MCP15-500.7

5H0816400000

March, 2018

INSTALLATION AND SERVICE MANUAL

commercial packaged ventilation system units

model MPR

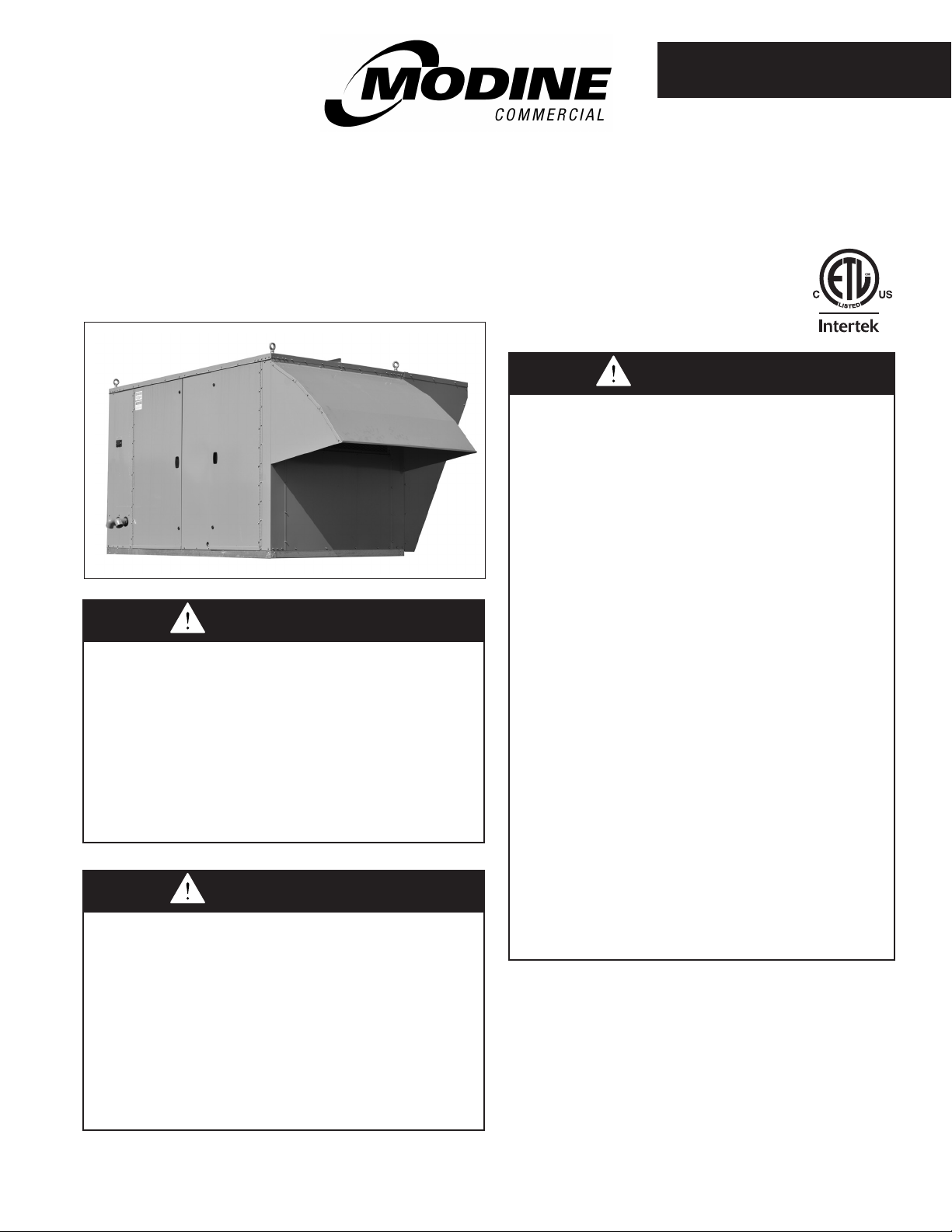

Model MPR Commercial Packaged Ventilation

System Unit (C-Cabinet size shown)

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive

harm. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

This unit contains R-410A high pressure

refrigerant. Hazards exist that could result in

personal injury or death. Installation,

maintenance, and service must only be

performed by an HVAC technician qualified in

R-410A refrigerant and using proper tools and

equipment. Due to much higher pressure of

R-410A refrigerant, DO NOT USE service

equipment or tools designed for refrigerants

other than R410A.

WARNING

WARNING

(for units with 24 digit model numbers)

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death or property

damage.

Be sure to read and understand the installation,

operation and service instructions in this manual.

Improper installation, adjustment, alteration,

service or maintenance can cause serious

injury, death or property damage.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch, do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from

a phone remote from the building.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local

factory sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description

of product ordered (including specifications where

applicable).

WARNING

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

1MCP15-500.7

SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING

THE SPECIAL PRECAUTIONS LISTED BELOW. FAILURE

TO PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERTY DAMAGE OR LOSS, PERSONAL

INJURY, OR DEATH. THESE INSTRUCTIONS ARE SUBJECT

TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

dANGeR

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

WARNING

de-energized.

11. This unit contains R-410A high pressure refrigerant.

Hazards exist that could result in personal injury or

death. Installation, maintenance, and service must only

be performed by an HVAC technician qualified in R-410A

refrigerant and using proper tools and equipment. Due

to much higher pressure of R-410A refrigerant, DO NOT

USE service equipment or tools designed for refrigerants

other than R410A.

12. The power supply wiring for the Energy Recovery

Section comes from a single point power connection on

the unit. Disconnect power supply at model MPR before

making wiring connections to prevent electrical shock

and equipment damage.

13. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating

plate on the appliance for complete appliance model

number, serial number, and company address. Any

substitution of parts or controls not approved by the

factory will be at the owner's risk.

WARNING

1. Failure to follow proper lifting instructions could result in

property damage, serious injury, or death. Lifting should

only be done by a qualified rigging company. Use ALL

lifting points. Test lift to ensure proper balance and

rigging. Never lift in high winds.

2. Disconnect power supply before making wiring

connections or working on this equipment. Follow all

applicable safety procedures to prevent accidental

power up. Failure to do so can result in injury or death

from electrical shock or moving parts and may cause

equipment damage.

3. For units equipped for dual power supply sources, both

sources of power must be disconnected to prevent

electrical shock and equipment damage.

4. All appliances must be wired strictly in accordance with

the wiring diagram furnished with the appliance. Any

wiring different from the wiring diagram could result in a

hazard to persons and property.

5. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

6. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than the

rated voltage.

7. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution or

equivalent for testing.

8. Gas pressure to appliance controls must never exceed

14" W.C. (1/2 psi).

9. To reduce the opportunity for condensation, the minimum

sea level gas input to the appliance, as indicated on the

serial plate, must not be less than 5% below the rated

input, or 5% below the minimum rated input of dual rated

units.

10. When the dead front disconnect switch(es) (for main

unit and/or powered convenience outlet option) is in the

“OFF” position, supply power remains energized at the

line (supply) side of the dead front disconnect switch(es).

The switch body is located inside of another junction

box to protect against contact with the live wiring.

The junction box must not be disassembled unless

the main power supply from the building to the unit is

CAUtIoN

1. Appliances are designed for outdoor installation only.

DO NOT LOCATE APPLIANCES INDOORS.

2. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the

rated voltage.

3. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

4. Units not approved for use in potable water systems.

5. Do not operate the unit with steam. The coil is not

designed for steam condensate removal which can

damage the unit.

6. Hot water supplied to the hot water heating option must

not exceed 180°F temperature or 75 PSIG pressure.

7. When servicing the unit, some components may be hot

enough to cause pain or injury. Allow time for cooling of

hot components before servicing.

8. Do not overcharge the refrigeration system. This can

lead to elevated compressor discharge pressure and

possibly flooding the compressor with liquid. This may

result in compressor failure not covered under warranty.

9. Do not reuse any mechanical or electrical component

which has been wet. Such components must be

replaced.

IMPoRtANt

1. To prevent premature heat exchanger failure, do

not locate ANY gas-fired appliances in areas where

corrosive vapors (i.e. chlorinated, halogenated or acid)

are present in the atmosphere.

2. A properly designed drain with trap must be installed

immediately after the unit evaporator coil condensate

drain pan connection. Failure to do so will result in

condensate that cannot properly drain from the unit,

2 MCP15-500.7

TABLE OF CONTENTS / SI (METRIC) CONVERSION FACTORS / UNIT LOCATION

TABLE OF CONTENTS

IMPoRtANt

eventually causing the drain pan to fill. To prevent

damage to the building or unit, a drain pan float switch

is included as standard and will disable the unit if the

maximum condensate level is reached.

3. To prevent premature heat exchanger failure, the input

to the appliance, as indicated on the serial plate, must

not exceed the rated input by more than 5%.

4. To prevent premature heat exchanger failure, check to

be sure the blower has been set to deliver the proper

airflow for the application. Refer to page 17 for Blower

Adjustments.

5. Start-up and adjustment procedures must be performed

by a qualified service agency.

6. All scroll compressors requires the correct supply power

phase rotation. Phase reversal may result in compressor

failure not covered under warranty. Refer to the Start-Up

Procedure section.

7. All refrigeration checks must be made by a qualified

R-410A refrigeration technician.

8. Do not release refrigerant to the atmosphere. When

adding or removing refrigerant, all national, state/

province, and local laws must be followed.

9. On units with the electric preheat option, to prevent

premature heat exchanger failure, check to be sure the

blower has been set to deliver the proper airflow for the

application. Refer to page 17 for Blower Adjustments.

10. The exhaust fan is not designed for high temperature

or smoke control exhaust applications. Exhaust air

temperature must not exceed 104°F. Operating the

exhaust fan above 104°F will result in failure of the

exhaust fan.

SI (METRIC) CONVERSION FACTORS

To Convert Multiply By To Obtain

"W.C. 0.24 kPa

psig 6.893 kPa

°F (°F-32) x 0.555 °C

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m

3

Special Design Requests

Modine Manufacturing Company will sometimes build units

with special features as requested by the customer. This

manual only covers standard features and does not include any

changes made for special feature requests by the customer.

Units built with special features are noted with an SPO (Special

Product Order) Number on the Serial Plate

To Convert Multiply By To Obtain

CFH 1.699 m

3

0.0374 mJ/m

Btu/ft

pound 0.453 kg

Btu/hr 0.000293 kW

gallons 3.785 liters

psig 27.7 "W.C.

/min

3

/min

3

Inspection on Arrival ............................................................ 1

Special Precautions ............................................................. 2

SI (Metric) Conversion Factors ........................................... 3

Special Design Requests .................................................... 3

Storage Prior to Installation ................................................. 3

Unit Location ....................................................................... 4

Installation ......................................................................4-15

Combustible Material and Service Clearances .........4-5

Roof Curb Installation ................................................... 4

General Rigging Instructions/Unit Installation ...........6-7

Duct & Condensate Drain Installation .......................... 8

Electrical Connections .................................................. 9

Gas Connections ........................................................ 10

Vent Terminals and Combustion Air Hoods ................ 11

Gas Heating Option Condensate Drains & Traps ......14

Hot Water Piping Connections ...................................15

Start-Up Procedure ......................................................16-29

General. ...................................................................... 16

Blower Adjustments .................................................... 17

Airflow Proving Switch and Dirty Filter Switch............ 19

Variable Air Movement Applications ........................... 19

Checking Refrigerant Charge ..................................... 20

Gas Heating Option .................................................... 21

Energy Recovery Option (B-Cabinet units only) ........ 28

Unit Features/Options Location Drawings .................... 30-35

Dimensions/Weights .................................................... 36-44

B-Cabinet Size Unit without Energy Recovery. .......... 36

B-Cabinet Size Unit with Energy Recovery. ............... 38

C-Cabinet Size Unit .................................................... 40

D-Cabinet Size Unit .................................................... 42

Base Model Weights ...................................................44

Option and Accessory Pressure Drop Tables ..............45-47

Maintenance .................................................................48-50

Service & Troubleshooting ...........................................51-55

Serial Plates ...................................................................... 56

Model Nomenclature ....................................................57-59

Commercial Warranty ...........................................Back Page

Storage Prior to Installation

If the unit is stored outside prior to installation, the unit should

be covered.

3MCP15-500.7

*Available as a factory

supplied, field installed

accessory.

Curb Gasketing*

2 x 4 Wooden

Nailing Strip*

Curb*

2” Acoustic

Fiberglass

(By Others)

Roof Deck

6” Inverted Channel

(Both Sides)

(By Others)

Roof

Trusses

Cant Strip

(By Others)

Roof Insulation

(By Others)

Counterflashing

(By Others)

Roofing Material

(By Others)

Insulation

(By Others)

UNIT LOCATION

dANGeR

Appliances must not be installed where they may be

exposed to potentially explosive or flammable atmosphere.

CAUtIoN

Appliances are designed for outdoor installation only.

DO NOT LOCATE APPLIANCES INDOORS.

IMPoRtANt

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors (i.e.

chlorinated, halogenated or acid) are present in the atmosphere.

Location Recommendations

1. When locating the packaged rooftop unit, Model MPR,

consider general space and cooling/heating requirements and

availability of gas and electrical supply.

2. Be sure the structural support at the unit location site is

adequate to support the weight of the unit and any other

required support structure. For proper operation the unit

must be installed in a level horizontal position.

3. All mechanical equipment generates some sound and

vibration that may require attenuation. Locating the

equipment away from the critical area is desirable within

ducting limitations. Frequently, units can be located above

utility areas, corridors, restrooms, and other non-critical

areas. Generally, a unit should be located within 15 feet of

a primary support beam. Smaller deflections mean lesser

vibration and noise transmission. For critical applications,

please consult with an acoustical attenuation expert.

4. Do not install units in locations where the flue products

(if equipped with a gas fired heating option) can be drawn

into the adjacent building openings such as windows, fresh

air intakes, etc.

5. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. For units with the gas heating option, be sure

clearances are maintained to the combustion air inlet

louvers and power exhauster discharge cover. Units are

designed for installation on non-combustible surfaces with

the minimum clearances shown in Figure 5.1.

