output current of the frequency inverter can be found in

the technical data in the Appendix from Page 107.

11

Page 15

About DF5 series frequency

inverters

09/01 AWB8230-1412GB

Intended use

The DF5 series frequency inverters are not domestic appliances.

They are designed only for industrial use as system components.

The DF5 series frequency inverters are electrical apparatus for

controlling variable speed drives with three-phase motors. They

are designed for installation in machines or for use in combination

with other components within a machine or system.

After installation in a machine, the frequency inverters must not be

taken into operation until the associated machine has been

confirmed to comply with the safety requirements of Machinery

Safety Directive (MSD) 89/392/EEC and meets the requirements of

EN 60204. The user of the equipment is responsible for ensuring

that the machine use complies with the relevant EU Directives.

The CE-mark attached to the DF5 series frequency inverters

confirm that, when used in a typical drive configuration, the

apparatus complies with the European Low Voltage Directive

(LVD) and the EMC Directives (Directive 73/23/EEC, as amended

by 93/68/EEC and Directive 89/336/EEC, as amended by 93/68/

EEC).

Frequency inverters of the DF5 series are suitable for use in public

and non-public networks in the described system configuration.

Depending on their location of use, external filtering may be

necessary.

Service and guarantee

In the unlikely event that you have a problem with your Moeller

frequency inverter, please contact your local sales office.

Please have the following data and information concerning the to

hand:

• exact frequency inverter type designation (a nameplate)

• date of purchase

• exact description of the problem which has occurred with the

frequency inverter.

If some of the information printed on the nameplate is not legible,

please state only the information which is clearly legible.

Information concerning the guarantee can be found in the Moeller

General Terms and Conditions of Sale.

Connection to IT networks (networks without a ground potential

reference point) is not permitted as the devices internal filter capacitors connect the network to the ground potential (enclosure). On

earth free networks, this can lead to dangerous situations or

damage to the device (isolation monitoring required).

On the output of the frequency inverter (terminals U, V, W) you

may not:

• connect a voltage or capacitive loads (e.g. phase compensation

capacitor),

• connect multiple frequency inverters in parallel,

• make a direct connection to the input (bypass).

Observe the technical data and terminal requirements. Refer to the

equipment nameplate or label and the documentation for more

details.

Any other usage constitutes improper use.

12

Page 16

09/01 AWB8230-1412GB

2 Engineering

This chapter describes the ”Features of the DF5” as well as guidelines and regulations concerning the following subjects:

• Connection to the mains

• EMC guidelines

Features of the DF5

Ambient temperatures

Operation

Storage Ta = –25 to +70 °C

Transport

Permissible ambient influences

Resistance to vibration Vibrations and shaking: maximum 5.9 m/s2 (0.6 g) at 10 to 55 Hz

Pollution degree

Packaging

Climatic conditions

Installation altitude

Mounting position

Free surrounding areas

Electrical data

Emitted interference IEC/EN 61800-3 (EN 55011 group 1, class B)

Noise immunity

Insulation resistance

Leakage current to PE

Degree of protection

Protection against direct contact

Protective isolation against switching circuitry

Protective measures

Control/regulation

Modulation method Pulse width modulation (PWM), V/f-predetermined control (linear,quadratic)

Switching frequency

Torque

Output frequency

Relay

1)

Range 0.5 to 360 Hz

Frequency resolution

Error limit at 25 °C g10 °C

Changeover contact • AC 250 V, 2.5 A (resistive load)

Ta = –10 to +40 °C with rated current Ie without derating,

up to +50 °C with reduced carrier frequency of 2 kHz and reduced output current to 80 % I

Ta = –25 to +70 °C

VDE 0110 Part 2, pollution degree 2

Dust proof packaging (DIN 4180)

Class 3K3 according to EN 50178 (non-condensing, average relative humidity 20 to 90 %)

Up to 1000 m above sea level

Vertically suspended

100 mm above and below device

IEC/EN 61800-3, industrial environment

Overvoltage category III according to VDE 0110

Greater than 3.5 mA according to EN 50178

IP20

Finger and back-of-hand proof (VBG 4)

Safe isolation from the mains. Double basic isolation according to EN 50178

Overcurrent, earth fault, overvoltage, undervoltage, overload, overtemperature, electronic motor

protection: I

5 kHz (WE), can be selected between 0.5 and 16 kHz

At start 1.5 x MN for 60 s with assigned motor rating, every 600 s

0.1 Hz, at digital setpoint, maximum frequency/1000 with analog setpoint

Digital setpoint definition g0.01 % of the maximum frequency

Analog setpoint definition g0.2 % of the maximum frequency

• AC 250 V, 0.2 A (inductive load, cos v = 0.4)

• AC 100 V, minimum 10 mA

• DC 30 V, 3 A (resistive load)

• DC 30 V, 0.7 A (inductive load, cos v = 0.4)

• DC 5 V, minimum 100 mA

2

t monitoring and PTC input (thermistor or temperature contacts)

e

13

Page 17

Engineering

Internal voltages

Control 24 V DC, maximum 30 mA

Setpoint value definition

Analog and digital actuation

Analog inputs • 1 input, 0 to 10 V, input impedance 10 kO

Digital inputs/outputs

Monitor output

Keypad (integrated)

Operation 6 function keys for control and parameter definition of the DF5

Display

Potentiometer

1) If the frequency inverter is to be installed in a control panel, enclosure or similar installation, the prevalent ambient temperature within these enclosures or control panels is considered to be the ambient temperature T

remains within permissible limits.

10 V DC, maximum 10 mA

• 1 input, 4 to 20 mA, load impedance 250 O

5 Freely programmable inputs

2 Outputs, open collector (maximum 27 V DC, 50 mA)

1 output for frequency or current, 10 V, maximum 1 mA

Four character 7 segment display and seven LEDs (status messages)

Setpoint definition (0 to 270°)

. The use of fans should be considered to ensure that the ambient temperature

a

09/01 AWB8230-1412GB

Connection to the mains

The DF5 series frequency inverters can be used without limitation

with every type of electrical grid (Electrical grids according to

IEC 364

-3).

Electrical grid types

Electrical grids with a direct earthing point (TT/TN

-systems):

• Operation of the frequency inverters of the DF5 series with TT

-systems is possible without limitation. Adhere to the rated

TN

data of the DF5 series frequency inverters.

If many frequency inverters with a single-phase supply are

h

connected to the mains, the symmetric distribution on all

three mains poles should be considered as well as the

loading of the common neutral pole (mains r.m.s current).

If necessary, the cross-section of the neutral pole must be

increased, if it conducts the total current of all singlephase devices.

Grids with isolated centre point (IT

-systems):

• Operation of the frequency inverters of the DF5 series with

IT

-systems is only conditionally possible. A prerequisite is a

suitable device (isolation monitoring), which monitors earth

faults and isolates the frequency inverter from the mains.

Caution!

With an earth fault in an IT

-system, the capacitors of the

frequency inverter which are switched to earth are subject

to a very high voltage. Therefore, safe operation of the

frequency inverter cannot be guaranteed. The situation

can be remedied with an additional isolating transformer

with an earthed centre point on its secondary, which is

then used to supply the input of the frequency inverter.

This constitutes an individual TN-system for the frequency

-/

inverter.

Mains voltage, Mains frequency

The rated data for the frequency inverters of the DF5 take the

European and American standard voltages into account:

• 230 V, 50 Hz (EU) and 240 V, 60 Hz (USA) with DF5-322,

• 400 V, 50 Hz (EU) und 460 V, 60 Hz (USA) with the DF5-340

The permitted mains voltage range is:

• 230/240 V: 180 V – 0% to 252V+0%

• 400/460 V: 342 V – 0% to 506V+0%

The permissible frequency range is 47 Hz – 0% to 63Hz+0%.

The device assignment of the motor rating to the mains voltage is

listed in Section ”Technical Data”, Page 107 in the Appendix.

14

Page 18

09/01 AWB8230-1412GB

Connection to the mains

Interaction with compensation devices

The DF5 series frequency inverters only accept a minimal fundamental reactive power from the AC voltage supply. Compensation

is therefore unnecessary.

Caution!

Operation of the frequency inverters of the DF5 series on

the mains with p.f. correction equipment is only permitted

when this equipment is dampened with chokes.

Fuses and cable cross-sections

When the devices are connected to the mains, the fuses and cable

cross-sections which are required are dependent on the rating of

the frequency inverter and the operation mode of the drive.

Caution!

The voltage drop under load conditions should be considered when selecting the cable cross-section. Compliance

to further standards (e.g. VDE 0113, VDE 0289) is the

responsibility of the user.

The recommended fuses and the assignment of the DF5 series

frequency inverters are listed in Section ”Cables and fuses”,

Page 112 in the Appendix.

The national and regional standards (e.g. VDE 0113, EN 60204)

must be observed and the necessary approvals (e.g. UL) at the site

of installation must be fulfilled.

When the device is operated in a UL

-approved fuses, fuse bases and cables can be used.

UL

-approved system, only

Protection of persons and domestic animals with residualcurrent protective devices

Residual-current circuit-breakers RCCB (according to VDE 0100,

also referred to as ELCBs). Universal current sensitive ELCBs according to EN 50178 and IEC 755.

