Modine Manufacturing Model FC, Model WCC Service Manual

Floor Model FC

Sizes 002 thru 014

INSTALLATION AND SERVICE MANUAL

steam/hot water cabinet unit heaters

Wall or Ceiling Model WCC

Sizes 002 thru 014

AIR11-500.6

5H0796080000

January, 2016

Wall or Ceiling Recessed

Model WCC

Sizes 002 thru 014

Contents

General Information ...............................................................1

Special Precautions ...............................................................2

SI (Metric) Conversion Factors ..............................................2

Unit Location..........................................................................2

Installation..............................................................................3

Unit Mounting ..................................................................3

Piping ..............................................................................3

Wiring ..............................................................................3

Mounting Height and Heater Throw ................................4

Operation ...............................................................................4

Prior to Operation ..............................................................4

Initial Start-up .....................................................................4

Automatic Control Operations ............................................4

Air Flow Arrangement ............................................................ 5

Controls and Features ...........................................................6

Specifications ........................................................................7

Dimensional/Motor Data ........................................................8

Floor Model FC ...............................................................8

Wall or Ceiling Model WCC ............................................9

Dimensional Data/Accessories/Options ........................10

Outside Air Wall Box .....................................................10

Duct Collars ..................................................................10

Maintenance ........................................................................ 11

Service.................................................................................11

Warranty ................................................................ Back Page

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency must

perform all installation and service of these

appliances.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

Modine Sales Representative.

2. Check rating plate on unit to verify that power supply meets

available electric power at point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where applicable).

General Information

Installation and service instructions in this manual are applicable

to the three types of steam/hot water cabinet unit heaters which

should be installed in their proper applications for their most

effective function as heating units.

The 1 & 2 row condensers are warranted for operation at

hot water pressures up to 200 lbs. per sq. in. gauge, and or

temperatures up to 240°F or steam pressures up to 10psig for

one row coils only.

The 3 & 4 row condensers are warranted for operation at

hot water pressures up to 200 lbs. per sq. in. gauge, and or

temperatures up to 200°F.

Motors are designed for continuous duty. They can operate in a

maximum ambient temperature of 104°F (40°C).

The unit heaters are listed by the Canadian Standards

Association as certified.

Model FC units are fully exposed floor mounted types.

Model WCC units are fully exposed wall or ceiling mounted

types, or partially of fully recessed.

Cabinet unit heaters are available with a variety of options

and control arrangements. Information on certain options

and controls (when provided) is supplied separately from this

manual.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS / UNIT LOCATION

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS

IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING

THE SPECIAL PRECAUTIONS LISTED BELOW. FAILURE

TO PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERTY DAMAGE OR LOSS, PERSONAL

INJURY, OR DEATH. THESE INSTRUCTIONS ARE SUBJECT

TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious

injury.

3. CAUTION: Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Units must not be installed where they may be exposed to a

potentially explosive or flammable atmosphere.

WARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating plate

on the appliance for complete appliance model number,

serial number, and company address. Any substitution of

parts or controls not approved by the factory will be at the

owner’s risk.

Table 2.1

SI (METRIC) CONVERSION FACTORS

To Convert Multiply By To Obtain

"W.C.

(inches water column)

psig 6.893 kpa

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m3/min

CFH 1.699 m3/min

btu/ft3 0.0374 mJ/m

pound 0.453 kg

btu/hr 0.000293 kW/hr

gallons 3.785 liters

°F

0.24 kPa

(°F-32) × 0.555

°C

3

UNIT LOCATION

DANGER

Units must not be installed where they may be exposed to a

potentially explosive or flammable atmosphere.

1. Units should not be installed in atmospheres where

corrosive fumes or sprays are present.

2. Be sure no obstructions block air intake or air discharge of

unit heater.

3. Columns, machinery, partitions, and other obstacles should

not interfere with air streams from unit heaters.

4. Unit heaters installed in a building exposed to a prevailing

wind should be located to direct a major volume of heated

air along the windward wall of the building.

5. Vertical delivery unit heaters should generally be located in

the central area of the space to be heated. Place horizontal

delivery units along the walls of the same building where

heat loss is usually greatest.

6. Arrange horizontal delivery units so they do not blow

directly at occupants.

7. When only vertical delivery units are installed, they should

be located so exposed walls are blanketed by their air

streams.

