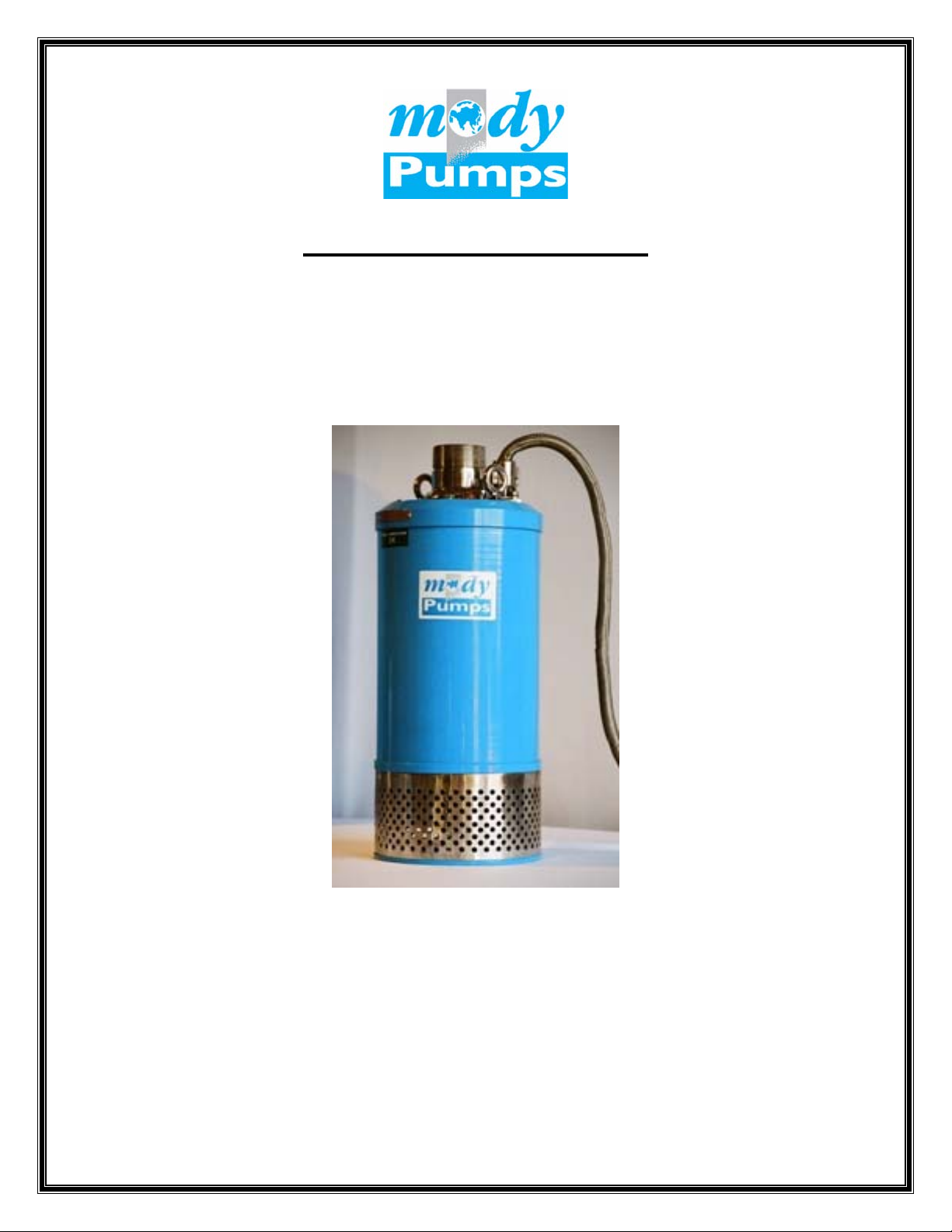

MODELS: G 506T, 536T, 556T

OPERATING INSTRUCTIONS, INSTALLATION & MAINTENANCE

MANUAL INCLUDING SPARE PARTS LIST

Mody Pumps Inc.

2166 Zeus Court

Bakersfield, CA 93308

Tel.: (661) 392-7600 FAX.: (661) 392-7601

EMAIL: sales@modypump.com

http://www.modypump.com

LLIIFFEE IISS PPRREECCIIOOUUSS -- TTHHIINNKK SSAAFFEETTYY

1. Most accidents can be avoided by using COMMON SENSE.

2. Please read the operation and maintenance instruction manual supplied with the

pump. If you did not receive one, please call your local distributor before pump

installation.

3. Do not wear loose apparel that may become entangled in the impeller or other

moving parts.

4. Always use appropriate safety equipment, such as safety glasses, when working on

the pump or piping.

5. Pumps build up heat and pressure during operation-allow time for pumps to cool

before handling or servicing.

6. Only qualified service personnel should install, operate and repair pump.

7. Keep clear of suction and discharge openings. DO NOT insert fingers in pump with

power connected.

8. Do not pump flammable or hazardous materials (gasoline, acids, alkalis, etc.)

9. Do not block or restrict discharge hose, as it may whip or burst catastrophically

under pressure.

10. Make sure lifting handles/hooks are securely fastened each time before lifting.

11. Do not lift pump by the power cord under any circumstances.

12. Do not exceed manufacturer's recommendation for optimum performance, as this

could cause the motor/pump to overheat and lead to premature wear or failure.

13. Secure the pump in its operating position so it does not tip over, fall or slide.

14. Keep away from impeller when power is connected.

15. Submersible Pumps are not approved for use in swimming pools, recreational water

installations, decorative fountains or any installation where human contact with the

pumped fluid is common.

16. Do not operate pump without adequate protection and safety devices in place.

17. Always replace safety devices that have been removed during service or repair.

18. To reduce risk of electrical shock, pump must be properly grounded in accordance

with the National Electric Code and all applicable state and local codes and

ordinances.

19. To reduce risk of electrical shock, always disconnect the pump from the power

source before handling or servicing.

20. Any wiring of pumps should be performed by a qualified electrician.

21. Never operate a pump with a power cord that has frayed or brittle insulation.

22. Cable should be protected at all times to avoid punctures, cuts, and

abrasions - inspect frequently.

23. Never handle connected - "hot" power cords with wet hands.

24. Never operate a pump with a plug-in type power cord without a ground fault circuit

interrupter, adequate overload and short circuit protection.

IMPORTANT !!! MODY Pumps Inc. is not responsible for losses, injury, or death resulting

from a failure to observe these safety precautions, misuse or abuse of pumps or

equipment.

Mody Pumps Inc.

:

2166 Zeus Court, Bakersfield, CA 93308 Tel.: (661) 392-7600 Fax: (661) 392-7601

INTRODUCTION

THE

“mody” MOTOR DRIVEN PORTABLE SUBMERSIBLE PUMPS HAVE BEEN DEVELOPED DUE TO

A LONG FELT NEED OF HAVING A TRULY MAINTENANCE FREE PUMPSET FOR VARIOUS

APPLICATIONS. THE PUMP IS A LIGHTWEIGHT, COMPACT UNIT ENABLING IT TO BE USED IN

MOST SEA-CRAFT AND DIFFICULT LAND INSTALLATIONS. THE UNIT CONSISTS OF A

VERTICAL CENTRIFUGAL PUMP WITH AN IN-BUILT SQUIRREL CAGE, INDUCTION ELECTRIC

MOTOR WHICH IS AVAILABLE FOR VARIOUS ELECTRIC SUPPLY CONFIGURATIONS. THE PUMPED

WATER IS USED AS A COOLING MEDIUM WHICH COOLS THE ELECTRIC MOTOR. THE PUMPSET

CAN ALSO BE USED IN ANY POSITION THUS MAKING IT IDEAL FOR DEWATERING IN

DIFFICULT LOCATIONS.

