Modulens AGC 10, AGC 15, AGC 25, AGC 35 Service Manual

Modulens

Gas fired floor-standing condensing boiler

AGC 10/15

AGC 15

AGC 25

AGC 35

EN

Installation and

Service Manual

300026081-001-08

Declaration of conformity

The device complies with the standard type described in

the EG declaration of conformity. It was manufactured and

commissioned in accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

Contents

1 Safety instructions and recommendations ..............................................6

1.1 General safety instructions .................................6

1.2 Recommendations ................................................7

1.3 Liabilities ...............................................................8

1.3.1 Manufacturer’s liability .............................................8

1.3.2 Installer’s liability .....................................................8

2 About this manual ......................................................................................9

2.1 Symbols used .......................................................9

2.1.1 Symbols used in the manual ...................................9

2.1.2 Symbols used on the equipment .............................9

2.2 Abbreviations ......................................................10

2.3 After Sales Service Internet Site .......................10

3 Technical specifications ..........................................................................11

3.1 Homologations ....................................................11

3.1.1 Certifications .........................................................11

3.1.2 Gas categories ......................................................11

3.1.3 Additional Directives ..............................................11

3.1.4 Factory test ...........................................................12

3.2 Technical specifications ....................................12

3.2.1 Sensor characteristics ...........................................13

4 Technical description ..............................................................................14

4.1 General description ............................................14

4.2 Main parts ............................................................14

4.3 Operating principle .............................................15

4.3.1 Skeleton Diagrams ................................................15

4.3.2 Circulation pump ...................................................17

4.3.3 Water flow rate ......................................................17

5 Installation ................................................................................................18

5.1 Regulations governing installation ...................18

5.2 Package list .........................................................18

5.2.1 Standard delivery ..................................................18

5.2.2 Accessories ...........................................................18

15/03/2016 - 300026081-001-08

1

Contents

5.3 Choice of the location ........................................19

5.3.1 Type plate .............................................................19

5.3.2 Positioning of the appliance ..................................20

5.3.3 Ventilation .............................................................21

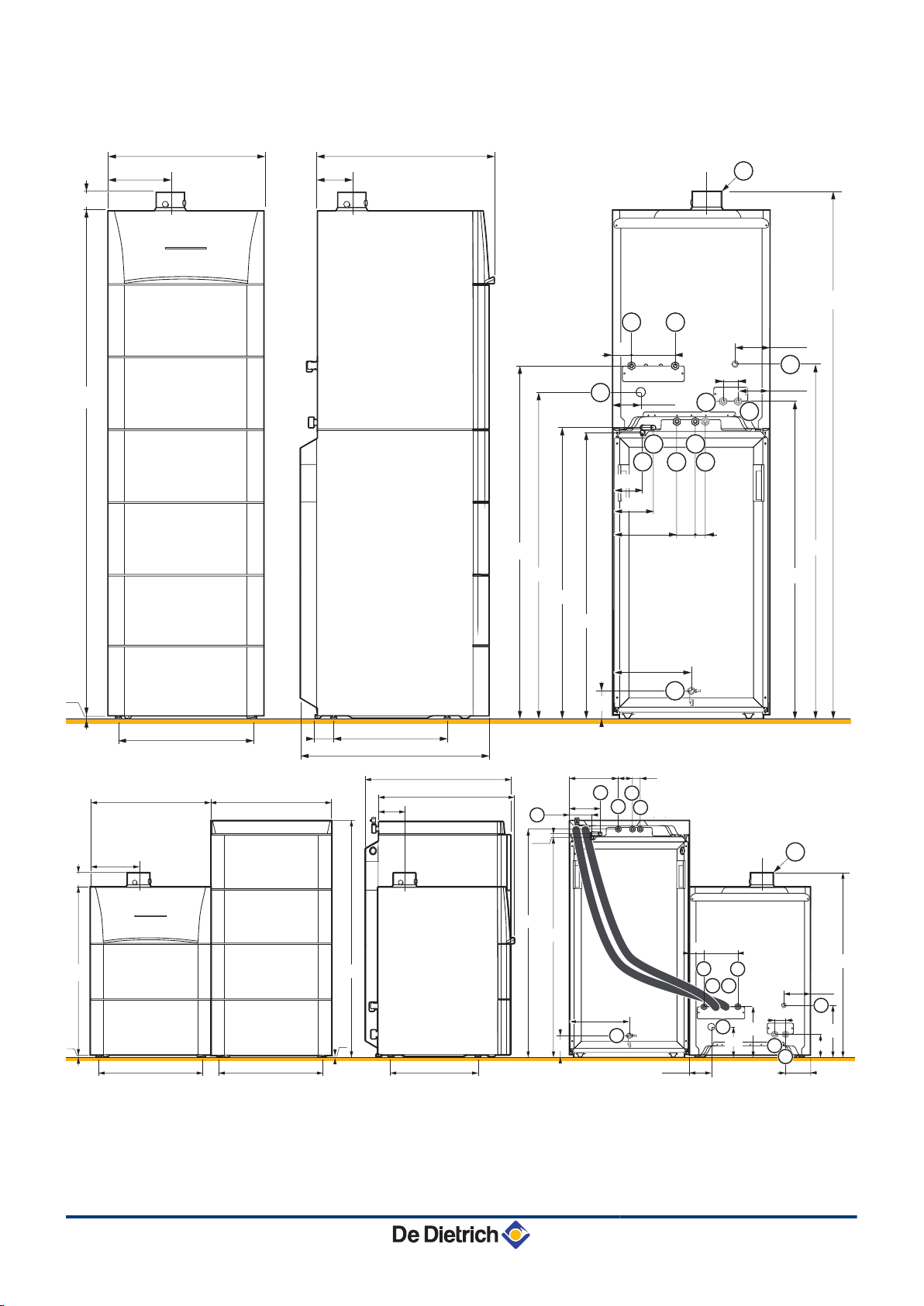

5.3.4 Main dimensions ...................................................21

5.4 Positioning the appliance ..................................26

5.4.1 Positioning the boiler on its own ............................26

5.4.2 Fitting the boiler to a DHW tank ............................28

5.4.3 Positioning the boiler to the left or right of a DHW

tank .......................................................................29

5.4.4 Reversing the opening direction of the control panel

door .......................................................................29

5.5 Hydraulic connections .......................................30

5.5.1 Flushing the system ..............................................30

5.5.2 Hydraulic connection of the heating circuit ............31

5.5.3 Connection of the water circuit for domestic

use ........................................................................31

5.5.4 Connecting the expansion vessel .........................31

5.5.5 Connecting the condensate discharge pipe ..........32

5.5.6 Filling the condensate trap ....................................33

5.6 Gas connection ...................................................33

5.7 Flue gas system connections ............................34

5.7.1 Classification .........................................................35

5.7.2 Lengths of the air/flue gas pipes ...........................36

5.8 Installing the outside sensor .............................37

5.8.1 Choice of the location ............................................37

5.8.2 Connecting the outside sensor ..............................37

5.9 Electrical connections ........................................38

5.9.1 Control unit ............................................................38

5.9.2 Recommendations ................................................39

5.9.3 Access to the connection terminal ........................40

5.9.4 Position of the PCBs .............................................41

5.9.5 Connecting a direct heating circuit ........................42

5.9.6 Connecting a heating circuit and a domestic hot water

tank .......................................................................43

5.9.7 Connecting two circuits and a domestic hot water

tank .......................................................................47

5.9.8 Hot water storage tank connection ........................48

5.9.9 Pool connection .....................................................53

5.9.10 Connecting a mixed tank .......................................54

5.9.11 Connecting the options .........................................56

5.9.12 Connection in cascade ..........................................57

15/03/2016 - 300026081-001-08

5.10 Electrical diagram ...............................................60

5.11 Filling the system ...............................................61

5.11.1 Water treatment ....................................................61

5.11.2 Filling the system ..................................................62

2

6 Commissioning ........................................................................................63

6.1 Control panel .......................................................63

6.1.1 Description of the keys ..........................................63

6.1.2 Description of the display ......................................64

6.1.3 Access to the various browsing levels ..................66

6.1.4 Browsing in the menus ..........................................68

6.2 Check points before commissioning ................69

6.2.1 Preparing the boiler for commissioning .................69

6.2.2 Gas circuit .............................................................69

6.2.3 Hydraulic circuit .....................................................71

6.2.4 Electrical connections ...........................................71

6.3 Putting the appliance into operation ................71

6.4 Gas settings ........................................................72

6.4.1 Adapting to another gas type ................................72

6.4.2 Checking and setting combustion .........................73

6.4.3 Basic setting for the gas/air ratio ...........................77

6.5 Checks and adjustments after

commissioning ...................................................77

6.5.1 Displaying the parameters in extended

mode .....................................................................77

6.5.2 Setting the parameters specific to the

installation .............................................................78

6.5.3 Naming the circuits and generators ......................81

6.5.4 Setting the heating curve ......................................82

6.5.5 Finalizing work ......................................................84

6.6 Reading out measured values ...........................85

6.7 Changing the settings ........................................86

6.7.1 Language selection ...............................................86

6.7.2 Calibrating the sensors .........................................87

6.7.3 Professional settings .............................................88

6.7.4 Configuring the network ........................................97

6.7.5 Return to the factory settings ..............................100

7 Switching off the appliance ...................................................................101

7.1 Installation shutdown .......................................101

7.2 Antifreeze protection ........................................101

8 Checking and maintenance ...................................................................102

8.1 General instructions .........................................102

8.2 Chimney sweep instructions ...........................102

8.3 Customising maintenance ...............................103

8.3.1 Maintenance message ........................................103

8.3.2 Contact details of the professional for After Sales

Support ................................................................104

15/03/2016 - 300026081-001-08

3

Contents

8.4 Standard inspection and maintenance

operations .........................................................104

8.4.1 Checking the hydraulic pressure .........................105

8.4.2 Checking the expansion vessel ...........................105

8.4.3 Checking the ionization current ...........................105

8.4.4 Checking the tightness of the flue gas evacuation and

air inlet connections ............................................105

8.4.5 Checking combustion ..........................................105

8.4.6 Checking and closing the automatic air vent .......106

8.4.7 Checking the safety valve ...................................106

8.4.8 Checking the condensate trap ............................106

8.4.9 Checking the burner and cleaning the heat

exchanger ...........................................................107

9 Troubleshooting .....................................................................................108

9.1 Anti-hunting ......................................................108

9.2 Messages (Code type Bxx or Mxx) ..................108

9.3 Message history ................................................111

9.4 Faults (Code type Lxx or Dxx) .........................111

9.4.1 Deletion of sensors from the memory in the

PCB .....................................................................120

9.5 Failure history ...................................................121

9.6 Parameter and input/output check (mode

tests) ..................................................................121

9.6.1 Control system sequence ....................................124

10 Spare parts ..............................................................................................126

10.1 General ..............................................................126

10.2 Spare parts ........................................................127

10.2.1 Casing .................................................................127

10.2.2 Water unit ............................................................128

10.2.3 Control panel .......................................................129

10.2.4 Casing .................................................................129

10.2.5 Spare parts list ....................................................130

11 Appendix – Information on the Ecodesign and Energy Labelling

Directives ................................................................................................133

15/03/2016 - 300026081-001-08

4

15/03/2016 - 300026081-001-08

5

1. Safety instructions and recommendations AGC 10/15 AGC 15 AGC 25 AGC 35

1 Safety instructions and

recommendations

1.1 General safety instructions

DANGER

This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have

been given supervision or instruction concerning

use of the appliance in a safe way and

understand the hazards involved. Children shall

not play with the appliance. Cleaning and user

maintenance shall not be made by children

without supervision.

