WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive harm.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

November, 2003

INSTALLATION AND SERVICE MANUAL

high intensity gas-fired infrared heaters

model MT

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency

must perform all installation and service of

these units.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to the transportation company and your local

sales representative.

2.

Check rating plate on unit to verify that the power supply

meets available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

9-500.3h

5H75283ALL

CAUTION

As with all infrared equipment, clearances to

combustible material are critical.

To prevent premature heat exchanger failure do

not locate ANY gas-fired units in areas where

chlorinated, halogenated, or acid vapors are

present in the atmosphere

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

DANGER

Appliances must not be installed where they may be exposed

to potentially explosive or flammable atmosphere.

Special Precautions

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN

ADDITION, PARTICULAR CARE MUST BE EXERCISED

REGARDING THE SPECIAL PRECAUTIONS LISTED BELOW.

FAILURE TO PROPERLY ADDRESS THESE CRITICAL

AREAS COULD RESULT IN PROPERTY DAMAGE OR LOSS,

PERSONAL INJURY, OR DEATH. THESE INSTRUCTIONS

ARE SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR

NATIONAL CODES.

Hazard Intensity Levels

1. DANGER: Indicates an imminently hazardous

situation which, if not avoided, WILL result in death or

serious injury.

2. WARNING: Indicates a potentially hazardous

situation which, if not avoided, COULD result in death or

serious injury.

3. CAUTION: Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor or

moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

Table of Contents

General Information .............................................................1

Inspection on Arrival ............................................................1

Special Precautions .............................................................2

SI (Metric) Conversion Factors............................................3

Unit Location........................................................................3

Location Recommendations .........................................3

Installation............................................................................3

Mounting .......................................................................3

Combustion/Ventilation Air Requirements.....................4

Gas Connections ..........................................................5

Electrical Connections ..................................................6

Start-Up Procedure..............................................................6

Pilot Flame Adjustment .................................................7

Main Burner Adjustment................................................7

Available Controls / Operating Sequence.....................8

Dimensions .........................................................................9

Maintenance ........................................................................9

Service & Troubleshooting.................................................10

Replacement Parts Ordering .............................................11

Model Number Designations.......................................11

Serial Number Designations .......................................11

Warranty.............................................................................12

CAUTION

1. Units are designed for indoor installation only. DO NOT

LOCATE UNITS OUTDOORS.

2. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

2

IMPORTANT

1. Approval requirements for infrared heaters specify that the

suspended type heaters shall be installed in accordance

with certain sections of the National Fire Codes published

by the National Fire Protection Association and various

ANSI standards. SOME of the requirements are listed

below.

Aircraft Hangars: Approval requirements are contained in

the current edition of ANSI/NFPA 409 (or in accordance

with the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are contained

in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of

local codes, in accordance with the current edition of

CAN/CGA B149 and the Canadian Electric Code, C22.1.

2. Start-up and adjustment procedures should be performed

by a qualified service agency.

3. To check most of the Possible Remedies in the trouble

shooting guide listed in Tables 10.1 and 11.1, refer to the

applicable sections of the manual.

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame; use a soap solution

or equivalent for testing.

2. Gas pressure to unit controls must never exceed 14"

W.C. (1/2 psi).

3. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage.

4. All units must be wired strictly in accordance with the

wiring diagram furnished with the unit. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

5. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

6. When servicing or repairing this equipment, use only

manufacturer-approved service replacement parts. A

complete replacement parts list may be obtained by

contacting Modine Manufacturing Company. Refer to the

rating plate on the unit for complete unit model number,

serial number, and company address. Any substitution of

non-approved parts or controls will be at the owner’s risk.

7. To prevent flame bail-out from the heater, the gas input to

the appliance, as indicated on the serial plate, must not

exceed the rated input by more than 5% or fall below the

rated input by more than 5%.

8. To prevent gas control circuit malfunction, the supply

voltage to the unit, as indicated on the serial plate must

not exceed or fall below the rated input voltage by more

than 5%.

IMPORTANT

Approval requirements for infrared heaters specify that the

suspended type heaters shall be installed in accordance

with certain sections of the National Fire Codes published

by the National Fire Protection Association and various

ANSI standards. SOME of the requirements are listed

below.

Aircraft Hangars: Approval requirements are contained in

the current edition of ANSI/NFPA 409 (or in accordance

with the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are contained

in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of local

codes, in accordance with the current edition of CAN/CGA

B149 and the Canadian Electric Code, C22.1.

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere.

CAUTION

Units are designed for indoor installation only.

DO NOT LOCATE UNITS OUTDOORS.

To Convert Multiply By To Obtain

" W.C.

(inches water column)

0.24 kPa

psig 6.893 kPa

°F

subtract 32 and then

°C

multiply by 0.555

inches 25.4 mm

feet 0.305 meters

cfm (ft3/min) 0.028 m3/min

cfh (ft3/hr) 1.699 m3/min

Btu/ft

3

0.0374 mJ/m

3

pound 0.453 kg

Btu/hr 0.000293 kW/hr

gallons 3.785 liters

Table 3.1

SI (METRIC) CONVERSION FACTORS

UNIT LOCATION

SI (METRIC) CONVERSION FACTORS / UNIT LOCATION / INSTALLATION

Location Recommendations

1. When locating the heater, consider the general space and

heating requirements and availability of gas and electrical

supply.

2. Be sure the structural support and chain at the unit

location is adequate to support the weight of the unit.

