Page 1

Modular Mining Systems

302395 User’s Guide and Repeater

M/LC Repeaters

Network Design Guide

Part Number 201327

February 2004

Page 2

RESTRICTIVE COVENANT

AND

DISCLAIMER

Copyright © 2004 by Modular Mining Systems, Inc.

Tucson, Arizona, U.S.A.

All rights reserved.

Modular Mining Systems, Inc., makes no representation regarding the fitness, quality, design, condition,

capacity, suitability, or performance of the equipment or of the material or workmanship thereof and/or compliance

of the system with the requirements of any law or regulations, and disclaims all warranties, either express or implied,

including but not limited to any implied warranty of merchantability or fitness for any particular purpose. Modular

Mining Systems, Inc., shall not be responsible for any loss or damage to property or injury or death to persons caused

by any defect or failure in the system hardware and/or software regardless of the form of action, whether in contract

or in tort, including negligence, strict liability, or otherwise. Modular Mining Systems, Inc., is not responsible for any

losses, financial or otherwise, that the customer, purchaser, or end user (hereafter, collectively, user) incurs nor shall

it be liable for any damages whatsoever (including, without limitation, damages for loss of business or investment

profits, business interruption, loss of business information or the like) arising out of the use, interruption in the use

of, or performance of the system hardware and/or software. User expressly agrees to indemnify and hold harmless

Modular Mining Systems, Inc., from and against all claims, damages, losses, and expenses, including but not limited

to: (i) any loss resulting from general or particular requirements of needs of user as defined in user’s originating

purchase order; (ii) any damages from loss of use, loss of data, loss of profits, or loss of business arising out of or in

connection with the performance of system hardware and/or software; (iii) any loss or damage to property or injury

or death to persons proximately resulting from system hardware and/or software, even if entirely due in whole or in

part to negligent acts or omissions of Modular Mining Systems, Inc.; and (iv) attorney’s fees and costs.

The information described in this document is furnished as proprietary information and may not be copied or sold

without the written permission of Modular Mining Systems, Inc.

Trademarks

The Modular distinctive font, PowerView, ProVision, and WebReports are trademarks of Modular Mining Systems,

Inc.

The Modular logo, DISPATCH, MasterLink, and IntelliMine are registered U.S. trademarks of Modular Mining

Systems, Inc.

All other brand names and product names used in this book are trademarks, registered trademarks, or trade names of

their respective holders.

Page 3

Contents

1. Introduction.......................................................................................................1

2. Design Principles of a M/LC Repeater Network............................................3

2.1 General Hardware Selection Guidelines..........................................................................3

2.1.1 M/LC Infrastructure Hardware...............................................................................................3

2.1.2 Data Rates and Range.............................................................................................................4

2.1.3 M/LC Point-to-Point Links.....................................................................................................4

2.1.4 Temperature Related Decisions..............................................................................................4

2.1.5 Sizing a Solar Repeater ..........................................................................................................4

2.1.6 Lightning Protection...............................................................................................................5

2.2 General Coverage Guidelines.......................................................................................... 6

2.2.1 Locations, Repeater Quantities, and Antennas.......................................................................6

2.2.2 Location Considerations and Antenna Selection....................................................................6

2.2.3 Overall System Throughput Design Considerations ..............................................................7

2.2.4 Channel Selection...................................................................................................................7

2.3 The 302395 Repeater Electronics Unit............................................................................ 8

2.3.1 Approved Antennas................................................................................................................8

2.4 FCC Statements ...............................................................................................................9

3. Antenna Evaluation.........................................................................................11

3.1 Antenna Characteristics................................................................................................. 12

3.1.1 Antenna Coverage Patterns ..................................................................................................12

3.1.2 Antenna Gain........................................................................................................................13

3.1.2.1 dBi (Decibels Relative to Isotropic)....................................................................................... 13

3.2 Antenna Types............................................................................................................... 14

3.3 Antenna Patterns............................................................................................................15

3.3.1 Lobes....................................................................................................................................15

February 2004 iii

Page 4

302395 User’s Guide and Repeater Network Design Guide

3.3.2 Relative Gain........................................................................................................................16

3.3.2.1 dB (Decibels) .........................................................................................................................16

3.3.2.2 Half Power Points (—3 dB Points) ........................................................................................17

3.3.3 Tilt Angle (Down Tilt) .........................................................................................................19

3.3.3.1 Vertical Coverage by Antenna Type......................................................................................19

3.4 Signal Patterns and Gain Characteristics for Antenna Types........................................20

3.4.1 Omnidirectional Antennas....................................................................................................20

3.4.2 Sector Antennas....................................................................................................................21

3.4.3 Parabolic Antenna ................................................................................................................22

3.5 Adjusting, Changing, or Relocating an Antenna........................................................... 23

3.5.1 Understanding the Requirements of Your Network.............................................................23

3.5.2 Recording Antenna Characteristics......................................................................................24

3.6 Obtaining Additional Guidance.....................................................................................24

4. Moving an Access Point..................................................................................25

4.1 Selecting a New Access Point Site................................................................................ 25

4.2 Relocation Procedures ................................................................................................... 25

4.3 Verifying Radio Coverage.............................................................................................25

5. Cisco Wireless Access Point Support ............................................................27

5.1 Cisco Initial Setup .......................................................................................................... 27

5.1.1 Site First Steps......................................................................................................................27

5.1.2 WAP Monitor.......................................................................................................................27

5.1.3 MasterLink/OMS/Dispatch Integration................................................................................30

5.2 Troubleshooting.............................................................................................................31

5.2.1 The System Log....................................................................................................................31

5.2.2 Association Page ..................................................................................................................31

5.2.3 Link Test...............................................................................................................................32

5.2.4 Ping test................................................................................................................................33

5.3 Serial Port Configuration...............................................................................................34

5.3.1 Initial Configuration (Serial Port).........................................................................................34

5.3.1.1 Connect PC to MasterLink/Cicso Repeater Hub.................................................................... 34

5.3.1.2 Hyper Terminal Setup ............................................................................................................34

5.3.1.3 Express Setup.........................................................................................................................36

5.4 Standard Configuration via HTTP................................................................................. 37

iv February 2004

Page 5

Contents—Continued

5.4.1.1 Ethernet connected.................................................................................................................38

5.4.1.2 Wireless..................................................................................................................................38

5.4.1.3 WEP ....................................................................................................................................40

5.4.1.4 Setting the Channel ................................................................................................................43

5.5 Password Recovery........................................................................................................ 43

6. Appendix A — 302395 Connection Diagram................................................45

Revision History ..............................................................................................47

List of Figures

Figure 1 Antenna Types..............................................................................................................................11

Figure 2 Antenna Patterns - Horizontal and Vertical Components.............................................................12

Figure 3 Typical Horizontal Patterns ..........................................................................................................14

Figure 4 Lobes in Antenna Pattern..............................................................................................................15

Figure 5 Antenna Pattern dB Scale .............................................................................................................16

Figure 6 Half Power Points.........................................................................................................................17

Figure 7 Horizontal and Vertical Lobes......................................................................................................18

Figure 8 Antenna Tilt Angle (Down Tilt) ...................................................................................................19

Figure 9 Omnidirectional Antennas............................................................................................................20

Figure 10 Sector Antennas..........................................................................................................................21

Figure 11 Parabolic Antenna.......................................................................................................................22

Revision A: February 2003 v

Page 6

302395 User’s Guide and Repeater Network Design Guide

vi February 2004

Page 7

1. Introduction

The Modular Mining Systems M/LC radio network provides high-quality, low-maintenance

communications to all mine operating areas. (M/LC stands for “MasterLink® Cisco” and is based on an

Ethernet Bridge from Cisco Systems.)

To keep the system working optimally, you can monitor performance reports and graphical displays.

Furthermore, equipment operators will inform you of any system degradation.