8. Mounting height is critical for optimum performance. Refer

to Mounting Height on page 4 before installation.

CAUTION

1. Do not reuse any electrical component which has been

wet. Such component must be replaced.

2. Do not operate the units within steam pressure greater

than 10 psig. Steam pressure must be 10 psig. or lower

to avoid excessive discharge air temperatures that could

cause burns or personal injury.

2

IMPORTANT

Start-up and adjustment procedures must be performed by a

qualified service agency.

AIR11-500.6

INSTALLATION - UNIT MOUNTING / PIPING / ELECTRICAL CONNECTIONS

INSTALLATION

Unit Mounting

1. Open front panel and line up end compartment with roughedin piping and position unit at ceiling or wall location. (Hinged

cabinet doors may be removed to facilitate unit installation.)

2. Fasten floor or wall mounted unit to wall studs through

the four mounting holes in the back of the unit. For ceiling

mounted units sizes 002-006, suspend four 1/4" threaded

hanger studs from ceiling joists to match mounting holes in

back of unit and fasten with lockwashers and hex nuts. (For

sizes 008-014, use a 3/8" threaded rod.)

Perma-Lap® Frames

A Perma-Lap® frame (see Figure 11.3 on page 10) provides

a finished appearance to a recessed wall or ceiling cabinet

unit heater. The installation is easy and assures a perfect fit

by neatly framing the heater and covering any irregularities

between the heater and the opening in the wall or ceiling.

Because the bond between wall or ceiling surfaces and the

Perma-Lap® framing is permanent, there is no opportunity for

air leakage which can cause wall streaking.

Since the enclosure front panel is never in contact with the wall

or ceiling, servicing the heater involves simply removing the

heater front panel and leaving the Perma-Lap® and cabinet

enclosure permanently fixed in the recess opening.

Perma-Lap® frames allow flexibility in recessing depth. Enclosures

may be flush, recessed or partially recessed. Desired unit projection

on partially recessed units is accomplished by positioning the unit

within the Perma-Lap® frame. The four sided Perma-Lap® frame

has a 3/8” projection and a 1 ½” width.

Piping

CAUTION

CAUTION

Failure to wire this unit according to this wiring diagram may

result in injury to the installer or user. For deviations, contact

the factory.

1. Installation of wiring must conform with local building

codes, or in the absence of local codes, with the National

Electric Code ANSI/NFPA 70 - Latest Edition. Unit must

be electrically grounded in conformance to this code. In

Canada, wiring must comply with CSA C22.1, Electrical

Code.

2. Electric wiring must be sized to carry the full load amp draw

of the motor and any controls that are used with the unit

heater. Overcurrent protectors should be sized based on

motor current rating shown on the unit serial plate, and

applicable national electric code procedures.

All units are provided with an electrical junction box. Make

wiring connections from 115V/60Hz/1Ø building service to

control box as shown on wiring diagram furnished with the

unit.

Any damage to or failure of Modine units caused by

incorrect wiring of the units is not covered by Modine’s

standard warranty.

3. Location of room thermostat, when supplied, should be in

the natural circulating path of room air. Mount thermostat

about five feet above floor level where it will not be affected

by heat from the unit or other sources of drafts that would

prevent it from properly controlling room temperature. See

instructions packed with the thermostat.

4. With ceiling mounted units, a multi-speed remote fan

switch is supplied as standard. The switch can be recessed

into a standard 2 x 4 electrical wall box.

1. Do not reuse any electrical component which has been

wet. Such component must be replaced.

2. Do not operate the units within steam pressure greater

than 10 psig. Steam pressure must be 10 psig. or lower

to avoid excessive discharge air temperatures that could

cause burns or personal injury.

1. On standard coil (single row), connections are 3/4" MPT on

unit sizes 002 through 006.

On high capacity coil (2 row), connections are 5/8" ID sweat

on unit sizes 002 through 006. On high capacity coil (3 & 4

row), connections are 3/4" NPT on unit sizes 002 through 006.

On unit sizes 008 through 014, either standard or high capacity

coil, connections are 1" NPT. On high capacity coil (3 & 4 row),

connections are 1" NPT on unit sizes 008 through 014.

2. Supply and return lines should be adequately sized to handle

heating requirements under maximum load.

3. Attach air vent fitting at the high point of the piping in the unit

on hot water systems.