6. On units that have fresh air openings, a method must be

provided to prevent water and debris from entering the unit

such as a rainhood, which is available as an accessory

from Modine. Where possible, install the unit so that the

inlet is not facing into the prevailing wind to prevent water

entrainment.

7. The exhaust fan is not designed for high temperature

or smoke control exhaust applications. Exhaust air

temperature must not exceed 104°F. Operating the

exhaust fan above 104°F will result in failure of the

exhaust fan.

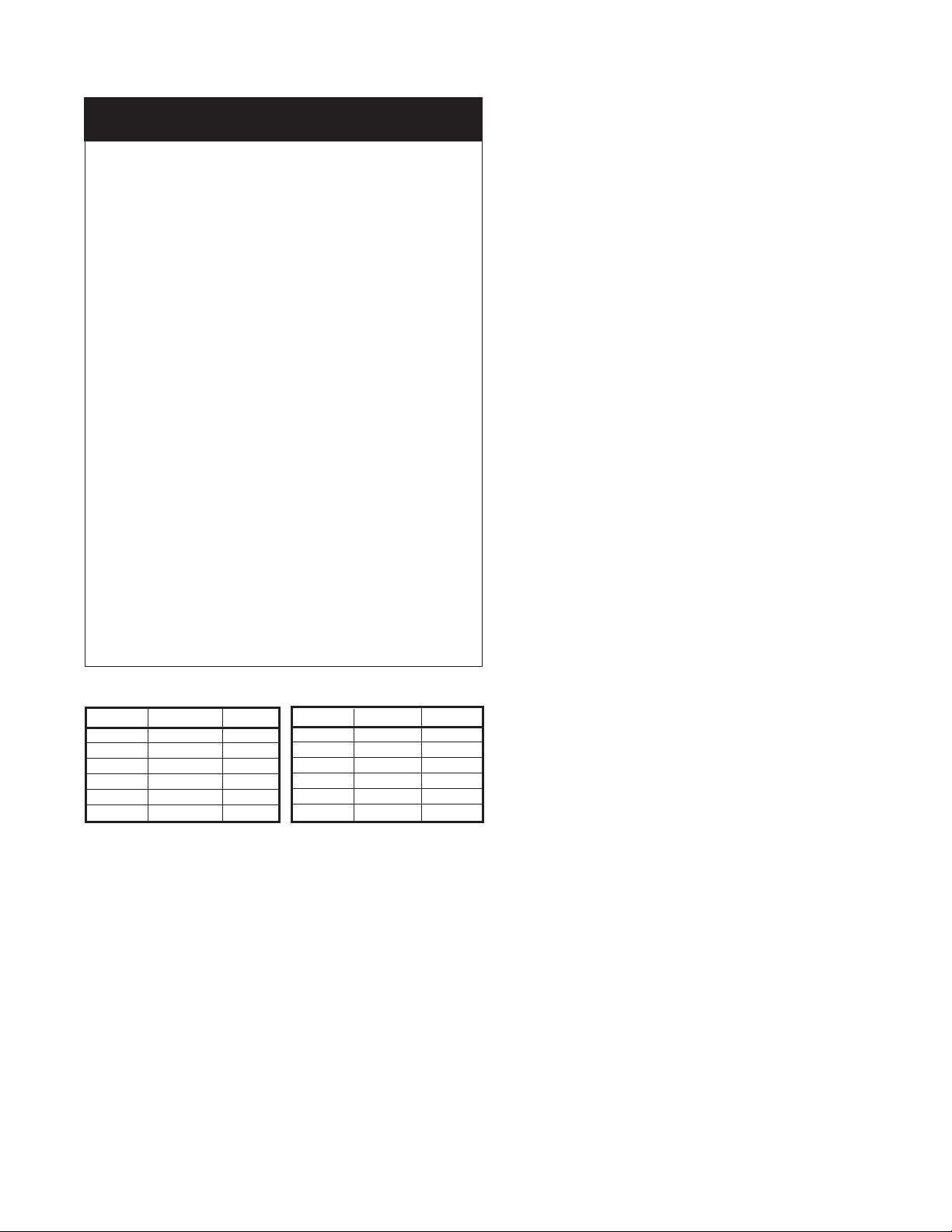

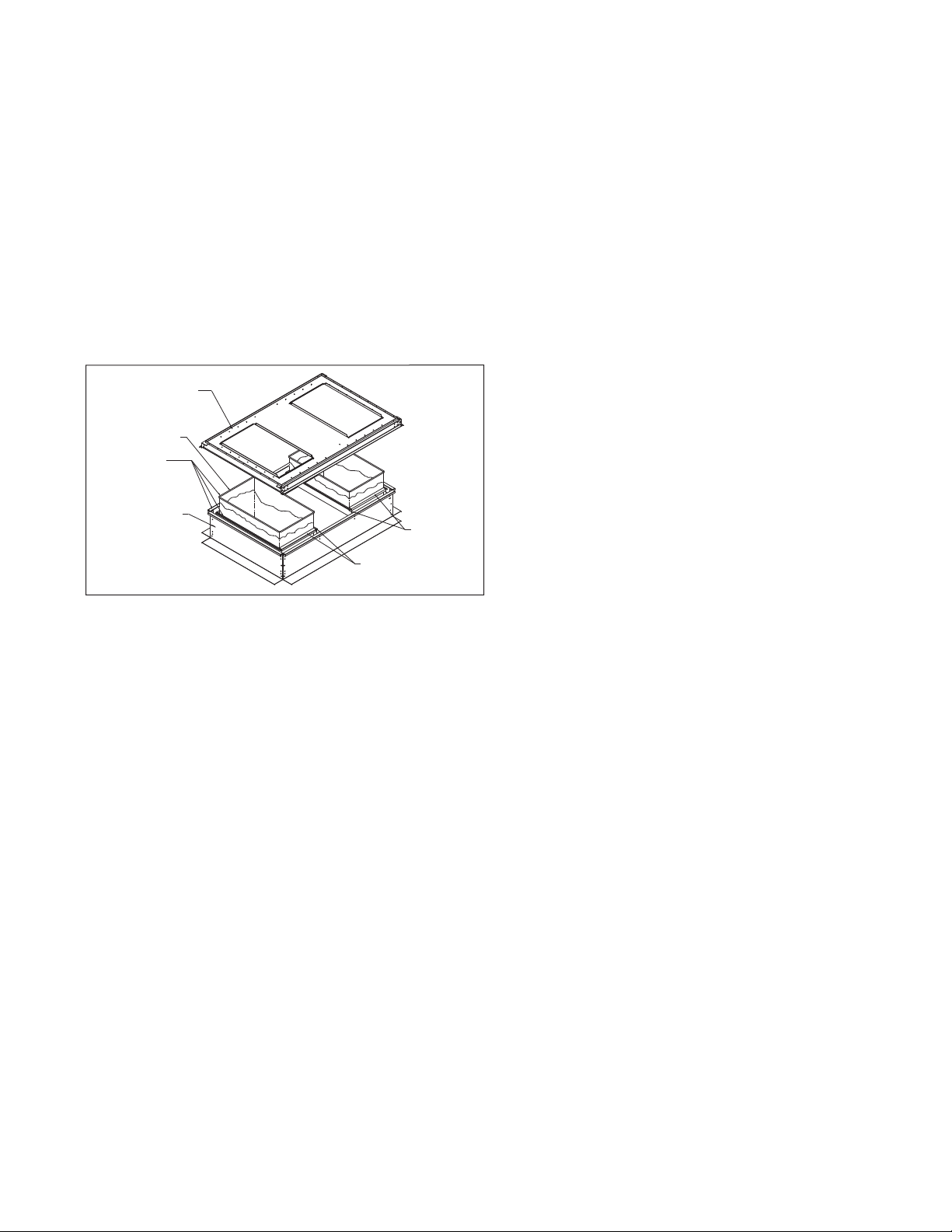

Roof Curb Installation

An optional roof curb is available to simplify site preparation

and raise the unit above roof water and snow level for

drainage. It can be installed in advance of the unit. The curb

is shipped knocked down with separate instructions (Literature

#MCP15-590) for its assembly, flashing, and sealing with the

roof. The following are some general guidelines for roof curb

installed units:

1. The roof structure must be adequately designed to support

the live weight load of the unit and any other required

support structure. The roof curb should be supported at

points no greater than five feet apart. Additional truss

reinforcement should be provided, if necessary.

2. Roof curbs supplied by Modine are fabricated from 10

gauge galvanized steel and supplied knocked down for

assembly on the job site. The curb consists of two side

pieces, two end pieces, gasketing, four joiner angles, four

2x4 inch wood nailing strips, nuts, bolts, and washers.

3. Outside dimensions must be held when installing curb.

Top surface must be level and straight to ensure weathertightness. If roof is pitched it will be necessary to construct

a sub-base on which to install the curb. All corners must

be square.

4. All dimensions are +1/8 inch.

5. When a roof curb is used in conjunction with factory

supplied discharge and/or return air connectors, the

ductwork can be fastened to the connectors prior to the

unit installation. The connectors will accept 90° flanged

ductwork (see Figure 7.1).

6. Final electric and gas connections must be made after unit

is installed to allow for tolerance in setting of unit on curb.

For electrical power supply allow approximately eight feet

of wire, plus provisions for weathertight flexible conduit for

connection to unit, as required by local codes.

7. Maintain a 12-inch minimum height from top of roof deck

to top of curb.

8. Caulk butt joints after curb is assembled and installed on

roof structural members and roof flashing is added.

9. For improved sound attentuation, line the roof deck within

the curb area with 2" acoustic fiberglass.