3

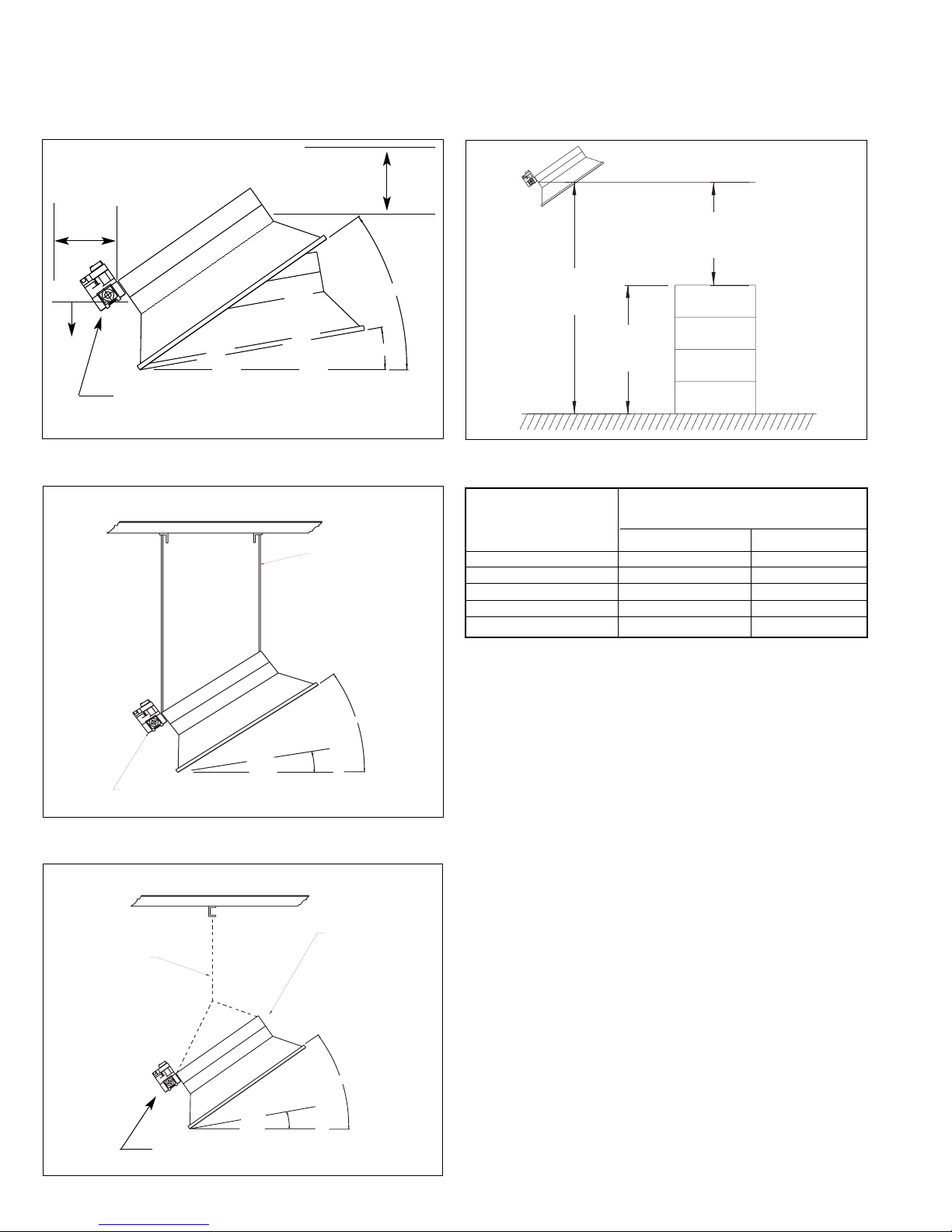

Table 3.2

Combustible Material Clearances

➀➀

Minimum Clearances to Combustible Materials

(inches)

Top Sides Rear Bottom

MT28/30/33 30 30 24 72

MT56/60/66 36 36 33 88

MT84/90/99 48 42 39 104

MT112/120/132 54 48 45 120

MT160 60 54 51 136

Model

No.

3. Be sure that the minimum clearances to combustible

materials and for serving are maintained. The minimum

clearances to combustibles are shown in Table 3.2.

4. Mounting height (measured from the bottom of unit) at

which heaters are installed is critical. Please refer to

mounting height information in Table 4.1.

5. Do not locate units in areas where chlorinated,

halogenated, or acid vapors are present in the atmosphere.

INSTALLATION

Mounting

Figures 4.2 and 4.3 illustrate typical rigid and chain mounting

arrangements, respectively, for a model MT infrared heater.

Check local codes for mounting requirements and use of flexible

gas connectors. Local codes may require rigid mounting. Heaters

must be mounted at angles from 10°to 35°from horizontal. The

gas manifold must be located on the low end of the heater, in a

horizontal position (parallel to the floor).

Where permissible, chain mounting is recommended. 5' chain

mounting sets are available as an accessory, allowing for 10° to

35° mounting angles. In the absence of this chain set, Number

1/0 Tenso chain (200 lb. working load) is recommended. “S”

hooks should be a minimum

1

/4" in diameter and the ends must

be closed after installation. Heaters located in aircraft hangers

or near overhead doors must be rigidly mounted to prevent

swinging. Under no circumstances should the gas supply line

or the electrical supply line to the heater be used to provide any

assistance in the suspension of the heater. Do not locate any

gas or electric service lines directly above or below the heater.

Insure that:

1. Clearances to combustibles (as shown on the rating plate

and in Table 3.2) are maintained.

2. For proper operation, the unit must be mounted on an angle

ten to thirty-five degrees (10°to 35°) from the horizontal

with the gas manifold located at the low end of the heater.

See Figure 4.1.

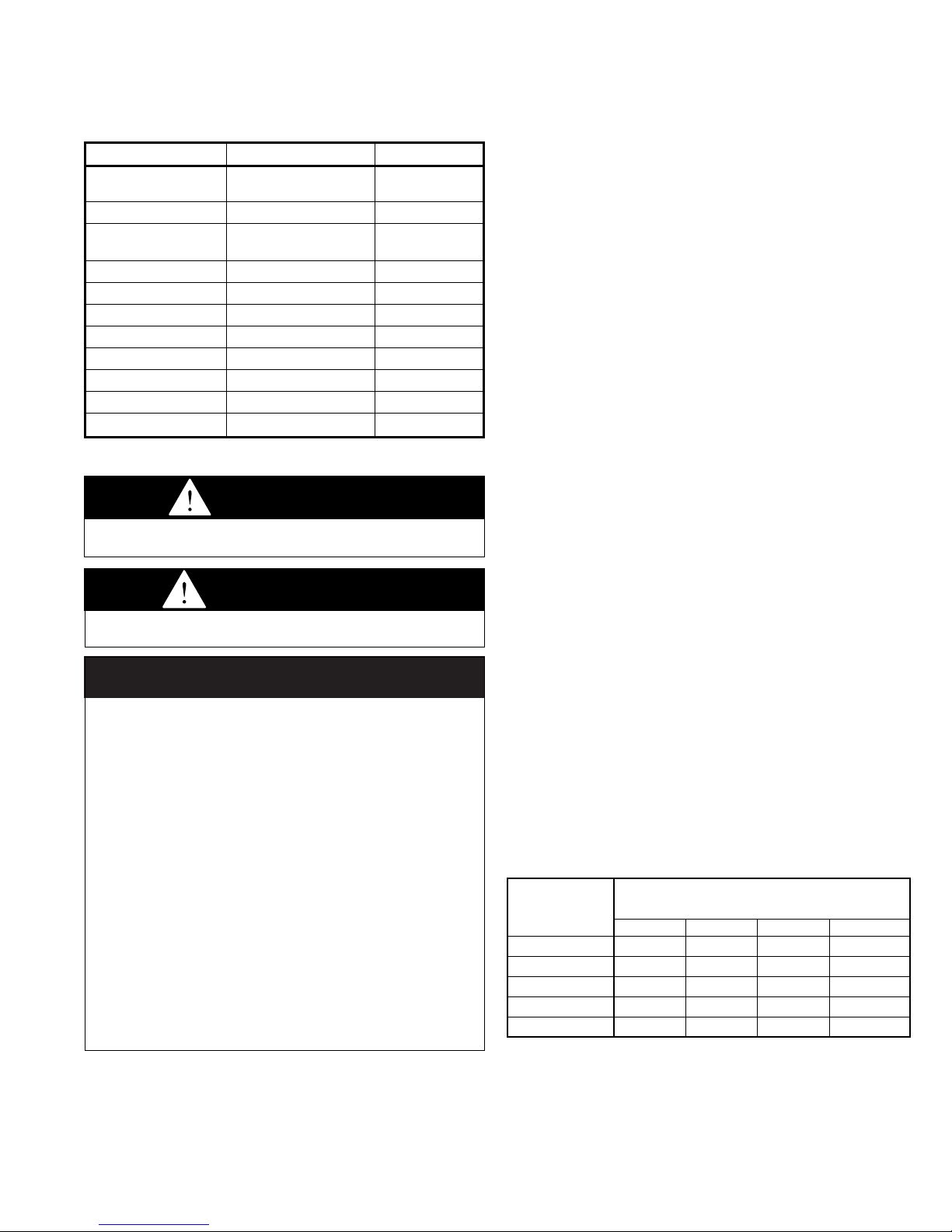

3. In locations used for storage of combustible materials,

signs shall be posted to specify the maximum permissible

stacking height to maintain required clearances from the

heater to the combustibles. See Figure 4.4.

