M-800 SERIES

PORTABLE ELECTRIC

SUBMERSIBLE PUMP FOR

CORROSIVE & ABRASIVE

APPLICATIONS

…………………………………………………….

Model M-802T

6” NPT or Hose

25 HP (19kW)

(High Volume - Low Head)

………………………………………………………

Model M-806T

4” NPT or Hose

25 HP (19kW)

(Low Volume - High Head)

………………………………………………………

M-800 DESIGN ADVANTAGES

• Stainless Steel Strainer, Shaft, Impeller, Outlet and

Hardware for maximum corrosion resistance.

• Choice of impeller materials:

1) 316 Stainless Steel for sea water and corrosive

applications and;

2) Nitride Hardened 410 Stainless Steel for abrasive

applications. (Standard)

• Tandem Tungsten Carbide/Tungsten Carbide and

Tungsten Carbide/Tungsten Carbide mechanical seals.

• Mechanical Seals in wholly enclosed pressure

compensated oil chamber.

• Field adjustable Nitrile Rubber-lined Diffuser/Wear Plate

Optimizes efficiency throughout the life of the pump.

Polyurethane Diffusers and Wear Plates are available.

• Automatic ON/OFF/ON Thermal Overloads embedded in Stator

Winding - requires built-in contactor optional.

• Seal Probe Sensor Option available. Requires external controls.

• 1 meter long SS Sheath protects the power cable in demanding

mine applications.

• Equipped with Sacrificial Zinc Anodes for maximum life

in a saline fluid environment.

Mody Pumps® Inc.