THE SERVICE LIFE OF A SUBMERSIBLE PUMP DEPENDS MAINLY ON TWO THINGS: THE

DEPENDABILITY OF THE SEALING SYSTEM AND THE WEAR RESISTANCE OF THE PUMP WEAR

PARTS.

“mody” SUBMERSIBLE SUMP PUMPS INCORPORATE A UNIQUE SEALING SYSTEM. THE

ALL

CONSTRUCTION CONSISTS OF TWO MECHANICAL SEALS, ARRANGED IN TANDEM, IMMERSED IN

AN OIL BATH. THE COMPLETE PACKAGE IS A PRESSURE COMPENSATED SEALING DEVICE

WHICH ENSURES A MINIMAL PRESSURE DIFFERENTIAL ACROSS THE SEAL FACES,

IRRESPECTIVE OF THE DEPTH SETTING OF THE PUMP OR THE HEAD AGAINST WHICH THE

PUMP IS OPERATING.

“mody” SUBMERSIBLE SUMP PUMPS, ALL WEAR PARTS ARE RUBBER LINED/COVERED AND

IN

ARE READILY REPLACEABLE AS NEEDED. BOTH WEAR AND ELECTRICITY CONSUMPTION ARE

STILL FURTHER REDUCED WHEN THE PUMPS ARE FITTED WITH BUILT-IN LEVEL CONTROLS

FOR AUTOMATIC STARTING AND STOPPING. IT IS HOWEVER RECOMMENDED THAT

IRRESPECTIVE OF TYPE OF PUMP, ADEQUATE MOTOR PROTECTION SWITCHGEAR SHOULD BE

USED AT THE INSTALLATION. WE STRONGLY RECOMMEND THE USE OF SUITABLE CONTROL

PANELS WHICH ARE AVAILABLE FROM US INCORPORATING ALL REQUIRED PROTECTION

DEVICES.

IT IS IN THE INTEREST OF THE USER THAT HE GO THROUGH THIS MANUAL IN DETAIL

PRIOR TO USING THE PUMP. THE MANUAL WILL HELP HIM UNDERSTAND THE CONSTRUCTIONAL

FEATURES AND TO OBTAIN TROUBLE FREE SERVICE FROM THE PUMP.

PLEASE NOTE THAT ALL PART NOS. REFERRED TO IN DISMANTLING AND RE-ASSEMBLY ARE

PERTAINING TO MODEL G 554T. NUMBERS FOR MODEL G 530T ARE INDICATED IN THE

DRAWINGS. THE CONSTRUCTION IS IDENTICAL.

PURPOSE:

THE PUMP HAS BASICALLY BEEN DESIGNED AS A DEWATERING UNIT TO PUMP OUT FLOODED

INSTALLATIONS OR ANY CONDITIONS THAT NEED DEWATERING OF UNWANTED FLUIDS. THE

PUMP HAS BEEN DESIGNED TO HANDLE WATER CONTAMINATED WITH OIL AS WELL AS

ABRASIVE PARTICLES NORMALLY ASSOCIATED WITH RAW WATER. THE MAXIMUM SIZE OF

PARTICLES THAT CAN BE HANDLED IS APPROX. 0.4”. THE MAXIMUM SPECIFIC GRAVITY OF

THE PUMPED FLUID SHOULD NOT EXCEED 1.1.

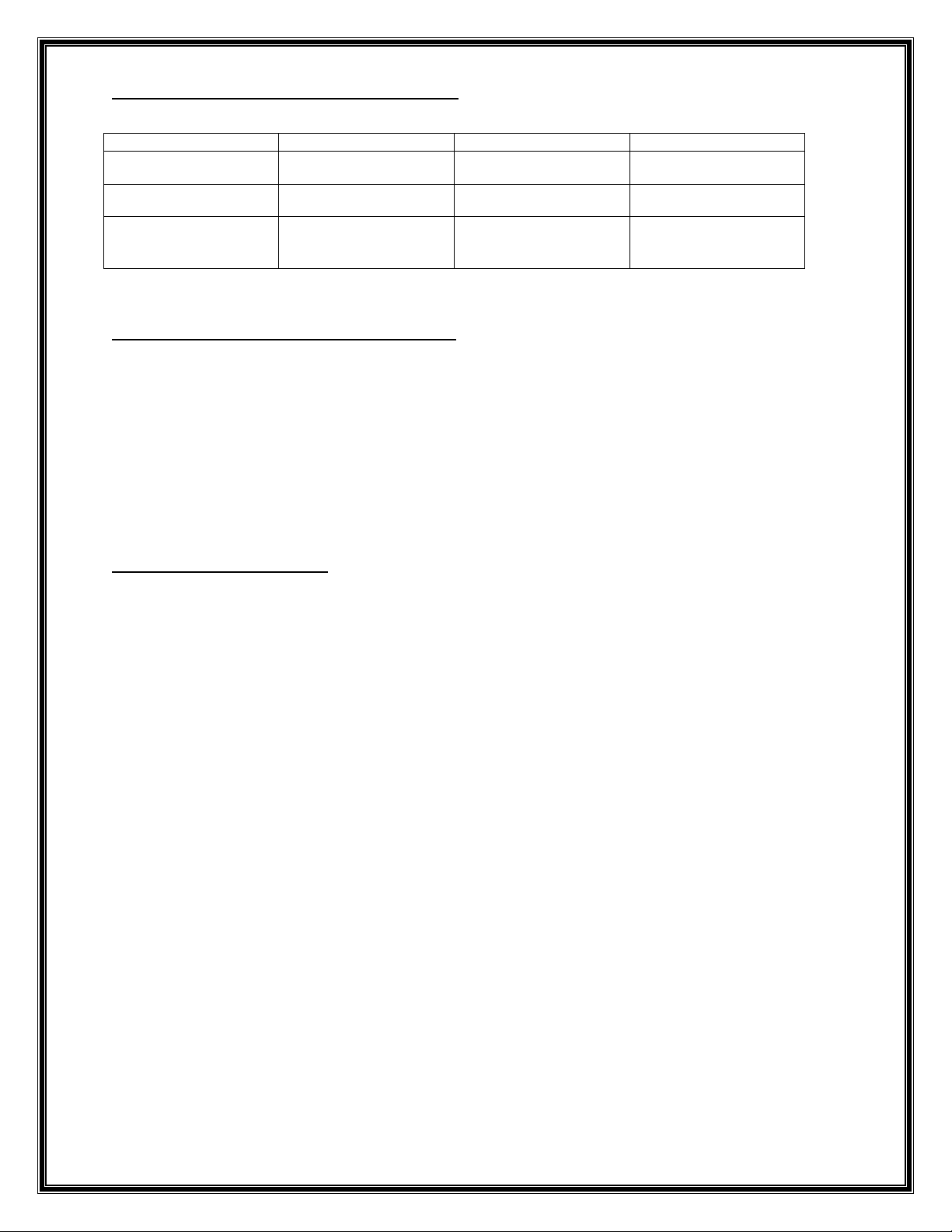

OVERALL DIMENSIONS AND WEIGHT:

G 506T G 536 T G 556 T

OVERALL HEIGHT

(APPROXIMATE)

MAX DIAMETER 10.75”/ 276MM 10.75”/ 276MM 10.75”/276MM

25”/640MM 28.5”/725MM 29.5”/750MM

MAX WEIGHT

(EXCLUDING CABLE)

115LBS/50KG 135LBS/61KG 147LBS/67KG

MAINTENANCE SERVICES REQUIRED.

