Modine Manufacturing MT28, MT30, MT33, MT56, MT60 Service Manual

...

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive harm.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

November, 2003

INSTALLATION AND SERVICE MANUAL

high intensity gas-fired infrared heaters

model MT

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency

must perform all installation and service of

these units.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to the transportation company and your local

sales representative.

2.

Check rating plate on unit to verify that the power supply

meets available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

9-500.3h

5H75283ALL

CAUTION

As with all infrared equipment, clearances to

combustible material are critical.

To prevent premature heat exchanger failure do

not locate ANY gas-fired units in areas where

chlorinated, halogenated, or acid vapors are

present in the atmosphere

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

DANGER

Appliances must not be installed where they may be exposed

to potentially explosive or flammable atmosphere.

Special Precautions

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN

ADDITION, PARTICULAR CARE MUST BE EXERCISED

REGARDING THE SPECIAL PRECAUTIONS LISTED BELOW.

FAILURE TO PROPERLY ADDRESS THESE CRITICAL

AREAS COULD RESULT IN PROPERTY DAMAGE OR LOSS,

PERSONAL INJURY, OR DEATH. THESE INSTRUCTIONS

ARE SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR

NATIONAL CODES.

Hazard Intensity Levels

1. DANGER: Indicates an imminently hazardous

situation which, if not avoided, WILL result in death or

serious injury.

2. WARNING: Indicates a potentially hazardous

situation which, if not avoided, COULD result in death or

serious injury.

3. CAUTION: Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor or

moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

Table of Contents

General Information .............................................................1

Inspection on Arrival ............................................................1

Special Precautions .............................................................2

SI (Metric) Conversion Factors............................................3

Unit Location........................................................................3

Location Recommendations .........................................3

Installation............................................................................3

Mounting .......................................................................3

Combustion/Ventilation Air Requirements.....................4

Gas Connections ..........................................................5

Electrical Connections ..................................................6

Start-Up Procedure..............................................................6

Pilot Flame Adjustment .................................................7

Main Burner Adjustment................................................7

Available Controls / Operating Sequence.....................8

Dimensions .........................................................................9

Maintenance ........................................................................9

Service & Troubleshooting.................................................10

Replacement Parts Ordering .............................................11

Model Number Designations.......................................11

Serial Number Designations .......................................11

Warranty.............................................................................12

CAUTION

1. Units are designed for indoor installation only. DO NOT

LOCATE UNITS OUTDOORS.

2. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

2

IMPORTANT

1. Approval requirements for infrared heaters specify that the

suspended type heaters shall be installed in accordance

with certain sections of the National Fire Codes published

by the National Fire Protection Association and various

ANSI standards. SOME of the requirements are listed

below.

Aircraft Hangars: Approval requirements are contained in

the current edition of ANSI/NFPA 409 (or in accordance

with the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are contained

in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of

local codes, in accordance with the current edition of

CAN/CGA B149 and the Canadian Electric Code, C22.1.

2. Start-up and adjustment procedures should be performed

by a qualified service agency.

3. To check most of the Possible Remedies in the trouble

shooting guide listed in Tables 10.1 and 11.1, refer to the

applicable sections of the manual.

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame; use a soap solution

or equivalent for testing.

2. Gas pressure to unit controls must never exceed 14"

W.C. (1/2 psi).

3. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage.

4. All units must be wired strictly in accordance with the

wiring diagram furnished with the unit. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

5. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

6. When servicing or repairing this equipment, use only

manufacturer-approved service replacement parts. A

complete replacement parts list may be obtained by

contacting Modine Manufacturing Company. Refer to the

rating plate on the unit for complete unit model number,

serial number, and company address. Any substitution of

non-approved parts or controls will be at the owner’s risk.

7. To prevent flame bail-out from the heater, the gas input to

the appliance, as indicated on the serial plate, must not

exceed the rated input by more than 5% or fall below the

rated input by more than 5%.

8. To prevent gas control circuit malfunction, the supply

voltage to the unit, as indicated on the serial plate must

not exceed or fall below the rated input voltage by more

than 5%.

IMPORTANT

Approval requirements for infrared heaters specify that the

suspended type heaters shall be installed in accordance

with certain sections of the National Fire Codes published

by the National Fire Protection Association and various

ANSI standards. SOME of the requirements are listed

below.