This document discusses the following topics:

• how to design an M/LC Repeater Network (i.e. infrastructure). Network design includes hardware

options, coverage issues, details on the 302395 Cisco electronics unit, and all FCC requirements

• how to select the appropriate antenna for each repeater location

• how to conduct a mobile access point relocation, and how to verify radio coverage at the new

location

• how to configure the 302395 Cisco electronics unit using configuration software

February 2004 1

Page 8

302395 User’s Guide and Repeater Network Design Guide

2 February 2004

Page Intentionally Left Blank

Page 9

2. Design Principles of a M/LC

Repeater Network

2.1 General Hardware Selection Guidelines

When selecting hardware components of a M/LC Repeater Network, there are several important issues

that must be addressed.

2.1.1 M/LC Infrastructure Hardware

Because Cisco bridges and access point have their own proprietary routing algorithms that dictate how to

make the “wireless” hops back to the hardline network, they can not be mixed with standard MasterLink

(M/L) repeaters.

IMPORTANT: ALL repeaters used in a mine must either be M/L or M/LC, but not a combination of the

two.

All of the mobile equipment in the mine should be standard M/L, and as such, will associate themselves

with one of the M/LC repeaters. As these mobile clients travel through the mine, they may change

associations often with the various M/LC repeaters.

M/LC Repeater Infrastructure includes the following:

• shovels

• base stations

• crusher bays

• mobile and fixed repeaters

Although it is possible for a shovel to be a M/L client instead of a M/LC repeater, it is highly

recommended that they be established as a M/LC repeater. This enables them to provide coverage to

surrounding haul trucks as the shovel digs itself into tights spots where coverage from a regular repeater

site is difficult. Remember, if the part number doesn’t contain an “M/LC” designation, it is not Ciscobased.

The GPS ground station need not be M/LC since its location is determined by other factors not related to

vehicle coverage (such as satellite constellation view, proximity to power, security, or even hardwired

Ethernet). A wireless M/L ground station needs only to associate itself with a M/LC repeater in order to

get its correction data through.

February 2004 3

Page 10

302395 User’s Guide and Repeater Network Design Guide

2.1.2 Data Rates and Range

The M/LC repeater hardware is based on the 802.11b specification and as such supports data rates of

1.0 Mbps, 2.0 Mbps, 5.5 Mbps, and 11.0 Mbps. As the data rate increases, the range deceases. At ½ watt

of output power, the expected ranges are as follows:

DATA RATE ANTENNAS EXPECTED RANGE

2.0 Mbps Two 6 dBi Omnis 8 miles

11.0 Mbps Two 6 dBi Omnis 3 miles

The M/LC Repeater network will always transmit at the highest data rate possible provided there is a

good RF link between the two access points. Therefore, in practically all instances, intra-access point

traffic will be at 11.0 Mbps. However, M/L hardware transmits at 2.0 Mbps, so communications between

clients and the M/LC access points will be at 2.0 Mbps.

2.1.3 M/LC Point-to-Point Links

In a M/LC infrastructure, any point-to-point links must also be Cisco-based. Point-to-point links generally

use the 24.0 dBi dish antennas at each end in order to provide a link for distances up to 24 miles.

Although they could use the same channel as the rest of the mine, it is best if they are on a separate

channel. However, it is even better if they operate completely out of the 2.4 GHz Frequency range in

order to keep the 2.4 GHz 802.11b channels as traffic free as possible. 5.8 GHz point-to-point links are

available from Modular Mining Systems. These Cisco 1400 Aironet links are compatible with a M/LC

repeater infrastructure. They are listed on the MMS intranet site.

2.1.4 Temperature Related Decisions

M/LC mobile repeaters do not ship with batteries because in many instances batteries are obtained locally.

However, if a mine site will be operating from 0 to –20 C for extended periods of time (several days),

then SLA (Sealed Lead Acid) AGM (Absorbed Glass Matte) batteries must be used. These are available

from Modular as part number 105900 and are 12V Size 27 108AH. Repeaters will ship with foam

insulated battery boxes, and the foam must be placed over the vent in cold weather.

If temperatures will be below –20 C for extended periods of time, then NiCad batteries are recommended

in order to avoid “blackout” periods. NiCads are relatively expensive and heavy. 20 NiCad cells provide

205AH at 1.2V each for a total of 448 lbs and 24V. With the battery box they weight over 600 lbs.

M/LC shovel and crusher systems are all LT (Low Temp) already since the mobile hubs used have the

larger Vicor power supplies. All cables are now Xtra-guard 4. Therefore, with respect to a M/LC

infrastructure, the battery configuration is the decision point. Also, see “Sizing a Solar Repeater” below.

2.1.5 Sizing a Solar Repeater

Modular provides a 150 W and a 300 W M/LC mobile solar repeater. The amount of sunlight during the

worst month of the year is what dictates which one should be purchased. A solar analysis may be obtained

by Emailing the city (or Lat / Long) mine location information to Modular. This analysis will estimate the

performance of each system during each of the 12 months of the year, and will include the optimum angle

of solar panel tilt. It is very important that the panels be tilted at this angle during installation and facing

perfectly South (if in Northern Hemisphere) or perfectly North (if in Southern Hemisphere).

In the rare case of excellent sunlight but constant colder temperatures (0 to –20 C), such as at very high

elevations, four SLA AGM batteries should be used in a 150 W mobile repeater. By design, usually only

4 February 2004

Page 11

Design Principles of a M/LC Repeater Network

two batteries are used with a 150 W repeater and four with a 300 W system, but you can always choose to

install four batteries in a 150 W system. (The battery box holds four.)

2.1.6 Lightning Protection

All M/LC repeaters come with some lightning protection. There are Polyphasors on the GPS and RADIO

RF inputs into the battery box. Also, power from the solar panels runs into a Delta lightning arrestor. All

chassis ground wires connect to one of the bolts at the base of the mast. However, the repeater uses no

lightning diverter at the top of the mast, nor does it use ground straps, or ground stake/rods.

If lightning is a concern at your installation, you can purchase the 302510 Lightning Protection Option

Kit from Modular for each mobile repeater. This kit includes the diverter at the top of the mast, ground

braids, copper straps, and a ground rod.

February 2004 5

Page 12

302395 User’s Guide and Repeater Network Design Guide

2.2 General Coverage Guidelines

Before designing a M/LC infrastructure, review the following general rules.

2.2.1 Locations, Repeater Quantities, and Antennas

Location Description

PITS

HAUL

ROADS

REPEATERS

SHOVELS

It is always desirable to have triple coverage inside of deep pits. Three repeaters

positioned around the edge at geographically different locations is recommended

(roughly 120 degrees apart). However, they also must have a clear line-of-sight to

other repeaters so there is a trade-off to be made between visibility to other

repeaters, and view of the pit. The vertical beamwidth of the antenna must be enough

to cover into the pit from the edge. Although a omni (or sector) antenna can be tilted

downward up to 10 degrees into the pit to aid in this endeavor, the other line-of-sight

repeaters must remain in the coverage pattern of the antenna (which would be tilted

up off the backside).

It is desirable to have right side and left side coverage although this is not always

possible.

Ideally, each repeater would provide coverage over a selected area of the mine while

at the same time, having a view of at least two other “upstream” repeaters.

“Upstream” repeaters are access points that must be used in order to reach a hardwired bridge (or zero-hop) node. Minimizing the number of required “hops” is

important in order to maximize bandwidth (i.e. maximize the amount of traffic). The

more “zero-hop” (i.e. direct wired) repeaters that are available, the better the system

throughput will be.

Shovels are the most difficult area to cover. That is why M/LC shovel systems have

been provided in order to provide the repeater function. A point-to-point link can be

used to increase the number of effective zero-hop sites. This aids greatly in covering

haul trucks near the shovel. When a 6 dBi omni is mounted on the shovel above the

cab on the six-foot mast, a good view of other repeater site(s) should be obtained.

CRUSHERS,

OTHER

FIXED

LOCATIONS

Fixed buildings are usually good locations for repeaters since they provide AC

power so that a lower cost AC repeater may be used. Many times the top of the roof

provides a good high coverage location. If Ethernet is available at the building, then

a “wired” “zero-hop” is available.

