8-504.6

5H101548A2

February, 2014

INSTALLATION AND SERVICE MANUAL

The SLIMLINE PERFORMER Ceiling Cassette

Models SSD, SSH and SCW

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury or

death, and could cause exposure to substances

which have been determined by various state

agencies to cause cancer, birth defects or other

reproductive harm. Read the installation, operating

and maintenance instructions thoroughly before

installing or servicing this equipment.

IMPORTANT

1. The use of this manual is specifically

intended for a qualified installation and

service agency. A qualified installation and

service agency must perform all installation

and service of these appliances.

2. SSD and SSH units contain the refrigerant

R-410A. Review the R-410A Material Safety

Data Sheet (MSDS) for hazards and first aid

measures.

3. Refrigerant charging should only be carried

out by an EPA-certified air conditioning

contractor.

This unit contains R-410A high pressure refrigerant.

Hazards exist that could result in personal injury or

death. Installation, maintenance, and service must only

be performed by an HVAC technician qualified in R410A refrigerant and using proper tools and equipment.

Due to much higher pressure of R-410A refrigerant, DO

NOT USE service equipment or tools designed for

refrigerants other than R410A.

WARNING

Inspection upon Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

factory sales representative.

2. Check serial plate on unit to verify that the power supply

meets available electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where

applicable).

Please be sure to leave it with the owner when you leave the job.

This manual is the property of the owner.

SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT, AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING THE

SPECIAL PRECAUTIONS LISTED BELOW. FAILURE TO

PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERY DAMAGE OR LOSS, PERSONAL INJURY,

OR DEATH. THESE INSTRUCTIONS ARE SUBJECT TO ANY

MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation which,

if not avoided, WILL result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

2.

if not avoided, COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if

3.

not avoided, MAY result in minor or moderate injury.

IMPORTANT: Indicates a situation which, if not avoided, MAY

4.

result in a potential safety concern.

DANGER

Appliances must not be installed where they may be

exposed to potentially explosive or flammable atmosphere.

WARNING

1. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage.

2. All appliances must be wired strictly in accordance with

the wiring diagram furnished with the appliance. Any

wiring different from the wiring diagram could result in a

hazard to persons and property.

3. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than

rated voltage.

5. When servicing or repairing of this equipment, use only

factory-approved service replacement parts. A

complete replacement parts list may be obtained by

contacting Modine Manufacturing Company. Refer to

the rating plate on the appliance for complete appliance

model number, serial number and company address.

Any substitution of parts or controls not approved by the

factory will be at the owner’s risk.

CAUTION

1. SSD and SSH units contain the refrigerant R-410A.

Review the R-410A Material Safety Data Sheet

(MSDS) for hazards and first aid measures.

2. Refrigerant charging should only be carried out by an

EPA-certified air conditioning contractor.

2

8-504.6

CAUTION

1. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the

rated voltage.

2. Units not approved for use in potable water systems.

3. Hot water supplied to the hot water heating option

must not exceed 200ºF temperature or 125 PSIG

pressure.

4. Do not overcharge the refrigeration system. This can

lead to elevated compressor discharge pressure and

possibly flooding to the compressor with liquid.

5. Do not attempt to reuse any mechanical or electrical

component which has been wet. Such component

must be replaced.

IMPORTANT

1. Make sure the ceiling grid is supported separately

from the appliance. The ceiling must not be

supported by any part of the appliance, fascia or

any associated wiring or pipe work.

2. Start-up and adjustment procedures should be

performed by a qualified service agency.

3. All refrigeration checks must be made by a qualified

R-410A refrigeration technician.

4. Do not release refrigerant to the atmosphere. When

adding or removing refrigerant, all national,

state/province and local laws must be followed

5. To check most of the Possible Remedies in the

troubleshooting guide listed in Tables 23.1 through

26.1, refer to the applicable sections of the manual.

Table of Contents

Inspection on Arrival

Special Precautions

Hazard Intensity Levels

SI (Metric) Conversion Factors

Unit Location

Installation

Start-Up Procedure

Start-Up Sheet - Example

Dimensions

Technical Data: SSD and SSH

Technical Data: Condensers for SSD Units

Technical Data: Condensers for SSH Units

Technical Data: SCW Units

Electrical Data – Ceiling Cassettes

Exploded Unit Drawing & Parts List: SCW 08 & 12

Exploded Unit Drawing & Parts List:

SSD/SSH/SCW 18 - 42

Maintenance – Indoor Unit

Troubleshooting – Indoor Unit

Replacement Parts

Model Nomenclature

Serial Plate Example

10-14

23-26

1

2

2

3

3-4

4-7

7-8

9

15

16

17

18

19

20

21

22

26

26

26

UNIT LOCATION

x

Table 3.1

SI (Metric) Conversion Factors

To Convert Multiply By To Obtain To Convert Multiply

“W.C. 0.249 kPa feet 0.305 m

ºF (ºF-32) x 5/9 ºC Gal/hr 0.00379 m³/hr

BTU 1.06 kJ Gal/hr 3.79 l/hr

BTU/ft3 37.3 kJ/m³ gallons 3.79 l

BTU/hr 0.000293 kW Horsepower 746 W

CFH (ft3/hr) 0.000472 m³/min inches 25.4 mm

CFH (ft3/hr) 0.00000787 m³/s pound 0.454 kg

CFM (ft3/min) 0.0283 m³/min psig 6.89 kPa

CFM (ft3/min) 0.000472 m³/s psig 27.7 “W.C.

By

To Obtain

UNIT LOCATION

DANGER

Appliances must not be installed where they may be

exposed to potentially explosive or flammable

atmosphere.

Unpacking

Remove the banding straps and lift the cardboard lid.

Remove the fascia, packed in bubble wrap, and polystyrene

packing pieces to expose the unit.

When removing the unit chassis from the box, the four

corner brackets should be utilized for lifting. In order to

protect the fascia from dirt and damage, it should be

returned to the box until it is ready to be installed.

Blank Off Pieces

When branch ducting is to be used, polystyrene pieces for

blanking off fascia openings are included with the fascia

packing. Up to two opposing sides may be blanked off. See

Installation – Duct Collars.

Positioning

Before any installation work commences, the condensing

unit location (where applicable), pipe work sizes and routes

should be designed in accordance with good refrigeration

practice.

The unit installation position should be selected with the

following points in mind:

1. The appliance must be installed on a structure that is

suitable to support the total weight of the appliance,

piping, refrigerant and condensate.

2. Piping, electrical panel and condensate pump access

panel should be readily accessible for maintenance

purposes. A clearance of 2 feet is recommended

around the electrical panel and condensate pump

access panel.

3. The unit should not be positioned less than 5 ft. from a

wall or similar obstruction, or in a position where the

discharge air could blow directly on to the thermostat.

4. The unit should not be positioned directly above any

obstructions.

5. The unit must be installed square and level.

6. The condensate drain should have sufficient downward

slope (1” in 100”) in any horizontal run between unit and

drain. Maximum condensate pump lift is 30”.

7. There should be sufficient room above the false ceiling

for installing the unit. Minimum distance as shown in

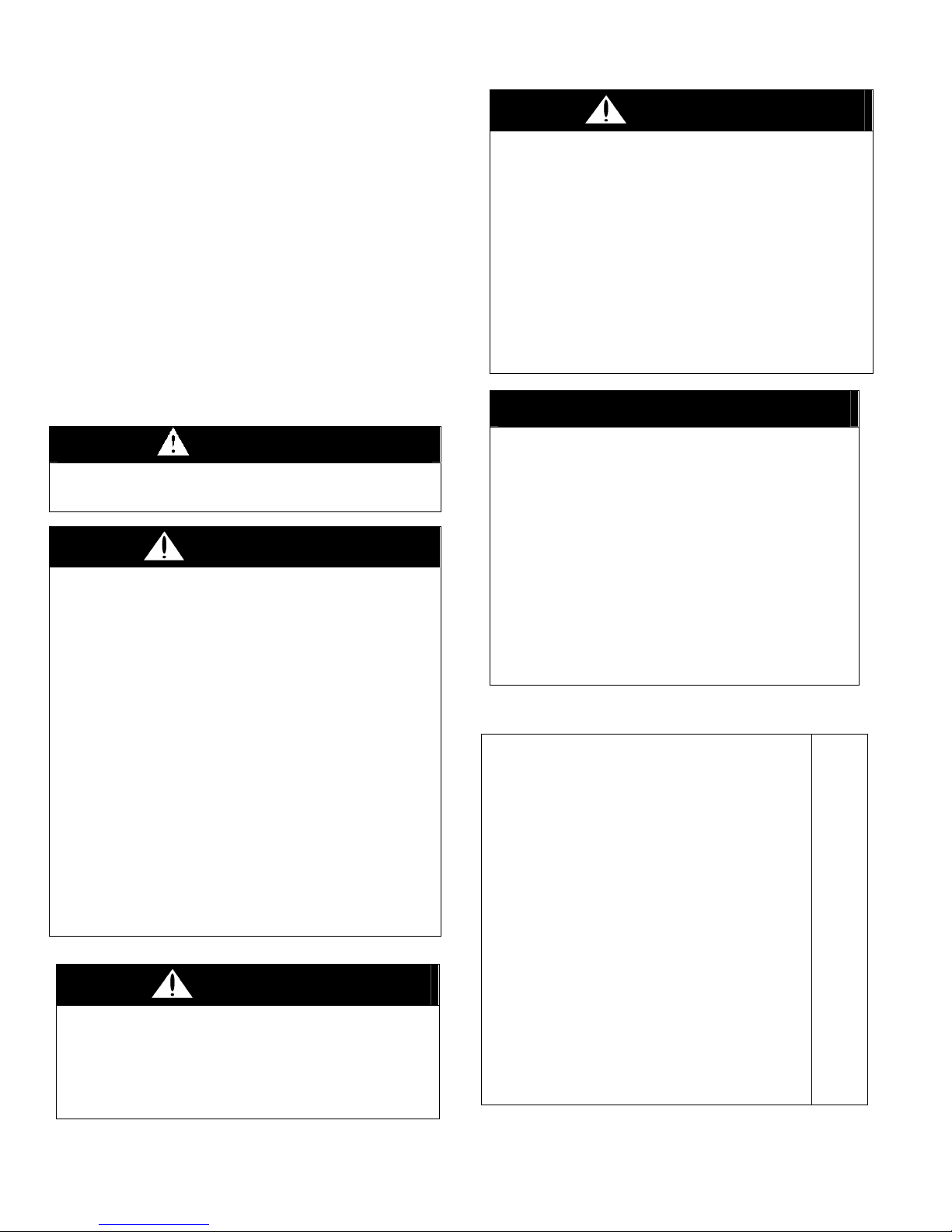

Figure 3.1 and Table 3.2.