4. Either gas piping or suspension mounting is flexible to

prevent fatigue failure from vibration or thermal expansion.

5. Adequate clearances to sprinkler heads are maintained.

➀ See figure 4.1 on page 4.

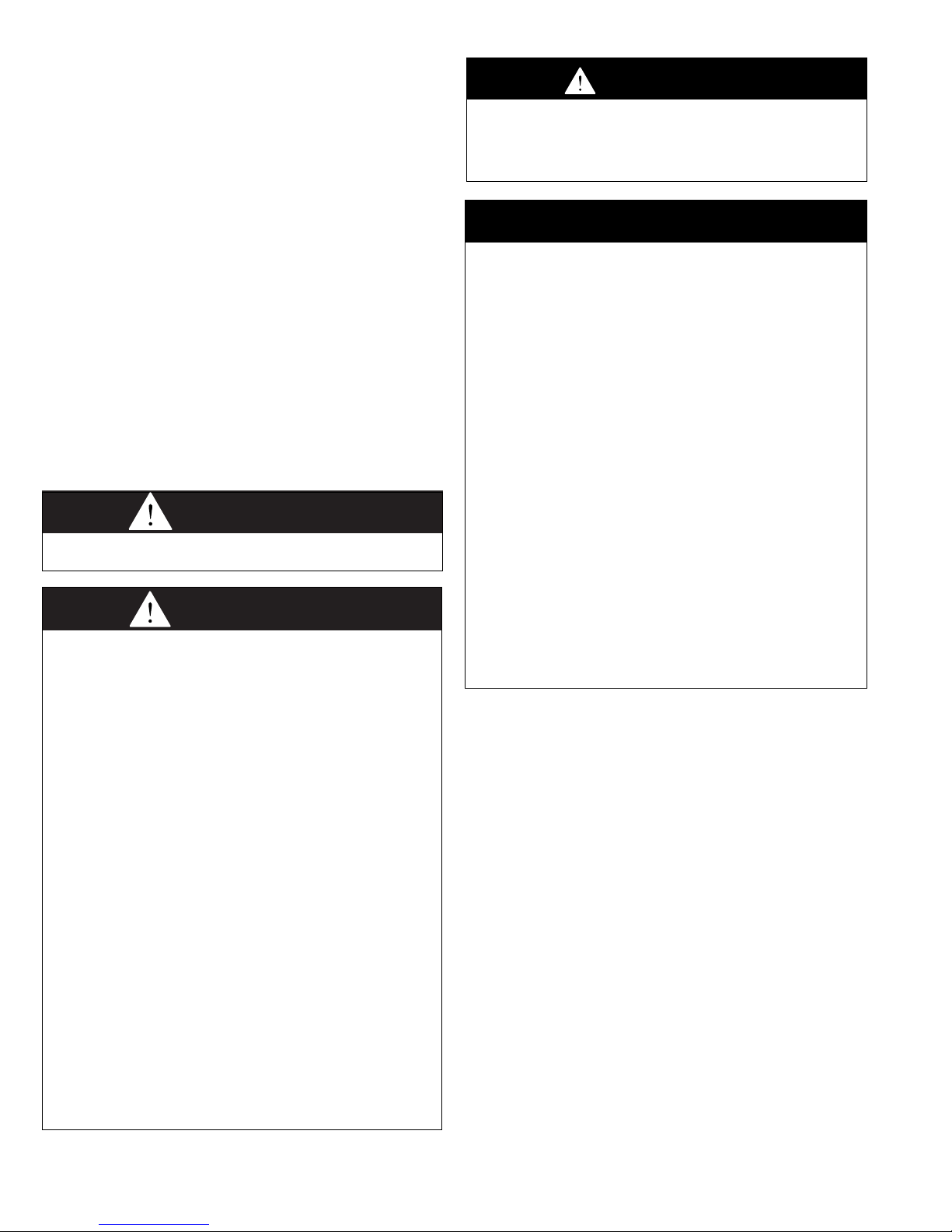

Figure 4.2

Typical Rigid Mounting Configuration

Figure 4.3

Typical Chain Mounting Configuration

Figure 4.4

Stacking Height

Table 4.1

Typical Mounting Height for Full Building Heating

INSTALLATION

Typical Mounting Height at Min/Max

Model No.

Mounting Angles (feet)

➀➀

10° 35°

MT28, 30, 33 8-14 7-12

MT56, 60, 66 14-20 12-16

MT84, 90, 99 20-26 16-24

MT112, 120, 132 26-32 20-30

MT160 26-40 22-38

➀➀

Mounting height values are recommendations only and may need to be

adjusted to meet requirements of actual installation.

4

e

OVERHEAD STRUCTURE AND FIELD CONNECTIONS MUST

N

G

l

t

d)

