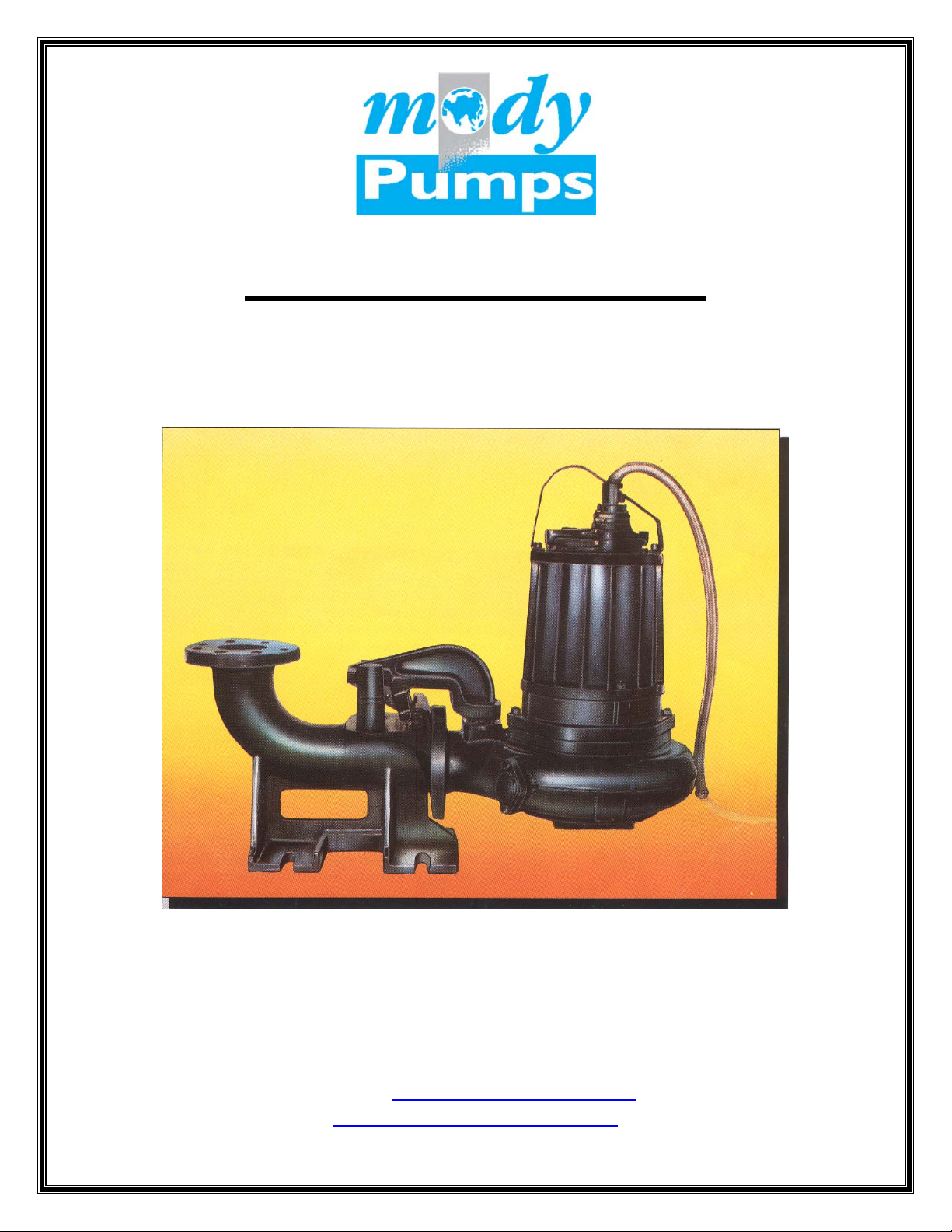

MODELS: MS 6152 & 6202

OPERATING INSTRUCTIONS, INSTALLATION & MAINTENANCE

MANUAL INCLUDING SPARE PARTS LIST

Mody Pumps Inc.

2166 Zeus Court

Bakersfield, CA 93308

Tel.: (661) 392-7600 FAX.: (661) 392-7601

E-Mail: sales@modypump.com

http://www.modypump.com

LLIIFFEE IISS PPRREECCIIOOUUSS -- TTHHIINNKK SSAAFFEETTYY

1. Most accidents can be avoided by using COMMON SENSE.

2. Please read the operation and maintenance instruction manual supplied with the

pump. If you did not receive one, please call your local distributor before pump

installation.