2.2.2 Location Considerations and Antenna Selection

Section 3 in this manual provides details of the antenna patterns and gains. Each repeater location must

have an appropriate antenna selected in order to fulfill the coverage goals of that location. Typically

around the edges of the mine property, sectors are used in order to keep the RF energy on the mine

property (which also maximizes the range at that location). Sector antennas are also used against large

structures if an omni is not possible at the very top. Typically, omni antennas are used in the middle of the

mine, on rooftops, on shovels, and other high points. Dishes are only used for point-to-point links.

Always make sure that no solid reflective objects are close to an antenna and in its beam pattern. This will

result in high energy reflections which will cause null (i.e. dead areas) in you desired coverage area.

6 February 2004

Page 13

Design Principles of a M/LC Repeater Network

2.2.3 Overall System Throughput Design Considerations

Even though intra-repeater (or intra-access point) traffic is at 11.0 Mbps, the “system” bandwidth or

throughput is reduced in direct proportion to the number of wireless access points (or “hops”) that a

message must be routed though in order to get to a bridge (an access point [AP] that is hardwired to the

LAN). Therefore, it is desirable to have as many “zero-hop” or “hardwired” APs as possible. Therefore,

always take advantage of all hardwired LAN locations as possible in order to install an AP. Good

examples of this are crushers, truck shops, and dispatch buildings with are often hardwired to the LAN

via fiber optics or even microwave links.

If a mine site is very large, and the hardwired Ethernet is only available at one location (which may not

even be a good site for an access point), then a point-to-point link should be used in order to construct

another “zero-hop” or “wired” equivalent access point. This is important to minimize bottlenecks and

avoid excessive “message hopping” though a repeater network. Although one of the 802.11b channels

may be used for this, often it is best to use a completely different frequency band in order to minimize 2.4

GHz traffic. The Cisco 1400 Aironet Bridges are highly recommended for this.

2.2.4 Channel Selection

802.11b LAN networks can use 11 channels of operation. These range from 1 (2412 MHz) to 11 (2462

MHz) and are separated by 5 MHz increments. However, because the occupied spectrum of each channel

is approximately 20 MHz, only three of these channels should ever be used at one time. Due to the RF

characteristics of the radio hardware, channel 1 almost always contains the most output power (and

slightly better performance). Assuming 0.3 dB per channel reduction, typically, channel 11 has 1.5 dB

less output power than channel 1. If good coverage and bandwidth can be achieved using only one

channel it should be channel 1. If two channels are decided on then it should be channel 1 and channel 11

since frequency separation is far more important than output power in this case. If three channels are to be

used, then channels 1, 6, and 11 would be used.

February 2004 7

Page 14

302395 User’s Guide and Repeater Network Design Guide

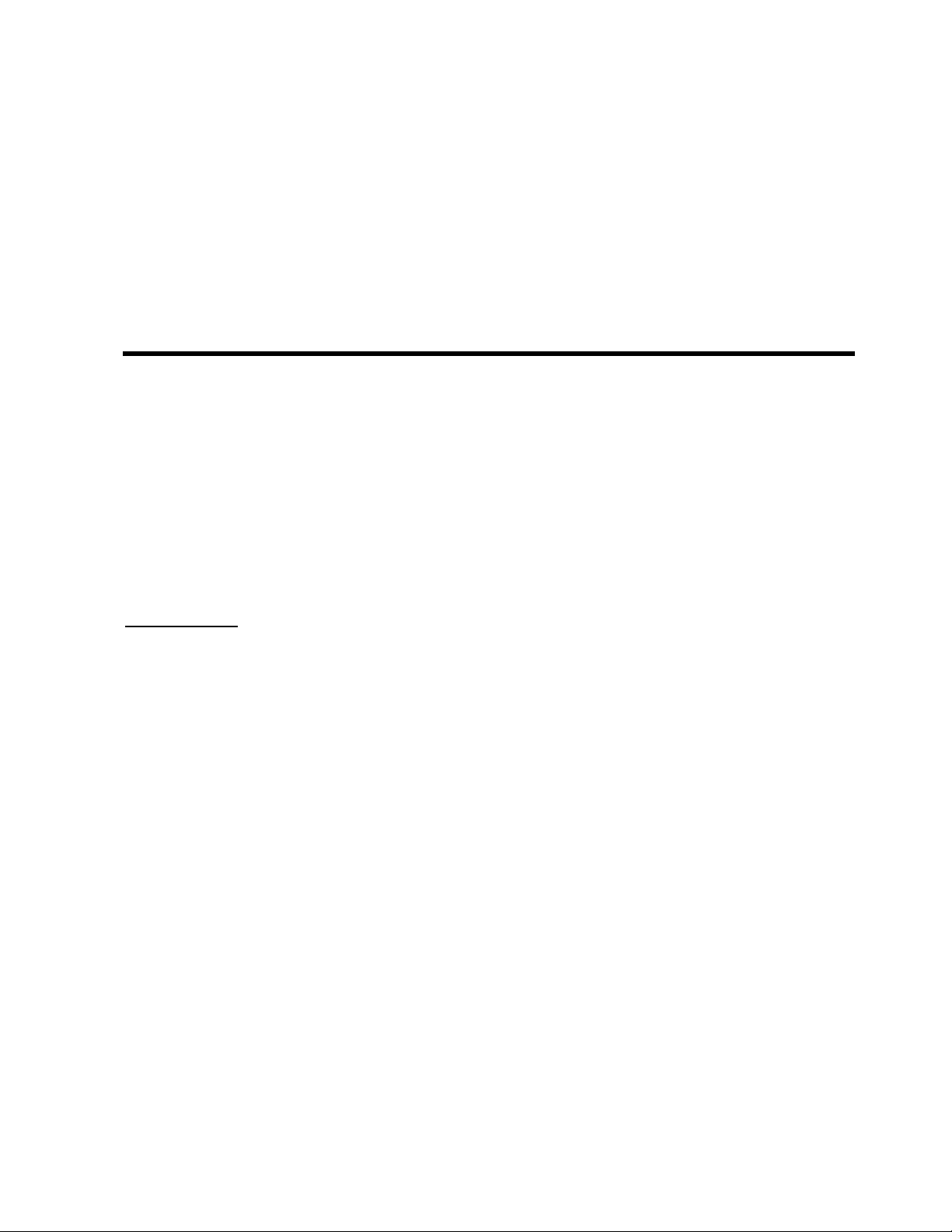

2.3 The 302395 Repeater Electronics Unit

The common element to all M/LC repeater infrastructure installations is the 302395 M/LC Electronics

unit. This contains the Cisco BR350 Bridge, the ½ bi-directional power amp, the SKII GPS, and the

MMS power and interface circuit board. When using this unit always following these guidelines:

• Keep the unit out of direct sunlight.

• Always provide lightning protection on the GPS and RADIO RF connectors.

• Always follow the “System Config” diagrams when setting up an installation.

• Use only approved antennas and power settings listed below.

2.3.1 Approved Antennas

Only five antennas are approved by the FCC. No other antennas may be used with this system. These

antennas are the following:

MMS

PN

105831 Omni 2.5 dBi gain ½ wave stub 360 deg 60 deg 50 dBm

105342 Omni 6.0 dBi gain black foamed

105920 Sector 10 dBi gain 90 deg 35 deg 50 dBm

105708 Sector 13 dBi gain 120 deg 16 deg 50 dBm

105735 Dish 24 dBi high gain 9 deg 9 deg 5.0 dBm

The patterns and usage of these antennas is covered in the next section.

ANTENNA

DESCRIPTION

(hardened)

HORIZONTAL

BEAMWIDTH

360 deg 25 deg 50 dBm

VERTICAL

BEAMWIDTH

POWER

SETTING

8 February 2004

Page 15

Design Principles of a M/LC Repeater Network

2.4 FCC Statements

MANDATORY SAFETY INSTRUCTIONS TO INSTALLERS AND USERS

1. Use only antennas supplied by Modular Mining Systems or dealer.

2. Antenna Minimum Safe Distance: 20 cm.

3. Antenna Gain: Zero dBd referenced to a dipole.

The Federal Communications Commission has adopted a safety standard for human exposure to RF

(radio frequency) energy which is below the OSHA (Occupational Safety and Health Act) limits.