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do

not operate electrical contacts or switches

( doorbell, light, motor, lift, etc..).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them

immediately.

5. If the gas leak is before the gas meter,

contact the gas supplier.

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Trace possible leaks and seal them

immediately.

6

15/03/2016 - 300026081-001-08

AGC 10/15 AGC 15 AGC 25 AGC 35

1.2 Recommendations

1. Safety instructions and recommendations

WARNING

4 Installation and maintenance of the boiler

must be carried out by a qualified

professional in compliance with prevailing

local and national regulations.

4 When working on the boiler, always

disconnect the boiler from the mains and

close the main gas inlet valve.

4 After maintenance or repair work, check all

installations to ensure that there are no

leaks.

CAUTION

The boiler must be installed in a frost-free

environment.

Keep this document close to the place where the

boiler is installed.

Casing components

Only remove the casing for maintenance and repair

operations. Put the casing back in place after

maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance

must never be removed or covered and must remain

legible during the entire lifespan of the appliance.

Immediately replace damaged or illegible instructions and

warning stickers.

Modifications

Modifications may only be made to the boiler after the

written permission of De Dietrich Thermique to do so.

15/03/2016 - 300026081-001-08

7

1. Safety instructions and recommendations

1.3 Liabilities

AGC 10/15 AGC 15 AGC 25 AGC 35

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the

requirements of the various applicable European

Directives. They are therefore delivered with [ marking

and all relevant documentation.

In the interest of customers, we are continuously

endeavouring to make improvements in product quality.

All the specifications stated in this document are therefore

subject to change without notice.

Our liability as the manufacturer may not be invoked in the

following cases:

4 Failure to abide by the instructions on using the

appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the

appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and

commissioning of the appliance. The installer must

respect the following instructions:

4 Read and follow the instructions given in the manuals

provided with the appliance.

4 Carry out installation in compliance with the prevailing

legislation and standards.

4 Perform the initial start up and carry out any checks

necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the

obligation to check the appliance and maintain it in

good working order.

4 Give all the instruction manuals to the user.

8

15/03/2016 - 300026081-001-08

D000241-C

AGC 10/15 AGC 15 AGC 25 AGC 35

2 About this manual

2.1 Symbols used

2.1.1. Symbols used in the manual

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, highlight hazards and guarantee correct

operation of the appliance.

2. About this manual

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

2.1.2. Symbols used on the equipment

4

~

Protective earthing

Alternating current

Before installing and commissioning the device, read

carefully the instruction manuals provided.

Dispose of the used products in an appropriate recovery

and recycling structure.

15/03/2016 - 300026081-001-08

This appliance must be connected to the protective earth.

9

1 2

M002628-A

2. About this manual AGC 10/15 AGC 15 AGC 25 AGC 35

Caution: danger, live parts.

Disconnect the mains power prior to any operations.

2.2 Abbreviations

4 3CE: Collective conduit for sealed boiler

4 DHW: Domestic hot water

4 Interscenario switch: Home automation switch that can be used

to centralise and control several scenarios

4 Hi: Lower heating value LHV (Nett)

4 Hs: Higher heating value HHV (Gross)

4 PPS: Polypropylene hardly inflammable

4 PCU: Primary Control Unit - PCB for managing burner operation

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - control panel PCB

4 SU: Safety Unit - Safety PCB

4 3WV: 3-way valve

4 HL: High Load - DHW tank with plate exchanger

4 SL: Standard Load - DHW tank with coil

4 SHL: Solar High Load - Solar DHW tank with plate exchanger

4 SSL: Solar Standard Load - Solar DHW tank with coil

2.3 After Sales Service Internet Site

The QR code or flashcode is used to access the internet site

containing the documentation and technical information regarding the

product. The QR code also appears on the appliance’s nameplate.

10

15/03/2016 - 300026081-001-08

AGC 10/15 AGC 15 AGC 25 AGC 35 3. Technical specifications

3 Technical specifications

3.1 Homologations

3.1.1. Certifications

CE identification no

NOx classification

Type of connection Chimney: B23, B

CE-0085CM0178

5 (EN 15502-1, EN 15502-2-1)

33

Flue gas outlet: C

C

93(x)

13(x)

, C

33(x)

, C

43(x)

, C53, C

83(x)

,

3.1.2. Gas categories

Gas category

II

2ESi3P

The boiler is preset in the factory to operate on natural gas H (G20).

¼For operation on another type of gas, see chapter: "Adapting

to another gas type", page 72.

Gas type Connection pressure (mbar)

Natural gas H (G20) 20

Natural gas L (G25) 25

Propane (G31) 37

3.1.3. Additional Directives

15/03/2016 - 300026081-001-08

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed.

For all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

11

3. Technical specifications AGC 10/15 AGC 15 AGC 25 AGC 35

3.1.4. Factory test

Before leaving the factory, each boiler is set for optimum performance

and tested to check the following items:

4 Electrical safety

4 Adjustment (CO2)

4 Domestic hot water mode

4 Water tightness

4 Gas tightness

4 Parameter settings

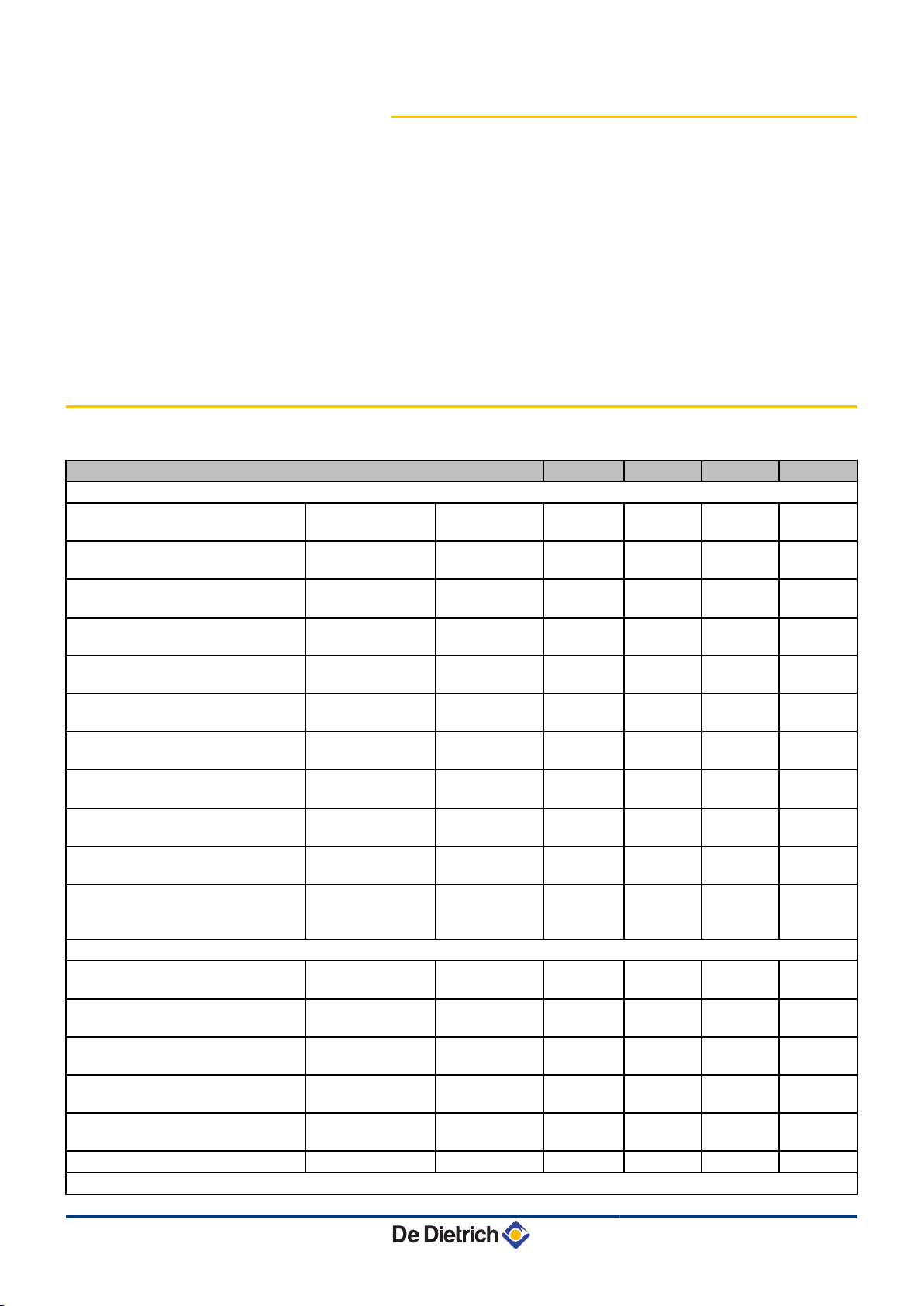

3.2 Technical specifications

Boiler type

General

Nominal output (Pn)

Heating System (80/60 °C)

Nominal output (Pn)

Heating System (50/30 °C)

Nominal output (Pn)

Heating System (40/30 °C)

Nominal input (Qn)

Heating System (Hi)

Nominal input(Qn)

Heating System (Hs)

Nominal input (Qnw)

DHW System (Hi)

Nominal input (Qnw)

DHW System (Hs)

Heating efficiency under full load (Hi)

(80/60 °C)

Heating efficiency under full load (Hi)

(50/30 °C)

Heating efficiency under partial load

(Hi) (Return temperature 60°C)

Heating efficiency under partial load

(EN 92/42) (Return temperature

30°C)

Data on the gases and combustion gases

Gas consumption - Natural gas H

(G20)

Gas consumption - Natural gas L

(G25)

Gas consumption - Propane G31 minimum-

Mass flue gas flow rate minimum-

Flue gas temperature minimum-

Maximum counter pressure

Characteristics of the heating circuit

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

- % 99,3 99,3 99,2 99,1

- % 107,0 105,3 102,0 102,2

- % 94,9 94,9 96,1 96,3

- % 110,2 110,2 110,1 110,6

minimummaximum

minimummaximum

maximum

maximum

maximum

AGC 10/15 AGC 15 AGC 25 AGC 35

kW 3,0 - 10,4 3,0 - 14,9 5,0 - 24,8 6,3 - 34,8

kW 3,4 - 11,2 3,4 - 15,8 5,6 - 25,5 7,0 - 35,9

kW 3,4 - 16,0 3,4 - 16,0 5,6 - 25,9 7,0 - 36.4

kW 3,1 - 10,5 3,1 - 15,0 5,2 - 25,0 6,5 - 35,1

kW 3,4 - 11,7 3,4 - 16,7 5,8 - 27,8 7,2 - 39,0

kW 3,1 - 15,0 3,1 - 15,0 5,2 - 29,3 6,5 - 35,1

kW 3,4 - 16,7 3,4 - 16,7 5,8 - 32,6 7,2 - 39,0

m3/h

m3/h

m3/h

kg/h 5,3 - 25,2 5,3 - 25,2 8,9 - 49,3 11,1 - 57,3

°C 30 - 65 30 - 65 30 - 80 30 - 75

Pa 80 80 130 140

0,33 - 1,59 0,33 - 1,59 0,55 - 3,10 0,69 - 3,71

0,38 - 1,85 0,38 - 1,85 0,64 - 3,61 0,80 - 4,32

0,13 - 0,61 0,13 - 0,61 0,21 - 1,20 0,27 - 1,44

12

15/03/2016 - 300026081-001-08

AGC 10/15 AGC 15 AGC 25 AGC 35 3. Technical specifications

Boiler type AGC 10/15 AGC 15 AGC 25 AGC 35

Water content (ex expansion vessel)