Figure 4.1 - Typical Curb Details

4 MCP15-500.7

CLEARANCES / ROOF CURB INSTALLATION

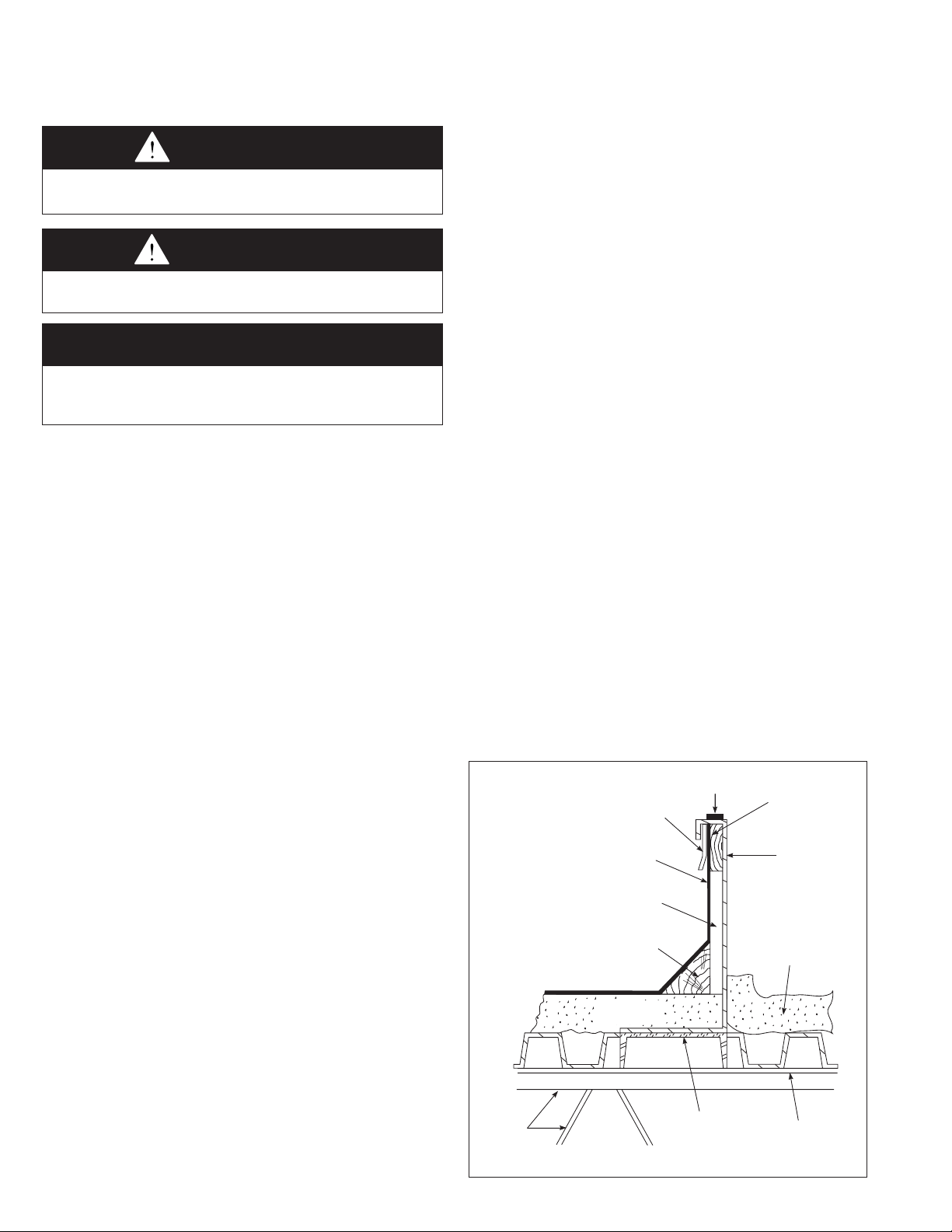

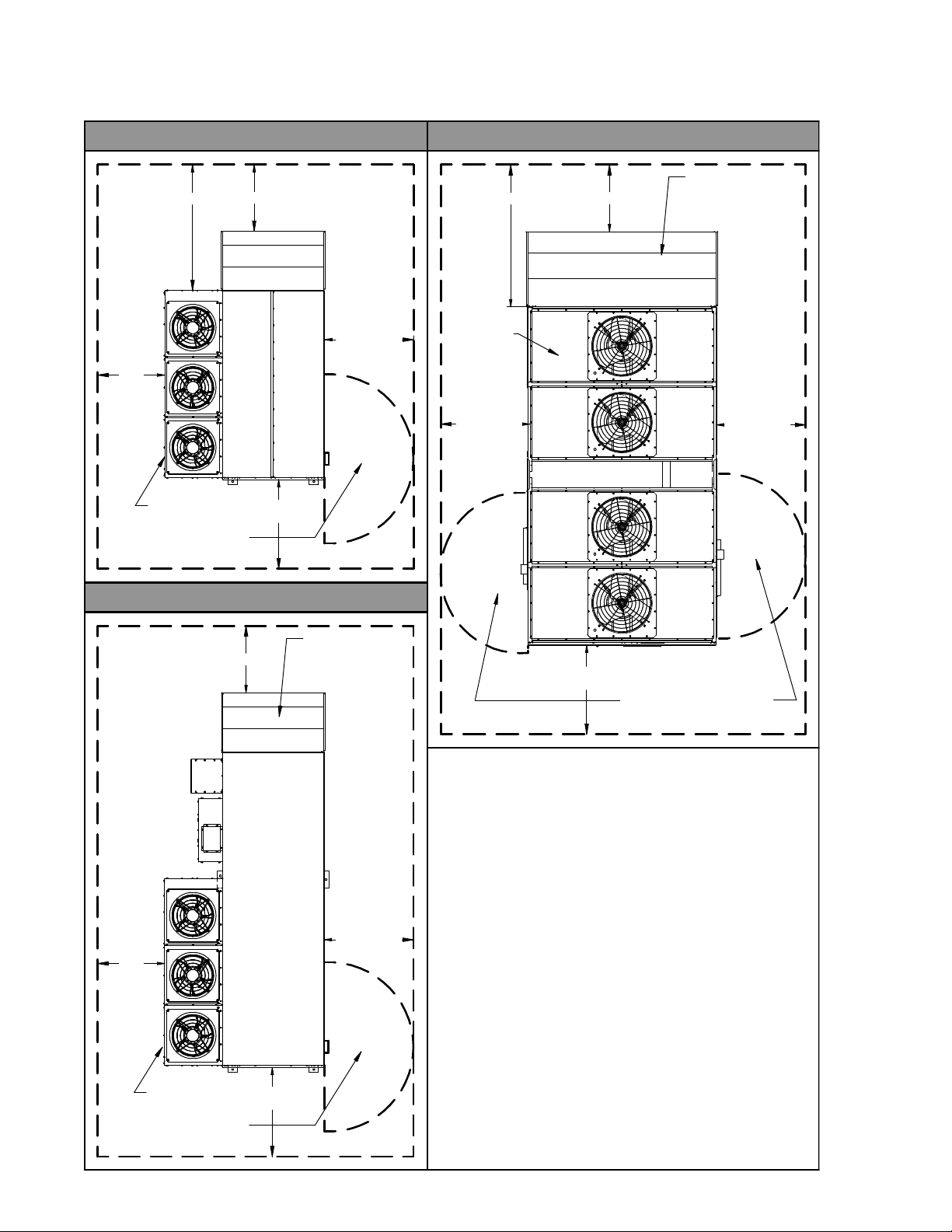

Figure 5.1 - Combustible Material & Service Clearances

B- AND C-CABINET UNITSWITHOUT ENERGY RECOVERY D-CABINET UNITSWITHOUT ENERGY RECOVERY

FIELD INSTALLED

SEE NOTE 2

36.0

SEE NOTE 2

36.0

ACCESSORY

RAINHOOD

48.0

SEE NOTE 3

36.0

SEE NOTE 4

FOR UNITS WITH GAS HEAT,

MAINTAIN 48" MINIMUM

FROM VENT TERMINATIONS

48.0

SEE NOTE 1

B- AND C-CABINET UNITSWITH ENERGY RECOVERY

FIELD INSTALLED

36.00

36.0

SEE NOTE 4

FOR UNITS WITH GAS HEAT,

MAINTAIN 48" MINIMUM

FROM VENT TERMINATIONS

48.0

SEE NOTE 1

ACCESSORY

RAINHOOD

48.0

SEE NOTE 3

SEE NOTE 4

48.00

SEE NOTE 3

48.00

SEE NOTE 1

FOR UNITS WITH GAS HEAT,

MAINTAIN 48" MINIMUM

FROM VENT TERMINATIONS

j The minimum recommended clearance for service is 48". For service

clearances less than shown, applicable local code requirements must be

followed. If the ability for future condenser coil replacement is desired, the

minimum clearance must be:

• 102" for B-Cabinet sized units

• 112" for C-Cabinet sized units

• 100” for D-Cabinet sized units

See Note k for alternate coil replacement direction.

k The minimum recommended clearance for service is 36". For service

clearances less than shown, applicable local code requirements must be

followed. If the ability for future condenser coil replacement is desired, the

minimum clearance must be (from the end panel of the condenser, not the

end of the inlet hood):

• 102” for B-Cabinet sized units

• 112” for C-Cabinet sized units

• 100” for D-Cabinet sized units

See Note j for alternate coil replacement direction.

l The minimum recommended clearance for service is 48". For service

clearances less than shown, applicable local code requirements must be

followed. If the ability for future evaporator coil, hot gas reheat coil, and/or

energy wheel replacement is desired, the minimum clearance must be:

• 55" for B-Cabinet sized units

• 64" for C-Cabinet sized units

• 100” for D-Cabint sized units

m Additional Required Clearances:

-Clearance above unit must be unobstructed.

-Clearance to combustibles below the unit is 6" minimum.

48.00

SEE NOTE 3

5MCP15-500.7

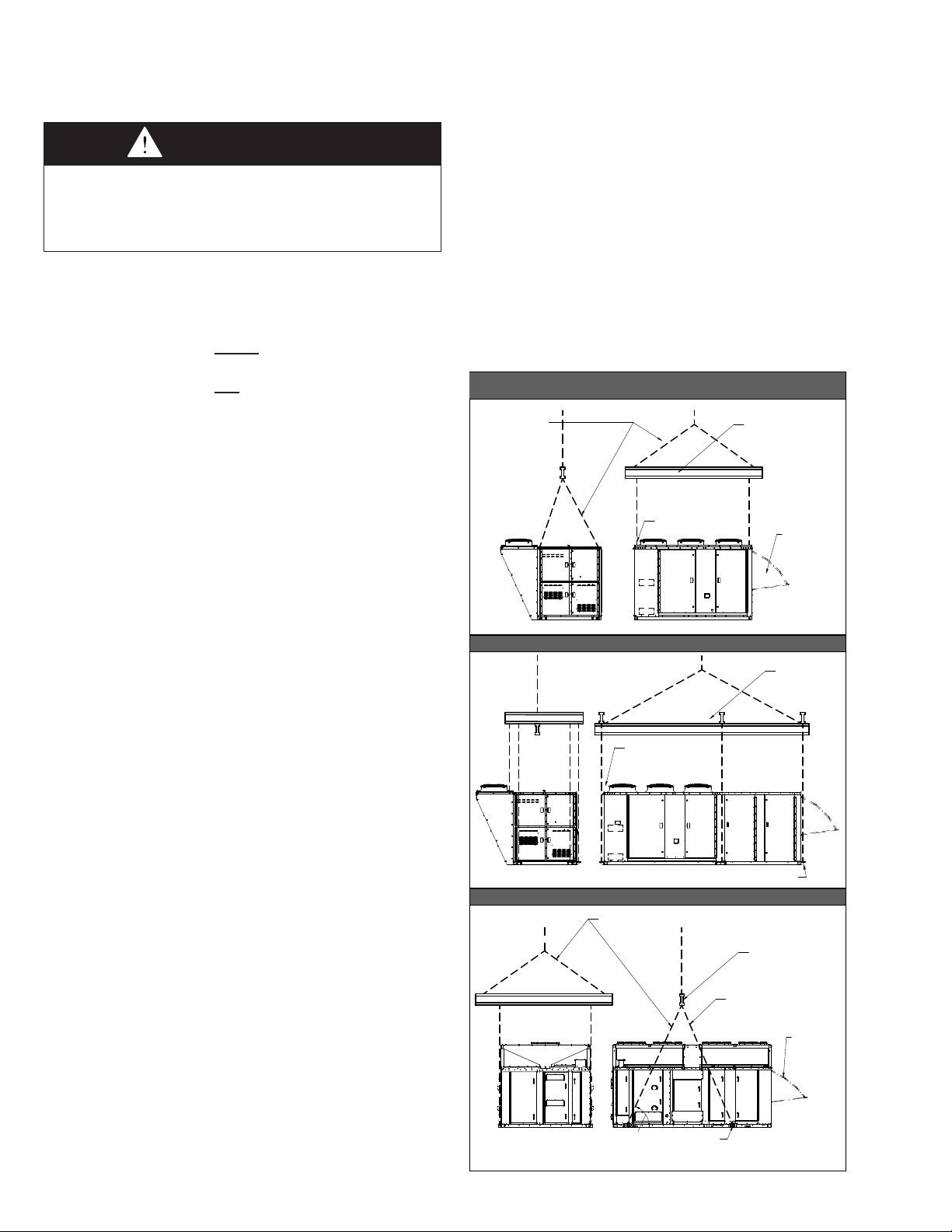

GENERAL RIGGING INSTRUCTIONS / UNIT INSTALLATION

SPREADER BAR

AND LIFTING

CHAINS/STRAPS

BY INSTALLER

ADJUST CHAIN/STRAP

LENGTH SO UNIT IS

LEVEL WHEN LIFTED

RAINHOOD

ACCESSORY

(FIELD INSTALL)

(4) 1.50" LIFTING EYE BOLTS

(EACH CORNER OF UNIT)

SPREADER BAR

AND LIFTING

CHAINS/STRAPS

BY INSTALLER

ENSURE THE LIFTING

CHAINS/STRAPS CLEAR

THE CASING ON EACH SIDE

(6) 1.0" LIFTING LUGS

MIN. 65

v

SPREADER BAR

AND LIFTING

CHAINS/STRAPS

BY INSTALLER

ADJUST CHAIN/STRAP

LENGTH SO UNIT IS

LEVEL WHEN LIFTED

RAINHOOD

ACCESSORY

(FIELD INSTALL)

ENSURE THE LIFTING

CHAINS/STRAPS CLEAR

THE CASING ON EACH SIDE

(4) 1.0" LIFTING LUGS

LIFTING LUG KIT IS SHIPPED LOOSE IN SUPPLY FAN SECTION.

INSTALL (4) LIFTING LUGS PER MCP15-505 USING (4) GRADE 5 BOLTS PER LUG, TORQUED TO 75 ft-lb.

B-CABINET UNIT - NO ENERGY RECOVERY

C-CABINET UNIT - ALL

D-CABINET UNIT - ALL

B-CABINET UNIT - WITH ENERGY RECOVERY

General Rigging Instructions

WARNING

Failure to follow proper lifting instructions could result in

property damage, serious injury, or death. Lifting should

only be done by a qualified rigging company. Use ALL lifting

points. Test lift to ensure proper balance and rigging. Never

lift in high winds.

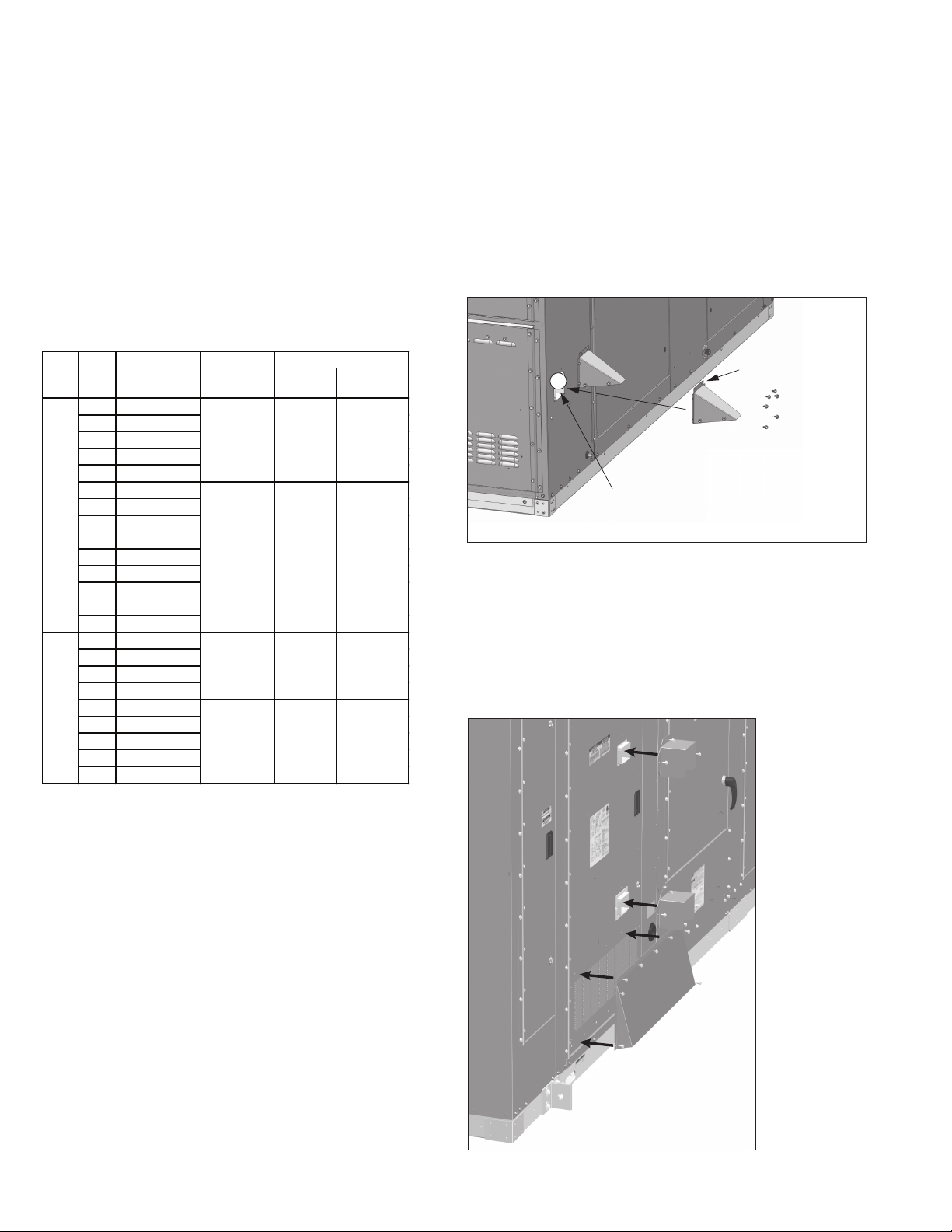

Lifting Lug Installation

Before attaching lifting equipment, verify location of lifting lugs

or eyes. B- and C-Cabinet sized units have the lifting lugs or

eyes factory installed as follows:

• B-Cabinet sized units without Energy Recovery include

(4) eye bolts at each corner on the top of the unit.