Antenna Mounting

The antenna supplied by Modular Mining Systems or dealer must not be mounted at a location such that

during radio transmission, any person or persons can come closer than the above minimum safe distance

to the antenna, i.e. 20 cm.

To comply with current FCC RF exposure limits, the antenna must be installed at or exceeding the

minimum safe distance shown above, and in accordance with the requirements of Modular Mining

Systems.

Base Station

Installation

Mobile Repeater

Installation

Mine Vehicle

Installation

The antenna should be fixed-mounted on an outdoor permanent structure. RF

exposure compliance must be addressed at the time of installation.

The antenna must be mounted on a mast that is 12 feet or higher so that RF

exposure compliance is satisfied.

The antenna should be fixed-mounted on the vehicle facing away from the

vehicle such that a person is not able to move in front of the antenna. RF

exposure compliance must be addressed at the time of installation.

Antenna Substitution

Do not substitute any antenna for the one supplied or recommended by Modular Mining Systems. You

may be exposing person or persons to harmful radio frequency radiation. You may contact Modular

Mining Systems for further instructions.

WARNING: Maintain a separation distance from the antenna to person(s) of at least 20 cm.

You, as the qualified end-user of this radio device, must control the exposure conditions of bystanders to

ensure the minimum separation distance (above) is maintained between the antenna and nearby persons

for satisfying RF Exposure compliance. The operation of this transmitter must satisfy the requirements of

Occupational / Controlled Exposure Environment, for work-related use. Transmit only when person(s) are

a least the minimum distance from the properly installed, externally mounted antenna.

Changes or Modifications

CAUTION: changes or modifications not expressly approved by Modular Mining Systems could void

the user's authority to operate the equipment.

February 2004 9

Page 16

302395 User’s Guide and Repeater Network Design Guide

10 February 2004

Page Intentionally Left Blank

Page 17

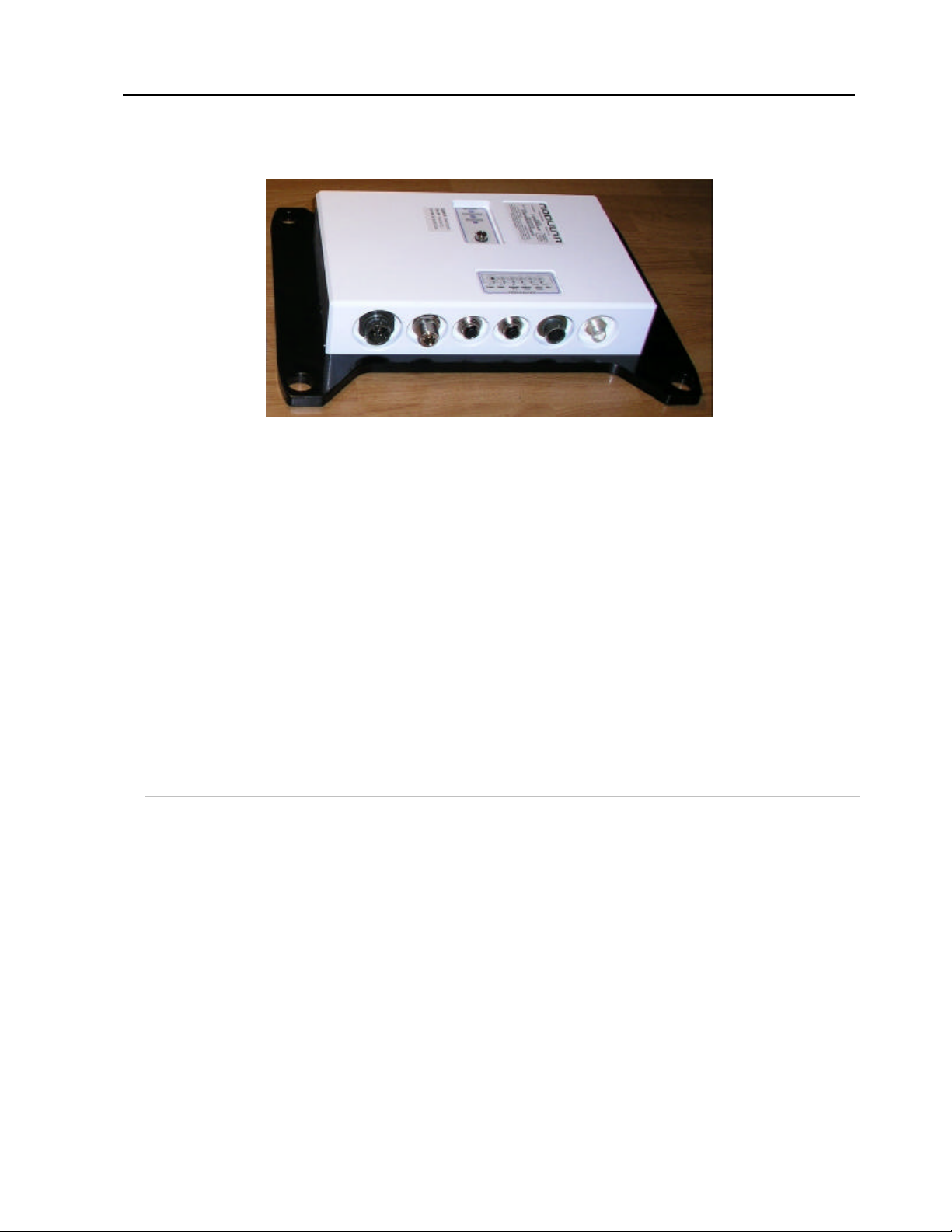

3. Antenna Evaluation

As part of the initial system design, Modular Mining Systems commissions an RF propagation study to

create a custom radio network for your mine. This design specifies

• the number and location of access points

• the type of antenna on each access point

• the azimuth, height, and elevation of each antenna

Antennas are selected and positioned to provide customized coverage so that every part of the active mine

area is serviced by at least two access points.

Omnidirectional

2.5 dBi

Omnidirectional

6 dBi

5 Antenna Types

Sector

10 dBi

Sector

13 dBi

Parabolic

24 dBi

Figure 1 Antenna Types

February 2004 11

Page 18

302395 User’s Guide and Repeater Network Design Guide

3.1 Antenna Characteristics

Antennas have three main characteristics:

horizontal coverage pattern

vertical coverage pattern

gain

(horizontal beamwidth)

(vertical beamwidth)

(signal amplification power)

3.1.1 Antenna Coverage Patterns

Antennas transmit and receive signals in a specific pattern; each pattern has a horizontal and vertical

component. (See Figure 2.)

Figure 2 Antenna Patterns - Horizontal and Vertical Components

12 February 2004

Page 19

Antenna Evaluation

3.1.2 Antenna Gain

Gain is the ability of an antenna to amplify received and transmitted signals. Numerically, it is the

comparison between an antenna’s maximum signal strength and the signal strength of a laboratory

standard.

3.1.2.1 dBi (Decibels Relative to Isotropic)

An antenna’s gain specification normally appears as a decibel value. The decibel scale is a logarithmic

scale used for representing comparative signal strengths; it is the ratio of one signal compared to a second

signal.

When describing antenna gain, “decibel” is abbreviated as “dBi” (decibels relative to isotropic).

“Relative” signifies that this measurement is a comparison between the antenna’s signal and a second

signal, and “isotropic” indicates that the second signal is the theoretical ideal laboratory standard.

For example, the network uses two different omni antennas having gains of 2.5 dBi and 6.0 dBi, and two

different sector antennas with gains of 10 dBi and 13 dBi.

Note: You will also see “decibel” abbreviated as “dB” (without the “i”). “dB”

signifies that a signal’s strength is being compared to the strength of a second

signal that is not the laboratory standard. For example, “dB” is used when

describing the relative strengths of a signal in different parts of a signal pattern.

(See section 3.3.2.1.)