4. Install piping to provide for expansion and contraction

normally encountered with temperature changes.

Electrical Connections

WARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard to

persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

Figure 3.1

Standard Wiring Diagram for Cabinet Unit Heaters

AIR11-500.6

ACCESSORY

MOTOR

STARTER

ACCESSORY

3

AQUASTAT

Motor Type

PSC

Shaded Pole

High Static

Return Air Option or

Rated Amps

Factory Installed

FIELD INSTALLED

THERMOSTAT

MOUNT INSIDE J-BOX

SPEED

CONTROL

Ground

See Below Motor Key For Motor

Information and Wiring Configuration

Terminal 4

Terminal 3

BLK

2.5 A

5.0 A RED

BLK WHT

10.0 A

FIELD INSTALLED

CONTROL VALVE

(ACCESSORY OR

BY OTHERS)

Motorized Damper Option or

FIELD INSTALLED

MOTORIZED DAMPER

(ACCESSORY)

1

2

Ground

WHT

N / A

RED

GRN

N / A

Factory Installed Disconnect Option or

16 AWG

MAIN

GROUND

OPTIONAL MOTOR PLUG

AND SOCKET CONNECTIONS

4

16 AWG

WHT

F1

BLK

FIELD INSTALLED

DISCONNECT

L1

L2

WHT

F2

BLK

115V / 60HZ /

1PH POWER

CIRCUIT

BREAKER

BY OTHERS

REQUIRED FOR

SIZES 008 - 014

3

INSTALLATION - MOUNTING HEIGHT / OPERATION

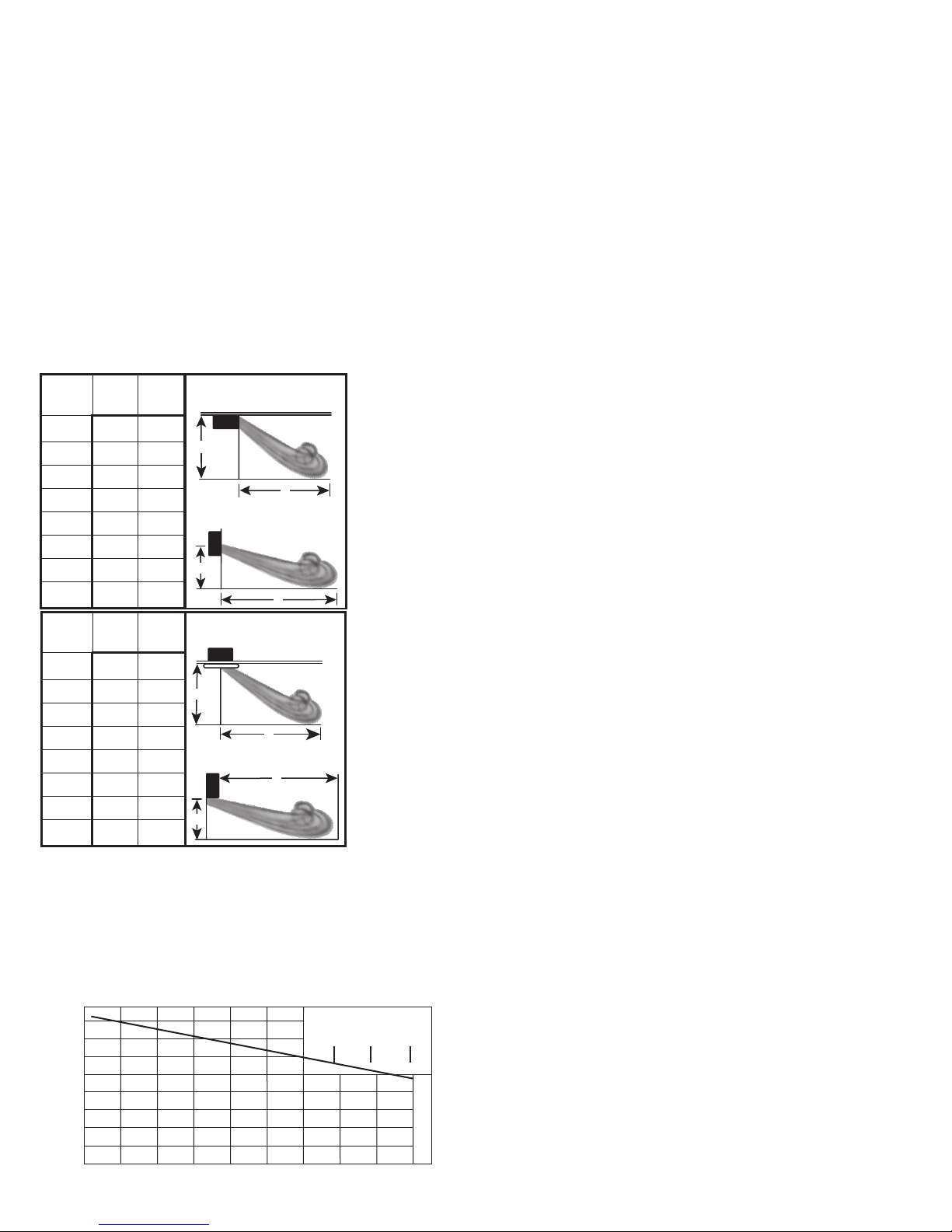

Mounting Height

Height at which cabinet unit heaters are installed is critical.

Maximum mounting heights for all units are listed in the tables

below. The data in tables are based on operating conditions of 2

lbs. steam or 220°F entering water with 60°F entering air. When

operating conditions are other than those above, refer to chart

for mounting height correction factor. To obtain the maximum

mounting height at actual operating conditions, multiply the

appropriate factor from chart by the mounting height in Tables.

The mounting heights must be followed closely to assure

maximum comfort.

Strong opposing drafts, large obstructions in the air stream of

the unit, and higher than normal discharge air temperatures

(resulting from high steam pressures) can prevent the heated air

discharged by the cabinet unit from reaching the floor.

Under unfavorable conditions such as these, allowances must be

made to assure maintenance of desired comfort.

Table / Figure 4.1 - Maximum Mounting Height

Size H T

(Ft.) (Ft.)

002 8 15

003 8 18

004 9 22

006 9 23

008 10 26

010 10 27