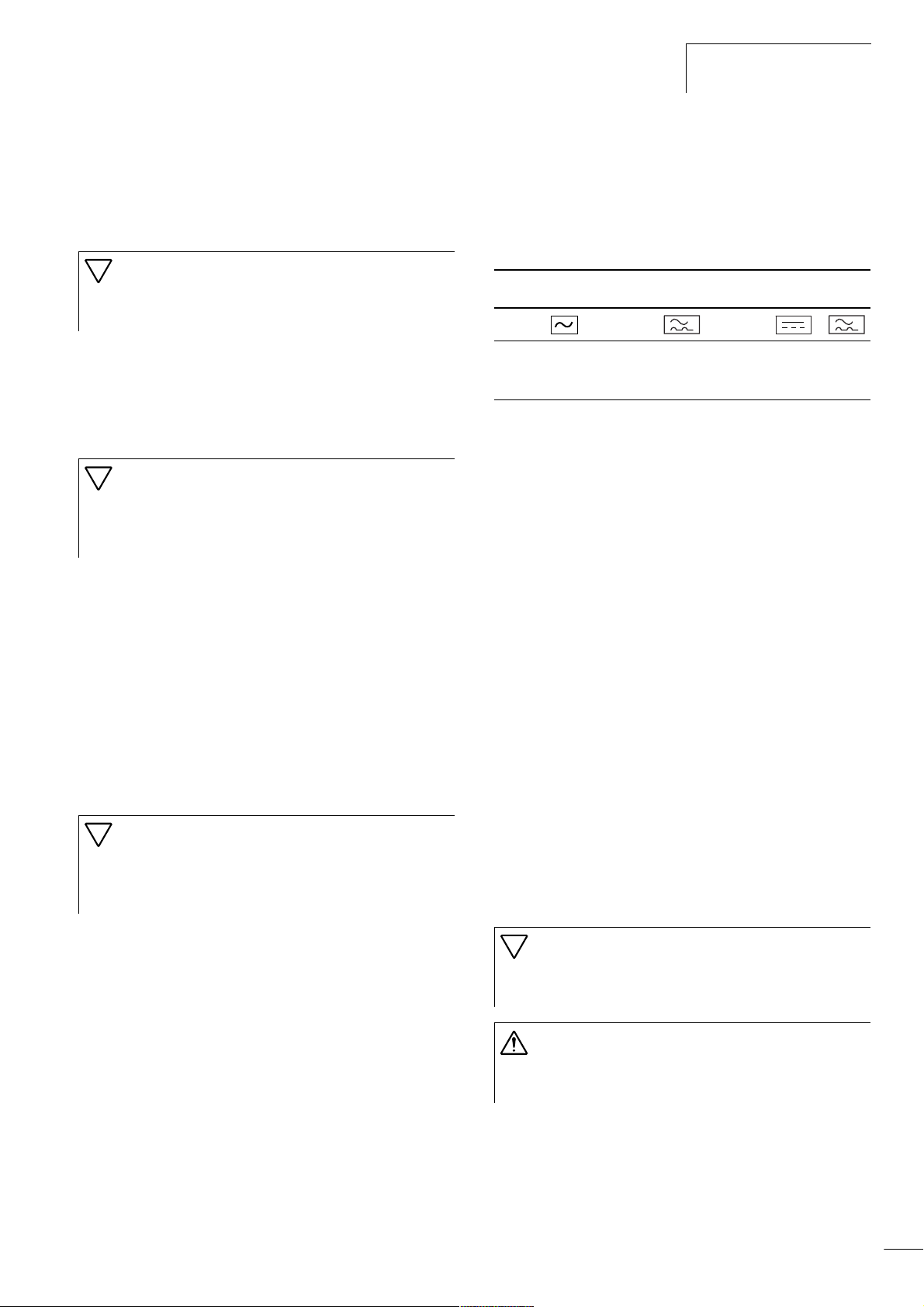

Identification on the residual-current circuit-breakers

Logo

Type alternating

current sensitive

(RCCB, Type AC)

pulse current

sensitive

(RCCB, Type A)

universal current

sensitive

(RCCB, Type B)

The frequency inverter is internally equipped with a mains rectifier.

With a short circuit to an exposed conductive part, a fault DC

current can block the trip of the alternating current sensitive or

pulse current sensitive residual-current circuit-breaker and thus

eliminate the protective function. We therefore recommend the

use of:

•“Pulse current sensitive residual-current circuit-breakers” with

a rated current f 30 mA with frequency inverters with a singlephase supply ( .

•”Universal current sensitive residual-current circuit-breakers”

with a rated current f 300 mA with frequency inverters with a

single-phase supply on frequency inverters with three-phase

supply .

The fault current recommended values of the DF5 series frequency

inverters and the assigned radio interference filter are listed in

Section ”Radio interference filter”, Page 115 in the Appendix.

The leakage currents to ground (according to EN 50178) are

greater than 3.5 mA. The PE terminal and the enclosure must be

connected to the earth-current circuit.

Caution!

The prescribed minimum cross-sections of PE-conductors

(EN 50178, VDE 0160) must be observed. Select the

cross-section of the PE

-conductor as least as large as the

terminal capacity of the power terminals.

Spurios tripping of a residual-current circuit-breaker can be

activated by the following:

• by capacitive compensation currents of the cable screens,

particularly with long screened motor cables,

• by simultaneous connection of multiple frequency inverters to

the mains supply,

• with the use of additional chokes and filters (radio interference

filter, line filter).

Caution!

Residual-current circuit-breakers may only be installed on

the primary side between the incoming supply and the

frequency inverter.

Warning!

Only use cables, residual-current circuit-breakers and

contactors which have a suitable rating. Otherwise there

is a danger of fire.

15

Page 19

Engineering

09/01 AWB8230-1412GB

Mains contactor

The mains contactor is connected to the mains side input cables

L1, L2, L3 (type dependant). It allows the operational switch on

and off of the DF5 series frequency inverters from the mains supply

as well as shutdown during a fault.

Mains contactors and the assignment with the DF5 series

frequency inverters are listed in Section ”Mains contactors”,

Page 113 in the Appendix.

Current peaks

In the following cases, a relatively high peak current can occur on

the primary side of the frequency inverter (i.e. on the supply

voltage side), which under certain conditions, can destroy the

input rectifier of the frequency inverter:

• Imbalance of the voltage supply greater than 3 %.

• The maximum power output of the supply point must be at least

10 times greater than the maximum frequency inverter rating

(approx 500 kVA).

• If sudden voltage dips in the supply voltage are to be expected,

e.g. :

– a number of frequency inverters are operated on a common

supply voltage.

– a Thyristor system and a frequency inverter or operated on a

common supply voltage.

– power factor correction devices are switched on or off.

In the cases mentioned, a mains choke with approx. 3 % voltage

drop at rated operation should be installed.

Mains choke

The mains choke (also referred to as a commutating choke or line

reactor) is connected to the mains side input cables L1, L2, L3 (type

dependent). It reduces the harmonics and leads to a reduction of

the apparent mains current by up to 30 %.

A mains choke also limits current peaks which occur, caused by

potential dips (e.g. caused by p.f. correction equipment or earth

faults) or switching operations on the mains.

The mains choke increases the lifespan of the DC link capacitors

and consequently the lifespan of the frequency inverter. Its use is

also recommended:

• with a single-phase supply (DF5-322),

• with derating (temperatures above +40 °C, sites of installation

which are more than 1000 m above sea level),

• with parallel operation of multiple frequency inverters on a

single mains supply point,

• with DC link coupling of multiple frequency inverters

(interconnected operation).

Mains chokes and the assignment to DF5 series frequency inverters are listed in Section ”Mains choke”, Page 116 in the

Appendix.

Line filter, Radio interference filter

Line filters are a combination of mains chokes and radio interference filters in a single enclosure. They reduce the current harmonics and dampen high frequency radio interference levels.

Radio interference filters only dampen high frequency radio interference levels.

16

Caution!

When line filters or radio interference filters are used, the

leakage current to earth increases. Observe this point

when residual-current circuit-breakers are used.

Page 20

09/01 AWB8230-1412GB

EMC guidelines

EMC guidelines

The limit values for emitted interference and immunity with variable speed drives are described in the IEC/EN 61800

-3 product

standard.

When operating the frequency inverters of the DF5 series in coun-

tries which are part of the European Union (EU), the EMC guideline

89/336/EEC must be observed. The following conditions described

must be observed in order to comply with this guideline:

Supply voltage (mains voltage) for the frequency inverter:

• voltage fluctuation g10 % or less

• voltage imbalance g3% or less

• frequency variation g4 % or less

If the above mentioned conditions are not fulfilled, the respective

mains choke must be installed (a Section ”Mains choke” in the

Appendix, Page 116).

EMC interference class

When installation is completed according to the Section ”Installa-

tion”, described in ”EMC guidelines” Page 17 and with the use of

a radio interference filter, the frequency inverters of the DF5 series

comply to the following standards:

• Emitted interference:

IEC/EN 61800-3 (EN 55011 group 1, class B)

• Noise immunity:

EN 61800-3, industrial environment

Noise immunity

DF5 series frequency inverters conform with the requirements of

the EC/EN 61800

-3 EMC-product standard for industrial use

(second environment), and the higher interference immunity

values in domestic environments (first environment) with the

assigned radio interference filters.

A domestic environment can be understood to be a connection

point (transformer feeder) to which domestic households are also

connected.

The EMC

-guideline for an industrial system requires electromag-

netic compatibility with the environment as a whole. The product

standard examines a typical drive system in principle as a complete

system, i.e. the combination of frequency inverter, cables and

motor.

Emitted interference and radio interference suppression

DF5 series frequency inverters conform with the requirements of

the EC/EN 61800

-3 EMC-product standard for domestic use (first

environment), and therefore also with the higher interference

immunity values in industrial environments (second environment)

with the assigned radio interference filters.

Ensure compliance to the limit values with the following points:

• reduction of performance related interference with line filters

and/or radio interference filters including mains chokes.

• reduction of the electromagnetic emission interference by

screening motor cables and signal cables.

• compliance with installation guidelines (EMC compliant

installation).