Water operating pressure minimum kPa (bar (MPa)) 80 (0,8) 80 (0,8) 80 (0,8) 80 (0,8)

Water operating pressure (PMS) maximum kPa (bar (MPa)) 300 (3,0) 300 (3,0) 300 (3,0) 300 (3,0)

Water temperature maximum °C 110 110 110 110

Operating temperature maximum °C 90 90 90 90

Electrical characteristics

Power supply voltage

Power consumption - Full load maximum W 101 101 116 132

Electrical protection index

Other characteristics

Weight (empty)

l 1,9 1,9 1,9 2,5

VAC 230 230 230 230

IP21 IP21 IP21 IP21

kg 56 56 56 50

3.2.1. Sensor characteristics

Outside sensor

Temperature in °C -20 -16 -12 -8 -4 0 4 8 12 16 20 24

Resistance in Ω 2392 2088 1811 1562 1342 1149 984 842 720 616 528 454

Outlet sensor circuit B+C

Domestic hot water sensor

Temperature in °C 0 10 20 25 30 40 50 60 70 80 90

Resistance in Ω 32014 19691 12474 10000 8080 5372 3661 2535 1794 1290 941

Boiler sensor

Return sensor

Temperature in °C -20 -10 0 10 20 25 30 40 50 60 70 80 90 100 110

Resistance in Ω 98932 58879 36129 22804 14773 12000 9804 6652 4607 3252 2337 1707 1266 952 726

15/03/2016 - 300026081-001-08

13

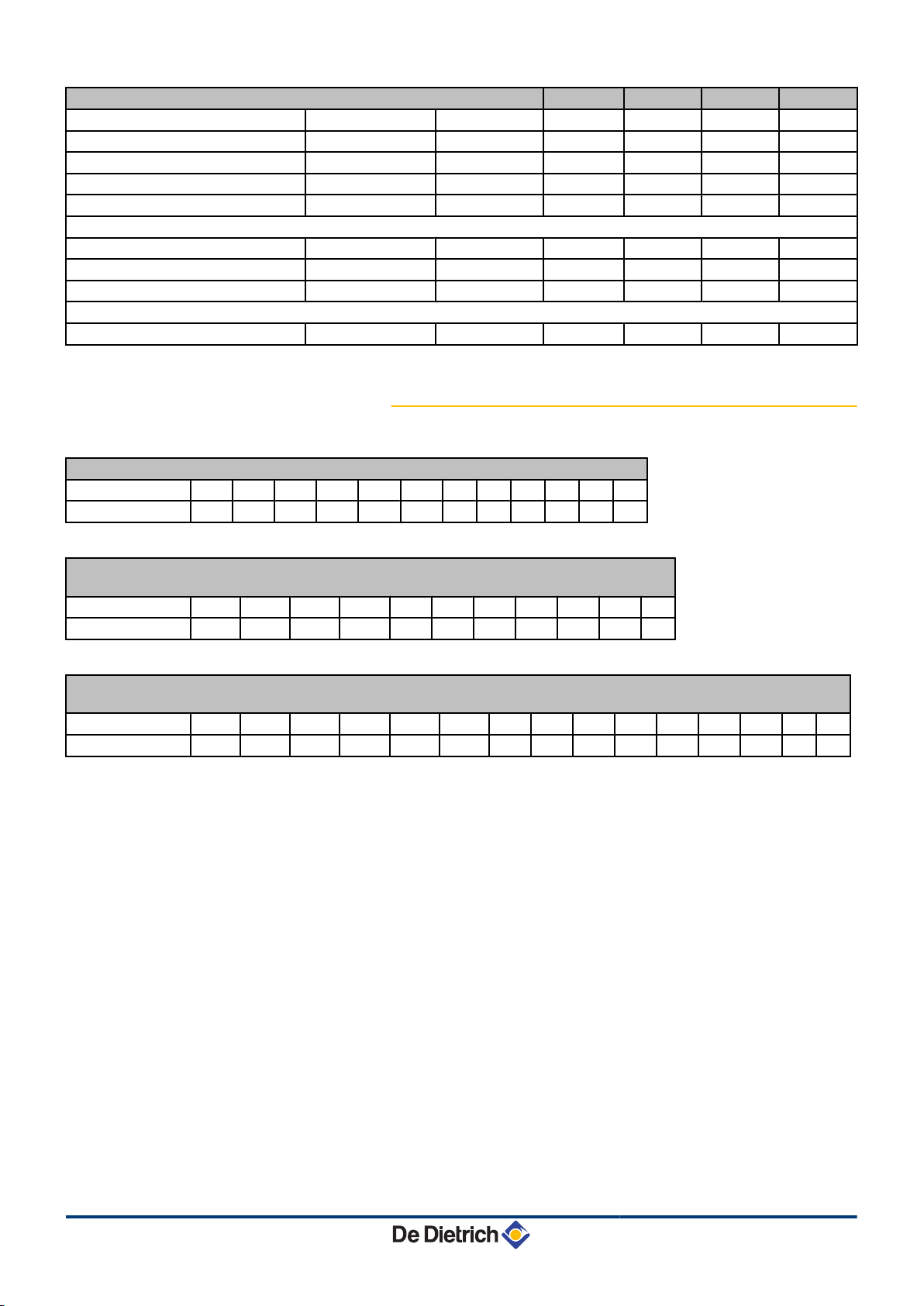

C003072-C

18

19

16

17

15

14

13

12

11

1234

10

9

5

6

7

8

4. Technical description AGC 10/15 AGC 15 AGC 25 AGC 35

4 Technical description

4.1 General description

Gas fired floor-standing condensing boiler

4 High efficiency heating.

4 Low pollutant emissions.

4 Top of the range electronic DIEMATIC iSystem control panel.

4 Flue gas evacuation via a forced flue, chimney, bi-flow, 3CE or

3CEP type connection.

4 Optional domestic hot water production in combination with a

DHW tank.

The boiler is fitted with an interior light. The interior light

comes on in the following cases:

4.2 Main parts

1

2

3

4

5

6

7

8

9

10

4 The boiler is switched on: The lighting is switched on

for 10 minutes.

4 The boiler is switched off: The lighting is switched on

for 30 minutes.