• B-Cabinet sized units with Energy Recovery include (6)

lifting lugs on the base, one at each corner and one on

each length-wise side of the unit between the corners.

• C-Cabinet sized units include (4) eye bolts at each corner

on the top of the unit. For units that include the shipped

separate Energy Recovery Module (model ERM) option,

refer to the latest revision of the Installation and Service

Manual, #MCP15-520, that shipped with the ERM for

separate rigging instructions.

• D-Cabinet sized units must have the lifting lugs installed in

the unit base assembly prior to rigging as follows:

1. Locate the lifting lug kit box, kit # 66802, located in

the supply fan compartment.

2. Install the kit per the “Installation Instructions, Lifting

Lugs D-Cabinet”, #MCP15-505, included with the kit.

3. After installing the kit, verify that all (4) lugs are

installed following the instructions in Step 2. Verify

that each lug is secured using (4) Grade 5 bolts

provided with the kit. Each bolt must be torqued to

75 ft-lb.

Unit Rigging and Lifting

Rigging and lifting of the units should only be done by a

qualified rigging company. With the lifting lugs or eyes

identified and installed, the units can be lifted by crane or

helicopter.

1. Follow site preparation instructions for the roof curb or

equipment stand before installation.

2. Check the Serial Plate(s) of unit with plans to be sure unit

is properly located. Although units may look outwardly

similar, their function, capacities, options, and accessories

will often vary.

3. Check unit dimensions of both the unit base and the curb

or stand on which the unit will be installed.

4. If the unit will be installed on a roof curb:

a. Thoroughly clean and dry the top of the curb surface.

b. Lay a bead of weather resistant caulking on top

perimeter of roof curb as illustrated in Figure 7.1. Note:

If roof curb is supplied by Modine, full perimeter gasket

material is supplied and caulking is not necessary.

5. When lifting the equipment, connect sturdy steel cables,

chains, or straps with eye loops as illustrated in Figure 6.1.

For stability in lifting and lowering and to prevent damage

to the unit, include a spreader bar as illustrated in Figure

6.1. Avoid twisting or uneven lifting of the unit. The cable

length from the lifting point on the unit to the spreader bar

should always be longer than the distance between the

outer lifting points.

6. Test lift the unit to check for proper rigging balance before

hoisting to the desired installation location.

7. Once lifted to the installation location, orient the hoisted

unit to match the ductwork locations and set evenly on the

curb or stand.

8. Following the instructions in this manual, make final unit

connections to the electric power supply and remote

control circuits. Connect the gas lines to the unit heating

compartment. Seal all utility line clearance holes on the unit

after connections are completed so they are watertight.

Figure 6.1 - Typical Rigging for Model MPR

6 MCP15-500.7

DUCT INSTALLATION AND UTILITY CONNECTIONS

RETURN AIR

CONNECTOR

DISCHARGE AIR

CONNECTOR

90° FLANGED

DUCTWORK

(By Installer)

UNIT BASE

(Shown without

unit for clarity)

ROOF

CURB

BEFORE UNIT

INSTALLATION

CAULK ALL MATING

SURFACES ➀

(Caulk by installer)

➀ If roof curb is supplied

by Modine, full perimeter

gasket material is supplied

and caulking is not necessary.

Duct Installation

1. The unit is designed to accept 90° flanged ductwork on both

the supply and return air openings. Refer to the roof curb or

the unit base dimensional drawings to determine the location

of the openings.

2. Acoustic duct liners are recommended on all internal supply

and return air ducts.

3. When ductwork is installed prior to unit arrival, flexible

connections should be included to make connections easier

and to simplify possible future service.

4. When a roof curb is used in conjunction with factory supplied

discharge and/or return air connectors, the ductwork can be

fastened to the connectors prior to the unit installation. The

connectors will accept 90° flanged ductwork (see Figure 7.1).

Figure 7.1 - Discharge and/or Return Air Connectors

5. To assure proper air flow from the unit, follow these duct

design recommendations:

a. Be sure ducts are properly sized and installed.

b. As a general rule, all discharge ducts should have a

A = Cross Sectional Area of Rectangular Duct

P = Perimeter of Rectangular Duct

D = Diameter of Round Cut

c. Wherever turns in the duct work are made, include

d. Supply air ducts in a “T” configuration should be

avoided to prevent air temperature stratification. If this

configuration must be used, provide appropriate mixing

devices and/or the necessary straight duct length before

the “T” to provide uniformly mixed air temperature

delivery to both supply air duct trunks.

Utility Connections

Utility and control connections can be made to the unit from

the bottom or through the fixed side panels. Holes can be field

drilled in fixed side panels to accommodate utility connections

as shown on the unit dimensional drawings and the utility

entrance location area label located on the unit. All gas and

electrical connections to the unit must be weatherized so they

are watertight.

straight run of at least three (3) hydraulic duct diameters

before making turns in the ductwork.

Hydraulic Duct Diameter for Rectangular Ducts = 4A/P

Hydraulic Duct Diameter for Circular Ducts = D

where:

turning vanes.

7MCP15-500.7

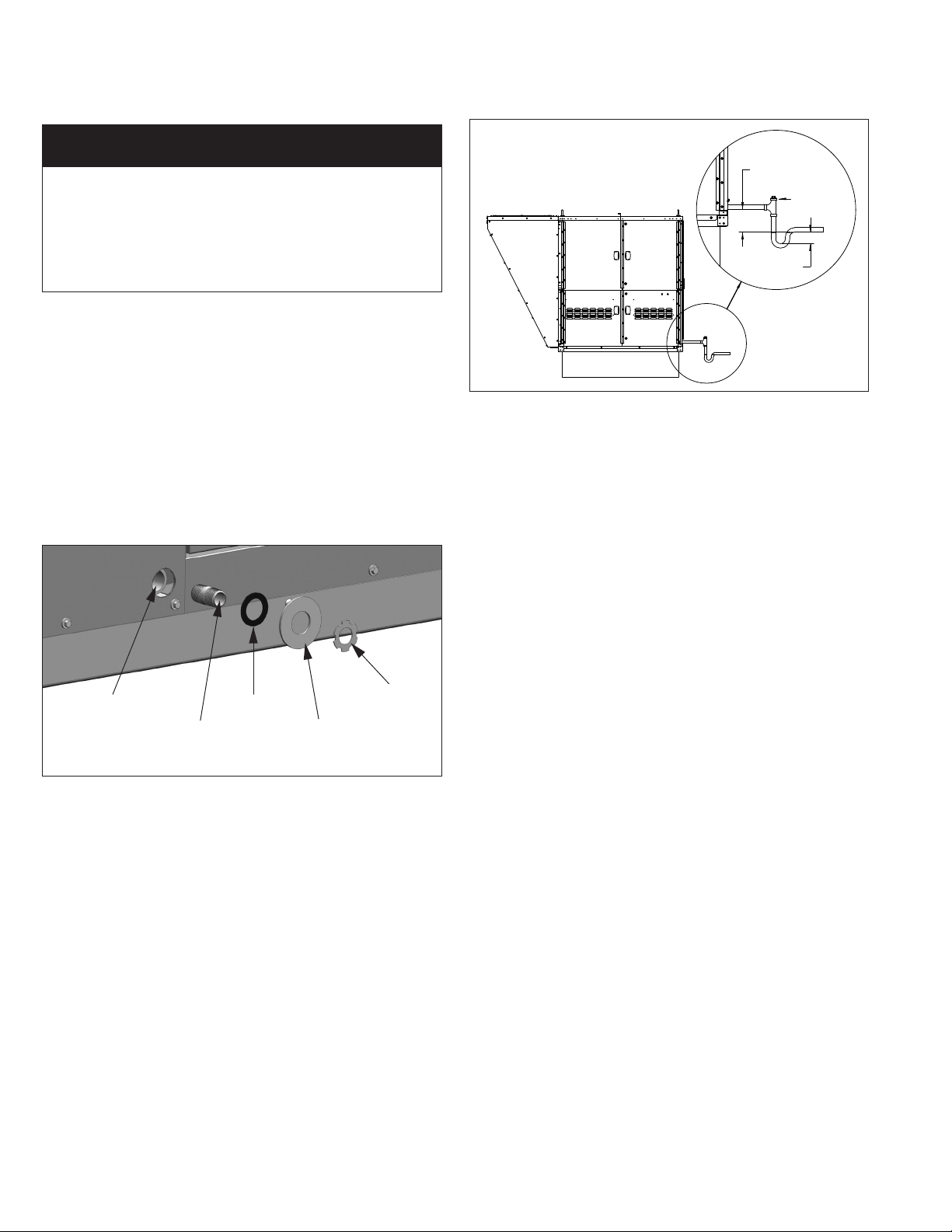

CONDENSATE DRAIN INSTALLATION

Evap Condensate Drain Trap Installation

IMPoRtANt

A properly designed drain with trap must be installed

immediately after the unit evaporator coil condensate drain

pan connection. Failure to do so will result in condensate

that cannot properly drain from the unit, eventually causing

the drain pan to fill. To prevent damage to the building or

unit, a drain pan float switch is included as standard and will

disable the unit if the maximum condensate level is reached.

All units require a drain system with a condensate trap to be

connected to the condensate drain pan connection which is

accessible from the exterior of the unit casing. Failure to install

a condensate drain trap may result in condensate overflowing

from the drain pan, causing damage to the unit and building.

See Figure 30.1 or 31.1 for location. The drain system is to be

installed as follows:

1. The condensate drain pan includes a 1-1/4" female NPT

stainless steel connection accessible from the exterior of the

unit casing. Do not reduce the drain diameter. A drain pan

connection kit is shipped loose for field installation to allow

connection exterior to the casing. Refer to Figure 8.1 for

assembly details.

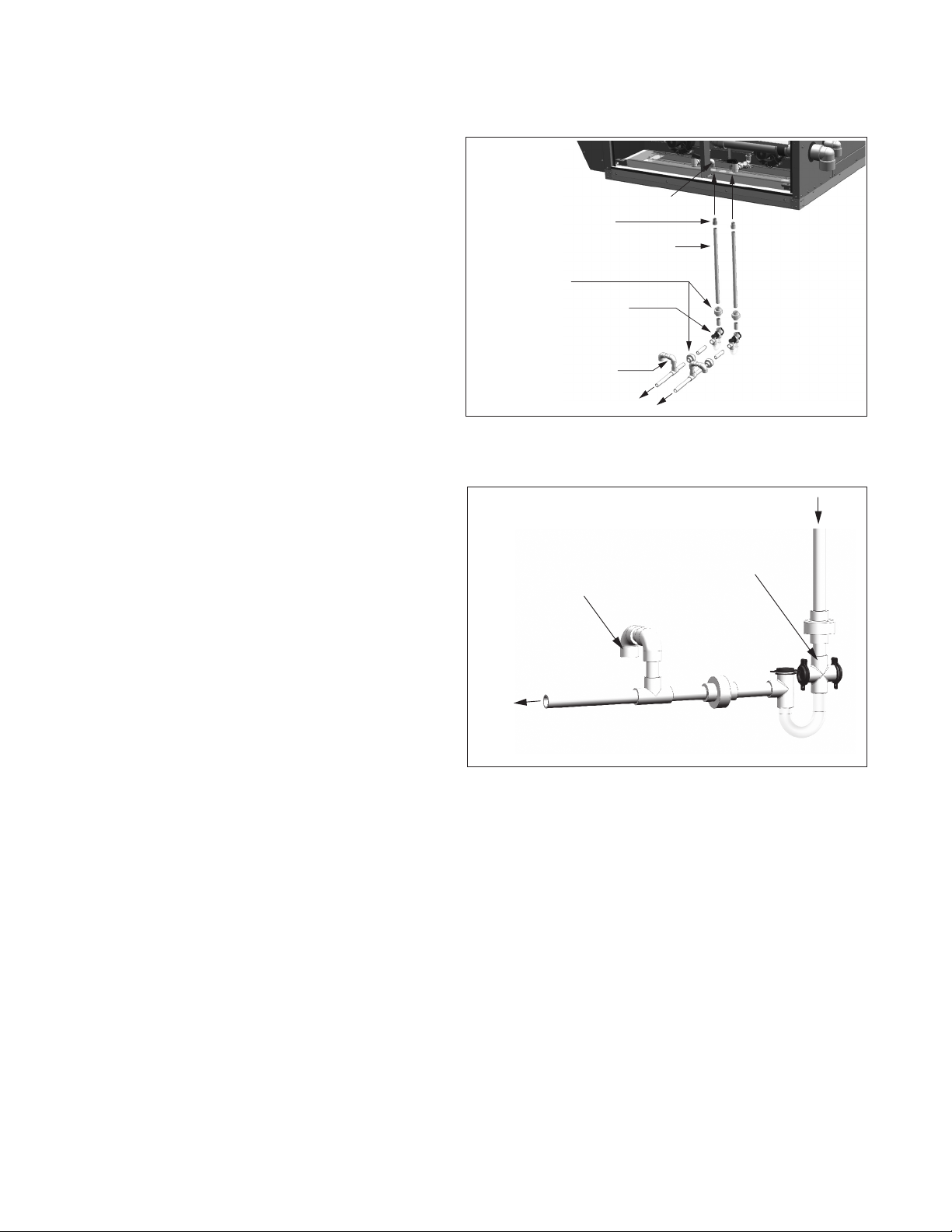

Figure 8.1 - Condensate Drain Pan Connection Kit

Threaded Connection on

Evap Coil Drain Pan

Threaded Nipple

Note: All kit components shown

are factory supplied for field installation.

