Modine Manufacturing Lodronic HCH Service Manual

1-660.0

5H0827900000

– ACCESSORY DOWNWARD DEFLECTOR HOOD

IMPORTANT

1. The use of this manual is specifically intended for a

qualified installation and service agency. All installation

and service of these kits must be performed by a

qualified installation and service agency.

2. These instructions must also be used in conjunction

with the Installation and Service Manual originally

shipped with the appliance, in addition to any other

accompanying component supplier literature.

August, 2019

INSTALLATION INSTRUCTIONS

30°, 60°, and 90° downward deflector hoods

LodronicTM Models HCH

Deflector Hood Model Application

The 30°, 60° and 90°, Downward Deflector Hoods are

designed for use on Lodronic

Assembly/Installation

The recommended procedure for assembly and installation

is described as follows:

Before beginning installation of the accessory hood,

remove all of the spring loaded louver blades from the

unit heater on which the hood is to be installed. These

blades will be relocated in the face of the hood

assembly after the hood assembly is complete (except

90° hoods). Not all blades from the unit heater will be

used on the hood, but all should be removed prior to

installing the hood. For 90° hoods, separate louvers will

ship with the hood assembly. To remove the spring

loaded louver blades, grasp the blade and apply

pressure against the louver blade retaining spring. After

compressing the spring, the tab on the opposite side of

the blade can be removed from the unit, freeing the

blade from the unit.

Note: Do not lose the louver blade retaining springs as they

will be required later to install the blades into the hood

assembly.

TM

hydronic unit heaters.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

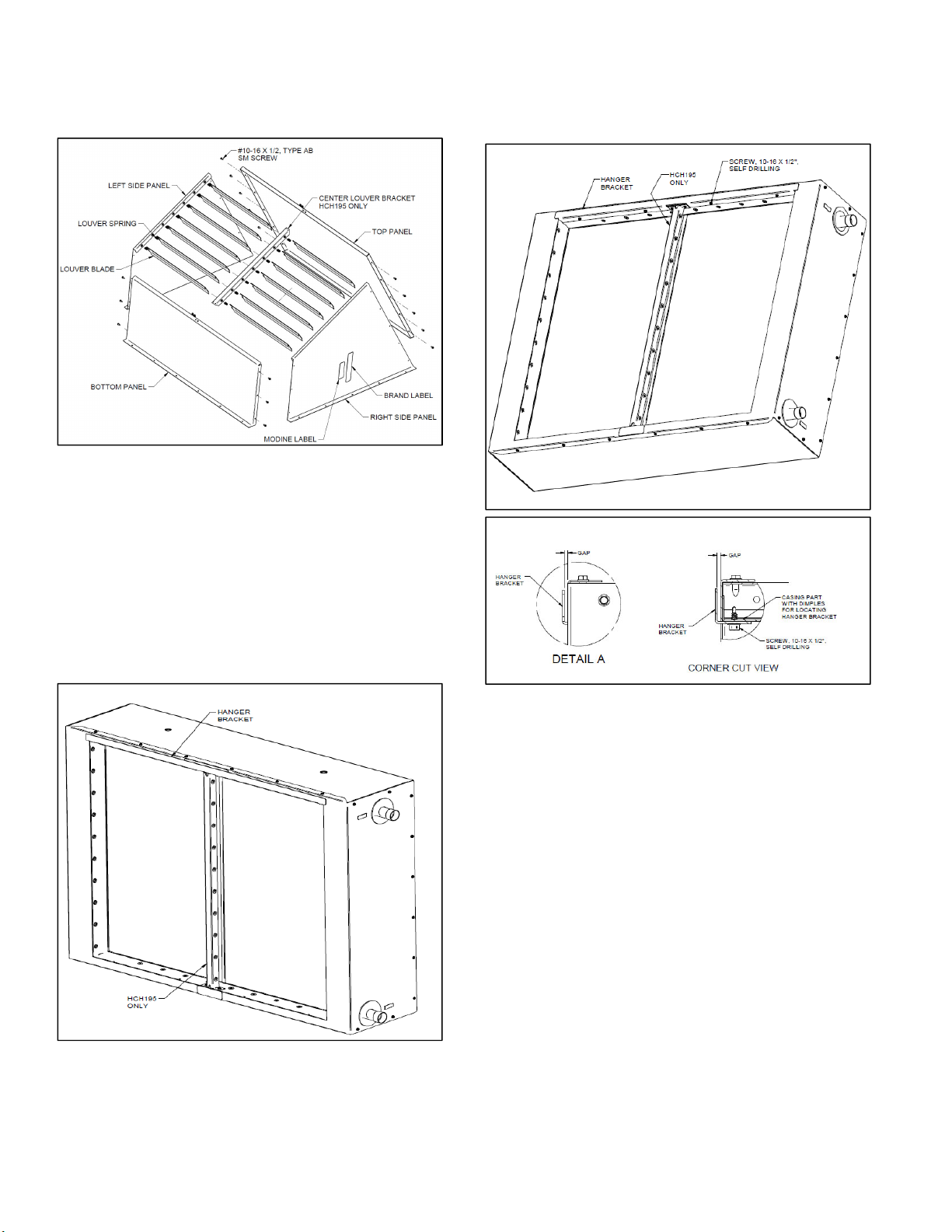

Figure 2.1 - Hood Exploded View

1. Install the hood hangar bracket to the top interior surface

of the unit opening (see figure 2.2), using the #10 x ½”

self drilling screws provided. Dimples located at the top

of the opening will provide locating points to secure the

bracket. Once the bracket is installed, ensure that there

is a small gap between the hangar bracket and the front

face of the unit. A screwdriver or similar tool may be

required if adjustment needs to take place to create a

gap.

Figure 2.2 – Hanger Bracket

2. Hood assembly is generally easiest if done with the

surfaces of the hood panels with flanges facing the floor.

Begin the hood assembly by positioning the hood bottom

so that the flanges are on the outside of a side panel.

Attach the bottom panel to the side panel of the hood

using the #10 x 1/2" sheet metal screws through the

provided holes. Repeat for the other side panel

3. Position the hood top so that the flanges are on the

outside of the side panels. Secure the hood to the side

panels using the #10 x 1/2" sheet metal screws through

the provided holes

4. Complete the hood frame by using the #10 x 1/2" sheet

metal screws through provided holes on the outlet

surface of the hood. Install the center louver channel if

provided.

5. Install the louvers taken from the unit (or provided with

the kit for 90° hoods). Take the louver springs used on

the unit, and place them over the tab of the louver.

Press the tab into the hood panel dimple, compressing

the spring. Slide the tab on the other end of the louver

into the dimple.

6. Provided Modine and Lodronic labels can be placed as

desired on the exterior of the hood.

1-660.0

Loading...

Loading...