Mod-U-Serve MCT-CF2 Service Manual

Service and Installation

Manual

Introduction …………………………………………. 2

Installation/Cleaning ……………………………... 3

Milk Coolers …………………………………………. 4

Cold Food Counters-NR …………………………. 9

Cold Food Counters ………………………………. 12

Frost Top Counters ……………………………….. 15

Hot Food Counters ………………………………… 18

Ice/Milk Counters ………………………………….. 22

Flat Top/Cashier Counters ……………………… 27

MUS Utility ………………………………………….... 30

MOD-U-SERVE Warranty …………………………. 36

For Service Information, call 1-888-955-5463

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Introduction

Price and Specifications

• MOD-U-SERVE reserves the right to change the price and specifications of the

equipment and/or materials without notice.

• Prices are F.O.B Factory.

• Prices include one year limited service warranty.

• Prices include five-year compressor body warranty.

Order Cancellation

Buyer may cancel its order, reduce quantities, revise specifications, or extend schedules

only by mutual agreement as to reasonable and proper cancellation charges. Any

expenses already incurred and commitments made by the seller shall be taken into

account, and buyer shall indemnify seller against any loss.

Customer’s Freight Damage Procedure

Before signing the carrier’s bill, the customer should do the following:

VISIBLE DAMAGE:

1. Inspect shipment for any damage. If you see damage or feel there may be

concealed damage, mark the carrier’s copy of the freight bill “DAMAGED.”

2. If there is damage to your shipment, action must be taken by you to notify within

48 hours of receipt. It is the duty of the carrier to give you a written report upon

notification.

CONCEALED DAMAGE:

1. If the damage is concealed, notify the carrier within 48 hours by telephone and in

writing. Ask them to send their agent to complete an inspection report. Retain all

cartons and merchandise for inspection. It is critical that the customer takes the

actions stated above.

Return of Product

Prior authorization must be granted by MOD-U-SERVE before equipment can be

returned for credit. Equipment approved for return is subject to a 25% restocking charge

on equipment and a 10% charge on parts. Returned equipment and parts must be shipped

prepaid, packed in the original carton, and be received in good condition.

2

Installation

• Receiving:

Inspect for damage upon arrival. If there is any visible damage upon arrival note such on bill of lading

before signing as received. If there is any concealed damage call the transporting agent at once and advise

them of the damage. Request an immediate inspection. This is for your protection in settling damage

claims.

• Location:

Be sure that the location has a floor strong enough to support total weight of the cabinet and contents.

Reinforce the floor as necessary to provide for maximum loading.

For the most efficient operation, be sure to provide good air circulation, inside and out.

IT IS RECOMMENDED THAT THE UNIT BE INSTALLED WITHIN TWENTY FOUR INCHES

(24”) MINIMUM CLEARANCE AT FRONT AND REAR. DO NOT INSTALL THE UNIT NEAR

ANY COMBUSTIBLE MATERIAL OR OBJECT AFFECTED BY HEAT OR MOISTURE.

• Leveling:

A level cabinet will look better and perform better.

Care and Cleaning

• Cleaning the Stainless:

The interior and exterior can be cleaned using soap and warm water. Always rub with the “grain” of the

stainless steel to avoid marring the finish. Do not use an abrasive cleaner because it will scratch the

stainless steel.

• Cleaning the Cold Well:

Any water or lime deposits left on the well can be removed with a vinegar/water mix or a lime removal

cleanser. Be sure to rinse off all the cleaning agents before using well again. Never use bleach to clean

wells.

• Cleaning the Condenser:

In order to maintain proper refrigeration performance, the condenser fins must be cleaned of dust, dirt,

and grease regularly. It is recommended that this be done at least every three months. If conditions are

such that the condenser is totally blocked in three months, the frequency of cleaning should be increased.

Clean the condenser with a vacuum cleaner or stiff brush. If extremely dirty, a commercially available

condense cleaner may be required.

Cleaning the DUPOINT CORIAN®:

•

Most dirt and stains can be removed using soapy water and ammonia based cleaners. Watermarks can be

removed using a damp cloth, towel dry.

Matte/Satin Finish:

pad.

Semi-Gloss Finish:

difficult stains. Cuts and scratches can be removed. For the proper procedure please contact factory.