Rubber Washer

Corrosion Resistant

Steel Washer

Corrosion Resistant

Steel Locknut

Figure 8.2 - Condensate Drain Trap Installation

Note: All piping components

shown are supplied by others.

•Thetrapdepthmustbe½xthetrapheight.Forexample,if

the trap height is the minimum 6”, the trap depth must be 3”

(see Figure 8.2).

•Formaintenance,itisrecommendedtohaveacapped

cleanout at the top of the trap as shown in Figure 8.2.

5. After the exit from the trap, the drain must be pitched

down from the unit connection at least 1” for every 10 feet

of horizontal run to promote proper drainage. If the local

installation code allows, the drain can be run to a waste

water system.

6. If the trap may experience below freezing temperatures

during non-cooling periods, heating wraps must be used to

avoid water from freezing in and damaging the trap and drain

system.

7. The trap must be primed before the unit is put into operation

and properly maintained on a regular schedule. Refer to the

Start-Up Procedure section and the Maintenance section for

additional guidance.

TRAP HEIGHT

(6" MINIMUM)

CAPPED

CLEANOUT

1/2 x TRAP

HEIGHT

2. The drain line should include provisions for disconnecting the

line at or near the unit for maintenance/servicing of the unit.

The drain line must not interfere with access panels, which

are removable for maintenance/service.

3. The drain line must include a trap immediately after the

unit, as shown in Figure 8.2. Failure to do so will result

in condensate that cannot properly drain from the unit,

eventually causing the drain pan to fill and overflow. If the

drain pan overflows, significant damage can occur to the unit

and/or building on which the unit is installed. A drain pan float

switch is included as standard and will disable the unit if the

maximum condensate level is reached.

4. The design of the trap is critical to ensure proper drainage.

If the trap is not constructed properly with the dimensions

as outlined in the following instructions, air could be drawn

through the drain pipe and into the system or could back up

into the drain pan.

•Thedrainislocatedonthesuctionsideofthemain

supply air fan, resulting in a negative pressure relative to

outside the unit cabinet. The trap height must be at least

6” to account for maximum negative pressure, including

allowance for dirty filters. Note that the trap height is the

difference in height from the drain connection of the unit to

the leaving side of the trap. Refer to Figure 8.2.

8 MCP15-500.7

ELECTRICAL CONNECTIONS

Electrical Connections

WARNING

1. Disconnect power supply before making wiring

connections or working on this equipment. Follow all

applicable safety procedures to prevent accidental

power up. Failure to do so can result in injury or death

from electrical shock or moving parts and may cause

equipment damage.

2. For units equipped for dual power supply sources, both

sources of power must be disconnected to prevent

electrical shock and equipment damage.

3. All appliances must be wired strictly in accordance with

the wiring diagram furnished with the appliance. Any

wiring different from the wiring diagram could result in a

hazard to persons and property.

4. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

5. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than

rated voltage.

roltage.

CAUtIoN

Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% less than the rated voltage.

1. Installation of wiring must conform with local building

codes, or in the absence of local codes, with the National

Electric Code ANSI/NFPA 70 - Latest Edition. Unit must be

electrically grounded in conformance to this code. In

Canada, wiring must comply with CSA C22.1, Part 1,

Electrical Code.

2. Two copies of the job specific wiring diagram are provided

with each unit, one permanently affixed to the inside of the

door of the controls compartment and the other as a loose

copy with the literature packet that ships with the unit.

Refer to this diagram for all wiring connections.

3. Control wiring consists of both 24V analog control wiring

and low current digital control signal wiring. To avoid signal

interference, the two types should be run in separate

conduits. If run in the same conduit, the digital signal wiring

should be shielded at one end of the wiring run. Wiring

should be twisted, stranded, and shielded communication

wire.

4. The wire gauge must be sized according to the National

Electric Code or CSA code based on amp draw and length

of run. Refer to Table 9.1 for maximum wire lengths and

the number of wires that can be wired to each low voltage

terminal block based on the wire gauge being used.

Table 9.1 - 24V and Digital Control Wire Lengths

Minimum

Recommended

Wire Gauge

22 n/a 120

20 n/a 200

18 75 300

16 125 500

14 175 n/a

24V Control Wiring Digital Control Wiring

Maximum Distance from

Control Device to Unit

5. For field wiring to the factory terminal strip, the terminal

strip connections are designed to clamp down on the wires.

To properly connect the wires to the terminal strip:

• Push a small flat-head screwdriver into the square hole on

the terminal. Press firmly until the screwdriver hits the

back stop and opens the terminal (see Figure 9.1).

• Remove approximately 3/8” of insulation from the end of

the wire and push the stripped wire into the oval hole in

the terminal.

• Remove the screwdriver. Pull on the wire to make sure

that it is securely clamped in the terminal.

• Make sure that the terminal clamp is in contact with bare

wire (insulation removed).

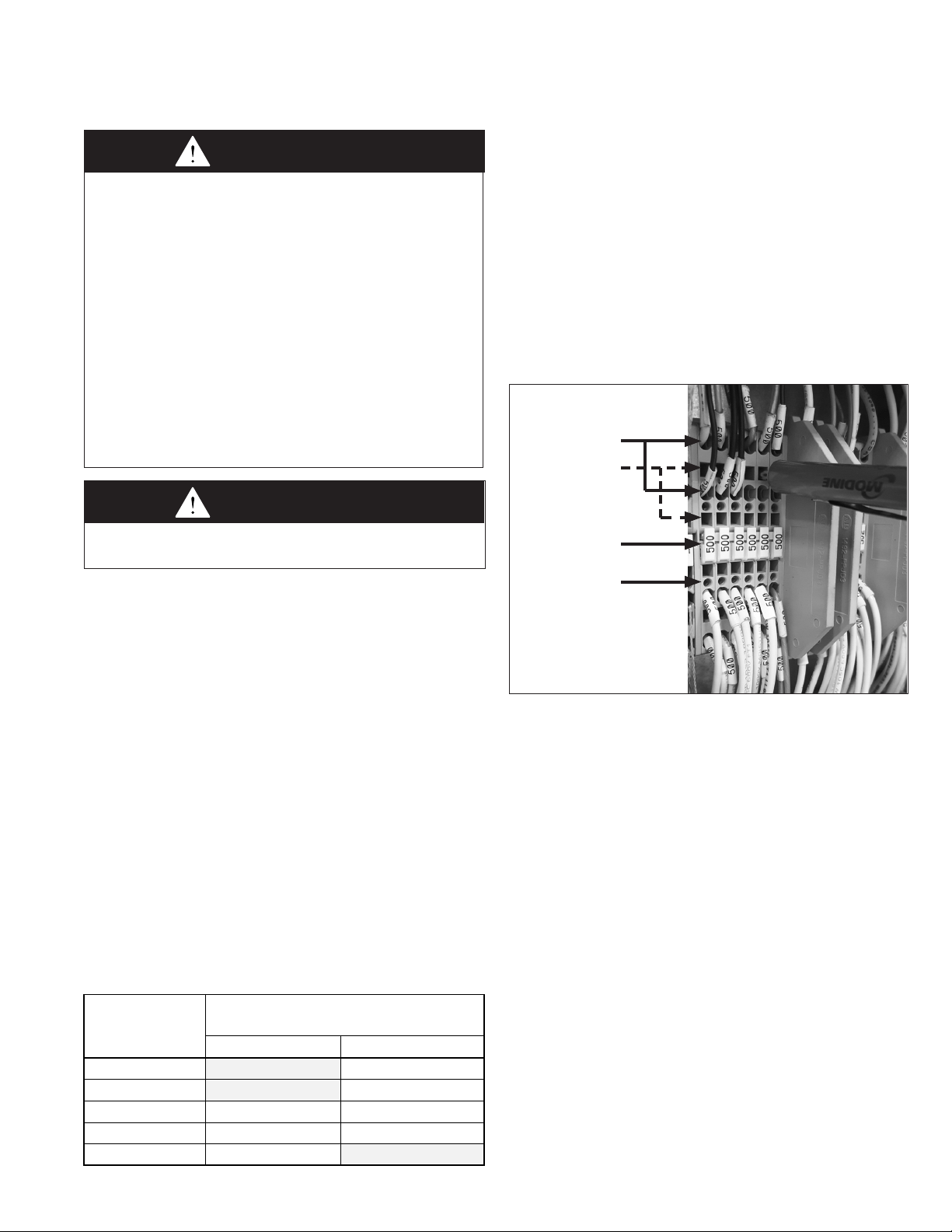

Figure 9.1 - Terminal Strip Wiring

Oval Holes

for Wiring

(two rows each)

Square Holes

for Wire Release

(two rows each)

Terminal

Numbers

Test Probe

Points

6. Depending on the configuration of the unit controls, there

may be sensors that are field installed. Review the unit

ordered to verify that the sensors supplied match the

configuration of the unit. The following are sensors that

may be included for field installation:

• Supply Air Temperature Sensor

This sensor is required on all units and should be

mounted in the supply air ductwork downstream of the

unit. The sensor should be located at least 5 feet, but not

more than 20 feet downstream from the unit discharge.

• Space Temperature/Humidity Sensor

This sensor is required on all units that have space

temperature/humidity reset control. The sensor is to be

wall-mounted in the space at a height of approximately

5 feet from the floor.

• Building Pressure Sensor

This sensor is required on all units that have space

pressure control, either through modulating dampers or

variable frequency drive control on the supply air blower.

The sensor is to be mounted inside a control panel in the

space and includes two pressure taps. One pressure tap

is for outside atmospheric pressure reference, the other is

for sampling the space pressure.

• Duct Pressure Sensor

This sensor is required on all units that have duct

pressure control through variable frequency drive control

on the supply air blower. The sensor is to be mounted

with the sensing probe inserted into the supply duct. The

atmospheric pressure sampling tap is left open.

9MCP15-500.7

ELECTRICAL CONNECTIONS / GAS CONNECTIONS

• Space CO2 Sensor

This sensor is required on all units that have demand

based ventilation control. The sensor is to be mounted in

the space at a height of approximately 5 feet from the

floor.

• Duct Mounted Smoke Detector

When ordered as a field installed accessory, the detector

should be mounted in the supply air or return air ductwork.

For further instructions on the above sensor(s), refer to

the installation instructions that shipped with the

sensor(s).

7. If the unit is a C-Cabinet sized unit with a Modine supplied

Energy Recovery Module, Model ERM, the wiring

connection between the MPR unit and the ERM unit must

be made by extending the loose end of the wire drop

located in the MPR unit outside air damper section, through

the transition duct between units, and connected to the

ERM control panel. Refer to the Installation & Service

Manual that shipped with the ERM (Literature #MCP15-

520) for additional instructions. If the unit is a B-Cabinet

sized unit with integral Energy Recovery, the unit is already

factory wired to the Energy Recovery section.

8. The power supply to the unit must be protected with a

fused or circuit breaker disconnect switch. Refer to the

Figures on pages 32 through 35 for the location of the

factory installed dead front disconnect option, if provided.

Field installed disconnect switches should be mounted

where required by the National Electric Code. Refer to the

Model Serial plate for MCA and MOP values for the unit.

9. The power supply must be within +/-5% percent of the

voltage rating and each phase must be balanced within 2

percent of each other. If not, advise the utility company.

10. External electrical service connections that must be

installed include:

a. Supply power (120, 208, 240, 480, or 600 volts).

b. Thermostats, building pressure sensors, or any other

accessory control devices that may be supplied (24

volts).

11. All outdoor electrical connections must be weatherized to

prevent moisture from entering the electrical compartment.

12. Electrical connections are made in the controls cabinet and

can be run through the bottom or side of the unit. Refer to

the unit and base dimensional drawings for locations of

wiring entrance. Refer to the wiring diagram for the terminal

location of all low voltage wiring.

REVIEW BEFORE PROCEEDING

THIS SECTION APPLIES TO UNITS WITH

(MODEL DIGIT 17=2 OR 3).

IF THE UNIT DOES NOT HAVE GAS HEAT,

Gas Connections

WARNING

1. All field gas piping must be pressure/leak tested prior

to operation. Never use an open flame. Use a soap

solution or equivalent for testing.

2. Gas pressure to appliance controls must never

exceed 14" W.C. (1/2 psi).

3. To reduce the opportunity for condensation, the

minimum sea level gas input to the appliance, as

indicated on the serial plate, must not be less than

5% below the rated input, or 5% below the minimum

rated input of dual rated units.

CAUtIoN

Purging of air from gas supply line should be performed as

described in ANSI Z223.1 - latest edition “National Fuel Gas

Code”, or in Canada in CAN/CGA-B149 codes.

IMPoRtANt

To prevent premature heat exchanger failure, the input to the

appliance, as indicated on the serial plate, must not exceed

the rated input by more than 5%.

1. Installation of piping must conform with local building codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - Latest Edition. In Canada,

installation must be in accordance with CAN/CGA-B149.1 for

natural gas units and CAN/CGA-B149.2 for propane units.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line. Refer to Table 11.1 to

determine the cubic feet per hour (cfh) for the size of unit

to be installed. Using this cfh value and the length of pipe

necessary, determine the pipe diameter from Table 11.2.