Aircraft Hangars: Approval requirements are contained in

the current edition of ANSI/NFPA 409 (or in accordance

with the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are contained

in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of local

codes, in accordance with the current edition of CAN/CGA

B149 and the Canadian Electric Code, C22.1.

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere.

CAUTION

Units are designed for indoor installation only.

DO NOT LOCATE UNITS OUTDOORS.

To Convert Multiply By To Obtain

" W.C.

(inches water column)

0.24 kPa

psig 6.893 kPa

°F

subtract 32 and then

°C

multiply by 0.555

inches 25.4 mm

feet 0.305 meters

cfm (ft3/min) 0.028 m3/min

cfh (ft3/hr) 1.699 m3/min

Btu/ft

3

0.0374 mJ/m

3

pound 0.453 kg

Btu/hr 0.000293 kW/hr

gallons 3.785 liters

Table 3.1

SI (METRIC) CONVERSION FACTORS

UNIT LOCATION

SI (METRIC) CONVERSION FACTORS / UNIT LOCATION / INSTALLATION

Location Recommendations

1. When locating the heater, consider the general space and

heating requirements and availability of gas and electrical

supply.

2. Be sure the structural support and chain at the unit

location is adequate to support the weight of the unit.

3

Table 3.2

Combustible Material Clearances

➀➀

Minimum Clearances to Combustible Materials

(inches)

Top Sides Rear Bottom

MT28/30/33 30 30 24 72

MT56/60/66 36 36 33 88

MT84/90/99 48 42 39 104

MT112/120/132 54 48 45 120

MT160 60 54 51 136

Model

No.

3. Be sure that the minimum clearances to combustible

materials and for serving are maintained. The minimum

clearances to combustibles are shown in Table 3.2.

4. Mounting height (measured from the bottom of unit) at

which heaters are installed is critical. Please refer to

mounting height information in Table 4.1.

5. Do not locate units in areas where chlorinated,

halogenated, or acid vapors are present in the atmosphere.

