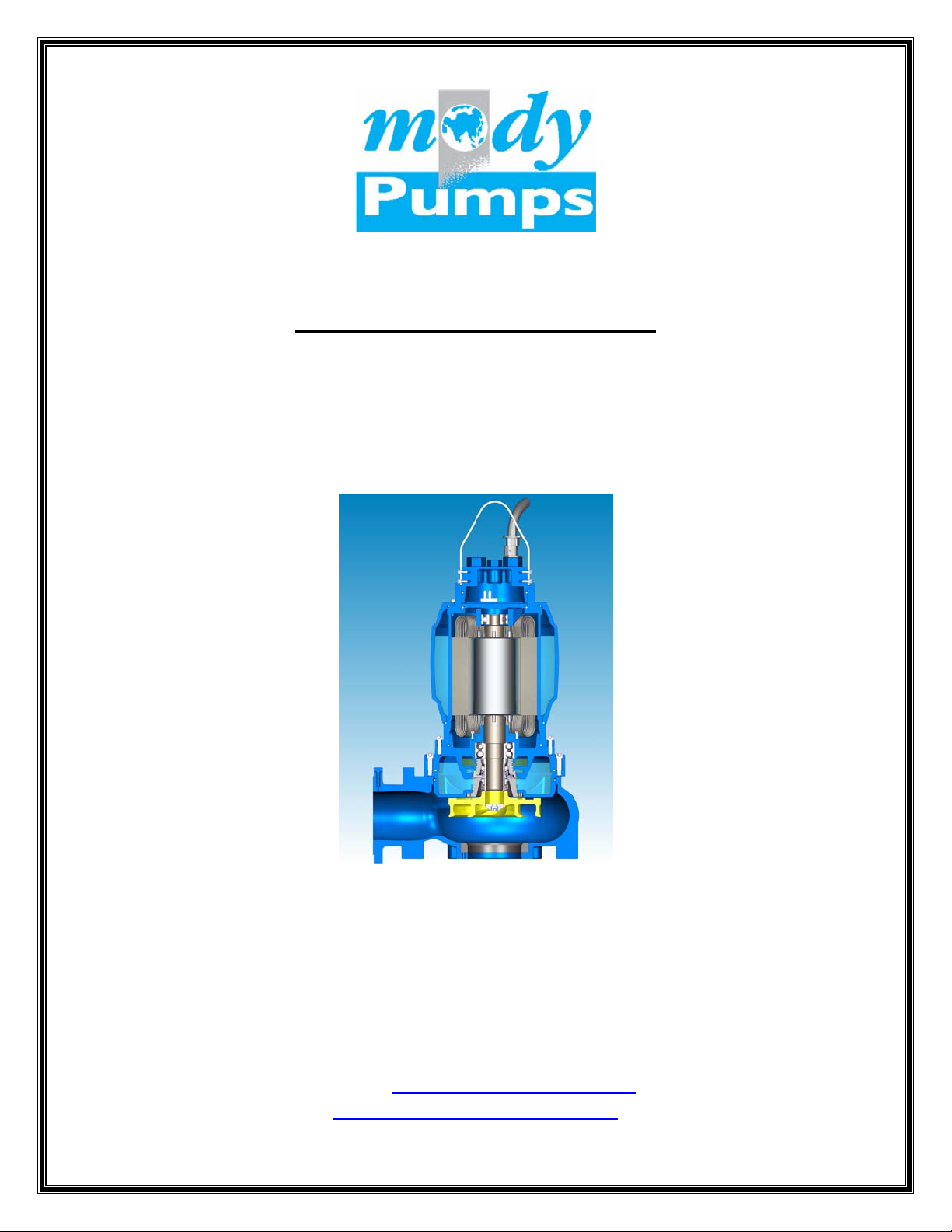

MODEL: MSP Series

OPERATING INSTRUCTIONS, INSTALLATION & MAINTENANCE

MANUAL INCLUDING SPARE PARTS LIST

Mody Pumps Inc.

2166 Zeus Court

Bakersfield, CA 93308

Tel.: (661) 392-7600 FAX.: (661) 392-7601

E-Mail: sales@modypump.com

http://www.modypump.com

LLIIFFEE IISS PPRREECCIIOOUUSS -- TTHHIINNKK SSAAFFEETTY

Y

1. Most accidents can be avoided by using COMMON SENSE.

2. Please read the operation and maintenance instruction manual supplied with the

pump. If you did not receive one, please call your local distributor before pump

installation.

3. Do not wear loose apparel that may become entangled in the impeller or other

moving parts.

4. Always use appropriate safety equipment, such as safety glasses, when working

on the pump or piping.

5. Pumps build up heat and pressure during operation-allow time for pumps to cool

before handling or servicing.

6. Only qualified service personnel should install, operate and repair pump.

7. Keep clear of suction and discharge openings. DO NOT insert fingers in pump

with power connected.

8. Do not pump flammable or hazardous materials (gasoline, acids, alkalis, etc.)

9. Do not block or restrict discharge hose, as it may whip or burst catastrophically

under pressure.

10. Make sure lifting handles/hooks are securely fastened each time before lifting.

11. Do not lift pump by the power cord under any circumstances.

12. Do not exceed manufacturer's recommendation for optimum performance, as this

could cause the motor/pump to overheat and lead to premature wear or failure.

13. Secure the pump in its operating position so it does not tip over, fall or slide.

14. Keep away from impeller when power is connected.

15. Submersible Pumps are not approved for use in swimming pools, recreational

water installations, decorative fountains or any installation where human contact

with the pumped fluid is common.

16. Do not operate pump without adequate protection and safety devices in place.

17. Always replace safety devices that have been removed during service or repair.

18. To reduce risk of electrical shock, pump must be properly grounded in

accordance with the National Electric Code and all applicable state and local

codes and ordinances.

19. To reduce risk of electrical shock, always disconnect the pump from the power

source before handling or servicing.

20. Any wiring of pumps should be performed by a qualified electrician.

21. Never operate a pump with a power cord that has frayed or brittle insulation.

22. Cable should be protected at all times to avoid punctures, cuts, and

abrasions - inspect frequently.

23. Never handle connected - "hot" power cords with wet hands.

24. Never operate a pump with a plug-in type power cord without a ground fault

circuit interrupter, adequate overload and short circuit protection.

IMPORTANT !!! Mody Pumps Inc. is not responsible for losses, injury, or death resulting

from a failure to observe these safety precautions, misuse or abuse of pumps or

equipment.