February 2004 13

Page 20

302395 User’s Guide and Repeater Network Design Guide

3.2 Antenna Types

Antennas are also classified by their characteristic horizontal pattern. The system uses three

classifications of antennas:

• omnidirectional (“omni”) antennas

• sector antennas

• parabolic antennas

Figure 3 shows general horizontal beamwidth patterns for these antenna types.

Figure 3 Typical Horizontal Patterns

Omnidirectional antennas transmit and receive signals equally well in all directions horizontally.

Sector antennas direct and receive most of their signals in one sector horizontally.

Parabolic antennas focus most of their transmission and reception signal in a small horizontal region.

You can visualize an antenna’s pattern as being similar to light emitted from a light bulb:

Antenna Type pattern similar to pattern description

omnidirectional bare light bulb light shines in all directions

sector floodlight light floods an area

parabolic spotlight light focused into narrow beam

14 February 2004

Page 21

Antenna Evaluation

3.3 Antenna Patterns

Antenna patterns have three main components:

• lobes

• relative gain

• tilt angle

3.3.1 Lobes

Antennas do not radiate and receive signals equally well in all directions. When depicted graphically, this

results in a pattern that has lobes in it.

Figure 4 Lobes in Antenna Pattern

Figure 4 shows the top view, or horizontal component, of an antenna’s radiation pattern. As you move

around the antenna, the signal strength changes — the farther a lobe extends from the center of the circle,

the stronger the signal is in that direction.

February 2004 15

Page 22

302395 User’s Guide and Repeater Network Design Guide

3.3.2 Relative Gain

As shown in Figure 4, the strength of an antenna’s signal varies as you move around the antenna’s signal

pattern. You might measure a signal a certain distance from an antenna where the signal is at its peak

power, and then measure the signal at another location the same distance from the antenna where the

signal might be only half as powerful as at the first location.

This difference in signal strength, or gain, is measured in decibels.

3.3.2.1 dB (Decibels)

When comparing antenna gains where one of the signals is not a laboratory standard, “decibel” is

abbreviated as “dB.” (For use of the “dBi” abbreviation for an antenna’s gain specification, see section

3.1.2.1.) Typically, when measuring signal strength in an antenna’s pattern, you compare your readings to

the antenna’s peak signal rather than to a laboratory standard.

A graph of an antenna’s pattern uses the decibel scale to indicate how an antenna’s gain varies across the

pattern.

Figure 5 Antenna Pattern dB Scale

Figure 6 shows a horizontal antenna pattern. The outermost ring signifies 100 percent signal power, or 0

(zero) percent signal loss. The next outermost circle (labeled —5) shows the region where the signal

strength has dropped 5 dB from the original 100 percent (0 dB) level. The next circles show where the

signal has dropped off 10 dB and 15 dB from the 0 dB level.

Note: A negative (—) dB value indicates a reduction in signal power.

Full radio signal power is obtained at 0 degrees, where there is 0 dB signal drop off. As you move to

either side of 0 degrees the signal power starts to drop off, and crosses the —5 dB point, the —10 dB

point, the —15 dB point, and finally the —20 dB point.

16 February 2004

Page 23

Antenna Evaluation

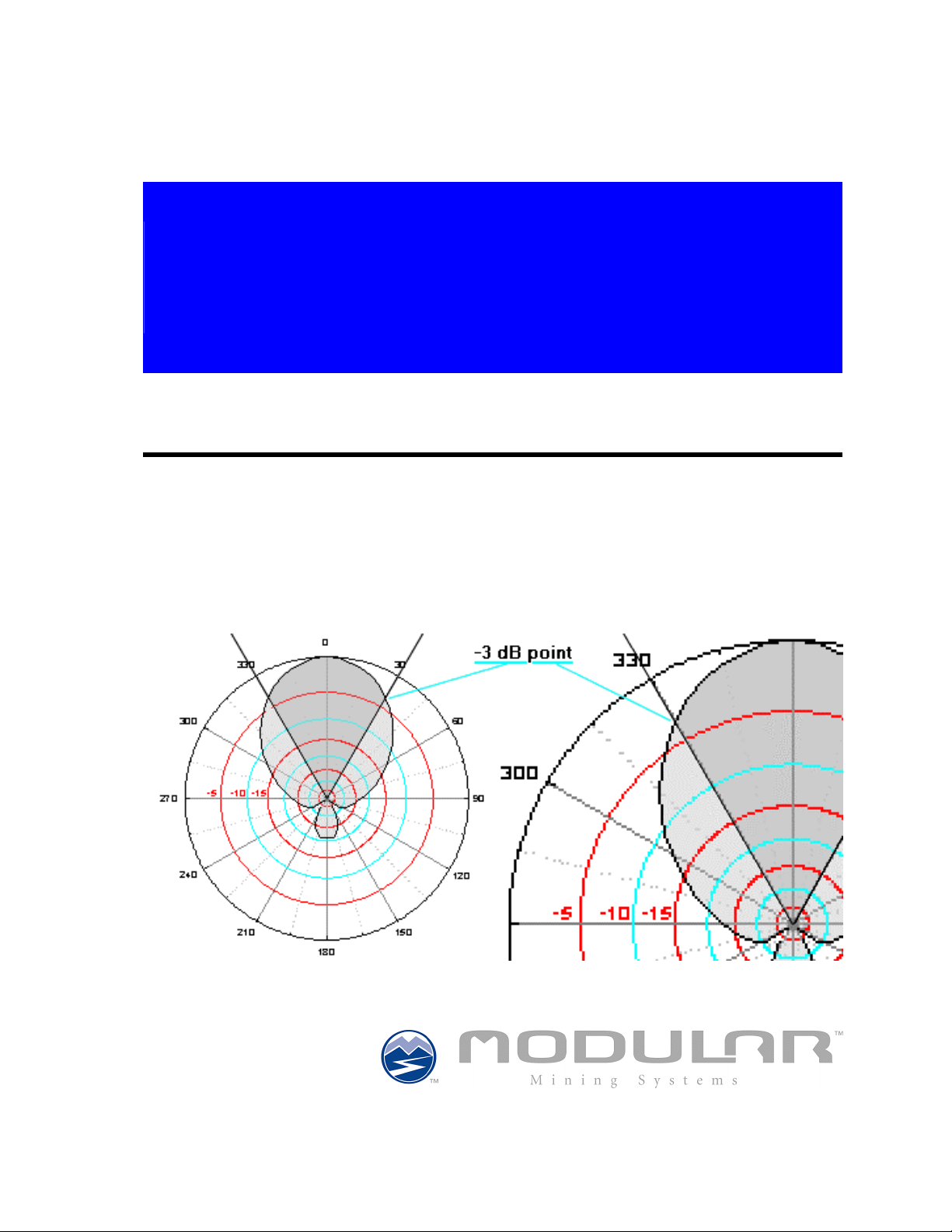

3.3.2.2 Half Power Points (—3 dB Points)

The most important part of an antenna’s signal pattern is that portion where the signal is at least at the 50

percent power level. This level is commonly referred to as the half power point, or the —3 dB point.

The antenna pattern in Figure 6 has its half power points (—3 dB points) at 330 degrees and 30 degrees,

giving this antenna a usable horizontal pattern of 60 degrees.

Figure 6 Half Power Points

This angle between the two half power points is also commonly referred to as the antenna’s beamwidth.

Figure 7 shows sample patterns for three antennas where the half power points are marked by dark lines

extending from the center of the pattern, and the primary part of the pattern is shaded in dark gray.

The antennas have the following horizontal and vertical components:

• Antenna A 180 degrees Horizontal 15 degrees Vertical

• Antenna B 60 degrees Horizontal 30 degrees Vertical

• Antenna C 30 degrees Horizontal 60 degrees Vertical

Note that as the horizontal component decreases, the vertical component increases. This relationship

always exists as long as the antenna’s signal amplification properties, or gain, remains the same.