012 11 26

014 11 27

Size H T

(Ft.) (Ft.)

Standard Air Flow

Ceiling-Mounted

H

T

Inverted Air Flow

Wall-Mounted

H

T

Standard Air Flow

Ceiling-Mounted

OPERATION

1. Make sure fuses are installed in fused disconnect switches.

2. Check all electrical connections to assure they are secure.

3. Check rigidity of unit mounting. Tighten all fasteners,

if necessary.

4. Inspect piping, strainers, traps, fittings, etc.

Initial Start-Up

1. Set thermostat to lowest position.

2. Turn on power supply to unit.

3. Open return gate valve, and then open supply gate valve

to unit.

4. Raise thermostat setting to desired position.

5. Adjust louvers (if provided) for desired heat distribution.

6. To insure proper sequence of operation, cycle unit on and

off a few times by raising and lowering thermostat setting.

7. Check for proper rotation of fan. See dimensional drawings

on page 8 or 9 for indication of fan rotation.

Automatic Control Operations

Install one of the following operating systems for continuous

automatic control.

Intermittent Fan Operation — Hot Coil

A room thermostat starts and stops the fan motor. An aquastat

is sometimes strapped to the return piping to prevent fan

operation when heat is not being supplied to the unit heater.

Continuous Fan Operation — Intermittent Hot/Cold

Coil

A room thermostat controls a valve which opens to allow steam

or hot water to supply the unit and closes to shut off the supply

when the thermostat is satisfied.

002 7 8

003 8 10

004 8 11

006 8 12

008 10 16

010 10 18

012 11 20

014 11 21

➀ Maximum mounting height and corresponding heat throw of heaters operating

at standard conditions (2 lbs. steam or 220°F entering water, 60° entering air).

H

T

Inverted Air Flow

Wall-Mounted

T

H

Table 4.2

Maximum Mounting Heights Correction Factors

These correction factors are to be used as multipliers to correct

the maximum recommended mounting heights “H” or heat

throw “T” of cabinet unit heaters when operated with steam

pressures other than 2 pounds or with water at other than

entering temperature of 220°F.

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

CORRECTION FACTOR “R”

150° 160° 170° 180° 190° 200° 210° 220° 230° 240°

4

AVERAGE WATER TEMP. (°F)

Steam Pressure

2 5

10

AIR11-500.6

Loading...

Loading...