N

G

l

t

OVERHEAD STRUCTURE AND FIELD CONNECTIONS MUST

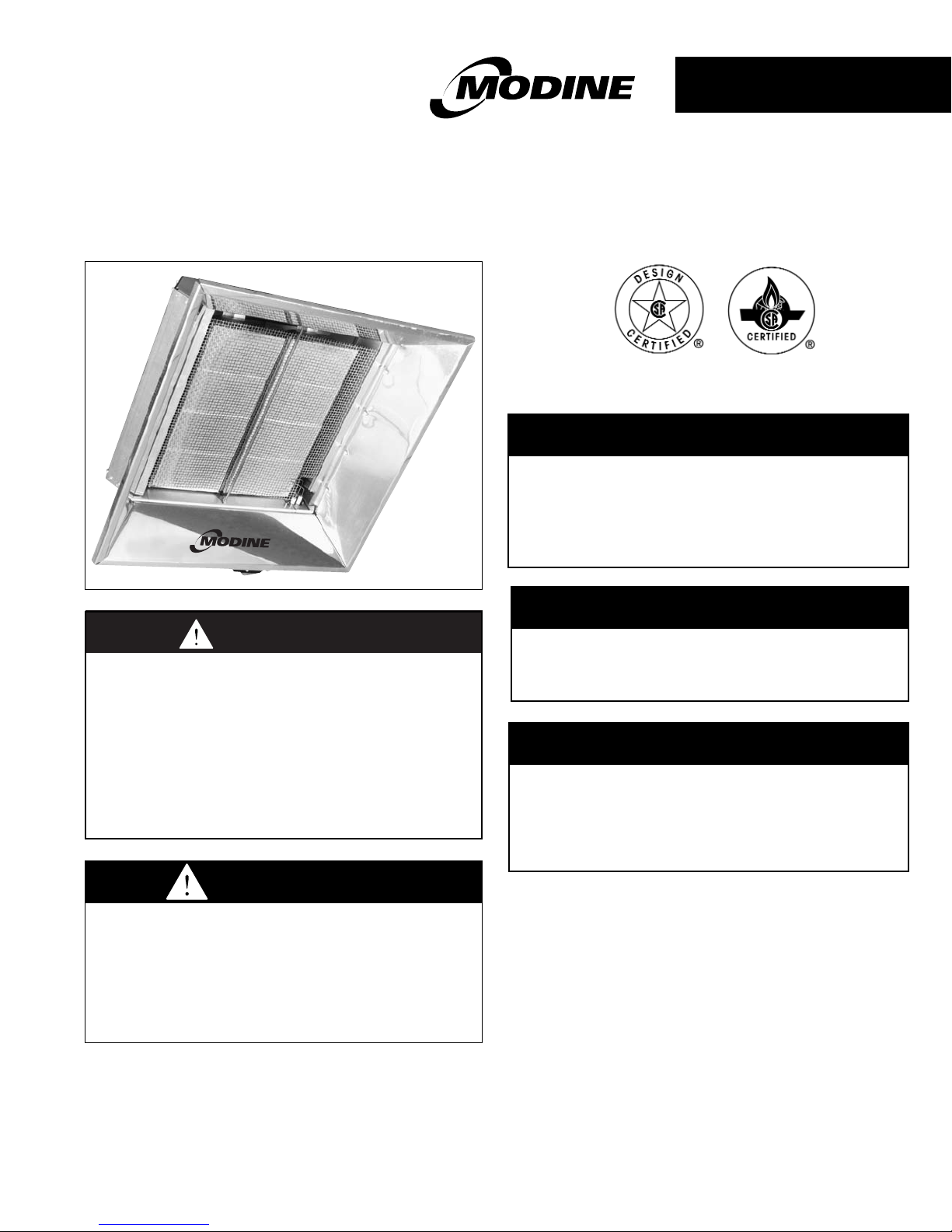

Figure 4.1

Combustible Material Clearances

REAR

BELOW

THE GAS MANIFOLD AND CONTROLS MUST BE

LOCATED AT THE LOW END OF THE HEATER

TOP

NOTE:

Gas manifold MUST be located on the low

side of the heater.

Combustion/Ventilation Air Requirements

Maintain positive air displacement of 4 cfm per 1000 Btu/hr for

natural gas and 5 cfm per 1000 Btu/hr for propane. The fresh

air supply must be located in the immediate proximity of the

unit(s). Fresh air intake openings are typically located high

on the building sidewalls at a comparable level to the heaters.

One square inch of net free inlet area per 1000 Btu/hr is

required. Multiple inlets, well distributed, should be used and

should direct air upward to prevent drafts at floor level. Inlets

are typically limited to 1 to 2 square feet in size.

It is recommended that units be interlocked with mechanical

exhaust fans for unvented applications. Mechanical exhaust

fans are typically located at high points of the building. For flat

roof areas, a series of small exhausters should be distributed

over the roof areas and interlocked with various heating zones.

BE ADEQUATE TO SUPPORT WEIGHT OF THE HEATER.

OTE:

as main and electrical

ines must not cross over

op of heater.

35˚ MAX.

10˚ MIN.

3/8" All thread rigid mount

(Used in aircraft hangers or

where draft conditions may b

expected.)

Minimum Clearance to

Combustible Materials

Mounting

Height

Stacking

Height

NOTE:

Gas manifold MUST be located

on the low side of the heater.

BE ADEQUATE TO SUPPORT WEIGHT OF THE HEATER.

OTE:

as main and electrical

ines must not cross over

op of heater.

5' Chain Mounting Set

Minimum

10˚

Horizontal Plane

'S' Hooks: 1/4" Dia. wire

(Crimp all 'S' hooks close

35˚ Maximum

Minimum

10˚

Horizontal Plane

35˚

Maximum

1. Installation of piping must conform with local building

codes, or in the absence of local codes, of the National

Fuel Gas Code, ANSI Z223.1 (NFPA 54) - Latest Edition. In

Canada, installation must be in accordance with CAN/CGAB149.1 for natural gas units and CAN/CGA-B149.2 for

propane units.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line. Refer to Table 7.1 to

determine the cubic feet per hour (cfh) for the type of gas

and size of unit to be installed. Using this cfh value and the

length of pipe necessary, determine the pipe diameter from

Table 5.1. Where several units are served by the same

main, the total capacity, cfh and length of main must be

considered. Avoid pipe sizes smaller than 1/2". Table 5.1

allows for a 0.3" W.C. pressure drop in the supply pressure

from the building main to the unit. The inlet pressure to the

unit must be 7-14" W.C. for natural gas and 11-14" W.C. for

propane gas. When sizing the inlet gas pipe diameter,

make sure that the unit supply pressure can be met after

the 0.3" W.C. has been subtracted. If the 0.3" W.C.

pressure drop is too high, refer to the Gas Engineers

Handbook for other gas pipe capacities.

3. Install a ground joint union with brass seat and a manual

shut-off valve adjacent to the unit for emergency shut-off

and easy servicing of controls, including a 1/8" NPT

plugged tapping immediately upstream of the gas supply

connection to the heater, accessible for test gauge

connection. See Figure 5.1.

4. Installation of a sediment trap in the gas supply line before

each unit is required to minimize the possibility of loose

scale or dirt within the gas supply line entering the heater

gas control system. See Figure 5.1.

5. An approved flexible connector may be used (local codes

permitting) as a convenient method of connecting the

heaters to the gas supply and to avoid placing stress on

the gas supply line.

6. When pressure/leak testing pressures above 14" W.C. (1/2

psi), close the field installed shut-off valve, disconnect the

appliance, and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

Figure 5.1

Recommended Sediment Trap/Manual Shut-Off Valve

Installation

INSTALLATION

5

Gas Pipe Capacities (Up to 14" W.C. Gas Pressure through Schedule 40 Pipe)

Cubic Feet per Hour with Pressure Drop of 0.3" W.C.

Natural Gas Specific Gravity – 0.60, Propane Specific Gravity – 1.50

Length Pipe Diameter

Of Pipe 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

(feet) Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

10 132 83 278 175 520 328 1050 662 1600 1008 3050 1922

20 92 58 190 120 350 221 730 460 1100 693 2100 1323

30 73 46 152 96 285 180 590 372 890 561 1650 1040

40 63 40 130 82 245 154 500 315 760 479 1450 914

50 56 35 115 72 215 135 440 277 670 422 1270 800

60 50 32 105 66 195 123 400 252 610 384 1150 725

70 46 29 96 60 180 113 370 233 560 353 1050 662

80 43 27 90 57 170 107 350 221 530 334 990 624

90 40 25 84 53 160 101 320 202 490 309 930 586

100 38 24 79 50 150 95 305 192 460 290 870 548

125 34 21 72 45 130 82 275 173 410 258 780 491

150 31 20 64 40 120 76 250 158 380 239 710 447

Table 5.1

Gas Pipe Capacities

Gas Connections

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas pressure to unit controls must never exceed 14"

W.C. (1/2 psi).

3. To prevent flame bail-out from the heater, the gas input

to the appliance as indicated on the serial plate, must not

exceed the rated input by more than 5% or fall below the

rated input by more than 5%.

SUPPLY LINE

GAS

SUPPLY LINE

3"

MIN.

GAS

SEDIMENT

TRAP

MANUAL GAS

SHUT-OFF VALVE

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

GROUND

JOINT

UNION

W/ BRASS

SEAT

TO

CONTROLS

Electrical Connections

1. Installation of wiring must conform with local building codes,

or in the absence of local codes, of the National Electric

Code ANSI/NFPA 70 - Latest Edition. Unit must be

electrically grounded in conformance to this code. In

Canada, wiring must comply with CSA C22.1 Part 1,

Electrical Code.

2. The power supply to the unit should be protected with a

fused disconnect switch.

3. Provide only the voltage to the heater as stamped on the

heater serial plate. Do not provide external power to a

heater equipped with a millivolt, self-energizing control

system (Control Codes 27 or 67).

4. Heaters equipped with 25V controls (Control Codes 04, 48,

or 75) require a step-down transformer having a VA rating

in excess of the total connected electrical load.

5. The heater is not to be energized until gas is available at

the heater. Failure to observe this point may result in failure

of control components.

6. Wiring must not be located directly above or below the

heater to avoid overheating of the wires. The wires must

not touch the sides of the heater.