3. Do not wear loose apparel that may become entangled in the impeller or other

moving parts.

4. Always use appropriate safety equipment, such as safety glasses, when working

on the pump or piping.

5. Pumps build up heat and pressure during operation-allow time for pumps to cool

before handling or servicing.

6. Only qualified service personnel should install, operate and repair pump.

7. Keep clear of suction and discharge openings. DO NOT insert fingers in pump

with power connected.

8. Do not pump flammable or hazardous materials (gasoline, acids, alkalis, etc.)

9. Do not block or restrict discharge hose, as it may whip or burst catastrophically

under pressure.

10. Make sure lifting handles/hooks are securely fastened each time before lifting.

11. Do not lift pump by the power cord under any circumstances.

12. Do not exceed manufacturer's recommendation for optimum performance, as this

could cause the motor/pump to overheat and lead to premature wear or failure.

13. Secure the pump in its operating position so it does not tip over, fall or slide.

14. Keep away from impeller when power is connected.

15. Submersible Pumps are not approved for use in swimming pools, recreational

water installations, decorative fountains or any installation where human contact

with the pumped fluid is common.

16. Do not operate pump without adequate protection and safety devices in place.

17. Always replace safety devices that have been removed during service or repair.

18. To reduce risk of electrical shock, pump must be properly grounded in

accordance with the National Electric Code and all applicable state and local

codes and ordinances.

19. To reduce risk of electrical shock, always disconnect the pump from the power

source before handling or servicing.

20. Any wiring of pumps should be performed by a qualified electrician.

21. Never operate a pump with a power cord that has frayed or brittle insulation.

22. Cable should be protected at all times to avoid punctures, cuts, and

abrasions - inspect frequently.

23. Never handle connected - "hot" power cords with wet hands.

24. Never operate a pump with a plug-in type power cord without a ground fault

circuit interrupter, adequate overload and short circuit protection.

IMPORTANT !!! Mody Pumps Inc. is not responsible for losses, injury, or death resulting

from a failure to observe these safety precautions, misuse or abuse of pumps or

equipment.

Mody Pumps Inc.

:

2166 Zeus Court, Bakersfield, CA 93308 Tel.: (661) 392-7600 Fax: (661) 392-7601

GENERAL INFORMATION.

THE

“MS” SERIES OF MODY'S SUBMERSIBLE SEWAGE PUMPS ARE PRIMARILY DESIGNED FOR

HANDLING SEWAGE, SLUDGE, SLURRIES, WASTEWATER AND LIQUID MANURE. THEY CAN ALSO

BE USED FOR HANDLING STORMWATER DRAINAGE WITH HIGH SOLIDS CONTENT.

THE SERVICE LIFE OF A SUBMERSIBLE PUMP PRIMARILY HINGES ON TWO ASPECTS: THE

DEPENDABILITY OF THE SEALING SYSTEM AND THE WEAR RESISTANCE OF THE PUMP ITSELF.

THE “MS” SERIES OF PUMPS ARE AVAILABLE WITH A WIDE RANGE OF IMPELLERS TO SUIT

PRACTICALLY EVERY PUMPING DUTY WITH HIGH EFFICIENCES. THE MS 6100 & 6200

HAVE TWO MODELS AS UNDER :

1. MS 6152 15HP SINGLE CHANNEL IMPELLER WITH 100MM/4” SOLID HANDLING CAPACITY.

2. MS 6202 20HP SINGLE CHANNEL IMPELLER WITH 100MM/4” SOLID HANDLING CAPACITY.

THE SINGLE CHANNEL IMPELLERS ARE IN CAST IRON CONSTRUCTION. THE PUMP VOLUTES

ARE ALSO IN CAST IRON WITH SMOOTH PROFILED GEOMETRY FOR CLOG FREE OPERATION AND

HIGH EFFICIENCES. COMPLETE STAINLESS STEEL CONSTRUCTION AVAILABLE. ALL VOLUTES

ARE FITTED WITH REPLACEABLE WEAR RINGS.

IT IS IN THE INTEREST OF THE USER THAT HE/SHE GO THROUGH THIS MANUAL IN DETAIL

PRIOR TO USING THE PUMP.

TECHNICAL DESCRIPTION.