8. In case of high humidity, clogged or damaged

condensate piping, incorrect installation or faulty

condensate pump, water may drip from the unit. Do not

install the appliance where dripping water can cause

damage.

Figure 3.1

Minimum Distance to Ceiling

30”

ma

A

Table 3.2

Minimum Distance to Ceiling

Models A

SCW 08 & 12 12¾”

SCW 18 & 20 11½”

SCW 33, 36 & SSD/SSH 18 - 42 13½”

Ceiling Opening Sizes

An opening in the false ceiling will then have to be cut to the

size shown in Table 3.3.

Table 3.3

Ceiling Opening Sizes

Models L x W

SCW 0/8 & 12 23” x 23”

SSD/SSH/SCW 18, 20 & 24 34” x 34”

SSD/SSH/SCW 30, 33, 36 & 42 46” x 34”

3

8-504.6

UNIT LOCATION/INSTALLATION

A

A cardboard template for ceiling cut-out and rod positions is

included with the unit.

Positioning Electro-Mechanical Thermostat

In addition to positioning the unit correctly, it is very

important to locate the wall mounted thermostat in the

optimum position to ensure good temperature control.

Therefore the installation should be selected with the

following points in mind:

1. Position the thermostat approximately 48 inches above

floor level.

2. Do not position thermostat where it can be di rectly

affected by the unit’s discharge air stream.

3. Avoid external walls and drafts from windows and doors.

4. Avoid positioning near shelves and curtains as these

restrict air movement.

5. Avoid heat sources e.g. direct sunlight, heaters, dimmer

switches and other electrical devices.

INSTALLATION

IMPORTANT

Make sure the ceiling grid is supported separately from

the appliance. The ceiling must not be supported by any

part of the appliance, fascia or any associated wiring or

pipe work.

Hanger Bolts

The hanger bolts can now be installed (use 3/8” all thread

rod) at the centers shown in Figure 4.1 and Table 4.1.

Figure 4.1

Hanger Bolt Mounting Dimensions

B

Installation Guide

An installation guide is included in the Airedale Owner

Information packet provided with the unit. Prepare the

installation guide by folding the flat metal piece, by hand,

along the perforations as shown in Figure 4.2.

Figure 4.2

Installation Guide Setup

FOLD SIDE BACK

FOLD TAB UP

The unit can now be lifted onto the hanging rods and levele d

at the correct distance from the ceiling with the aid of the

installation guide.

1. Hold the tab on the installation guide against the bottom

of the cassette case with the guide pointing away from

the cassette. See Figure 4.3.

2. Adjust the height of the cassette until the guide is level

with the bottom of the false ceiling.

Figure 4.3

Installation Guide Position

Table 4.1

Hanger Bolt Mounting Dimensions

Models A B

SCW 08 & 12 19½” 23”

SSD/SSH/SCW 18, 20 & 24 28½” 31½”

SSD/SSH/SCW 30, 33, 36 & 42 28½” 43½””

Check the strength of the unit mounting hanger bolts. Refer

to Tables 15.1 and 18.1 for unit weights.

4

OUTER CASE

INSULATION

A

CASSETTE CASE

TAB

FALSE CEILING

GUIDE IN POSITION

INNER CASE

INS U L A T IO N

3. Secure the unit in position with locknuts and washers on

both sides of the unit bracket. Ensure the threaded rod

does not protrude more than 2” below the mounting

bracket as shown in Figure 5.1.

8-504.6

INSTALLATION

Figure 5.1

Threaded Rod Dimension

3/8”

Threaded Rod < 2”

Condensate Piping

The unit is supplied with a 3/8" ID flexible hose for

connection to copper or plastic drain piping.

When installing the unit the following points should be

remembered:

1. Maximum pump lift is 30”.

2. The highest point in the condensate piping should be as

close to the unit as possible. See Figure 5.2.

Figure 5.2

Condensate Piping

INCORRECT CORRECT

3. Condensate piping should sl ope downwards in the

direction of water flow with a minimum gradient of 1” in

100”. There must not be any uphill gradients other than

in the first 30” of piping from the unit.

4. When multiple units are connected to a comm on

condensate drain, ensure the drain is large enough to

cope with the volume of condensate from all units. It is

also recommended to have an air vent in the condensate

piping to prevent any air locks.

5. Condensate piping must not be installe d where it may be

exposed to freezing temperatures.

Duct Collars

Branch duct and fresh air duct collars can be attached to the

unit chassis by following the steps below:

1. Up to 2 branch ducts can be attached per unit.

2. Refer to the relevant dimensional drawing on pages 10 to

14 to become familiarized with knock-out hole locations.

3. The insulation is pre-cut to aid location and removal of

the relevant section. Rub hand across surface of

insulation to reveal exact location of knock-out.

4. Remove the metal knockout from the chassis.

5. Attach the duct collar to the chassis using self tappin g

screws.

6. Replace washable filter with the pleated filter provided

with fresh air duct collar kit.

Note: See Figures 10.1, 11.1, 12.1, 13.1 and 14.1 for

Branch Duct and Fresh Air Duct locations and dimensions.

Piping Installation – SSD and SSH Units

CAUTION

1. SSD and SSH units contain the refrigerant R-410A.

Review the R-410A Material Safety Data Sheet

(MSDS) for hazards and first aid measures.

2. Refrigerant charging should only be carried out by an

EPA-certified air conditioning contractor.

Note: R-410A refrigerant is the only approved refrigerant for

this system.

The unit should be piped up in accordance with good

refrigeration and/or plumbing practices.

The outdoor condensing unit must be connected to the

indoor unit coil using field supplied refrigerant grade (AC R)

copper tubing that is internally clean and dry. Units should

be installed only with the tubing sizes for the approved

system combination as specified in Tables 16.1 and 17.1.

Condensing units are factory charged with refrigerant for a

matching indoor coil plus 15 feet of field supplied lines.

See the installation and maintenance manual provided with

the condensing unit for installation, evacuation and system

charge information.