With frequency inverters, performance related and emitted interference increase with the switching frequency. The frequency of

occurrence of performance related interference also increase with

longer motor cables. When the respective radio interference filter

is used, the EN 61800-3 standard is complied to as follows:

Conformity

General Limited

First environment

(Public power grid)

Second environment (Industrial)

1) This is a product with limited conformity according to IEC/

EN 61800-3. This product can cause radio frequency interference in

domestic environments. In this case, it is necessary that the user

undertakes the required protection measures.

Up to 10 m motor cable

lengths with 16 kHz

(maximum switching

frequency)

Up to 20 m motor cable

lengths with maximum

5 kHz switching frequency

Up to 50 m Up to 50 m

Up to 50 m

1)

17

Page 21

09/01 AWB8230-1412GB

18

Page 22

09/01 AWB8230-1412GB

3 Installation

The DF5 series frequency inverters should be installed in a control

panel or in a metal enclosure (e.g. IP54).

During installation or assembly operations on the

h

frequency inverter, all ventilation slots and openings

should be covered to ensure that foreign bodies and

objects do not penetrate the device.

DF5 Installation

The DF5 series frequency inverters must be installed vertically on a

non-flammable base.

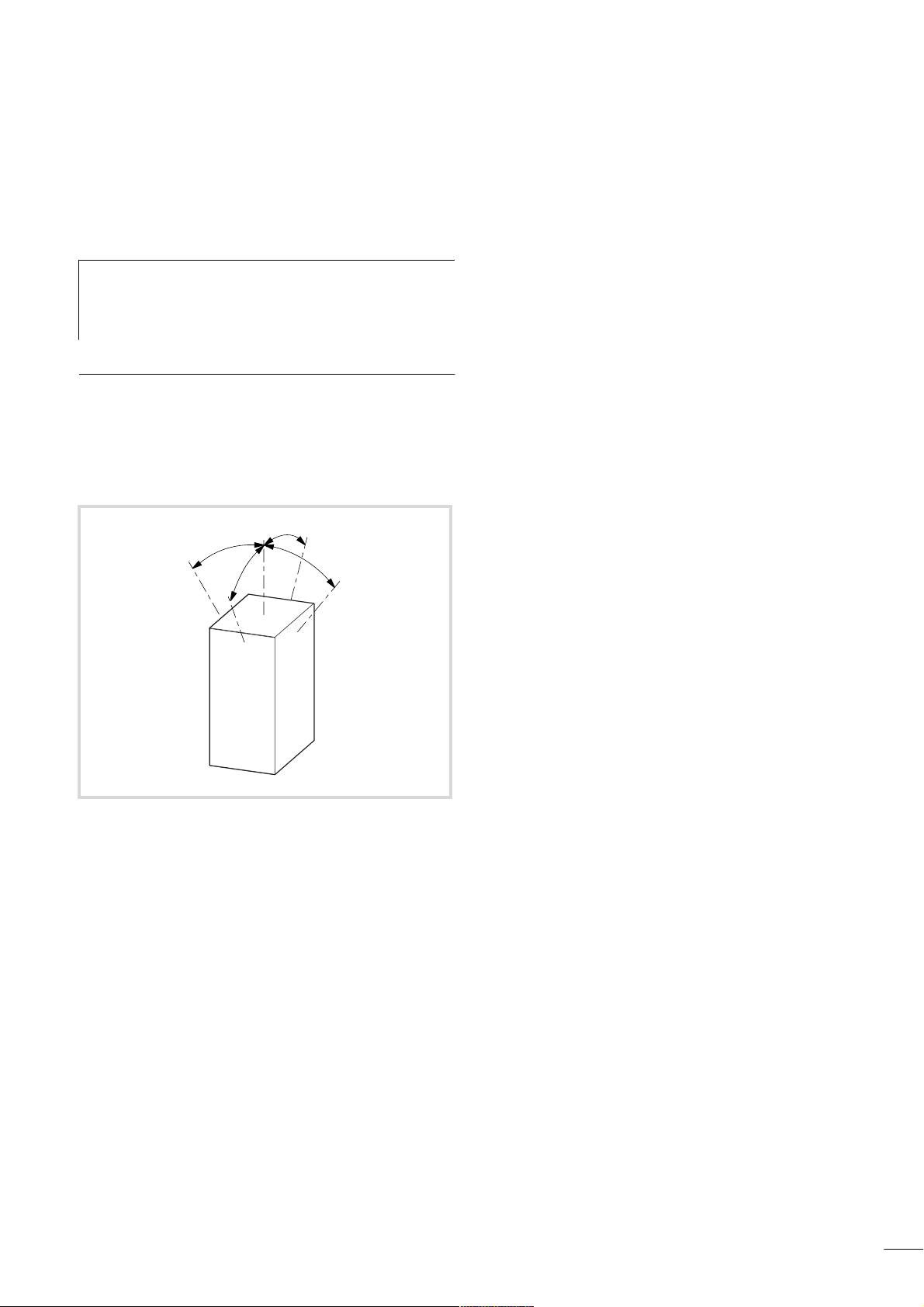

Mounting position

F 30˚

F 30˚

Figure 6: Mounting position

F 30˚

F 30˚

19

Page 23

Installation

09/01 AWB8230-1412GB

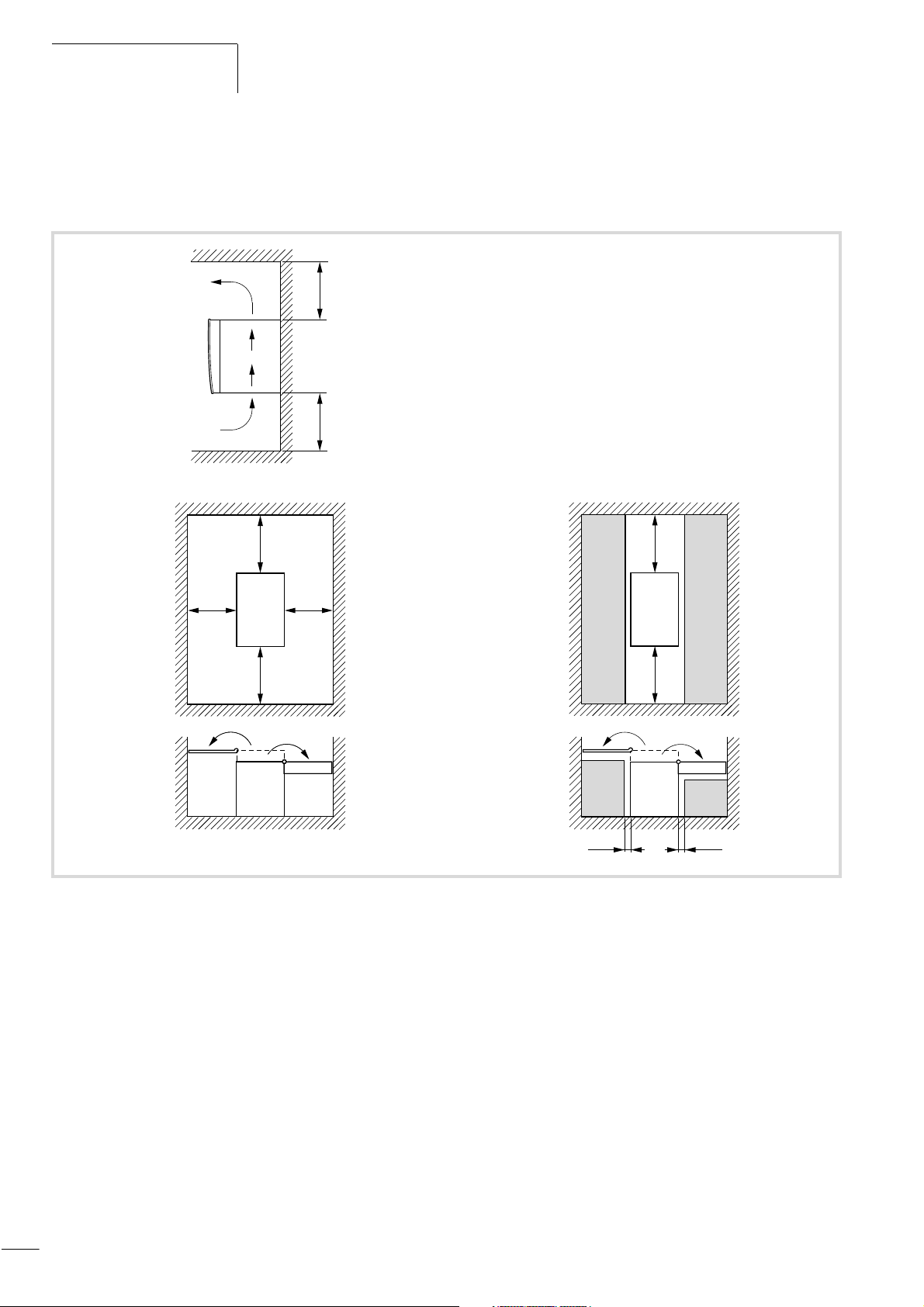

Installation dimensions

A free space of 100 mm minimum is required above and below the

device (thermal air circulation).

f 100f 100

f 100f 100

f 80

f 120

Please ensure that the front cover of the enclosure can always be

opened and closed without impediment to ensure that the control

terminals can be connected.

f 100

Figure 7: Installation dimensions

Dimensions and weights of the DF5 can be found in the Appendix

Section ”Dimensions and weights” from Page 111.