February 2004 17

Page 24

302395 User’s Guide and Repeater Network Design Guide

180 degrees Horizontal ANTENNA A 15 degrees Vertical

60 degrees Horizontal ANTENNA B 30 degrees Vertical

30 degrees Horizontal ANTENNA C 60 degrees Vertical

Figure 7 Horizontal and Vertical Lobes

18 February 2004

Page 25

Antenna Evaluation

Basically, higher gain antennas concentrate more of the available RF energy into a smaller, more focused

beam. The total amount of energy radiated from each antenna is therefore approximately the same

(assuming that each is equally matched to 50 ohms).

3.3.3 Tilt Angle (Down Tilt)

Figure 7 shows an antenna with a narrow vertical pattern. Because of this pattern, when you use this type

antenna in an open pit mine, you must verify that it provides radio coverage in all areas where you need it.

For example, the left side of Figure 8 shows an access point that is providing coverage to the upper

portion of a pit. Any equipment traveling in that part of the pit can communicate with the access point,

but vehicles near the bottom of the pit will not have reliable radio contact.

The access point on the right side of Figure 8 has its antenna tilted downward. Now equipment near the

bottom of the pit will have an improved signal, but equipment in the upper portion of the pit will have

poor coverage.

Level Antenna Antenna with Down Tilt

Figure 8 Antenna Tilt Angle (Down Tilt)

To change an antenna’s tilt angle, adjust the antenna mounting hardware or alter the antenna’s mounting

position.

Note: For antennas mounted on mobile access points, you can change the tilt of

the antenna by adjusting the vertical height of the outriggers on the trailer.

3.3.3.1 Vertical Coverage by Antenna Type

Certain antenna types are more suitable for covering areas with large vertical elevations.

Parabolic

antennas

Parabolic antennas increase gain at the expense of beamwidth - they

have a narrow horizontal pattern and a narrow vertical pattern. (may

have limited usefulness in the situation shown in Figure 8)

Omnidirectional

antennas

Omnidirectional antennas (“omnis”) have a 360 degree horizontal

pattern, but some have a narrow vertical beamwidth. (may have

limited usefulness in the situation shown in Figure 8)

Sector antennas

Sector antennas have a smaller horizontal coverage pattern than

omnis but provide better vertical coverage and higher gain.

February 2004 19

Page 26

302395 User’s Guide and Repeater Network Design Guide

3.4 Signal Patterns and Gain Characteristics for Antenna Types

This section describes signal patterns and gain characteristics for antennas used in the radio network.

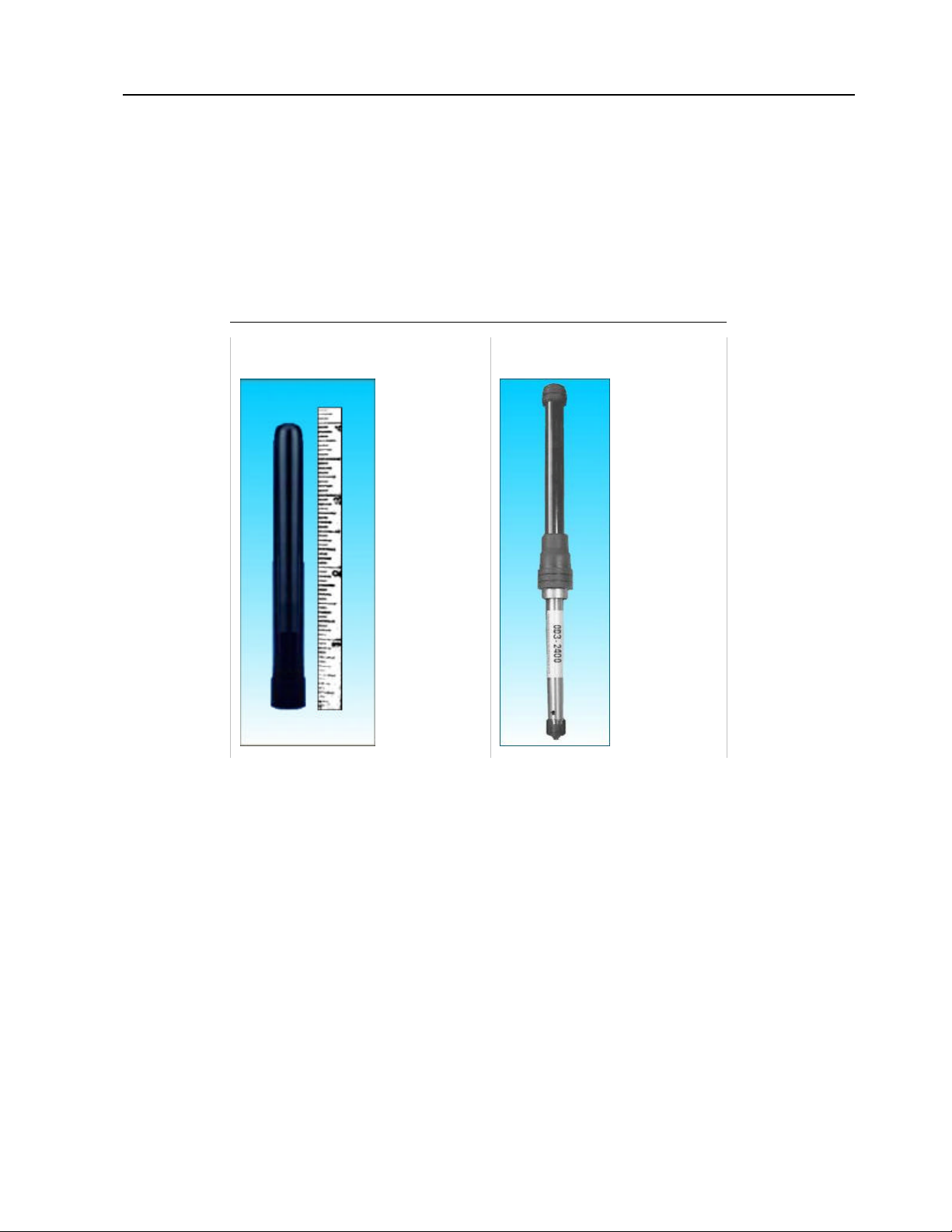

3.4.1 Omnidirectional Antennas

The network uses two omnidirectional antenna models.

Omni Antennas

Low Gain Medium Gain

Figure 9 Omnidirectional Antennas

Characteristics of Omni Antennas

Horizontal

Pattern

360 Deg

Vertical

Pattern

60 Deg

Gain

2.5 dBi

Horizontal

Pattern

360 Deg

Vertical

Pattern

25 Deg

Gain

6.0 dBi

Horizontal Pattern

Vertical Pattern

Gain

20 February 2004

omni-directional antennas provide full 360 degree

coverage

taller higher-gain omni antennas have more narrowly

focused vertical coverage

gain increases as vertical pattern becomes more focused

Page 27

Antenna Evaluation

3.4.2 Sector Antennas

The network uses two sector antenna models.

Sector Antennas

Medium Gain High Gain

Horizontal

Pattern

90 Deg

Vertical

Pattern

35 Deg

Gain

10 dBi

Figure 10 Sector Antennas

Characteristics of Sector Antennas

Medium Gain

High Gain

tall vertical pattern covers deeper pits, but narrower

horizontal pattern provides less horizontal coverage

wider horizontal coverage and higher gain than medium

gain antenna, but narrower vertical pattern requires

antenna tilt for good vertical pit coverage

Horizontal

Pattern

120 Deg

Vertical

Pattern

16 Deg

Gain

13 dBi

February 2004 21

Page 28

302395 User’s Guide and Repeater Network Design Guide

3.4.3 Parabolic Antenna

The network uses one parabolic antenna model.

Parabolic Antenna

Figure 11 Parabolic Antenna

Horizontal

Pattern

9 Deg

Vertical

Pattern

9 Deg

Gain

24 dBi

Characteristics of Parabolic Antennas

Horizontal / Vertical

Pattern

Gain

Ice / No Ice

narrow beams for focused transmission power and

improved reception, with proper antenna aiming

high gain due to focused pattern

ice model designed to withstand freeze/thaw cycles

22 February 2004

Page 29

Antenna Evaluation

3.5 Adjusting, Changing, or Relocating an Antenna

If you have determined that your communications problem is not caused by a hardware malfunction, then

you can evaluate the following antenna options:

• redirecting or changing an antenna on an existing access point

• moving an access point

• adding a new access point

Prior to changing the network, however, you need to review the design of the existing network, and

understand the placement of each access point and the use of each antenna on each access point.