7. Control wire used to connect the heater to the thermostat

must have adequate ampacity and insulation temperature

rating for the total connected load.

START-UP PROCEDURE

1. Turn off power to the unit at the disconnect switch. Check

that fuses or circuit breakers are in place and sized

correctly. Turn all hand gas valves to the “OFF” position.

2. Check that the supply voltage matches the unit supply

voltage listed on the serial plate. Verify that all wiring is

secure and properly protected. Trace circuits to insure the

unit has been wired according to the wiring diagram.

3. Verify that there is adequate ventilation for intake of fresh

air and exhaust of products of combustion.

4. Perform a visual inspection of the unit to make sure no

damage has occurred during installation.

5. Recheck the gas supply pressure. The inlet pressure to the

unit must be 7-14" W.C. for natural gas and 11-14" W.C. for

propane gas. The gas supply pressure must never exceed

14" W.C. If the pressure exceeds 14" W.C., a gas pressure

regulator must be added upstream of the combination gas

valve.

6. Open the field installed manual shut-off valve and turn

power on to the unit.

7. Follow the procedure on the heater’s Lighting Instruction

Label to put the heater into operation. Be certain the gas

line is purged of air prior to attempting to operate the unit.

8. For units equipped with a pilot, check the pilot flame length

(See Pilot Flame Adjustment section).

9. Check to make sure that the main gas valve opens upon a

call for heat from the thermostat.

10. Check to insure that gas controls sequence properly (See

Control Operating Sequence, page 8).

CAUTION

Purging of air from gas lines should be performed as

described in ANSI Z223.1 - Latest Edition “National Fuel Gas

Code”, or in Canada, CAN/CGA-B149 codes.

6

INSTALLATION / START-UP PROCEDURE

WARNING

Disconnect power supply before making wiring connections to

prevent electrical shock and equipment damage.

All units must be wired strictly in accordance with wiring

diagram furnished with the unit. Any wiring different from the

wiring diagram could result in a hazard to persons and

property.

Any original factory wiring that requires replacement must be

replaced with wiring material having a temperature rating of at

least 105°C.

To prevent gas control circuit malfunction, the voltage to the

unit, as indicated on the serial plate, must not exceed or fall

below the rated input voltage by more than 5%.

IMPORTANT

Start-up and adjustment procedures should be performed by a

qualified service agency.

7

START-UP PROCEDURE

Pilot Flame Adjustment (Intermittent Pilot and

Millivolt Standing Pilot control systems – Control

Codes 04, 08, 27, and 67

The pilot burner is orificed to burn properly with an inlet

pressure of 7-14" W.C. on natural gas and 11-14" W.C. on

propane gas, but final adjustment must be made after

installation. If the pilot flame is too long or large, it is possible

that it may cause soot on the burner assembly. If the pilot flame

is shorter than shown, it may cause poor ignition and result in

the controls not opening the combination gas control. A dirty

pilot orifice may cause a short flame. Pilot flame condition

should be observed periodically to assure trouble-free

operation.

To adjust the pilot flame:

1. Create a call for heat from the thermostat.

2. Remove the cap from the pilot adjustment screw. For

location, see the combination gas control literature supplied

with unit.

3. Adjust the pilot flame length by turning the screw in or out

to achieve a soft steady flame 3/4" to 1" long and

encompassing 3/8"-1/2" of the tip of the flame sensing rod

or power-pile (See Figure 7.1).

4. Replace the cap from the pilot adjustment screw.

Main Burner Adjustment

The gas pressure regulator (integral to the combination gas

control) is adjusted at the factory for average gas conditions.

It is important that gas be supplied to the heater in accordance

with the input rating on the serial plate. Actual input should be

checked and necessary adjustments made after the heater is

installed. Over-firing, a result of too high an input, reduces the life

of the appliance and increases maintenance. Under no

circumstances should the input exceed that shown on the serial

plate.

Measuring the manifold pressure is done at the test port on the

main gas valve on the unit (See Figure 7.2).

To adjust the manifold pressure:

1. The correct manifold pressure is 6" W.C. for natural gas

and 10" W.C. for propane gas. Adjust the main gas

pressure regulator spring to achieve the proper manifold

pressure (see Figure 7.2).

2. Move the field installed manual shut-off valve to the “OFF”

position.

3. Remove the 1/8" pipe plug in the gas valve adjacent to the

manifold and attach a water manometer of “U” tube type

that is at least 12" high.

4. Move the field installed manual shut-off valve to the “ON”

position.

5. Create a call for heat from the thermostat.

6. After adjustment, move the field installed manual shut-off

valve to the “OFF” position and replace the 1/8" pipe plug.

7. After the plug is in place, move the field installed manual

shut-off valve to the “ON” position and recheck pipe plugs

for gas leaks with a soap solution.

Figure 7.1

Correct Pilot Flame (Millivolt Powerpile shown)

Figure 7.2

Gas Valve Features

Pilot Adjustment

Screw (Under Cap)

Regulator Adjustment

Screw (Under Cap)

Plugged Outlet

Pressure Tap

Pilot Line

Connectio

n

Control

Knob

Type of Gas Natural Propane

Model

Btu/Ft.

3

1040 2500 No. of

Size

Specific Gravity 0.60 1.53 Orifices

Manifold Pressure In. W.C. 6.0 10

MT-28

cfh 26.4 -

1

Orifice Drill Size #43 -

MT-30

cfh 28.8 12.0

1

Orifice Drill Size #42 #52

MT-33

cfh 32.2 -

1

Orifice Drill Size #41 -

MT-56

cfh 52.9 -

2

Orifice Drill Size #43 -

MT-60

cfh 57.7 24.0

2

Orifice Drill Size #42 #52

MT-66

cfh 64.4 -

2

Orifice Drill Size #41 -

MT-84

cfh 79.3 -

3

Orifice Drill Size #43 -

MT-90

cfh 86.5 36.0

3

Orifice Drill Size #42 #52

MT-99

cfh 96.6 -

3

Orifice Drill Size #41 -

MT-112

cfh 105.8 -

4

Orifice Drill Size #43 -

MT-120

cfh 115.4 48.0

4

Orifice Drill Size #42 #52

MT-132

cfh 128.8 -

4

Orifice Drill Size #41 -

MT-160

cfh 153.8 64.0

4

Orifice Drill Size #38 #49

Table 7.1

Manifold Pressure and Gas Consumption

8

Control Systems Options

The MT series infrared heaters are available with a choice of

three different gas control options. The available controls and

associated control codes are (see Table 8.1 for description of

Control Codes):

• Direct spark ignition with 100% safety lockout with manual

reset

Natural Gas – Control Code 47 or 48

Propane Gas – Control Code 97 or 75

• Intermittent pilot ignition with non-100% shut-off

Natural Gas only – Control Code 08 or 04

• Millivolt, self-energizing with standing pilot and 100% safety

shutoff

Natural Gas – Control Code 27

Propane Gas – Control Code 67

Control Operating Sequence

Direct Spark Ignition Gas Controls – Control Codes

47, 48, 97, and 75

Utilizes a single-stage combination gas control, an ignition

control, and a single-stage thermostat.

1. The thermostat calls for heat.

2. The main gas valve opens and the spark igniter sparks in

an attempt to light the gas at the ceramic burner.

3. Once the burner is lit, the flame sensor proves ignition and

stops the spark igniter from sparking. If ignition is not

proven (the burner does not light) within 15 seconds, the

system will lockout, de-energizing the gas valve and ignition

control system. If the system locks out, it may be reset by

an interruption of the power source. The system will then

attempt to light the burner, if a call for heat from the

thermostat remains.