Mody Pumps Inc.: 2166 Zeus Court, Bakersfield, CA 93308 Tel.: (661) 392-7600 Fax: (661) 392-7601

Contents

Identification plate 1

General description 1

Applications 1

Product description 1

Handling 1

Installation 2

Electrical connections 3

Operation 3

Service & maintenance 3

Technical data

Motor winding connection schemes

Identification plate

General description

The MODY MSP SERIES submersible

sewage pumps can be used in a variety of

residential, commercial and industrial

applications such as:

• Sewage System

• Flood and Pollution control

• Dewatering / Effluent

• Farms

• Hospitals

• Trailer Courts

• Hotels

MODY MSP SERIES pumps are subjected to

a thorough inspection before leaving the

factory and equipped with operating

instructions for fitting, starting, care etc. which

conform to international safety regulations.

These instructions describe the procedures to

be used for fitting, operation and

maintenance of standard submersible

waste water pumps.

Applications

This starting & operation manual are

applicable to the electric driven

submersible waste water pumps specified

on the front page. The pumps are

designed to be used for pumping raw

sewage water with solid contents. The

pumps are suitable for heavy duty

drainage applications and clean water too.

The manufacturer guaranties that the new

pump airborne noise level do not exceed

70 db(A) when submerged. For dry

installation the corresponding level is

75 db(A). Be aware that under wrong

operated duty points, noise level might be

higher.

Do not start the pump if any parts

belonging to the pump are missing.

If humans should be in contact with the

pumped liquid e.g. construction sites, lifting

stations etc. a grounded connection

including an earth leakage detector must

be used. Never install the pumps in

swimming pools, special regulations apply.

Caution! This range of pumps is forbidden

to handle in flammable liquids nor used in

explosive environment.

Product description

Limitations

Immersion depth to max 20m (66 ft ).

Media temperature up to 40

Higher media temperature on request.

Pump models

Example: MSP3-150.X VX3 6-300

MSP3 = module range

150 = standard outlet discharge in mm

X = version of volute

V = vortex impeller or

C = channel impeller

X = version of impeller, more than

one X can appear to indicate

other types.

3 = family pumps

6 = number of poles (rpm)

e.g. 6=1,200 rpm

300 = diameter of impeller in mm

Motor

3 phase squirrel cage induction motor for

60 Hz, degree of protection IP68,

insulation class H (180°C).

Motor protection

All stators are equipped with 3 built-in

thermal switches and are connected in

series which opens at 135°C and closes at

approx 90°C and are marked F1 & F2

control cable. To maintain warranty on the

pumps, these thermal switches must be

o

C (115 oF ).

connected in series to control circuit of

control panel.

Cooling system

Models MSP2, MSP3 are standard

equipped with a closed internal cooling

system in all 3 types of installation, but can

be ordered without this system as an

option. Note that if ordered without closed

internal cooling system cannot be installed

as dry pit

The closed internal cooling system

functions as follows:

An internal impeller, located between the

two mechanical shaft seal, circulates the

cooling liquid in a closed loop through

channels to a cooling jacket surrounding

the stator housing. Thus, the heat

generated by the motor, is transferred to

the cooling liquid and finally dissipated to

the pumped liquid via a cooling flange

(heat exchange), without any physical

contact by the pumped sewage media.

Coolant: 70% water and 30% propylene

glycol.

Moisture sensor

All pumps are supplied with 3 moisture

sensors made of aluminum.

One sensor is placed in the seal oil

chamber; another sensor is placed in the

lower motor stator housing and a third

sensor is placed inside the motor cable

terminal board area.

The moisture detection control cable is

marked D. This control cable should be

connected to a relay (optional or by others)

in the control panel, which is activated by a

decrease in resistance to ground. Set the

alarm between 20 - 100 kOhm. Voltage

output applied to the moisture cable 12 24 VAC.

Power Cable

The pumps are standard equipped with

10m electric cable of the type H07RNF. If

longer cable is required, voltage drop must

be taken in consideration.

Handling

When transporting the pumps they must be

properly secured. Special attention must

be give to the cables; these cannot

withstand rolling heavy parts. All pumps

must be securely stored in vertical or

horizontal positions.

Always protect cable ends from moisture

and water as well, so that no moisture will

penetrate into the cable.

Before lifting the pump, check to determine

if the handle on the pump is properly

attached. Always use the lifting handle. Do

not use the cables or discharge hose. All

fixing screws and bolts must be securely

fastened before lifting. Human injury may

result if above is not properly secured.

1

After a long period of storage, the pump must

be inspected carefully. Rotate the impeller by

hand before start-up and check carefully

seals and cable entry

WARNING! Never start up the pump without

impeller. This will damage (in a few seconds)

the O-ring that seals between the rotor-shaft

and the sleeve of the mechanical seal

cartridge. Both sleeve and rotor shaft could

also be damaged due to excessive friction!

Installation

When installing the pump, reduce the risk of

accidents. Be aware that the machine is

extremely heavy and that it contains electrical

open wires.

Before starting the installation, check and

secure all screws for the lifting handle, stator

and volute fixing bolts. Ensure that these are

all safety tightened.

Lifting chains, cranes etc. must always be

designed to fully accommodate the weight of

the complete pump units. For safety reasons

never walk under suspended load.