Flue gas discharge pipe

Flue gas measuring point

Heat exchanger

Ignition/ionization electrode

Box for the control PCBs

Control panel

Command module

Water pressure sensor

Circulation pump

Hydroblock

11

14

12

13

14

15

16

17

18

3-way valve

Safety valve

Casing

Expansion vessel

Combined venturi and gas valve unit

Fan

Air intake silencer

Mixer pipe

15/03/2016 - 300026081-001-08

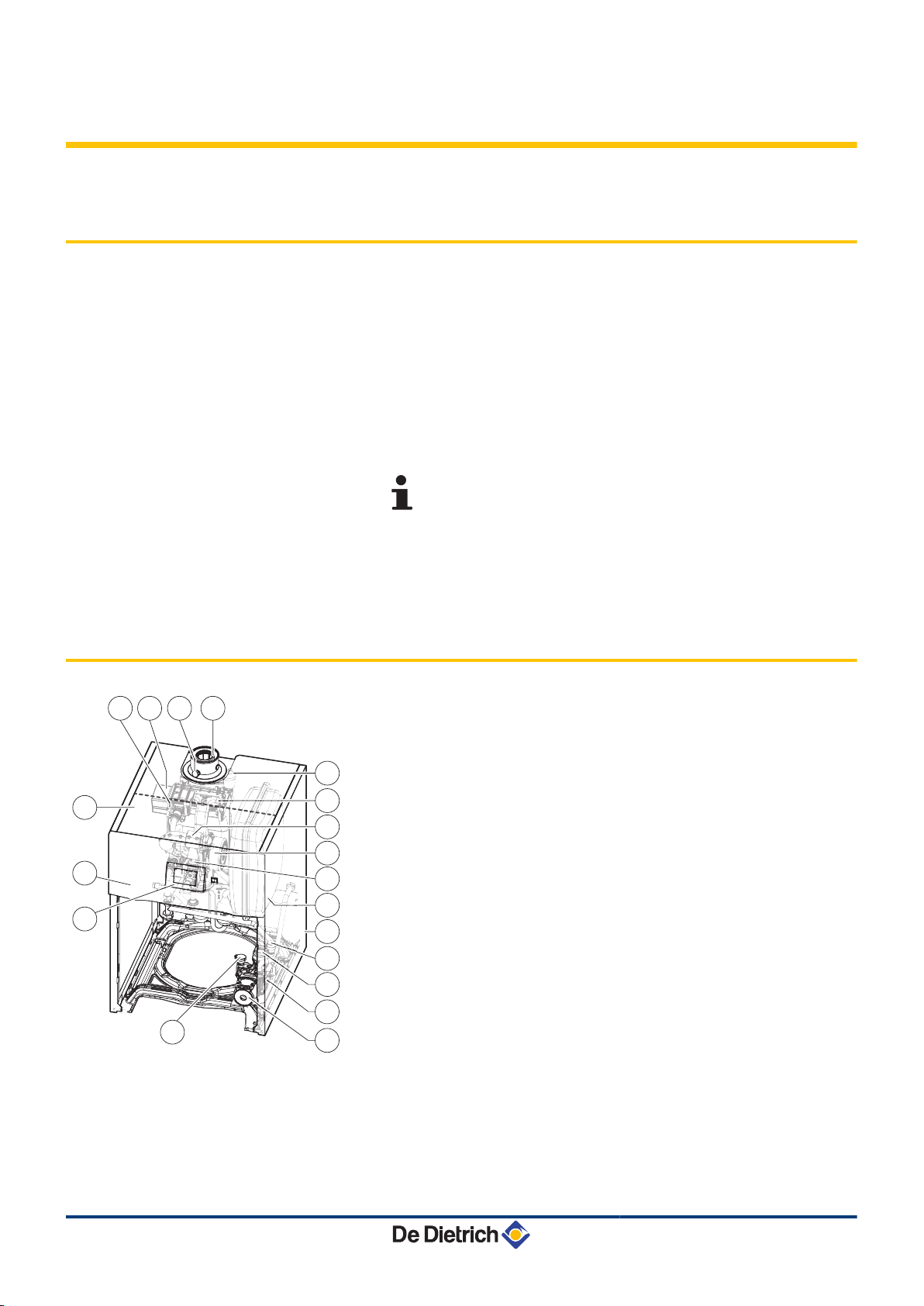

C003073-C

1

2

8

9

7

3 4 5 6

AGC 10/15 AGC 15 AGC 25 AGC 35 4. Technical description

4.3 Operating principle

19

Automatic air vent

4.3.1. Skeleton Diagrams

Boiler self-standing

n

1

2

3

4

5

6

7

Heat exchanger

Hydroblock

Heating flow

Primary DHW tank flow

Primary DHW tank return

Heating return

3-way valve

8

9

Circulation pump

Expansion vessel

15/03/2016 - 300026081-001-08

15

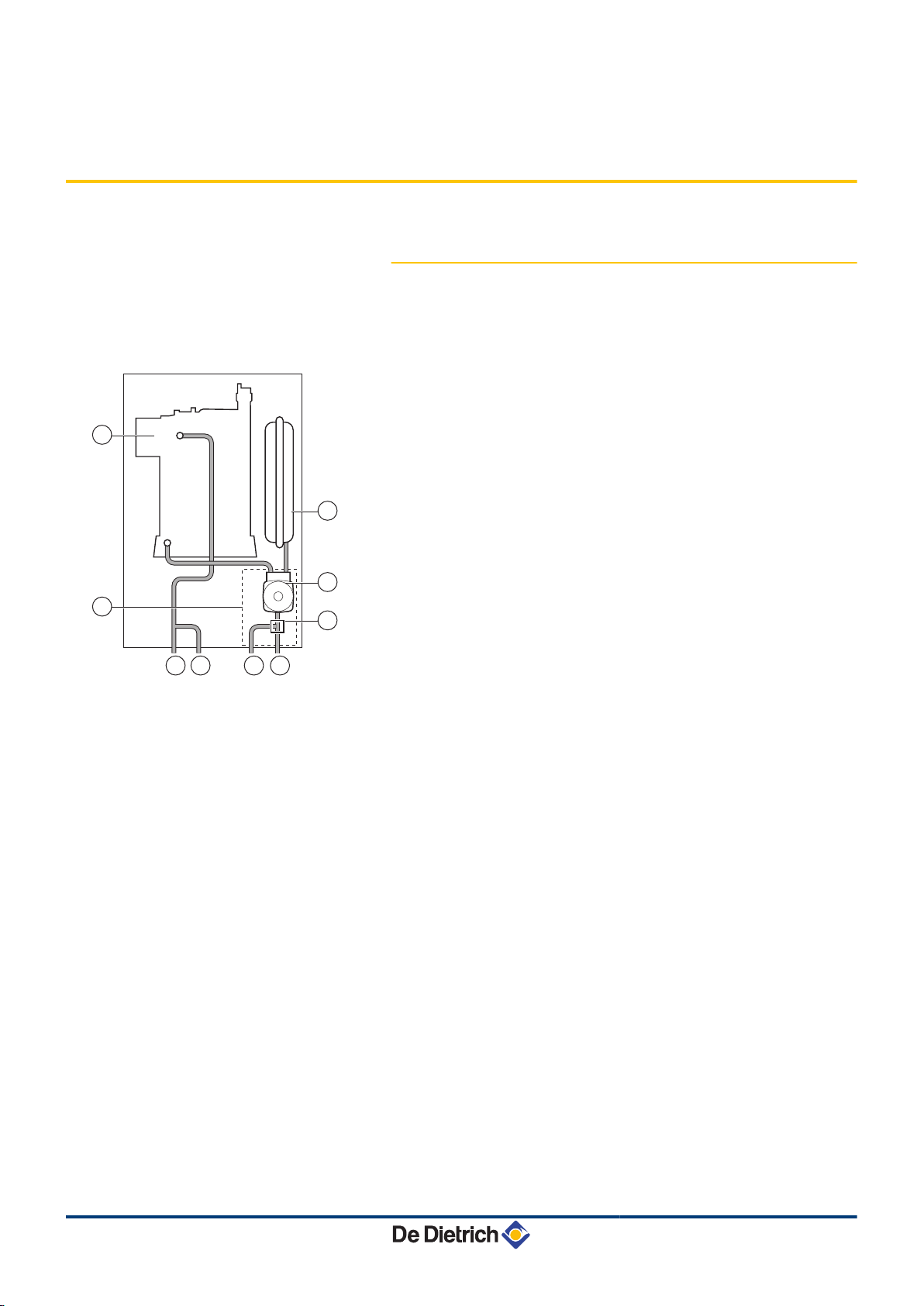

M002513-F

1

2

8

9

7

3

10

12

13

14

4

5

6

11

19

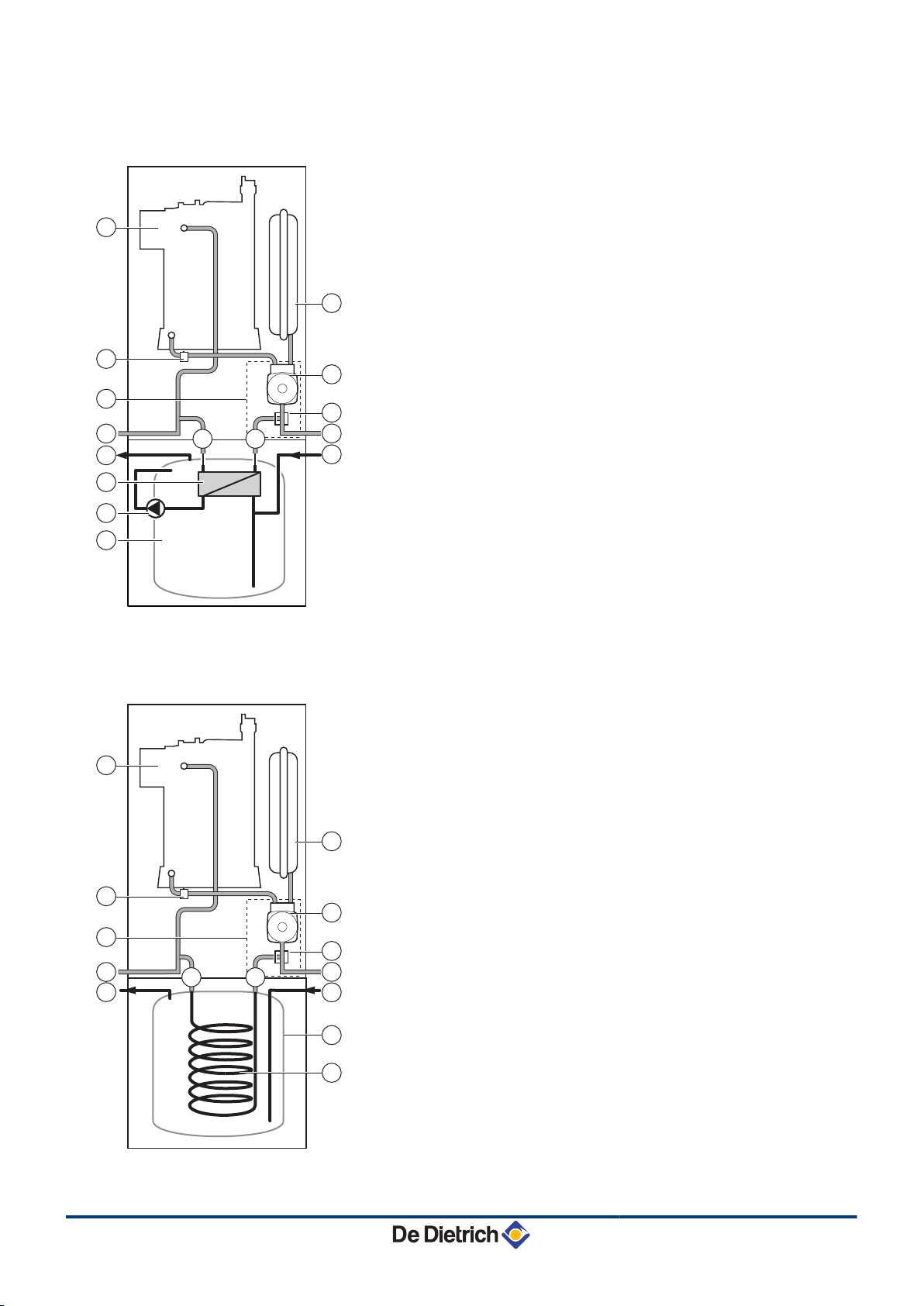

M002514-D

1

2

8

9

7

3

15

16

17

18

4

5

6

19

4. Technical description AGC 10/15 AGC 15 AGC 25 AGC 35

Boiler with 100HL / 220SHL type domestic hot water

n

tank

1

2

3

4

5

6

7

8

9

10

11

12

13

14

19

Heat exchanger

Hydroblock

Heating flow

Plate exchanger inlet

Plate exchanger outlet

Heating return

3-way valve

Circulation pump

Expansion vessel

Domestic hot water outlet

Domestic cold water inlet

Plate heat exchanger

Domestic hot water pump

Domestic hot water tank

Safety valve

Boiler with 100SL / 160SL / 200SSL type domestic hot

n

water tank

1

2

3

4

5

6

7

8

9

15

16

17

18

19

Heat exchanger

Hydroblock

Heating flow

Coil exchanger inlet

Coil exchanger outlet

Heating return

3-way valve

Circulation pump

Expansion vessel

Domestic hot water outlet

Domestic cold water inlet

Domestic hot water tank

Domestic water coil

Safety valve

16

15/03/2016 - 300026081-001-08

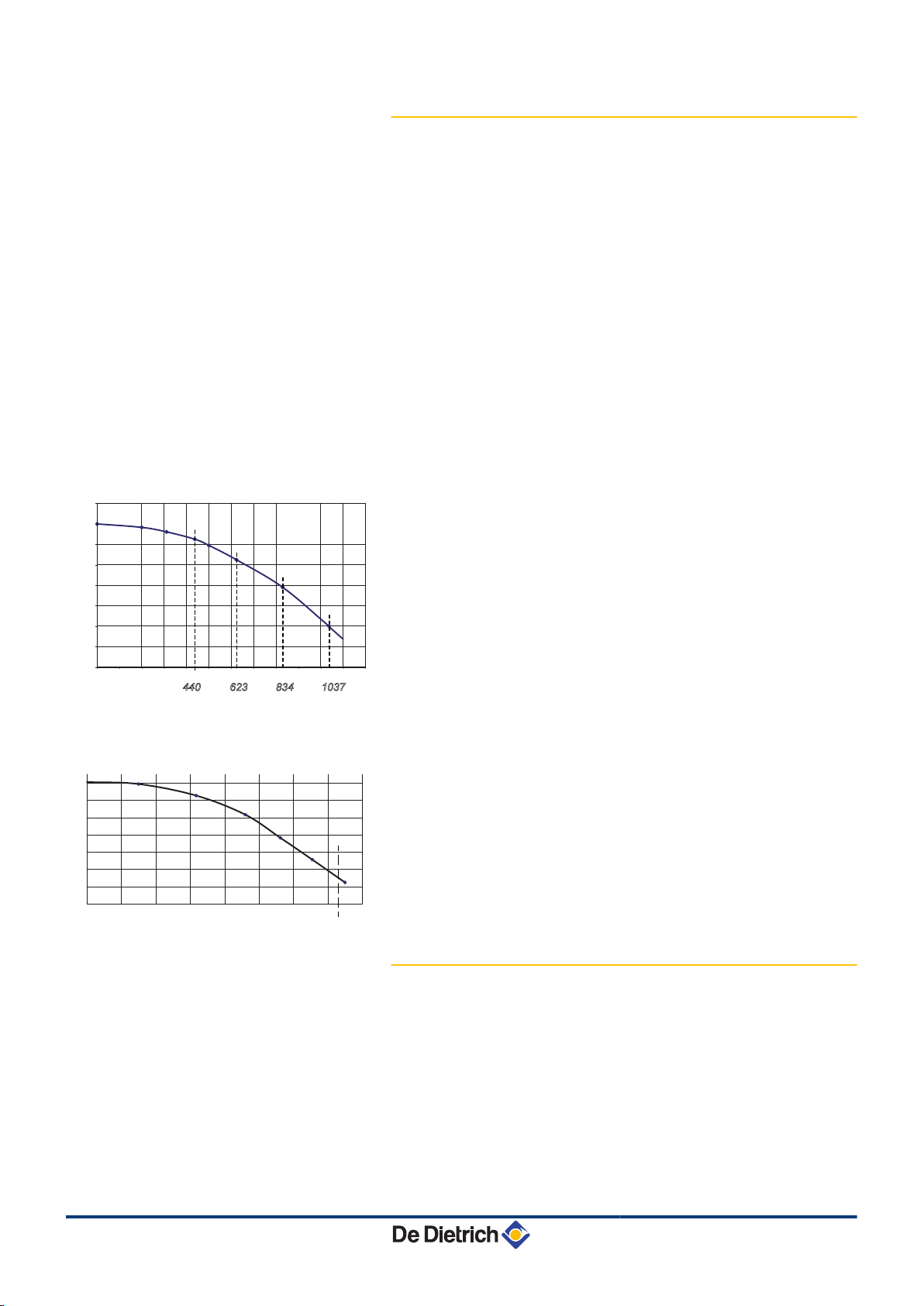

H (mbar)

C003452-E

Q (l/h)

0 200 400 600 800 1000 1200

0

100

200

300

400

500

600

700

800

B

A

C

D

1037834623440

0

0 200 400 600 800 1000 1200 1400

1465

1600

100

200

300

400

500

600

700

H (mbar)

Q (l/h)

A

L000697-A

AGC 10/15 AGC 15 AGC 25 AGC 35

4. Technical description

4.3.2. Circulation pump

The boiler is fitted with a modulating pump which is regulated by the

control panel as a function of ΔT.