INSTALLATION

Mounting

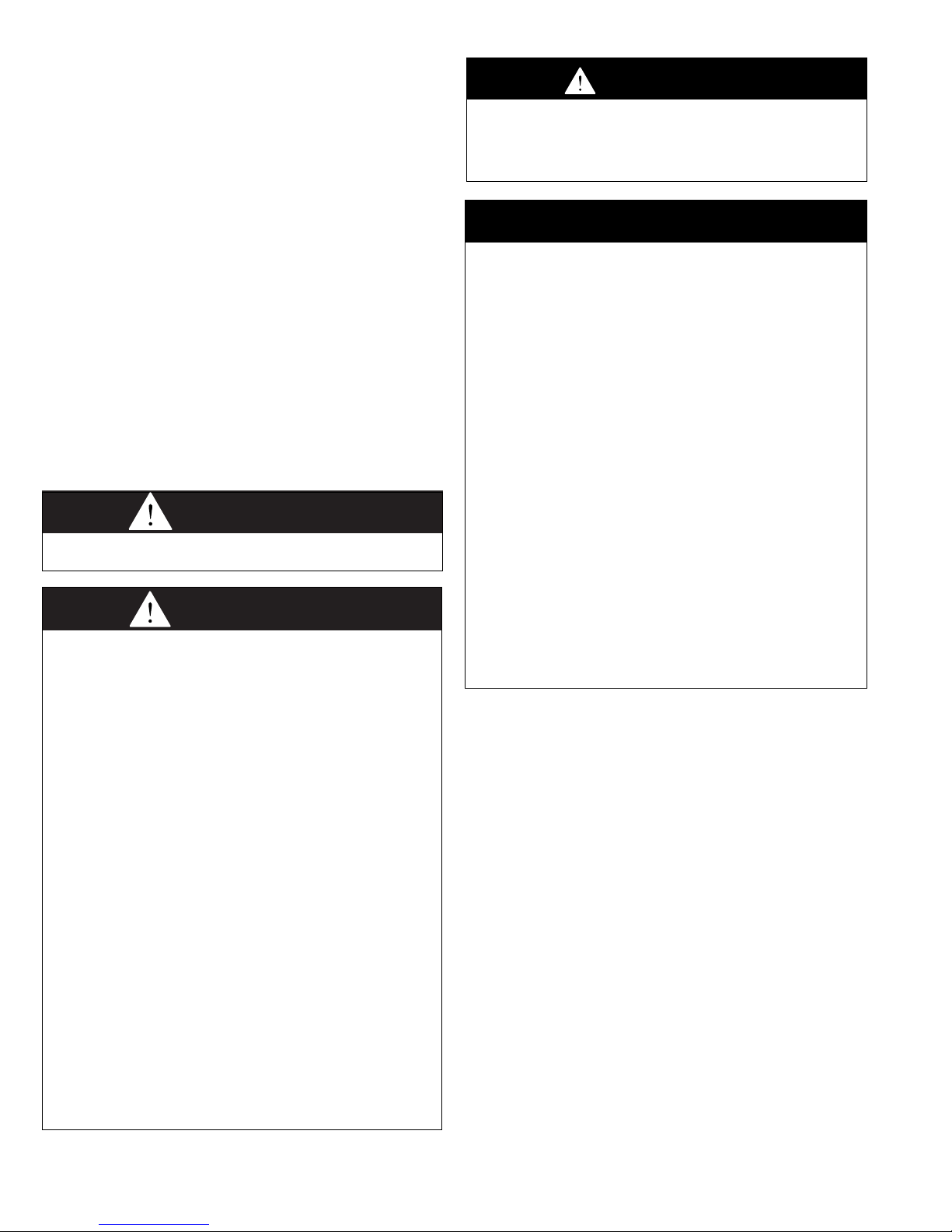

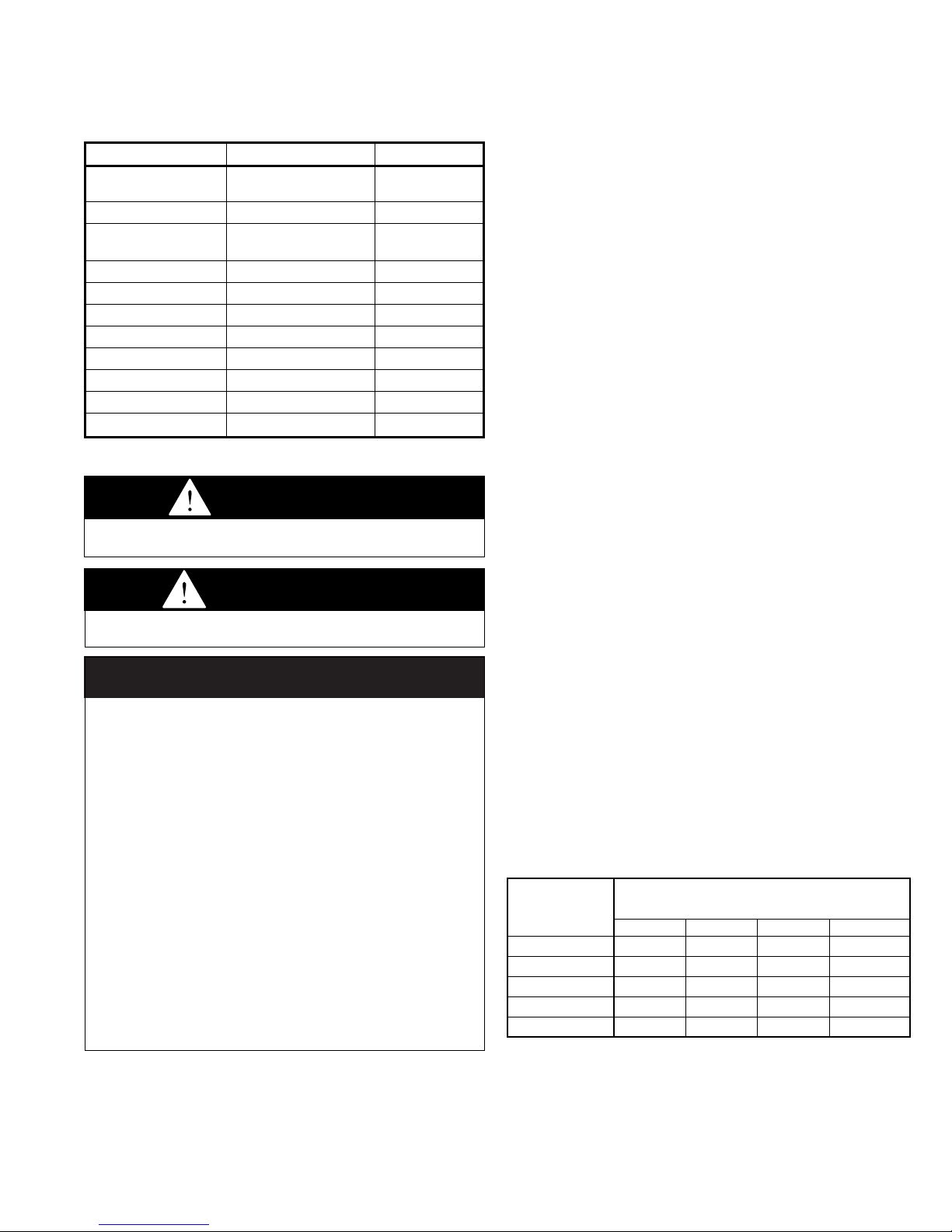

Figures 4.2 and 4.3 illustrate typical rigid and chain mounting

arrangements, respectively, for a model MT infrared heater.

Check local codes for mounting requirements and use of flexible

gas connectors. Local codes may require rigid mounting. Heaters

must be mounted at angles from 10°to 35°from horizontal. The

gas manifold must be located on the low end of the heater, in a

horizontal position (parallel to the floor).

Where permissible, chain mounting is recommended. 5' chain

mounting sets are available as an accessory, allowing for 10° to

35° mounting angles. In the absence of this chain set, Number

1/0 Tenso chain (200 lb. working load) is recommended. “S”

hooks should be a minimum

1

/4" in diameter and the ends must

be closed after installation. Heaters located in aircraft hangers

or near overhead doors must be rigidly mounted to prevent

swinging. Under no circumstances should the gas supply line

or the electrical supply line to the heater be used to provide any

assistance in the suspension of the heater. Do not locate any

gas or electric service lines directly above or below the heater.

Insure that:

1. Clearances to combustibles (as shown on the rating plate

and in Table 3.2) are maintained.

2. For proper operation, the unit must be mounted on an angle

ten to thirty-five degrees (10°to 35°) from the horizontal

with the gas manifold located at the low end of the heater.

See Figure 4.1.