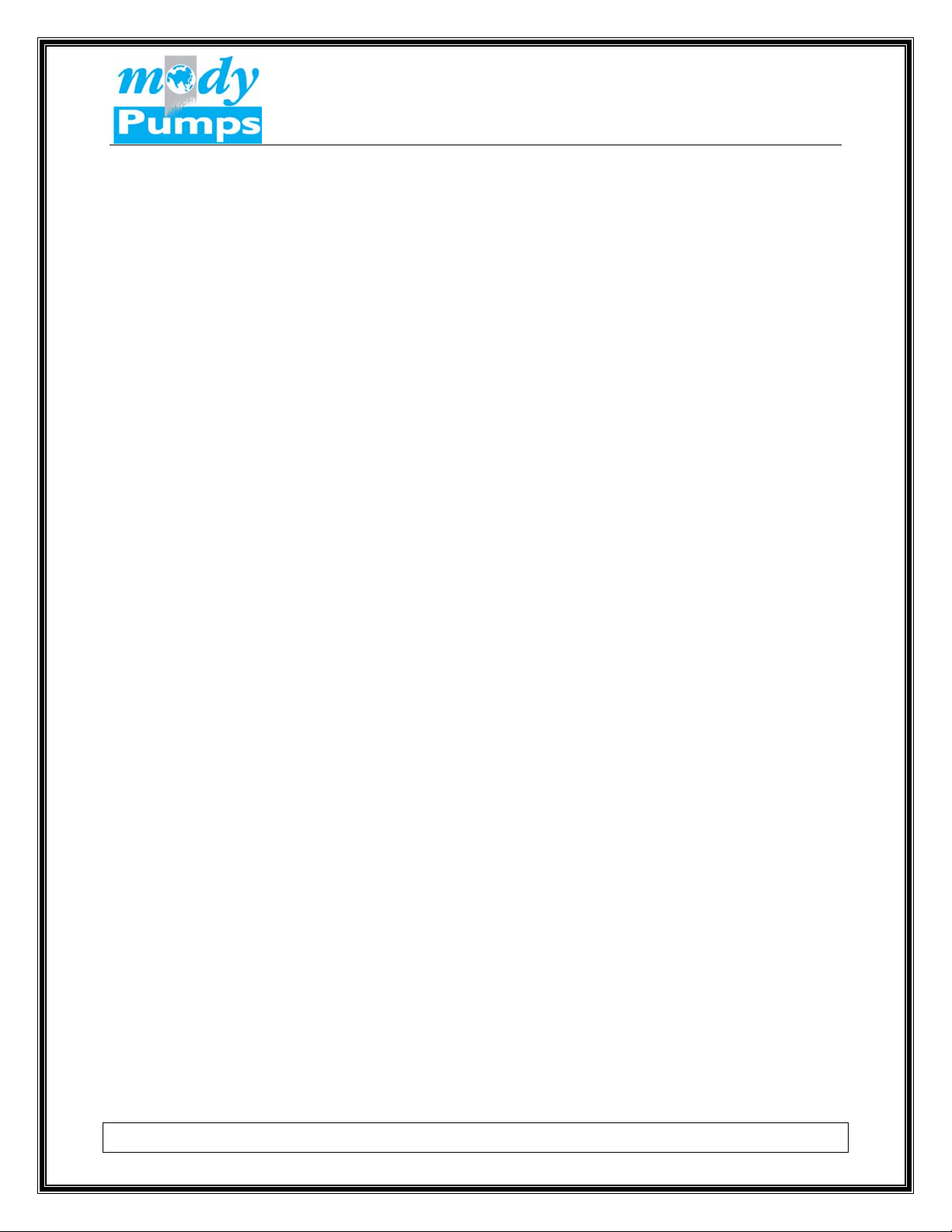

Discharge base elbow - DBE

guide rail bracket so the rails are accurately

located in vertical and parallel positions to

each other.

Connect the discharge pipe to the DBE. A

non return valve and gate valve sized

according to the flow velocity from the pump

are strongly recommended.

The lifting tackle must be installed directly at

the point above the center of gravity of the

pump for proper automatic coupling to and

release from the DBE, which is appropriately

designed for this purpose, when lifting and

lowering the pump from and to the DBE.

Dry pit installation

telescopic in design. The suction pipe can be

connected in any direction by changing the

location of the legs. After elevation

Place the

discharge base

elbow (DBE) at

the bottom of the

sump. If one

pump is installed,

place the pump in

the center of the

tank. Fit the guide

rails to the upper

All MSP2 and

MSP3 modules

can be installed

dry with adjustable support legs

and a separately

supplied suction

elbow, or a fixed

suction base

elbow (SBE) unit.

Adjustable support consists of

three legs that are

adjustment, the legs are set and fixed by

two screws that lock the pump

arrangement into position. The bottom leg

pads can then be secure by bolting and

anchoring them in the concrete foundation.

The suction pipe is connected vertically to

the pump suction flange.

Note: The motor unit is easier to remove or

re-install if the suction pipe is equipped

with a drain valve. This can be opened

when the motor is going to be or removed

or reinstalled.

The discharge pipe should be equipped

with a drain valve as well, in order to bleed

air from the system during first start-up.

Afterwards this valve can be fitted with a

manometer to measure the discharge

pressure.

Before starting, carefully inspect the cables

for defects and check the level of coolant

in the cooling jacket.

Portable version / installation

This version needs

extra attention while

operating. The pump

can be supplied with

a support ring.

Place the pump on a

firm surface. Keep

the cables straight

and secure so that they cannot be nipped

or cut in any way.

WARNING! Never remove the support ring,

human contact might occur and make

injury.

If there is risk of overturning, place and fit

the pump on a steel plate.

When hoses are used as discharge

connection, remember that friction losses

are higher than in a pipe and flow may be

less than expected.

Electrical connections

The electrical installation must be

inspected by authorized electrician before

switching-on.

Make sure that the electrical terminals and

starting equipment is installed in such way

that it cannot be flooded. The electrical

installation must apply to national and local

regulations.

All pumps are supplied with built-in thermal

switches in the stator windings. These are

marked F1, F2 on the control cable and

must always be connected in series to the

control circuit in the control panel.

CAUTION! All electrical equipment must

always be earthed (grounded). This applies

both to the pump and to any monitoring

equipment.

The control cable marked D is connected

to the moisture sensors. This cable should

be connected to a conductive liquid level

relay in the control panel. An alarm should

be given in event of moisture intrusion.

Your local MODY representative can

supply you with the conductive liquid level

relay as an option.

Make sure that the power supply, voltage,

frequency and starting method

corresponds to the nameplate data fitted

on the pump.

The motor can operate by voltage

tolerances at +/- 10%. The motor might be

overloaded and burned out if this is

exceeded.

For power supply cable, and control cable

connections, refer to the motor winding

connection schematics in this manual.

• Direct online starting DOL

• Star-Delta starting Y-∆

Starting equipment in the control panel

must be provided with over current

protection sensitive to phase failure. A 3phase asymmetry control relay is

recommended, adjusted to 15% phase

asymmetry

The power supply should be fused with

low-blow fuses.

15 Starts per hour (regularly spaced) are

permitted

Replacing the power cable

If the cable has been compressed or

damaged it must be replaced to avoid

water entry.

When changing the cable always change

the rubber cable seal was well. Never

change cable dimensions from the original

cable or cable seal dimensions from the

original seal, as water may enter the motor

if these are not properly sized.

If the same cable is re-used due to any

repair work, always cut away a piece at the

cable entry in order to seal on a non

compressed cable sheath.

For safety reasons the grounded conductor

strand should always be longer than all the

other conductor strands. If the motor cable

is accidentally wrenched off, the grounded

conductor should be the last to break away

from its terminal. This applies to both ends

of the cable.

Electromagnetic Compatibility,

EMC

The pump does not generate any

electromagnetic (EMC) that would affect

other equipment. However, if the pump

power is supplied by a frequency inverter,

the power cables may require screening.

All MSP2 and MSP3 pump modules

comply with directive EN89/336/EEC

regarding EMC.