f 100

f 10f 10

20

Page 24

09/01 AWB8230-1412GB

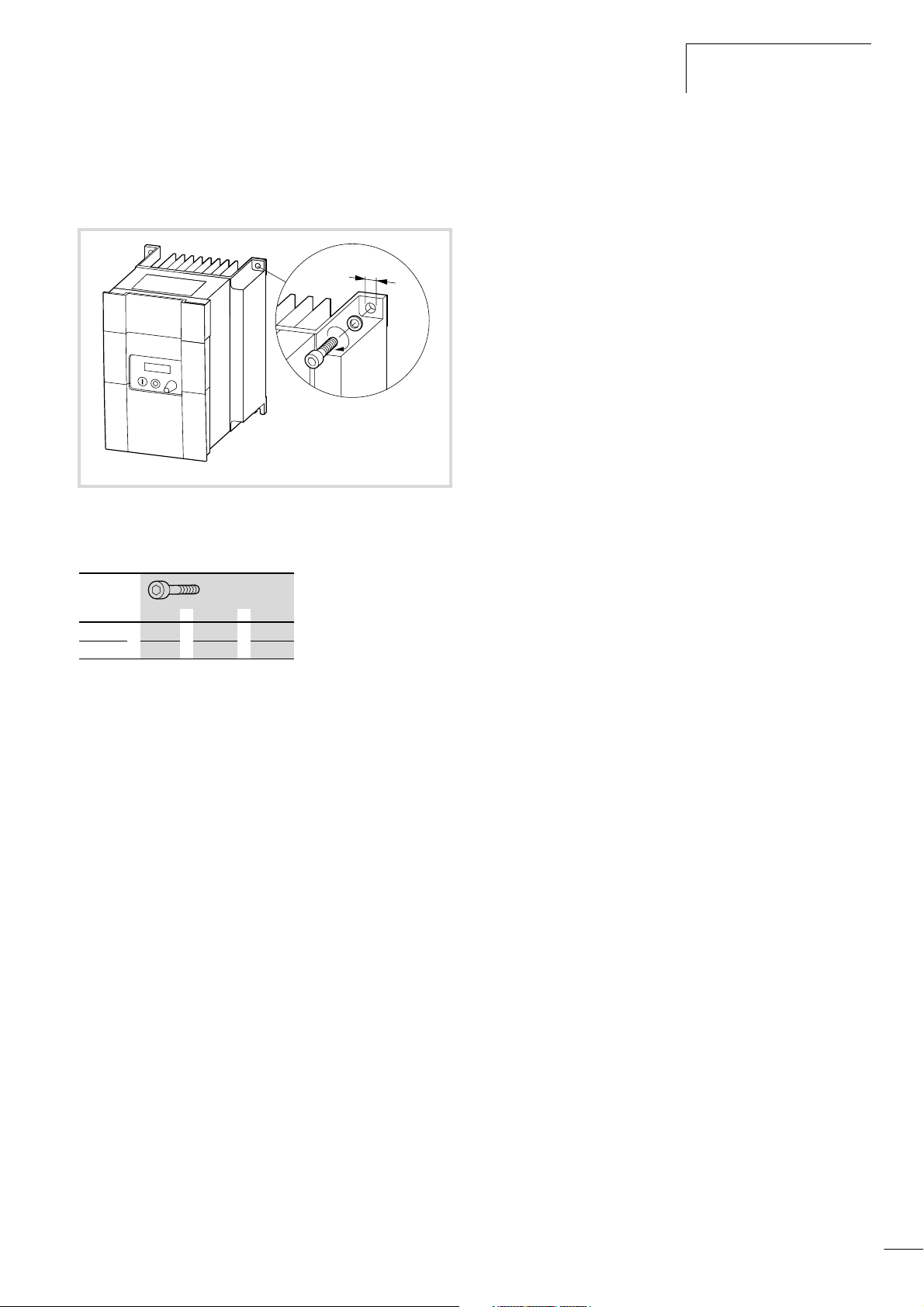

DF5 attachment

Install the DF5 series frequency inverter according to Fig. 8 and

tighten the screws with the following torques (a Table 1):

o

DF5 Installation

Figure 8: DF5 attachment

Table 1: Tightening torque's of the attachment screws

o

[mm]

5 M4 3 Nm 26 lbin

7

M6 4 Nm 35 lbin

21

Page 25

Installation

EMC compliance

09/01 AWB8230-1412GB

EMC compliant installation

The frequency inverter operates with fast electronic switching

devices e.g. transistors (IGBT). For this reason, radio interference

can occur on the output of the frequency inverter, which may

effect other electronic devices located in the direct vicinity such as

radio receivers or measurement instruments. In order to offer

protection against this radio frequency interference (RFI), the

devices should be screened and installed as far away as possible

from the frequency inverters.

We recommend the following measures for EMC compliant installation:

• installation of the frequency inverter in a metallic, electrically

conducting enclosure with a good connection to earth.

• installation of a radio interference filter on the input of the

frequency inverter in its direct vicinity

• screened motor cables (short cable lengths).

Z1

Uh

G1

6

Radio interference filter usage

The RFI filter should be installed in the direct vicinity of the

frequency inverter. The connection cable between the frequency

inverter and filter should be as short as possible. Screened cables

are required if the length exceeds 30 cm.

The radio interference filters assigned for the DE5-LZ... series

(a Section ”Radio interference filter” in the Appendix,

Page 115) enable the installation below (foot-print) or on the side

(book-type) of the DF5 series frequency inverters.

3h

a

M

E

E

Figure 9: DF5 and radio interference filter in a sealed enclosure

Z1: RFI filter

G1:frequency inverter

a Screened motor cable

X Ground the metallic enclosure via a cable which should be as

short as possible (a Fig. 9).

Figure 10: foot-print-Aufbau

Figure 11: Seitlicher Anbau

22

Radio interference filters produce leakage currents which can be

significantly larger than the rated values in the event of a fault

(phase failure, load unbalance). The filters must be earthed before

use in order to avoid dangerous voltages. As the leakage currents

Page 26

09/01 AWB8230-1412GB

EMC compliance

are high frequency interference sources, the earthing measures

must be undertaken with low resistance's on surfaces which as

large as possible.

Z1 G1

R2

L1

L2

L3

PE

L1

L2

L3

L/L1

S2

L2

T2

N/L3

e

U

V

W

3h

M

E

E

Figure 12: Earthing measures

Z1: EMC filter

G1:frequency inverter

With leakage currents f 3.5 mA, the VDE 0160 and EN 60335

stipulate that either:

• the protective conductor must have a cross-section f 10 mm

• the protective conductor is monitored to ensure continuity or

• an additional protective conductor is also installed.

For the frequency inverters of the DF5 series use the assigned filter

DE5-LZ....

EMC measures in the control panel

To ensure EMC-compliant setup, connect all metallic components

of the devices and of the control cabinet with each other using a

large cross-section conductor with good HF conducting properties.

Do not make connections to painted surfaces (Eloxal, yellow chromated). If there is no alternative, use contact and scraper washers

to ensure contact with the base metal. Connect mounting plates

to each other, and the cabinet doors with the cabinet using

contacts with large surface areas and short HF wires.

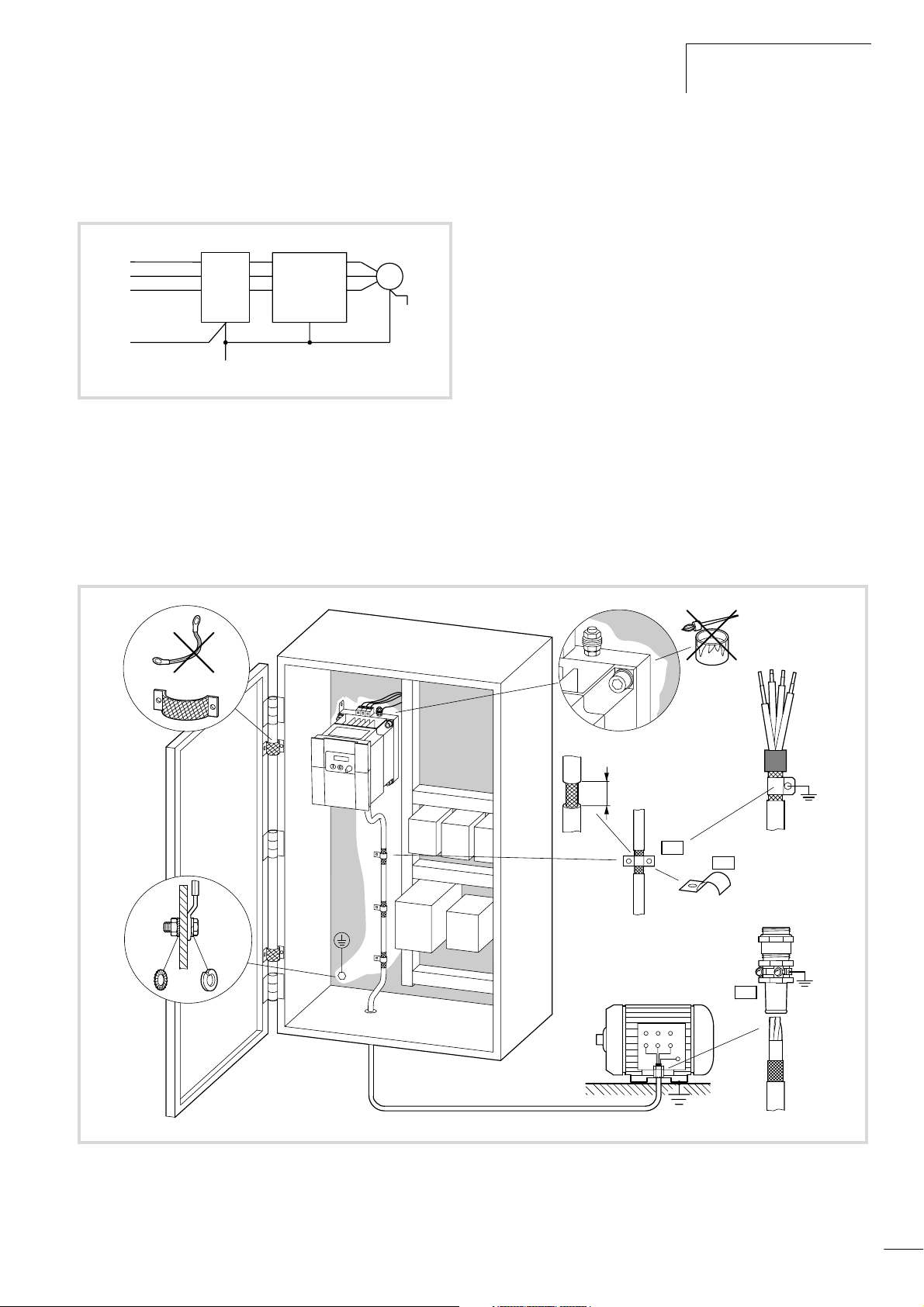

An overview or all EMC measures can be seen in the following

figure.