2166 Zeus Court, Bakersfield, CA 93308. USA

Tel.: (661) 392-7600 • Fax: (661) 392-7601

http://www.modypump.com

E-mail: sales@modypump.com

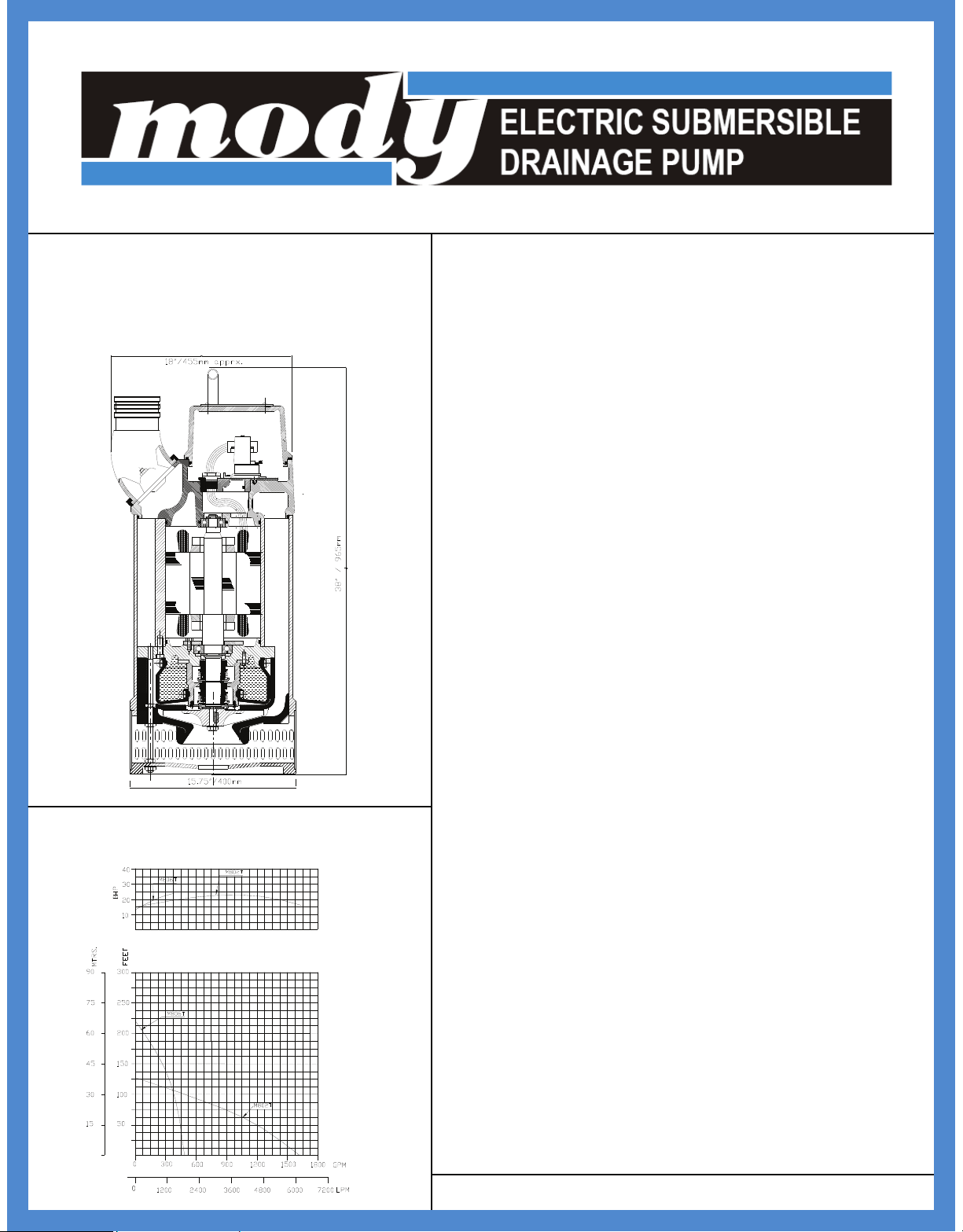

M-800 SERIES 25HP (19kW)

PERFORMANCE CURVES

MODEL: M802T/M806T (50/60 Hz)

M-800 SERIES

MATERIALS OF CONSTRUCTION

AND ENGINEERING DATA

MOTOR

2-pole induction continuous rated motor with squirrel cage rotor.

Stator insulation class 'H' (180ºC)

Speed : 3400 RPM @ 60 Hz, 2800 RPM @ 50 Hz

Power Rating : 25HP @ 60 Hz, 19kW @ 50Hz Full Load

Current FLA: 34 Amps @ 460v. 39 Amps @ 400v.

Max. temperature of the pump liquid : 104°F/40°C

Max. start/stop per hour : 15

Star - Delta Starting Optional

POWER SUPPLY

3 phase, 50/60 Hz, AC Supply. Available in any voltage frequency

combination.(208/220/230/380/415/460/575/1000V)

BALL BEARINGS

Single row deep groove upper bearing. Double angular contact lower bearings.

The bearings are enclosed with high temperature grease-containing special

Anti-corrosion additive.

POWER CABLE

Waterproof/oil proof, rubber-insulated, neoprene-sheathed copper conductor

flexible cable, 50ft. (15m) length standard. Type SOOW in North America,

EPR in the Middle East and HO7RN in the EU.

SHAFT SEAL

Tandem Tungsten Carbide/Tungsten Carbide and Tungsten Carbide/Tungsten

Carbide Mechanical seals wholly enclosed in a pressure compensated oil chamber.

CORROSION RESISTANT

Epoxy coated Steel Outer Casing

Epoxy coated Aluminum Stator Casing

Nitrile Rubber– Lined Diffuser/Wear plate.

Shaft: 431 Stainless Steel

Hardware: 304 Stainless Steel

Impeller: Nitride Hardened 410SS to 56HRC is Standard.

pH Range 5 - 8

STRAINER

304 Stainless Steel with 1-9/16” (25.5mm) X 3/8” (10mm) {M 802},

3/8” (10mm) Round Holes {M 806}

SUBMERGENCE

Submergence below liquid surface min 5” (127mm) max. 50’ (15m).

WEIGHTS

M 802: 410lbs. (186Kg)

M 806: 425lbs. (193Kg)

(Approx. without cable)

Due to continuous product development, specifications are subject to change without notice.

Vol. 11, Rev. 1, Jan. 2008

Loading...

Loading...