4. The unit continues to operate until the thermostat is

satisfied, at which time the main gas valve closes 100%

and the unit shuts off.

Intermittent Pilot Ignition with Non-100% Shut-Off

Gas Controls – Control Codes 08 and 04

Utilizes a single-stage combination gas control, an ignition

control, and a single-stage thermostat.

1. The thermostat calls for heat.

2. The pilot gas valve opens and the pilot spark igniter sparks

in an attempt to light the pilot.

3. The pilot flame sensor attempts to prove pilot ignition. If the

pilot does not light, ignition sparking and pilot gas flow will

continue until the pilot flame is established.

4. Once the pilot is lit, the pilot flame sensor proves ignition

and stops the spark igniter from sparking. At the same time

the main gas valve is opened and the ceramic burner is lit.

The unit continues to operate until the thermostat is

satisfied, at which time the main gas and pilot gas valves

are closed 100% and the unit shuts off.

Millivolt, Self-Energizing with Standing Pilot and

100% Safety Shutoff Gas Controls – Control Codes

26 and 67

Utilizes a single-stage combination gas control and a singlestage millivolt thermostat.

1. The pilot is manually lighted with the gas valve control knob

depressed in the PILOT position and held (approximately 1

minute) until the millivolt generator is heated sufficiently to

keep the pilot valve open. The control knob is then turned

to the ON position.

2. Upon a call for heat, the millivolt thermostat contacts close,

completing the circuit to the gas valve. The gas valve will

open and the ceramic burner is lit from the standing pilot.

3. Once the millivolt thermostat is satisfied, the main gas valve

closes 100% and the unit shuts off, with the pilot valve

remaining open with a standing pilot.

4. If the pilot goes out, the millivolt generator will cool and

interrupt the circuit to the pilot valve. Both the pilot and

main gas valves are closed 100%. The unit remains

inactive until step 1 is repeated.

START-UP PROCEDURE

Table 8.1

Performance and Available Control Systems

➀ ➁

➀ Model MT high intensity infrared heaters with direct spark or intermittent pilot ignition are equipped with 25 volt controls.

➁ Control codes specified for line voltage supply include 115V/25V step-down transformers.

Direct Spark Ignition of Burner

➀

Intermittent Pilot

➀

Millivolt, Self Energizing

100% Safety Lockout with Manual Reset Non 100% Shut Off Standing Pilot, 100% Safety Shut Off

Control Code - Supply/Thermostat Voltage Control Code - Supply/Thermostat Voltage Control Code - Thermostat Voltage

Natural Gas Propane Gas Natural Gas Natural Gas Propane Gas

Model No.

47 - 115V ➁ 48 - 25V 97 - 115V ➁ 75 - 25V 08 - 115V ➁ 04 - 25V 27 - Millivolt 67 - Millivolt

MT-28

••

N/A N/A

•• •

N/A

MT-30

•••• • • • •

MT-33

••

N/A N/A

•• •

N/A

MT-56

••

N/A N/A

•• •

N/A

MT-60

•••• • • • •

MT-66

••

N/A N/A

•• •

N/A

MT-84

••

N/A N/A

•• •

N/A

MT-90

•••• • • • •

MT-99

••

N/A N/A

•• •

N/A

MT-112

••

N/A N/A

•• •

N/A

MT-120

•••• • • • •

MT-132

••

N/A N/A

•• •

N/A

MT-160

••••

N/A N/A N/A N/A

9

DIMENSIONS / MAINTENANCE

Figure 9.1

Unit Drawing

Table 9.1

Dimensions

Dimensions Radiating Shipping

(Inches) Area Weight

A B (Sq. Inches) (Lbs.)

MT28,30,33 17.12 7.63 93 30

MT56,60,66 24.00 14.44 186 40

MT84,90,99 30.75 21.25 279 48

MT112,120,132,160 37.58 28.08 372 59

Model

Numbers

Note: All models except MT160 include a secondary re-radiating grid screen (shown in drawing above).

MAINTENANCE

All heating equipment should be serviced before each

heating season to assure proper operation. The following

items may require more frequent service based on the

environment in which the unit is installed, and how long

the unit is operated.

Burner Assembly

Disconnect all electrical power to the heater and close

the gas supply valve installed adjacent to the heater.

With an air hose regulated to 15 psig maximum, blow

off any dust and dirt that has accumulated on the heater,

by blowing across the ceramic burner (not directly at the

ceramic burner). Do not insert the air hose into the inlet

of each venturi tube.

Burner Orifice

Remove each burner orifice, clean, and reinstall on the

heater manifold. Drill sizes can be found in Table 7.1.

Pilot Assembly (not applicable for Direct Spark Ignition)

Remove the pilot burner assembly. With an air hose regulated to 15

psig maximum, blow the assembly clean and replace in the original

position.

Electrical Wiring

The electrical wiring should be checked annually for loose

connections or deteriorated insulation.

Gas Piping & Controls

The gas valves and piping should be checked annually for

general cleanliness and tightness. The gas controls should be

checked to insure that the unit is operating properly.

A

B

23.75

16.13

4X .312 Dia Mounting Holes

9.00

4.75

17.00

No Gas 1. Main gas is off. 1. Open manual gas valve.

2. Power supply is off. 2. Turn on main power.

3. Air in gas line. 3. Purge gas line.

4. External regulator malfunctioning. 4. Replace external regulator.

5. External regulator reversed. 5. Remove and install regulator properly.

Pilot does not light 1. Main gas is off. 1. Open gas shut-off valve.

2. Power supply is off. 2. Turn on main power.

3. Air in gas line. 3. Purge gas line.

4. Dirt in pilot orifice. 4. Check for plugged pilot orifice and clean

with compressed air if necessary.

5. Gas pressure out of proper range. 5. Adjust to a maximum of 14" W.C.

Minimum for Natural Gas - 7" W.C.

Minimum for Propane Gas - 11" W.C.

6. Pilot valve does not open. 6. Check wiring for 24 volts to valve.

Defective ignition controller or gas valve.

7. No spark at igniter. 7.

a. Loose wire connections. a. Check all ignition controller wiring.

b. Pilot sensor is grounded. b. Replace sensor if cracked or worn.

c. Defective ignition controller. c. Replace ignition controller.

Pilot goes out on 100% 1. Defective pilot interrupter in combination gas 1. Replace combination gas valve.

shut-off when hold down valve .

button is released 2. Defective pilot flame sensor. 2. Replace pilot flame sensor.

3. Insufficient heat on pilot flame sensor. 3. Check pilot orifice for size. Clean pilot burner.

4. Improper pilot flame sensor location. 4. Check position with respect to pilot.

5. Connection is poor contact at valve end of the 5. Insure clean and tight contact.

sensing element.

6. Low gas pressure. 6. Provide proper gas pressure.

Main burners do not light 1. Defective valve. 1. Replace valve.

(Pilot is lit) 2. No electrical power to gas valve. 2. Check wiring to gas valve.

3. Defective pilot sensor. 3. Replace pilot sensor.

4. Defective ignition controller. 4. Replace ignition controller.

5. Improper thermostat wiring. 5. Verify wiring compared to diagram.

6. Manual valve closed on combination gas valve. 6. Turn knob to ON position on combination

gas valve.

Direct spark fails to ignite 1. Electrode improperly located 1. Relocate to correct position.

main burner(s) 2. Electrode ceramic cracked 2. Replace electrode

3. Electrode wire is loose, broken, or frayed. 3. Reconnect loose wire or replace broken or

frayed wire and/or electrode.