THE FOLLOWING CHECKS TO BE DONE AT INTERVALS INDICATED BELOW:

1. CONDITION OF SEALS TO BE CHECKED AT EVERY 2500 HRS. OF OPERATION BY

ASCERTAINING THE CONDITION OF OIL IN THE SEAL CHAMBER.

2. MONTHLY RUNNING OF PUMP FOR AT LEAST 5/10 MINUTES AND CHECKING OF AMPERES

DRAWN AND INSULATION RESISTANCE. (MIN. INSULATION RESISTANCE 1 MEG OHM. AND

MAX. CURRENT DRAWN AS PER NAME PLATE)

SAFETY PRECAUTIONS:

1. ENSURE THAT THE INSULATION RESISTANCE OF THE MOTOR IS AT LEAST 1 MEG. OHM

BEFORE ENERGIZING THE UNIT.

2. CHECK THAT THE AVAILABLE POWER SUPPLY (VOLTAGE, PHASE, FREQUENCY) MATCHES

WITH THE DETAILS ON THE PUMP NAMEPLATE.

3. ENSURE THAT THE GROUND WIRE IN THE 4 CORE CABLE SUPPLIED WITH THE PUMP IS

SECURELY EARTHED.

4 ENSURE HOSE CONNECTION IS CORRECTLY AND SECURELY FITTED

5. ENSURE DELIVERY HOSE IS FREE FROM KINKS AND SHARP BENDS.

6. DO NOT LIFT OR PULL THE PUMP UNDER ANY CIRCUMSTANCES BY MEANS OF THE CABLE.

THE PUMP MUST BE LOWERED/LIFTED FROM THE SPACE TO BE PUMPED BY USING A LIFTING

ROPE ATTACHED TO THE HANDLE/EYEBOLT PROVIDED IN THE PUMP.

7. AT THE STARTING MOMENT THE PUMP SHALL MAKE A KICK WHICH IS OPPOSITE TO THE

DIRECTION OF ROTATION OF THE IMPELLER. ENSURE THE KICK IS IN THE CORRECT

DIRECTION (SEE THE ARROW CAST ON THE CONTACTOR COVER OF THE PUMP). SHIFT ANY

TWO PHASES IN THE MALE PLUG IF THE KICK IS WRONG.

8. DRY RUNNING OF THE PUMP IS NOT DESIRABLE. HOWEVER THE PUMP WILL NOT BE

DAMAGED OR SUFFER ANY ILL EFFECTS IF IT IS RUN DRY FOR SHORT PERIODS (UPTO

APPROX. 30 MINUTES).

9. THE MAXIMUM PUMP SUBMERGENCE RECOMMENDED IS 100 FEET.

10. THE MAXIMUM SPECIFIC GRAVITY OF PUMPED FLUID SHOULD NOT EXCEED 1.1.

PUMP IS DESIGNED TO OPERATE IN FLUIDS WITH pH from 5 – 8.

11. IF PUMP IS NOT USED AND LYING IN STORAGE FOR MORE THAN 30 DAYS PLEASE

ENSURE THAT THE SEAL FACES ARE NOT GAUGE LOCKED – ROTATE THE IMPELLER/KICK

START THE UNIT ONCE A MONTH. REFER TO INSTRUCTIONS ON DISASSEMBLY/REASSEMBLY OF

MECH. SEALS IN THE EVENT THE FACES HAVE LOCKED.

12. ENSURE CORRECT OVERLOAD BREAKERS ARE INSTALLED IN POWER CIRCUIT BEFORE

STARTING THE PUMP. (REFER TO AMP RATING ON NAMEPLATE).

FAULT FINDING IN THE UNIT.

TROUBLE GUIDE CAUSE REMEDY

1.FUSES BLOWN. 1.REPLACE FUSES

2.CABLE DAMAGED 2.SHORTEN/REPLACE CABLE

PUMP DOES NOT START.

4.BLOCKED IMPELLER. 4.CLEAN BOTTOM PARTS.

6.STATOR WINDING BURNT. 6.REPLACE STATOR/REWIND

1.BLOCKED IMPELLER. 1.CLEAN BOTTOM PARTS.

2.IMPELLER ROT.WRONG 2.SHIFT TWO PHASE CONN.

PUMP STARTS BUT STOPS

VOLTAGE.

4.VOLTAGE LOW/HIGH 4.CONTACT POWER CO.

5.CLOGGED STRAINER 5.CLEAN STRAINER

6.PUMP RUNNING DRY 6.SWITCH OFF POWER

7.WATER TOO WARM 7.SWITCH OFF POWER

(ABOVE 60 DEGREES C)

1.IMPELLER ROT.BACKWARD. 1.SHIFT TWO PHASE CONN.

2.PUMP WORN DOWN. 2.REPLACE WEAR PARTS

PUMP GIVES TOO LITTLE

OUTPUT

4.PRESSURE HEAD TOO HIGH 4.USE PUMPS IN TANDEM.

5.DISCHARGE HOSE TORN 5.USE NEW HOSE

6.LEAKING/CRACKED OUTLET 6.REPL.OUTLET/GASKET.

TOO SMALL.

3.NO POWER. 3.CHECK POWER SUPPLY.

. 3.CONNECTED FOR WRONG 3.CHECK & RECONNECT.

3.LONG HOSE AND DIAMETER 3.CHECK PRESSURE LOSSES

TECHNICAL DESCRIPTION:

THE MODY SUBMERSIBLE PUMP IS IN ITSELF A COMPLETE PUMPING STATION. BESIDES A

POWER SUPPLY AND A DISCHARGE HOSE NO EXTRA EQUIPMENT IS REQUIRED. THE COMPLETE

PUMPSET IS IN A MODULAR CONSTRUCTION ENSURING GOOD AND SIMPLE SERVICEABILITY.

THE MAJOR DESIGN FEATURES ARE AS UNDER:

THE MOTOR

A RUGGED ALUMINUM DIE CAST/COPPER ROTOR DYNAMICALLY BALANCED TO GRADE 2.5

ACCURACY OF ISO 942.A STAINLESS STEEL SHAFT RUNNING IN TWO BALL BEARINGS.

INSULATION CLASS "H" (180 DEGREES CELSIUS). END WINDINGS DULY EPOXY COATED TO

PREVENT DETERIORATION OF INSULATION EVEN IN EXTREMELY HUMID CONDITIONS. WINDING

WIRE IS DUAL COATED SUITABLE FOR "H" CLASS INSULATION.

THE SEAL CHAMBER

THE HEART OF THE MODY PUMP. DUAL MECHANICAL, TUNGSTEN CARBIDE V/S TUNGSTEN

CARBIDE SEAL FACES (LOWER SEAL) AND TUNGSTEN CARBIDE V/S TUNGSTEN CARBIDE

(UPPER SEAL), SECONDARY SEALS OF HNBR RUBBER AND METAL PARTS IN STAINLESS

STEEL, RUNNING IN AN OIL BATH, ENCLOSED IN A PRESSURE COMPENSATING RUBBER OIL

BAG - CREATES THE ULTIMATE SEAL SOLUTION. THE DESIGN OPTIMIZES SEAL LIFE AND

ALLOWS FOR SIX MONTHLY (2500 HOURS) SERVICE INTERVALS.