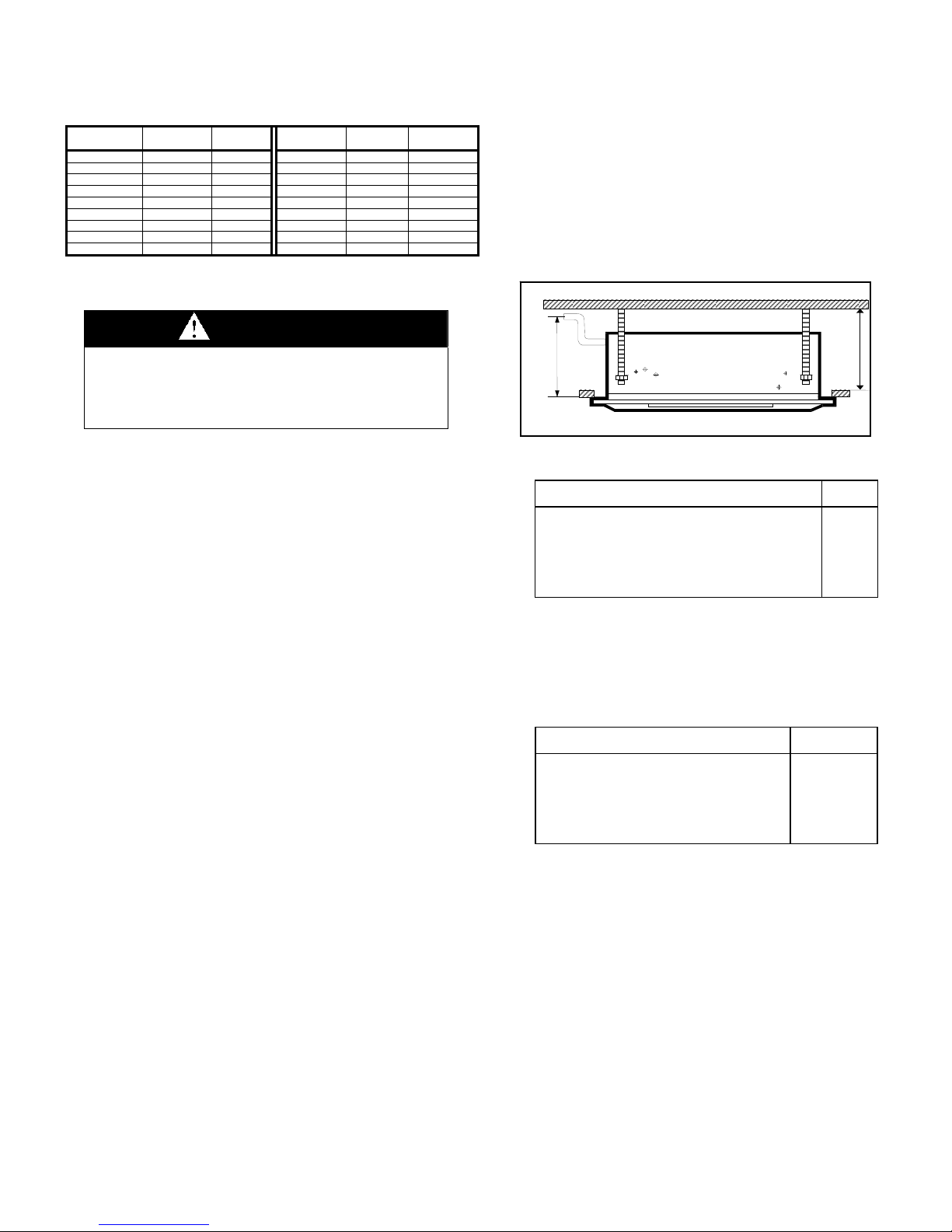

Piping Installation – Hot/Chilled Water Coils

1. Branch p iping to and from the unit should include s wing

joints to allow for expansion and contraction of the

piping without placing a strain on the unit coil.

2. Install pipe unions and shut-off valves in lines to and

from each coil to allow maintenance or replacement of

unit without shutting down and draining entire system.

See Figure 6.1.

3. Include a circuit setter in return line for water flow

regulation.

4. A drain valve (hose bib) should also be provided for

each coil line to allow removal of water from the coil if

located in an area subject to freezing.

5. It is advisable to use a pipe line strainer before each

coil.

6. Provide adequate pipe hangers, supports, or anchors to

secure the piping system independently of the unit.

5

8-504.6

INSTALLATION

Figure 6.1

Hot/Chilled Water Coil Piping Installation

Piping Insulation

Refrigerant, chilled water and condensate pipes should be

insulated right up to the unit chassis to prevent condensation

which can damage the ceiling and objects located below the

piping. Chilled water valves must also be insulated to

prevent sweating.

Wiring

WARNING

1. Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage.

2. All appliances must be wired strictly in accordance

with the wiring diagram furnished with the appliance.

Any wiring different from the wiring diagram could

result in a hazard to persons and property.

3. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than

rated voltage.

This equipment in its standard form is designed for an

electrical supply of 208-230V, 1Ph, 60Hz. When connection

to a 115V, 1Ph, 60Hz supply is necessary, a factory

mounted step up transformer must be fitted to the unit.

Any damage to or failure of units caused by incorrect wiring

of the units is not covered by warranty.

Once the refrigeration pipe work is complete, the electrical

supply can be connected by routing the cable through the

appropriate casing hole and connecting the supply and

ground cables to the unit’s power terminals. A plastic sleeve

is provided inside the control panel. Low voltage control

wiring must run through the plastic sleeve on the inside of

the control panel.

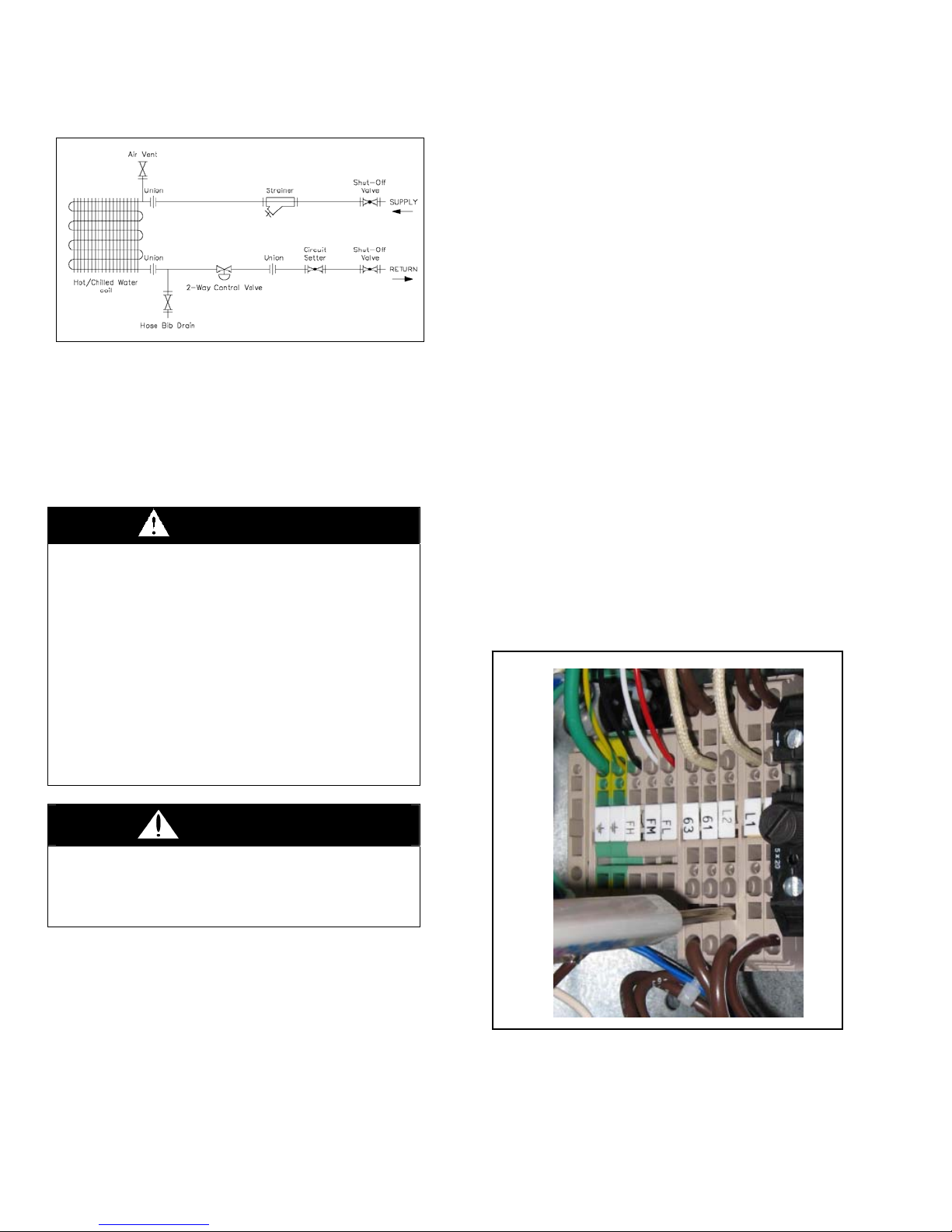

Terminal Strip Connections

The terminal strip connections are designed to clamp down

on the wires. To properly connect the wires to the terminal

strip:

1. Push a small flat head screwdriver into the square hole

on the terminal. Press firmly until the screwdriver hits

the back stop and opens the terminal. See Figure 6.2.

2. Remove approximately 3/8” of insulation from the end of

the wire and push the stripped wire into the oval hole in

the terminal.

3. Remove the screwdriver. Pull on the wire to make sure

that it is securely clamped in the terminal.

4. Make sure that the terminal clamp is in contact with bare

wire (insulation removed).

Figure 6.2

Terminal Strip

CAUTION

Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the rated

voltage.

Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric

Code ANSI/NFPA 70 – Latest Edition. Unit must be

electrically grounded in conformance to this code. In

Canada, wiring must comply with CSA C22.1, Electrical

Code.

Electric wiring must be sized to carry the full load amp draw

of the motor, starter and any controls that are used with the

unit. See Table 19.1 for Electrical Data.

6

Fascia Assembly

Once the services have been connected, the four (4) fascia

mounting bolts can be unscrewed approximately 1” from the

condensate tray support channels.

8-504.6

INSTALLATION/START-UP PROCEDURE

F

The fascia can now be unpacked for fitting to the unit

chassis. Ensure the black fir tree fasteners holding the

fascia polystyrene are pushed in firmly in case of transit

vibration. If a fascia aperture needs blanking off, then take

one of the polystyrene blanking pieces and push it into the

recess in the polystyrene fascia insulation. See Figure 7.1.

Install the fascia by removing the inlet grilles and filters,

locating the four fascia mounting bolts on the chassis

through the four keyhole brackets on the fascia and then

sliding the fascia sideways until it locks into position.

Note: Up to two non-adjacent sides can be blanked off.

Figure 7.1

Fascia Blanking Piece

ascia Blanking Piece

Side view of fascia

Note: Make sure the foam insulating strip profile on the

fascia matches the square and angled corners of the

unit housing.

Before tightening the fascia to the unit, connect the two

halves of the vane motor’s plug and socket connection

(medium and large size units).

On microprocessor controlled units, ensure that the display

panel cable is routed to the electrical panel and securely

fastened to its connector on the microprocessor circuit

board. (Refer to the unit’s electrical wiring schematic). Take

care to ensure that the connector is connected in the proper

orientation and that the wires are not routed such that they

may become trapped, cut, broken or chafed.