The graph shows the manometric height at various outputs. The

parameters MIN.PUMP SPEED and MAX.PUMP SPEED are used to

modify the pump settings.

4 If flow noise can be heard in the system, it is possible to reduce

the maximum pump speed with the parameter MAX.PUMP

SPEED (First of all, vent the heating system).

4 If circulation in the radiators is too low or the radiators do not fully

heat up, increase the minimum pump speed with the parameter

MIN.PUMP SPEED.

Pump specifications

n

10/15 - 15 - 25 kW boilers

H

Q

Manometric height available for the heating circuit

Water flow

Useful output (ΔT 20 K)

A

B

C

D

10 kW

15 kW

20 kW

25 kW

35 kW boilers

H

Q

A

Manometric height available for the heating circuit

Water flow

Useful output 35 kW (ΔT 20 K)

4.3.3. Water flow rate

15/03/2016 - 300026081-001-08

The boiler’s modulating control system limits the maximum difference

in temperature between the heating flow and return and the maximum

speed at which the flow temperature increases. In this way, the boiler

does not require a minimum water flow rate.

17

5. Installation AGC 10/15 AGC 15 AGC 25 AGC 35

5 Installation

5.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

5.2 Package list

5.2.1. Standard delivery

The delivery includes:

4 The boiler, fitted with a connection cable

4 Outside sensor

4 Installation and Service Manual

4 User Guide

5.2.2. Accessories

Various options are available depending on the configuration of the

installation.

Boiler options

Description package

Condensates neutralisation station DU13

Condensates neutralisation station without lift pump BP52

Flue gas safety thermostat JA38

adapter 80/125 HR38

3-way internal valve kit JA6

External circuit kit JA7

Reduced elbow kit JA43

Propane conversion kit AGC 15 JA39

Propane conversion kit AGC 25 JA40

Propane conversion kit AGC 35 JA41

18

15/03/2016 - 300026081-001-08

C003074-E

Auf ERDGAS H eingestellt

für DE: Erdgas E

Réglé au gaz naturel H

Geregeld voor aardgas H

Preset for natural gas H

G20 - 20 mbar

8366-4038

1 2

AGC 10/15 AGC 15 AGC 25 AGC 35 5. Installation

Control system options

Description package

RX12 cable AD134

TELCOM 2 voice remote monitoring module AD152

Flow sensor AD199

DHW sensor AD212

Optional PCB for 3-way valve AD249

Hot water storage tank sensor AD250

Outside radio-controlled temperature sensor AD251

Boiler radio module AD252

Radio remote control AD253

Interactive remote control AD254

Room sensor FM52

Domestic hot water tank options

Description package

100HL domestic hot water calorifier ER225

160SL domestic hot water calorifier ER223

220SHL domestic hot water calorifier ER220

Boiler and DHW calorifier connection kit SL / SSL JA8

Boiler and DHW calorifier connection kit HL / SHL JA9

Connecting kit between boiler and other DHW tank JA10

5.3 Choice of the location

5.3.1. Type plate

The data plates provide important information on the

appliance: serial number, model, gas category, etc.

1

2

This data plate is affixed to the inside side panel of the

appliance in the factory.

When installation has been completed, affix the data plate

provided in the instructions bag to the casing of the

appliance in a position where it can be seen.

15/03/2016 - 300026081-001-08

19

C003080-F

1100

min.500

320

(1)

680

min.

250

844

500

M002515-C

1700

min.500

320

(1)

min.

250

844

500

M002516-C

1100

min.500

320

(1)

min.

250

A

500

5. Installation AGC 10/15 AGC 15 AGC 25 AGC 35

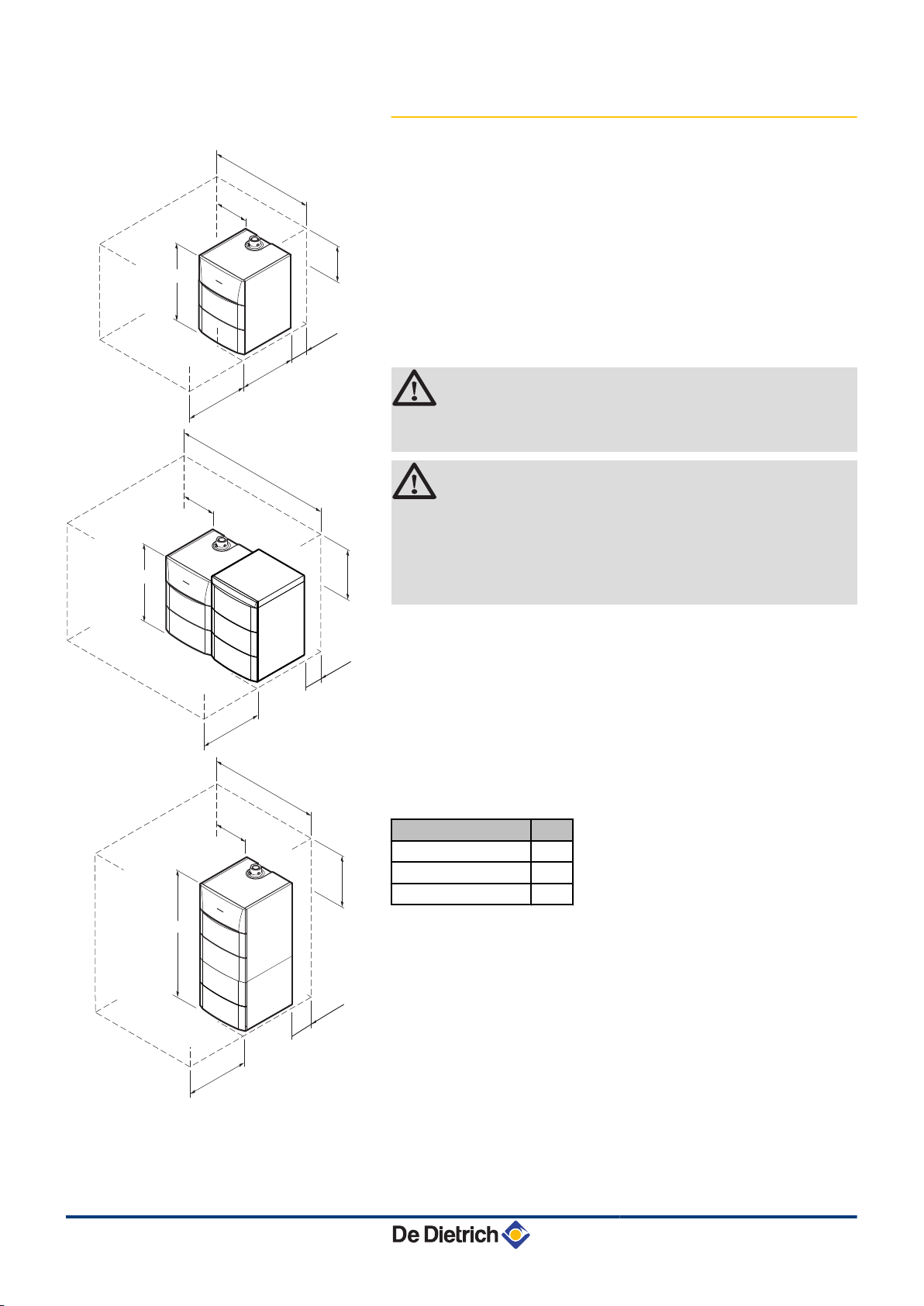

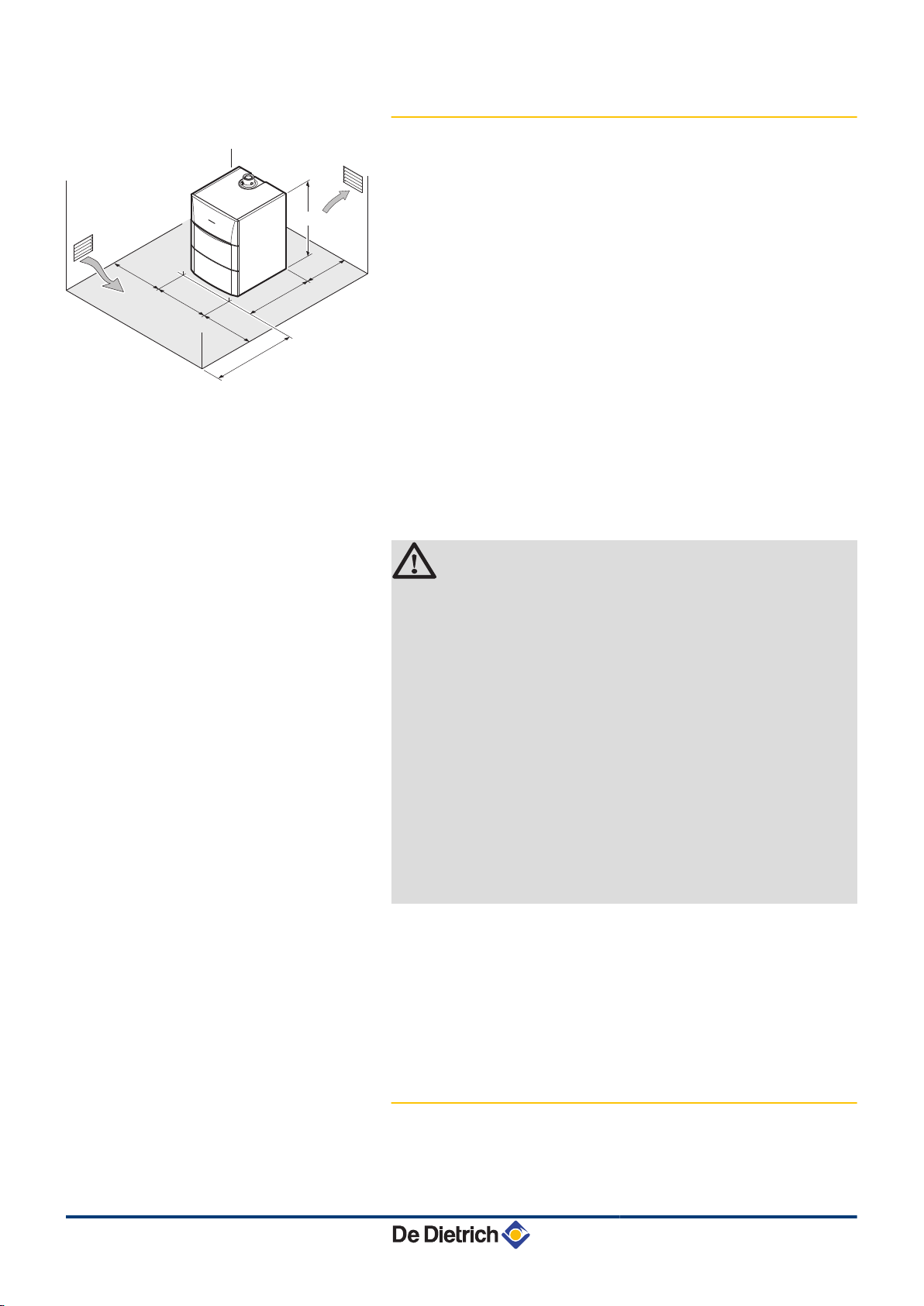

5.3.2. Positioning of the appliance

(1)

Minimum recommended distance

4 Before mounting the boiler, decide on the ideal position for

mounting, bearing the Directives and the dimensions of the

appliance in mind.