4. Low manifold gas pressure. 4. Provide proper gas pressure.

5. Gas valve fails to open. 5. Replace gas valve.

6. Ignition detection control defective. 6. Replace ignition control module.

Flashback (burning of 1. Heater mounted at incorrect angle. 1. Angle to be 10

°

to 35°from horizontal.

gas/air mixture inside 2. Excessive drafts. 2. Shield or relocate heater from drafts.

plenum) 3. Gas leak at manifold, gas valve, and/or pilot 3. Check all connections with soap solution

tube connections. and tighten as necessary.

4. Separation of ceramic tiles. 4. Replace burner assembly.

5. Ceramic grid(s) cracked. 5. Replace burner assembly.

Unit cycles off and on 1. Insufficient heat on pilot element. 1. Check pilot orifice, clean pilot burner.

2. Excessive drafts. 2. Shield or relocate unit from drafts.

10

SERVICE & TROUBLESHOOTING

Table 10.1 - Troubleshooting

Trouble Possible Cause Possible Remedy

IMPORTANT

To check most of the Possible Remedies in the troubleshooting

guide listed in Tables 10.1 and 11.1, refer to the applicable

sections of the manual.

CAUTION

Do not attempt to reuse any mechanical or electrical

controllers which have been wet. Replace defective controller.

WARNING

When servicing or repairing this equipment, use only factoryapproved service replacement parts. A complete replacement

parts list may be obtained by contacting Modine Manufacturing

Company. Refer to the rating plate on the appliance for

complete appliance model number, serial number, and

company address. Any substitution of parts or controls not

approved by the factory will be at the owner’s risk.

11

Table 11.1

Troubleshooting Continued

SERVICE & TROUBLESHOOTING / REPLACEMENT PARTS ORDERING

Heater will not turn off 1. Defective thermostat. 1. Repair or replace thermostat.

2. Gas valve stuck open. 2. Replace gas valve.

3. Unit undersized. 3. Check design conditions. If the unit is

undersized, additional heater(s) may be

required.

Dark spots on ceramic 1. Foreign matter behind the ceramic tile(s). 1. Clean ceramic tiles or replace.

Carbon formation on 1. Misaligned orifice. 1. Replace orifice.

ceramic surface of 2. Pilot depositing carbon. 2. Clean pilot burner, check pilot orifice.

burner 3. Obstruction in venturi tube. 3. Clean with a soft brush.

4. Low gas pressure. 4. Provide proper gas pressure.

5. Wrong gas supplied to the heater. 5. Check label for gas required.

Low heater output 1. Low inlet or manifold gas pressure 1. Adjust for proper gas pressure.

2. Orifice partially blocked with foreign matter. 2. Remove orifice, clean, and reinstall.

3. Products of combustion not adequately vented. 3. Provide adequate ventilation for products

of combustion.

4. Manifold misaligned from excessive torque 4. Replace the manifold.

applied at time of gas pipe installation.

5. Foreign matter in venturi tube. 5. Clean with a soft brush.

6. Gas supply piping too small. 6. Replace piping or increase gas supply

pressure.

7. Unit undersized. 7. Check design conditions. If unit is

undersized, an additional unit(s) or other

heat source must be added.

Gas odor 1. Loose pipe connection. 1. Check all connections with a soap solution

and tighten as necessary.

Control assembly 1. Heater not mounted correctly. 1. Angle to be 10

°

to 35°from horizontal.

overheating 2. Heater mounted too close to ceiling. 2. Check to main

t

ain proper top clearance.

Trouble Possible Cause Possible Remedy

For Servicing

If a qualified service person cannot solve a problem with the installation, please consult with your local gas company or

sales representative.

When servicing, repairing or replacing parts on these units, locate the model identification plate of the unit and always give the

complete Model Number and Serial Number from the model identification plate. The serial plate is located on the side of the

reflector. For a complete description of the Model Number or Serial Number, see Figures 11.1 and 11.2.

MT 30 G 47

Figure 11.1

Model Number Designations

Figure 11.2

Serial Number Designations

MT

High Intensity

Infrared Heater

Ignition

G - Spark Ignition

C - Standing Pilot, Millivolt System

Model

28

30

33

56

60

66

84

90

99

112

120

132

160

Control Code

Direct Spark Ignition

47 - Natural Gas, 115V

48 - Natural Gas, 25V

97 - Propane Gas, 115V

75 - Propane Gas, 25V

Intermittent Pilot Ignition

04 - Natural Gas, 25V

08 - Natural Gas, 115V

Millivolt, Self-Energizing

27 - Natural Gas, Millivolt

67 - Propane Gas, Millivolt

101 26 99 - 1256

SEQUENCE

NUMBER

YEAR OF

MANUFACTURE

99 – 1999

00 – 2000

etc.

WEEK OF

MANUFACTURE

01 – 1st week of year

26 – 26th week of year

SERIES IDENTITY

NUMBER

Identifies series of controls

Seller warrants its products to be free from defects in material and workmanship,

EXCLUSIVE, HOWEVER, of failures attributable to the use of materials substituted

under emergency conditions for materials normally employed. This warranty covers

replacement of any parts furnished from the factory of Seller, but does not cover

labor of any kind and materials not furnished by Seller, or any charges for any

such labor or materials, whether such labor, materials or charges thereon are due

to replacement of parts, adjustments, repairs, or any other work done. This

warranty does not apply to any equipment which shall have been repaired or

altered outside the factory of Seller in any way so as, in the judgment of Seller, to

affect its stability, nor which has been subjected to misuse, negligence, or

operating conditions in excess of those for which such equipment was designed.

This warranty does not cover the effects of physical or chemical properties of water

or steam or other liquids or gases used in the equipment.

BUYER AGREES THAT SELLER’S WARRANTY OF ITS PRODUCTS TO BE

FREE FROM DEFECT IN MATERIAL AND WORKMANSHIP, AS LIMITED

HEREIN, SHALL BE IN LIEU OF AND EXCLUSIVE OF ALL OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED, WHETHER ARISING FROM

LAW, COURSE OF DEALING, USAGE OF TRADE, OR OTHERWISE, THERE

ARE NO OTHER WARRANTIES, INCLUDING WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PURPOSE,WHICH EXTEND BEYOND

THE PRODUCT DESCRIPTION CONFIRMED BY BUYER AND SELLER AS OF

THE DATE OF FINAL AGREEMENT.

This warranty is void if the input to the product exceeds the rated input as

indicated on the product serial plate by more than 5% on gas-fired and oil-fired

units, or if the product in the judgment of SELLER has been installed in a corrosive

atmosphere, or subjected to corrosive fluids or gases, been subjected to misuse,

negligence, accident, excessive thermal shock, excessive humidity, physical

damage, impact, abrasion, unauthorized alterations, or operation contrary to

SELLER’S printed instructions, or if the serial number has been altered, defaced or

removed.

Heat Exchangers

For Seller’s non-sep

arated combustion Gas-Fired Unit Heaters

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY HEAT EXCHANGER

WHICH SHALL, WITHIN TEN YEARS FROM DATE OF FIRST BENEFICIAL

USE BY BUYER OR ANY OTHER USER, WITHIN TEN YEARS FROM DATE

OF RESALE BY BUYER OR ANY OTHER USER, WITHIN TEN YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION,

OR WITHIN ONE HUNDRED TWENTY-SIX MONTHS FROM DATE OF

SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST, BE RETURNED

TO SELLER WITH TRANSPORTATION CHARGES PREPAID AND WHICH

THE EXAMINATION OF SELLER SHALL DISCLOSE TO HAVE BEEN

DEFECTIVE; EXCEPT THAT WHEN THE PRODUCT IS TO BE USED BY

BUYER AS A COMPONENT PART OF EQUIPMENT MANUFACTURED BY

BUYER, BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL

BE LIMITED TO ONE YEAR FROM DATE OF SHIPMENT FROM SELLER.