The fascia can now be tightened up to the unit chassis until

a good seal is obtained between fascia and chassis.

Note: Do not over tighten the bolts. To do so may cause

damage to the fascia.

With filters in place, the inlet grilles can now be fitted to the

fascia to complete the installation.

START-UP PROCEDURE

IMPORTANT

Start-up and adjustment procedures should be

performed by a qualified service agency.

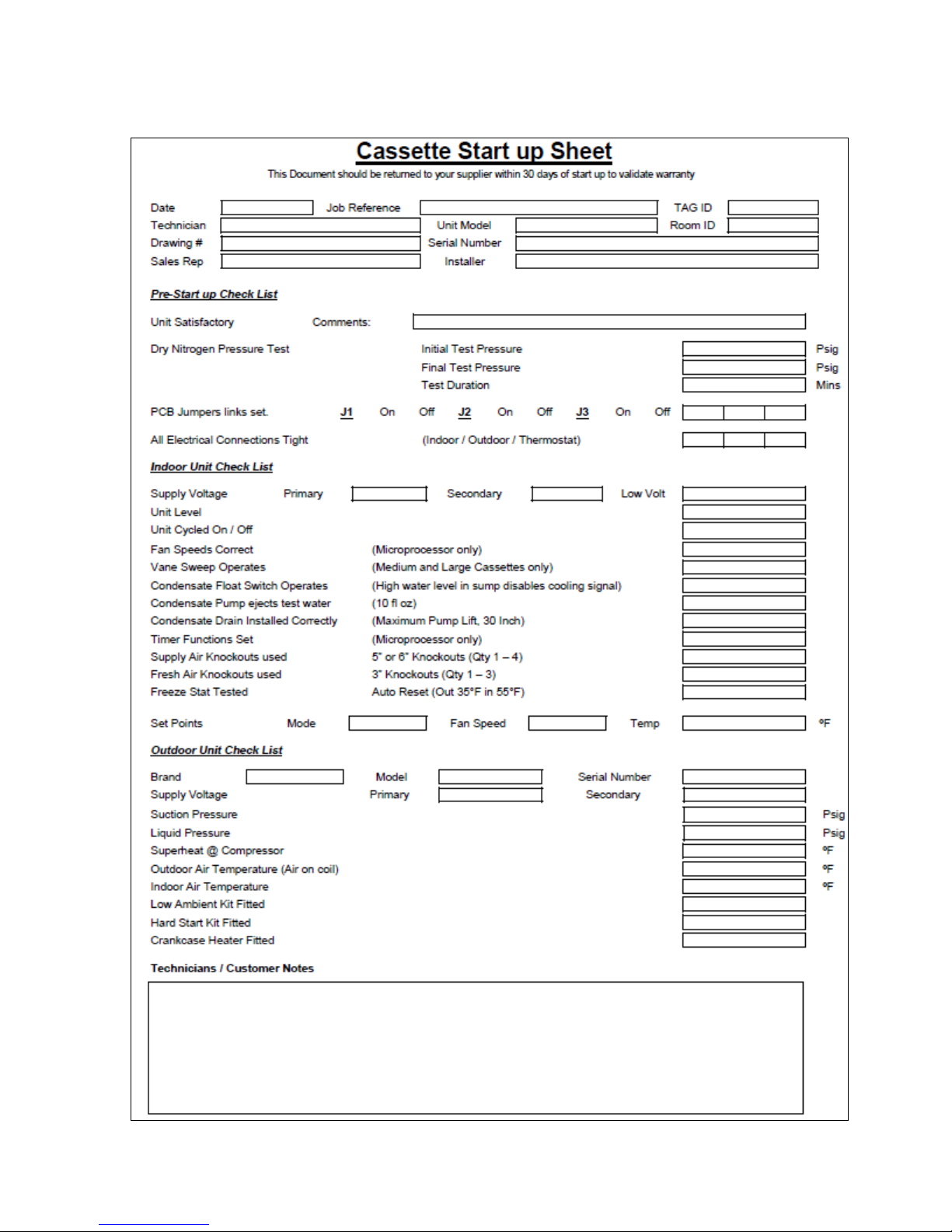

See start-up sheet example - Figure 9.1

8-504.6

Pre-Start Checks

Once installation is complete it is important that the following

pre-start checks are made:

1. All piping is complete and insulate d where necessary.

2. All fans are able to rotate freely.

3. The unit and interconnecting piping have been

evacuated correctly and the condensing unit service

valves are open (SSD and SSH units only).

4. All electrical connections (both power and control) are

properly terminated.

5. All condensate drains are installed correctly.

6. The power supply is of the correct voltage and

frequency.

7. The units are properly grounded in accordance with

current electrical codes.

8. For microprocessor controlled units, check that the

display panel cable is properly connected to the

microprocessor main circuit board and that the jumper

links are correctly set (refer to unit wiring schematic). If

the links are set incorrectly, remove main power supply

before making any changes.

9. For microprocessor controlled units, check that the

battery on the main circuit board is in place and properly

connected. Check also that the batteries are installed in

infrared/pendant transmitter. When a pendant

transmitter is used, ensure it is properly located on to the

wall mounting bracket.

SSD and SSH Units – Control Circuit Checks

Note: See the installation and maintenance manual

provided with the condensing unit for start-up information.

1. Ensure that the condensing unit start-up procedure has

been carried out, as detailed in the condensing unit

installation and maintenance manual.

2. The compressor should be isolated b y removing the

connection at the Y1 terminal on the indoor unit. Main

power can now be applied to the indoor and outdoor

units. A system electrical check can now be carried out.

3. Switch on the indoor unit via the infrared/pendant

transmitter or wall mounted thermostat and check that

the fan cycles correctly. - Note, in some models there is a

2 minute fan run on time to remove residual heat from

the unit, if the unit is switched off during the heating

mode.

4. On models with microprocessor controls, check that the

High, Medium and Low fan speeds are operating

correctly by changing the fan speed via the transmitter.

5. On medium and large size units, check that the motorized

vane sweep functions correctly by toggling the function on

or off, either via the transmitter (micro units) or via the toggle

switch on the side of the electrical panel (electro-mechanical

units).

6. On micro controlled units, should it be required, check

that the built-in timer function is programmed and

operating correctly. When the timer is activated, the red

LED on the fascia display panel should be lit.

7

START-UP PROCEDURE

7. Check the operation of the condensate pump by pouring

7-8 ounces of water down the pump outlet, switch the

unit on, select cooling mode and the lowest possible

temperature set point then observe the water being

pumped from the unit.

8. Where fitted, check the operation of the hot water valv e

or the electrical heat elements by switching the system to

the heating mode and selecting the highest possible

temperature set point.

9. The compressor signal Y1 (disconnected from the indoor

unit in step 1) can now be re-connected and main power

applied to the system.

Note: The 24V power for the indoor unit control circuit is

supplied from a unit factory-installed transformer. When the

indoor and outdoor units are supplied from separate main

supplies, care must be taken to ensure that the outdoor unit

is isolated whenever the indoor unit power is removed.

Failure to do so may result in freeze ups and other damage

to the unit.

Chilled Water Unit – Control Circuit Checks

A thorough pipe work check and pressure test should be

performed before the unit controls are set up

1. Isolate the unit from the chilled water supply. A system

electrical check can now be carried out.

2. Switch on the indoor unit via the infrared/pendant

transmitter or wall mounted thermostat and check that

the fan cycles correctly. - Note, in some models there is a

2 minute fan run on time to remove residual heat from

the unit, if the unit is switched off during the heating

mode.

3. On models with microprocessor controls, check that the

High, Medium and Low fan speeds are operating

correctly by changing the fan speed via the transmitter.

4. On medium and large size units, check that the motorized

vane sweep functions correctly by toggling the function on

or off, either via the transmitter (micro units) or via the toggle

switch on the side of the electrical panel lid (electromechanical units).

5. On micro controlled units, should it be required, check

that the built-in timer function is programmed and

operating correctly. When the timer is activated, the red

LED on the fascia display panel should be lit.

6. Check the operation of the condensate pump by pouring

7-8 ounces of water down the pump outlet, switch the

unit on, select cooling mode and the lowest possible

temperature set point then observe the water being

pumped from the unit.

7. Check the operation of the chilled water valve by

switching the system to the cooling mode and forcing a

call for cooling.

8. Where fitted, check the operation of the hot water valve

or the electrical heat elements by switching the system to

the heating mode and forcing a call for heat.

9. Allow chilled water to enter the unit and vent air from the

unit by opening the 1/4" air bleed. Re-tighten the bleed

screw once all air has been removed.

10. Repeat steps 1-4 above for all units in the same system.

The units are now ready for the system balance to be

performed.

8

Sequence of Operation

Electro-Mechanical Controls: A 24V signal from the

thermostat to terminal G supplies power the blower motor(s),

condensate pump and vane motor (if equipped). A toggle

switch on the control box can be used to switch the

oscillating vanes on or off. The condensate pump will run

continuously, as long as the blower is energized. A call for

heating, at terminal W, or cooling, at terminal Y, will energize

the water valve actuator and allow water to flow through the

cassette coil. When the call for heating or cooling is satisfied

the valve will close.

If the temperature drops below the set-point of the coil freeze

stat, the water valve with automatically open to circulate

water through the coil.

If the condensate float switch detects a high level of water in

the condensate tray, the switch will open, activate the

condensate pump and disable the heating/cooling signal

until the water level drops down to normal.

Micro-Processor Controls: See the Infra-Red Remote

Controller Installation and Service Manual, 8-507.