4 When choosing the position for mounting the boiler, bear in mind

the authorised position of the combustion gas discharge outlets

and the air intake opening.

4 To ensure adequate accessibility to the appliance and facilitate

maintenance, leave enough space around the boiler.

WARNING

It is forbidden to store inflammable products and materials

in the boiler room or close to the boiler, even temporarily.

CAUTION

4 The boiler must be installed in a frost-free

environment.

4 A connection to the mains drainage system for the

discharge of condensate must be available close to

the boiler.

20

(1)

Minimum recommended distance

DHW calorifier type A

100 HL 1408

160 SL 1688

220 SHL 1968

15/03/2016 - 300026081-001-08

C003075-E

680

min. 500

600

844

320

(1)

500

(1)

500

(1)

AGC 10/15 AGC 15 AGC 25 AGC 35

5. Installation

5.3.3. Ventilation

(1)

Connection to a chimney

n

Minimum recommended distance

Do not obstruct the air inlets in the room (even partially).

The compulsory cross section of aeration vents in the premises in

which the boiler is installed must comply with the standards current

in the country.

CAUTION

In order to avoid damage to the boiler, it is necessary to

prevent the contamination of combustion air by chlorine

and/or fluoride compounds, which are particularly

corrosive. These compounds are present, for example, in

aerosol sprays, paints, solvents, cleaning products,

washing products, detergents, glues, snow clearing salts,

etc. Therefore:

15/03/2016 - 300026081-001-08

4 Do not pull in air evacuated from premises using such

products: hairdressing salons, dry cleaners,

industrial premises (solvents), premises containing

refrigeration systems (risk of refrigerant leakage),

etc.

4 Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded

by such chloride or fluoride compounds, the

contractual guarantee cannot be applied.

Forced flue connection

n

If the discharge of combustion gases and the intake of combustive air

are done using a concentric flue, ventilation of the boiler room is only

necessary if a mechanical connector is fitted to the gas supply (as per

the description in the DTU 61.1 standard).

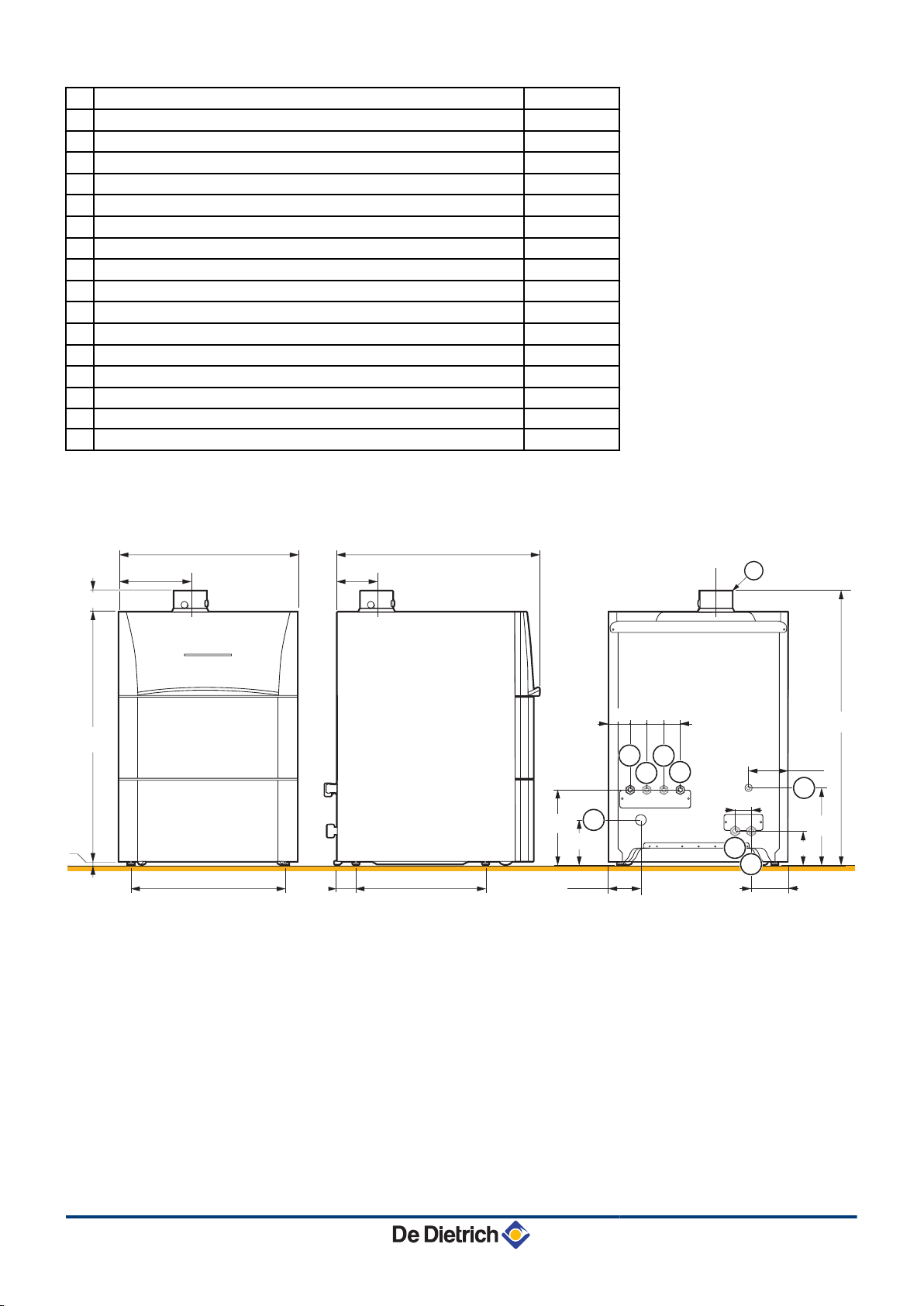

5.3.4. Main dimensions

Key

n

21

C003076-C

600

520 436

844

918

240

74

251

105,5

128,5

70

57

55

55

55

112

150

254

680

132

1

5

6

7

8

2

3

4

121,5

(1)

16

61

5. Installation AGC 10/15 AGC 15 AGC 25 AGC 35

Direct heating circuit return G¾"

A

Direct heating circuit flow G¾"

Z

Gas supply G1/2"

E

Condensates discharge - PVC pipe Ø 24x19 mm

R

Primary return independent DHW tank - Package JA10 (option) G¾"

T

Primary flow independent DHW tank - Package JA10 (option) G¾"

Y

Heating flow circuit with mixing valve - Package JA6 / JA7 (option) G¾"

U

Heating return circuit with mixing valve - Package JA6 / JA7 (option) G¾"

I

Domestic cold water inlet G¾"

P

Domestic hot water outlet G¾"

a

DHW circulation loop return - Pipe G¾"

z

DHW drain valve (on the front of the DHW tank) ext. Ø 14 mm

e

Primary solar coil inlet ext. Ø 18 mm

r

Primary solar coil outlet ext. Ø 18 mm

t

Air/flue gas connection Ø 60/100 mm

y

(1) Adjustable feet 0 to 20 mm

Boiler only

n

22

15/03/2016 - 300026081-001-08

M002517-B

1408

520

723

70

55

245 70

167

816

715

4

1482

598

818

3

680

132

600

240

74

105,5

87

300

128,5

40

121,5

680

(2)

1 2

7

8

11

10

13

12

436

16

61

AGC 10/15 AGC 15 AGC 25 AGC 35 5. Installation

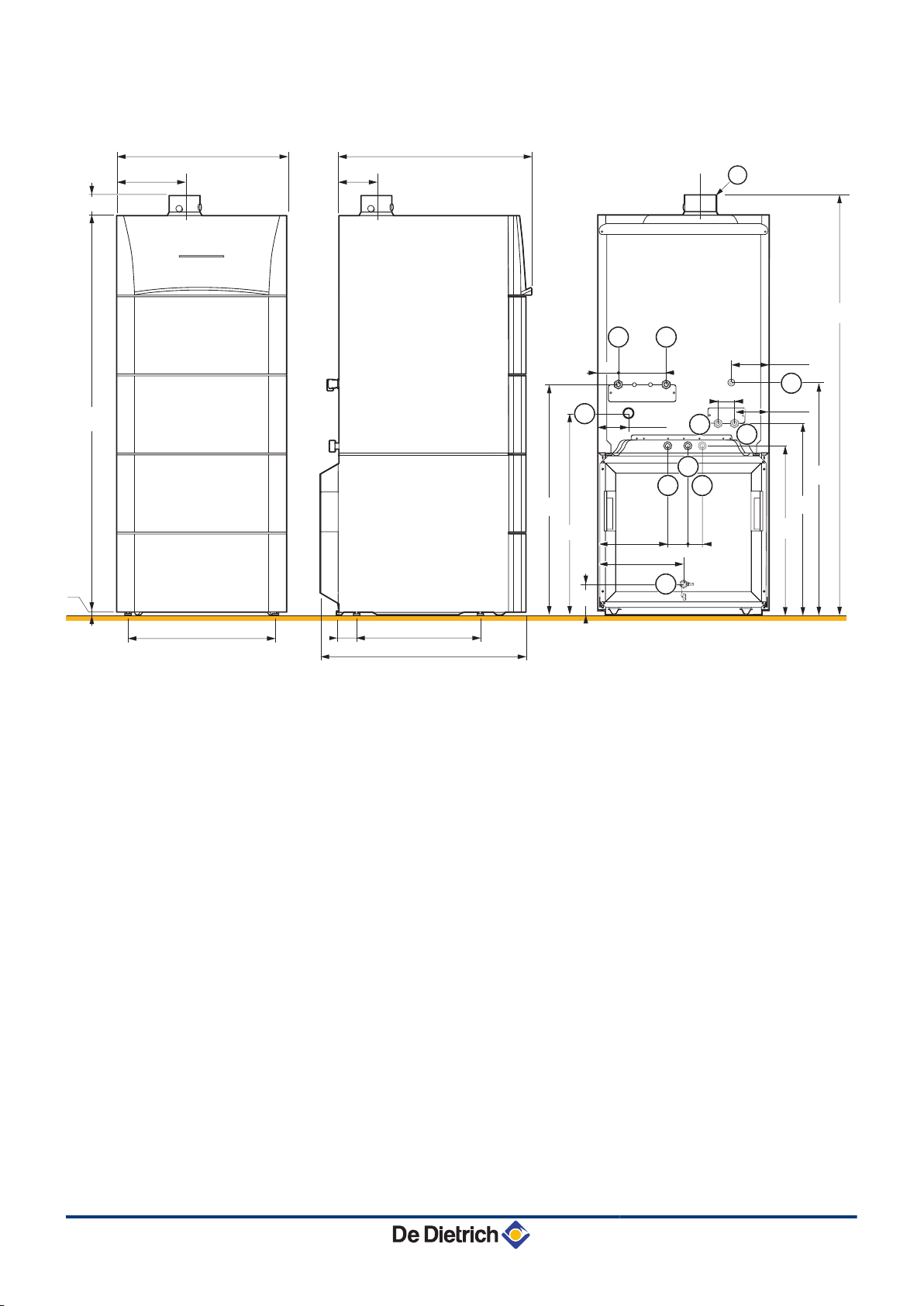

Boiler with 100HL type domestic hot water tank

n

15/03/2016 - 300026081-001-08

23

M002518-B

520

723

70

55

245 70

40

167

4

3

680

132

600

240

74

105,5

87

300

128,5

121,5

(2)