3.5.1 Understanding the Requirements of Your Network

Before adjusting, changing, or relocating an antenna, you should gather the following information:

1. Review the characteristics of the present network.

a. What is its intended coverage area?

b. What are all the signal obstructions (buildings, terrain, etc.) that were considered in the original

design?

c. What is the intended coverage area for each antenna in the network?

2. What conditions have changed that now require an alteration to the original network?

a. Has the original coverage area changed?

b. Are there new signal obstructions (buildings, terrain, etc.)?

c. Which antennas are affected by these changes?

February 2004 23

Page 30

302395 User’s Guide and Repeater Network Design Guide

3.5.2 Recording Antenna Characteristics

When you have isolated your network problem to a single access point, record the specifications for that

access point’s antenna.

What are the characteristics of the antenna on the mobile access point that you are evaluating?

Antenna Characteristics

Antenna type: omnidirectional

sector

parabolic

Antenna gain: __________ dBi

If a sector antenna,

horizontal pattern:

Angle between antenna

and no coverage area:*

What is the angle between the areas of heavy no

*

coverage clusters and the repeater antenna?

Refer to the RF Theory section of the MasterLink Design Manual for detailed information on antenna

types, patterns, and ranges.

90 degrees

120 degrees

__________ degrees

3.6 Obtaining Additional Guidance

Before contacting regional support for assistance you will want to collect all relevant information on the

condition of your network.

When you discover a no coverage area in the mine, answer the following questions:

1. Is the no coverage area in a new mine operations area?

2. Has the mine recently altered the network? (For example, has a mobile access point been moved?)

3. Are the antennas that serve the no coverage area operating properly?

4. Does any structure or terrain block the signal?

5. Does the no coverage area fall within the primary horizontal and vertical signal lobes of the antenna

serving the area?

Note: To measure antenna angles you will need to take simple field measurements

with a protractor or bubble level device.

For major changes in mining operations, you may need to add additional access points. Contact your

regional Modular Mining Systems support office if you think this is the case.

24 February 2004

Page 31

4. Moving an Access Point

Because a mine’s layout is constantly changing, the radio network provides access points that can be

moved when necessary.

4.1 Selecting a New Access Point Site

Mine operations may require that you move an access point a short distance, where the access point, in its

new location, maintains line-of-sight contact with all its associated coverage areas.

Be aware of potential signal blockage problems at the new location. After moving the access point, verify

good radio coverage at the new site. (See section 4.3, “Verifying Radio Coverage.”)

If you must move an access point a long distance, and line-of-sight contact cannot be maintained to all

previous coverage areas, have a radio engineer determine the new site location so that all serviced areas

continue to receive proper coverage.

4.2 Relocation Procedures

Once you have selected a new access point site, refer to Appendix C of the MasterLink Mobile Access

Point Assembly Manual for relocation procedures.

4.3 Verifying Radio Coverage

After you move the access point to its new site you verify proper radio coverage by performing a drive

test in the coverage area.

February 2004 25

Page 32

302395 User’s Guide and Repeater Network Design Guide

26 February 2004

Page 33

5. Cisco Wireless Access Point Support

5.1 Cisco Initial Setup

5.1.1 Site First Steps

To configure the Cisco Aironet 350 Access Point to work at a customer site, you need to do the

following:

1. Configure Ethernet Connected devices as Root Bridges

2. Configure static IP addresses.

3. Configure device names (mpr11, etc).

4. Configure customer specific WEP keys.

You can do all of these things by either connecting with each device via the serial port (see Appendix A —

302395 Connection Diagram), or by connecting them all to a network that has a DHCP server and using

the Web browser based interface.

To use the DHCP/Web interface, connect all devices to the network and power them on. After they have

been powered on for several minutes, you can use the command line query tool (FindWAPM) to report

the IP addresses of all the Access Point parents on the network. The FindWAPM tool queries the network

for the Wireless Access Point Monitors that are built into the repeater box, and reports back what devices

it finds. Once you connect a device, you can use the steps in Appendix B to configure each one.

5.1.2 WAP Monitor

The WAP Monitor is a small computer attached to the Cisco via Ethernet. It has a SK2 GPS receiver as

well as circuitry to monitor temperature and battery voltage. This device has its own MAC and IP

addresses. The FindWAPM utility will find all of these devices and report back their information.

cnb4:src$ FindWAPM

Reply from 172.19.250.26:

Lat: 114817500 Lon: 3895190176 Elev: 1028 Num Sats: 8 GPS Age: 11930

Parent IP: 172.19.254.123

Temp: 30.6 Voltage: 27.2

Reply from 172.19.250.29:

Lat: 114838080 Lon: 3895227796 Elev: 1005 Num Sats: 8 GPS Age: 11895

Parent IP: 172.19.254.117

Temp: 28.0 Voltage: 27.2

Reply from 172.19.250.27:

February 2004 27

Page 34

302395 User’s Guide and Repeater Network Design Guide

Lat: 114841260 Lon: 3895267816 Elev: 1000 Num Sats: 8 GPS Age: 19271

Parent IP: 172.19.254.118

Temp: 30.6 Voltage: 27.3

Reply from 172.19.250.25:

Lat: 114827520 Lon: 3895306156 Elev: 1018 Num Sats: 8 GPS Age: 19807

Parent IP: 172.19.254.124

Temp: 28.0 Voltage: 28.2

The default configuration is to use DHCP to get an IP address for these devices. If you do not have a

DHCP server, you must temporarily enable a server, then go to the DHCP assigned IP address of each

device and configure it with a static IP address. You can do this through the HTTP interface by entering

the IP address you find with the FindWAPM utility. In the above example of the FindWAPM output,

going to the WAPM at 172.19.250.26 would display the following screen:

28 February 2004

Page 35

Cisco Wireless Access Point Support

To change the IP address, click the “View or Change current configuration” link, which will take you to

the following screen:

February 2004 29

Page 36

302395 User’s Guide and Repeater Network Design Guide

5.1.3 MasterLink/OMS/Dispatch Integration

The Network.hosts file should contain entries for all Cisco WAPs:

172.17.0.123 mpr123 cisco

172.17.0.120 mpr120 cisco

After adding these entries, reload OMSns with ‘OMSns –r’

Modify /dsp/client/psw/OMSrun to contain a line that will start the CiscoDiags daemon:

CiscoDiags&

Verify that MasterLink mobile devices (trucks/shovels/etc.) are getting the network metric information by

connecting via OMStip and typing ‘wan0 status’. If they are getting the information, IP addresses for the

Cisco APs will appear in the list. This metric information is sent to all mobile equipment through a

broadcast message once every 20 seconds.

30 February 2004

Page 37

Cisco Wireless Access Point Support

5.2 Troubleshooting

5.2.1 The System Log

Each WAP keeps a log in RAM of important events (if the device is powered down, the log is lost).

Check this log if you are experiencing any problems.

5.2.2 Association Page

If you connect to any Cisco WAP in the network and view the Associations page, you can select the

“Entire Network” checkbox and click the “Save as Default” button to see the entire network at a glance.

From this screen, you can see what AP each device is associated with.

February 2004 31

Page 38

302395 User’s Guide and Repeater Network Design Guide

5.2.3 Link Test

The Cisco Link test is available from the association page. You can only perform a link test when two

devices are associated. From the parent device, click the MAC address of the device you want to test

with, and you should see a link test button. If you do not see this button, the device you are connected to

isn’t associated (either as a child or parent) with the station whose MAC address you clicked.

Below are the results of a normal good link test.