8-504.6

START UP SHEET – EXAMPLE

Figure 9.1

Start Up Sheet – EXAMPLE

9

8-504.6

DIMENSIONS – SMALL CHASSIS

Figure 10.1

Dimensions – Small Chassis: SCW 08 and SCW 12

25 3/16

1 11/16

25 3/16

1. CW Inlet

2. CW Outlet

3. HW Coil Inlet (Optiona l)

4. HW Coil O u tle t (Optional)

5. Branch Duct Opening (x3)

6. Fresh Air Intake (x2)

7. Pump Inspection Port

8. Condensate Drain

9. Control Panel

10. Mounting Bracket

10 11/16

2 3/4

5

5

O

7

8 13/16

5 3/16

11 5/16

4 11/16

3 11/16

8

9

2 5/8

22 1/2

22 15/16

7/8

10

12 9/16

22 1/2

19 9/16

19 1/2

3 3/8

11 1/4

A

6 1/2

5 1/8

3 3/4

A

1 7/16

2 1/16

9 13/16

1 1/8

2 3/4

6

VIEW A-A

3

2 5/8

10

3 5/8

1 2

8-504.6

4

DIMENSIONS – MEDIUM CHASSIS

Figure 11.1

Dimensions – Medium Chassis: SCW 18 and SCW 20

37

37

11/16

32 3/8

28 11/16

1. CW Coil Inlet

2. CW Coil O u tlet

3. HW Coil Inle t (Optiona l)

4. HW Coil O u tlet (Optiona l)

5. Fresh Air Intake (x3)

6. Branch Duct Opening (x4)

7. Pump Inspection Port

8. Condensate Drain

9. Control Panel

10. Mounting Bracket

2 5/8

9 1/2

2 3/4

7 13/16

A

2 3/4

3 1/8

5

A

3 3/16

1 5/16

8 11/16

11 13/16

3

8

9

32 5/16

31 3/8

12 9/16

28 9/16

3

4

4 15/16

2 3/4

VIEW A-A

10

1 13/16

8 5/8

1

6

2 3/4

4 7/8

4 5/8

1 5/8

5 5/16

7 3/4

2

5

5 3/8

6

7

5 3/8

8 13/16

11

8-504.6

DIMENSIONS – LARGE CHASSIS

Figure 12.1

Dimensions – Large Chassis: SCW 33 and SCW 36

49 3/16

2 1/4

37

32 3/8

28 11/16

1. CW Coil Inlet

2. CW Coil Outlet

3. HW Coil Inlet (Optional)

4. HW Coil Outlet (Optional)

5. Fresh Air Intake (x3)

6. Branch Duct Opening (x4)

7. Pump Inspection Port

8. Condensate Drain

9. Control Panel

10. Mounting Bracket

2 5/8

11 1/2

4 3/4

9 13/16

2 3/4

A

3 1/8

5

A

6

19 5/8

43 1/2

6 3/8

8 13/16

3 5/8

3 3/8

8

9

12 7/16

3

7/8

12 9/16

28 9/16 1 7/8

10

7 3/16

1

6

4 5/8

3

1 5/8

2 3/4

2 3/4

4

4 7/8

4 3/4

2

5

2 3/16

7 9/16

9 13/16

7

VIEW A-A

12

8-504.6

DIMENSIONS – MEDIUM CHASSIS

Figure 13.1

Dimensions – Medium Chassis: SSD/SSH 18 and SSD/SSH 24

11/16

37

1. DX Suction Line

2. DX Liquid Line

3. HW Coil Inlet (Optiona l)

4. HW Coil O utlet (Optiona l)

5. Fresh AIr Intak e (x3)

6. Branch Duct Opening (x4)

7. Pump Inspec tion P ort

8. Condensate Drain

9. Control Panel

10. Mountin g B r a c k et

37

2 5/8

11 5/8

4 3/4

32 3/8

A

28 11/16

A

32 5/16

6 1/4

4 3/8

10

12 1/16

3

8

9

31 3/8

3 7/16

4 7/8

2 3/4

10

12 9/16

1 7/828 9/16

1 5/8

4 1/16

5 1/16

6

7

6 5/16

8 13/16

5 3/4

9 13/16

1

2

4

2 3/4

3

3 1/8

5

VIEW A-A

2 3/4

2 3/4

8-504.6

9 13/16

5

4 7/8

13

DIMENSIONS – LARGE CHASSIS

Figure 14.1

Dimensions – Large Chassis: SSD/SSH 30, SSD/SSH 36 and SSD/SSH 42

1 1/8

49 3/16

37

1. DX Suction Line

2. DX Liquid Line

3. HW Coil Inle t (Optional)

4. HW Coil Outlet (Optional)

5. Fres h AIr Intak e (x 3 )

6. Branch Duct Opening (x4)

7. Pum p In s pection Port

8. Condensate Drain

9. Control Panel

10. Mounting Bracket

2 5/8

11 1/2

4 3/4

32 3/8

A

28 11/16

A

6 3/8

6 3/8

6

8

7

8 13/16

4 3/8

3

15

44 7/16

15

9

43 1/2

10

12 9/16

28 9/16 1 7/8

2 3/4

2 3/4

9 13/16

6 5/16

2 7/8

4 7/8

2 7/8

2 7/8

3 1/2

4 7/8

6 7/16

9 13/16

2 3/4

4 7/16

3 1/8

5

VIEW A-A

1

4

2

3

14

5

8-504.6

4 13/16

TECHNICAL DATA – DX COOLING ONLY AND HEAT PUMP UNITS

Table 15.1

Technical Data – DX Cooling Only and Heat Pump Units

Units SSD/SSH 18 SSD/SSH 24 SSD/SSH 30 SSD/SSH 36 SSD/SSH 42

Nominal Cooling Capacity (1) BTU/h 19200 23000 31400 38200 42500

Nominal Heating Capacity (2) BTU/h 16400 21400 27400 32400 37200

Nominal System SEER (3) 13 13 13 13 13

HSPF 7.7 7.7 7.7 7.7 7.7

Construction

Material: Fascia High Impact Polystyrene

Material: Chassis Galvanized Steel

Color: Fascia Pearl Grey

Fire rating UL94 VO

Evaporator

Type Finned Tube

Quantity 1 1 1 1 1

Face Area Ft² 4.0 4.0 5.2 5.2 5.2

Nominal Airflow High cfm 590 670 920 1000 1130

Med cfm 540 590 800 920 1000

Low cfm 465 540 680 800 920

Discharge 4-way 4-way 4-way 4-way 4-way

Fan

Type Centrifugal

Quantity 1 1 2 2 2

Diameter in 14 14 14 14 14

Horsepower (per fan) HP 1/8 1/8 1/8 1/8 1/8

Refrigeration

Number of Circuits 1 1 1 1 1

Refrigerant Type R-410A R-410A R-410A R-410A R-410A

Weights

Weight - Chassis lb 66 66 97 97 97

Weight - Fascia lb 18 18 21 21 21

Connections (4)

Suction in 3/4 3/4 3/4 3/4 3/4

Liquid in 3/8 3/8 3/8 3/8 3/8

Condensate (ID) in 3/8 3/8 3/8 3/8 3/8

Filtration

Type Wire Framed Periframe (Standard)

Quantity 2 2 3 3 3

Arrestance 80% 80% 80% 80% 80%

Condensate Pump

Maximum Head in 30 30 30 30 30

Nominal Flowrate gpm 0.1 0.1 0.1 0.1 0.1

Options

Electric Heating Capacity kW 3.0 3.0 5.0 5.0 5.0

HW Heating Capacity (5) BTU/h 38,746 41,993 56,609 59,600 64,268

HW Coil Connection (OD) in 7/8 7/8 7/8 7/8 7/8

Max Branch Duct Connections (qty) 2 2 2 2 2

Branch Duct Diameter in 5 5 6 6 6

Branch Duct Air Volume (6) cfm 115 130 180 200 220

Fresh Air Connections (qty) 1-3 1-3 1-3 1-3 1-3

Fresh Air Duct Diameter in 3 3 3 3 3

Fresh Air Volume (7) cfm 60 65 85 90 95

(1) Nominal cooling capacity based on 80/67°F DB/WB and 95/75ºF DB/WB ambient

(2) Nominal heating capacity based on 70/60°F DB/WB and 47/43°F DB/WB ambient.

(3) Test conditions based on ARI 210/240.

(4) Refrigerant line sizes should always match condensing unit connection sizes.

(5) Nominal heating capacity based on 70/60°F DB/WB and water temperature of 180ºF inlet / 160ºF outlet.

(6) Maximum air volume available through one branch duct 6' long, with Cassette fan(s) at high speed and corresponding fascia

aperture closed.

(7) Maximum fresh air through all knockouts connected to one 10' long duct with fan at high speed.

15

8-504.6

TECHNICAL DATA – CONDENSERS FOR DX COOLING ONLY UNITS

Table 16.1

Technical Data – Condensers for DX Cooling Only Units

Units

Performance

Nominal System Cooling Capacity BTU/h 18,000 24,000 30,000 36,000 42,000

Nominal System SEER 13 13 13 13 13

Construction

Material: Chassis Pre-Treated Galvanized Painted Steel

Color Champagne

Dimensions/Weights

Height (includes Fan Guard) in 28 28 28 28 30

Width in 23½ 23½ 23½ 29 29

Depth in 23½ 23½ 23½ 29 29

Weight lb 97 129 131 145 173

Compressor

Type

Crankcase Heater Fitted No No No No No

Condenser

Coil Construction

Connections (1)

Suction in

Liquid in

Refrigerant Charge

Condenser-factory charge lbs-oz 3 - 3 3 - 13 3 - 14 4 - 9 4 - 5

Charge Per Foot of Pipework oz 0.58 0.62 0.62 0.62 0.67

(1) Refrigerant line sizes should always match condensing unit connection sizes.