Difficult stains can be removed with an abrasive cleaner and a green Scotch Brite®™

Use Soft Scrub®™ or diluted bleach and a white Scotch Brite®™ pad to remove

3

Milk Coolers

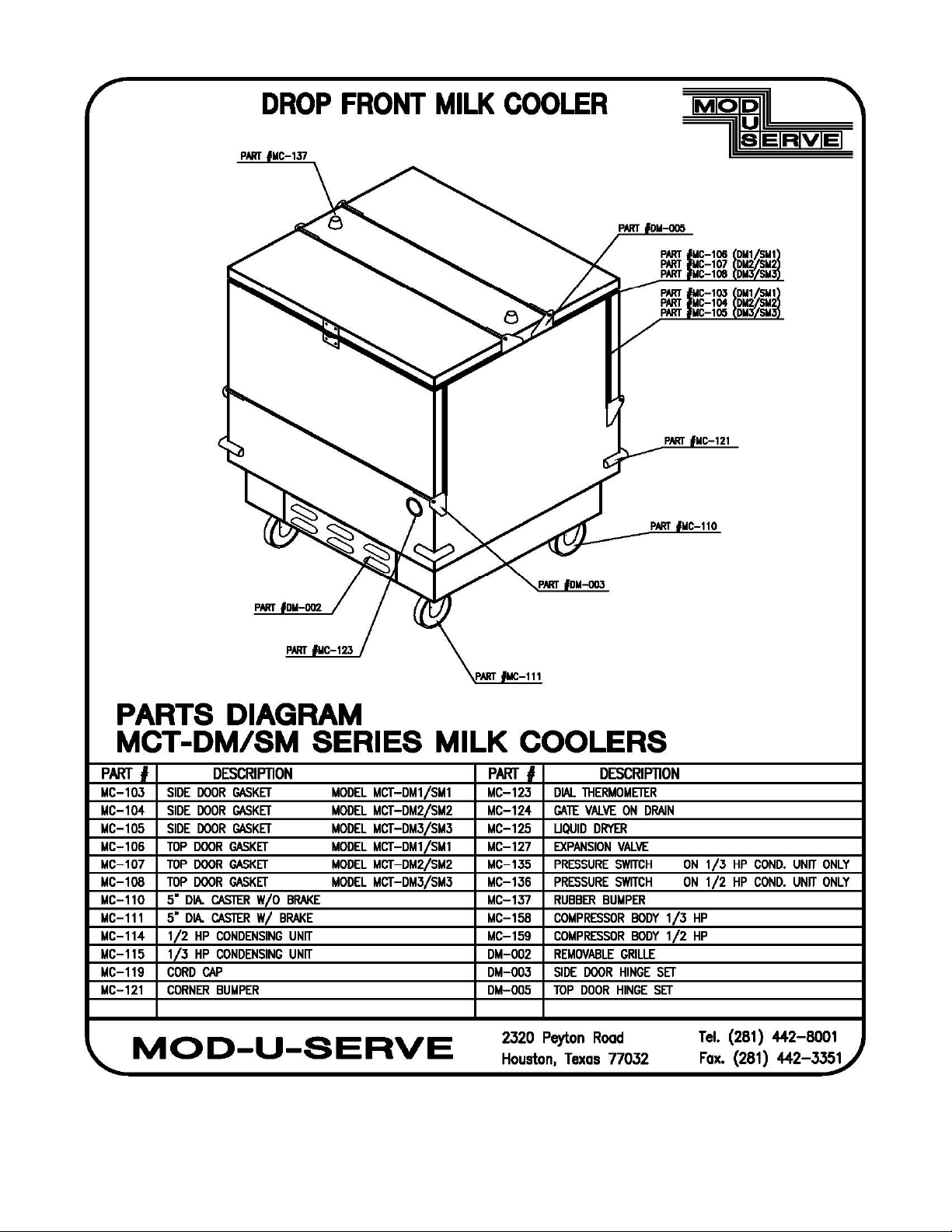

Model Numbers

Single Drop Door

MCT-SM1 34” Length 8 Case

MCT-SM2 49” Length 12 Case