Where several units are served by the same main, the total

capacity, cfh and length of main must be considered. While

the gas connection(s) on the unit may be smaller than 1", do

not use pipe sizes smaller than 1" leading up to the unit. At

the unit, reduce the pipe size down to the appropriate size

(refer to Table 11.1 for connection sizes). Table 11.2 allows

for a 0.3" W.C. pressure drop in the supply pressure from the

building main to the unit. The inlet pressure to the unit must

be 6-7" W.C. for natural gas and should not drop below 6.0"

W.C. when the unit is operating. When sizing the inlet gas

pipe diameter, make sure that the unit supply pressure can

be met after the 0.3" W.C. has been subtracted. If the 0.3"

W.C. pressure drop is too high, refer to the Gas Engineer’s

Handbook for other gas pipe capacities.

OPTIONAL GAS HEAT

SKIP TO PAGE 15.

roltage.

10 MCP15-500.7

GAS

GAS CONNECTIONS

Furnace Size

(Btu/hr)

Gas Consumption

(CFH)

Gas

Connection

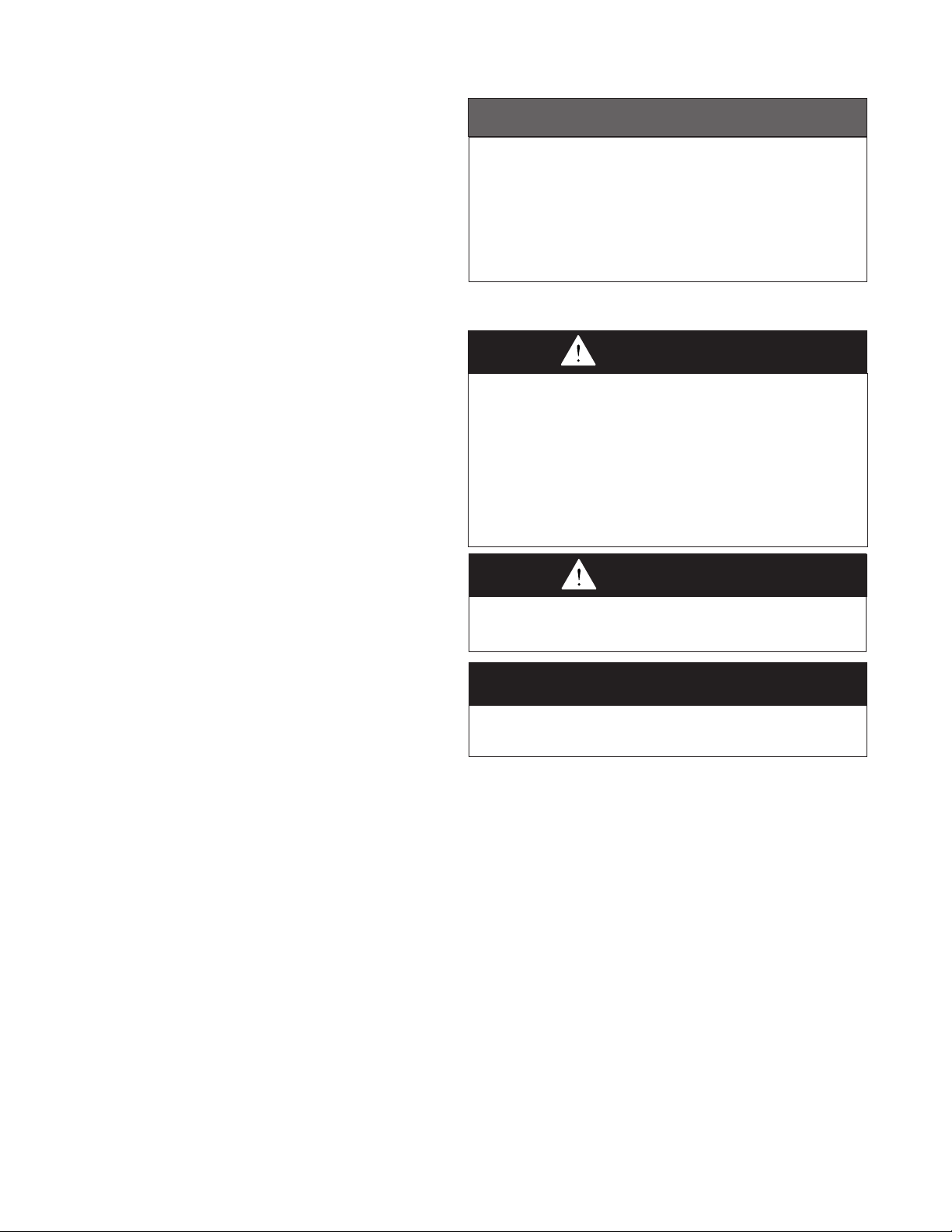

Table 11.1 - Natural Gas Heating Gas Consumption

Digit 6 Digit 18

F 150,000 143 1/2"

G 200,000 190 3/4"

H 250,000 238 3/4"

B

J 300,000 286 3/4"

K 400,000 381 3/4"

R 175,000 167 1/2"

S 225,000 214 3/4"

T 310,000 295 3/4"

J 300,000 286 3/4"

K 400,000 381 1"

C

L 500,000 476 1"

L 600,000 571 1"

U 350,000 333 1"

V 450,000 429 1"

K 400,000 381 1.5" x 2

L 500,000 476 1.5" x 2

M 600,000 571 1.5" x 2

Q 800,000 762 1.5" x 2

D

1 900,000 857 1.5" x 2

2 1,000,000 952 1.5" x 2

3 1,200,000 1143 1.5" x 2

4 1,400,000 1333 1.5" x 2

5 1,600,000 1524 1.5" x 2

j Natural gas consumption based on a heating value of 1050 Btu/cu. ft.

k C-Cabinet units consist of two furnaces that together total the value shown in

Table 11.1.

l D-Cabinet units consist of two furnaces that together total the value shown

in Table 11.1 for sizes up to 800,000 Btu/hr. For sizes over 800,000 Btu/hr,

the unit consists of four furnaces that together total the value shown in Table

11.1.

3. The gas piping to the unit can enter the unit from the side

of the unit (refer to the unit dimensions) or from below (refer

to the base dimensions). A drill locator sticker and dimple is

located on the side of the unit to indicate the safe area for

drilling the hole for side gas pipe entry on B- and C-Cabinet

sized units. D-Cabinet sized units include a holes with

grommets for side pipe entry. Install a ground joint union

with brass seat and a manual shut-off valve external of the

unit casing, and adjacent to the unit for emergency shut-off

and easy servicing of controls, including a 1/8" NPT plugged

tapping accessible for test gauge connection (see Figure

11.1). Verify the manual shut-off valve is gas tight on an

annual basis.

NOTE: For bottom piped units, some local codes may require

a manual shutoff valve external to the unit casing. In this case,

the gas piping must exit the unit through the side, followed by

the manual shut-off valve, piped back into the unit side, and

lead to an additional union and manual shut-off valve.

4. Provide a sediment trap before each unit in the line where

low spots cannot be avoided (see Figure 11.1).

5. When Pressure/Leak testing pressures above 14" W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

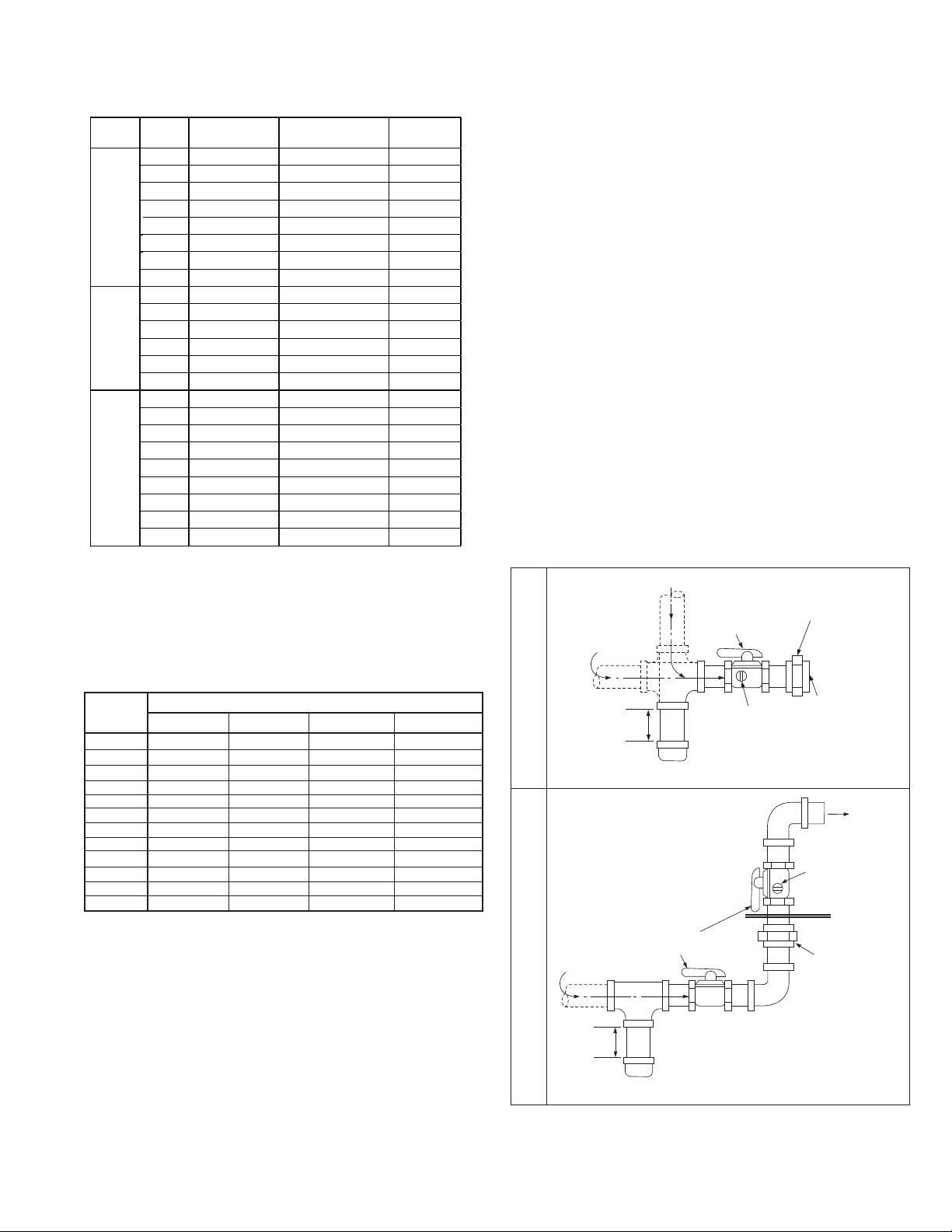

Figure 11.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation

GAS

SUPPLY LINE

SUPPLY LINE

MANUAL GAS

SHUT-OFF VALVE

GROUND JOINT

UNION WITH

BRASS SEAT

Table 11.2 - Gas Pipe Capacities (Cu. Ft. per Hour) m

Pipe

Length

(feet)

1" 1-1/4" 1-1/2" 2"

10 520 1050 1600 3050

20 350 730 1100 2100

30 285 590 890 1650

40 245 500 760 1450

50 215 440 670 1270

60 195 400 610 1150

70 180 370 560 1050

80 170 350 530 990

90 160 320 490 930

100 150 305 460 870

125 130 275 410 780

150 120 250 380 710

m Gas pipe capacities based on gas pressure up to 14" W.C. through Schedule

40 pipe with a pressure drop of 0.3" W.C. for Natural gas with a specific

gravity of 0.60.

Gas Pipe Diameter

TO GAS

CONTROLS

MIN.

3"

PLUGGED

1/8" NPT TEST

GAUGE CONNECTION

Side Gas Connection

SEDIMENT

TRAP

CONTROLS

PLUGGED 1/8"

NPT TEST GAUGE

CONNECTION

Through hole

in bottom of unit.

(caulk hole to prevent

GROUND

JOINT

UNION

W/ BRASS

SEAT

water leakage.)

MANUAL GAS

SEDIMENT

TRAP

SHUT-OFF VALVE

GAS

SUPPLY LINE

Bottom Gas Connection

j Valve is in the “OFF” position when handle is perpendicular to pipe.

MIN.

3"

j

TO

11MCP15-500.7

GAS HEATING OPTION VENT TERMINALS AND COMBUSTION AIR HOODS

Vent

Terminals

Combustion

Air Hoods

6

Type

Field Installe d Qty

(Btu/hr)

18

Vent Terminals and Combustion Air Hoods

1. Do not operate the units without the factory supplied (shipped

loose) power exhauster vent system/vent termination(s) or

combustion air hoods if applicable. Refer to Table 12.1 to

determine how many terminals and hoods are required based

on the model MPR nomenclature.

2. Do not modify or obstruct the combustion air inlet louvers or

the power exhauster discharge cover terminations.

3. Do not add any vents other than those supplied by the

manufacturer. For units that require vent extension kits, refer

to Literature #MCP15-574, “Installation Instructions,

Extended Vent Kit, Model MPR Gas Heat”.

Table 12.1 - Power Exhauster Vent Terminal and

Combustion Air Hood Quantity

Digit

B

C

D

Furnace Size

Digit

F 150,000

G 200,000

H 250,000

J 300,000

K 400,000

R 175,000

S 225,000

T 310,000

J 300,000

K 400,000

L 500,000

L 600,000

U 350,000

V 450,000

K 400,000

L 500,000

M 600,000

Q 800,000

1 900,000

2 1,000,000

3 1,200,000

4 1,400,000

5 1,600,000

Furnace

Non-

Condensing

Condensing

Non-

Condensing

Condensing

Non-

Condensing

Non-

Condensing

1

1 n/a

2

2

2 2

4 2

n/a

n/a

n/a

Non-Condensing Furnaces (B, C, or D-Cabinet)

For Non-Condensing furnace types, as determined from Table

12.1, refer to Figure 12.1 for vent termination installation details,

otherwise skip to the section titled Condensing Furnaces. For

units that require vent extension kits, refer to Literature

#MCP15-574, “Installation Instructions, Extended Vent Kit,

Model MPR Gas Heat”.