BEARINGS:

SINGLE ROW DEEP GROOVE BALL BEARINGS SEALED FOR LIFE WITH SPECIAL HIGH

TEMPERATURE BEARING GREASE REQUIRING NO PERIODIC MAINTENANCE WHATSOEVER.

THE HYDRAULIC ELEMENTS:

TWO STAINLESS STEEL IMPELLERS IN TANDEM RUNNING AGAINST A RUBBER LINED

DIFFUSERS AND A GUIDE PLATE, CONSTITUTE THE HYDRAULIC ELEMENTS OF THE PUMP. THE

IMPELLERS/DIFFUSERS CAN BE ADJUSTED TO MAINTAIN MAXIMUM OUTPUT AFTER USAGE

WITHOUT PARTS REPLACEMENT. IT IS IMPORTANT, HOWEVER, TO MAINTAIN CLEARANCES

BETWEEN THE WEAR PARTS.

CABLE GLAND ASSEMBLY. (REFER DRG.)

THE PUMP IS SUPPLIED WITH 50 FEET CABLE AS STANDARD. THE CABLE IS A 4 CORE EPR

SHEATHED AND INSULATED CABLE CONFORMING TO INTERNATIONAL STANDARDS. THE CABLE

IS WATERPROOF AND CAN BE COMPLETELY SUBMERGED IN WATER. THE CABLE IS TERMINATED

IN THE PUMP AT THE CABLE GLAND. THE GLAND ASSEMBLY SEALS THE CABLE ON THE

OUTSIDE SHEATH AS WELL AS A WATER DAM ARRANGEMENT IS PROVIDED WHICH SEALS THE

INDIVIDUAL CORES OF THE CABLE. THIS FEATURE IS UNIQUE AND IS ESSENTIAL TO

PREVENT WATER SEEPING THROUGH THE CORES OF THE CABLE INTO THE CONTACTOR CHAMBER

IN THE EVENT OF A CUT CABLE. THE CABLE IS ALSO SHEATHED FOR THE FIRST ONE METER

BY MEANS OF A CABLE GRIP MADE OF STAINLESS STEEL. THIS IS ESSENTIAL TO ENSURE

THAT THERE IS NO UNDUE STRAIN ON THE CABLE IF THE PUMP IS PULLED OR LOWERED

INADVERTENTLY BY MEANS OF THE CABLE. COMPLETE DETAILS OF THE CABLE GLAND

ASSEMBLY ARE SHOWN IN THE DRAWING.

GALVANIC CORROSION PROTECTION (FOR SEA-WATER DUTY PUMPS ONLY)

THE PARTS OF THE "MODY" SUBMERSIBLE PUMP THAT ARE IN CONTACT WITH SEA- WATER

ARE PRIMARILY OF STAINLESS STEEL AND ALUMINUM. AS SEAWATER IS AN ELECTROLYTE

THE PROBLEM OF GALVANIC CORROSION EXISTS DUE TO THE DIFFERENT ELECTRIC

POTENTIALS OF THE MATERIALS IN FLOWING SEAWATER. TO PREVENT THIS, THE PUMPS ARE

EQUIPPED WITH ZINC ANODES FIXED ON THE OUTER CASING AND DIFFUSER. ZINC, BEING

THIS LESS "NOBLE" METAL (MORE NEGATIVE POTENTIAL) GETS CORRODED THUS PREVENTING

CORROSION OF ALUMINUM AND STEEL. IT IS HOWEVER NECESSARY TO INSPECT THE

CONDITION OF THE REPLACEABLE ANODES PERIODICALLY AND REPLACE WHENEVER

NECESSARY. (INSPECTION ONCE IN A YEAR IS ENOUGH.)

NON REPAIRABLE ITEMS

1. ALL "O" RINGS TO BE REPLACED WHENEVER PARTS ARE DISMANTLED.

2. SEAL ELASTOMER PARTS SHOULD NEVER BE RE-USED AFTER DIS-ASSEMBLY.

3. DO NOT REFILL BEARING GREASE. ALWAYS REPLACE COMPLETE NEW BEARING WITH

SPECIAL HIGH TEMPERATURE GREASE.

ELECTRICAL INFORMATION:

MOTORS ARE DESIGNED TO OPERATE ON SINGLE VOLTAGE AND FREQUENCY. MAX. DEVIATION

IN VOLTAGE ALLOWED IS + - 6 % AND FREQUENCY +- 3%. CHECK NAMEPLATE FOR

OPERATING VOLTAGE AND FREQUENCY.

LINE TO LINE RESISTANCE VALUES FOR NINE LEAD STATORS

230V 460

G 506 T 0.63 Ω 2.5 Ω

G 536 T 0.45 Ω 1.80 Ω

G 556 T 0.31 Ω 1.23 Ω

DISMANTLING AND OVERHAULING.

GENERAL OVERHAUL AND OIL CHECK. (REF.DRGS.NO.DW/131//00 SHEET 1&2)

1. ALWAYS REPLACE O-RINGS WITH NEW ONES WHENEVER DISMANTLING AND RE-ASSEMBLING

A PUMP. NEVER RE-USE OLD O-RINGS.

2. REMOVE BASE PLATE (76), STRAINER (75), NUT (18) AND DIFFUSER (74). THE

DRAWING SHOWS THESE DETAILS. CHECK BY HAND THAT THE ROTOR SHAFT IS NOT BLOCKED.

3. UNSCREW IMPELLER NUT (73), REMOVE LOCK WASHER (72), AND REMOVE 1ST IMPELLER

(65). SLIDE OFF IMPELLER FROM SHAFT. REMOVE KEY (71) AND KEEP ASIDE. UNSCREW

NUT HOLDING GUIDE PLATE (70) AND PRY OFF GUIDE PLATE. SLIDE OFF SHAFT SLEEVE

(66) FROM ROTOR SHAFT. UNSCREW NUTS HOLDING DIFFUSER 2(18) AND PRY OFF

DIFFUSER. REMOVE SECOND IMPELLER FROM SHAFT AND REMOVE KEY UPPER (64).

4. PLACE THE PUMP ON THE BOTTOM STUDS (62). TAP THE OUTER CASING (68) WITH

NYLON TIPPED HAMMERS TILL IT LOOSENS FROM THE TOP BRACKET (22). SEPARATE THE

OUTER CASING FROM THE TOP BRACKET BY EMPLOYING TWO SCREWDRIVERS AS LEVERS AND

PUSH THE OUTER CASING DOWNWARDS TILL IT STANDS ON THE FLOOR. LIFT THE UNIT BY

THE TIE BOLTS (3) CLEAR OFF THE OUTER CASING.

4. THE SEAL CHAMBER CONTAINS APPROX. 1.5 LITRES OF OIL. THE LEVEL AND CONDITION

OF THE OIL SHOULD BE CHECKED EVERY SIX MONTHS. UNSCREW THE OIL PLUGS (66) AND

POUR OUT SOME OIL. NOTE THAT THE OIL GETS A SLIGHTLY DARKER SHADE, BUT THIS IS

NORMAL AND IS NO CAUSE FOR WORRY. IF THE OIL IS EMULSIFIED BY WATER, THE SEALS

HAVE WORN OUT AND MUST BE REMOVED FROM THE ROTOR FOR FURTHER ACTION.