2

,

PE

Figure 13: EMC-compliant setup

15

PES

W2

U2

V2

U1

W1

V1

PES

PES

PE

23

Page 27

Installation

09/01 AWB8230-1412GB

Fit additional RFI filters or mains filters and frequency inverters as

closely as possible to each other and on a single metal plate

(mounting plate).

Lay cables in the control cabinet as near as possible to the ground

potential. Cables that hang freely act as antennae.

To prevent transfer of electromagnetic energy, lay interferencesuppressed cables (e.g. mains supply before the filter) and signal

lines as far away as possible (at least 10 cm) from HF-conducting

cables (e.g. mains supply cable after a filter, motor power cable).

This applies especially where cables are routed in parallel. Never

use the same cable duct for interference-suppressed and HF

cables. Where unavoidable, cables should always cross over at

right angles to each other.

Never lay control or signal cables in the same duct as power

cables. Analog signal cables (measured values, setpoints and

correction values) must be screened.

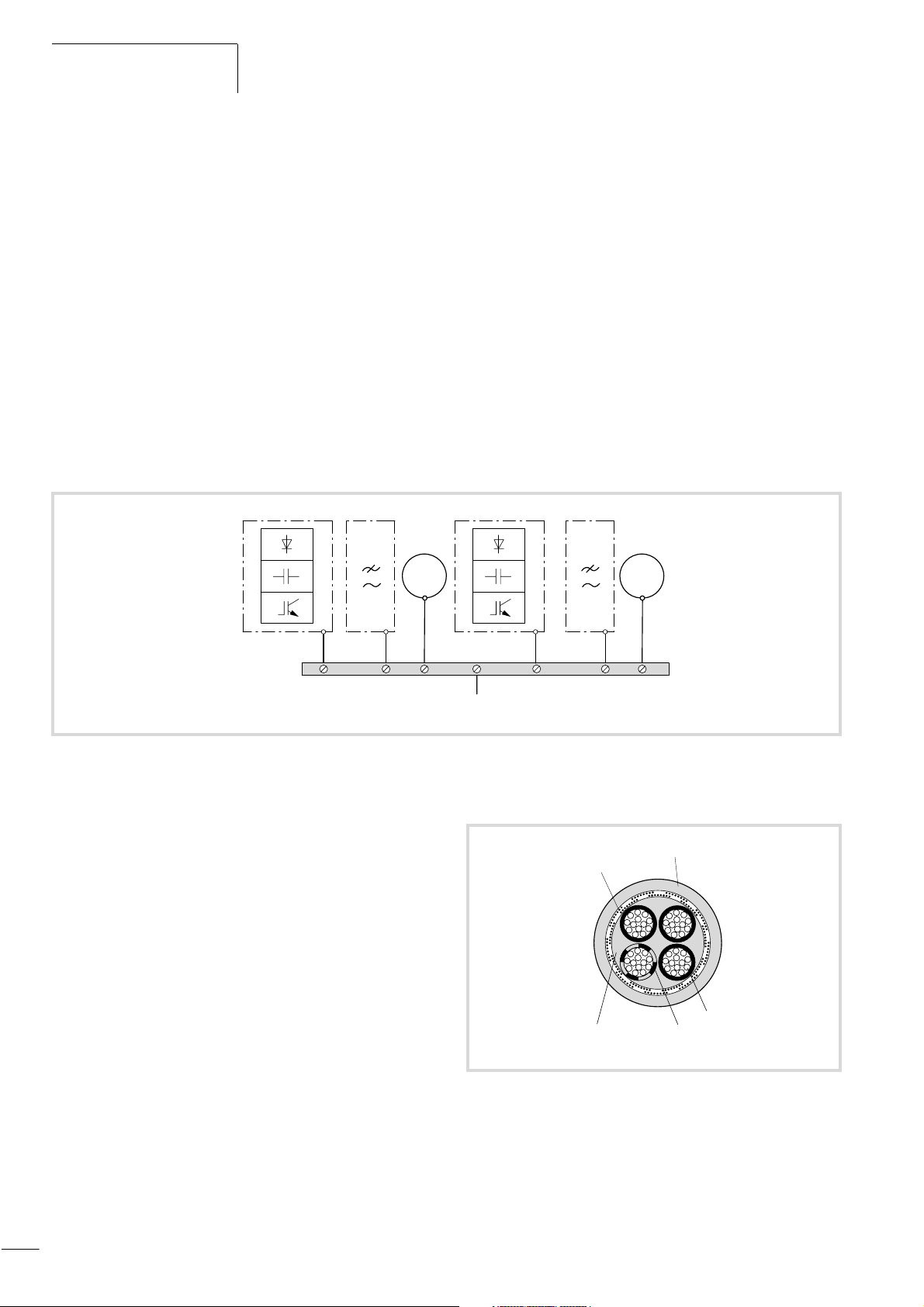

Z1G1 Gn Zn

M1

3h

Grounding

Connect the ground plate (mounting plate) with the protective

earth using a short cable. To achieve the best results, all conducting components (frequency inverter, mains filter, motor filter,

mains choke) should be connected by an HF wire, and the protective conductor should be laid in a star configuration from a central

earthing point. This produces the best results.

Ensure that the earthing measures have been correctly implemented (a Fig. 14). No other device which has to be earthed

should be connected to the earthing terminal of the frequency

inverter. If more than one frequency inverter is to be used, the earthing cables should not form a closed loop.

Mn

M

PE

M

3h

PE

Figure 14: Star-type point to point earthing

PE

Screening

Unscreened cables behave like antennae, i.e. they act as transmitters and receivers. To ensure EMC-compliant connection, screen

all interference-emitting cables (frequency inverter/motor output)

and interference-sensitive cables (analog setpoint and measured

value cables).

The effectiveness of the cable screen depends on a good screen

connection and a low screen impedance. Use only screens with

tinned or nickel plated copper braiding, braided steel screens are

unsuitable. The screen braid must have an overlap ratio of at least

85 percent and an overlap angle of 90°.

PE PE

e

a

e

Figure 15: Sample motor cable

a CU screen braid

b PVC outer sheath

c Strands (CU-strands)

d PVC core insulation

3 x black, 1 x green/yellow

e Textile braid and PVC inner material

b

c

d

24

Page 28

09/01 AWB8230-1412GB

EMC compliance

The screened cable between frequency inverter and motor should

be as short as possible. Connect the screen to earth at both ends

of the cable using a large contact surface connection.

Lay the cables for the supply voltage separately from the signal

cables and control cables.

Never unravel the screening or use pigtails to make a connection.