2

Operation

Before initial start-up after repair or in a new

installation, always check direction of

rotation. The pump must always rotate in an

anti-clockwise direction. If the rotation is

clock-wise, transpose two phases in the

electric control panel so that it will change to

proper rotational direction.

Be aware of the starting torque, it may be

very strong depending on the size of the

pump. Do not hold the pump when checking

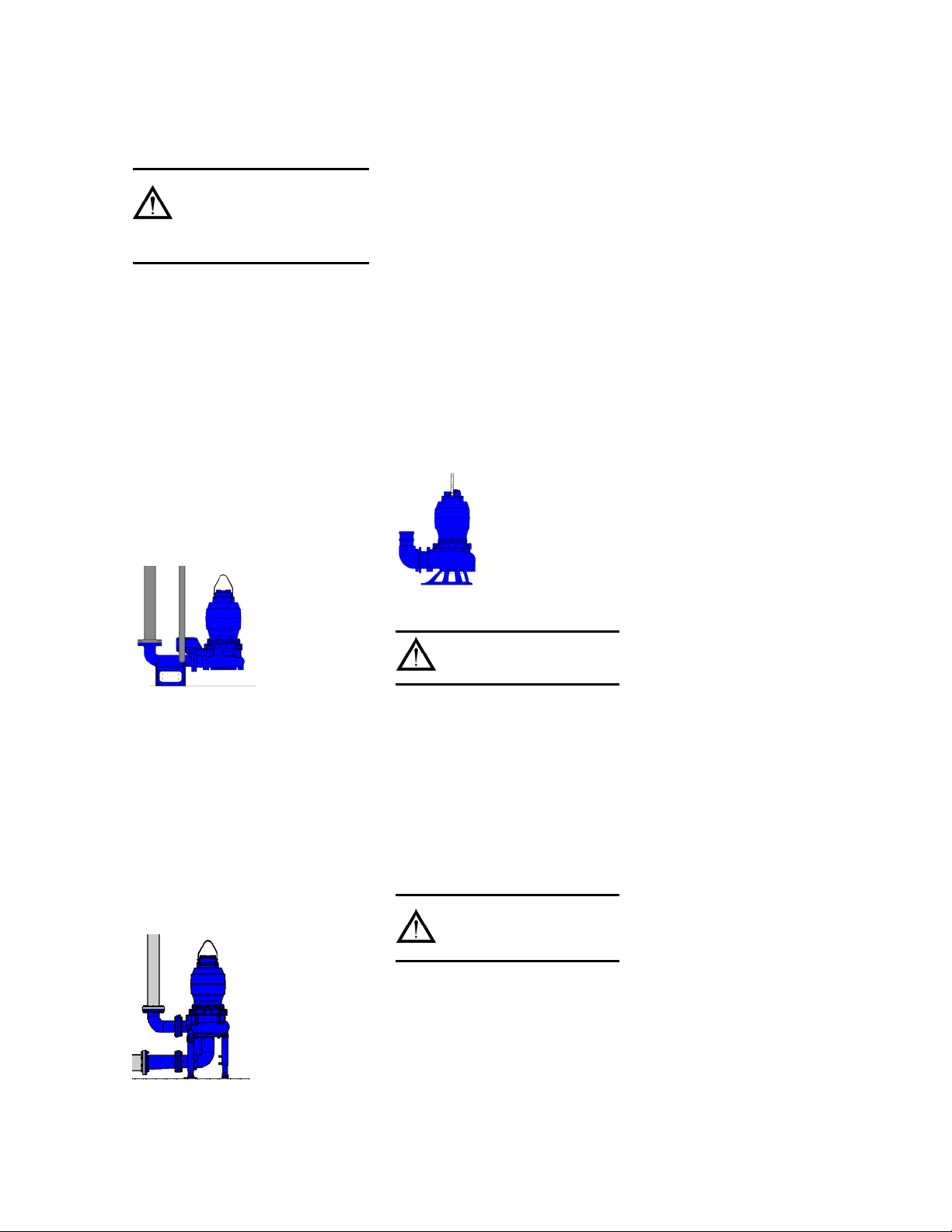

Inspection

CAUTION! Before undertaking any service

work, make sure that the pump is

thoroughly clean, and bear in mind the

importance of observing good personal

hygiene. Follow your local safety

instructions.

Pump

Section

Inspection Action in

the rotation. The pump must be heavily

supported and never started when hanging in

a chain without proper support when

performing a rotational check or in operation.

WARNING! As the pump will pump up to 70%

of the nominal flow at wrong rotation, never

use the visual flow rate to determine the

direction of rotation. Most times, the pump

creates heavy noise and vibration when

operates at wrong rotation.

WARNING! Do not insert your hand or any

other object into the pump volute and impeller

if any power supply is connected. Remove

physically the cable even if security devices is

activated

Service and

maintenance

Regular inspection and preventive

maintenance will ensure more reliable

operation. The pump should be inspected

every six months or more often if the

operating conditions are difficult. The cable

should be checked more frequently. For a

complete overhaul of the pump, please

contact an authorized MODY service facility

workshop or your MODY dealer.

CAUTION! When the pump or motor section

has been laid on its side, always secure it with

wedges from both sides to prevent it from rolling

away.

CAUTION! Parts must be replaced by genuine

spares, including screws, to ensure correct

strength.

CAUTION! Before maintenance and repair

work, motor leads must first be completely

disconnected from the power supply.

Never work on electrical systems during a

thunder storm.

All work on the electrical system may only be

performed by qualified electricians.

Cables Check that the

Cooling

water

Visible Parts Check that all

Impeller /

Wear ring

Shaft seal Check that the

Hoses,

pipes and

valves

sheath is not

damaged.

Check that the

cables are not

kinked or

nipped.

Check the

cooling water

level of coolant

parts are in

good condition,

and that bolts

and nuts are

securely

tightened.

Check that the

parts are not

worn to such an

extent that the

pump

performance is

affected.

oil is clean and

is not mixed with

water.

See under

“Changing the

oil”.

Check that the

equipment does

not leak or is

otherwise

damaged.

Changing the oil

Change of oil is done in the same way on

cooled and un-cooled pumps. Remove the

plug marked “outlet” and let the old oil pour

out through the groove under the plug.

Discard of any used oil in accordance with

local regulations. Fasten the plug so that

the lower but not the top O-ring gasket

seals. Loosen the plug marked “inlet” and

fill up with oil and then fasten both oil

plugs. Use food grade oil of same quality

and performance as Enerpar M002, white

oil.