SSD 18 SSD 24 SSD 30 SSD 36 SSD 42

YCJD18 YCJD24 YCJD30 YCJD36 YCJD42

Rotary Recip Recip Recip Recip

Plate Fin

Microchannel

5/8 3/4 3/4 3/4 7/8

3/8 3/8 3/8 3/8 3/8

Plate Fin

Microchannel

Cassette Unit

Condenser Model

Plate Fin

Microchannel

Plate Fin

Microchannel

Plate Fin

Microchannel

16

8-504.6

TECHNICAL DATA – CONDENSERS FOR HEAT PUMP UNITS

Table 17.1

Technical Data – Condensers for Heat Pump Units

Units

Performance

Nominal System Cooling Capacity BTU/h 18,000 24,000 30,000 36,000 42,000

Nominal System SEER 13 13 13 13 13

Construction

Material: Chassis Pre-Treated Galvanized Painted Steel

Color Champagne

Dimensions/Weights

Height (includes Fan Guard) in 28 32 36 40 40

Width in 34 34 34 34 34

Depth in 34 34 34 34 34

Weight lb 172 184 196 208 208

Compressor

Type

Crankcase Heater Fitted

Condenser

Coil Construction

Connections (1)

Suction in 3/4 3/4 3/4 3/4 7/8

Liquid in

Refrigerant Charge

Condenser-factory charge lbs-oz 6 - 6 8 - 13 9 - 0 9 - 7 9 - 12

Charge Required-Per Foot of

Pipework oz 0.62 0.62 0.62 0.62

(1) Refrigerant line sizes should always match condensing unit connection sizes.

SSH 18 SSH 24 SSH 30 SSH 36 SSH 42

YHJD18 YHJD24 YHJD30 YHJD36 YHJD42

Scroll Recip Recip Recip Scroll

No Yes Yes Yes

Round Tube

Plate Fin

3/8 3/8 3/8 3/8

Round Tube

Plate Fin

Cassette Unit

Condenser Model

Round Tube

Plate Fin

No

Round Tube

Plate Fin

3/8

0.67

Round Tube

Plate Fin

17

8-504.6

TECHNICAL DATA – CHILLED WATER UNITS

Table 18.1

Technical Data – Chilled Water Units

Nominal Cooling Capacity (1) BTU/h 6,601 11,091 17,592 19,087 29,722 35,258

Construction

Material: Fascia High Impact Polystyrene

Material: Chassis Galvanized Steel

Color: Fascia Pearl Grey

Fire rating UL94 VO

Chilled Water Coil

Type Finned Tube

Quantity 1 1 1 1 1 1

Face Area Ft² 1.8 1.8 2.8 2.8 5.2 5.2

Nominal Airflow High cfm 350 350 630 700 970 1160

Med cfm 300 300 530 630 890 970

Low cfm 260 260 500 530 785 890

Discharge 4-way 4-way 4-way 4-way 4-way 4-way

Unit water Volume gal 0.29 0.29 0.45 0.45 0.79 0.79

Fan

Type Centrifugal

Quantity 1 1 1 1 2 2

Diameter in 12 12 15 15 14 14

Horsepower (per fan) HP 1/8 1/8 1/8 1/8 1/8 1/8

Units

Weights

Weight - Chassis lb 40 40 64 64 97 97

Weight - Fascia lb 5 5 18 18 21 21

Connections

Chilled Water Inlet in 5/8 5/8 7/8 7/8 7/8 7/8

Chilled Water Outlet in 5/8 5/8 7/8 7/8 7/8 7/8

Condensate (ID) in 3/8 3/8 3/8 3/8 3/8 3/8

Filtration

Type Wire Framed Periframe (Standard(

Quantity 1 1 2 2 3 3

Arrestance 80% 80% 80% 80% 80% 80%

Condensate Pump

Maximum Head in 30 30 30 30 30 30

Nominal Flowrate gpm 0.1 0.1 0.1 0.1 0.1 0.1

Options

Electric Heating Capacity kW 1.5 1.5 3.0 3.0 5.0 5.0

HW Heating Capacity (2) BTU/h 13,799 N/A 29,258 30,946 46,455 51,600

HW Coil Connection (OD) in 5/8 N/A 5/8 5/8 5/8 5/8

Max Branch Duct Connections (qty) 2 2 2 2 2 2

Branch Duct Diameter in 5 5 5 5 6 6

Ducted Air Volume (3) cfm 80 80 100 125 200 220

Fresh Air Connections (qty) 1-2 1-2 1-3 1-3 1-3 1-3

Fresh Air Duct Diameter in 3 3 3 3 3 3

Fresh Air Volume (4) cfm 40 40 60 65 90 95

(1) Nominal cooling capacity based on 80/67°F DB/WB and water temperature of 45ºF inlet / 55ºF outlet.

(2) Nominal heating capacity based on 70/60°F DB/WB and water temperature of 180ºF inlet / 160ºF outlet.

(3) Maximum air volume available through one branch duct 6' long, with Cassette fan(s) at high speed and corresponding fascia

aperture closed.

(4) Maximum fresh air through all knockouts connected to one 10' long duct with fan at high speed.

SCW08 SCW12 SCW 18 SCW 20 SCW 33 SCW 36

18

8-504.6

ELECTRICAL DATA – CEILING CASSETTES

Table 19.1

Electrical Data – Ceiling Cassettes

Nominal

Capacity

(Digit4,5)

08and12

SmallChassis

18,20and24

Medium

Chassis

30,33,36and

42

LargeChassis

SupplyVoltage

(Digit6)

A:115/60/1

J:110/50/1

B:208/60/1

C:230/60/1

K:220/50/1

H:277/60/1‐‐ ‐0.3 0.4 15

A:115/60/1

J:110/50/1

B:208/60/1

C:230/60/1

K:220/50/1

H:277/60/1‐‐ ‐0.5 0.6 15

A:115/60/1

J:110/50/1

B:208/60/1

C:230/60/1

K:220/50/1

H:277/60/1‐‐ ‐0.8 1.0 15

Performance(WithElectricHeat) Performa nce(NoElectricHeat)

Recommended

FLA MCA

FuseSize FLA MCA

‐ ‐ ‐ 0.7 0.9 15

6.3 7.8 15

6.9 8.6 15

6.6 8.2 15

‐ ‐ ‐ 1.1 1.4 15

12.4 15.4 20

13.6 17.0 20

13.0 16.3 20

‐ ‐ ‐ 1.9 2.4 15

20.7 25.9 30

22.8 28.5 30

21.8 27.3 30

Recommended

FuseSize

0.4 0.4 15

0.6 0.7 15

1.0 1.2 15

19

8-504.6

EXPLODED UNIT DRAWING & PARTS LIST – SCW2/8 & SCW2/12

Figure 20.1

Exploded Unit Drawing & Parts List – SCW 08 & 12

1 Cassette Chassis 9 Fan/Motor Assembly 17 Receiver (Microprocessor Only)

2 Chilled Water Coil 10 Coil/Return Air Sensors

3 Elec t r i c Hea t e r E l e m e n t A s s e m b l y 11 Grille 19 Control Box Lid

4 Condensate Tray 12 Airedale Label 20 Control Box

5 Condensate Tray Supports (2) 13 Air Deflector Vanes (4) 21 PCB Controller (Microprocessor Only)

6 Condensate Pump 14 Freeze Protection Thermostat

7 High Level Switch 15 F ilter 23 Wall Mounted Controller (Ele ctro-

8 Condensate Pump Assembly

(Shown Inverted)

20

16 Fascia Assembly 24 Remote Handset (Microprocessor Only)

(Microprocessor Only)

(Electro-Mechanical version only)

8-504.6

18 Terminal Rail, Relays & Timer (Micro &

Electro- Mechanical Version)

22 Coil Support Brackets

Mechanical Only)

EXPLODED UNIT DRAWING & PARTS LIST – SSD/SSH/SCW 18 - 42

Figure 21.1

Exploded Unit Drawing & Parts List – SSD/SSH/SCW 18 - 42

1. Cassette Chassis

2. Evaporator Coil

3. Condensate Tray

4. Condensate Tray Support

5. High Level Switch (Shown Inverted)

6. Condensate Pump (Shown Inverted)

7. Fan & Motor Assembly

8. Fan Inlet Ring

9. Grille

10. Infrared Receiver

11. Vane

12. Vane Motor Assembly

13. Filter

14. Fascia

15. Remote Handset

16. Control Box Lid

17. Control Box PCB

18. Control Box

19. Coil Bracket

20. Expansion Valve

21

8-504.6

MAINTENANCE – INDOOR UNIT/DISASSEMBLY PROCEDURE

MAINTENANCE – INDOOR UNIT

WARNING

When servicing or repairing of this equipment, use only

factory-approved service replacement parts. Refer to

the rating plate on the appliance for complete appliance

model number, serial number and company address.

Any substitution of parts or controls not approved by the

factory will be at the owner’s risk.

CAUTION

Do not attempt to reuse any mechanical or electrical

controllers which have been wet. Replace defective

controller.