FOR GAS-FIRED PRODUCTS INSTALLED IN HIGH HUMIDITY

APPLICATIONS AND UTILIZING STAINLESS STEEL HEAT EXCHANGERS,

BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE

LIMITED TO TEN YEARS FROM DATE OF SHIPMENT FROM SELLER.

For Seller's Low Intensity Gas-Fired Infrared Heaters

BUYER'S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY HEAT EXCHANGER

WHICH SHALL, WITHIN FIVE YEARS FROM DATE OF FIRST BENEFICIAL

USE BY BUYER OR ANY OTHER USER, WITHIN FIVE YEARS FROM DATE

OF RESALE BY BUYER OR ANY OTHER USER, WITHIN FIVE YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION,

OR WITHIN 66 MONTHS FROM DATE OF SHIPMENT FROM SELLER,

WHICHEVER OCCURS FIRST, BE RETURNED TO SELLER WITH

TRANSPORTATION CHARGES PREPAID AND WHICH THE EXAMINATION

OF SELLER SHALL DISCLOSE TO HAVE BEEN DEFECTIVE; EXCEPT THAT

WHEN THE PRODUCT IS TO BE USED BY BUYER AS A COMPONENT

PART OF EQUIPMENT MANUFACTURED BY BUYER, BUYER'S REMEDY

FOR BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO ONE YEAR

FROM DATE OF SHIPMENT FROM SELLER.

Heat Exchanger (Condensers) for all Seller’s products except nonseparated comb

ustion Gas-Fired Unit Heaters and Infrared Heaters, all

Burners except Infrared Heaters, and Sheet Metal for all Seller's products

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY HEAT EXCHANGER

(CONDENSER) OR BURNER WHICH SHALL, WITHIN ONE YEAR FROM

DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER,

WITHIN ONE YEAR FROM DATE OF RESALE BY BUYER IN ANY

UNCHANGED CONDITION, OR WITHIN EIGHTEEN MONTHS FROM DATE

OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST, BE

RETURNED TO SELLER WITH TRANSPORTATION CHARGES PREPAID

AND WHICH THE EXAMINATION OF SELLER SHALL DISCLOSE TO HAVE

BEEN DEFECTIVE; EXCEPT THAT WHEN THE PRODUCT IS TO BE USED

BY BUYER AS A COMPONENT PART OF EQUIPMENT MANUFACTURED

BY BUYER, BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN,

SHALL BE LIMITED TO ONE YEAR FROM DATE OF SHIPMENT FROM

SELLER.

Burners

For Seller's Low Intensity Gas-Fired Infrared Heaters

BUYER'S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY BURNER WHICH

SHALL, WITHIN TWO YEARS FROM DATE OF FIRST BENEFICIAL USE BY

BUYER OR ANY OTHER USER, WITHIN TWO YEARS FROM DATE OF

RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN 30

MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER

OCCURS FIRST, BE RETURNED TO SELLER WITH TRANSPORTATION

CHARGES PREPAID AND WHICH THE EXAMINATION OF SELLER SHALL

DISCLOSE TO HAVE BEEN DEFECTIVE; EXCEPT THAT WHEN THE

PRODUCT IS TO BE USED BY BUYER AS A COMPONENT PART OF

EQUIPMENT MANUFACTURED BY BUYER, BUYER'S REMEDY FOR

BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO ONE YEAR FROM

DATE OF SHIPMENT FROM SELLER.

For Seller's High Intensity Gas-Fired Infrared Heaters

BUYER'S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY BURNER WHICH

SHALL, WITHIN TEN YEARS FROM DATE OF FIRST BENEFICIAL USE BY

BUYER OR ANY OTHER USER, WITHIN TEN YEARS FROM DATE OF

RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN 126

MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER

OCCURS FIRST, BE RETURNED TO SELLER WITH TRANSPORTATION

CHARGES PREPAID AND WHICH THE EXAMINATION OF SELLER SHALL

DISCLOSE TO HAVE BEEN DEFECTIVE; EXCEPT THAT WHEN THE

PRODUCT IS TO BE USED BY BUYER AS A COMPONENT PART OF

EQUIPMENT MANUFACTURED BY BUYER, BUYER'S REMEDY FOR

BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO ONE YEAR FROM

DATE OF SHIPMENT FROM SELLER.

All Other Components Excluding Heat Exchanger (Condenser), Burner,

and Sheet Metal

For all Seller's products except Direct-Fired Heaters and High Intensity

Gas-Fired Infrared Heaters

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY PART OR PARTS

WHICH SHALL, WITHIN TWO YEARS FROM DATE OF FIRST BENEFICIAL

USE BY BUYER OR ANY OTHER USER, WITHIN TWO YEARS FROM DATE

OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

THIRTY MONTHS FROM DATE OF SHIPMENT FROM SELLER,

WHICHEVER OCCURS FIRST, BE RETURNED TO SELLER WITH

TRANSPORTATION CHARGES PREPAID AND WHICH THE EXAMINATION

OF SELLER SHALL DISCLOSE TO HAVE BEEN DEFECTIVE; EXCEPT THAT

WHEN THE PRODUCT IS TO BE USED BY BUYER AS A COMPONENT

PART OF EQUIPMENT MANUFACTURED BY BUYER, BUYER’S REMEDY

FOR BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO ONE YEAR

FROM DATE OF SHIPMENT FROM SELLER.

For Seller's Direct-Fired Heaters and High Intensity Gas-Fired Infrared Heaters

BUYER’S REMEDY FOR BREACH OF WARRANTY EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW IS LIMITED TO REPAIR OR

REPLACEMENT AT THE SELLER’S OPTION ANY PART OR PARTS WHICH

SHALL WITHIN A PERIOD OF ONE YEAR FROM DATE OF FIRST

BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN ONE YEAR

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION,

OR WITHIN 18 MONTHS FROM DATE OF SHIPMENT FROM SELLER,

WHICHEVER OCCURS FIRST, BE RETURNED TO SELLER WITH

TRANSPORTATION CHARGES PREPAID AND WHICH THE EXAMINATION

OF THE SELLER SHALL DISCLOSE TO HAVE BEEN DEFECTIVE.

BUYER AGREES THAT IN NO EVENT WILL SELLER BE LIABLE FOR COSTS

OF PROCESSING, LOST PROFITS, INJURY TO GOODWILL, OR ANY OTHER

CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND RESULTING

FROM THE ORDER OR USE OF ITS PRODUCT, WHETHER ARISING FROM

BREACH OF WARRANTY, NONCONFORMITY TO ORDERED

SPECIFICATIONS, DELAY IN DELIVERY, OR ANY LOSS SUSTAINED BY THE

BUYER.

WARRANTY

Commercial HVAC&R Division

Modine Manufacturing Company

1221 Magnolia Avenue

Buena Vista, Virginia 24416

Tel: 1-800-828-4328 (HEAT)

Fax: 540-261-1563 / 540-261-1903 (Service & Parts)

© 2003 Modine Manufacturing Company 11/03 - 4.5M Litho in USA

Loading...

Loading...