CAUTION! In the event of inward leakage,

the oil housing may be pressurized.

When removing the oil plug, hold a piece of

cloth over it to prevent oil from splashing.

the event

of a

fault.

Fit a new

cable.

Correct

the fault.

Fill up

with

cooling

liquid.

Replace

worn

parts.

Tighten

any loose

bolts and

nuts.

Adjust

the wear

ring.

In the

event of

slight

leakage,

change

the oil.

Adjust or

replace

defective

parts.

NOTE! Old oil should be entrusted to an oil

disposal company in accordance with local

regulations.

3

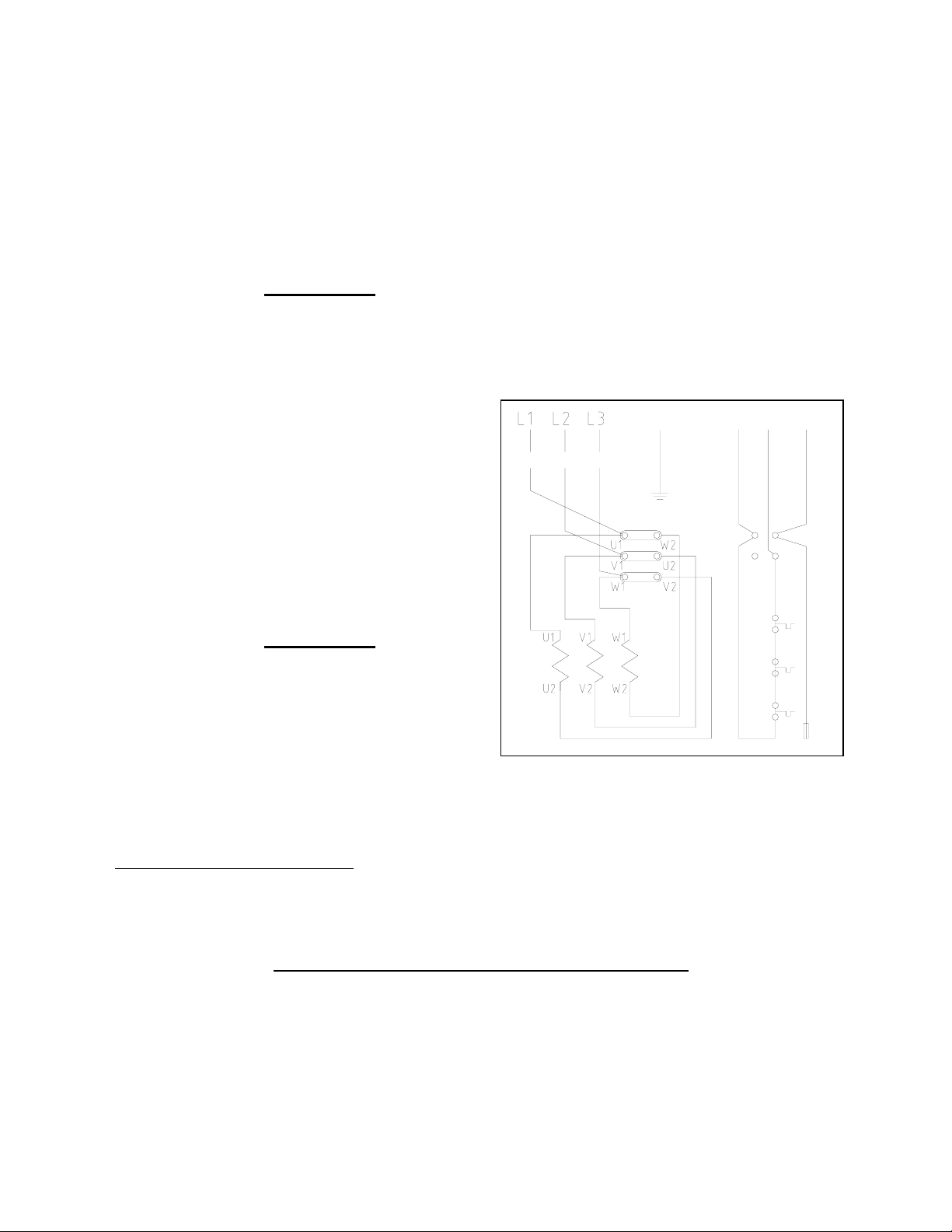

3 ~ Direct on –line starting DOL

Motor connection:

1 Power Supply Cable

+ 1 Control Cable

Color Coding

U Black

Power Supply V Brawn

W Grey

PE Yellow

F1 Black

Control F2 Brawn

D* Grey

1 Power Supply and

Control Cable

Ʀ

3~ Direct - on - line

starting DOL

Motor connection : ǻ

PE

UVW

F1 F2 D

Color Coding

U Black-1

V Black-2

W Black-3

PE Yellow

F1 Black-4

F2 Black-5

D* Black-6

*Not available for PX1-65.0 Series

Internal Connection on Motor’s Terminal Board

U1, U2 : Black

V1, V2 : Red

W1, W2 : Orange

Thermal switches

Moisture

4

3 ~ Star-Delta starting Y-

Ʀ

Motor connection:

2 Power Supply Cable

+ 1 Control Cable

Color Coding

U1 Black

Power Supply V1 Brawn

(

cable1) W1 Grey

PE Yellow

U2 Black

Power Supply V2 Brawn

(

cable2) W2 Grey

PE Yellow

F1 Black

Control F2 Brawn

D Grey

ǿǿǿ Ʀ

3~ Star-Delta starting Ȋ-ǻ

Motor connection : III ǻ

F1 F2

U1 V1 W1

U2 V2 W2

D

Thermal switches

Moisture

1 Power Supply Cable

+ 1 Control Cable

Color Coding

U1 Black-1

V1 Black-2

W1 Black-3

PE Yellow

Power Supply U2 Black-4

V2 Black-5

W2 Black-6

PE Yellow

F1 Black

Control F2 Brawn

D Grey

Internal Connection on Motor’s Terminal Board

U1, U2 : Black

V1, V2 : Red

W1, W2 : Orange

1 Power Supply and

Control Cable

Color Coding

U1 Black-1

V1 Black-2

W1 Black-3

U2 Black-4

V2 Black-5

W2 Black-6

PE Yellow

F1 Black-7

F2 Black-8

D Black-9

5

MSP2 PARTS LIST

ITEM

NO. PART DESCRIPTION QTY MATERIAL

1 LATCH BOLT (FAST LOCK) (SMALL) 2 AISI 304 STAINLESS STEEL

2 LOWER BEARING HOUSING 1 ASTM A48 CLASS 35 CAST IRON

3 WASHER SPACER 2 TEFLON

4 IMPELLER WASHER 1 AISI 304 STAINLESS STEEL

7 BEARING LOWER 1 3307B.2ZTNG

8 COOLING FLANGE LOWER 1 ASTM A48 CLASS 35 CAST IRON

9 IMPELLER VORTEX VX2-80 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

IMPELLER VORTEX VX2-100 ASTM A395 DUCTILE IRON, GRADE 60-40-18

IMPELLER VORTEX VXX2-100/150 ASTM A395 DUCTILE IRON, GRADE 60-40-18

10 UPPER BEARING HOUSING 1 ASTM A48 CLASS 35 CAST IRON

11 SHAFT FOR 170 STATOR 1 AISI 304 STAINLESS STEEL

12 STATOR HOUSING PX2-1 1 ASTM A48 CLASS 35 CAST IRON

12a STATOR HOUSING PX2-2 1 ASTM A48 CLASS 35 CAST IRON

13 COOLING JACKET 1 ASTM A48 CLASS 35 CAST IRON

14 MOTOR COVER 1 ASTM A48 CLASS 35 CAST IRON

16 COOLING TUBE 1 RUBBER / STAINLESS STEEL

18 SHAFT ROTOR 1 SIEMENS

19 NAME PLATE 1 AISI 304 STAINLESS STEEL

20 VOLUTE-100 1 ASTM A48 CLASS 35 CAST IRON

20a VOLUTE-150 1 ASTM A48 CLASS 35 CAST IRON

20b VOLUTE-80 1 ASTM A48 CLASS 35 CAST IRON

21 WIRE CORE 1 SIEMENS

22 SEAL CATRIDGE ASSEMBLY 1

24 COOLANT HOSE ASSEMBLY 2 RUBBER / STAINLESS STEEL

25 CABLE SEAL compl. 1

26 HANDLE 1 AISI 304 STAINLESS STEEL

29 ADAPTER 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

30 O-RINGS 1 NITRILE RUBBER

31 O-RINGS 1 NITRILE RUBBER

32 O-RINGS 1 NITRILE RUBBER

33 O-RINGS 1 NITRILE RUBBER

34 BEARING UPPER 1 6305DDU C3

35 BOLT 2 AISI 304 STAINLESS STEEL

36 BOLT 1 AISI 304 STAINLESS STEEL

37 BOLT 4 AISI 304 STAINLESS STEEL

38 BOLT 4 AISI 304 STAINLESS STEEL

39 BOLT 4 AISI 304 STAINLESS STEEL

40 BOLT 4 AISI 304 STAINLESS STEEL

41 BOLT 4 AISI 304 STAINLESS STEEL

42 BOLT 6 AISI 304 STAINLESS STEEL

43 O-RINGS 1 NITRILE RUBBER

44 O-RINGS 1 NITRILE RUBBER

45 O-RINGS 1 NITRILE RUBBER

46 CHANNEL IMPELLER-100 CX2-100 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

46b CHANNEL IMPELLER-150 CX2-150 ASTM A395 DUCTILE IRON, GRADE 60-40-18

47 WEAR RING PX2-100 1 ASTM A48 CLASS 35 CAST IRON

WEAR RING PX2-150 1 ASTM A48 CLASS 35 CAST IRON

48 BOLT 4 AISI 304 STAINLESS STEEL

49 GUIDE PIN 2 STEEL

O-RING KIT 1 NITRILE RUBBER

6

22-March-2007 Items subject to change without notice MODY PUMPS INC

A

B

C

D

E

F

26

8

34

41

47

11

25

39

7

33

14

43

19

35

10

1

42

45

31

3

2

44

13

30

16

24

12

37

321 54 678

21

18

32

8

38

22

4

9

40

48

29

46

4

3

36

49

20

47

2

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR:

ANGULAR:

NAME

STELIOS

DESIGN

CHK'D

APPV'D

MFG

Q.A

7

A

B

PRINT

FINISH:UNLESS OTHERWISE SPECIFIED:

SIGNATURE

C

DATE

MATERIAL:

20/02/07

DEBUR AND

BREAK SHARP

EDGES

D

MODY PUMPS INC

TITLE:

MSP2 ASSEMBLY

DWG NO.