6. UNSCREW NUTS (18) AND FOUR STUDS (17) AND REMOVE WEAR PLATE (31). THIS CAN

BE EASILY DONE BY INSERTING TWO SCREWDRIVERS BETWEEN WEAR PLATE AND LOWER

BRACKET (15) AND PRYING THE WEAR PLATE LOOSE. ALL THE PUMP PARTS HAVE BEEN

DISMANTLED. REPLACE WORN PARTS. REMOVE SAND GUARD (59) BY UNSCREWING FOUR

CHEESE HEAD SCREWS (74) FROM THE SEAL HOUSING (28).

7. THE OIL DIAPHRAGM (56) IS NOW IN VIEW. UNSCREW BOTH THE OIL PLUGS (66) AND

DRAIN OUT THE OIL FROM THE OIL CHAMBER. LOOSEN SCREWS AND NUTS (35/54) FROM THE

BIG OIL CLAMP (55) AND REMOVE CLAMP. TURN OIL DIAPHRAGM INSIDE OUT AND REMOVE

SMALL OIL CLAMP IN THE SAME FASHION. REMOVE OIL DIAPHRAGM. SLIDE OFF OUTER

RETAINING SPRING (61) FROM ROTOR SHAFT AND REMOVE LOWER MECHANICAL SEAL FROM

ROTOR SHAFT. BE VERY CAREFUL IN HANDLING THE TUNGSTEN CARBIDE SEAL FACE. LEAVE

TUNGSTEN CARBIDE SEAT IN THE SEAL HOUSING (38). UNSCREW FOUR NUTS (65) AND PULL

OUT SEAL HOUSING (38). THE TUNGSTEN CARBIDE SEAL FACE WILL COME OUT WITH THE

SEAL HOUSING. HANDLE THE FACE CAREFULLY. THE UPPER MECHANICAL SEAL IS NOW IN

VIEW. REMOVE THE UPPER SEAL IN THE SAME WAY AS THE LOWER SEAL.

8. REMOVE THE FOUR NOS DEEP SEATED CAP SCREWS (16) THAT HOLD THE LOWER BEARING

BRACKET AGAINST THE INNER CASING. BY MEANS OF TWO NOS SCREWDRIVERS REMOVE THE

LOWER BEARING BRACKET FROM THE INNER CASING (12). THE COMPLETE ROTOR (11) WITH

BEARING (68), BEARING COVER AND TUNGSTEN CARBIDE SEAT WILL COME OUT WITH THE

LOWER BEARING BRACKET. REMOVE BOLTS (70) AND REMOVE BEARING COVER. PULL OUT

ROTOR WITH BEARING FROM LOWER BEARING BRACKET. (IF THIS IS DIFFICULT USE A HAND

PRESS TO REMOVE ROTOR FROM BEARING BRACKET. ENSURE NO DAMAGE TO THE TUNGSTEN

CARBIDE SEAT IN BEARING BRACKET). THE TC SEAT WITH CUP SEAL HOLDER CAN NOW BE

PUSHED OUT FROM THE BEARING SIDE BY GENTLY TAPPING THE SAME. (USE FINGERS OR A

NYLON TIPPED LIGHT HAMMER ONLY).

9. CHECK BOTH UPPER AND LOWER BEARINGS (9 & 68) FOR ANY RADIAL OR AXIAL PLAY OR

ANY ABNORMAL NOISE WHILE SPINNING THE SAME. CHECK FOR ANY LEAKAGE OF GREASE

THROUGH THE SHIELD OF THE BEARING. IF BEARING SEEMS WORN OUT OR ANY GREASE

LEAKAGE IS OBSERVED, REPLACE BEARING. (DO NOT USE ANY STANDARD BEARING PROCURED

FROM THE MARKET. THE PUMPS USE A SPECIAL BEARING WHICH IS PRE-FILLED WITH

SPECIAL HIGH TEMPERATURE GREASE WHICH ARE AVAILABLE FROM US READILY).

10. THE TOP BRACKET (6) IS HELD IN POSITION BY FOUR BOLTS (4) ON THE INNER

CASING. UNSCREW THE BOLTS AND REMOVE THE INNER CASING WITH THE HELP OF PULLER

FOR STATOR (T8003). ALTERNATIVELY TWO SCREWDRIVERS MAY BE USED TO PRY THE TOP

BRACKET FROM THE STATOR.

11. THE STATOR IS SHRINK-FITTED IN THE INNER CASING AND IS SUPPLIED WITH THE

O-RINGS (14) AS ONE UNIT. THE STATOR CAN NOW BE CHECKED FOR ANY ELECTRICAL

FAULTS.

RE-ASSEMBLY OF THE PUMPSET:

THE PUMP CAN BE RE-ASSEMBLED AS PER PROCEDURE GIVEN BELOW. PLEASE HOWEVER NOTE

THE FOLLOWING:

A) ALWAYS REPLACE NEW O-RINGS AND DISCARD OLD ONES.

B) REPLACE LOCK WASHER WHEN RE-ASSEMBLING.

1. THE CHECKED/REPAIRED STATOR IS KEPT UPRIGHT AND THE TOP BRACKET IS GUIDED

THROUGH THE FOUR BOLTS (4).

2. SLIDE BEARING COVER (13) ON ROTOR SHAFT.

3. FIT BEARINGS (IF REMOVED OR REPLACED) ON ROTOR SHAFT (USE EITHER A HAND

PRESS OR SHRINK THE SAME -- DO NOT HAMMER THE BEARINGS ON THE SHAFT-- YOU MAY

BEND THE SHAFT AND ALSO DAMAGE THE BEARINGS) AND FIT CIRCLIPS ON TOP AND BOTTOM

GROOVES ON SHAFT. (IF THE BEARINGS ARE SHRINK FITTED ON THE SHAFT, HEAT THE

BEARINGS IN OIL TO A MAXIMUM TEMPERATURE OF 120 DEGREES CELSIUS AS A HIGHER

TEMPERATURE WILL LIQUEFY THE GREASE IN THE BEARING AND RENDER THE SAME

UNUSABLE).

4. SLIDE LOWER BEARING BRACKET (15) ON TO LOWER BEARING AND ALIGN FOUR NOS

HOLES ON BEARING COVER WITH THE TAPPED HOLES ON LOWER BEARING BRACKET. FIT THE

BOLTS (70) AND TIGHTEN BEARING COVER.

5. FIT COMPLETE ROTOR ASSEMBLY IN STATOR HOUSING GUIDING UPPER BEARING IN TOP

BRACKET BEARING SEAT. TIGHTEN FOUR CAP SCREWS (16). FIT UPPER TC SEAT IN LOWER

BEARING BRACKET (LIGHTLY OIL THE RUBBER SEAT CUP --ENSURE THE SEAT SITS SQUARE

IN THE BRACKET) AND SLIDE ON UPPER SEAL ASSEMBLY ON ROTOR SHAFT. (USE SEAL

ASSEMBLY MANDREL (T9006) TO ASSIST IN SLIDING BELLOWS ON TO THE SHAFT). LIGHTLY

OIL THE ROTOR SHAFT BEFORE PUSHING BELLOWS ON SHAFT. USE EXTREME CARE SO THAT

THE SEAL FACES ARE NOT DAMAGED. SLIDE ON RETAINER SPRING (61) AND FIT IN GROOVE

ON SHAFT.