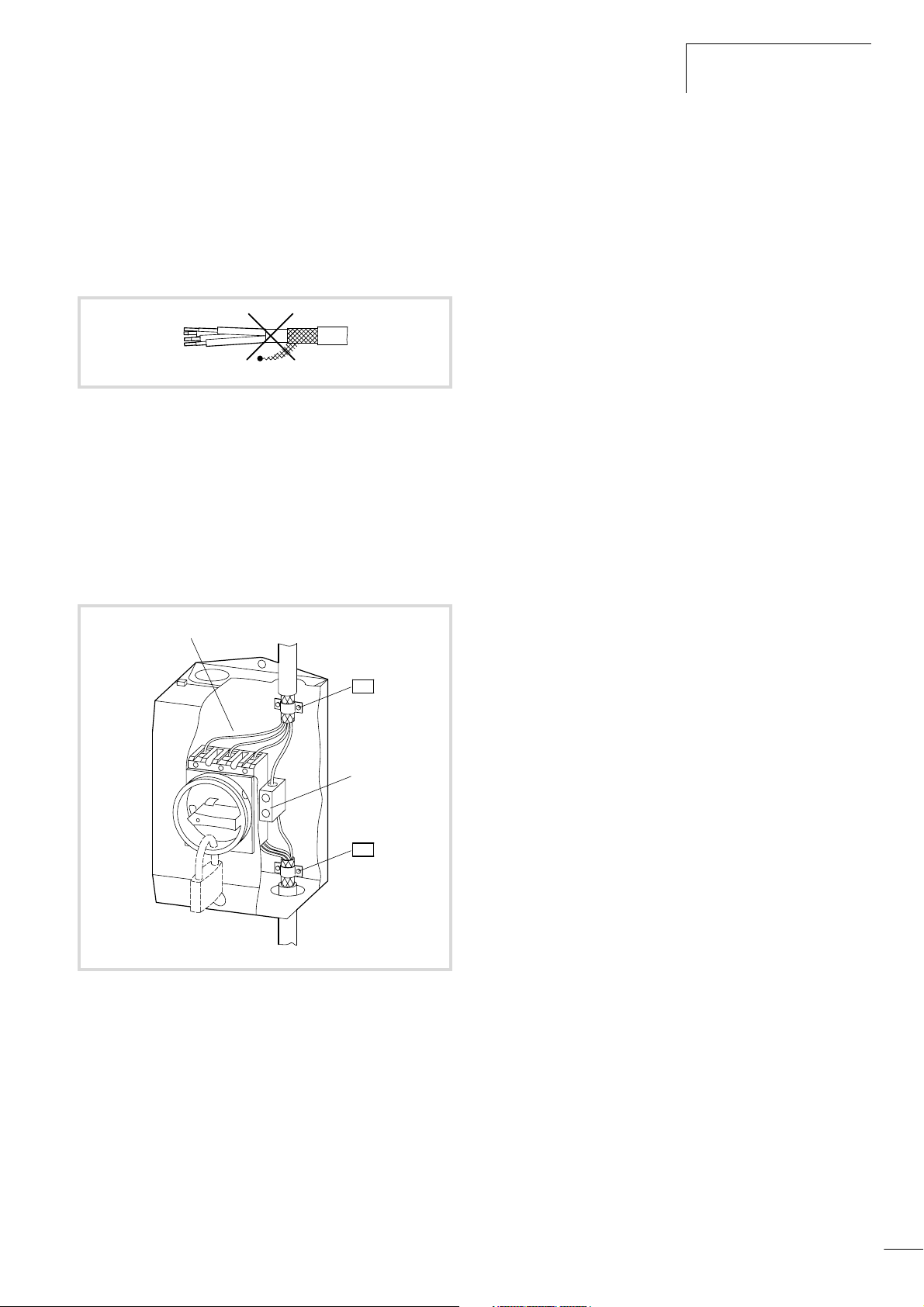

Figure 16: Inadmissible screen grounding (pigtails)

If contactors, maintenance switches, motor protection relays,

motor reactors, filters or terminals are installed in the motor

cabling, interrupt the screen near these components and connect

it to the mounting plate (PES) using a large contact surface

connection. The free, unscreened connecting cables should not be

longer then about 100 mm.

Example: Maintenance switch

In an EMC-compliant control cabinet (metal-enclosed, damped to

about 10 dB), the motor cables do not need to be screened

provided that the frequency inverter and motor cables are spatially

separated from each other and arranged in a separate partition

from the other control system components. The motor cable screening must then be connected via a large surface area connection

at the control cabinet (PES).

The control cable and signal (analog setpoint and measured value)

cable screens must be connected only at one cable end. Connect

the screen to ground using a large-area contact surface; ensure

that the connection has a low impedance. Digital signal cable

screens must be connected at both cable ends with large-surface,

low-resistance connections.

a

PES

b

PES

Figure 17: Maintenance switch, e.g. T… in an enclosure

a Metal plate

b Insulated PE-terminal

25

Page 29

Installation

Electrical connection

In this section, you will find information for connection of the

motor and the supply voltage to the power terminals, and the

signal cables to the control terminals and signalling relay.

Warning!

The wiring stages may only commence after the frequency

inverters have been correctly installed and attached.

Otherwise, there is a danger of electrical shock or injury.

Warning!

Wiring may only be carried out under no voltage

conditions.

Warning!

Only use cables, residual-current circuit-breakers and

contactors which have a suitable rating. Otherwise there

is a danger of fire.

09/01 AWB8230-1412GB

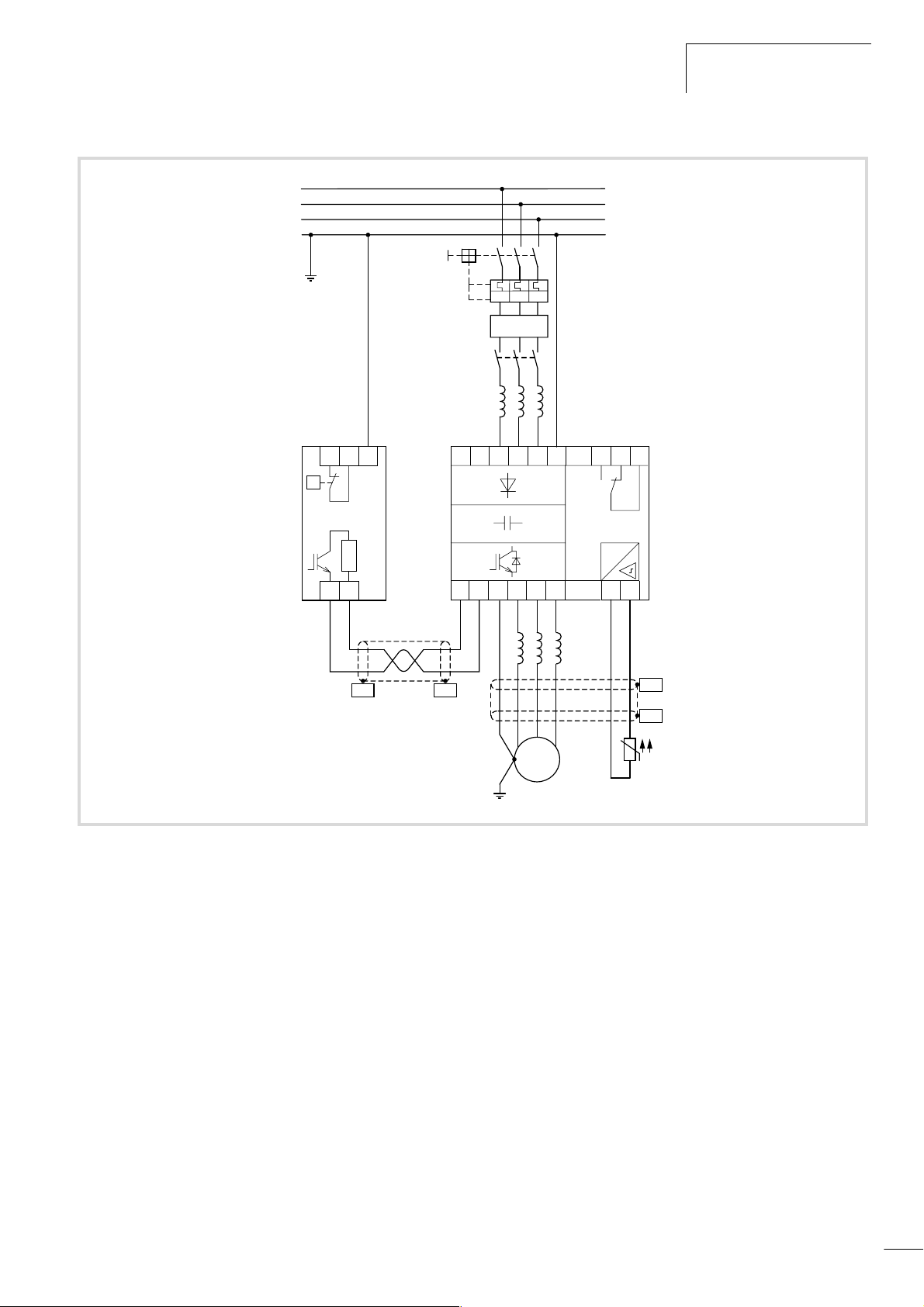

An overview of the connections can be found in the following

illustration.

26

Page 30

09/01 AWB8230-1412GB

a

L1

L2

L3

PE

Electrical connection

3 h 400 V, 50/60 Hz

b

I > I > I >

j

T1 T2 PE

i

DE4-BM4...

–UG

+UG

PES

c

d

e

f

PES

DC+ DC–

i

L1 L2

PE

FI

U

L3 PE

VW

M

3

˜

K14 K12 K11

#

L5

g

PES

h

PES

i

Figure 18: Power connection, example with 400 V

a Network configuration, mains voltage, mains frequency

interaction with p.f. compensation systems

b Fuses and cable cross-sections

c Protection of persons and domestic animals with residual-current

protective devices

d Mains contactor

e Mains choke, radio interference filter, line filter

f Mounting, installation

power connection

EMC measures

example of circuits

g Motor filter

dv/dt filter

sinusoidal filter

h Motor cables, cable length

i Motor connection

parallel operation of multiple motors on an single frequency inverter

j Braking resistors, braking units

DC link coupling

DC supply

27

Page 31

Installation

09/01 AWB8230-1412GB

Connecting the power section

The flap on the front enclosure must be opened in order to connect

the cables to the supply voltage and signal relay terminals.

Complete the following steps with the tools stated and

h

without the use of force.

Open the front cover and the front of the enclosure

X First of all open the front cover

1

X Loosen the screw

I

MIN

PRG

MAX

ENTER

2

1

POWER

RUN

PRG

I

PRG

Hz

A

MIN

MAX

ENTER

Figure 19: Opening the front cover

2

Figure 20: Loosen the screw

28

Page 32

09/01 AWB8230-1412GB

X Flap open the front cover and remove the terminal shroud. Power terminal arrangement

The arrangement of the power terminals can be seen in the

following figure.

4

a

L+

DC+ DC–

Electrical connection

3

a

Figure 21: Open the front cover and remove the terminal shroud

a Power terminals

Table 2: Description of the power terminals

Terminal

designation

L, L1, L2, L3, N Supply voltage (mains

U, V, W Frequency inverter

L+, DC+

DC+, DC–

e, PE

Function Description

• Single-phase mains voltage: Connection to L and N

voltage)

• Three-phase mains voltage: Connection to L1, L2, L3

Connection of a three-phase motor

output

External DC choke Normally, the terminals L+ and DC+ are assigned with a

jumper. If a d.c.-link choke is used, the jumper must be

removed.

DC link These terminals are used for the connection of an optional

braking resistor as well as for DC linking and DC feed of

multiple frequency inverters.

Earthing Enclosure earthing (prevents the presence of dangerous

voltages on the enclosure with a malfunction)

L/L1 L2 U V WN/L3

L1 L2 L3

M

3 h

Figure 22: Arrangement of the power terminals

a Internal connection. Remove if a d.c.-link choke is used.