1 2

7

8

11

10

13

436

12

1688

1762

1098

1096

994

956

880

16

61

M002519-D

245 70

10

11

12

520

723

87

300

(2)

13

600 600

520 436

844

917,5

240

74

920

251

105,5

128,5

70

55

167

112

150

254

680

132

1

5

6

7

8

2

3

121,5

(1)

4

16

5. Installation AGC 10/15 AGC 15 AGC 25 AGC 35

Boiler with 160SL type domestic hot water tank

n

24

15/03/2016 - 300026081-001-08

M002520-B

520

723

70

55

245 70

167

4

3

680

132

600

240

74

105,5

88

300

128,5

121,5

(2)

1 2

7

8

11

10

13

16

43661

1378

1375

1274

1160

1116

1236

40

12

157

115

1968

2042

14

15

M002521-C

(2)

600 600

520 520 436

844 1201

918

240

74

251

1116

1160

18,5

105,5

128,5

55

112

150

254

680

723

132

7

8

3

4

121,5

(1)

70

167

1

2

245

157

115

70

40

88

300

13

11

10

12

14

15

5

6

16

AGC 10/15 AGC 15 AGC 25 AGC 35 5. Installation

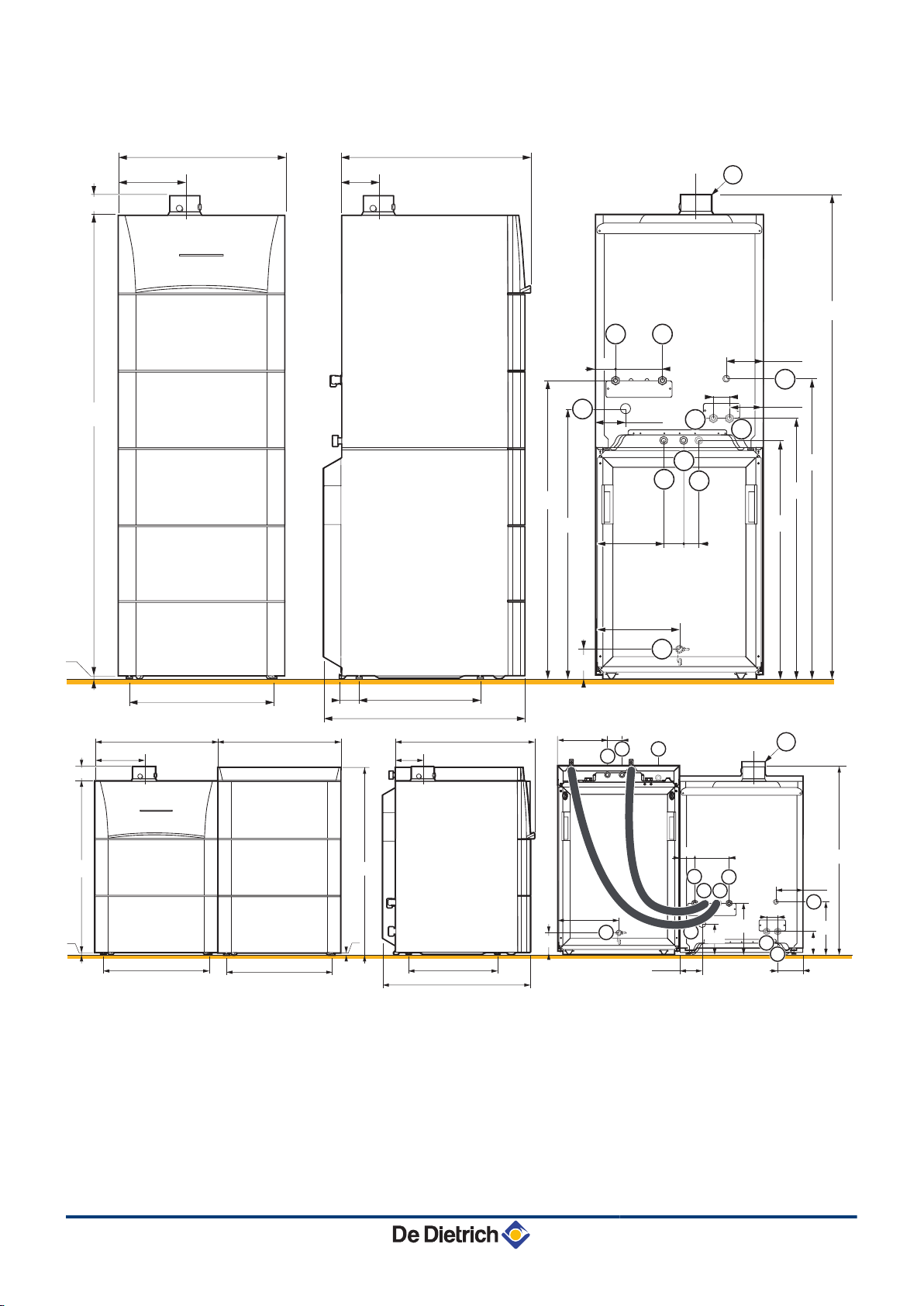

Boiler with 220SHL type domestic hot water tank

n

15/03/2016 - 300026081-001-08

25

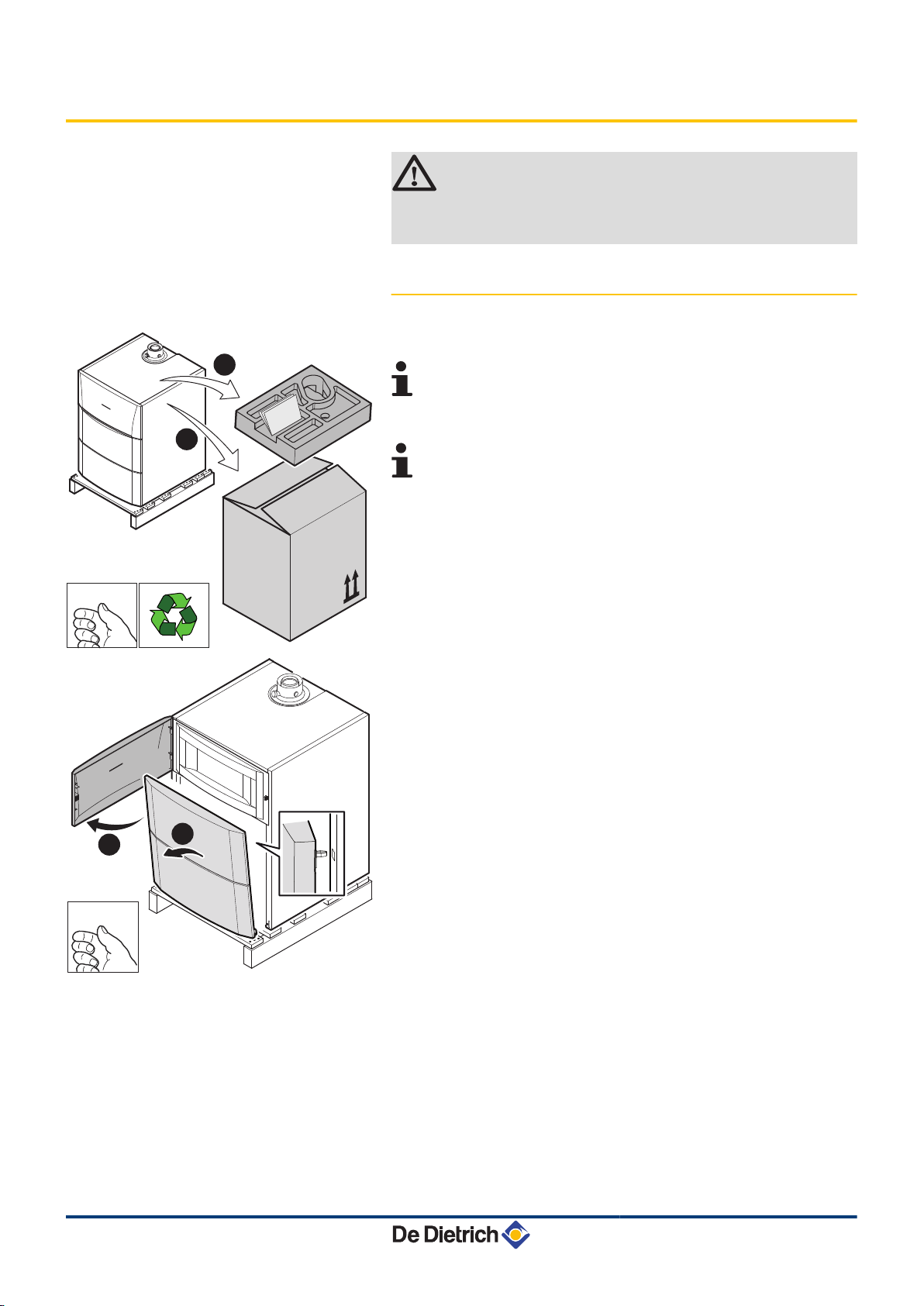

C003109-B

1

2

notice

handleiding

C003110-C

4

3

5. Installation AGC 10/15 AGC 15 AGC 25 AGC 35

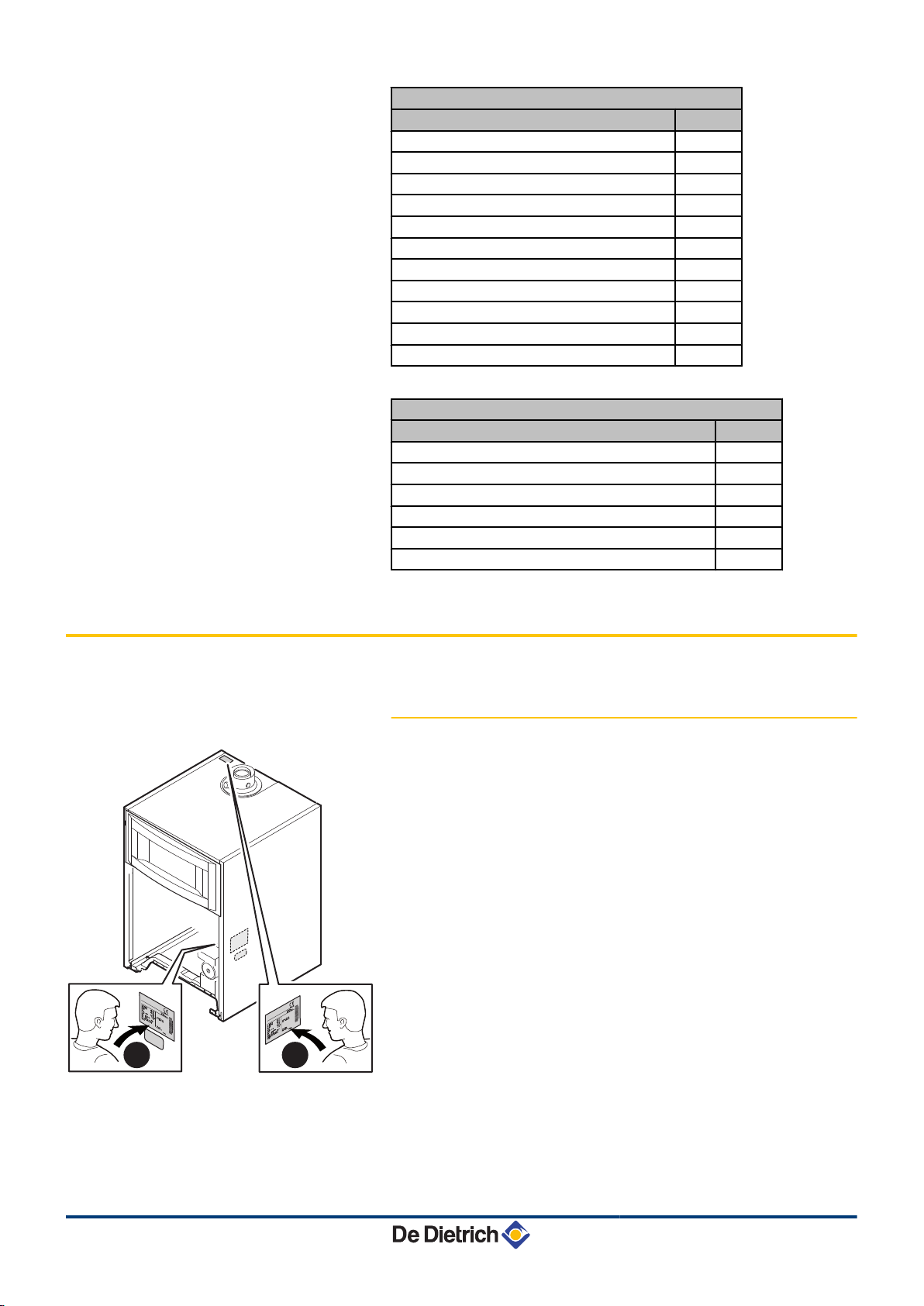

5.4 Positioning the appliance

CAUTION