THE PUMPSET IS IN A MODULAR CONSTRUCTION ENSURING EASY AND SIMPLE

SERVICEABILITY. THE MAJOR DESIGN FEATURES ARE AS UNDER:

A] THERMAL PROTECTION : SEE UNDER "MOTOR PROTECTION" .

B] THE MOTOR: A RUGGED ALUMINUM DIE CAST ROTOR, DYNAMICALLY BALANCED TO GRADE

2.5 ACCURACY OF ISO 942. A STAINLESS STEEL SHAFT RUNNING IN TWO DEEP GROOVE

BALL BEARINGS. INSULATION CLASS "F" (155 DEGREES CELSIUS). END WINDINGS DULY

EPOXY COATED TO PREVENT DETERIORATION OF INSULATION EVEN IN EXTREMELY HUMID

CONDITIONS. WINDING WIRE IS DUAL COATED SUITABLE FOR "H" CLASS INSULATION.

C] THE SEAL CHAMBER: THE HEART OF THE "MODY" PUMP. DUAL MECHANICAL SEALS,

TUNGSTEN CARBIDE V/S TUNGSTEN CARBIDE SEAL FACES. SECONDARY SEALS OF NITRILE

RUBBER AND METAL PARTS IN STAINLESS STEEL, RUNNING IN AN OIL BATH. THE SEALS

HAVE BEEN SPECIFICALLY DESIGNED WITH EXTREMELY SHORT WORKING LENGTHS KEEPING

IMPELLER OVERHANG TO THE MINIMUM. THIS ENSURES EXTENDED SEAL AND BEARING LIFE.

D] BEARINGS: DOUBLE ROW ANGULAR CONTACT LOWER BEARING, WITH SINGLE ROW DEEP

GROOVE UPPER BALL BEARING GREASED FOR LIFE WITH A SPECIAL HIGH TEMPERATURE

BEARING GREASE REQUIRING NO PERIODIC MAINTENANCE WHATSOEVER.

E] THE HYDRAULIC ELEMENTS: SINGLE CHANNEL IMPELLERS WITH LARGE SOLID HANDLING

CAPACITY. SMOOTH PROFILED VOLUTES FOR HIGH EFFICIENCES.

F] CABLE GLAND ASSEMBLY: THE PUMP IS SUPPLIED WITH 50’ CABLE AS STANDARD. THE

CABLE IS AWG #8 SOOW 4 CORE WITH AN OPTION AVAILABLE FOR 6 CORE WHEN THERMAL

OVERLOADS ARE REQUIRED. THE CABLE IS TERMINATED IN THE PUMP AT THE CABLE GLAND.

THE GLAND ASSEMBLY SEALS THE CABLE ON THE OUTSIDE SHEATH. A WATER DAM

ARRANGEMENT IS ALSO PROVIDED WHICH SEALS THE INDIVIDUAL CORES OF THE CABLE.

THIS FEATURE IS UNIQUE AND IS ESSENTIAL TO PREVENT WATER SEEPING THROUGH THE

CORES OF THE CABLE INTO THE TERMINAL CHAMBER IN THE EVENT OF A CUT CABLE. THE

CABLE IS ALSO SHEATHED FOR THE 1ST ONE METRE LENGTH BY MEANS OF A CABLE GRIP

MADE OF STAINLESS STEEL. THIS IS ESSENTIAL TO ENSURE THAT THERE IS NO UNDUE

STRAIN ON THE CABLE IF THE PUMP IS PULLED OR LOWERED INADVERTENTLY BY MEANS OF

THE CABLE. COMPLETE DETAILS OF THE CABLE GLAND ASSEMBLY ARE SHOWN IN THE

DRAWING.

SERIES

G] ELECTRICAL INFORMATION : MOTORS ARE DESIGNED TO OPERATE ON SINGLE VOLTAGE

AND FREQUENCY. MAXIMUM DEVIATION IN VOLTAGE ALLOWED IS -/+ 6% AND FREQUENCY -/+

3%. CHECK NAME PLATE FOR OPERATING VOLTAGE AND FREQUENCY.

DESIGN PARAMETERS :

• LOWEST LIQUID LEVEL SHOULD BE 0.2 MTRS (8”) ABOVE PUMP CASING.

• THE MAXIMUM SUBMERGENCE RECCOMENDED IS 15 METRES.(50’)

• THE SPECIFIC GRAVITY OF THE PUMPED FLUID SHOULD NOT EXCEED 1.1.