MCT-SM3 64” Length 16 Case

Double Drop Door

MCT-DM1 34” Length 8 Case

MCT-DM2 49” Length 12 Case

MCT-DM3 64” Length 16 Case

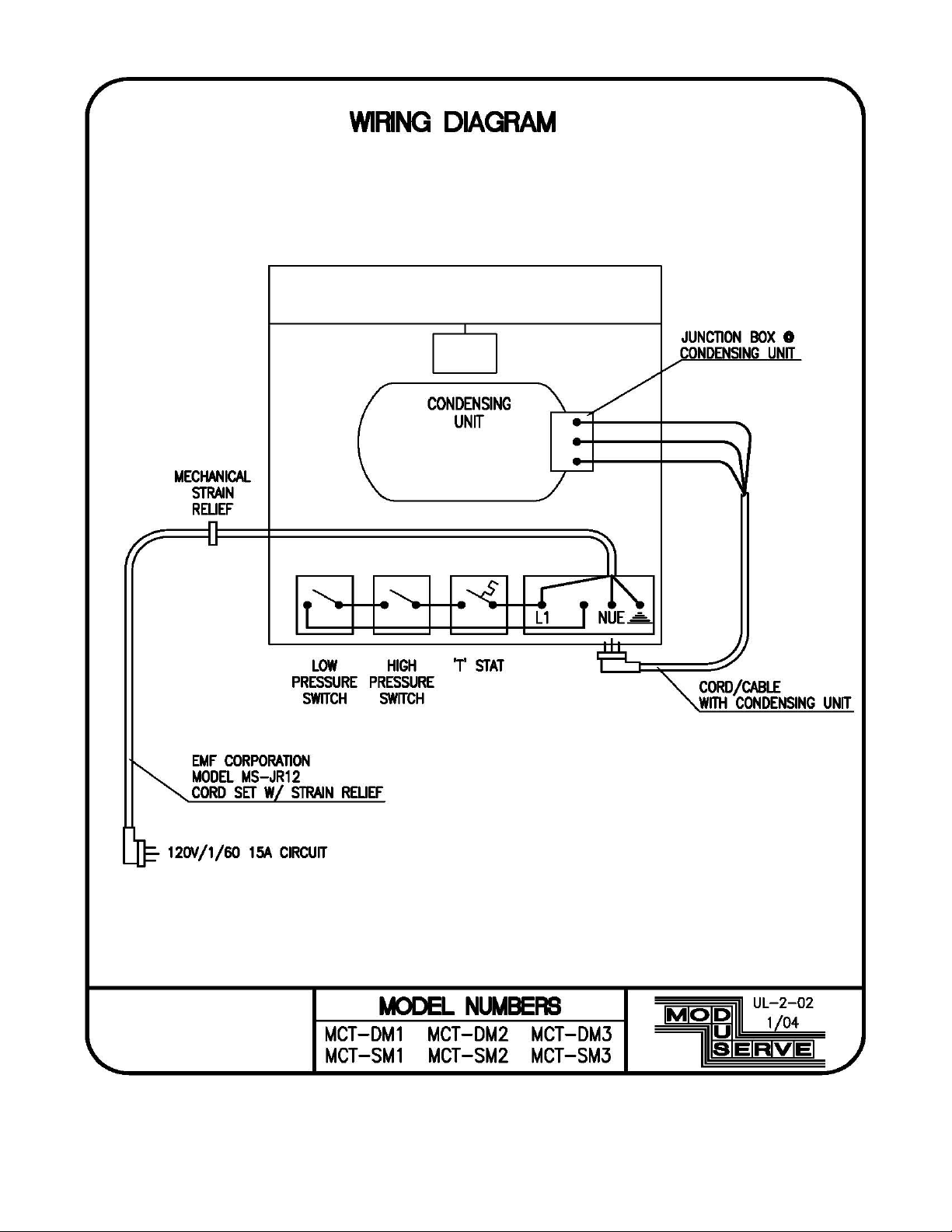

Electrical

120 Volts, AC. 15 Amp Circuit (NEMA 5-15P). Plugs into a 5-15 R receptacle. The amp

draw is 9.9 amps.

1/3 HP Compressor. Refrigeration is R-404-A.