4 Have 2 people available.

4 Handle the appliance with gloves.

5.4.1. Positioning the boiler on its own

1. Remove the packaging around the boiler.

The boiler is bolted to the pallet.

2. Remove the protective packaging.

The technical documentation is housed in the protective

block.

3. Open the access door on the control panel.

4. Remove the front panel by pulling firmly from both sides.

26

15/03/2016 - 300026081-001-08

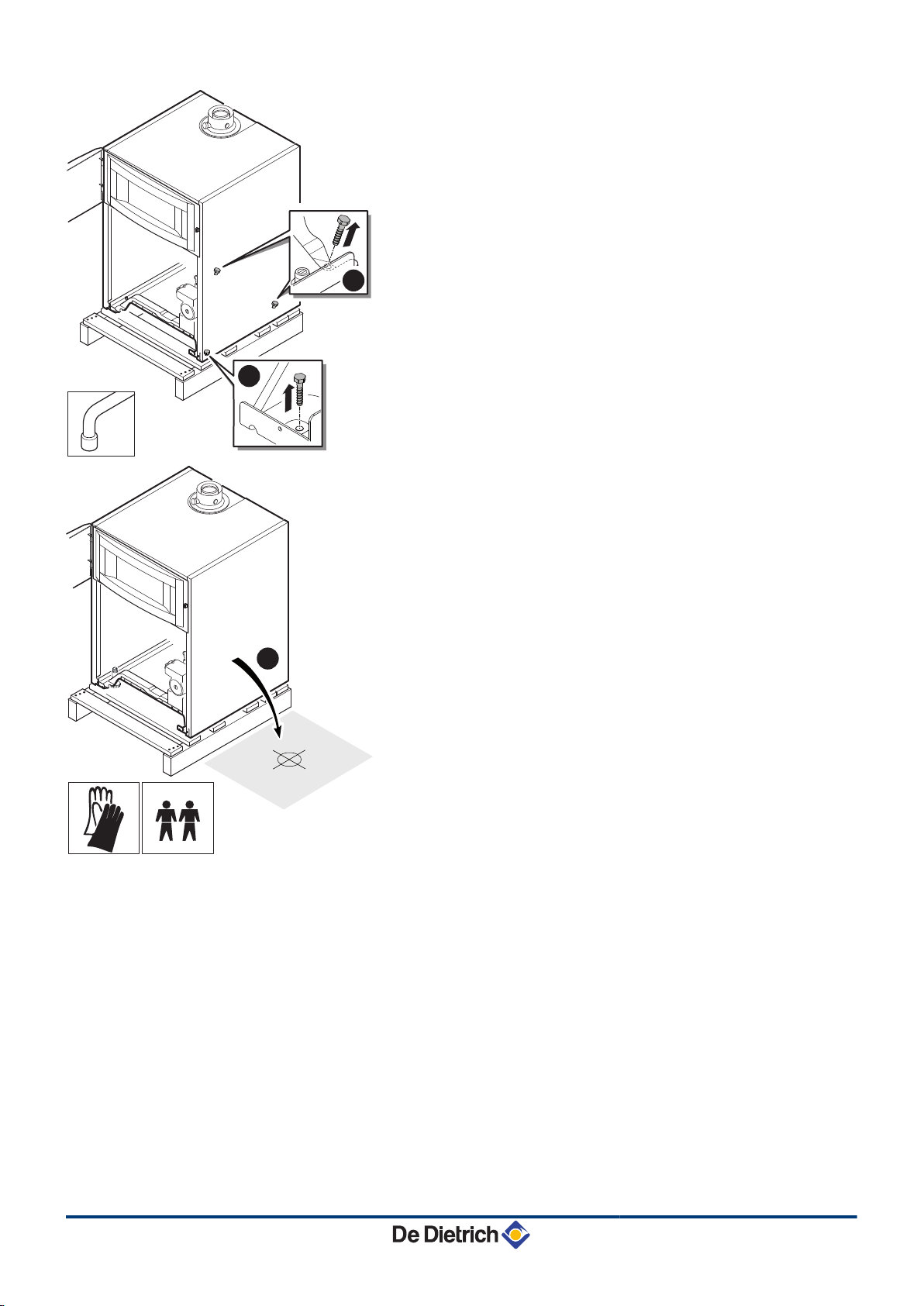

C003111-D

5

5

C003217-C

6

AGC 10/15 AGC 15 AGC 25 AGC 35 5. Installation

5. Remove the retaining screws.

6. Lift the boiler and position it on the ground

15/03/2016 - 300026081-001-08

27

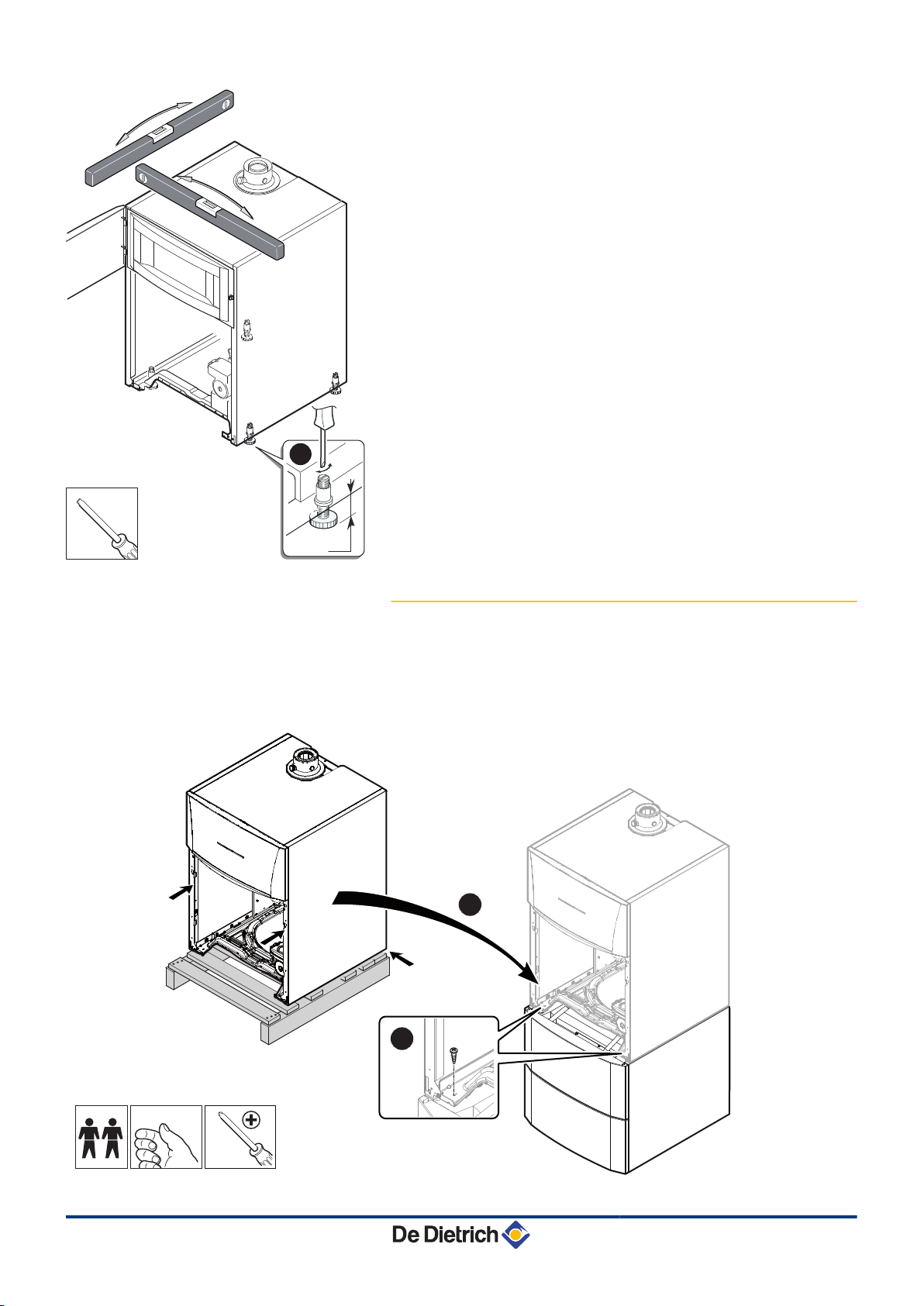

C003078-C

(1)

7

M002522-B

4

3

5. Installation

AGC 10/15 AGC 15 AGC 25 AGC 35

7. Level the appliance using the adjustable feet.

(1) Adjustment range: 0 to 20 mm

8. Refit the front panel.

5.4.2. Fitting the boiler to a DHW tank

1. Put the DHW tank in place.

Refer to the DHW tank’s installation, use and maintenance

¼

instructions.

2. Carry out steps 1 to 6 described above.

See chapter "Positioning the boiler on its own", page 26

¼

3.

28

Position the boiler on the DHW tank.

15/03/2016 - 300026081-001-08

Loading...

Loading...