6. PRESS HOME BY HAND LOWER SEAL TUNGSTEN CARBIDE SEAT INTO SEAL HOUSING (28).

LIGHTLY OIL RUBBER SEAT CUP BEFORE PRESSING IN CAVITY. THE SEAT MUST SIT SQUARE

IN THE HOUSING.

7. FIT SEAL HOUSING (38) INTO LOWER BRACKET AND TIGHTEN NUTS (65).

8. SLIDE ON LOWER SEAL ASSEMBLY ON SHAFT. APPLY LIGHT COAT OF OIL ON SHAFT

BEFORE SLIDING BELLOWS ON THE SAME. (USE SAME SEAL MANDREL AS USED FOR THE

UPPER SEAL TO SLIDE BELLOWS ON SHAFT). FIT RETAINER SPRING AS FOR THE UPPER

SEAL ASSEMBLY

9. INSTALL SAND GUARD (59) INTO SEAL HOUSING USING THE 4 CHEESE HEAD SCREWS.

10. TURN OIL BAG INSIDE OUT AND FIT OIL BAG "VEE" SECTION INTO GROOVE IN SEAL

HOUSING (28). USING SMALL OIL BAG CLAMPS AND SCREWS & NUTS CLAMP THE OIL BAG TO

THE SEAL HOLDER. TURN OIL BAG TO CLAMP THE LARGER SIDE "VEE" SECTION TO THE

GROOVE IN THE LOWER BEARING BRACKET IN THE SAME WAY.

11. FIT ONE DRAIN PLUG WITH "O" RING IN LOWER BEARING BRACKET AND FILL OIL IN

THE OIL BAG. PERIODICALLY PRESS THE OIL BAG TO LET AIR ESCAPE SO THAT FILLING

IS PROPER AND NO AIR IS ENTRAPPED IN THE OIL BAG. (A SMALL AMOUNT OF AIR IN THE

OIL BAG WILL NOT BE DETRIMENTAL IN ANY WAY). REPLACE PLUG WITH "O" RING.

12. SLIDE ON WEAR PLATE AGAINST LOWER BEARING BRACKET AND TIGHTEN THE SAME. FIT

OUTER CASING ON TOP BRACKET WITH "O" RING (14). FIT UPPER KEY (28) ON THE SHAFT

AND SLIDE ON IMPELLER. CLEARANCES BETWEEN IMPELLER AND WEAR PLATE CAN BE

ADJUSTED BY MEANS OF THE TRIMMING SPACERS (29). SLIDE SHAFT SLEEVE (27) ONTO

SHAFT AND WITH THE HELP OF TOOL (MANDREL SPACER) AND NUT (24), LOCK IMPELLER.

FIT DIFFUSER 2 (19) AND ADJUST CLEARANCES BETWEEN IMPELLER AND DIFFUSER TO A

MINIMUM. LOCK DIFFUSER BY MEANS OF NUTS (18). SLIDE ON GUIDE PLATE (73) AND

TIGHTEN AGAINST DIFFUSER 2. CHECK THAT THE IMPELLER IS FREE. REMOVE MANDREL

SPACER AND FIT IMPELLER AND KEY (72) ON SHAFT. MAINTAIN CLEARANCE BETWEEN

IMPELLER AND GUIDE PLATE TO THE MINIMUM. LOCK IMPELLER BY MEANS OF LOCK WASHER

(25) AND NUT (24). FIT DIFFUSER (20) AND ADJUST CLEARANCE TO THE MINIMUM. LOCK

DIFFUSER (20) BY MEANS OF NUTS (18).

13. FIX STRAINER (21), BASE PLATE (22) AND TIGHTEN NUTS (18)

OIL SPECIFICATIONS

USE NON-CONDUCTING, NON-FOAMING OIL ONLY

A) EXXON UNIVOLT 61

B) SHELL TELLUS 29.

C) CHEVRON SUPERLA WHITE # 9

USE NON-CONDUCTING, NON-FOAMING, NON-DETERGENT OIL ONLY

PARTS CATALOG:

1. COMPONENTS LIST: AS PER DRAWING NO. DW/171/172/173/00(SHEET 1 & 2).

DRAWINGS:

1. SECTIONAL ASSEMBLY (DW/171/172/173/00) (SHEET 1)

2. SECTIONAL ASSEMBLY (DW/171/172/173/00) (SHEET 2)

R: RECOMMENDED SPARES FOR TWO YEARS OPERATION

SR.NO DESCRIPTION PART NO. RECOMMENDED QTY.

1. MECHANICAL SEAL 535-022-00 1 NO.

2. MECHANICAL SEAL 535-022-00 1 NO.

3. "O" RING SET 375-0

4. CABLE GROMMET

5. CABLE LEAD GROMMET 260-016-66 2 NOS (506)

6. UPPER BEARING 020-005-07 1 NO.

7. LOWER BEARING 020-011-07 1 NO.

8. STRAINER 640-012-21 1 NO.

9. IMPELLER 300-XXX-22 2 NOS*

1O. DIFFUSER 1 175-011-80 1 NO.

11. DIFFUSER 2 175-012-80 1 NO.

12. GUIDE PLATE 265-002-80 1 NO.

13. WEAR PLATE 715-004-80 1 NO.

14. LOCK WASHER 695-004-21 2 NOS

260-013-66 2 NOS (506)

11-66 2 SETS.