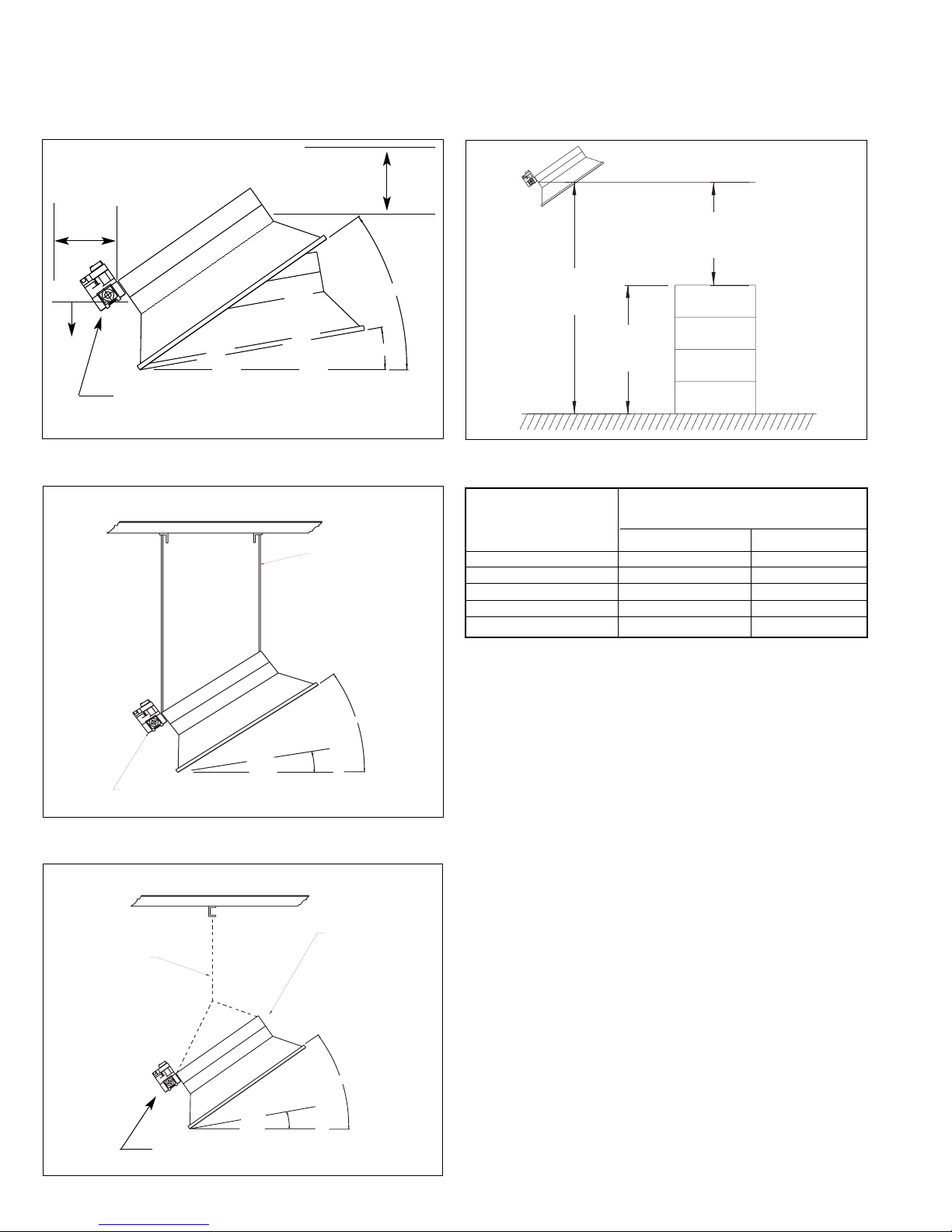

3. In locations used for storage of combustible materials,

signs shall be posted to specify the maximum permissible

stacking height to maintain required clearances from the

heater to the combustibles. See Figure 4.4.

4. Either gas piping or suspension mounting is flexible to

prevent fatigue failure from vibration or thermal expansion.

5. Adequate clearances to sprinkler heads are maintained.

➀ See figure 4.1 on page 4.

Figure 4.2

Typical Rigid Mounting Configuration

Figure 4.3

Typical Chain Mounting Configuration

Figure 4.4

Stacking Height

Table 4.1

Typical Mounting Height for Full Building Heating

INSTALLATION

Typical Mounting Height at Min/Max

Model No.

Mounting Angles (feet)

➀➀

10° 35°

MT28, 30, 33 8-14 7-12

MT56, 60, 66 14-20 12-16

MT84, 90, 99 20-26 16-24

MT112, 120, 132 26-32 20-30

MT160 26-40 22-38

➀➀

Mounting height values are recommendations only and may need to be

adjusted to meet requirements of actual installation.

4

e

OVERHEAD STRUCTURE AND FIELD CONNECTIONS MUST

N

G

l

t

d)

N

G

l

t

OVERHEAD STRUCTURE AND FIELD CONNECTIONS MUST

Figure 4.1

Combustible Material Clearances

REAR

BELOW

THE GAS MANIFOLD AND CONTROLS MUST BE

LOCATED AT THE LOW END OF THE HEATER

TOP

NOTE:

Gas manifold MUST be located on the low

side of the heater.

Combustion/Ventilation Air Requirements

Maintain positive air displacement of 4 cfm per 1000 Btu/hr for

natural gas and 5 cfm per 1000 Btu/hr for propane. The fresh

air supply must be located in the immediate proximity of the

unit(s). Fresh air intake openings are typically located high

on the building sidewalls at a comparable level to the heaters.

One square inch of net free inlet area per 1000 Btu/hr is

required. Multiple inlets, well distributed, should be used and

should direct air upward to prevent drafts at floor level. Inlets

are typically limited to 1 to 2 square feet in size.

It is recommended that units be interlocked with mechanical

exhaust fans for unvented applications. Mechanical exhaust

fans are typically located at high points of the building. For flat

roof areas, a series of small exhausters should be distributed

over the roof areas and interlocked with various heating zones.

BE ADEQUATE TO SUPPORT WEIGHT OF THE HEATER.

OTE:

as main and electrical

ines must not cross over

op of heater.

35˚ MAX.

10˚ MIN.

3/8" All thread rigid mount

(Used in aircraft hangers or

where draft conditions may b

expected.)

Minimum Clearance to

Combustible Materials

Mounting

Height

Stacking

Height

NOTE:

Gas manifold MUST be located

on the low side of the heater.

BE ADEQUATE TO SUPPORT WEIGHT OF THE HEATER.

OTE:

as main and electrical

ines must not cross over

op of heater.

5' Chain Mounting Set

Minimum

10˚

Horizontal Plane

'S' Hooks: 1/4" Dia. wire

(Crimp all 'S' hooks close

35˚ Maximum

Minimum

10˚

Horizontal Plane

35˚

Maximum

Loading...

Loading...