4

5

5

6

7

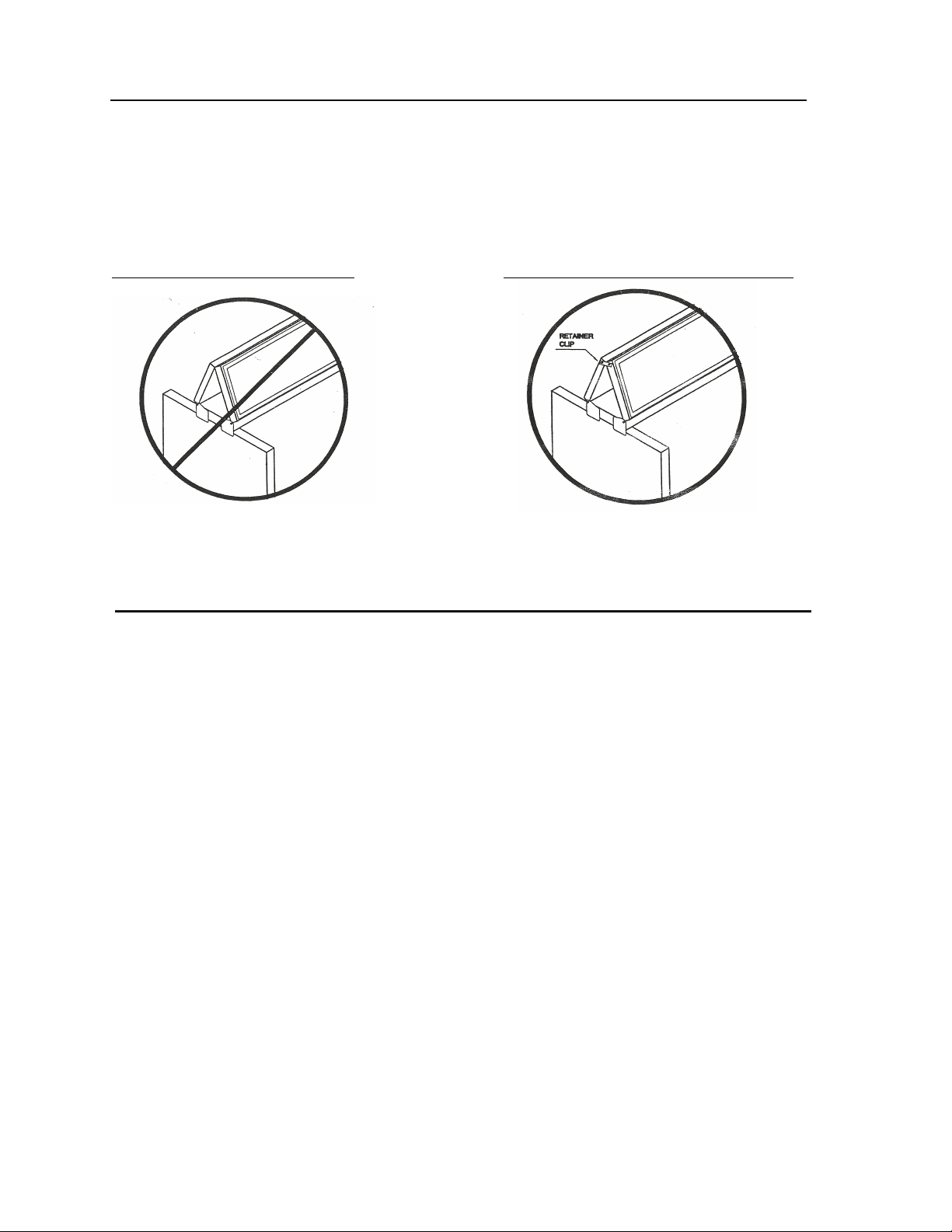

Important Features

W

Operating Ambient Temperature: For proper operation ambient temperature may

not exceed 75° Fahrenheit.

Operating Relative Humidity:

Do Not Prop Open Top Doors

RONG

For proper operation relative humidity may not

exceed 55%.

Use Retainer to Secure Top Doors

RIGHT

Daily Maintenance

• Fill your MOD-U-SERVE milk cooler with milk for your next day’s breakfast and lunch before you leave

each afternoon.

• Repeat daily until Friday.

• For low volume usage, milk along the milk cooler walls must be rotated with interior milk to prevent

freezing.

• Every Friday, unload and unplug your MOD-U-SERVE milk cooler to allow any ice buildup to defrost.

• After unloading: wipe, wash, or hose out the interior of your milk cooler with warm soapy water. Open the

gate valve on the bottom of the cooler to allow cooler to drain any excess water.