* CHOOSE IMPELLER FROM DATA SHEETS AT THE END OF THE MANUAL

PUMP MODEL G506T VER 1.0

Y

D.NO. PART NO. DESCRIPTION QT

1 065-014-79 CABLE (4CORE, 2.5 SQ.MM.) 15m

2 230-004-21 CABLE GLAND 1

3 085-022-21 CABLE CLAMP 1

4 525-021-21 PH.PAN HD.SCREW 2

5 662-002-66 CABLE SUPPORT 1

6 370-006-21 HEX NUT 2

7 700-004-21 WASHER 2

8 380-010-66 "O" RING 1

9 260-036-66 CABLE GROMMET 1

10 600-018-40 CABLE GLAND SPACER 1

11 260-016-66 CABLE LEAD GROMMET 1

12 235-004-21 CABLE GLAND BASE 1

13 380-007-66 "O" RING 1

14 380-005-66 "O" RING 1

15 365-026-00 WIRE NUT CONNECTOR 3

16 365-027-00 WIRE NUT CONNECTOR 3

17 525-007-40 EARTHING SCREW 1

18 370-008-21 HEX NUT 38

19 650-020-21 STUD 2

20a 405-021-21 OUTLET (3" HOSE) 1

20b 405-103-21 OUTLET (3" BSPT) 1

20c 405-059-21 OUTLET (3" NPT) 1

21 220-005-66 GASKET (OUTLET) 1

22 035-012-30 TOP BRACKET 1

23 380-013-66 "O" RING 1

24 380-028-66 "O" RING 2

25 625-006-33 STATOR CASING 1

26 010-006-26 ZINC ANODE 2

27 520-008-21 CAP SCREW 8

28 619-018-00 BARE STATOR 1

29 350-022-21 NAME PLATE 1

30 465-006-21 RIVET 6

31 270-005-21 LIFTING HOOK 2

32 650-013-21 STUD 2

33 045-018-21 HEX HD.BOLT 4

34 700-006-21 WASHER 12

35 635-009-21 ROTATION ARROW 1

36 080-004-08 CIRCLIP 1

37 020-005-07 UPPER BEARING 1

38 480-034-00 ROTOR COMPLETE 1

39 045-004-21 HEX HD.BOLT 4

40 037-003-30 BEARING COVER 1

41 020-011-07 LOWER BEARING 1

42 080-006-08 CIRCLIP 1

43 035-013-30 LOWER BEARING BRACKET 1

44 520-003-21 SOCKET HEAD SCREW 4

45 520-002-21 OIL PLUG 2

46 380-001-66 "O" RING 2

47 535-022-00 MECHANICAL SEAL 2

48 080-005-21 CIRCLIP 2

49 545-008-21 SEAL HOUSING 1

50 650-003-21 STUD 4

PUMP MODEL G506T VER 1.0

D.NO. PART NO. DESCRIPTION QTY

51 700-002-21 WASHER 4

52

53 600-034-21 CAP FOR CIRCLIP 1

54 150-004-66 OIL DIAPHRAGM 1

55 525-022-21 PH.PAN HD.SCREW 4

56 370-002-21 HEX NUT 8

57 085-007-21 OIL BAG CLAMP SMALL 1

58 085-008-21 OIL BAG CLAMP BIG 1

59 515-008-21 SAND GUARD 1

60 525-025-21 PH.PAN HD.SCREW 4

61 715-004-80 WEAR PLATE 1

62 650-052-21 STUD ASSEMBLY 4

63 600-0

64

65a 300-035-22 IMPELLER 50Hz 2

65b 300-036-22 IMPELLER 60Hz 2

66 585-023-21 SHAFT SLEEVE 1

67 380-036-66 "O" RING 1

68 400-016-31 OUTER CASING 1

69 175-012-80 DIFFUSOR(UPPER) 1

70 265-002-80 GUIDE PLATE 1

71 320-016-21 KEY (LOWER ) 1

72 695-004-21 LOCK WASHER 1

73 370-014-21 LOCK NUT 1

74 175-011-80 DIFFUSOR(LOWER) 1

75 640-026-21 STRAINER 1

76 030-006-30 BASE PLATE 1

77 705-001-21 SPRING WASHER 4

78 375-011-66 "O" RING SET 1

370-005-21 HEX NUT 4

20-21 TRIMMING SPACER AS REQD.

320-017-21 KEY ( UPPER ) 1

PUMP MODEL G536T/E VER 1.0

D.NO. PART NO. DESCRIPTION QTY

1 065-016-79 CABLE AWG 10/4 SOOW 50'

2 230-004-21 CABLE GLAND 1

3 085-022-21 CABLE CLAMP 1

4 525-021-21 PH.PAN HD.SCREW 2

5 662-002-66 CABLE SUPPORT 1

6 370-006-21 HEX NUT 2

7 700-004-21 WASHER 2

8 380-010-66 "O" RING 1

9 260-029-66 CABLE GROMMET 1

10 600-057-40 CABLE GLAND SPACER 1

11 260-031-66 CABLE LEAD GROMMET 1

12 235-004-21 CABLE GLAND BASE 1

13 380-007-66 "O" RING 1

14 380-005-66 "O" RING 1

15 365-026-00 WIRE NUT CONNECTOR 3

16 365-027-00 WIRE NUT CONNECTOR 3

17 525-007-40 EARTHING SCREW 1

18 370-008-21 HEX NUT 38

19 650-020-21 STUD 2

20a 405-021-21 OUTLET (3" HOSE) 1

20b 405-103-21 OUTLET (3" BSPT) 1

20c 405-059-21 OUTLET (3" NPT) 1

21 220-005-66 GASKET (OUTLET) 1

22 035-012-30 TOP BRACKET 1

23 380-013-66 "O" RING 1

24 380-028-66 "O" RING 2

25 625-007-33 STATOR CASING 1

26 010-006-26 ZINC ANODE 2

27 520-008-21 CAP SCREW 4

28 619-021-00 BARE STATOR 1

29 350-022-21 NAME PLATE 1

30 465-006-21 RIVET 6

31 270-005-21 LIFTING HOOK 2

32 650-013-21 STUD 2

33 045-018-21 HEX HD.BOLT 4

34 700-006-21 WASHER 12

35 635-009-21 ROTATION ARROW 1

36 080-004-08 CIRCLIP 1

37 020-005-07 UPPER BEARING 1

38 480-057-00 ROTOR COMPLETE 1

39 045-004-21 HEX HD.BOLT 4

40 037-003-30 BEARING COVER 1

41 020-011-07 LOWER BEARING 1

42 080-006-08 CIRCLIP 1

43 035-013-30 LOWER BEARING BRACKET 1

44 520-003-21 SOCKET HEAD SCREW 4

45 520-002-21 OIL PLUG 2

46 380-001-66 "O" RING 2

PUMP MODEL G536T/E VER 1.0

D.NO. PART NO. DESCRIPTION QTY

47 535-022-00 MECHANICAL SEAL 2

48 080-005-21 CIRCLIP 2

49 545-008-21 SEAL HOUSING 1

50 650-003-21 STUD 4

51 700-002-21 WASHER 4

52 370-005-21 HEX NUT 4

53 600-034-21 CAP FOR CIRCLIP 1

54 150-004-66 OIL DIAPHRAGM 1

55 525-022-21 PH.PAN HD.SCREW 4

56 370-002-21 HEX NUT 8

57 085-007-21 OIL BAG CLAMP SMALL 1

58 085-008-21 OIL BAG CLAMP BIG 1

59 515-008-21 SAND GUARD 1

60 525-025-21 PH.PAN HD.SCREW 4

61 715-004-80 WEAR PLATE 1

62 650-052-21 STUD 4

63

64

65a 300-097-22 IMPELLER 50Hz 2

65b 300-119-22 IMPELLER 60Hz 2

66 585-023-21 SHAFT SLEEVE 1

67 380-036-66 "O" RING 1

68 400-018-31 OUTER CASING 1

69 175-012-80 DIFFUSOR(UPPER) 1

70 265-002-80 GUIDE PLATE 1

71 320-016-21 KEY (LOWER ) 1

72 695-004-21 LOCK WASHER 1

73 370-014-21 LOCK NUT 1

74 175-011-80 DIFFUSOR(LOWER) 1

75 640-026-21 STRAINER 1

76 030-006-30 BASE PLATE 1

77 705-001-21 SPRING WASHER 4

78 380-011-66 "O" RING SET 1

600-020-21 TRIMMING SPACER AS REQD.