N/L3L2L/L1 U V W

M

3 h

29

Page 33

Installation

Power terminal connection Laying the cables

Warning!

The supply voltage must suit the frequency inverter which

is selected (a Section ”Appendix”, Page 107):

• DF5-322: Single-phase or three-phase: 230 V

(180 to 264 V g 0%)

• DF5-340: three-phase 400 V (342 to 506 V g 0%)

Lay the cables for the power section separately from the signal

cables and control cables.

The motor cables which are to be connected must be screened.

The maximum cable length must not exceed 50 m. With larger

cable lengths, a motor choke is required for dv/dt-limitation

If the cable leading from the frequency inverter to motor is longer

than approx. 10 m, it is possible that the available thermal relays

Warning!

The mains voltage may not be connected for any reason

to the output terminals U, V and W. Danger of electrical

(bimetallic relays) will malfunction due to high frequency harmonics. Install a motor filter on the output of the frequency inverter

in this case.

shock or fire.

Warning!

Warning!

Each phase of the supply voltage for the frequency

inverter must be protected by a fuse (danger of fire).

Do not connect cables to the terminals in the power

section which are not designated. These terminals are

partially without function (dangerous voltages) or are

reserved for DF5 internal purposes.

09/01 AWB8230-1412GB

Warning!

Ensure that all power cables are correctly tightened on the

Tightening torques and conductor cross-sections

power section.

Warning!

The frequency inverter must be earthed. Danger of

electrical shock or fire.

Table 3: Tightening torque's and conductor cross-sections for the power terminals

L, L1, L2, L3, N

L+, DC+, DC–

U, V, W, PE

DF5- mm

322-018

322-037

322-055

340-037

340-075

340-1K5

340-2K2

322-075

322-1K1

340-3K0

340-4K0

322-1K5

322-2K2

340-5K5

340-7K5

2

AWG mm mm Nm

1.5 16 6 to 8 7.1 M3.5

1.5 16 8 to 10 9 M4 1.2 to 1.3 1

2.5 14 8 to 10 9 M4 1.2 to 1.3 1

4 12 12 to 14 13 M5 2 to 2.2 2

X Screw on the cables tightly according to Table 3.

M4 (PE)

Warning!

Tighten the screws on the terminals correctly

(a Table 3), so that they do not come loose

unintentionally.

0.8 to 0.9 1

30

Page 34

09/01 AWB8230-1412GB

e

PES

PE

Figure 23: Cable connection to the power terminals

Connecting the supply voltage

X Connect the supply voltage to the power terminals:

– Single-phase supply voltage: L, N and PE

– Three-phase supply voltage: L1, L2, L3 and PE

Electrical connection

31

Page 35

Installation

Connecting the motor cable

X Connect the motor cable to the U, V, W and PE terminals:

L1

L

N

PE

F1

PE PE

L2

L3

PE

Q1

09/01 AWB8230-1412GB

F1, Q1 =

h

III

K1M

L1

Z1

DF5-322...

1 h 230 V, 50/60 Hz

G1

K1M

V2U2

L1 L2 L3

W1V1U1

PE

W2

PE

PE

1

PE

2

N

L

PE

N

L

PE

L1

Z1

L1 L2 L3

DF5-322...

3 h 230 V, 50/60 Hz

DF5-340...

3 h 400 V, 50/60 Hz

W

DC+

DC–L+U

V

PE

PES

PES

X1

PES

PES

PE

M1

M

3 ~

Figure 24: Power terminal connection example

F1, Q1:Line protection

K1M: Mains contactor

L1: Mains choke

Z1: RFI filter

Observe the electrical connection data (rating data) on

h

the rating label (nameplate) of the motor.

The stator winding of the motor can be connected as a star or delta

configuration in accordance with the rating data on the nameplate.

32

e

Page 36

09/01 AWB8230-1412GB

Electrical connection

U1 V1 W1

W2 U2 V2

Figure 25: Connection types

/ 400 V230

0,75S1

kW

rpm

1410 50 Hz

Figure 26:

Frequency inverter

Mains voltage Single-phase

Mains current

Motor circuit

Motor current

Motor voltage

Example of a motor nameplate

DF5322--075 DF5340--075

230 V

9 A 3.3 A

Delta Star

4 A 2.3 A

3 AC 0 to 230 V 3 AC 0 to 400 V

Warning!

If motors whose insulation is not suitable for operation

with frequency inverters are used, the motor may be

destroyed.

U1 V1 W1

W2 U2 V2

4.0 / 2.3

ϕ

cos

3-phase 400 V

0.67

U1 V1 W1

W2 U2 V2

FWD

Figure 27: Direction of rotation, change of rotation direction

U1 V1 W1

W2 U2 V2

REV

You reverse the direction of rotation of the motor shaft with

frequency inverter operation on the DF5 by:

A

• exchanging two of the phases connected to the motor.

• triggering terminal 1 (FWD = clockwise) or

2 (REV = anticlockwise).

• applying a control command via the interface or fieldbus interface connection.

The speed of a three-phase motor is determined by the number of

pole pairs and the frequency. The output frequency of the DF5

series frequency inverter can be varied infinitely in the range from

0.5 to 360 Hz.

Connection of pole-changing three-phase motors (Dahlander

changing pole motors), rotor-fed three-phase commutator shunt

motors (slipring rotor) or reluctance motors, synchronous motors

and servo motors is possible, when they are approved for use with

frequency inverters by the motor manufacturer.

Warning!

The operation of a motor with speeds higher than the

rated speed (nameplate) can cause mechanical damage to

the motor (bearings, unbalance) and the machinery to

which it is connected and can lead to dangerous operating conditions!

If you use a motor filter or a sinusoidal filter here, the rate of

voltage rise can be limited to values of approx. 500 V/ms

(DIN VDE 0530, IEC 2566).

In the factory default setting, frequency inverters of the DF5 series

have a clockwise rotating field. Rotation of the motor shaft to the

right is achieved by connecting the motor and frequency inverter

terminals as follows:

Motor DF5

U1

V1

W1

U

V

W

Caution!

Uninterrupted operation in the lower frequency range

(less than approx. 25 Hz) can lead to thermal damage

(overheating) with self-ventilated motors. Possible

counter-measures include: Over-dimensioning or external

cooling independant of motor speed.

Observe the manufacturers recommendations for operation of the motor.

33

Page 37

Installation

Parallel connection of motors on a frequency inverter

The DF5 series frequency inverters can control multiple motors

connected in parallel. If differing motor speeds are required, they

must be selected via the number of pole pairs and/or the gear

transmission ratio.

09/01 AWB8230-1412GB

K1M

F1

M1

Figure 28: Parallel connection of multiple motors

U1 V1 W1

M

3

˜

K2M

F2

M2

Caution!

If a frequency inverter controls a number of motors in

parallel, the contactors for the individual motors must be

designed for AC

-3 operation. You may not use the mains

contactors from the table in the Appendix Section ”Mains

contactors”, Page 113. These mains contactors are only

designed for the mains (primary) currents of the frequency

inverter. If they are used in the motor circuit, the contacts

could weld.

The load resistance on the output of the frequency inverter is

reduced by parallel connection of the motors. The total stator

inductivity is reduced and the leakage capacitance increases. As a

result, the current distortion is larger when compared to operation

with a single motor load. In order to reduce the current distortion,

chokes or sinusoidal filters can be used on the frequency inverter

output.

The current consumption of all the connected motors may

h

not exceed the rated output current I

of the frequency

2N

inverter.

It is not possible to use electronic motor protection when

h

operating the frequency inverter with a number of

connected motors. You must however, protect each motor

with Thermistors and/or overload relays.

K3M

U1 V1 W1

M

3

˜

F3

M3

U1 V1 W1

M

3

˜

If motors with large differences in output power (e.g. 0.37 kW and

2.2 kW) are connected in parallel to the output of a frequency

inverter, problems can occur during the start phase and at low

speeds. It is possible, that motors with a low motor rating are

unable to develop the required torque. This is due to the relatively

high ohmic resistance's in the stators of these motors. They require

a higher voltage during the start phase and at low speeds.

Motor cable

Only screened motor cables may be used for EMC related compatability. The length of the motor cable and the associated use of

further components has an influence on the operating mode and

the operational behaviour. With parallel operation (multiple

motors connected to the frequency inverter output) the resulting

cable lengths l

l

= SlM x Wn

res

SlM: Sum of all motor cable lengths

: Number of motor circuits

n

M

With long motor cables, the leakage currents can cause

h

must be calculated:

res

M

the “earth fault” fault indication due to parasitic cable

capacities. In this case, motor filters must be used.

Keep the motor cables as short as possible as it will positively

influence the drive behaviour.

34

Page 38

09/01 AWB8230-1412GB

Electrical connection

Motor filters, dv/dt-filters, sinusoidal filters

Motor filters (chokes) compensate for capacitive currents with

long motor cables and with grouped drives (multiple connection of

parallel drives to a single inverter).

The use of motor filters is recommended (observe the manufacturers instructions):

• with grouped drives

• with the operation of three-phase current asynchronous motors

with maximum frequencies greater than 200 Hz,

• with the operation of reluctance motors or permanently-excited

synchronous motors with maximum frequencies greater than

120 Hz.

With dv/dt filters, the voltage on the motor terminals are limited

to values less than 500 V/ms. They should be applied with motors

with unknown or insufficient withstand voltage for the insulation.

Caution!

During the engineering phase, the voltage drop associated with motor filters and dv/dt filters must be considered as it can be up to 4 % of the frequency inverter

output voltage.

When sinusoidal filters are used, the motors are supplied with

voltage and current which is almost sinusoidal.

Bypass operation

If you want to have the option of operating the motor with the

frequency inverter or directly from the mains supply, the incoming

supplies must be locked mechanically:

Caution!