• MAXIMUM FLUID TEMPERATURE IS 40 DEG. CELSUIS.

• pH OF THE PUMPED FLUID : 6 - 11

INSTALLATION

PUMPS ARE AVAIABLE FOR THREE TYPES OF INSTALLATION:

P TYPE INSTALLATION: SEMI PERMANENT/WET. PUMPS ARE LOWERED DOWN GUIDE BARS TO

AUTOMATICALLY CONNECT TO DISCHARGE PIPING. PLEASE SEE ILLUSTRATION AT END OF

MANUAL FOR DETAIL DIMENSIONS AND INSTALLATION.

S TYPE INSTALLATION: PORTABLE/WET. VERSATILE, MULTIPURPOSE, EASY TO INSTALL AND

MOVE FROM SUMP TO SUMP. PUMP IS AVAILABLE WITH HOSE/FLANGE TYPE OUTLET

CONNECTION AND INDEPENDENT BASE STAND. SEE ILLUSTRATION AT END OF MANUAL.

D TYPE INSTALLATION: THIS IS A DRY WELL INSTALLATION OR IN LINE PUMPING

SYSTEMS. FLANGED CONNECTION TO FIXED SUCTION AND DELIVERY PIPELINES. SUITABLE

FOR HORIZONTAL OR VERTICAL MOUNTING FOR DRY INSTALLATIONS. POWER LIMITATIONS

EXIST FOR CERTAIN MODELS AND EXTERNAL COOLING MAY BE NECESSARY. PLEASE CONTACT

FACTORY/SALES IF PUMP IS TO BE USED WITH THIS TYPE OF INSTALLATION.

• CHECK THAT THE SITE VOLTAGE CORRESPONDS WITH THAT OF THE PUMP.

• CHECK THAT FUSES ARE INTACT.

• USE SHORTEST POSSIBLE HOSE OF RECOMMENDED DIMENSION. AVOID SHARP BENDS,

CREASES AND CONTRACTIONS. FOR P TYPE AND D TYPE INSTALLATIONS ENSURE ALL

ACCESSORIES ARE AVAILABLE BEFORE STARTING INSTALLATION.

• NEVER LIFT OR PULL THE PUMP BY MEANS OF THE CABLE. SUSPEND THE PUMP BY A

ROPE/CHAIN OR PREFERABLY PLACE IT ON A SOLID BASE. FOR P TYPE INSTALLATIONS

THE REQUISITE CHAIN & TACKLE EQUIPMENT MUST BE AVAILABLE. PLEASE READ OUR

PUBLICATION REGARDING “P” TYPE INSTALLATION.

• WIRE THE PUMP TO THE MAINS CORRECTLY. ALWAYS USE A STARTER OR A PANEL BOARD.

SEE INSTRUCTIONS UNDER "MOTOR PROTECTION" BELOW.

• WHEN THE PUMP IS ENERGIZED IT WILL KICK, WHICH IS OPPOSITE TO THE DIRECTION

OF ROTATION OF THE IMPELLER. SHIFT TWO PHASES IN THE POWER CONNECTION IF THE

KICK IS IN THE WRONG DIRECTION. THE CORRECT DIRECTION IS INDICATED ON THE

PUMP COVER AT THE TOP OF THE PUMP.

• CHECK LEVEL AND CONDITION OF THE OIL AT SERVICE EVERY SIX MONTHS. IF THE OIL

IS EMULSIFIED BY WATER THE SEALS MUST BE REMOVED FROM THE ROTOR SHAFT FOR

FURTHER ACTION. THE SHAFT SEAL SHOULD BE CHECKED FOR WEAR EVERY 2500 HRS. OF

OPERATION. IF SEAL FACES SHOW ANY SIGNS OF WEAR, THEY SHOULD BE REPLACED.

.

HRC FUSE RECOMMENDED

MAINS VOLTAGE AT SITE MS 6152 MS 6202

220 VOLTS 3 PHASE 60 AMPS 70 AMPS

380 VOLTS 3 PHASE 40AMPS 50 AMPS

415 VOLTS 3 PHASE 30 AMPS 40 AMPS

460 VOLTS 3 PHASE 30 AMPS 40 AMPS

TROUBLE GUIDE CAUSE REMEDY

1.FUSES BLOWN. 1.REPLACE FUSES

2.CABLE DAMAGED 2.SHORTEN/REPLACE CABLE

PUMP DOES NOT START

4.BLOCKED IMPELLER. 4.CLEAN BOTTOM PARTS.