002-400-561

SHEET 1 OF 1SCALE:1:5

E

1 567

A3

F

MSP3 PARTS LIST

ITEM

NO. PART DESCRIPTION QTY MATERIAL

1 LOWER COOLING FLANGE 1 ASTM A48 CLASS 35 CAST IRON

2 COVER 1 ASTM A48 CLASS 35 CAST IRON

3 COOLING JACKET 1 ASTM A48 CLASS 35 CAST IRON

4 VOLUTE-100 1 ASTM A48 CLASS 35 CAST IRON

4a VOLUTE-150 ASTM A48 CLASS 35 CAST IRON

4b VOLUTE-80 ASTM A48 CLASS 35 CAST IRON

5 HANDLE 1 AISI 304 STAINLESS STEEL

6 BEARING COVER 1 ASTM A48 CLASS 35 CAST IRON

7 BEARING UPPER 1 S.K.F. 62306.2RSR.C3

8 BEARING LOWER 1 S.K.F.3310.A/C3

9 STATOR PX3-2 1 ASTM A48 CLASS 35 CAST IRON

STATOR PX3-1 ASTM A48 CLASS 35 CAST IRON

10 SHAFT ROTOR PX3-2 1 AISI 431 STAINLESS STEEL

SHAFT ROTOR PX3-1 AISI 431 STAINLESS STEEL

11 TERMINAL PLATE 1 ASTM A48 CLASS 35 CAST IRON

12 FAST LOCK WASHER (LARGE) 4 TEFLON

13 LATCH ǺȅLT (FAST LOCK) 4 AISI 304 STAINLESS STEEL

14 BOLT 4 AISI 304 STAINLESS STEEL

15 ADAPTER 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

17 IMPELLER WASHER 1 AISI 304 STAINLESS STEEL

18 CHANNEL IMPELLER CX3-100 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

18a CHANNEL IMPELLER CXX3-150 ASTM A395 DUCTILE IRON, GRADE 60-40-18

18b CHANNEL IMPELLER CXXX3-150 ASTM A395 DUCTILE IRON, GRADE 60-40-18

19 BOLT 4 AISI 304 STAINLESS STEEL

20 BOLT 4 AISI 304 STAINLESS STEEL

21 KEY 1 AISI 304 STAINLESS STEEL

22 PX3 CARTRIDGE ASSEMBLY 1

23 ROTOR BODY 1 SIEMENS

24 POWER CABLE. H07RN-F

25 WIRE CORE 1 SIEMENS

26 CABLE CONTACTS 1

27 O-RING 1 NITRILE RUBBER

28 O-RING 1 NITRILE RUBBER

29 O-RING 2 NITRILE RUBBER

30 O-RING 1 NITRILE RUBBER

31 O-RING 1 NITRILE RUBBER

32 O-RING 1 NITRILE RUBBER

33 O-RING 1 NITRILE RUBBER

34 CABLE SEAL compl. ASTM A48 CLASS 35 CAST IRON

35 IMPELLER VORTEX VX3-100/150 1 ASTM A395 DUCTILE IRON, GRADE 60-40-18

35a IMPELLER VORTEX VXX3-150 ASTM A395 DUCTILE IRON, GRADE 60-40-18

IMPELLER VORTEX VX3-80 ASTM A395 DUCTILE IRON, GRADE 60-40-18

36 WEAR RING PX3-100 1 ASTM A48 CLASS 35 CAST IRON

36a WEAR RING PX3-150 ASTM A48 CLASS 35 CAST IRON

37 LOWER BEARING HOUSING 1 ASTM A48 CLASS 35 CAST IRON

38 COOLANT TUBE ASSEMBLY for PX3-2 2 RUBBER / STAINLESS STEEL

COOLANT TUBE ASSEMBLY for PX3-1 RUBBER / STAINLESS STEEL

40 GUIDE PIN 2 STEEL

8

22-March-2007 Items subject to change without notice MODY PUMPS INC

MSP3 PARTS LIST

ITEM

NO. PART DESCRIPTION QTY MATERIAL

41 SCREW 1 AISI 304 STAINLESS STEEL

42 PLUG 1 AISI 304 STAINLESS STEEL

43 PLUG 1 AISI 304 STAINLESS STEEL

45 BOLT 1 AISI 304 STAINLESS STEEL

46 BOLT 4 AISI 304 STAINLESS STEEL

47 BOLT 10 AISI 304 STAINLESS STEEL

48 BOLT 4 AISI 304 STAINLESS STEEL

49 BOLT 6 AISI 304 STAINLESS STEEL

50 CABLE SEAL compl.control power 1 ASTM A48 CLASS 35 CAST IRON

51 CONTROL CABLE. H07RN-F

O-RING KIT NITRILE RUBBER

9

22-March-2007 Items subject to change without notice MODY PUMPS INC

A

B

C

D

E

F

24

50

8

51

23

8

34

5

10

14

46

21

2

47

29

26

6

11

29

7

45

48

3

31

37

32

38

28

27

30

9

49

321 54 67

25

8

20

13

12

1

33

4

22

18

47

35

3

36

40

43

19

17

41

4

42

2

15

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR:

ANGULAR:

NAME

STELIOS

DESIGN

CHK'D

APPV'D

MFG

Q.A

10

A

B

PRINT

FINISH:

DEBUR AND

BREAK SHARP

EDGES

MODY PUMPS INC

DATESIGNATURE

MATERIAL:

5/10/06

C

D

TITLE:

DWG NO.

SCALE: 1:10

MSP3 ASSEMBLY

003-400-500

SHEET 1 OF 1

E

1 567

A3

F

A

B

C

D

E

F

20

1

8

49

21

2

22

50

26

45

3

5

13

14

25

15

16

4

6

19

52

18 17

7

8

23

24

51

25

26

27

28

29

30

31

32

39

34

33

4

9

40

41

10

53

321 54 678

11

12

A

43

42

50

44

35

3

36

47

37

2

38

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR:

ANGULAR:

NAME

STELIOS

DESIGN

CHK'D

APPV'D

MFG

Q.A

PRINT

B

FINISH:

DEBUR AND

BREAK SHARP

EDGES

MODY PUMPS, INC

.

Bakersfield, CA USA

SIGNATURE

C

DATE

16/07/08

MATERIAL:

TITLE:

MSP4 ASSEMBLY

DWG NO.

004-400-500

SHEET 1 OF 2SCALE:

DE

1 567

A3

F

ITEM NO.

DRAWING

NUMBER

MSP4 PARTS LIST

QTY

STD MAT'L OF CONSTRUCTION

1

004-000-039

HANDLE

1

stainless steel 304

2

004-000-404

screw

4

stainless steel 304

3

004-000-019

MOTOR COVER

1

cast iron GG25

4

004-000-013

UPPER BEARING HOUSING

1

cast iron GG25

5

004-000-043

O-RINGS

1

NBR

6

004-000-043

O-RINGS

1

NBR

7

004-000-043

O-RINGS

1

NBR

8

004-000-007

COOLING JACKET

1

cast iron GG25

9

004-000-402

BEARING UPPER

1

6309DDUCM

10

004-000-038

SHAFT ROTOR PX4-1

1

stainless steel 304

10a

004-000-014

SHAFT ROTOR PX4-2

11

004-000-017

STATOR HOUSING PX4-1

1

cast iron GG25

11a

004-000-006

STATOR HOUSING PX4-2

1

cast iron GG25

12

004-000-413

screw

6

stainless steel 304

13

004-000-043

O-RINGS

1

NBR

14

004-000-043

O-RINGS

2

NBR

15

004-000-031

CABLE COVER for control cable

1

cast iron GG25

16

004-000-417

screw

6

stainless steel 304

17

004-000-046

CONTROL CABLE

1

18

004-000-047

POWER CABLE

2

19

004-000-032

CABLE COVER for power cable

2

cast iron GG25

20

004-000-011

ROTOR BODY

1

siemens

21

004-000-008

WIRE CORE

1

siemens

22

002-000-062

MOISTURE SENSOR

1

Aluminioum/rubber

23

004-000-043

O-RING

1

NBR

24

004-000-043

O-RING

1

25

plug(for w/o cooling jacket version)

2

stainless steel 304

26

004-000-403

plug

1

stainless steel 304

27

004-000-419

screw

1

stainless steel 304

27

004-000-401

BEARING

2

7214 BEAT85SUN

28

004-000-043

O-RING

1

29

004-000-405

BOLT

6

stainless steel 304

30

003-000-032

LATCH BOLT (FAST LOCK)

6

stainless steel 304

31

003-000-034

FAST LOCK WASHER (LARGE)

6

TEFLON

32

004-000-009

LOWER COOLING FLANGE

1

cast iron GG25

33

004-000-043

O-RING

1

34

004-000-024

ADAPTER

1

cast iron GG25

35

004-000-029

VOLUTE MSP4-150.0

1

cast iron GG25

35a

VOLUTE MSP4-200.0

1

cast iron GG25

35b

VOLUTE MSP4-80.0

1

cast iron GG25

35c

VOLUTE MSP4-300.0

1

cast iron GG25

36

004-000-023

WEAR RING MSP4-150

1

cast iron GG25

36a

WEAR RING MSP4-200

1

cast iron GG25

36b

WEAR RING MSP4-300

1

cast iron GG25

37

004-000-033

IMPELLER WASHER

1

stainless steel 304

38

004-000-414

screw

1

stainless steel 304

39

004-000-409

screw

6

stainless steel 304

ITEM NO.