IMPORTANT

To check most of the Possible Remedies in the

troubleshooting guide listed in Tables 23.1 through 26.1,

refer to the applicable sections of the manual.

Maintenance Schedule

Every THREE (3) MONTHS

1. Check the air filter condition. Clean if necessar y (see

Filter Removal and Cleaning, below).

Every SIX (6) MONTHS

1. Same as three (3) months, PLUS

2. Clean condensate tray with biocide suitable for

polystyrene.

3. Clean fascia.

Every TWELVE (12) MONTHS

1. Same as six (6) months, PLUS

2. Check all electrical connections for security.

3. Check condensate pump operation.

4. Check the heating and cooling action, to ensure proper

operation.

Filter Removal and Cleaning

1. Disconnect power.

2. Unclip the catches along the edge of each g r ille and

allow them to hang from the fascia by the molded plastic

hinges located along the opposite edge.

3. If desired, the grilles can be removed from the fascia

completely.

4. The filter can now be easily slid out of the small plastic

retaining clips on the back of each grille.

5. Gently vacuum clean the filters on a medium vacuum

power.

6. When cleaned, the filters can be replaced by reversing

steps 2 to 4.

Recommended Spares

One complete set of air filters.

DISASSEMBLY PROCEDURE

Disconnect power supply before disassembly to prevent

electrical shock and injury from moving parts.

Fan Removal

1. Unclip the grille catches and remove the grille(s) from the

fascia.

2. a. For model sizes 08, & 12 only, remove the fascia by

loosening the four fascia mounting bolts and then slide

the fascia horizontally until it releases from the chassis.

Drain the condensate tray by removing the small black

rubber drain plug, catching the condensate (if any) in a

suitable container. Remove the self tapping screws

securing the two insulated metal condensate tray support

channels and pull the channels away from the

condensate tray. Pull the condensate tray downwards

away from the chassis.

2. b. For model sizes 18 to 42 only, remove the M6

screws from the black plastic inlet ring and pull the inlet

ring downwards from the condensate tray.

3. Remove the electrical panel lid and disconnect the fan

connections from within the electrical panel.

4. Rotate the fan by hand until two M6 nuts are visible

through the fan mounting access holes. Remove the two

nuts.

5. Rotate the fan 90° until the remaining two nut s are visible

and remove while supporting the fan to prevent it from

falling. The fan can now be dropped down from the unit.

Condensate Tray Removal

1. Unclip the grille catches and remove the grille(s) from the

fascia.

2. Remove the fascia by loosening the fascia mounti ng

bolts and then slide the fascia horizontally until it

releases from the chassis. If the unit is microprocessor

controlled, remove the display panel cable from within

the electrical panel before removing the fascia.

3. Drain the condensate tray by removing the small black

rubber drain plug, catching any condensate in a suitable

container.

4. Remove the self tapping screws securing the t wo

insulated metal condensate tray support channels and

pull the channels away from the condensate tray. Pull

the condensate tray, complete with inlet ring (inlet ring on

model sizes 18 to 42 only) downwards away from the

chassis.

Condensate Pump Removal

1. Disconnect the condensate pump and float switch wires

from inside the electrical panel.

2. Unscrew the three M4 screws holding the pump

inspection plate in place and pull the pump and mounting

bracket away from the chassis while feeding the pump

wires between condensate tray and insulation.

22

8-504.6

TROUBLESHOOTING – INDOOR UNIT

A

Table 23.1

Troubleshooting – Indoor Unit

TROUBLE

Red Alarm LED flashing

POSSIBLE CAUSE POSSIBLE REMEDY

Faulty float switch.

See section “Condensate High Level”

at 1 second intervals

(Microprocessor units only)

Red Alarm LED flashing

at 5 second intervals

(Microprocessor units only)

Both Yellow Heat &

Cool LEDs flashing

(Microprocessor units only)

Unit Will Not Operate

Fans Will Not Run

Faulty fan capacitor. Check fan capacitors, replace if necessary.

Faulty fan motor. Check fan motor protector for open circuit, replace if

Faulty PC Board. On electro-mechanical units check for a signal at “G”

Fan Trip.

Indoor coil sensor failure.

(Connected to micro terminals ‘T3’)

Return Air Sensor failure.

(Connected to micro terminals ‘T1’)

Control Board (PCB) battery

failure.

No power mains power. Check p ower supply to the unit. For micro units, check

No 24V control circuit power. Check the 24V feed from the control transformer. If not

Control circuit disabled by unit

protection device.

Infrared receiver failure.

(micro units only)

Transmitter failure.

(micro units only)

Microprocessor failure.

(micro units only)

Loose wire. Check all fan wire connections. Use unit’s electrical

See section “Fans Will Not Run”

fter checking the above, use the unit wiring schematic to

isolate the indoor coil sensor and measure the resistance.

Sensor is 50K@72°F type. Check and replace if necessary.

Use the unit wiring schematic to isolate the return air sensor

and measure the resistance. Sensor is 50K@72°F type.

Check and replace if necessary.

Check battery and replace if necessary. See the Infra-Red

Remote Controller Installation and Service Manual, 8-507,

for procedure.

power to the micro and check the on-board micro fuse.

present, check transformer windings – replace if necessary.

In some models, particularly electro-mechanical units, some

protection devices (such as freeze-stats, fan trips, etc) are

wired in line with the 24V control circuit feed to cause the

unit to shut down in an alarm condition. Use the unit’s wiring

schematic to identify these devices and investigate

accordingly.

If audible bleep is heard on signal transmission from

transmitter and the green LED is lit or flashing, receiver is

OK. If there are no LEDs lit and the unit will not respond to

the transmitter, press the On/Off button on the fascia display

panel. If the unit responds to the On/Off button receiver is

OK. Check transmitter.

Try new batteries first, if receiver bleeps on transmitting

signal, transmitter is OK. If no response press On/Off button

on unit fascia. If the unit responds to the On/Off button

transmitter is faulty.

The microprocessor is the least likely component to be at

fault. Investigate all other possibilities in every section of this

troubleshooting guide first. Replace the micro only after all

other avenues of investigation are exhausted.

schematic to verify that fan is wired correctly.

necessary.

terminal.

On micro units check for steady green light on display panel.

23

8-504.6

TROUBLESHOOTING – INDOOR UNIT

A

Table 24.1

Troubleshooting – Indoor Unit

TROUBLE

POSSIBLE CAUSE POSSIBLE CAUSE

No Cooling

Water Leaking From

Unit

(see also “Condensate High

Level”)

Incorrect MODE setting.

(micro units only)

Set point too high. Check the set point on the transmitter or wall mounted

Compressor protection delay.

(micro units only)

Compressor protection delay.

(Electro-mechanical DX units only)

Dirty or blocked air filter.

High condensate level trip. Drain the condensate tray and investigate. See

Indoor coil temperature too low. Check refrigerant charge by measuring operating

Sensor failure.

(micro units only)

Outdoor unit tripped. Check outdoor unit - refer to outdoor unit

Faulty valve actuator.

(Chilled water units only)

Condensate plug loose or missing. Check that the rubber condensate plug is securely

Check that the transmitter MODE is set to Cooling or

uto Mode.

thermostat and adjust if necessary.

Check that the green On/Off LED is not flashing. If it

is flashing, wait for ten minutes then re-check if

cooling is operating. (Applies to chilled water units also)

Wait for ten minutes and then re-check if cooling is

operating.

See section “Coil Freeze”.

section “Condensate High Level”

pressures. Check filters condition. (See page 22 for

filter removal and cleaning instructions)

If any of the sensors are faulty the microprocessor will

disable the cooling operation (see AIR 8-507, Infra-

Red Controller, Installation and Service Manual).

troubleshooting section.

Check cooling signal present at actuator. Check

actuator by manually opening the valve. Replace

actuator if necessary.

fitted to the underside of the unit’s polystyrene drip

tray. On some models this is located underneath the

fascia support rails on the pump side of the unit.

PCB jumper links not set correctly.

(micro units only)

Unit installed unevenly. With fascia removed, ensure that the unit chassis is

Condensate drain piping installed

incorrectly.

Blocked/kinked condensate pipe. Check condensate piping for blocks/kinks, clear as

Condensate pump blocked or

failed.

Float switch failure. Check that the float switch operates correctly and is

Check jumper links. Refer to unit wiring diagram.

level (at the face) both front to back and left to right, to

ensure correct condensate flow.

Check that the site installed condensate gravity drain

slopes ‘downhill’ away from the unit. (See page 5 of

this manual for installation guide)

necessary. Check for a water tight connection

between the condensate outlet and the site installed

condensate gravity drain.

Clear any blockages and ensure that power is being

applied to the pump. If the pump still does not run,

replace the pump.

properly positioned. Float switch is normally closed,

opens on rise of water level.

24

8-504.6

TROUBLESHOOTING – INDOOR UNIT

A

Table 25.1

Troubleshooting – Indoor Unit

TROUBLE

Condensate High Level

(micro units: red alarm LED

will flash at one second

intervals)

Coil Freeze

No Heating (Hot Water)

No hot water / pumps failed. Check hot water source and supply to unit.

Faulty valve / actuator. Check actuator by manually opening and closing valve,

Faulty heater relay. Check signals to relay and check action of relay contacts.

No Heating (Electric Heat)

POSSIBLE CAUSE POSSIBLE REMEDY

Maximum pump lift exceeded. Check that the condensate pump head is no greater than

30”. (See page 5 of this manual for installation guide)

Blocked/kinked condensate pipe.