5.STATOR WINDING BURNT. 5.REPLACE STATOR.

1.BLOCKED IMPELLER. 1.CLEAN BOTTOM PARTS.

2.IMPELLER ROT.WRONG 2.SHIFT TWO PHASE CONN.

PUMP STARTS BUT STOPS

VOLTAGE.

4.VOLTAGE TOO LOW/HIGH. 4.APPROACH POWER CO.

5.LIQUID DENSITY HIGH 5.HIGHER HP REQUIRED.

6.BI-METAL TRIPS. 6.CHECK CURRENT.

1.IMPELLER ROT.BACKWARD. 1.SHIFT TWO PHASE CONN.

2.PUMP WORN DOWN. 2.REPLACE IMPELLER.

PUMP GIVES TOO LITTLE

WATER.

4.PRESSURE HEAD TOO HIGH 4.INSTALL BIGGER PUMP.

5.WEARING RING WORN OUT. 5.REPLACE WEAR RING.

TOO SMALL.

3.NO POWER. 3.CHECK POWER SUPPLY

. 3.CONNECTED FOR WRONG 3.CHECK & RECONNECT.

3.LONG HOSE AND DIAMETER 3.CHECK PRESSURE LOSSES

MOTOR PROTECTION

IT IS ESSENTIAL THAT THE PUMP BE USED WITH A STARTER AND PREFERABLY A PANEL

BOARD. PANEL BOARDS INCORPORATING ALL PROTECTIVE DEVICES ARE AVAILABLE WITH US.

THE FULL LOAD AMPERE RATINGS OF THE TWO MODELS ARE AS PER TABLE BELOW. THE

OVERLOAD RELAY IN THE STARTER SHOULD CHOSEN ACCORDINGLY AND AMPERES SET AT THE

FULL LOAD SETTING FOR THE PARTICULAR MODEL OF THE PUMP. (DETAILS BELOW ARE FOR

230/460 VOLT PUMPS. CHECK FULL LOAD AMPERES FOR DIFFERENT VOLTAGES ON PUMP NAME

PLATE)

MODEL FULL LOAD AMPERES

MS 6152 20 AMPS @ 460V

MS 6202 28 AMPS @ 460V

IMPORTANT.

THE PUMP IS SUPPLIED WITH A FOUR CORE CABLE AND THE FUNCTION OF THE SAME IS AS

UNDER:

• RED/YELLOW(WHITE)/BLUE(BLACK) ARE THE POWER CORES.

• GREEN CORE IS FOR EARTHING.

• IN THE EVENT THERMAL OVERLOAD PROTECTION IS REQUIRED A SIX CORE CABLE WILL

BE SUPPLIED OR A TRAILING CABLE WILL BE USED.

THREE THERMAL SWITCHES ARE EMBEDDED IN THE MOTOR WINDING OF WHICH TWO ARE

CONNECTED IN SERIES. THESE ARE CONNECTED TO THE WHITE CORES OF THE CABLE. THE

WHITE CORES OF THE CABLE ARE TO BE CONNECTED IN SERIES WITH THE CONTACTOR COIL

OF THE STARTER. THIS IS MOST IMPORTANT.

IN THE EVENT OF OVERHEATING OF THE STATOR WINDING FOR ANY REASON, THE EMBEDDED

THERMAL SWITCHES WILL OPEN, CAUSING THE STARTER COIL TO DROP OUT AND ISOLATE

THE PUMP UNIT FROM THE MAINS. THESE SWITCHES DO NOT PROVIDE ANY PROTECTION IN

THE CASE OF A SHORT CIRCUIT, AND ADEQUATE H.R.C. FUSES SHOULD BE USED FOR SHORT

CIRCUIT PROTECTION.

.

GENERAL OVERHAUL AND OIL CHECK. (THIS APPLIES TO BOTH

MODELS)

TO CARRY OUT A GENERAL OVERHAUL, IT IS ESSENTIAL THAT A COMPLETE

SET OF TOOLS BE AVAILABLE.

DIS-ASSEMBLY (REFER DRG.NO.MS/827 SHEET 1 & 2) AT END OF MANUAL

• IT IS MANDATORY THAT ALL "O" RINGS BE REPLACED WHENEVER A PUMP IS OVERHAULED

OR DISMANTLED. UNDER NO CIRCUMSTANCES SHOULD OLD "O" RINGS BE USED, EVEN IF

THEY SEEM O.K. BE CAREFUL NOT TO SCRATCH SEALING SURFACES. ALWAYS GREASE NEW

“O” RINGS BEFORE INSTALLATION.