• Leave cooler doors open and let the cooler dry over the weekend.

• Plug in the cooler and shut the doors early Monday morning.

• Reload your MOD-U-SERVE milk cooler with milk as soon as the cooler has reached proper temperature.

• Clean louvers and condensing coils every two months.

• Gaskets should be checked regularly for breaks or tears. Gaskets should be replaced every 12 months.

8

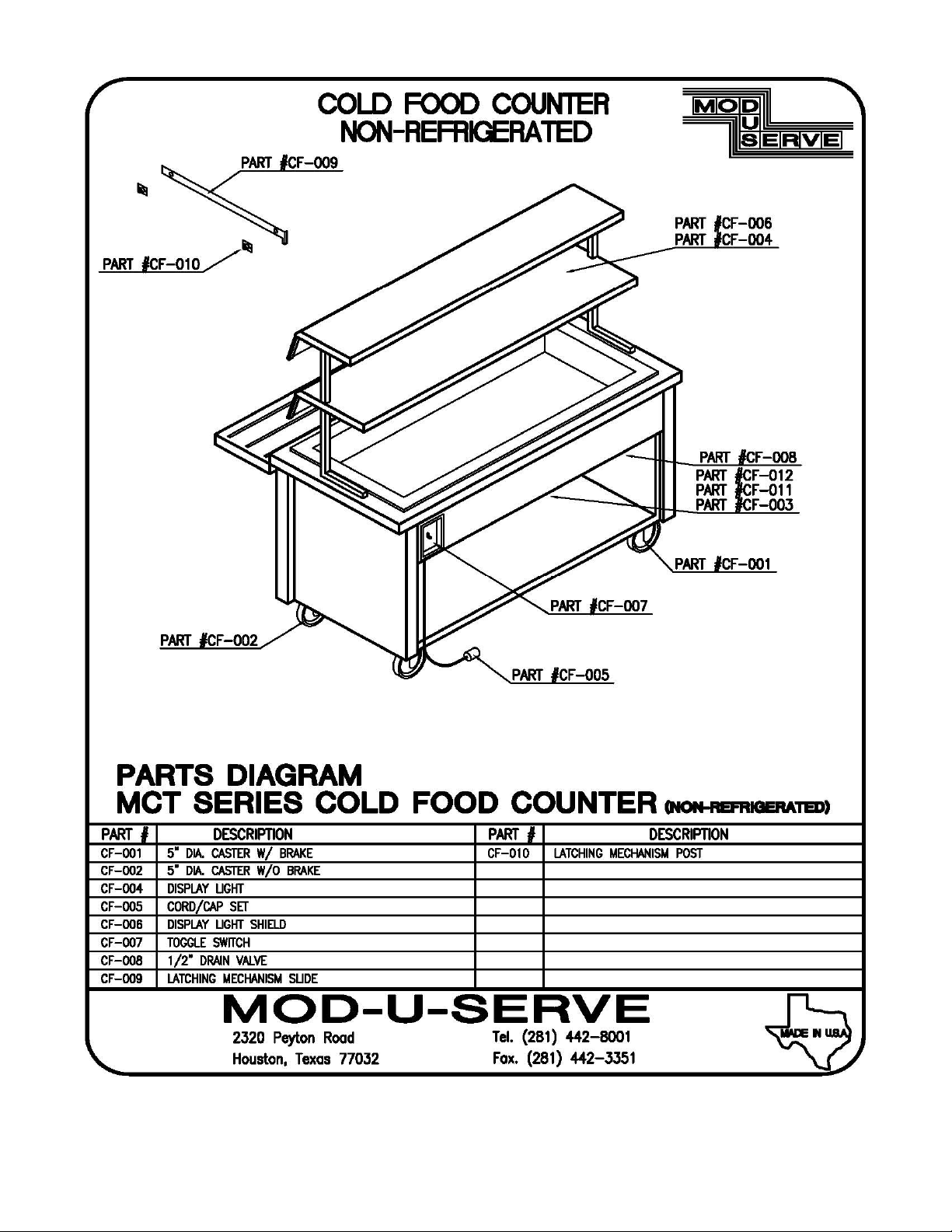

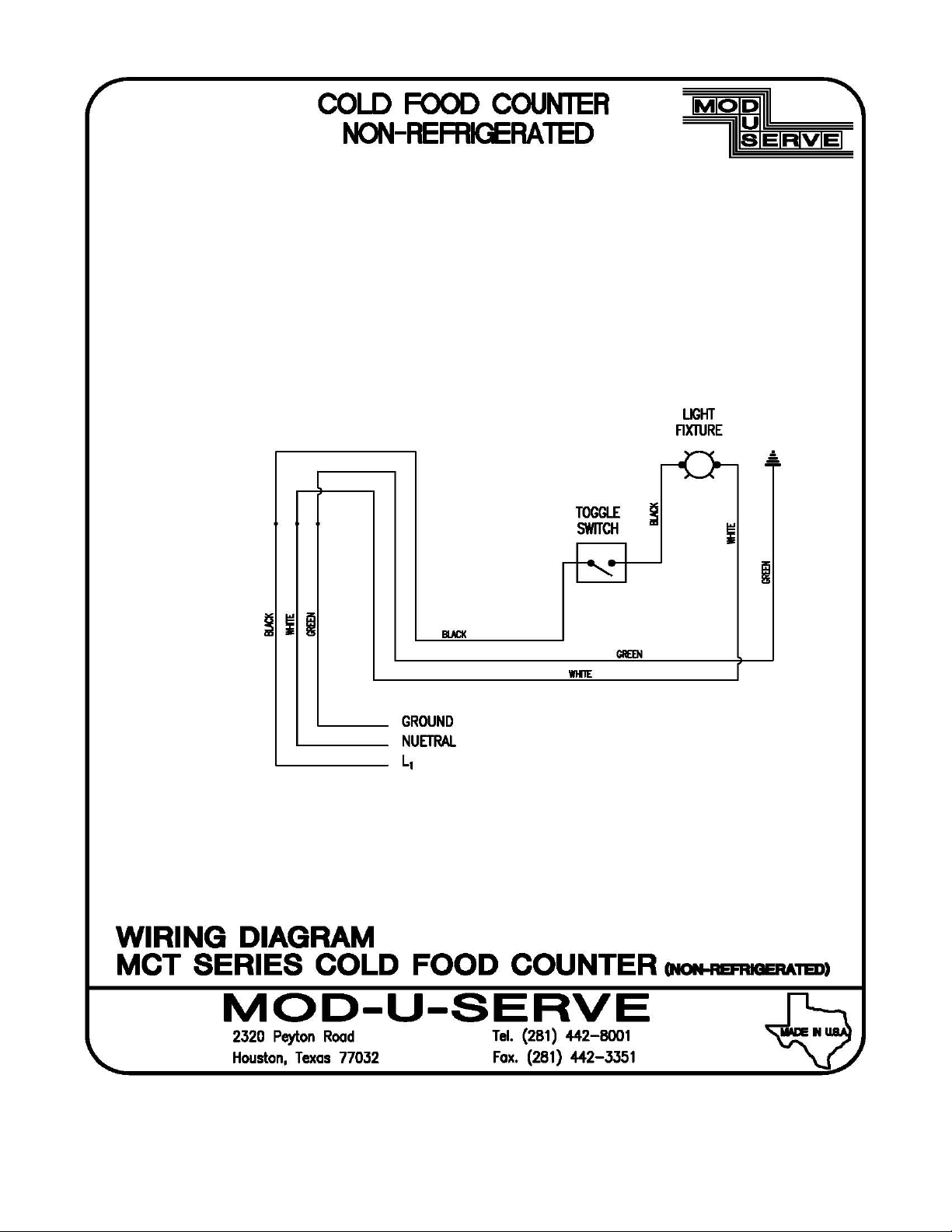

Cold Food Counters

Non-Refrigerated

Model Numbers

MCT-CF2-NR 36” Length Mobile Cold Pan Counter– 2 pan capacity

MCT-CF3-NR 50” Length Mobile Cold Pan Counter– 3 pan capacity

MCT-CF4-NR 64” Length Mobile Cold Pan Counter– 4 pan capacity

MCT-CF5-NR 78” Length Mobile Cold Pan Counter– 5 pan capacity

MCT-CF6-NR 92” Length Mobile Cold Pan Counter– 6 pan capacity

Electrical

120 Volts, AC. 15 Amp Circuit (NEMA 5-15P). Plugs into a 5-15 R receptacle.

9

10

11

Loading...

Loading...