Switch-over between the frequency inverter and the

mains supply must be undertaken in a no voltage state.

Warning!

The frequency inverter outputs (U, V, W) may not be

connected to the mains voltage (destruction of the device,

danger of fire).

L2

L3

L1

Q1

>

I>I>I

K1M

L1 L2 L3

Caution!

During the engineering phase, it is necessary to consider

that the sinusoidal filter on the output voltage and the

switching frequency of the frequency inverter must be

adapted to suit each other.

The voltage drop on the sinusoidal filter can be up to

15 % of the frequency inverter output voltage.

G1

S1

M1

Figure 29: Bypass motor control

UVW

M

3h

35

Page 39

Installation

Connecting the signalling relay

The following figure indicates the position of the signalling relay.

a

09/01 AWB8230-1412GB

Figure 30: Connecting the signalling relay

a Signalling relay terminals

When connecting the signalling relay, support the open

h

enclosure front.

Table 4: Description of the signalling relay terminals

Terminal designation

K11 Default settings:

K12

K14

Table 5: Signalling relay conductor cross-sections and tightening torques

Description

• Operating signal: K11-K14 closed.

• Fault message or power supply off:

K11-K12 closed

Characteristics of the relay contacts:

• Maximum 250 V AC/2.5 A (resistive) or 0.2 A (inductive, power factor = 0.4);

Minimum 100 V AC/10 mA

• Maximum 30 V DC/3.0 A (resistive) or 0.7 A (inductive, power factor = 0.4);

Minimum 5 V DC/100 mA

K12K11 K14

2

mm

n

1 x 0.14 to 1.5 6 6 to 16 0.4 x 2.5 0.5 to 0.6

0.14 to 0.75 6 – 0.4 x 2.5 0.5 to 0.6

2 x

36

mm AWG mm Nm

M3

Page 40

09/01 AWB8230-1412GB

X Fit the terminal shroud to the enclosure again and close the

enclosure front.

1

2

Electrical connection

PES

Figure 31: Close the power section

PE

37

Page 41

Installation

09/01 AWB8230-1412GB

Connecting the control signal terminals

The following figure shows the arrangement of the individual

control signal terminals.

L54321P24

h O OI L FM CM2 12 11

Figure 32: Location of the control signal terminals

Function of the control signal terminals

ESD measures

Discharge yourself on an earthed surface before touching

the frequency inverter and its accessories.

This prevents damage to the devices through electrostatic

discharge.

Table 6: Meaning of the control signal terminals

No. Function Level Default setting Technical data, description

L Common reference

potential

5 Digital input

4 Digital input

3 Digital input

2 Digital input

1 Digital input

P24 Control voltage output

h Setpoint voltage output

OAnalog input

OI Analog input

L Common reference

potential

FM Analog output

0 V – Reference potential for the internal voltage sources

P24 and H

HIGH = +12 to +27 V

LOW = 0 to +3 V

+24 V – Supply voltage for actuation of digital inputs 1 to 5.

+10 V – Supply voltage for external setpoint potentiometer.

0 to +10 V Frequency setpoint value

4 to 20 mA Frequency setpoint value

0V – Reference potential for the internal voltage source

0 to +10 V Frequency actual value

Reset PNP logic, configurable, Ri=33kO

Reference potential: Terminal L

FF2 (FF3) = fixed frequency 2

(3)

FF1 (FF3) = fixed frequency 1

(3)

REV = anticlockwise rotation

FWD = clockwise rotation

(0 to 50 Hz)

(0 to 50 Hz)

(0 to 50 Hz)

PNP logic, configurable, Ri=5kO

Reference potential: Terminal L

Load carrying capacity: 30 mA

Reference potential: Terminal L

Load carrying capacity: 10 mA

Reference potential: Terminal L

Ri = 10 kO

Reference potential: Terminal L

RB = 250 O

Output: Terminal L

P24 and H

Configurable, monitored DC voltage; 10 V corres-

ponds to set final frequency (50 Hz).

Accuracy: g5 % from final value

Load carrying capacity: 1 mA

Reference potential: Terminal L

38

Page 42

09/01 AWB8230-1412GB

Electrical connection

No. Function

CM2 External control voltage

Level Default setting Technical data, description

Up to 27 V – Connection: Reference potential (0 V) of the

input

12 Transistor output

11 Transistor output

Up to 27 V = CM2 RUN (operation) Configurable, open collector

Frequency setpoint reached

Control signal terminal wiring

Wire the control signal terminals to suit their application. For a

description of how to change the functions of the control signal

terminals, see Section ”Programming the control signal terminals”

from Page 49 .

Caution!

Never connect terminal P24 with terminals L, H, OI or FM.

external voltage source for the transistor outputs,

terminals 11 and 12.

Load carrying capacity: Up to 100 mA

(sum of terminals 11 + 12)

Load carrying capacity: Up to 50 mA

Caution!

Never connect terminal H with terminal L.

Use twisted or screened cables for connecting to the control signal

terminals. Earth the screen on one side with a large contact area

near the frequency inverter. The cable length should not exceed

20 m. For longer cables, use a suitable signal amplifier.

The following figure shows a sample protective circuit for the

control signal terminals

1

2

H O

F 20 m

L

4K7

R1 REV FWD

Figure 33: Control terminal connection (factory setting)

2 1

M

P24

15

PES

PE

PES

M

ZB4-102-KS1

3

Cu 2.5 mm

M4

2

39

Page 43

Installation

When connecting a relay to one of the digital outputs 11 or 12,

connect a free-wheel diode in parallel with the relay, so that the

self-induction voltage generated when the relay is switched off

cannot destroy the digital outputs.

CM2 1211

+ 24 V

100 mA

09/01 AWB8230-1412GB

ba

Figure 34: Relay with free-wheel diode

Use relays that switch reliably at 24 V H and a current of

h

about 3 mA.

Lay the control and signal cables separately from the

h

mains and motor cables.

f 100

Figure 35: Crossover of signal and power cables

a Power cable: L1, L2, L3 or L and N, U, V, W, L+, DC+, DC–

b Signal cables: H, O, OI, L, FM, 1 to 5, 11 and 12, CM2, P24

40

Page 44

09/01 AWB8230-1412GB

Example for the protective circuit of the digital inputs when the

internal P24 supply voltage is used, or when a separate external

24 V power supply is used:

Electrical connection

+24 V

+24 V

24 V

+24 V

Q..

Q..

Q..

Q..

Q..

0 V

24 V

Q..

Q..

Q..

Q..

Q..

P24

5

4

3

2

1

L

+24 V

DF5

5

4

3

2

1

Figure 36: Triggering of the digital inputs

0 V

L

DF5

41

Page 45

Installation

Caution!

Before commissioning, remove the covering on the upper

ventilation slots and openings, as the frequency inverter

will otherwise overheat a Fig. 37.

09/01 AWB8230-1412GB

Figure 37: Removing the upper cover

42

Page 46

09/01 AWB8230-1412GB

4 DF5 Operation

This section describes how to commission the DF5 series frequency

inverters and deals with issues that need to be observed during its

operation.

Initial startup

Observe the following points before you take the frequency

inverter into operation:

• Ensure that the power cables L and N or L1, L2 and L3 as well

as the frequency inverter outputs U, V and W are correctly

connected.

• The control lines must be connected correctly.

• The earth terminal must be connected correctly.

• Only the terminals marked as earthing terminals must be

earthed.

• The frequency inverter must be installed vertically on a nonflammable surface (e.g. a metal surface).

• Remove any residue from wiring operations – such as pieces of

wire – and all tools from the vicinity of the frequency inverter.

• Make sure that the cables connected to the output terminals are

not short-circuited or connected to earth.

• Ensure that all terminal screws have been tightened sufficiently.

• Make sure that the frequency inverter and the motor are correct

for the mains voltage.

• The configured maximum frequency must match the maximum

operating frequency of the connected motor.

• Never operate the frequency inverter with opened power

section covers. The front enclosure must be closed and secured

with the screw provided.

The control signal terminals are wired as follows.

OH

F 20 m

4K7

Figure 38: Connecting control signal terminals (default settings)

X Switch on the supply voltage.

2L

1 P24

PES

S2

S1

M

M

FWD

REVR1

The POWER and Hz LEDs light up (keypad). The display should

indicate 0.0.

X Close switch S1 (FWD = clockwise rotation).

X With potentiometer R1, you can set the frequency and therefore

the motor speed.

The motor turns clockwise and the display indicates the set

frequency.

X Open switch S1.

Caution!

Do not carry out h.v. tests. Built-in overvoltage filters are

fitted between the mains voltage terminals and earth,

which could be destroyed.

Sparkover voltage and insulation resistance tests (megger

h

tests) have been carried out by the manufacturer.

The motor speed is reduced to zero (Display: 0.0).

X Close switch S2 (REV = anticlockwise rotation).

X With potentiometer R1, you can set the frequency and therefore

the motor speed.

The motor turns anticlockwise and the display indicates the set

frequency.

X Open switch S2.

The motor speed is reduced to zero (Display: 0.0).

If both switches S1 and S2 are closed, the motor will not start. The

motor speed reduces to zero during operation if you close both

switches.

43

Page 47

DF5 Operation

09/01 AWB8230-1412GB

Caution!

Check the following points during or after the “initial

operation” so that damage to the motor does not occur:

• Was the direction of rotation correct?

• Has a fault occurred during acceleration or

deceleration?

• Was the frequency display correct?

• Did any unusual motor noises or vibrations occur?

If a fault has occurred due to overcurrent or overvoltage, increase

the acceleration or deceleration time (a Section ”Acceleration

time 1”, Page 76 and Section ”Deceleration time 1” Page 77).

By default, the ON key and the potentiometer on the keypad

(a Fig. 39 and a Table 7) have no functions assigned to