32 February 2004

Page 39

Cisco Wireless Access Point Support

5.2.4 Ping test

You can use the broadcast ping (ping –b 172.17.255.255) if you are using Linux. All possible devices will

respond, giving you a quick idea of the latency and reliability of the network. Below is an example of the

command:

cnb4:mms$ ping -b 172.19.255.255

WARNING: pinging broadcast address

PING 172.19.255.255 (172.19.255.255) from 172.19.0.5 : 56(84) bytes of data.

64 bytes from 172.19.0.5: icmp_seq=1 ttl=255 time=0.036 ms

64 bytes from 172.19.255.5: icmp_seq=1 ttl=255 time=1.51 ms (DUP!)

64 bytes from 172.19.254.104: icmp_seq=1 ttl=64 time=1.73 ms (DUP!)

64 bytes from 172.19.254.103: icmp_seq=1 ttl=64 time=2.32 ms (DUP!)

64 bytes from 172.19.254.123: icmp_seq=1 ttl=64 time=9.95 ms (DUP!)

64 bytes from 172.19.254.117: icmp_seq=1 ttl=64 time=11.4 ms (DUP!)

64 bytes from 172.19.254.118: icmp_seq=1 ttl=64 time=16.1 ms (DUP!)

64 bytes from 172.19.254.124: icmp_seq=1 ttl=64 time=23.9 ms (DUP!)

64 bytes from 172.19.0.5: icmp_seq=2 ttl=255 time=0.019 ms

64 bytes from 172.19.255.5: icmp_seq=2 ttl=255 time=1.49 ms (DUP!)

64 bytes from 172.19.254.104: icmp_seq=2 ttl=64 time=1.73 ms (DUP!)

64 bytes from 172.19.254.103: icmp_seq=2 ttl=64 time=2.03 ms (DUP!)

64 bytes from 172.19.254.117: icmp_seq=2 ttl=64 time=5.65 ms (DUP!)

64 bytes from 172.19.254.118: icmp_seq=2 ttl=64 time=9.26 ms (DUP!)

64 bytes from 172.19.254.123: icmp_seq=2 ttl=64 time=11.8 ms (DUP!)

64 bytes from 172.19.254.124: icmp_seq=2 ttl=64 time=12.6 ms (DUP!)

64 bytes from 172.19.0.5: icmp_seq=3 ttl=255 time=0.015 ms

64 bytes from 172.19.255.5: icmp_seq=3 ttl=255 time=1.53 ms (DUP!)

64 bytes from 172.19.254.104: icmp_seq=3 ttl=64 time=1.63 ms (DUP!)

64 bytes from 172.19.254.103: icmp_seq=3 ttl=64 time=2.04 ms (DUP!)

64 bytes from 172.19.254.117: icmp_seq=3 ttl=64 time=6.71 ms (DUP!)

64 bytes from 172.19.254.118: icmp_seq=3 ttl=64 time=7.66 ms (DUP!)

64 bytes from 172.19.254.123: icmp_seq=3 ttl=64 time=10.2 ms (DUP!)

64 bytes from 172.19.254.124: icmp_seq=3 ttl=64 time=13.1 ms (DUP!)

--- 172.19.255.255 ping statistics ---

3 packets transmitted, 3 received, +21 duplicates, 0% loss, time 2017ms

rtt min/avg/max/mdev = 0.015/6.445/23.981/6.106 ms

February 2004 33

Page 40

302395 User’s Guide and Repeater Network Design Guide

5.3 Serial Port Configuration

5.3.1 Initial Configuration (Serial Port)

5.3.1.1 Connect PC to MasterLink/Cicso Repeater Hub

1. Using a standard SLIP cable, connect the COM1 serial port on the PC to the service serial port on

the MasterLink/Cisco Repeater Hub.

2. Turn off power to the MasterLink/Cisco Repeater Hub.

5.3.1.2 Hyper Terminal Setup

Access the PC HyperTerminal connector or other terminal emulator software and configure it to talk to

the MasterLink/Cisco Repeater Hub serial port by doing the following:

1. On the PC, select Start=>Programs=>Accessories=>Communications=>HyperTerminal.

The Connection Description dialog box appears:

2. In the Name box, type a name for the connection session and click the OK button.

The Connect To dialog box appears.

3. In the Connect using box, use the menu to enter COM1, as shown below, and then click the OK

button.

34 February 2004

Page 41

Cisco Wireless Access Point Support

The COM1 Properties dialog box appears.

4. Using the pull-down menus, in the Bits per second box, enter 9600; in the Data bits box, enter 8;

in the Parity box, enter None; in the Stop bits box, enter 1; and in the Flow control box, enter

None, as shown below.

5. Click the OK button.

6. Power up the MasterLink/Cisco Repeater Hub.

The HyperTerminal window appears and text scrolls as the Cisco 350 boots up.

February 2004 35

Page 42

302395 User’s Guide and Repeater Network Design Guide

5.3.1.3 Express Setup

After the Cisco finishes booting, do the following to perform an express setup of the Cisco 350.

3. Type s in the HyperTerminal window to display the Setup screen.

4. Type ex to display the Express Setup screen, shown below.

5. To change a field, start typing the name of the field that is shown in brackets. As soon as you

have typed enough of the name for the device to know which field you want to edit, the field will

auto complete the rest of the name. For instance, to set the “Config. Server Protocol”, type “Pr”

and you will see the word “Protocol” appear. Now hit enter to edit this field.

6. Setup and save IP/Mask/Gateway, and any other fields you wish to edit at this point.

36 February 2004

Page 43

Cisco Wireless Access Point Support

5.4 Standard Configuration via HTTP

Now connect to the device through a web browser, using the IP address you specified in the setup.

February 2004 37

Page 44

302395 User’s Guide and Repeater Network Design Guide

5.4.1.1 Ethernet connected

Role: Root Bridge

5.4.1.2 Wireless

Role: Non-Root Bridge w/clients

Select the “Ensure Compatibility With: 2Mb/sec Clients” checkbox.

Set the following parameters:

• Set the system name as desired (mpr120, etc.) (from express setup page)

• Set the SNMP admin community to “mms”. This is needed for the CiscoDiags application to get

the network metric information to send to MasterLink devices (from express page)

• SSID (MLINK is the default for MasterLink) (from express setup page)

• Disable DNS (speeds boot-up time)

• Username/password (same for all WAPs to make upgrading firmware or configuration easier via

the distribute firmware feature).

38 February 2004

Page 45

Cisco Wireless Access Point Support

First, enable the user manager:

Now, add a user and set all the permissions:

February 2004 39

Page 46

302395 User’s Guide and Repeater Network Design Guide

5.4.1.3 WEP

First, set the WEP key to whatever key you chose to use:

40 February 2004

Page 47

Cisco Wireless Access Point Support

After clicking the OK button, return to this screen to enable encryption:

February 2004 41

Page 48

302395 User’s Guide and Repeater Network Design Guide

Set Long preambles (MasterLink requires long preambles to be set). Do this from the Root Radio:

Advanced screen.

42 February 2004

Page 49

Cisco Wireless Access Point Support

5.4.1.4 Setting the Channel

From the Root Radio: Hardware screen:

• Set both receive and transmit antenna to ‘Right’.

• Select the desired Channel, and set “Search for less-congested Radio Channel?” to “No”.

5.5 Password Recovery

If the password for the Cisco devices is lost, refer to the Cisco document: “Password Recovery Procedure

for Cisco Aironet Equipment” located at

http://www.cisco.com/en/US/products/hw/wireless/ps430/products_password_recovery09186a00800949d

0.shtml.

The short description of how to reset the configuration, including all passwords, is to connect to the

device via the serial cable, then reboot it. Within four minutes of rebooting, you can type ‘:resetall’

(without the quotes). If the device prompts you for a username/password, just press enter and type

:resetall when it returns you to the prompt.

After this procedure is done, all configuration steps in this document will need to be performed again.

February 2004 43

Page 50

302395 User’s Guide and Repeater Network Design Guide

44 February 2004

Page 51

6. Appendix A — 302395 Connection

Diagram

February 2004 45

Page 52

302395 User’s Guide and Repeater Network Design Guide

46 February 2004

Page 53

Revision Date Comments

— February 2002 First issue

Revision History

Loading...

Loading...