DRAWING

NUMBER

MSP4 PARTS LIST

QTY

STD MAT'L OF CONSTRUCTION

40

004-500-001

SEAL CATRIDGE ASSEMBLY

141004-00-411

screw

8

stainless steel 304

42

004-000-415

screw

2

stainless steel 304

43

004-000-026

IMPELLER CX4-151

1

Ductile Iron GGG40

43a

IMPELLER CXX4-151

1

43b

IMPELLER VX4-151

1

43c

IMPELLER CXX4-201

1

43d

IMPELLER VXX4-201

1

44

004-000-416

screw

2

stainless steel 304

45

004-000-043

O-RINGS

1

NBR

47

004-000-420

screw

6

stainless steel 304

49

004-000-431

screw

4

stainless steel 304

50

004-000-421

plug1stainless steel 304

51

004-000-002

LOWER BEARING HOUSING PX4-1

1

cast iron GG25

51a

LOWER BEARING HOUSING PX4-2

1

cast iron GG25

52

plug1stainless steel 304

53

KEY1stainless steel 304

Ductile Iron GGG40

Ductile Iron GGG40

Ductile Iron GGG40

Ductile Iron GGG40

RETURNED GOODS POLICY:

RETURN OF MERCHANDISE REQUIRES A “RETURNED GOODS

AUTHORIZATION” OR RGN NUMBER. CONTACT YOUR LOCAL MODY

PUMPS INC. DISTRIBUTOR OR THE FACTORY DIRECTLY.

PRODUCTS THAT ARE RETURNED MUST BE PRESSURE WASHED,

CLEANED, SANITIZED AND DECONTAMINATED AS NECESSARY PRIOR

TO SHIPMENT. THIS ENSURES THAT EVERYONE IN CONTACT WITH

RETURNED UNITS ARE NOT EXPOSED TO HEALTH HAZARDS. ALL

APPLICABLE LAWS AND REGULATIONS SHALL APPLY.

LIMITED WARRANTY

We warrant to our immediate customer and to the ultimate consumer that products of our manufacture will be free

of defects in material and workmanship under normal use and service for the following time periods, when installed

and maintained in accordance with our instructions.

PUMPS: One (1) year from date of installation or (18) months from date of shipment, whichever occurs first. As

used herein, “the ultimate consumer” is defined as the purchaser who first uses the product after it’s initial

installation or, in the case for product designed for non-permanent installation, the first owner who uses the product.

It is the purchaser’s or any sub-vendor’s obligation to make known to the ultimate consumer the terms and

conditions of this warranty. This warranty gives you specific legal rights, and there may also be other rights which

vary from state to state. In the event the product is covered by the Federal Consumer Product Warranties Law (1)

the duration of any implied warranties associated with the product by virtue of said law is limited to the same

duration as stated herein, (2) this warranty is a LIMITED WARRANTY, and (3) no claims of any nature

whatsoever shall be made against us, until the ultimate consumer, his successor, or assigns, notifies us in writing of

the defect, and delivers the product and/or defective part(s) freight prepaid to our facility or nearest authorized

service station. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY AND ALL

WARRANTIES WITH RESPECT TO ANY PRODUCT SHALL BE TO REPLACE OR REPAIR AT OUR

ELECTION, FOB POINT OF MANUFACTURE OR AUTHORIZED REPAIR STATION, SUCH

PRODUCTS AND/OR PARTS AS PROVEN DEFECTIVE. THERE SHALL BE NO FURTHER

LIABILITY, WHETHER BASED ON WARRANTY, NEGLIGENCE OR OTHERWISE. Unless expressly

stated otherwise, guarantees in the nature of performance specifications furnished in addition to the foregoing

material and workmanship warranties on a product manufactured by Mody Industries Pvt. Ltd., if any, are subject to

laboratory tests corrected for field performance. Any additional guarantees, in the nature of performance

specifications must be in writing and such writing must be signed by our authorized representative. Due to

inaccuracies in field testing if a conflict arises between the results of field testing conducted by or for user, and

laboratory tests corrected for field performance, the latter shall control. Components or accessories supplied by us

but manufactured by others are warranted only to the extent of and by the terms and conditions of the original

manufacturer’s warranty. RECOMMENDATIONS FOR SPECIAL APPLICATIONS OR THOSE

RESULTING FROM SYSTEMS ANALYSES AND EVALUATIONS WE CONDUCT, WILL BE BASED

ON OUR BEST AVAILABLE EXPERIENCE AND PUBLISHED INDUSTRY INFORMATION. SUCH

RECOMMENDATIONS DO NOT CONSTITUTE A WARRANTY OF SATISFACTORY

PERFORMANCE AND NO SUCH WARRANTY IS GIVEN.

This warranty shall not apply when damage is caused by (a) improper installation, (b) improper voltage, (c)

lightning, (d) sand or other abrasive materials, (e) scale or corrosion build-up due to excessive chemical content.

Any modification of the equipment will also void the warranty. We will not be responsible for loss, damage or labor

cost due to interruption of service caused by defective parts. Neither will we accept charges incurred by others

without our prior written approval. This warranty is void if our inspection reveals the product was used in a manner

inconsistent with normal industry practice and/or our specific recommendations. The purchaser is responsible for

communication of all necessary information regarding the application and use of the product. UNDER NO

CIRCUMSTANCES WILL WE BE RESPONSIBLE FOR ANY OTHER DIRECT OR CONSEQUENTIAL

DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST INCOME, LABOR

CHARGES, DELAYS IN PRODUCTION, IDLE PRODUCTION, WHICH DAMAGES ARE CAUSED BY

ANY DEFECTS IN MATERIAL, AND/OR WORKMANSHIP AND/OR DELAYS IN SHIPMENT. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTY,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

No rights extended under this warranty shall be assigned to any person, whether by operation or otherwise, without

our prior written approval.

Mody Pumps Inc.: 2166 Zeus Court, Bakersfield, CA 93308 Tel.: (661) 392-7600 Fax: (661) 392-7601

Loading...

Loading...