Figure 12.1 - Power Exhauster Vent Terminal for

Non-Condensing Gas Furnace Option

Note: Caulk mating

surfaces before

2

Gas Furnace

Vent Outlet

k C-Cabinet sized unit shown with two vent terminals. B-Cabinet sized units

have only one and D-Cabinet with have either one on each side of the

cabinet (two total) or two on each side of the cabinet (four total).

attaching to the unit

(6) Screws for

Fastening Gas

Furnace Vent

Outlet Cover

(supplied with kit)

For D-Cabinet units, the furnace doors must have the

combustion air hoods field installed as shown in Figure 12.2,

using the screws included with the kit. Once complete, proceed

to the “Start-Up” section.

Figure 12.2 - Combustion Air Hood Installation

(D-Cabinet only)

For specific instructions on each configuration in Table 12.1,

refer to the appropriate section from the following sections

titled:

• Non-Condensing Furnaces (B, C, or D-Cabinet), or

• Condensing Furnace (B-Cabinet), or

• Condensing Furnace (C-Cabinet)

12 MCP15-500.7

Note: Caulk mating surfaces

before attaching to the unit.

Also shown are the vent terminals for reference.

(refer to

Instructions

Step 1)

(refer to Instructions Step 3)(refer to Instructions Step 2)

(refer to Instructions Step 1) (refer to Instructions Step 2)

GAS HEATING OPTION VENT TERMINALS AND COMBUSTION AIR HOODS

Condensing Furnaces (B-Cabinet)

For B-Cabinet units with Condensing furnace types, as

determined from Table 12.1 on page 12, refer to Figures 13.1

and 13.2 for vent termination installation details. The

installation steps are as follows:

Step 1: Insert short vent pipe length into the vent pipe

reducer. Insert that assembly into the rubber coupling

on the power exhauster outlet. Tighten the clamp on

the flexible coupling to secure the vent pipe.

Step 2: Insert the outer vent pipe with termination elbow

through the enclosure wall grommet and into the vent

pipe section installed in Step 1.

Once complete, proceed to the “Condensate Drain and Trap

Installation” section.

Condensing Furnaces (C-Cabinet)

Figure 13.1 - Power Exhauster Vent Terminal for

Condensing Gas Furnace Option

For C-Cabinet units with Condensing furnace types, as

determined from Table 12.1 on page 12, refer to Figures 13.3

and 13.4 for vent termination installation details. The

installation steps are as follows:

Step 1: Insert small diameter outside vent pipe termination

through enclosure wall grommet and into the flexible

rubber coupling on the right side power exhaust

outlet. Tighten the clamp on the flexible coupling to

secure the vent pipe.

Step 2: Insert large diameter inner vent pipe assembly into

the flexible rubber coupling on the left side power

exhaust outlet. Tighten the clamp on the flexible

coupling to secure the vent pipe.

Step 3: Insert large diameter outside vent pipe termination

through enclosure wall grommet and into the

interlocking joint of the inner vent pipe assembly from

Step 2.

Step 4: Verify that the bird screens are inserted in the outlet

elbow.

Once complete, proceed to the “Condensate Drain and Trap

Installation” section.

Figure 13.3 - Power Exhauster Vent Terminal for

Condensing Gas Furnace Option

Figure 13.2 - Orientation of Installed Vent Terminal

for Condensing Gas Furnace Option (B-Cabinet)

Discharge Elbow must be

oriented to exhaust

straight down.

Figure 13.4 - Orientation of Installed Vent Terminal

for Condensing Gas Furnace Option (C-Cabinet)

Discharge Elbows must

be oriented to exhaust

straight down.

13MCP15-500.7

3/4" Threaded Elbow on Heat Exchanger Drain

Assembly (included with kit)

3/4" Male Threaded PVC Adapter

(included with kit)

3/4" PVC Pipe (by others) with Sufficient Length

to Reach the Heat Exchanger Drain Assembly

from the Inside of the Building

3/4" Unions (by others)

Recommended for Ease of Future Service

PVC "EZ-Trap" (included with kit) for

Proper Drain Trapping (a 3/4" to 1" bushing

by others may be required)

Note: The trap must be located in a heated

space or protected to avoid freezing.

Vacuum Breaker and Drain Piping

Components (by others)

To Building

Drain System

From Heat

GAS HEATING OPTION CONDENSATE DRAIN AND TRAP INSTALLATION

Condensate Drain and Trap Installation

(Condensing Furnace Type Only)

For Condensing furnace types, as determined from Table 12.1

on page 12, during heating operation, condensate is produced

in the furnace sections. The installation requires condensate

drain systems from each furnace section, as shown in Figures

14.1 and 14.2 and described below. Condensate trap kits are

provided with the unit.

1. For proper heating system performance, the condensate

drain system must include a trap for each furnace.

B-Cabinet units have one furnace while C-Cabinet units

have two furnaces.

2. All joints must be watertight to prevent leakage of

condensate. The drains must be extended down through

the base of the unit and into the heated space below.

3. Each heat exchanger drain assembly includes a threaded

elbow that is oriented down. Once the male threaded PVC

adapters, included with the kit, are glued to the PVC drain

pipe (by others) that extends into the space, they are to be

routed up through the holes in the unit base pan and

screwed into the elbow connections. The threads must be

sealed to prevent leaks.

4. Unions are recommended to permit maintenance of the

drains and to facilitate service of the heater. A union is

shown on both sides of each trap.

5. A vacuum breaker is required after each trap. The vacuum

breaker should be constructed so that dirt and debris do

not enter and clog the drain system.

6. Local code permitting, the condensate drain systems may

be joined after the traps and connected to a sanitary drain

within the building. Because the condensate produced is

acidic, some municipalities may require that the

condensate be neutralized before being discharged into the

sanitary sewer. A condensate neutralizer tube kit is

available from Modine to reduce the pH of the condensate.

A single tube can be used for drains that are joined after

the traps providing the tube is installed after the junction.

Refer to the instructions that come with the kit.

7. For proper operation, the traps must be primed with water.

The traps must be installed with the higher side connected

to the heater and the lower side connected to the drain.

8. If there is an opportunity that the temperature in the space

will fall below freezing during non-operating periods, the

condensate drain systems and secondary heat exchanger

must be completely drained to prevent freeze damage.

Alternately, heat tape can be applied to the drain pipe

system in accordance with the heat tape manufacturers

instructions.

Figure 14.1 - Furnace Condensate Drain/Trap

System j

j C-Cabinet sized unit shown with two condensate drain systems. B-Cabinet

sized units require only one drain system.

Figure 14.2 - Drain System Trap/Vacuum Breaker

Exchanger Drain

Assembly on Unit

Note: Drain pipe from unit

Vacuum Breaker

To Building

Drain System

Note: Refer to figure above for determination of parts supplied by others.

must enter the high side of

the drain trap.

14 MCP15-500.7

HOT WATER PIPING CONNECTIONS

REVIEW BEFORE PROCEEDING

THIS SECTION APPLIES TO UNITS WITH

OPTIONAL HOT WATER HEAT

(MODEL DIGIT 17=4).

IF THE UNIT DOES NOT HAVE HOT WATER

HEAT, SKIP TO PAGE 16.

CAUtIoN

1. Units not approved for use in potable water systems.

2. Do not operate the unit with steam. The coil is not designed

for steam condensate removal which can damage the unit.

3. Hot water supplied to the hot water heating option must

not exceed 180°F temperature or 75 PSIG pressure.

1. Models with a factory installed hot water heating coil (for use

with water or propylene glycol fluids) are supplied with 1-1/2"

sweat connections (1.625").

Figure 15.1 - Hot Water Coil Connections

•On3-wayvalvecontrolconfigurations,includeabalancing

valve between the supply line and control valve to balance

the system.

•Includeahosebibdrainvalveonthebottomofthesupply

manifold to allow for periodic flushing of the system to

remove sediments from the coil.

•Includeapipelinestraineronthesupplylinetoprevent

sediment from reaching the coil.

•Includeanairventatthetopofthereturnmanifoldtobleed

off accumulated air in the system. Air in the system will

generate noise and may cause water hammer that can

damage the joints of the piping and coil.

•Includeeithera2-wayor3-waymodulatingcontrolvalve

designed for a 0-10VDC control signal. The valves will be

automatically modulated by the unit’s Carel controller to

maintain the supply air temperature setpoint. Note that the

control valve must be a normally open, spring return type

valve. This is to allow hot water to flow through the coil for

freeze protection when the unit is shut down. Refer to the

Freeze Stat Option section for additional detail.

•Hotwaterpipesshouldbeinsulatedtoreduceheatlossand

to prevent overheating of the end compartment.

9. Leak test the coil and connections as outlined in the

Start-Up section.

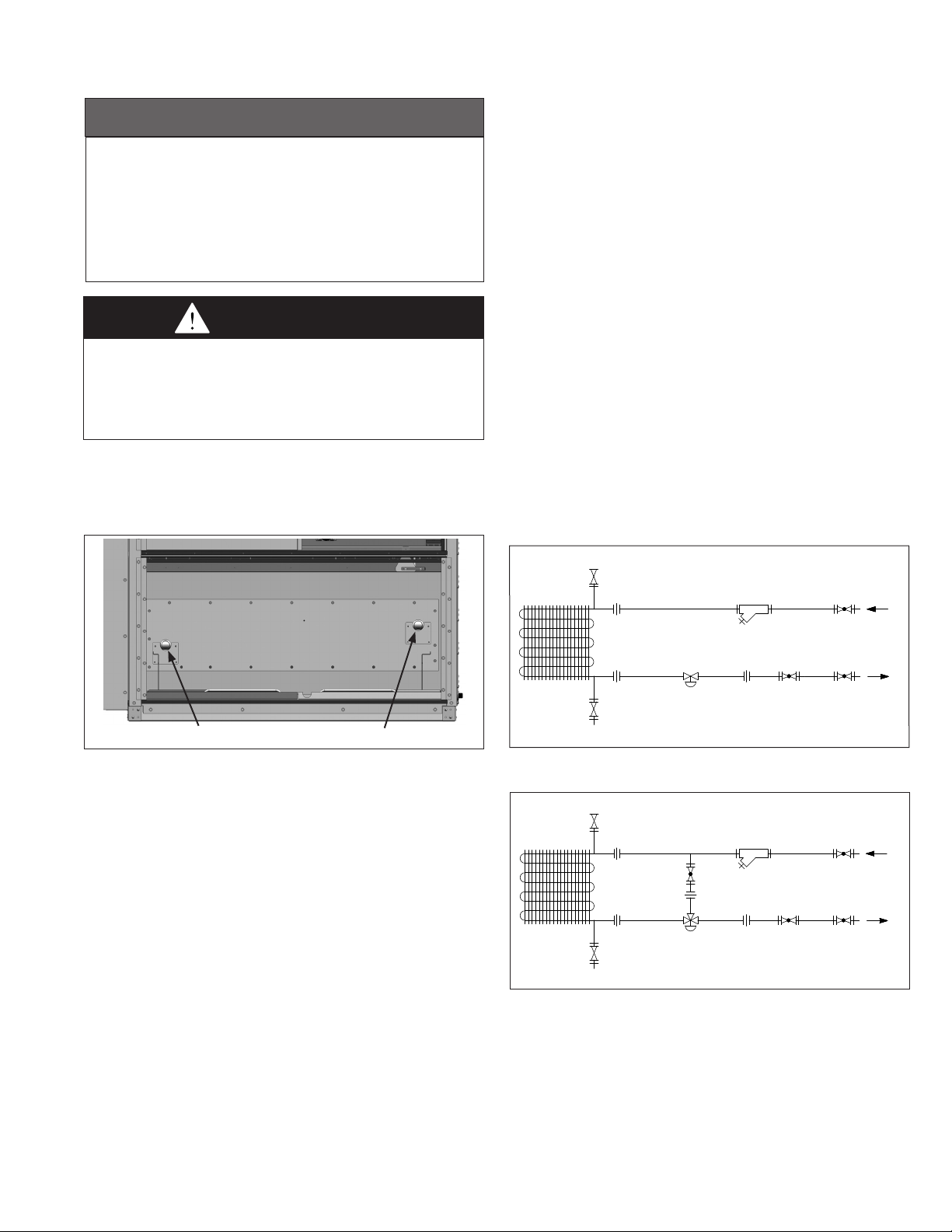

Figure 15.2 - Typical 2-Way Piping Installation

(piping and components by others)

Supply Connection Return Connection

2. The entering water temperature (EWT) supplied to the

heating coil must not exceed 180°F.

3. The fluid flow rate must not exceed 50 gallons/minute (GPM)

and fluid pressure must not exceed 75 psi.

4. It is recommended to use an inhibited glycol solution that is

designed for HVAC applications for corrosion protection and

freeeze protection for the lowest possible outside air

temperatures for the installed location. Failure to protect

against freezing can result in damage to the coil and

property.

5. Provide adequate pipe hangers, supports, or anchors to

secure the piping system independently of the coil to prevent

excess vibration and stress that can damage the piping and

joints.

6. All field brazing and welding should be performed using high

quality materials and an inert gas purge (such as nitrogen) to

reduce oxidation of the internal surface of the coil.

7. System piping should be flexible enough to allow for thermal

expansion and contraction of the coil and piping components.

8. Refer to Figures 15.2 and 15.3 for typical piping system

design and the following recommended items:

•Installshut-offvalvesinlinestoandfromtheunittoallow

for maintenance or replacement of the coil without shutting

down and draining the entire system.

•Installunionsforeaseofpipingcomponent/coilremoval.

•Includeacircuitsetterinthereturnlinetoregulateflow.