Condensate pump blocked or

failed.

Coil freeze up.

Cooling coil freeze protection

thermostat tripped.

(Auto-reset when freeze cleared)

Dirty or blocked air filter. Clean / replace filters as necessary. (See page 22 for

System head pressure set too

low.

Loss of refrigerant. Check system for refrigerant leaks and repair before re-

Incorrect MODE setting.

(micro units only)

Set point too low. Check the set point on the transmitter or wall mounted

Blocked or dirty filters causing

low airflow.

Incorrect MODE setting.

(micro units only)

Set point too low. Check the set point on the tra nsmitter or wall mounted

Overheat cut out tripped.

(See also section “Electric

Overheat”)

Heater element failed. Investigate and replace if necessary.

Faulty heater relay. Check signals to relay and check action of relay contacts.

See section “Water Leaking From Unit”.

See section “Water Leaking From Unit”.

coil freeze condition may have caused excessive

condensate to collect in the drip tray. See section “Coil

Freeze”.

Freeze stat is normally closed, opens during freeze.

Where fitted, the stat will disable the cooling action

(sometimes the entire system) during coil freeze

conditions. Use the unit’s wiring schematic to investigate.

filter removal and cleaning instructions)

Check condensing pressure, installation of low ambient kit

may be required.

charging.

Check that the transmitter MODE is set to Heat or Auto

Mode.

thermostat and adjust if necessary.

Check filters condition. (See page 22 for filter removal

and cleaning instructions)

replace if faulty.

Replace relay or PCB if necessary.

Check that the transmitter MODE is set to Heat or Auto

Mode.

thermostat and adjust if necessary.

Investigate cause of over heat condition.

Possible low airflow, check filter condition. (See page

22 for filter removal and cleaning instructions)

Possible fan failure. Check fans.

(See section “Fans Will Not Run”)

Remove power from unit and reset manual overheat cut-

out by rubbing. DO NOT PRESS.

Consult Factory for instruction if necessary.

Replace relay or PCB if necessary.

25

8-504.6

TROUBLESHOOTING/REPLACEMENT PARTS

MODEL NUMBER DESIGNATION/SERIAL PLATE

Table 26.1

Troubleshooting – Indoor Unit (Continued)

TROUBLE

ELECTRIC OVERHEAT

The electric heat circuit contains one automatic reset and one manual reset overheat cutout protection switch for each electric heat element fitted to the unit. The cut-outs are

wired in line with the main power flowing in each element and operate as describ ed below.

1. Auto Cut-out – if the auto cut-out trips, the electric heat is temporarily disabled until

the unit temperature falls and causes the overheat cut-out to automatically reset.

2. Manual Cut-out – if the manual cut-out trips, the electric heat is disabled until the unit

temperature falls and the overheat cut-out is manually reset. It will typically take five

minutes for the unit temperature to fall sufficiently to allow the cut-out to be reset. The

cut-out should only be reset by a qualified and competent electrician and with the

mains power switched off. Ensure the elements have cooled sufficiently.

REPLACEMENT PARTS

For ease of identification when ordering replacement parts or

contacting the factory about your unit, please quote the unit

type and unit serial number. This information can be found

on the serial plate attached to your unit. See Figure 26.2.

When a component part fails, a replacement part should be

obtained through our Parts Department. If the part is

considered to be under warranty, the following details are

required to process this requirement:

1. Full description of part required, including Unit’s part

number, if known.

2. The original equipment serial number.

3. An appropriate purchase order number.

Figure 26.1

Model Number Designations

Figure 26.2

Serial Plate EXAMPLE

26

8-504.6

THIS PAGE INTENTIONALLY LEFT BLANK

27

8-504.6

COMMERCIAL WARRANTY

Seller warrants its products to be free from defects in material and

workmanship, EXCLUSIVE, HOWEVER, of failures attributable to the use of

materials substituted under emergency conditions for materials normally

employed. This warranty covers replacement of any parts furnished from

the factory of Seller, but does not cover labor of any kind and materials not

furnished by Seller, or any charges for any such labor or materials, whether

such labor, materials or charges thereon are due to replacement of parts,

adjustments, repairs, or any other work done. This warranty does not apply

to any equipment which shall have been repaired or altered outside the

factory of Seller in any way so as, in the judgment of Seller, to affect its

stability, nor which has been subjected to misuse, negligence, or operating

conditions in excess of those for which such equipment was designed. This

warranty does not cover the effects of physical or chemical properties of

water or steam or other liquids or gases used in the equipment.

BUYER AGREES THAT SELLER’S WARRANTY OF ITS PRODUCTS TO

BE FREE FROM DEFECT IN MATERIAL AND WORKMANSHIP, AS

LIMITED HEREIN, SHALL BE IN LIEU OF AND EXCLUSIVE OF AL L

OTHER WARRANTIES, EITHER EXPRESS OR IMPLIED, WHETHER

ARISING FROM LAW, COURSE OF DEALING, USAGE OF TRADE, OR

OTHERWISE, THERE ARE NO OTHER WARRANTIES, INCLUDING

WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE,

WHICH EXTEND BEYOND THE PRODUCT DESCRIPTION CONFIRMED

BY BUYER AND SELLER AS OF THE DATE OF FINAL AGREEMENT.

This warranty is void if the input to the product exceeds the rated input as

indicated on the product serial plate by more than 5% on gas-fired and oilfired units, or if the product in the judgment of SELLER has been installed in

a corrosive atmosphere, or subjected to corrosive fluids or gases, been

subjected to misuse, negligence, accident, excessive thermal shock,

excessive humidity, physical damage, impact, abrasion, unauthorized

alterations, or operation contrary to SELLER’S printed instructions, or if the

serial number has been altered, defaced or removed.

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY COMPONENT

Component

Applicable Models

Heat Exchangers

Gas-Fired Units except PSH/BSH

Heat Exchangers

Low Intensity Infrared Units

Compressors

Condensing Units for Cassettes

Burners

Low Intensity Infrared Units

Other

Components excluding Heat Exchangers,

Coils, Condensers, Burners, Sheet Metal

Heat Exchangers/Coils

Indoor and Outdoor Duct Fur naces and

System Units, PSH/BSH, Steam/Hot Water

Units, Oil-Fired Units, Electric Units,

Cassettes, Vertical Unit Ventilators,

Geothermal Units

Compressors

Vertical Unit Ventilators, Ge othermal Units

Burners

High Intensity Infrared Units

Sheet Metal Parts

All Products

Modine Manufacturing Company has a continuous product improvement program, and therefore reserves the right to change design and specifications without notice.

TEN YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

TEN YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN TEN YEARS FROM

DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN ONE HUNDRED

TWENTY-SIX MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

FIVE YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

FIVE YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN FIVE YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN SIXTY-SIX

MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

TWO YEARS FROM DATE OF FIRST BENEFICIAL USE BY BU YER OR ANY OTHER USER, WITHIN

TWO YEARS FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CON D ITION, OR WITHIN

THIRTY MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

ONE YEAR FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

ONE YEAR FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

WHICH SHALL, WITHIN THE APPLICABLE WARRANTY PERIOD

DEFINED HEREIN AND UPON PRIOR WRITTEN APPROVAL, BE

RETURNED TO SELLER WITH TRANSPORTATION CHARGES PREPAID

AND WHICH THE EXAMINATION OF SELLER SHALL DISCLOSE TO

HAVE BEEN DEFECTIVE; EXCEPT THAT WHEN THE PRODUCT IS TO

BE USED BY BUYER AS A COMPONENT PART OF EQUIPMENT

MANUFACTURED BY BUYER, BUYER’S REMEDY FOR BREACH, AS

LIMITED HEREIN, SHALL BE LIMITED TO ONE YEAR FROM DATE OF

SHIPMENT FROM SELLER. FOR GAS-FIRED PRODUCTS INSTALLED IN

HIGH HUMIDITY APPLICATIONS AND UTILIZING STAINLESS STEEL

HEAT EXCHANGERS, BUYER’S REMEDY FOR BREACH, AS LIMITED

HEREIN, SHALL BE LIMITED TO TEN YEARS FROM DATE OF

SHIPMENT FROM SELLER.

These warranties are issued only to the original owner-user and cannot be

transferred or assigned. No provision is made in these warranties for any

labor allowance or field labor participation. Seller will not honor any

expenses incurred in its behalf with regard to repairs to any of Seller’s

products. No credit shall be issued for any defective part returned without

proper written authorization (including, but not limited to, model number,

serial number, date of failure, etc.) and freight prepaid.

OPTIONAL SUPPLEMENTAL WARRANTY

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years on certain compressors.

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years or nine (9) years on certain

heat exchangers.

EXCLUSION OF CONSUMABLES & CONDITIONS BEYOND SELLER’S

CONTROL

The above referenced warranty shall not be applicable to any of the

following items: refrigerant gas, belts, filters, fuses and other items

consumed or worn out by normal wear and tear or conditions beyond

Seller’s control, including (without limitation as to generality) polluted or

contaminated or foreign matter contained in the air or water utilized for heat

exchanger (condenser) cooling or if the failure of the part is caused by

improper air or water supply, or improper or incorrect sizing of power supply.

“APPLICABLE WARRANTY PERIOD”

Commercial Products Group

Modine Manufacturing Company

1500 DeKoven Avenue

Racine, WI 53403

Phone: 1.866.823.1631 (toll free)

www.modinehvac.com/schoolsystems

Modine Manufacturing Company 2014

Loading...

Loading...