320-017-21 KEY ( UPPER ) 1

PUMP MODEL G556T/E VER 1.0

D.NO. PART NO. DESCRIPTION QTY

1 065-016-79 CABLE AWG 10/4 SOOW 50'

2 660-093-00 CABLE GLAND & GRIP 1

3 085-022-21 CABLE CLAMP 1

4 525-021-21 PH.PAN HD.SCREW 2

5 662-002-66 CABLE SUPPORT 1

6 370-006-21 HEX NUT 2

7 700-004-21 WASHER 2

8 380-010-66 "O" RING 1

9 260-029-66 CABLE GROMMET 1

10 600-057-40 CABLE GLAND SPACER 1

11 260-031-66 CABLE LEAD GROMMET 1

12 235-004-21 CABLE GLAND BASE 1

13 380-007-66 "O" RING 1

14 380-005-66 "O" RING 1

15 365-027-00 WIRE NUT CONNECTOR 3

16 365-025-00 WIRE NUT CONNECTOR 3

17 525-007-40 EARTHING SCREW 1

18 370-008-21 HEX NUT 38

19 650-020-21 STUD 2

20a 405-021-21 OUTLET (3" HOSE) 1

20b 405-103-21 OUTLET (3" BSPT) 1

20c 405-059-21 OUTLET (3" NPT) 1

21 220-005-66 GASKET (OUTLET) 1

22 035-012-30 TOP BRACKET 1

23 380-013-66 "O" RING 1

24 380-028-66 "O" RING 2

25 625-006-33 STATOR CASING 1

26 010-006-26 ZINC ANODE 2

27 520-008-21 CAP SCREW 4

28 619-023-00 BARE STATOR 1

29 350-022-21 NAME PLATE 1

30 465-006-21 RIVET 6

31 270-005-21 LIFTING HOOK 2

32 650-013-21 STUD 2

33 045-018-21 HEX HD.BOLT 4

34 700-006-21 WASHER 12

35 635-009-21 ROTATION ARROW 1

36 080-004-08 CIRCLIP 1

37 020-005-07 UPPER BEARING 1

38 480-066-00 ROTOR COMPLETE 1

39 045-004-21 HEX HD.BOLT 4

40 037-003-30 BEARING COVER 1

41 020-011-07 LOWER BEARING 1

42 080-006-08 CIRCLIP 1

43 035-013-30 LOWER BEARING BRACKET 1

44 520-003-21 SOCKET HEAD SCREW 4

45 520-002-21 OIL PLUG 2

46 380-001-66 "O" RING 2

PUMP MODEL G556T/E VER 1.0

D.NO. PART NO. DESCRIPTION QTY

47 535-022-00 MECHANICAL SEAL 2

48 080-005-21 CIRCLIP 2

49 545-008-21 SEAL HOUSING 1

50 650-003-21 STUD 4

51 700-002-21 WASHER 4

52 370-005-21 HEX NUT 4

53 600-034-21 CAP FOR CIRCLIP 1

54 150-004-66 OIL DIAPHRAGM 1

55 525-022-21 PH.PAN HD.SCREW 4

56 370-002-21 HEX NUT 8

57 085-007-21 OIL BAG CLAMP SMALL 1

58 085-008-21 OIL BAG CLAMP BIG 1

59 515-008-21 SAND GUARD 1

60 525-025-21 PH.PAN HD.SCREW 4

61 715-004-80 WEAR PLATE 1

62 650-052-21 STUD ASSEMBLY 4

63

64 320-017-21 KEY ( UPPER ) 1

65a 300-111-22 IMPELLER 50Hz 2

65b 300-117-22 IMPELLER 60Hz 2

66 585-023-21 SHAFT SLEEVE 1

67 380-036-66 "O" RING 1

68 400-037-31 OUTER CASING 1

69 175-012-80 DIFFUSOR(UPPER) 1

70 265-002-80 GUIDE PLATE 1

71 320-016-21 KEY (LOWER ) 1

72 695-004-21 LOCK WASHER 1

73 370-014-21 LOCK NUT 1

74 175-011-80 DIFFUSOR(LOWER) 1

75 640-025-21 STRAINER 1

76 030-006-30 BASE PLATE 1

77 705-001-21 SPRING WASHER 4

78 380-011-66 "O" RING SET 1

600-020-21 TRIMMING SPACER AS REQD.

LIMITED WARRANTY

We warrant to our immediate customer and to the ultimate consumer that products of our manufacture will be free of

defects in material and workmanship under normal use and service for the following time periods, when installed and

maintained in accordance with our instructions.

PUMPS: One (1) year from date of installation or (18) months from date of shipment, whichever occurs first. As used

herein, “the ultimate consumer” is defined as the purchaser who first uses the product after it’s initial installation or, in

the case for product designed for non-permanent installation, the first owner who uses the product. It is the purchaser’s

or any sub-vendor’s obligation to make known to the ultimate consumer the terms and conditions of this warranty. This

warranty gives you specific legal rights, and there may also be other rights which vary from state to state. In the event

the product is covered by the Federal Consumer Product Warranties Law (1) the duration of any implied warranties

associated with the product by virtue of said law is limited to the same duration as stated herein, (2) this warranty is a

LIMITED WARRANTY, and (3) no claims of any nature whatsoever shall be made against us, until the ultimate

consumer, his successor, or assigns, notifies us in writing of the defect, and delivers the product and/or defective part(s)

freight prepaid to our facility or nearest authorized service station. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply. THE SOLE AND EXCLUSIVE REMEDY FOR

BREACH OF ANY AND ALL WARRANTIES WITH RESPECT TO ANY PRODUCT SHALL BE TO

REPLACE OR REPAIR AT OUR ELECTION, FOB POINT OF MANUFACTURE OR AUTHORIZED

REPAIR STATION, SUCH PRODUCTS AND/OR PARTS AS PROVEN DEFECTIVE. THERE SHALL BE

NO FURTHER LIABILITY, WHETHER BASED ON WARRANTY, NEGLIGENCE OR OTHERWISE.

Unless expressly stated otherwise, guarantees in the nature of performance specifications furnished in addition to the

foregoing material and workmanship warranties on a product manufactured by Mody, if any, are subject to laboratory

tests corrected for field performance. Any additional guarantees, in the nature of performance specifications must be in

writing and such writing must be signed by our authorized representative. Due to inaccuracies in field testing if a

conflict arises between the results of field testing conducted by or for user, and laboratory tests corrected for field

performance, the latter shall control. Components or accessories supplied by us but manufactured by others are

warranted only to the extent of and by the terms and conditions of the original manufacturer’s warranty.

RECOMMENDATIONS FOR SPECIAL APPLICATIONS OR THOSE RESULTING FROM SYSTEMS

ANALYSES AND EVALUATIONS WE CONDUCT, WILL BE BASED ON OUR BEST AVAILABLE

EXPERIENCE AND PUBLISHED INDUSTRY INFORMATION. SUCH RECOMMENDATIONS DO NOT

CONSTITUTE A WARRANTY OF SATISFACTORY PERFORMANCE AND NO SUCH WARRANTY IS

GIVEN.

This warranty shall not apply when damage is caused by (a) improper installation, (b) improper voltage, (c) lightning,

(d) sand or other abrasive materials, (e) scale or corrosion build-up due to excessive chemical content. Any modification

of the equipment will also void the warranty. We will not be responsible for loss, damage or labor cost due to

interruption of service caused by defective parts. Neither will we accept charges incurred by others without our prior

written approval. This warranty is void if our inspection reveals the product was used in a manner inconsistent with

normal industry practice and/or our specific recommendations. The purchaser is responsible for communication of all

necessary information regarding the application and use of the product. UNDER NO CIRCUMSTANCES WILL WE

BE RESPONSIBLE FOR ANY OTHER DIRECT OR CONSEQUENTIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LOST PROFITS, LOST INCOME, LABOR CHARGES, DELAYS IN PRODUCTION,

IDLE PRODUCTION, WHICH DAMAGES ARE CAUSED BY ANY DEFECTS IN MATERIAL, AND/OR

WORKMANSHIP AND/OR DELAYS IN SHIPMENT. THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY

OTHER EXPRESS OR IMPLIED WARRANTY, INCLUDING ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

No rights extended under this warranty shall be assigned to any person, whether by operation or otherwise, without our

prior written approval.

Mody Pumps Inc.: 2166 Zeus Court, Bakersfield, CA 93308 Tel.: (661) 392-7600 Fax: (661) 392-7601

Loading...

Loading...