• ALWAYS ISOLATE THE UNIT FROM ELECTRICAL POWER BEFORE ATTEMPTING ANY

OVERHAUL.

• THE TRANSPORTABLE VERSION IS SUPPLIED WITH A PUMP BASE. REMOVE BASE BEFORE

ANY FURTHER DISASSEMBLY. THE PERMANENT INSTALLATION VERSION IS SUPPLIED WITH

A SLIDING BRACKET FIXED ON THE VOLUTE OF THE PUMP.

• LAY THE PUMP ON ITS SIDE ON A BENCH OR OVER TWO SUPPORTS. TURN THE PUMP SO

THAT THE OIL ORIFICE FACES DOWNWARDS. USING AN ALLEN KEY UNSCREW OIL PLUG

(34) TO DRAIN OIL FROM THE SEAL CHAMBER. IT IS EASIER TO DRAIN THE OIL IF

THE OTHER OIL HOLE CAP SCREW IS ALSO REMOVED. BE CAREFUL. IF THE SEAL HAS

LEAKED, THE OIL CASING MAY BE UNDER PRESSURE. HOLD A RAG OVER THE OIL PLUG

TO PREVENT SPLATTER.

• UNSCREW NUTS (14) AND REMOVE PUMP VOLUTE (21) FROM SEAL HOUSING (19). REMOVE

CAP SCREW (27) AND SPRING WASHER (26). REMOVE LOCK WASHER (25) AND SLIDE

IMPELLER OF THE MOTOR SHAFT. IF THE IMPELLER IS SLIGHTLY TIGHT USE A WOODEN

MALLET TO TAP THE SAME OFF THE SHAFT. REMOVE KEY (30) AND KEEP ASIDE

CAREFULLY.

• THE LOWER MECHANICAL SEAL IS LOCKED ON THE SHAFT BY MEANS OF A CIRCLIP (32).

THE MECH. SEAL ASSEMBLY CAN NOW BE REMOVED FROM THE SHAFT BY HAND. BE VERY

CAREFUL WITH THE SEALING SURFACES SO THAT THEY DO NOT SUFFER DAMAGE OR GET

SCRATCHED IN ANY WAY. LEAVE THE SEAL SEAT IN THE SEAL HOUSING.

• UNSCREW NUTS (14) HOLDING THE SEAL HOUSING AGAINST THE STATOR CASING AND

REMOVE SEAL HOUSING. USE A WOODEN MALLET TO TAP OFF THE SAME. THE UPPER

MECH. SEAL IS NOW IN VIEW. REMOVE THE SEAL IN EXACTLY THE SAME MANNER AS THE

LOWER MECH. SEAL.

• UNSCREW HEX HD BOLTS (36) HOLDING THE LOWER BEARING BRACKET AGAINST THE

STATOR CASING. USE JACKOUT BOLTS IF NECESSARY. THE COMPLETE ROTOR ASSEMBLY

WITH LOWER BEARING BRACKET AND LOWER BEARINGS CAN BE PULLED OUT FROM THE

STATOR ASSEMBLY. THE LOWER BEARING BRACKET CAN BE REMOVED FROM THE ROTOR BY

REMOVING THE BEARING COVER. THE BEARING CAN NOW BE EXAMINED.

• UNSCREW NUTS (4) HOLDING THE PUMP COVER AND PRY OUT THE SAME. REMOVE THE

WIRE CONNECTORS (43) TO SEPARATE THE POWER CABLE FROM THE MOTOR LEADS. THE

WIRE CONNECTORS CAN BE UNSCREWED COUNTER CLOCKWISE TO RELEASE THE SAME.

UNSCREW NUT FOR GROMMET (45) AND REMOVE RUBBER GROMMET (44). REMOVE BOLT

(42) AND PRY OUT UPPER BEARING BRACKET (7).

• THE STATOR IS NOW AVAILABLE FOR ELECTRICAL CHECKS, IF ANY ARE REQUIRED. WE

RECOMMEND MEASURING LINE TO LINE RESISTANCE BETWEEN THE THREE POWER LEGS, A

MEGGING TEST AND IF AVAILABLE A HIGH POT.

)

Loading...

Loading...