HOSE BIB DRAIN

SHUT-OFF

VALV E

SHUT-OFF

VALV E

SUPPLY

RETURN

HOT WATER

COIL

AIR VENT

UNION

UNION

2-WAY CONTROL

VALV E

STRAINER

UNION

CIRCUIT

SETTER

Figure 15.3 - Typical 3-Way Piping Installation

(piping and components by others)

HOSE BIB DRAIN

SHUT-OFF

VALV E

SHUT-OFF

VALV E

SUPPLY

RETURN

HOT WATER

COIL

AIR VENT

UNION

UNION

BALANCING

VALV E

3-WAY CONTROL

VALV E

UNION

STRAINER

UNION

CIRCUIT

SETTER

Optional Factory Installed Freeze Stat

When equipped with the optional Coil Freeze Stat, an autoresetting capillary type freeze stat (see Figure 50.1) is factory

installed immediately below and across the face of the hot

water coil. The stat is set to trip at 40°F (adjustable) and will

automatically reset when the coil temperature rises 5°F above

the setpoint. If the stat has tripped, the unit controls would

respond by closing the outdoor air damper, opening the return

air damper (if applicable), de-energize the supply air fan, open

the hot water coil valve 100%, and log the alarm on the

controller. The freeze stat can be removed from the unit for

servicing as discussed in the Maintenance section.

15MCP15-500.7

START-UP PROCEDURE

General

1. When the dead front disconnect switch(es) (for main

unit and/or powered convenience outlet option) is in the

“OFF” position, supply power remains energized at the

line (supply) side of the dead front disconnect switch(es).

The switch body is located inside of another junction

box to protect against contact with the live wiring.

The junction box must not be disassembled unless

the main power supply from the building to the unit is

de-energized.

2. For units equipped for dual power supply sources, both

sources of power must be disconnected to prevent

electrical shock and equipment damage.

WARNING

WARNING

CAUtIoN

When servicing the unit, some components may be hot

enough to cause pain or injury. Allow time for cooling of hot

components before servicing.

IMPoRtANt

1. To prevent premature heat exchanger failure, check to

be sure the blower has been set to deliver the proper

airflow for the application. Refer to page 17 for Blower

Adjustments.

2. Start-up and adjustment procedures must be performed

by a qualified service agency.

3. All scroll compressors requires the correct supply

power phase rotation. Phase reversal may result in

compressor failure not covered under warranty. Refer to

the Start-Up Procedure section.

4. The exhaust fan is not designed for high temperature

or smoke control exhaust applications. Exhaust air

temperature must not exceed 104°F. Operating the

exhaust fan above 104°F will result in failure of the

exhaust fan.

1. Turn off power to the unit at the disconnect switch. If

equipped with gas heating option, turn all hand gas valves

to the “OFF” position.

Note: The dead front disconnect switch, if included, is

factory installed in the controls/compressor compartment

section (refer to the figures on pages 32 through 35). The

disconnect switch is designed so that it must be turned

“OFF” before entry to the compartment can be obtained.

When in the “OFF” position, power is disconnected to all

unit wiring electrically following the switch (see

WARNING).

2. For units equipped for dual power supply sources, both

sources of power must be disconnected to prevent

electrical shock and equipment damage.

3. Open the power compartment, controls compartment, and

blower access doors.

4. Check that the supply voltage matches the unit supply

voltage listed on the Unit Serial Plate. For units equipped

for dual power supply sources, the voltage on both the

main feed and the auxiliary feed must match the unit

supply voltage listed on the Unit Serial Plate.

5. Check that fuses or circuit breakers are in place and sized

correctly.

6. Verify that all wiring is secure and properly protected. Trace

circuits to ensure that the unit has been wired according to

the wiring diagram.

7. Check that all electrical and gas connections are

weatherized.

8. For C-Cabinet sized units, if the unit is installed with a

Modine supplied Energy Recovery Module, Model ERM,

verify that the wiring connection between the MPR unit and

the ERM unit has been properly installed. If the unit is a

B-Cabinet sized unit with integral Energy Recovery, the unit

is already factory wired to the Energy Recovery section.

9. For units with gas heating, check to ensure that the

combustion air inlet louvers and the power exhauster

discharge cover (Non-Condensing as determined from

Table 12.1 on page 12) or the vent elbow terminations

(Condensing as determined from Table 12.1 on page 12)

are free from obstructions.

10. For units with condensing gas heating, check that the

condensate drain system is properly installed and the trap

has has been primed with water.

11. For units with Hot Water Heat (Digit 17=4), check the

following:

• Open air vents so that air is eliminated from within the coil

circuitry and headers. Verify that vents and drains are not

obstructed and do discharge a stream of water.

• Open all required valves to fill the coil. Once the coil is

full, close all air vents.

• Perform an initial hydrostatic leak test of all brazed,

threaded or flanged joints, valves and interconnecting

piping, and the hot water coil. Recheck the coil level and

correct if necessary.

• When the setup is found to be leak free, flush the coil

through the drain valve to eliminate grease, oil, flux and

sealing compounds present from the installation.

• Recheck the coil and all connections for water leaks.

• Check water flow rates and pressure drops and compare

to design.

• Check that the hot water supplied to the coil does not

exceed 180°F temperature or 75 PSIG pressure. Verify

that the appropriate glycol mixture is used for freeze

protection.

12. Check to see that there are no obstructions to the intake

and discharge of the unit.

13. Verify that the belts are aligned in the sheave grooves

properly and are not angled from sheave to sheave.

14. On belt driven blowers, blower bearings are permanently

lubricated unless they are pillow block bearings or if they

have grease fittings. For motors or blower bearings that are

not permanently lubricated, lubricate according to the

manufacturer’s instructions. Refer to the Maintenance

section on page 48.

15. Check to make sure that all filters are in place and that

they are installed properly according to direction of air flow.

Pleat direction must be vertical to ensure optimum

performance.

16. Perform a visual inspection of the unit to make sure no

damage has occurred during installation.

16 MCP15-500.7

START-UP PROCEDURE - CONTINUED

17. Check that the evaporator drain pan drain trap has been

primed with water.

18. Turn on power to the unit at the disconnect switch.

Note: Units include one blower door switch per access

door (one on B- and C-Cabinet, two on D-Cabinet) that are

factory installed inside the blower access section door(s).

When a blower section door is opened, the switch is

opened and interrupts power to the low voltage circuit and

de-energizes the blower motor controller. D-Cabinet units

also have the same switches on the evaporator/hot gas

reheat coil access sections.

19. Check the Carel microprocessor controller and supply fan

blower motor for electrical operation. If the unit is equipped

with the optional building power exhauster module (with or

without energy recovery), check the blower motor for

electrical operation. If these do not function, recheck the

wiring diagram. Check to ensure that none of the Control

Options (for example, smoke detector, etc.) have tripped.

20. Check to make sure that the damper(s) operate properly

without binding.

21. Check that the supply power wiring is wired with the

correct phase rotation. For units equipped for dual power

supply sources, correct phase rotation must be verified on

both the main feed and the auxiliary feed. Incorrect phase

rotation can damage the equipment. Check the phase

rotation as follows:

• For units equipped with single speed motor

starters on the supply fan: Check the blower wheel

for proper direction of rotation when compared to the

air flow direction arrow on the blower housing. Blower

wheel rotation, not air movement, must be checked as

insufficient air will be delivered if the blower wheel is

running backwards. If the blower wheel is rotating in

the opposite direction, the phase reversal must be

corrected by changing the incoming power feed legs at

the supply to the unit, NOT the individual components

on the unit. Recheck for proper rotation.

• For units equipped with a variable frequency drive

on the supply fan: The VFD will correct the phase

rotation for the supply fan, but will not correct the phase

rotation for the rest of the unit, therefore observing the

supply blower wheel rotation direction is not an

accurate indicator of correct phase rotation. Scroll

compressors will only compress in one rotational

direction. Verification of proper rotation direction is

made by observing that suction pressure drops and

discharge pressure rises when the compressor is

energized. Reverse rotation will result in no pressure

differential as compared to normal values. There is no

negative impact on durability caused by operating the

compressors in the reversed direction for a short period

of time (under one hour) but should not be allowed to

operate longer than the time it takes to verify rotation.

If the compressor is rotating in the opposite direction,

the phase reversal must be corrected by changing the

incoming power feed legs at the supply to the unit,

NOT at the compressor. Recheck for proper rotation.

22. Check the blower speed (rpm). Refer to Blower

Adjustments for modification.

23. Check the motor speed (rpm).

24. Check the motor voltage. On three phase systems, check to

make sure all legs are in balance.

25. Check the motor amp draw to make sure it does not exceed

the motor nameplate rating. Check all legs to ensure system

is balanced.

26. For units equipped for dual power supply sources, the unit

should be started separately on the main power feed and

again on the auxiliary power feed to verify proper unit and

control operation.

Note: Units equipped for dual power supply sources have the

unit power wiring separated into two circuits as follows:

Circuit #1

• Compressors

• Condenser fans

• Electric heating section (if applicable).

• Energy recovery wheel (if applicable)

Circuit #2

• Main unit controller

• Supply fan

• Dampers

• Gas heating section (if applicable)

• Exhaust fan (if applicable)

• Energy recovery wheel bypass damper (if applicable)

When operating in a full power state with the main power

feed, both Circuit #1 and Circuit #2 should be powered.

When operating in a low power state with the auxiliary power

feed, only Circuit #2 should be powered.

Blower Adjustments

The units are designed for ease of airflow adjustments, within a

range, for field balancing against actual external static pressure

conditions. If the static pressure external to the unit is above

or below the original design point for the unit, the blower will

deliver an airflow volume that is lower or higher than required.

When equipped with the building exhaust option (with or

without energy recovery), the air balancing must be performed

for both the main unit supply fan, as well as the exhaust fan.

The blower speed (supply and/or exhaust blowers) may be

adjusted to achieve the desired air volume, provided:

• The allowable temperature rise range and the maximum

supply air temperature for heating is not exceeded as

shown in Table 18.1, and

• The airflow is within the allowable limits shown on the

serial plate for both heating and cooling, and

• The total static pressure does not exceed the limit shown

on the unit serial plate, and

• It is within the range of adjustability for the unit, and

• The motor amp draw must not exceed the motor

nameplate rating.

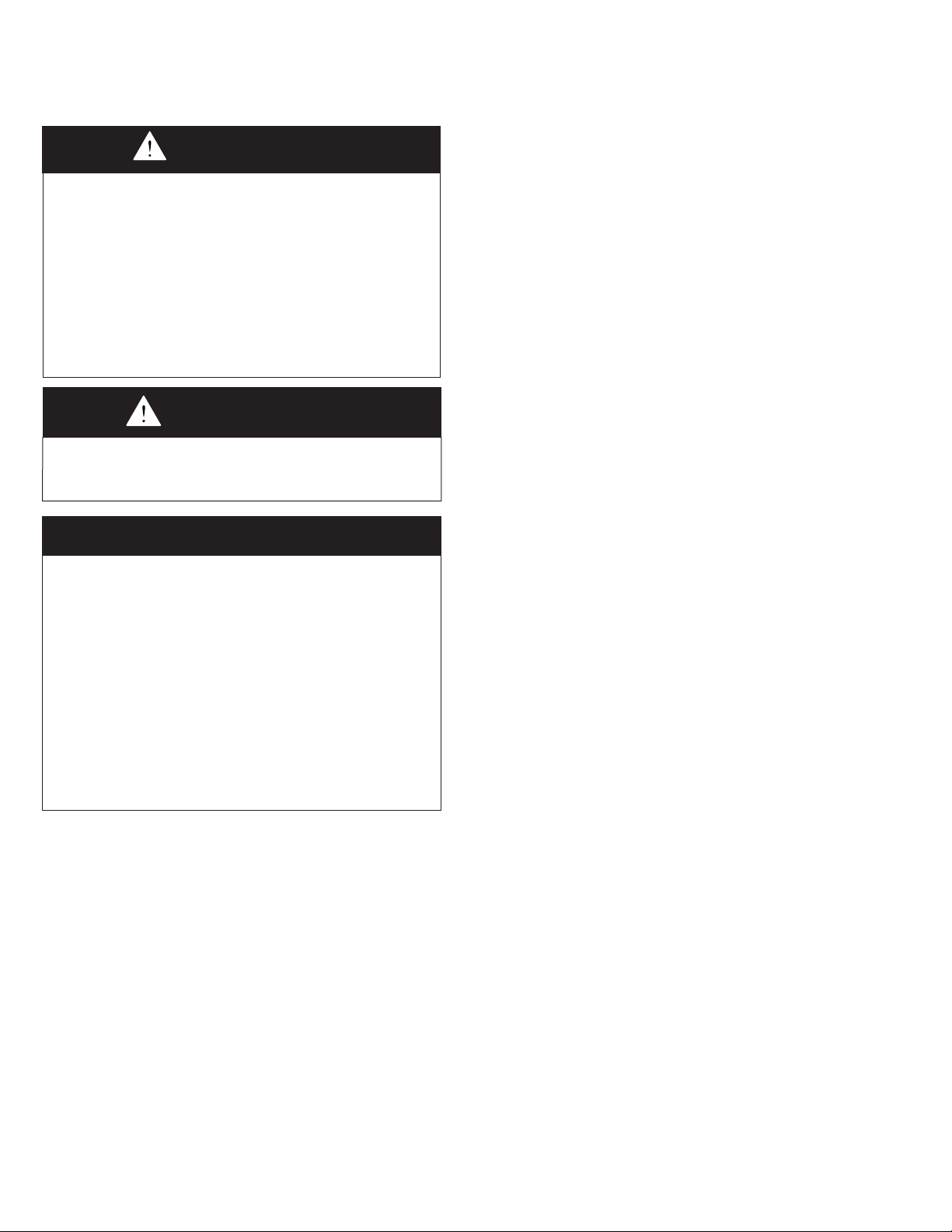

The blower speed adjustment method is dependant on the

following configurations:

• Direct Drive where the blower is driven directly by the

motor as seen in Figure 18.1. This is the current

standard supply fan configuration for all units.

• Belt Drive where the blower is driven by the motor with a

belt and sheaves as seen in Figure 18.2. This is the

current standard exhaust fan configuration (if equipped)

for all units. It was also used on supply fans for units

shipped before 2018.

Once the blower/motor configuration of the unit is determined,

follow the appropriate instructions in the sections on the

following pages.

17MCP15-500.7

START-UP PROCEDURE - CONTINUED

Figure 18.1 - Direct Drive Blower Example

Direct Driven Blower